Procedure and system for control of refiner to improve energy efficiency and pulp quality

A refiner and slurry technology, which is applied in the fields of beating/refining control devices, pulp beating/refining methods, textiles and papermaking, etc., can solve the problems of not providing reliable control of pulp quality parameters, different pulp quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

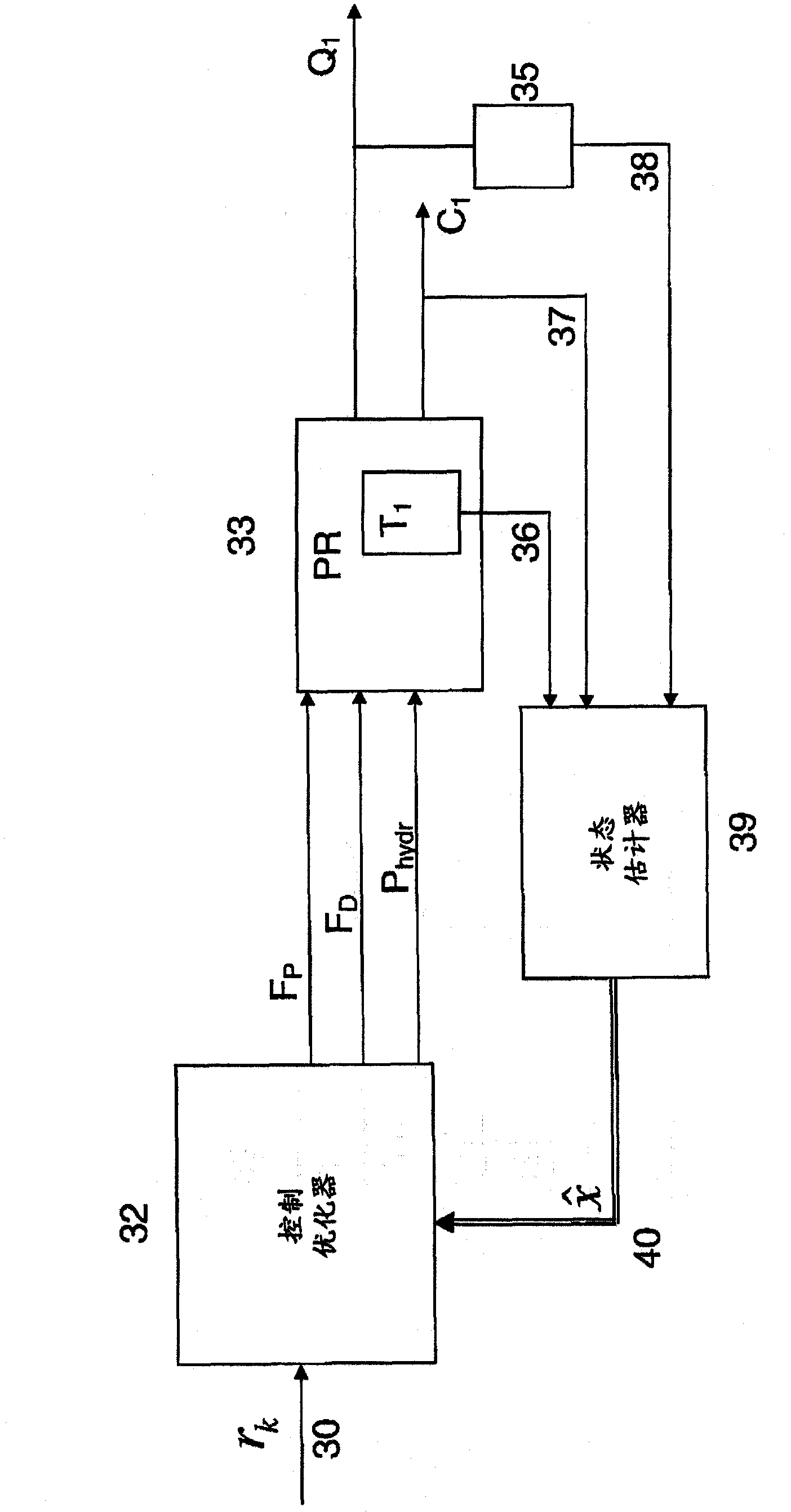

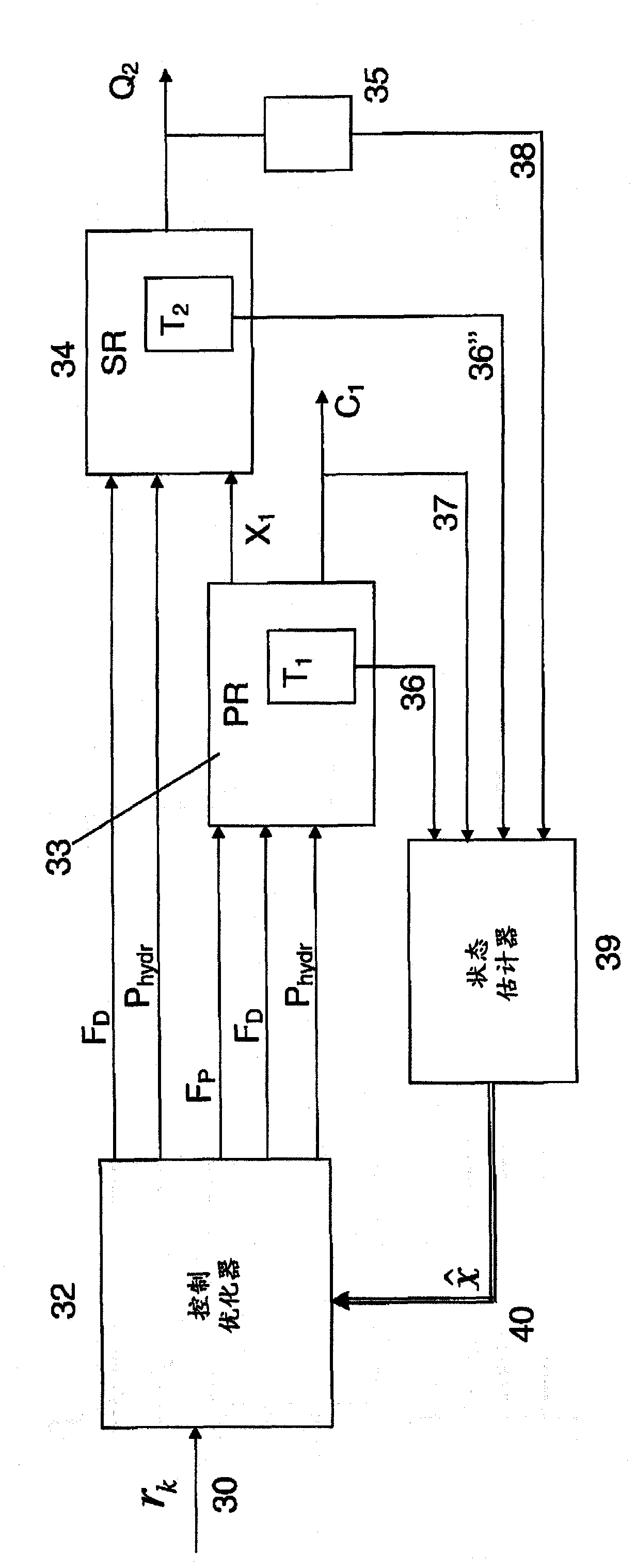

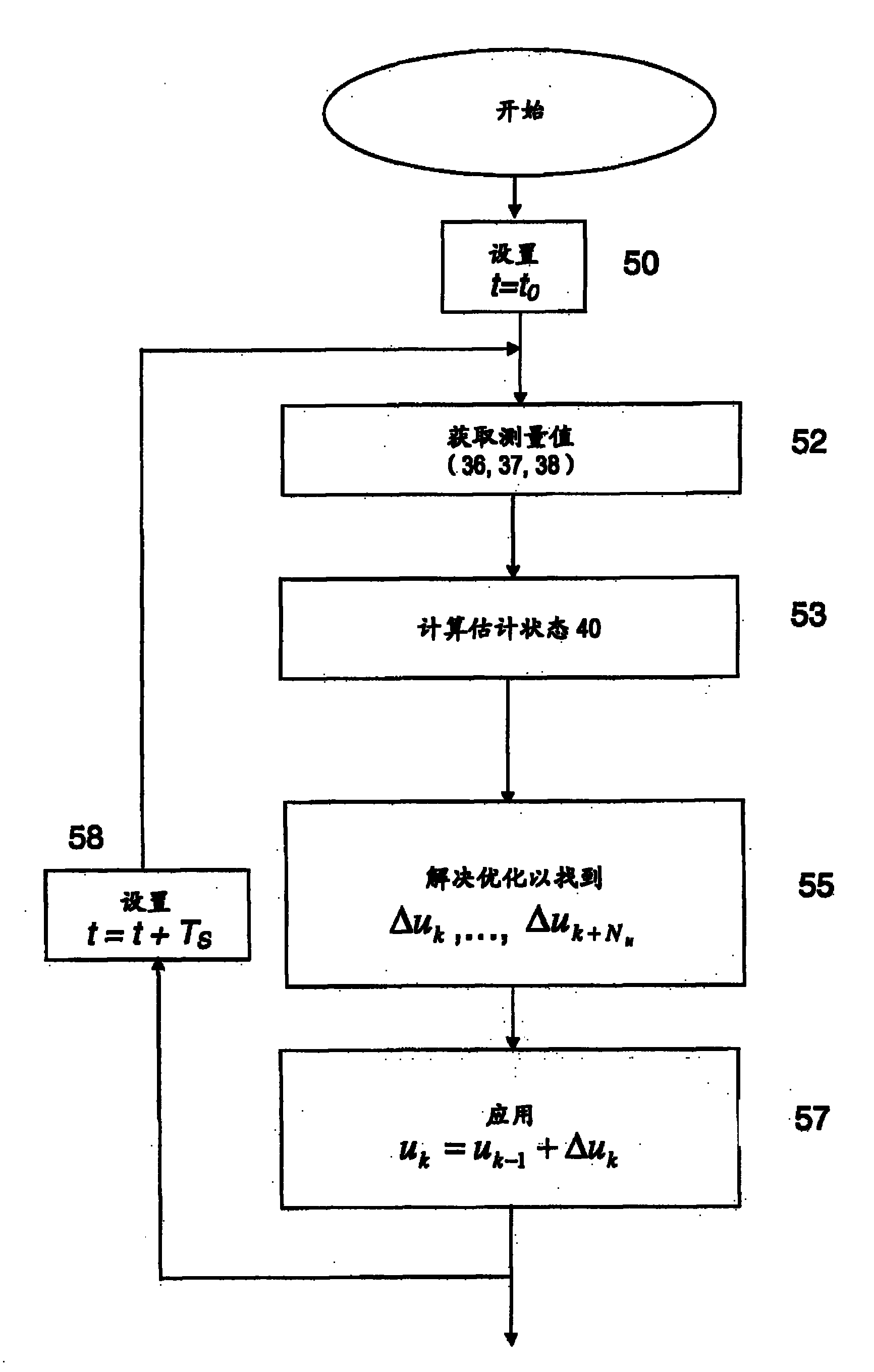

[0077] figure 1 A schematic diagram of a method of controlling a TMP slurry refiner is shown. The illustration shows a process with a single refiner 33 and a first control unit 32 . One or more setpoints 30 are input to a first control unit or control optimizer 32 or similar device having the same function. The first control unit, the control optimizer, is arranged to manipulate external process variables as input to the process 33, such as the hydraulic pressure P that presses the refiner plates together hydr , indicated as F p wood chips 5 flow flow and indicated as F D of dilution water 2'. From process 33 a refined slurry is produced. An external variable 37 representing the slurry consistency 37 from the process and the quality Q from the sampling unit 35 is input to a second control unit, a state estimator 39 . An internal value 36 is fed to the state estimator 39, which represents the use of e.g. Figure 6 The temperature curve or pressure curve obtained from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com