Paper pulp quality control method and system of high-concentration defibrination system

A high-consistency refining and pulping technology, applied in pulp beating/refining methods, beating/refining control devices, papermaking, etc., can solve complex dynamic characteristics, difficulties in modeling and control of high-consistency refining systems, and laboratory analysis Long cycle and other issues, to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

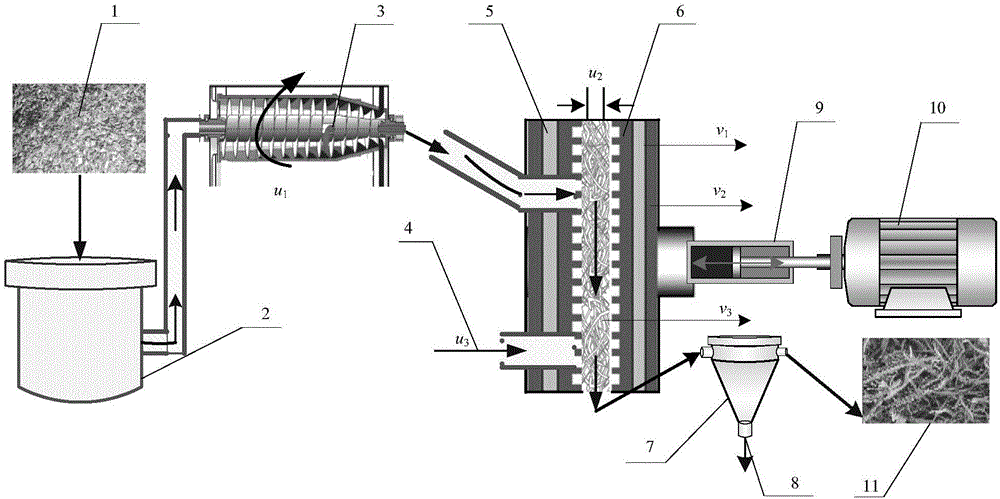

[0072] The process flow of a typical high-consistency refining system is as follows: figure 1 As shown, the wood chips 1 are first sent to the pre-steaming bin 2 for pretreatment, and the pretreated wood chips 1 are sent to the grinding area under the action of the feeding screw conveyor 3, and at the same time, a certain amount of dilution water 4 is injected into the grinding area, and the motor 10 drives The hydraulic cylinder 9 works, thereby driving the mill fixed plate 5 and the mill motor plate 6 to cooperate and grind the slurry to discharge the steam 8 under the action of the gas-slurry separator 7, and finally obtain the pulp 11 that meets the production demand.

[0073] The input variable is the feeding screw speed u 1 (rpm), disc clearance u 2 (mm), dilution water flow u 3 (kg / min), the state variable is output v ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com