Novel solid-state cigarette core of electronic cigarette and preparation method for novel solid-state cigarette core

An electronic cigarette and wick technology, applied in the field of electronic cigarettes, can solve the problems of excessive inhalation of tar and suspended particles, unfavorable consumers' health, and backflow of the cigarette holder, so as to reduce the content of tar and harmful particulate matter, increase the heating area and heat Efficiency, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

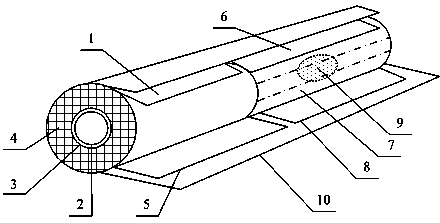

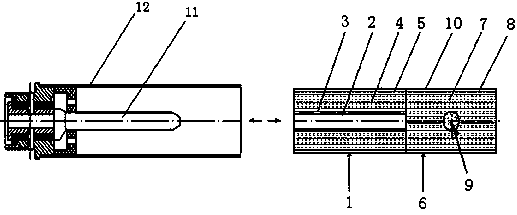

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a novel electronic cigarette solid cigarette core, comprising the following steps:

[0043] S1 adopts the conventional papermaking process, refines tobacco raw materials to obtain tobacco fiber pulp, and then mixes pulp with long fiber pulp at a ratio of 3:7 by mass, makes sheets, squeezes, and dries to make fiber paper base; the tobacco The raw materials are tobacco leaves and tobacco leaf fragments, and the specific ratio is not required; the long-fiber pulp is licorice fiber pulp;

[0044] S2 impregnate the fragrance-carrying material on the fiber paper base, the impregnation amount is 5% of the mass of the fiber paper base, and obtain the fiber paper substrate after drying; the fragrance-carrying material is extracted from propylene glycol, nicotine and tobacco The specific ratio is not required;

[0045] S3 Rolling the fibrous paper base material, and then pressing it with a hollow mold to obtain a hollow fiber material carrier layer adsorbed ...

Embodiment 2

[0054] A method for preparing a novel electronic cigarette solid cigarette core, comprising the following steps:

[0055] S1 adopts the conventional papermaking process, refines tobacco raw materials to obtain tobacco fiber pulp, and then mixes pulp with long fiber pulp at a ratio of 6:4 in mass ratio, sheets, presses, and dries to make fiber paper base; the tobacco The raw material is tobacco powder; the long fiber pulp is licorice fiber pulp;

[0056] S2 impregnate the fragrance-carrying material on the fiber paper base, the impregnation amount is 50% of the mass of the fiber paper base, and obtain the fiber paper substrate after drying; the fragrance-carrying material is propylene glycol and tobacco raw material particles, specifically The ratio is not required;

[0057] S3 Rolling the fibrous paper base material, and pressing it with a hollow mold to obtain a hollow fiber material carrier layer adsorbed with fragrance-carrying material; the thickness of the hollow fiber m...

Embodiment 3

[0065] A method for preparing a novel electronic cigarette solid cigarette core, comprising the following steps:

[0066] S1 adopts conventional papermaking process, refines tobacco raw materials to obtain tobacco fiber pulp, and then mixes pulp with long fiber pulp at a ratio of 5:5 in mass ratio, makes sheets, squeezes, and dries to make fiber paper base; the tobacco The raw materials are tobacco stems and tobacco flakes, and the specific ratio is not required; the long-fiber pulp is fragrant waxy bamboo fiber pulp;

[0067] S2 Coat the fragrance-carrying material on the fiber paper base, the coating amount is 15% of the mass of the fiber paper base, and obtain the fiber paper substrate after drying; the fragrance-carrying material is vegetable glycerin and tobacco raw materials Particles, the specific ratio is not required;

[0068] S3 Rolling the fibrous paper base material, and pressing it with a hollow mold to obtain a hollow fiber material carrier layer adsorbed with f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com