Patents

Literature

279 results about "Granular matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granular matter like grain, sugar, sand and pills, often give rise to unexpected effects during transport, processing or storage. This often causes stagnation in industrial processes or excessive energy consumption.

Mapping fracture dimensions

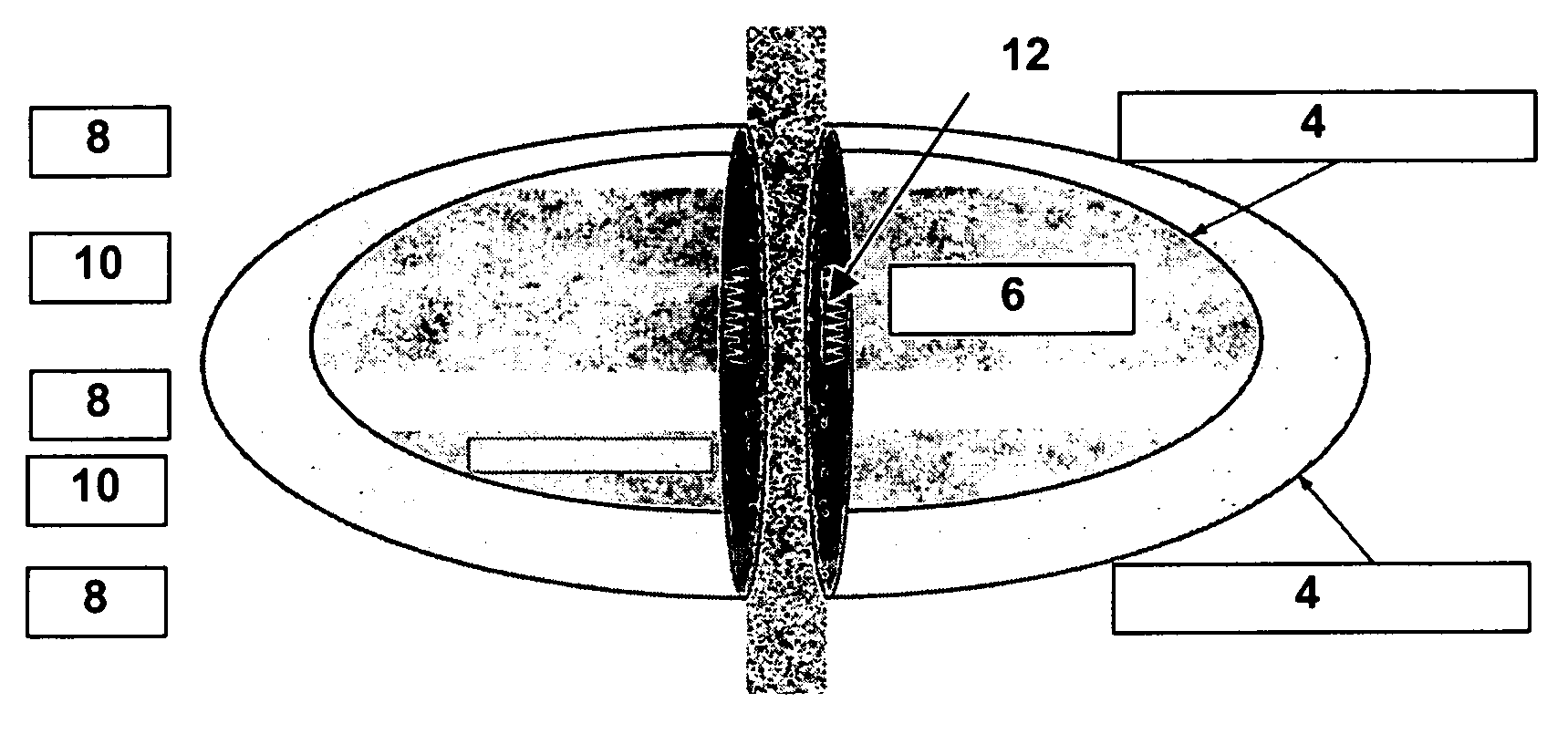

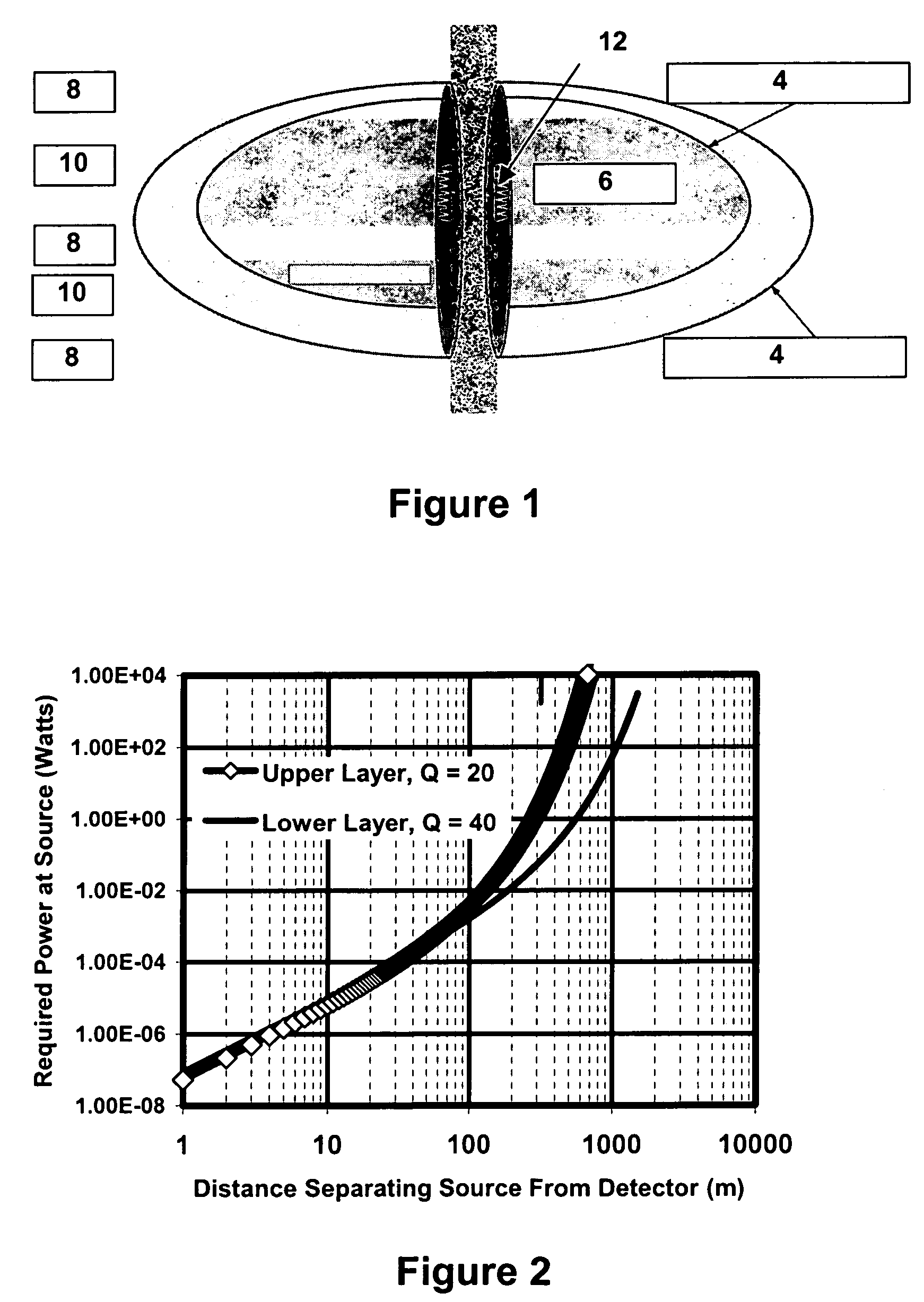

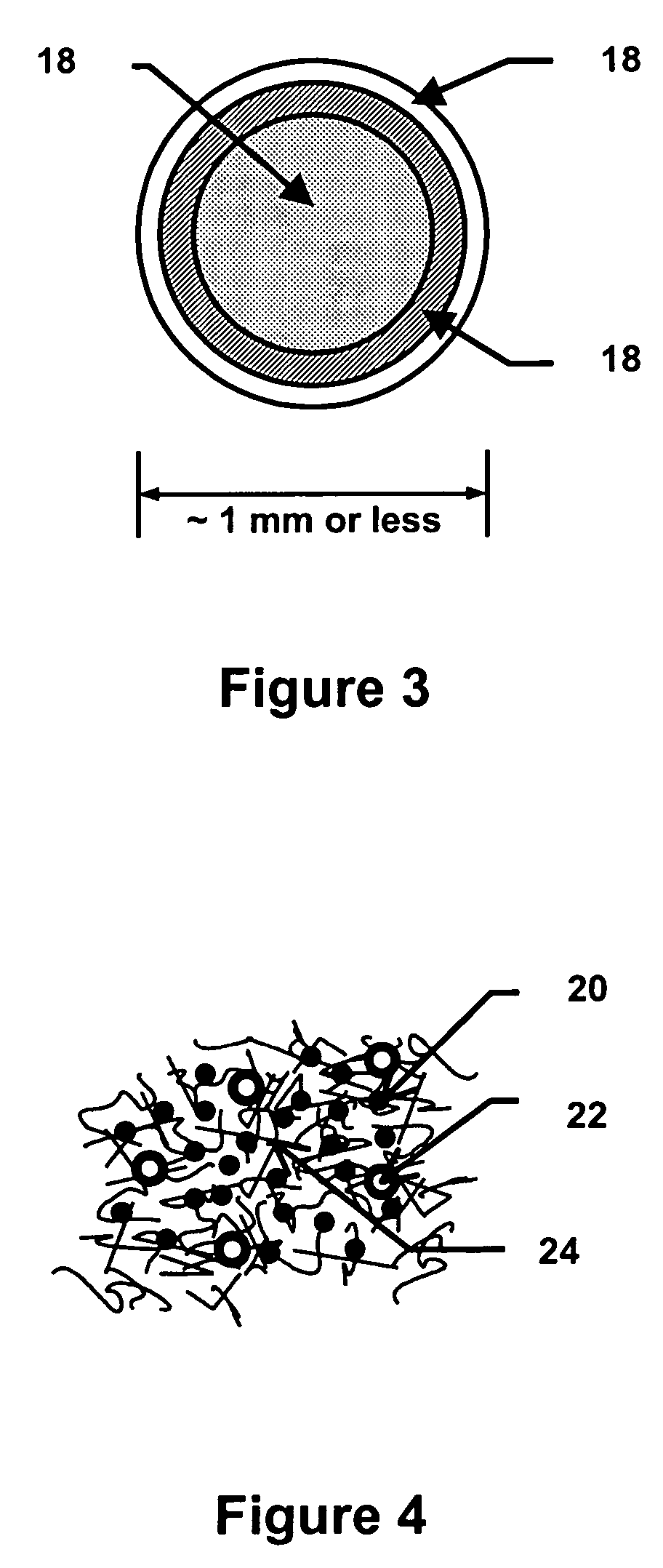

Hydraulic fracture dimensions and, optionally, fracture closure pressure and time are determined by adding particulate matter that discharges to create an acoustic signal to the proppant, allowing the particulate matter to discharge, and detecting the acoustic signal with geophones or accelerometers. The particulate matter may be spheres or fibers. The discharge may be explosion, implosion, detonation, or rapid combustion or ignition. The discharge may be triggered by fracture closure or by chemical reaction.

Owner:SCHLUMBERGER TECH CORP

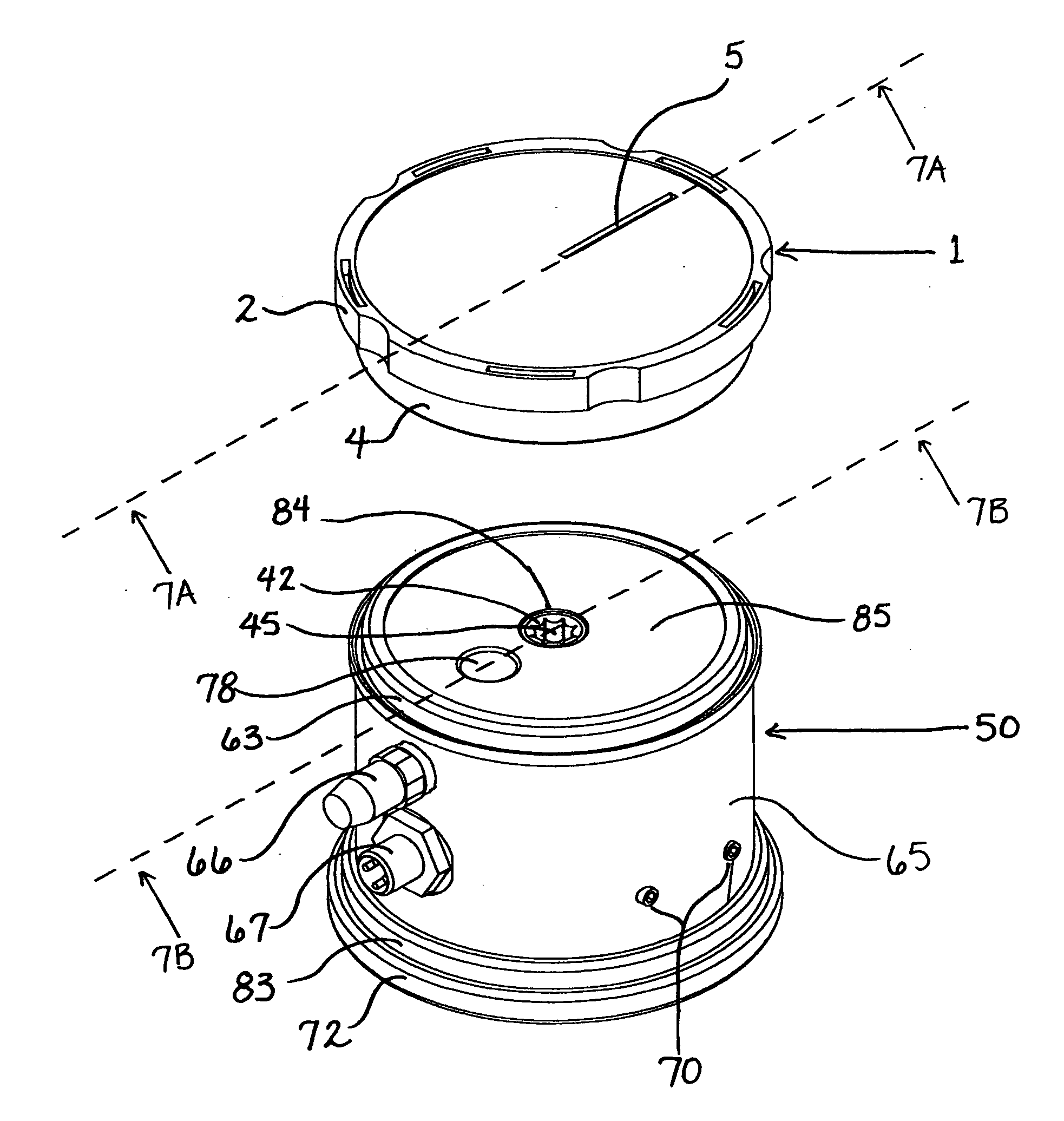

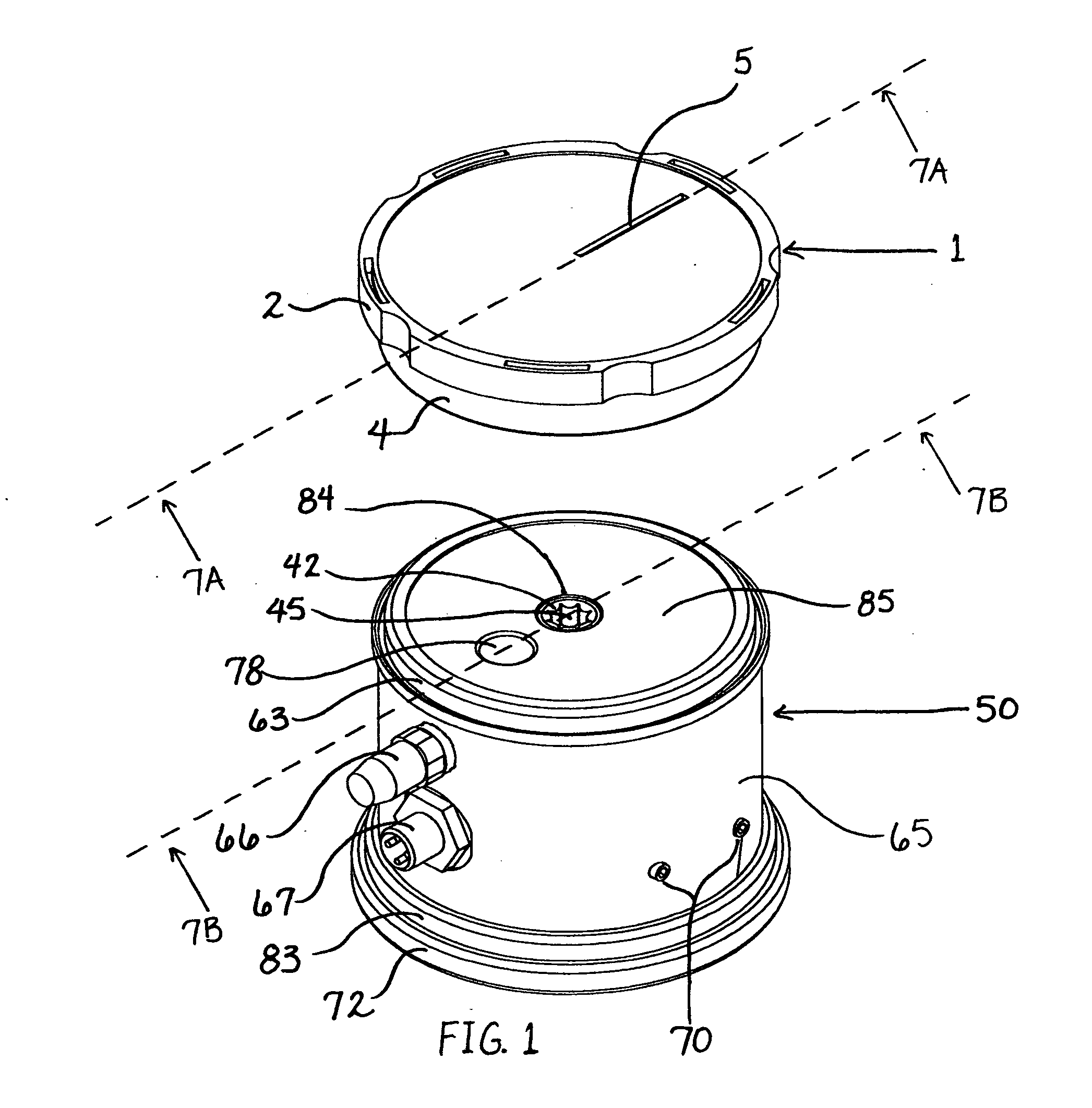

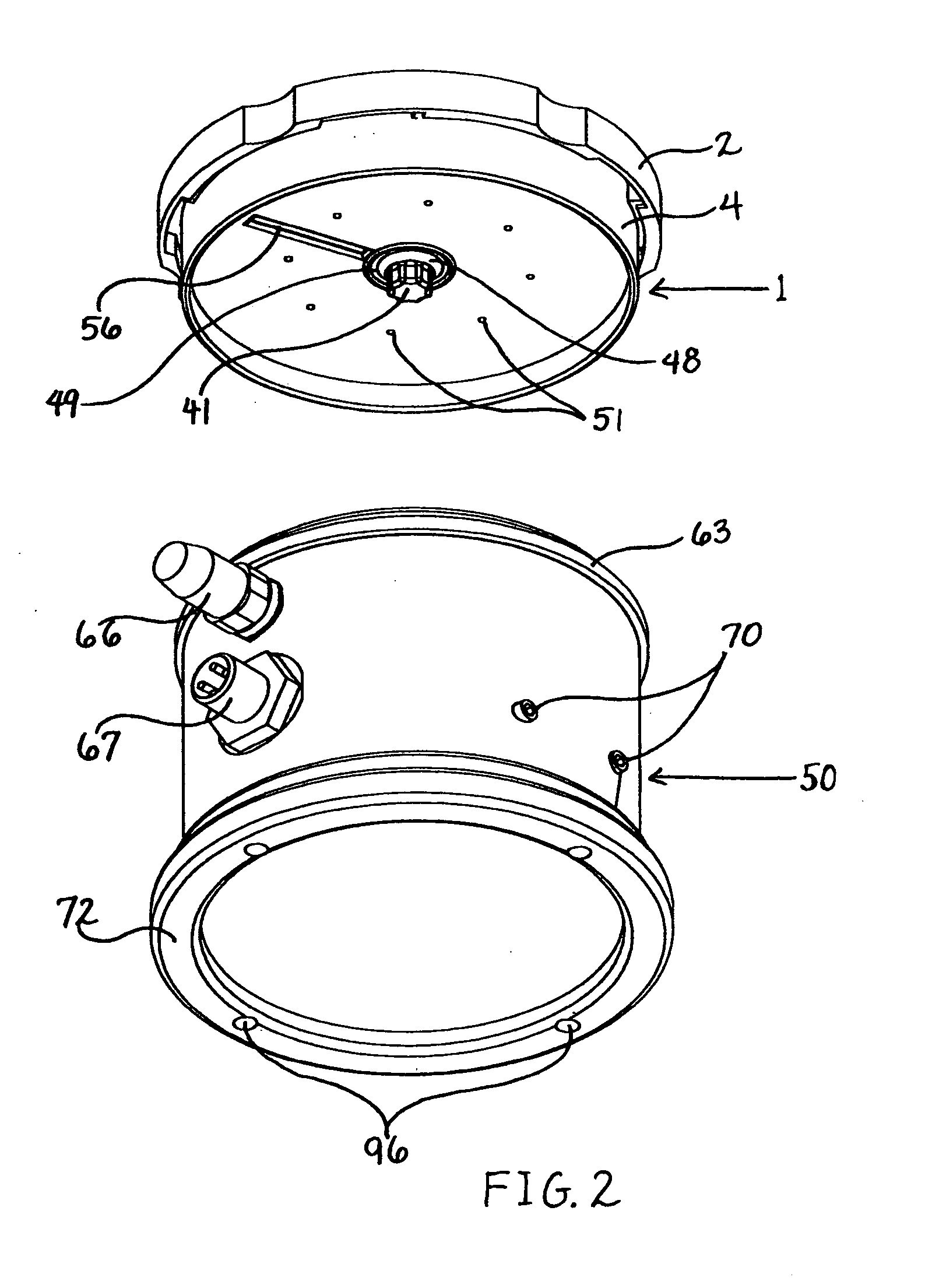

Single use sterile slit impact sampling cassette with rotatable capture tray

A single use sterile slit impact sampling cassette with rotatable capture tray for recovering particulate matter from ambient air, having a lid with a slit shaped air inlet, dish with an air outlet, and capture tray. The dish and lid assemble to form a sealed sample chamber, which houses the capture tray. The assembled cassette is sterile packaged with its inlet and outlet covered before use. The cassette is placed on a base for operation, which supplies the required vacuum for sampling, and rotational means for the capture tray. Air drawn into the air inlet is accelerated to a velocity that ensures impingement, or entrainment of particulate matter from the sampled air volume onto, or within the capture media. The sampled air volume is evacuated from the sample chamber through an air outlet. The cassette is then removed from the operative base, and then may be analyzed for the target contaminants.

Owner:SWENSON ERIK AXEL +1

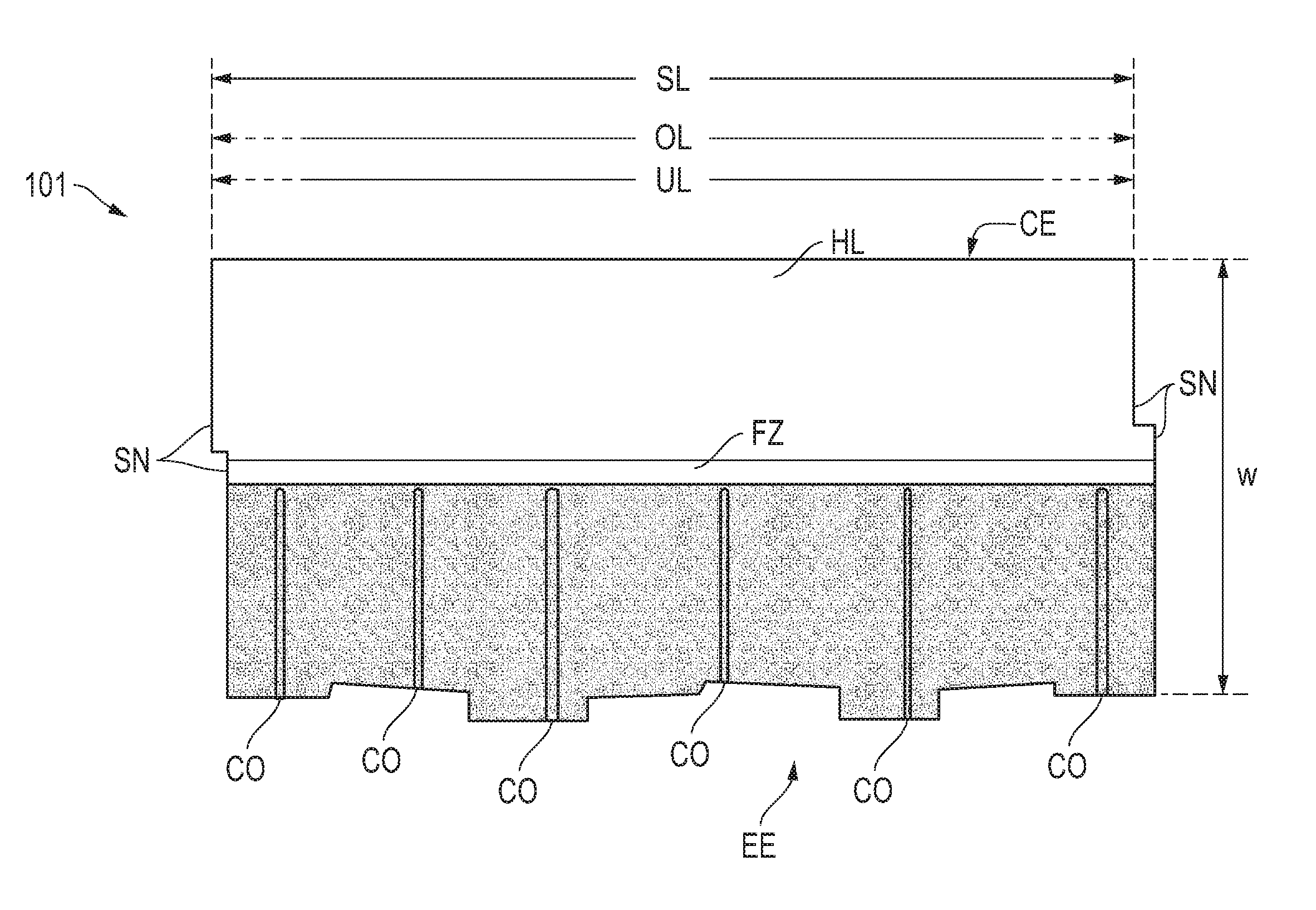

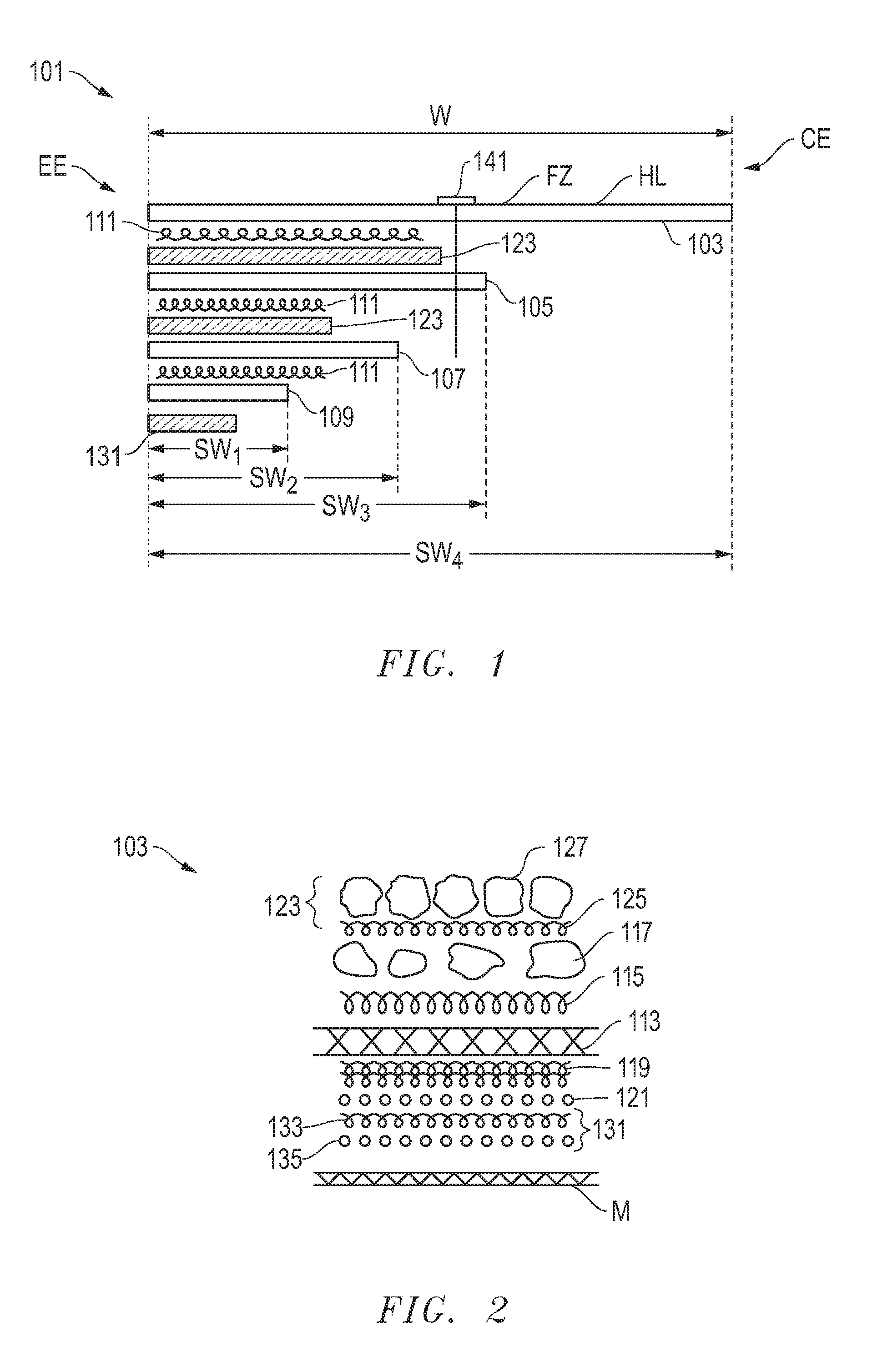

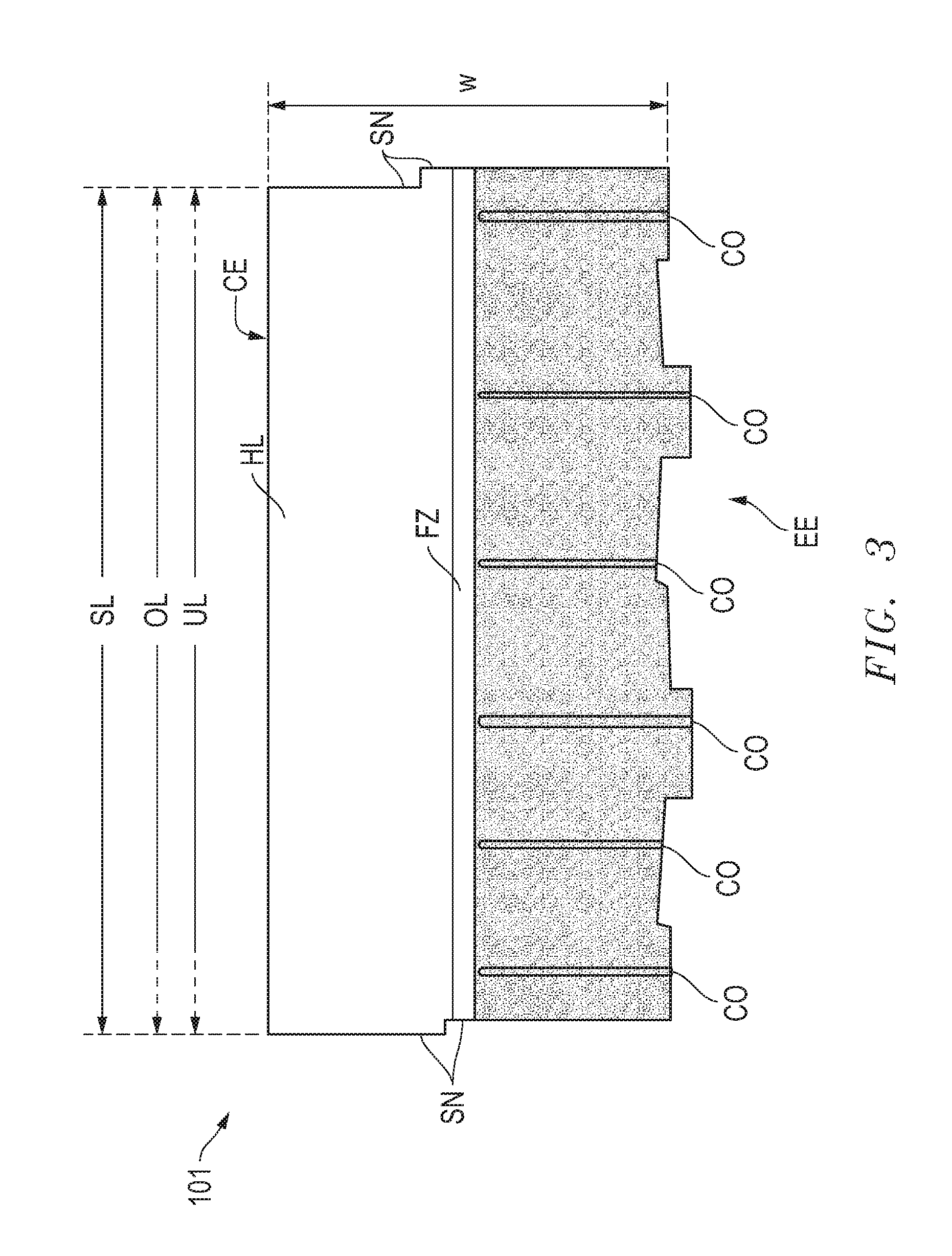

System, method and apparatus for wedge-shaped, multi-layer asphalt roofing

A roofing shingle includes strata that are stacked and laminated together by adhesive. Each of the strata may have a strata width that differs from the other strata. Each of the strata may include a substrate, a top asphalt layer on top of the substrate, granular matter on the top asphalt layer, a bottom asphalt layer on a bottom of the substrate, and mineral matter on the bottom asphalt layer.

Owner:CERTAINTEED CORP

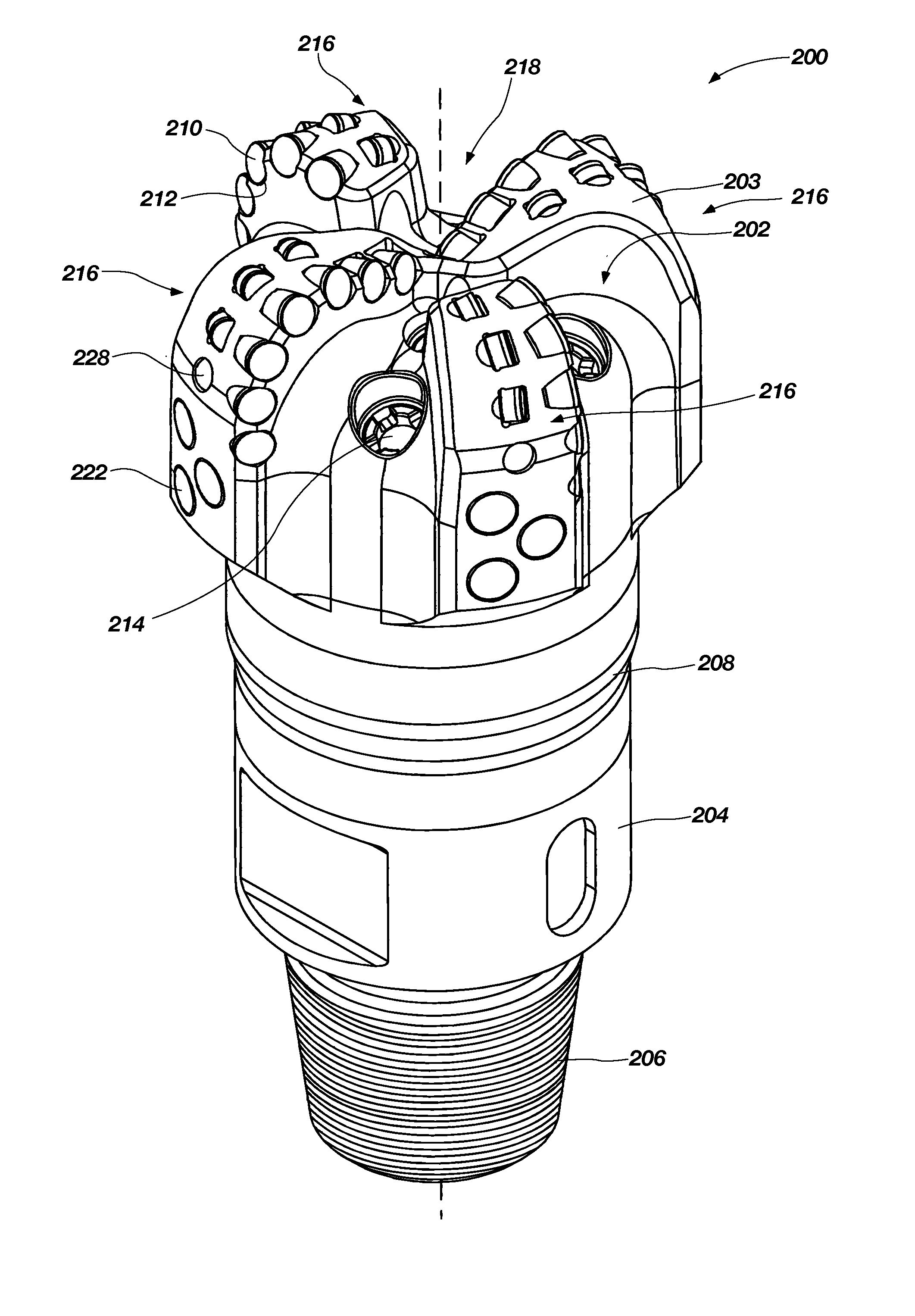

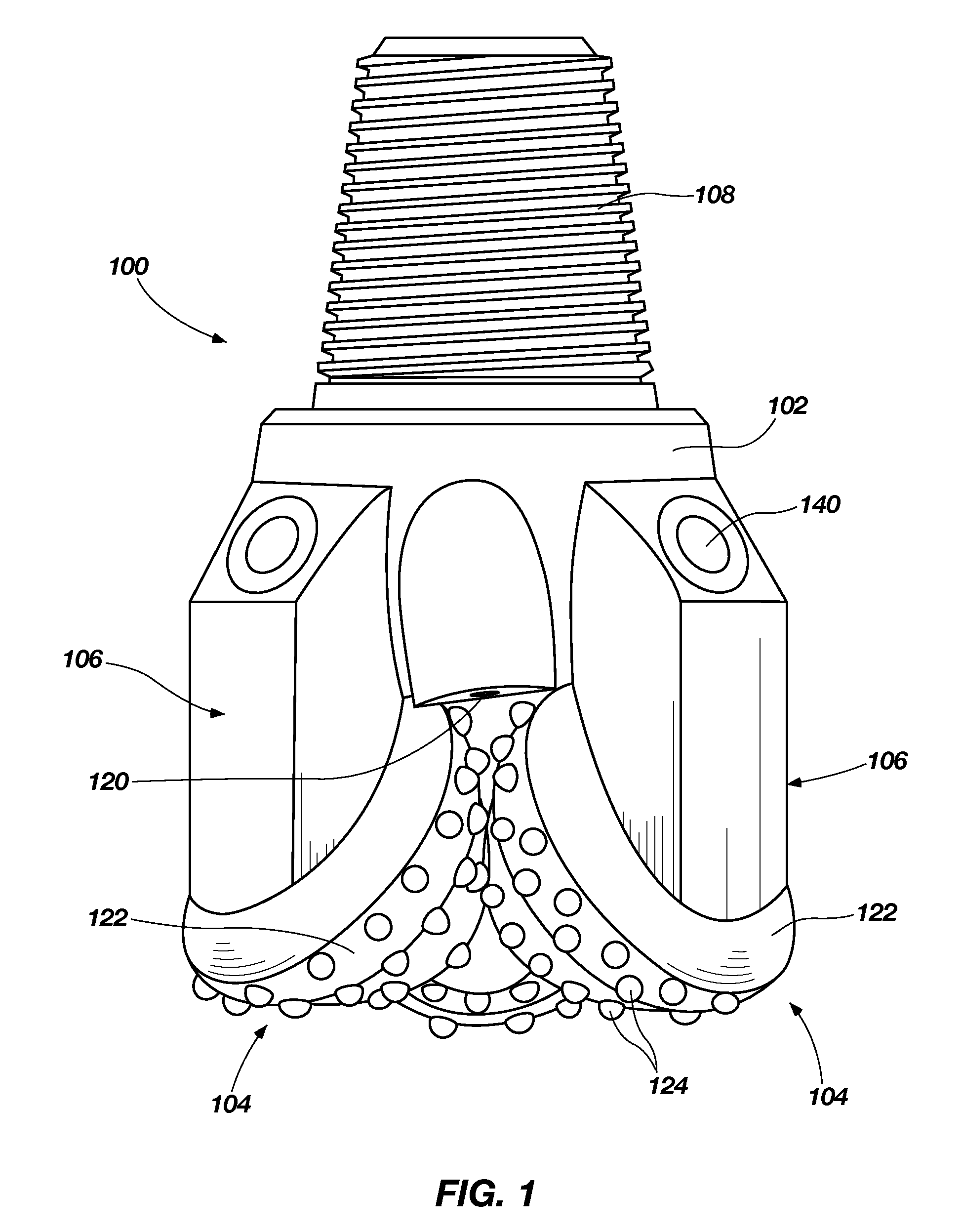

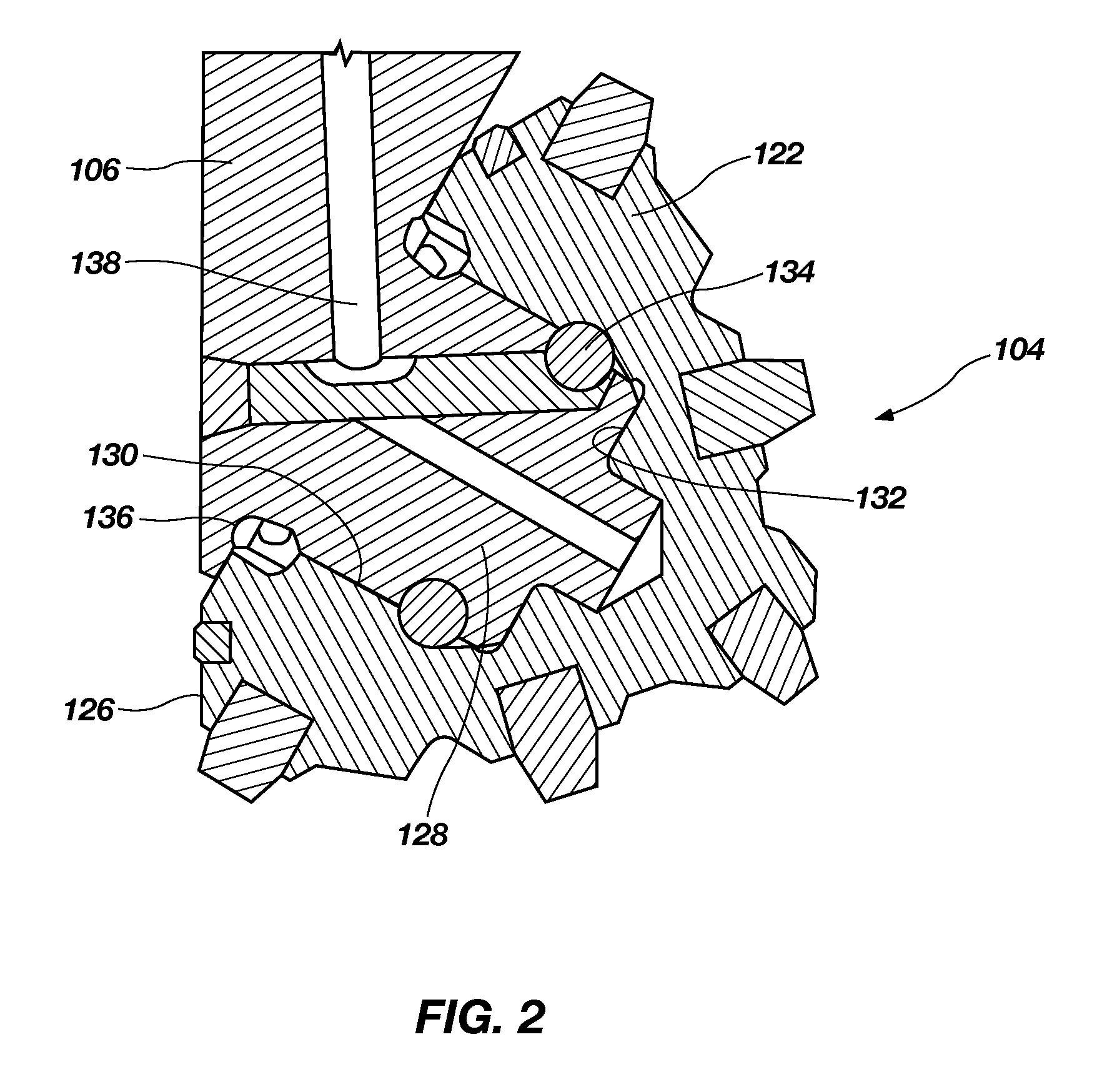

Methods of forming at least a portion of earth-boring tools, and articles formed by such methods

Methods of forming at least a portion of an earth-boring tool include providing at least one insert in a mold cavity, providing particulate matter in the mold cavity, melting a metal and the hard material to form a molten composition, and casting the molten composition. Other methods include coating at least one surface of a mold cavity with a coating material having a composition differing from a composition of the mold, melting a metal and a hard material to form a molten composition, and casting the molten composition. Articles comprising at least a portion of an earth-boring tool include at least one insert and a solidified eutectic or near-eutectic composition including a metal phase and a hard material phase. Other articles include a solidified eutectic or near-eutectic composition including a metal phase and a hard material phase and a coating material in contact with the solidified eutectic or near-eutectic composition.

Owner:BAKER HUGHES INC

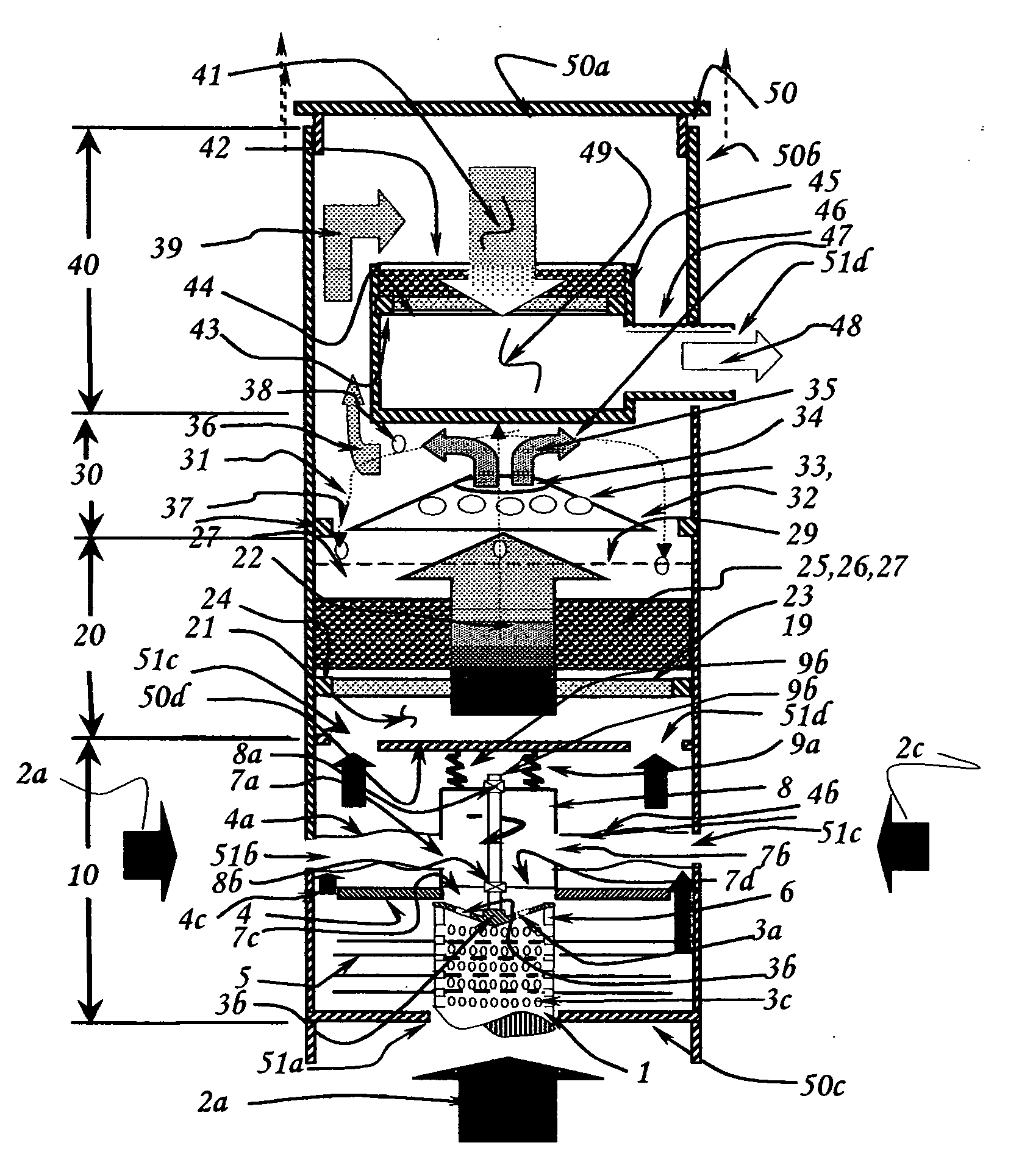

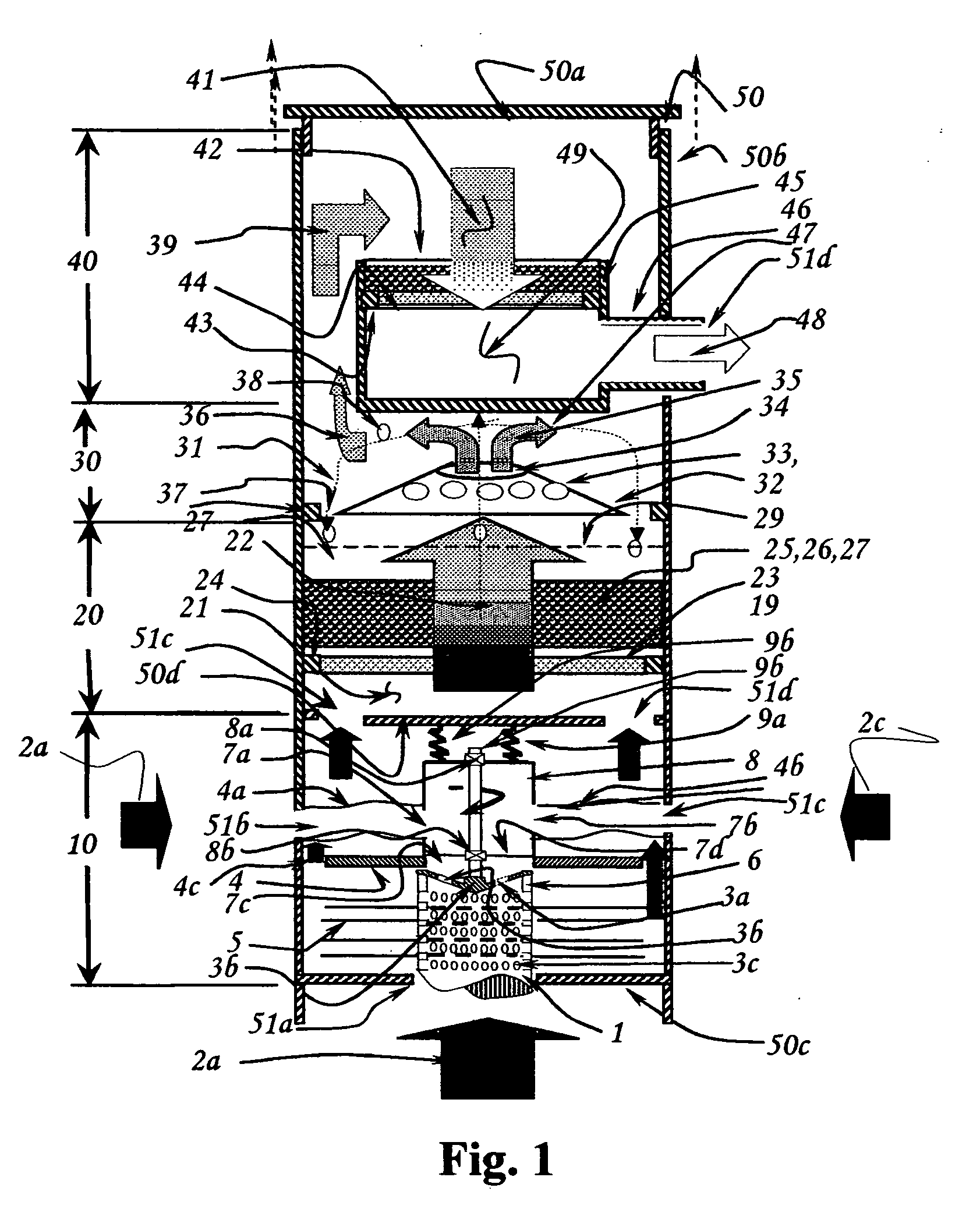

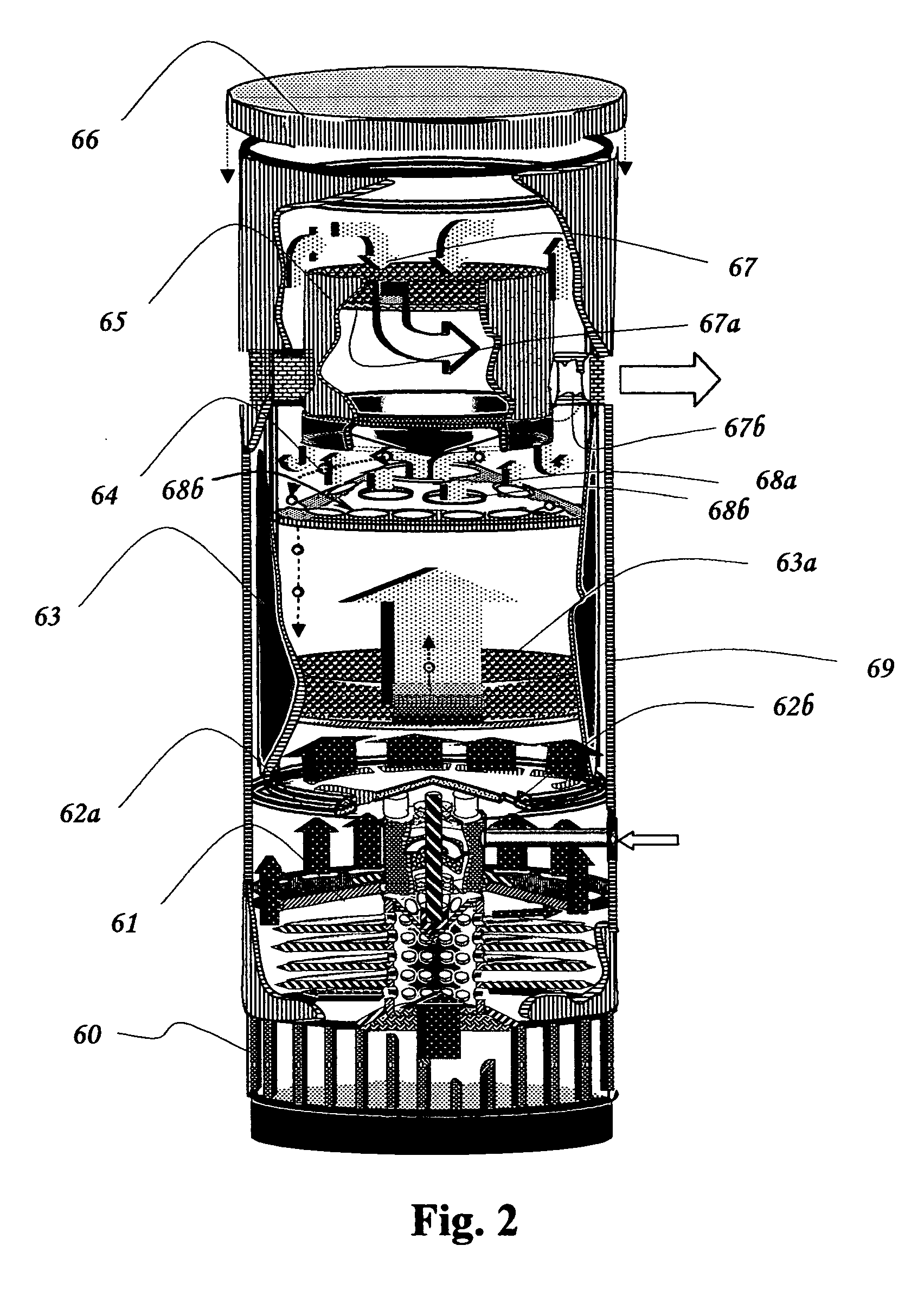

Method and apparatus for pollution control of confined spaces

A method of improve the removal of particulate matter, heavy metals, neutralizing acid, and kill microorganism pollutants, known to be in contaminated air volumes of occupied confined spaces, when exposed in close contact under pressure to a mixture of alkaline sorbent materials, having a known synergism between said pollutants using a self propelled fluidized bed reactor and packed bed filter apparatus system to optimize the contact collection efficiency of submicron particles and organic compounds.

Owner:AVINA DAVID CHRISTOPHER

Air filter for removing particulate matter and volatile organic compounds

InactiveUS20050132886A1Maximize likelihoodEfficient removalElectrostatic separationFiltration separationParticulatesReticulated foam

The present invention relates to an air filter for removing contaminants from air. Such a filter is useful in removing particulate matter, as well as volatile organic compounds (VOC's). In particular, the air filter of the present invention includes a reticulated foam substrate having a gel applied thereto. The substrate may be used alone or in combination with an electrostatic filter, which helps to trap smaller particles (i.e., less than 3 microns in diameter). The substrate itself may trap larger particles (i.e., greater than 3 microns in diameter).

Owner:INVISTA NORTH AMERICA R L

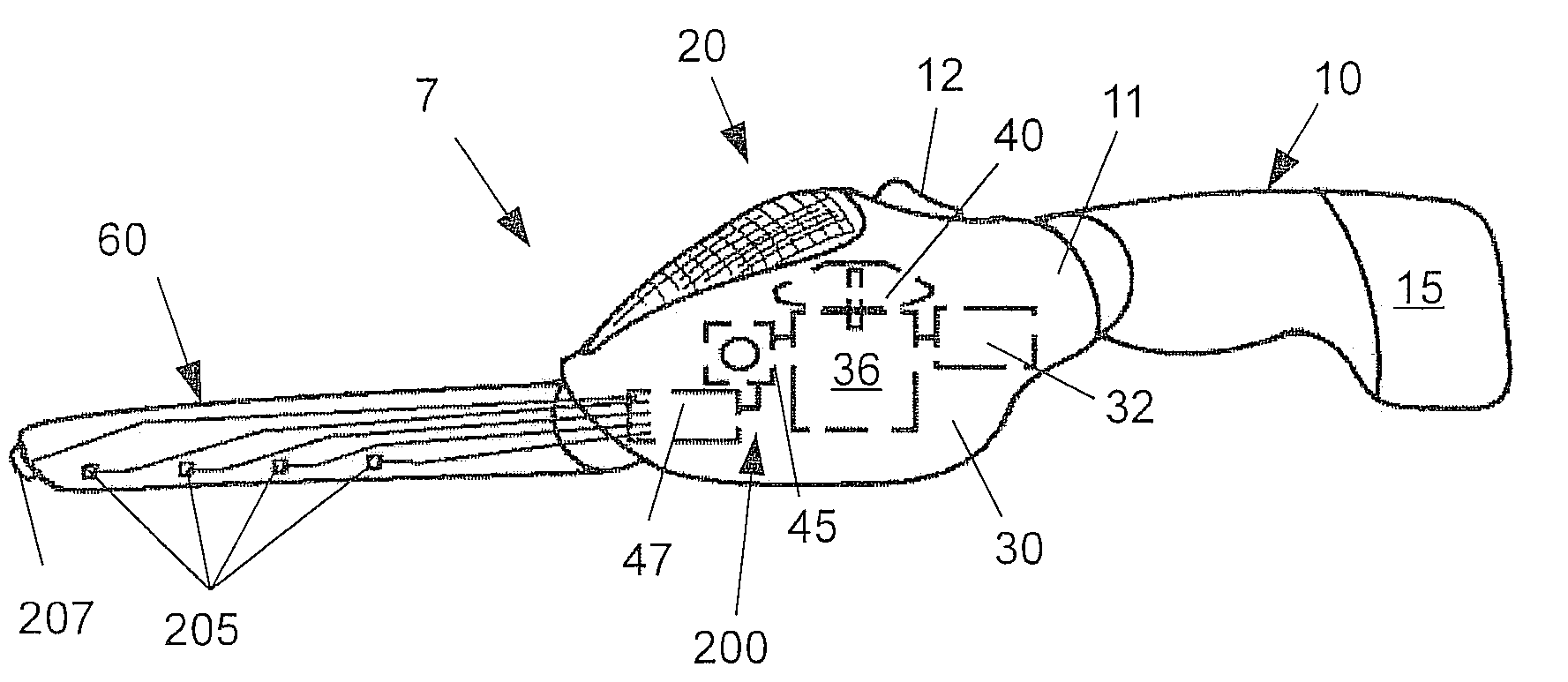

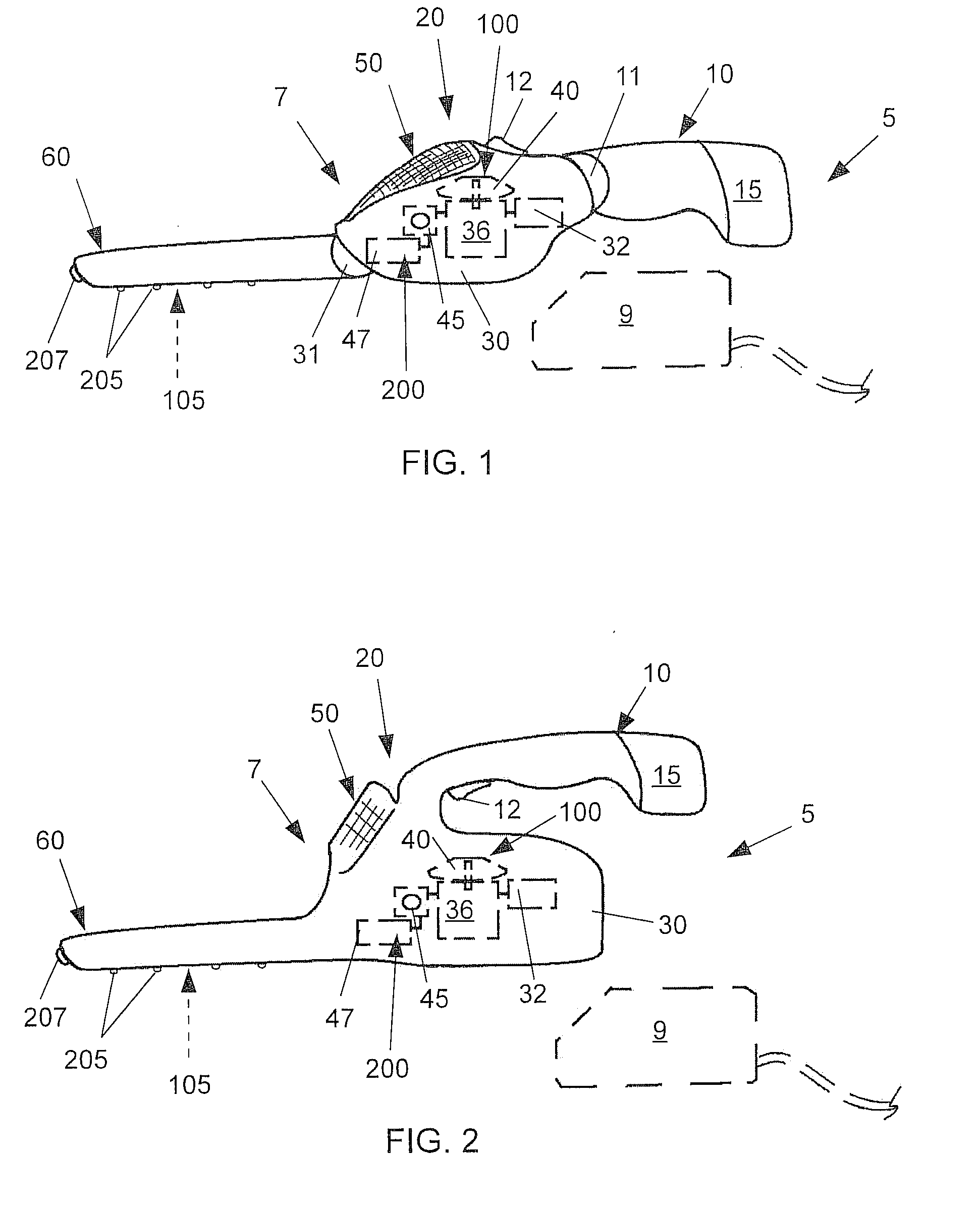

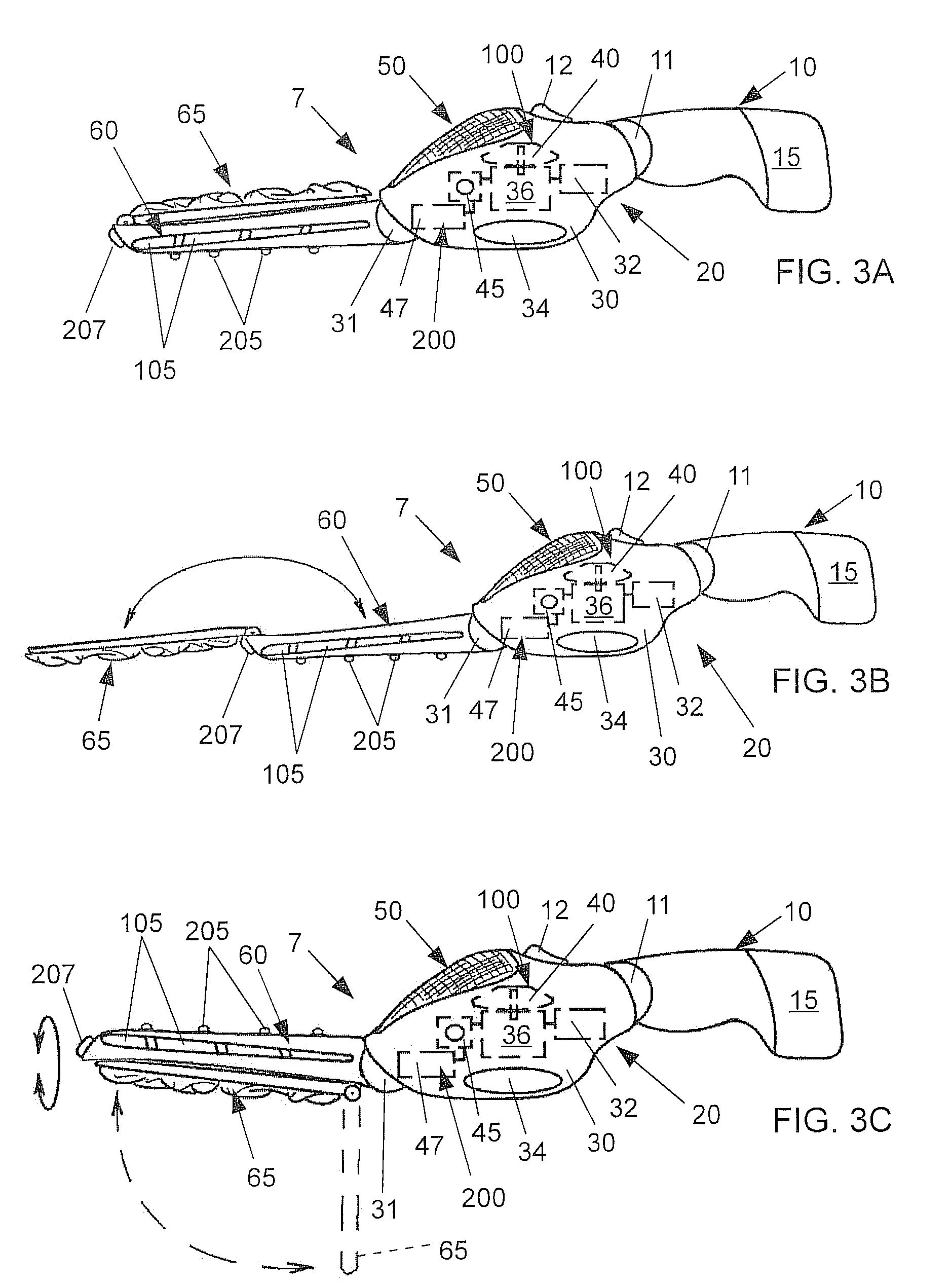

Handheld Portable Devices for Touchless Particulate Matter Removal

ActiveUS20090044372A1Increase pressureMechanical suction controlSuction nozzlesParticulatesEngineering

Handheld portable devices for dislodging and capturing particulate matter that has accumulated on various surfaces or structures are provided. The devices create opposing airflows that can intimately interface with each other during use. A vacuum airflow is drawn into the device, defining a vacuum affected zone upon the surface being cleaned. A high pressure airflow is emitted that penetrates through or passes adjacent to the opposing vacuum airflow and contacts the surface being cleaned, dislodging particulate matter therefrom. The high pressure airflow can be emitted from multiple nozzles as a series of airflow bursts that discretely contact the surface being cleaned. The configuration of each nozzle, as well as the overall arrangement and positions of all the nozzles together, are selected to impart the desired particulate matter dislodging characteristics to the device.

Owner:SC JOHNSON & SON INC

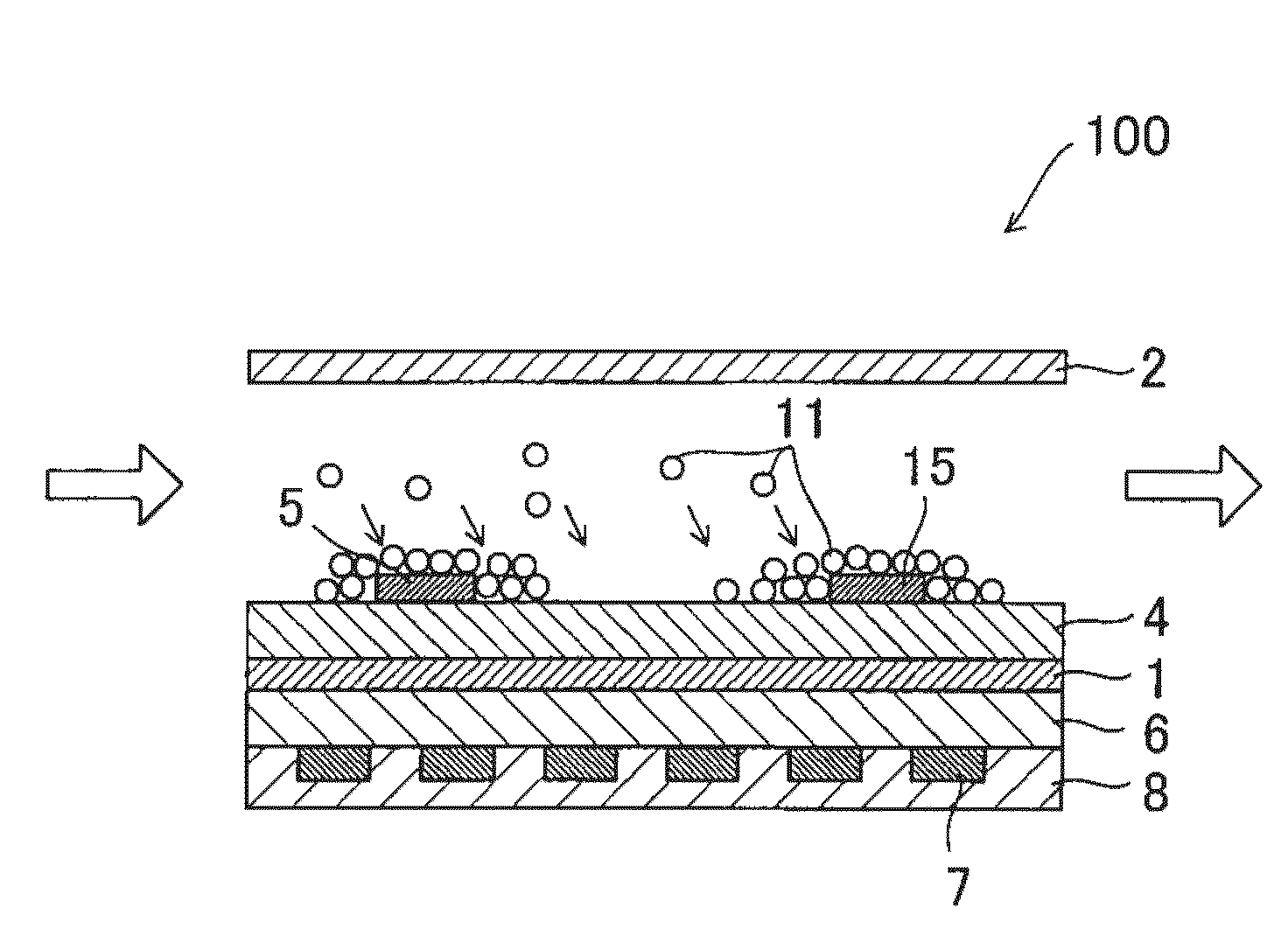

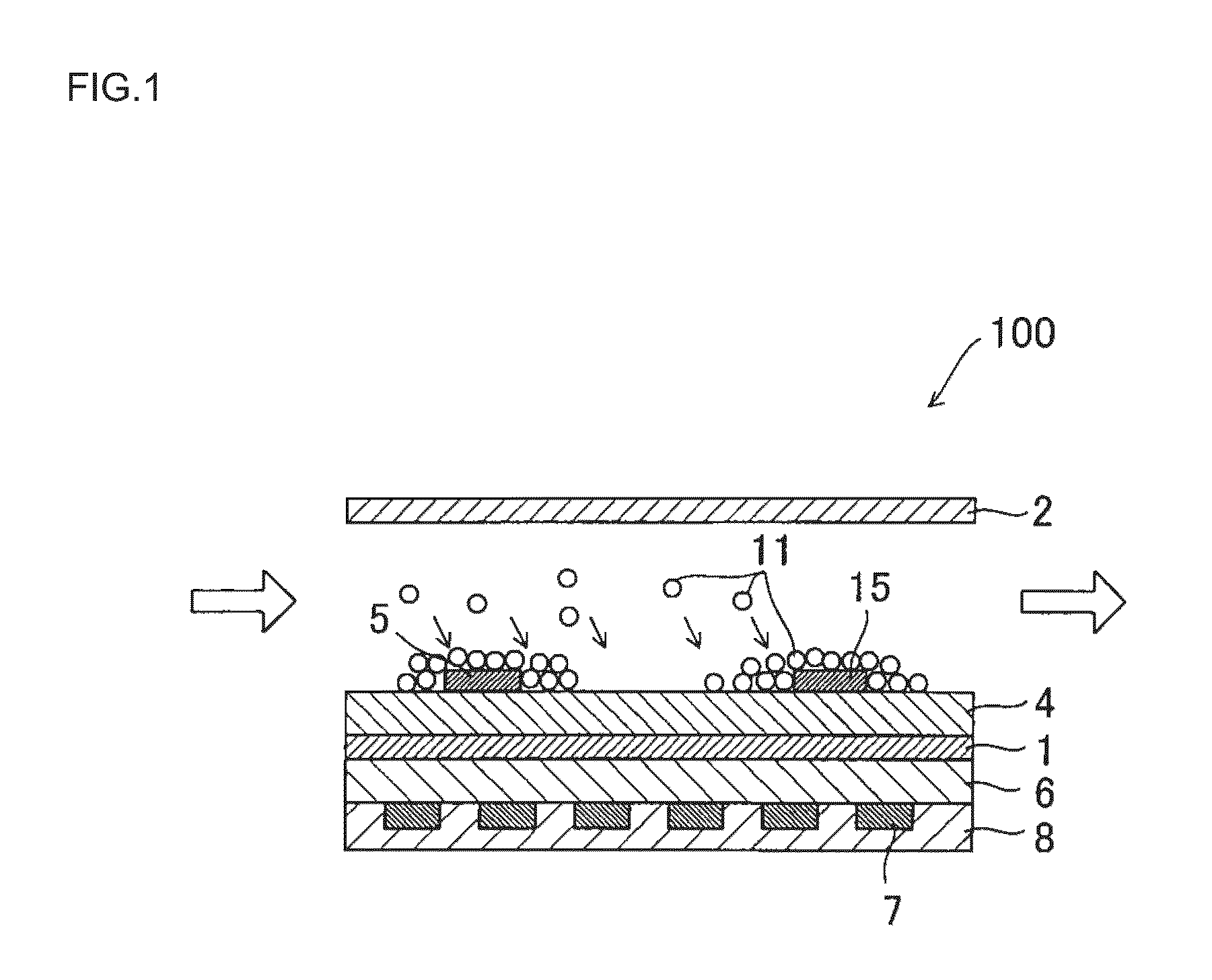

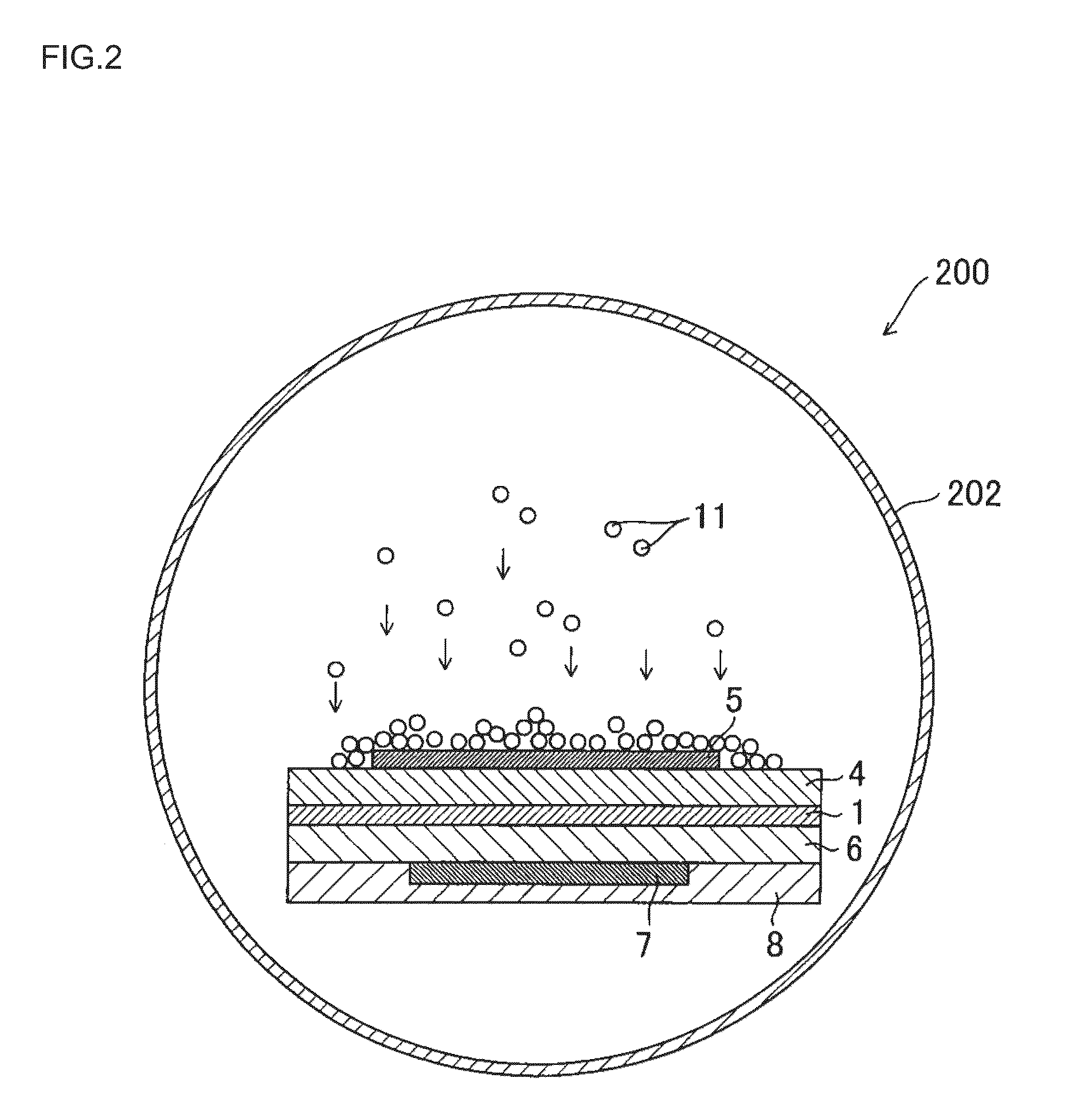

Particulate matter detection device

ActiveUS20100000863A1High measurement sensitivityCompactly receivedElectrical controlExhaust apparatusParticulatesEngineering

A particulate matter detection device 100 includes a first electrode 1 whose one surface is covered with an inter-electrode dielectric material 4; a second electrode 2 disposed on the side of the one surface of the first electrode 1, to perform the discharge of electricity by a voltage applied between the first electrode 1 and the second electrode; and a pair of measurement electrodes 5, 15 disposed on the surface of the inter-electrode dielectric material 4 so as to face each other; characteristic measurement means 3 for measuring electric characteristics between the pair of measurement electrodes 5 and 15; and particulate matter amount calculation means 13 for obtaining the amount of the particulate matter 11 collected by the surface of the inter-electrode dielectric material 4, based on the change amount of the electric characteristics.

Owner:NGK INSULATORS LTD +1

Sludge dewatering agent and dewatering method thereof

InactiveCN101100345AFast dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningIron saltsOrganic matter

This invention discloses a waste-sludge dewatering agent. It contains (by the weight of the water content in waste-sludge being treated) of: iron salt 1-3%; ion-dispersing agent with surface-activity 1-5%; granular matter 3-6% and the rest water 60-70%. This inventive dewatering of waste-sludge method is also a waste-sludge temperament method, comprises procedures of: adding water into said sludge, agitating for 1-3 minutes; adding iron salt and reacting, during agitating, for 2-6 minutes; adding ion-dispering agent and reacting, during agitating, for 2-8 minutes; adding granular matter and reacting, during agitating, for 2-6 minutes. This inventive method for dewatering of waste-sludge has advantages of: fast dewatering, excellent results and no reducing of organic matters during this dewatering process.

Owner:GUANGZHOU PUDE ENVIRONMENTAL EQUIP

Novel solid-state cigarette core of electronic cigarette and preparation method for novel solid-state cigarette core

InactiveCN104223366AIncrease contact areaIncrease the heating areaTobacco devicesHeater RodEngineering

The invention relates to a novel solid-state cigarette core of an electronic cigarette and a preparation method for the novel solid-state cigarette core, belongs to the technical field of electronic cigarettes, and particularly relates to a solid-state cigarette core of the electronic cigarette and a preparation method thereof. The solid-state cigarette core of the electronic cigarette is prepared by heating an aroma carrier material and has a filtering effect. Through a design of a hollow cigarette core, a contact area between the cigarette core and a heating rod is increased, and a heating area and the heating efficiency of an atomizer are increased; a fibrous material is taken as a carrier to fully adsorb the aroma carrier material, and by indirectly heating the thermosensitive solid aroma carrier material, smoke which can be inhaled by a consumer is formed, and the consumer is endowed with the natural tobacco feel. Meanwhile, through reasonable combination of the paper hollow cigarette core and a filter element, the aroma carrier function and the filtration function of the material are perfectly combined, the smoke which has certain resistance to suction and which can be inhaled by the consumer is formed, the contents of tar and harmful granular matters in the smoke of the electronic cigarette are reduced, the smoking feel similar to the conventional cigarettes is endowed, and the electronic cigarette smoking pleasure is greatly improved.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

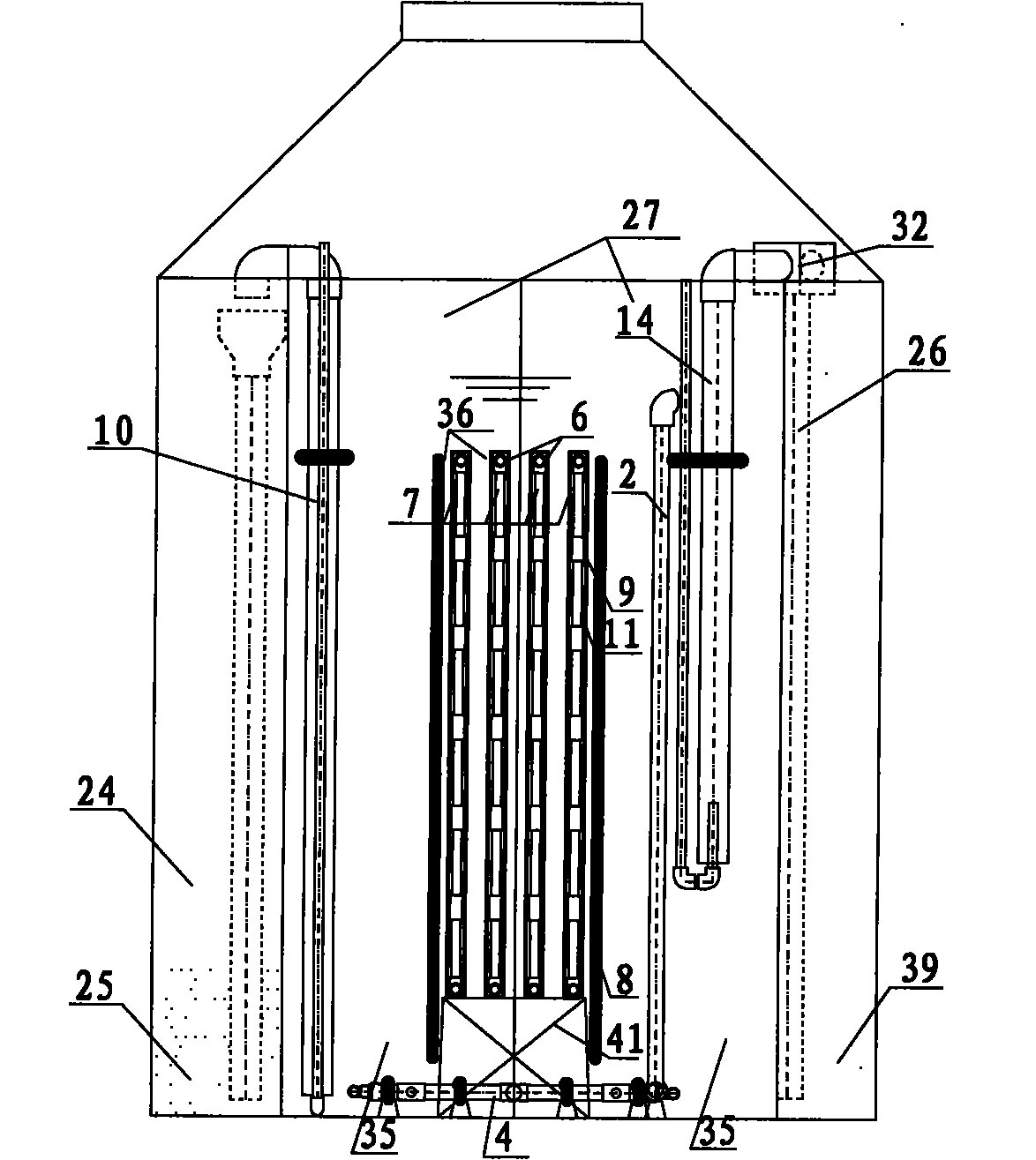

Particulate matter removal apparatus

InactiveUS20080066621A1Improve heating efficiencyRegenerate in small quantityCombination devicesAuxillary pretreatmentParticulatesThermal energy

A filter is made with heat-insulating ceramic fibers, and where the filter is increased in pressure loss due to particulate matter captured after filtration of exhaust gas, gas flow is blocked, a heating element is used to heat the surface of the filter, thereby burning and removing particulate matter. The filter is of heat insulating properties, by which a heat insulating material is arranged near the particulate matter capturing face of the filter, and the heating element is incorporated between the surface of the filter and the heat insulating material. The filter can be regenerated at a higher heating efficiency in a smaller quantity of thermal energy. The heat insulating material is also used as a filter, by which the apparatus can be made more compact. A charging element is arranged upstream of the filter material, by which the filter material is increased in particulate matter capturing performance, thereby suppressing the rate of increase in the pressure loss and improving heating efficiency of particulate matter.

Owner:NISSIN ELECTRIC CO LTD

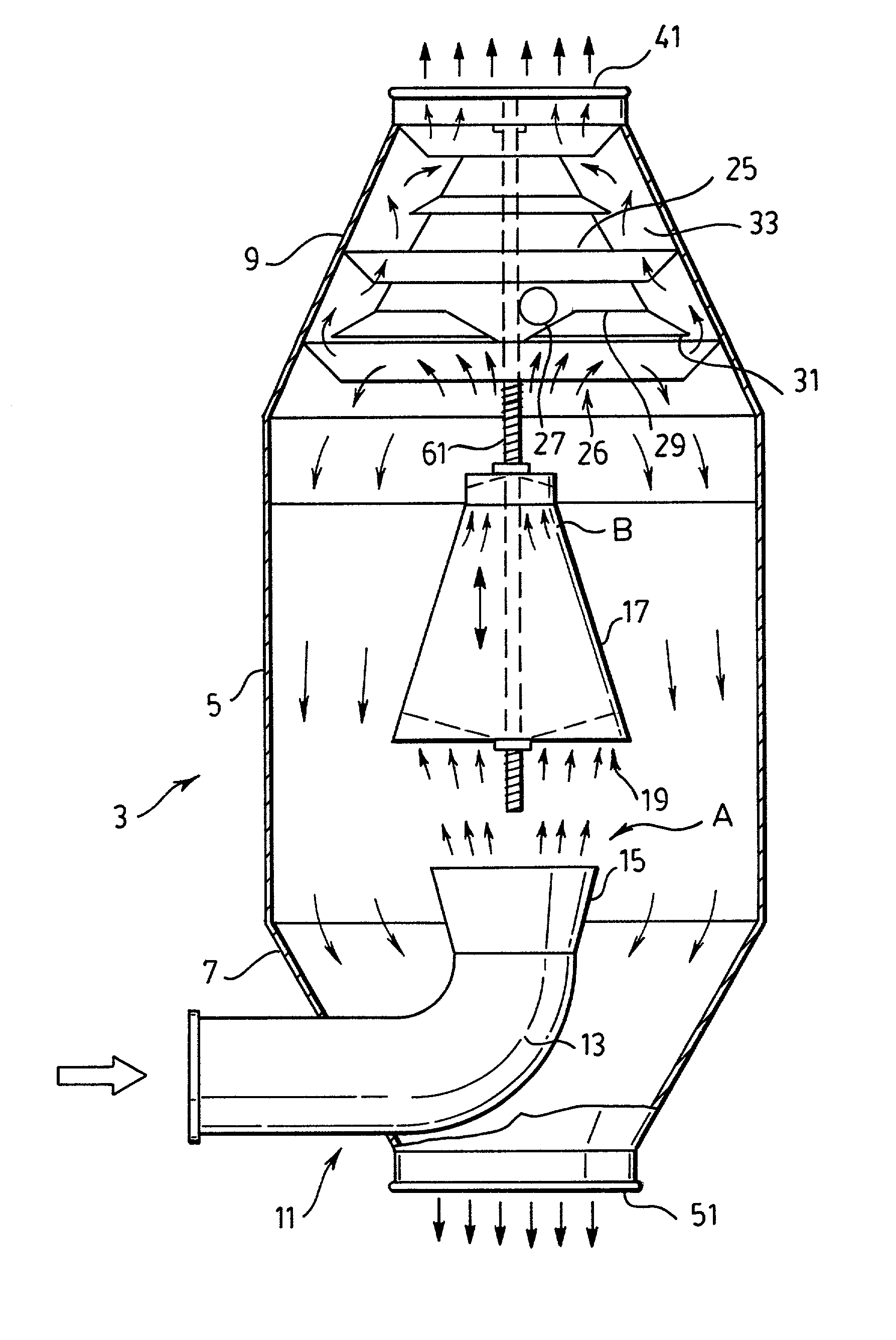

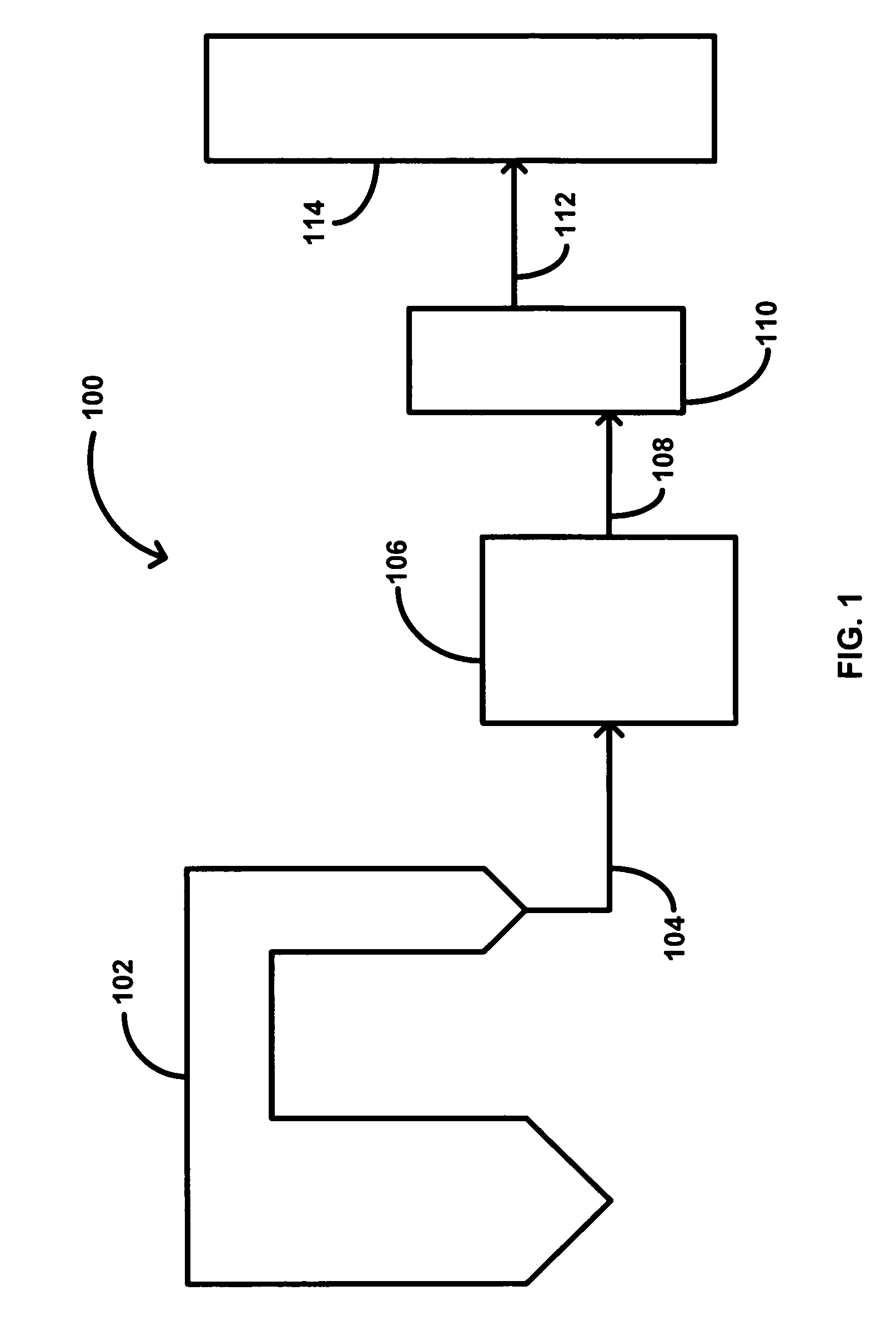

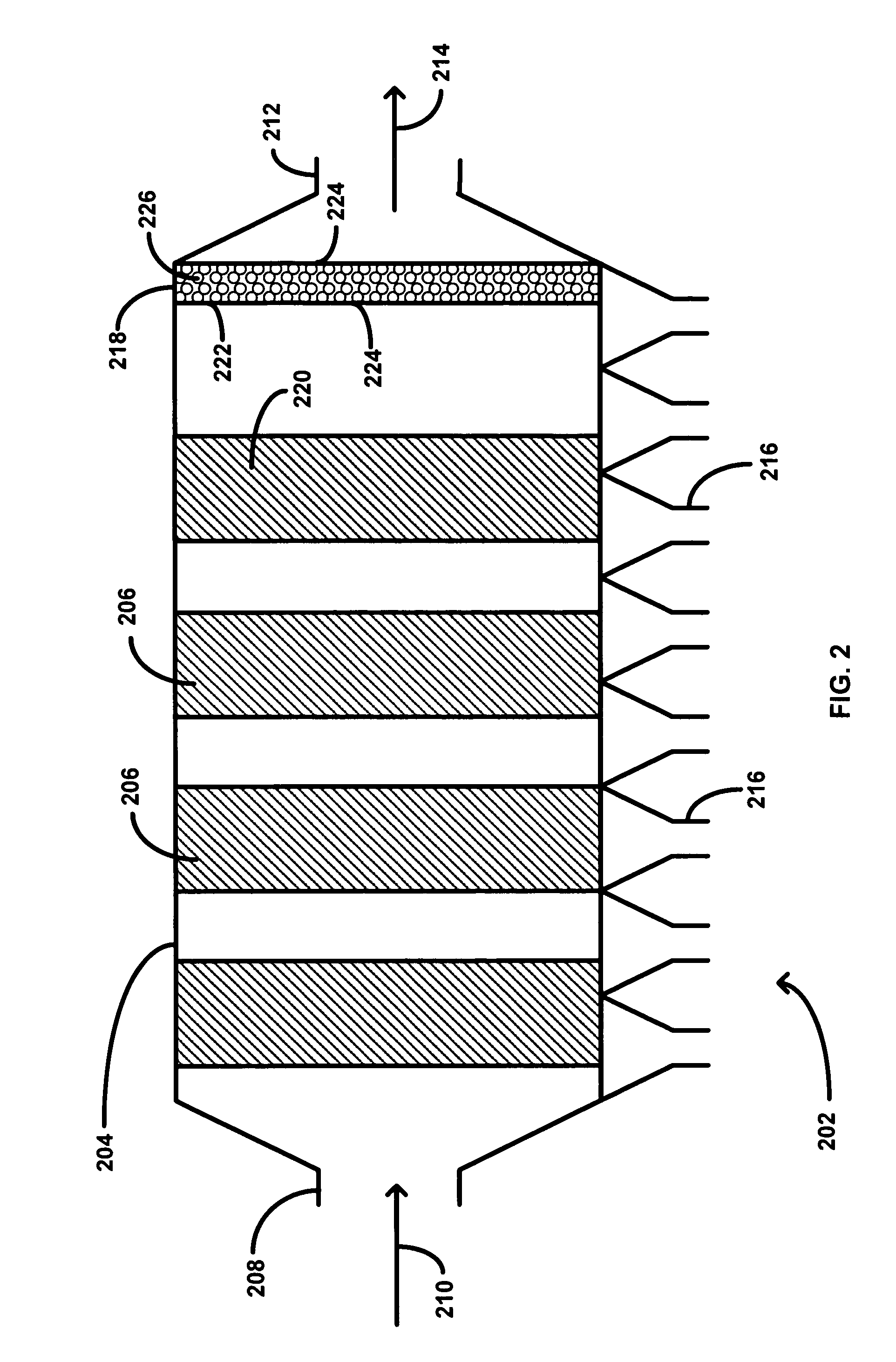

Method and system for separating particulate matter

InactiveUS20060081503A1Reduce the amount requiredIncreasing an available pathwayGas current separationContaminated soil reclamationParticulatesEngineering

The present invention is directed to a system and method for continuously or substantially continuously separating particulate matter based on particle size and / or density of the matter. The system includes a separation chamber having a bottom portion disposed within a cavity of a rotatable bowl having fluid therein, preferably water. The internal cavity of the separation chamber is maintained under negative pressure such that fluid is drawn through the separation chamber at a predetermined velocity to separate the solids. Larger, dewatered and / or denser solids are directed to the cavity of the rotatable bowl and can be removed by rotation of the bowl while the smaller and / or less dense solids and fluid travel up through the separation chamber.

Owner:WEGNER PAUL C

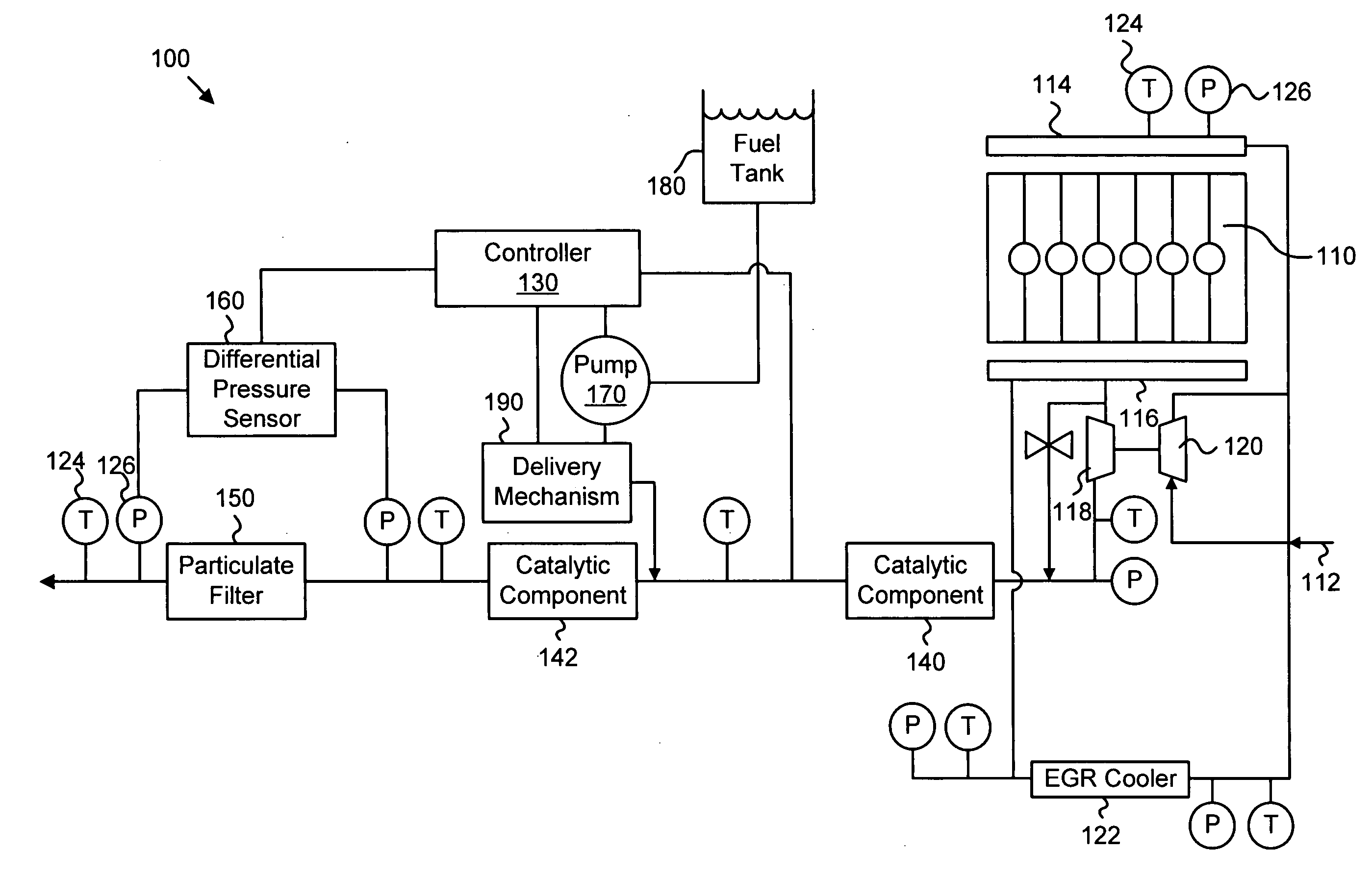

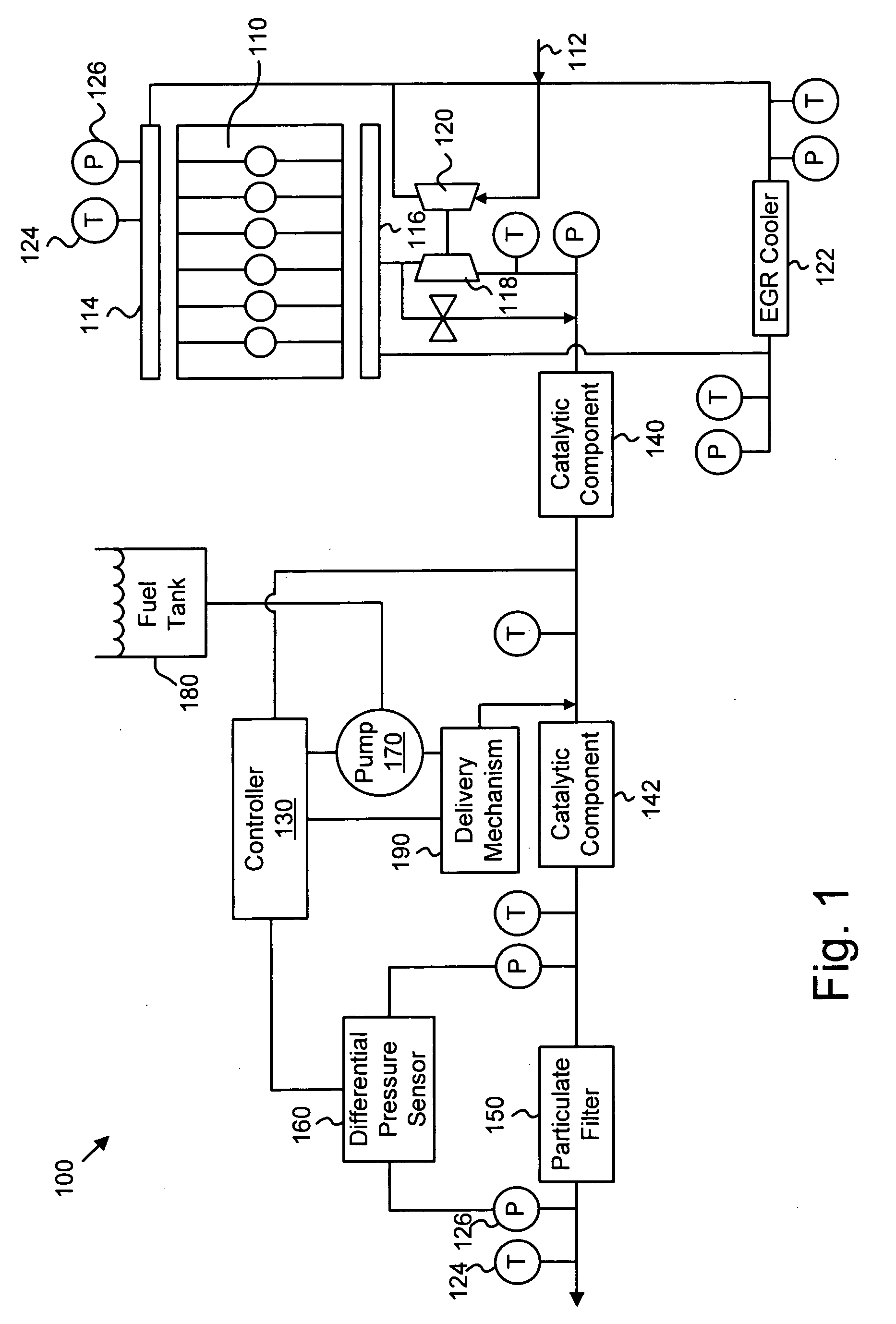

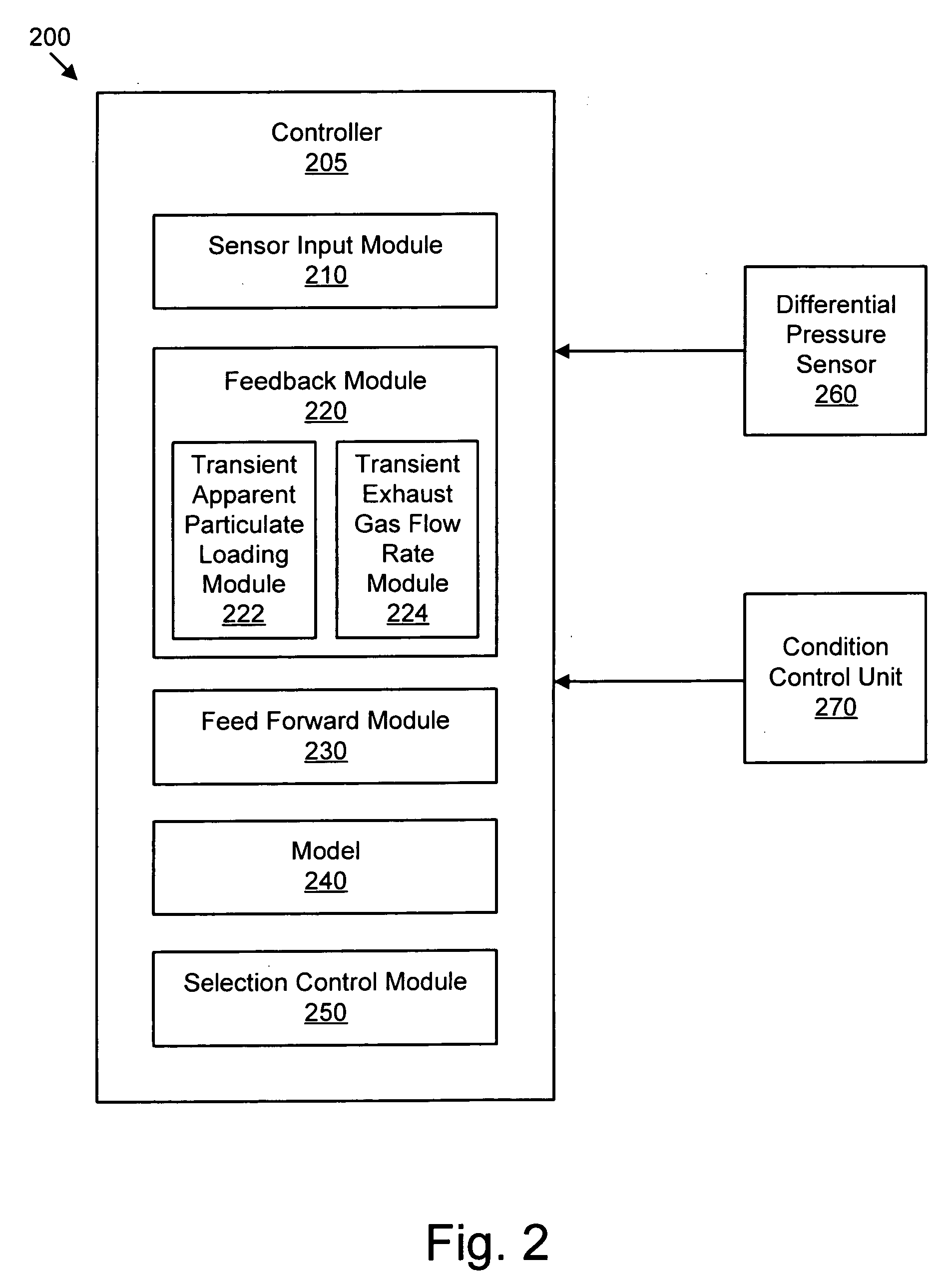

Apparatus, system, and method for determining the distribution of particulate matter on a particulate filter

ActiveUS20070056271A1Easy to determineLoad accuratelyNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesDifferential pressure

An apparatus, system, and method are disclosed for determining the distribution of particulate matter on a particulate filter. The apparatus, in one embodiment, determines a first distribution of particulate matter by comparing the pressure change across the particulate filter with a change in engine operating conditions. The apparatus may include an input module for receiving input corresponding to engine operating conditions and input from a differential pressure sensor and a feedback module to determine a first distribution of particulate matter. The apparatus may further include a feed forward module for determining a particulate distribution trend and a selection control module to combine the first distribution of particulate matter with the particulate distribution trend to determine a second distribution of particulate matter. The distribution may be defined as a uniform distribution factor in certain embodiments.

Owner:CUMMINS INC

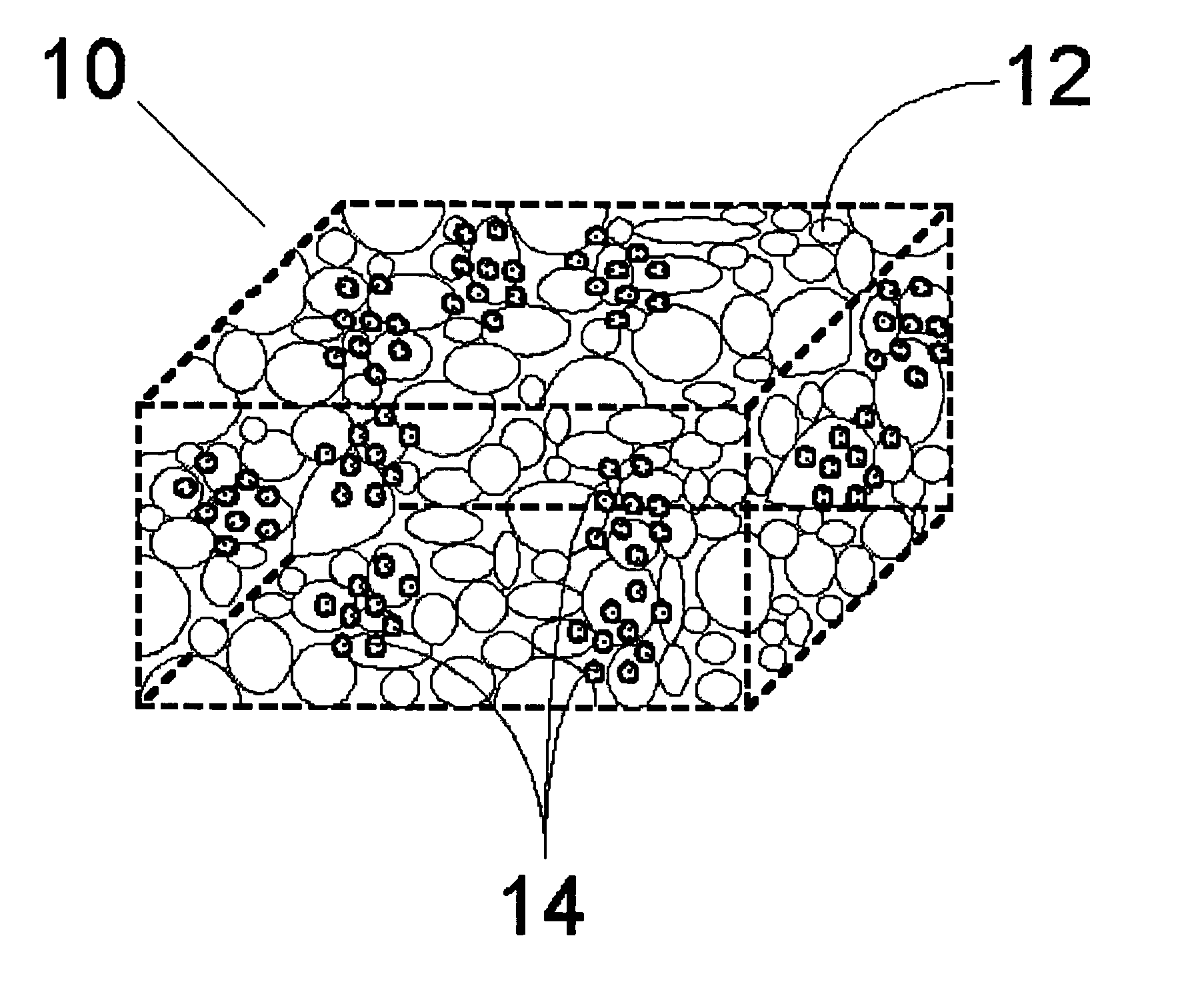

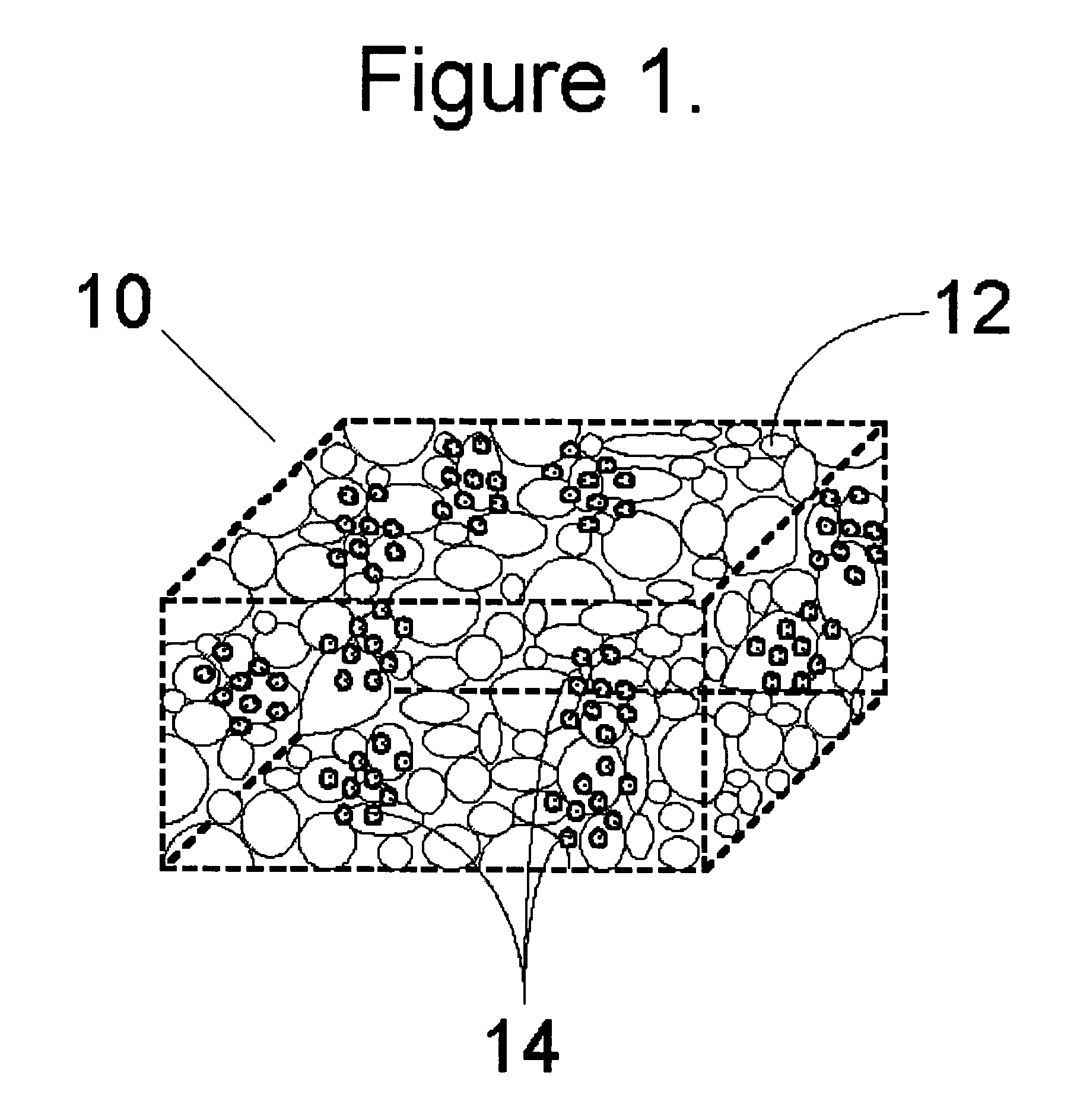

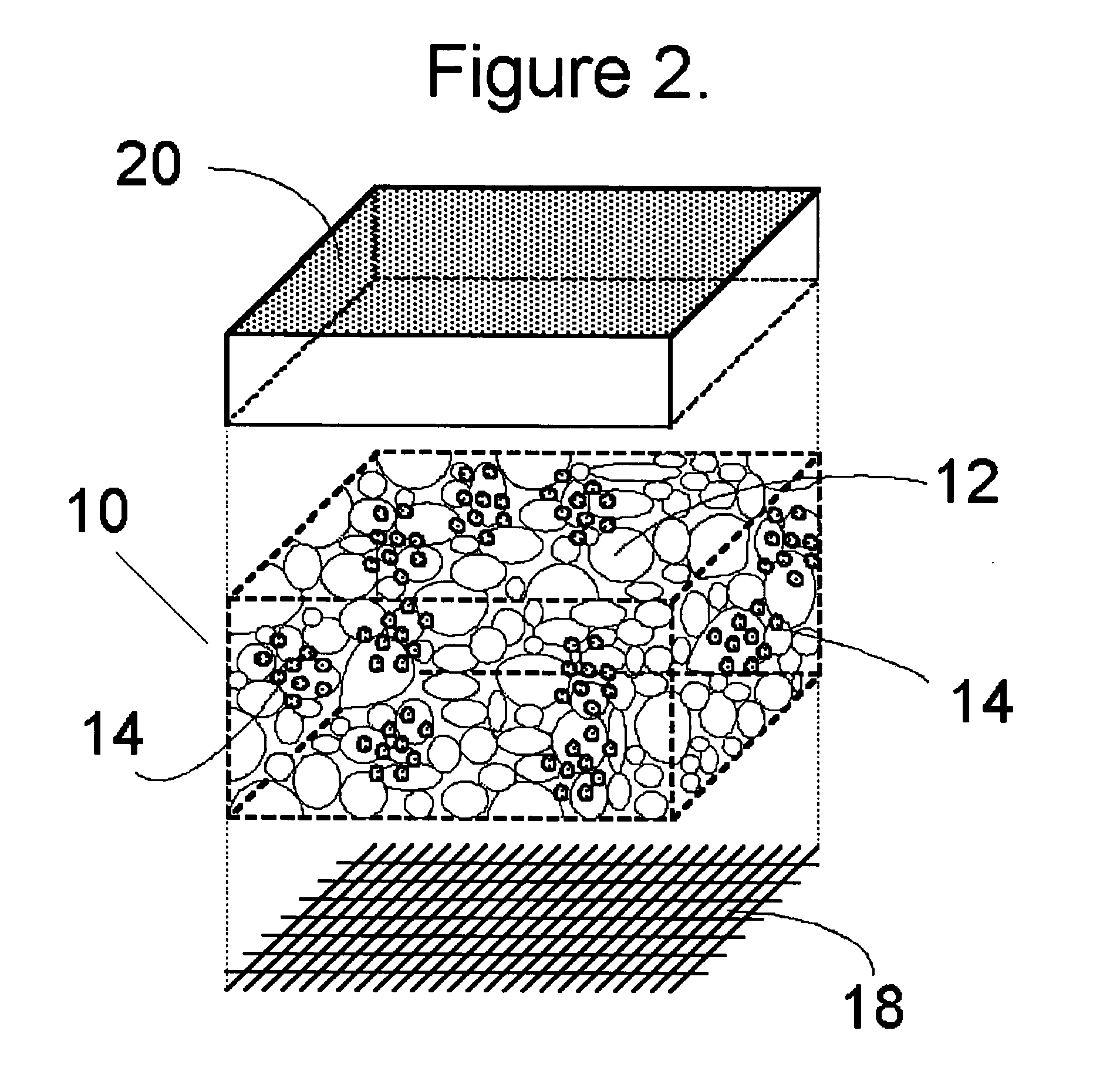

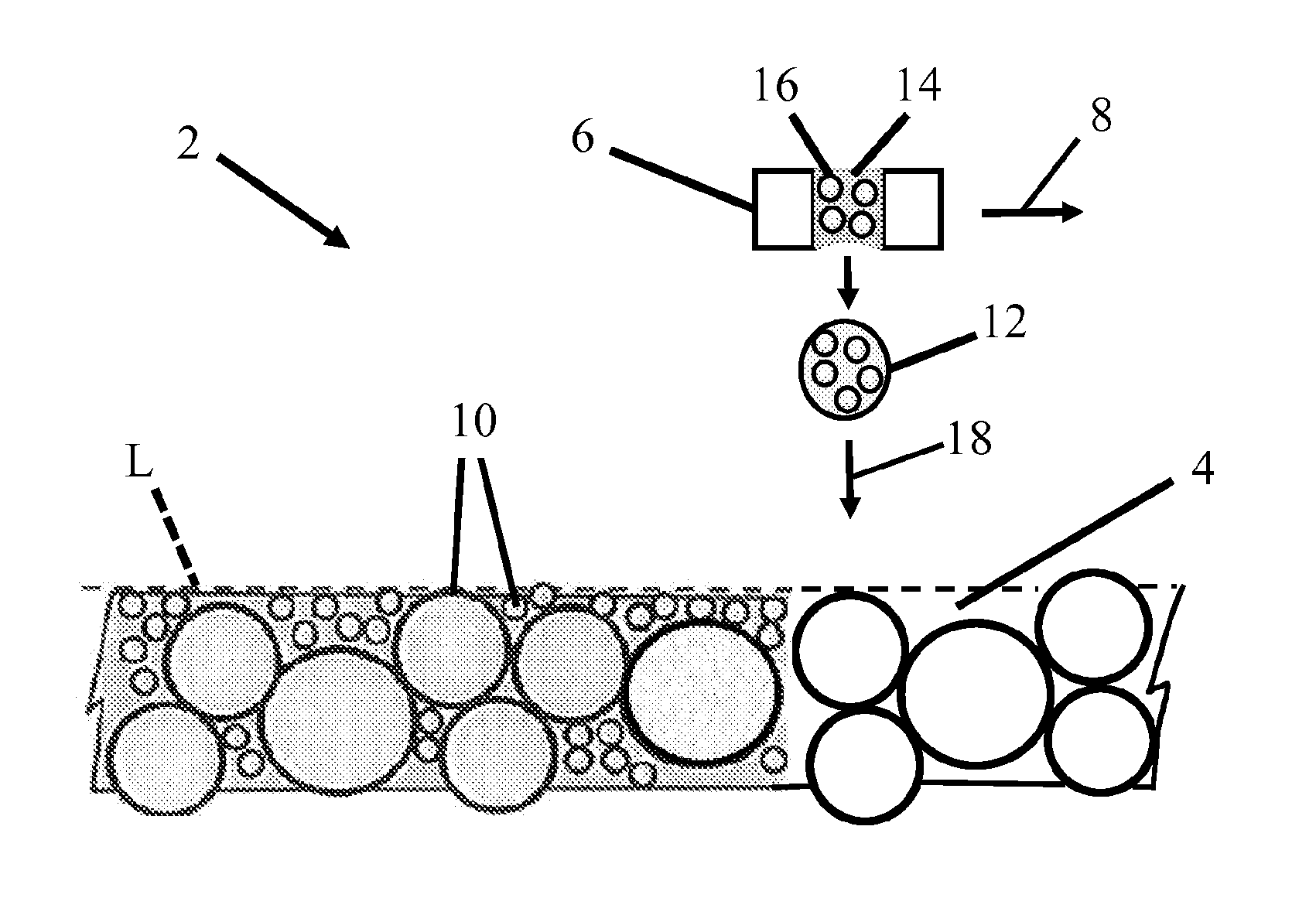

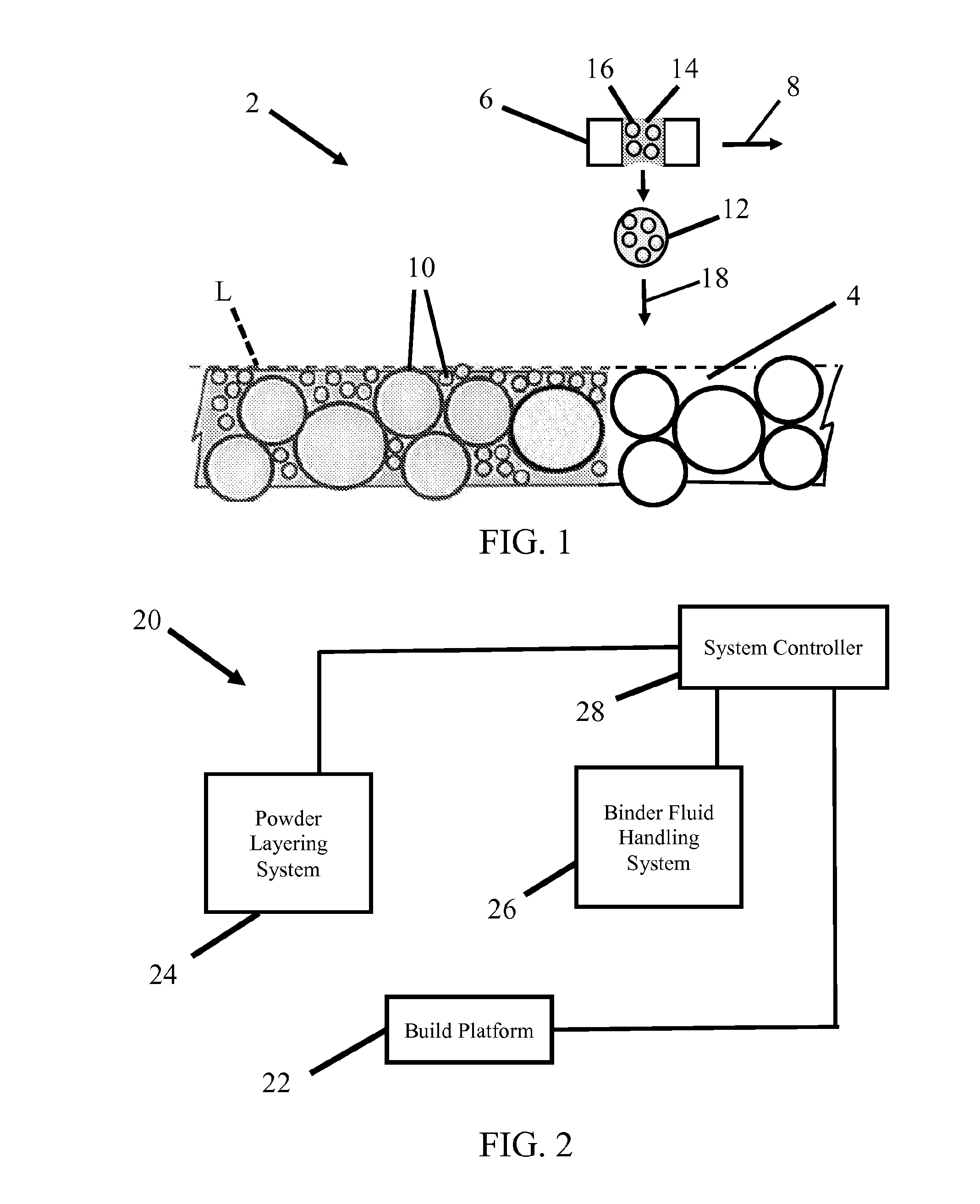

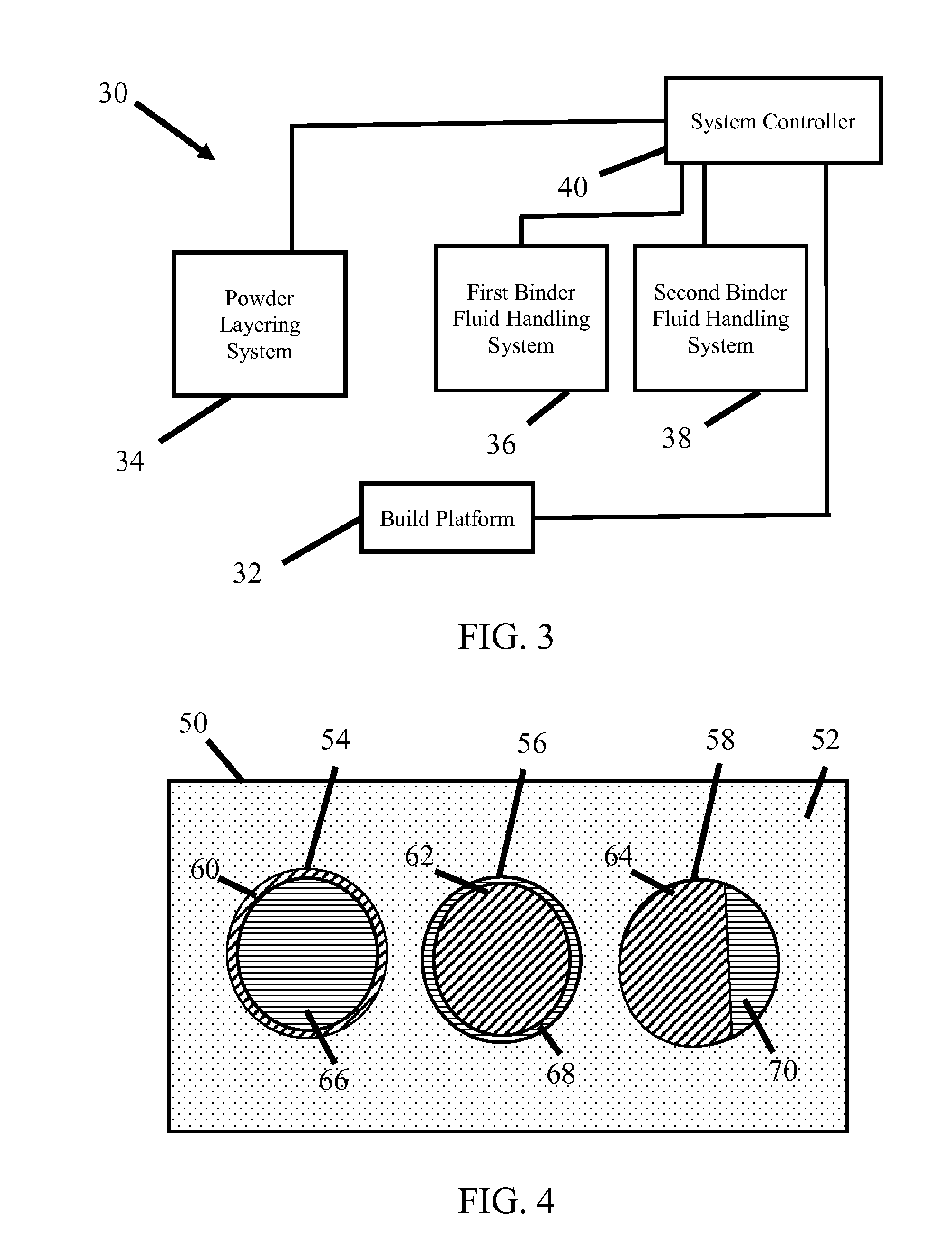

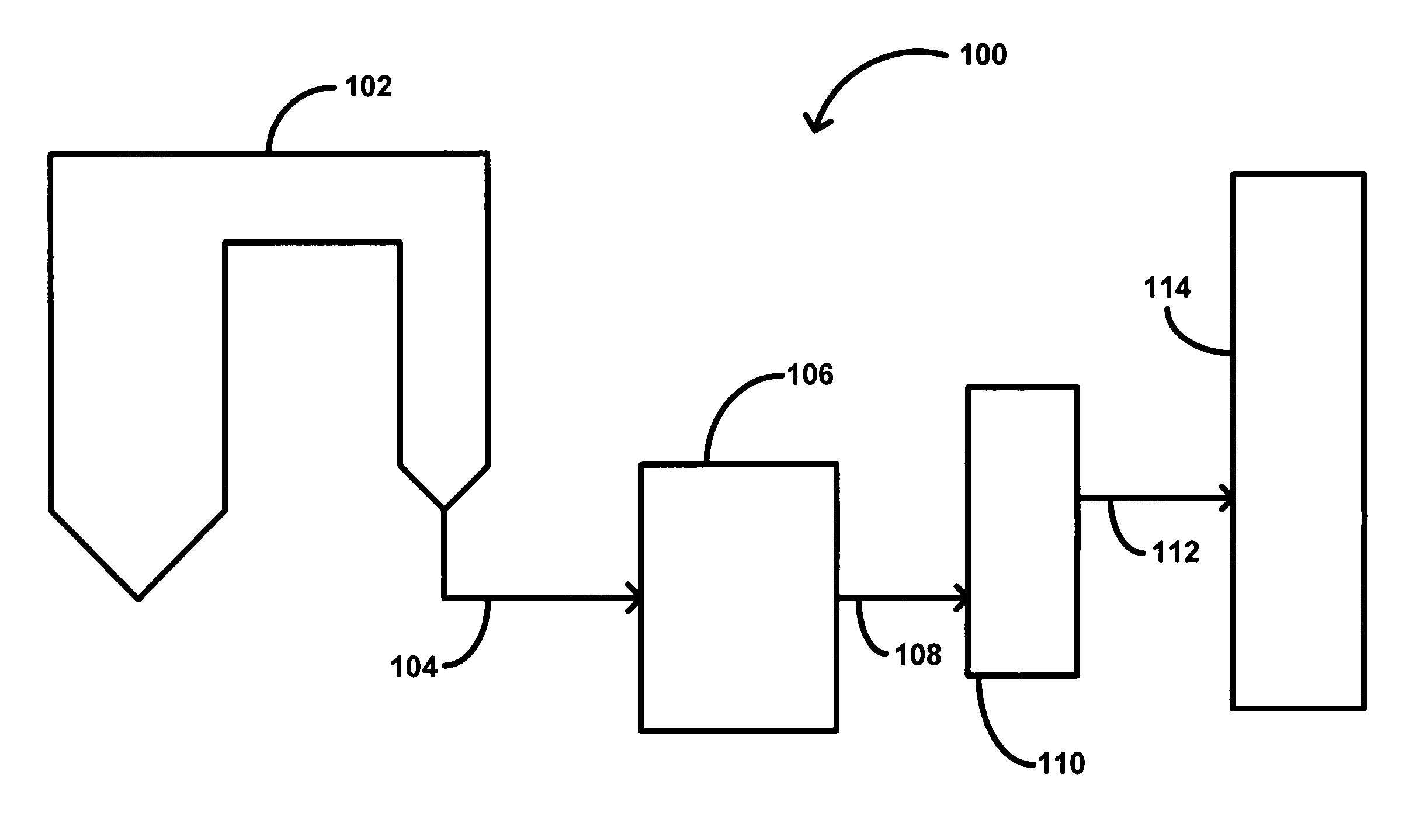

Methods and Systems for Three-Dimensional Printing Utilizing Multiple Binder Fluids

InactiveUS20160332373A1High densityImprove resolutionAdditive manufacturing apparatus3D object support structuresSurface finishThermal coefficient

Methods and systems (2) are disclosed for making articles (114) by three-dimensional printing. The methods include selectively printing by jet deposition on successive layers (4) of a build material powder (10) at least one of a first binder fluid and a second binder fluid. At least one of the first and second binder fluids includes a particulate matter (16) having mean particle size diameter which is less than that of the build material powder (10). The first binder fluid is characteristically different from the second binder fluid. The particulate matter (16) selectively deposited with a binder fluid can be used to locally tailor the physical properties of the article (114), e.g. by alloying with the build material powder, increasing densification, acting as a local infiltrant or infiltrant stop during heat treatment, locally modulating the local stress fields (e.g. by a mismatch of thermal coefficients of expansion), etc. Among the possible locally tailored properties is the surface finish of an interior or exterior surface of the article (114).

Owner:THE EX ONE

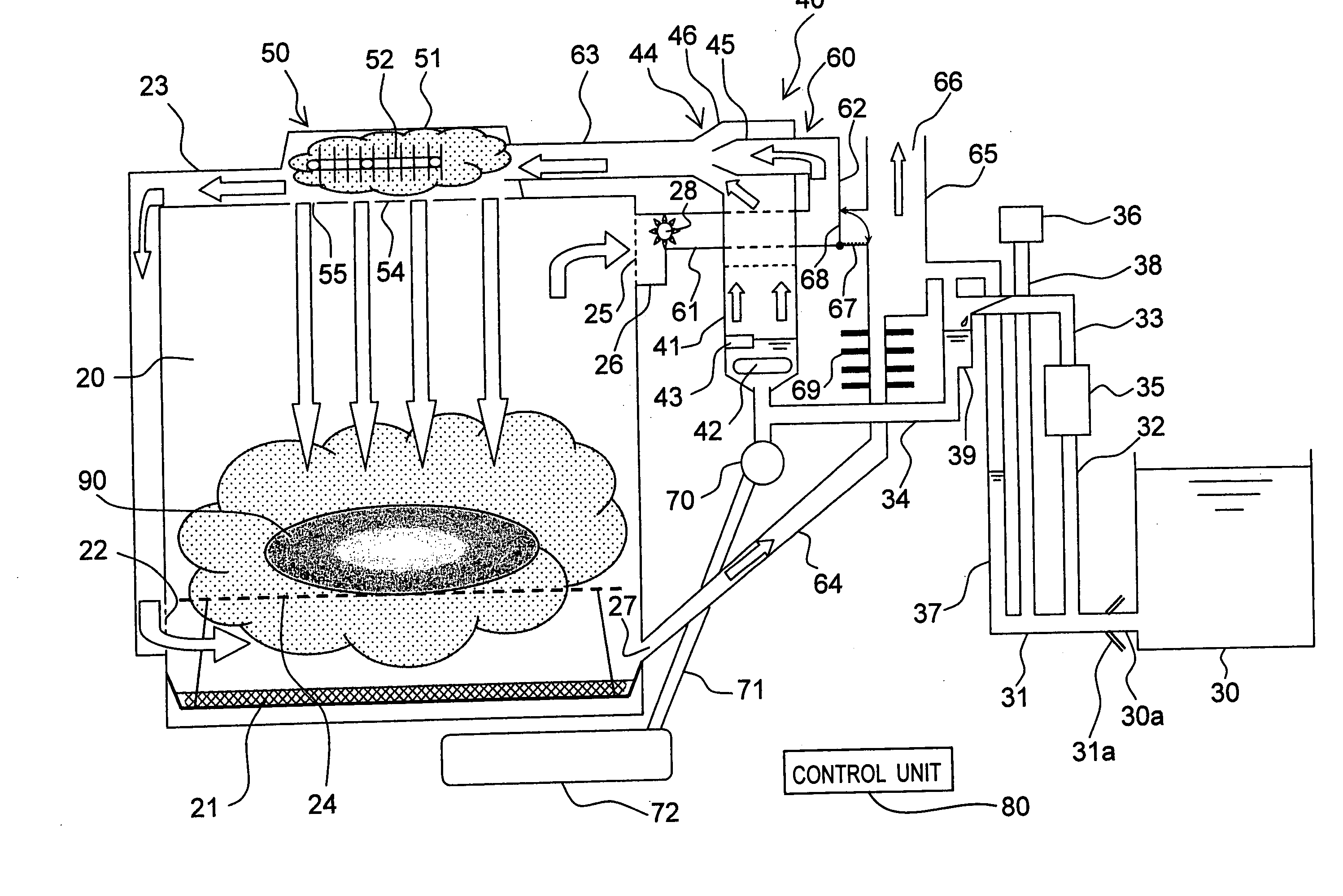

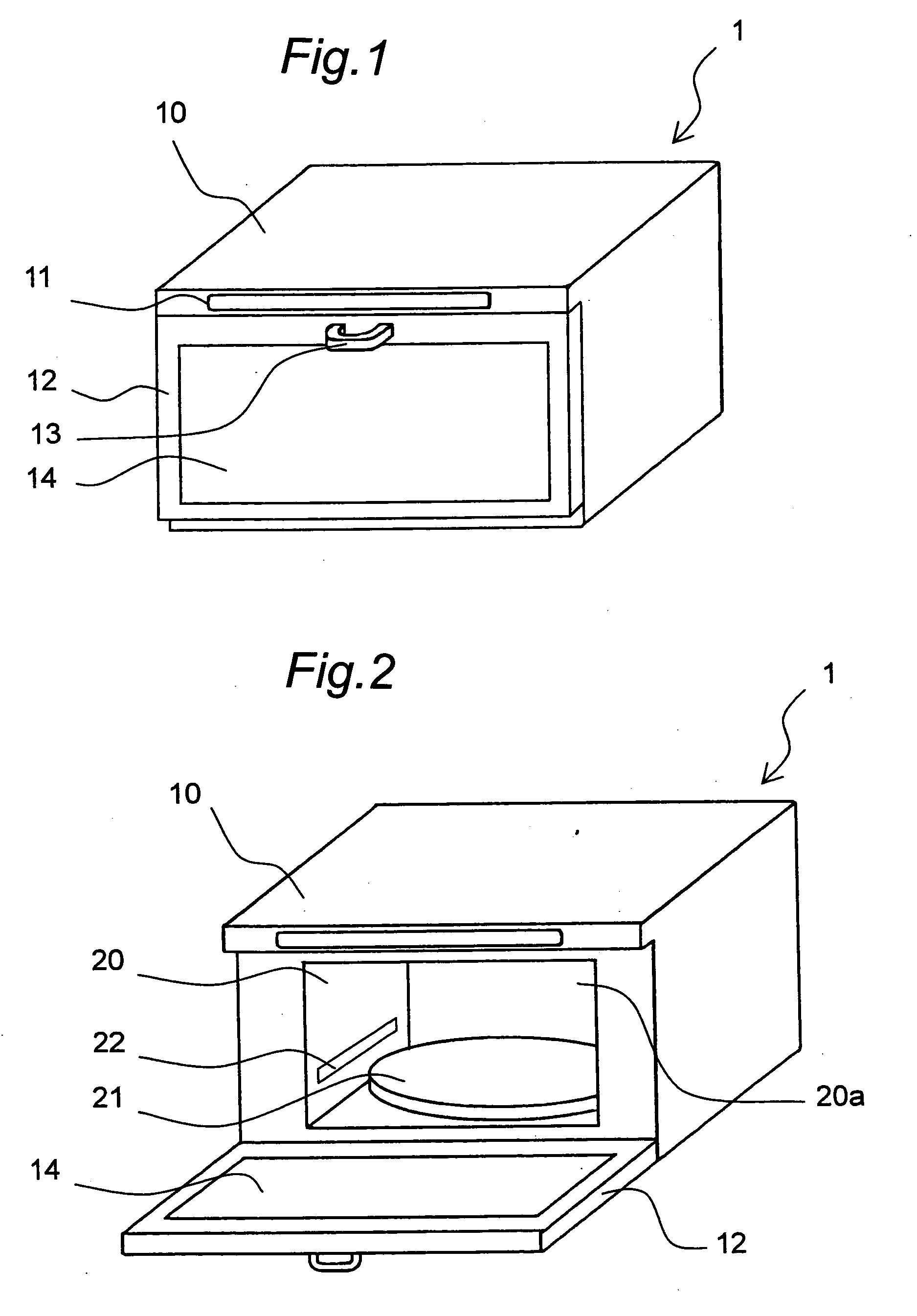

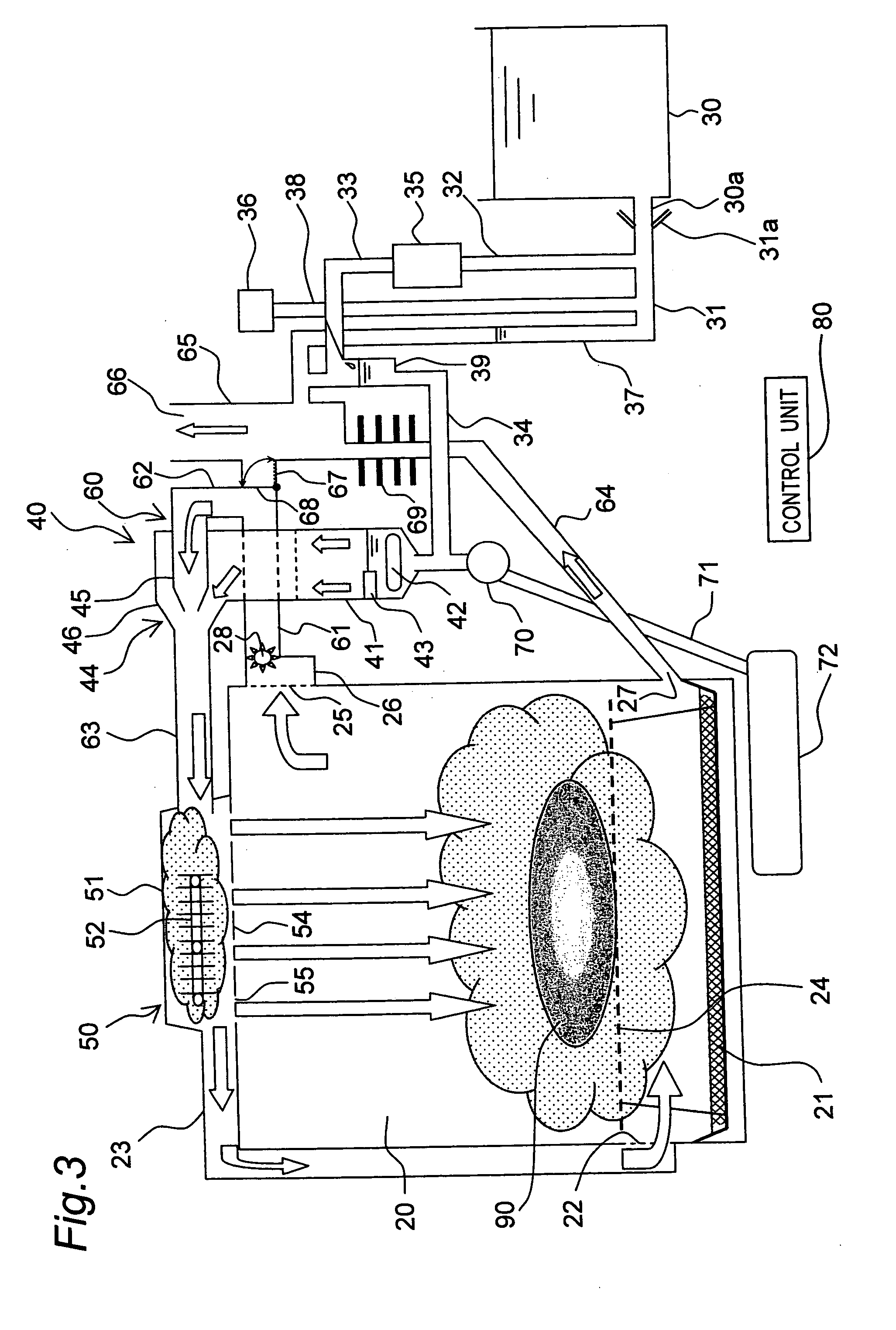

Steam Cooker

InactiveUS20070227364A1Efficient condensationShort timeDomestic stoves or rangesBoiling over preventionEngineeringSuperheater

In a steam cooker, for heating of a food which is a mass of granular matters or linear matters such as rice or chow mein, a steam superheater is not turned on or is turned on with a very weak electric power so that steam supplied from steam supply pipes (94A to 94C) is substantially not superheated. Steam of 80° C. to 90° C. derived from the steam supply pipe (94B) is jetted out right downward from an opening (111a) of a steam jet pipe (111). Then, steam located around an end portion of the steam jet pipe (111) in a tray-shaped case (51) is pulled in by steam jetted out from the opening (111a), so that a large amount of steam is jetted against a bowl of rice or a dish of chow mein. As a result, surfaces of, for example, rice grains are prevented from immediately going beyond 100° C., so that condensation at the surfaces of the rice grains is efficiently achieved, and supply of condensed latent heat and penetration of condensed water (hot water) to the rice grains is efficiently achieved.

Owner:SHARP KK

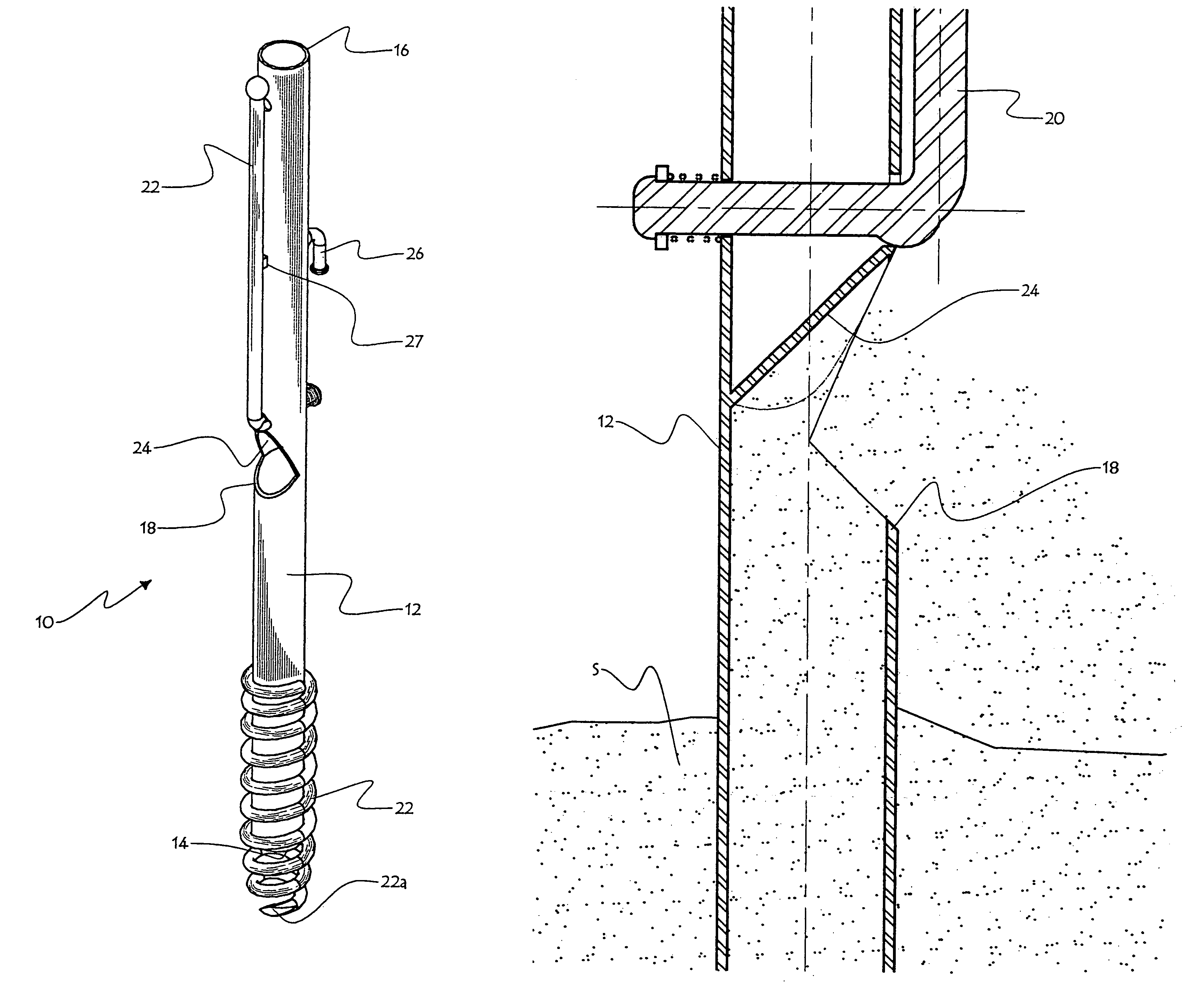

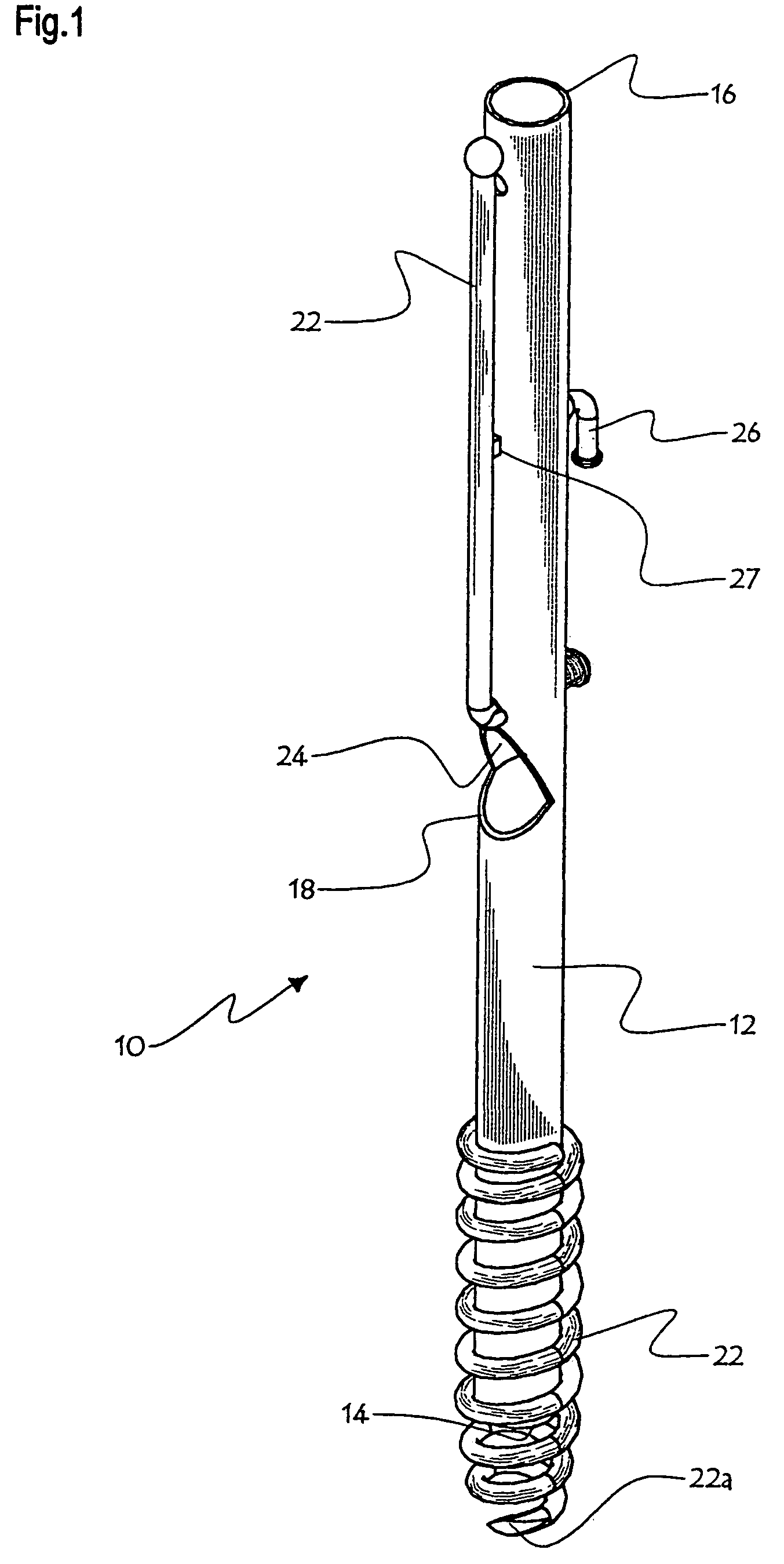

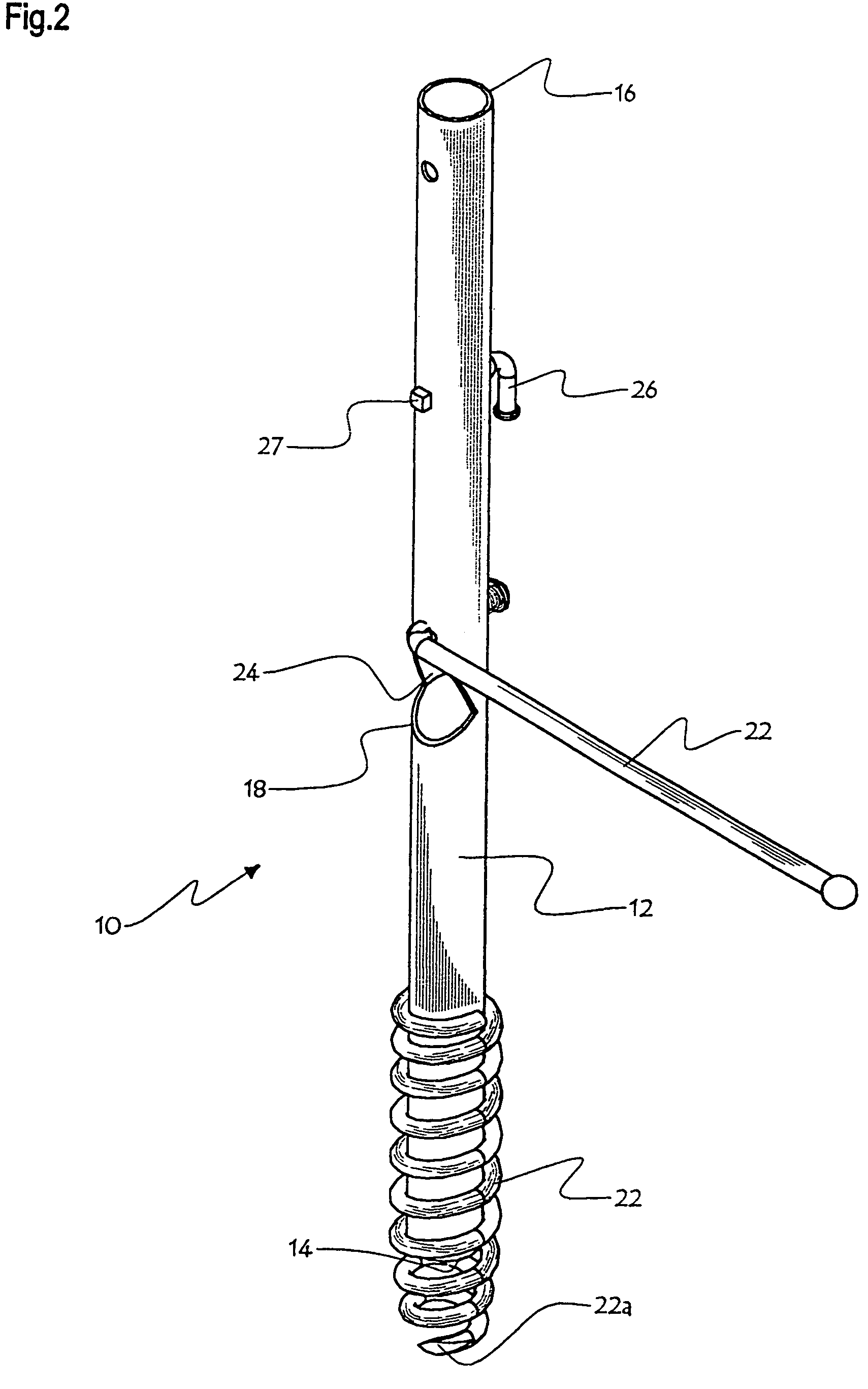

Support device destined to be anchored in the ground

The device, destined to be anchored in the ground of granular composition, comprises a rod with a hollow tubular section, the latter having an open upper end wherein can be fixed an object and an intermediate orifice on its flank. The orifice enables evacuation of the granular matter constituting the ground and penetrating into the rod through its open lower end when the device is being anchored in the ground.

Owner:PATSALARIDIS DIMITRIOS

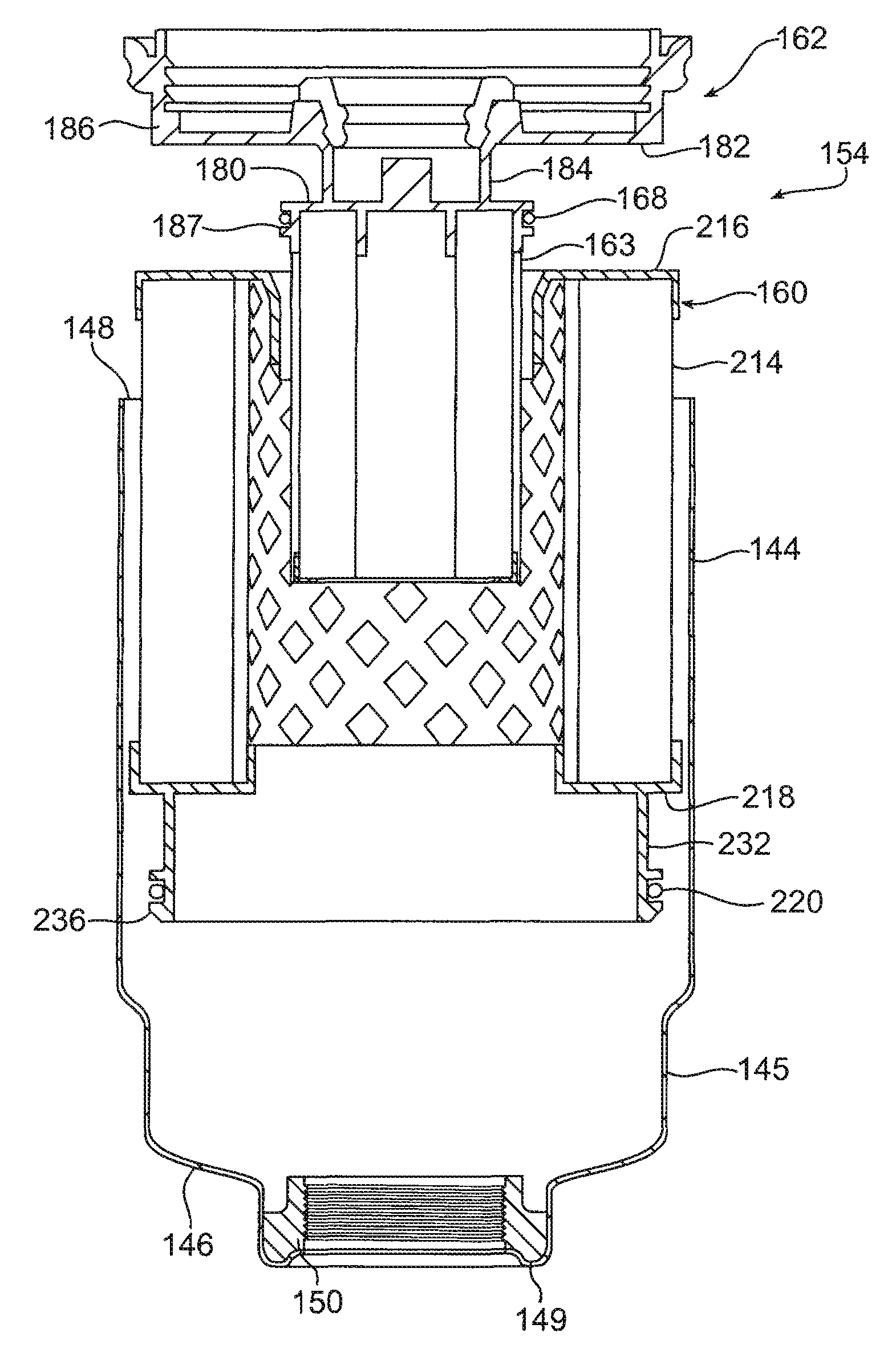

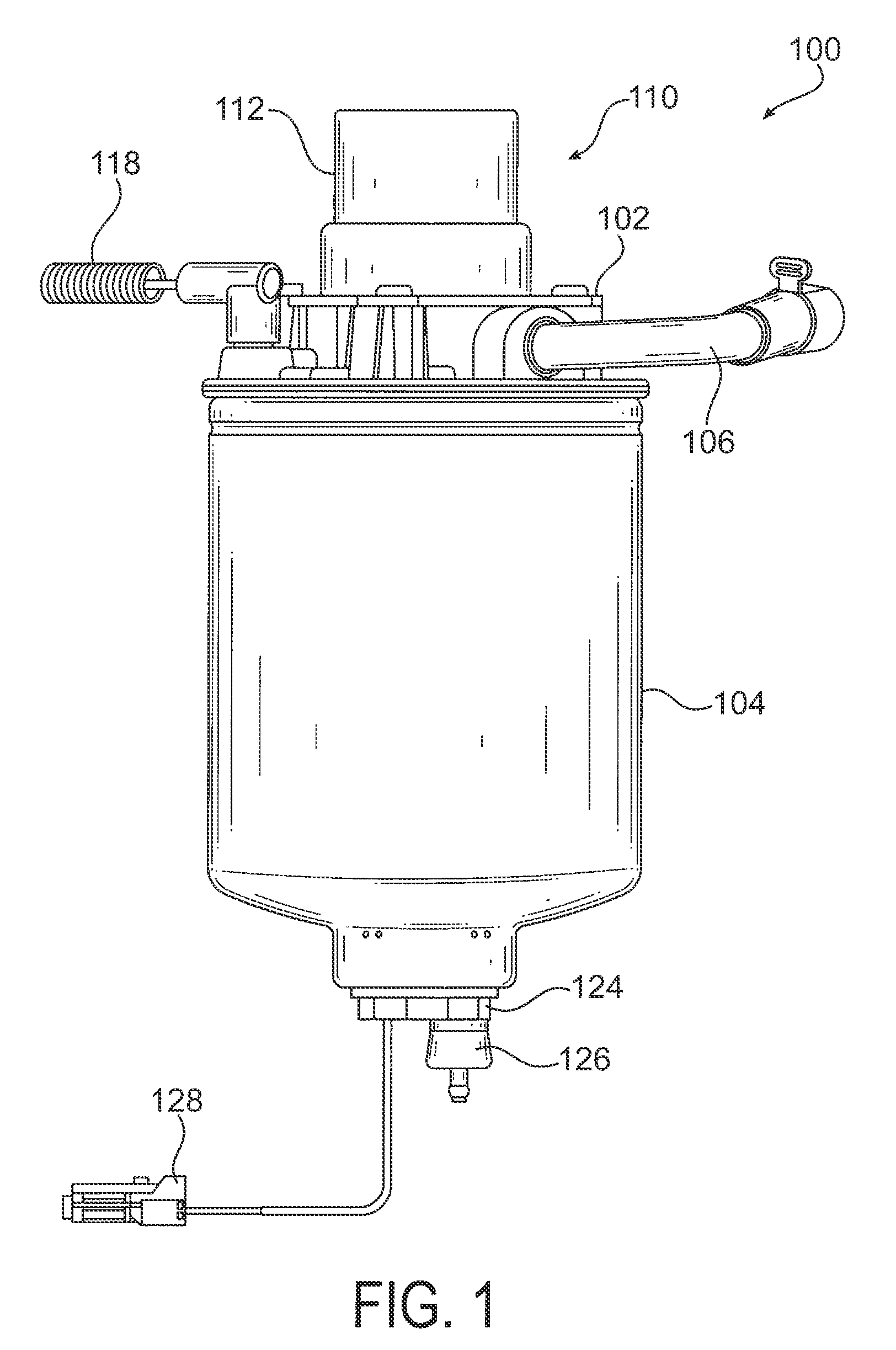

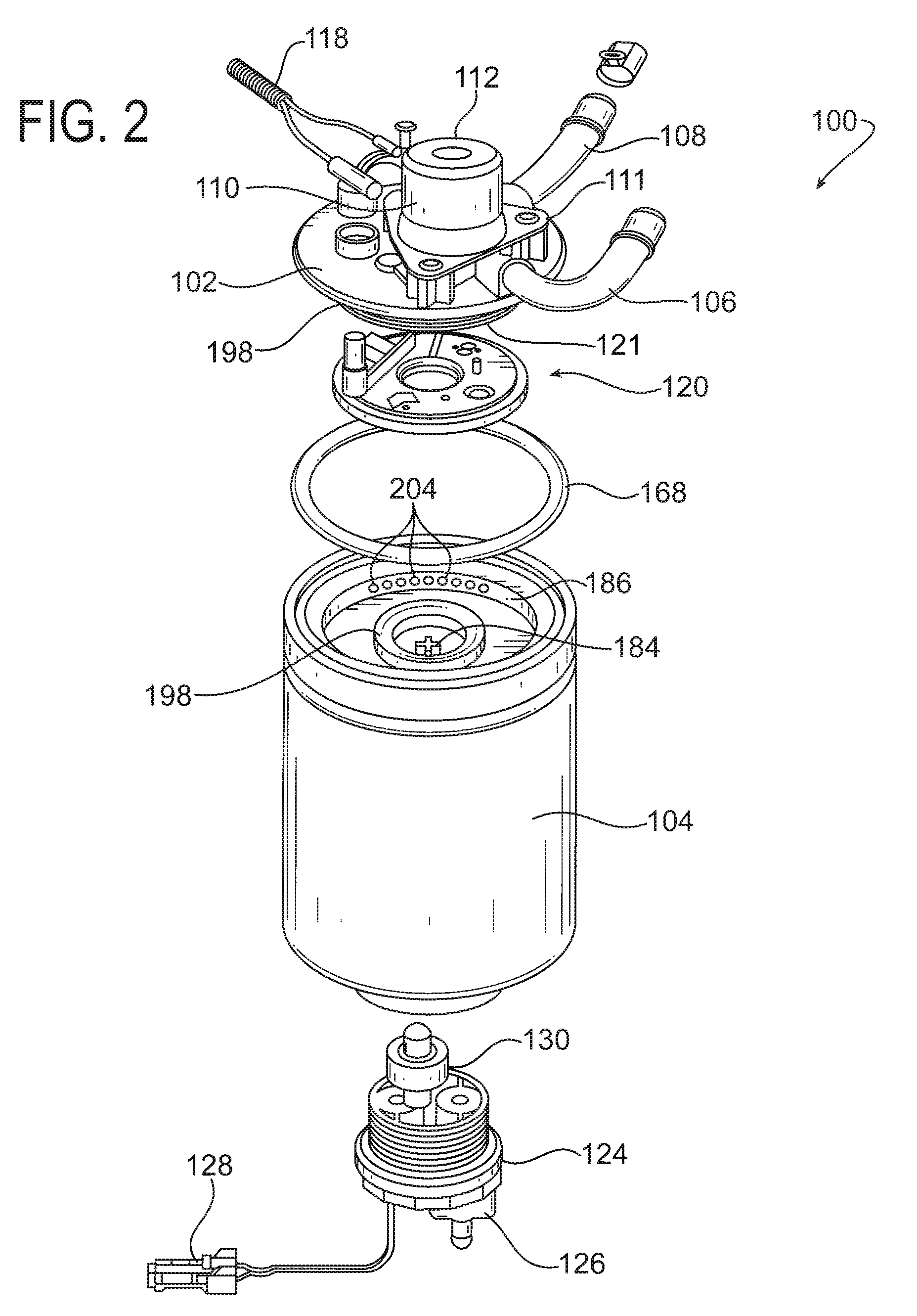

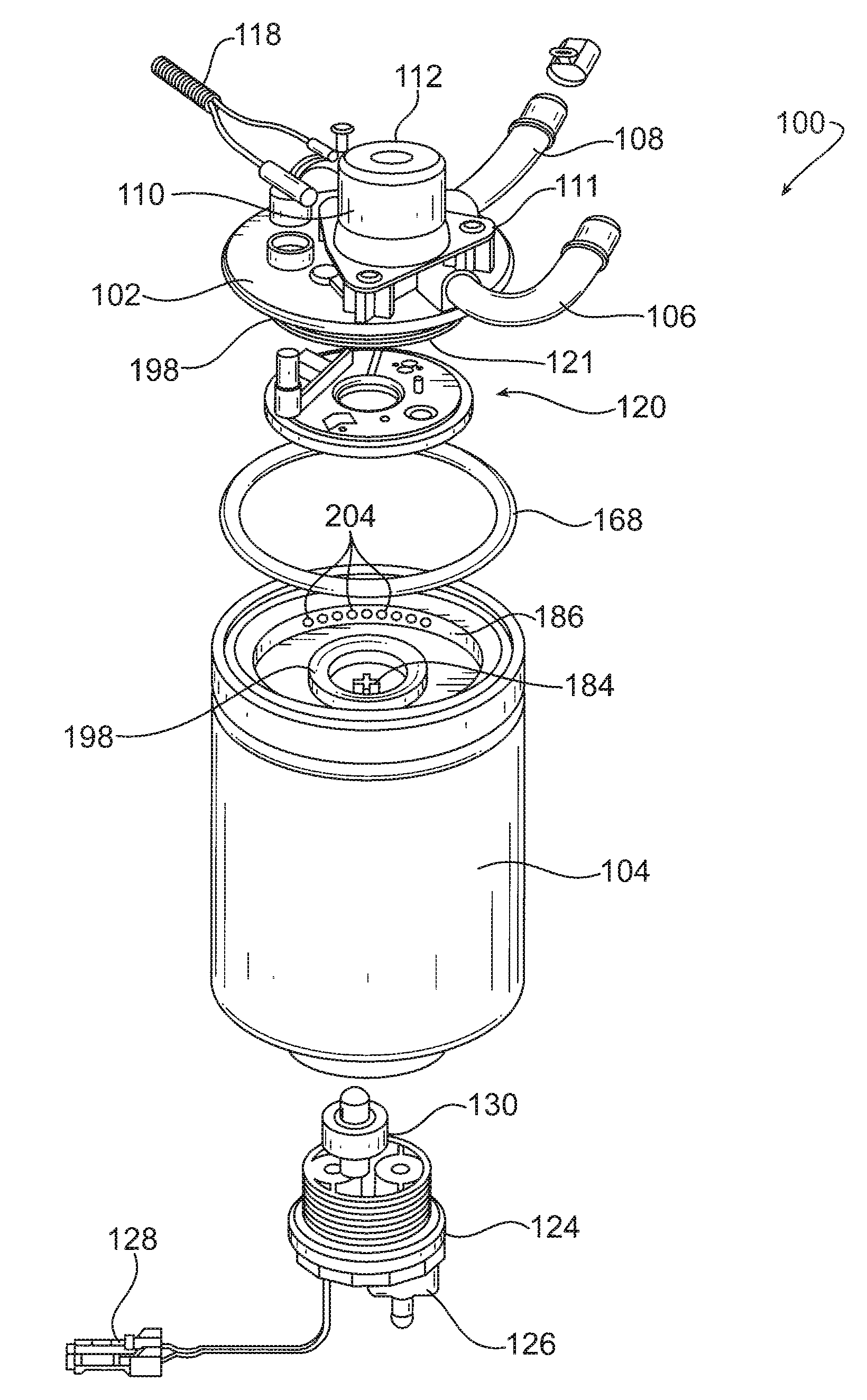

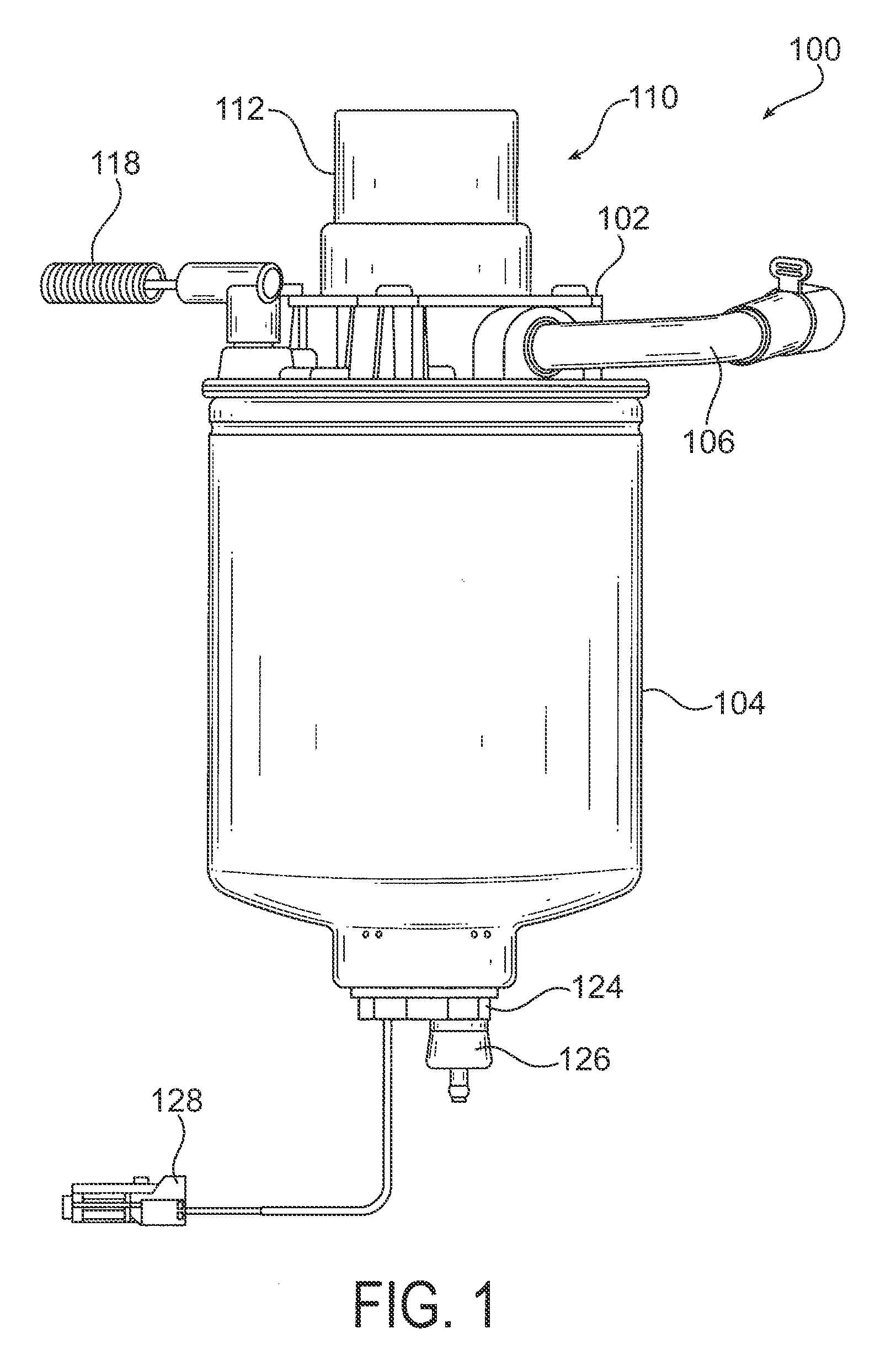

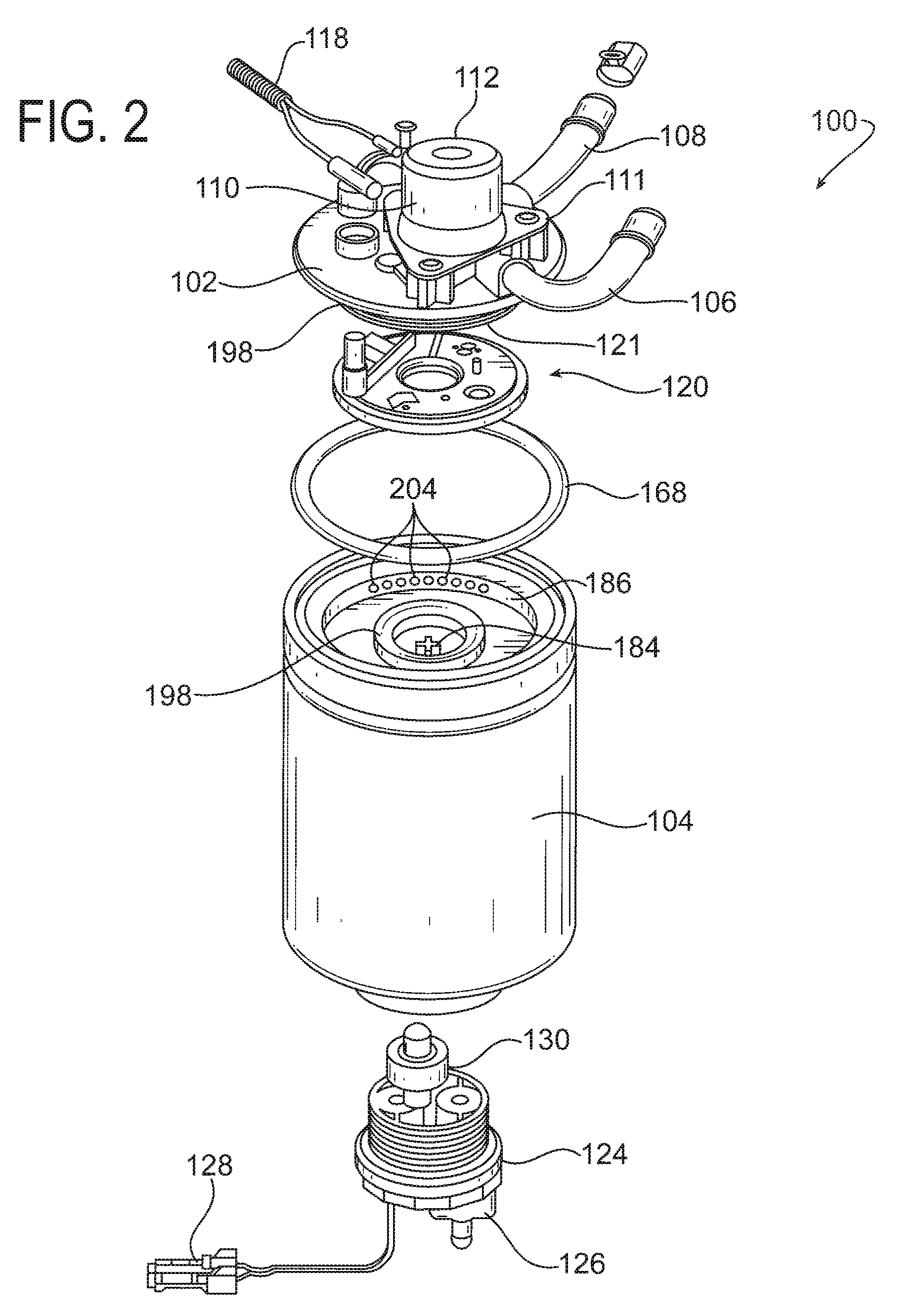

Coalescing element

ActiveUS8034240B2Simple and straightforward to manufactureSimple and straightforward to and assembleSeparation devicesSedimentation separationFilter mediaScrew thread

Owner:PARKER INTANGIBLES LLC

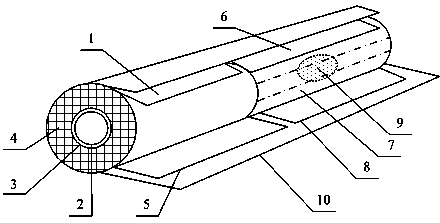

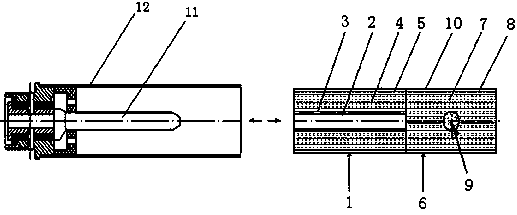

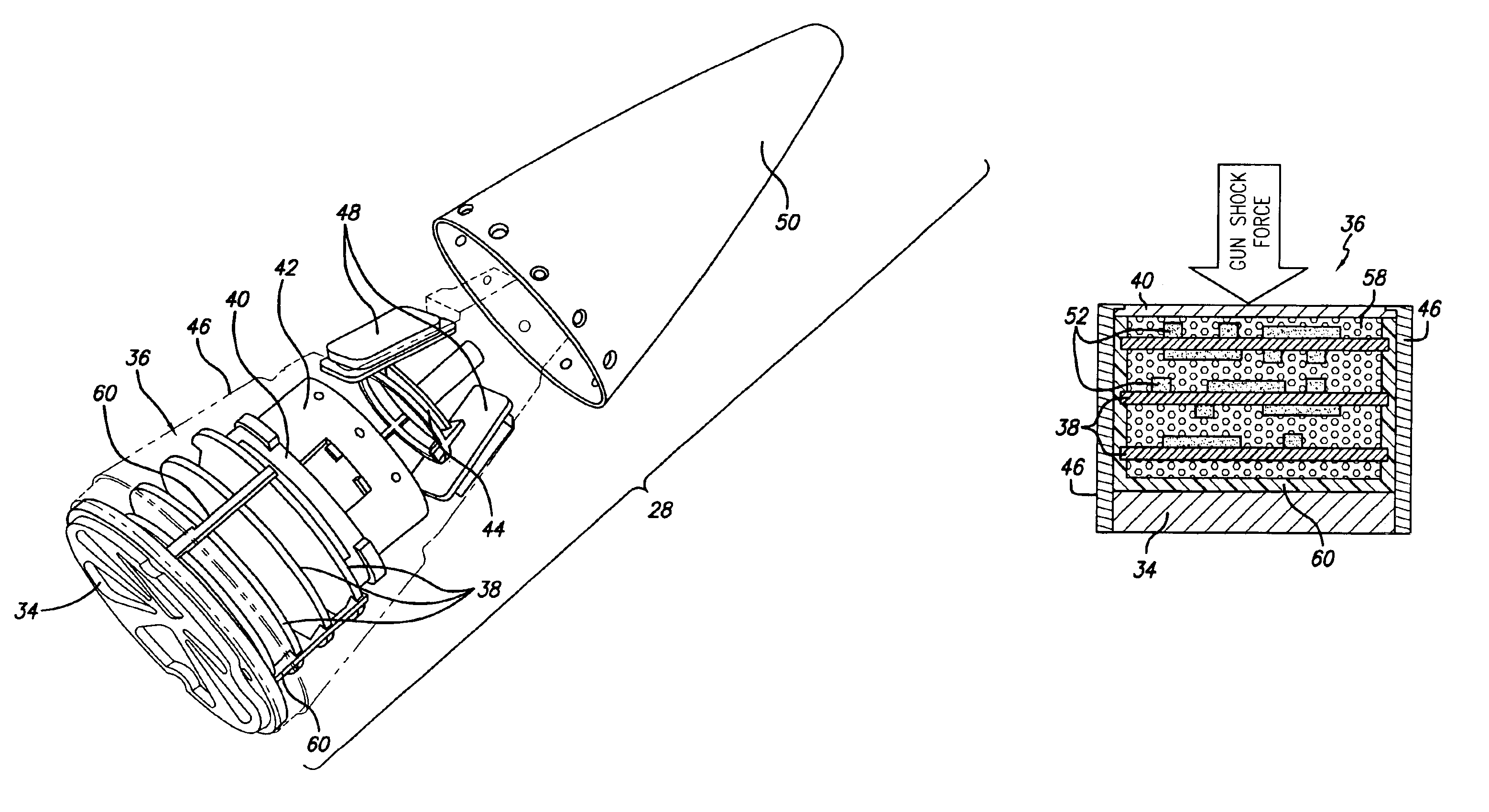

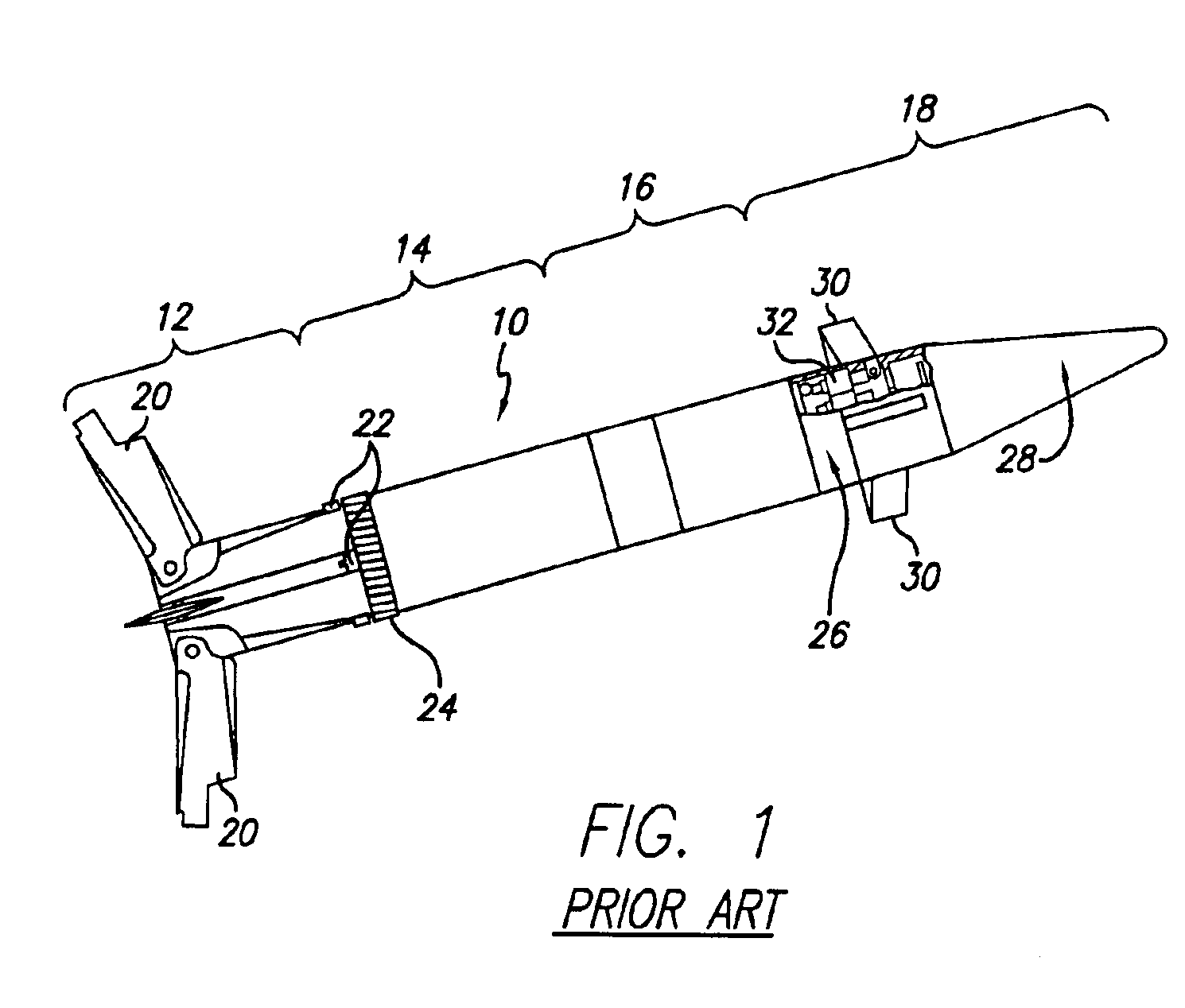

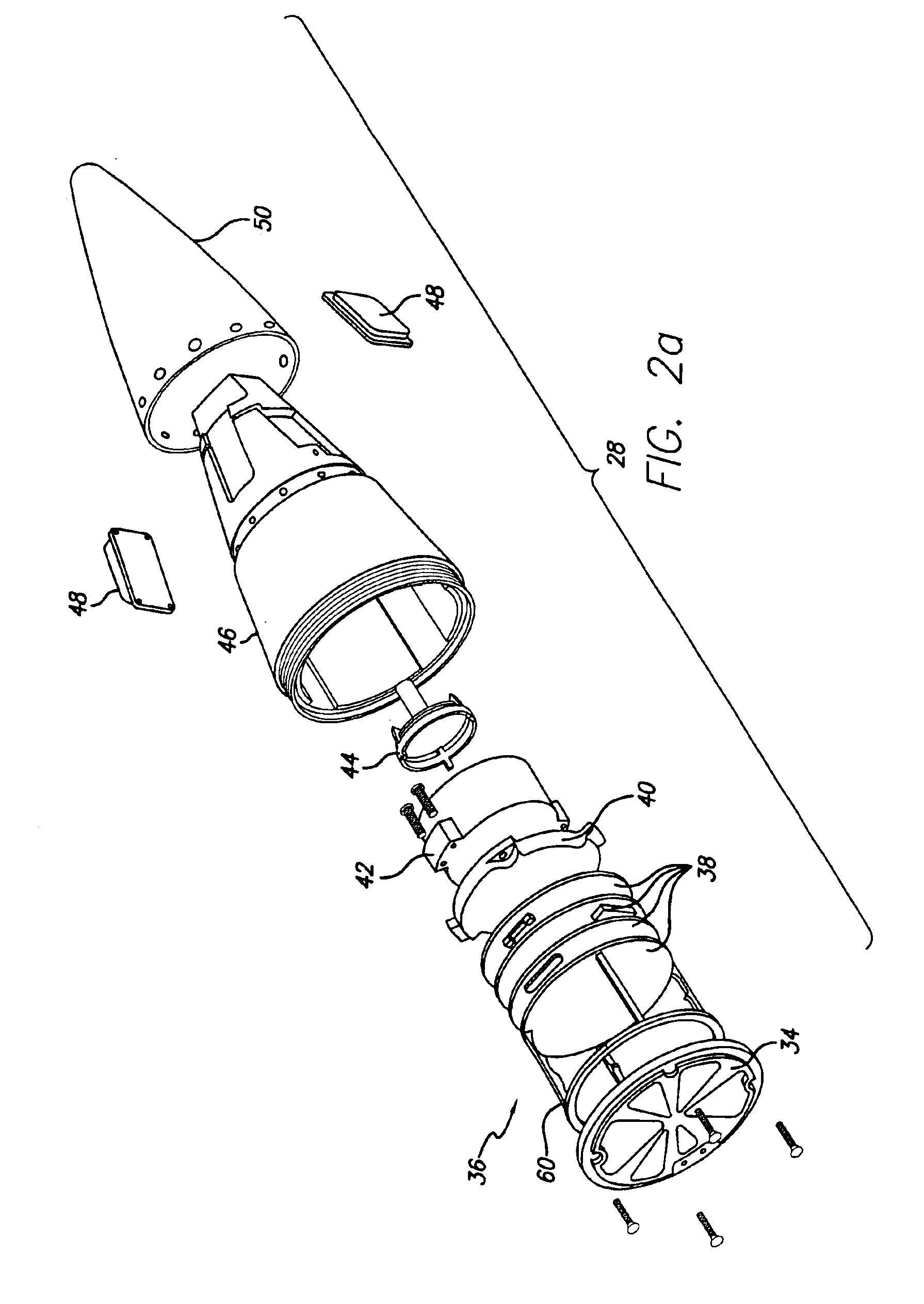

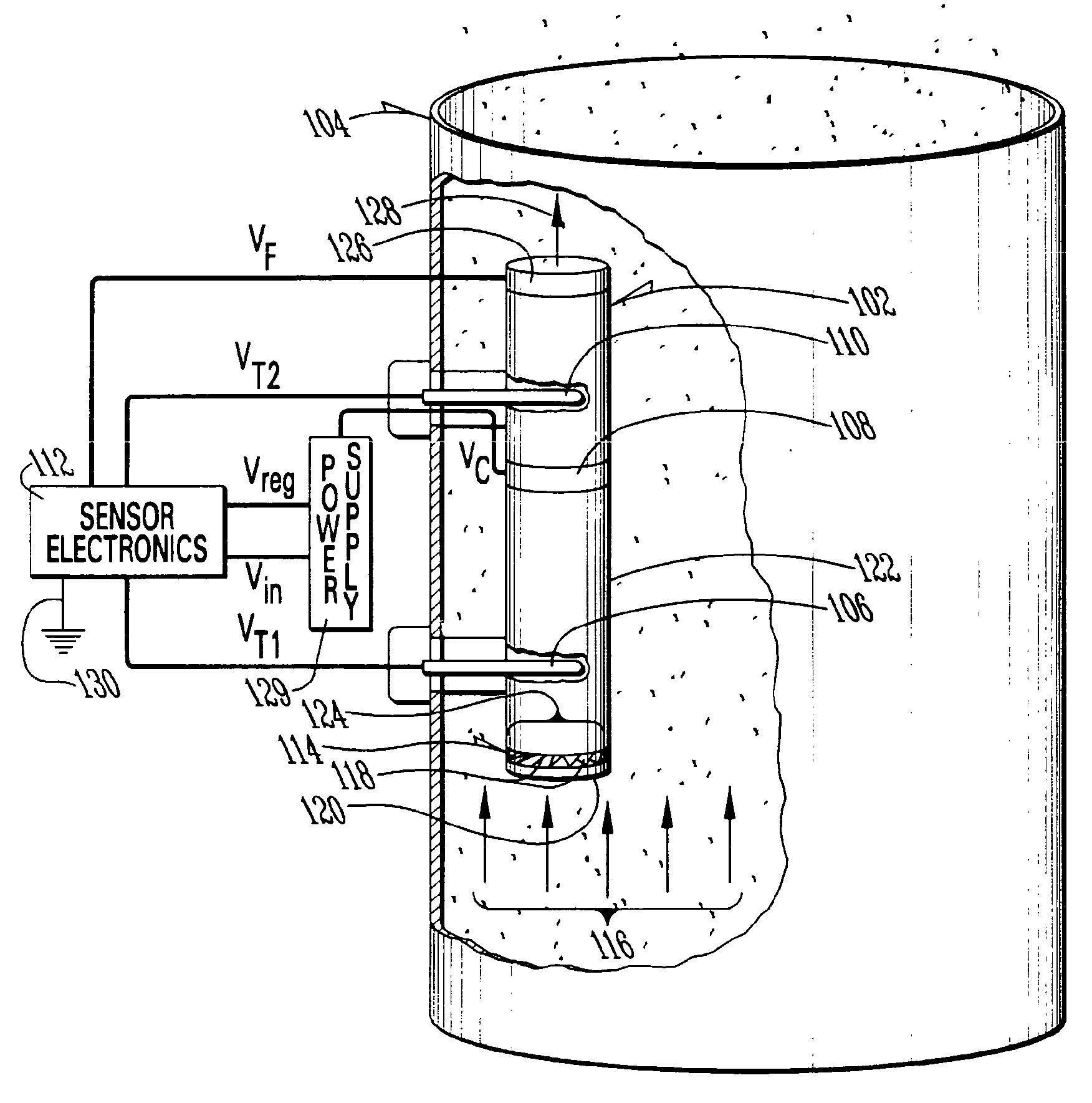

Granular matter filled weapon guidance electronics unit

InactiveUS6892646B1Evenly distributedDirection controllersPrinted circuits stress/warp reductionEngineeringInterconnection

A guidance electronics unit is provided for an explosively-launched vehicle, e.g., a projectile or missile, comprising a plurality of circuit card assemblies, each circuit card assembly containing a plurality of electronic components and interconnections, each circuit card assembly maintained in a housing and spaced apart. All spaces surrounding each circuit card assembly are filled with a granular material to provide support for each circuit card assembly during explosive launch. Further, a method for supporting circuit card assemblies in the guidance electronics unit is provided. The problem of enabling guidance electronics to survive the large loads encountered during an explosive launch out of a gun, such as a howitzer, or missile launch tube is thereby solved.

Owner:RAYTHEON CO

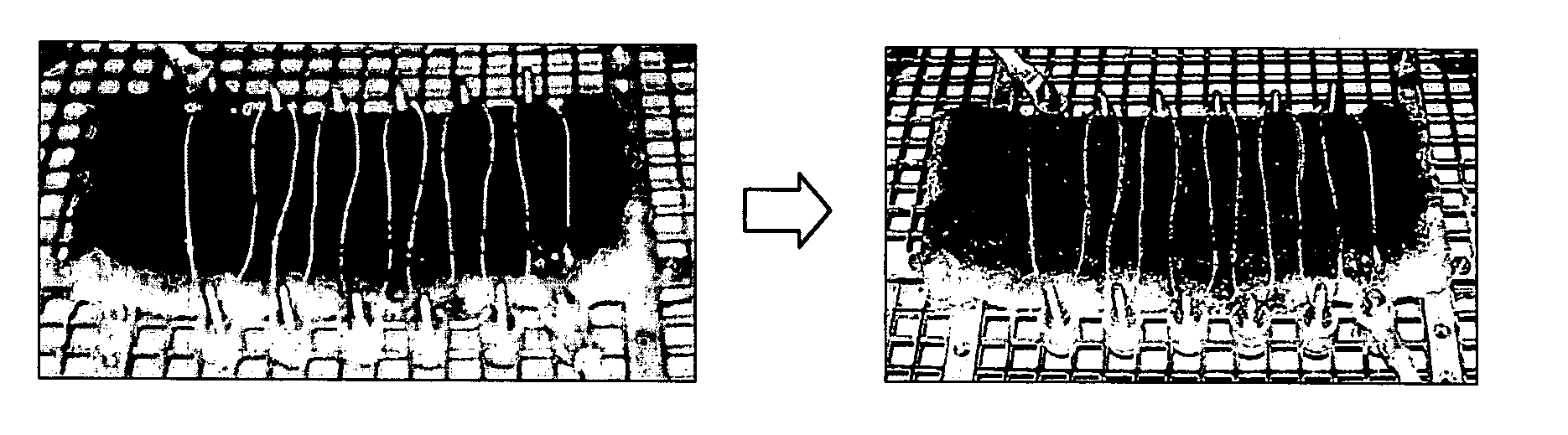

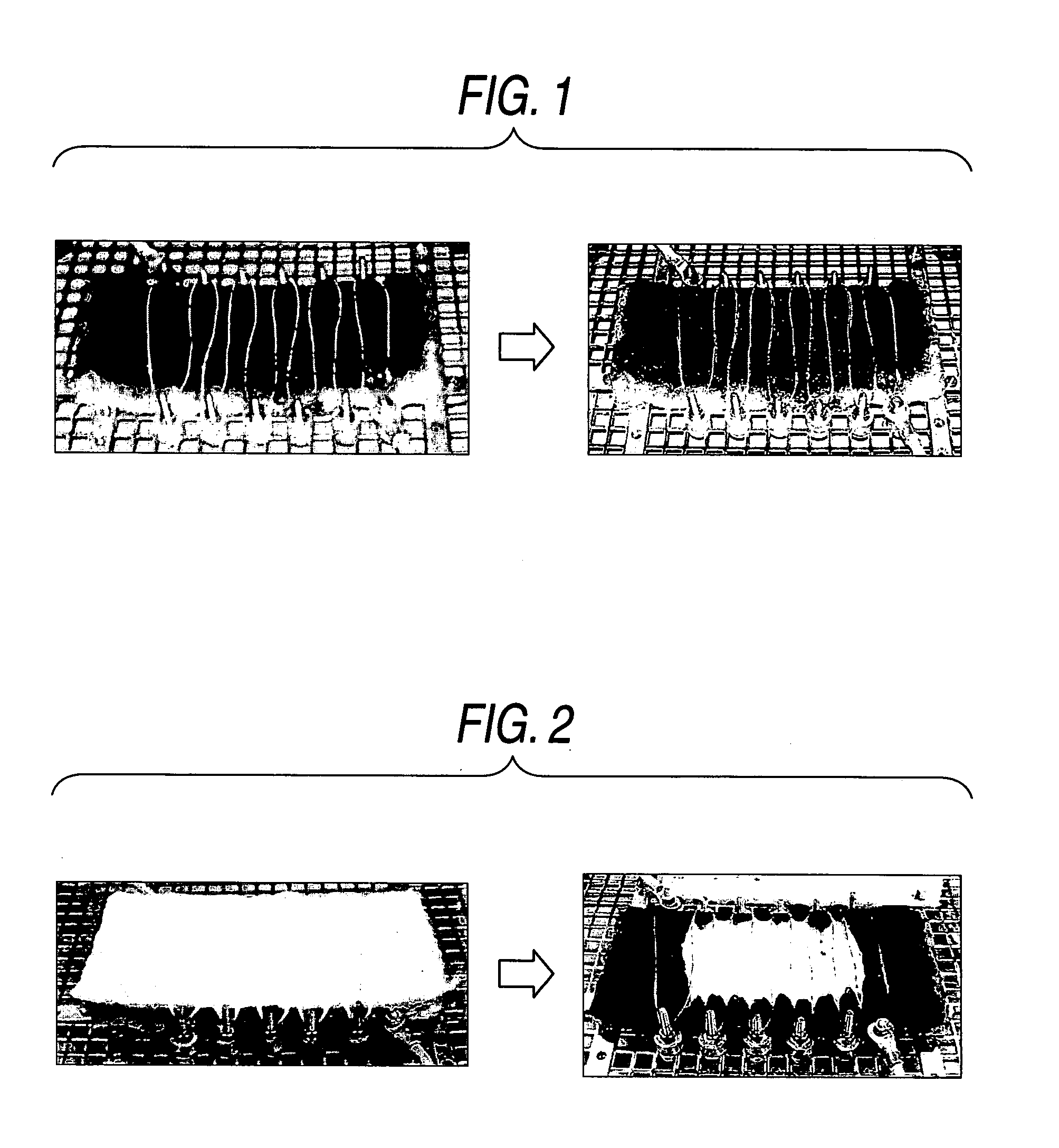

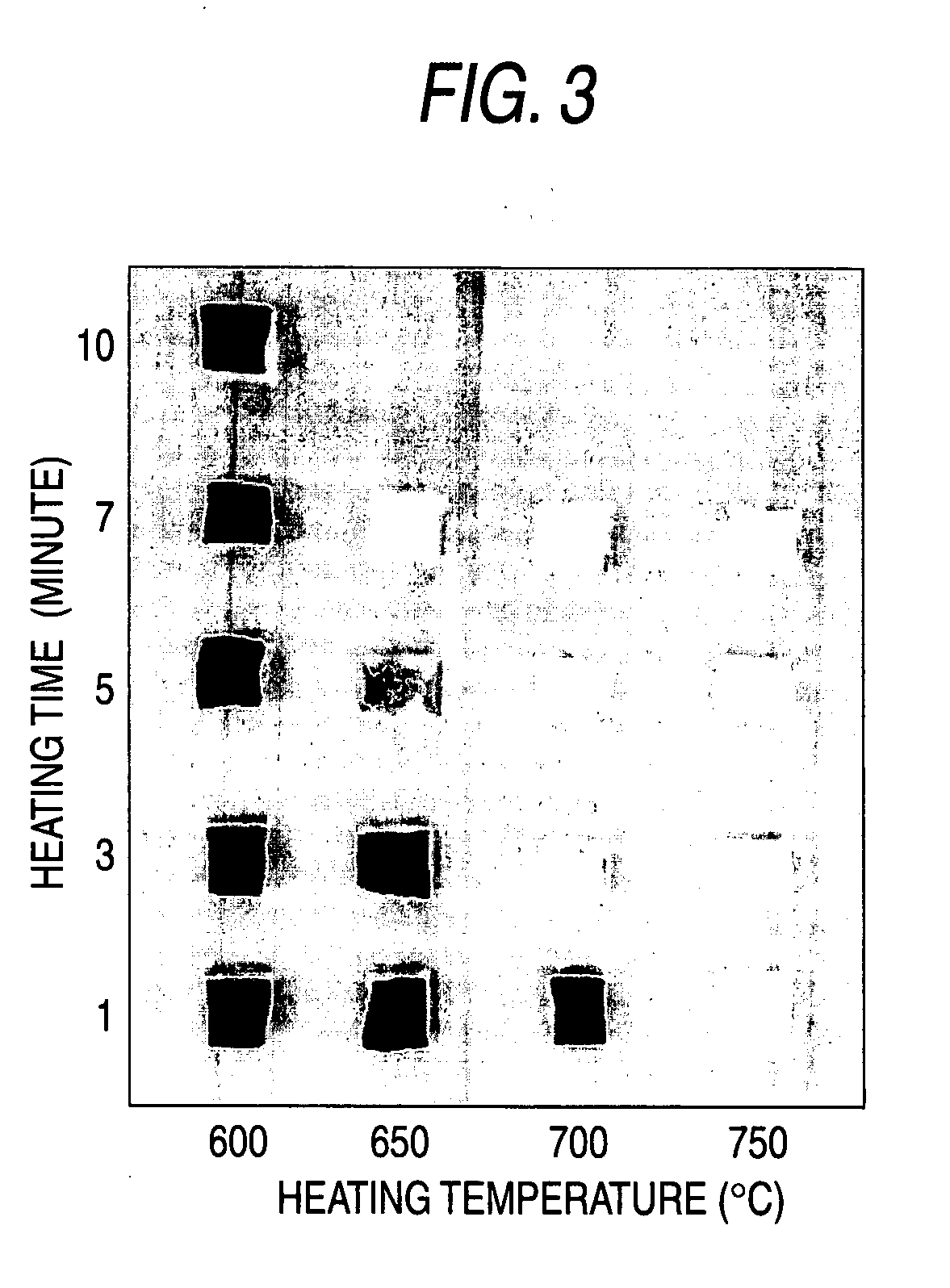

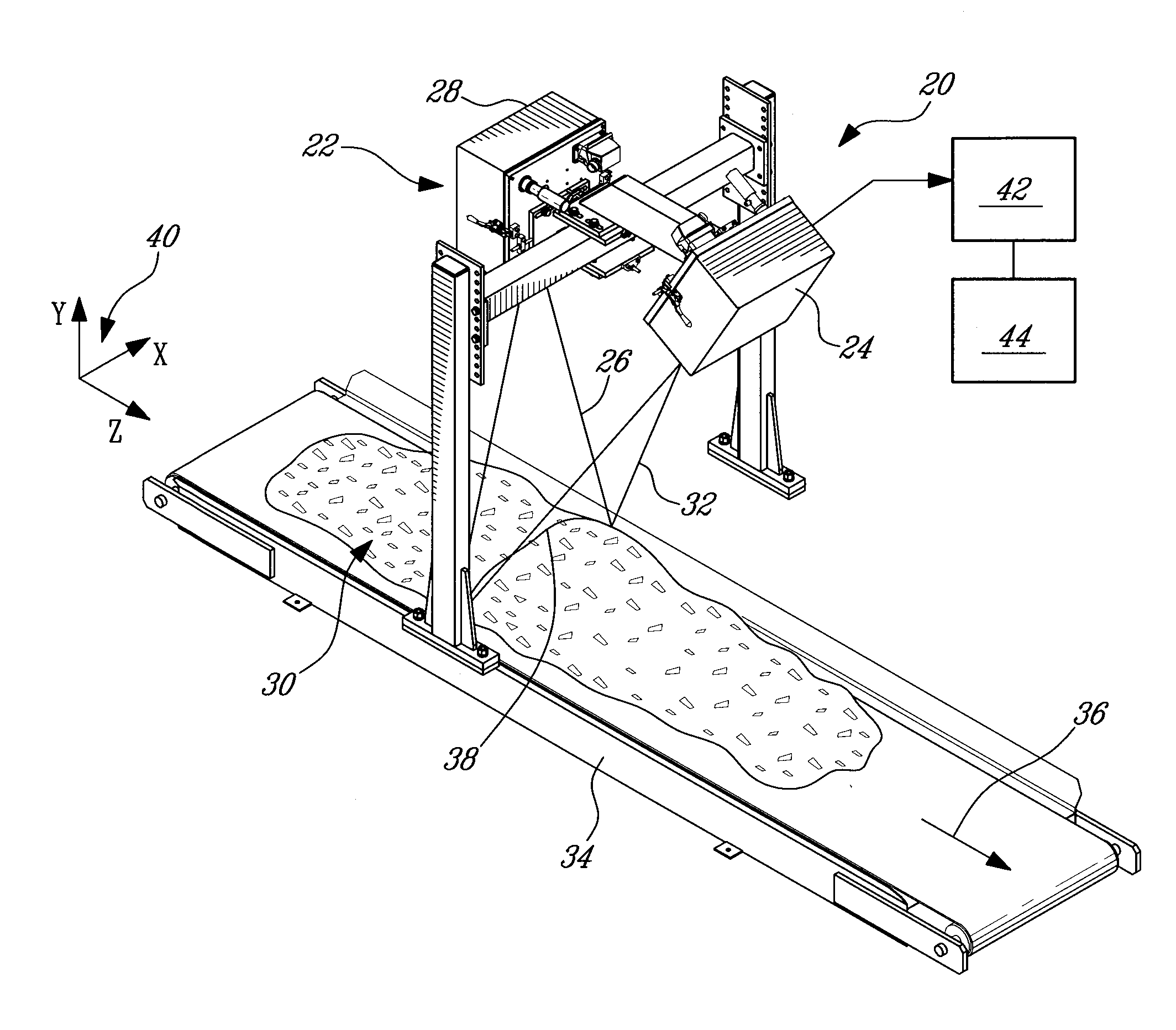

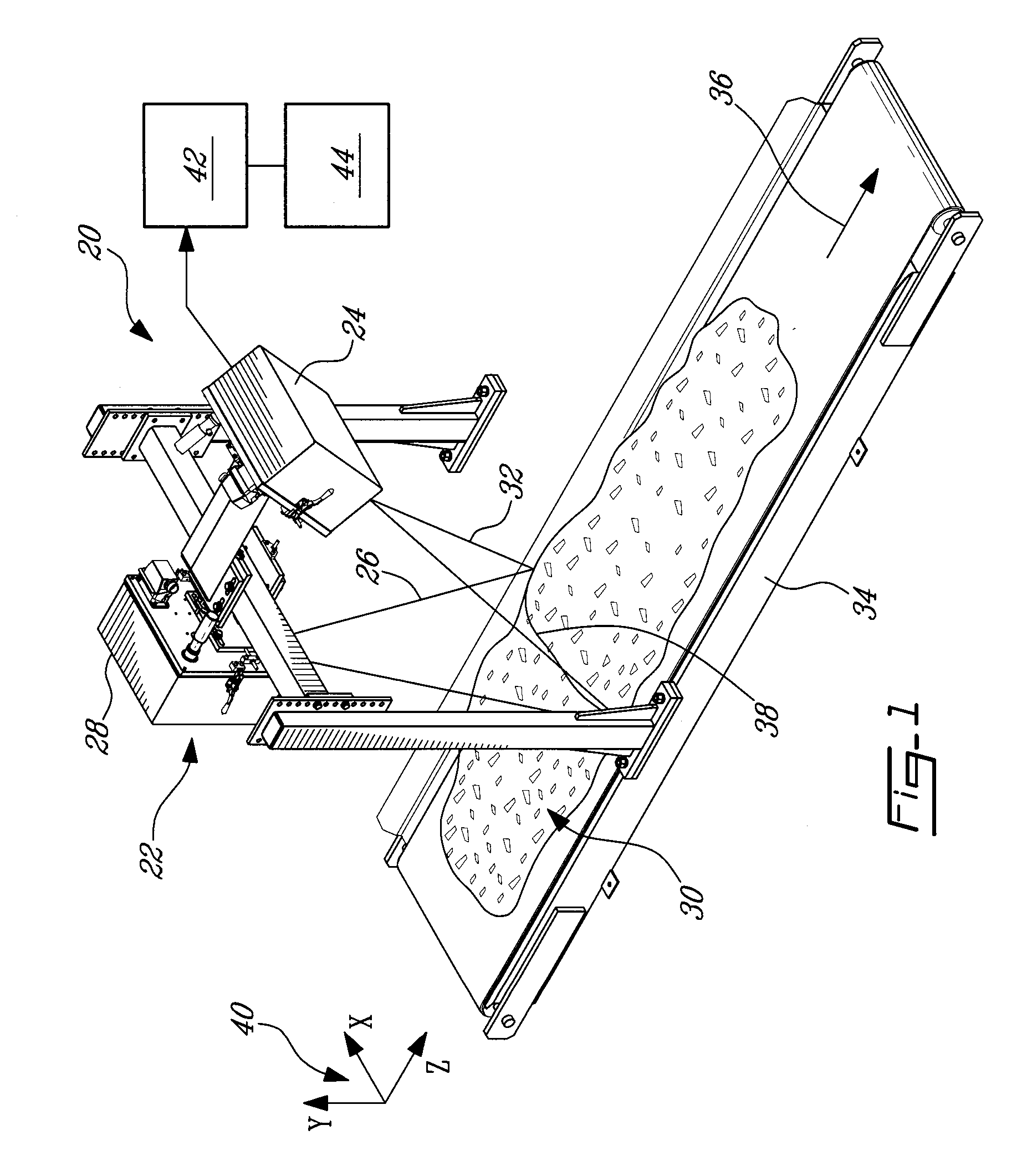

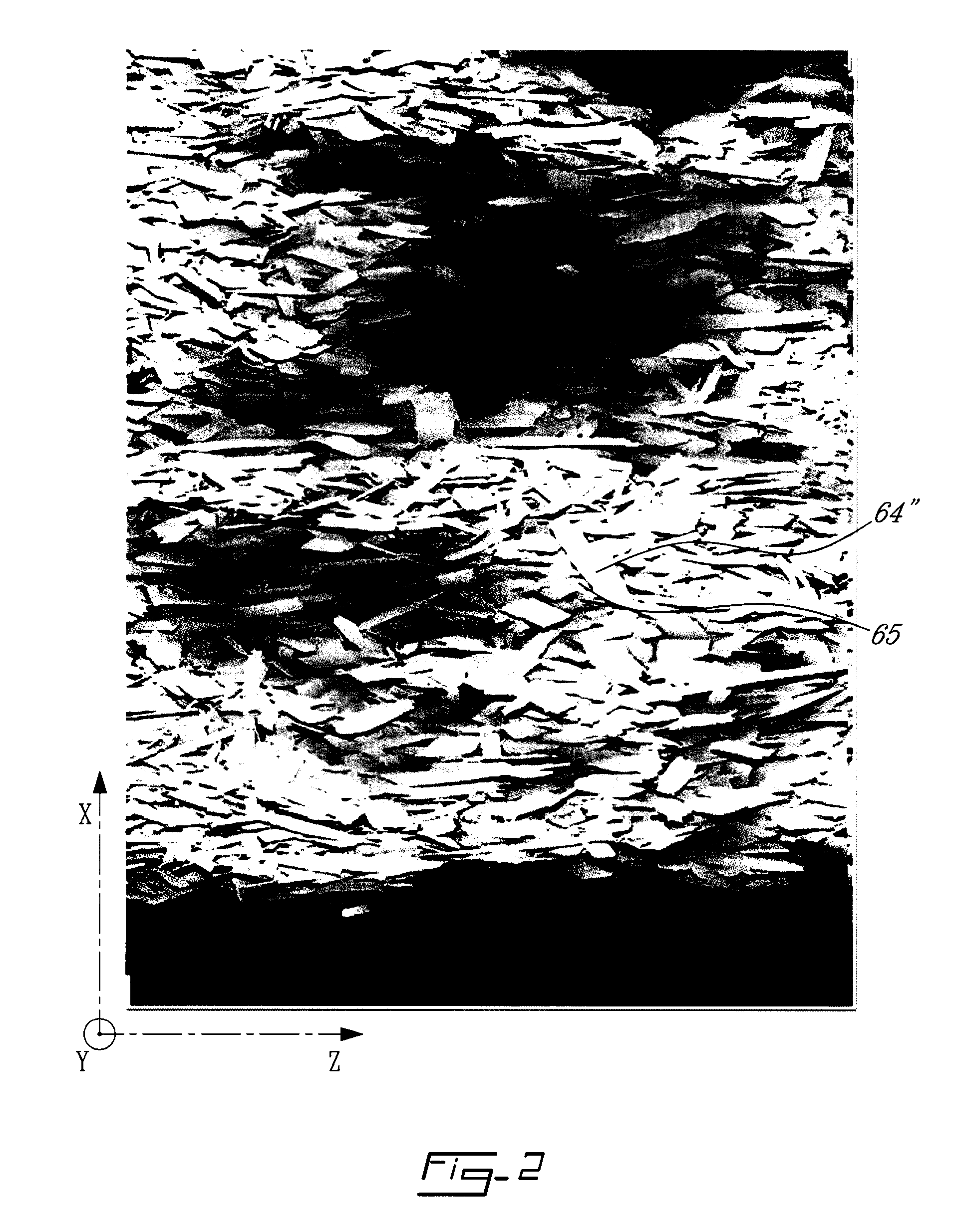

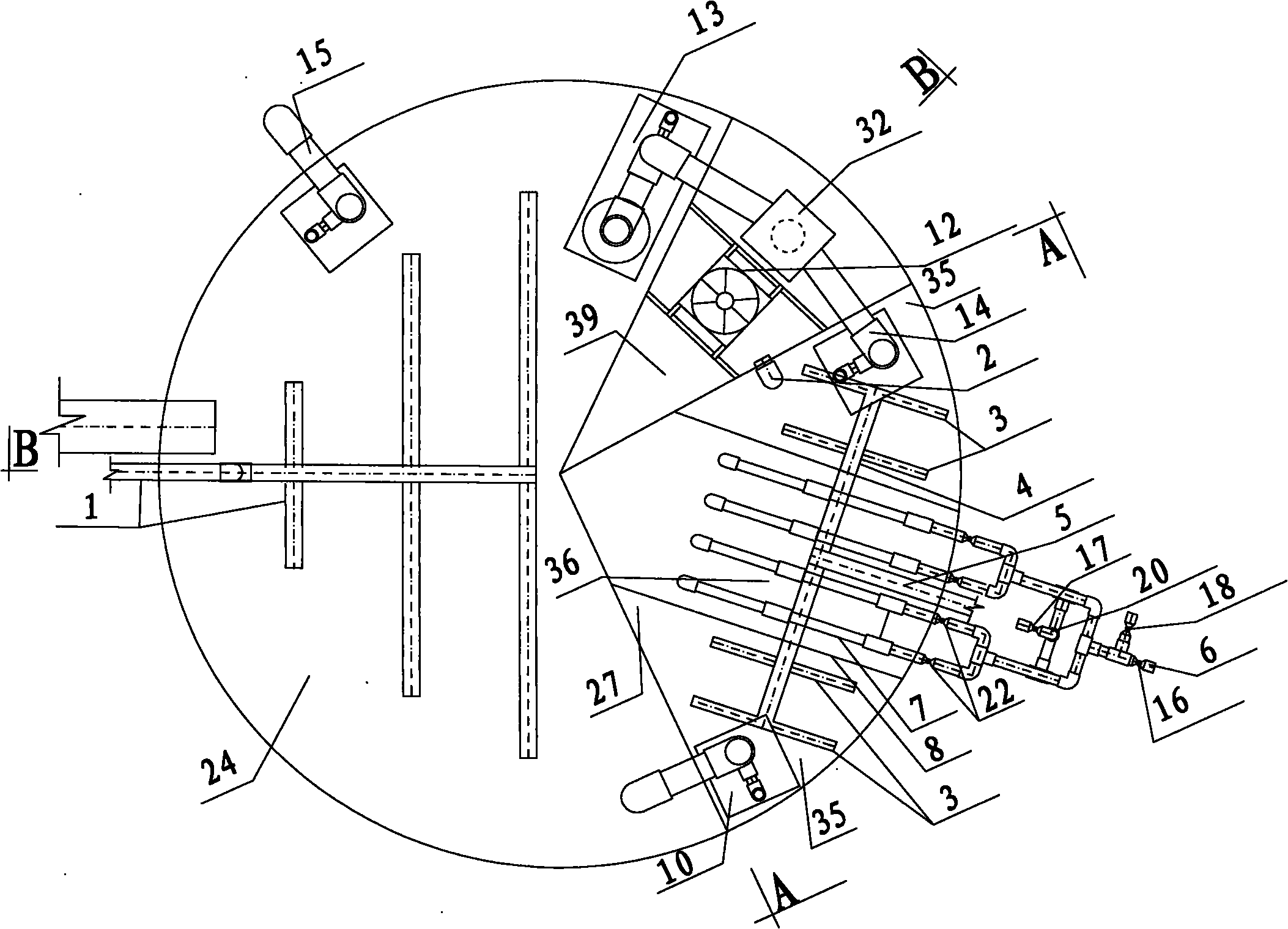

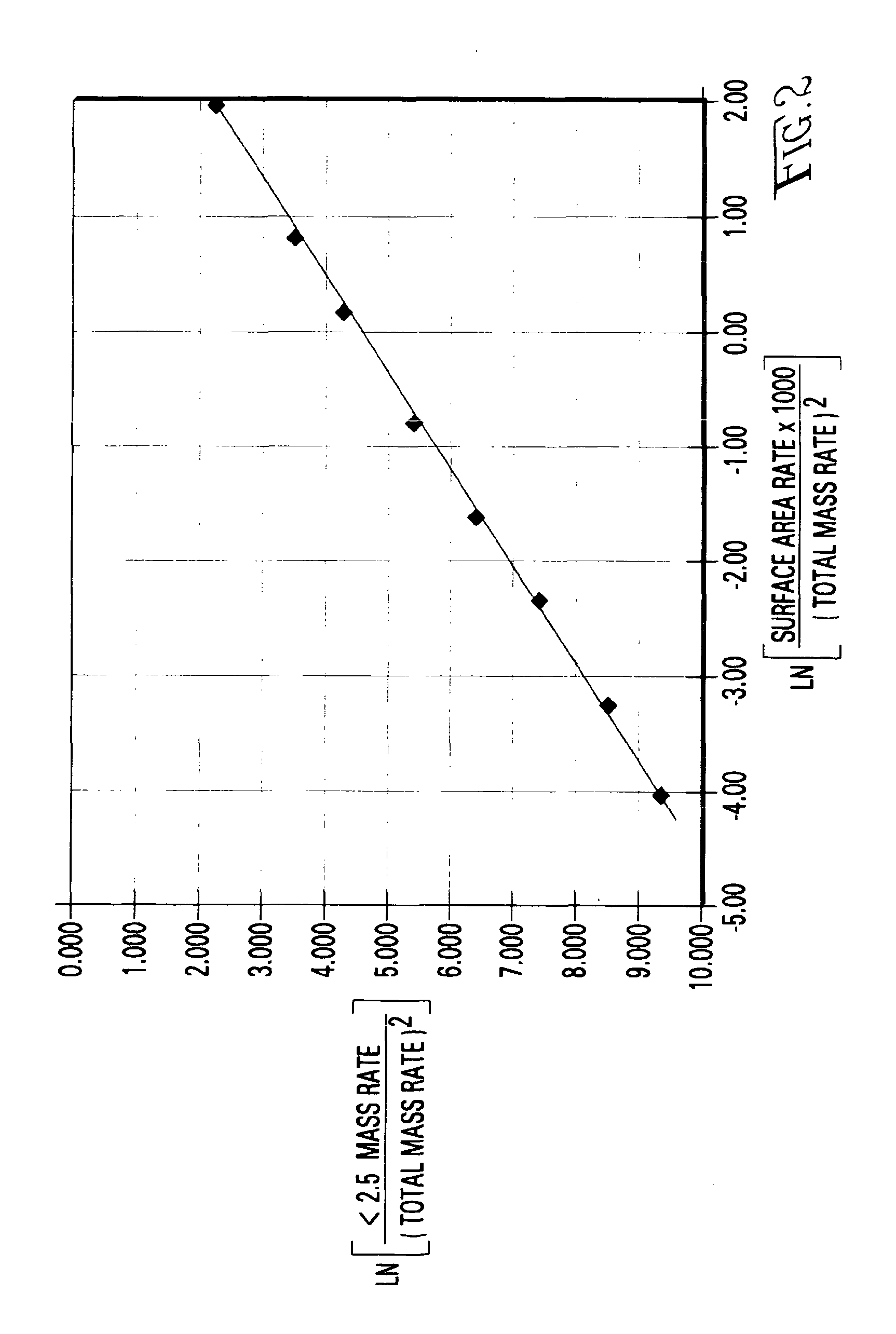

Apparatus and method for measuring size distribution of granular matter

A method and apparatus for measuring size distribution of bulk matter consisted of randomly orientated granules, such as wood chips, make use of scanning the exposed surface of the granular matter to generate three-dimensional profile image data defined with respect to a three-coordinate reference system, The image data is segmented to reveal regions associated with distinct granules, and values of the size-related parameter for the revealed regions are estimated. Then, a geometric correction to each ones of estimated size-related parameter values is applied, to compensate for the random orientation of corresponding distinct granules. Finally, the size distribution of bulk matter is statistically estimated from the corrected size-related parameter values.

Owner:CENT DE RES & DEV IND DU QUEBEC

Coalescing element

ActiveUS20100219117A1Simple and straightforward to manufactureSimple and straightforward to and assembleSeparation devicesWater/sewage treatmentFilter mediaEngineering

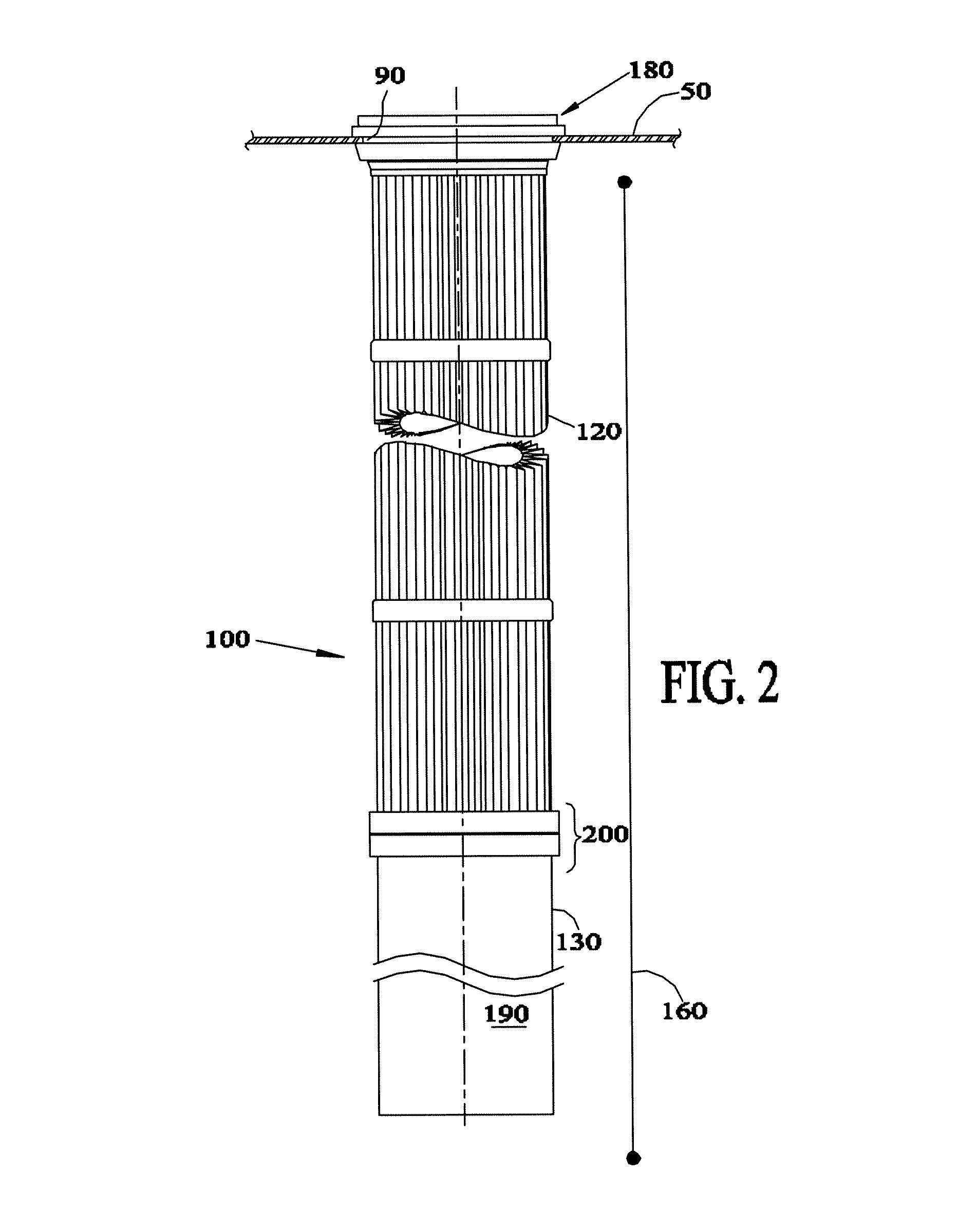

A filter element includes a cylindrical housing enclosing a ring-shaped filter media assembly. The media assembly includes inner and outer media rings, moveably supported relative to one another, to remove particulate matter and water from a fluid stream. The outer ring surrounds the inner ring and is sealed by a first seal to the housing. An end cap assembly at the upper end of the element includes an annular end cap piece attached to an upper end of the inner ring, a flat plate, and a threaded flange portion bounding the periphery of the plate. A second seal is provided between the upper end cap of the inner ring, and an upper end cap of the outer ring. The housing is secured to the media assembly by forming an open end of the housing around the flange portion.

Owner:PARKER INTANGIBLES LLC

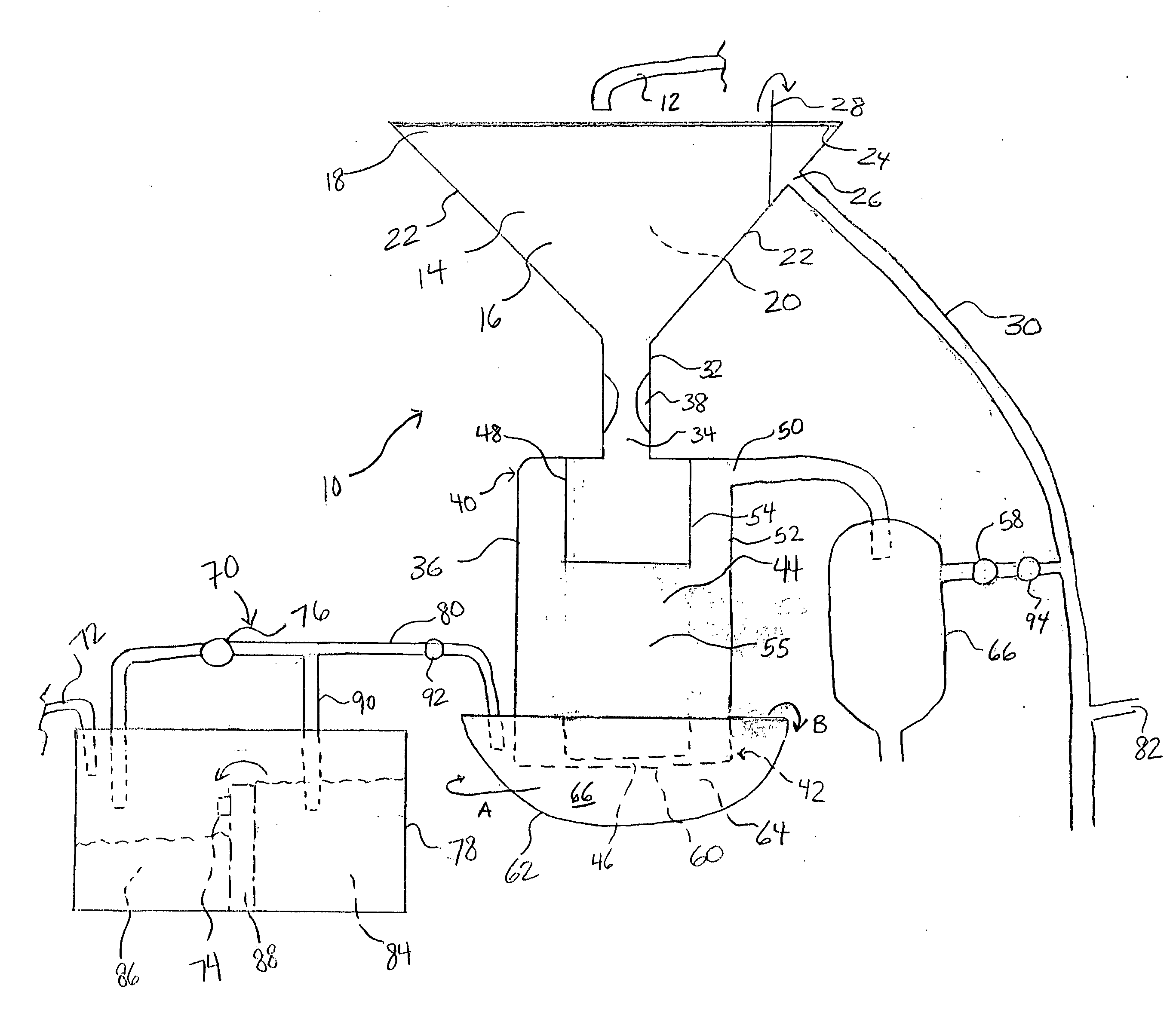

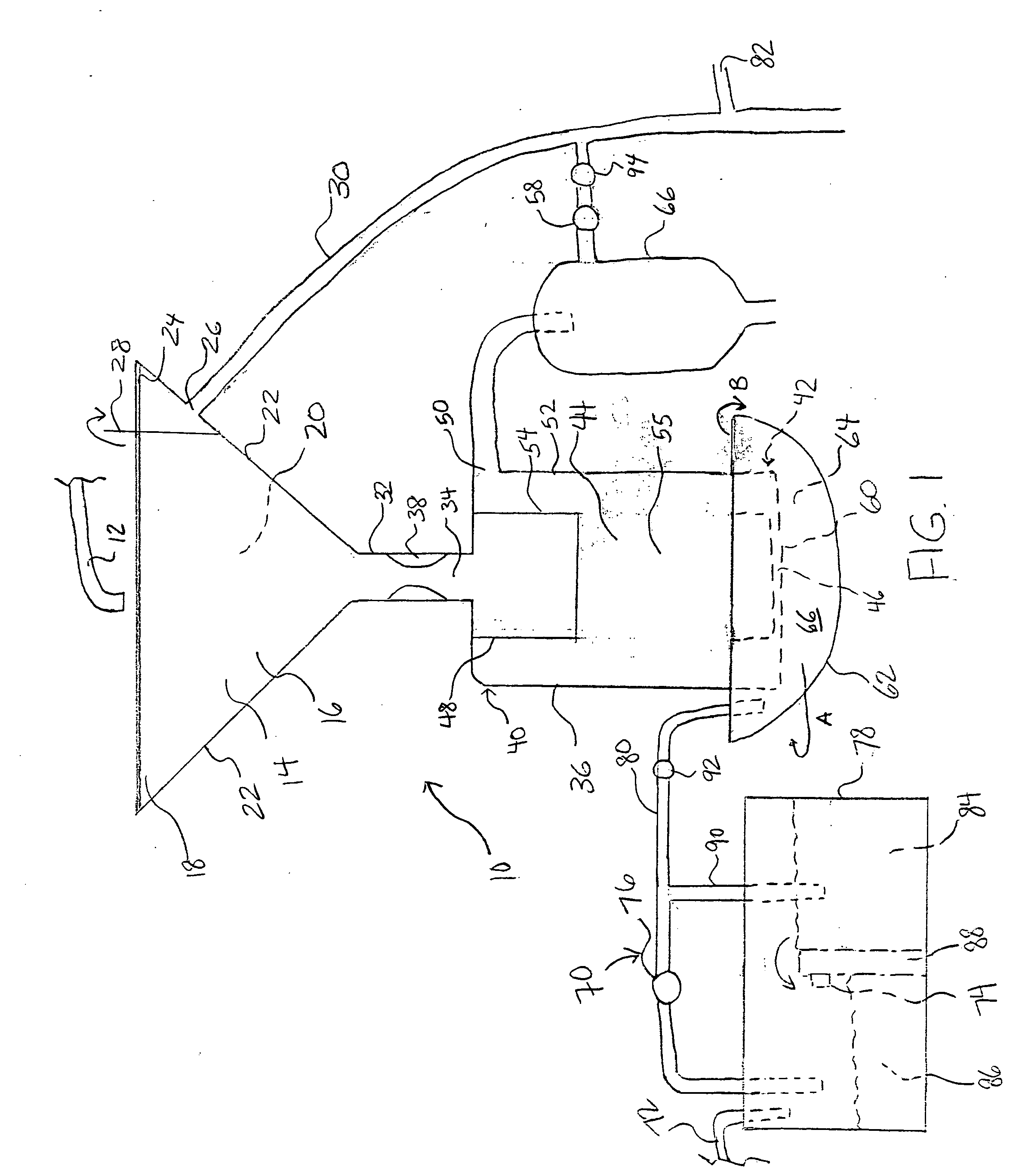

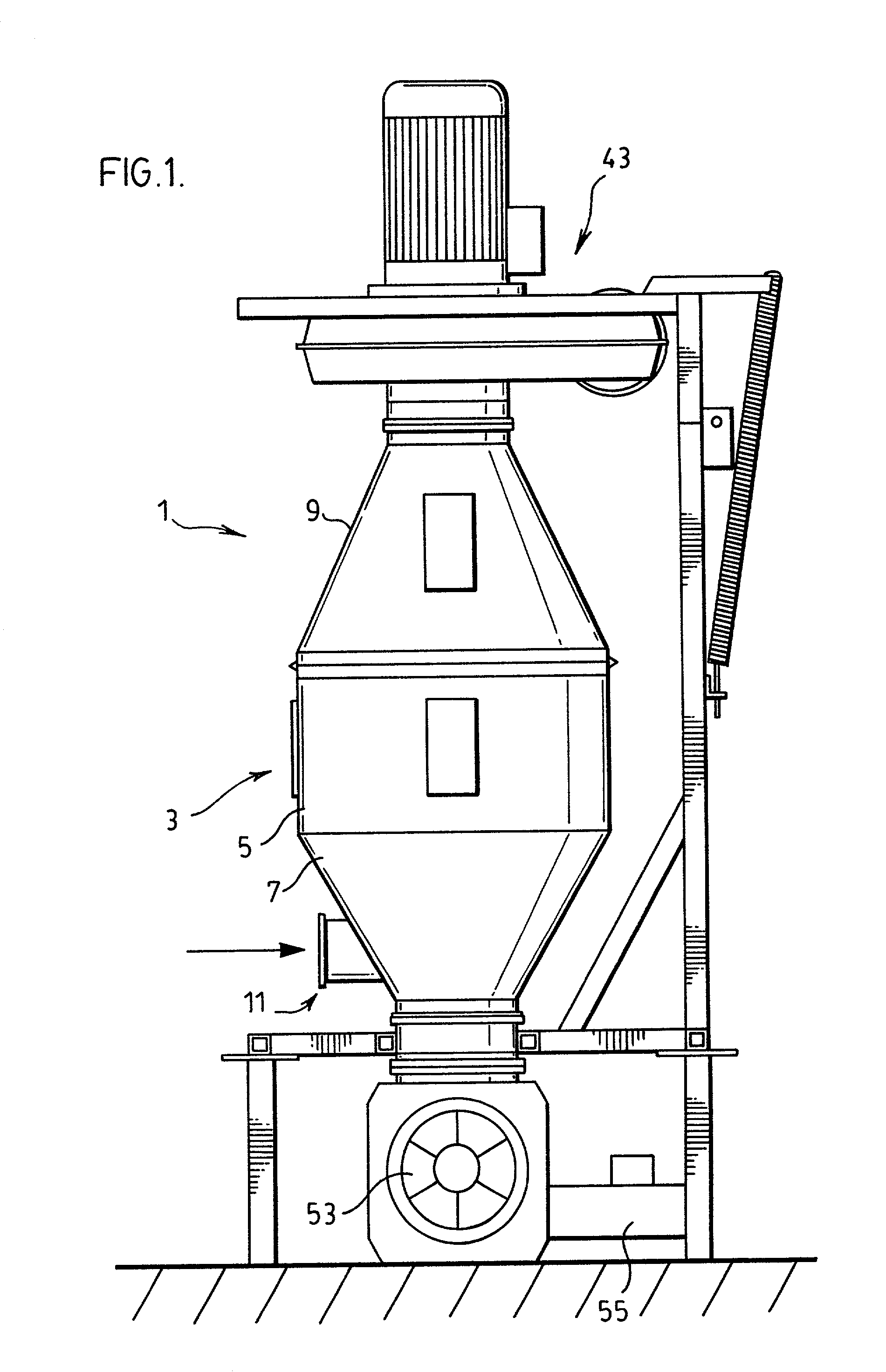

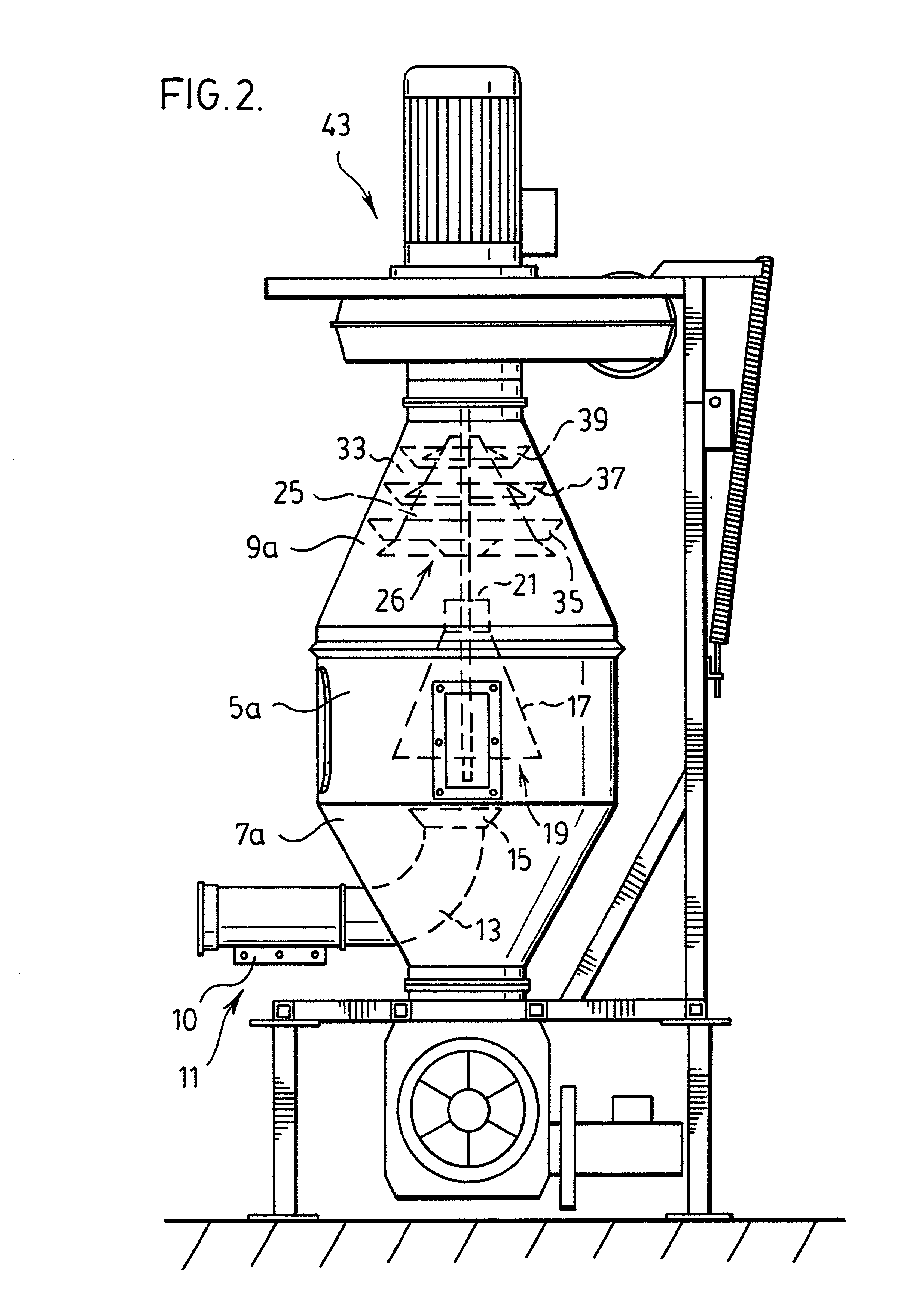

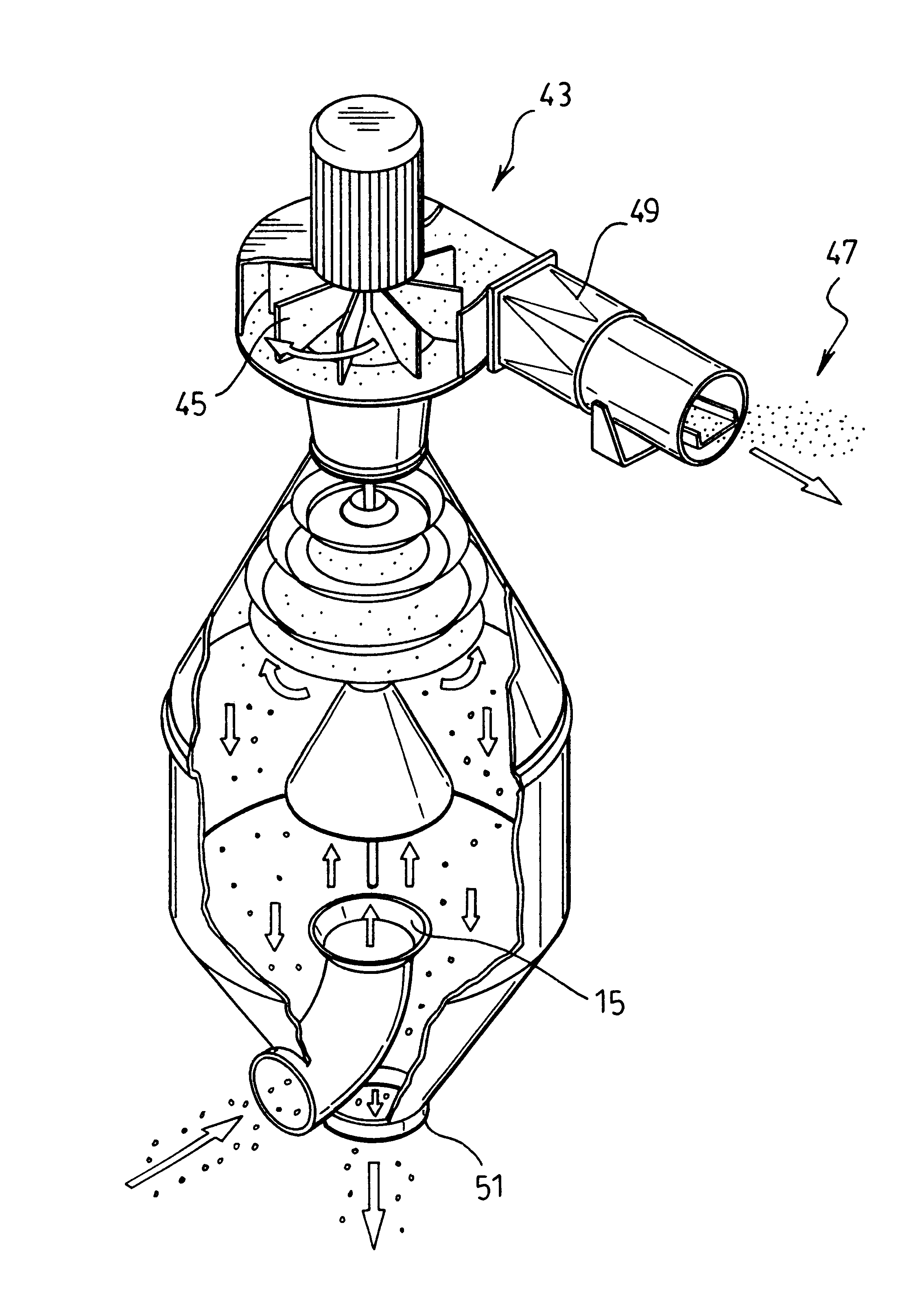

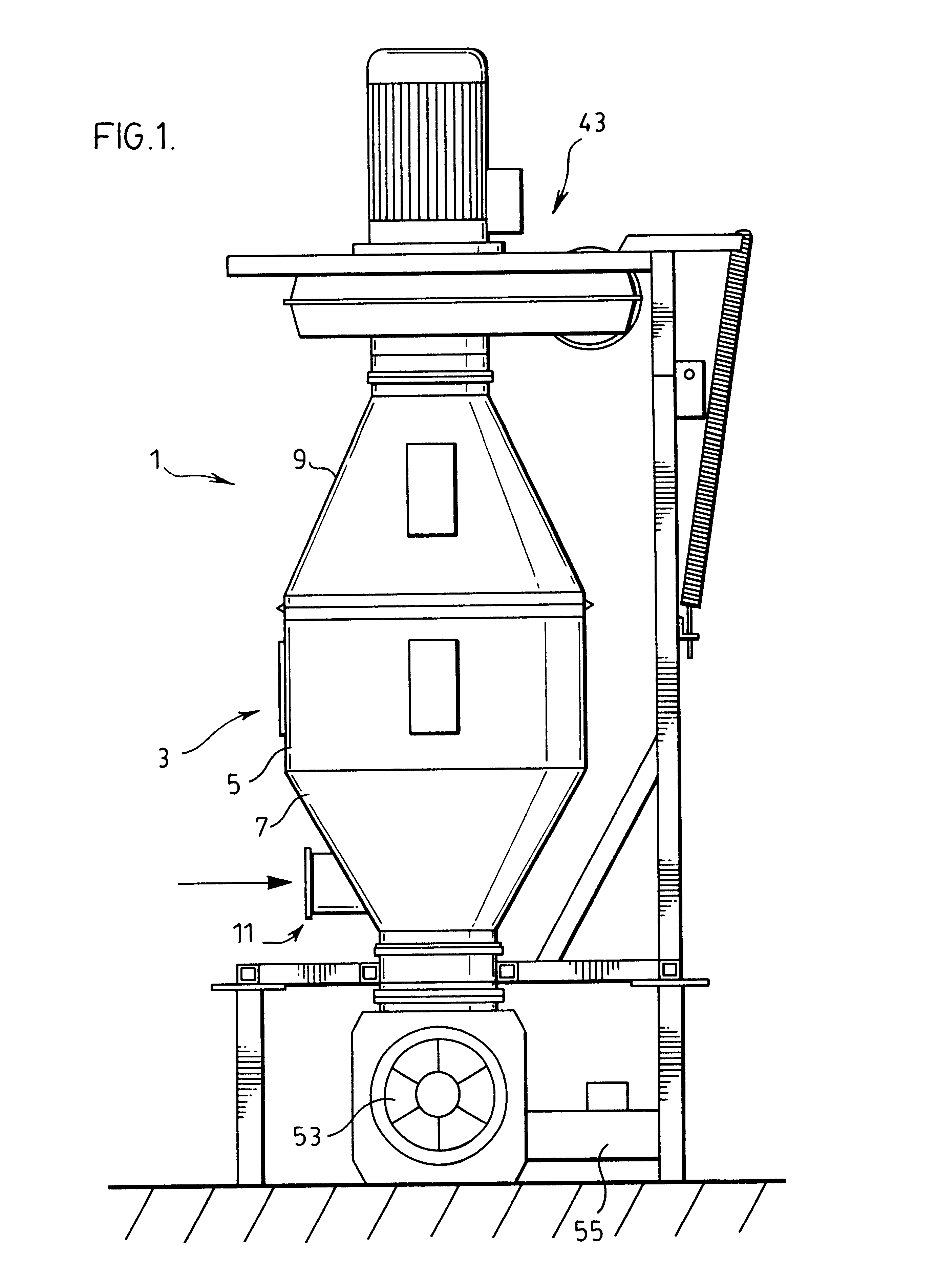

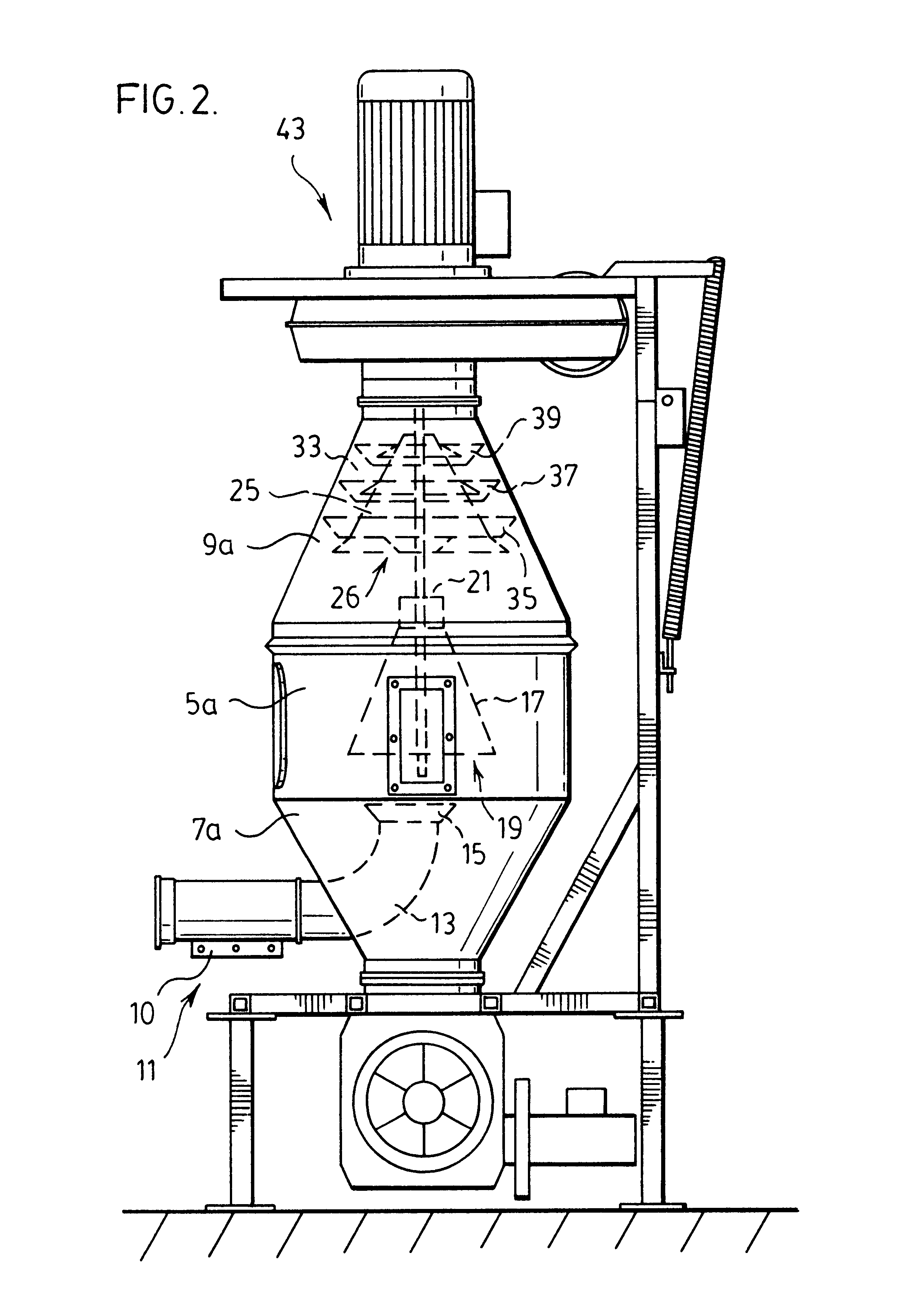

Method apparatus for separating unwanted matter from granular material

In a method of separating unwanted fine matter from heavier granular matter a flow of the material is produced under vacuum firstly through alternating expansion and contraction passages and then against impact surfaces to cause multiple redirections of the material and separation of the heavier granular material from the material flow.

Owner:VAN OIRSCHOT FRANK

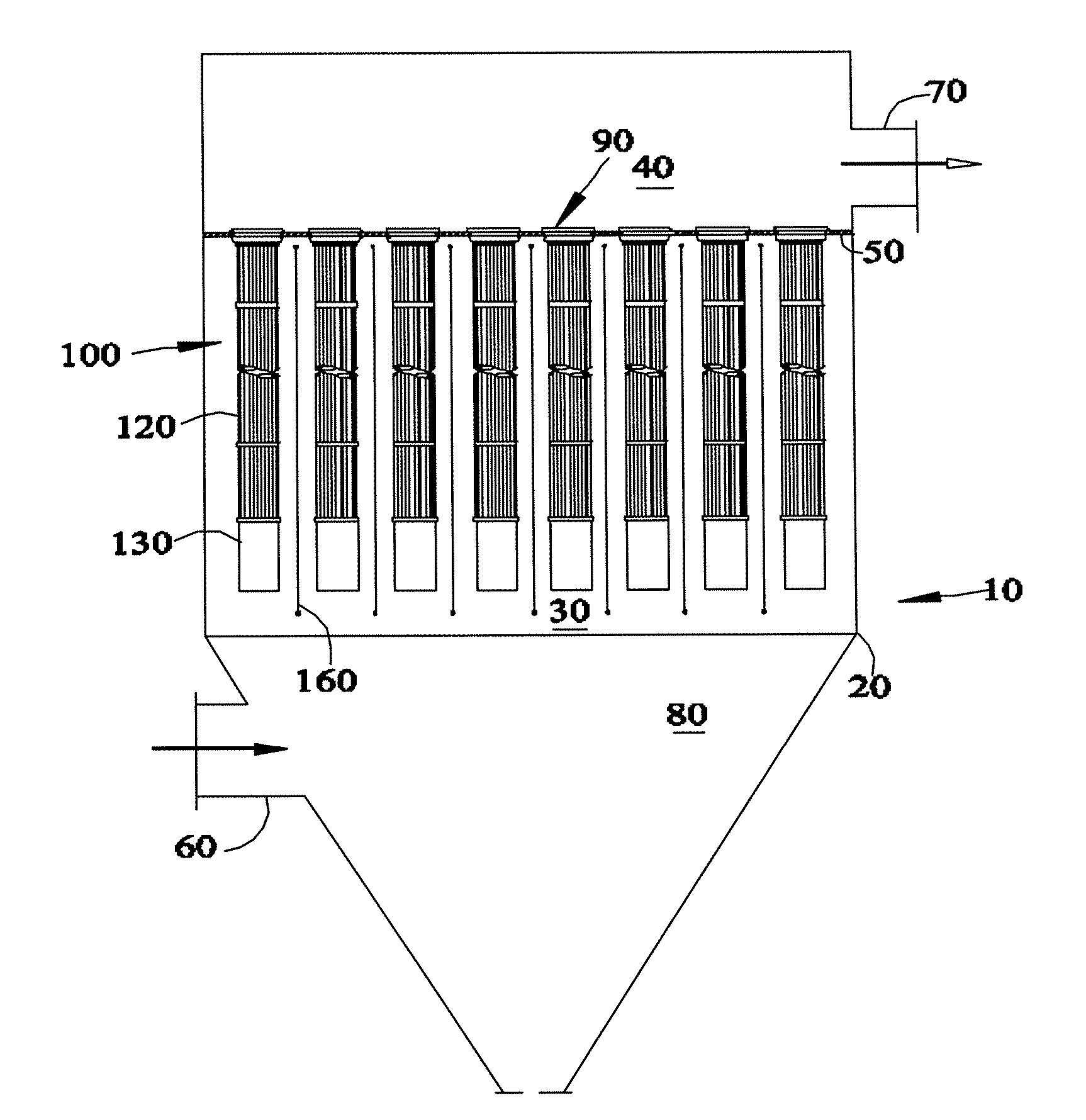

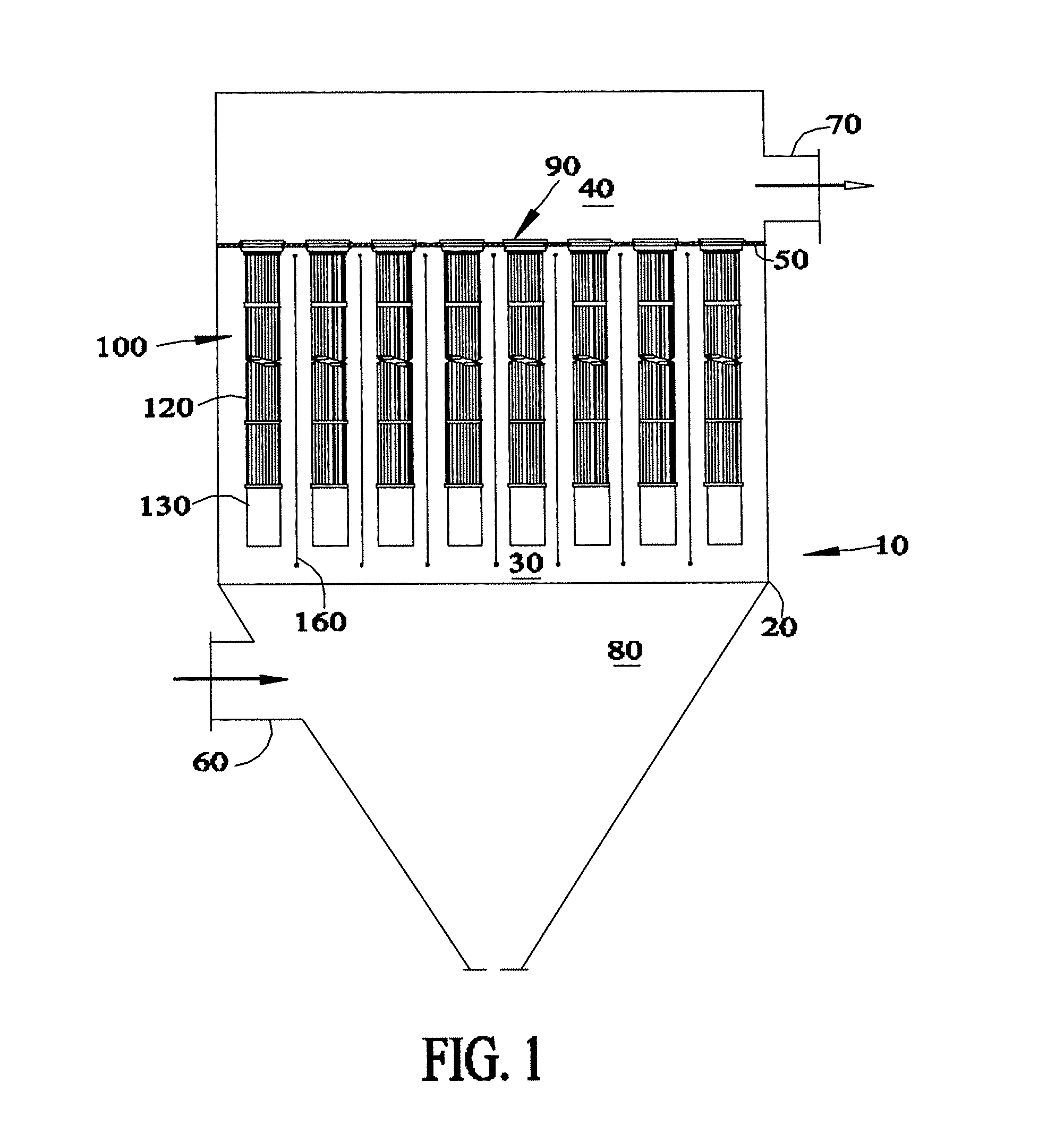

Apparatus and method for the removal of particulate matter in a filtration system

InactiveUS20060174768A1Long useful lifeDispersed particle filtrationTransportation and packagingParticulatesFiltration

A particulate filtration system for removing particulates suspended in a fluid include, in an exemplary embodiment, a filter element and a pre-collector body component operably connected to the filter element. The pre-collector body component is capable of receiving an electrical charge to attract and remove particles suspended in the fluid.

Owner:BHA ALTAIR

Method apparatus for separating unwanted matter from granular material

In a method of separating unwanted fine matter from heavier granular matter a flow of the material is produced under vacuum firstly through alternating expansion and contraction passages and then against impact surfaces to cause multiple redirections of the material and separation of the heavier granular material from the material flow.

Owner:VAN OIRSCHOT FRANK

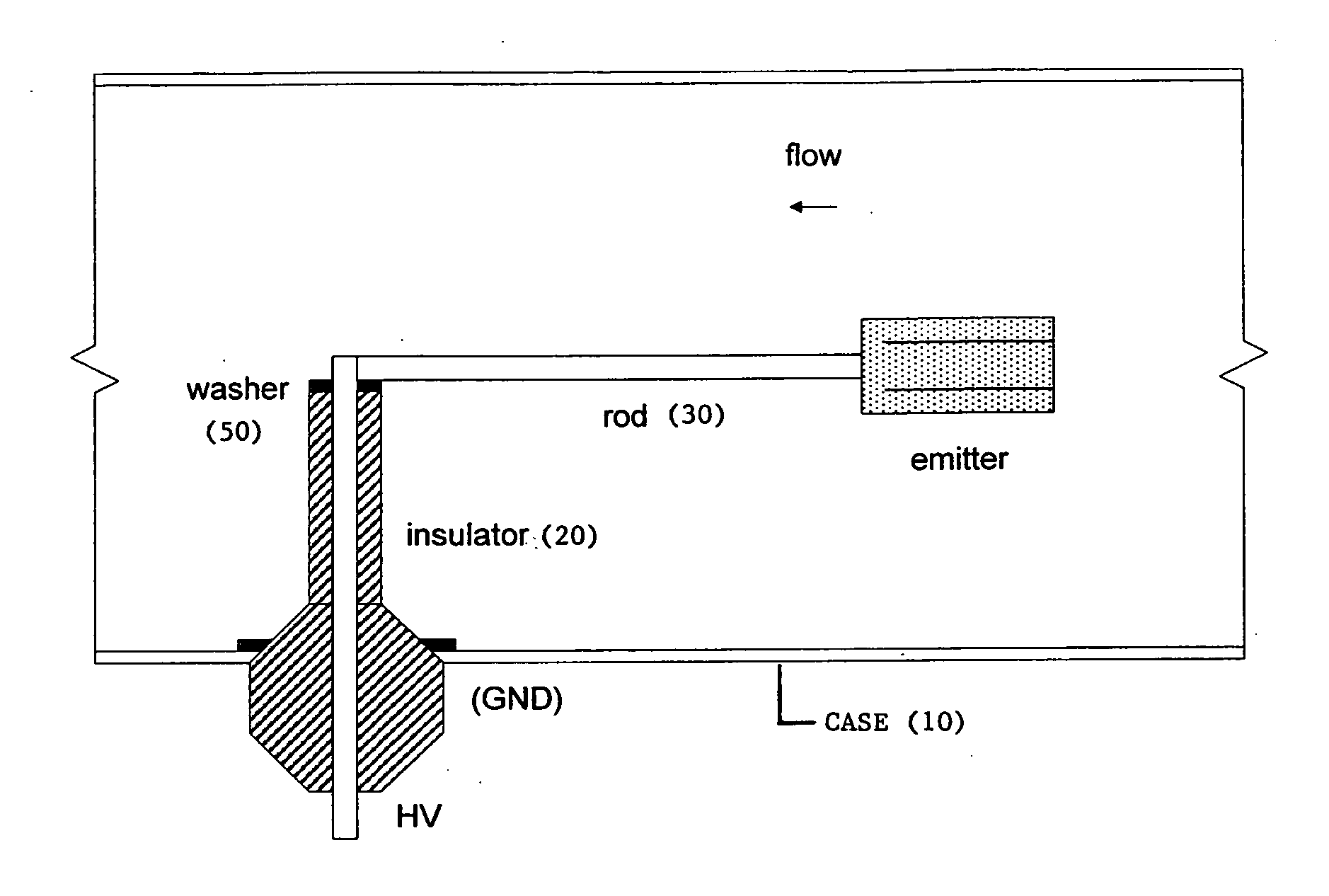

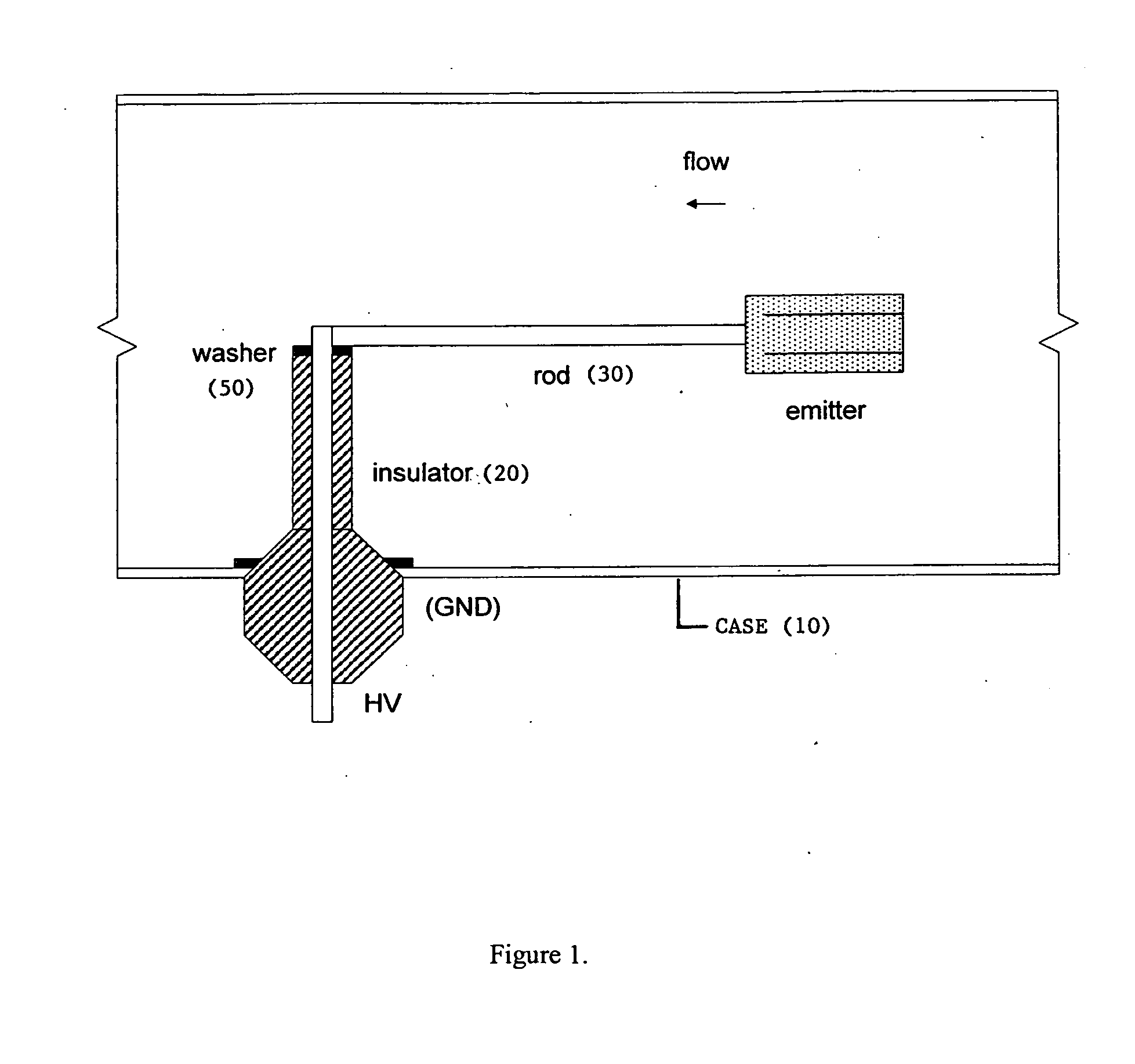

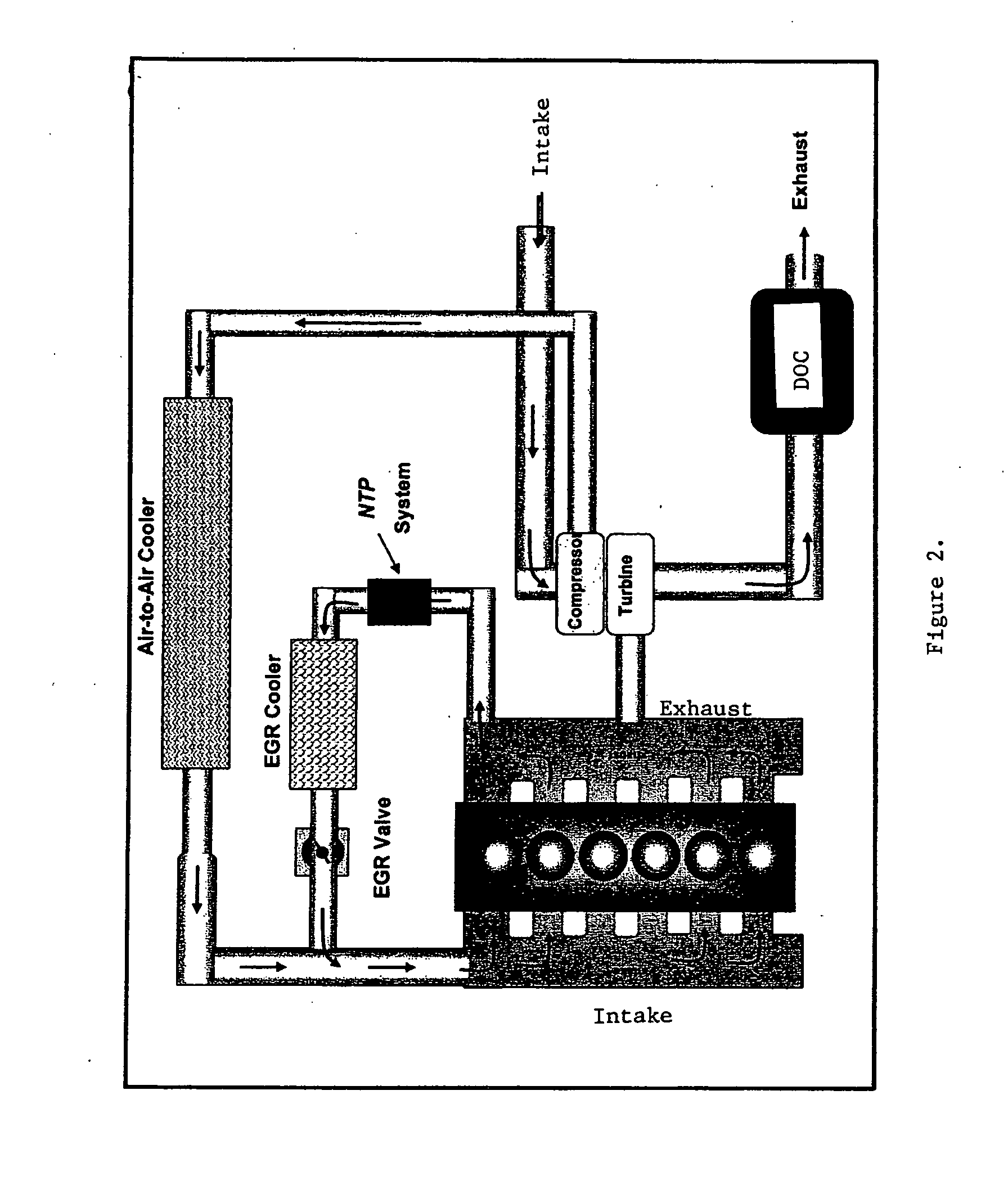

Non-thermal plasma particulate removal systems and methods thereof

ActiveUS20090241775A1Reduce the amount requiredReduce buildInternal combustion piston enginesExhaust apparatusParticulatesNonthermal plasma

The present invention is broadly directed to non-thermal plasma-based systems for reducing the amount of particulate matter in a gas stream, as well as to methods for using such systems. The present invention is particularly directed to such non-thermal plasma-based particulate matter reduction systems with self-cleaning surfaces. Particularly contemplated are self-cleaning surfaces that reduce particulate matter buildup such as is likely to cause the reduction of non-thermal plasma production in the system, and therefore the ability of such systems to reduce the amount of particulate matter in the gas stream.

Owner:ENVIRONMENTAL ENERGY TECH

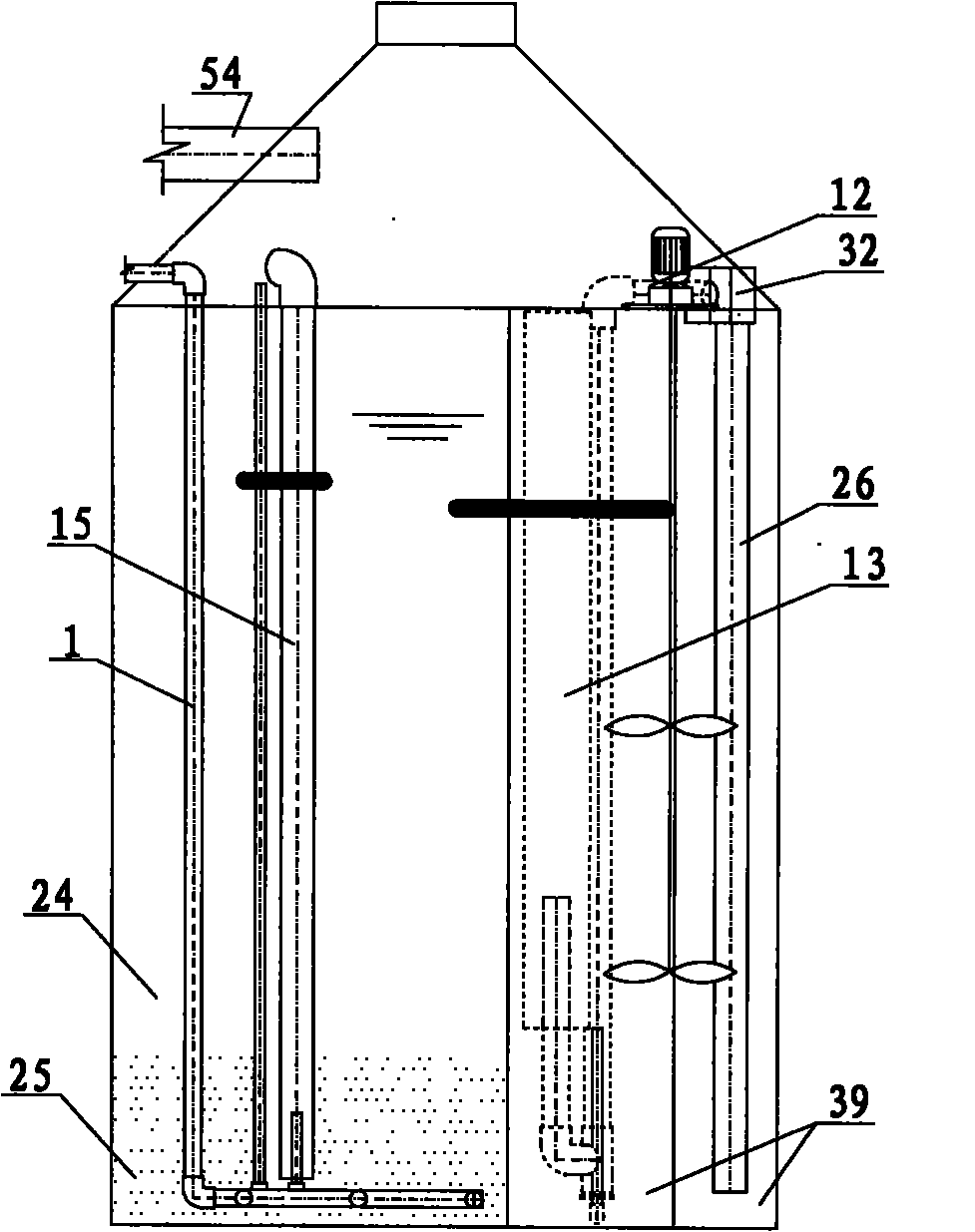

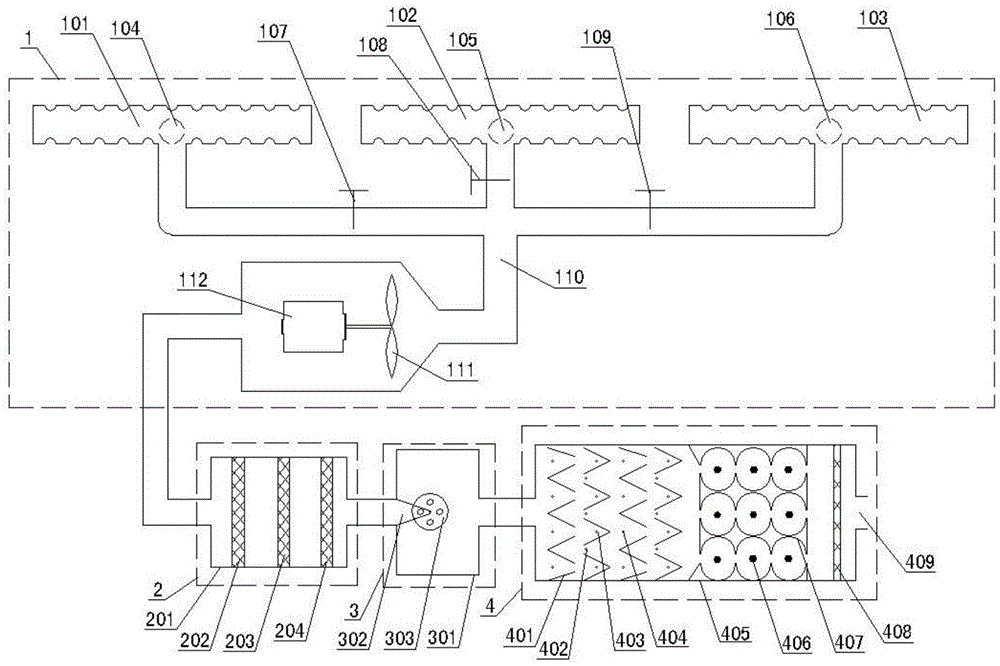

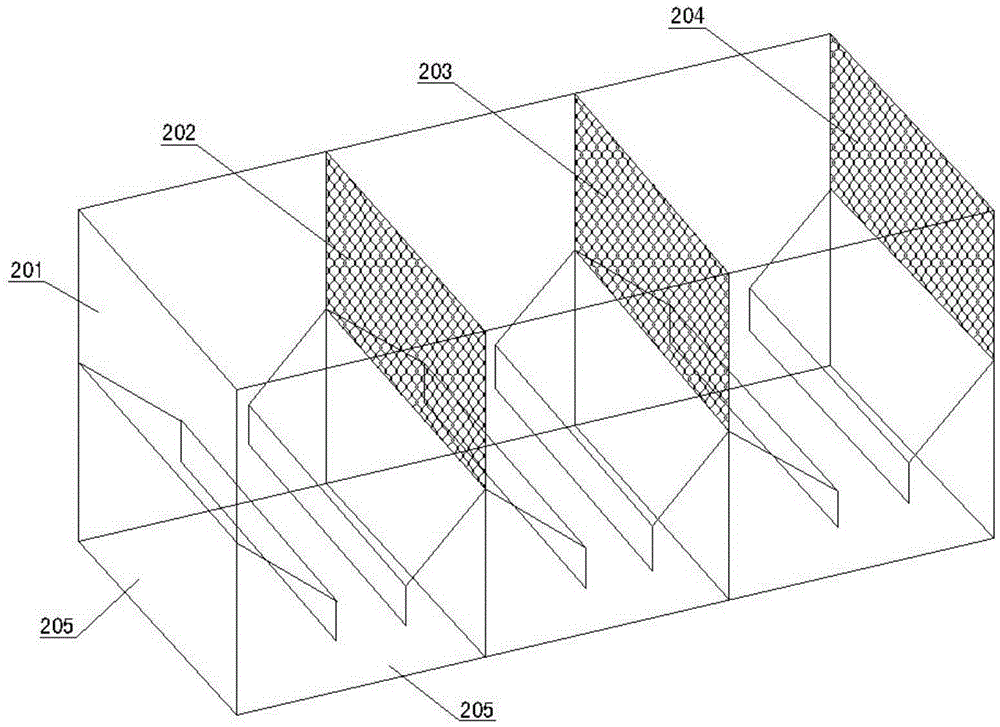

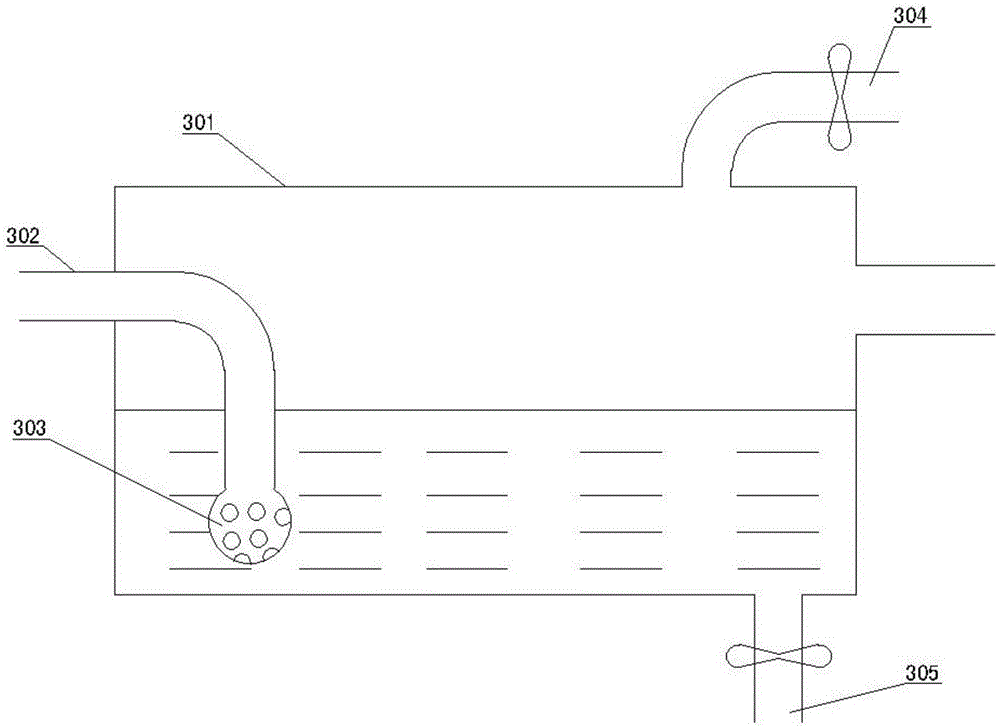

Integrated air-lift loop dynamic membrane bioreactor

InactiveCN101851043AReduce processing costsMeet the needs of decentralized sewage treatment with low investment costsWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesRural areaWater quality

The invention relates to an integrated air-lift loop dynamic membrane bioreactor, which is characterized in that the bioreactor is in a cylindrical platform shape, and the structure of the bioreactor is divided into an anaerobic regulating pool, an anoxia tank, an air-lift loop dynamic membrane bioreactor and other units; the anaerobic regulating pool has the functions of water quality and quantity regulation, anaerobic hydrolytic acidification of inlet water and sludge volume reduction, and the main body adopts a nitrogen and carbon removal operation mode by the A / O process; the air-lift loop dynamic membrane bioreactor is an air-lift loop aerobic bioreactor in which air at two sides lifts and air at the center reflows, and filter components are is arranged in a central region; and diatomaceous earth and other granular matters are added to form granular sludge so as to form the air-lift loop dynamic membrane bioreactor; and an air lifter is adopted to lift sewage and sludge, and has different functions of isolating oil and scum, exhausting and preventing a great deal of sludge at the bottom from being greatly lifted, and the like. The invention facilitates on-site installation and operation management, has good water inlet quality, stable operation and low cost, and can fully meet the actual requirements of decentralized wastewater treatment in rural areas.

Owner:TONGJI UNIV

Sorbent filter for the removal of vapor phase contaminants

Methods and apparatuses are described for removing a contaminant, such as a vaporous trace metal contaminant like mercury, from a gas stream. In one embodiment, a primary particulate collection device that removes particulate matter is used. In this embodiment, a sorbent filter is placed within the housing of the primary particulate collection device, such as an electrostatic precipitator or a baghouse, to adsorb the contaminant of interest. In another embodiment, a sorbent filter is placed within a scrubber, such as a wet scrubber, to adsorb the contaminant of interest. In some embodiments, the invention provides methods and apparatuses that can advantageously be retrofit into existing particulate collection equipment. In some embodiments, the invention provides methods and apparatuses that in addition to removal of a contaminant additionally remove particulate matter from a gas stream.

Owner:ELECTRIC POWER RES INST INC

Site road raised dust processing system

InactiveCN105597927AReduce wasteEasy to useCombination devicesMagnetic separationLower limitInhalable particles

The invention discloses a site road raised dust processing system. The site road raised dust processing system is characterized by comprising a raised dust suction device, a large particle filter device used for filtering out large particles in raised dust, a water washing device humidifying raised dust and air and dissolving soluble substances in raised dust, and a static coagulation dust removal device used for removing inhalable particles in raised dust. A raised dust concentration detection unit is arranged in the raised dust suction device and detects the road raised dust concentration. When the road raised dust concentration reaches the set upper limit value, the site road raised dust processing system is started to work, and when the road raised dust concentration is decreased to the set lower limit value, the site road raised dust processing system is turned off. For application occasions of site raised dust, inhalable particles in raised dust and solid large particles in raised dust are effectively removed, and the site raised dust pollution is reduced.

Owner:HEFEI UNIV OF TECH

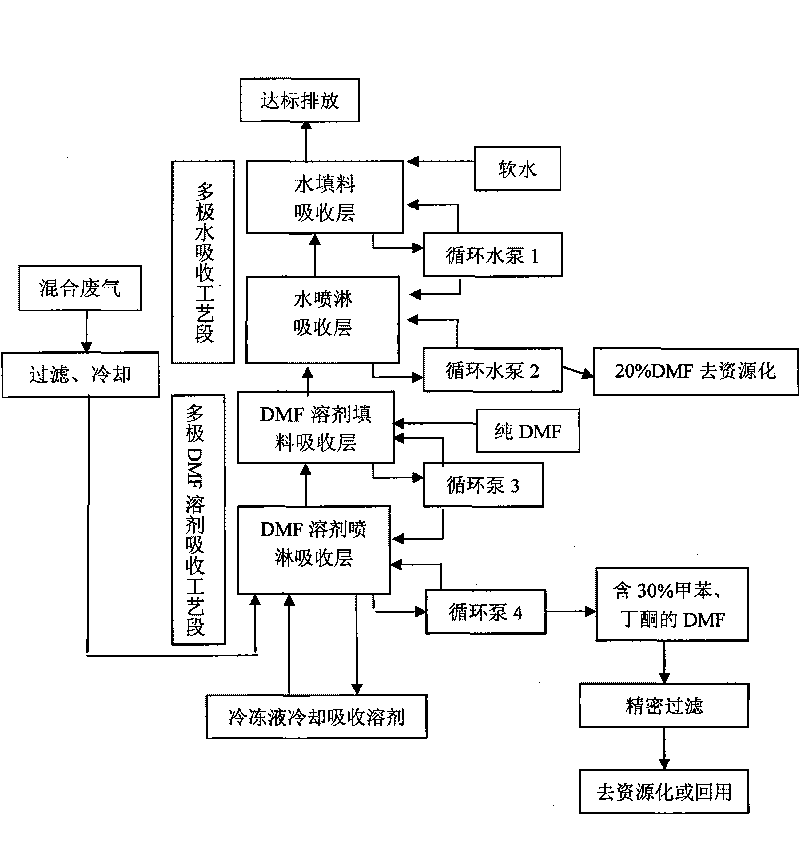

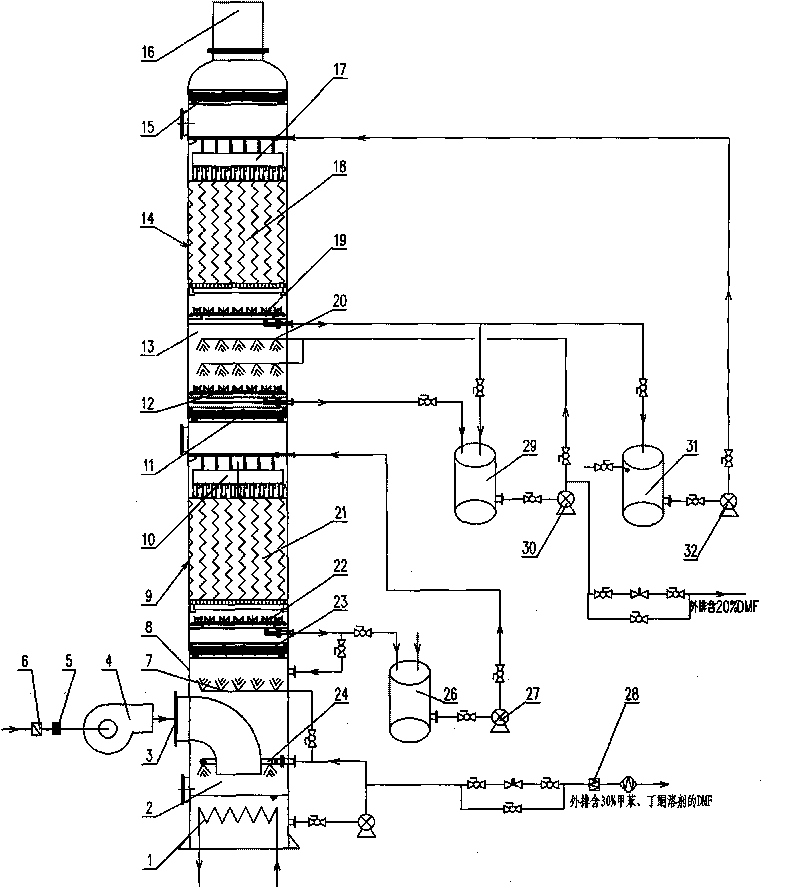

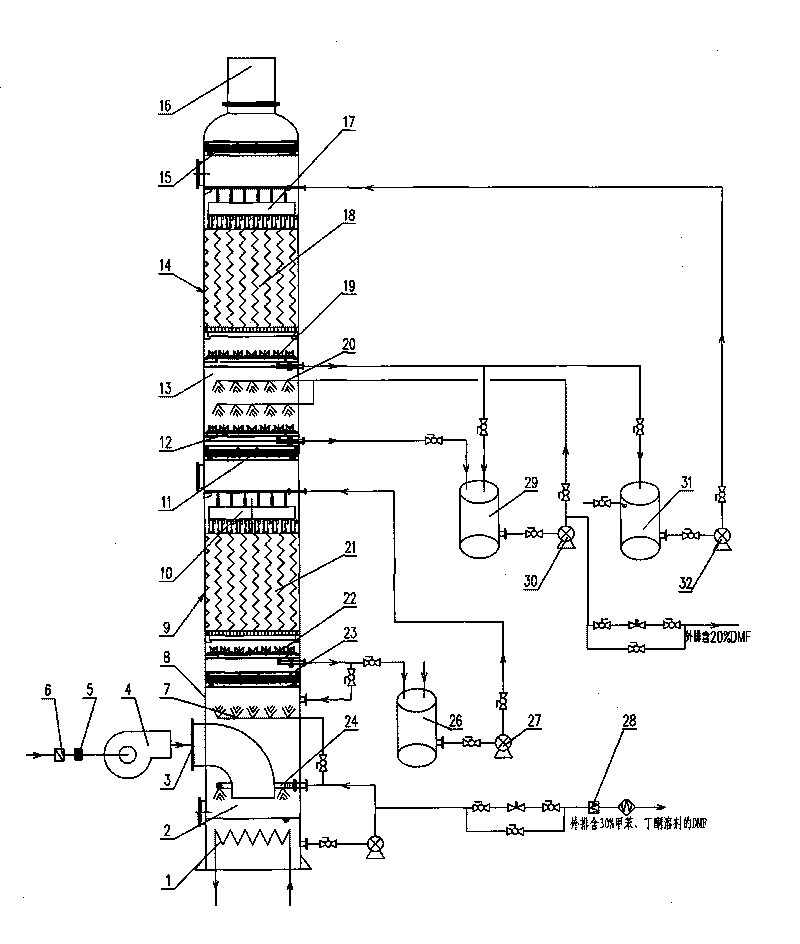

Method and device for recovering mixed waste gas in synthetic leather production

InactiveCN101700451AReduce the temperatureEffectively filter outCombination devicesRecovery methodEnvironmental engineering

The invention discloses a method for recovering mixed waste gas in synthetic leather production, which comprises the following steps of: filtering granular matters or fibrous matters from the mixed waste gas, and cooling the mixed waste gas; absorbing the cooled mixed waste gas by circulating spraying and packing contact by using dimethyl formamide as an absorbing solvent; refrigerating the dimethyl formamide absorbing liquid which absorbs the mixed waste gas; absorbing the waste gas which is absorbed by a packing layer in a contact way by circulating water spraying and contact with water again in the packing absorbing layer; and discharging the tail gas which is absorbed by water packing and reaches the standard. The invention also discloses a recovering device for realizing the method for recovering mixed waste gas, which comprises a tower body, wherein a dimethyl formamide spraying chamber, a dimethyl formamide packing chamber, a water spraying chamber and a water packing chamber are arranged in the tower body. The invention has sufficient gas-liquid contact and high waste gas recovering rate, and not only achieves the purpose of recycling toluene, butanone and DMF but also avoids the environment pollution.

Owner:东台同济华康消防器材科技有限公司

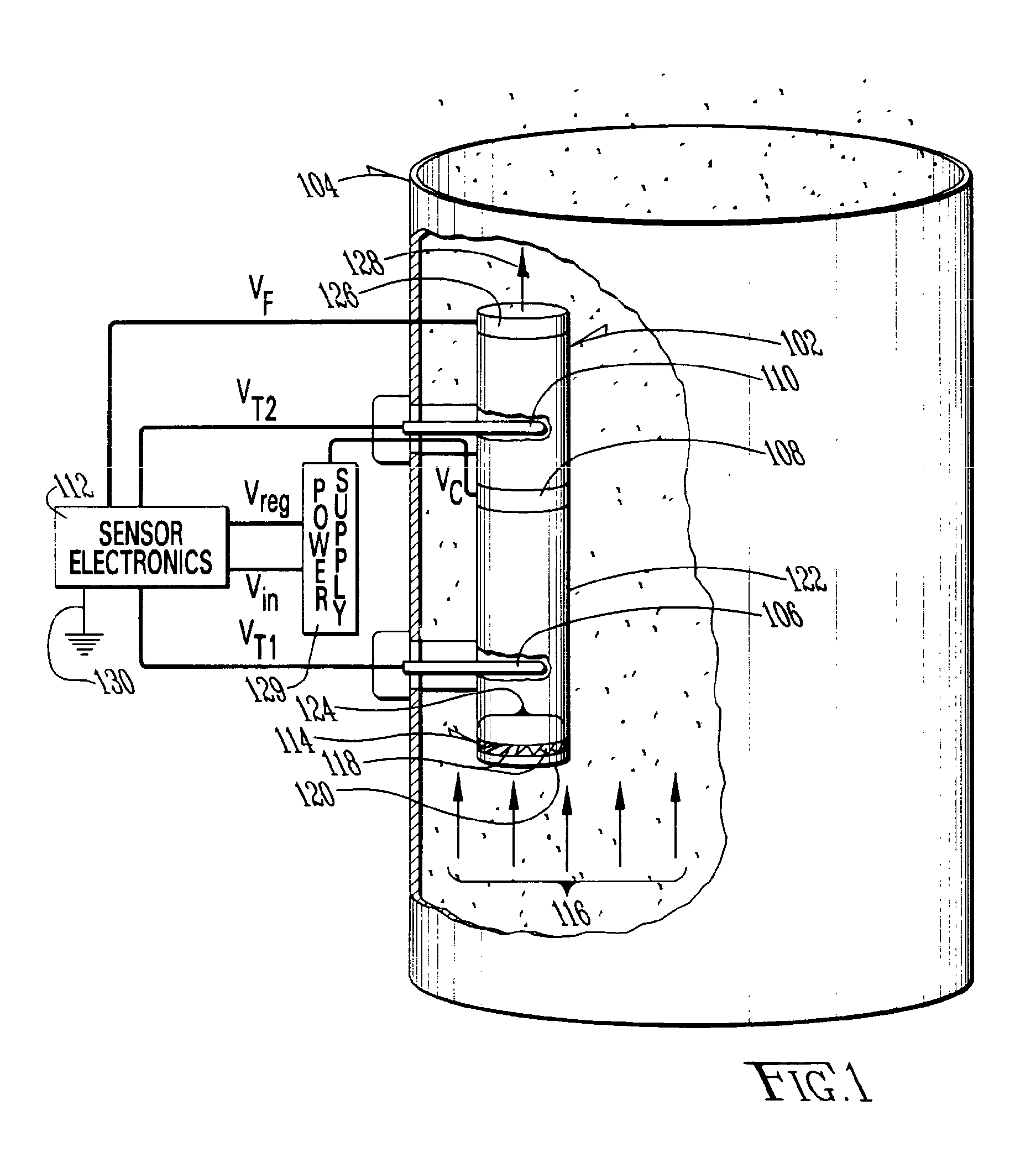

Method and apparatus for monitoring particles in a flowing gas

InactiveUS20050050968A1Inexpensive to buildInexpensive to maintainParticle size analysisParticulatesEngineering

Owner:MRIGLOBAL

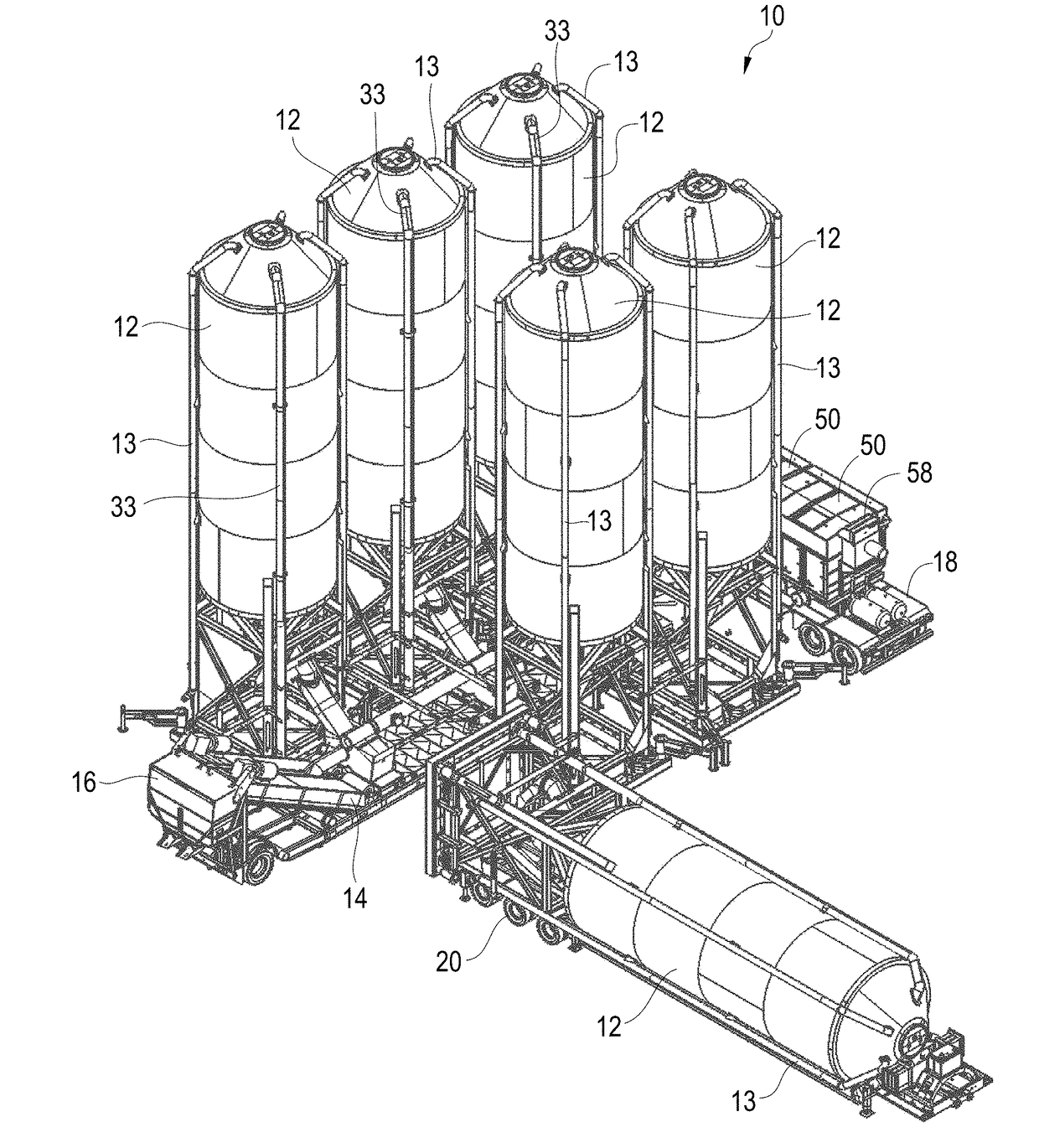

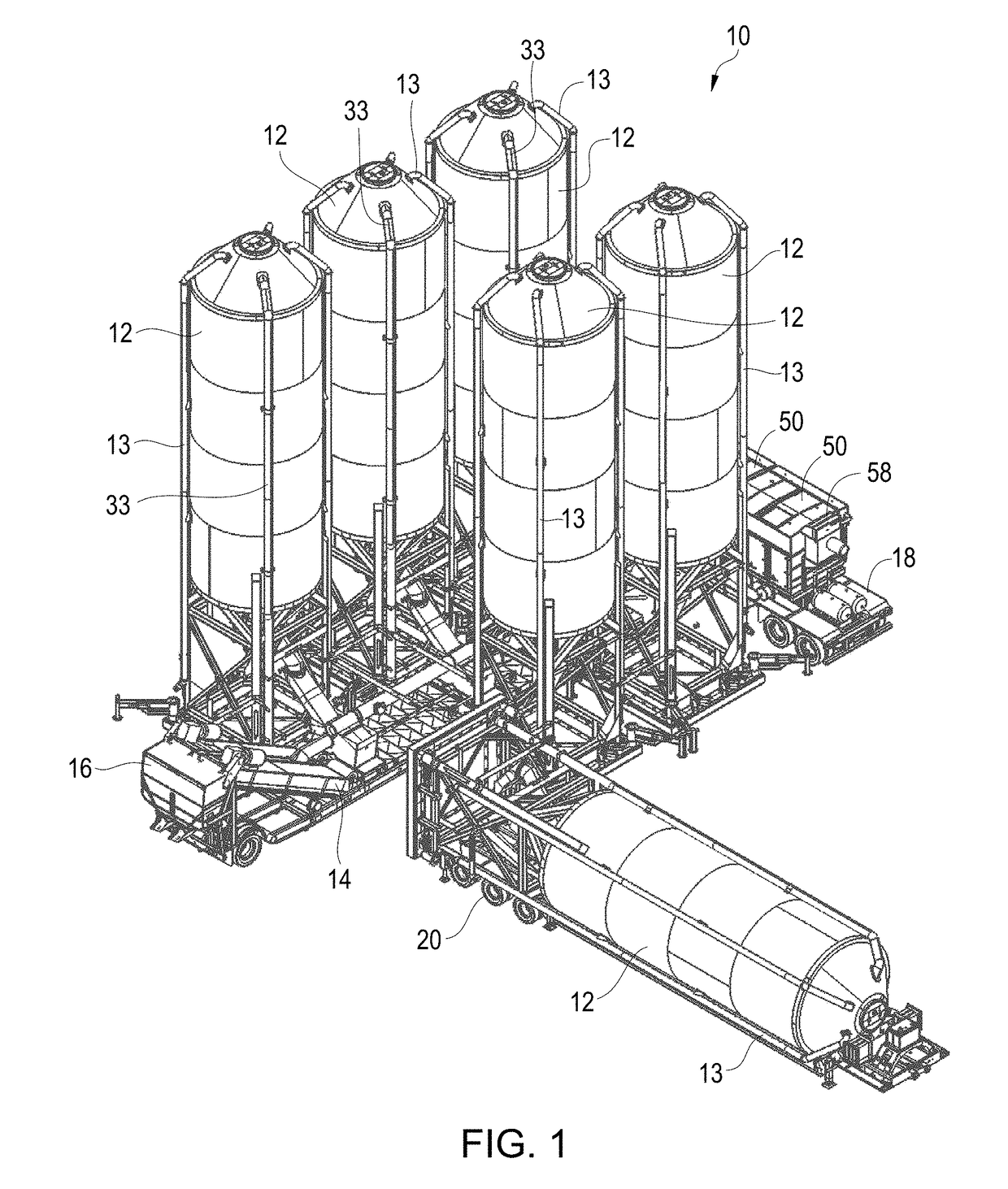

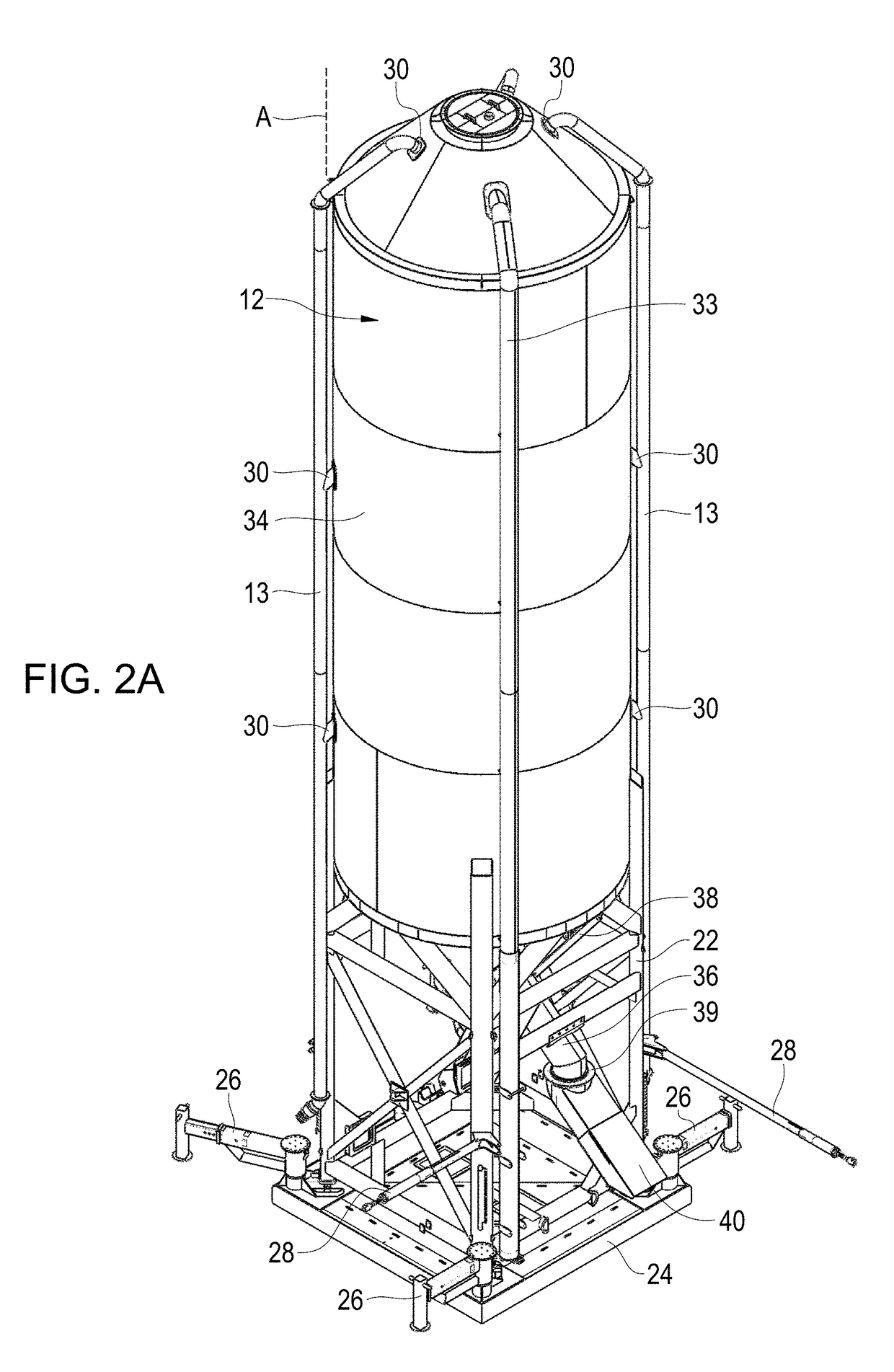

Proppant Delivery System And Related Method

ActiveUS20170291780A1Inhibition releaseConveyorsControl devices for conveyorsParticulatesEngineering

A delivery system for feeding particulate matter to a target location at a well site, including a transportable conveyor belt assembly; one or more silos in fluid communication with a particulate supply line, each of the silo inlets extending through a side wall of the respective silo and disposed at a different location from the others along a longitudinal axis of the respective silo; and for each silo an enclosed chute detachably attachable thereto so as to receive into the chute particulate matter gravity fed out of the respective silo and convey such matter into the housing of the conveyor belt assembly. The silos, the chutes and the housing enclose the particulate matter as it passes from the silos through the chutes and conveyor belt assembly to the target location, to inhibit the release of dust generated from movement of the particulate matter from the silos to the target location.

Owner:NEXTIER COMPLETION SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com