Suction port assembly and a vacuum cleaner having the same

A technology for vacuum cleaners and suction ports, which is applied in the direction of vacuum cleaners, mechanical devices for controlling suction, and suction nozzles, and can solve problems such as not being very effective and impossible to determine dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

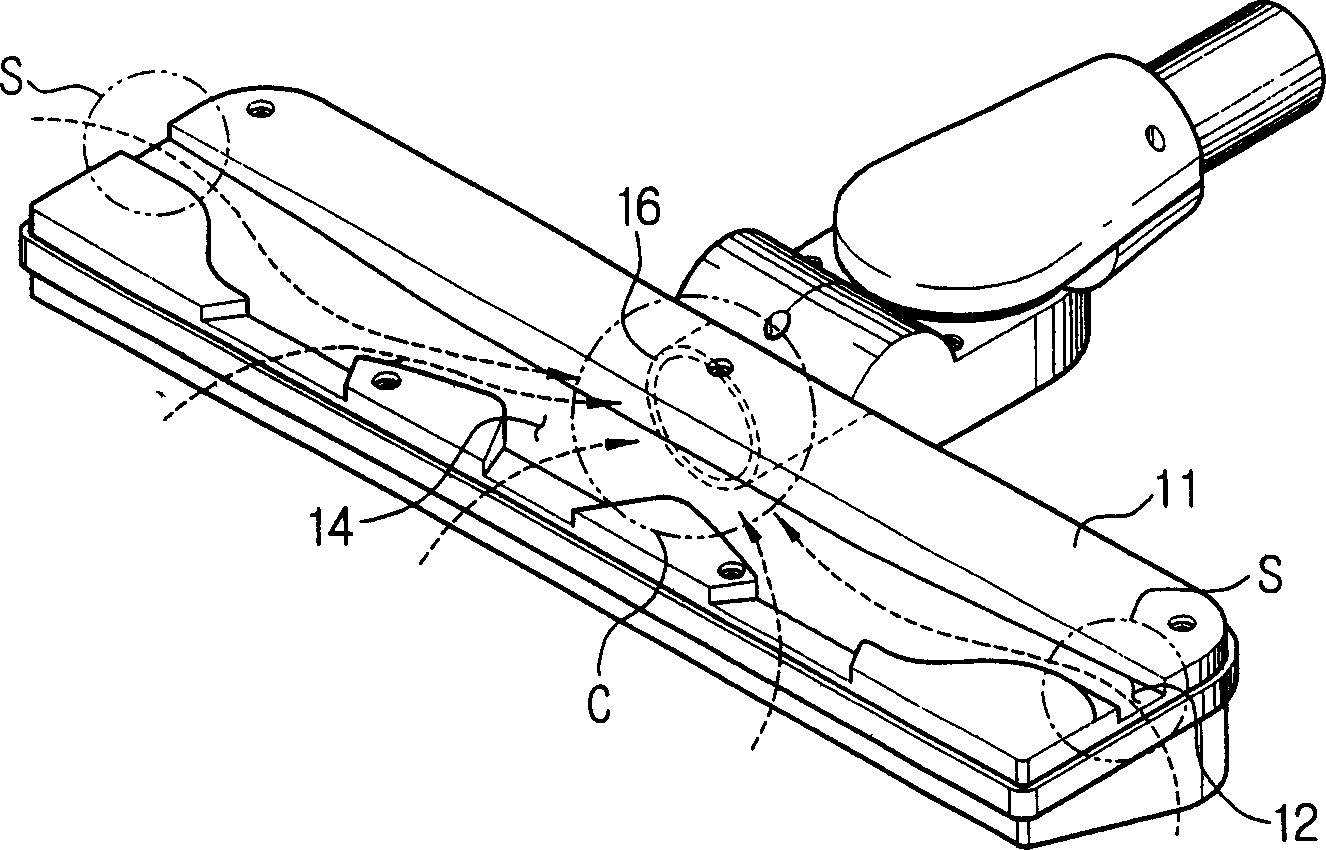

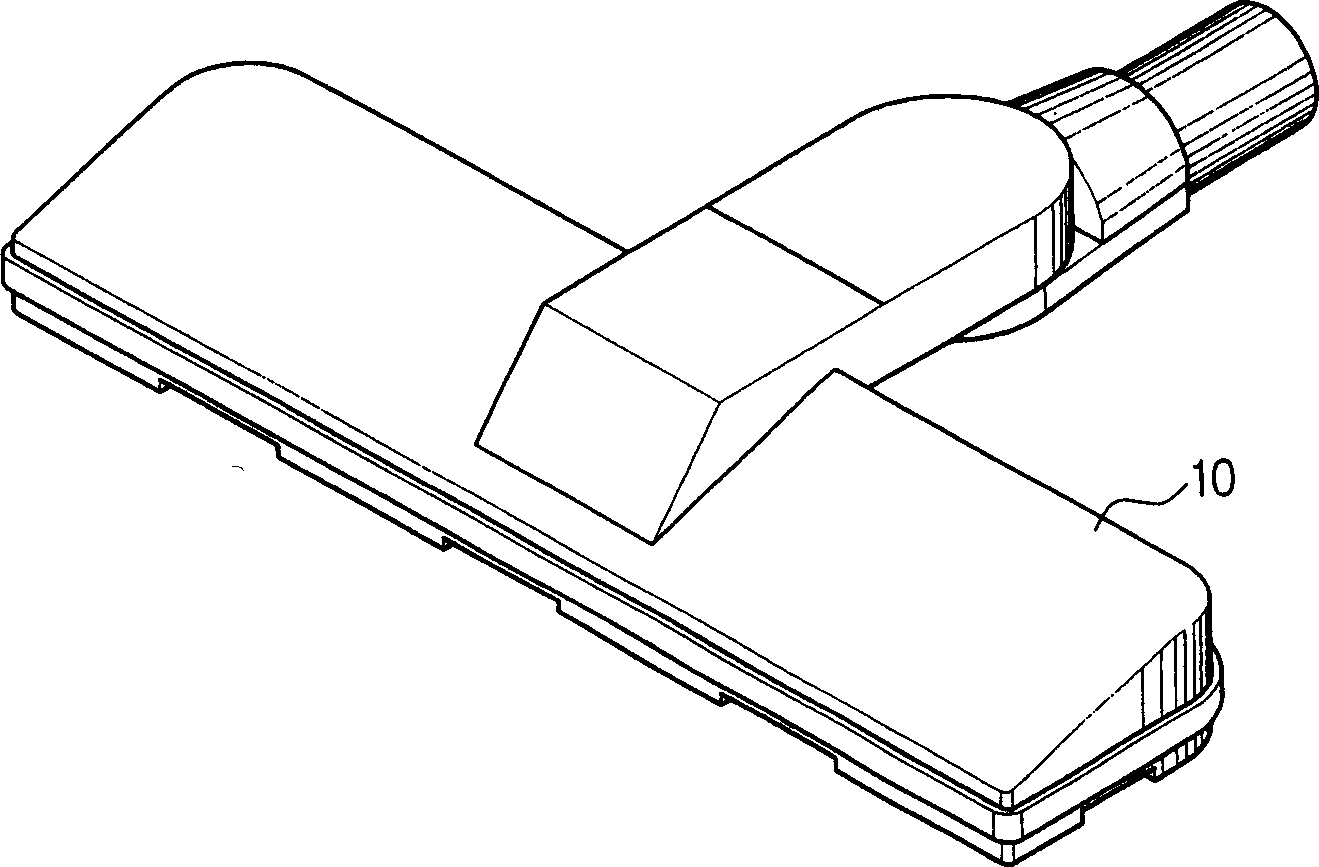

[0025] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

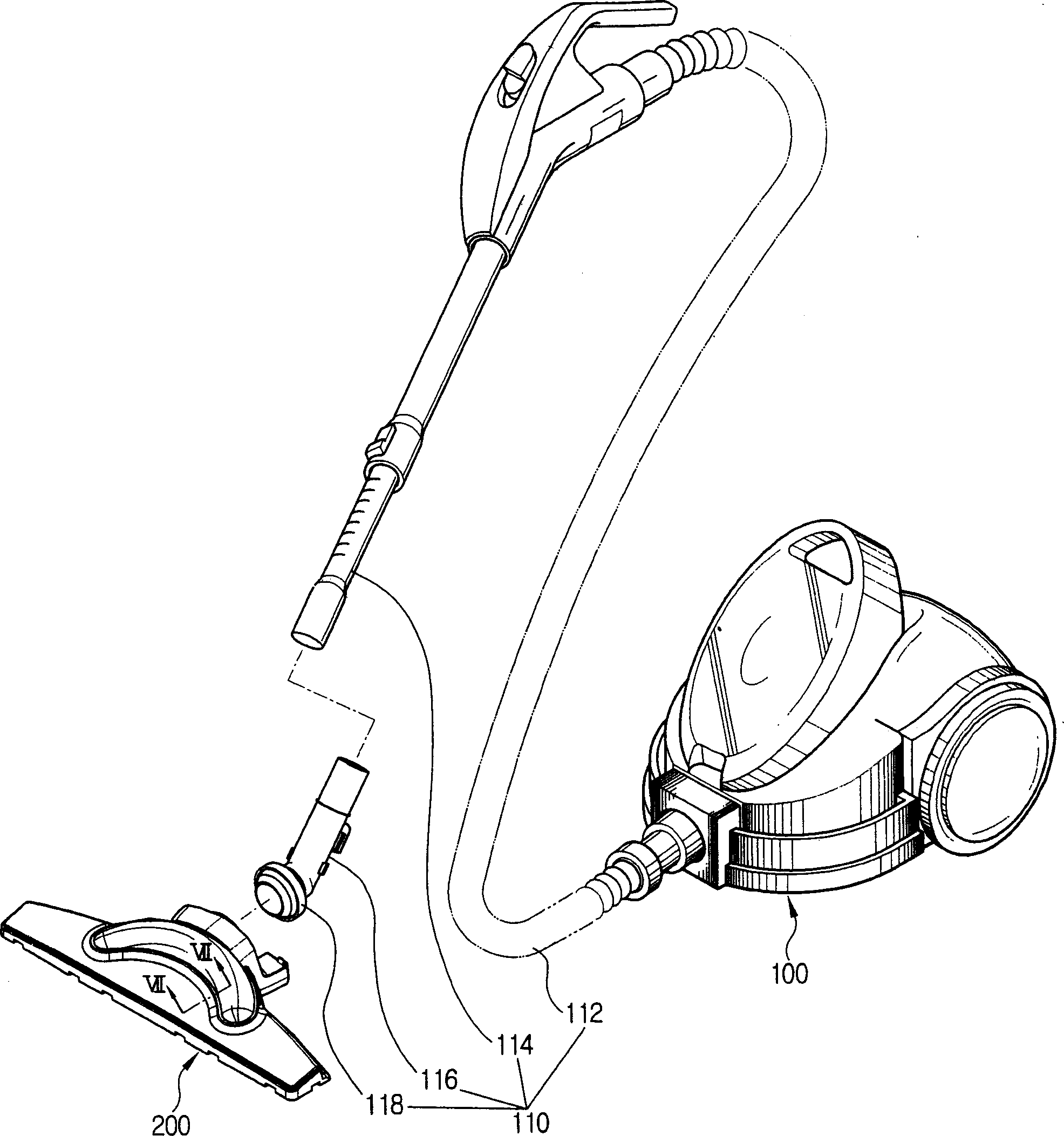

[0026] figure 2 is a perspective view of a vacuum cleaner according to one embodiment of the present invention. The vacuum cleaner includes: a cleaner main body 100, in which a vacuum source is installed; a suction port assembly 200, which uses vacuum force generated by the vacuum source to suck dirt from a surface to be cleaned; and an extension passage 110, which is connected to the suction port Assembly 200 and cleaner body 100 . Dirt is sucked from the suction port assembly 200 into the cleaner main body 100 through the extension passage 110 .

[0027] The extension passageway 110 includes an extension tube connector 116 having a rotatable articulating or universal joint 118 rotatably connected to the suction port assembly 200 at one end. A first end of extension tube 114 is connected to a second or opposite end of extension connector 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com