System and method for performing wind cleaning on wood chips

A technology of air washing and wood chips, applied in chemical instruments and methods, wood treatment, wood processing equipment, etc., can solve the problems of high cost and large amount of waste water, and achieve the effect of compact structure, low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

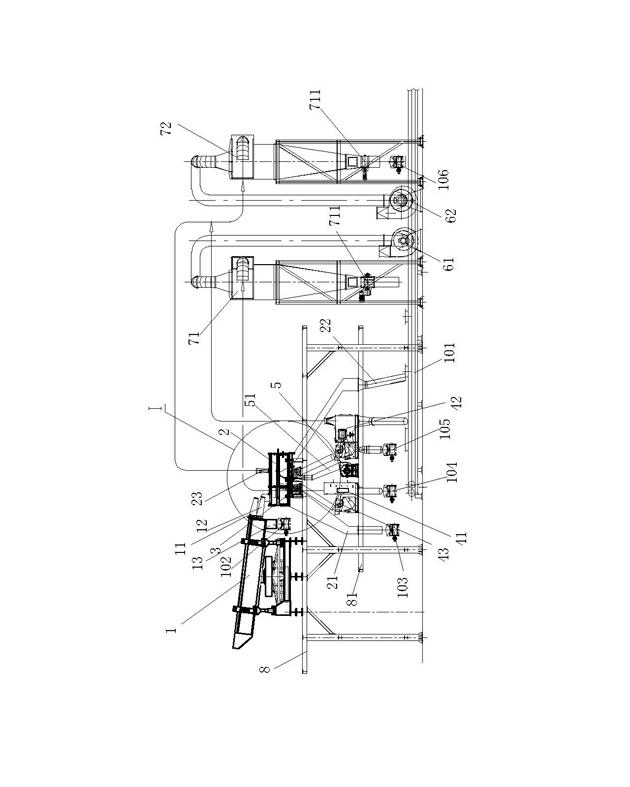

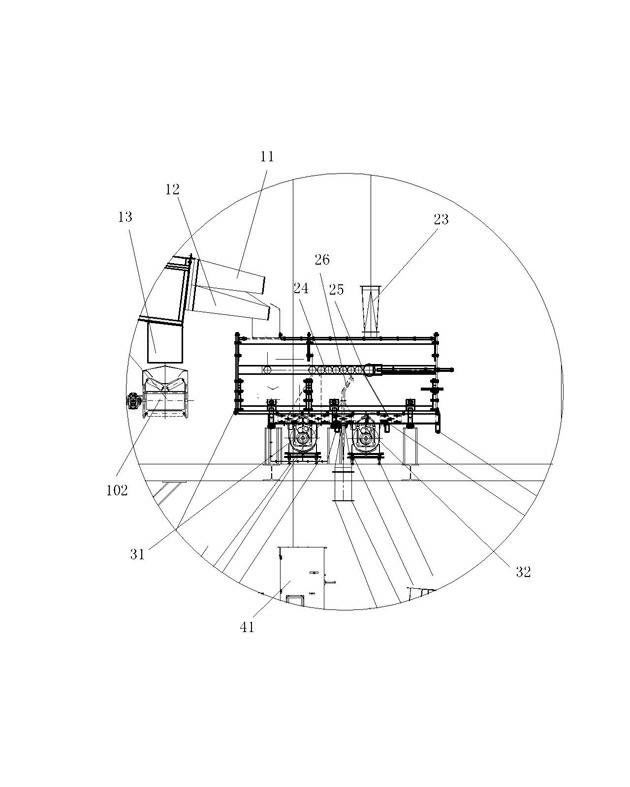

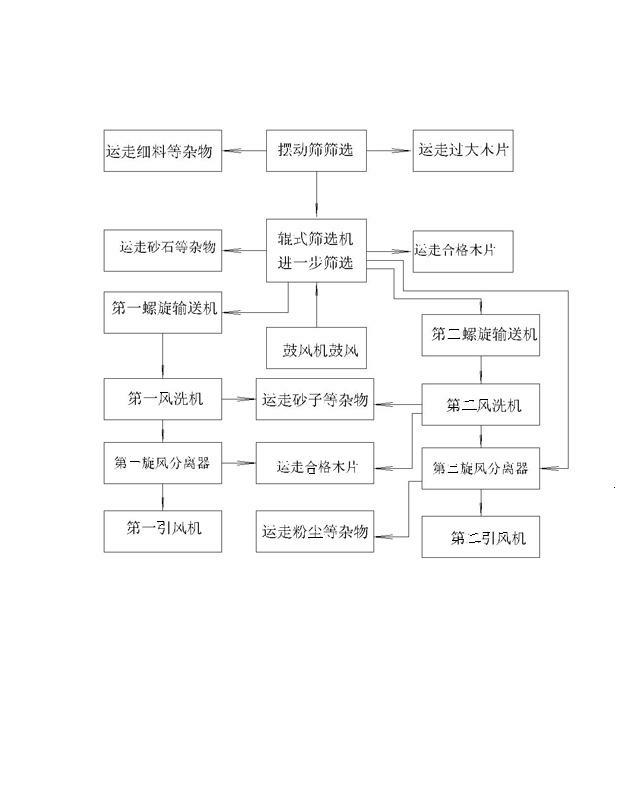

[0027] Such as figure 1 , figure 2 As shown, the air washing system for wood chips of the present invention includes a swing screen 1 arranged on the upper platform, a roller screen 2, a first screw conveyor 31 and a second screw conveyor 32 with opposite discharge directions, and is arranged on the middle platform, The first air washing machine 41 and the second air washing machine 42 respectively connected with the first screw conveyor 31 and the second screw conveyor 32, several air blowers 5, 4 sundry conveyors and qualified wood chips arranged at the bottom The conveyor 101 , the first induced draft fan 61 , the second induced draft fan 62 , the first cyclone separator 71 , and the second cyclone separator 72 are arranged on one side of the platform 8 .

[0028] During the swinging process of the swing screen 1, the wood chips and sundries to be separated are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com