Patents

Literature

242results about "Mechanical suction control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

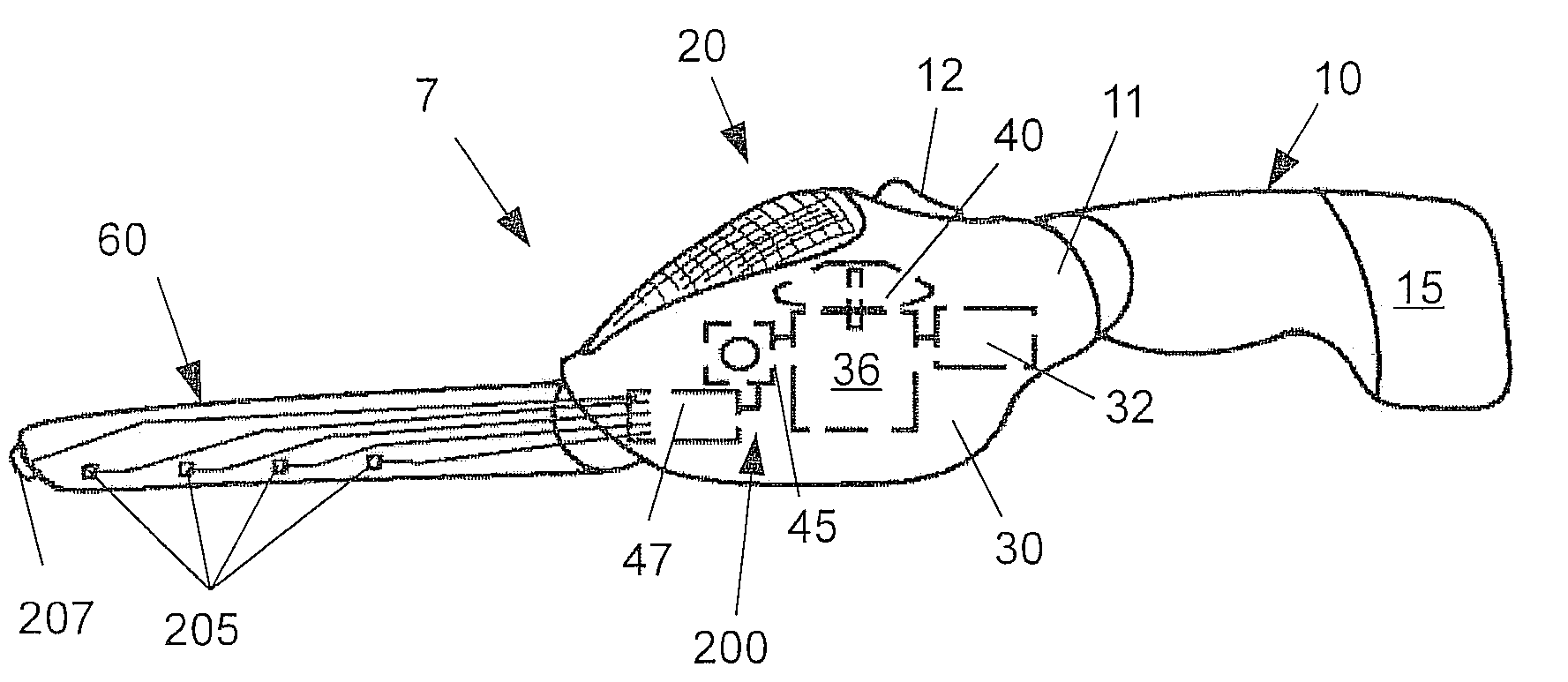

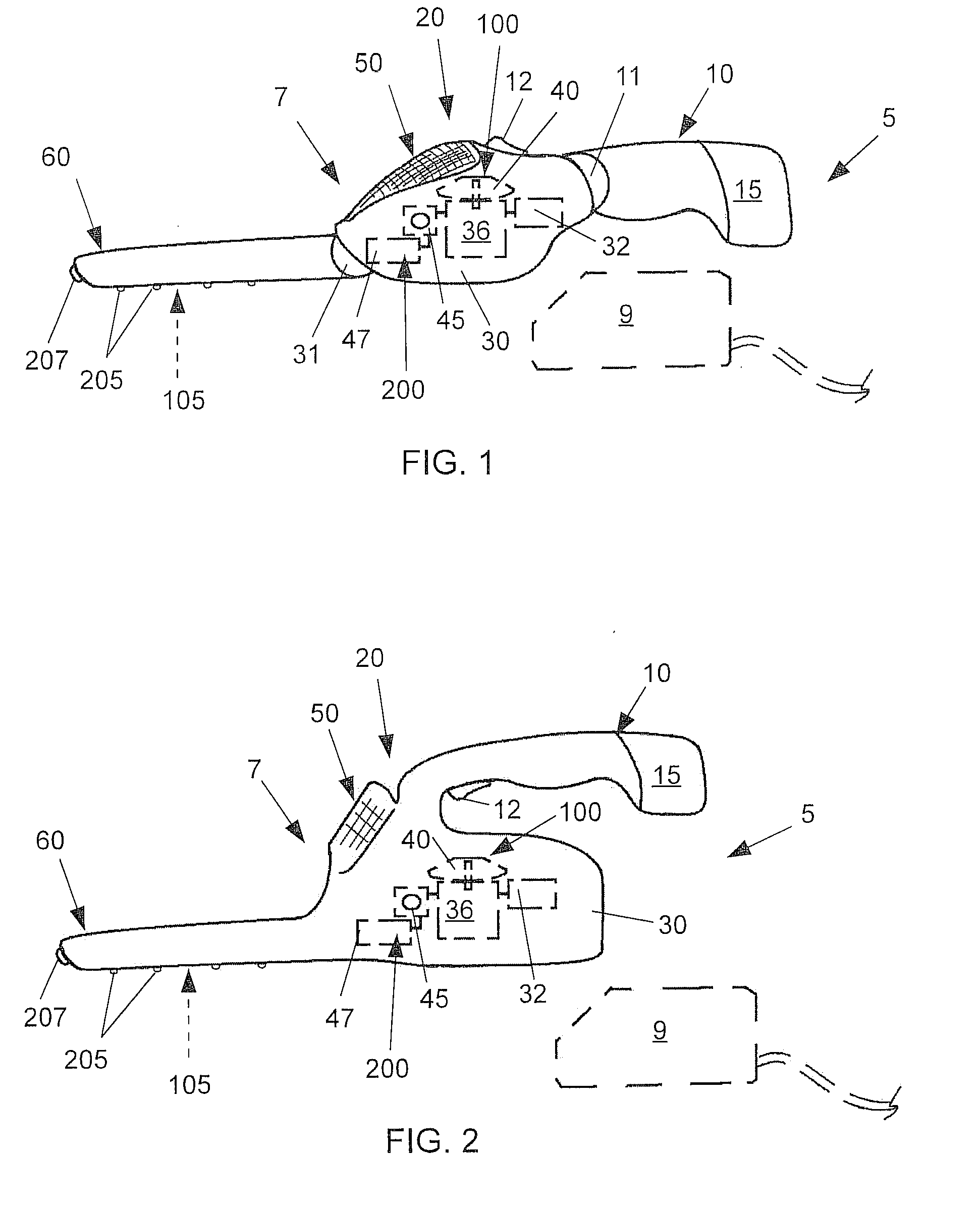

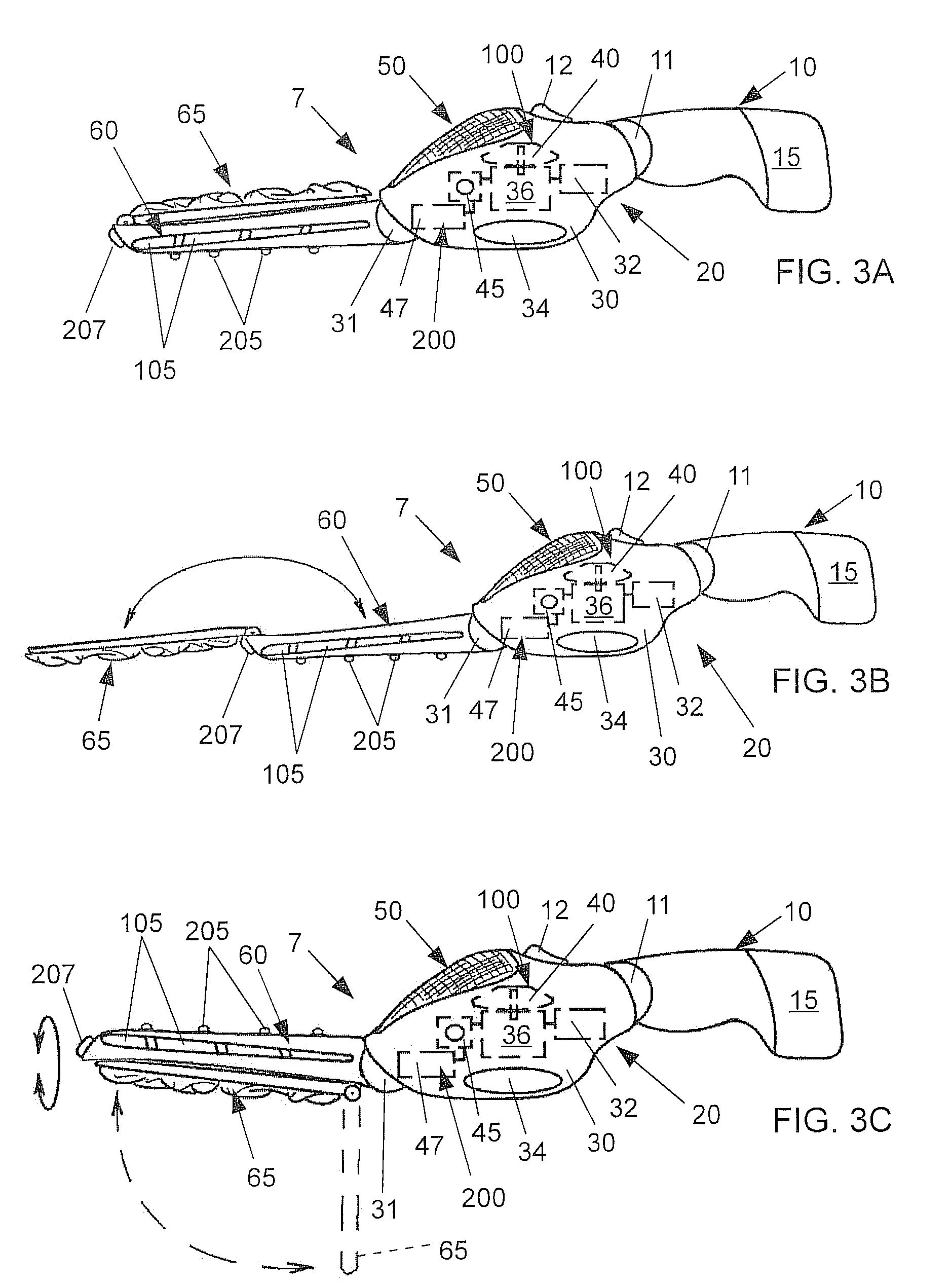

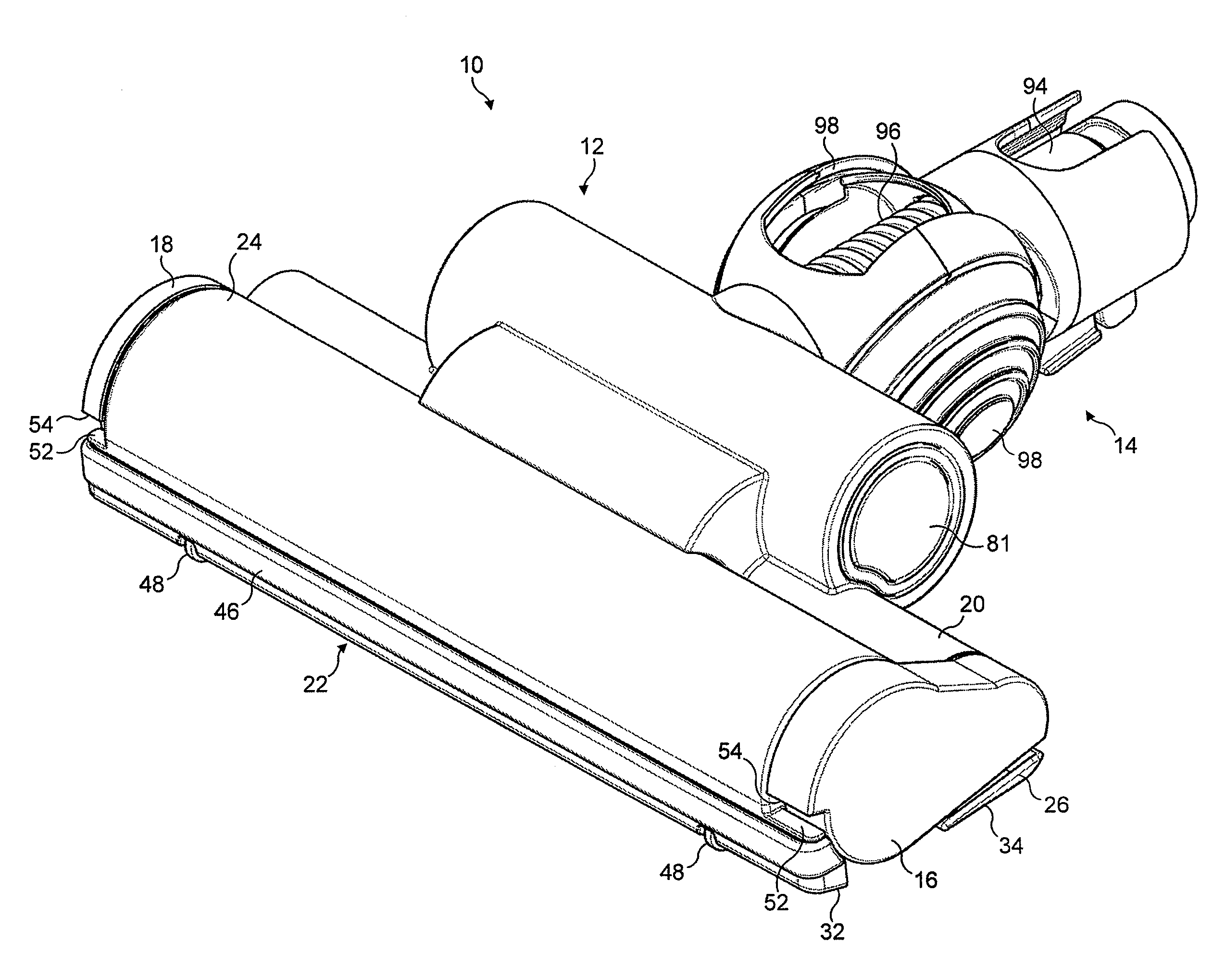

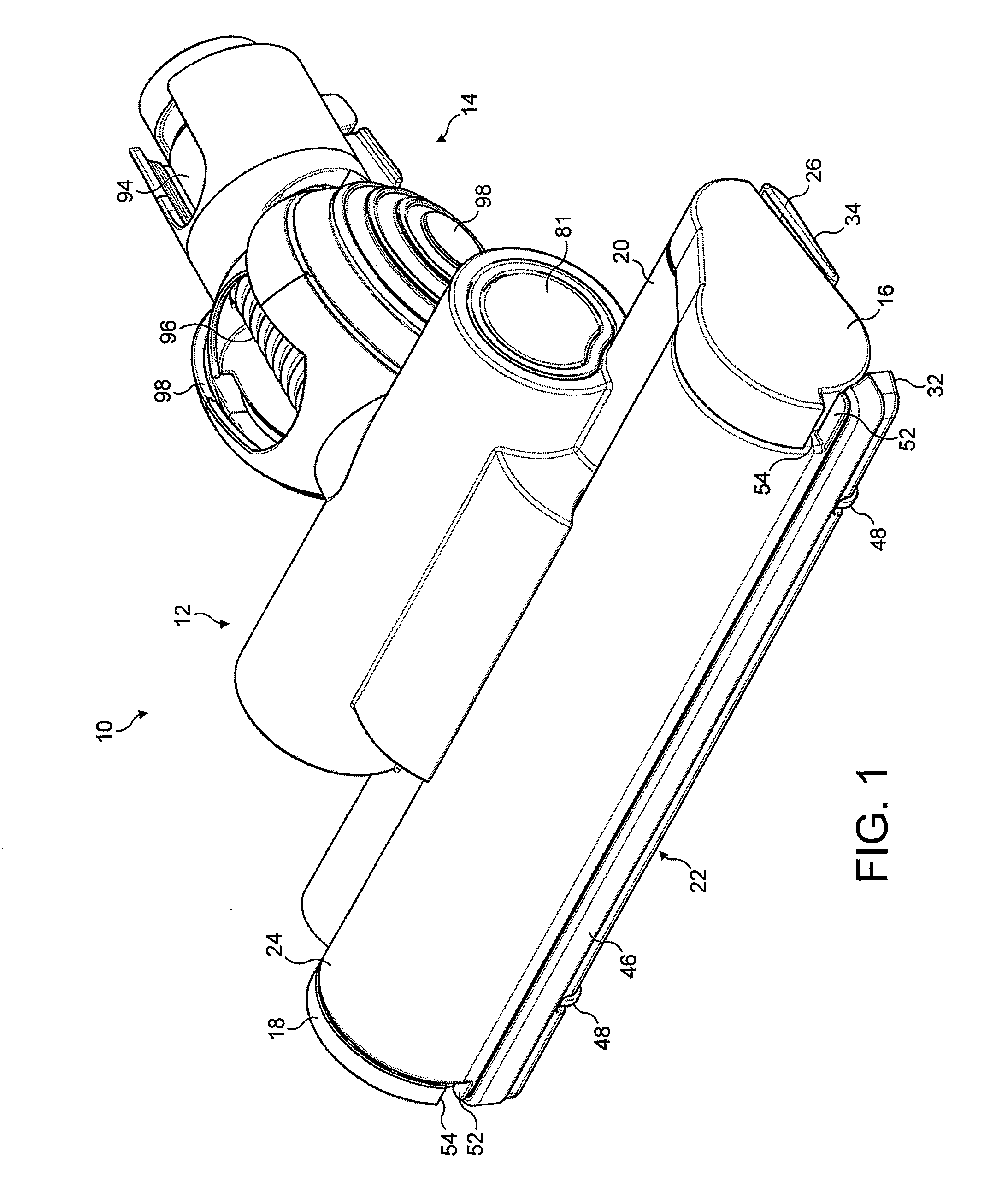

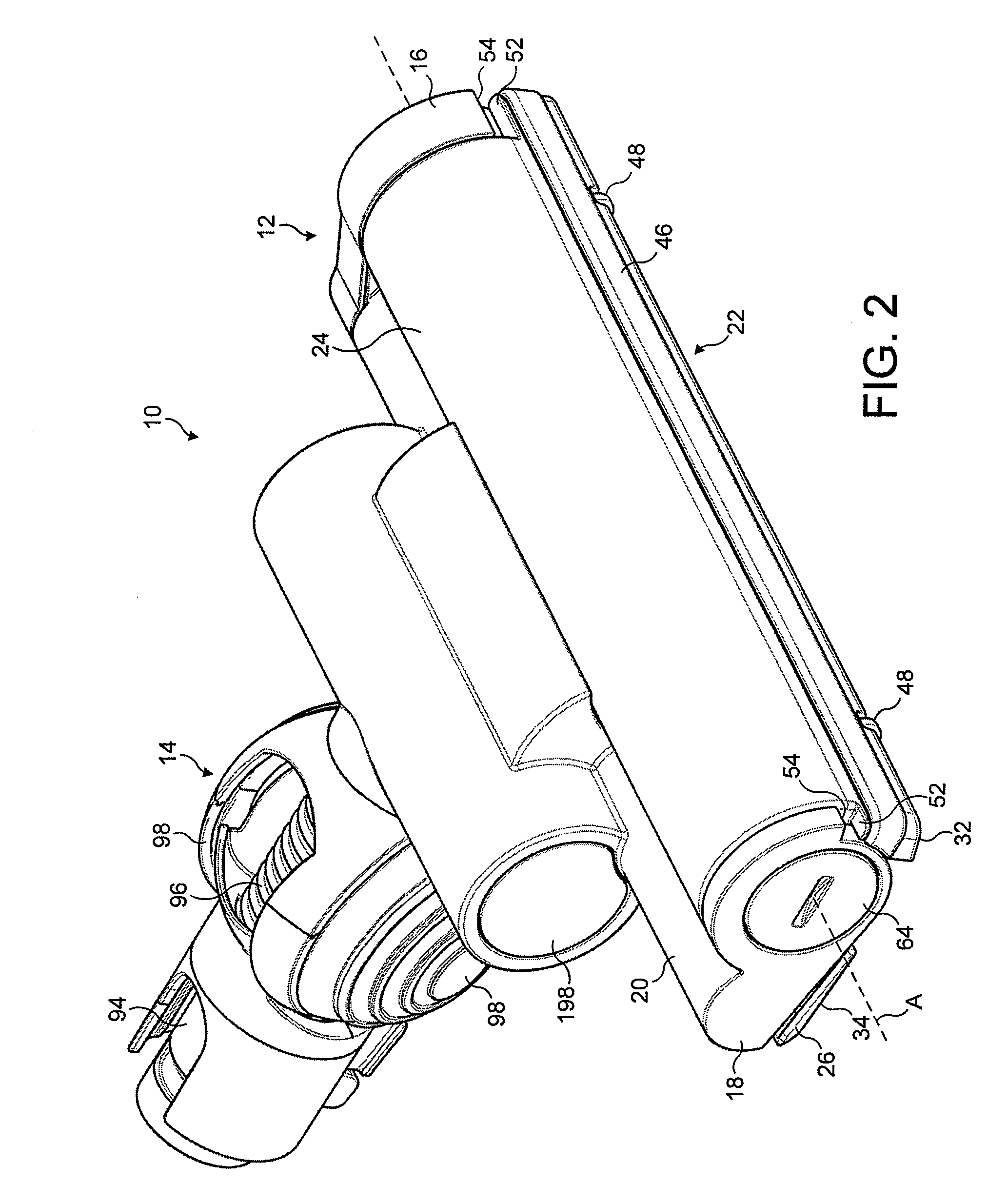

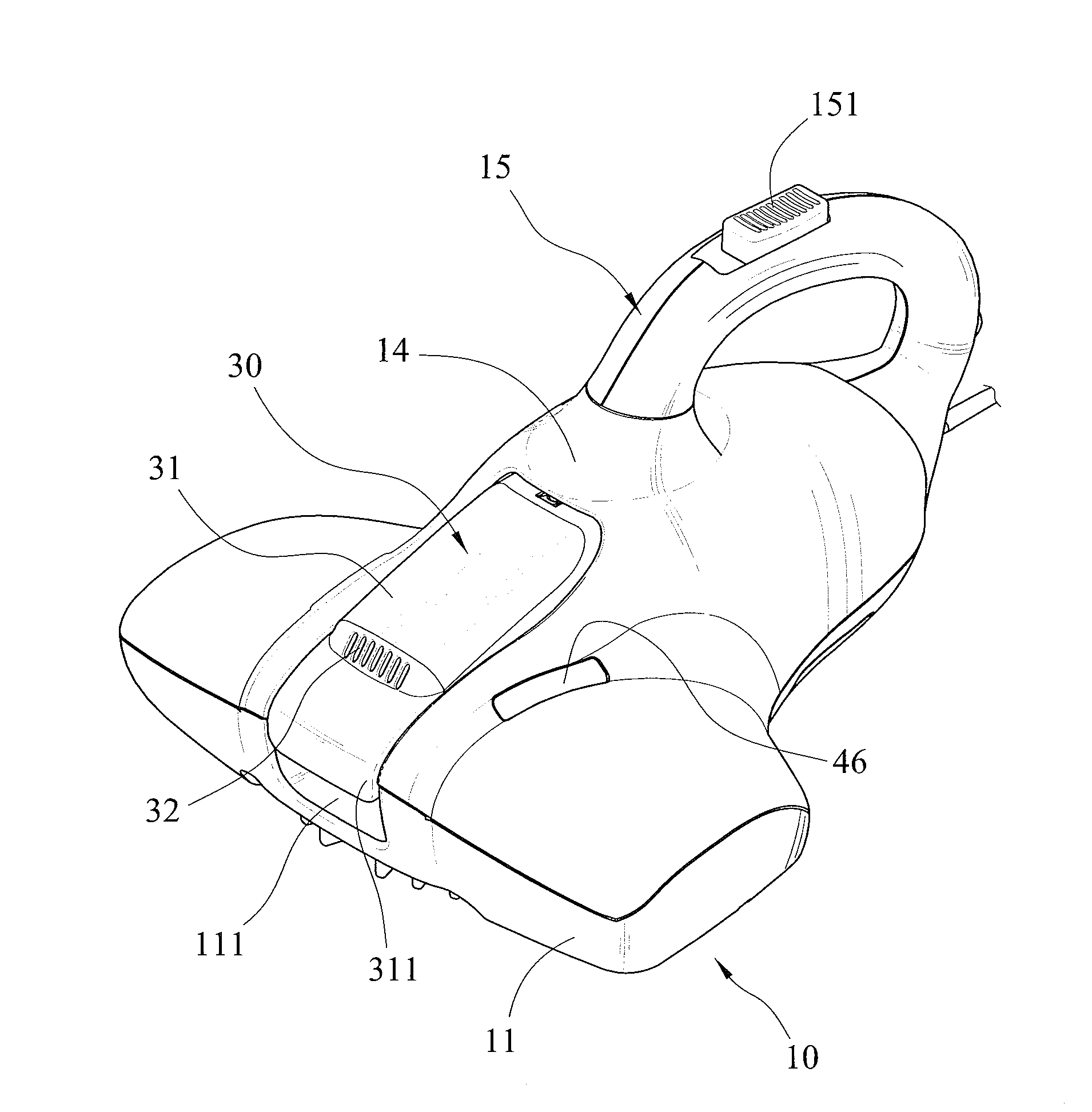

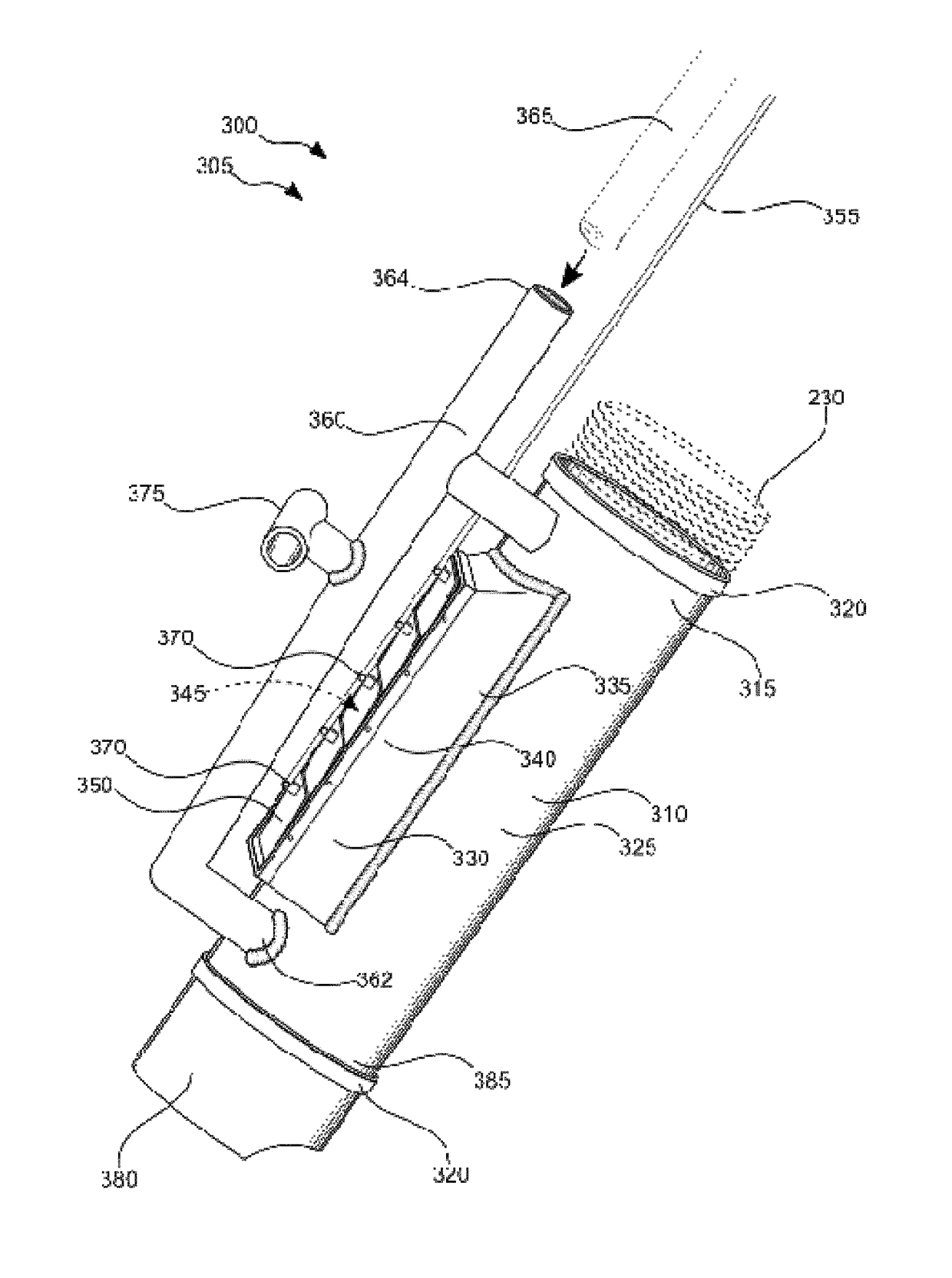

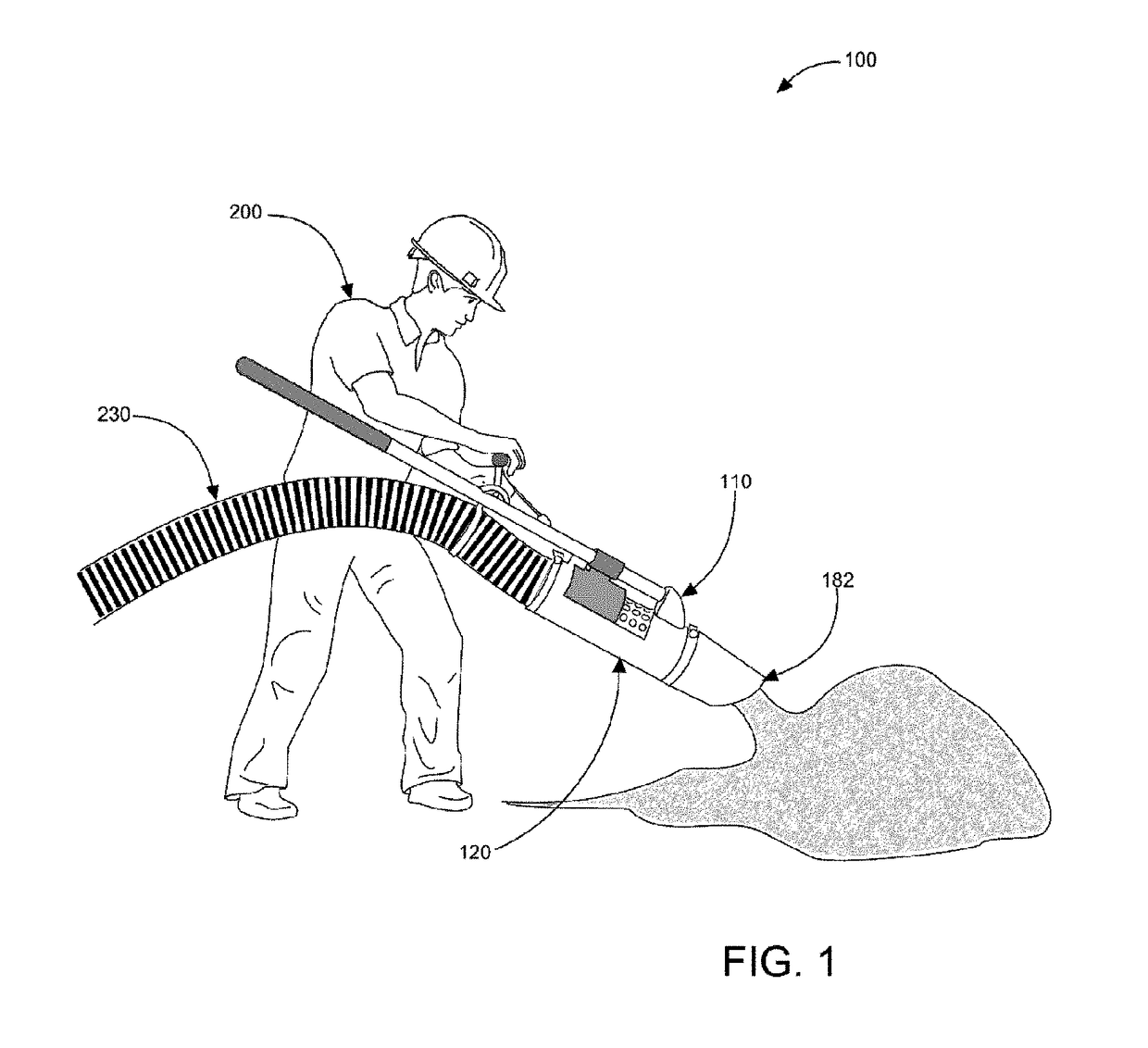

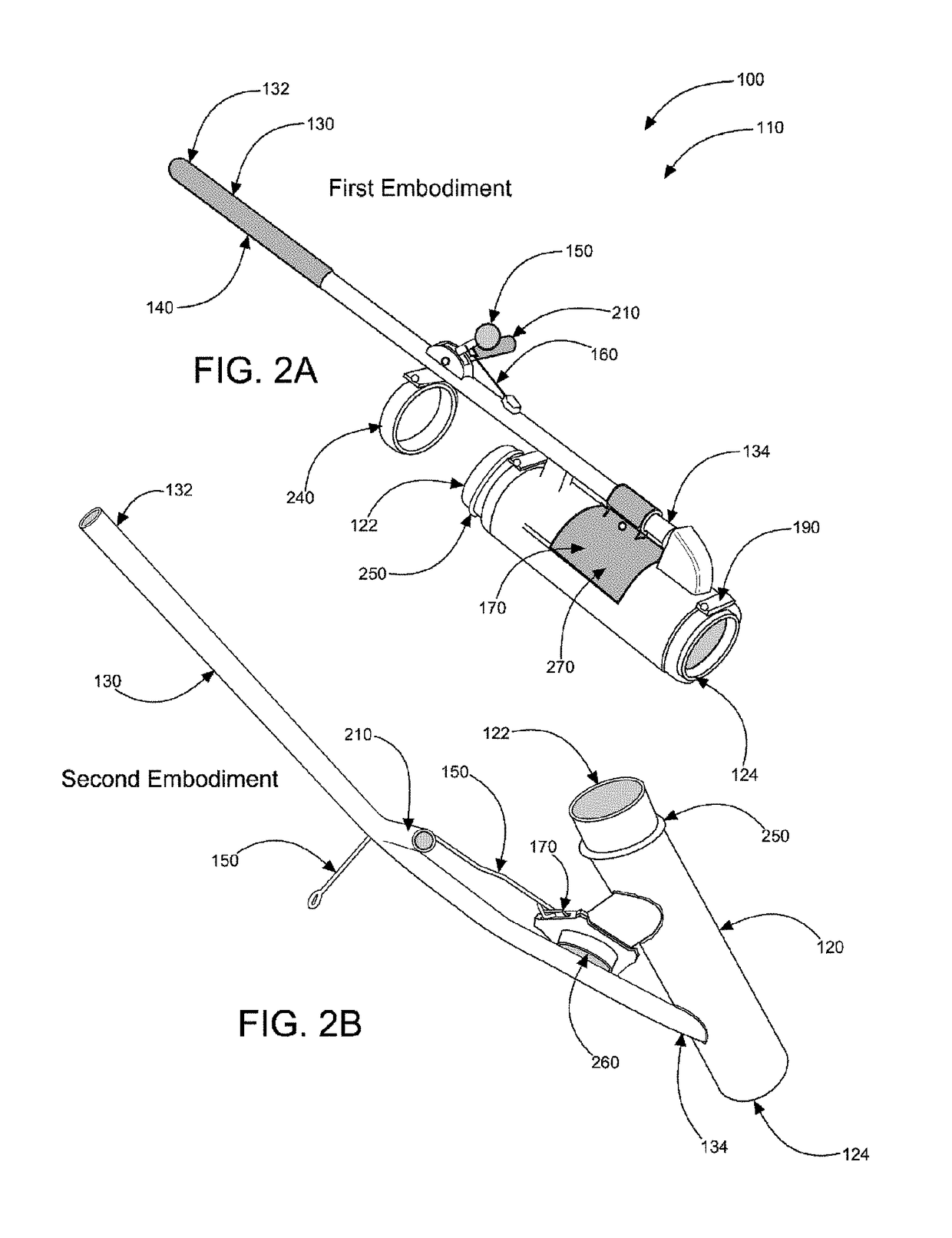

Handheld Portable Devices for Touchless Particulate Matter Removal

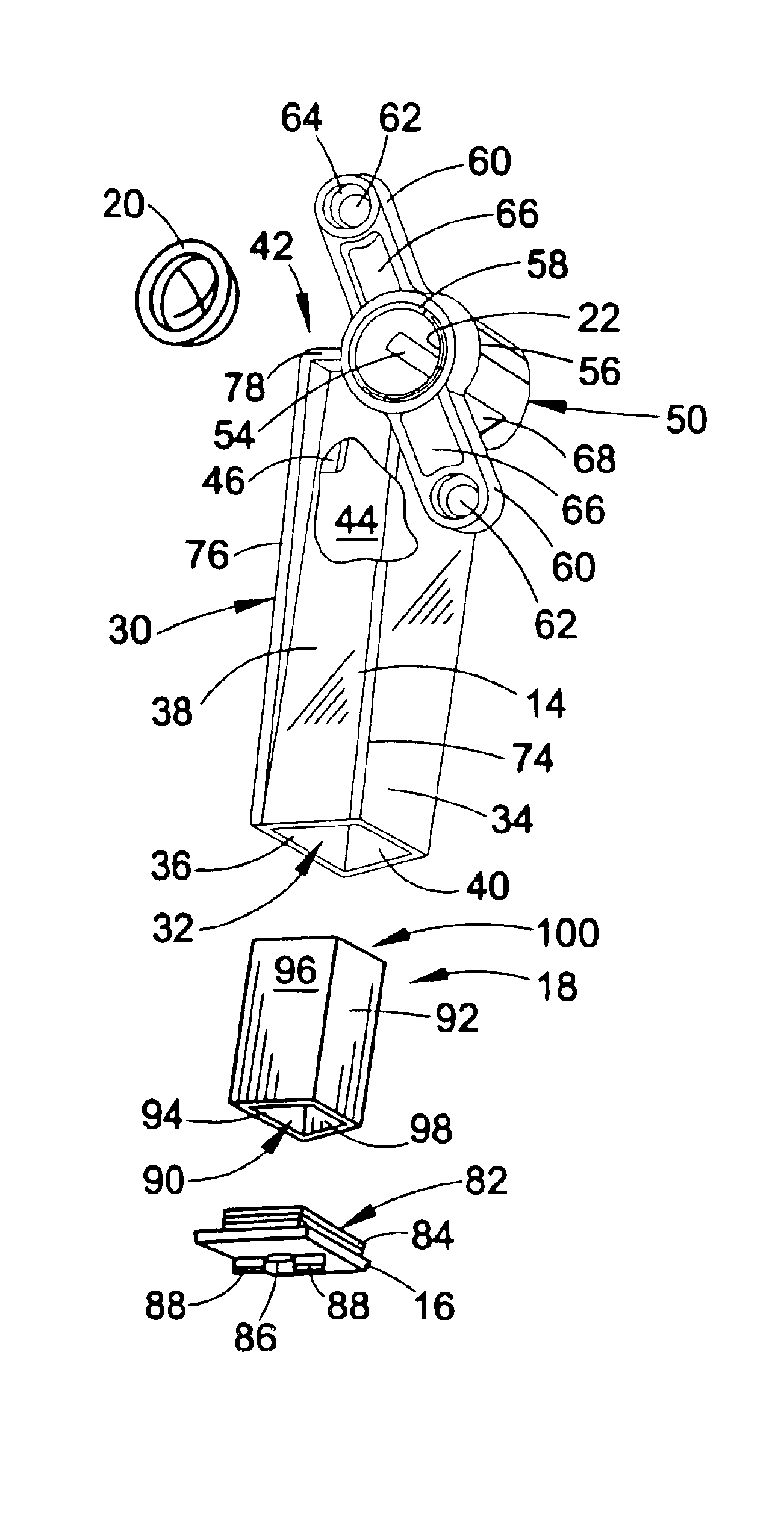

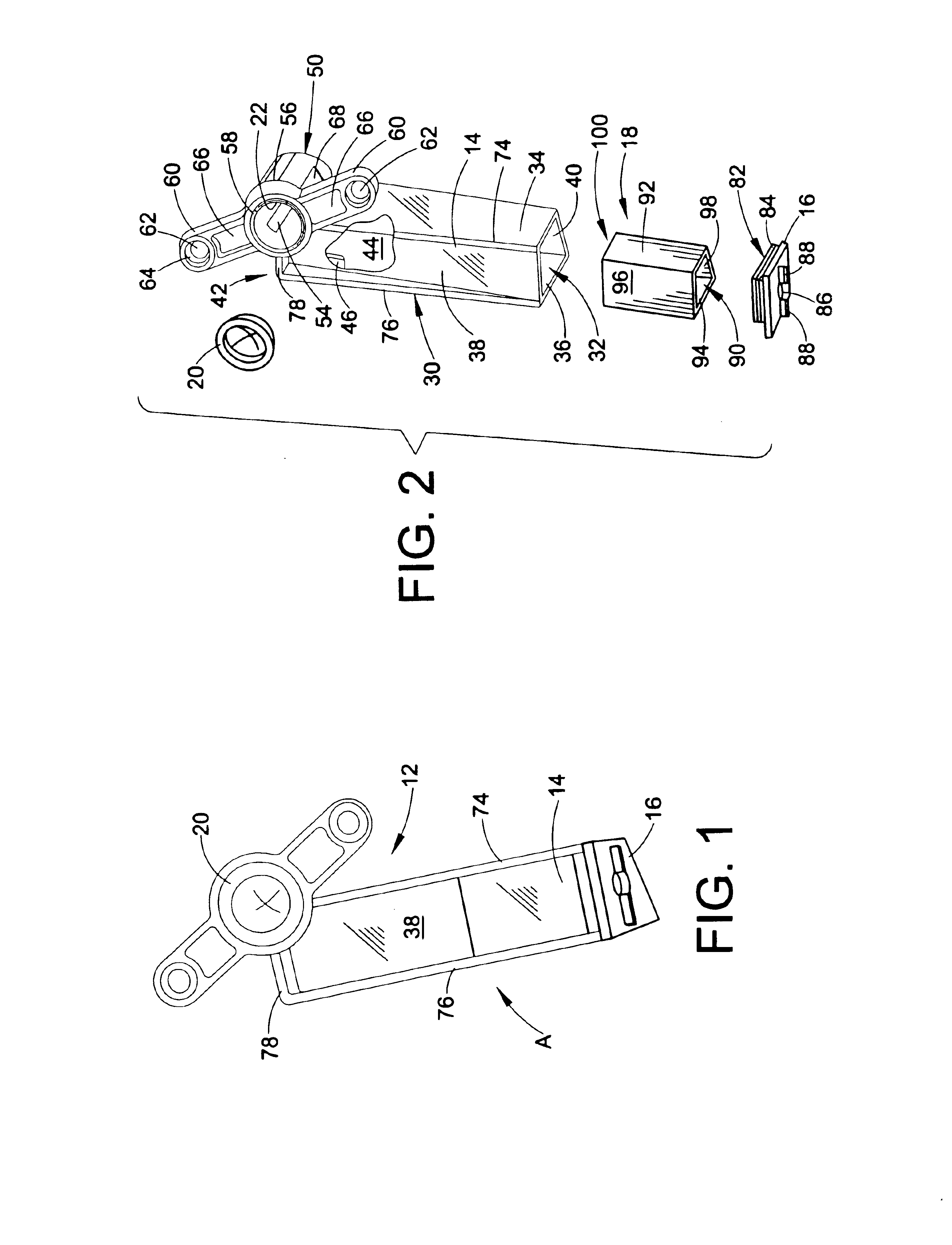

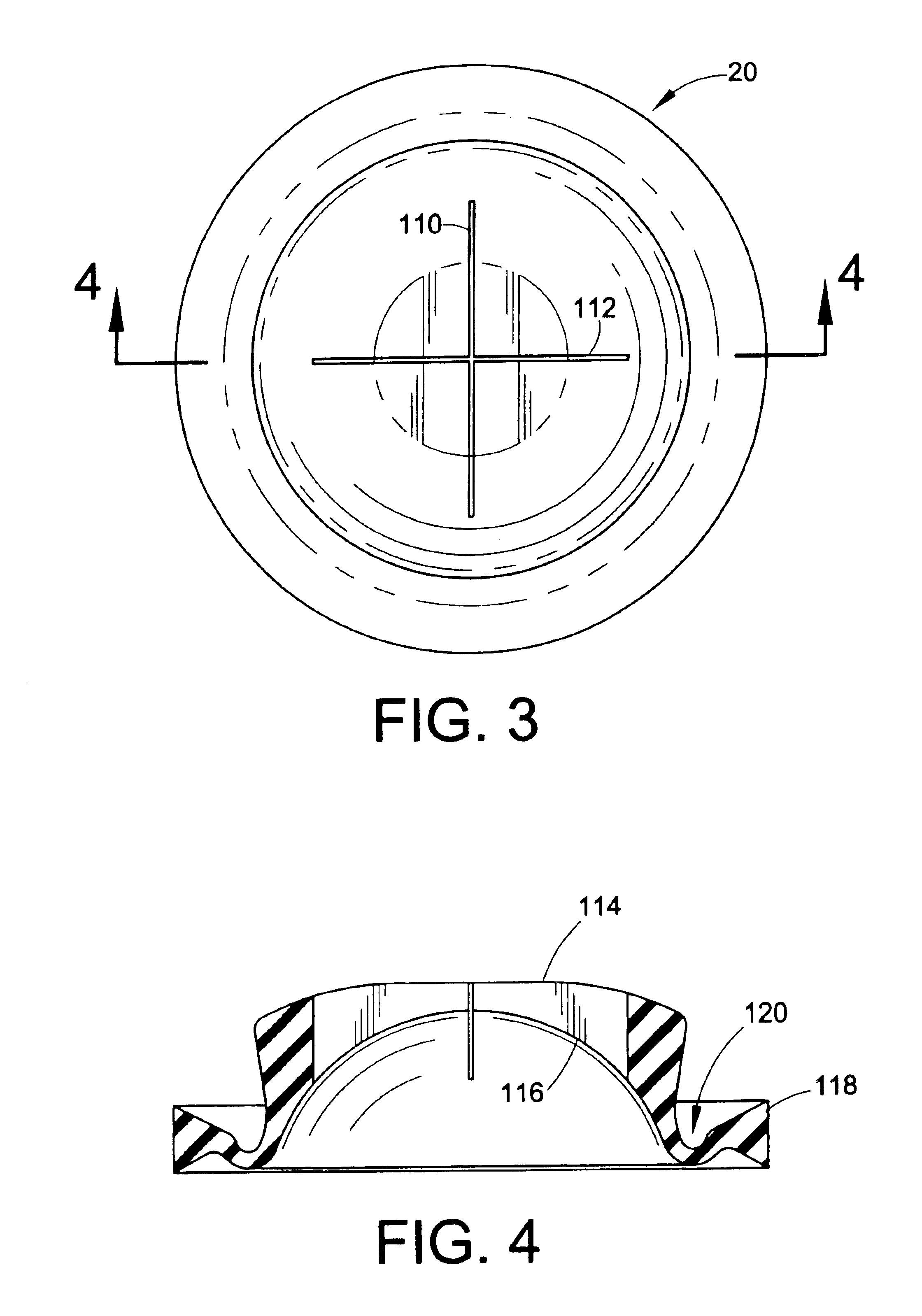

ActiveUS20090044372A1Increase pressureMechanical suction controlSuction nozzlesParticulatesEngineering

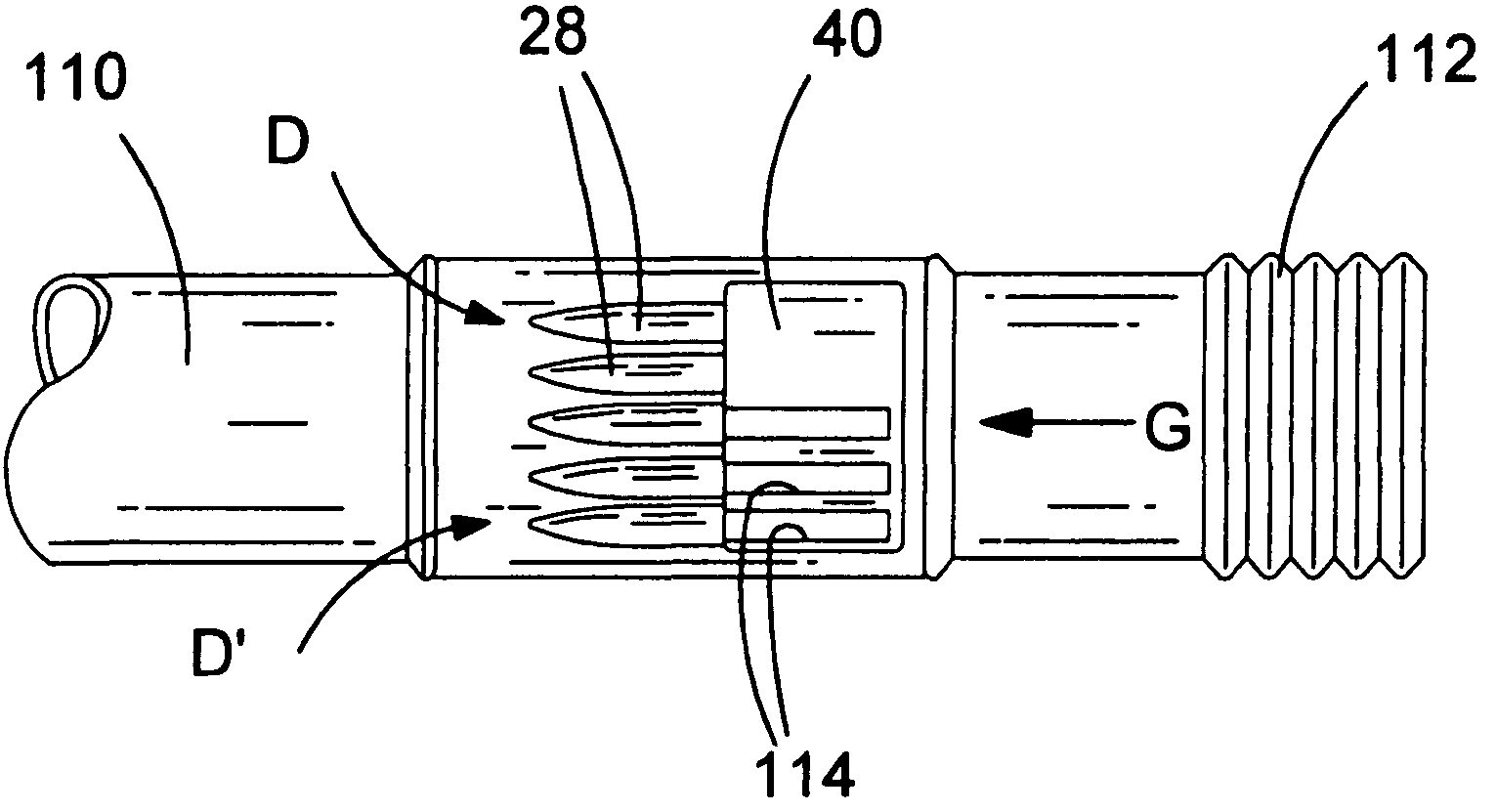

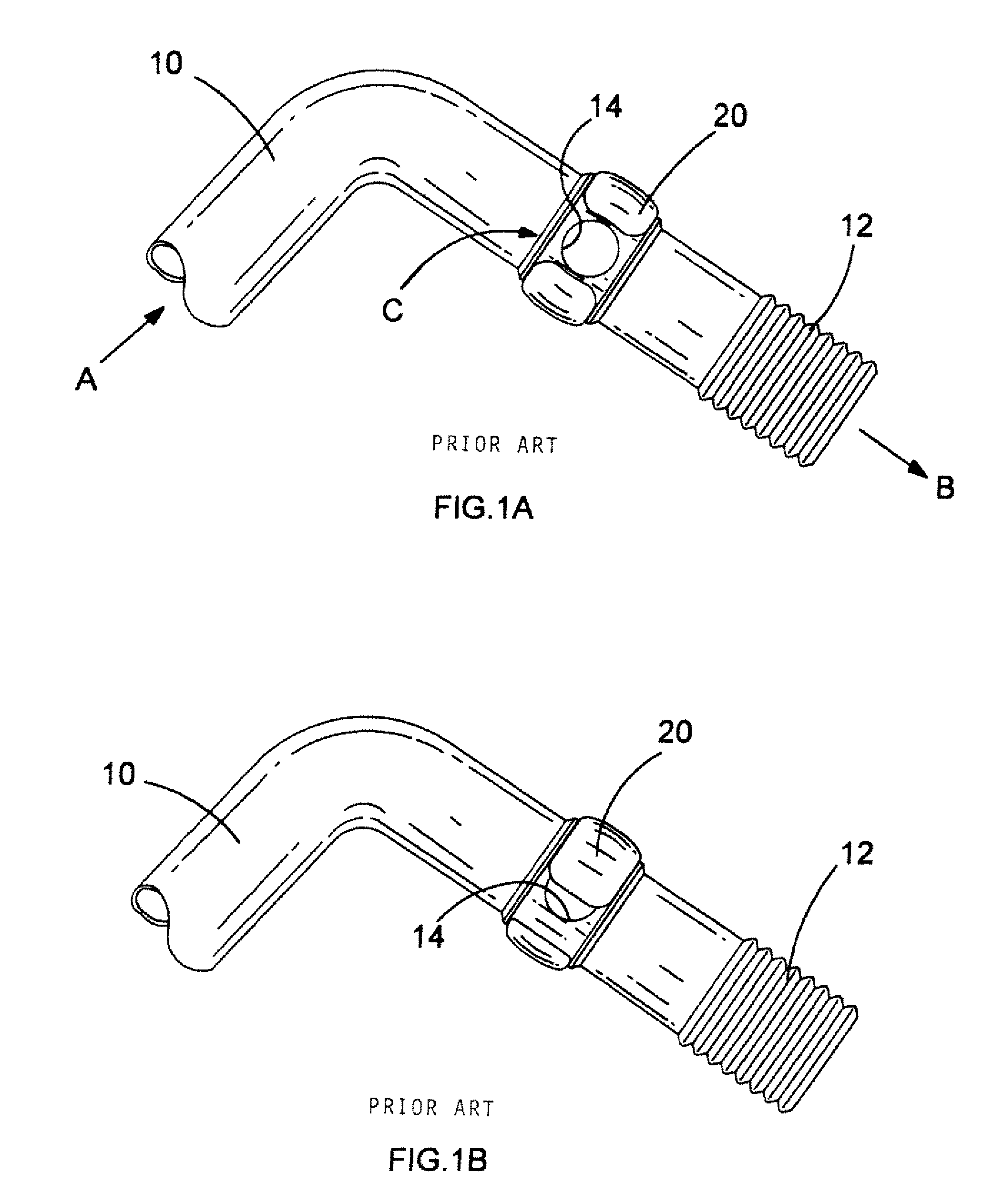

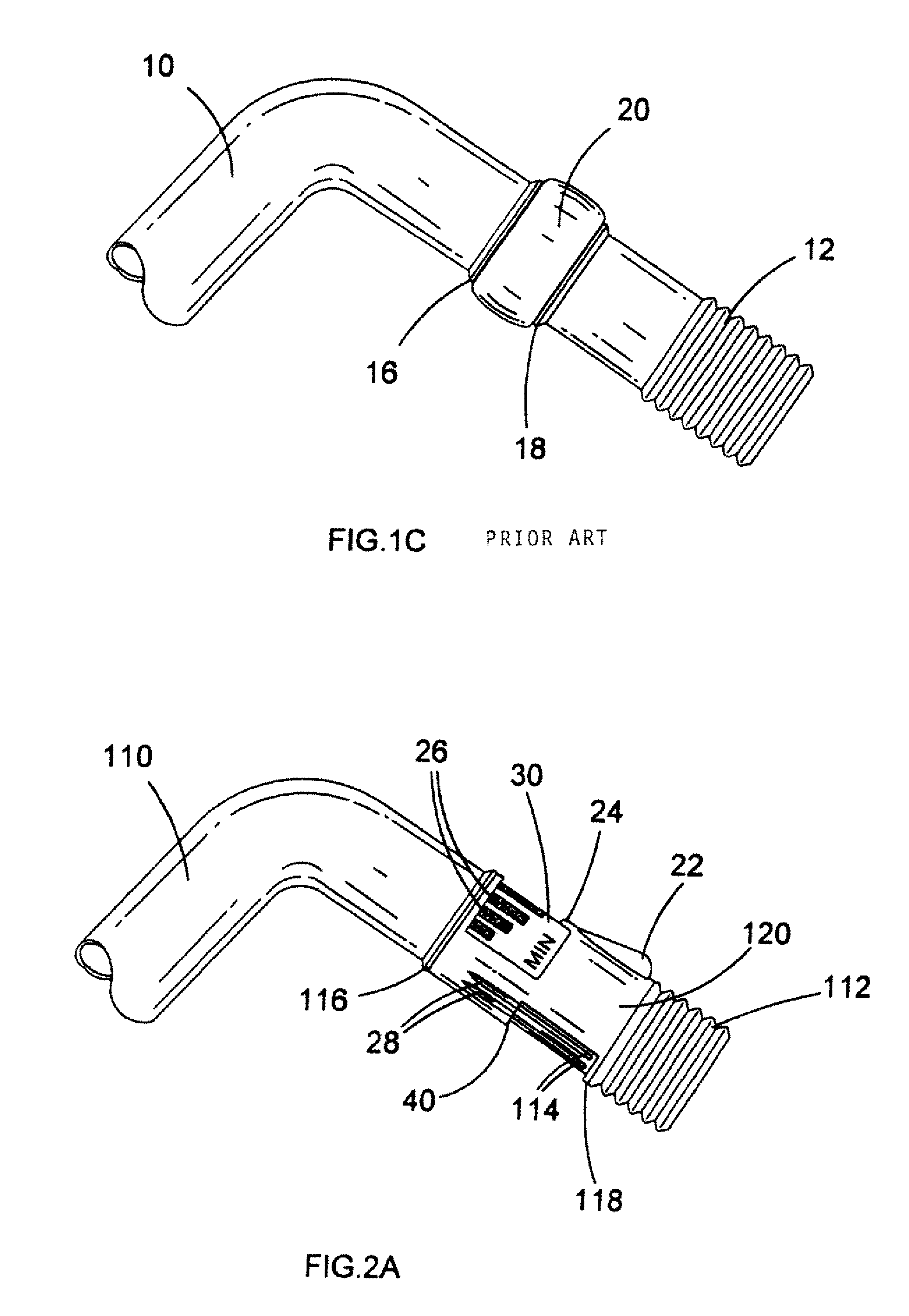

Handheld portable devices for dislodging and capturing particulate matter that has accumulated on various surfaces or structures are provided. The devices create opposing airflows that can intimately interface with each other during use. A vacuum airflow is drawn into the device, defining a vacuum affected zone upon the surface being cleaned. A high pressure airflow is emitted that penetrates through or passes adjacent to the opposing vacuum airflow and contacts the surface being cleaned, dislodging particulate matter therefrom. The high pressure airflow can be emitted from multiple nozzles as a series of airflow bursts that discretely contact the surface being cleaned. The configuration of each nozzle, as well as the overall arrangement and positions of all the nozzles together, are selected to impart the desired particulate matter dislodging characteristics to the device.

Owner:SC JOHNSON & SON INC

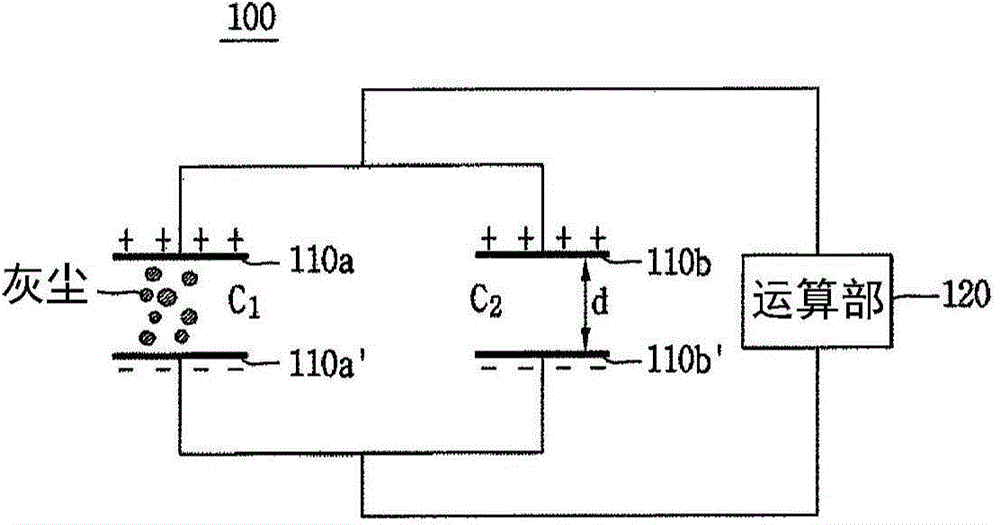

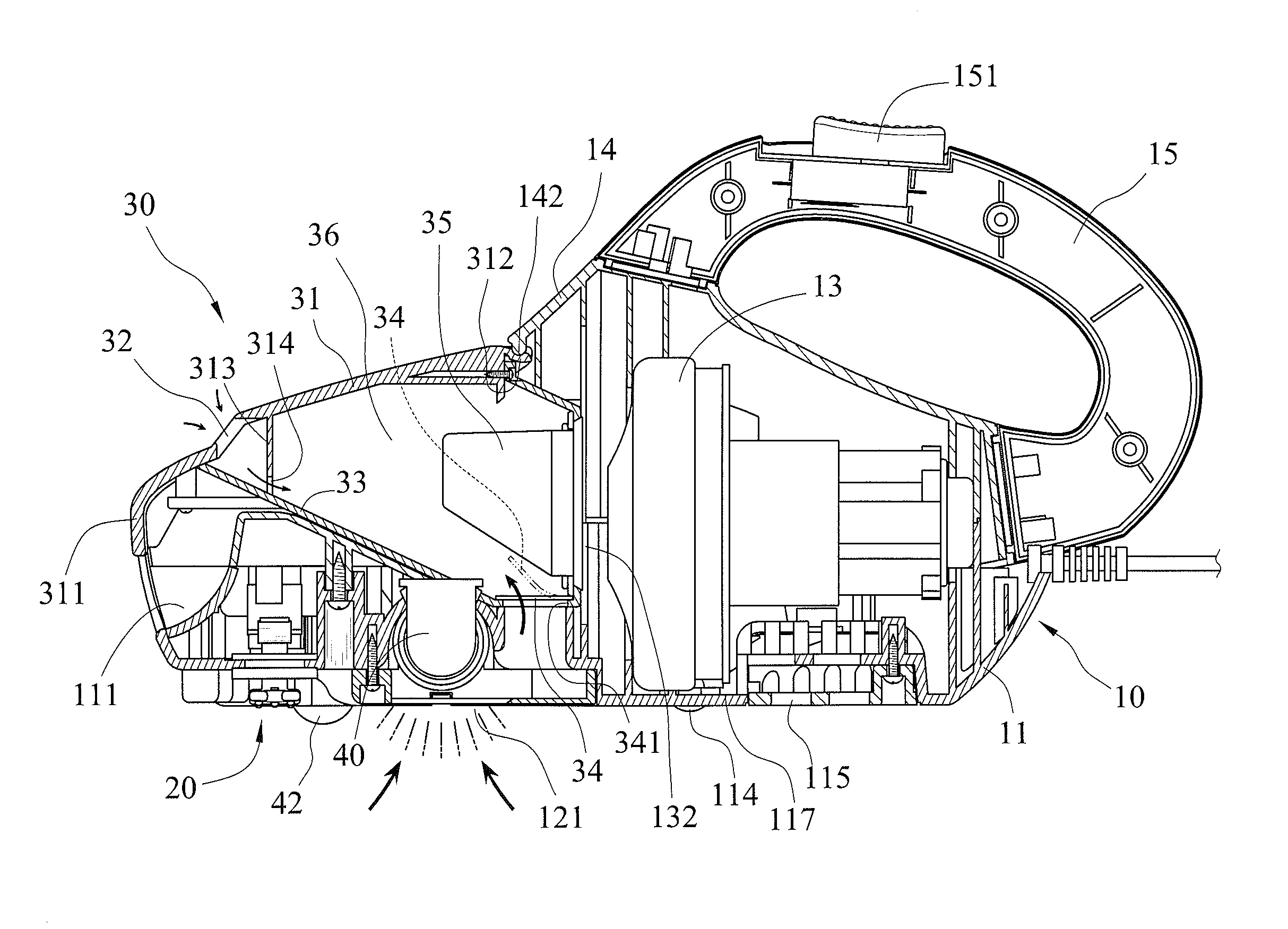

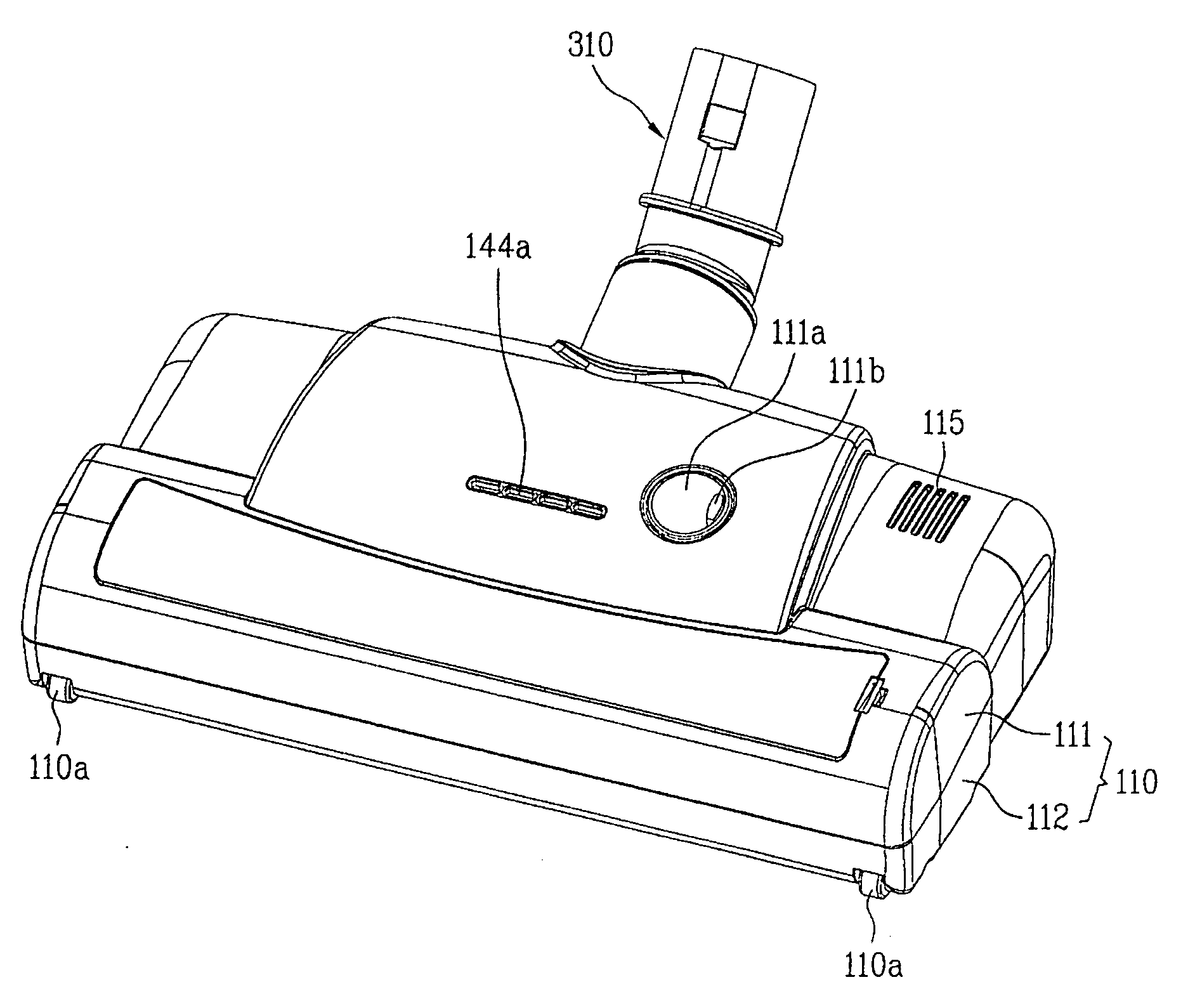

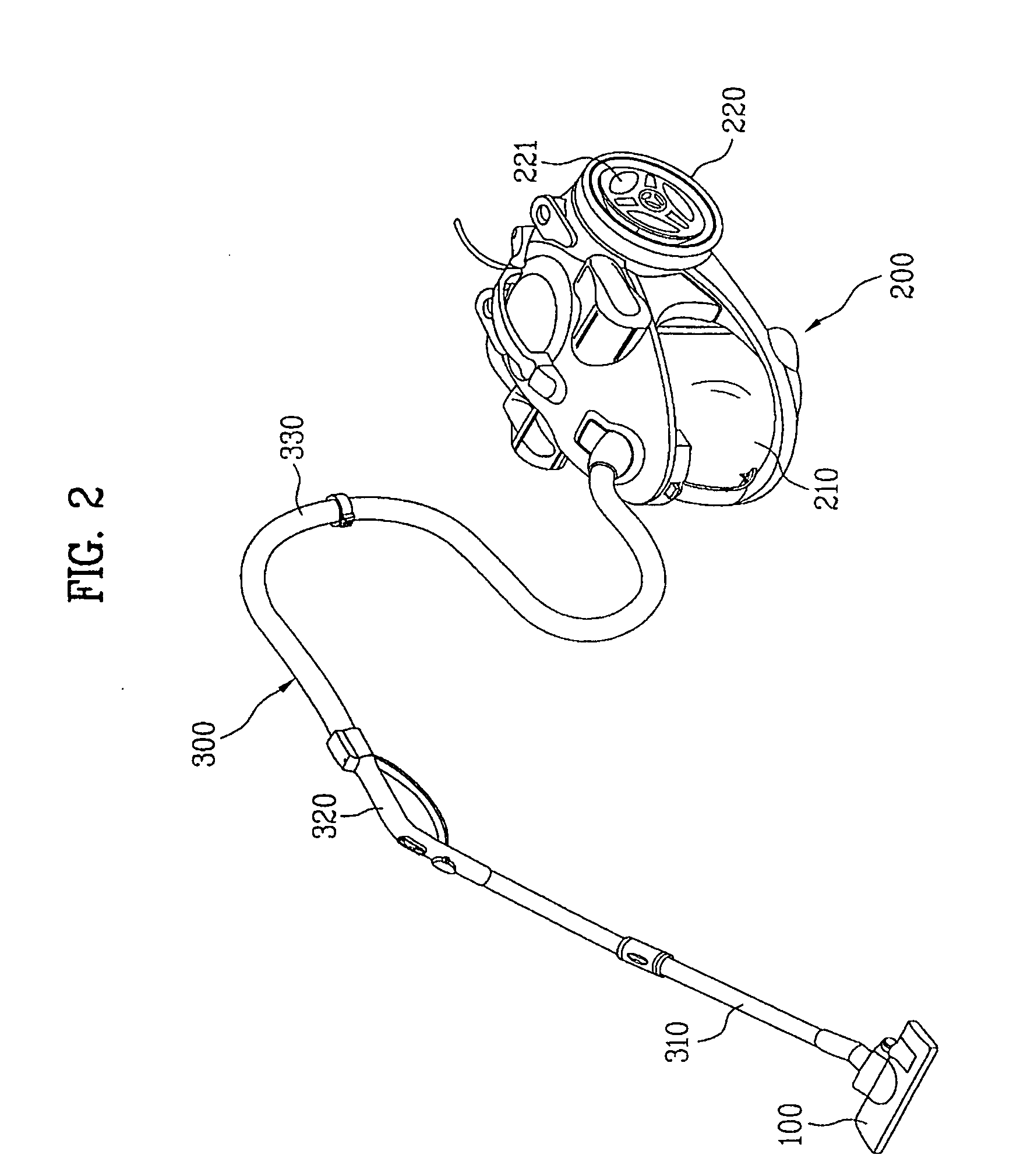

Robot cleaner and method for sensing dust

ActiveCN104545699APrevents problems with degraded inhalation performanceCleaning filter meansSuction filtersCapacitanceSuction force

The present disclosure provides a robot cleaner including a suction motor installed within a main body to generate a suction force, at least two conductive plates (111, 112) spaced apart from each other to form a flowing path for external air introduced by the suction force, and a calculator (120) to measure a capacitance value between the at least two conductive plates (111, 112). A porous structure (210; 350) may be provided having at least one through hole (H) through which external air introduced by the suction force flows, a filter (33, 34; 310, 320, 330) disposed on one surface of the porous structure (210; 350) to filter dust contained in the air, and a power supply unit (220) configured to apply alternating current (AC) power to at least a partial surface of the porous structure (210, 350).

Owner:LG ELECTRONICS INC

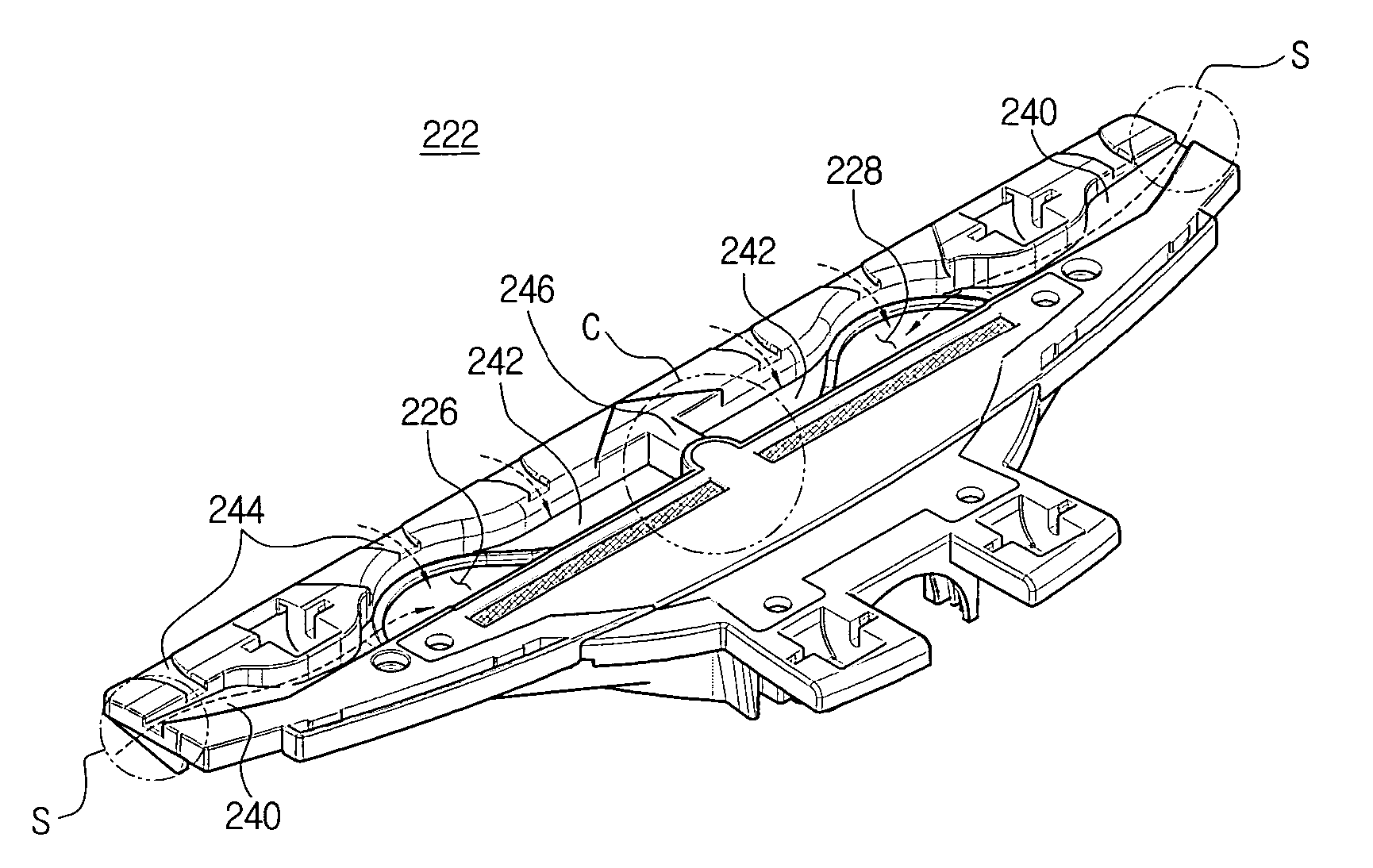

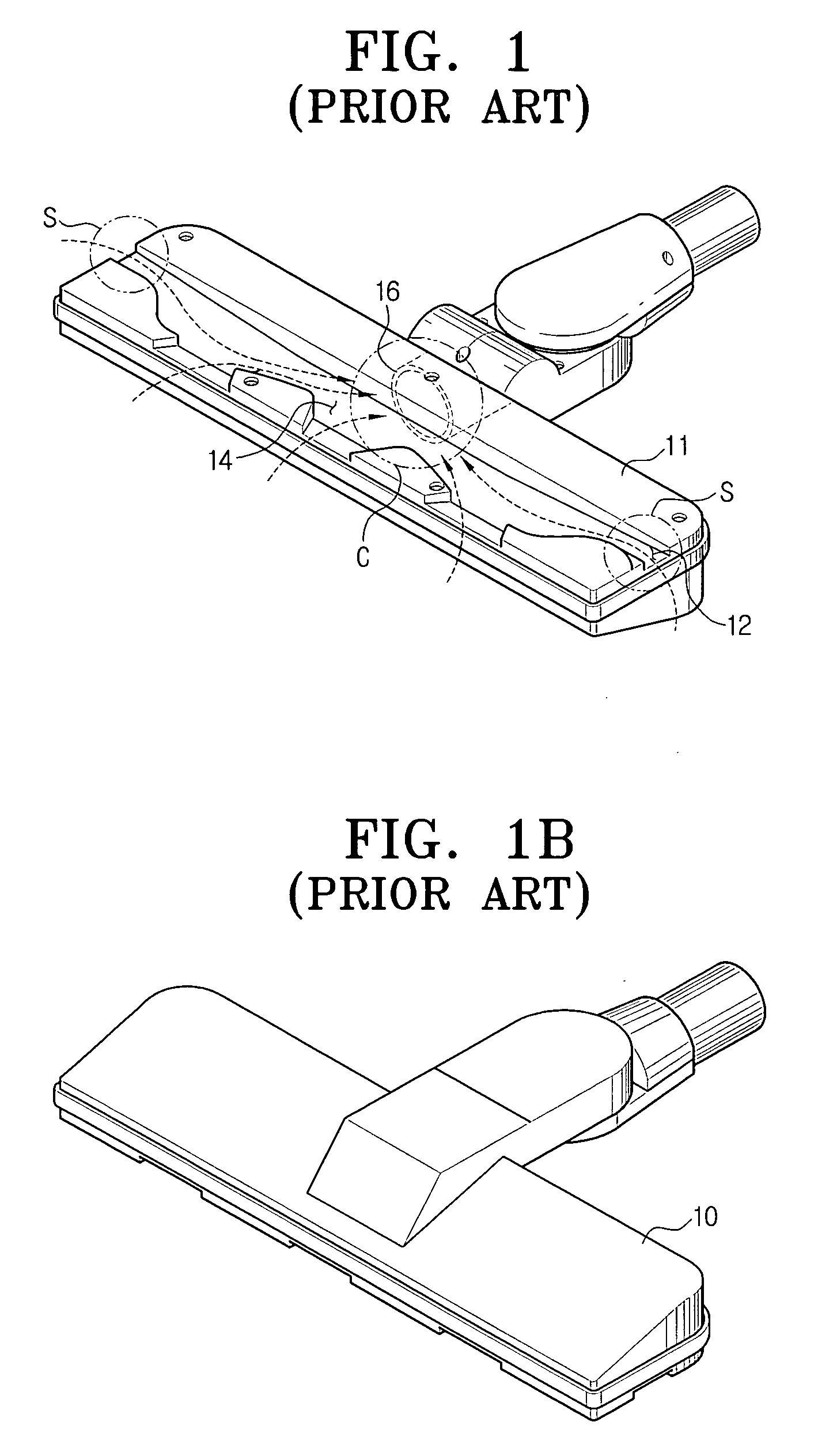

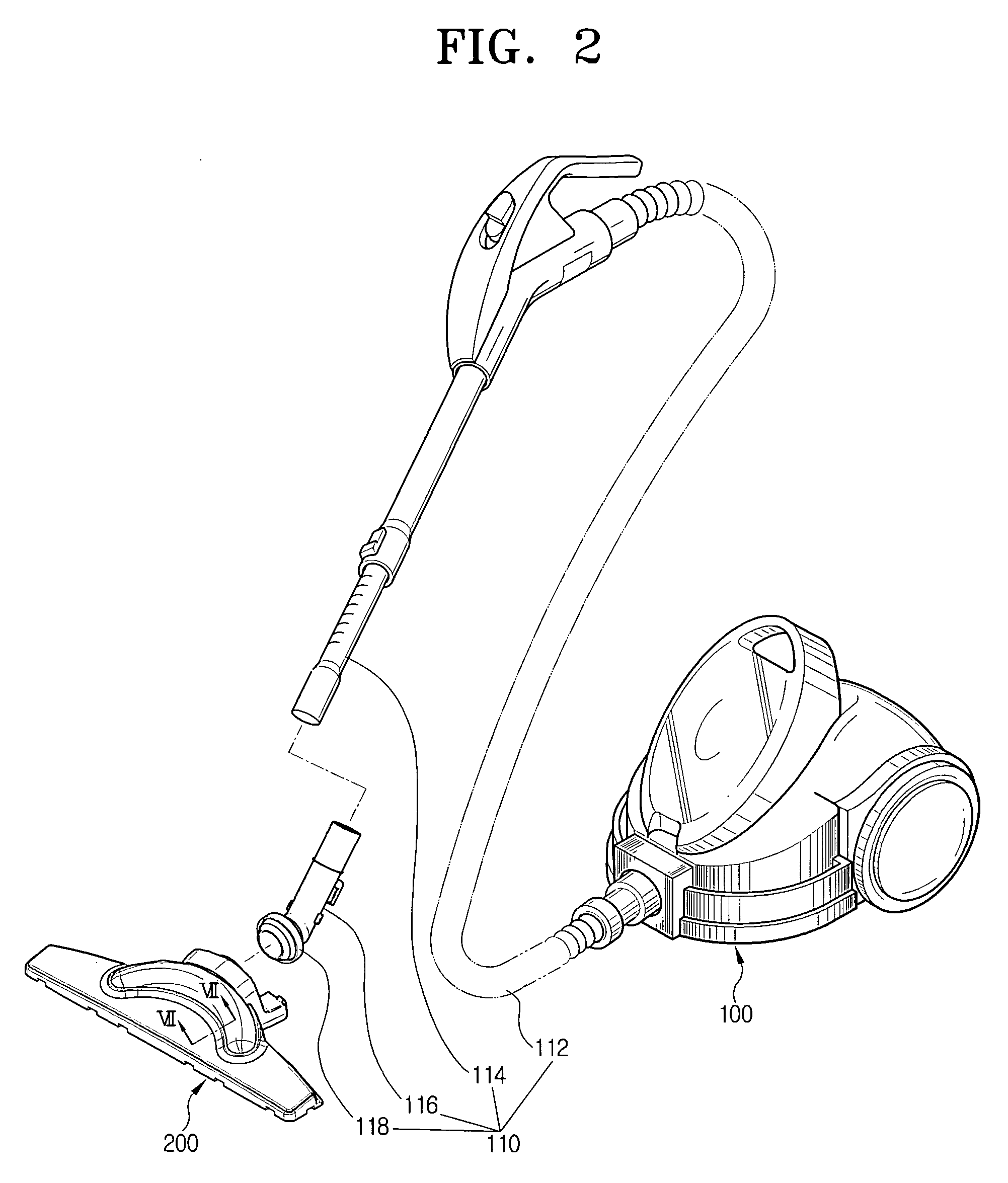

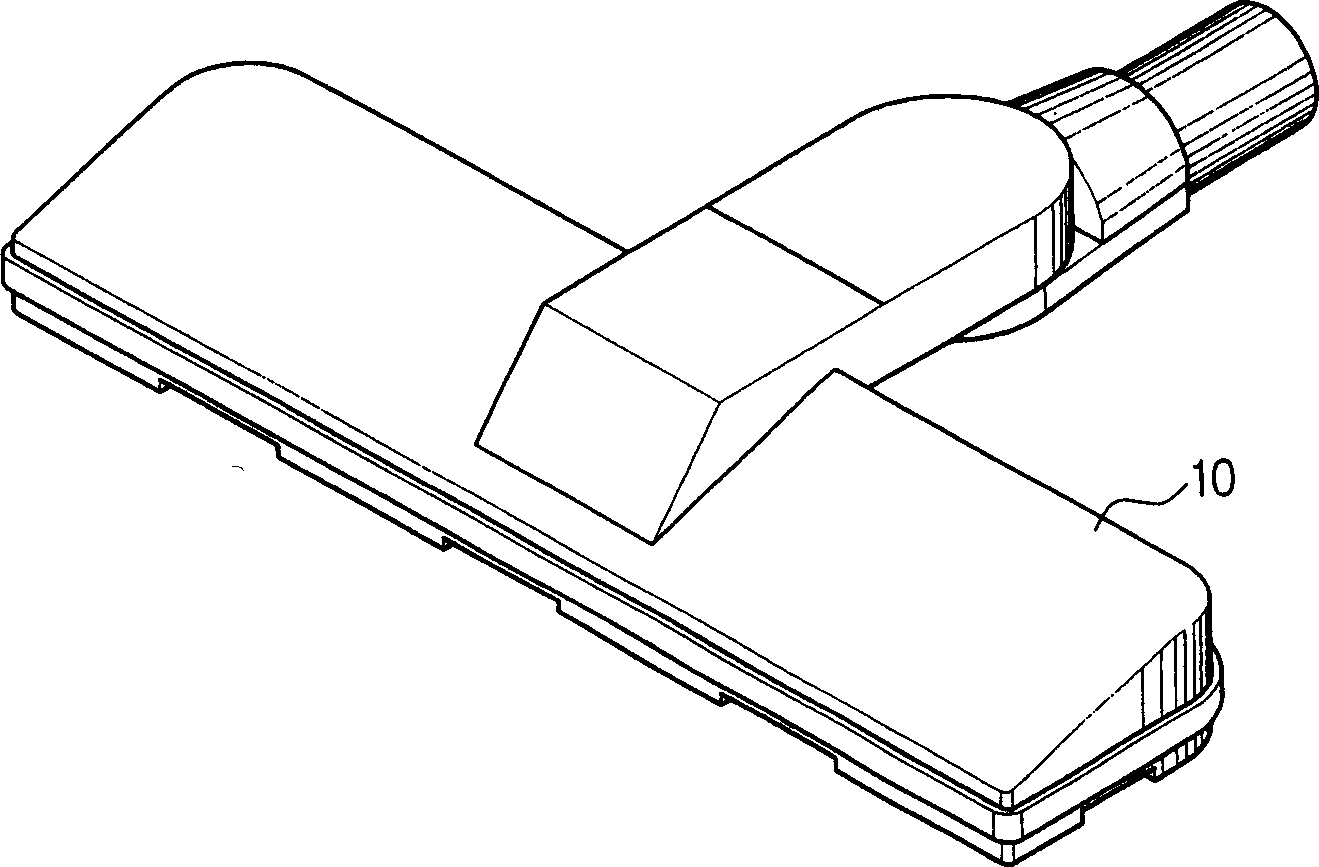

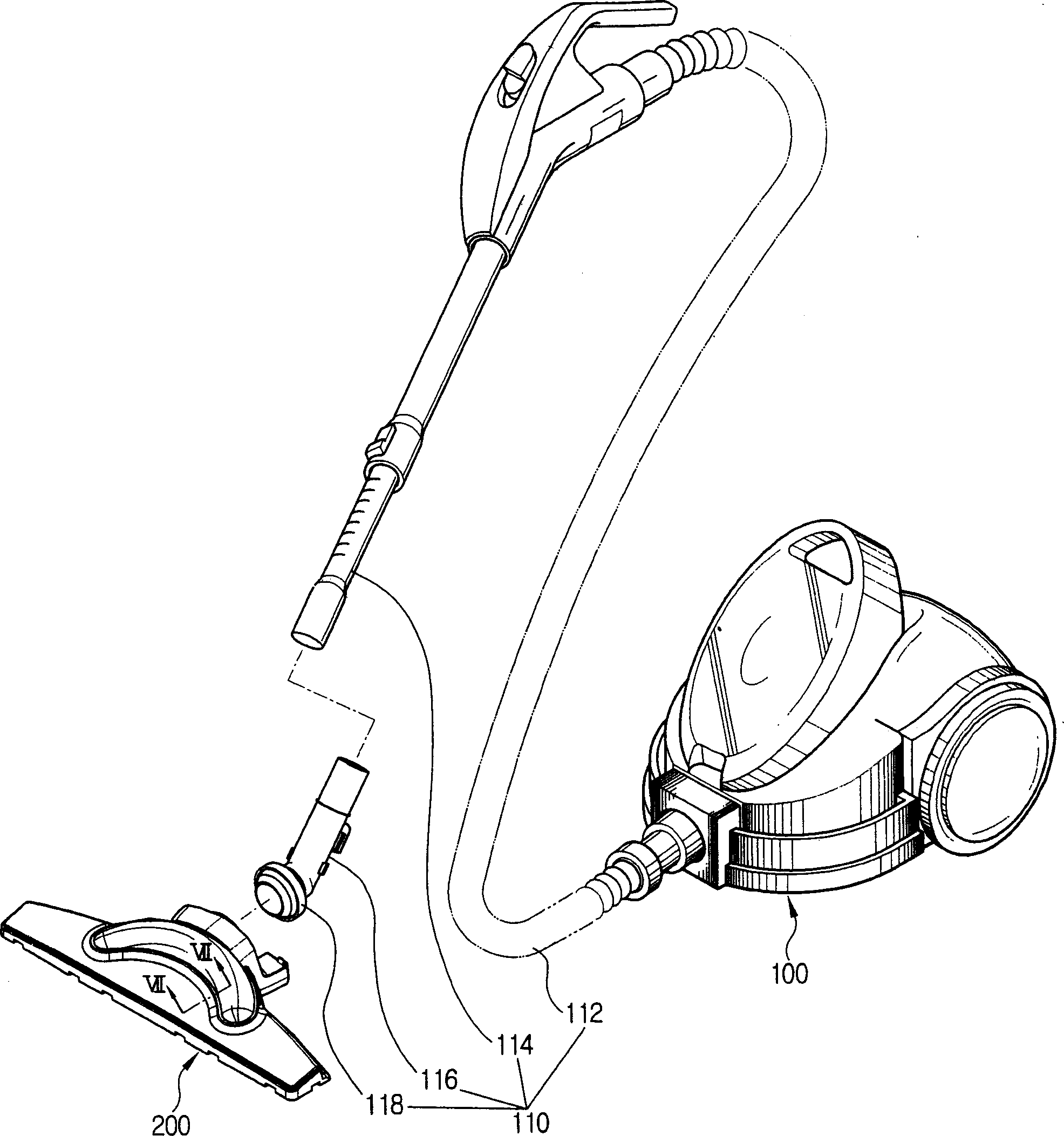

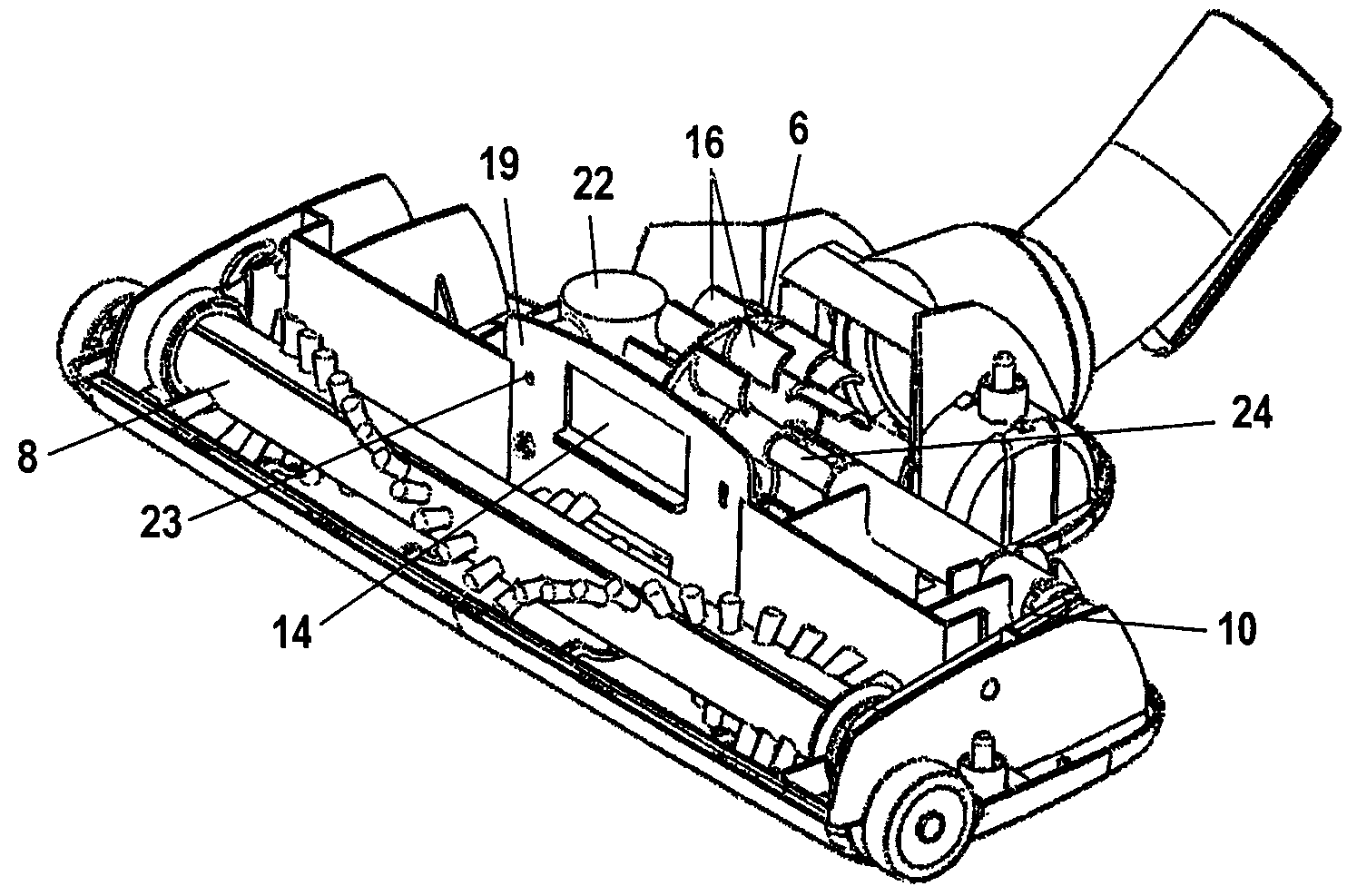

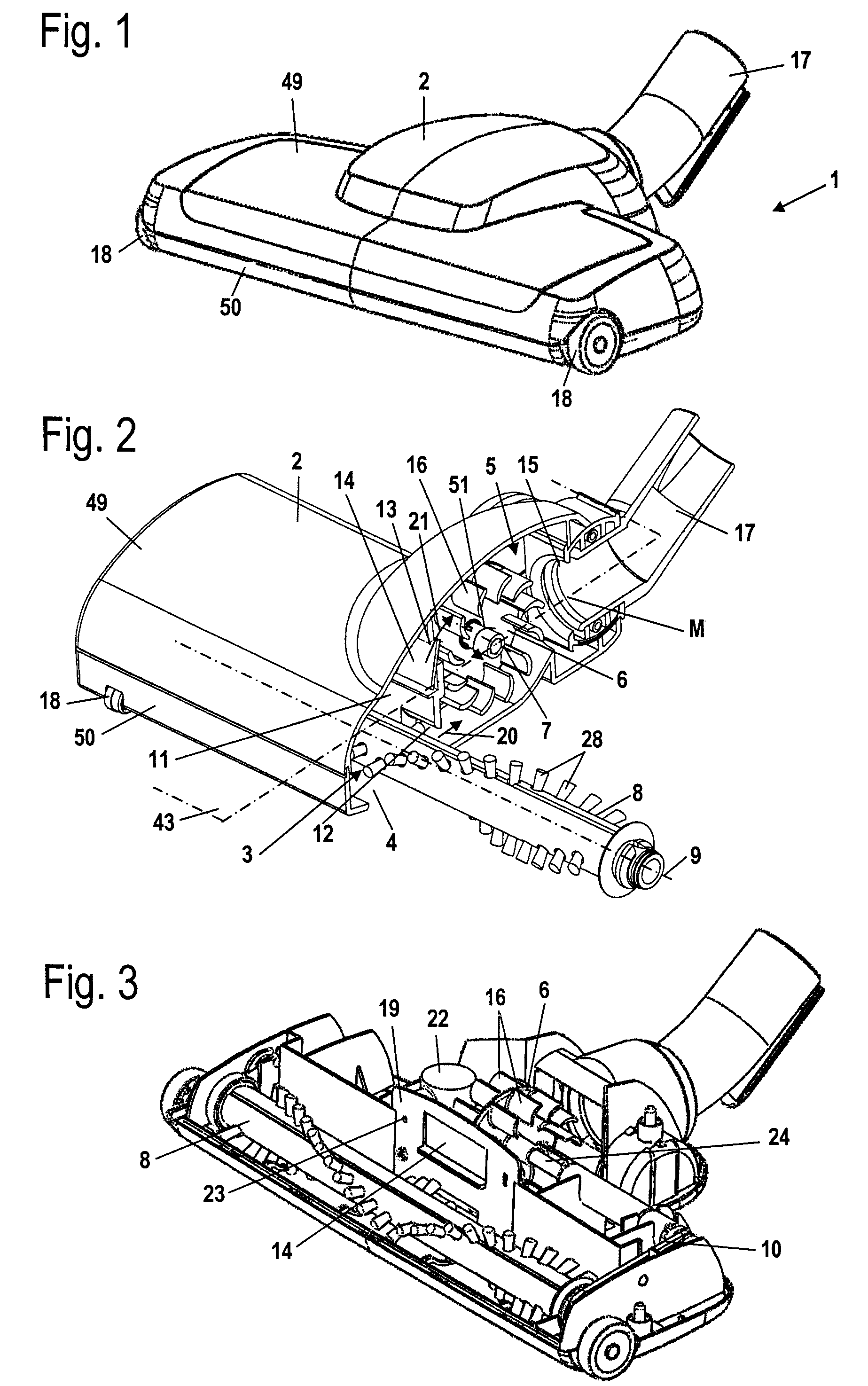

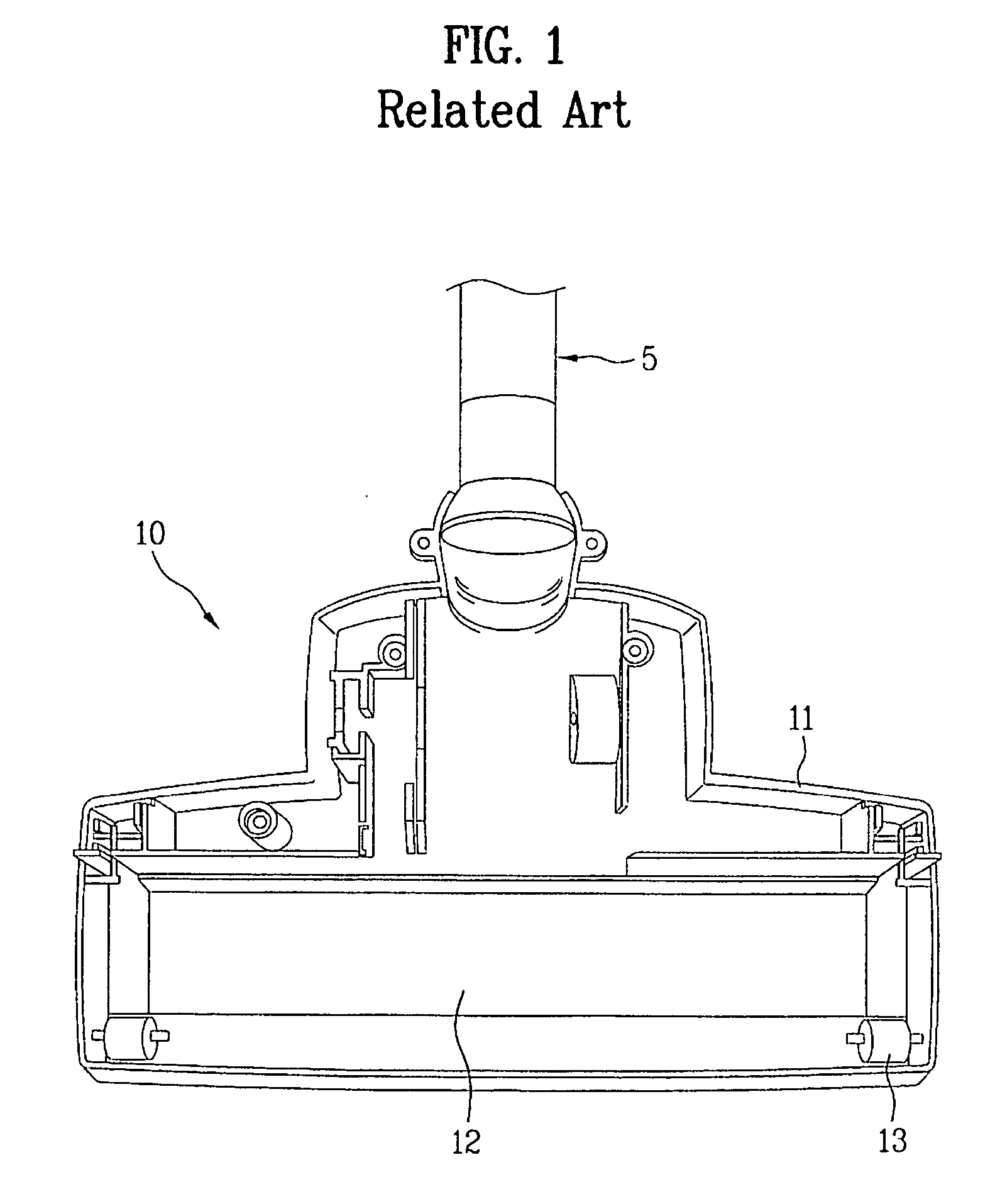

Suction port assembly and a vacuum cleaner having the same

InactiveUS20060000053A1Easy to cleanEasy to assembleMechanical suction controlSuction nozzlesWide areaEngineering

A suction port assembly for a vacuum cleaner and a vacuum cleaner having such a suction port comprises upper and lower housings, a plurality of suction ports formed in the lower housing, and a plurality of suction paths formed in the upper and lower housings to guide the air drawn in through the suction ports. With this arrangement, the efficiency of cleaning the lateral sides of the suction port assembly can be enhanced, and thus a wide area can be efficiently cleaned.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

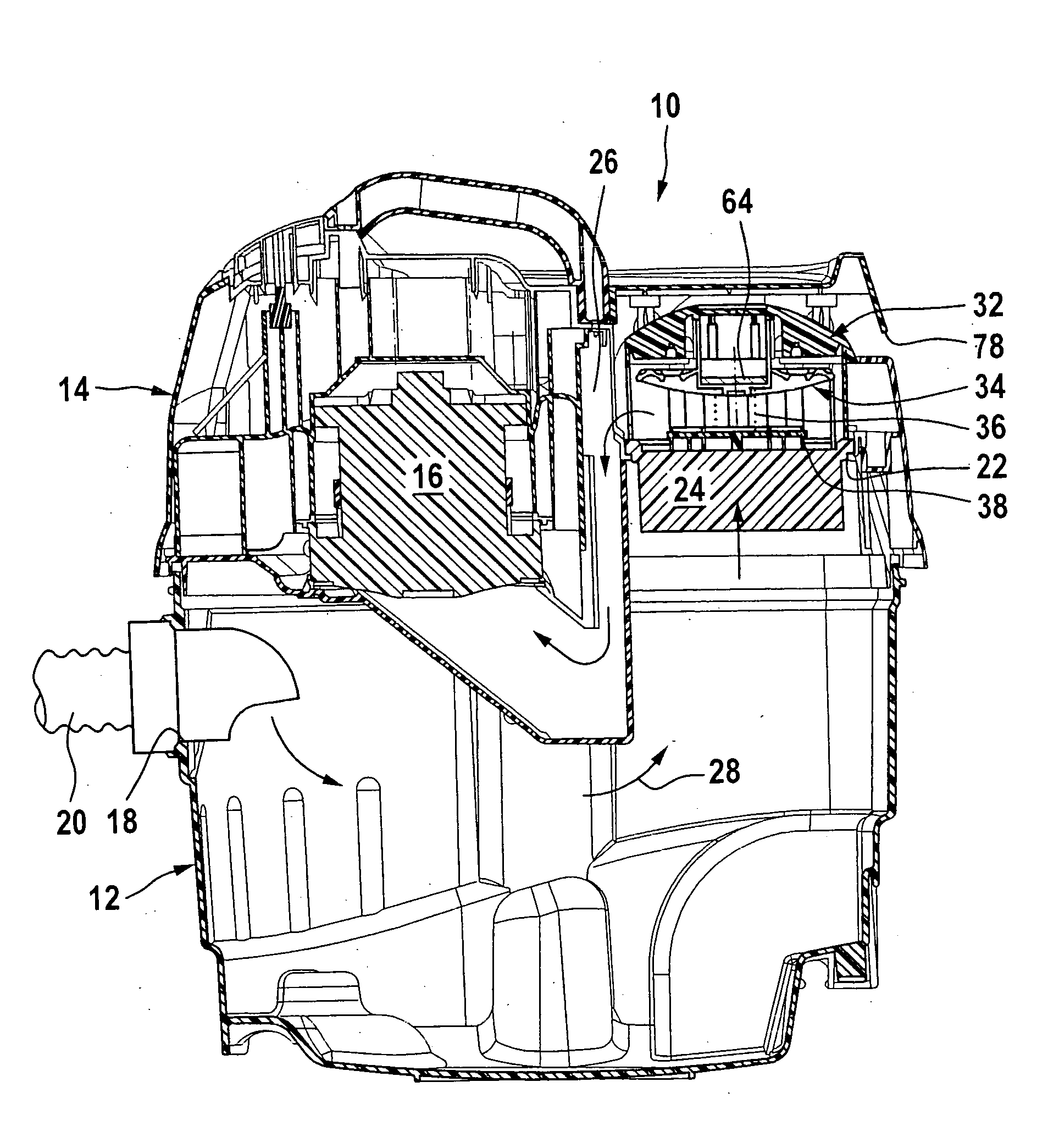

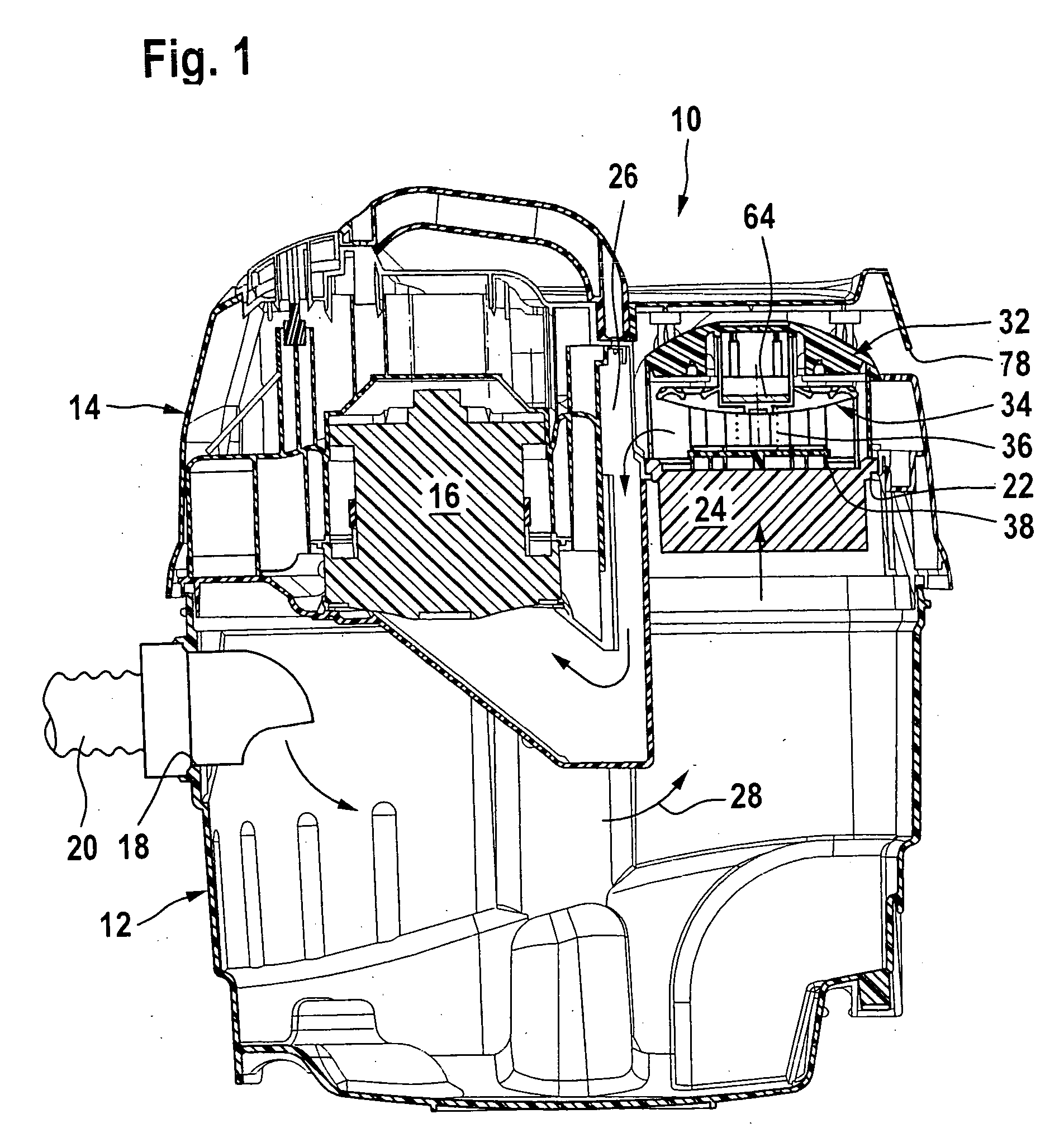

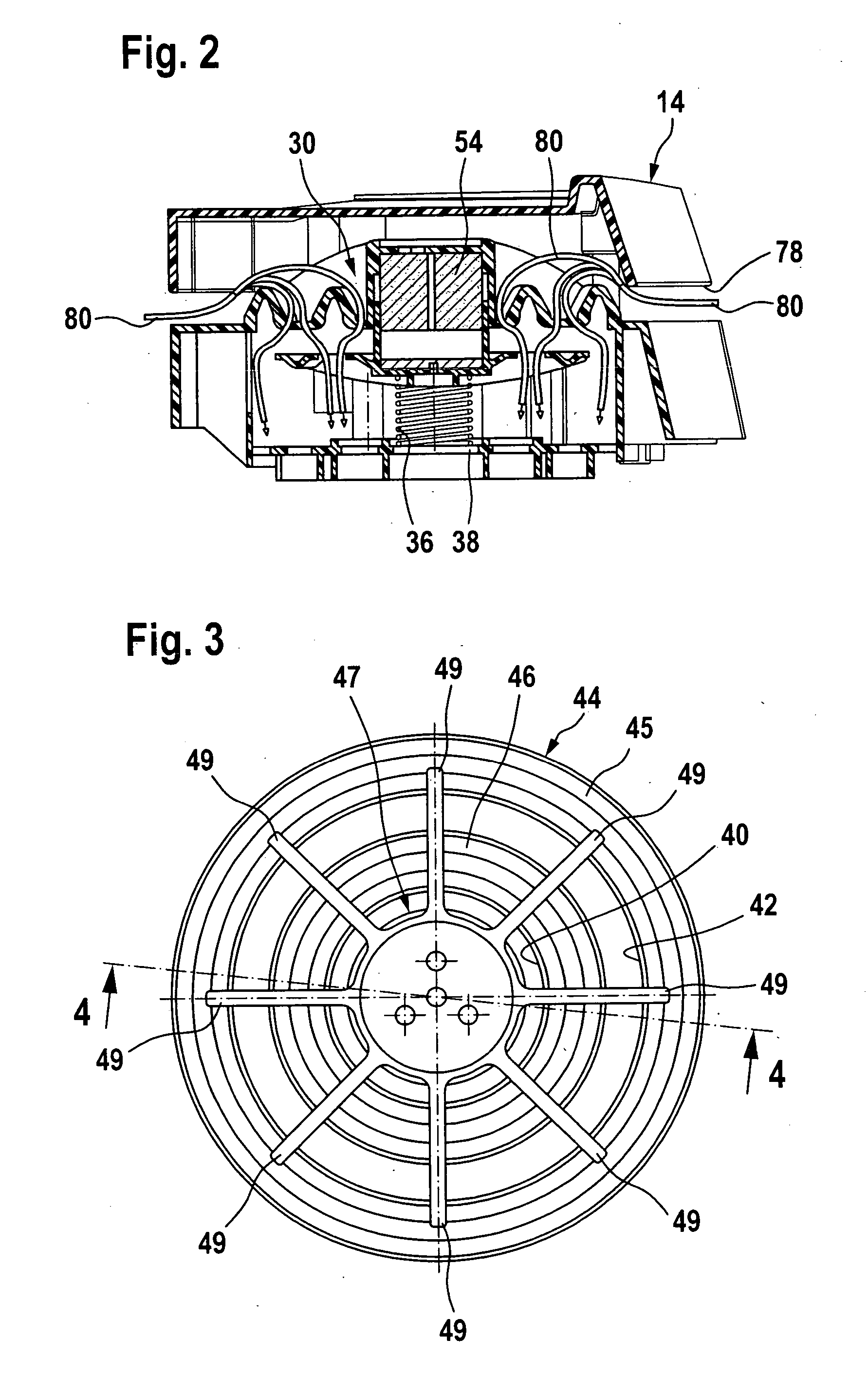

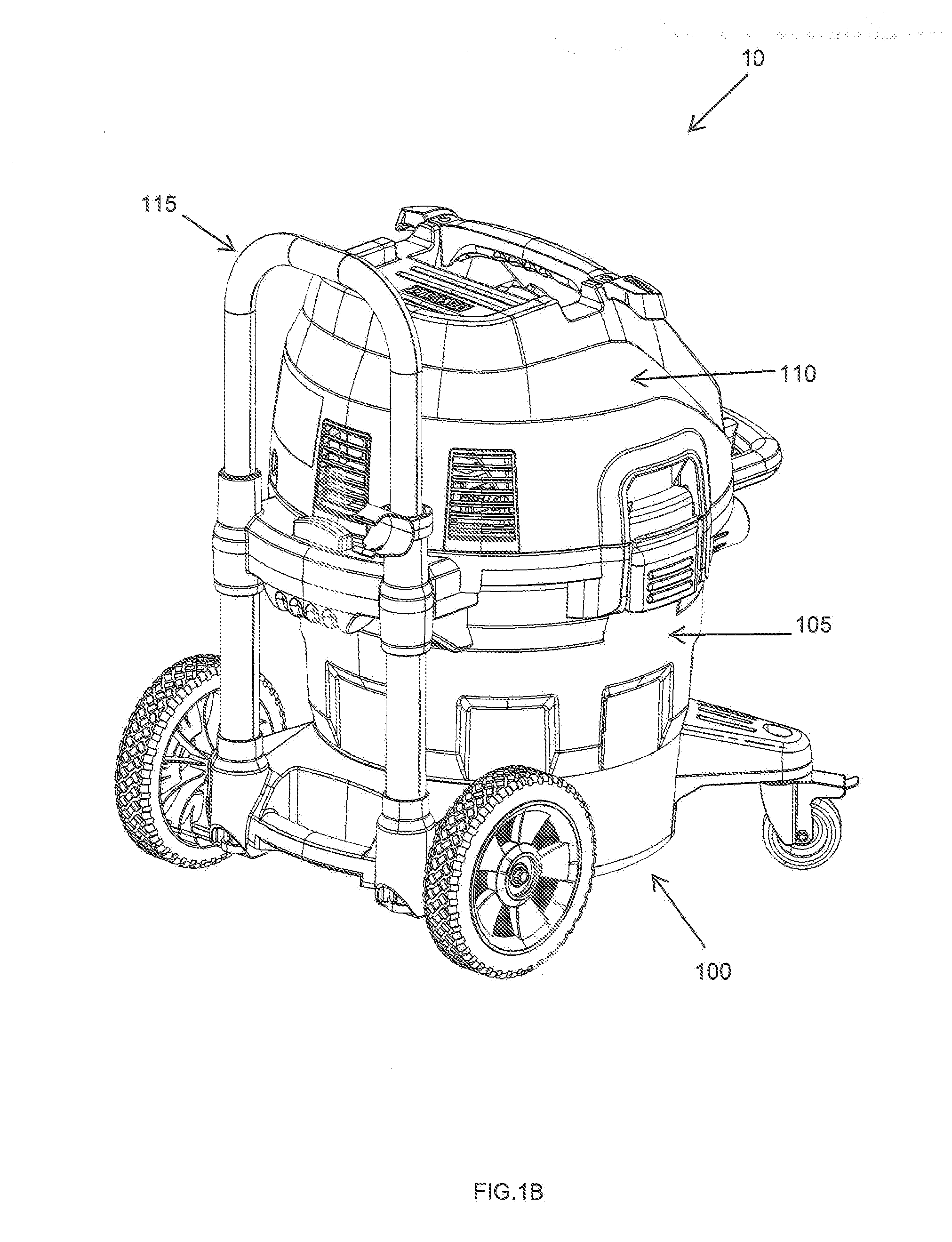

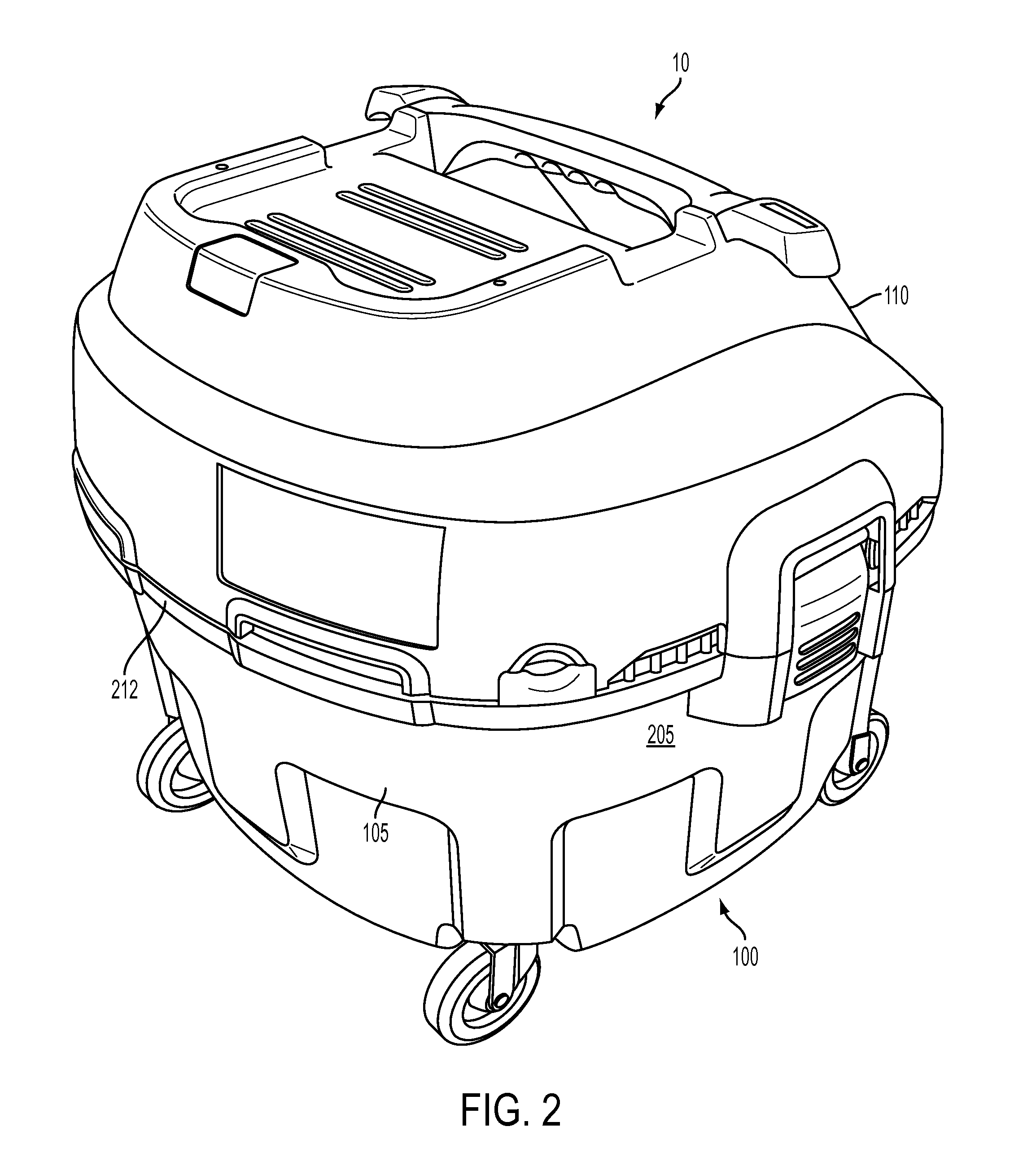

Vacuum cleaning device

ActiveUS20080086835A1Easy to cleanMaintain negative pressureCleaning filter meansMechanical cleaningLine tubingDifferential pressure

The invention relates to a vacuum cleaning device comprising a dirt collection container which has a suction inlet and is in flow connection with at least one suction unit via at least one filter and at least one suction line, and comprising at least one external air inlet which opens into the suction line downstream of the at least one filter and is adapted to be closed by means of at least one closing valve, the closing valve having a movable valve body which, in a closed position, bears against at least one valve seat so as to form one or more sealing lines, the at least one sealing line delimiting an area which, in the closed position of the closing valve, is acted upon by a differential pressure. In order to develop the vacuum cleaning device in such a way that the at least one closing valve is of structurally simple design and the at least one filter can be completely cleaned within a short period of time, the invention proposes that the square of the total length of all sealing lines is at least 25 times the total size of all areas which are delimited by the sealing lines and acted upon by a differential pressure.

Owner:ALFRED KARCHER GMBH & CO KG

Vacuum cleaner

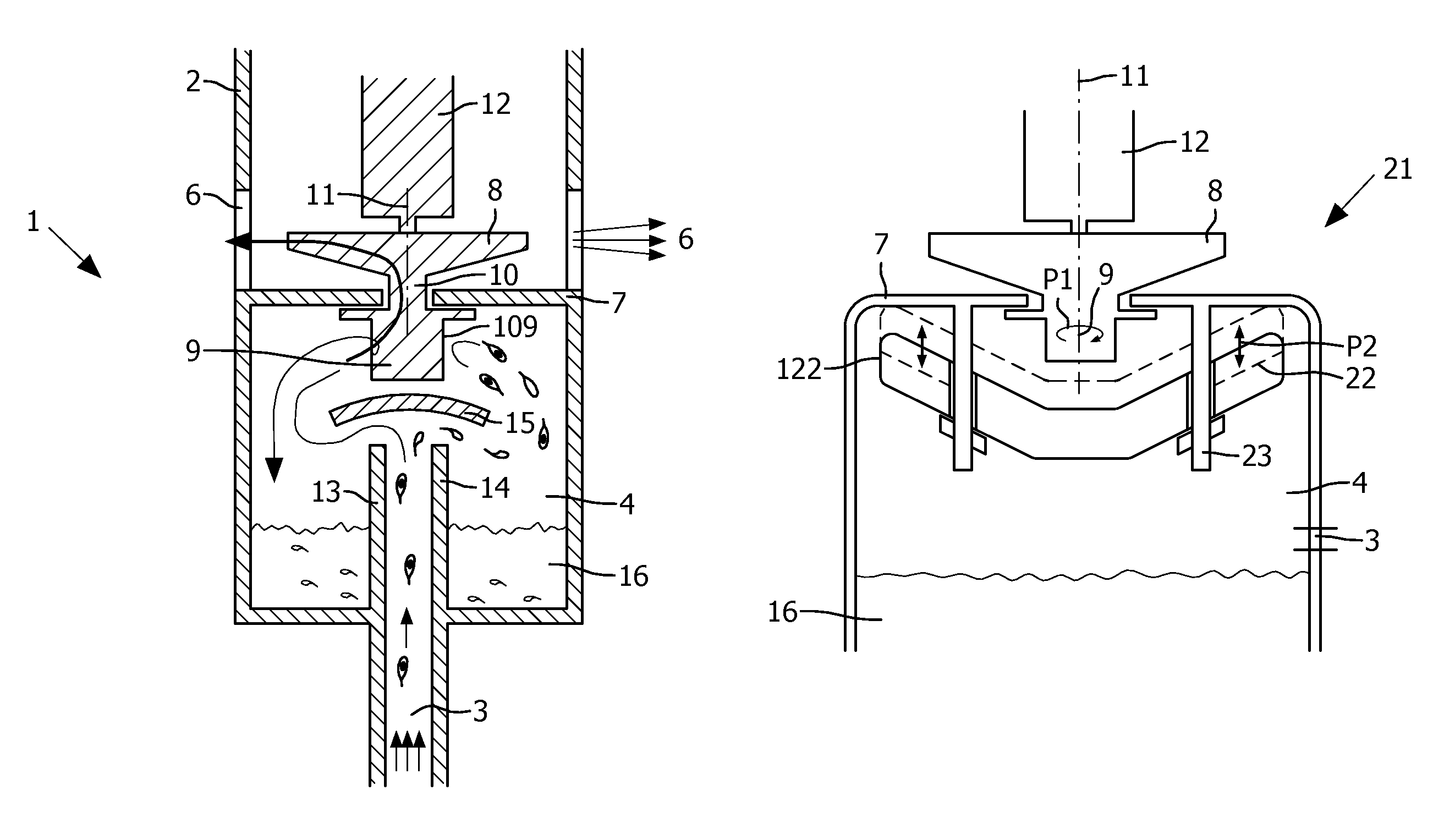

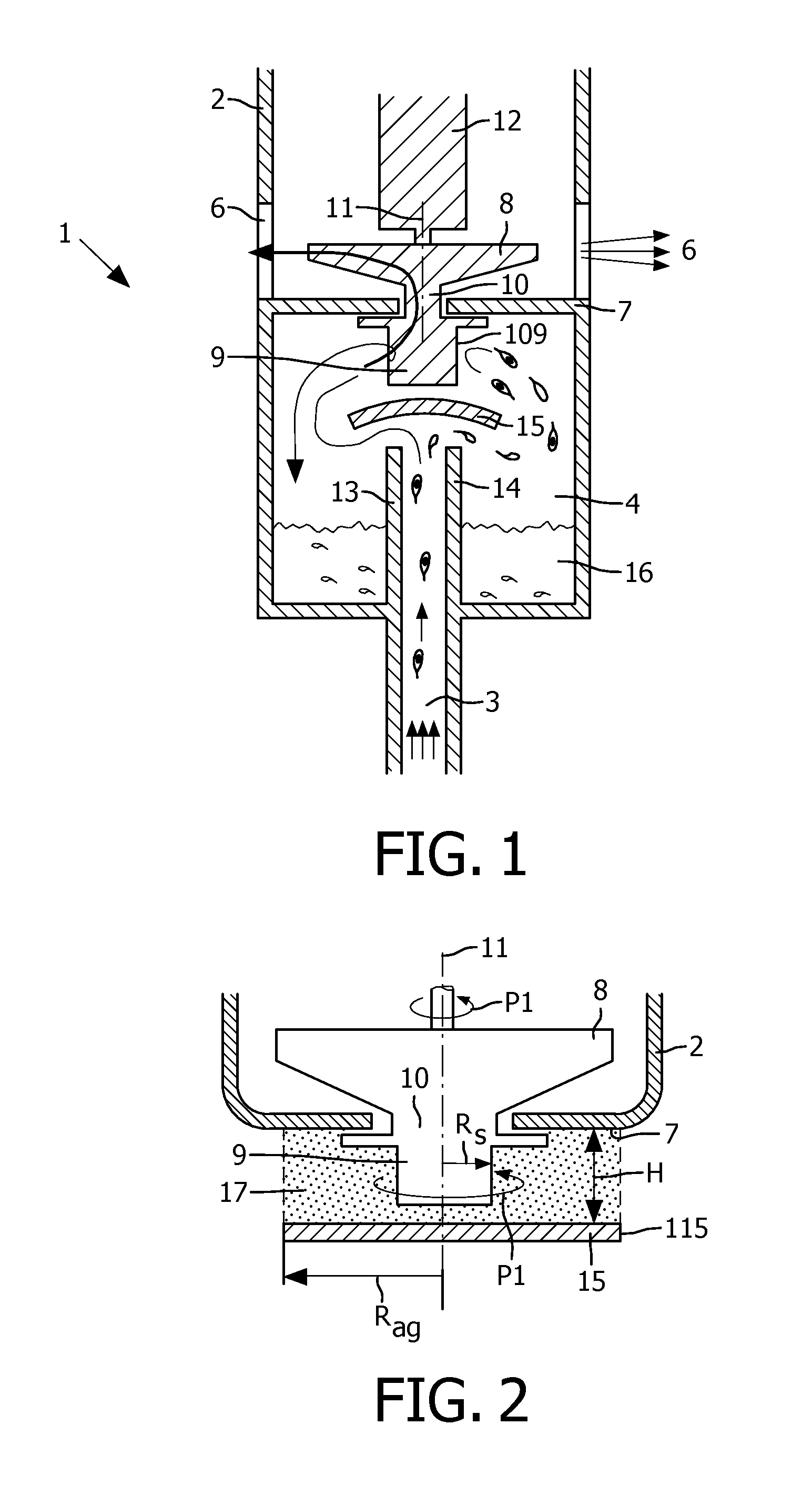

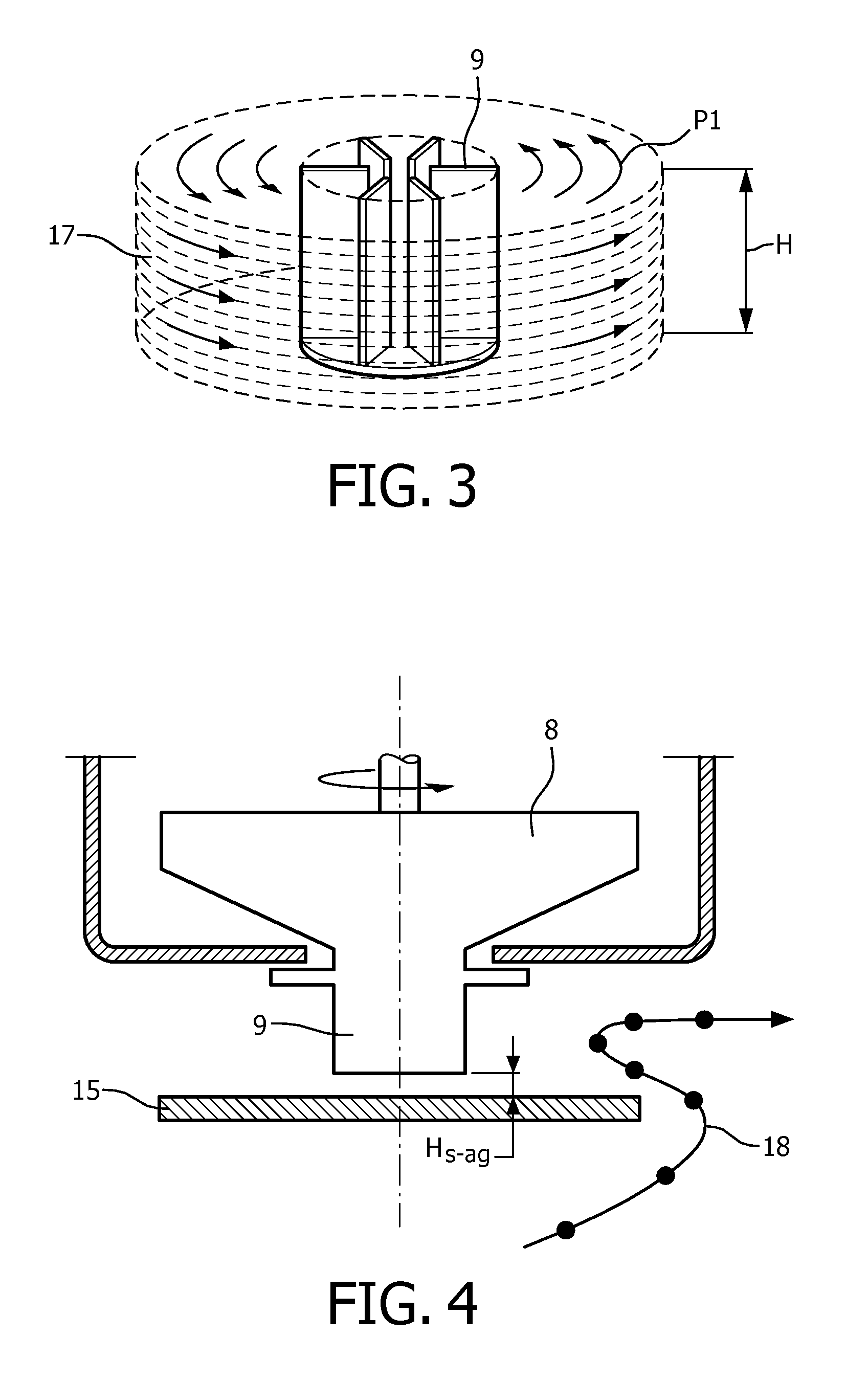

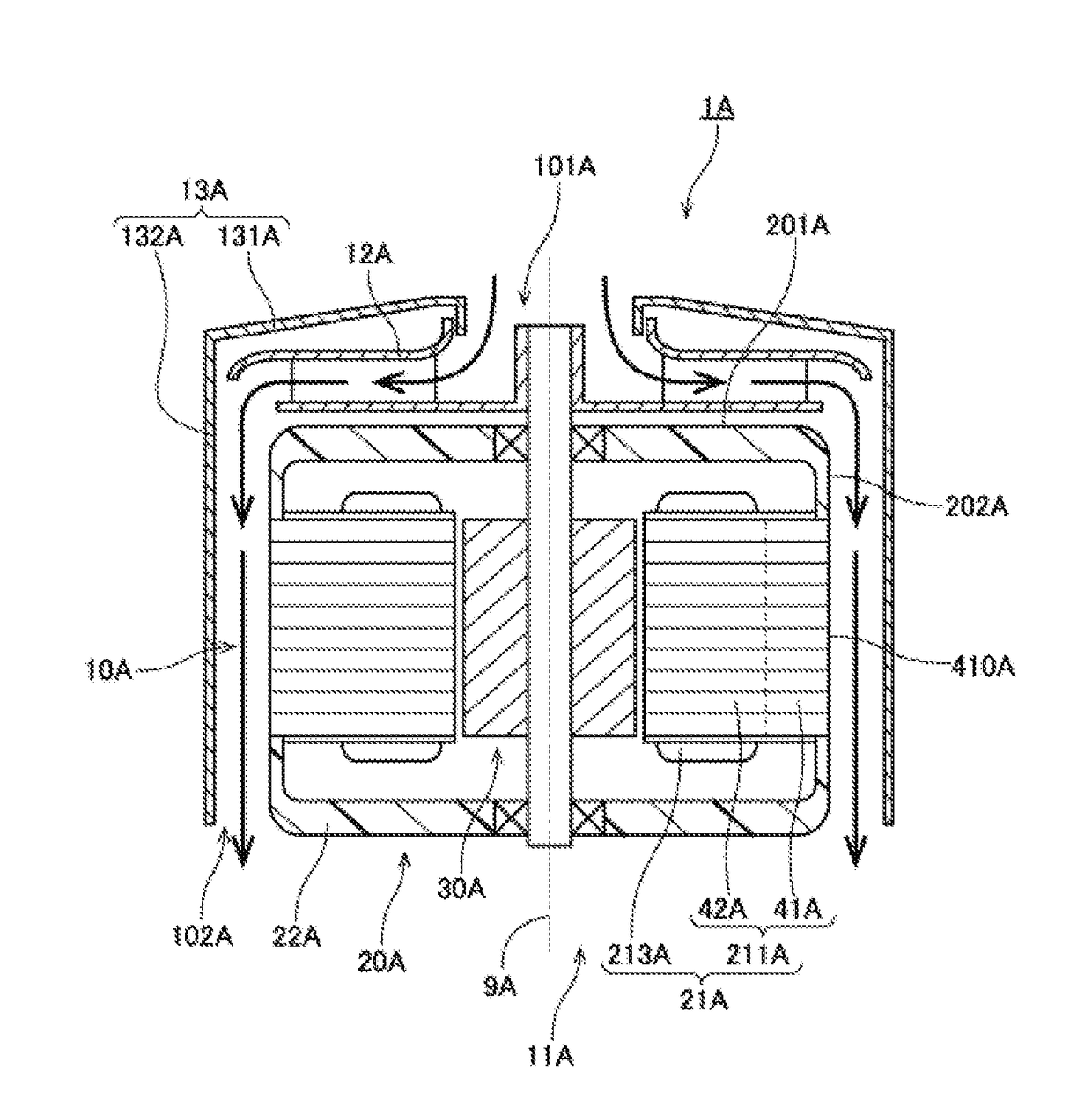

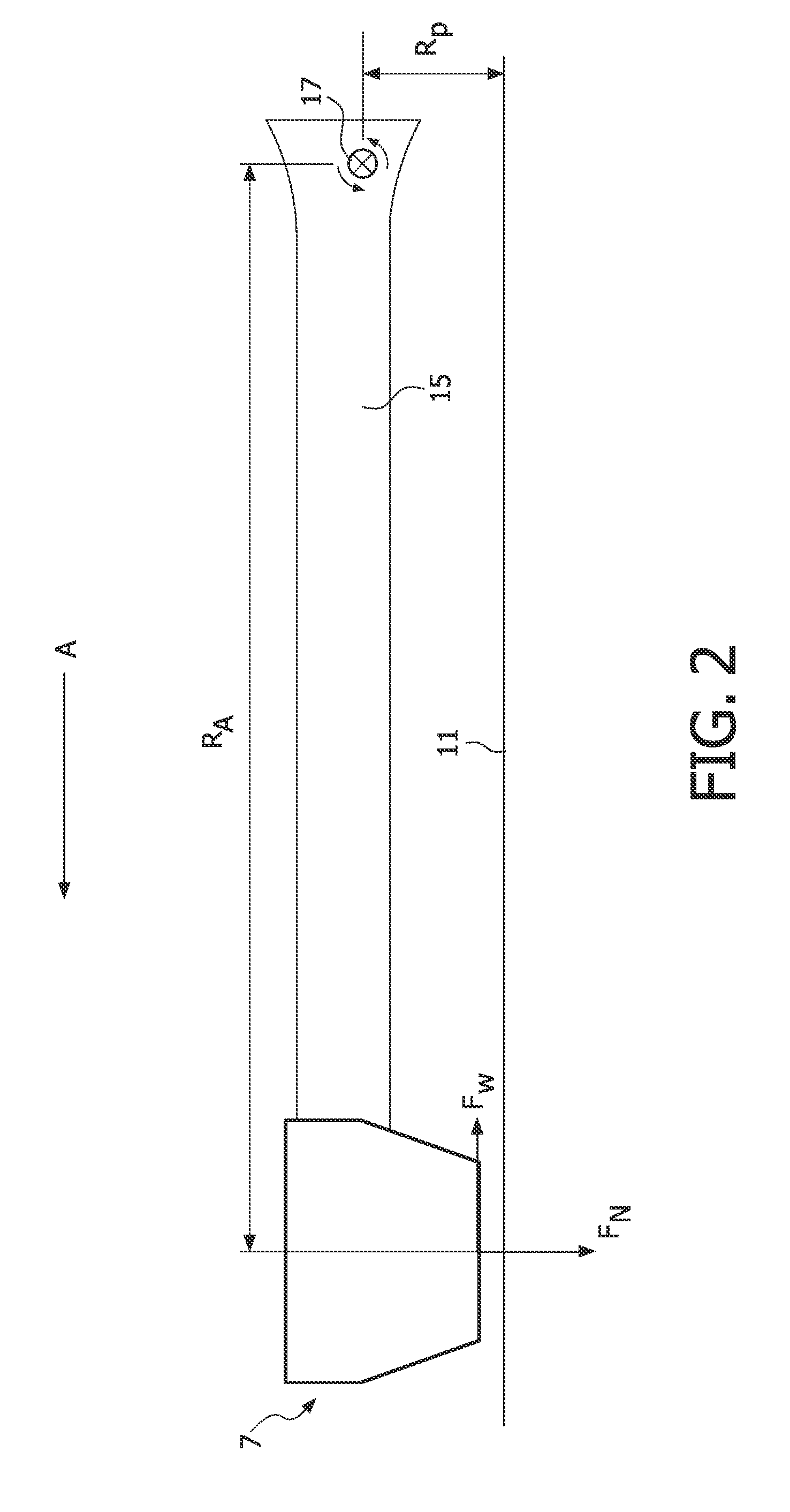

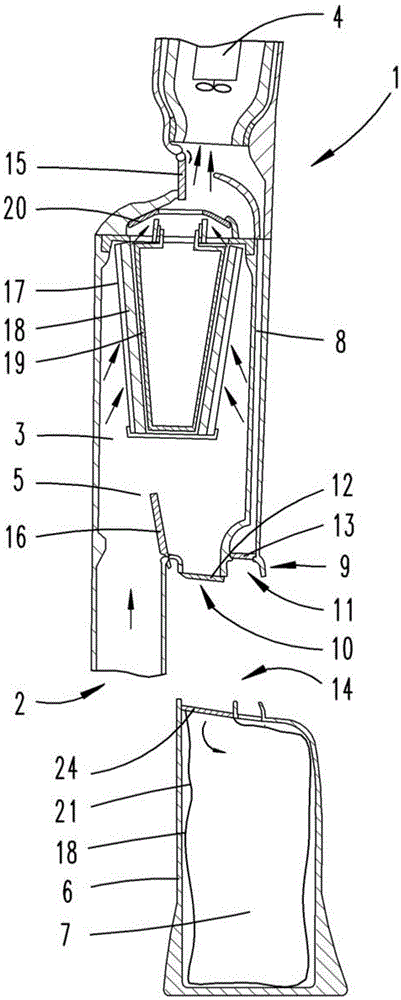

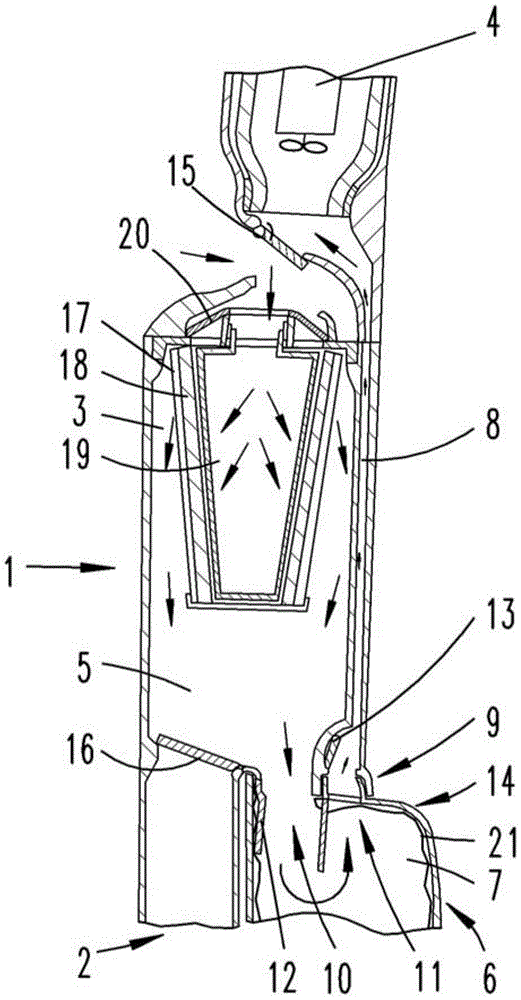

A vacuum cleaner (1, 21, 31) comprises an air inlet opening (3), an air outlet opening (6) and a rotatable separator (9) for separating air and airborne particles. The separator (9) comprises at least one air entrance opening (109) located between the air inlet opening (3) and the air outlet opening (6). The vacuum cleaner (1, 21, 31) is provided with air-guide means (15, 22, 37) for guiding at least part of the air towards the separator (9). In use, the air-guide means (15, 22, 37) provides an at least partially closed boundary in axial direction for a column of rotating air (17) around the separator (9). The minimum distance (Rag) of an edge (115, 122) of the air-guide means (15, 22, 37) to the rotating axis (11) of the separator (9) is larger than a distance (Rs) of the air entrance opening (109) of the separator (9) to the rotating axis (11) of the separator (9).

Owner:VERSUNI HLDG BV

Suction port assembly and a vacuum cleaner having the same

InactiveCN1714730AEasy to cleanMechanical suction controlSuction nozzlesWide areaMechanical engineering

A suction port assembly for a vacuum cleaner and a vacuum cleaner having such a suction port comprises upper and lower housings, a plurality of suction ports formed in the lower housing, and a plurality of suction paths formed in the upper and lower housings to guide the air drawn in through the suction ports. With this arrangement, the efficiency of cleaning the lateral sides of the suction port assembly can be enhanced, and thus a wide area can be efficiently cleaned.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

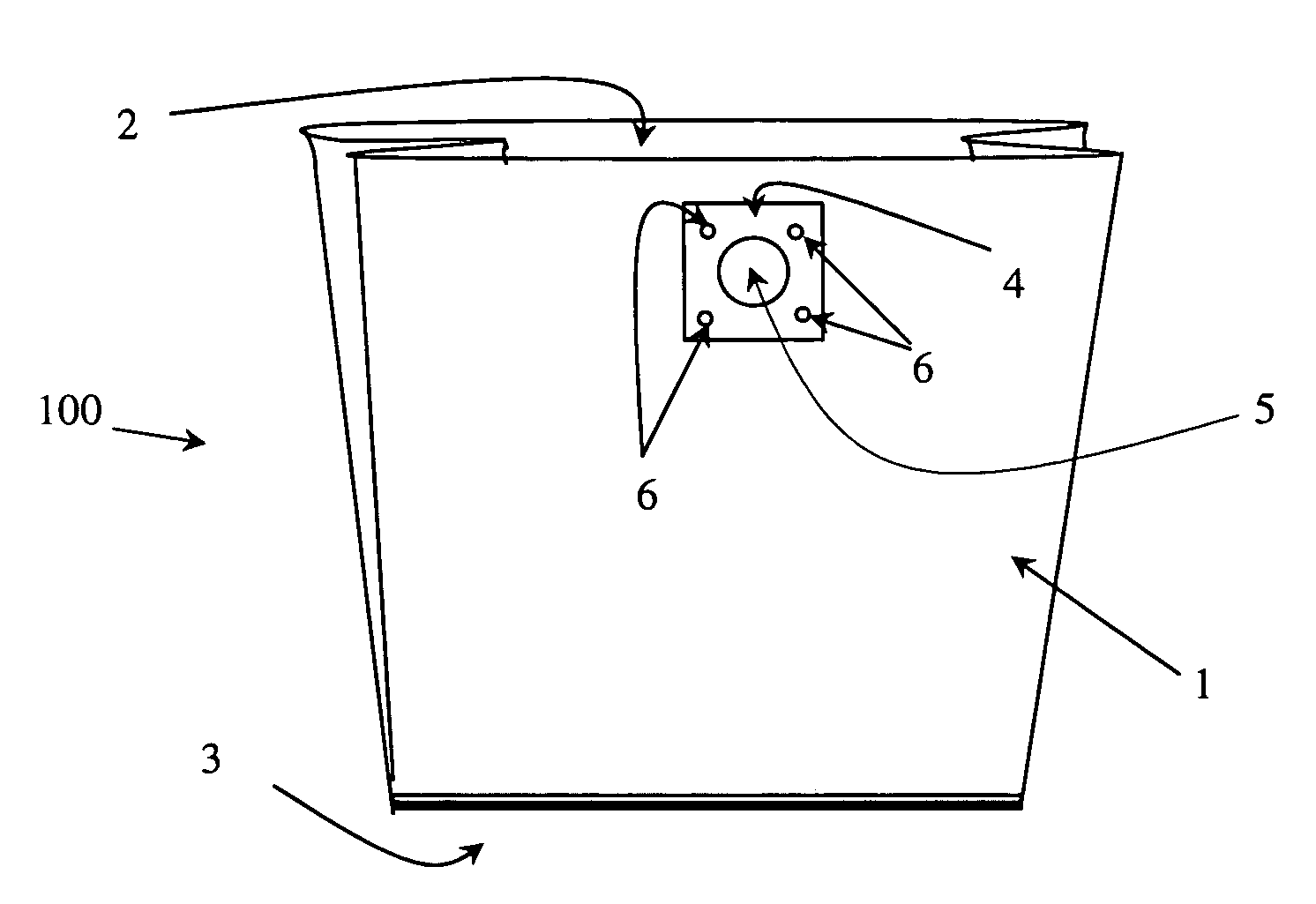

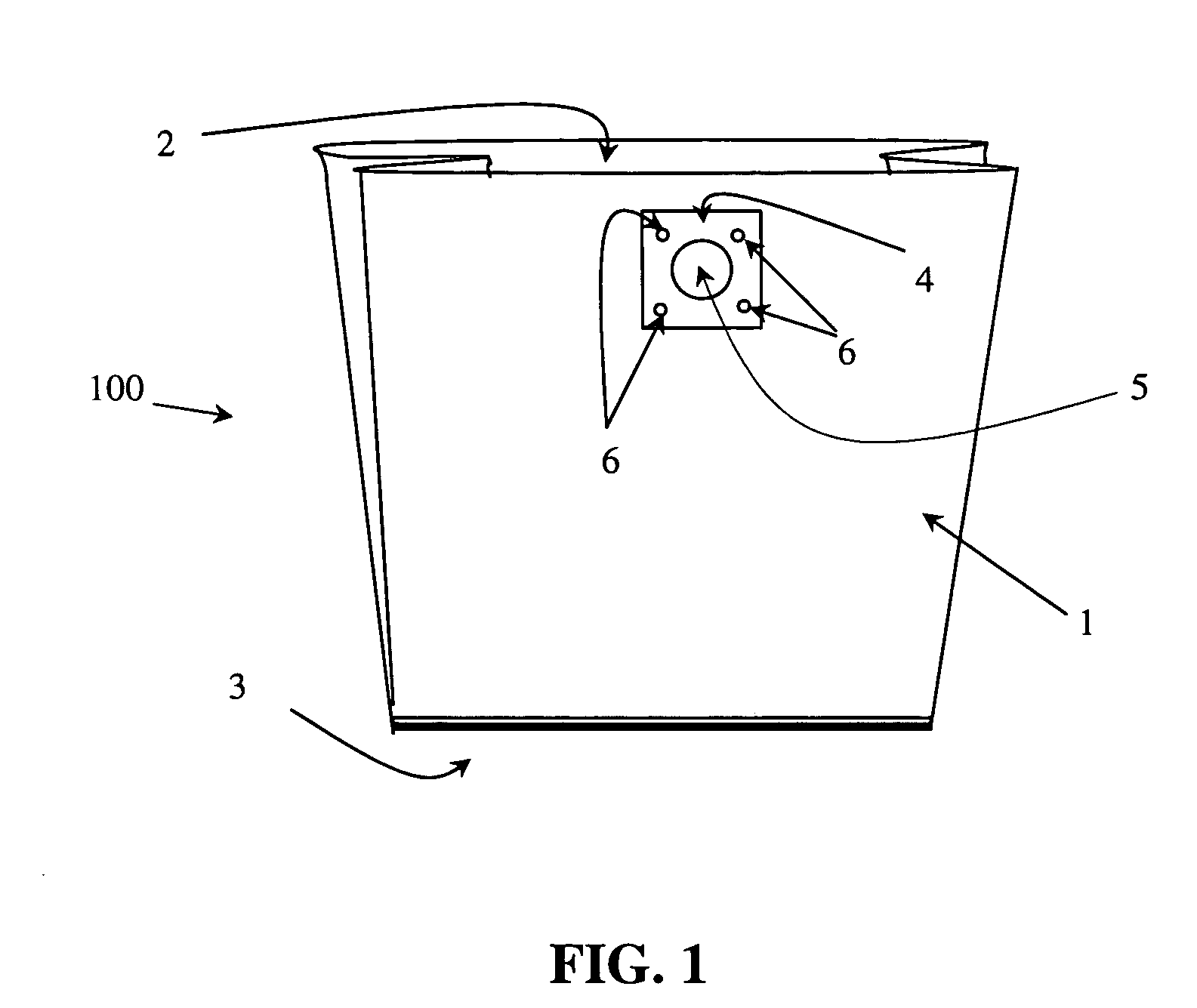

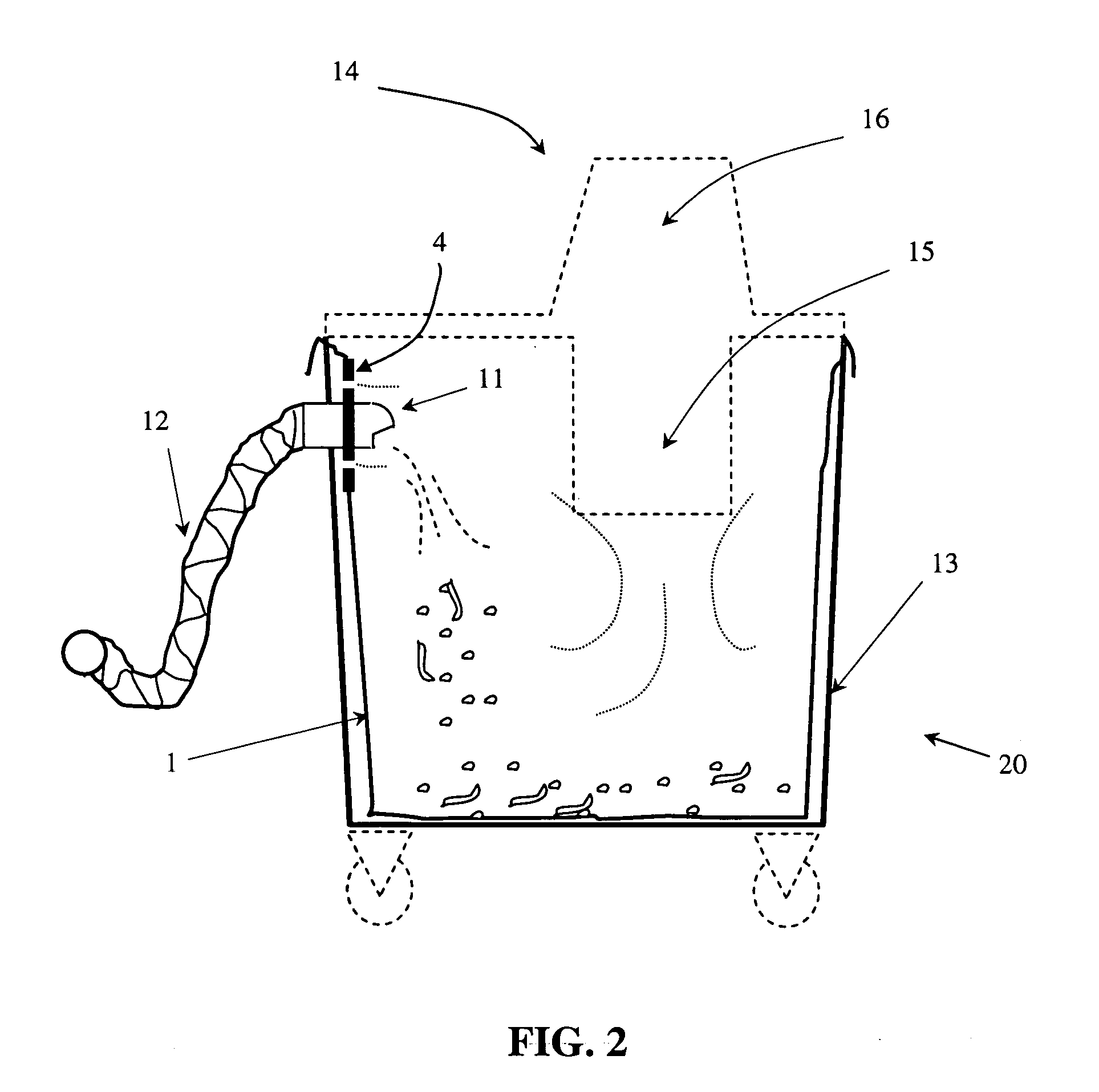

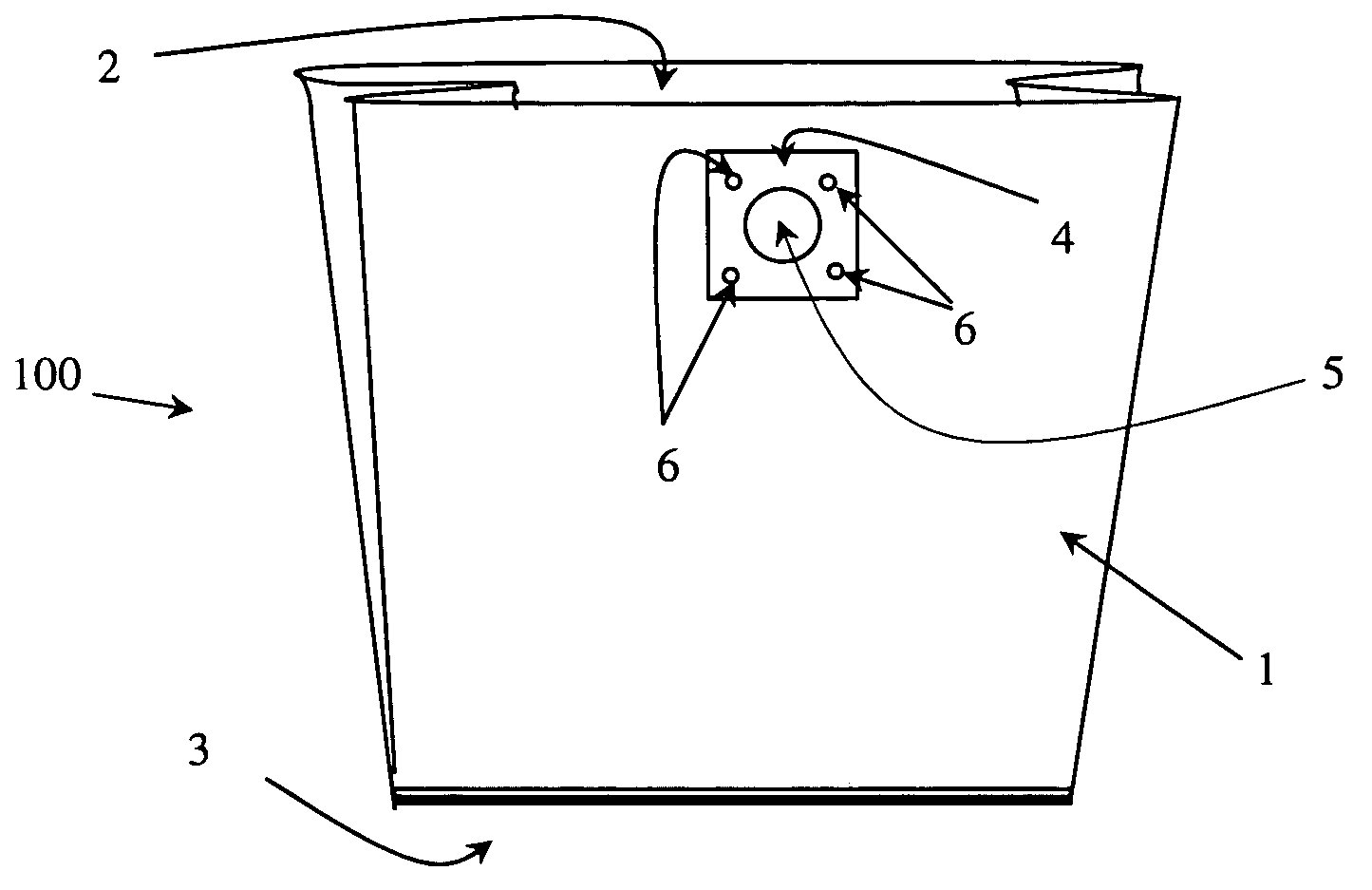

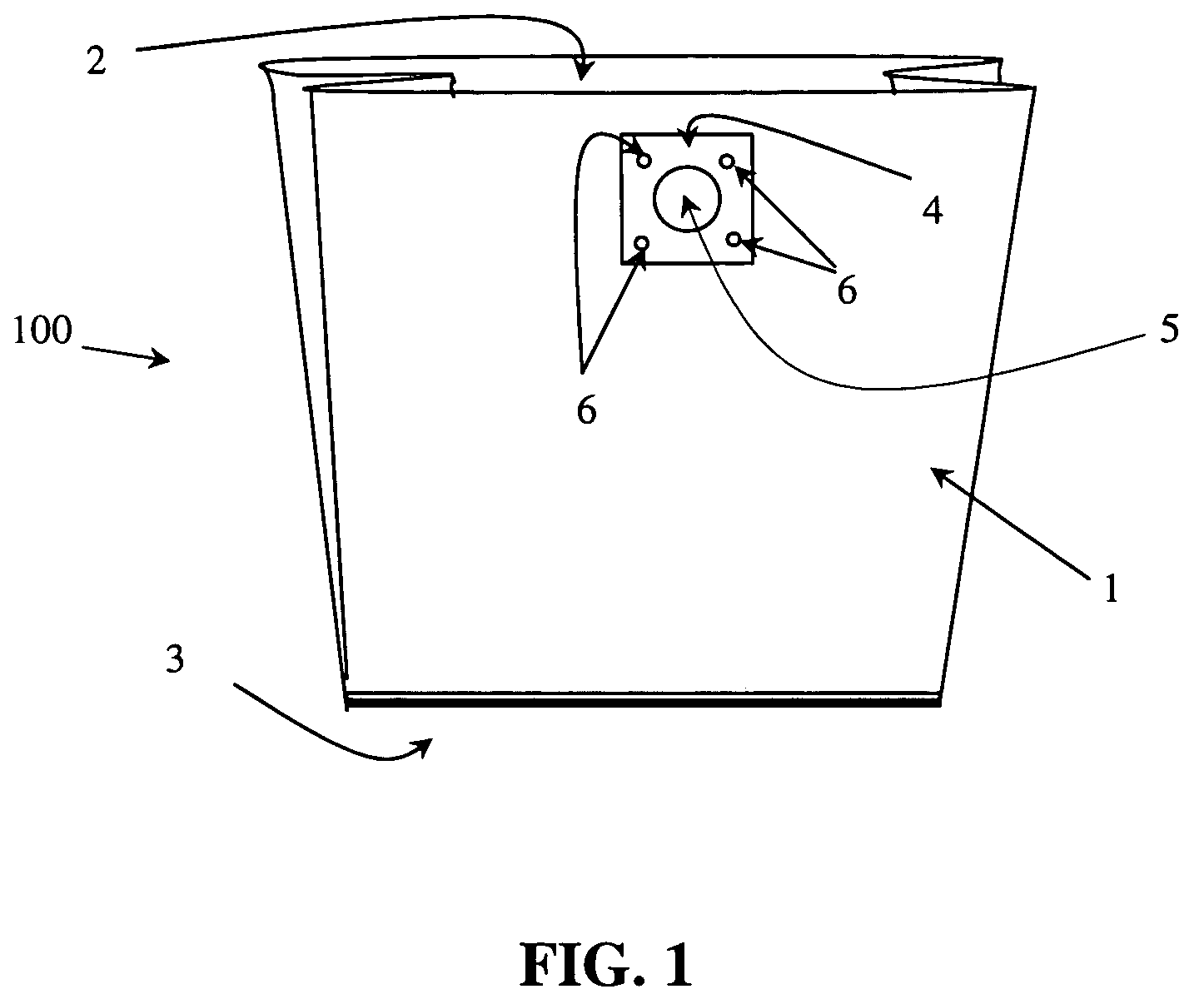

Disposable vacuum bags

A disposable open bag for a power tool such as a Shop-Vac cleaner is disclosed. The bag can comprise a mounting plate with an opening for receiving debris from the intake of the power tool. The mounting plate is also provided with a vent opening(s), e.g., to prevent the bag from closing in on the air filter and blocking the airflow. The said bag provides a cleaner and more convenient means of collection of the debris, leaves, and particulate maters directly into the bag.

Owner:SHOP VAC

Vacuum cleaning head

InactiveUS20110214248A1Easy to useIncrease the internal volumeMechanical suction controlSuction nozzlesEngineeringPressure difference

A vacuum cleaning head includes a housing having a suction opening for admitting an air flow to the head, an agitator for agitating a surface to be cleaned, the agitator having an active state and an inactive state, a duct for receiving the air flow from the housing, and a control assembly for controlling the state of the agitator. The control assembly includes a pressure chamber having an interior volume in fluid communication with the duct and which is variable between an expanded configuration and a contracted configuration in response to a pressure difference between the interior volume and ambient air, an actuator for effecting a transition of the agitator from one of the active state and the inactive state to the other of the active state and the inactive state in response to a transition of the pressure chamber to the contracted configuration, and a control mechanism having a first state for preventing the pressure chamber from adopting the contracted configuration, and a second state for allowing the pressure chamber to adopt the contracted configuration. The control mechanism is arranged to change between the first and second states in response to an increase in the interior volume of the pressure chamber, for example in response to an increase in the air pressure within the duct.

Owner:DYSON TECH LTD

Disposable vacuum bags

A disposable open bag for a power tool such as a Shop-Vac cleaner has a mounting plate with an opening for receiving debris from the intake of the power tool. The mounting plate is also provided with a vent opening(s), e.g., to prevent the bag from closing in on the air filter and blocking the airflow. The said bag provides a cleaner and more convenient means of collection of the debris, leaves, and particulate matters directly into the bag.

Owner:SHOP VAC

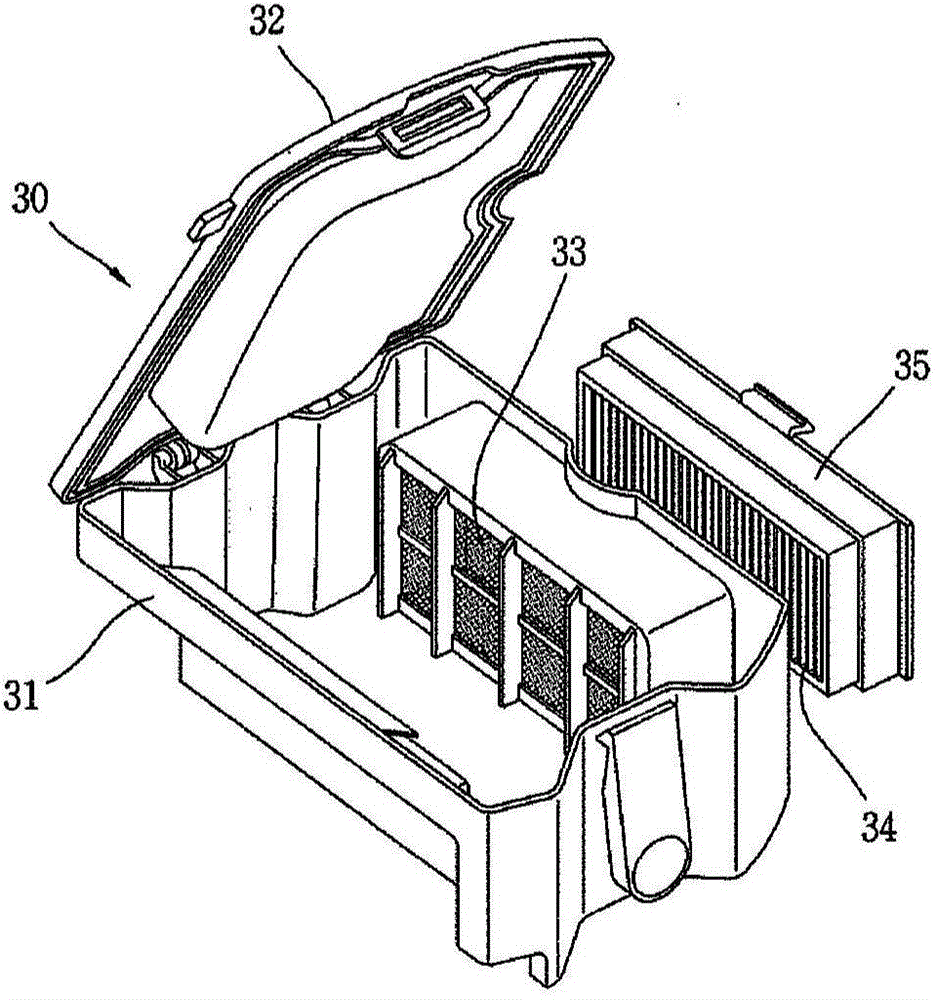

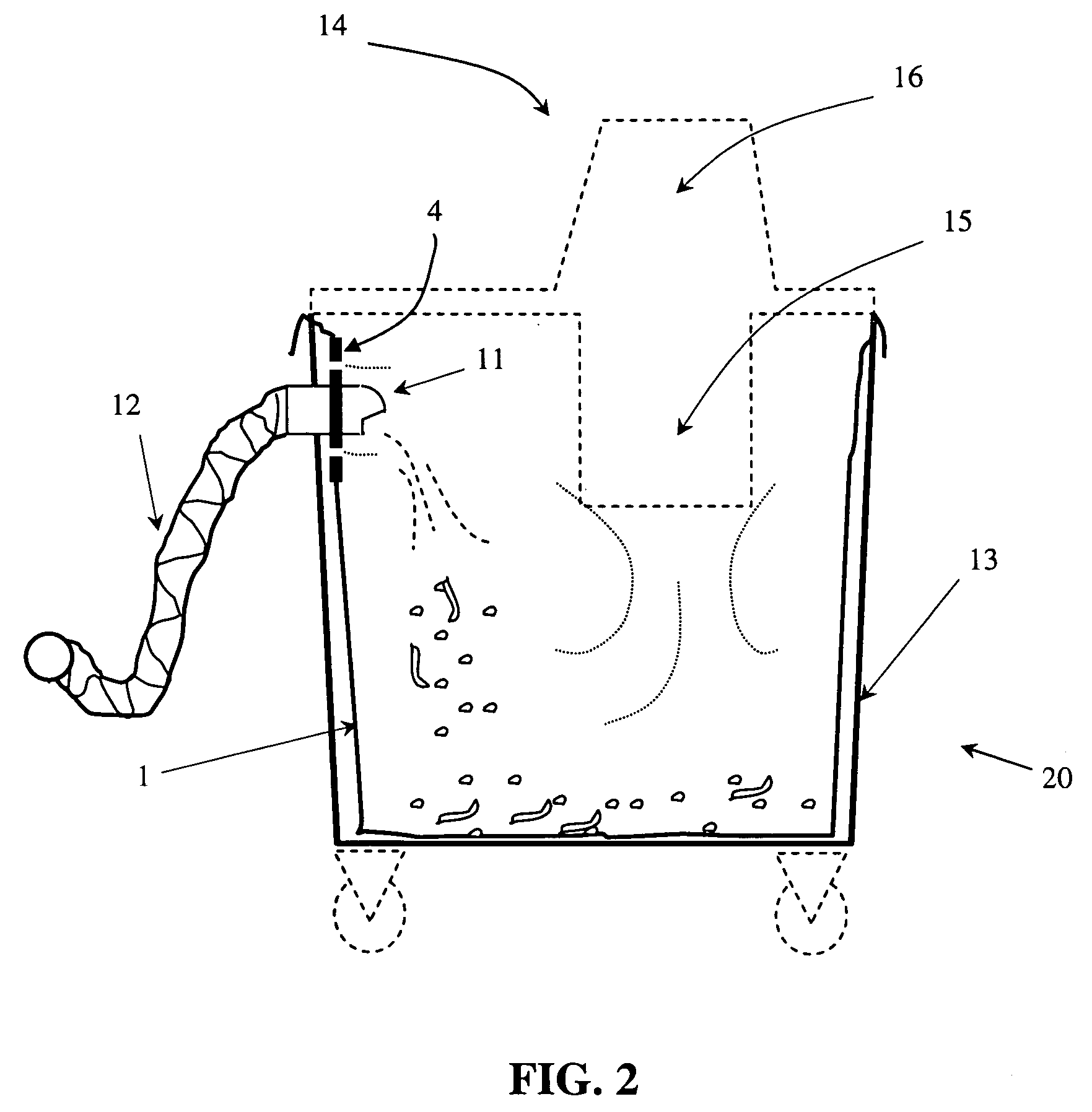

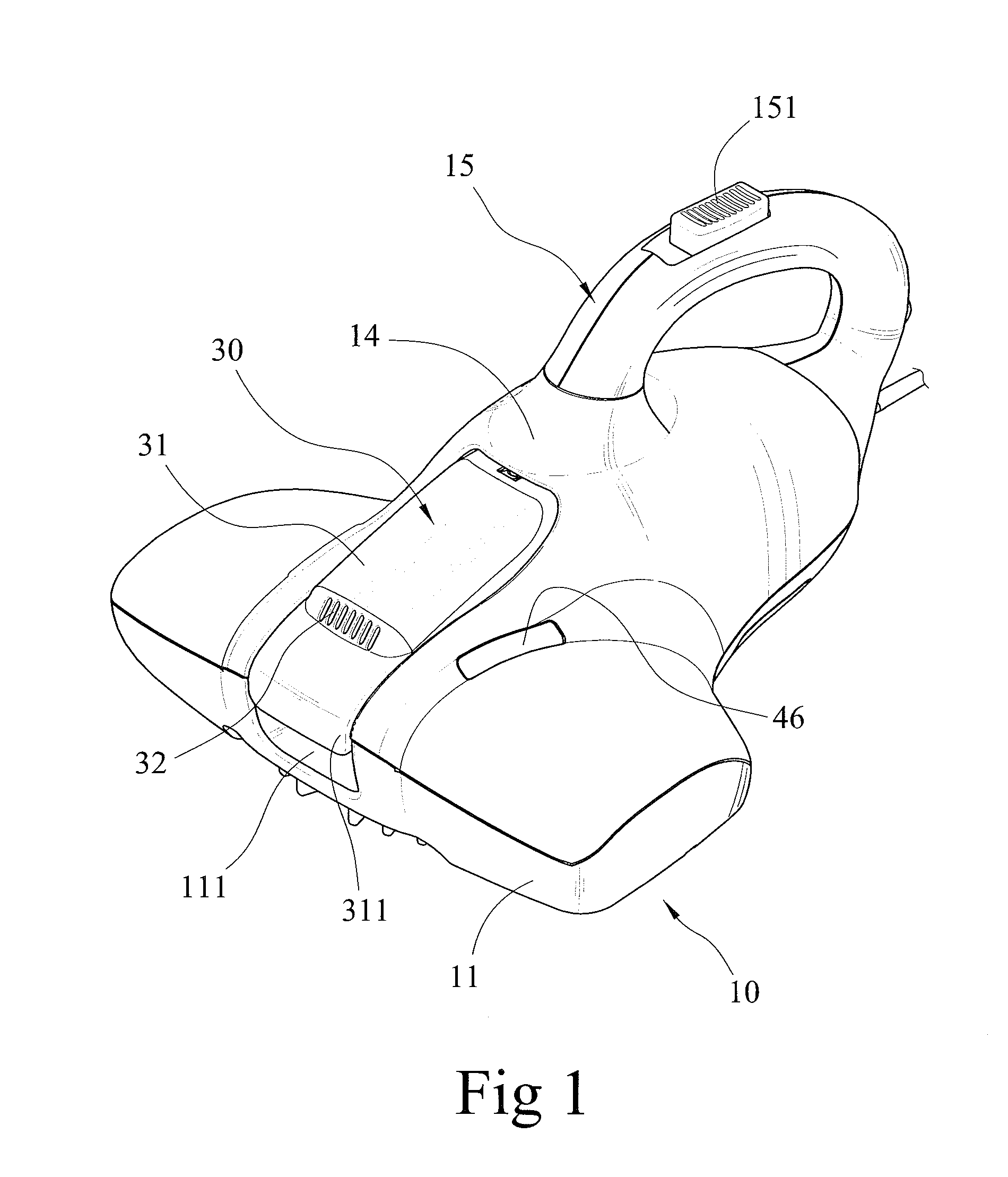

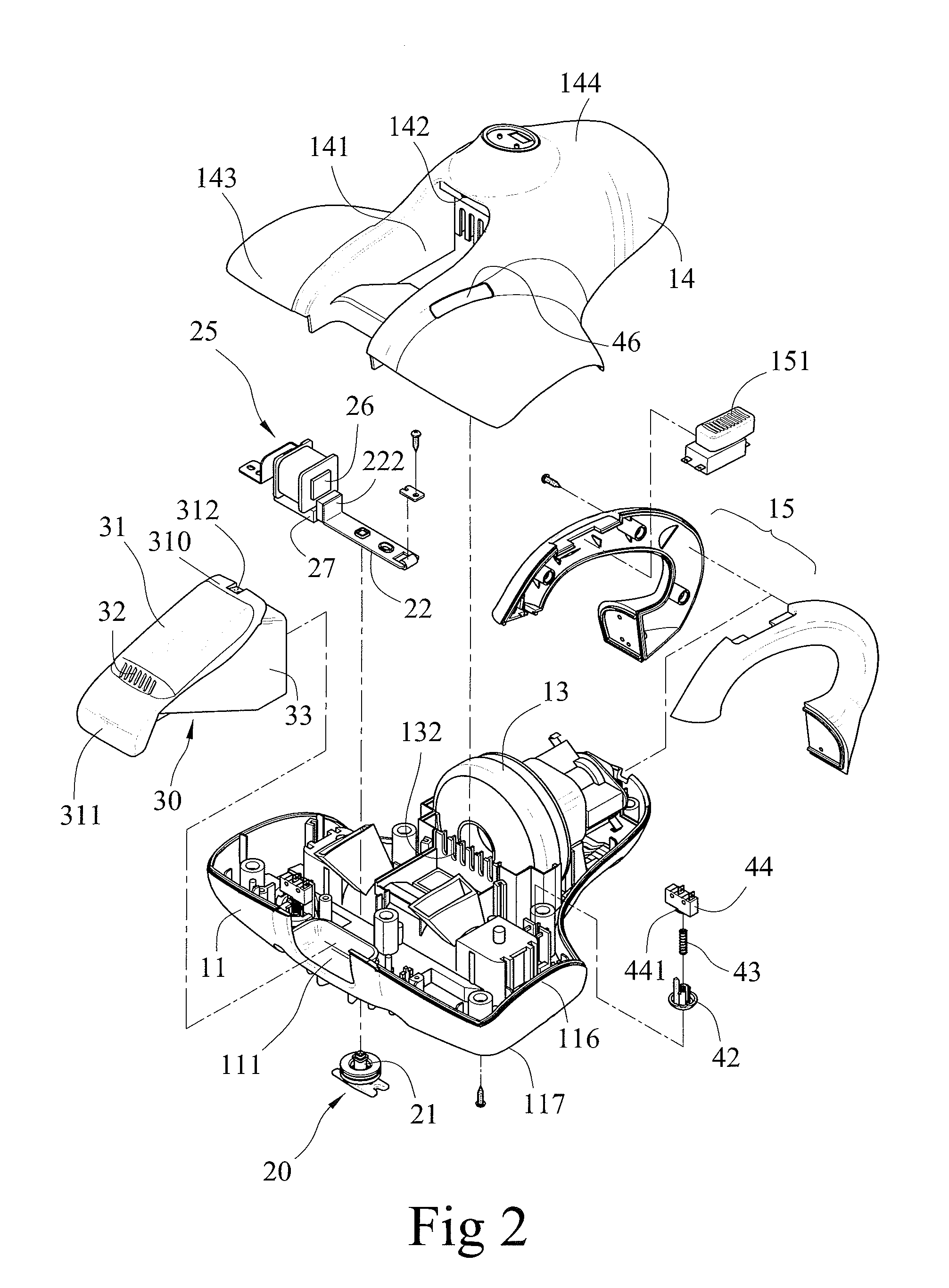

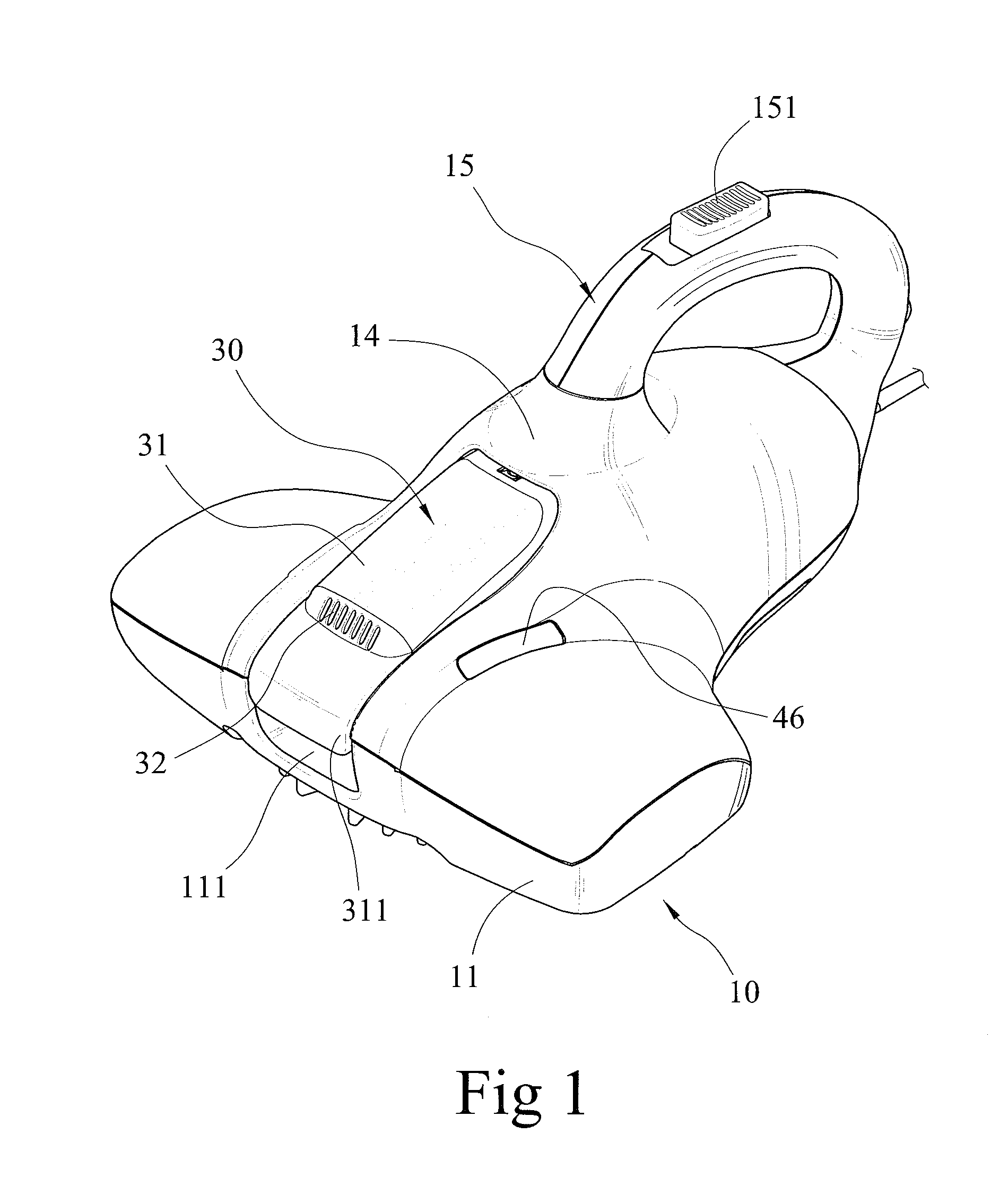

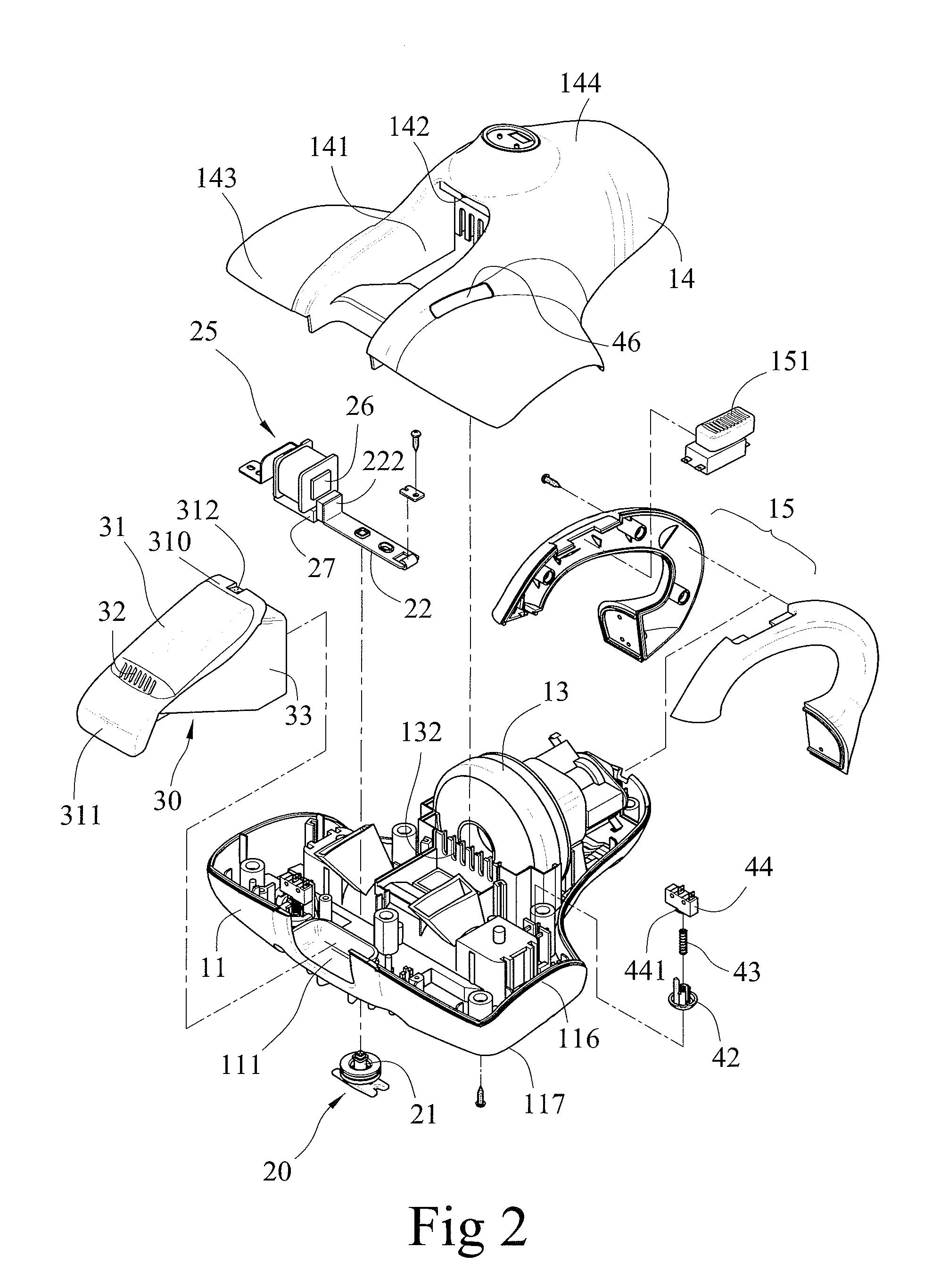

Double Suction Type Sterilizing Vacuum Cleaner

ActiveUS20110138568A1Reduce pressureFacilitated releaseMechanical suction controlCleaning using gasesEngineeringHIT device

A double suction type sterilizing vacuum cleaner includes a base seat and an upper cover mounted on an upper side of the base seat. A main suction port is provided in the base seat. A hitting device is mounted on the base seat and adapted to hit a cleaning object under the base seat. A sterilizing lamp is mounted in the base seat for sterilizing purposes. A dust collecting box is detachably mounted to the upper cover and defines an air channel in communication with the main suction port. A secondary suction port is provided in the dust collecting box and in communication with the air channel. When the main suction port is blocked, an ambient air can be supplied to the air channel through the secondary suction port, facilitating the release of the blocking situation in the main suction port.

Owner:YEJEN APPLIANCES SHENZHEN

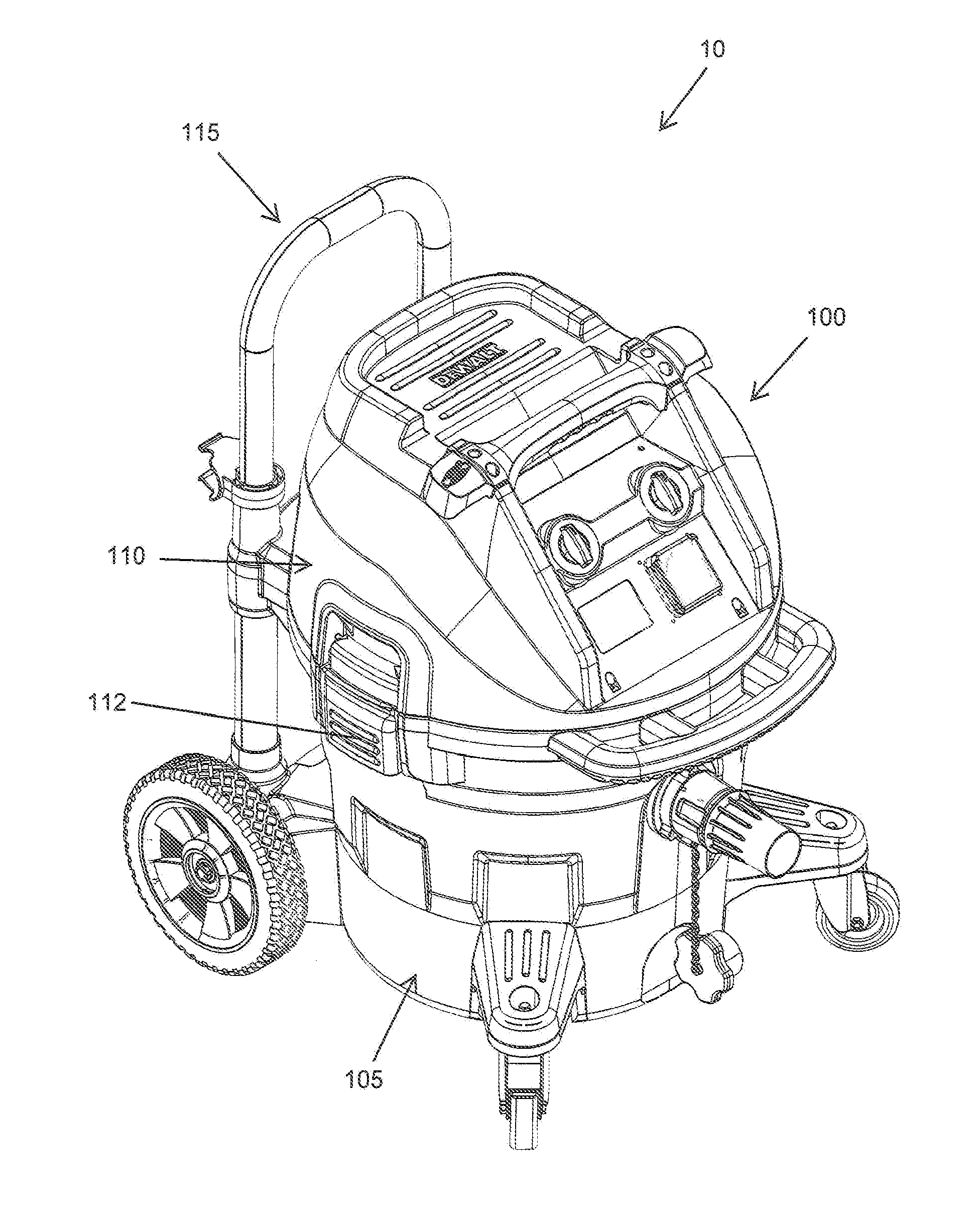

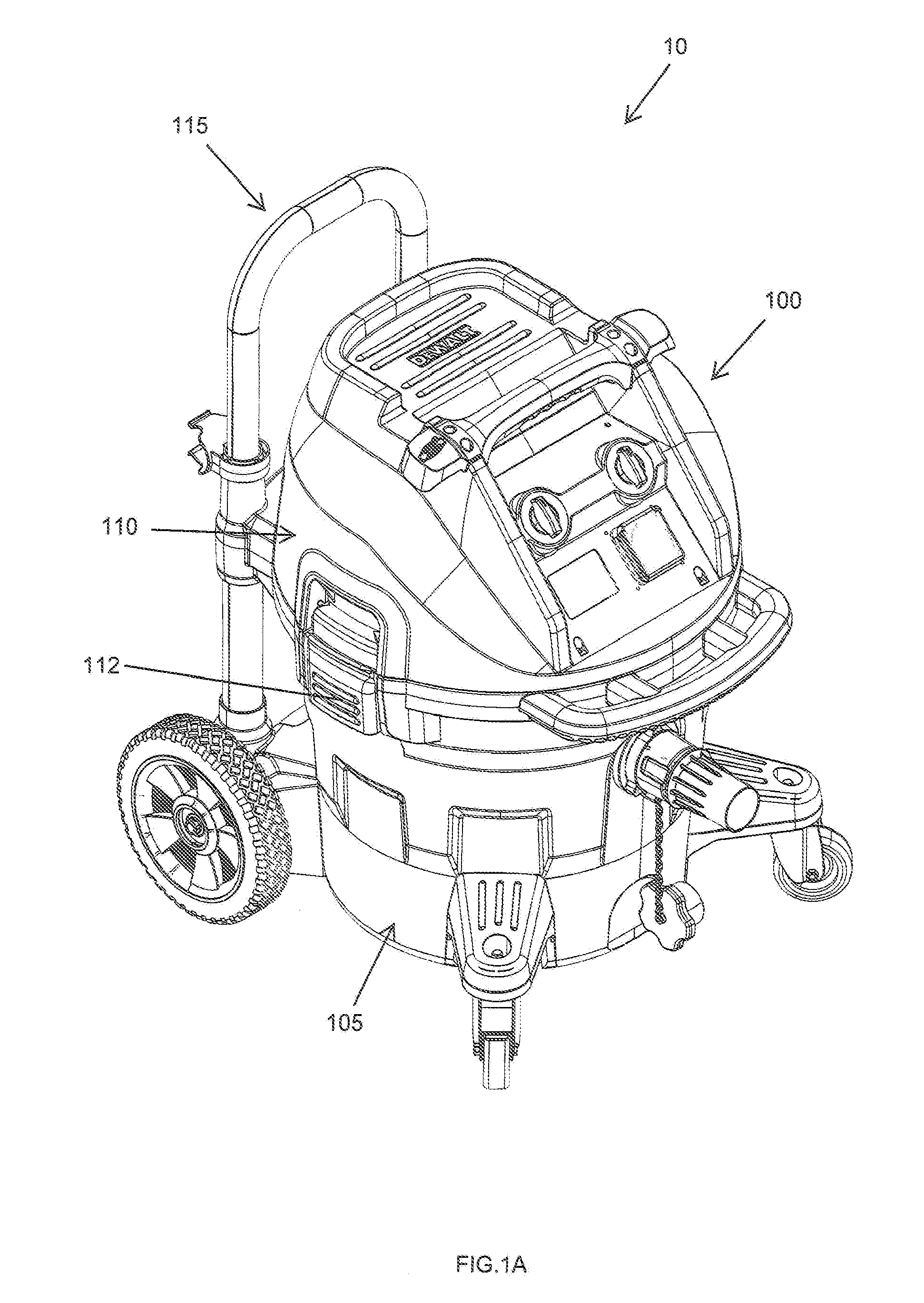

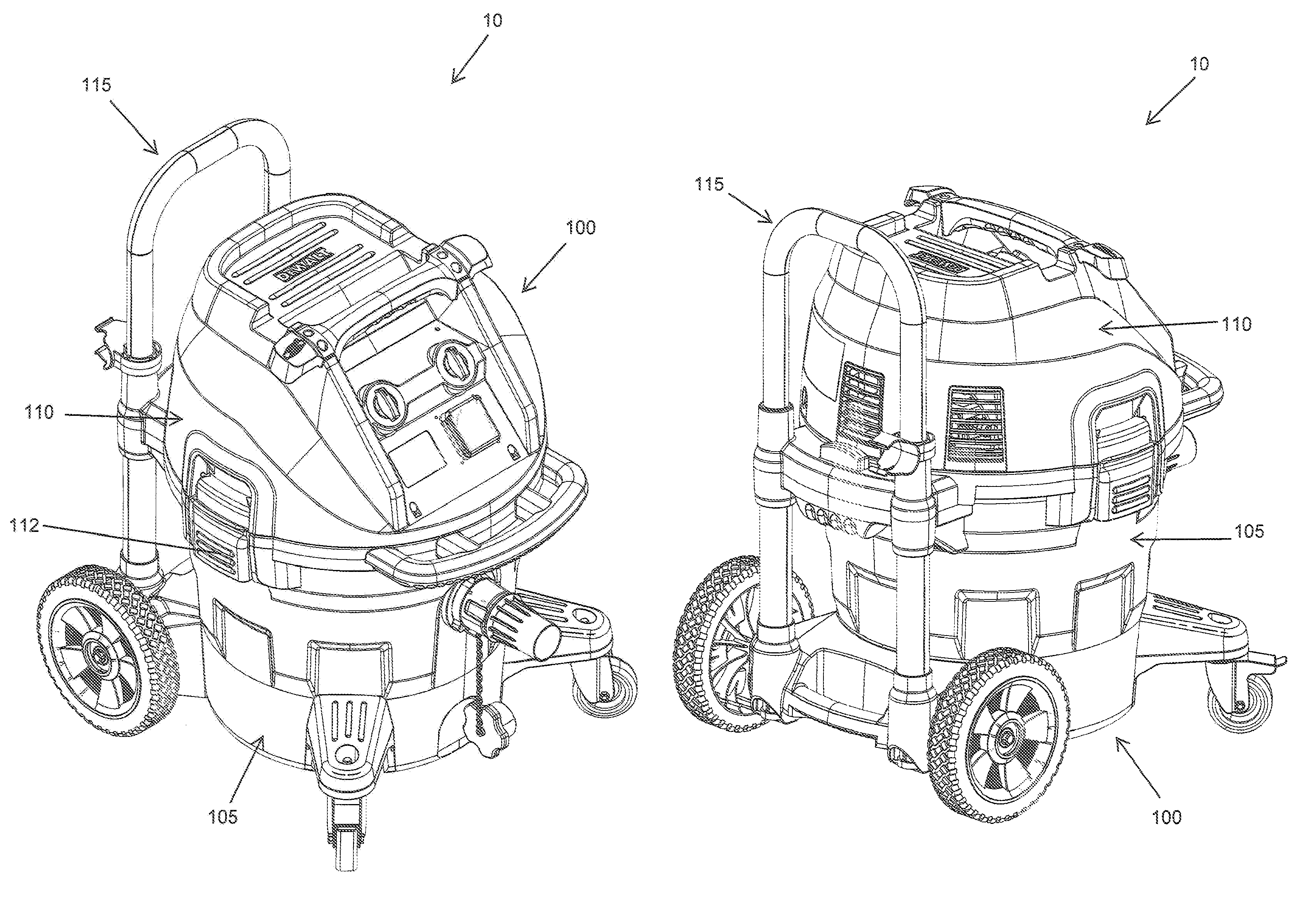

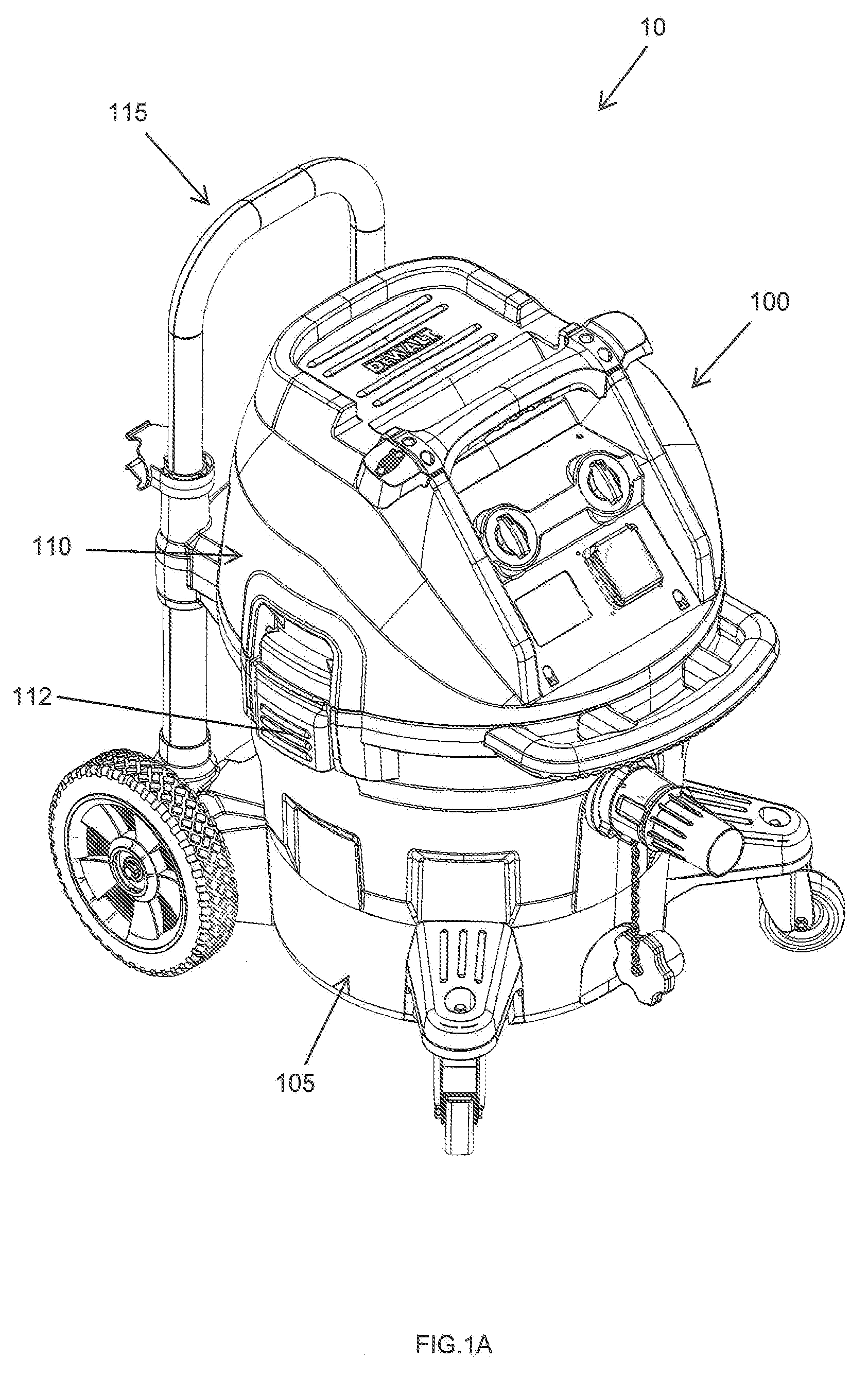

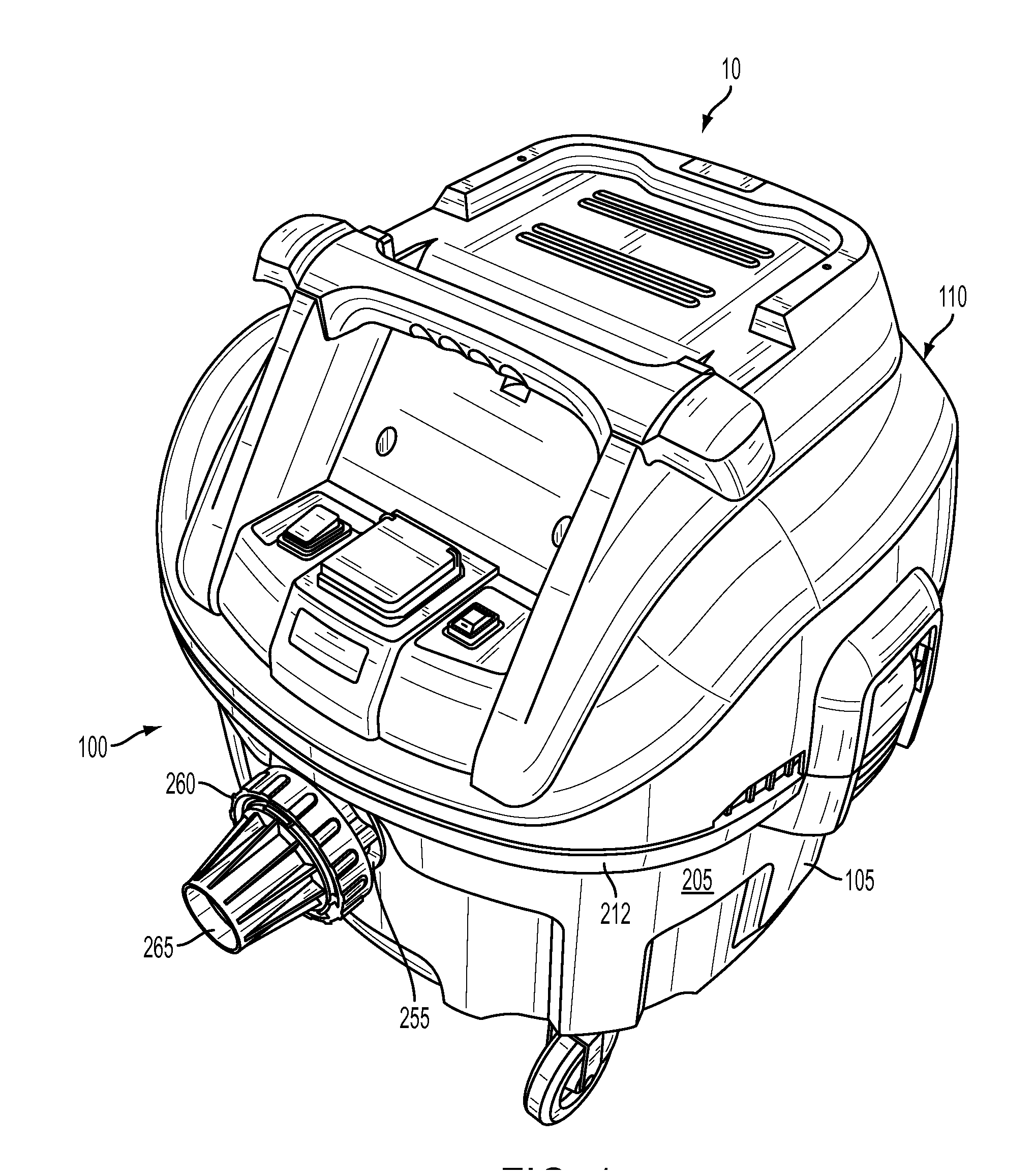

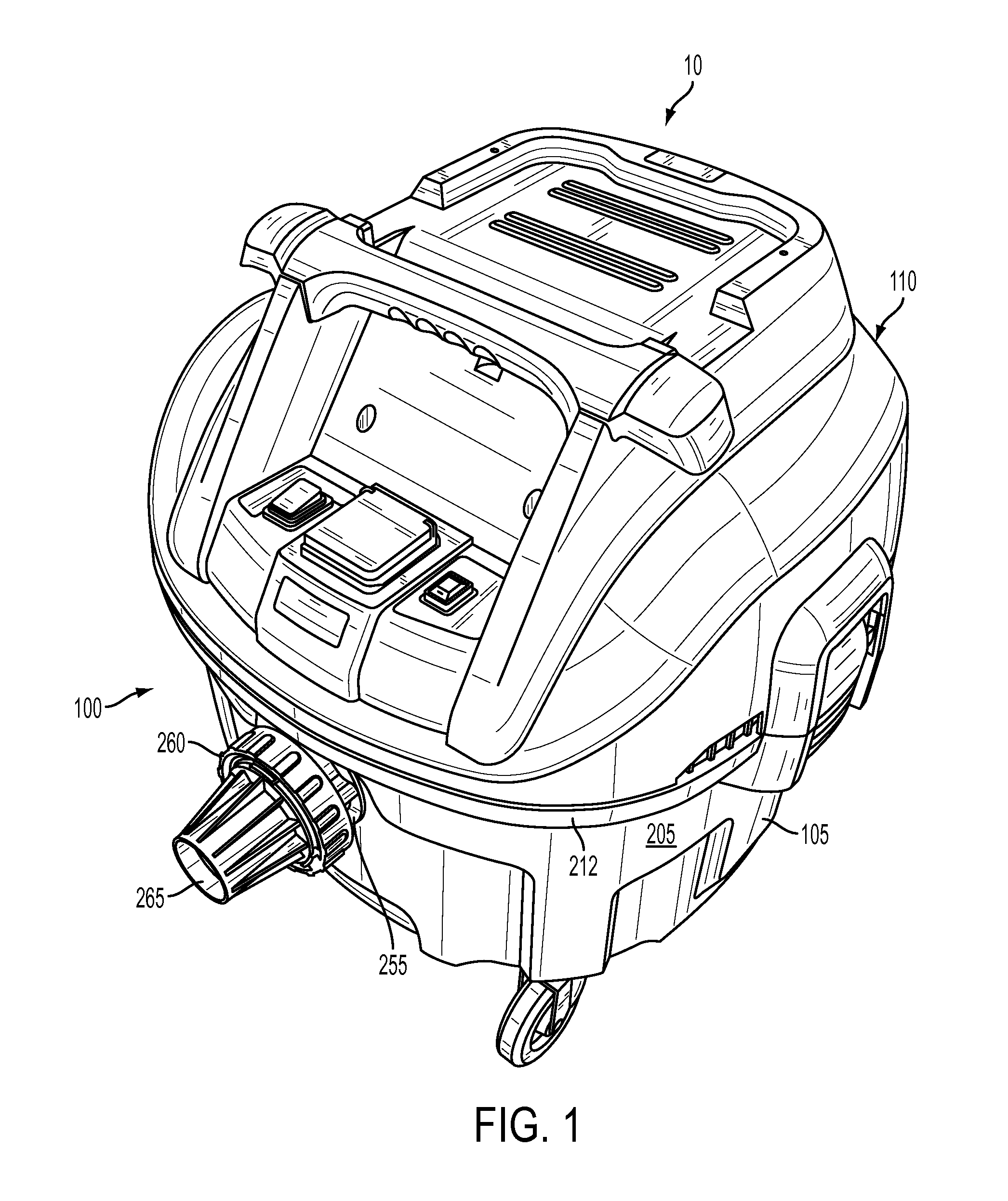

Vacuum

The present invention is directed to a vacuum including a dust extraction system. The system includes a filter assembly, an airflow generation assembly, and valve assembly. The airflow generation assembly is configured to draw contaminated air toward the filter assembly and exhaust filtered air as a discharge stream. The filter assembly is configured to remove contaminants from the contaminated airflow by capturing particulate material suspended within the airflow. The valve assembly is configured to selectively direct filtered airflow into the filter assembly such that the filtered air stream cleans the filter.

Owner:BLACK & DECKER INC

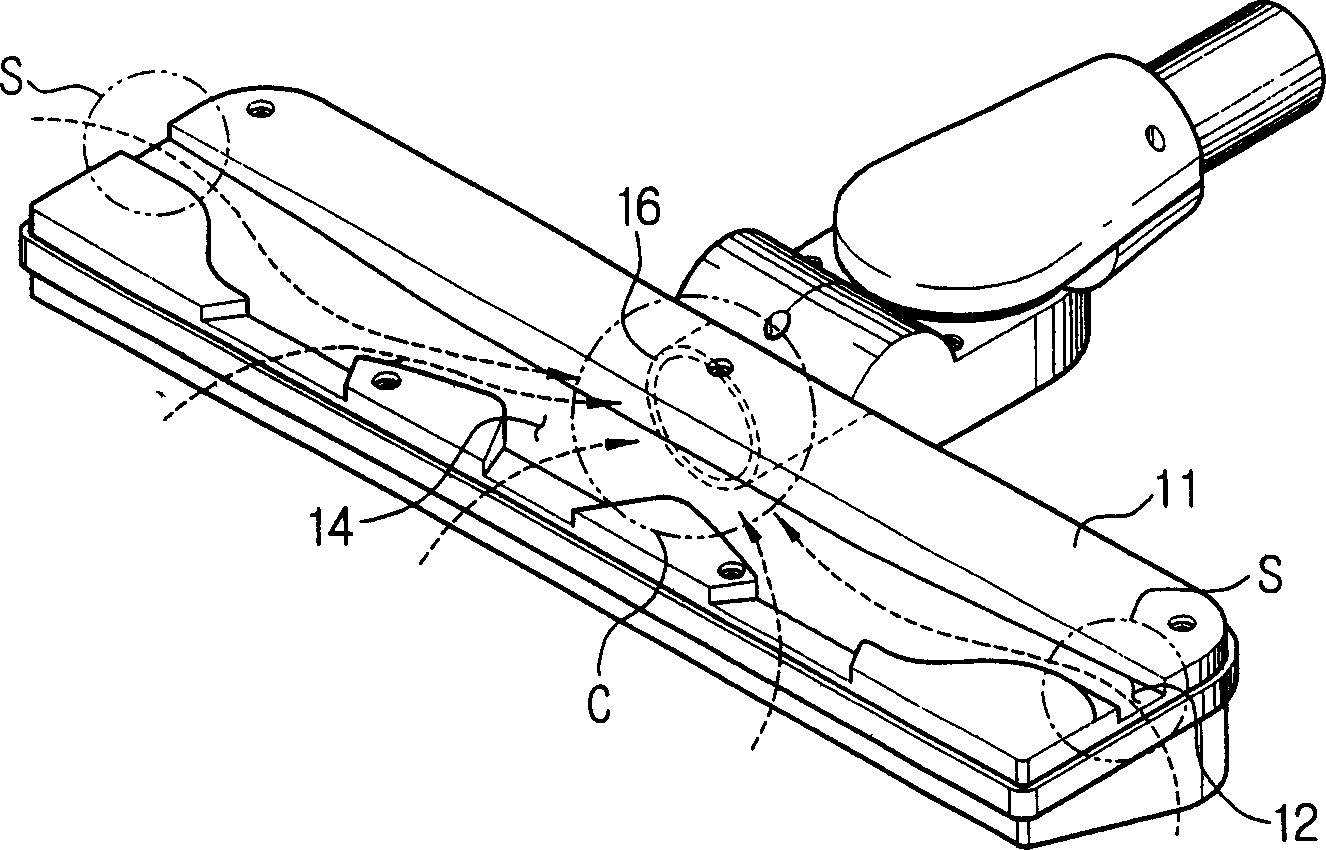

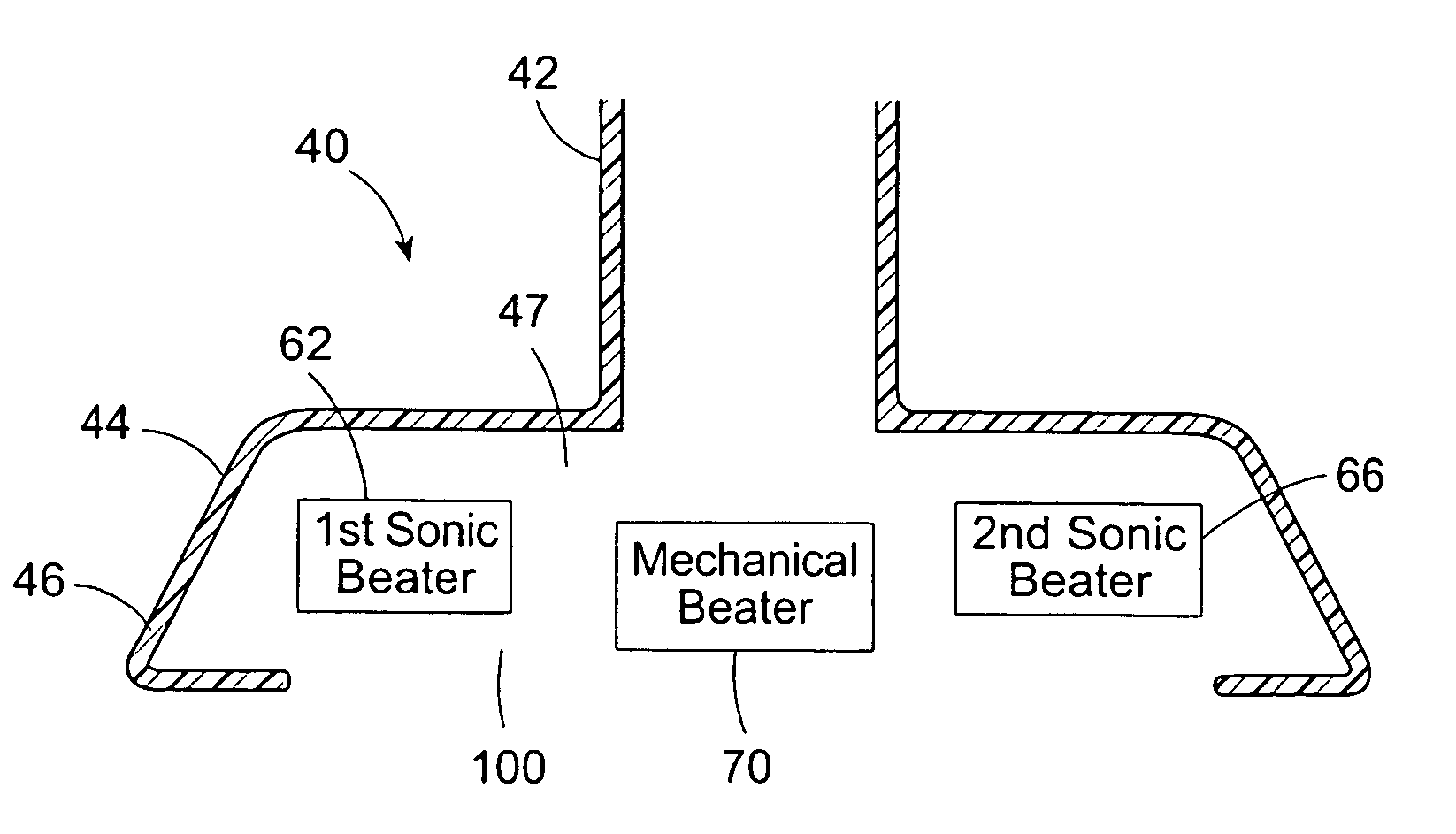

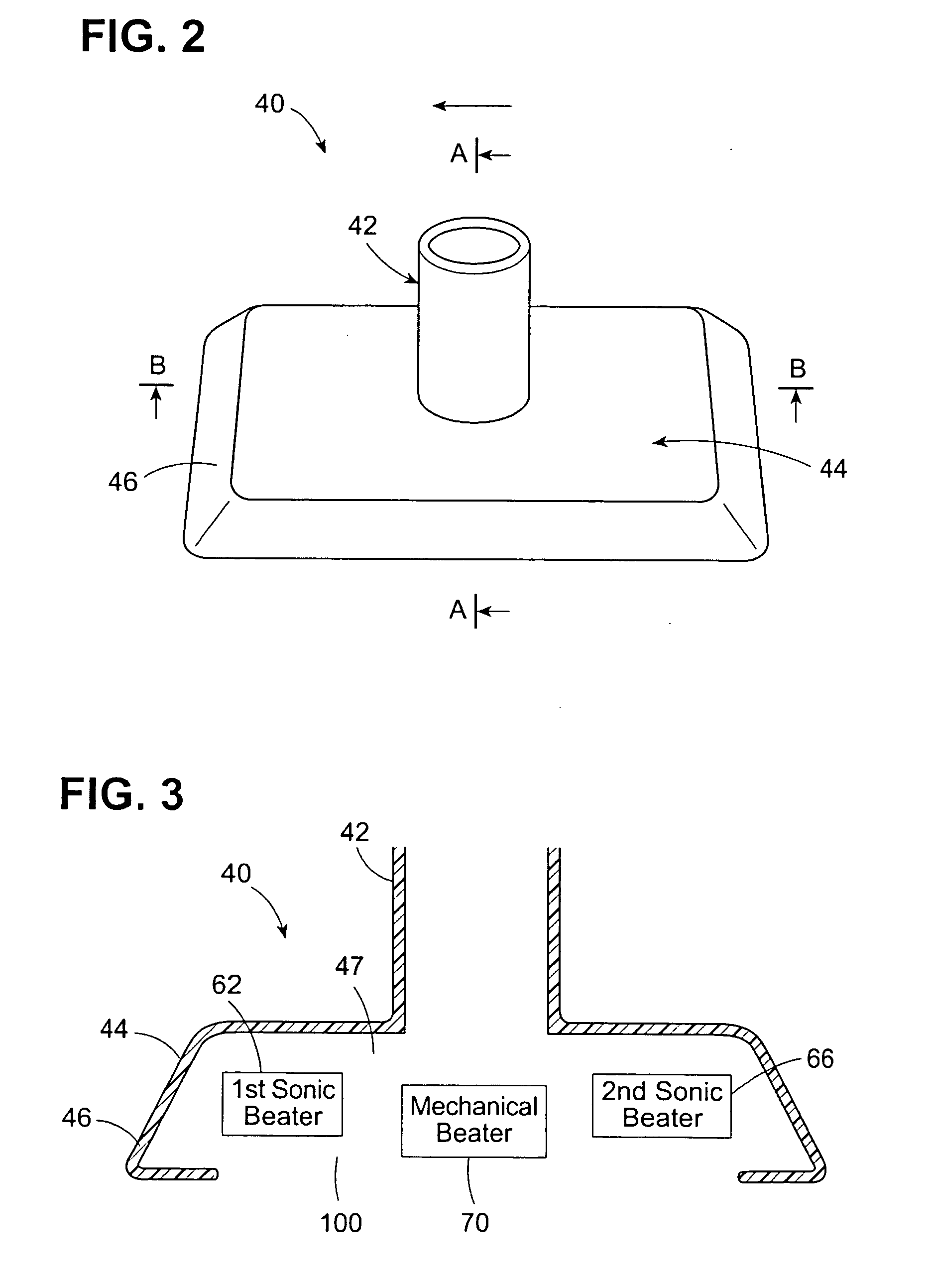

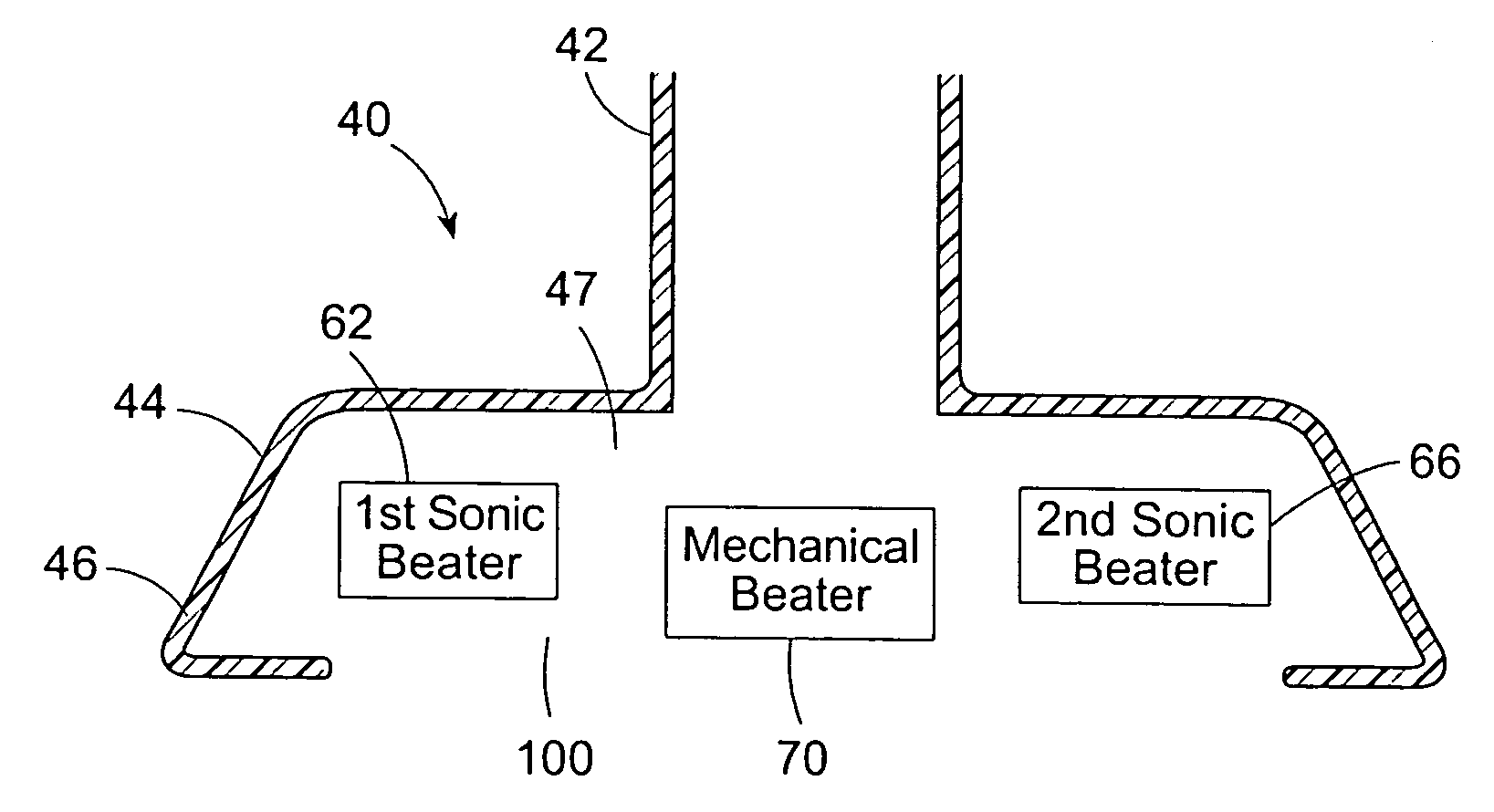

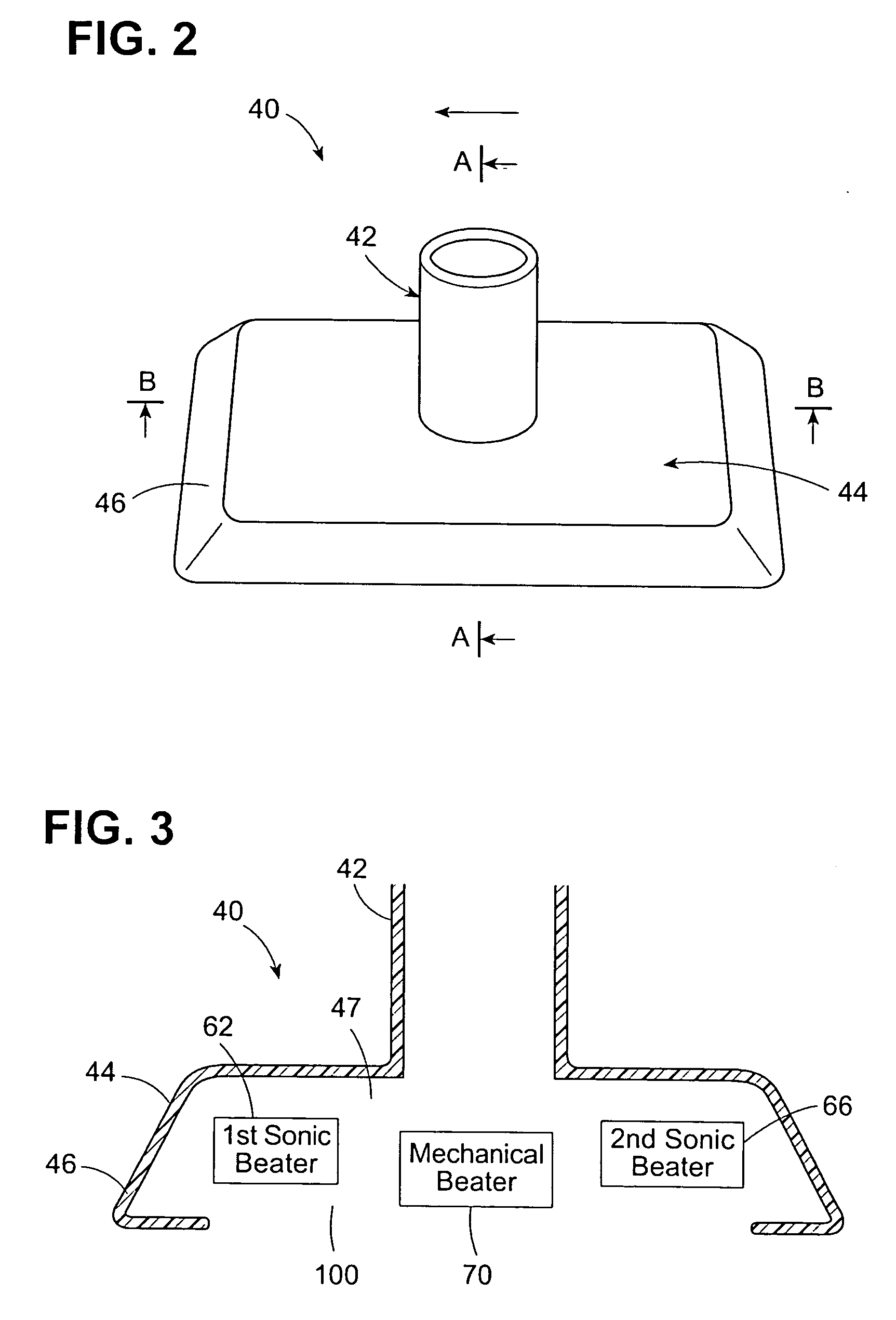

Vacuum cleaner nozzle including mechanical beater and sonic beater

ActiveUS20050278890A1Easy to cleanClean thoroughlyMechanical suction controlSuction nozzlesEngineeringVacuum cleaner

A vacuum cleaner nozzle including a nozzle head, the nozzle head having at least one mechanical beater and at least one sonic beater.

Owner:ZENITH TECH

Airflow control mechanism

InactiveUS7779860B2Operating means/releasing devices for valvesMechanical suction controlEngineeringGuide tube

The present invention provides an airflow control mechanism comprising a conduit for air having an inlet located at a first end thereof and an outlet located at a second end thereof; a first opening formed in a side of said conduit and able to provide a secondary inlet thereto; a movable collar at least partially surrounding said conduit at a location alignable with said first opening, such that said collar is able to at least partially occlude said first opening; further comprising a second opening beside the first opening as part of the secondary inlet, wherein the collar is also alignable with the second opening, such that the collar is able to at least partially occlude the second opening at the same time as the first opening. Thus with this airflow control mechanism, a user may select whether to occlude both the first and the second openings, in which case air will pass directly from the inlet to the outlet without any air also entering through the secondary inlet, or to occlude neither the first and second openings, in which case air entering the secondary inlet will contribute to the total amount of air exiting the outlet, or to occlude just one of the first and second openings, in which case, a fixed amount of air which is less than the secondary inlet being fully open, but more than the secondary inlet being fully closed, will enter through the secondary inlet and contribute to the total amount of air exiting the outlet. Thus the user will be provided with a highly predictable and repeatable setting for the airflow control mechanism between the fully open and fully closed positions of the secondary inlet.

Owner:BLACK & DECKER INC

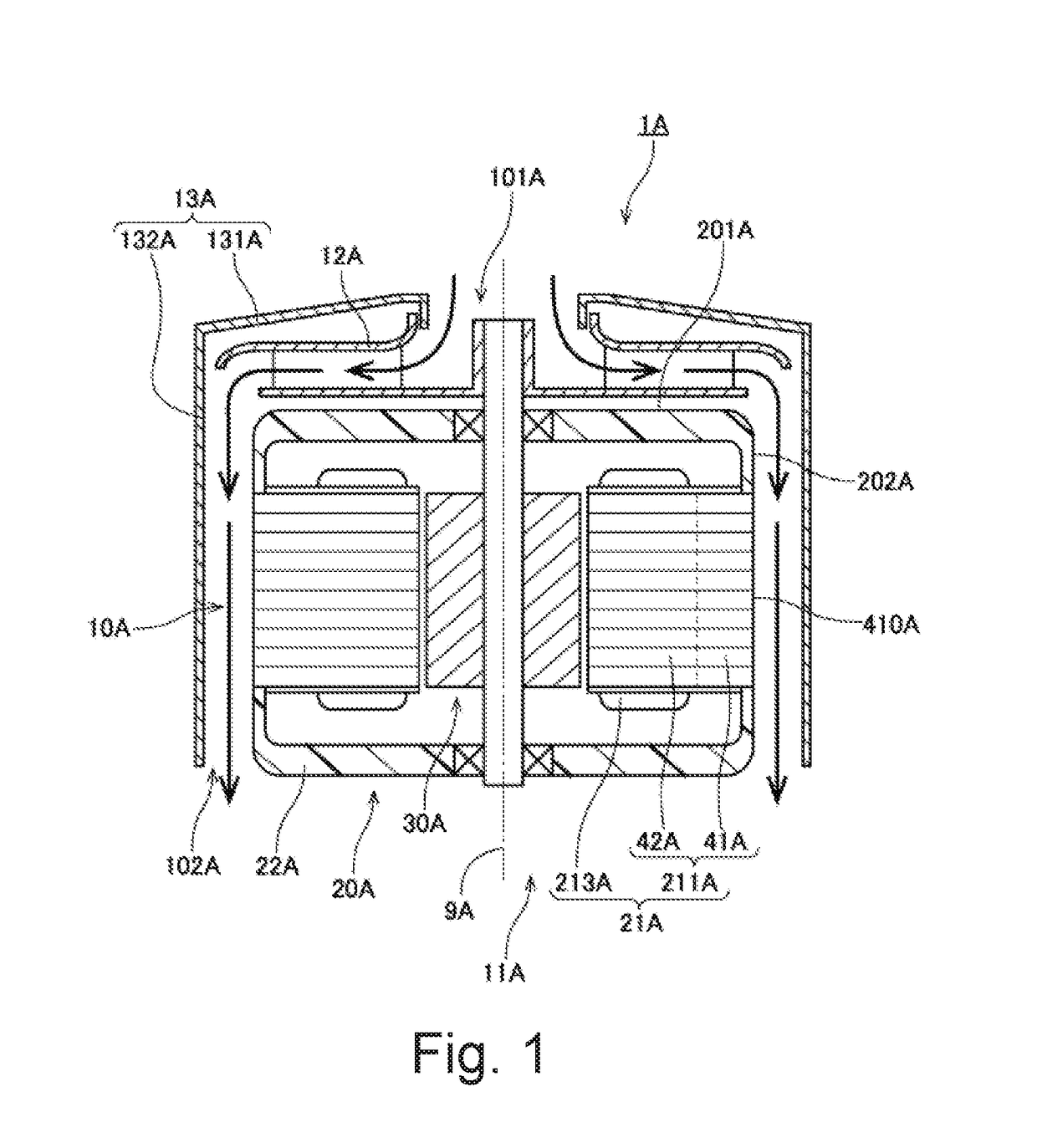

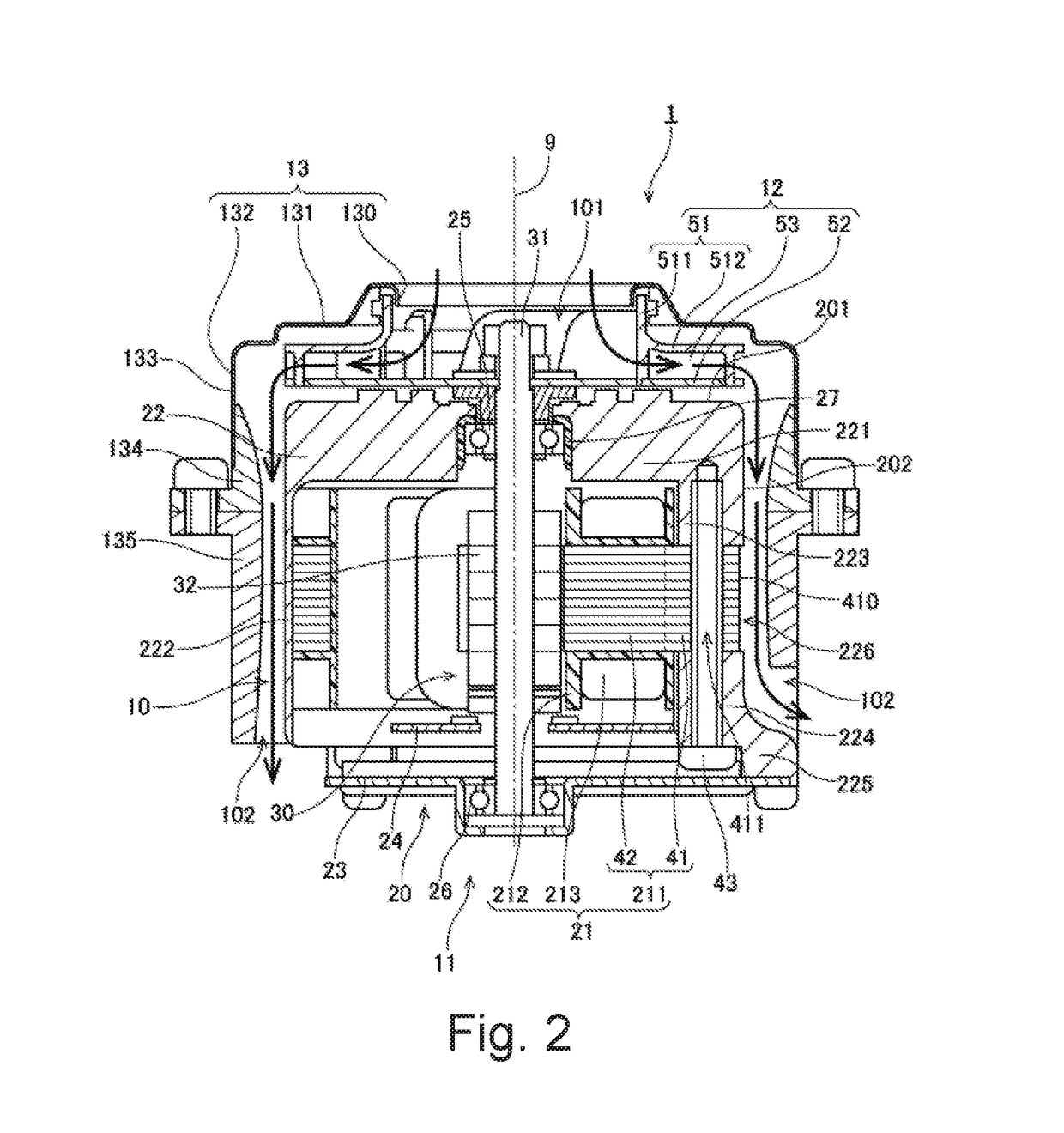

Centrifugal blower and vacuum cleaner

A centrifugal blower includes a motor including a stator and a motor cover, a centrifugal impeller rotating together with a rotating portion of the motor, and a blower casing. The stator includes a stator core including a toric core back. The motor cover includes an upper surface, and a cylindrical outer peripheral surface extending downwards. The blower casing disposed above the impeller includes an upper side casing top plate portion in which an intake port is disposed at the middle, and a cylindrical wall portion extending downwards from the upper side casing top plate portion. An inner peripheral surface of the wall portion and the outer peripheral surface of the motor cover forms a flow path continuous in the axial direction. A discharge port is formed in a lower end portion of the flow path. The core back includes an exposed portion exposed to the flow path.

Owner:NIDEC CORP

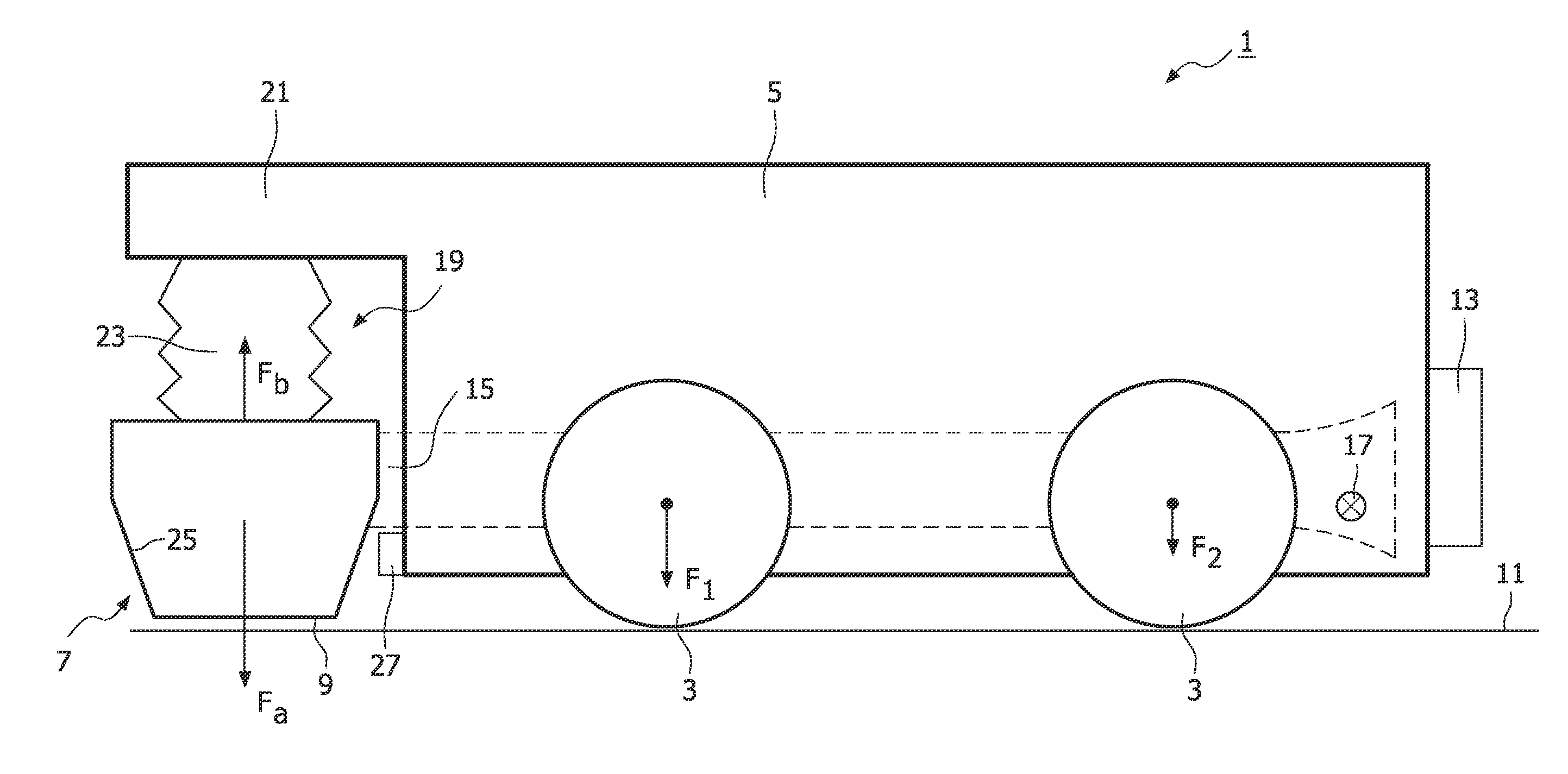

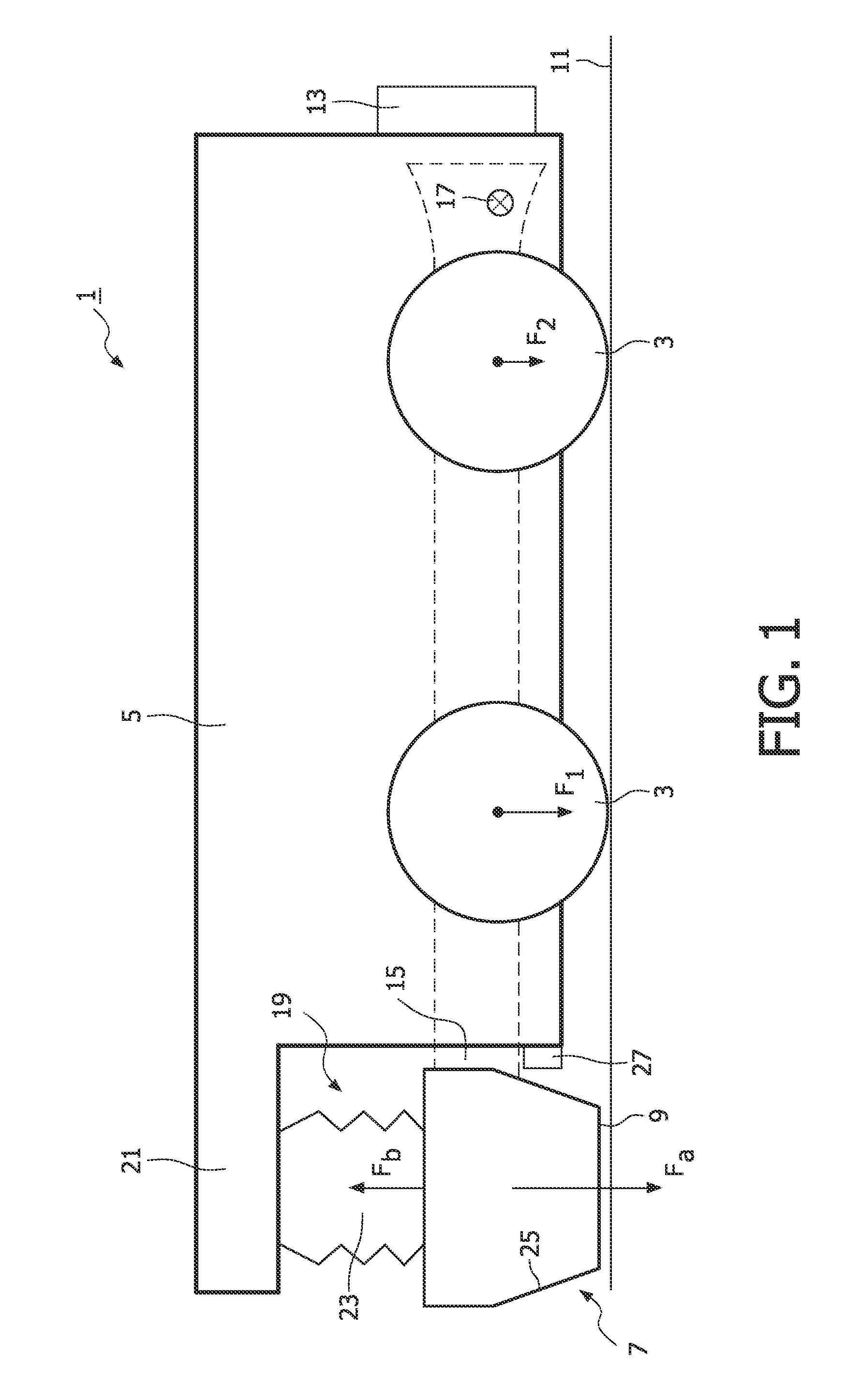

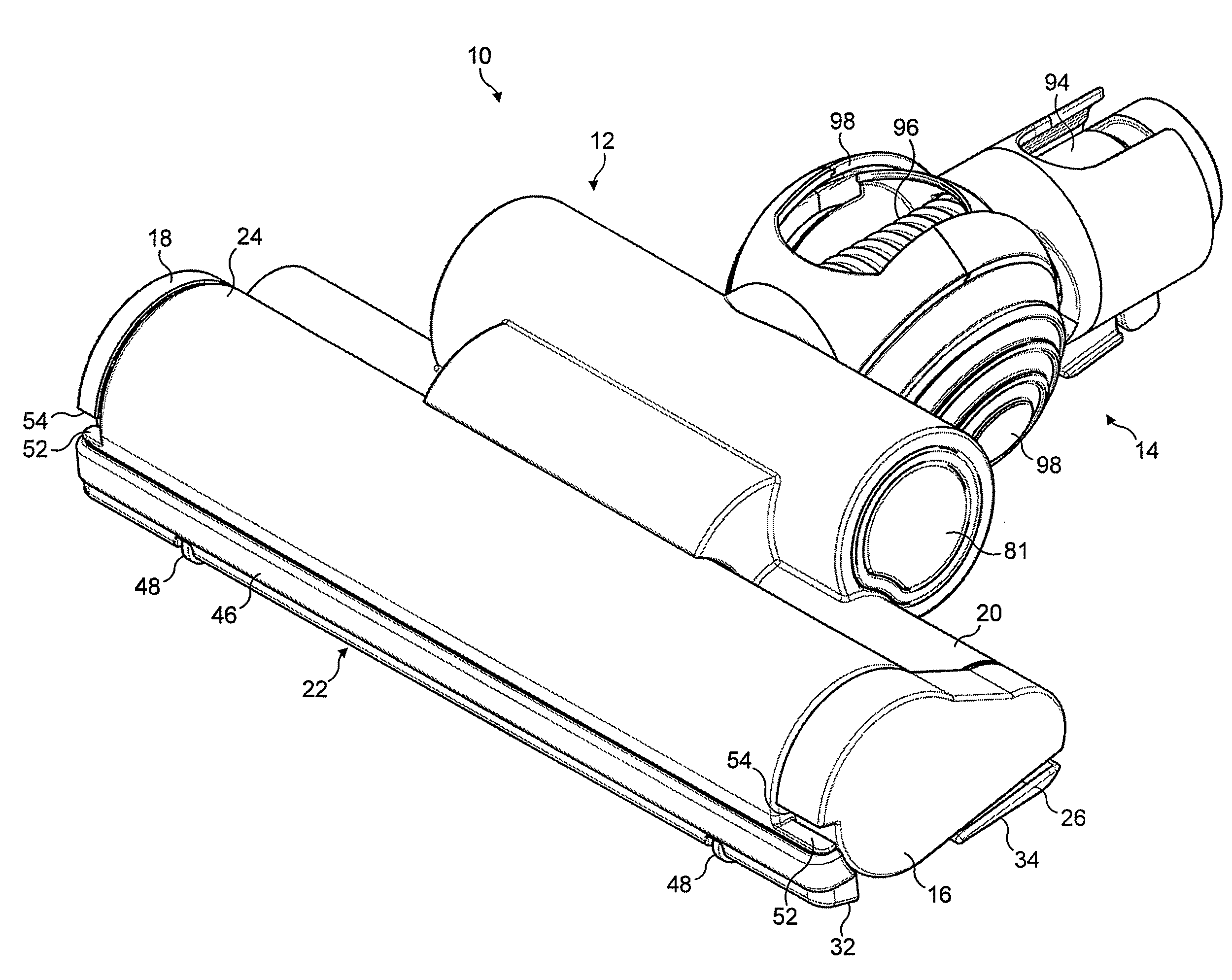

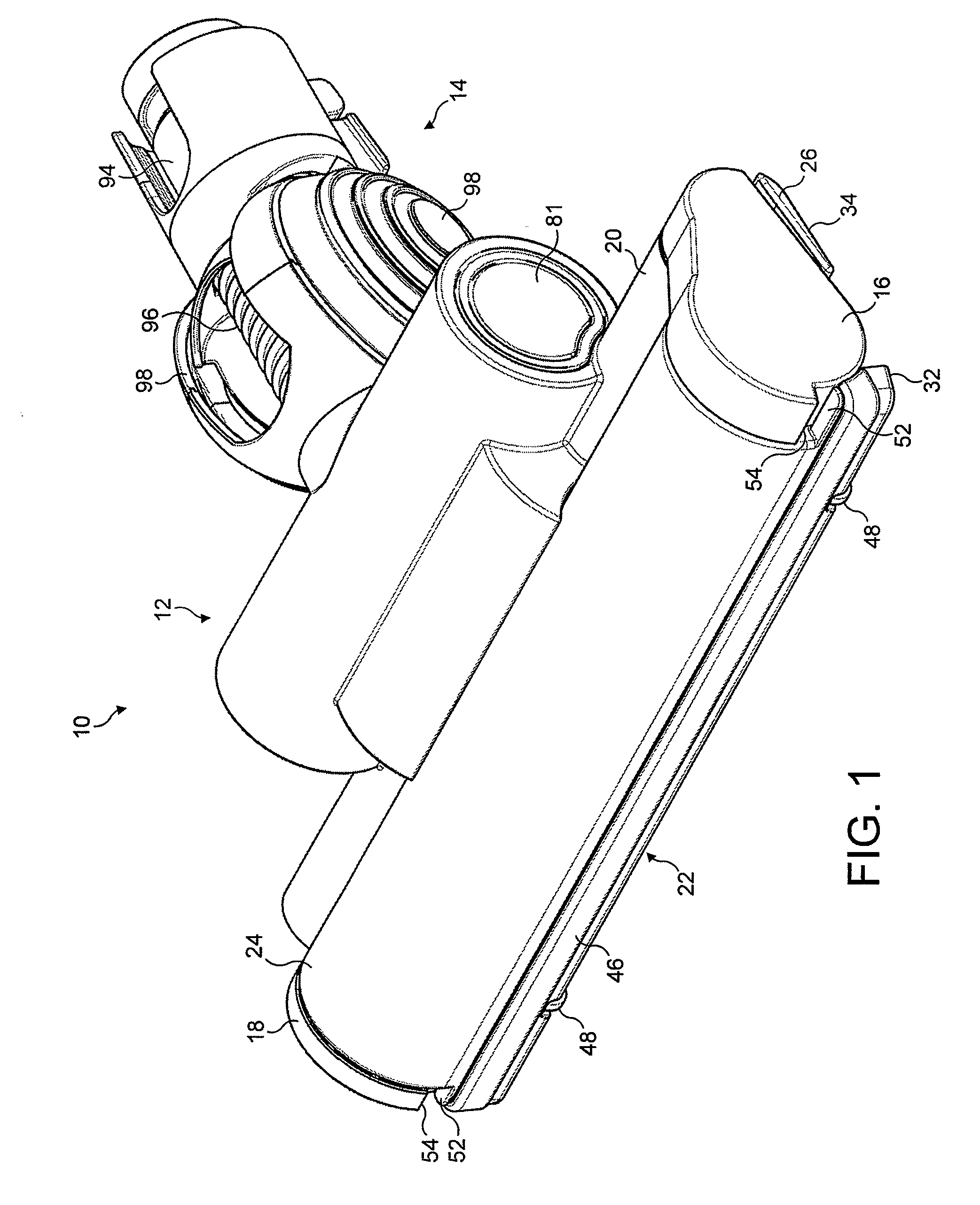

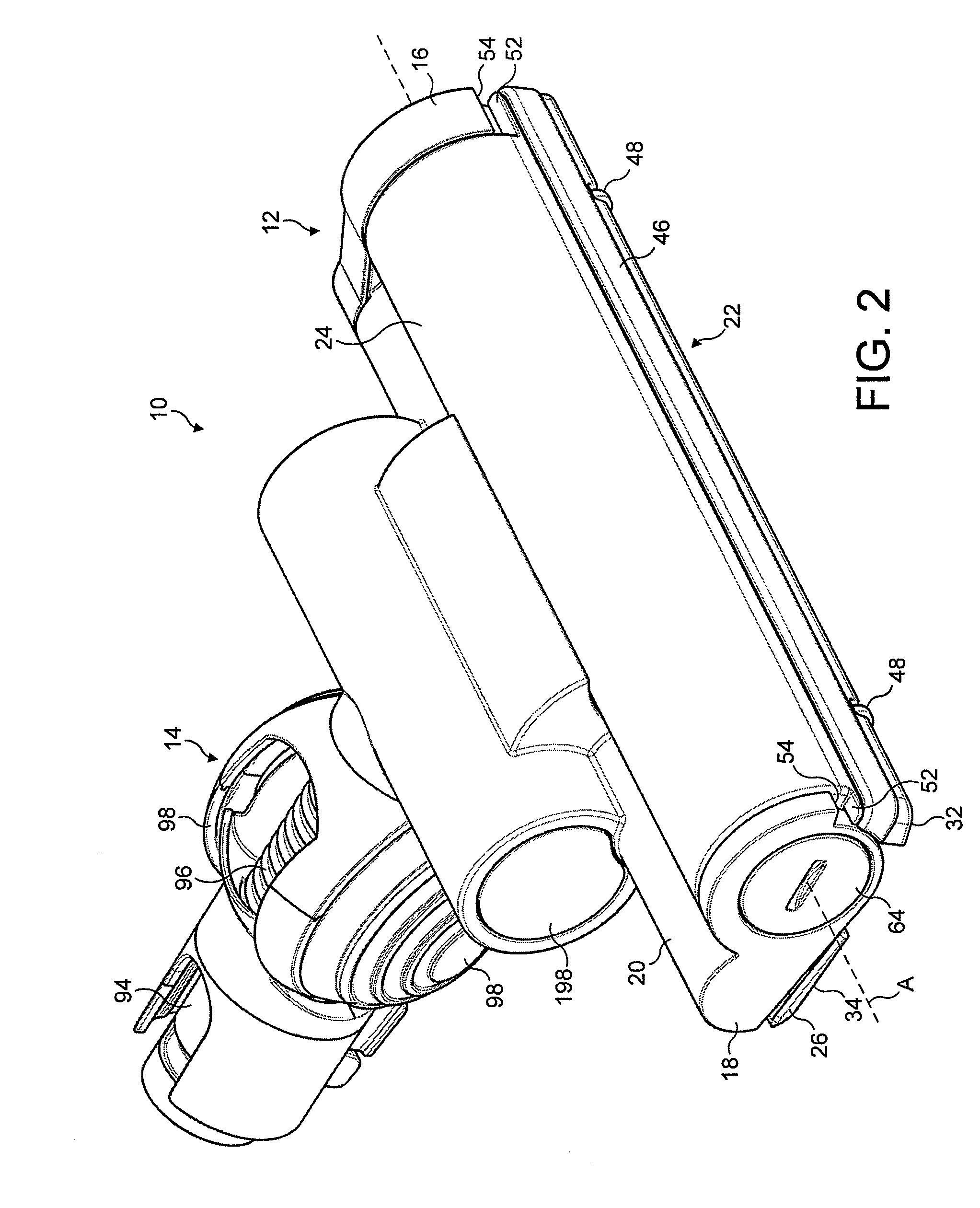

Suction unit and autonomous vacuum cleaner

ActiveUS20110239397A1Reduce disadvantagesGreat tractionMechanical suction controlSuction nozzlesInterior spaceCoupling

The invention relates to a suction unit and a vacuum cleaner. The suction unit comprises a drive system for driving the suction unit on a surface to be treated; a chassis supporting the drive system; a nozzle for removing particles from a surface to be treated, which nozzle is configured to move with relation to the chassis in a direction away from the surface to be treated, the nozzle having an interior space defining an opening that faces the surface to be treated; and an outlet communicating with the interior space, the outlet being arranged for communication with a fan unit during operating conditions. The suction unit further comprises coupling means for coupling the nozzle to the chassis, wherein the coupling means is arranged to exert a force that is directed away from the surface to be treated when the underpressure in the interior space increases. In this manner the problem of the suction unit getting stuck on the floor can be overcome or at least reduced. Furthermore, the traction of the drive system can be improved. An autonomous vacuum cleaner according to the invention comprises such a suction unit and further comprises a dust chamber, and a fan unit that communicates with the dust chamber. The fan unit communicates with the outlet for creating an underpressure in the interior space of the nozzle during operating conditions.

Owner:VERSUNI HLDG BV

Vacuum cleaning head

InactiveUS20110214252A1Conveniently providedEasy to useMechanical suction controlSuction nozzlesDifferential pressureMechanical engineering

A vacuum cleaning head includes a pressure chamber having a first chamber section and a second chamber section which is moveable relative to the first chamber section in response to a pressure differential thereacross from a first position to a second position, and a control mechanism located within the pressure chamber. The control mechanism has a first state for inhibiting the movement of the second chamber section in response to said pressure differential beyond a third position intermediate the first and second positions, and a second state for allowing the second chamber section to move in response to said pressure differential to the second position. The control mechanism is arranged to change between the first and second states in response to a movement of the second chamber section from the third position. This can allow the pressure chamber to toggle between different configurations through varying the pressure differential across the second chamber section, for example to raise or lower part of the cleaner head, or to selectively activate or deactivate an agitator.

Owner:DYSON TECH LTD

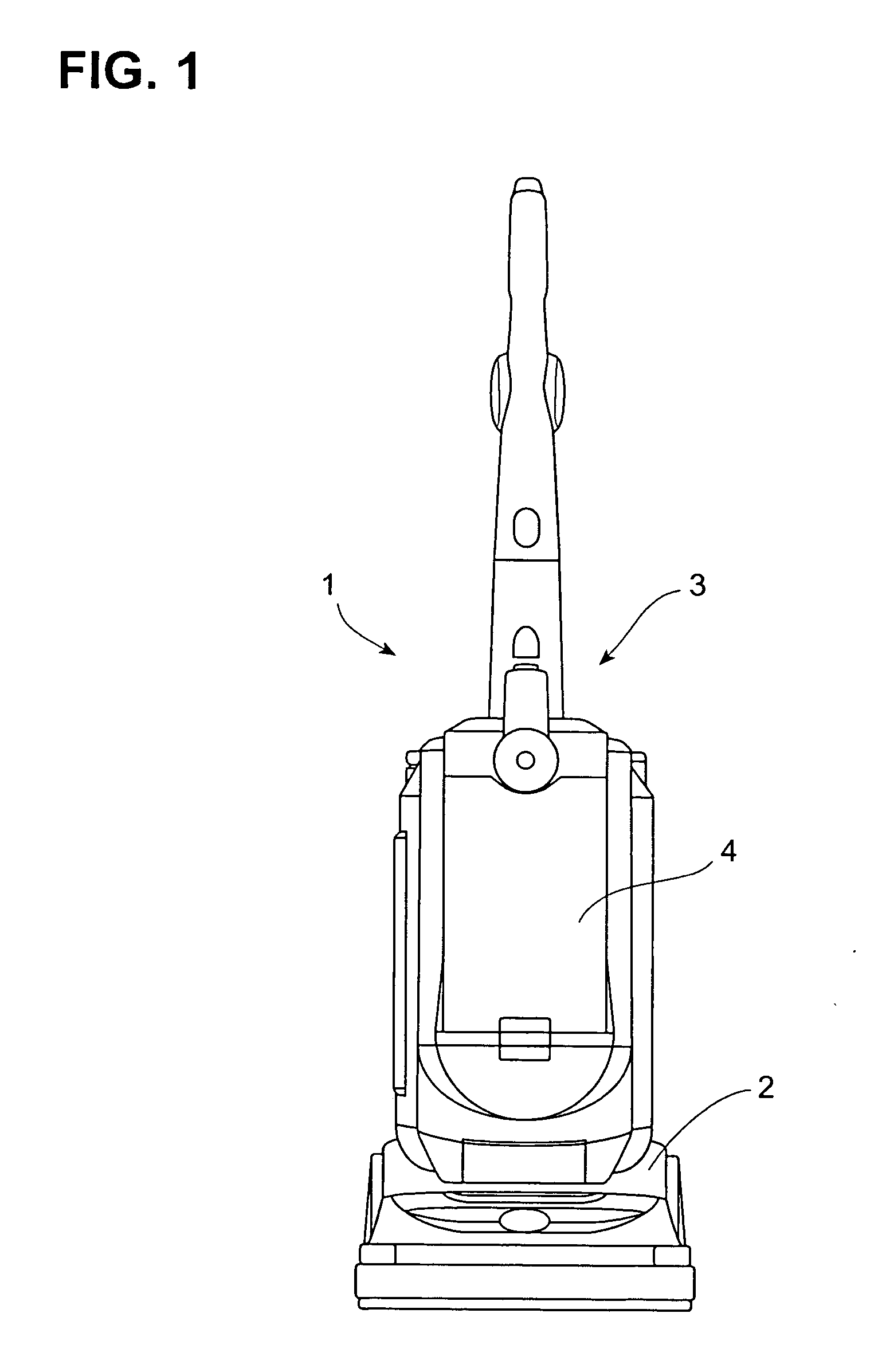

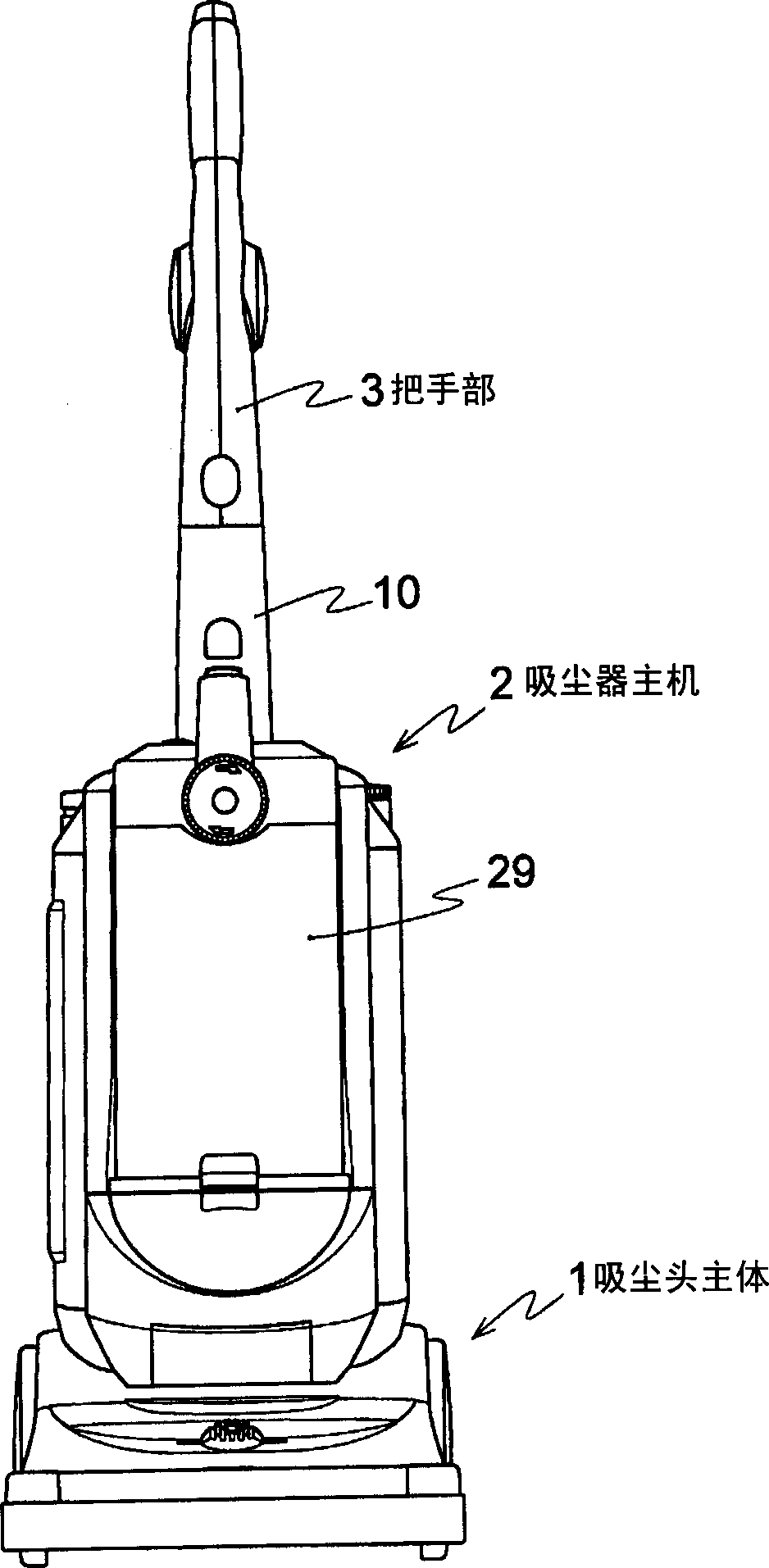

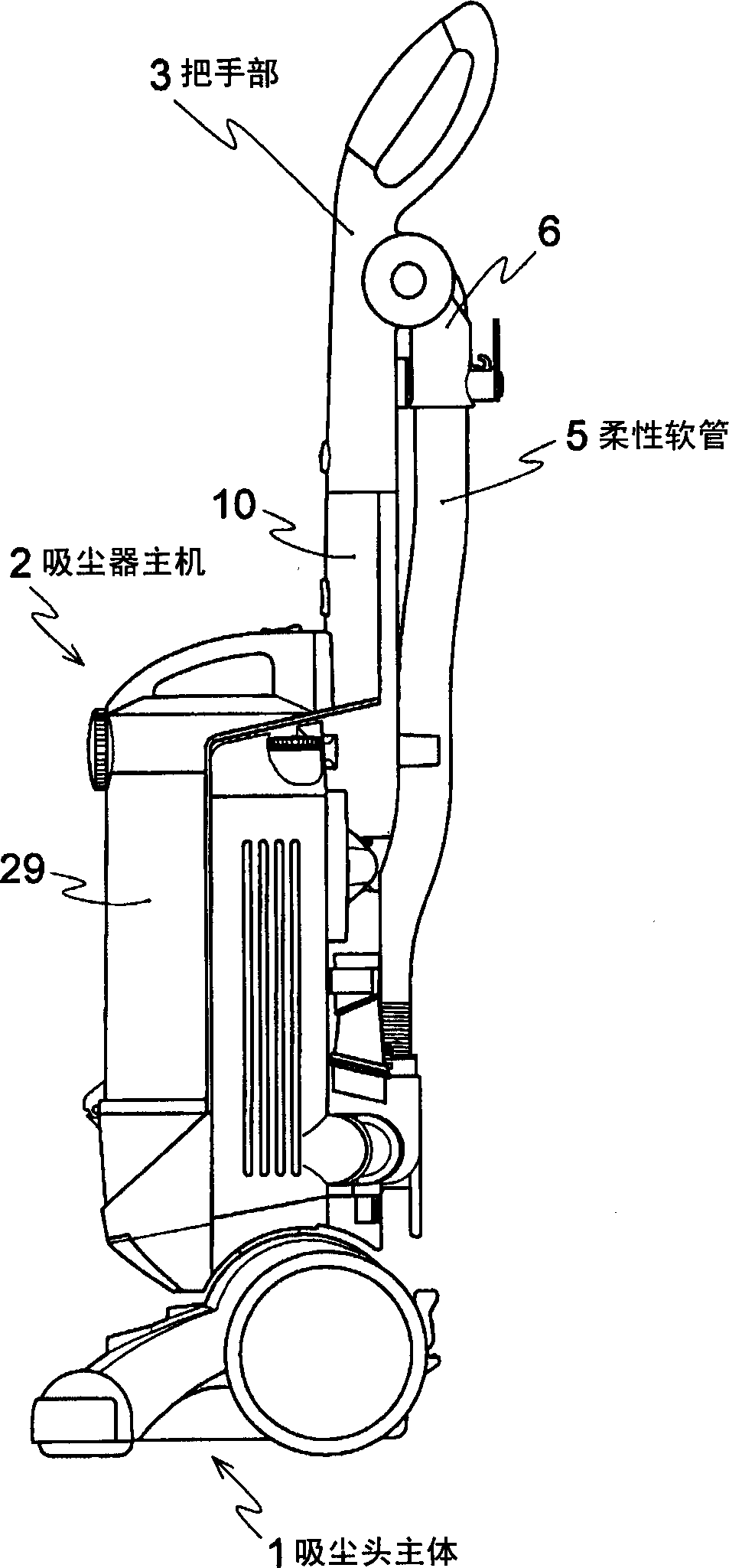

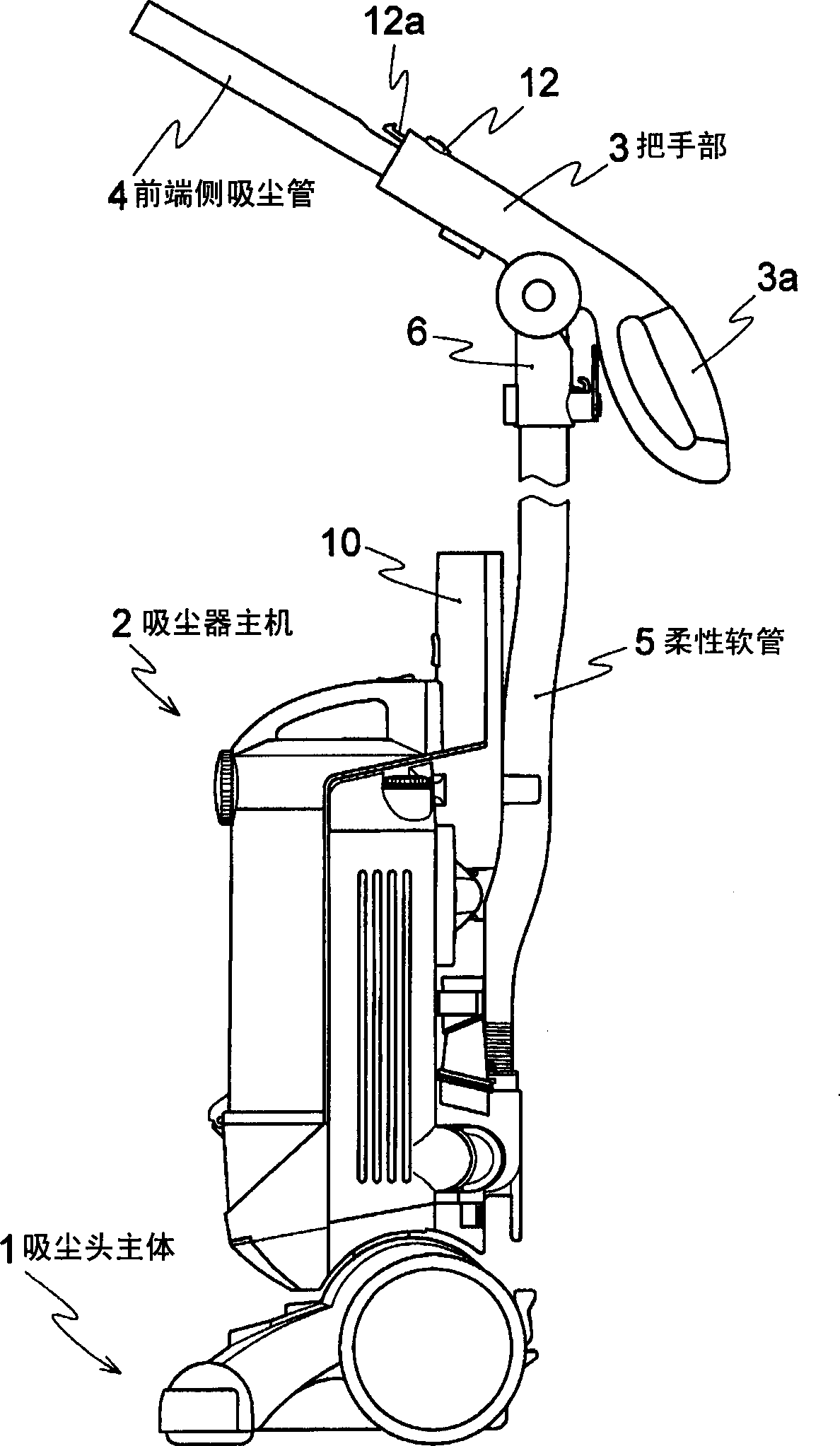

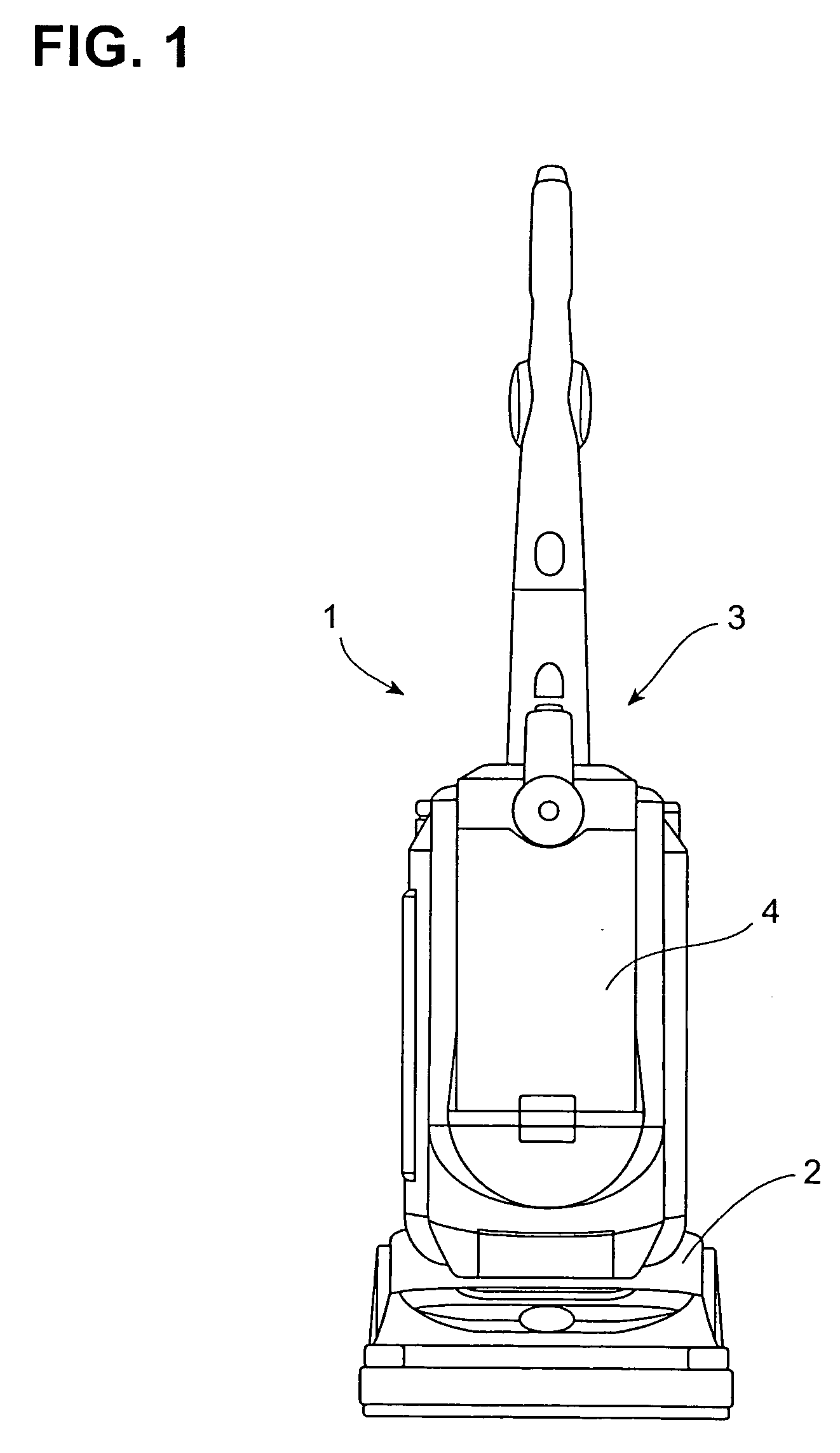

Electric vacuum cleaner

PURPOSE: To provide a vacuum cleaner of an upright type which enables both of floor cleaning and cleaning at hand, has improved suction efficiency from a suction tool body in floor cleaning and in which dust clogging is suppressed. CONSTITUTION: This vacuum cleaner is provided with the suction tool body 1 and a cleaner body 2 supported so as to freely swing on the suction tool body 1, is provided with a main body side flow passage from the suction tool body 1 to a dust collecting chamber of the cleaner body 2 and a flow passage for cleaning at hand to the dust collecting chamber, and is provided with an at-hand cleaning flow passage opening / closing means for closing the flow passage for cleaning at hand in a state of inclining the cleaner body 2 and performing floor cleaning and opening the flow passage for cleaning at hand in a state of erecting the cleaner body 2.

Owner:SANYO ELECTRIC CO LTD

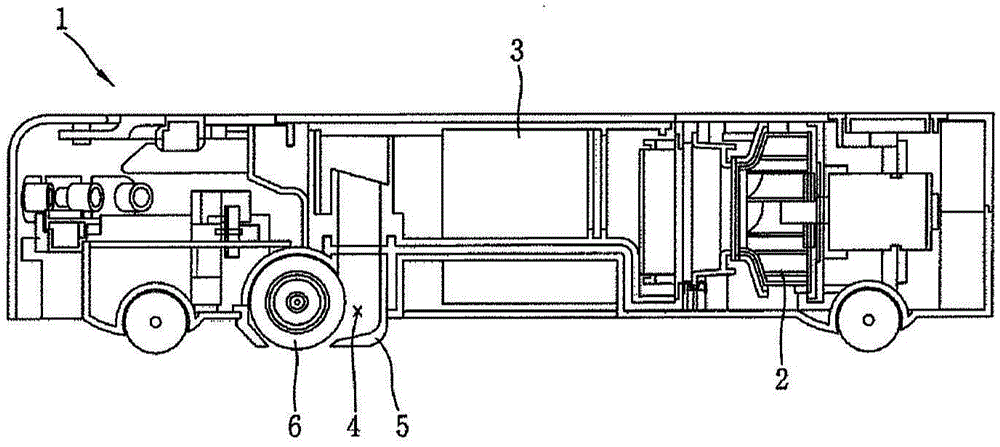

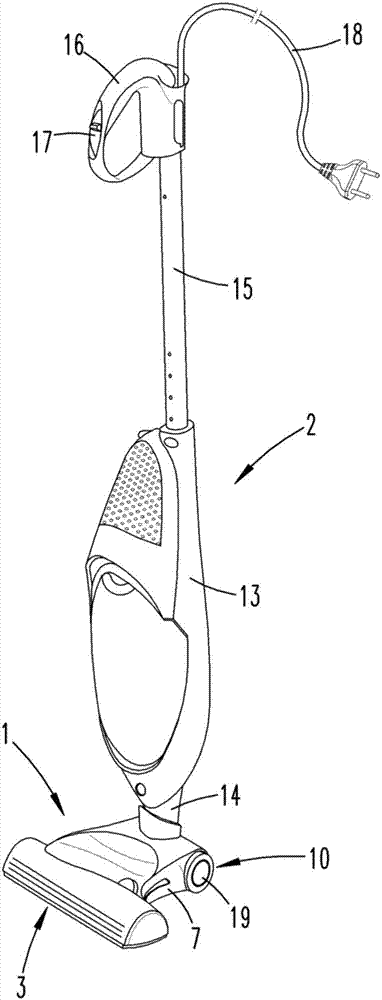

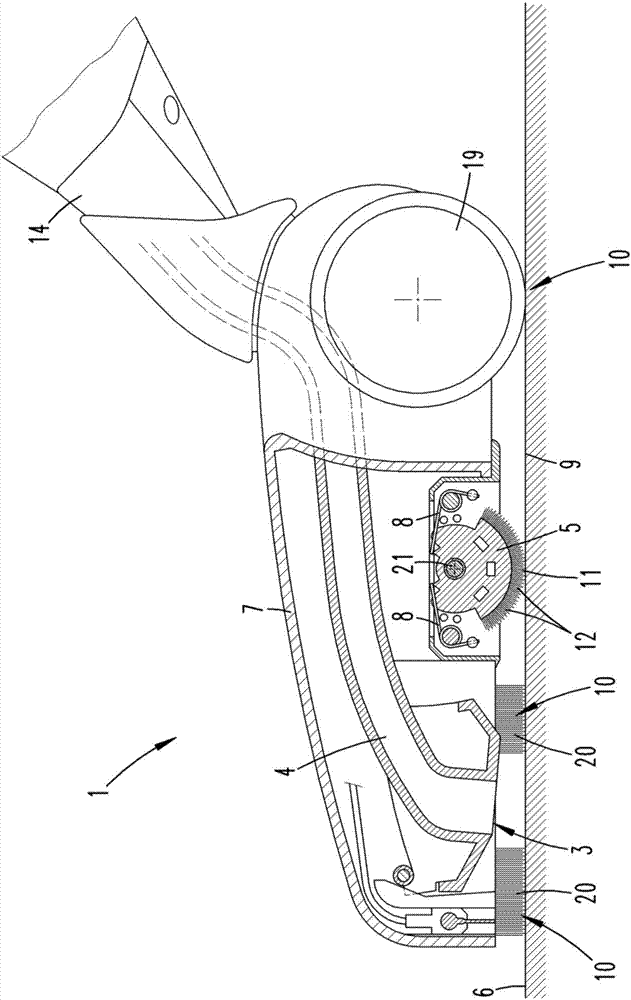

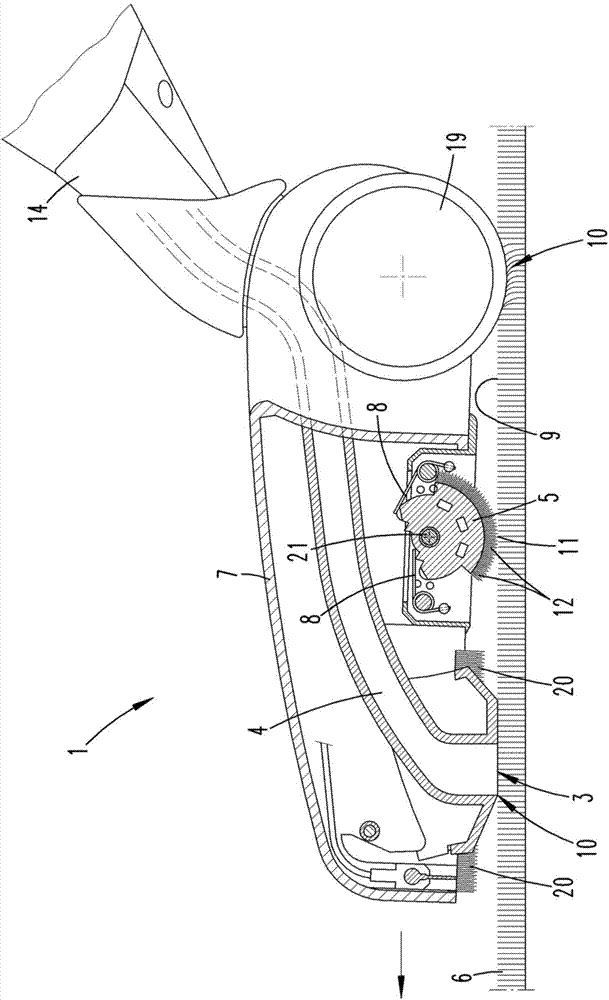

Dust collector

InactiveCN105747993ASimple and time-saving connectionPrevent inflowCleaning filter meansSuction filtersEngineeringDust collector

The invention relates to a dust collector (1), comprising a suction nozzle (2), a dust collector dust collection chamber (3) and a fan (4), wherein the suction nozzle (2) is connected with the fan (4) through a suction channel (5) during suction operation of the dust collector (1), so that sucked articles are conveyed to the dust collector dust collection chamber (3), the dust collector (1) is connected with a base station (6) for clean operation, so that the sucked articles contained in the dust collector dust collection chamber (3) are conveyed into a base station dust collection chamber (7) of the base station (6) via the fan (4) of the dust collector (1). In order to improve the dust collector, it is suggested that the dust collector (1) has a cleaning air channel (8) constructed independent of the suction channel (5) and used for connecting the fan (4) and the dust collector dust collection chamber (3) in the form of fluid technology, and a multichannel interface (9) configured for the cleaning air channel (8) and the suction channel (5), and the dust collector has a first connector (10) which connects the base station dust collection chamber (7) with the suction channel (5) and a second connector (11) which connects the base station dust collection chamber (7) with the cleaning air channel (8). The invention also relates to a system consisting of the base station (6) and the dust collector (1).

Owner:VORWERK & CO INTERHOLDING GMBH

Vacuum

The present invention is directed to a vacuum including a dust extraction system. The system includes a filter assembly, an airflow generation assembly, and valve assembly. The airflow generation assembly is configured to draw contaminated air toward the filter assembly and exhaust filtered air as a discharge stream. The filter assembly is configured to remove contaminants from the contaminated airflow by capturing particulate material suspended within the airflow. The valve assembly is configured to selectively direct filtered airflow into the filter assembly such that the filtered air stream cleans the filter.

Owner:BLACK & DECKER INC

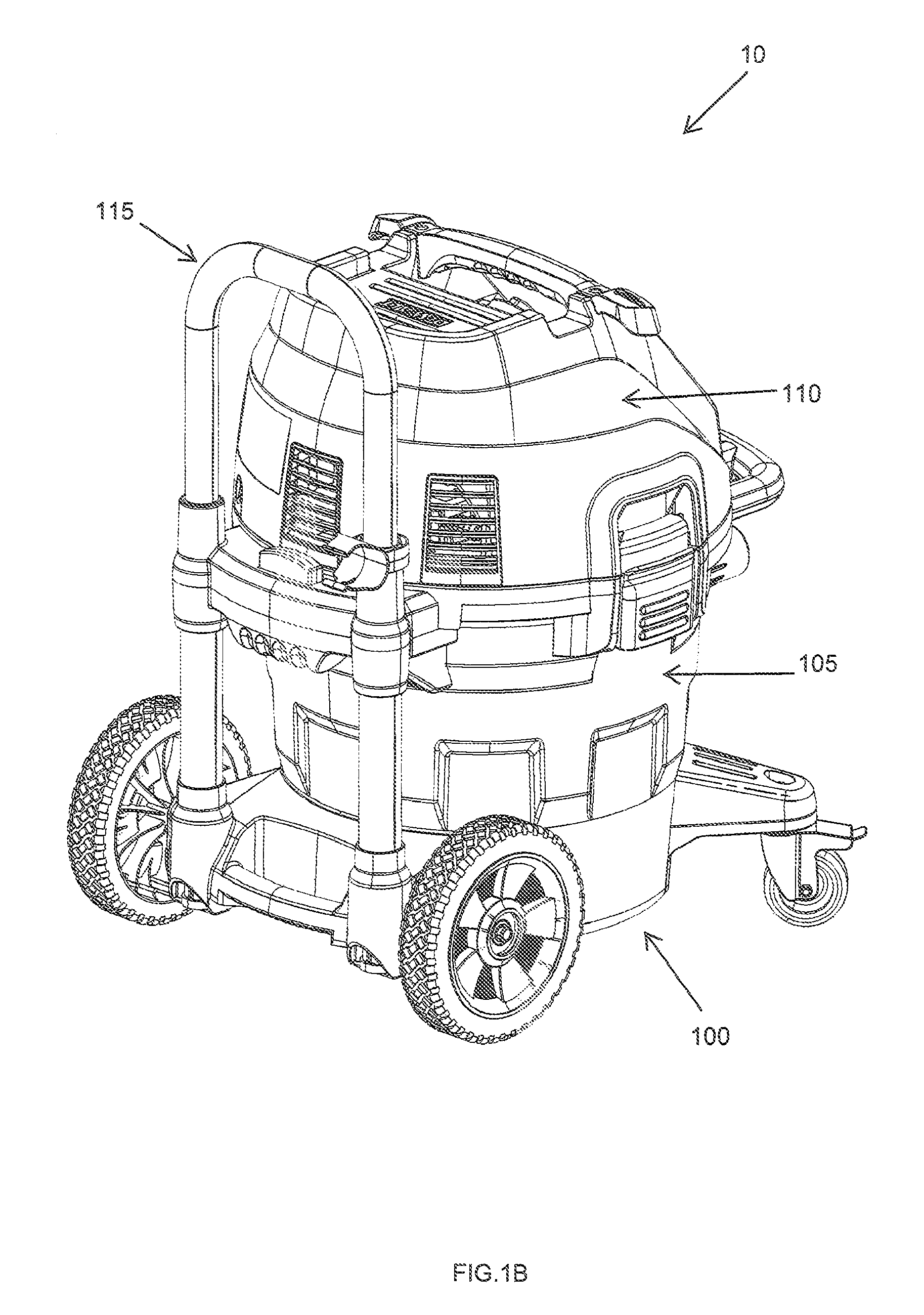

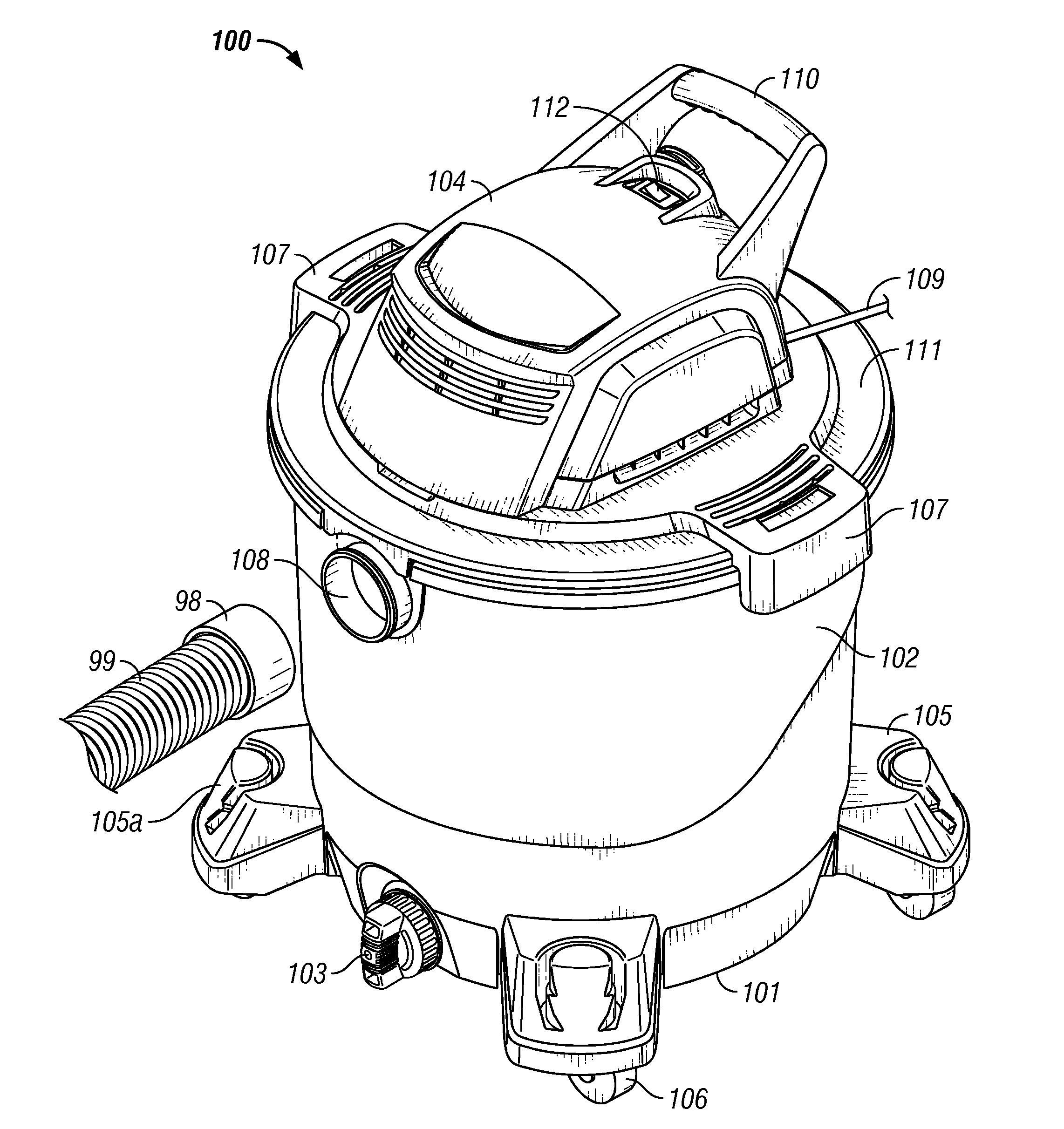

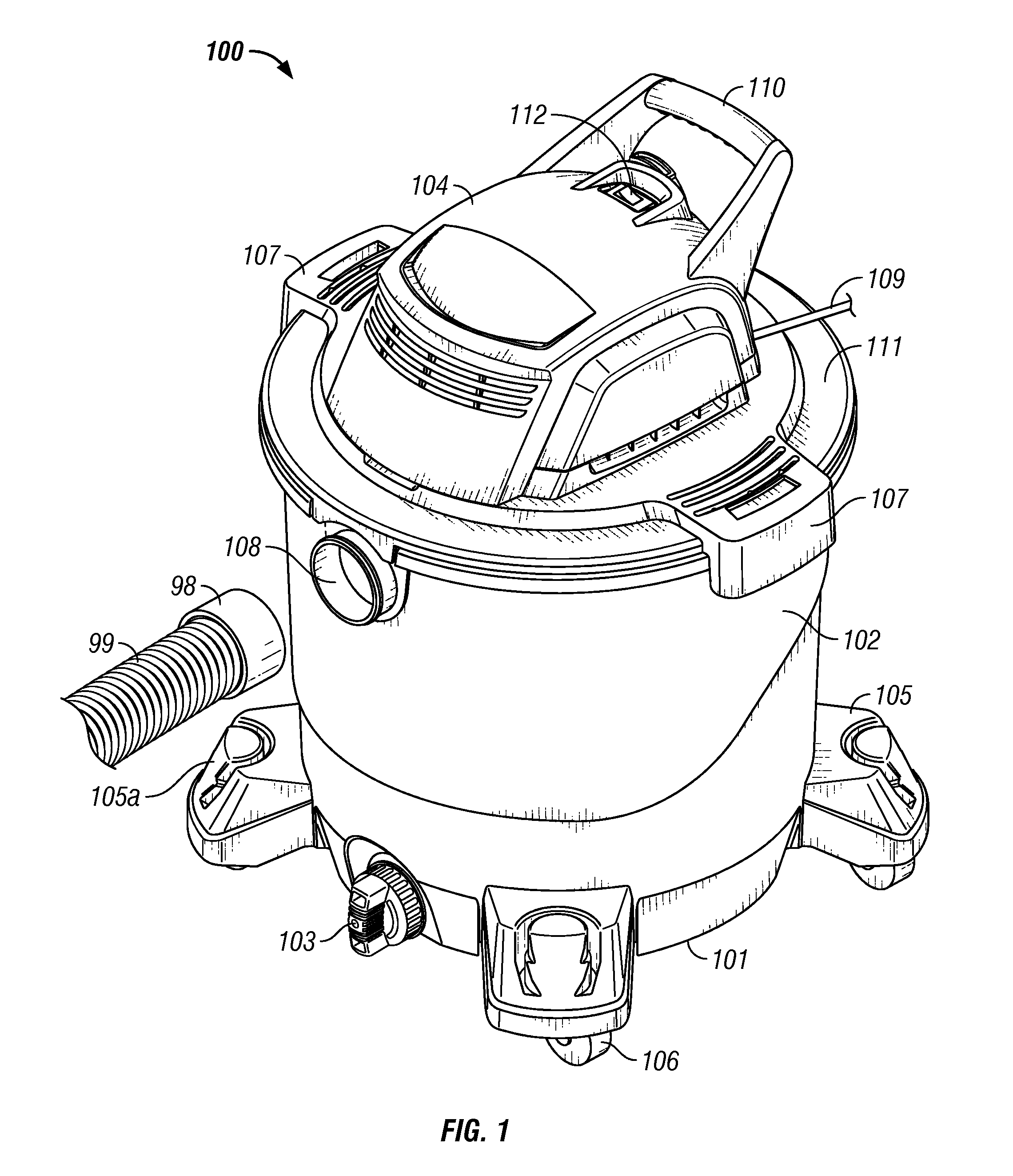

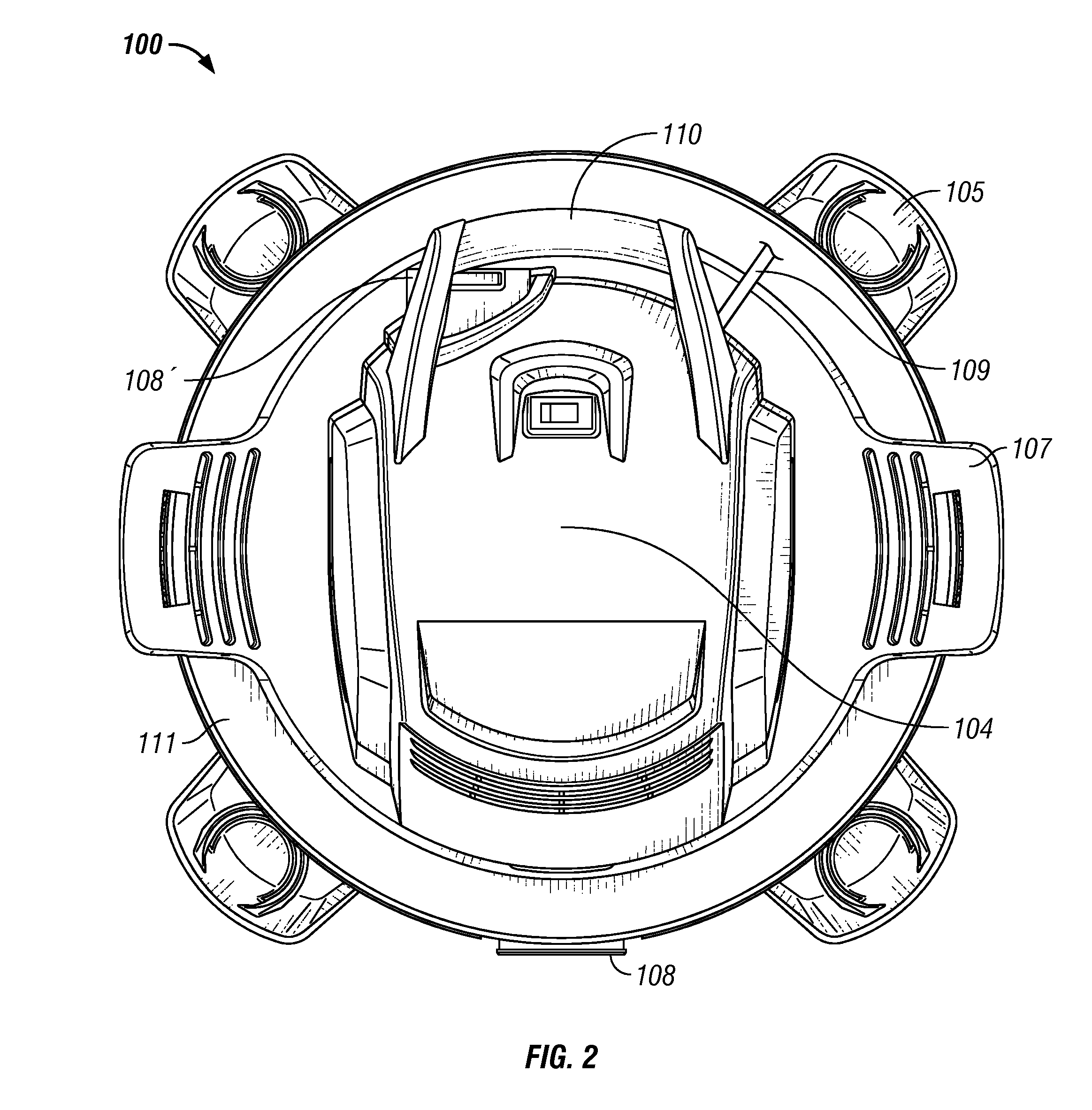

Vacuum Bypass Vent and Vacuums Incorporating Such Bypass Vents

A vacuum appliance capable of picking up both wet and dry material is described, wherein the vacuum appliance includes an impeller configured to induce liquid into the vacuum appliance, a motor configured to turn the impeller, a restrictor assembly to prevent the liquid from being ingested into the motor, and a bypass vent assembly configured to allow sufficient air to reach the motor in order to keep the motor cool while the restrictor is preventing the liquid from being ingested into the motor. The vacuum appliance also includes a drum configured to retain the liquid and an impeller intake between the impeller and the drum. The restrictor may comprise a float configured to rise with a level of the liquid in the drum and prevent the liquid from entering the impeller intake. The bypass vent assembly may be configured to allow airflow to bypass the restrictor and / or the drum.

Owner:EMERSON ELECTRIC CO

Airflow indicator

An airflow indicator for a vacuum cleaner is provided. The airflow indicator comprises a housing mounted to a casing of the vacuum cleaner. A piston chamber is defined within the housing. A piston is received in the piston chamber and is movable therein between a first position and a second position. A first port is formed in the housing and communicates with the piston chamber. The first port is open to ambient. A second port is formed in the housing and communicates with the piston chamber. The second port is spaced from the first port and is open to the filter chamber of the vacuum cleaner. A valve is mounted to the housing for obstructing air passage into the piston chamber. The valve includes a diaphragm having a slit that opens in response to a predetermined pressure differential between the first port and the second port.

Owner:ROYAL APPLIANCE MFG

Double suction type sterilizing vacuum cleaner

ActiveUS8424156B2Reduce pressureFacilitated releaseCleaning filter meansSuction filtersEngineeringHIT device

A double suction type sterilizing vacuum cleaner includes a base seat and an upper cover mounted on an upper side of the base seat. A main suction port is provided in the base seat. A hitting device is mounted on the base seat and adapted to hit a cleaning object under the base seat. A sterilizing lamp is mounted in the base seat for sterilizing purposes. A dust collecting box is detachably mounted to the upper cover and defines an air channel in communication with the main suction port. A secondary suction port is provided in the dust collecting box and in communication with the air channel. When the main suction port is blocked, an ambient air can be supplied to the air channel through the secondary suction port, facilitating the release of the blocking situation in the main suction port.

Owner:YEJEN APPLIANCES SHENZHEN

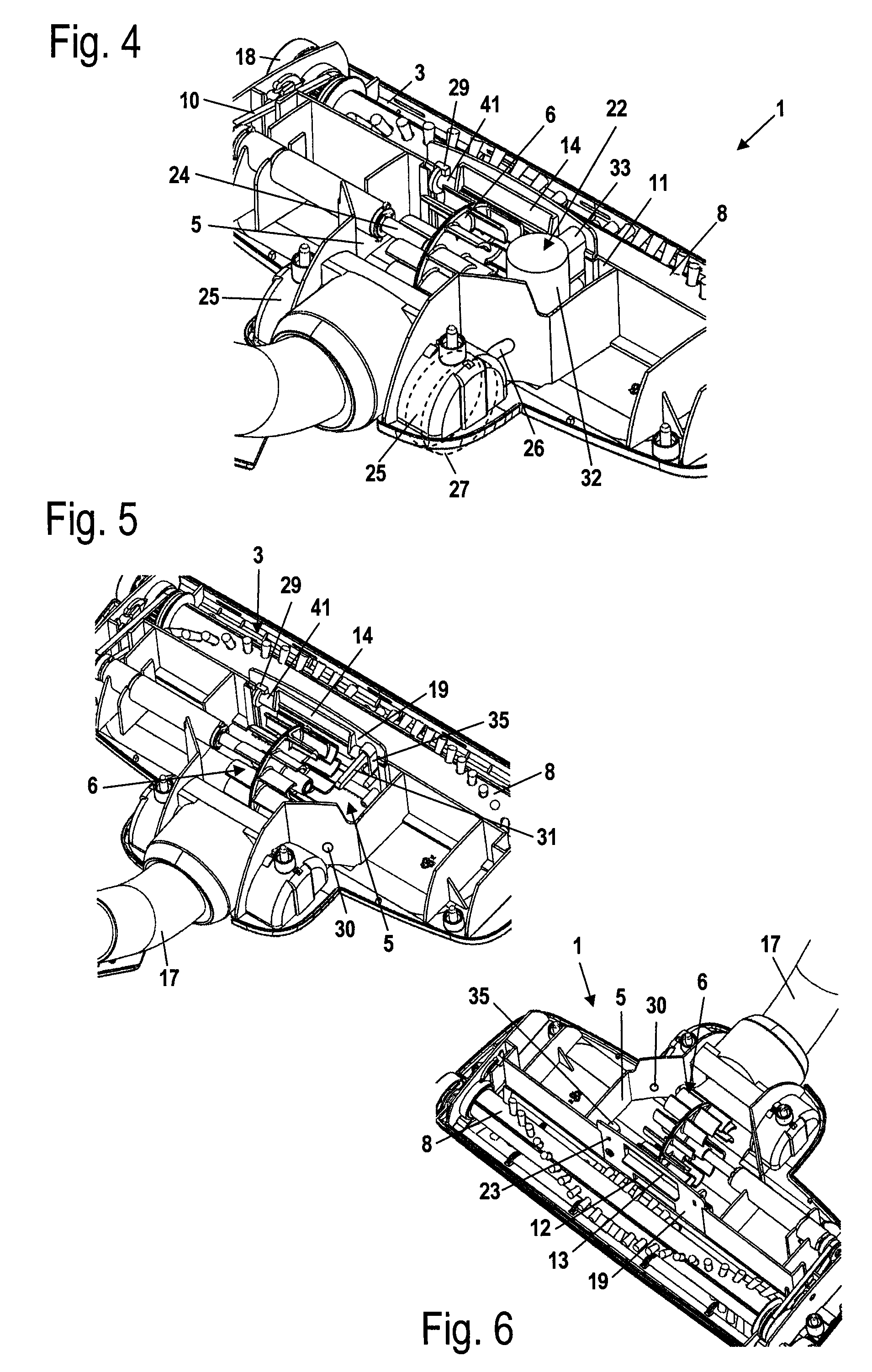

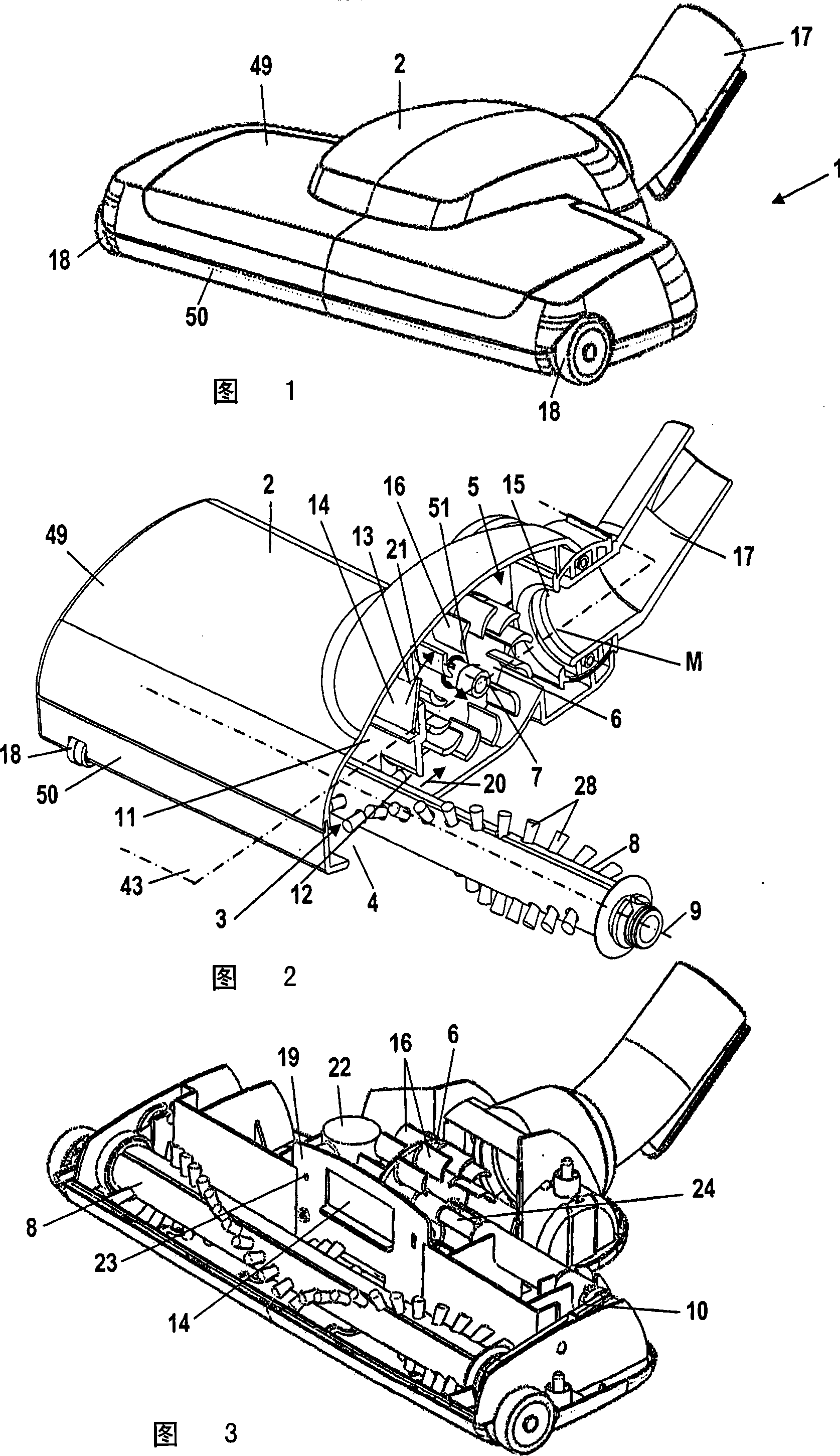

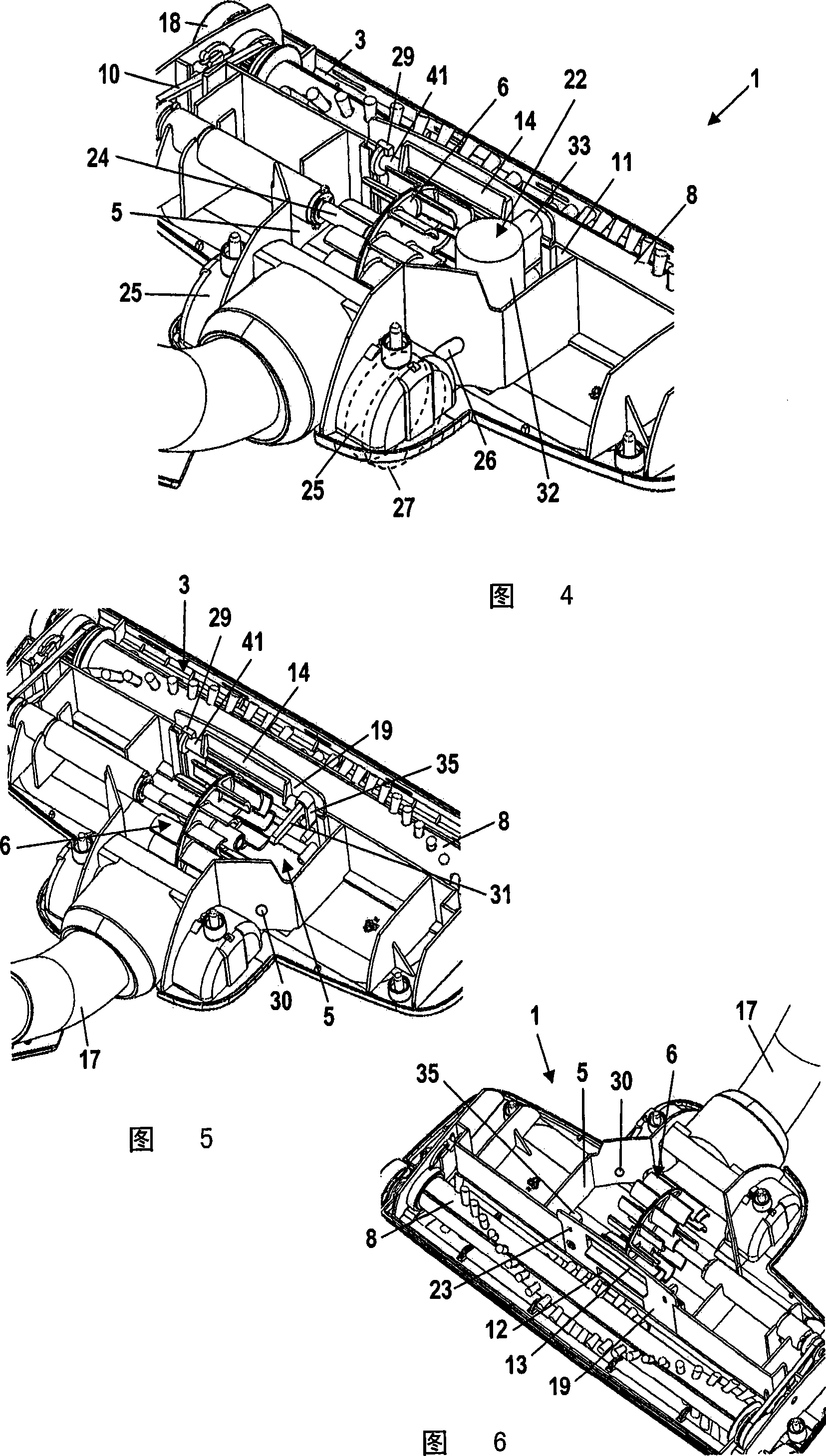

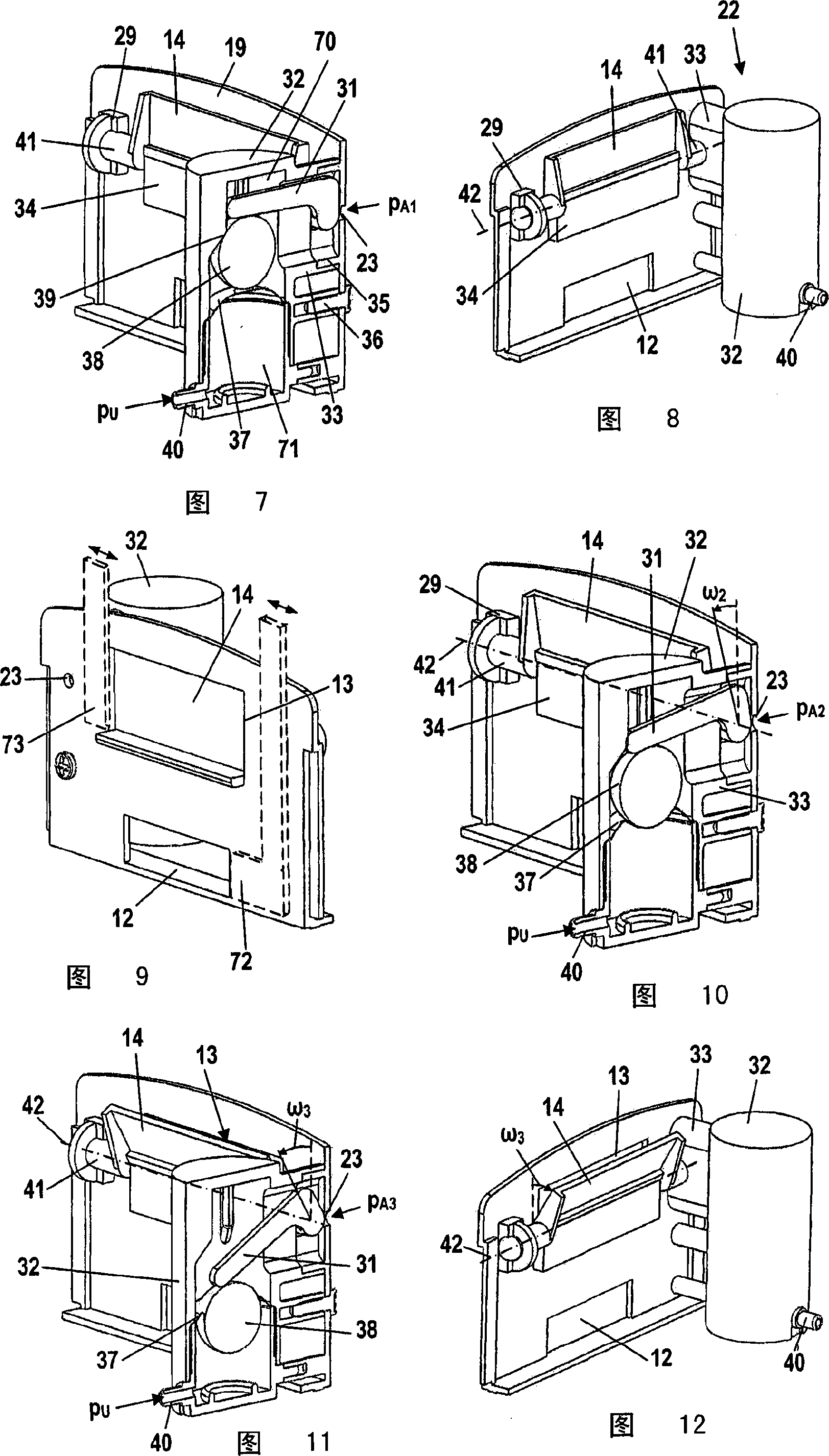

Vacuum cleaning tool and method for its operation

InactiveUS7941893B2Easy to adjustEasy to cleanSuction filtersMechanical suction controlTurbineWaste management

A vacuum cleaning tool has a housing having a connecting socket for effecting flow communication to a vacuum device of a vacuum cleaning device. The housing has a suction opening through which a working air flow enters the housing. The housing has an outlet opening through which the working air flow exits from the housing. A cleaning tool is rotatably supported in the housing. An air turbine is rotatably supported in a turbine chamber of the housing and drives the cleaning tool in rotation. A control device controls the drive power for driving the cleaning tool based on a pressure existing in the vacuum cleaning tool.

Owner:DUPRO AG

Intake nozzle and vacuum cleaner having the same

InactiveUS20060021188A1Improve throughputMechanical suction controlSuction nozzlesVacuum cleanerNozzle

An intake nozzle and vacuum cleaner having the same are disclosed, by which an air intake force can be adjusted. The present invention includes a nozzle case, a first air intake port provided to a bottom of the nozzle case to suck an air including dust by an air intake force generated from driving an air intake device, and an intake force adjusting device varying an intake force of the first intake port.

Owner:LG ELECTRONICS INC

Vacuum cleaning tool and method for its operation

InactiveCN101133931AAdjustable maximum flow cross-sectionSimple structureMechanical suction controlSuction nozzlesEngineeringAirflow

The suction cleaner has a housing (2) with a connecting piece (17) for connection to a suction device of the suction cleaning device. The suction cleaner has a suction hole (4) through which the working airflow flows into the housing (2); and a discharge hole (15) through which the working airflow leaves the housing (2) . The suction cleaner has a cleaner which is rotatably supported in the casing (2) and has a drive device for driving the cleaner to rotate. Good cleaning results and up to turbine power Good fit to different floor conditions. The method for operating the suction cleaner provides that the drive power of the cleaner is controlled as a function of the pressure (p) in the suction cleaner.

Owner:DUPRO AG

Vacuum cleaner nozzle including mechanical beater and sonic beater

ActiveUS20050278891A1Easy to cleanClean thoroughlyMechanical suction controlSuction nozzlesSpray nozzleEngineering

A vacuum cleaner nozzle including a nozzle head, the nozzle head including at least one mechanical beater and at least one sonic beater, the at least one sonic beater including a beater portion and an ultrasonic actuating member that vibrates the beater portion.

Owner:ZENITH TECH

Vacuum

The present invention is directed to a vacuum including a dust extraction system. The system includes a filter assembly, an airflow generation assembly, and valve assembly. The airflow generation assembly is configured to draw contaminated air toward the filter assembly and exhaust filtered air as a discharge stream. The filter assembly is configured to remove contaminants from the contaminated airflow by capturing particulate material suspended within the airflow. The valve assembly is configured to selectively direct filtered airflow into the filter assembly such that the filtered air stream cleans the filter.

Owner:BLACK & DECKER INC

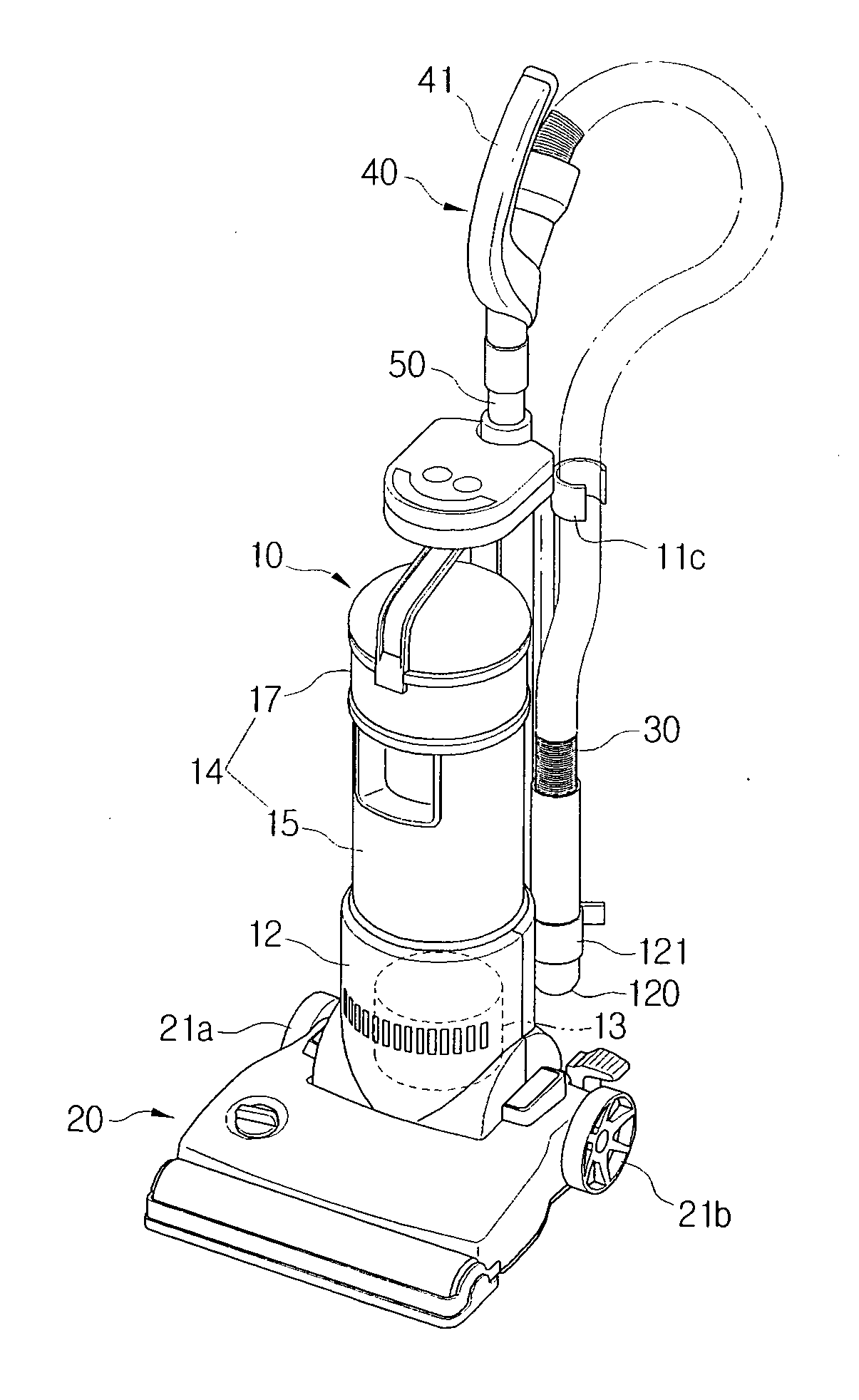

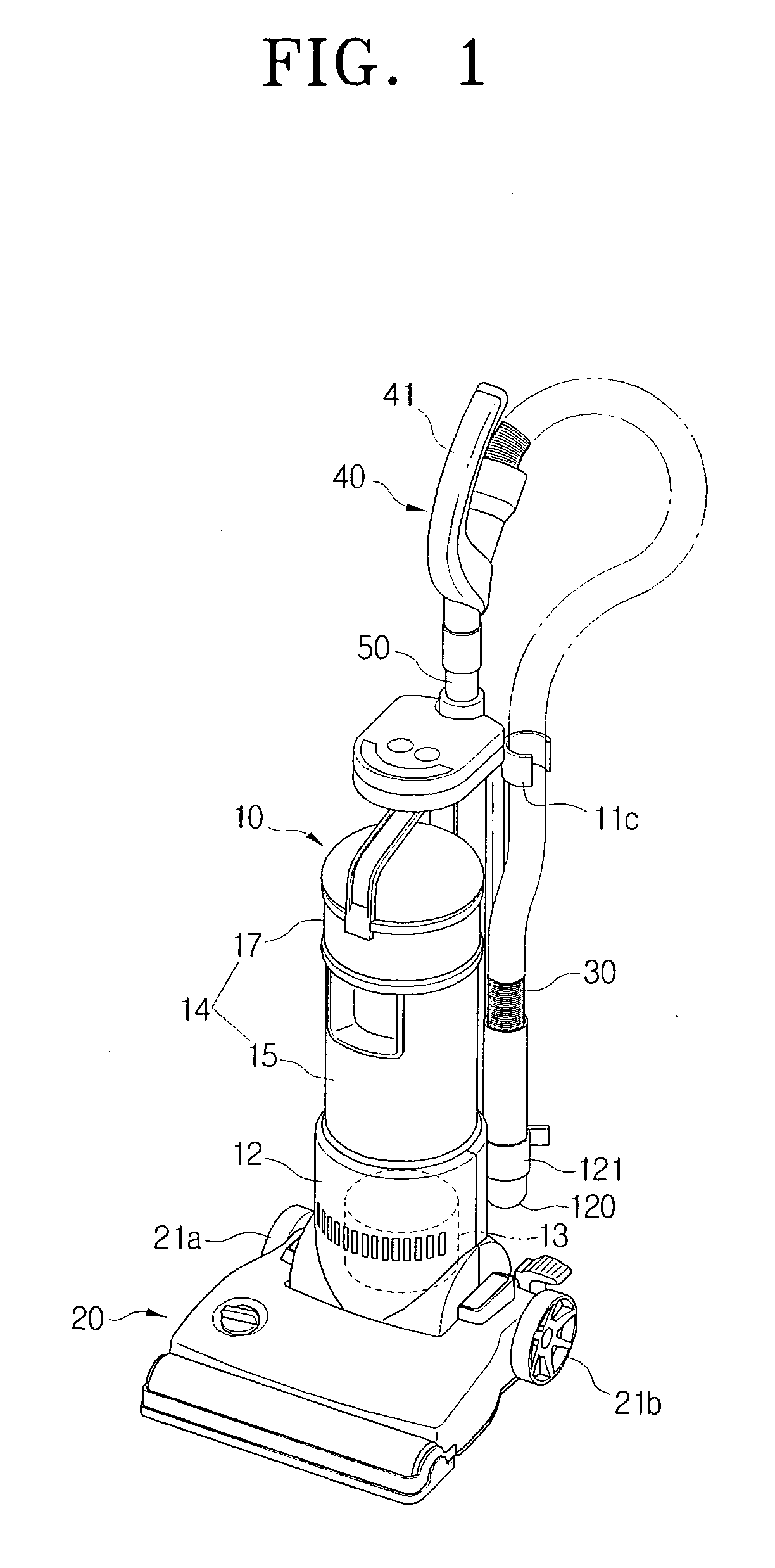

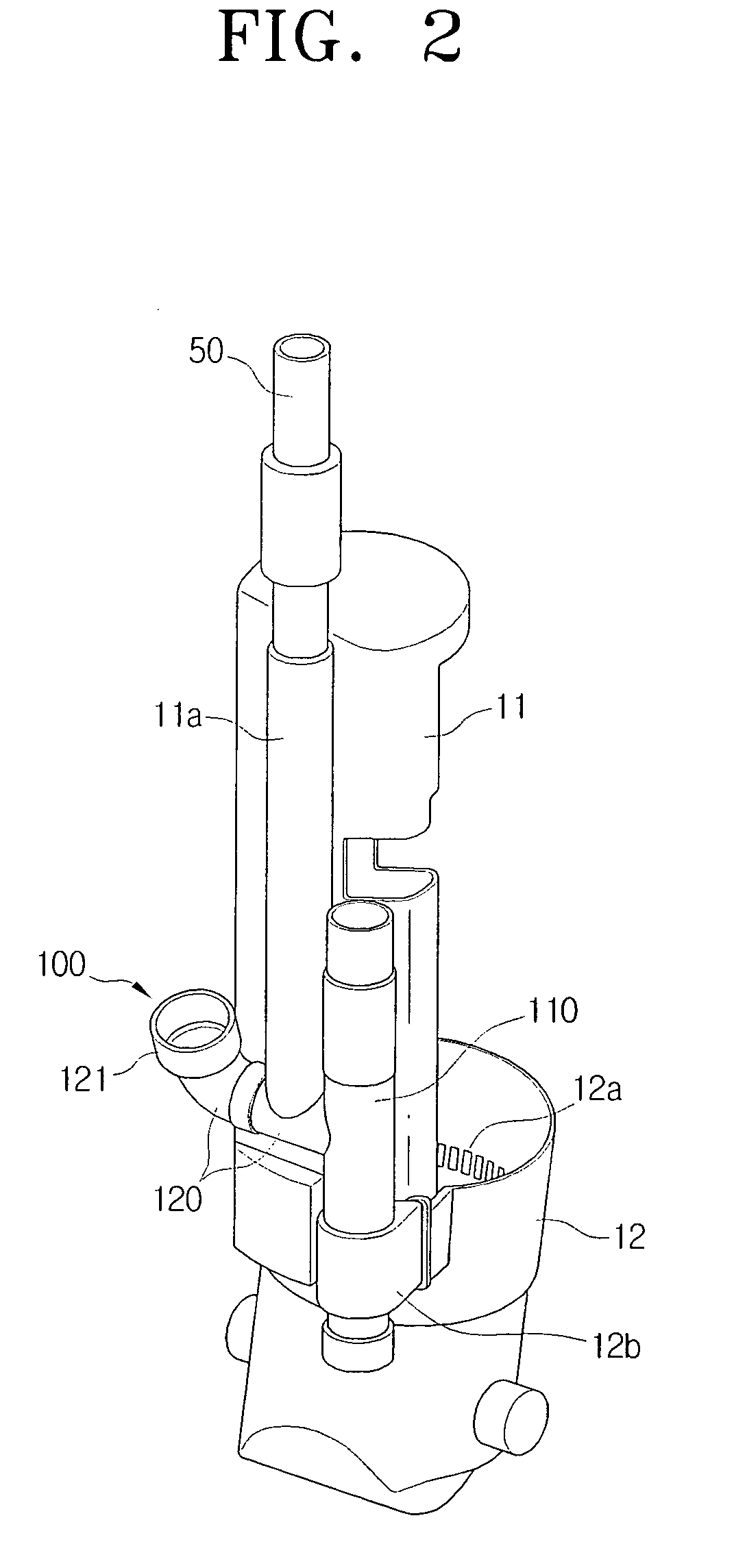

Upright vacuum cleaner having suction path diverting valve

An upright vacuum cleaner is provided that includes a cleaner body having a suction motor, a dust-collecting unit, and a body frame where the suction motor and the dust-collecting unit are disposed, a suction inlet body which is hinged to a lower end of the body frame, a hose which has one side fluidly communicating with the body frame and the other side fluidly communicating with an extension pipe through a manipulation handle, and a suction path diverting valve which is disposed on the body frame and has a valve member elastically arranged on a suction path. As the extension pipe is inserted into or withdrawn from a socket on the body frame, the valve member selectively diverts the suction path to a first suction path flowing from the suction inlet body to the dust-collecting unit or a second suction path flowing from the extension pipe to the dust-collecting unit.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Suction nozzle for a vacuum cleaning device

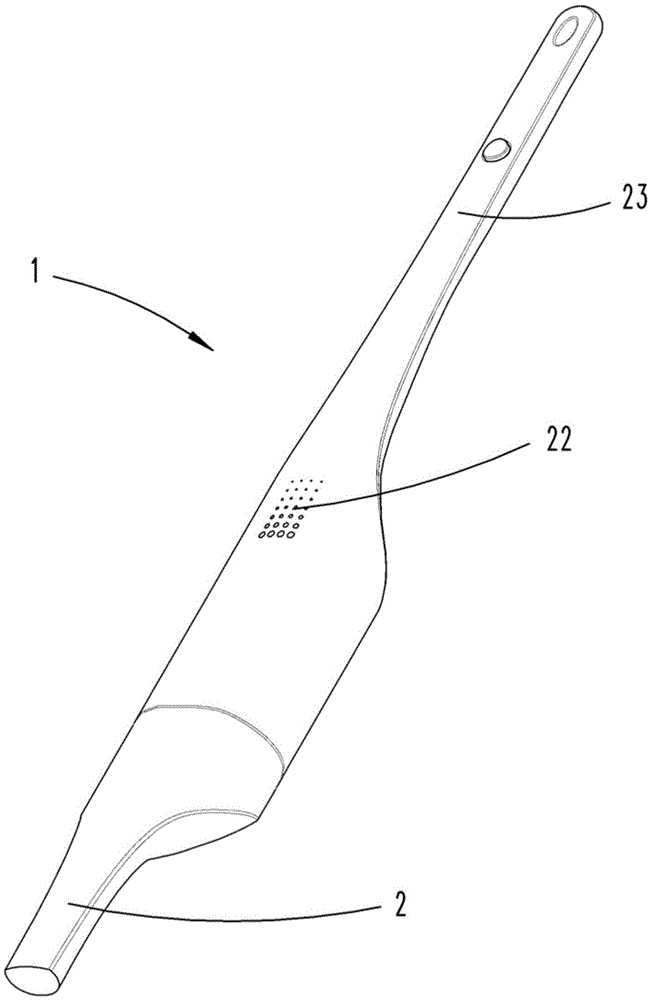

ActiveCN107397502AAdequate exerciseTravel ConfirmationMechanical suction controlSuction nozzlesEngineeringGround level

The invention relates to a suction nozzle (1) for a vacuum cleaning device (2). The suction nozzle (1) has a suction mouth (3) and a suction channel (4) for connecting the suction mouth (3) to a blower of the vacuum cleaning device (2), wherein the suction nozzle (1) comprises a sensor (5), which is movably mounted on a housing (7) of the suction nozzle (1) and is used for detecting the nature of a surface (6) to be cleaned. The suction channel (4) moves relative to surface (6) depending on the detection result of the sensor (5), in particular from a hard bottom position to a carpet position or vice versa. In order to improve the detection result of the sensor (5), it is proposed that the sensor (5), which is in a normal operation state in the suction nozzle, has permanent contact with the surface (6) regardless of the type of surface (6) and moves on the basis of a frictional force between the surface (6) and the sensor (5).

Owner:VORWERK & CO INTERHOLDING GMBH

Vacuum hose handling and safety vacuum release system

ActiveUS9702101B1ConvenientlyEasily materialMechanical machines/dredgersMechanical suction controlEngineeringVacuum tube

A vacuum hose handling and safety vacuum release system, a tubular column attachable to an industrial vacuum hose end having a long handle and a short T-handle positioned at right angles to each other that will allow a user to strategically place the metallic vacuum tube conveniently and easily to vacuum debris in a safe manner. The tube has at least one bypass orifice that the user can open to reduce or eliminate the suction at the nozzle via a lever pivotally located adjacent the T-handle.

Owner:FICKS DAVID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com