A method and a system for controlling a refiner, for refining a product containing cellulose, such as pulp, and an information of a quality index of the product

A technology for pulping machines and cellulose, applied in general control systems, control/regulation systems, pulp beating/refining methods, etc., to achieve precise initial control, minimize the need for trial operation and testing, and improve process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

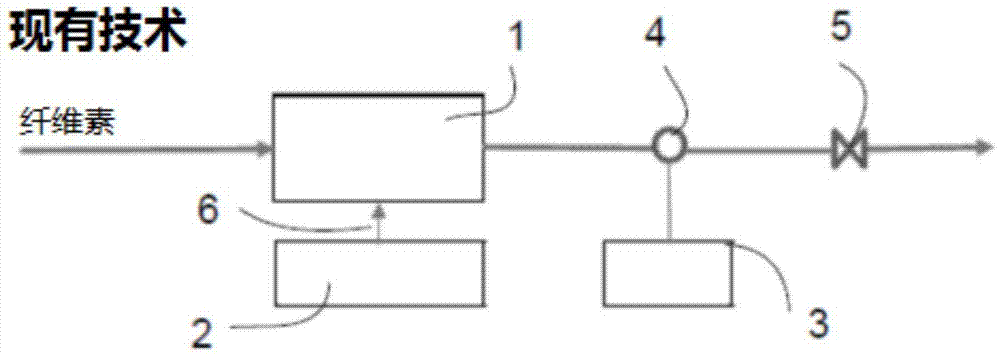

[0056] image 3 Shown is a control system for a mill according to the prior art, where pulp is produced from a pulping machine with constant energy consumption. The process control parameters include the preparation consistency and flow characteristics of the slurry and the specific tool type at the station. These parameters however do not give a statistically reliable indication or prediction of seminal plasma CSF values. The main components of the system shown include the pulp input, the refiner 1, the specific energy consumption of this refiner controlled by the process control system 2 via signal 6, the CSF measuring unit 3,4 and the pulp slurry controlled via valve 5 exit.

[0057] The CSF value is read at the unit 3 and the process control system 2 adjusts according to this feedback so that the refining process in the refiner 1 is more or less efficient.

example 2

[0059] Figure 4 Shown is a pulper using the control system of the present invention. Such as image 3 , there are feedbacks from the CSF measurement units 3 and 4, and the above-mentioned conventional process control parameters, and the feedback is the input signal 9 of the grinding paper module unit 8 . Again, here's the quality index BotniaFOX TM is used as an input value as a base value for calculating the pulping description of the pulp fed into the control system 7 . This creates a feed-forward loop 8-7->1, improving control quality and process speed. The delay of the control system using the predefined quality index information of the pulp is smaller than that of the CSF feedback control loop 4->3->8->7->1. In practice, this means that if a process parameter changes, including quality index values, it is possible to correct the operation of the refiner in 6 even before the CSF value in 4 changes to an undesired value .

[0060] The method of the present invention ...

example 3

[0065] Figure 5 Shown is another embodiment of the invention in which a stock quantity control loop is added at 11,12,13. This allows products, such as paper, to maintain a constant CSF value and tensile strength at the same time. Such as Figure 4 The CSF value is controlled. If the flow meter 13, which measures the slurry flow rate in valve 12, receives an indication that quality indicators and the following other process parameters have changed, then the amount of cellulose in 11 will be changed to ensure that the desired tensile strength is maintained or achieved or stiffness. It will be appreciated that the control loop is enabled by the predictability of the process provided by the pulp quality index and the inventive concept that this index can provide a statistically significant and stable indication of refining properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com