Vacuum cleaning tool and method for its operation

A technology of cleaning machines and cleaners, which is applied to cleaning equipment, mechanical devices for controlling suction, suction nozzles, etc., and can solve problems such as lack of matching, insufficient matching, and insufficient cleaning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

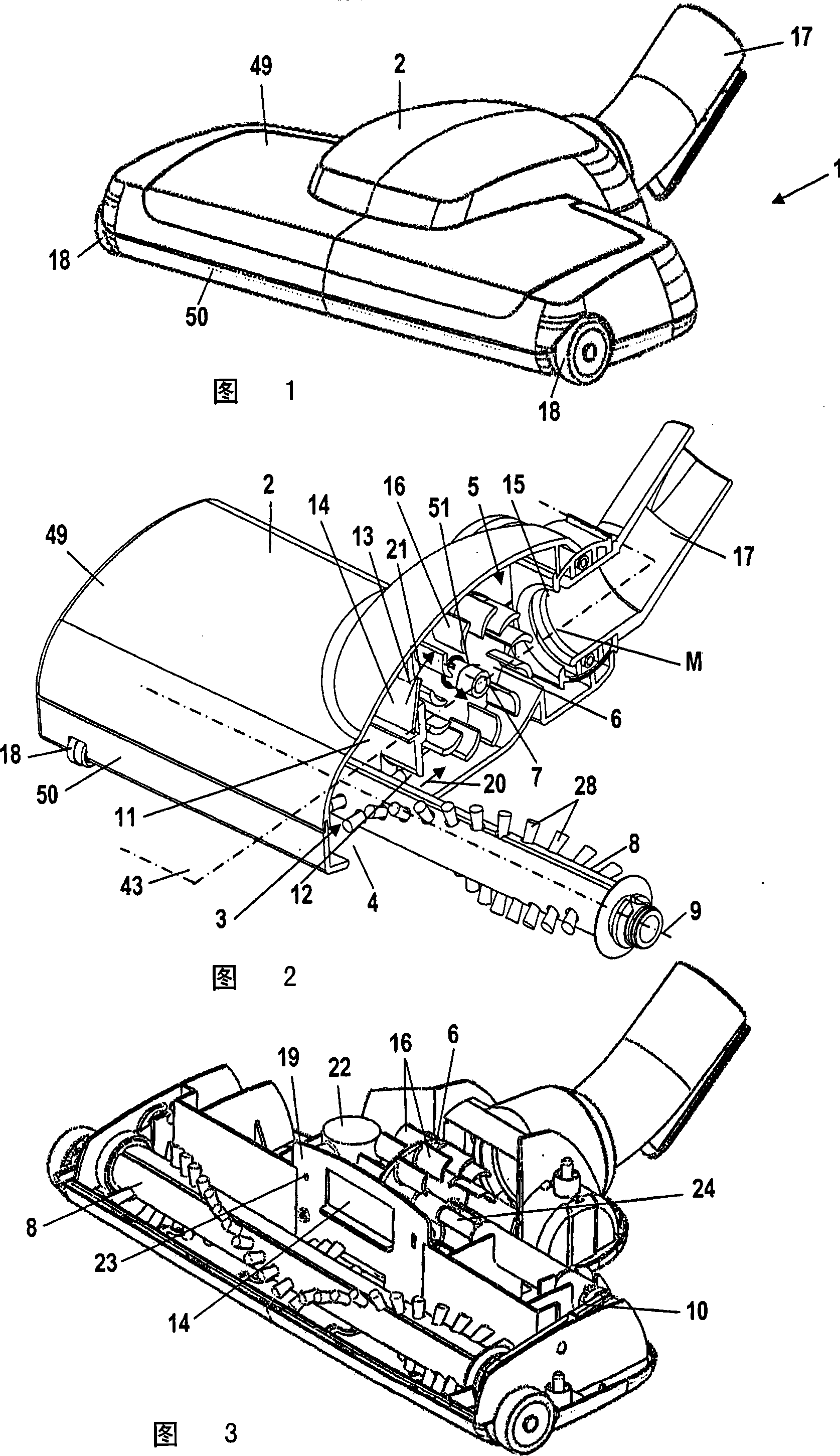

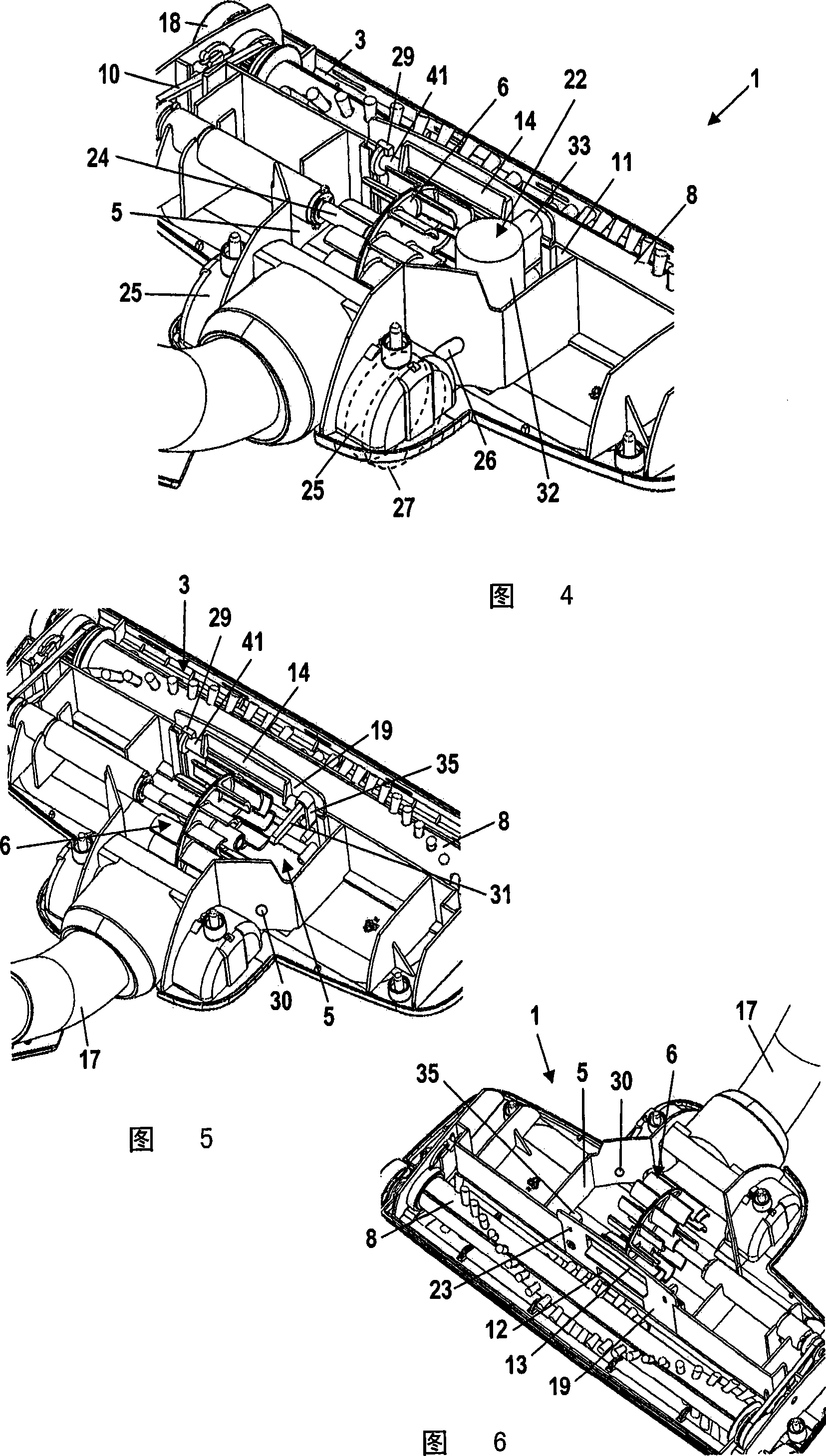

[0031] The extractor cleaner 1 shown in FIG. 1 has a housing 2 . The housing is composed of an upper case 49 and a lower case 50 . Two front wheels 18 are rotatably fastened to the housing. On the housing 2 of the vacuum cleaner 1 there is provided a connecting piece 17 for connection to the suction device of the vacuum cleaner.

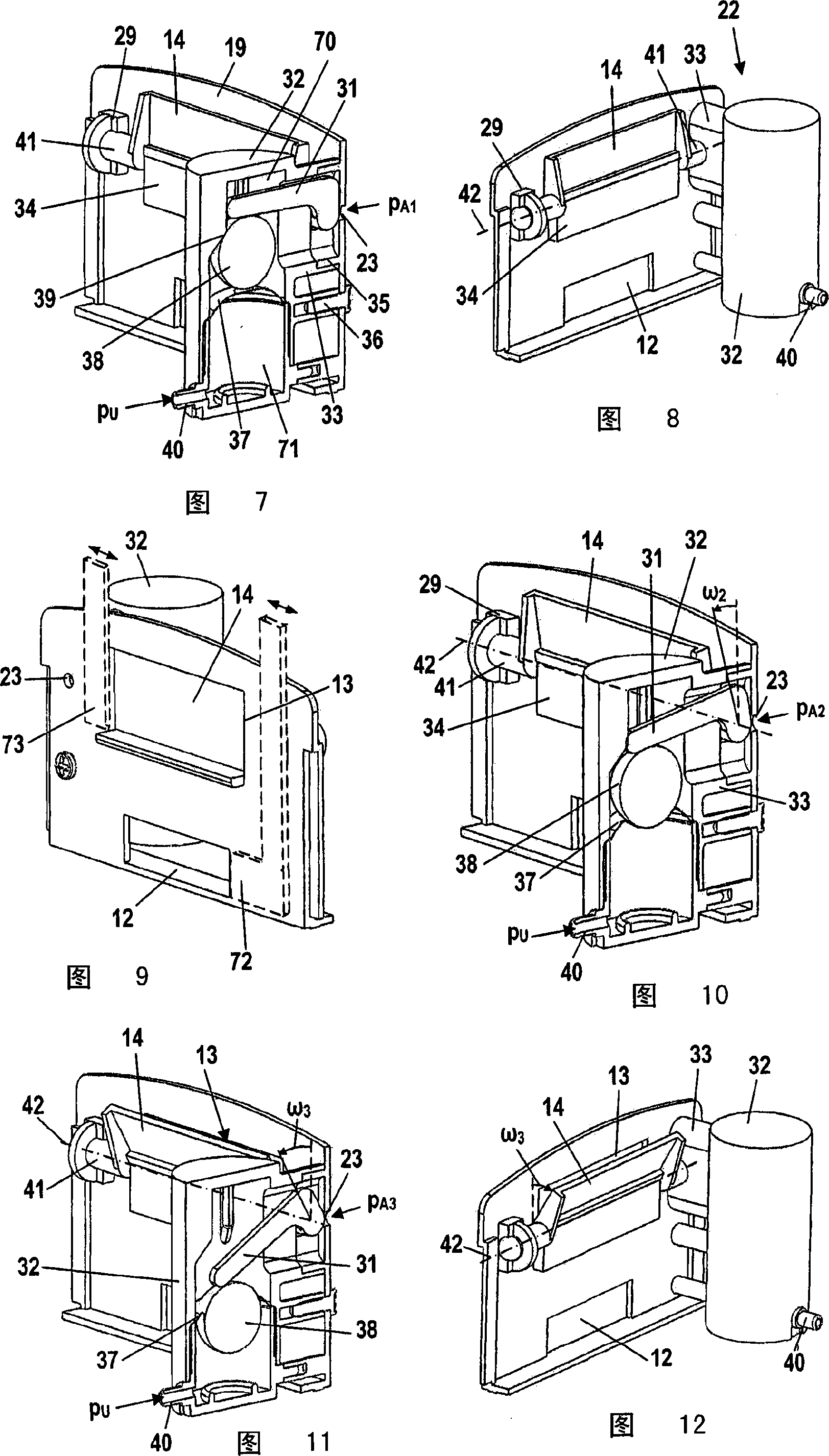

[0032] FIG. 2 shows a sectional view of the suction cleaner. As shown in FIG. 2 , front wheels 18 may also be provided at the front side of the housing 2 . A suction hole 4 is formed in the lower case 50 . The suction opening extends over the entire width transversely to the working direction of the suction cleaning machine 1 . The suction hole 4 is a slit-shaped design. A cleaner, ie a brush roller 8 , is mounted rotatably about an axis of rotation 9 above the suction opening 4 . On this brush roller 8, many bristles 28 are fixed. Transversely to the working direction and parallel to the axis of rotation 9 of the brushroll 8, the housing 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com