Patents

Literature

60results about How to "Wasted space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

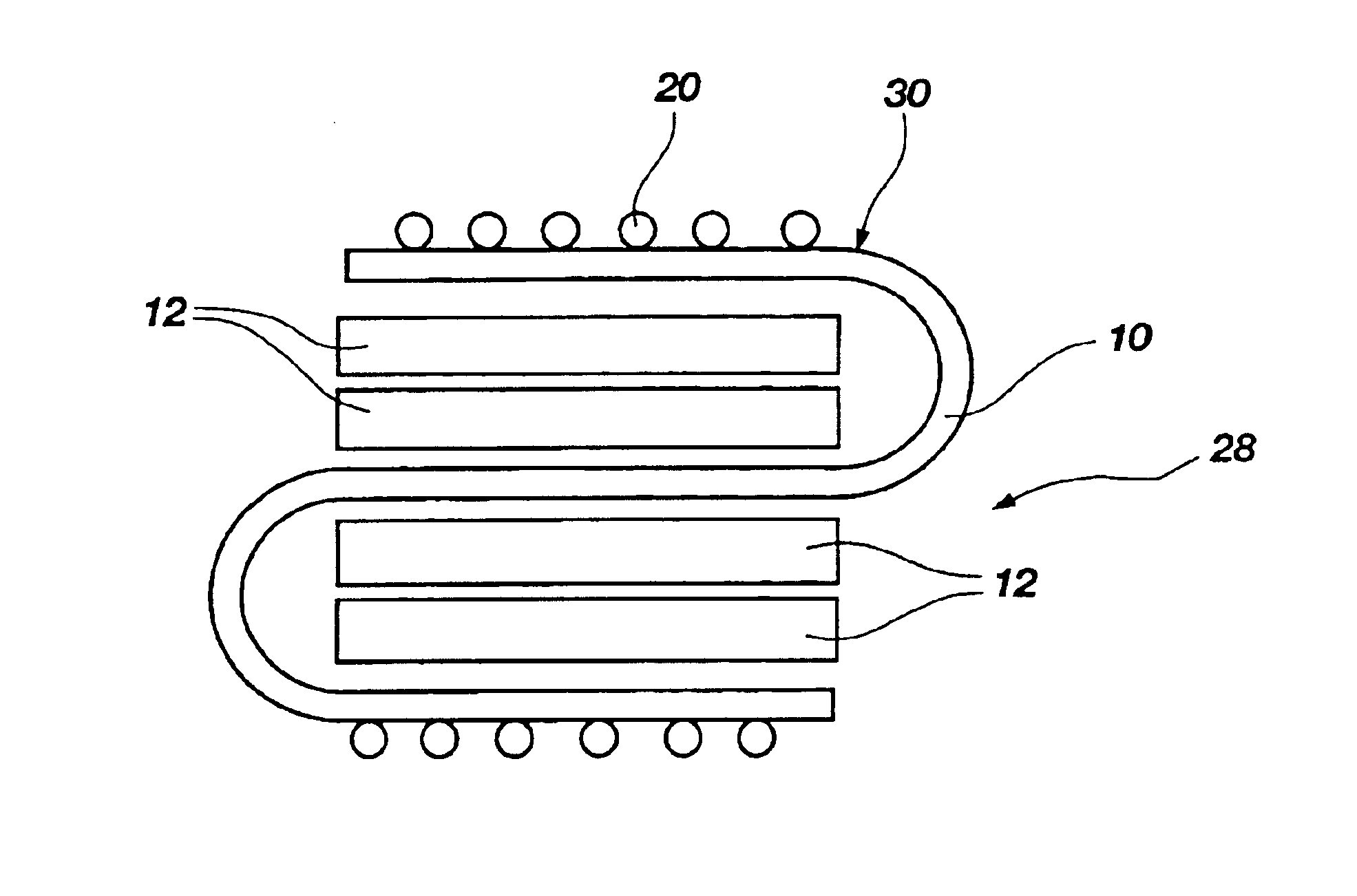

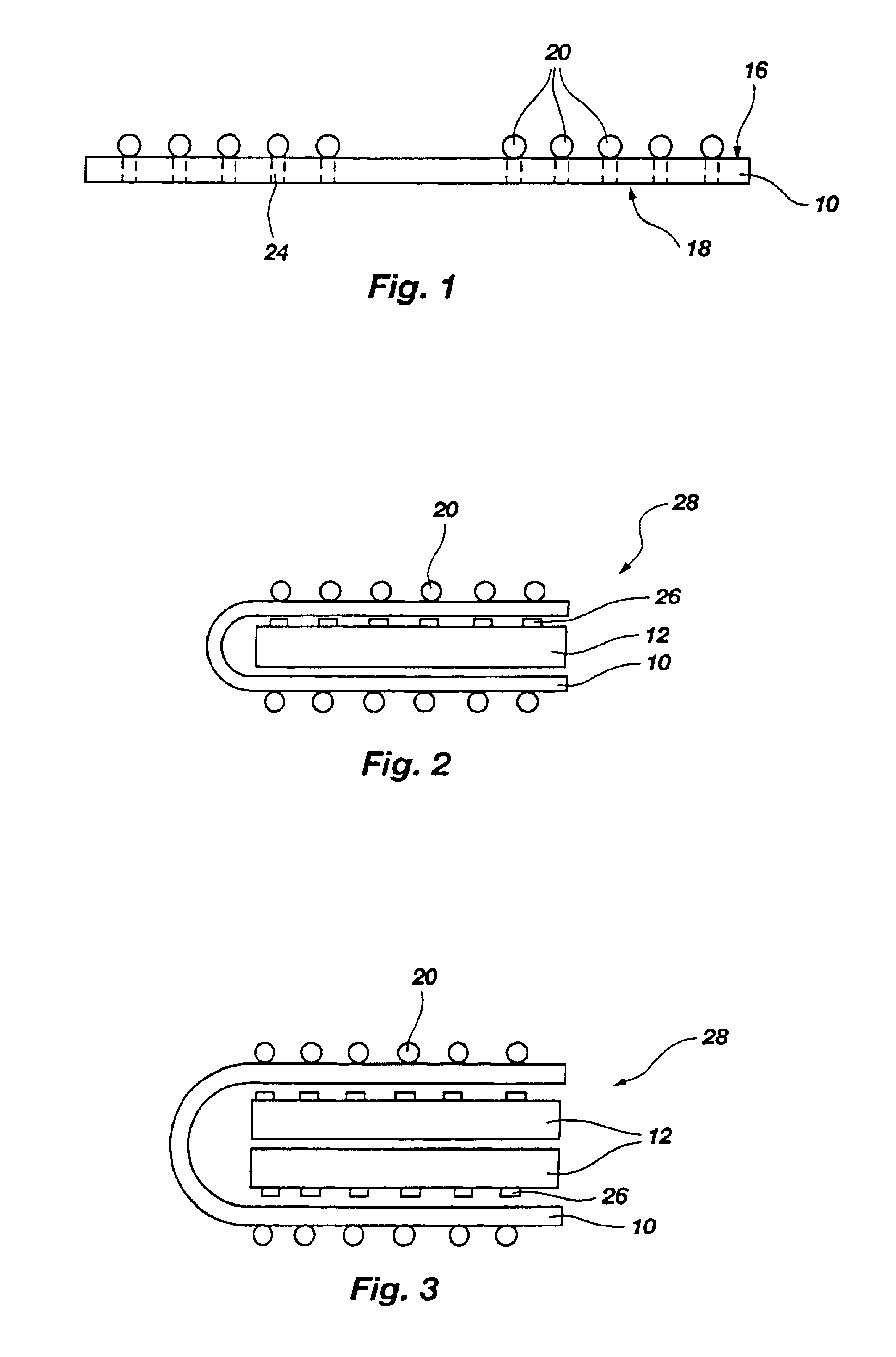

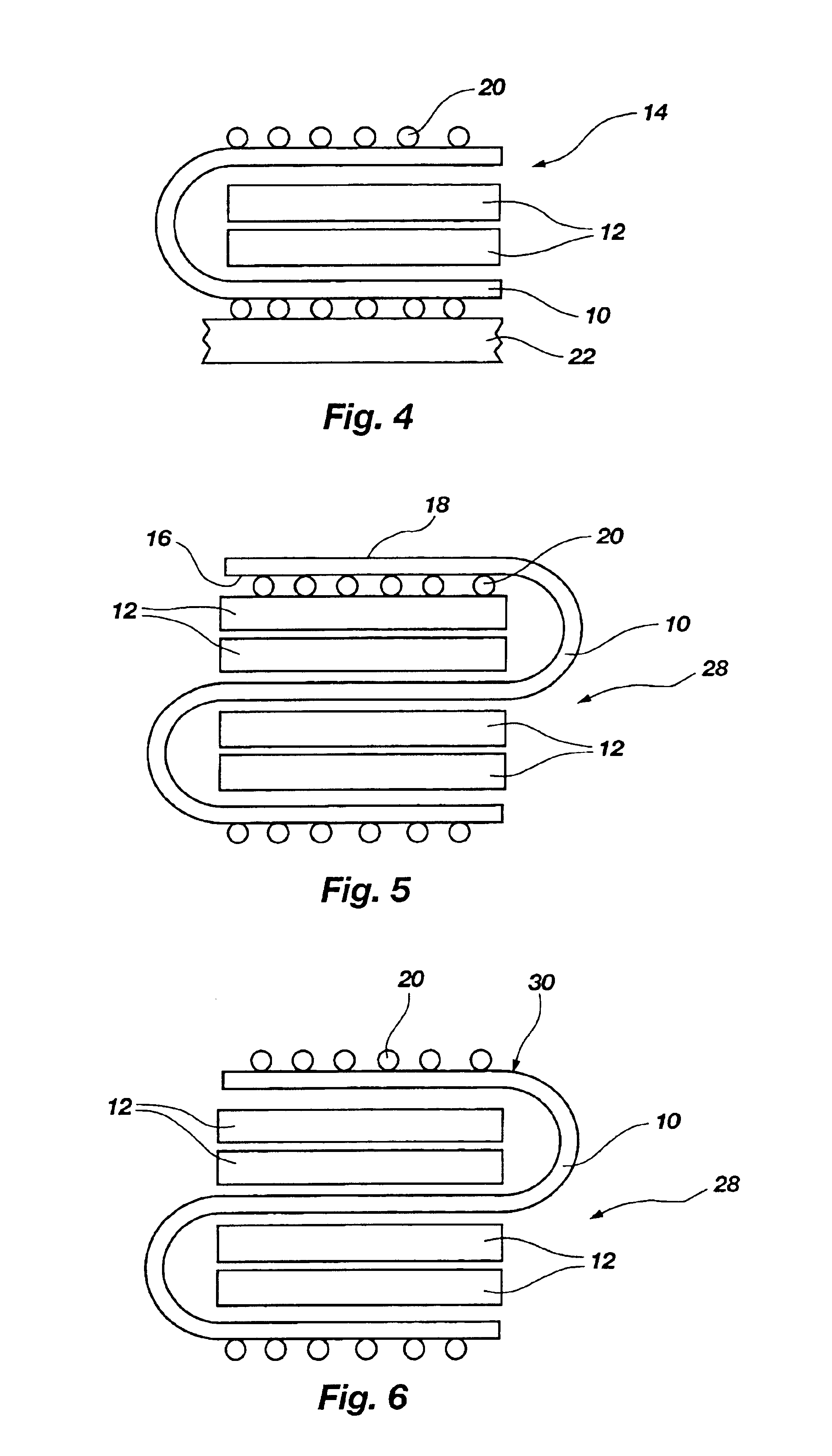

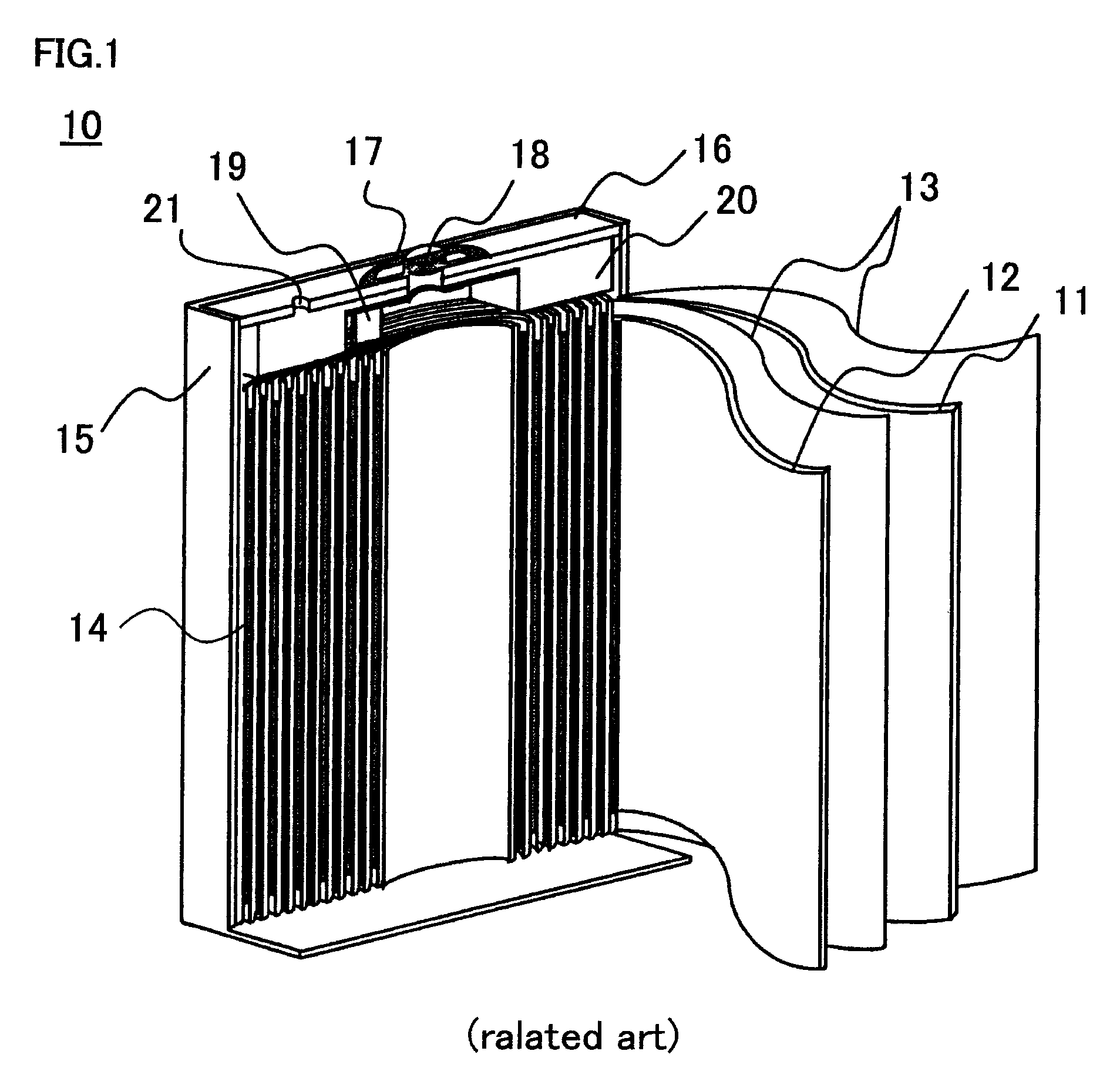

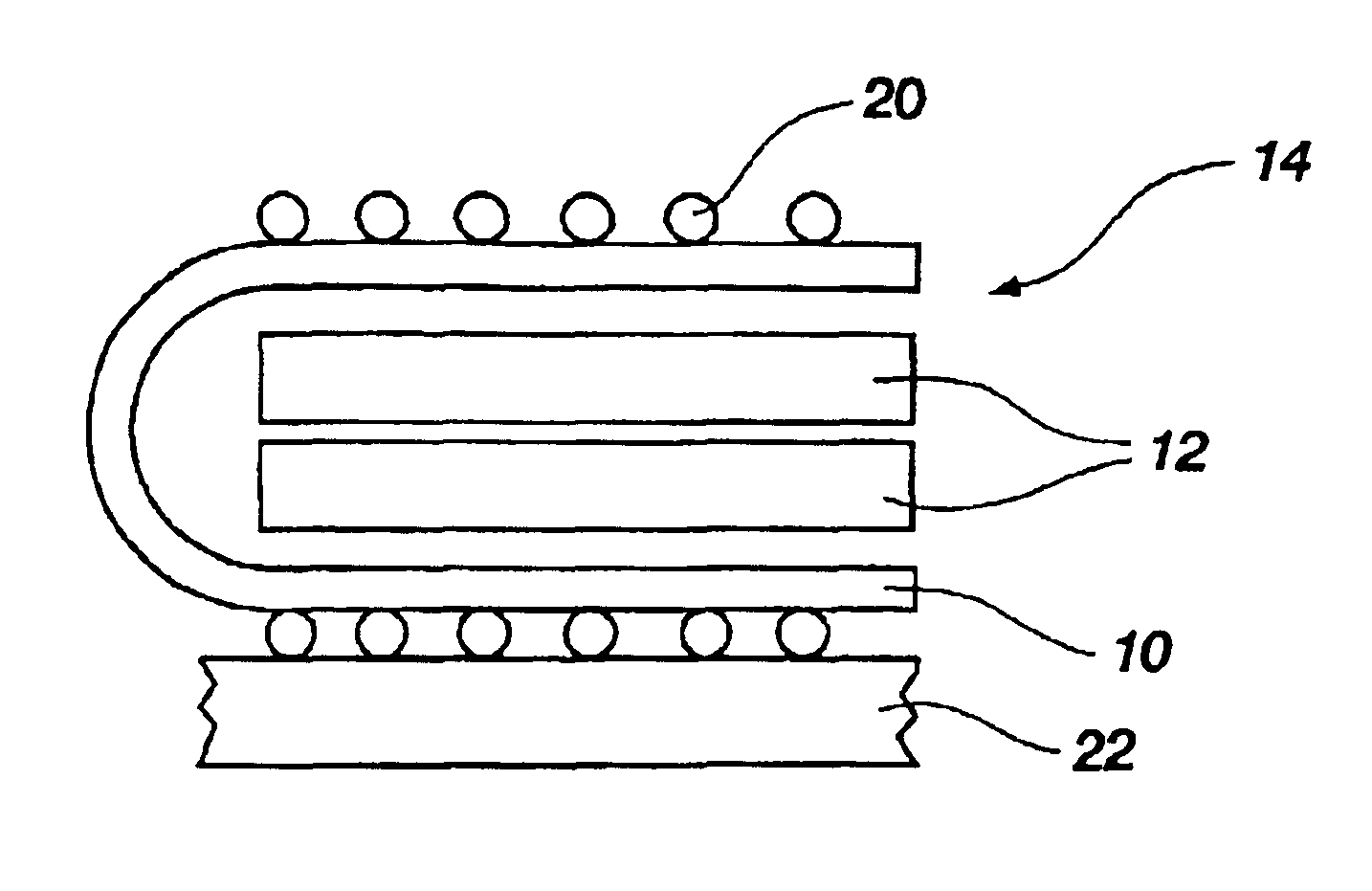

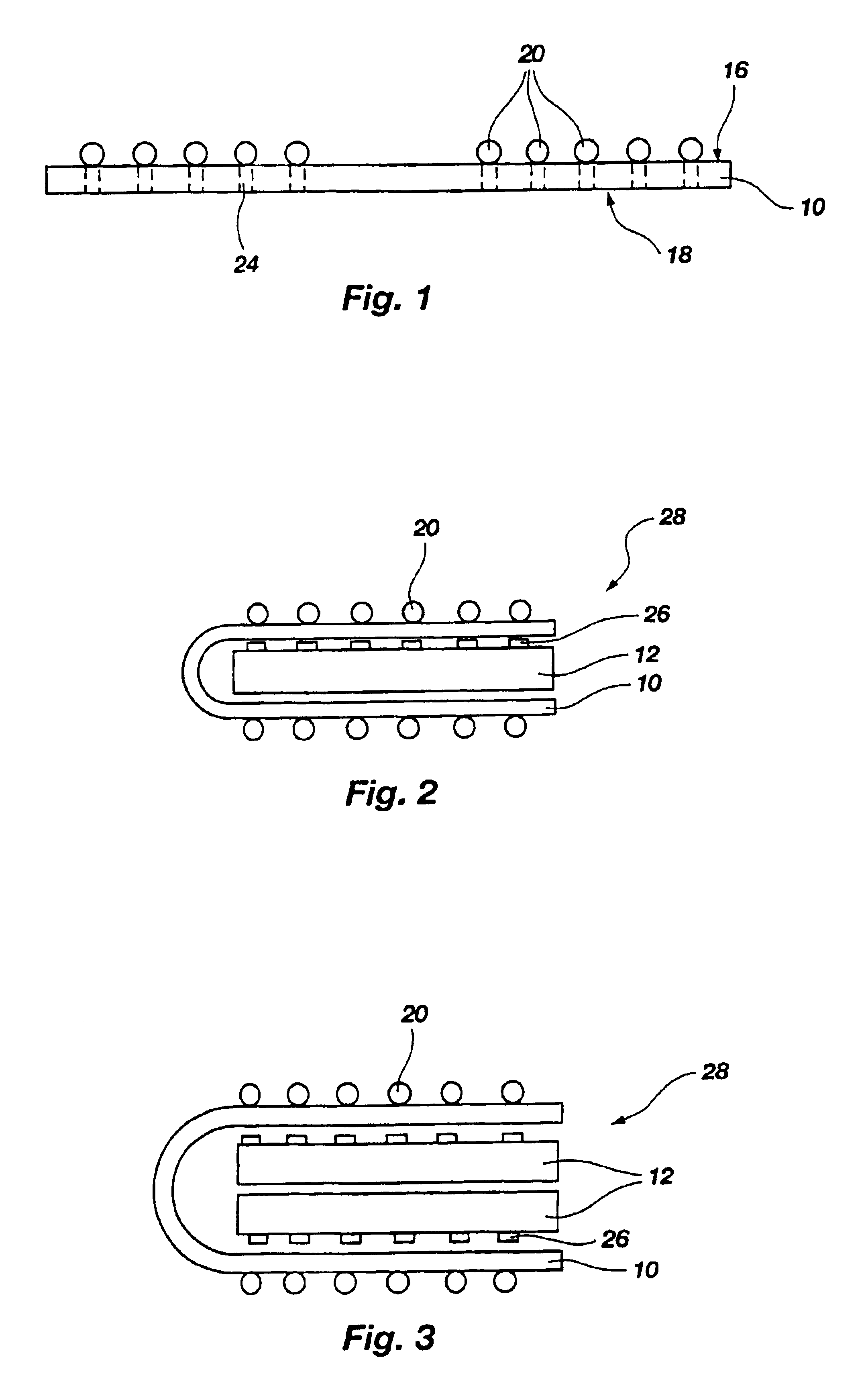

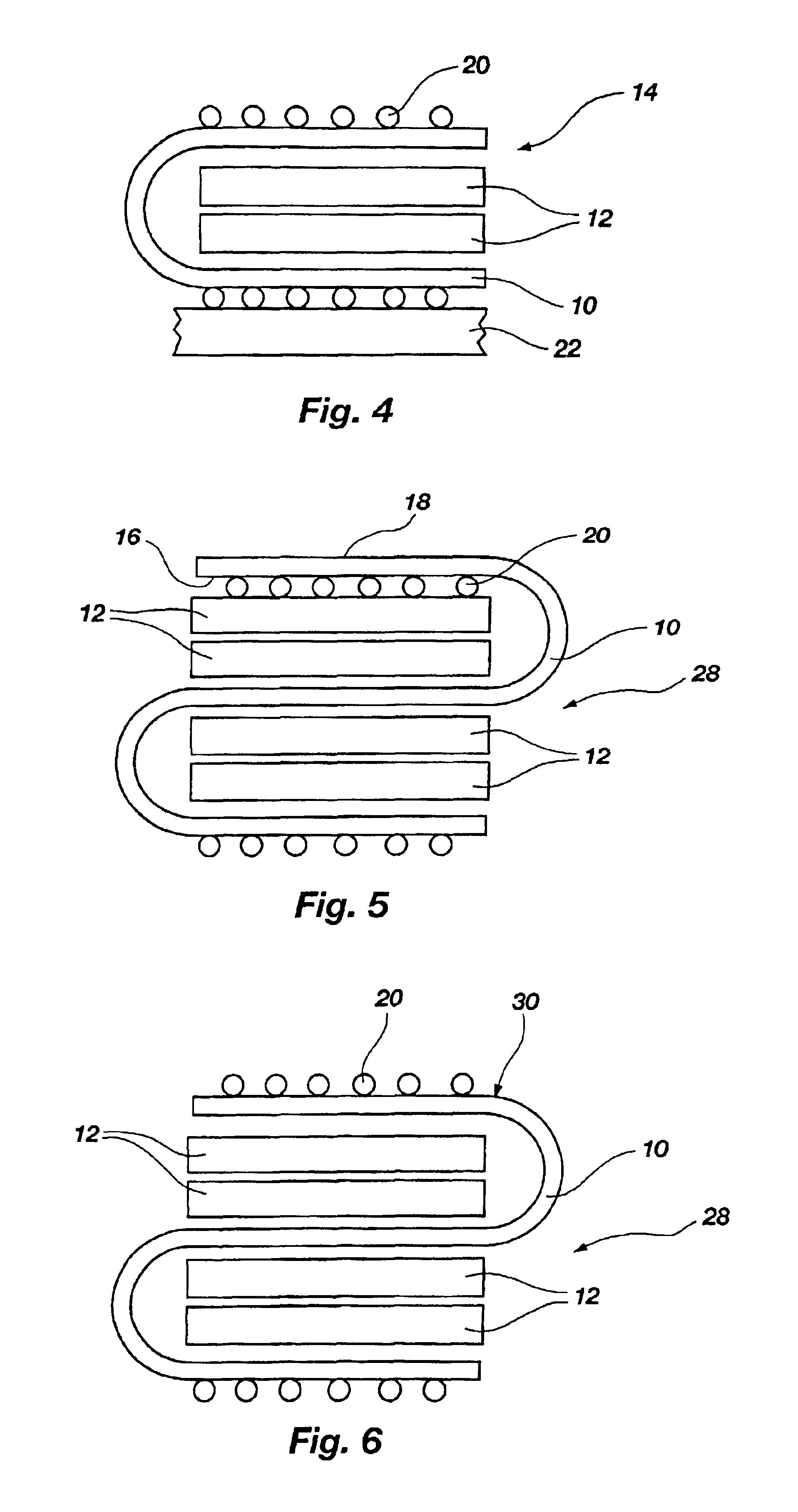

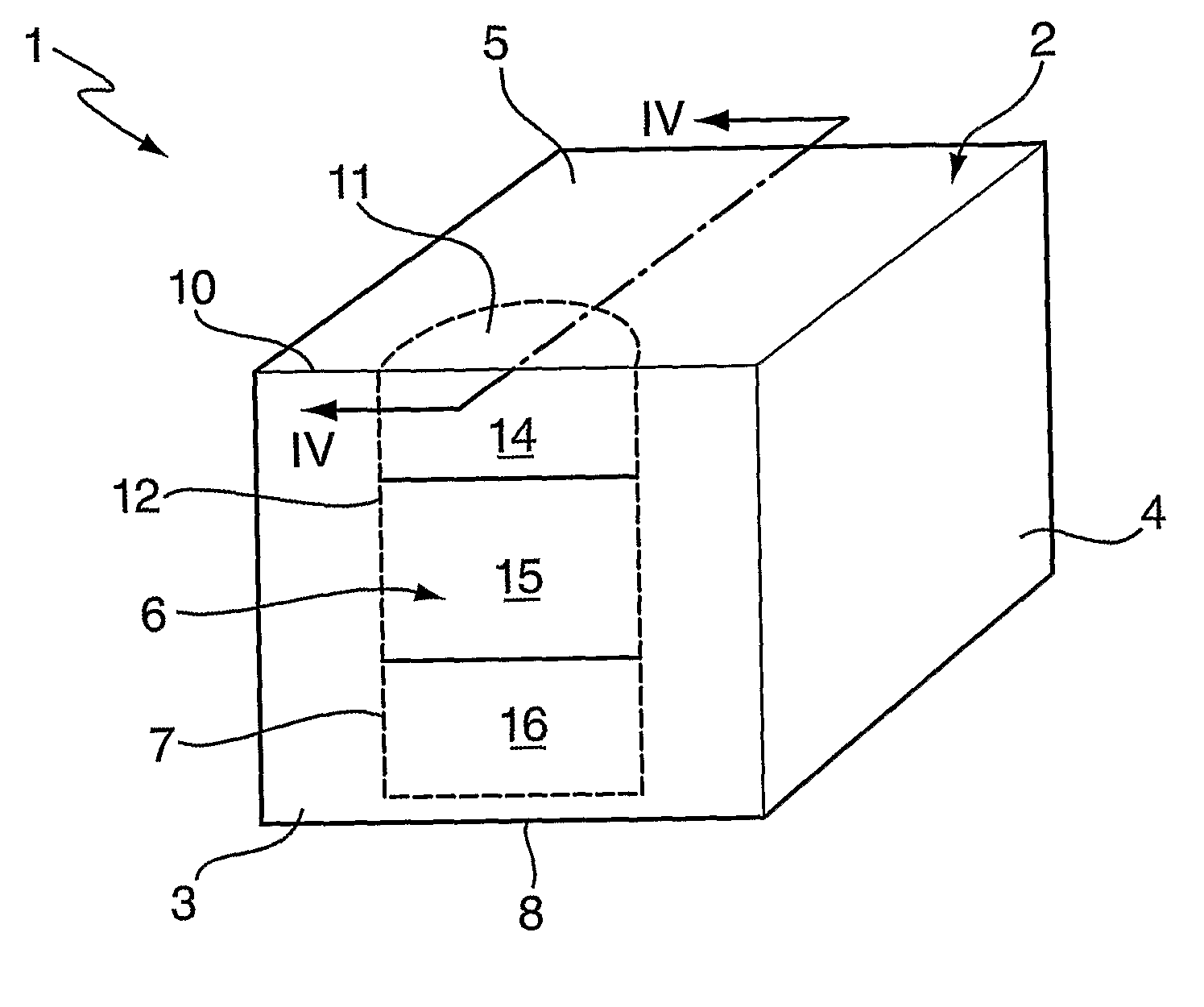

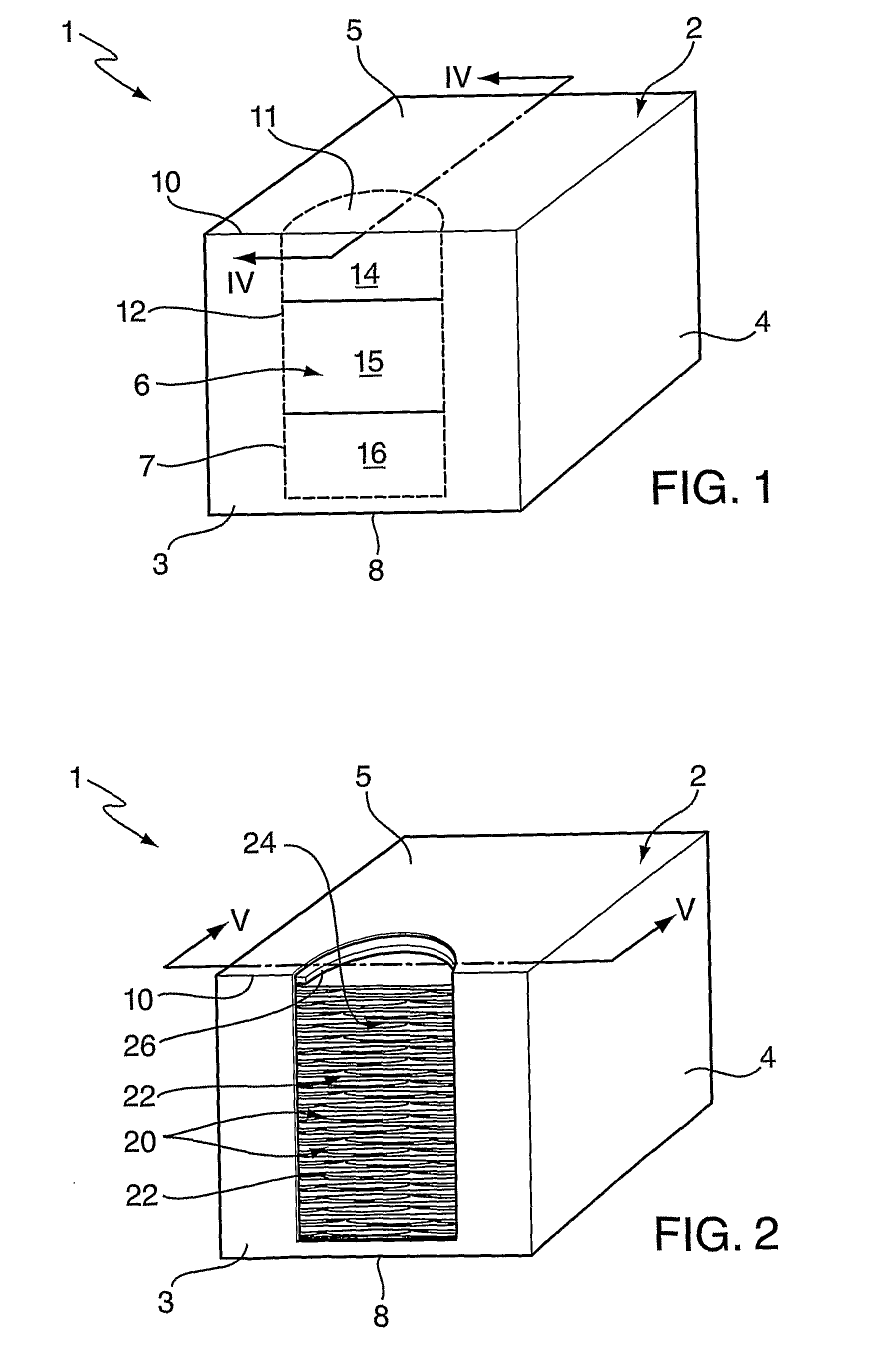

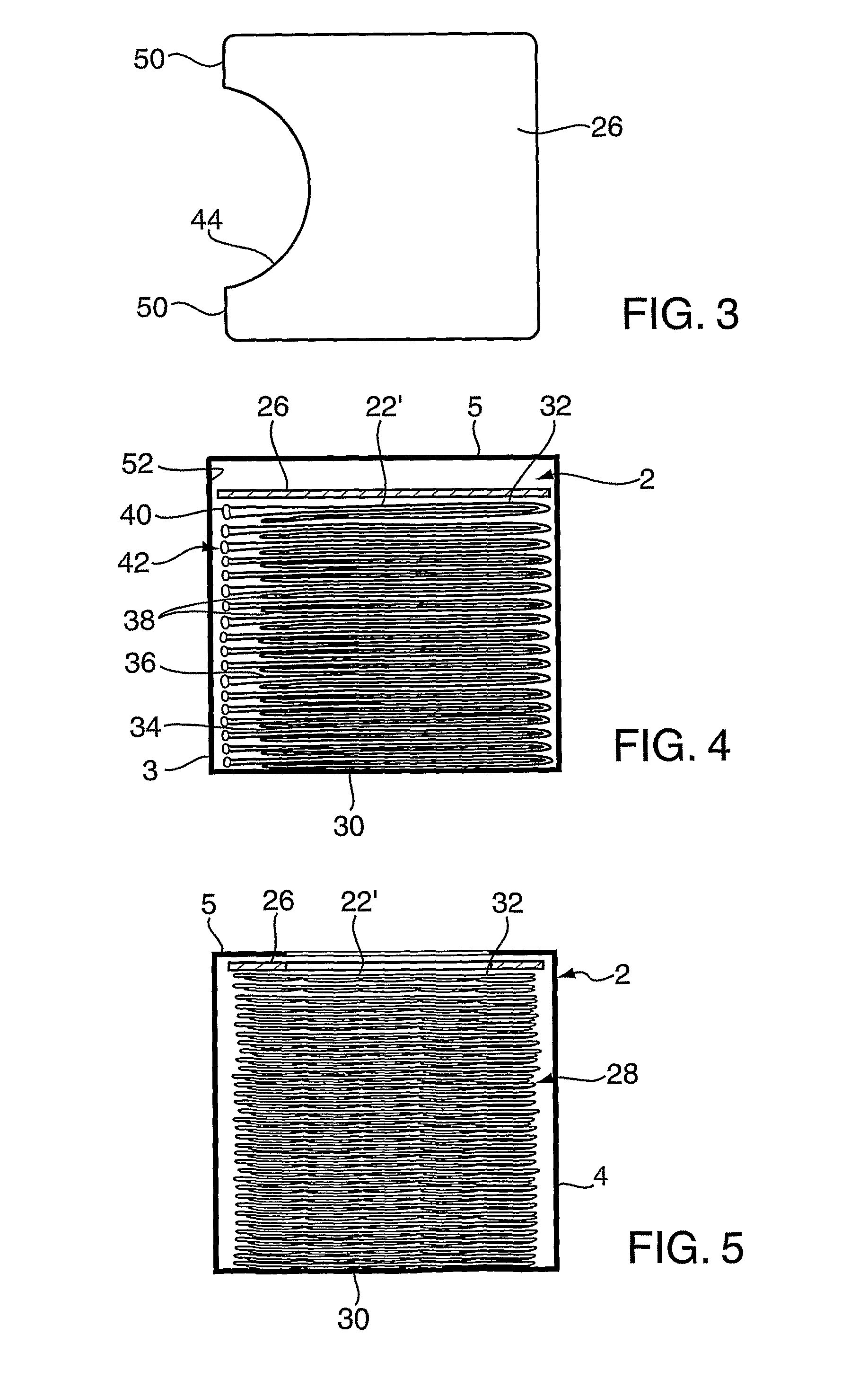

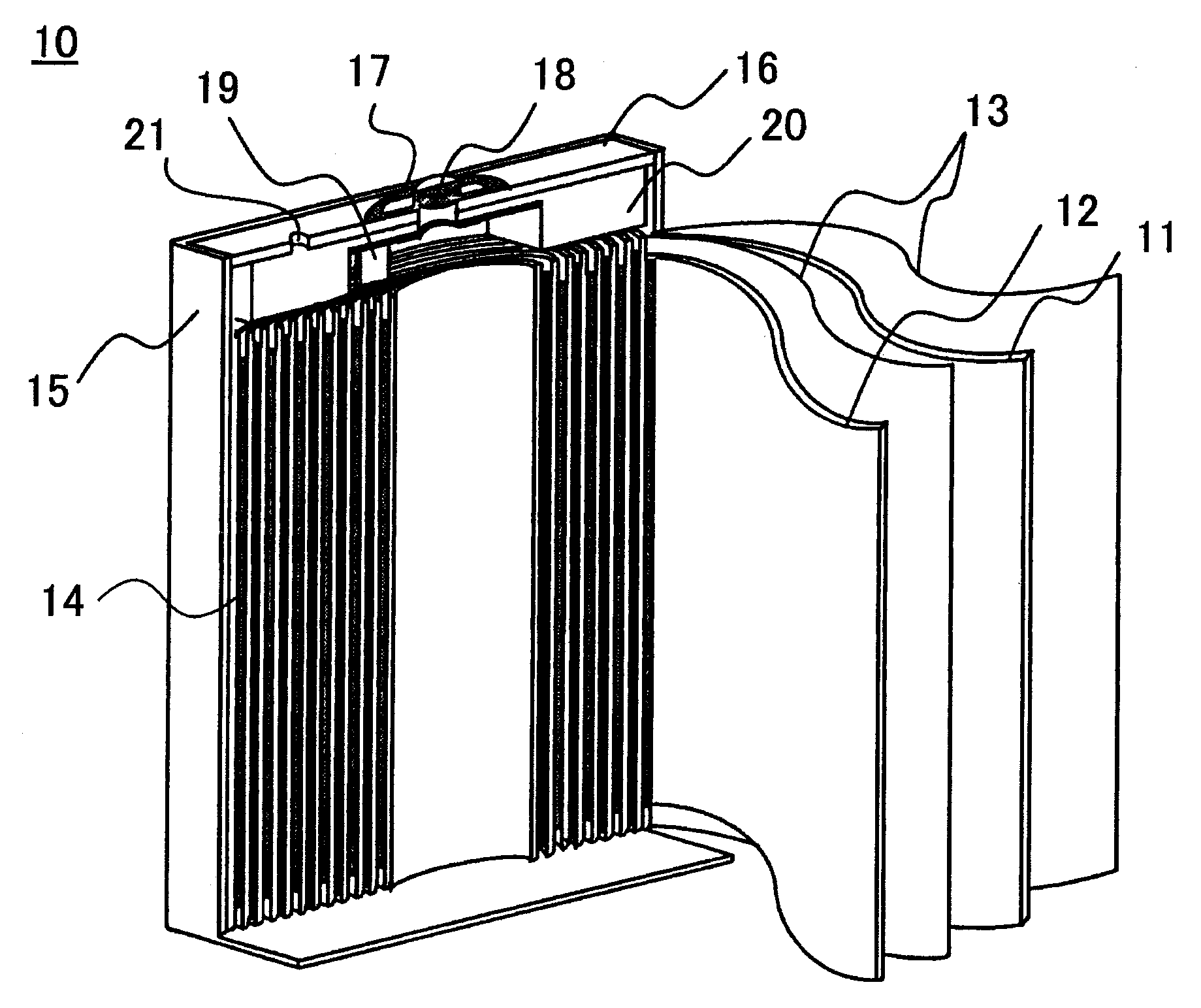

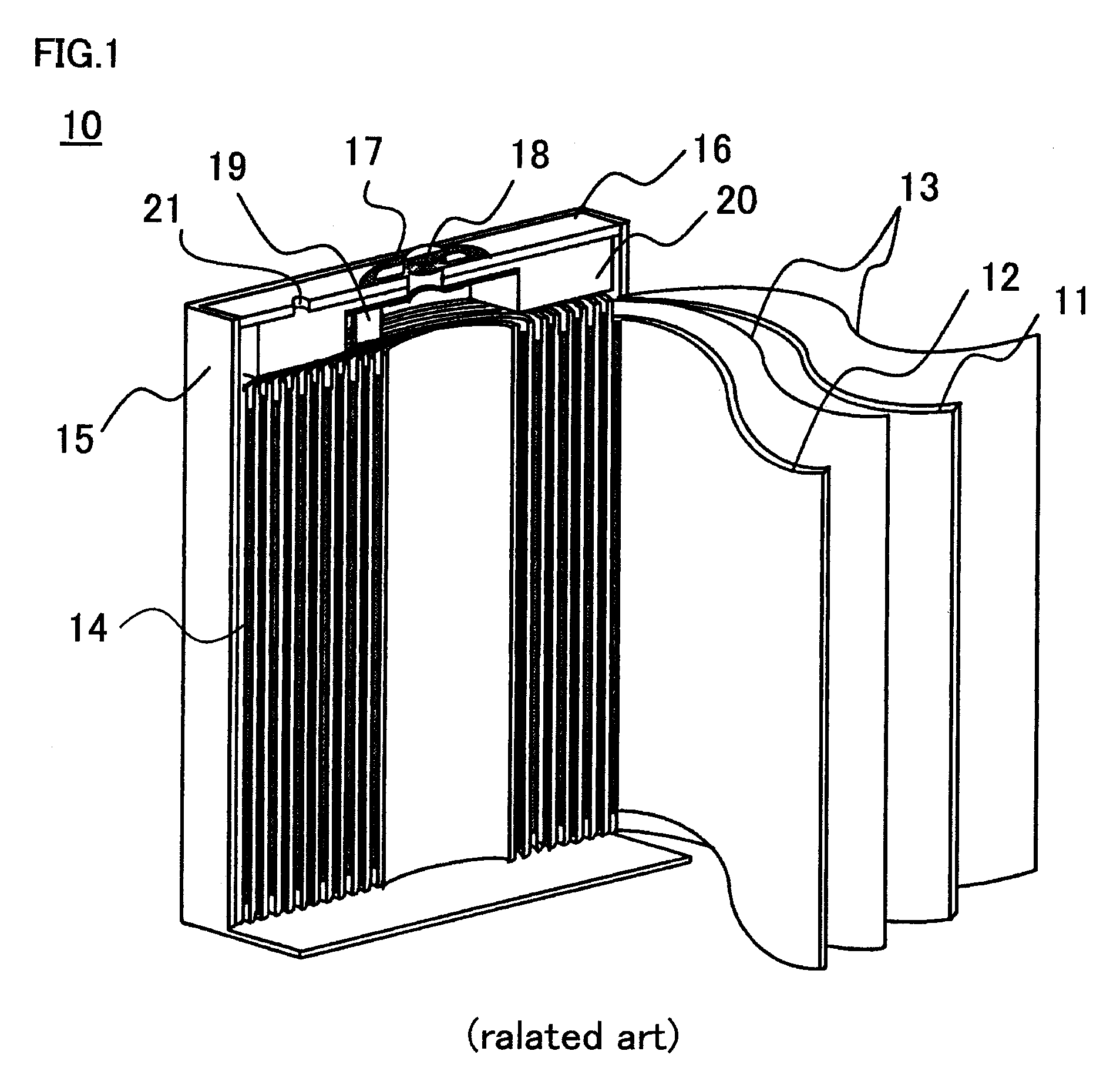

Folded interposer

InactiveUS6884653B2Efficient stackingWasted spaceSemiconductor/solid-state device detailsPrinted circuit aspectsHigh densitySemiconductor package

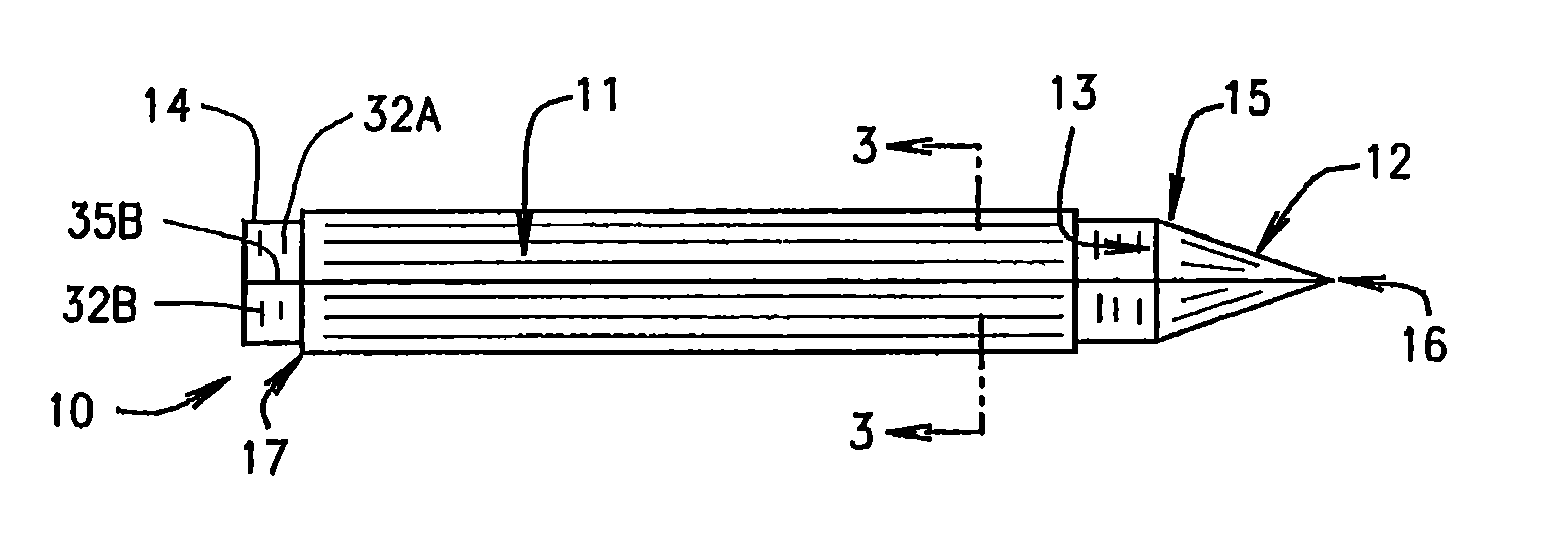

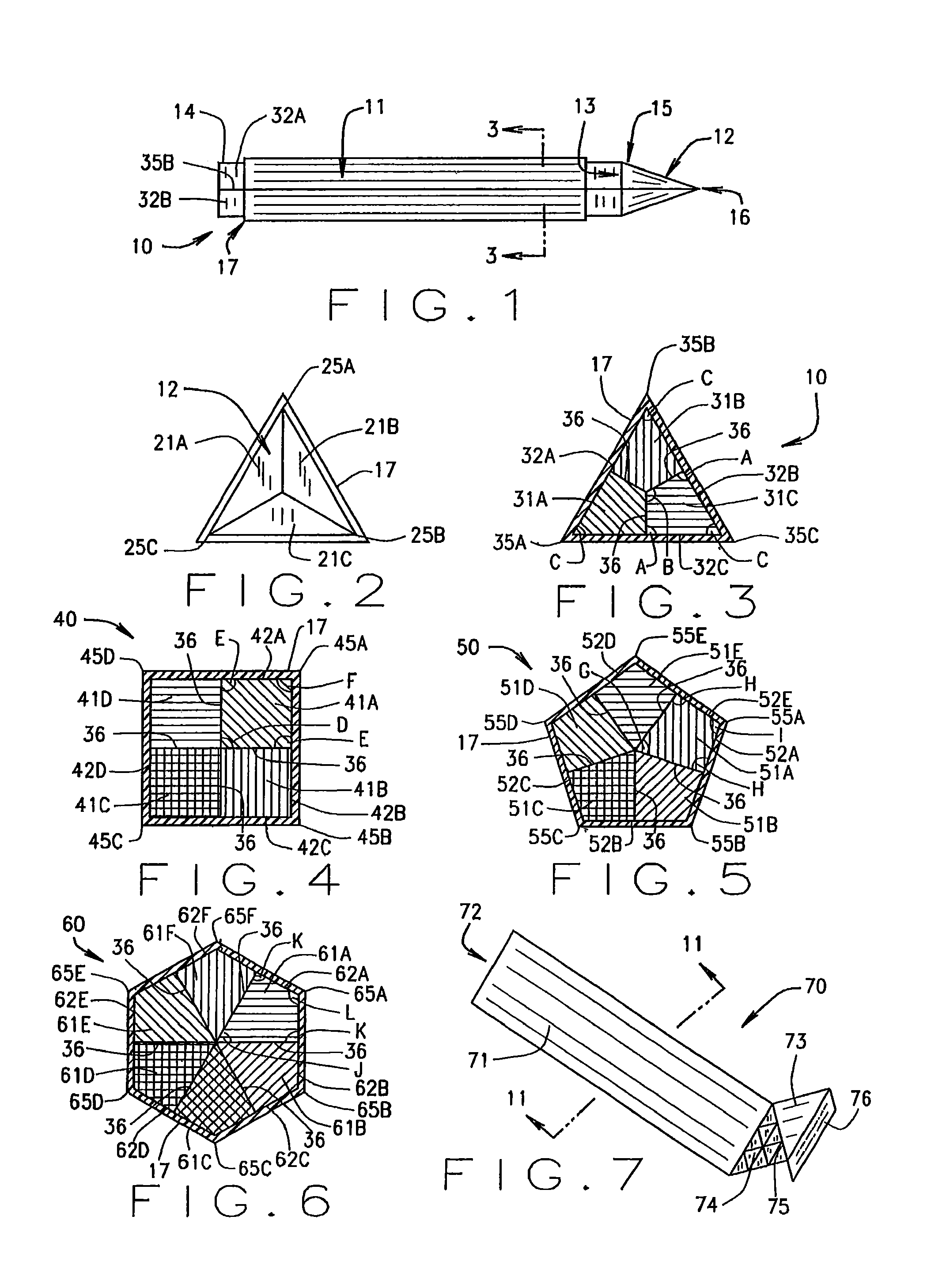

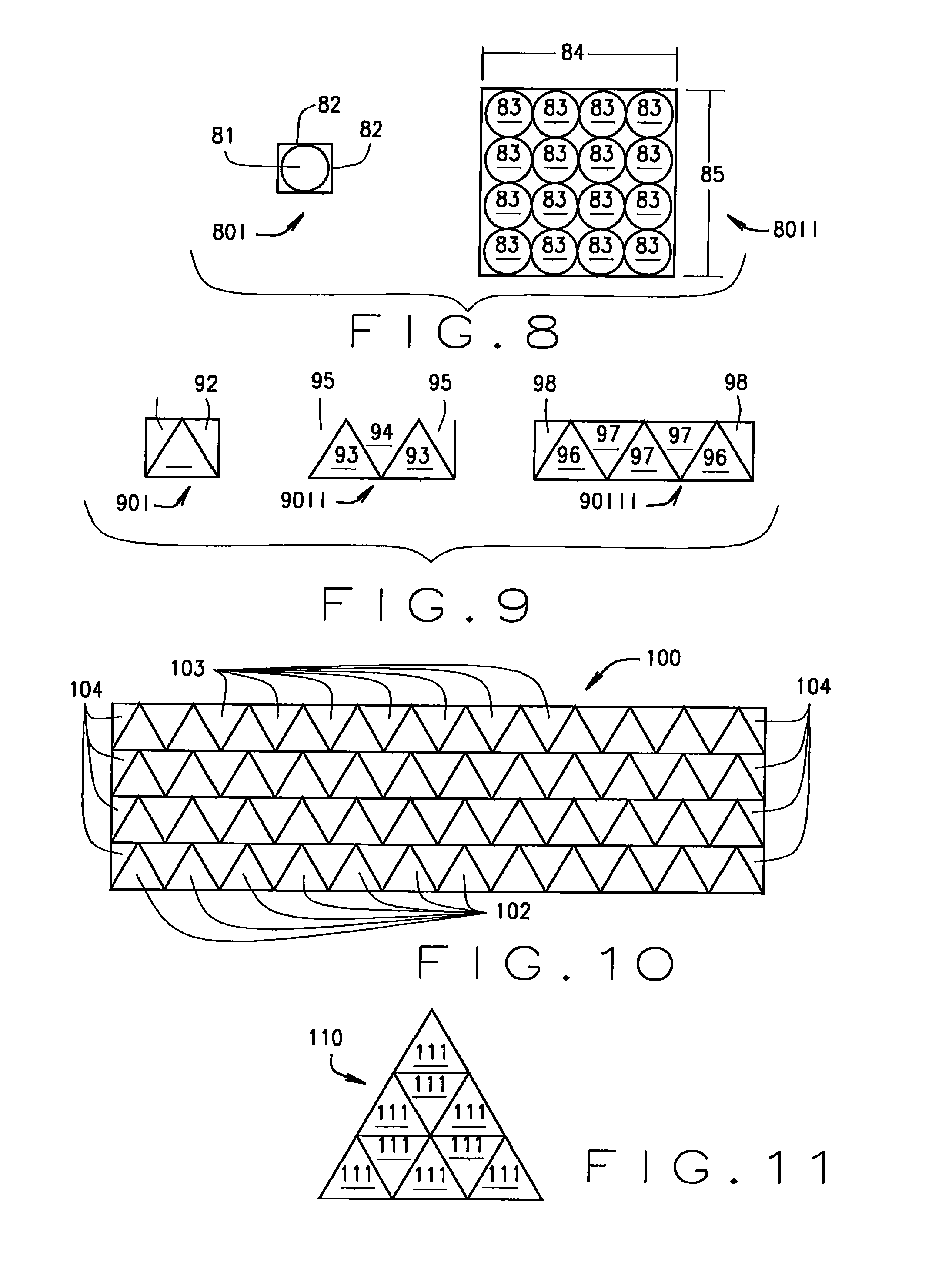

A folded interposer used to achieve a high density semiconductor package is disclosed. The folded interposer is comprised of a thin, flexible material that can be folded around one or multiple semiconductor dice in a serpentine fashion. The semiconductor dice are then attached to a substrate through electrical contacts on the interposer. The folded interposer allows multiple semiconductor dice to be efficiently stacked in a high density semiconductor package by reducing the unused or waster space between stacked semiconductor dice. Vias extending through the folded interposer provide electrical communication between the semiconductor dice and the substrate. The present invention also relates to a method of packaging semiconductor dice in a high density arrangement and a method of forming the high density semiconductor package.

Owner:MICRON TECH INC

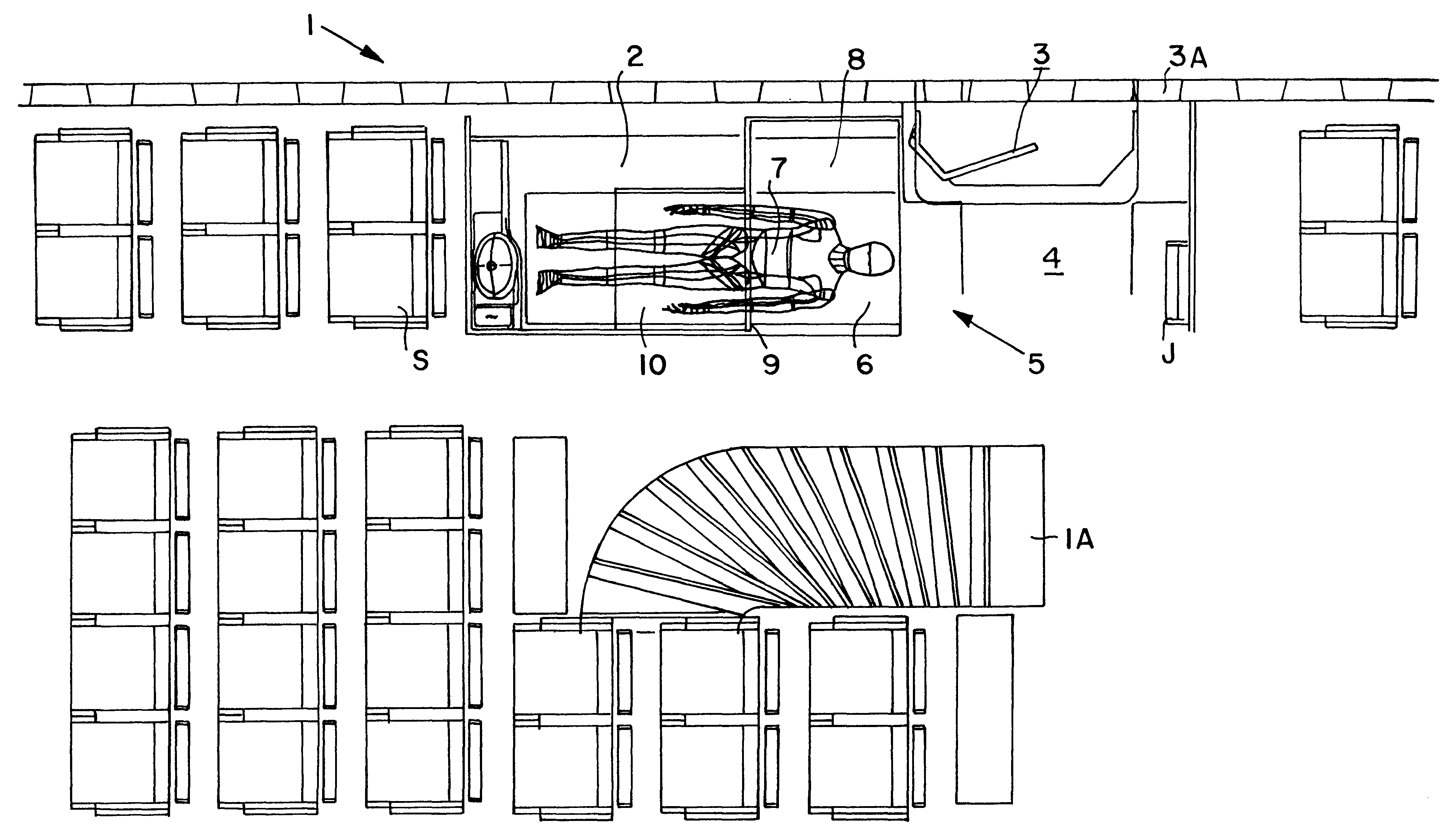

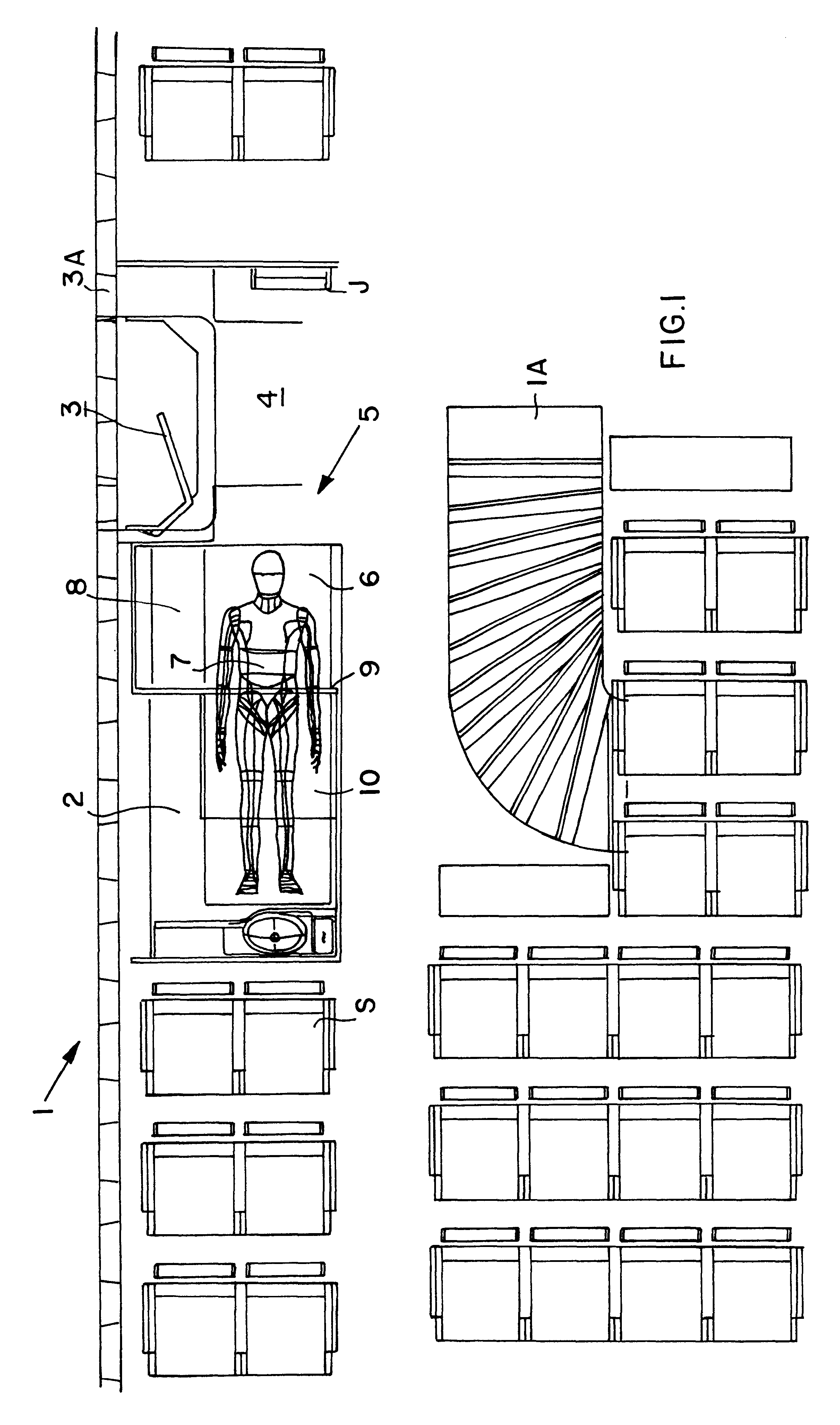

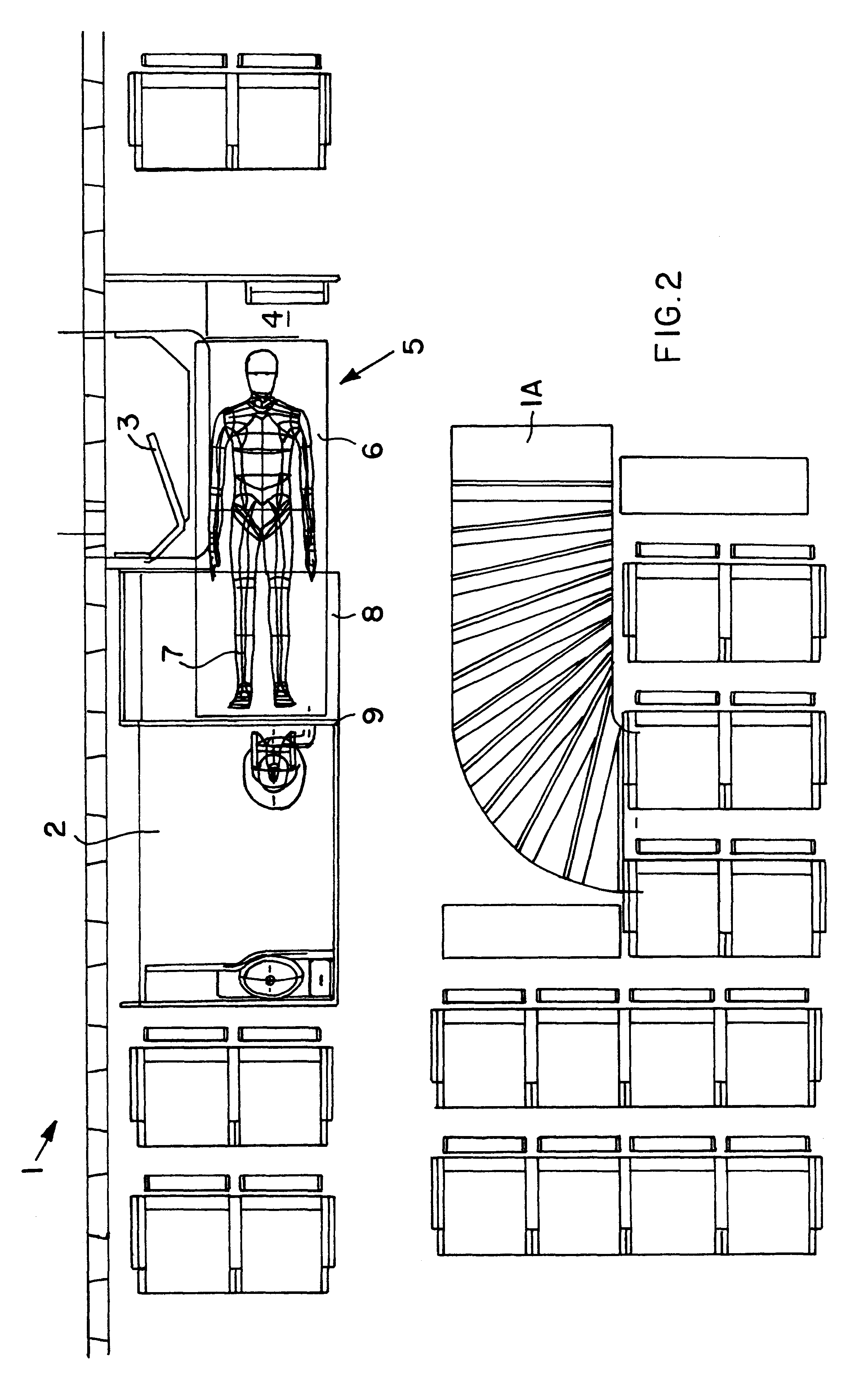

Patient transport arrangement in an aircraft

InactiveUS6273366B1Economical and adaptableFlexible deploymentSeating arrangementsAir-treatment apparatus arrangementsAirplanePatient Transport

A patient transport arrangement is provided in the passenger cabin of an aircraft and includes a patient stretcher, medical supplies and equipment, and a compartment that is variably and adaptably useable as a restroom compartment and as a medical care compartment. The compartment is arranged adjacent to the doorway clearance area in front of the cabin door of the aircraft. The adaptable compartment includes a foldable wall element so that the stretcher can extend at least partially into the compartment during take-off, landing and ground operations of the aircraft while leaving the doorway clearance area unobstructed, and so that the stretcher can be repositioned out of the compartment and into the doorway clearance area during cruise flight so as to allow the compartment to be used as a passenger restroom during the flight. This arrangement makes efficient use of space within the passenger cabin that would otherwise be unused during various phases of flight.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

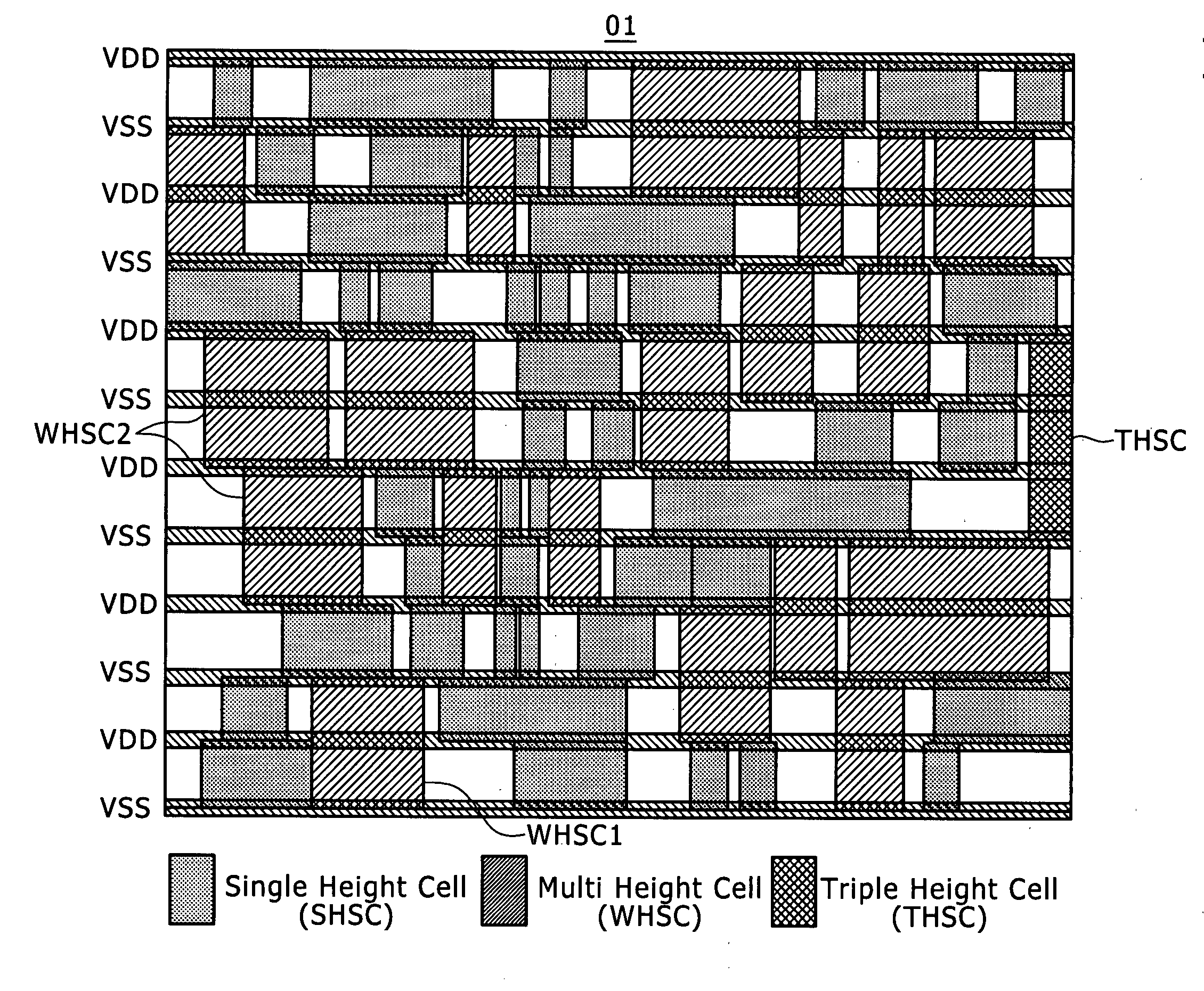

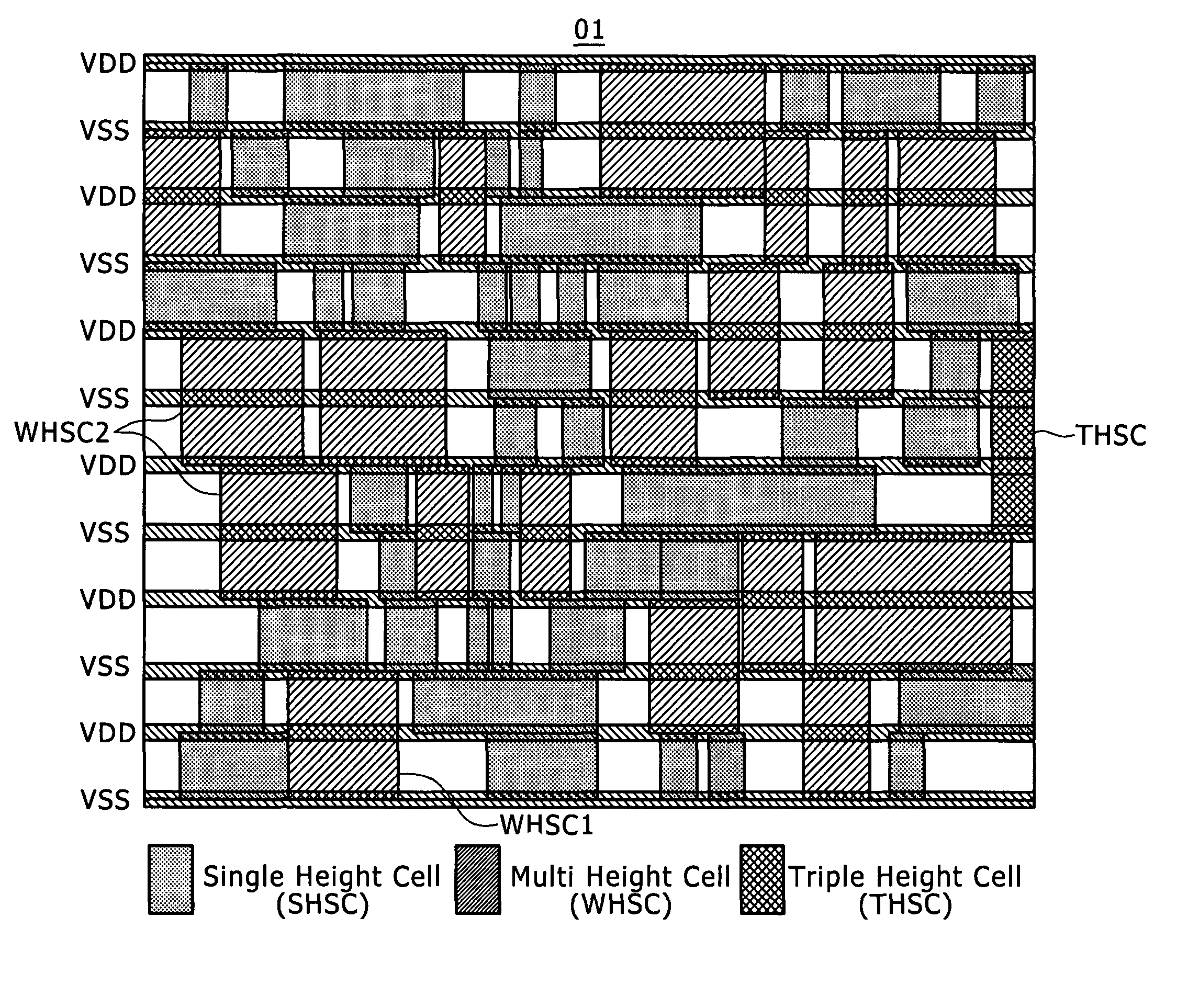

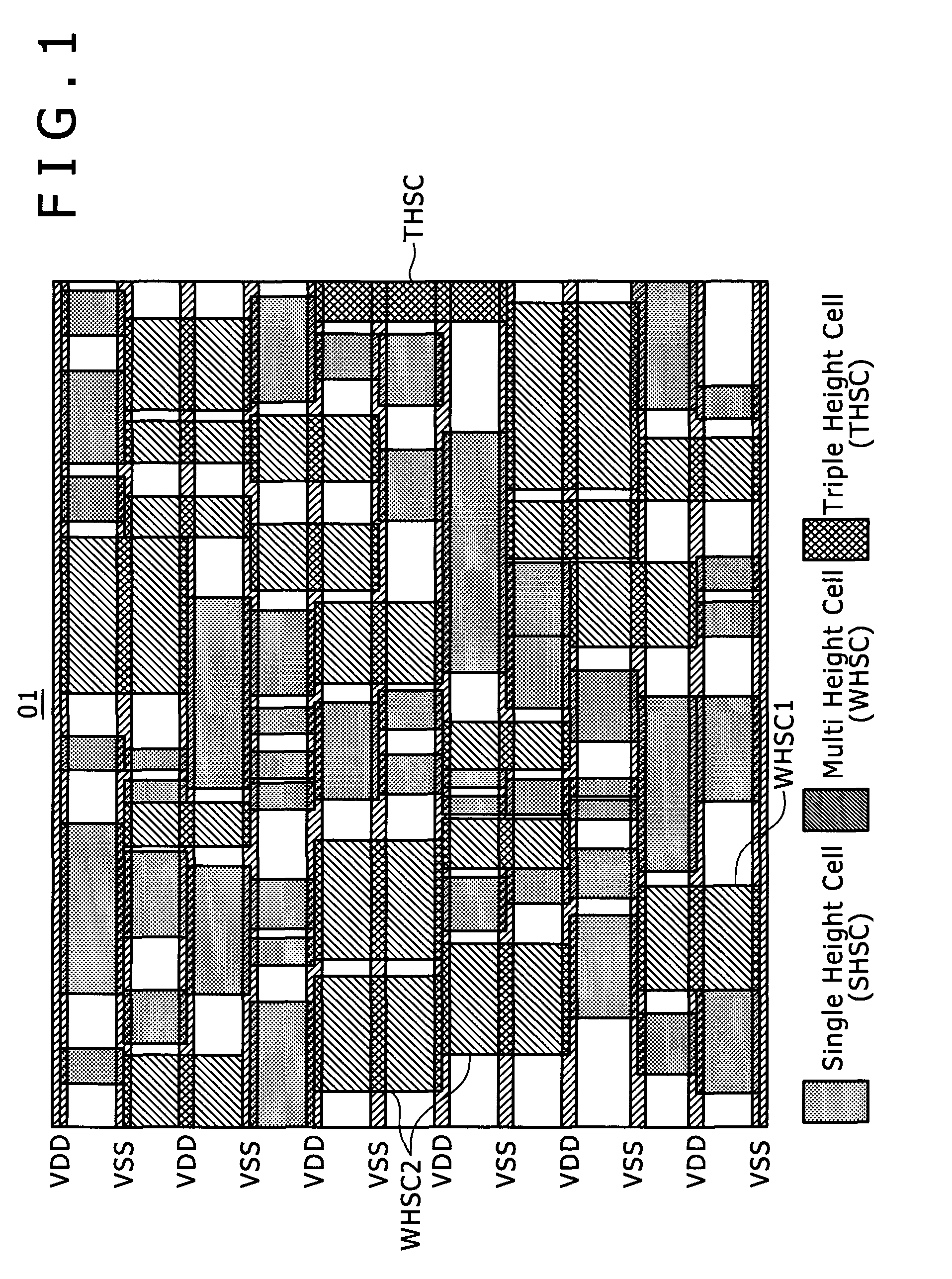

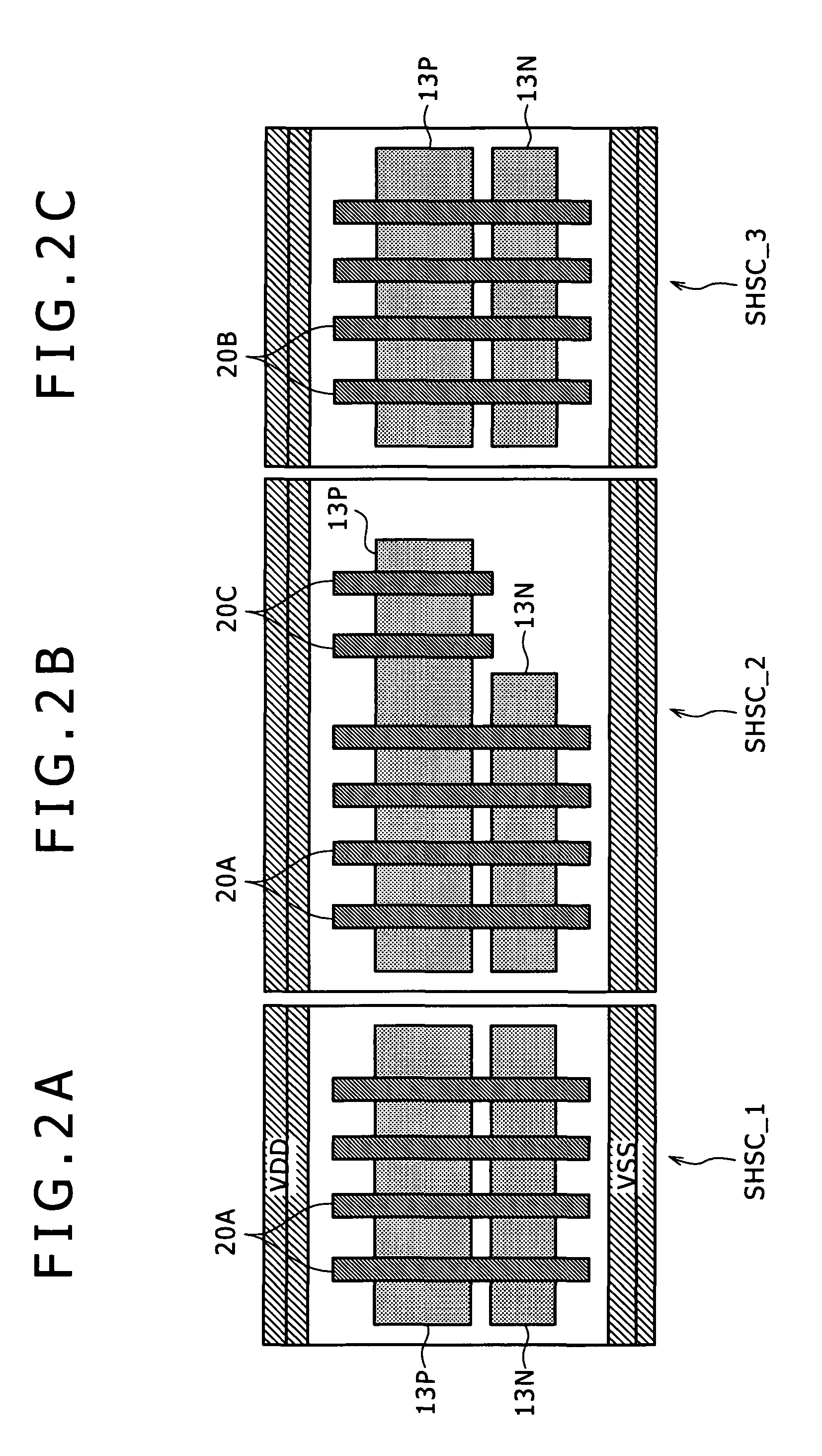

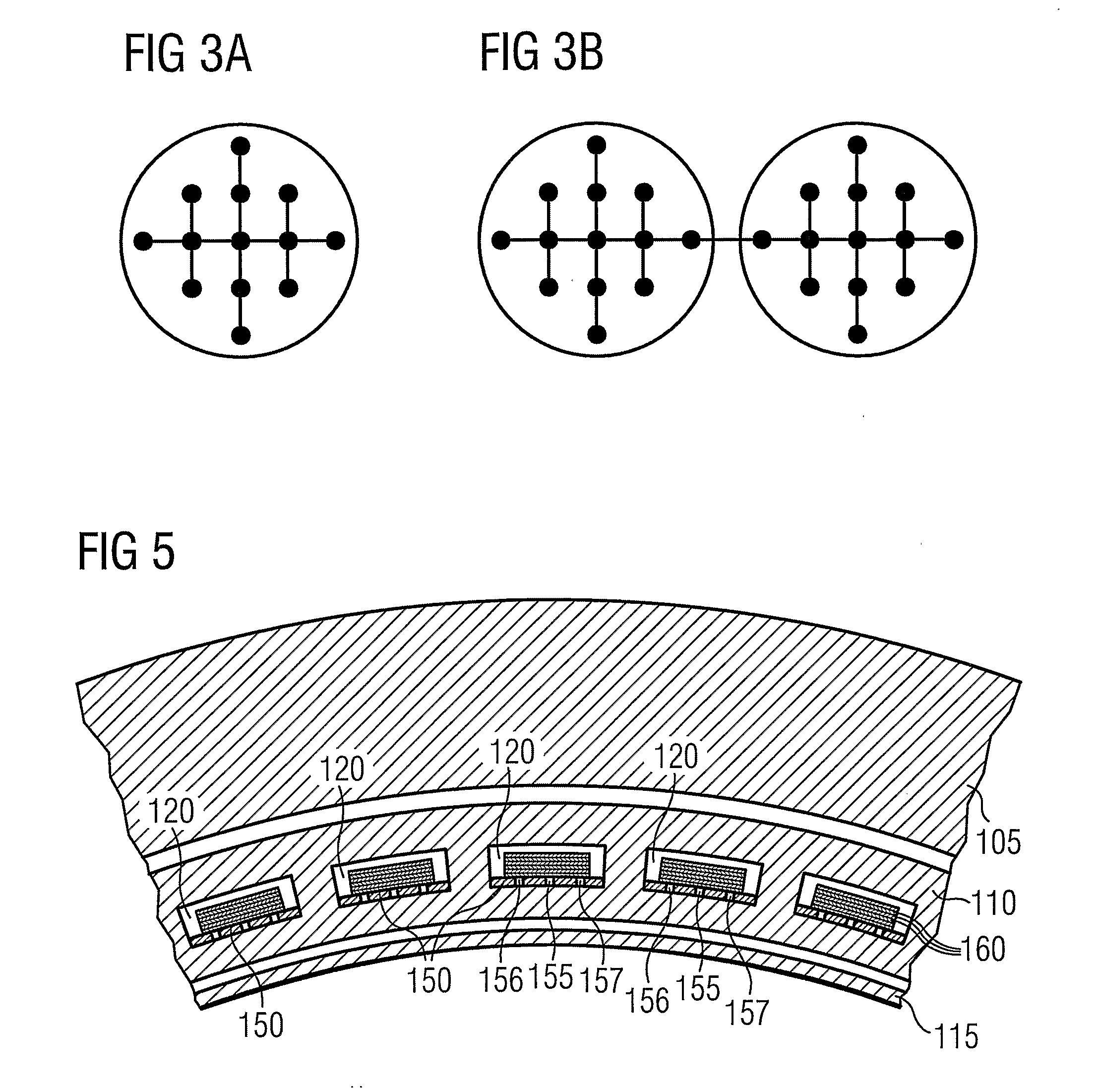

Semiconductor integrated circuit

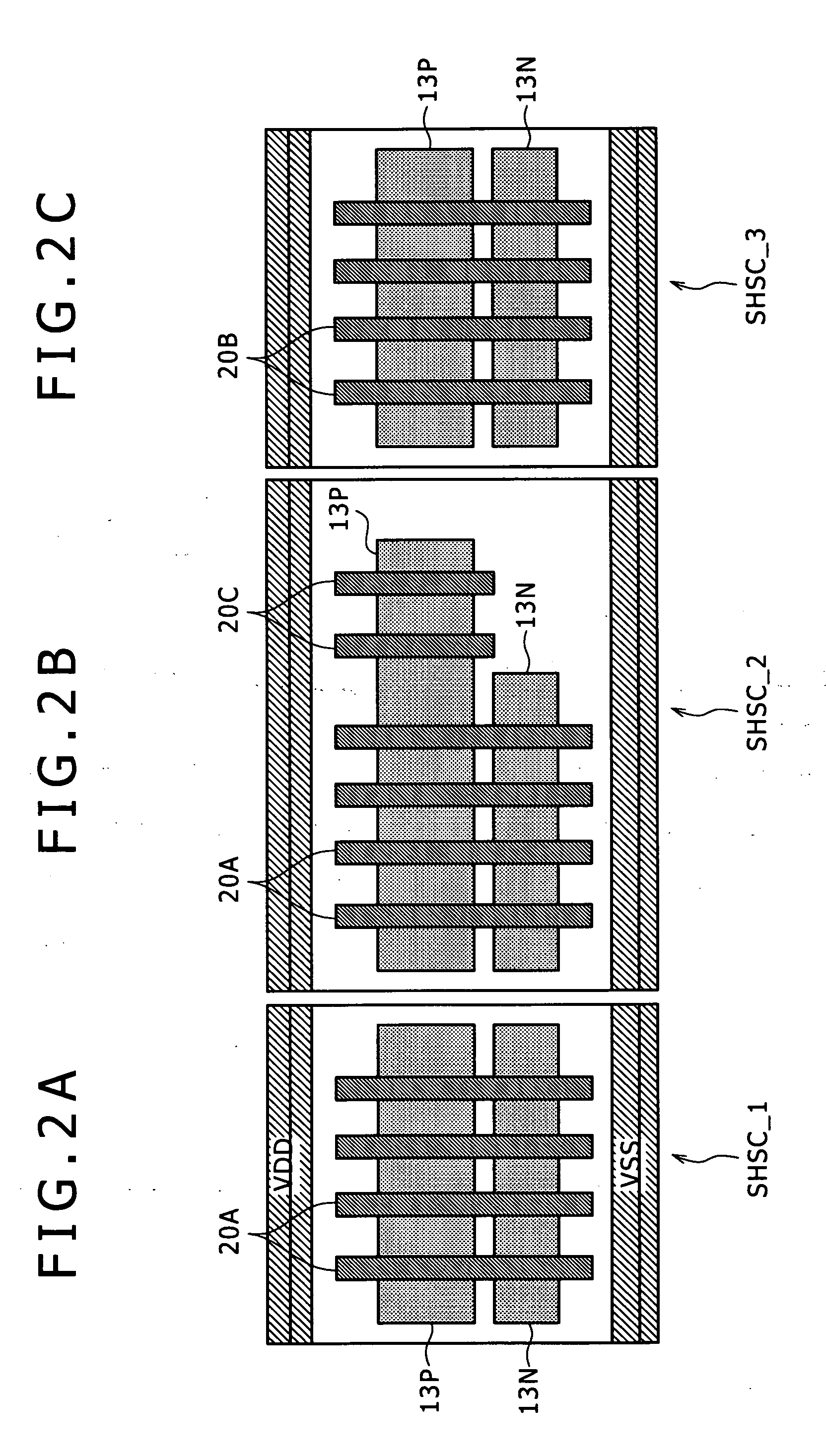

ActiveUS20110049575A1Eliminating wasted spaceReduce in quantitySolid-state devicesLogic circuitsEngineeringSemiconductor

Disclosed herein is a semiconductor integrated circuit, wherein a desired circuit is formed by combining and laying out a plurality of standard cells and connecting the cells together, of which the cell length, i.e., the gap between a pair of opposed sides, is standardized, the plurality of standard cells forming the desired circuit include complementary in-phase driven standard cells, each of which includes a plurality of complementary transistor pairs that are complementary in conductivity type to each other and have their gate electrodes connected together, and N (≧2) pairs of all the complementary transistor pairs are driven in phase, and the size of the standardized cell length of the complementary in-phase driven standard cell is defined as an M-fold cell length which is M (N≧M≧2) times the basic cell length which is appropriate to the single complementary transistor pair.

Owner:SONY CORP

Positive electrode for nonaqueous electrolyte secondary battery, and production method thereof

InactiveUS7981544B2Good effectWasted spaceFinal product manufactureActive material electrodesManganese oxideCobalt

A positive electrode for a nonaqueous electrolyte secondary battery using a positive electrode active material mixture according to an embodiment of the invention includes a positive electrode active material capable of intercalating and deintercalating a lithium ion, a conductive agent and a binder, in which the positive electrode active material is produced by coating cobalt-based lithium composite oxide represented by a general formula: LiaCo1-sM1sO2 with lithium nickel cobalt manganese oxide represented by a general formula: LibNitCouMnvO2, the ratio r1 / r2 of the average particle diameter r1 of the cobalt-based lithium composite oxide and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 2≦r1 / r2≦50, and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 0.5 μm≦r2≦20 μm. By containing such a constitution, a positive electrode for a nonaqueous electrolyte secondary battery in which even when the charging discharging is repeated at a high potential of 4.5 V based on lithium, not only is the retention characteristics in a charged state excellent, but also the enhancing the capacity and the energy density of the battery can be achieved; and a production method thereof, can be provided.

Owner:SANYO ELECTRIC CO LTD

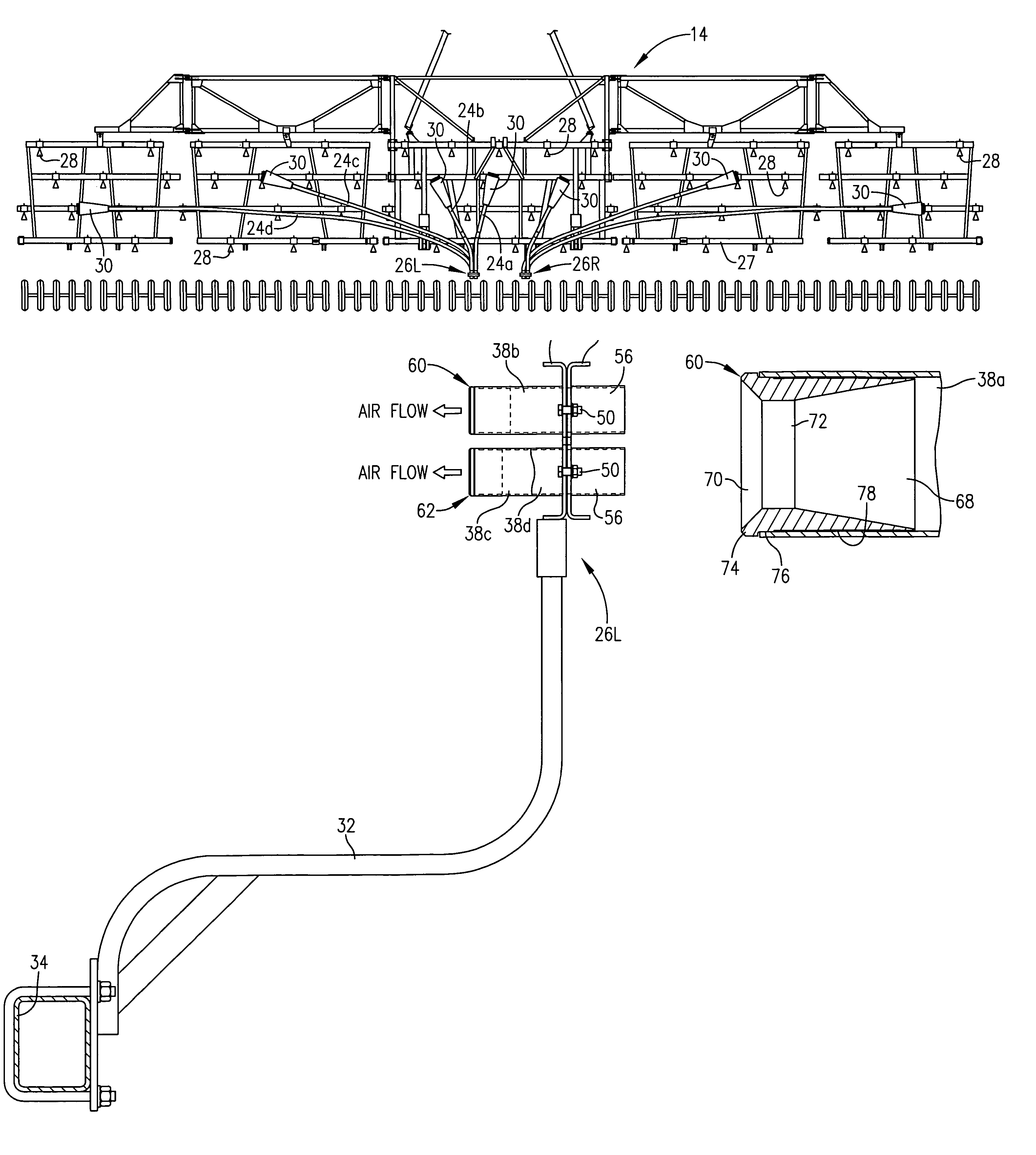

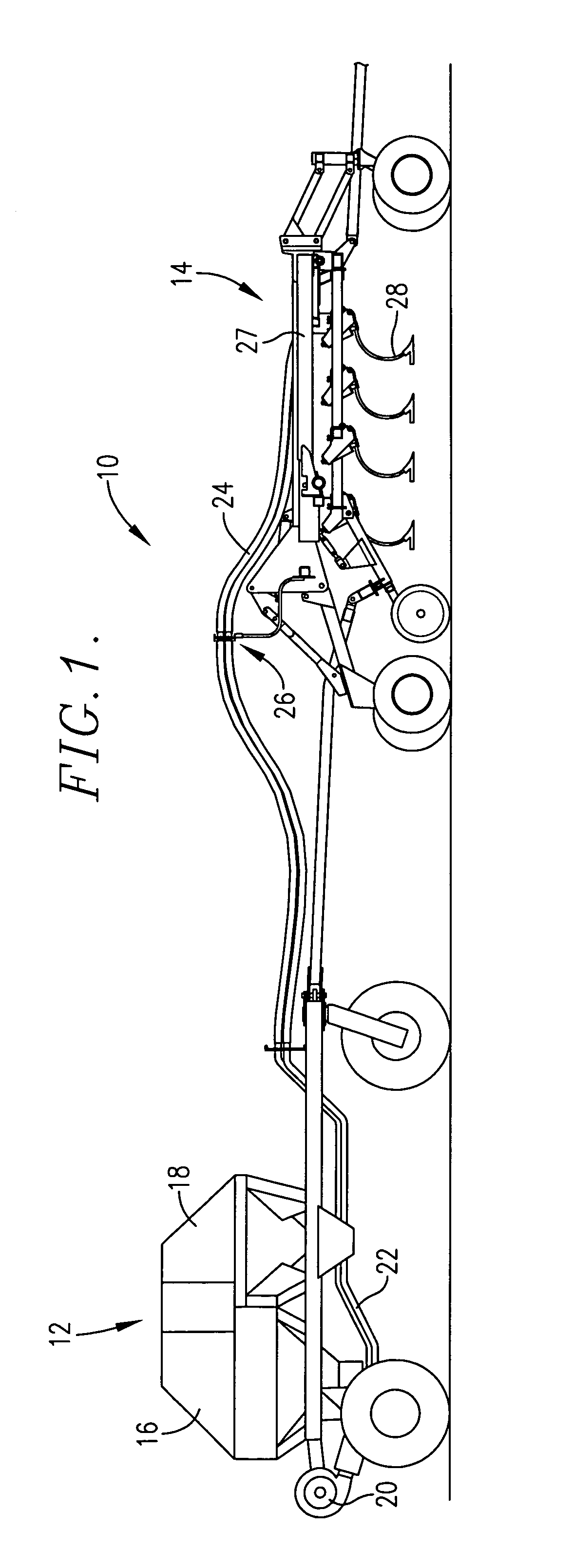

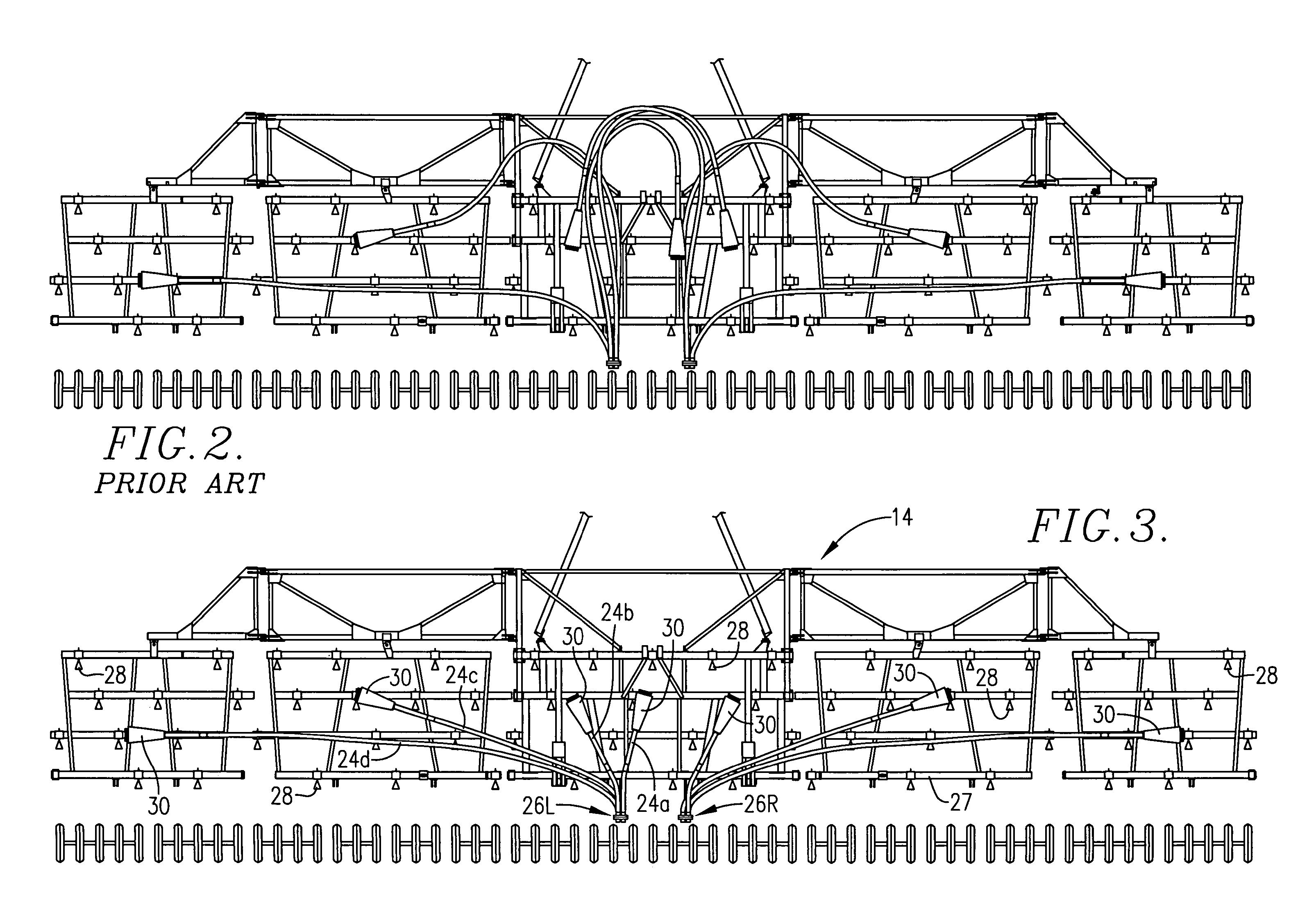

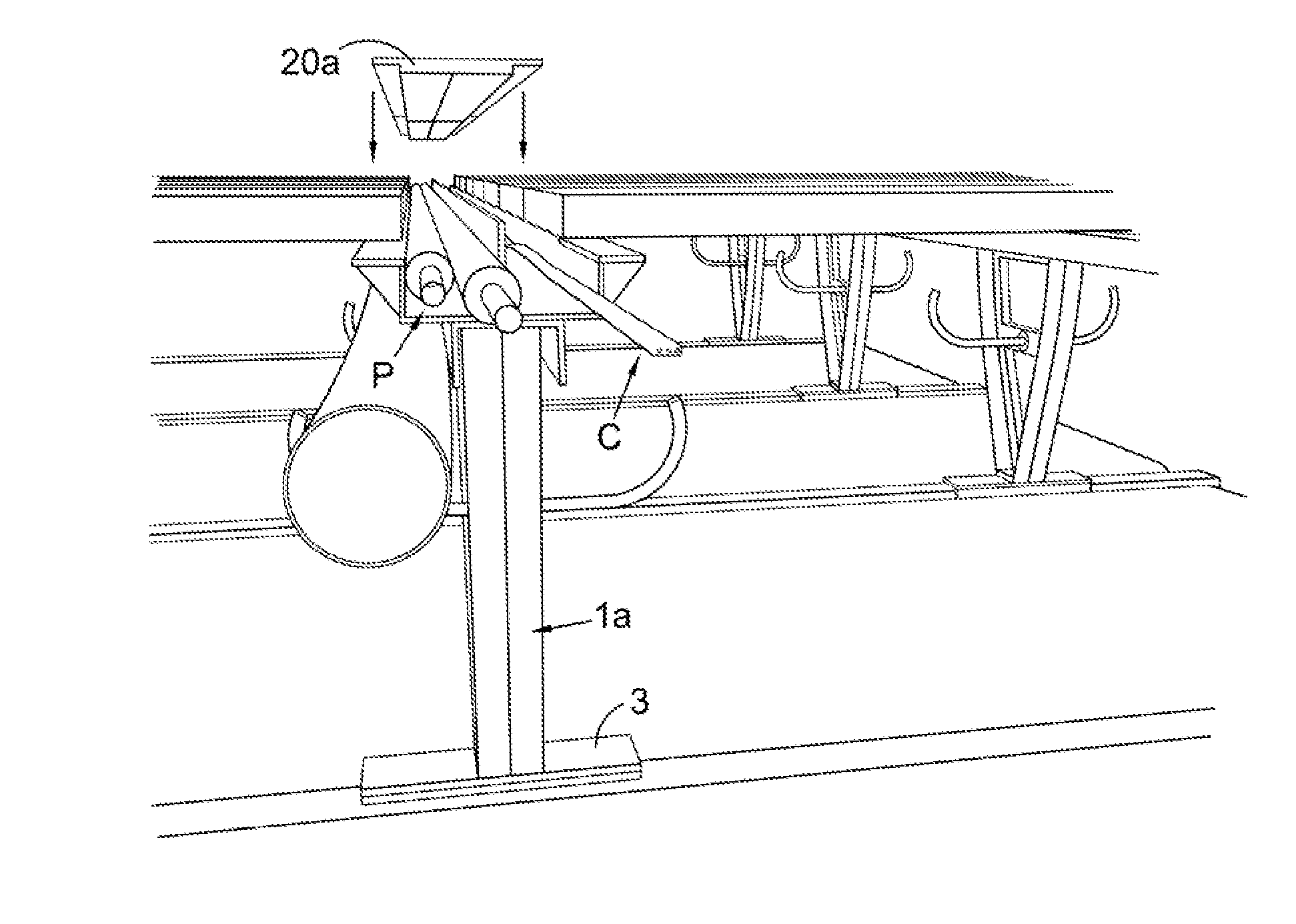

Pneumatic distribution system for air seeders

The primary distribution hoses on the tillage implement of a pneumatic seeding machine are of different lengths as needed to reach distribution heads or splitters on the implement that further divide the primary streams of materials into individual streams leading directly to the ground-engaging openers of the implement. Notwithstanding the differential in hose length, outlet pressures at the distribution heads are made uniform through the provision of internal flow restrictors associated with those hoses that are shorter than the longest hoses on the machine. Throat diameters of the restrictors vary in accordance with the pressure drop that is needed to match the difference in hose length between the longest hose and the restricted hose. In a preferred embodiment, the restrictors are mounted within nipples on the coupling assembly that releasably connects conduits from a seed cart with the primary hoses on the implement.

Owner:MORRIS EQUIP LTD

Folded interposer

InactiveUS6982869B2Efficient stackingHigh densityComputer controlSimulator controlHigh densityInterposer

A folded interposer used to achieve a high density semiconductor package is disclosed. The folded interposer is comprised of a thin, flexible material that can be folded around one or multiple semiconductor dice in a serpentine fashion. The semiconductor dice are then attached to a substrate through electrical contacts on the interposer. The folded interposer allows multiple semiconductor dice to be efficiently stacked in a high density semiconductor package by reducing the unused or wasted space between stacked semiconductor dice. Vias extending through the folded interposer provide electrical communication between the semiconductor dice and the substrate. The present invention also relates to a method of packaging semiconductor dice in a high density arrangement and a method of forming the high density semiconductor package.

Owner:MICRON TECH INC

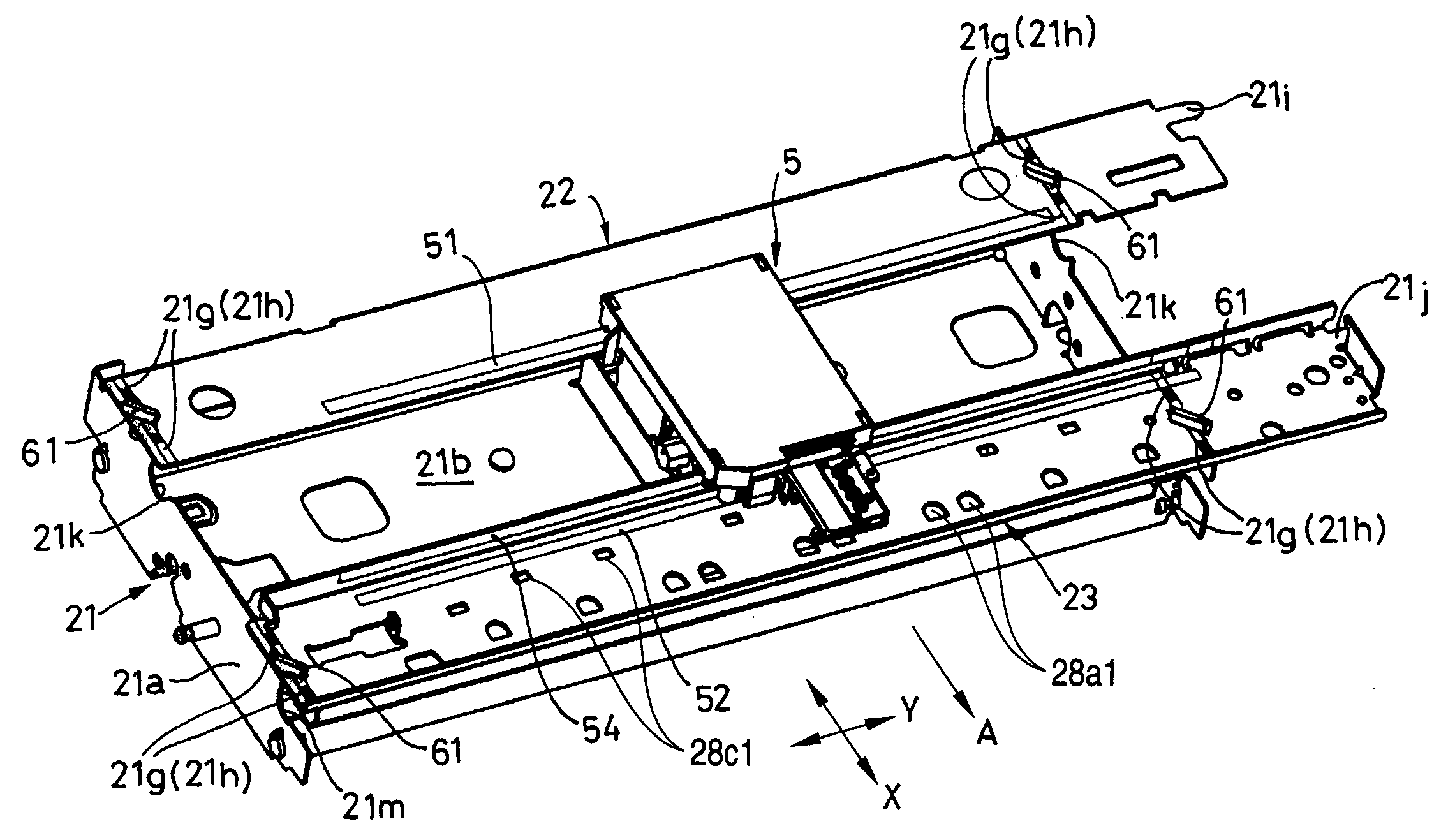

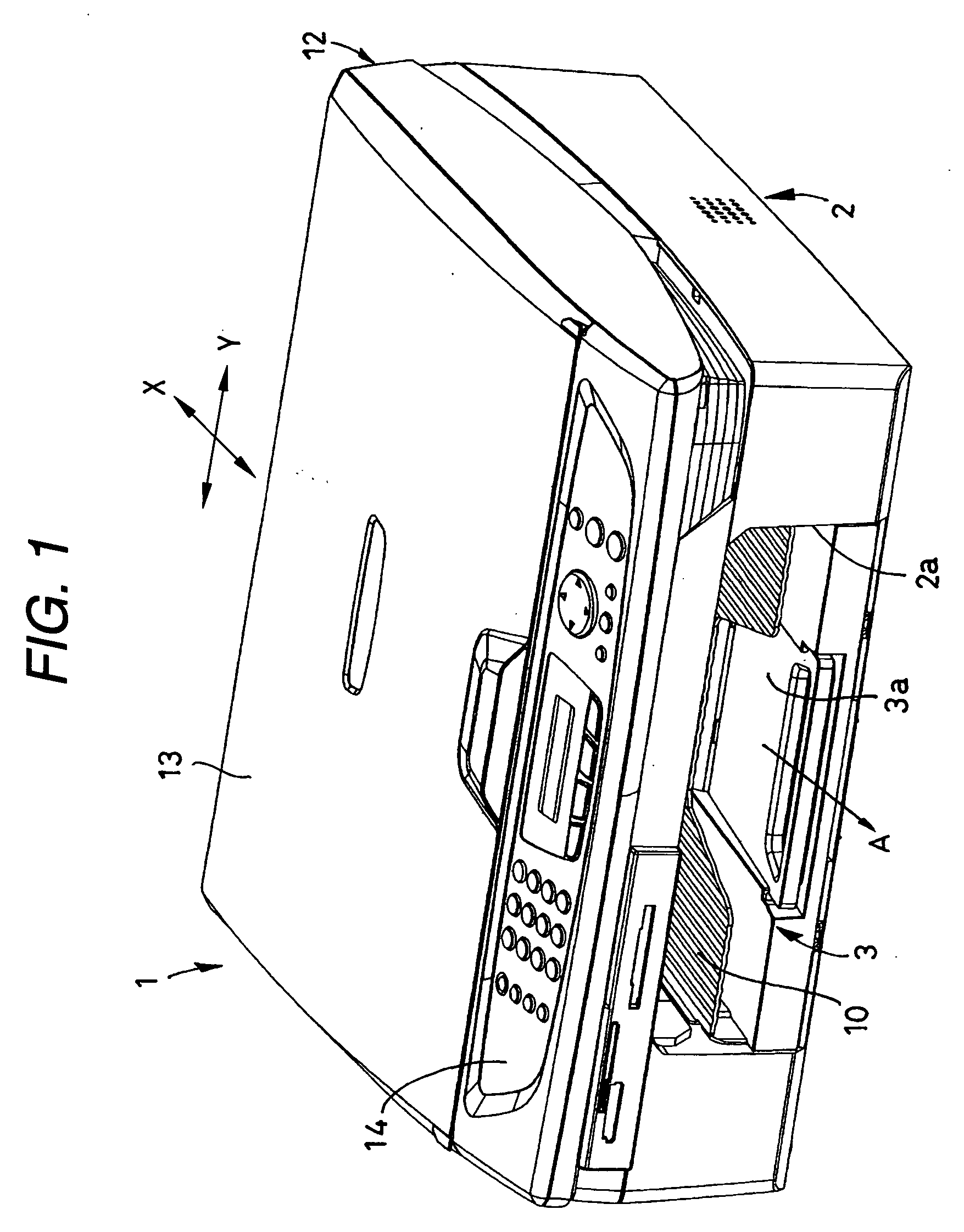

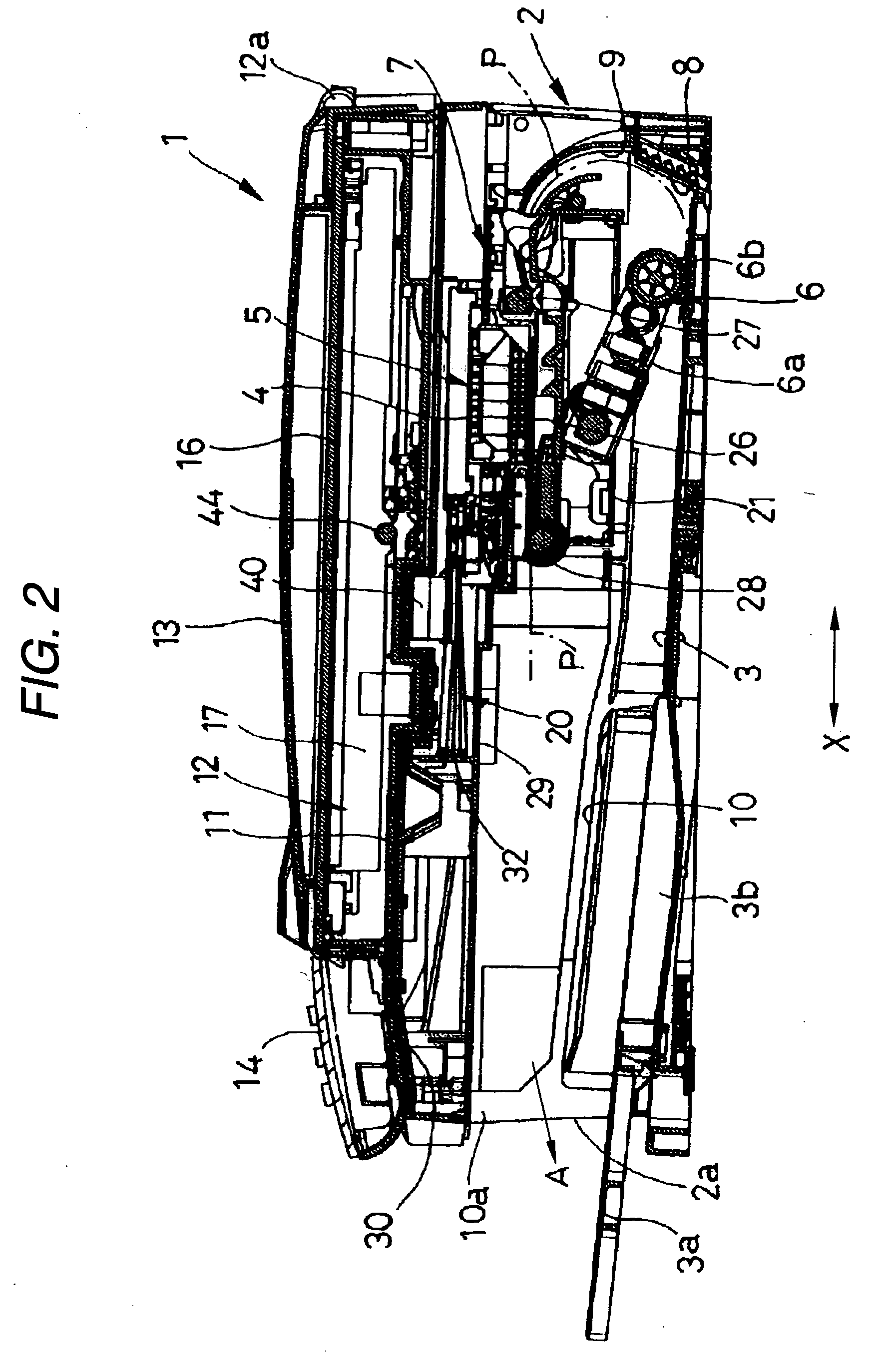

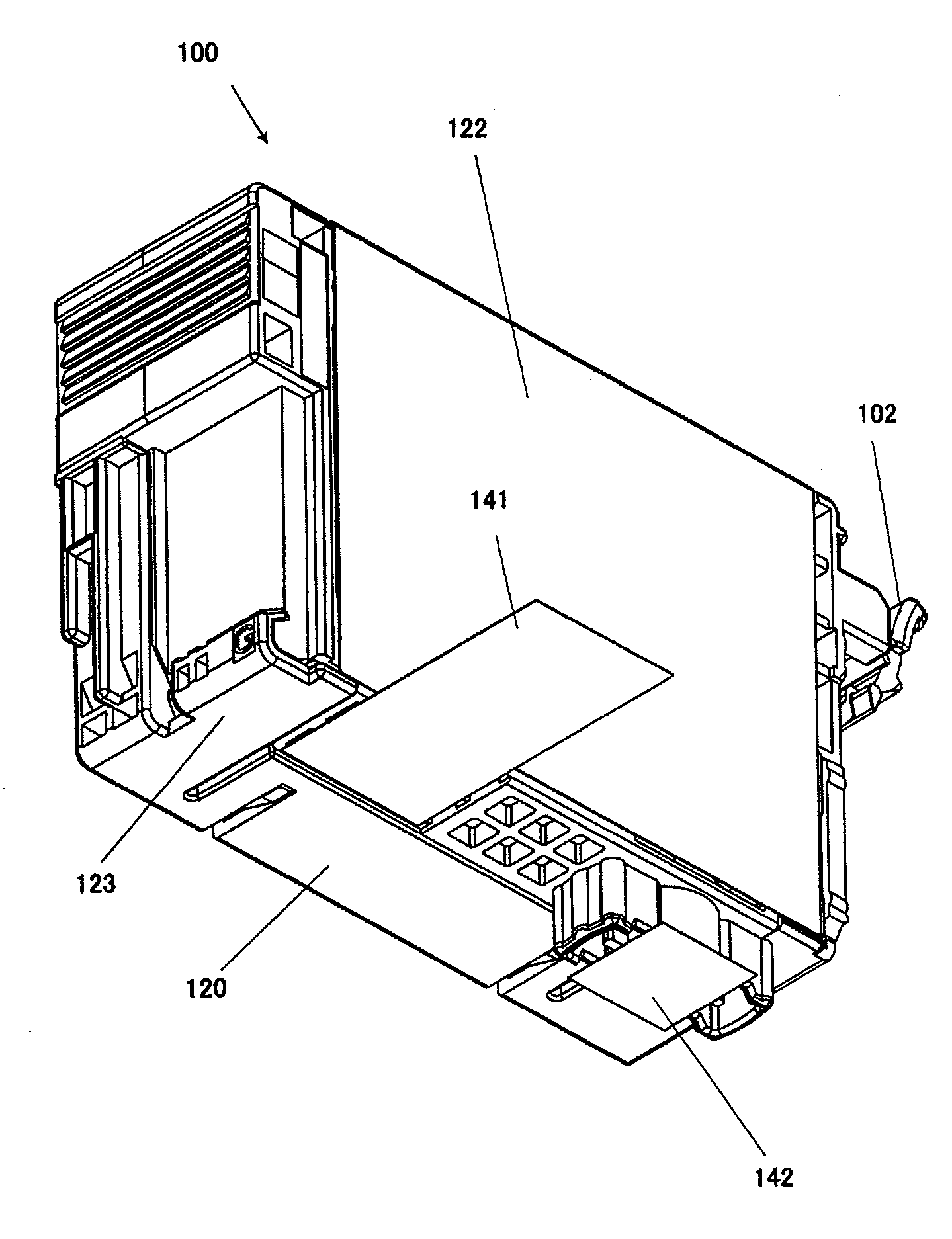

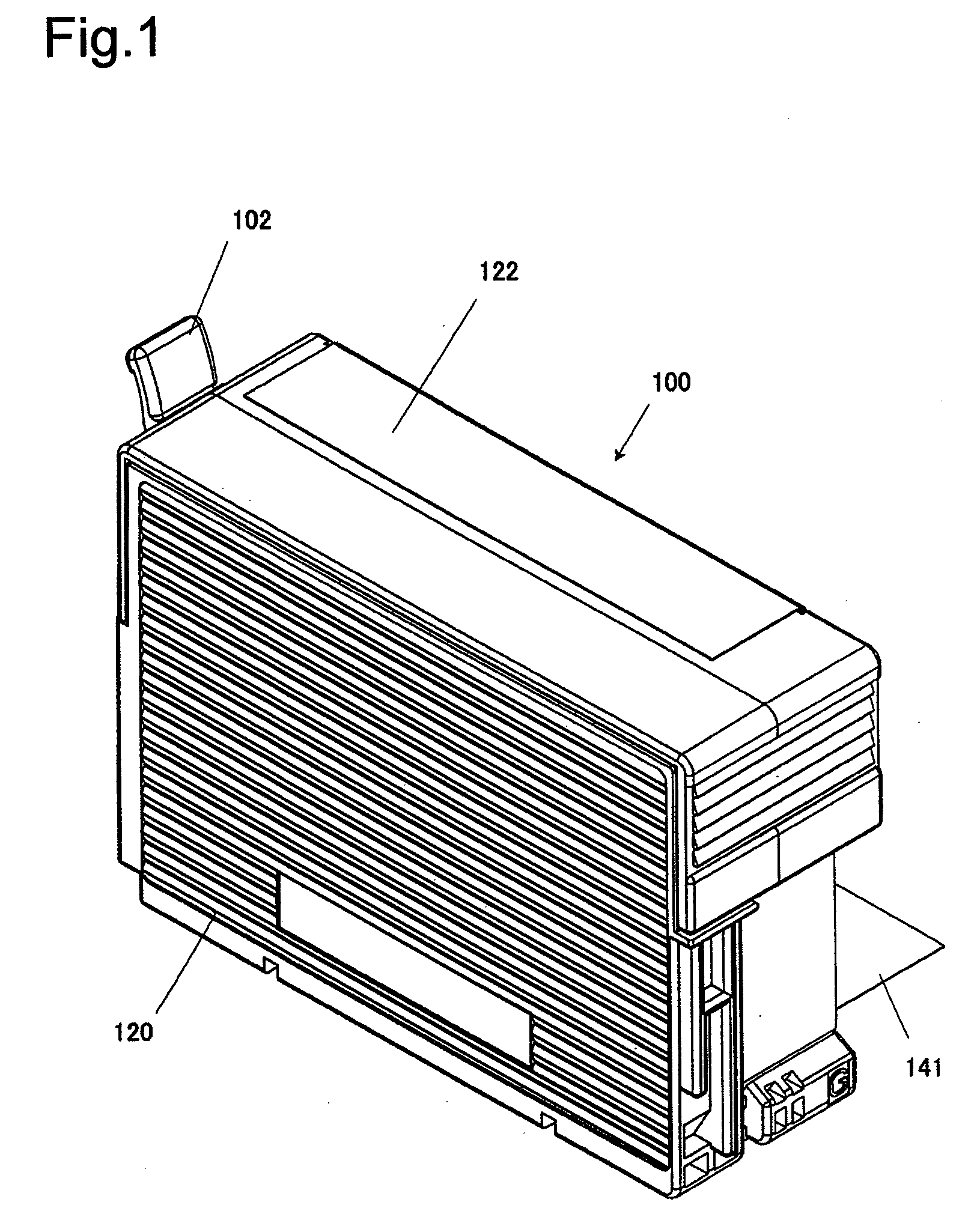

Image recording apparatus

An image recording apparatus includes: a carriage that carries a recording head capable of recording an image on a recording medium and reciprocates in a main scanning direction; a substantially box-shaped main frame having an open upper side and a pair of side plates extending in a sub-scanning direction orthogonal to the main scanning direction; and first and second guide members over which the carriage extends and by which the carriage is guided, the first and second guide members being disposed to be apart from each other by a predetermined distance in the sub-scanning direction, extended in the main scanning direction at the upper side of the main frame and fixed to the pair of side plates.

Owner:BROTHER KOGYO KK

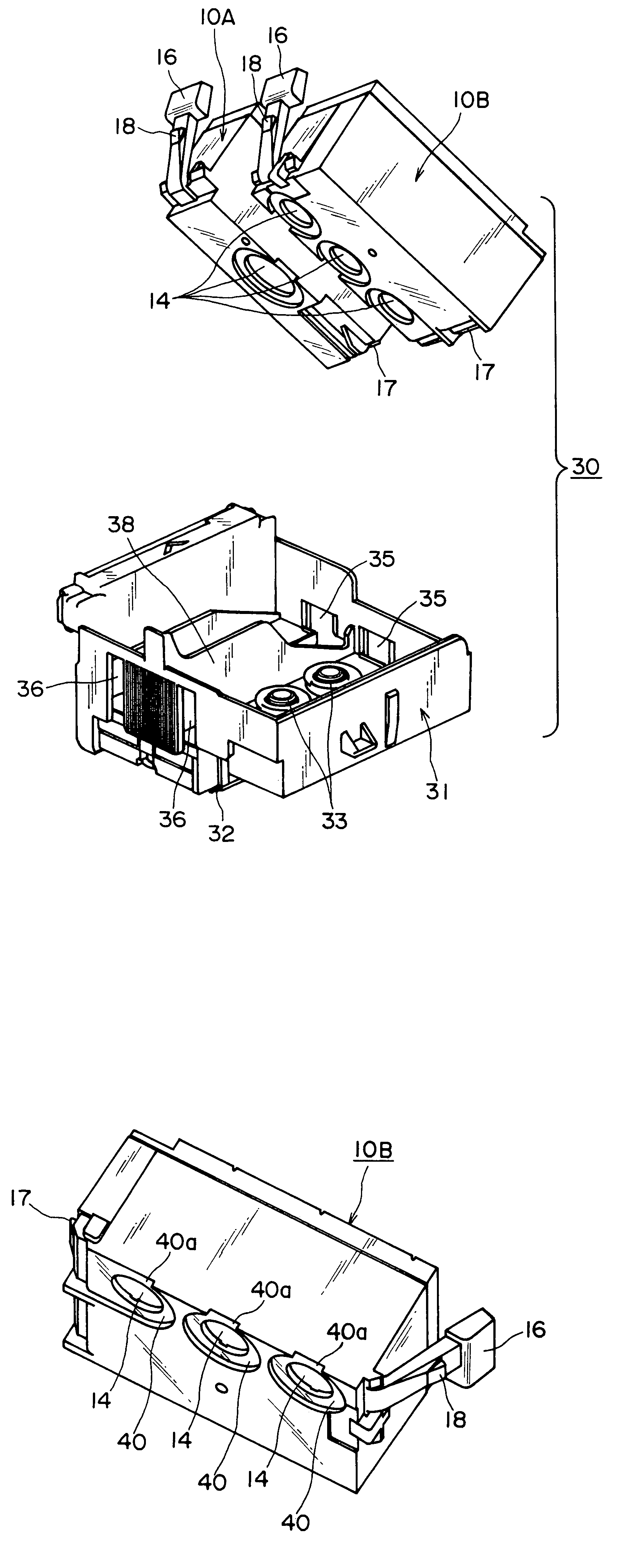

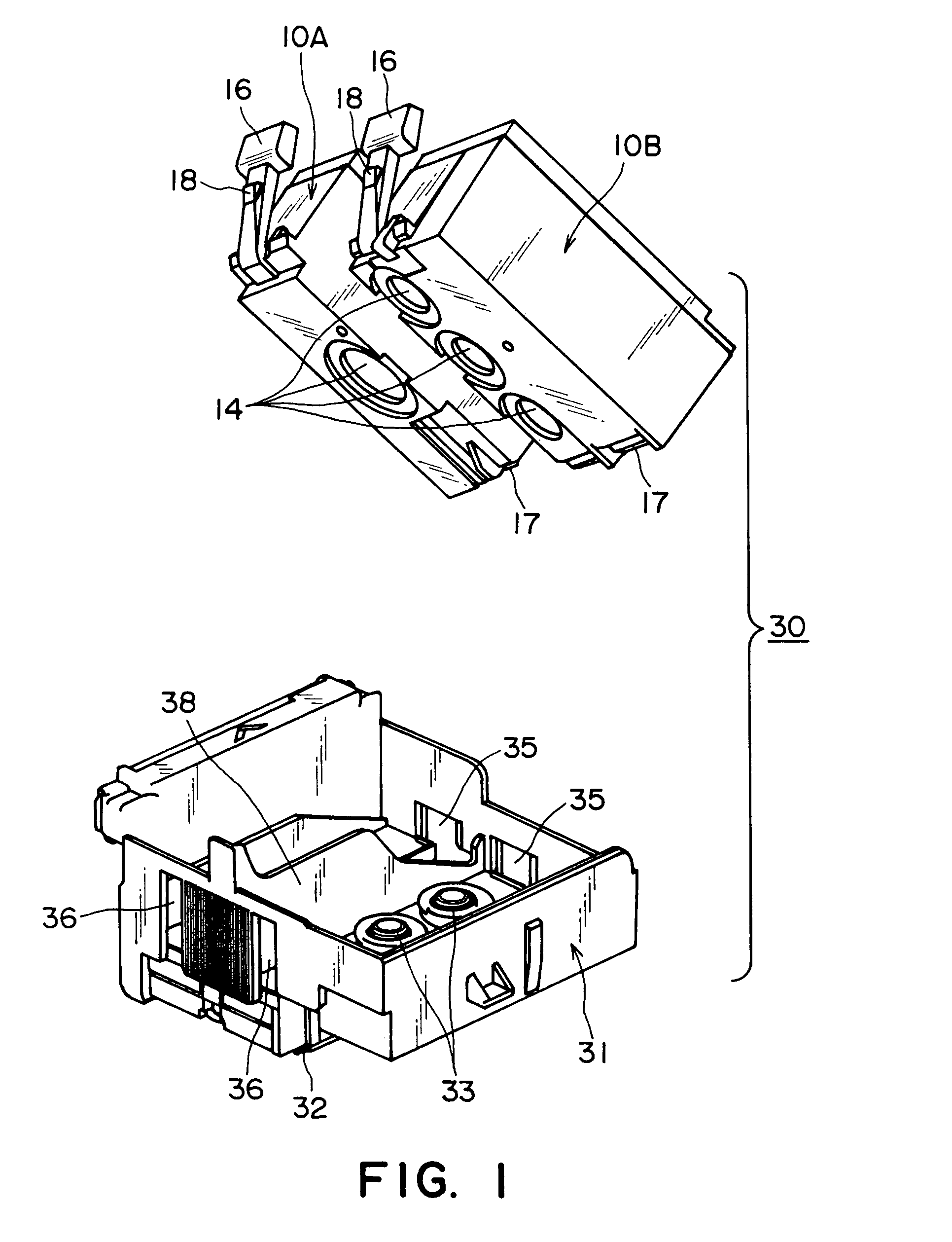

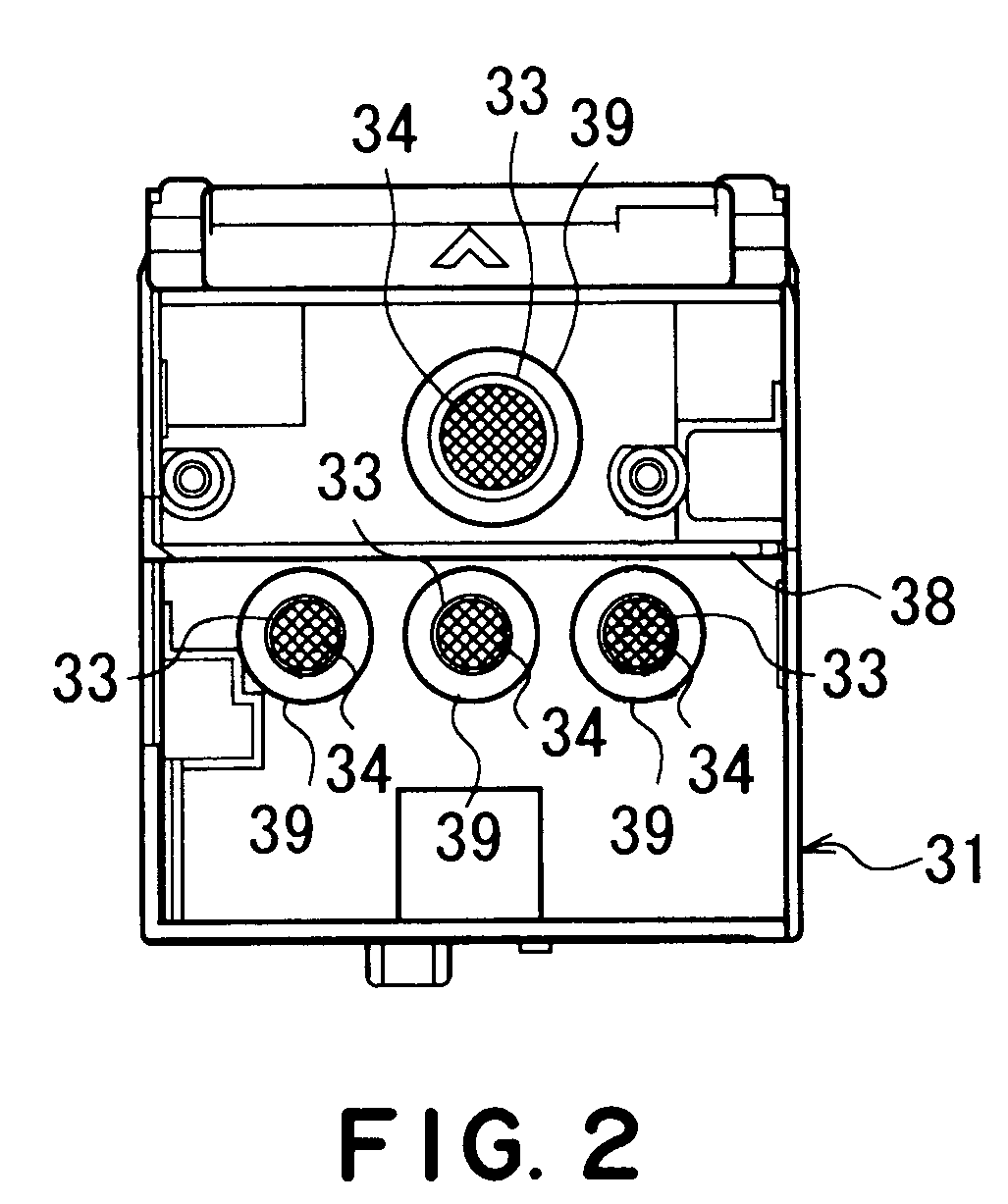

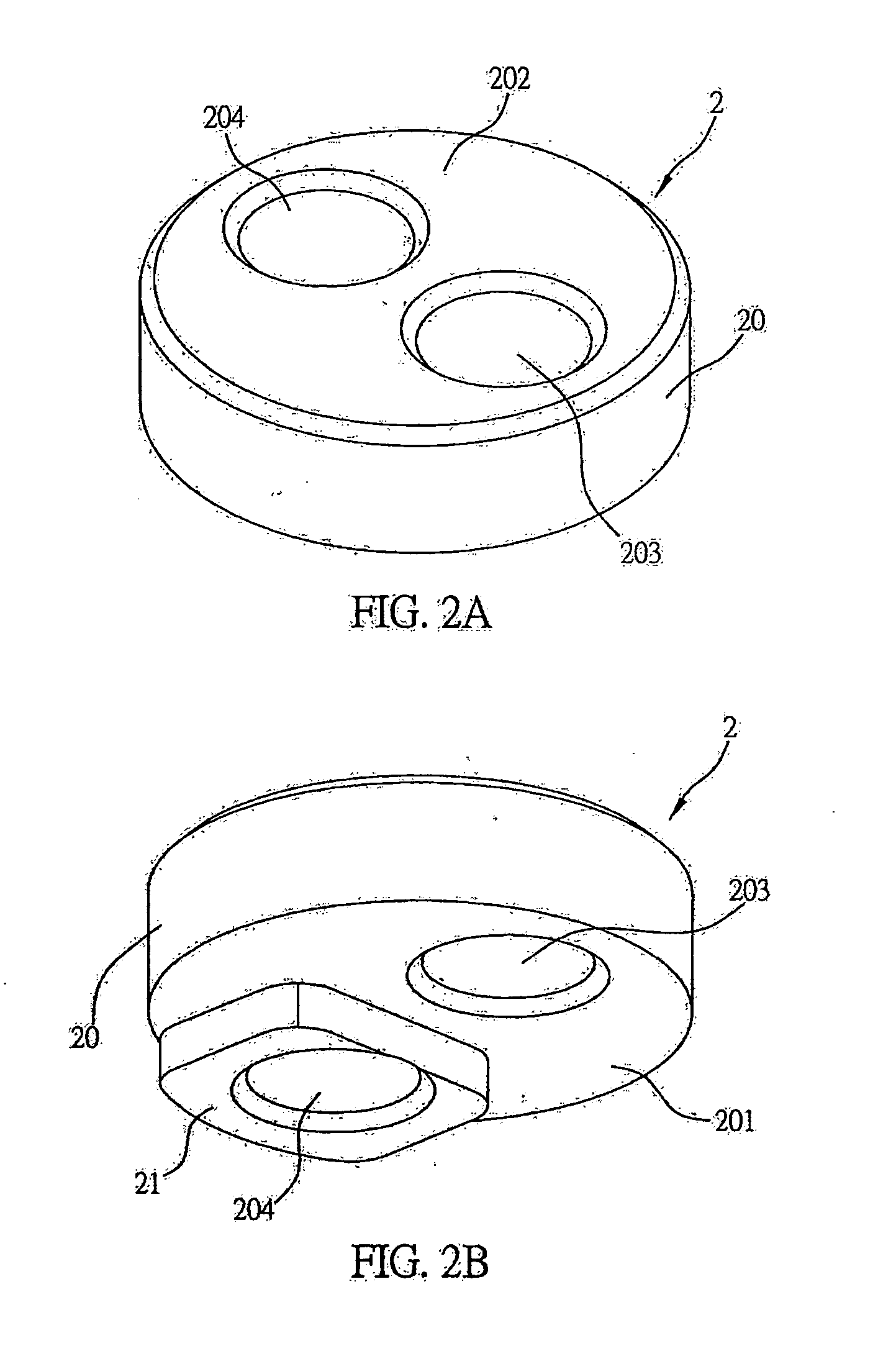

Ink container, recording head and recording device using same

InactiveUS7134747B2Stable ink supplyReduce remaining amountPrintingEngineeringMechanical engineering

An ink container includes a casing having a substantially rectangular shape; a plurality of ink accommodating portions defined by partition in the casing; ink supply ports provided, in a bottom side of the casing, for the ink accommodating portions, respectively; wherein the ink container is detachably mountable to a holder provided with a recording head portion for ejecting ink accommodated in the ink accommodating portion, wherein the plurality of ink supply ports are disposed deviated toward one of long edge of the bottom side; and a plurality of dimple portions in which the supply ports are formed, respectively, and the dimples is cut away and opens adjacent to the one of edges.

Owner:CANON KK

Dispensing of gloves

InactiveUS20110062179A1Wasted spaceMinimized volumeDispensing apparatusDiagnosticsMechanical engineeringEngineering

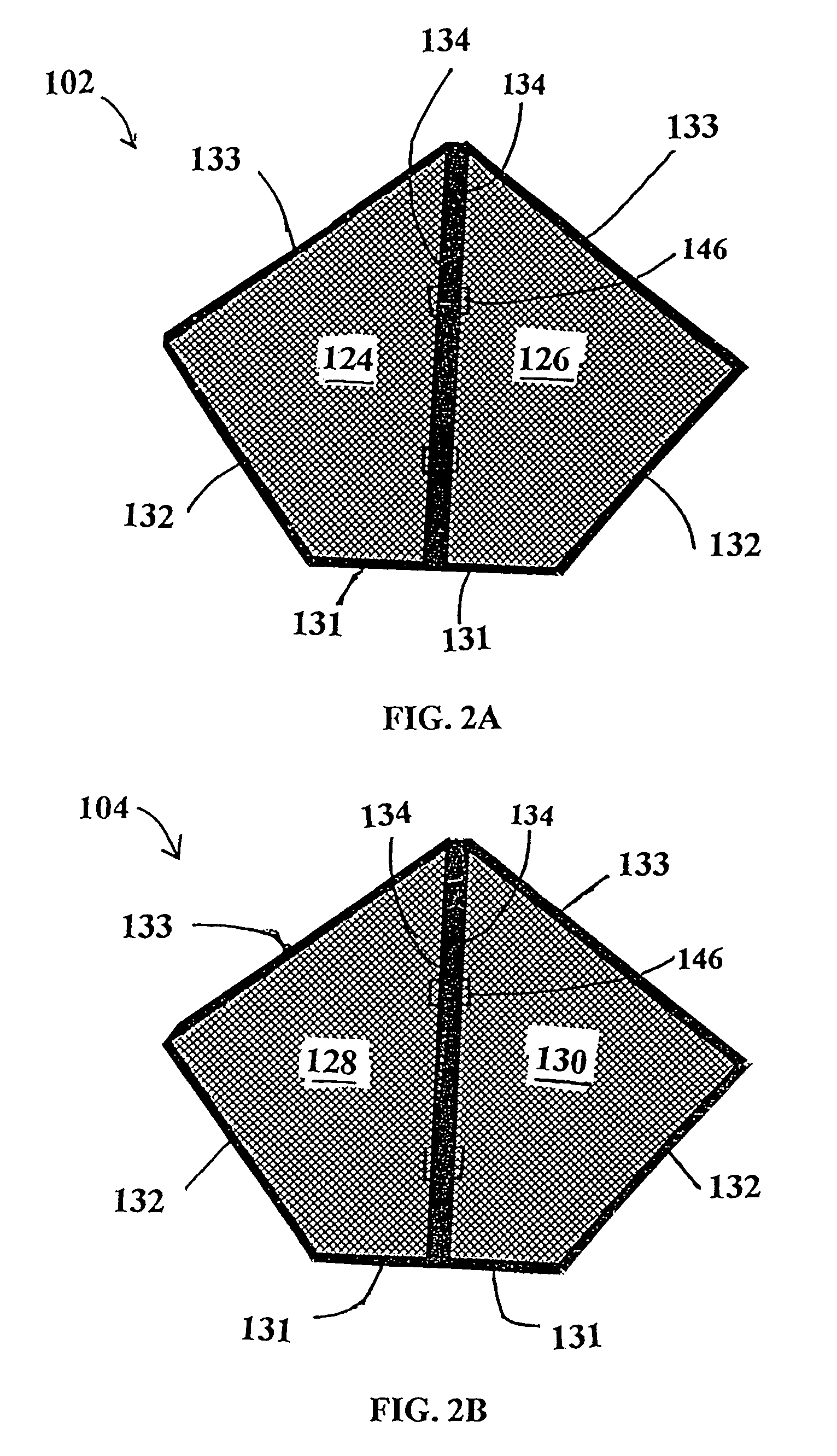

The present invention relates to the dispensing of gloves from a dispenser. The dispenser (1) comprises a container (2) and a plurality of disposable gloves (22). The container (2) has a plurality of faces (3, 4, 5), and each glove (22) has a cuff portion (36) and a finger portion (34), the cuff portion having a cuff (40) and the gloves being stacked one on another with the cuffs of the gloves being aligned on one side (42) of the stack (20) of gloves held within the container (2). The container (2) has in use a dispensing aperture (24) in at least one face (3, 5) of the container through which gloves (22) can be dispensed. The gloves (22) are oriented in the container (2) so that the gloves are positioned for dispensing cuff-first through the aperture (24), and the finger portion (34) of each glove (22) is folded back against the cuff portion (36) of the same glove to protect the finger portion from user contact and contamination during dispensing of the glove. The cuff portion has a cuff opening for receiving a user's hand, the cuff opening facing outwards with respect to the dispensing aperture.

Owner:ALTEVO

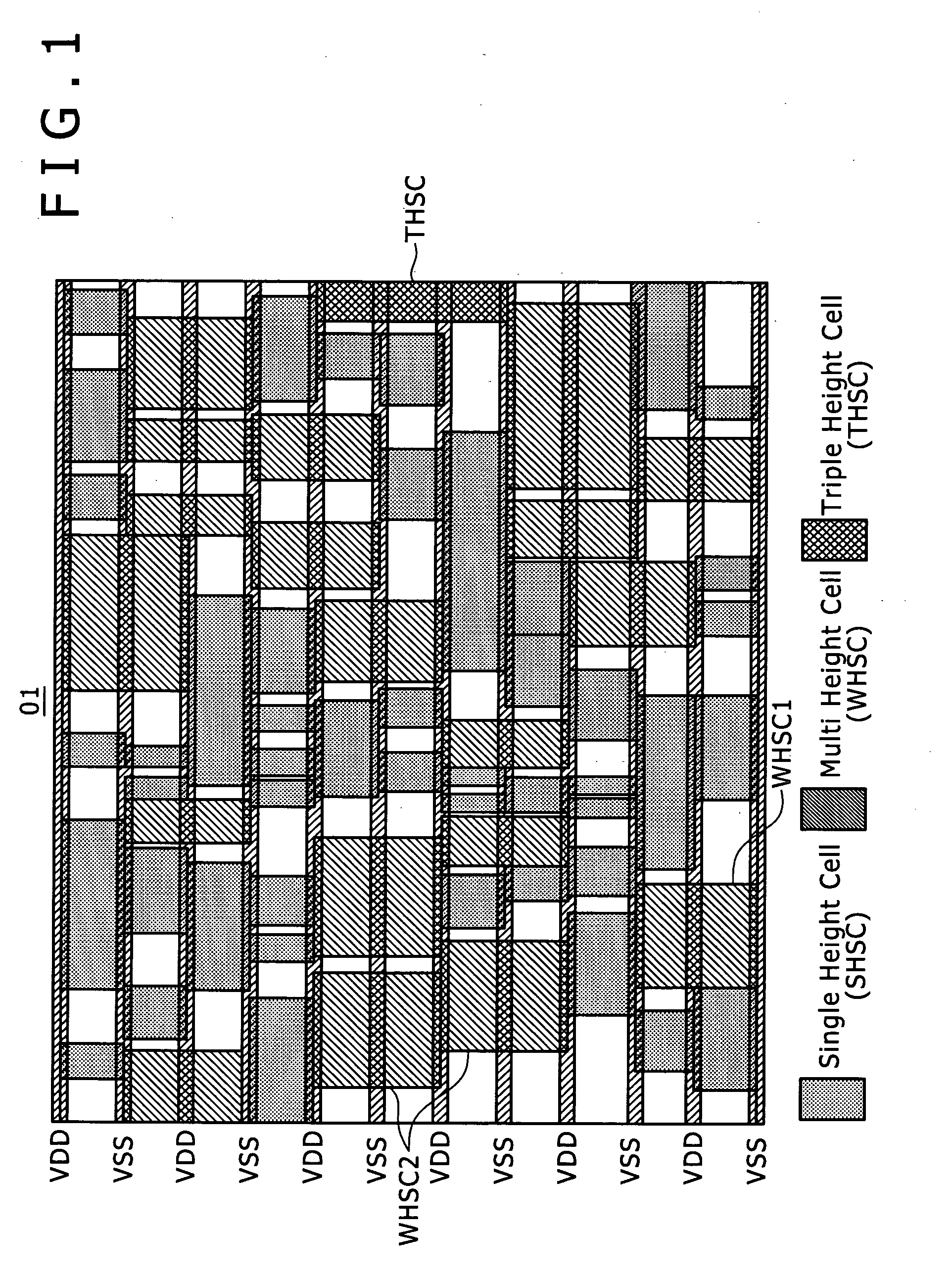

Semiconductor integrated circuit

ActiveUS8357955B2Workability is degradedLow costSolid-state devicesLogic circuitsEngineeringSemiconductor

Disclosed herein is a semiconductor integrated circuit, wherein a desired circuit is formed by combining and laying out a plurality of standard cells and connecting the cells together, of which the cell length, i.e., the gap between a pair of opposed sides, is standardized, the plurality of standard cells forming the desired circuit include complementary in-phase driven standard cells, each of which includes a plurality of complementary transistor pairs that are complementary in conductivity type to each other and have their gate electrodes connected together, and N (≧2) pairs of all the complementary transistor pairs are driven in phase, and the size of the standardized cell length of the complementary in-phase driven standard cell is defined as an M-fold cell length which is M (N≧M≧2) times the basic cell length which is appropriate to the single complementary transistor pair.

Owner:SONY CORP

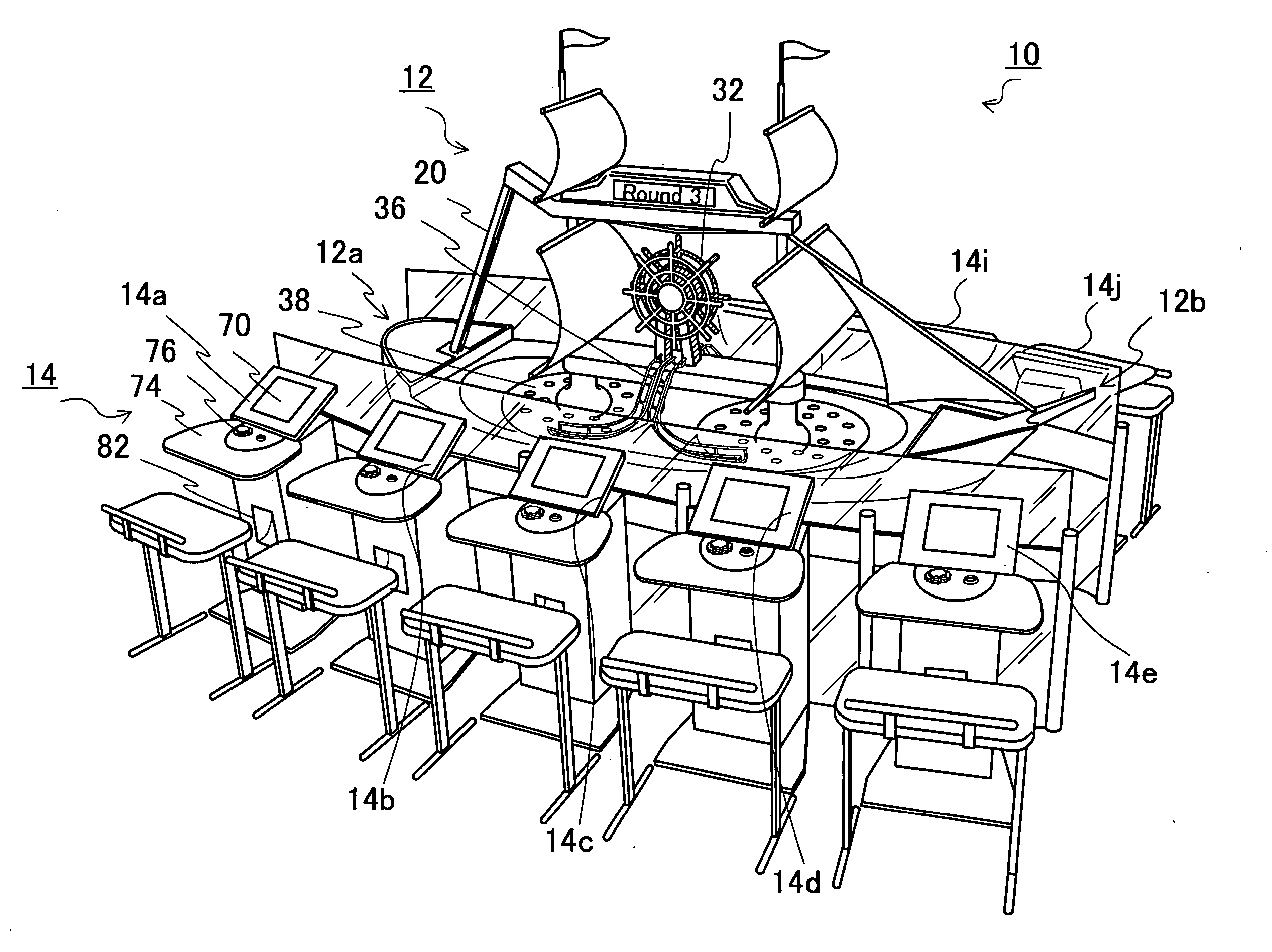

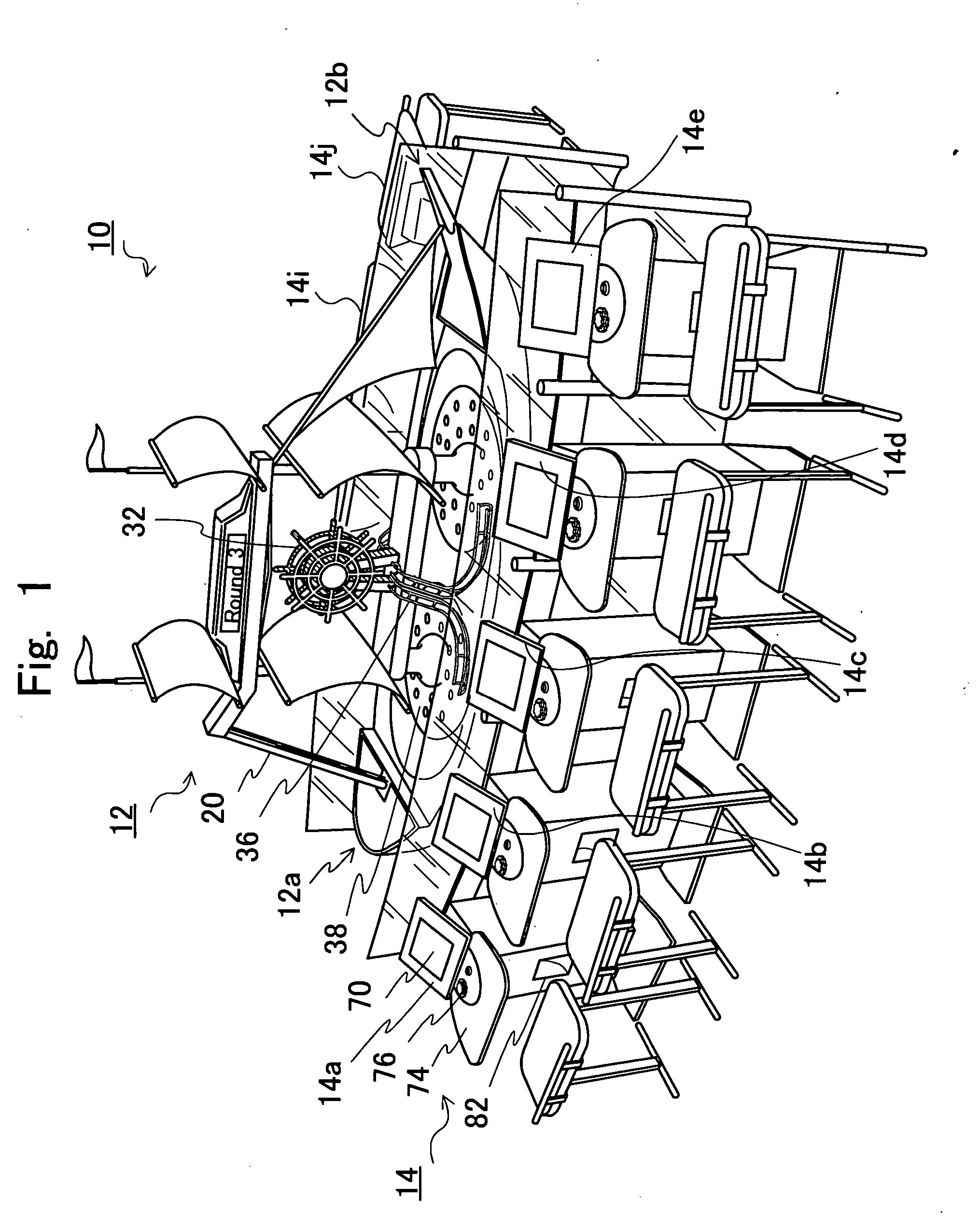

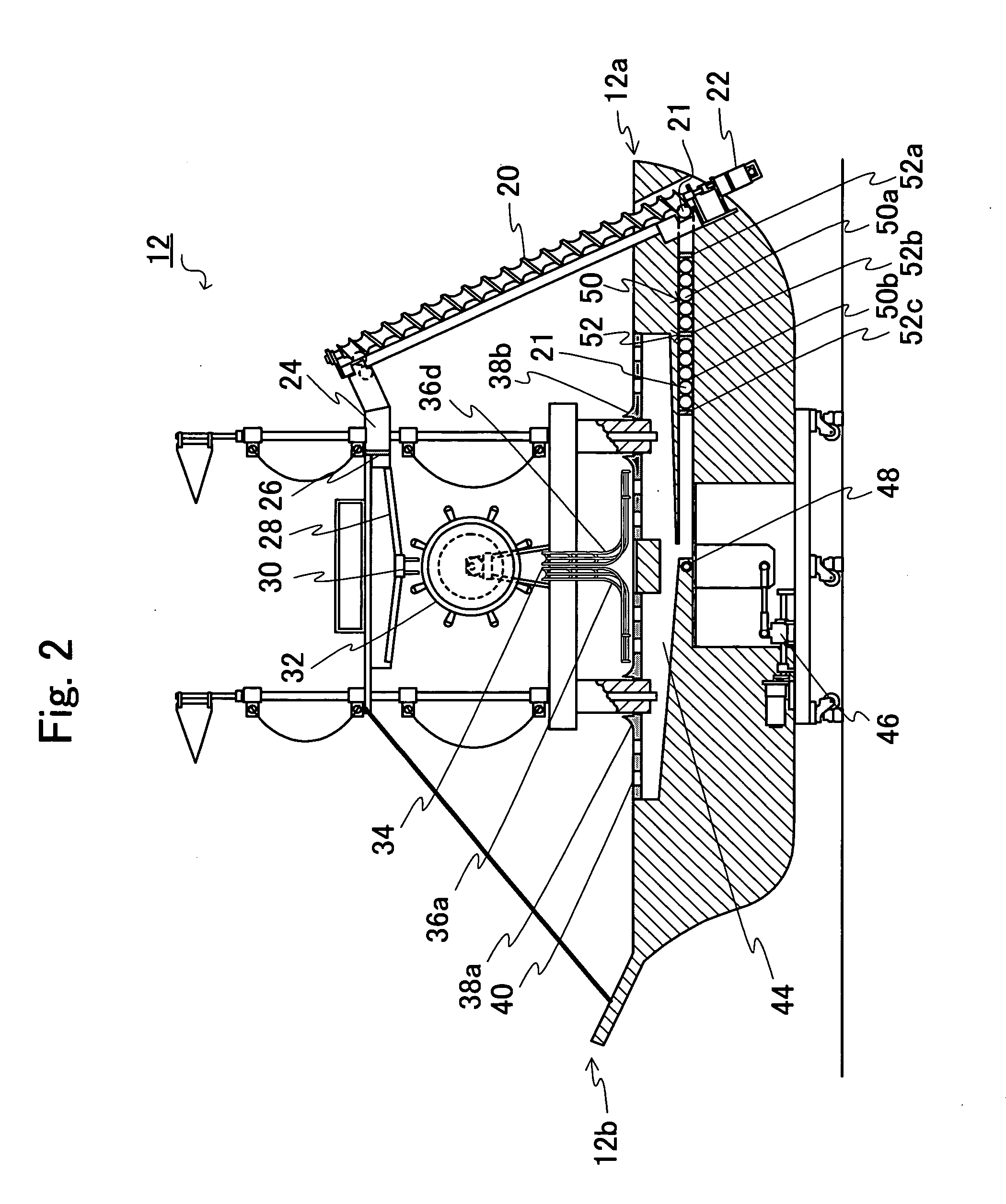

Game machine and program

InactiveUS20060163806A1Increased sense of anticipationIncrease speedBoard gamesCard gamesGame playerEngineering

A gaming machine having rotation control means for controlling a base member so that the base member is counterclockwise and clockwise rotatable, a first lottery ball introducing device for throwing in a lottery ball in substantially the same direction as a direction vector when the base member is rotated, a second lottery ball introducing device for throwing in a lottery ball in a direction facing the first lottery ball introducing device, lottery ball throw-in means for throwing in a lottery ball from any one of the first lottery ball introducing device and the second lottery ball introducing device, and lottery ball detecting means for detecting which one of the first lottery ball introducing device and the second lottery ball introducing device the lottery ball is thrown in from, wherein the base member control means has a function of determining the rotating direction of the base member on the basis of the detection result of the lottery ball detecting means. Accordingly, in a gaming machine such as a bingo game, after a lottery ball is thrown in, it is prevented from entering a lottery hole, and enjoyment of the game player is perpetuated.

Owner:UNIVERSAL ENTERTAINMENT CORP

Positive electrode for nonaqueous electrolyte secondary battery, and production method thereof

InactiveUS20080193846A1Good effectWasted spaceFinal product manufactureActive material electrodesManganese oxideCobalt

A positive electrode for a nonaqueous electrolyte secondary battery using a positive electrode active material mixture according to an embodiment of the invention includes a positive electrode active material capable of intercalating and deintercalating a lithium ion, a conductive agent and a binder, in which the positive electrode active material is produced by coating cobalt-based lithium composite oxide represented by a general formula: LiaCo1-sM1sO2 with lithium nickel cobalt manganese oxide represented by a general formula: LibNitCouMnvO2, the ratio r1 / r2 of the average particle diameter r1 of the cobalt-based lithium composite oxide and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 2≦r1 / r2≦50, and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 0.5 μm≦r2≦20 μm. By containing such a constitution, a positive electrode for a nonaqueous electrolyte secondary battery in which even when the charging discharging is repeated at a high potential of 4.5 V based on lithium, not only is the retention characteristics in a charged state excellent, but also the enhancing the capacity and the energy density of the battery can be achieved; and a production method thereof, can be provided.

Owner:SANYO ELECTRIC CO LTD

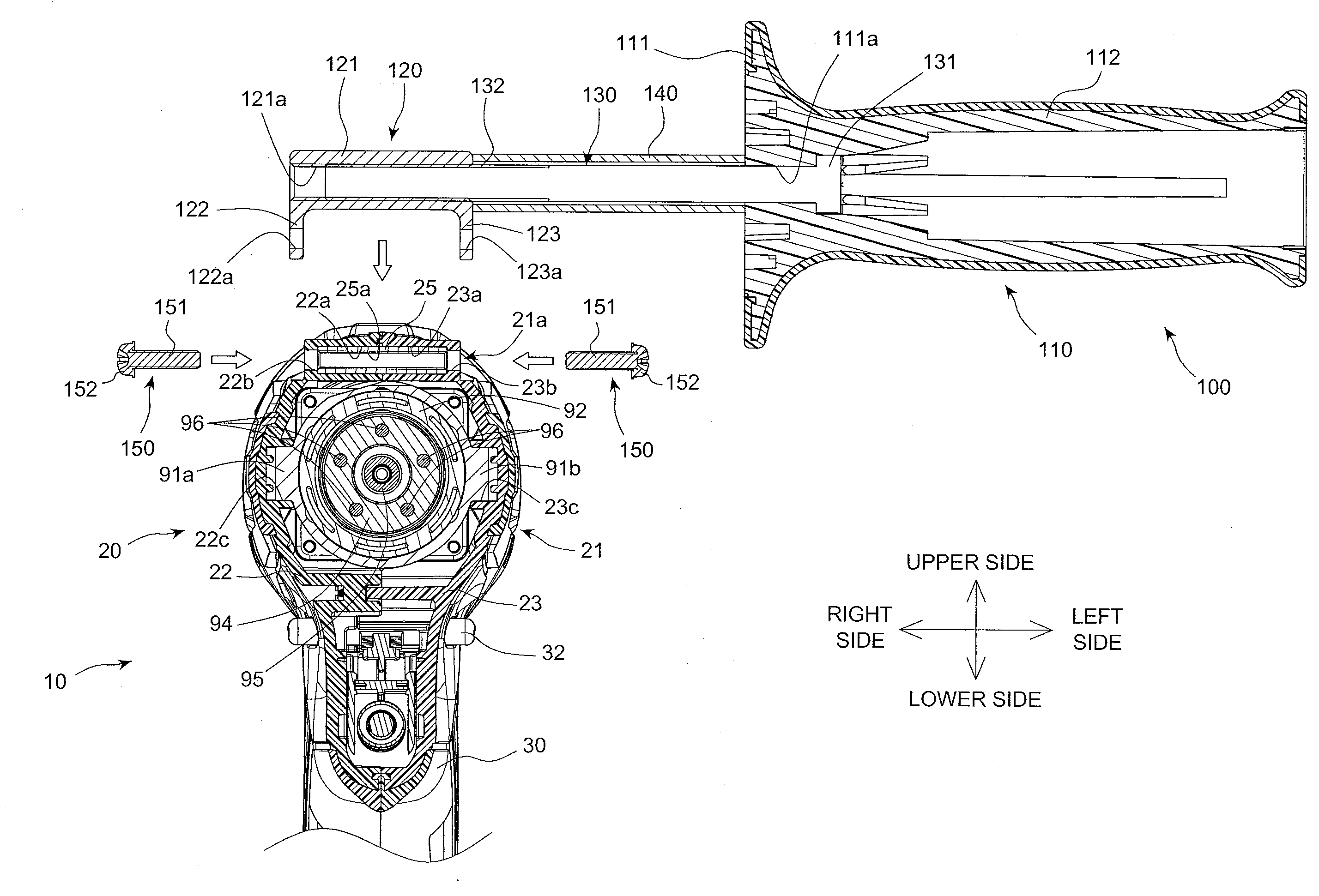

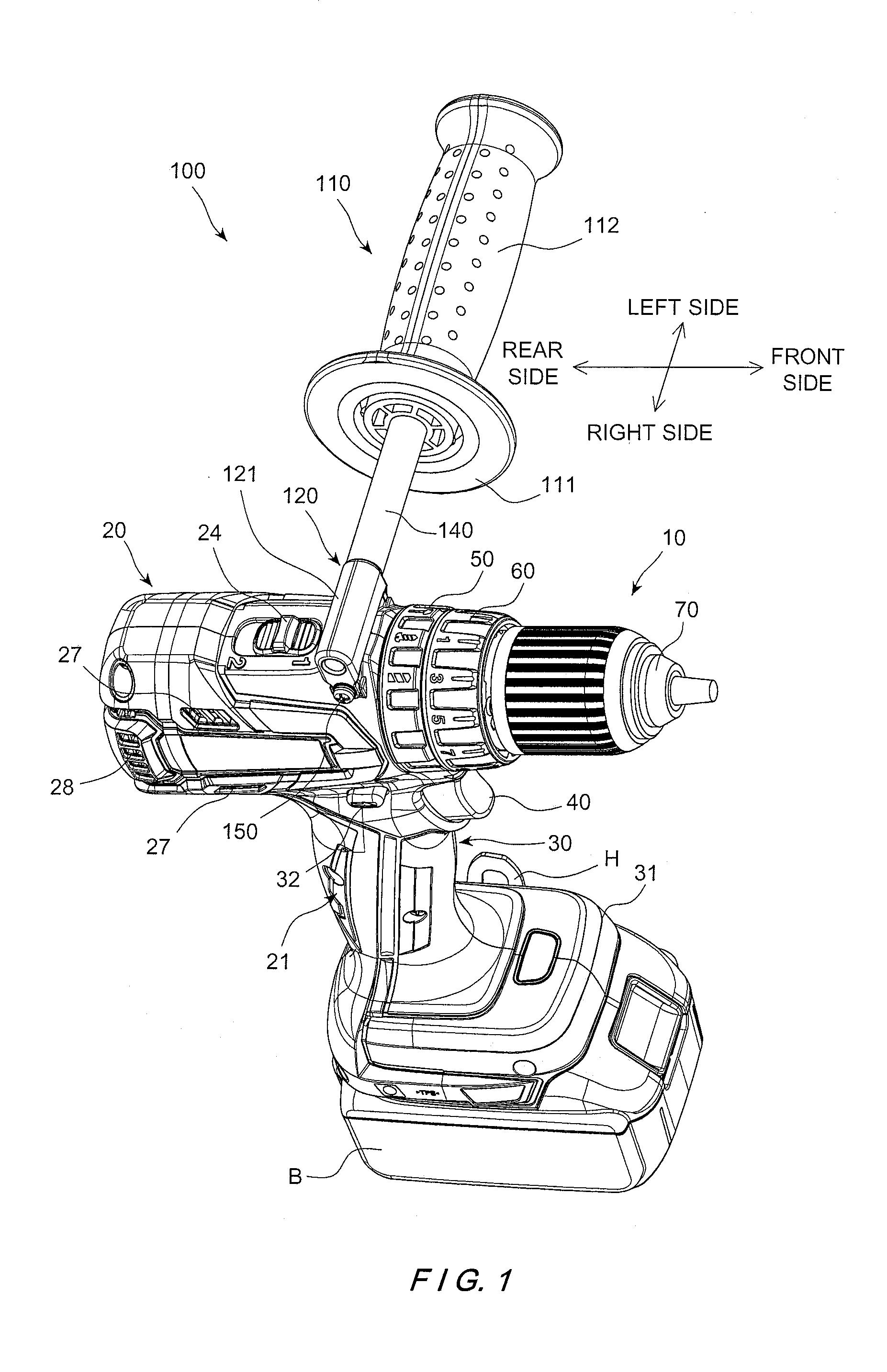

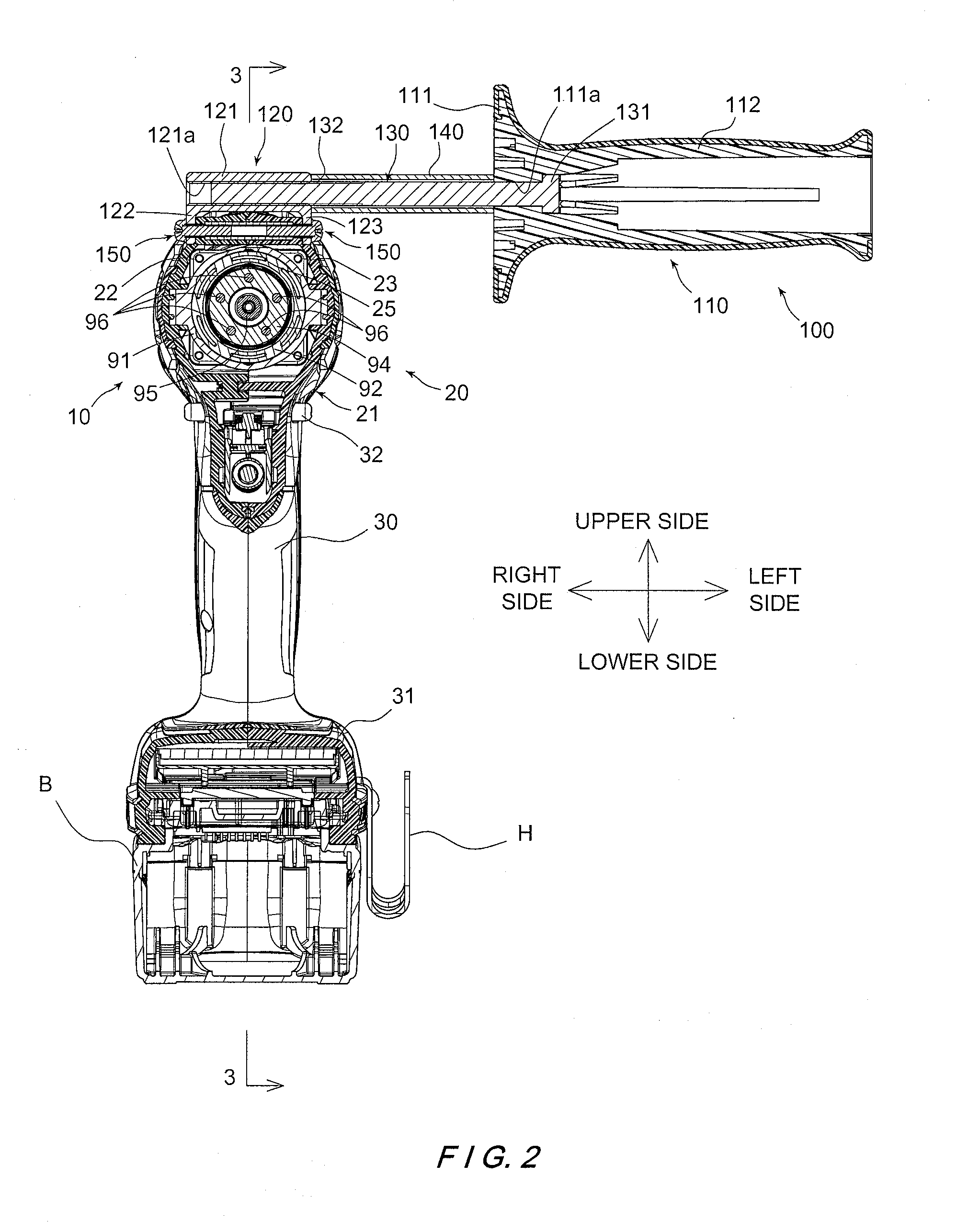

Power tool and power tool accessory member

InactiveUS20140251650A1Wasted spaceOperator-supported drilling machinesPortable percussive toolsElectric machineryEngineering

A power tool includes a motor unit, a main body portion, a grip portion and a female thread part. The main body portion accommodates the motor unit therein. The grip portion extends from the main body portion. The female thread part is retained to the main body portion. The female thread part includes a female thread configured and arranged to engage with a male thread of a male thread part of a power tool accessory member.

Owner:MAKITA CORP

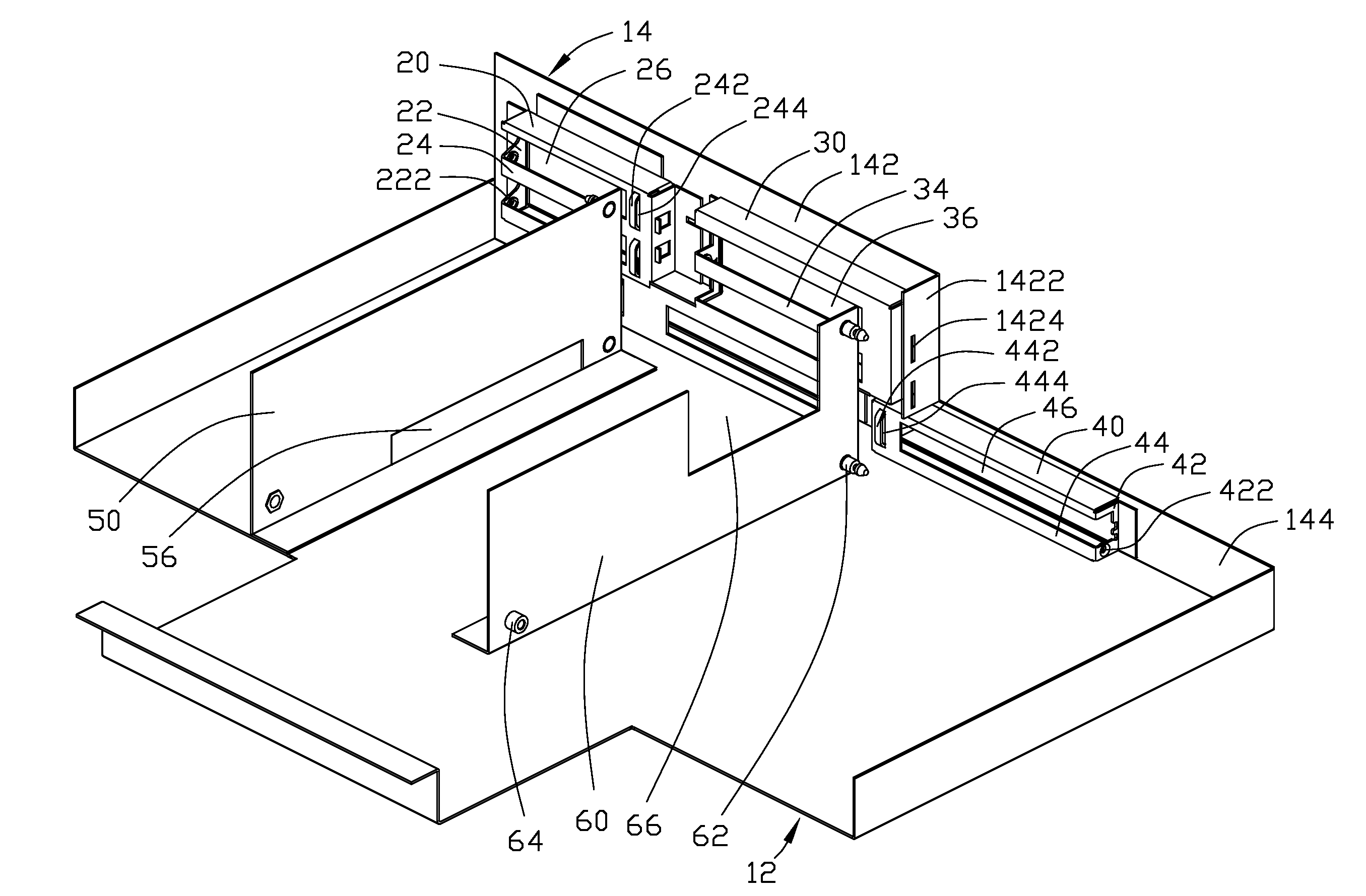

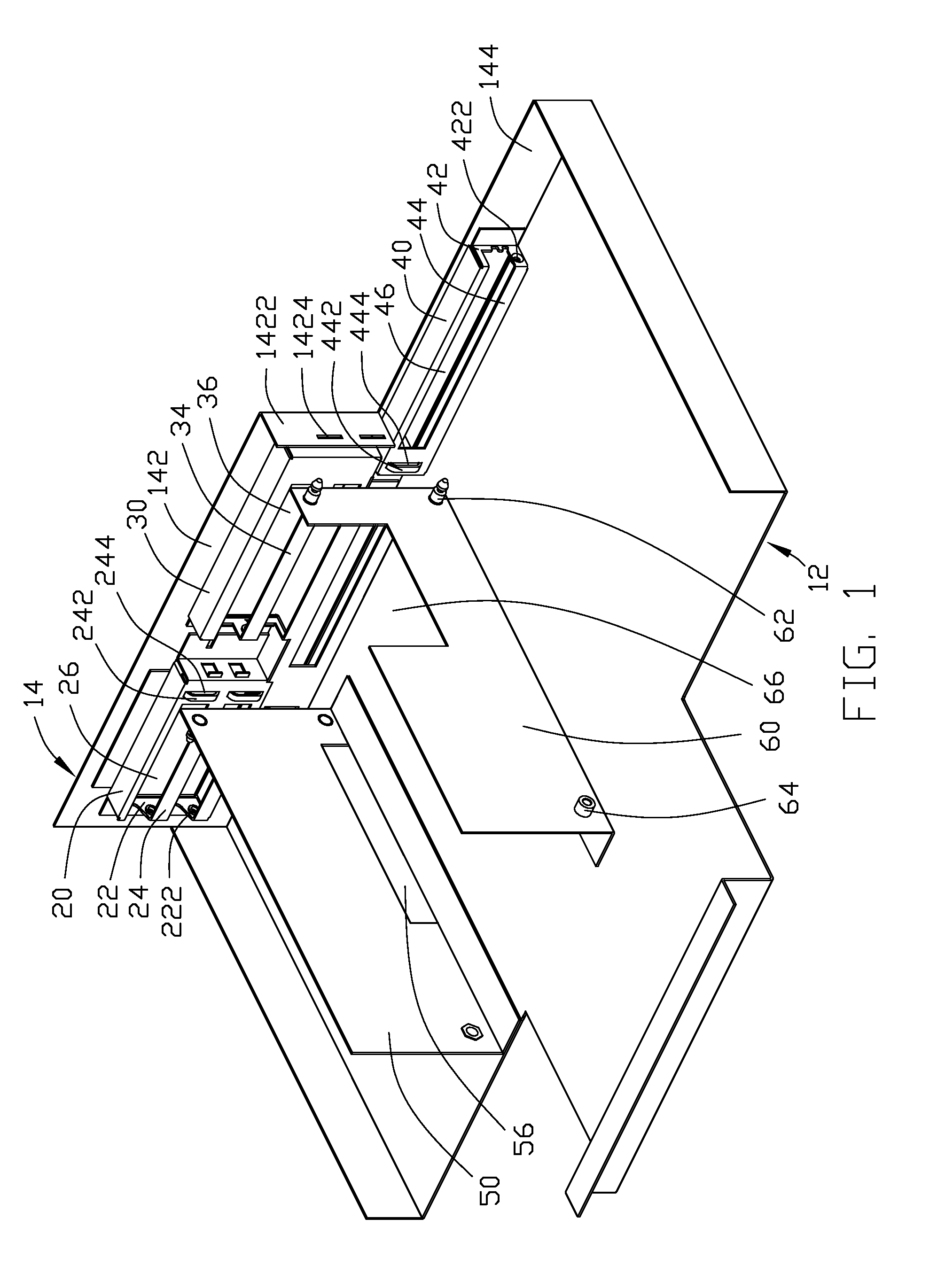

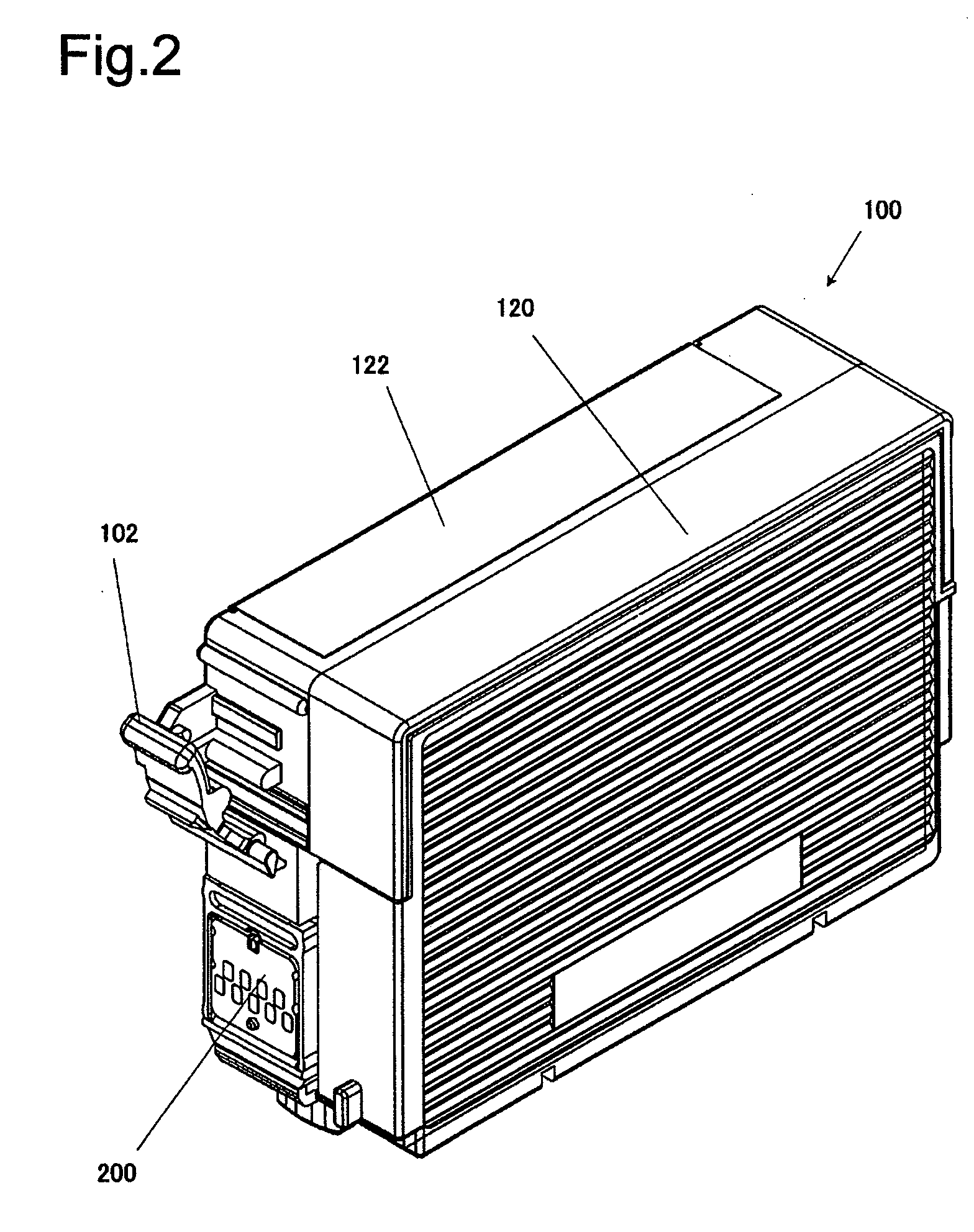

Computer enclosure for securing riser card

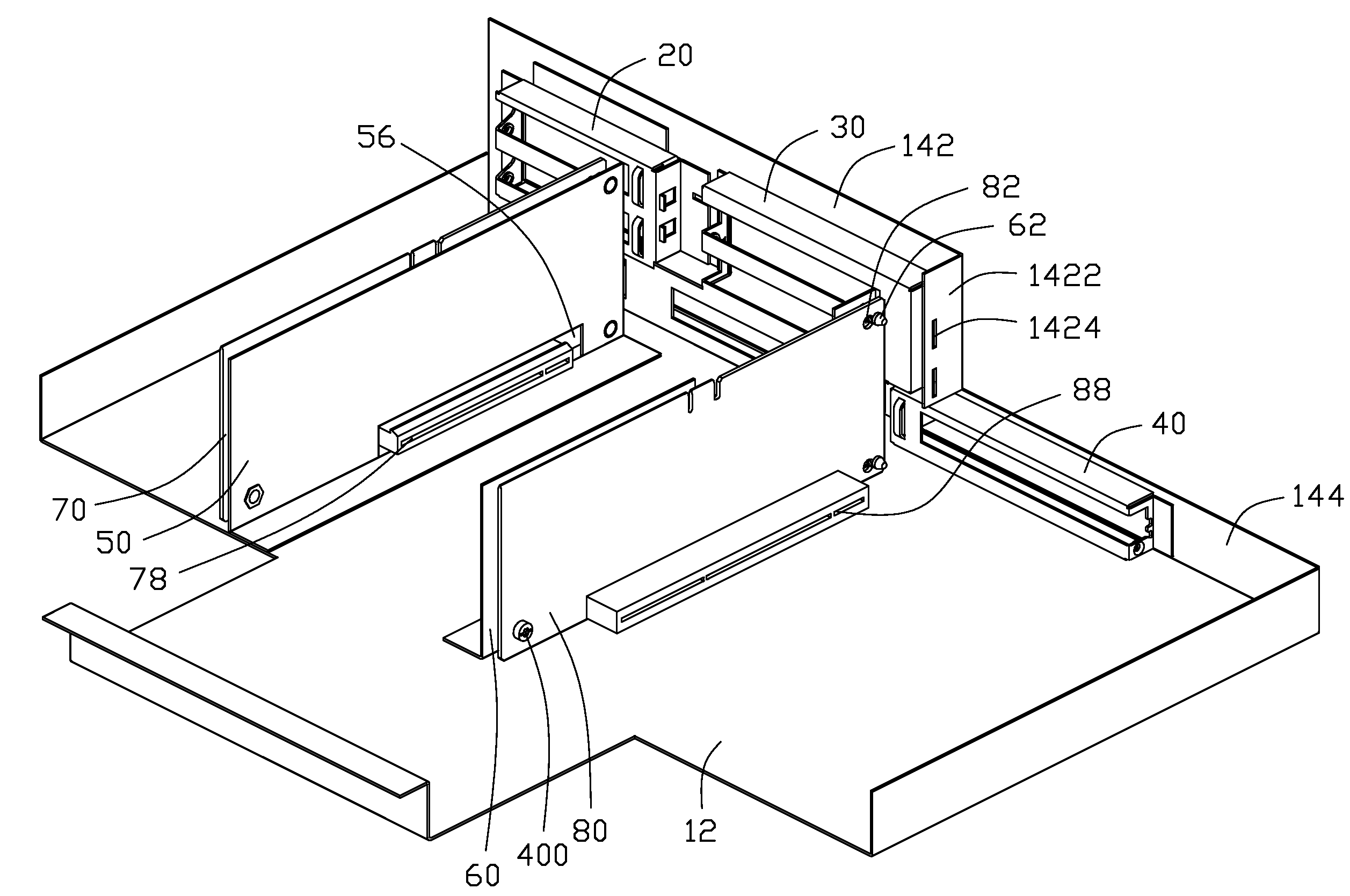

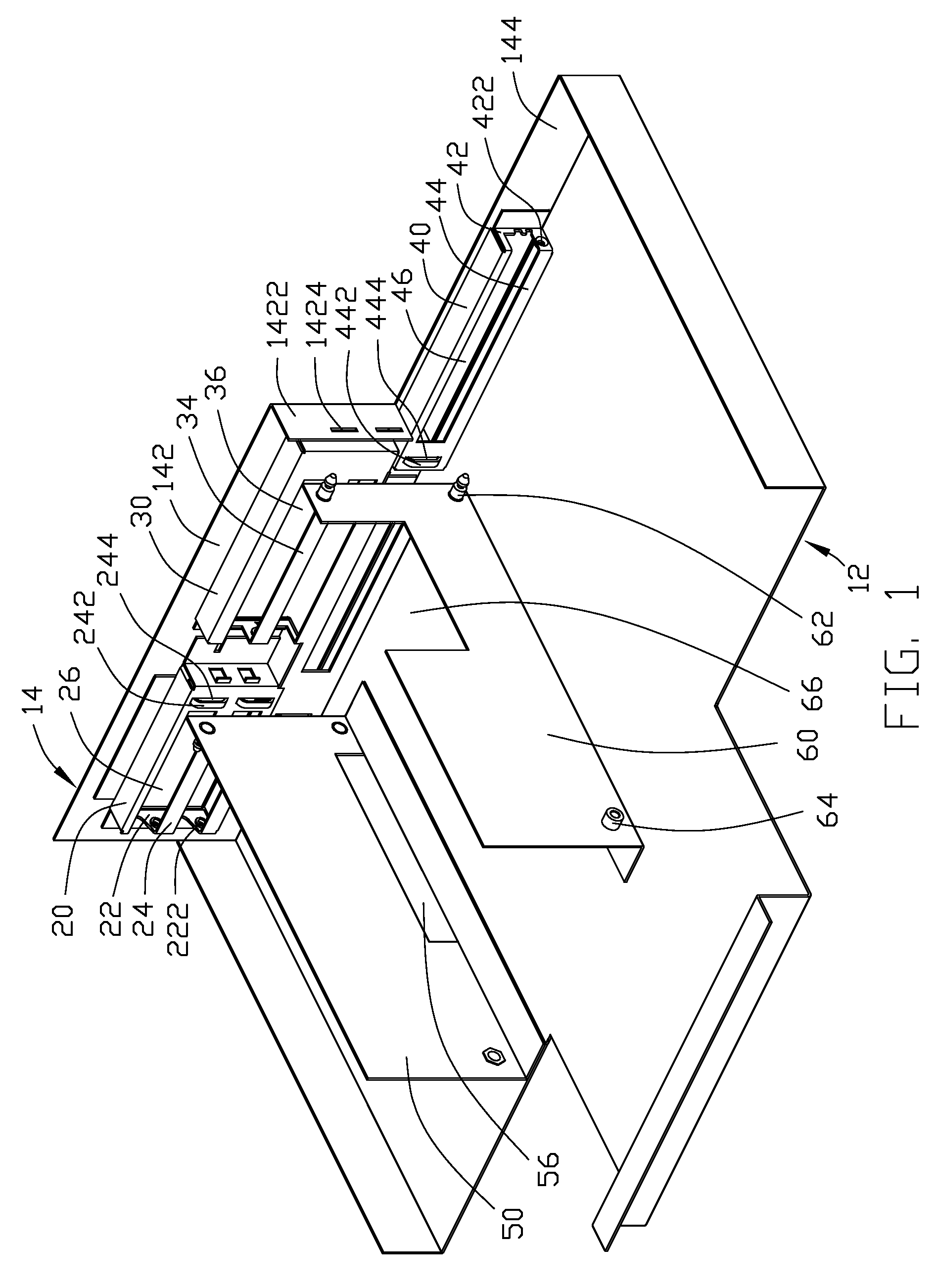

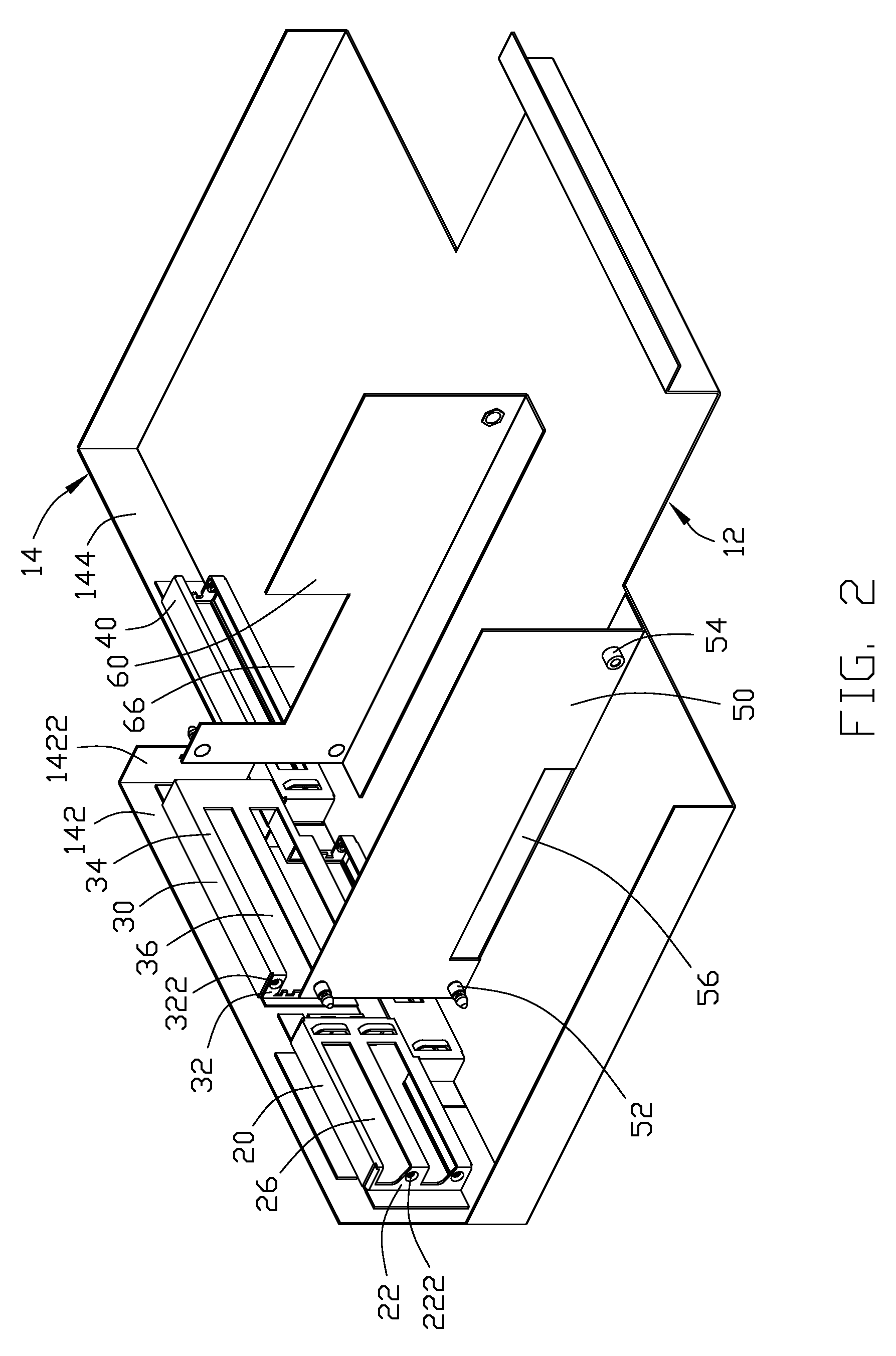

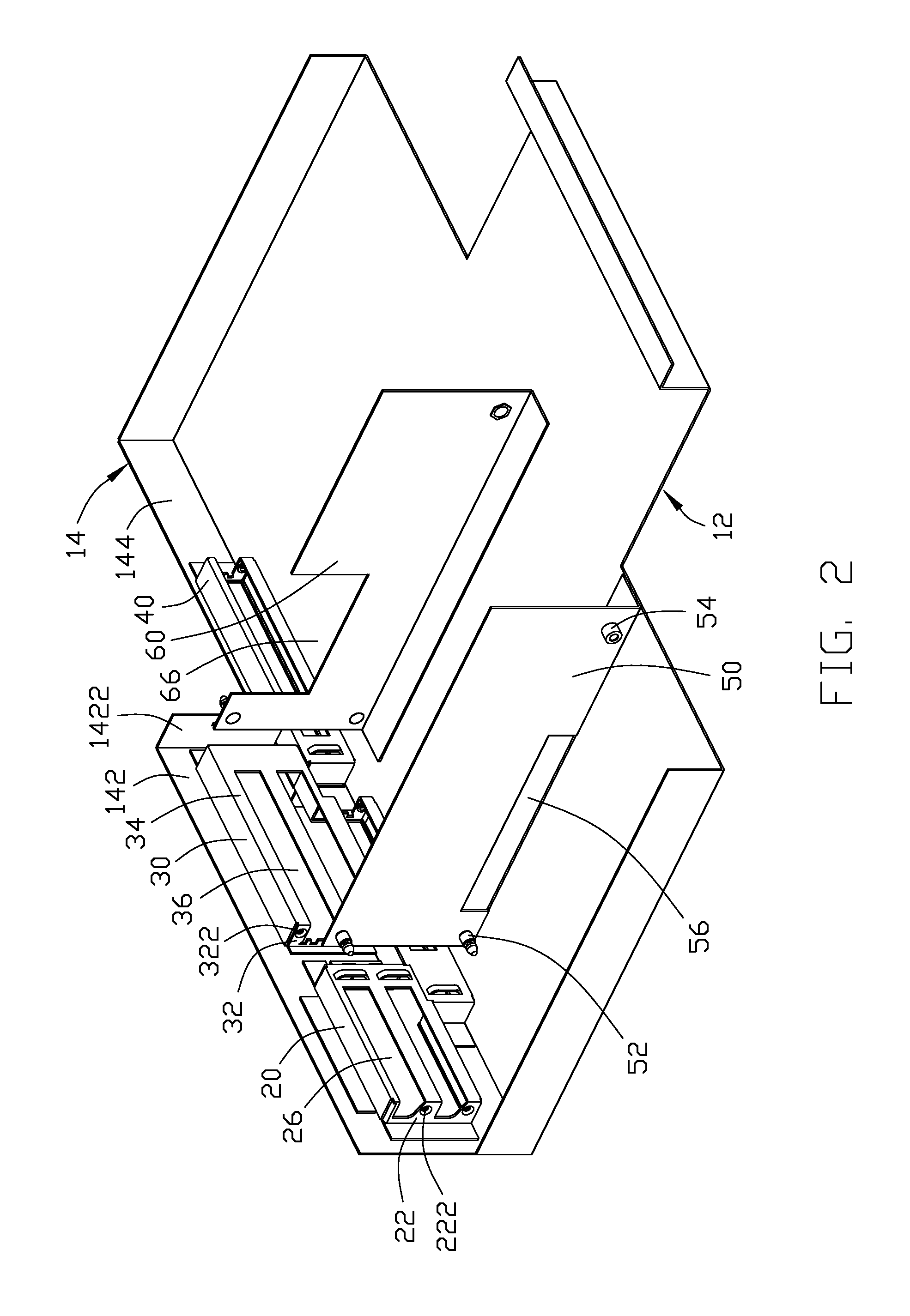

InactiveUS7746630B2Increase the number ofWasted spaceDigital data processing detailsFurniture partsExpansion cardRiser card

A computer enclosure includes a bottom plate (12), a rear plate (14), and a mounting plate (60). The rear plate is perpendicular to the bottom plate for securing an expansion card (100) thereon. The mounting plate is perpendicularly secured on the bottom plate for securing a riser card (80) thereon, and perpendicular to the rear plate. A receiving structure (66) is defined in the mounting plate for a socket (88) formed on the riser card inserting therethrough to electronically receive a part of the expansion card.

Owner:HON HAI PRECISION IND CO LTD

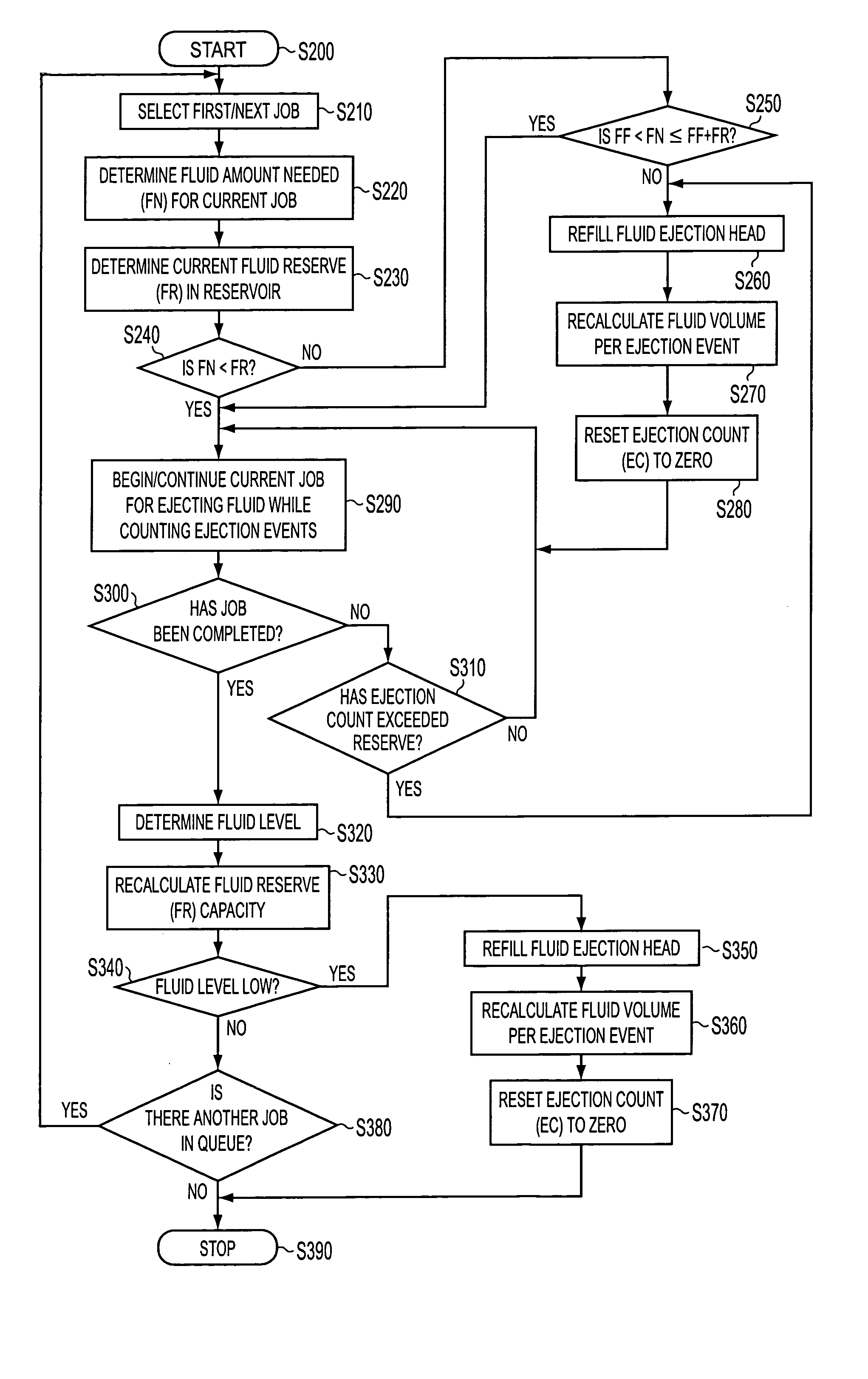

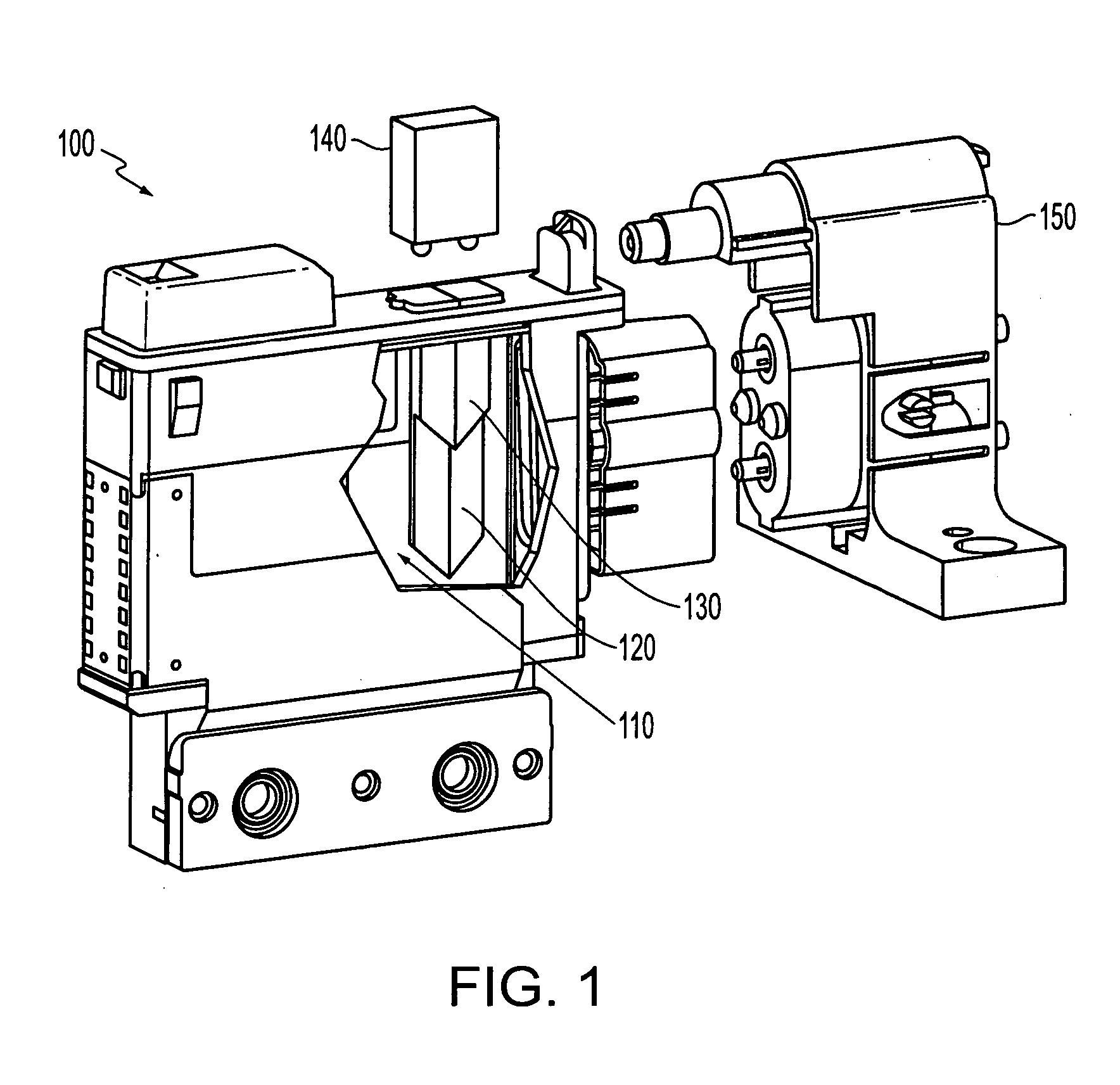

Systems and methods for controllably refilling a fluid quantity sensing fluid ejection head

A controller for a fluid ejecting system having a refillable container includes an ejection count initializing circuit, routine or application, a count incrementing circuit, routine or application, at least one fluid level indicator, and a fluid quantity circuit, routine or application for determining an expended quantity of fluid, a fluid reserve capacity circuit, routine or application for determining a fluid reserve capacity in the container, an ejection job determining circuit, routine or application for determining a fluid job requirement, a reserve comparing circuit, routine or application to compare the fluid reserve capacity and the fluid job requirement, and a refill condition determining circuit, routine or application to determine that the container is to be refilled. Counts for a ejection amount and a reserve capacity are incremented in response to a specific amount of fluid being ejected from the container. The expended quantity of fluid is based on the ejection amount count subsequent to the fluid level being indicated. The fluid reserve capacity is based on the reserve capacity count and the expended quantity of fluid. The fluid job requirement is based on the expended quantity of fluid and a job number of ejected amounts of fluid. The container is determined to be refilled upon at least a condition wherein the fluid job requirement exceeds the fluid reserve capacity, and a condition wherein the fluid level is below a refill threshold.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Computer enclosure for securing riser card

InactiveUS20090073645A1Increase the number ofWasted spaceDigital data processing detailsFurniture partsComputer caseRiser card

A computer enclosure includes a bottom plate (12), a rear plate (14), and a mounting plate (60). The rear plate is perpendicular to the bottom plate for securing an expansion card (100) thereon. The mounting plate is perpendicularly secured on the bottom plate for securing a riser card (80) thereon, and perpendicular to the rear plate. A receiving structure (66) is defined in the mounting plate for a socket (88) formed on the riser card inserting therethrough to electronically receive a part of the expansion card.

Owner:HON HAI PRECISION IND CO LTD

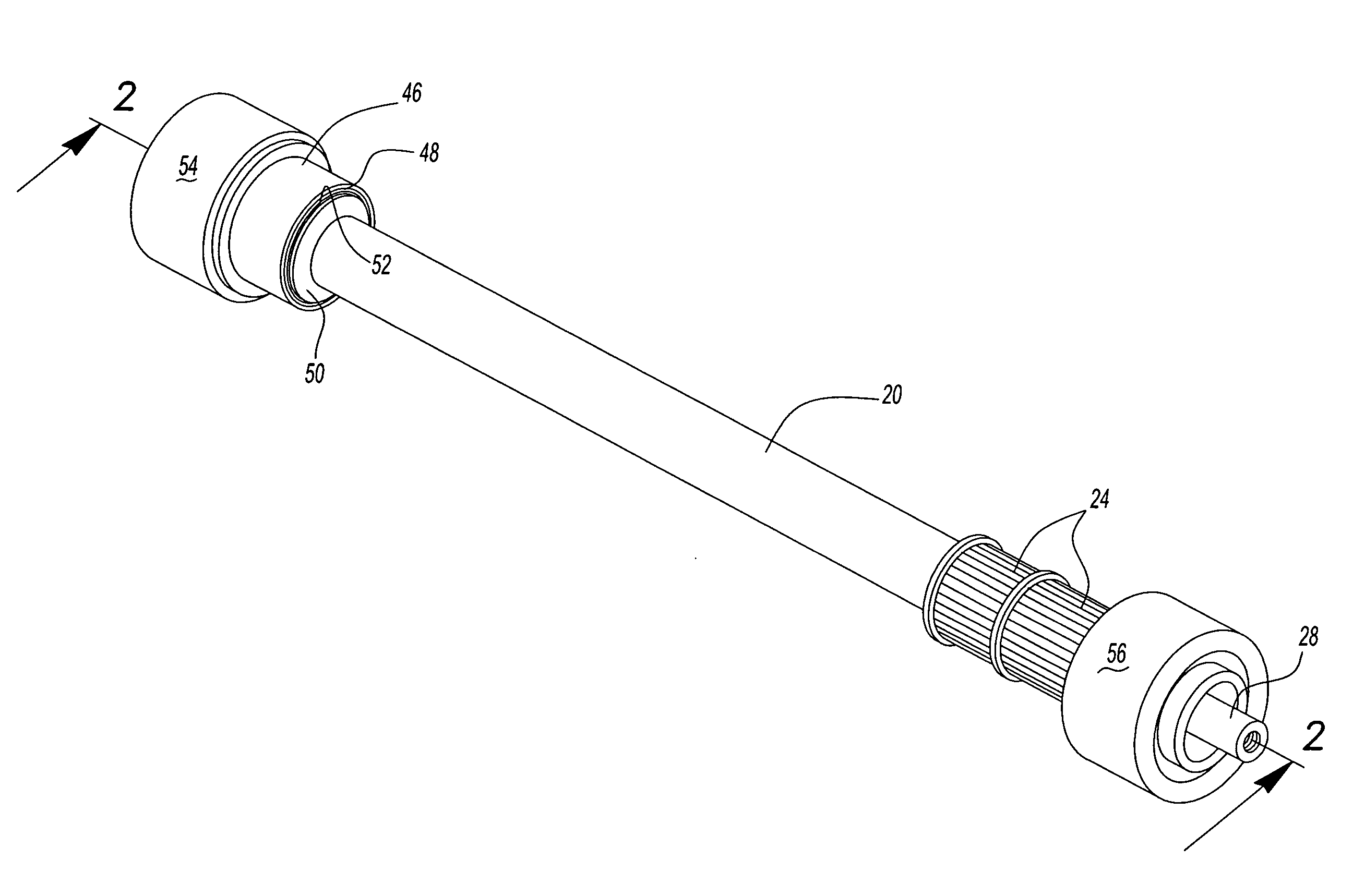

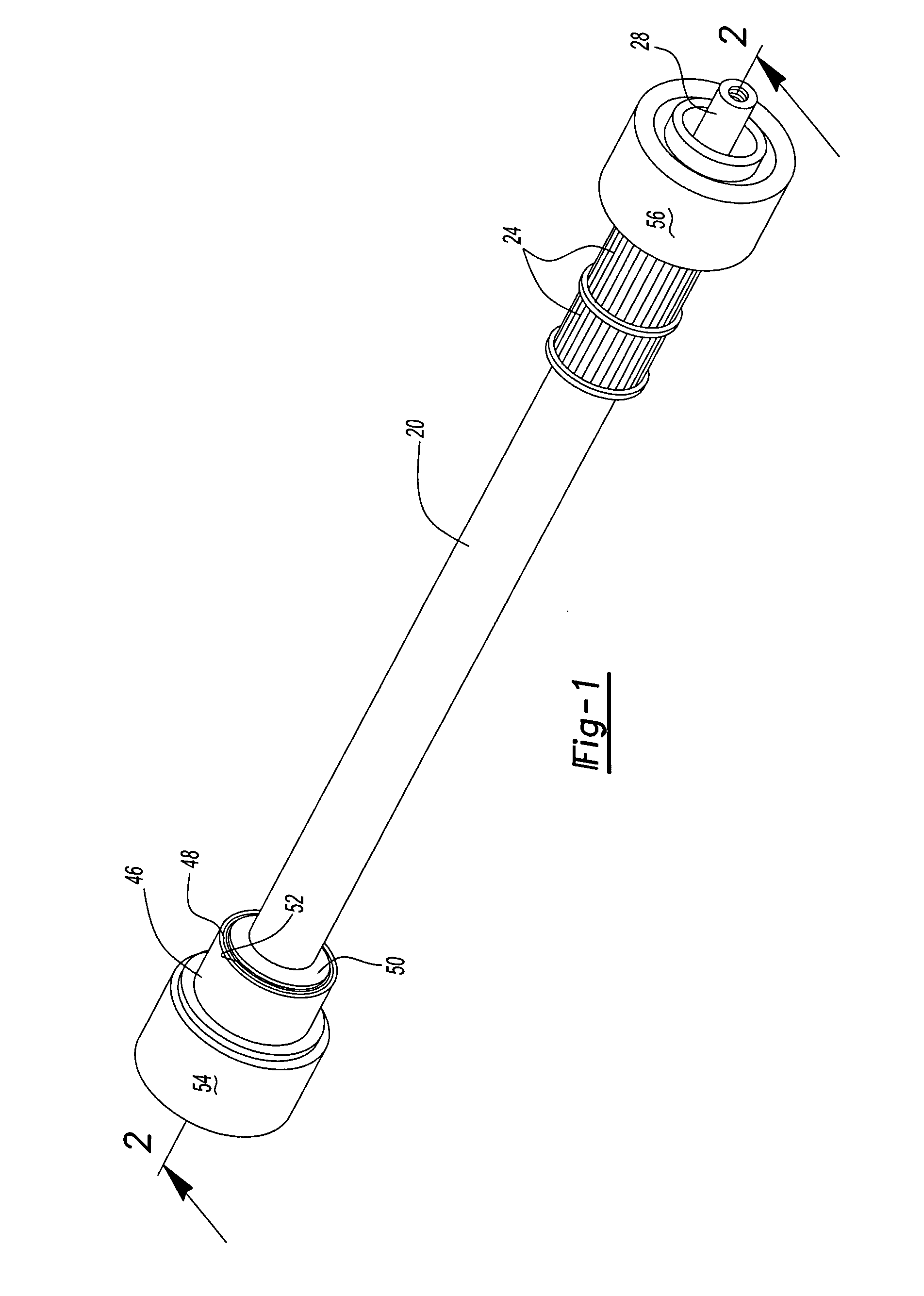

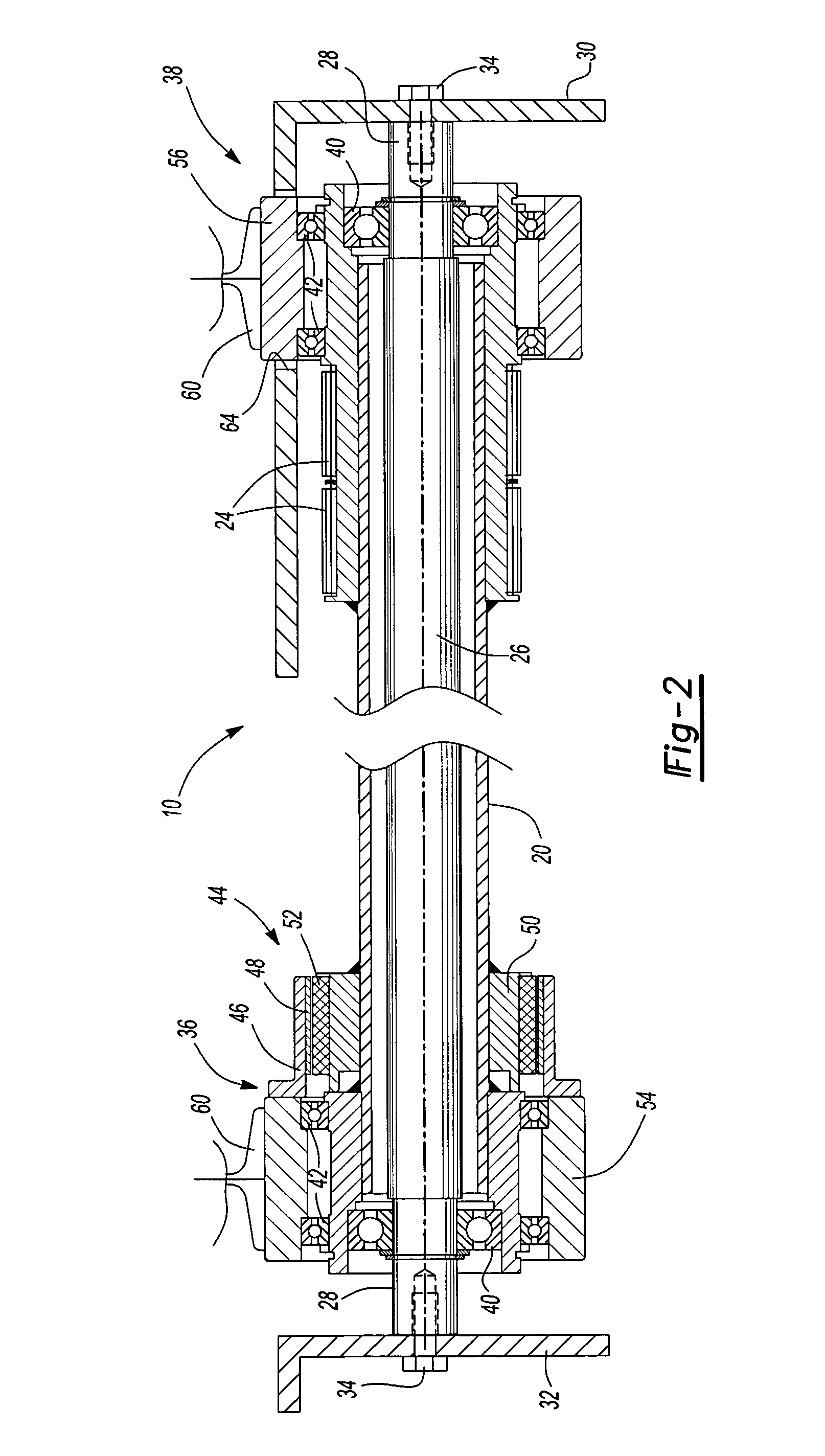

Conveyor with accumulating slip rolls

InactiveUS20080236998A1Reducing and eliminating wasted conveyor spaceConserve costConveyor partsRoller-waysEngineeringDelivery system

A magnetic accumulating slip roller assembly of a conveyor including a drive axle rotatably driven by a motor, spaced rollers for receiving a skid or other element to be conveyed by the conveyor system supported on the drive axle including a drive roller and an idler roller and a magnetic clutch between the drive roller and the drive axle allowing the drive roller to rotatably slip as the drive axle is rotated by the motor. In the disclosed embodiment, the drive axle is tubular and rotatably supported on a fixed inner axle.

Owner:DURR SYST INC

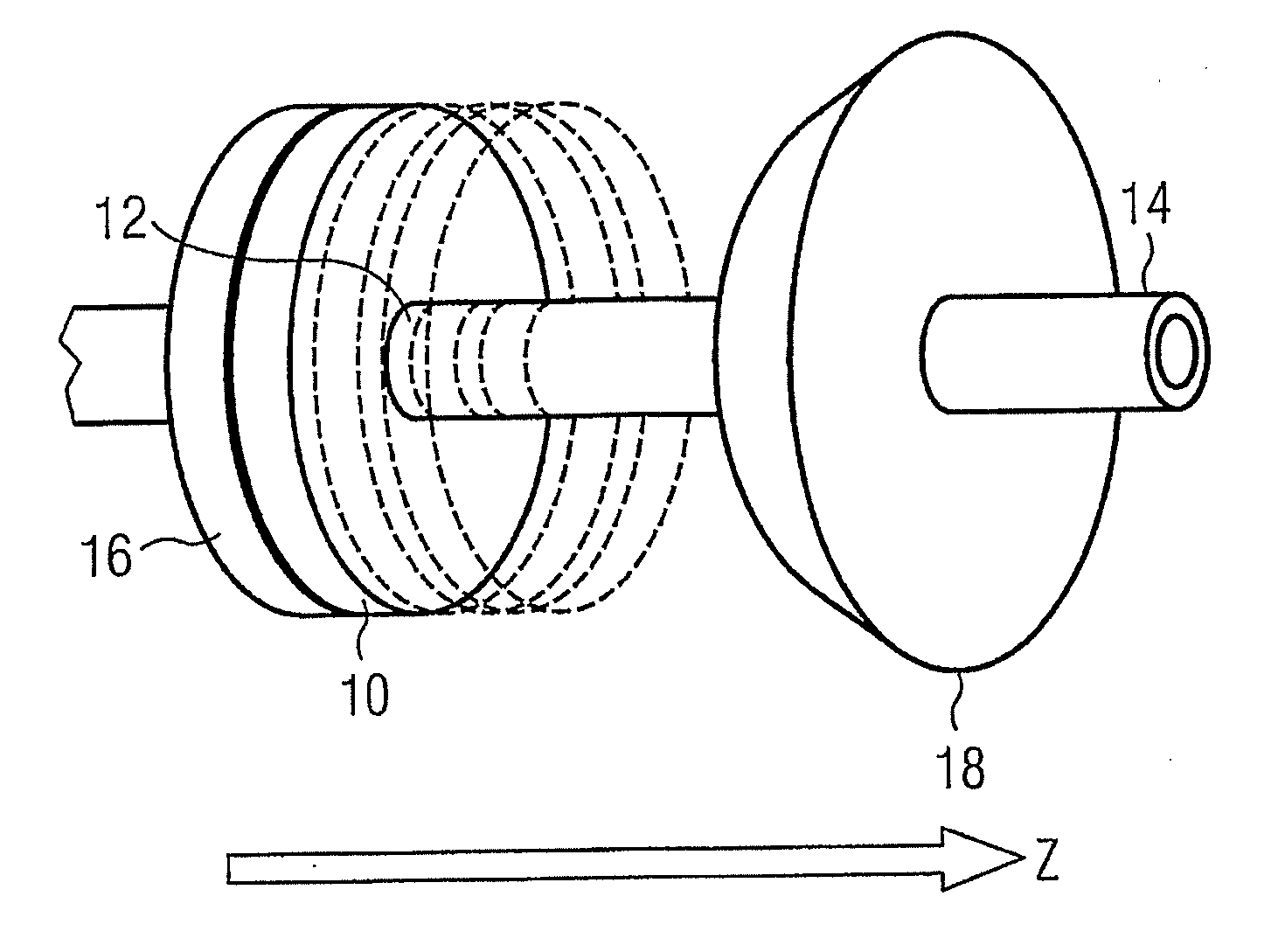

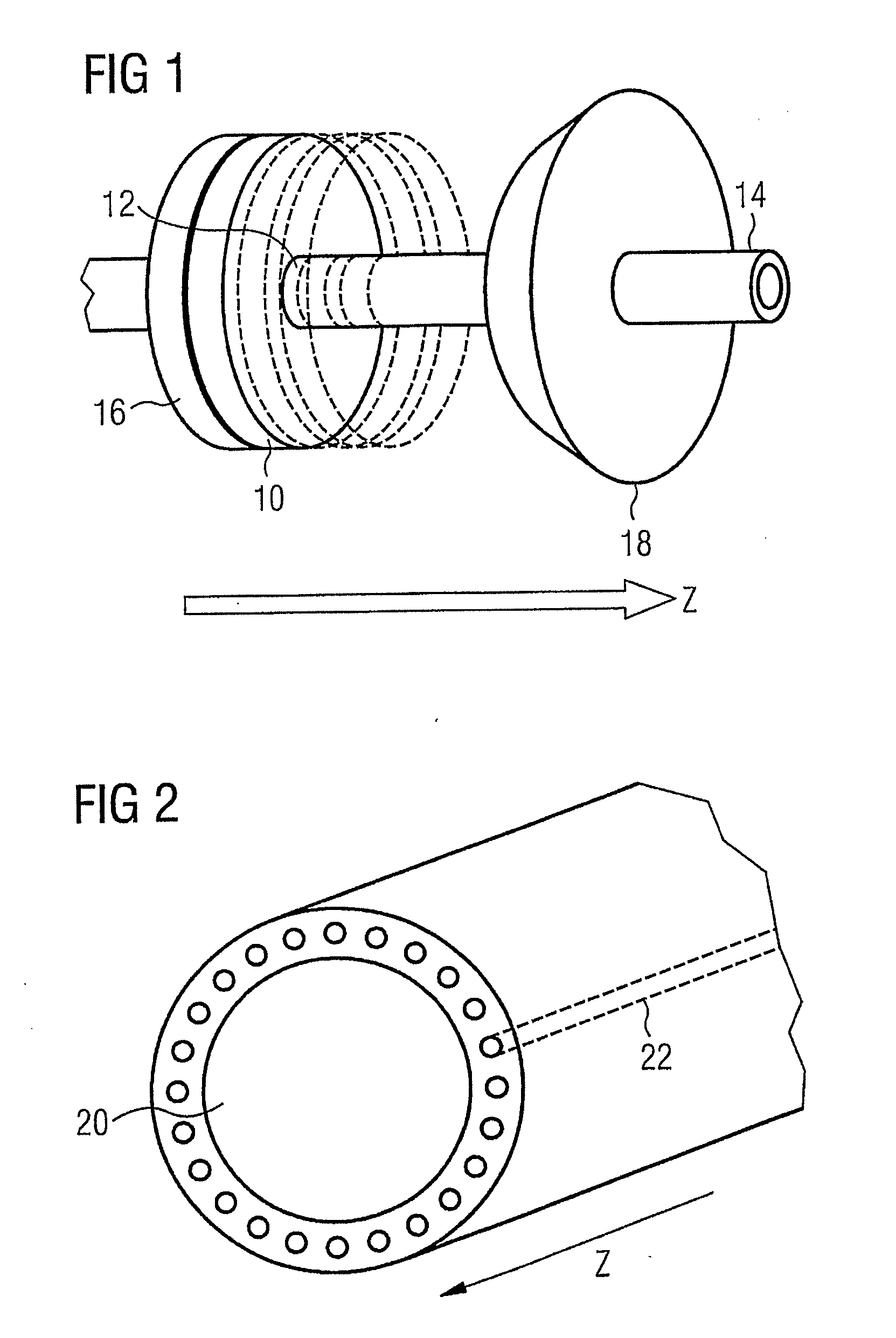

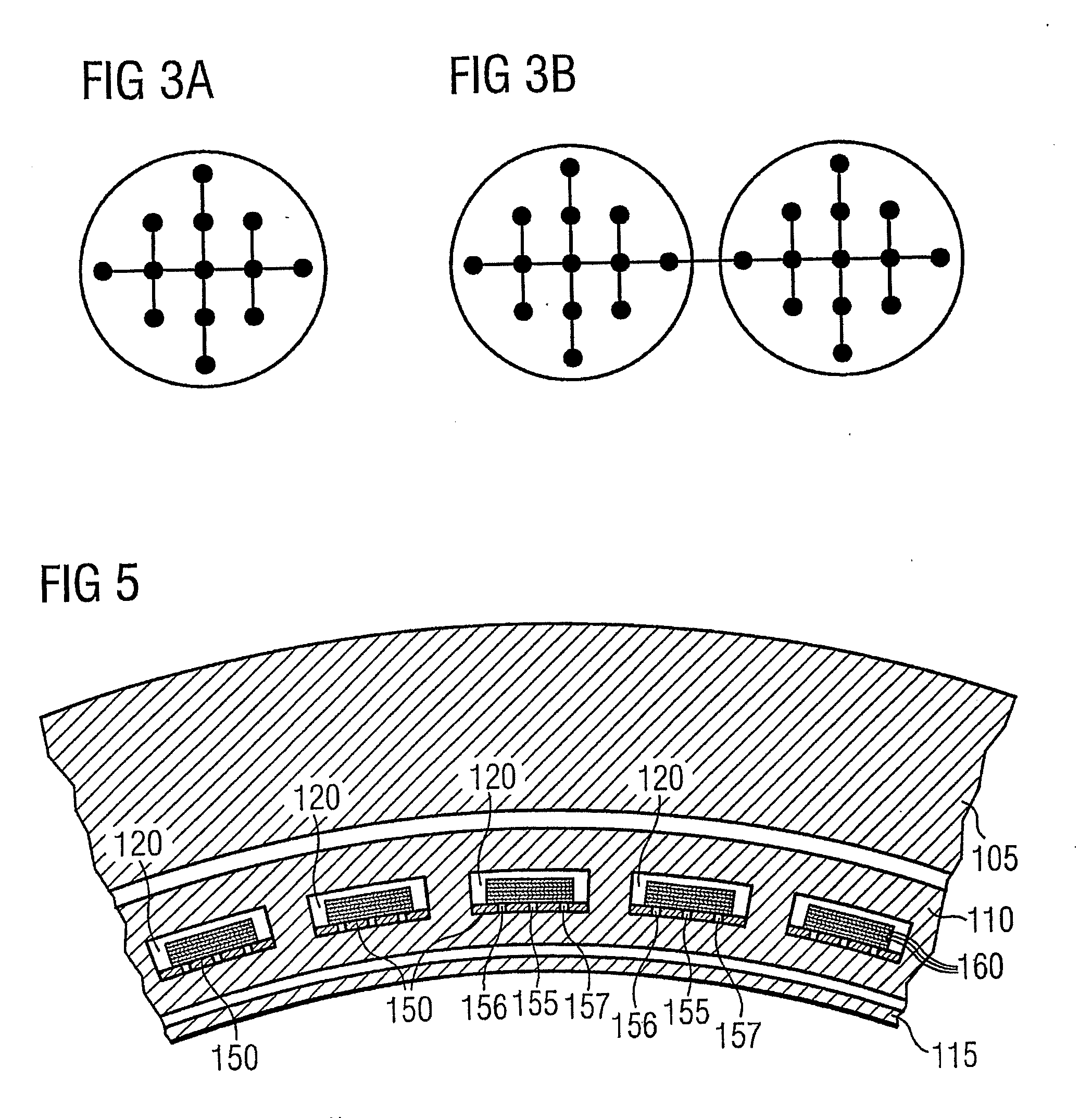

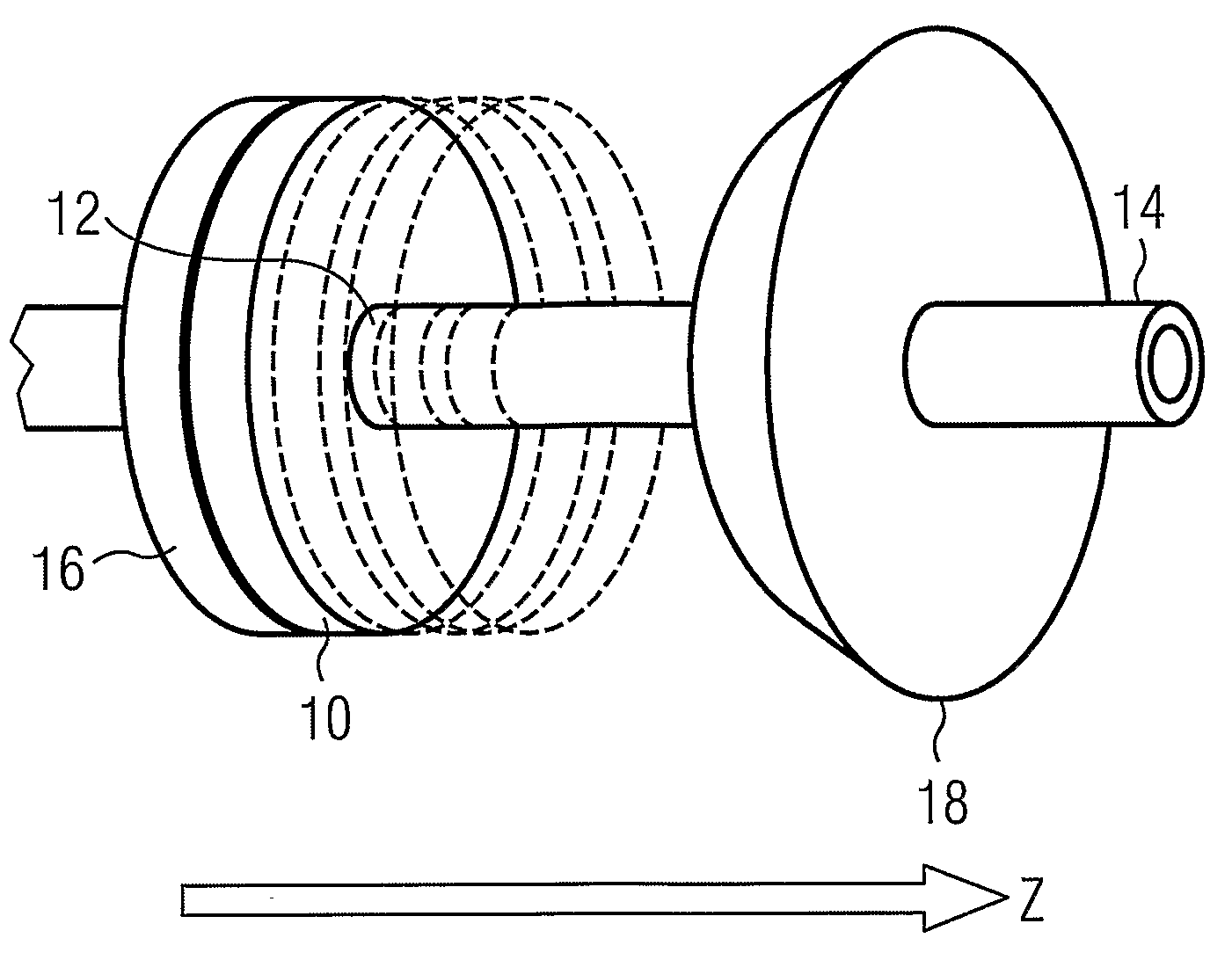

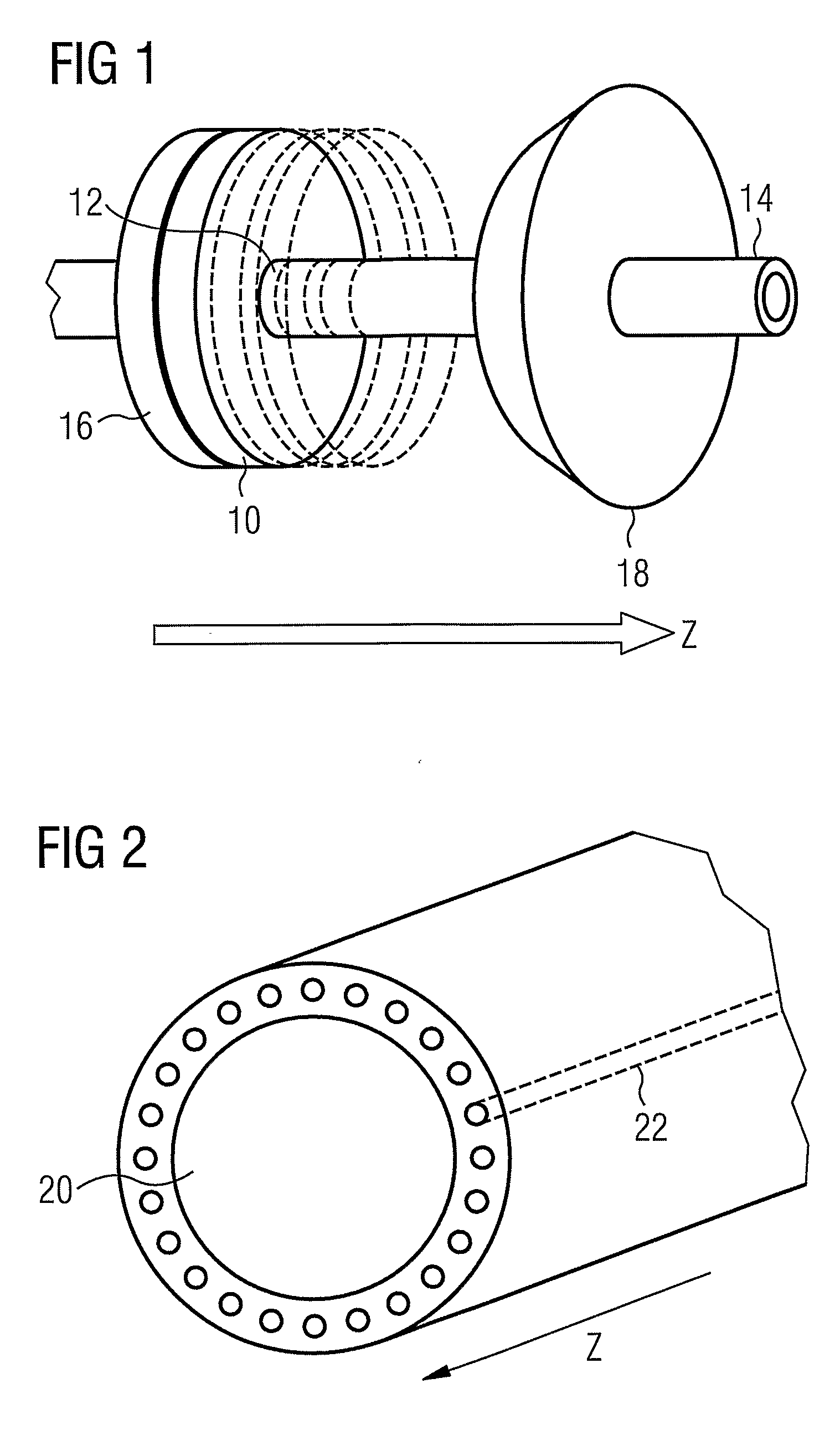

Passive shimming of magnet systems

InactiveUS20100207630A1Lower the volumeShorten and widen boreMeasurements using NMR imaging systemsElectric/magnetic detectionEngineeringMagnet

In a method and an arrangement for shimming a cylindrical magnet system, that has a cylindrical magnet having a bore therein with an axis extending therethrough, and a gradient coil assembly located within the bore, shimming is accomplished by stacking a number of planar pieces of shim material in each of said tubes, with each of the tubes having an axis parallel to the axis of the cylindrical magnet, and with the planar pieces of shim material and stacked in the tubes in respective planes that are perpendicular to the axis of the cylindrical magnet.

Owner:SIEMENS MAGNET TECH

Passive shimming of magnet systems

InactiveUS20090096453A1Lower the volumeShorten and widen boreElectric/magnetic detectionMeasurements using magnetic resonanceEngineeringMagnet

In a method and an arrangement for shimming a cylindrical magnet system, that has a cylindrical magnet having a bore therein with an axis extending therethrough, and a gradient coil assembly located within the bore, shimming is accomplished by stacking a number of planar pieces of shim material in each of said tubes, with each of the tubes having an axis parallel to the axis of the cylindrical magnet, and with the planar pieces of shim material and stacked in the tubes in respective planes that are perpendicular to the axis fo the cylindrical magnet.

Owner:SIEMENS PLC

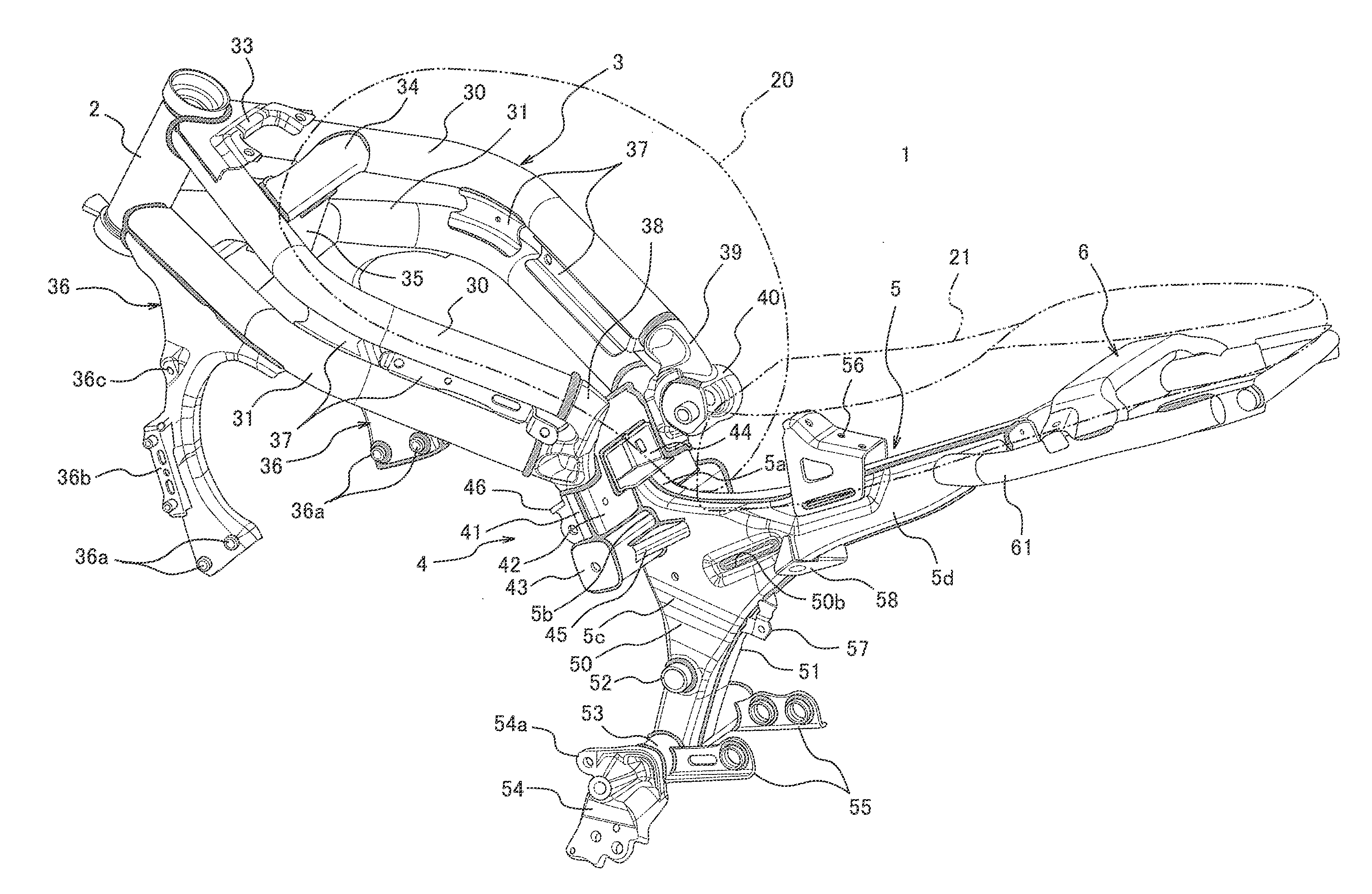

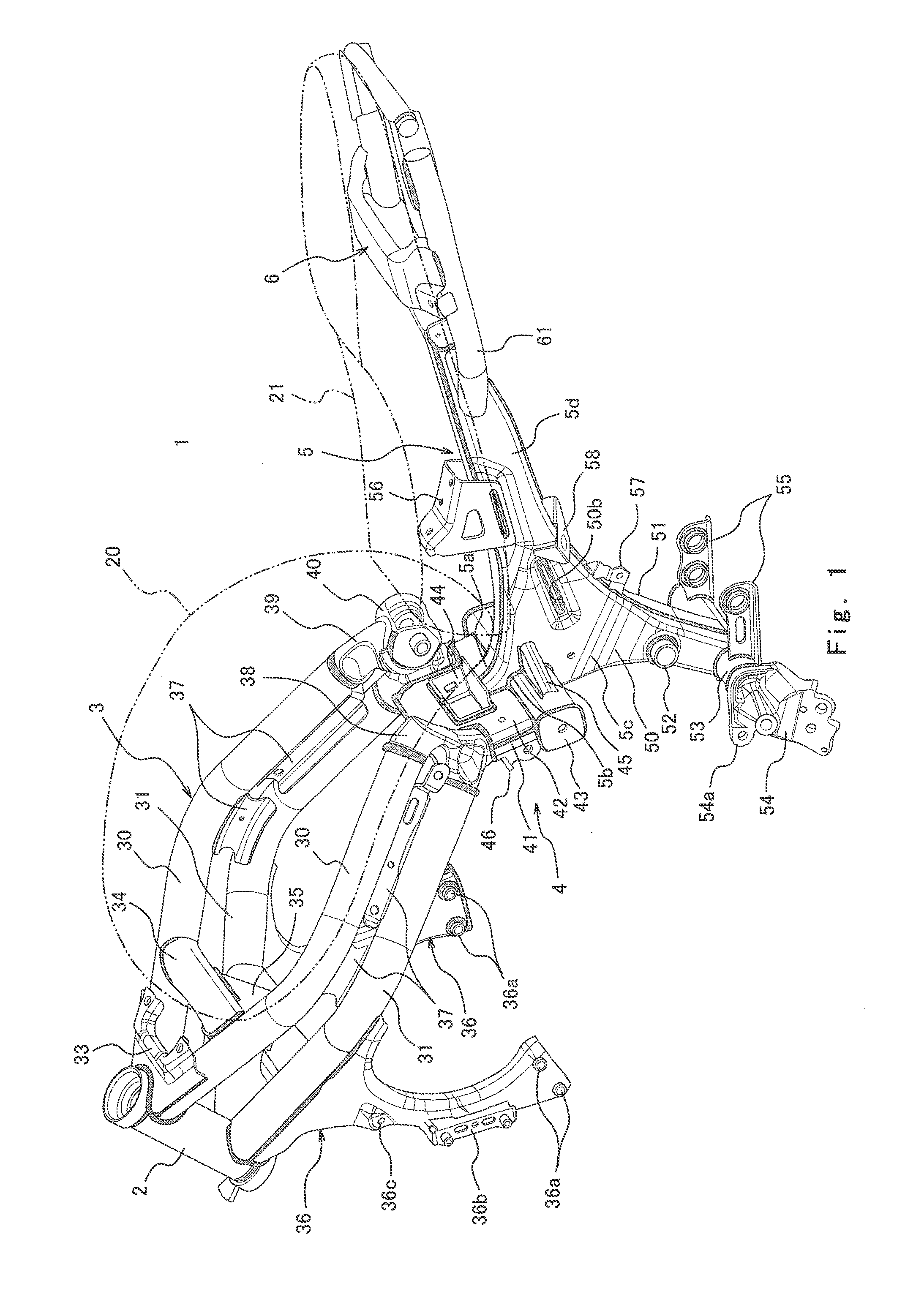

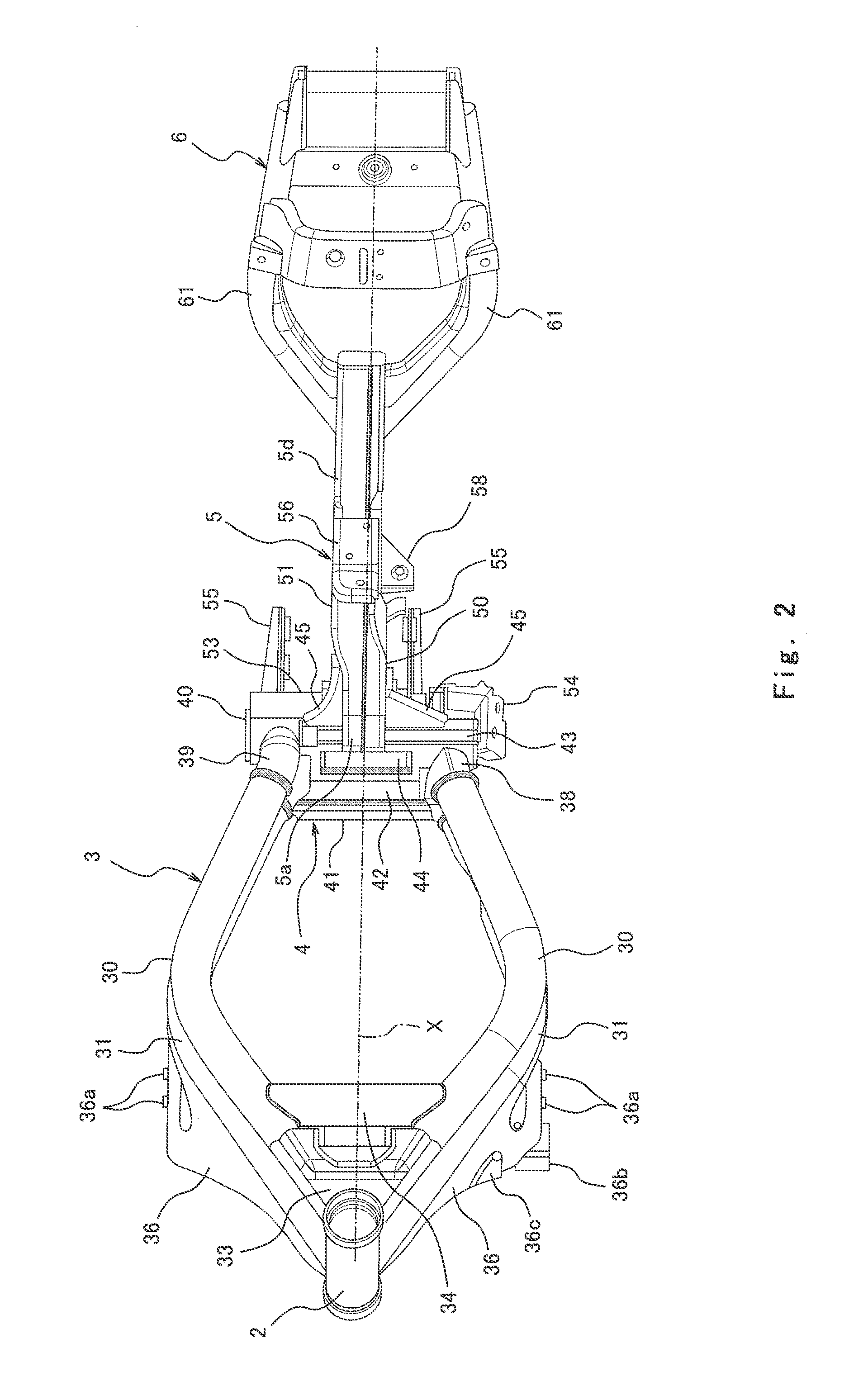

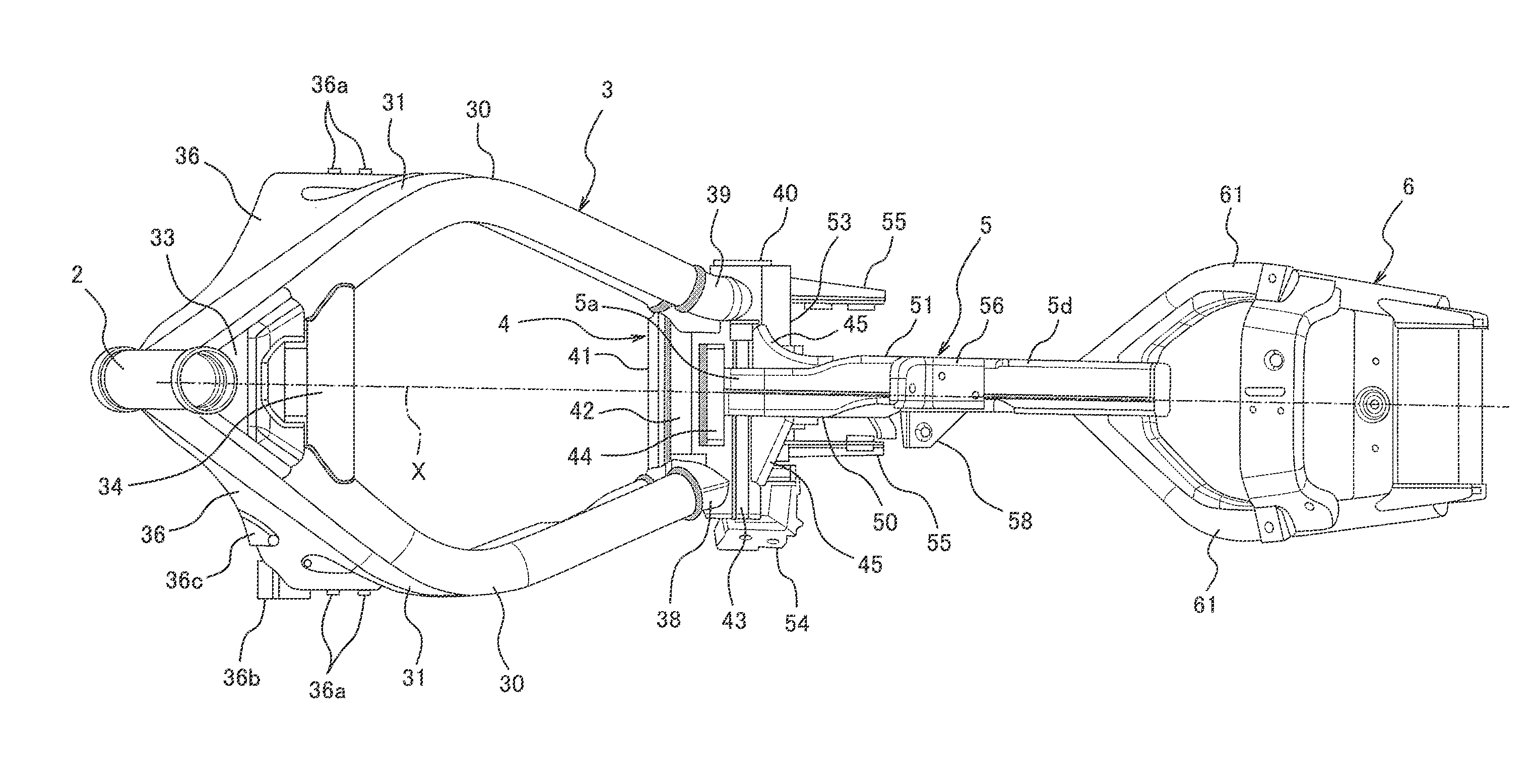

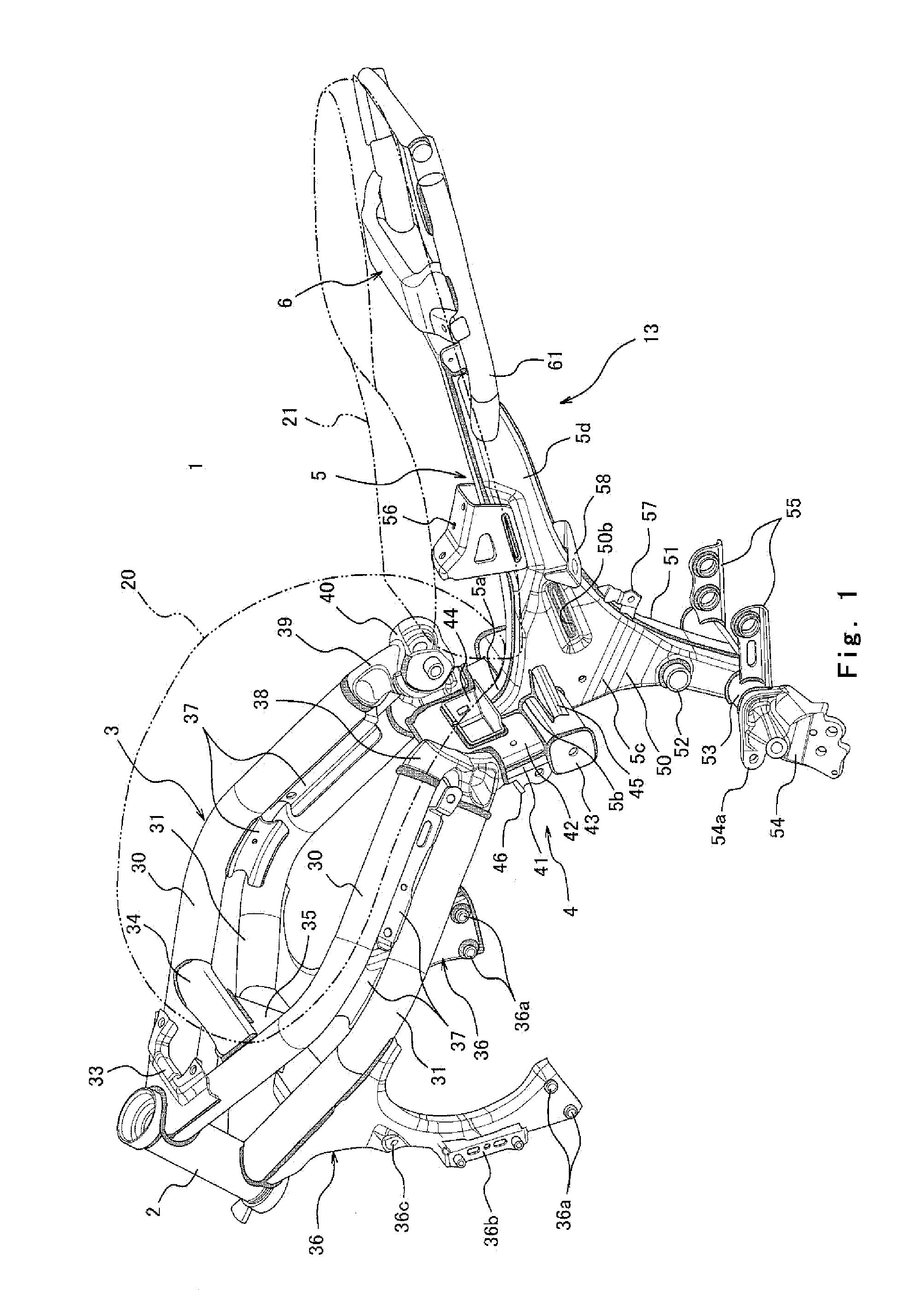

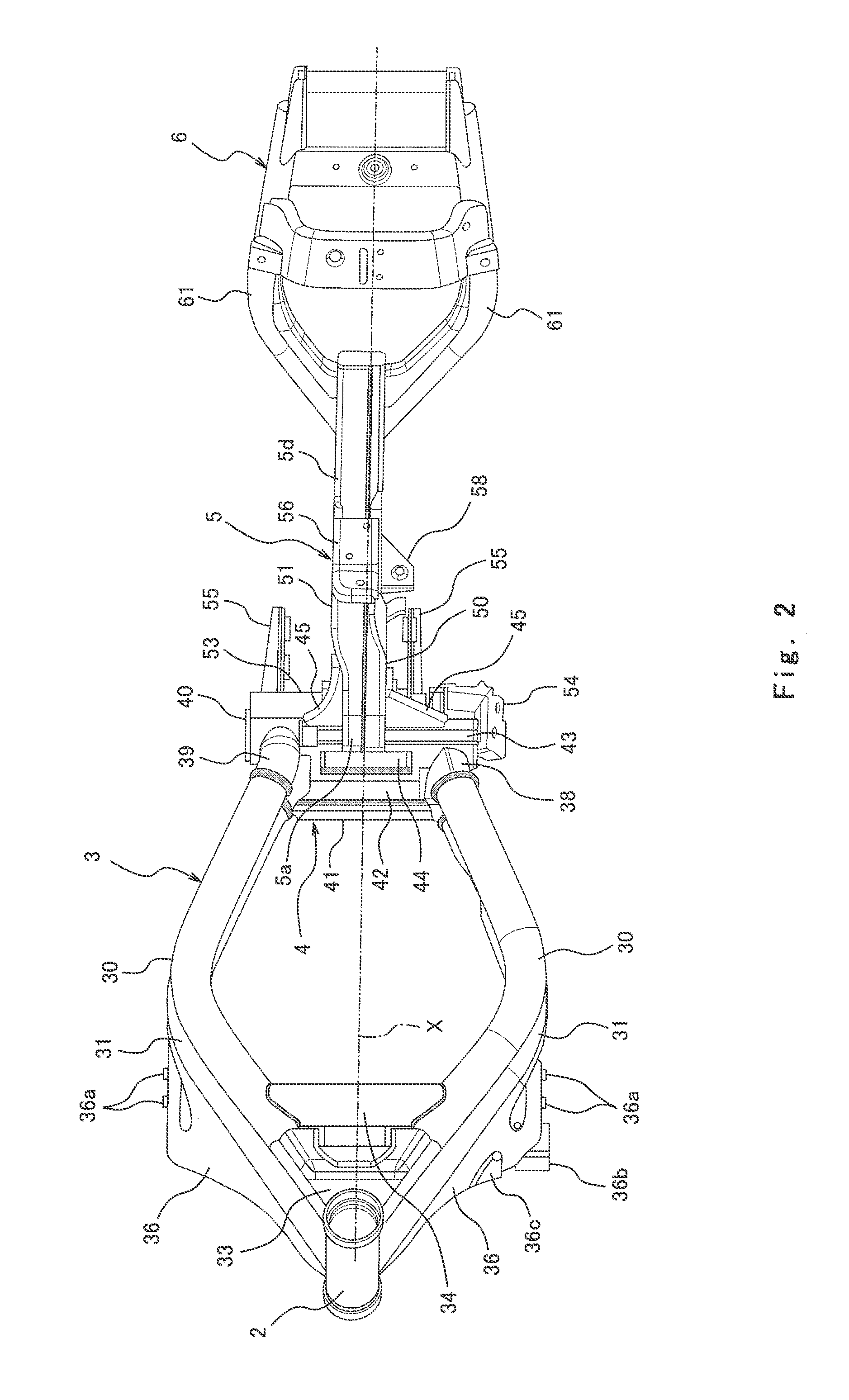

Motorcycle

In a vehicle body frame including a front frame portion extending rearward from a head pipe, and a rear frame portion extending downward or rearward from a rear end of the front frame portion, a forward portion of the rear frame portion, for example, a lumbar frame, includes a reduced-width portion overlapping with a vehicle body center line extending in a forward and rearward direction when viewed from above, and having a shape in which a width in a rightward and leftward direction is smaller than a length in an upward and downward direction. Devices incorporated into the motorcycle, such as a canister, a battery, an ABS unit, and a suspension unit, are laid out in spaces lateral relative to the reduced-width portion. Thus, the devices can be mounted to the vehicle body frame easily and efficiently.

Owner:KAWASAKI MOTORS LTD

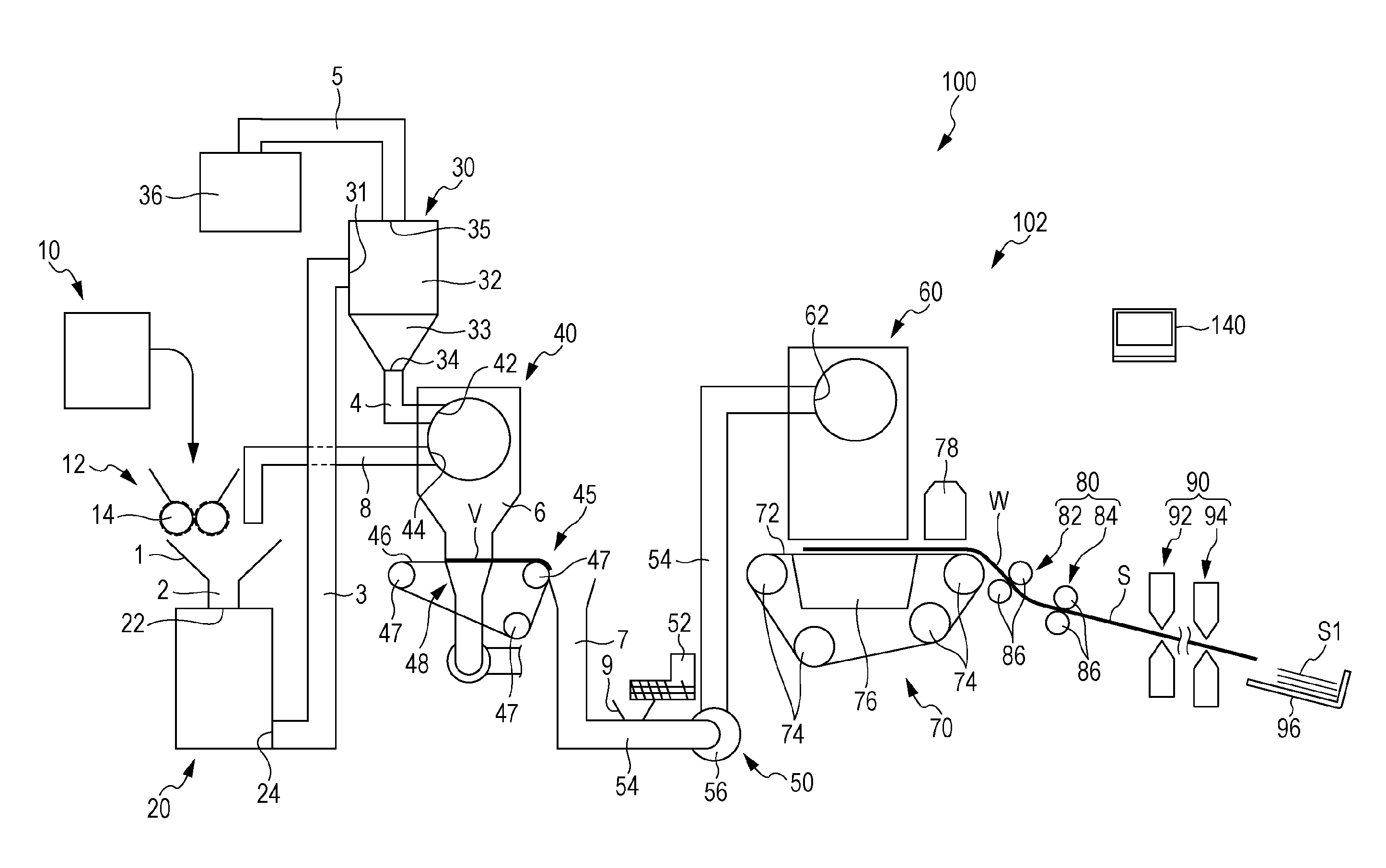

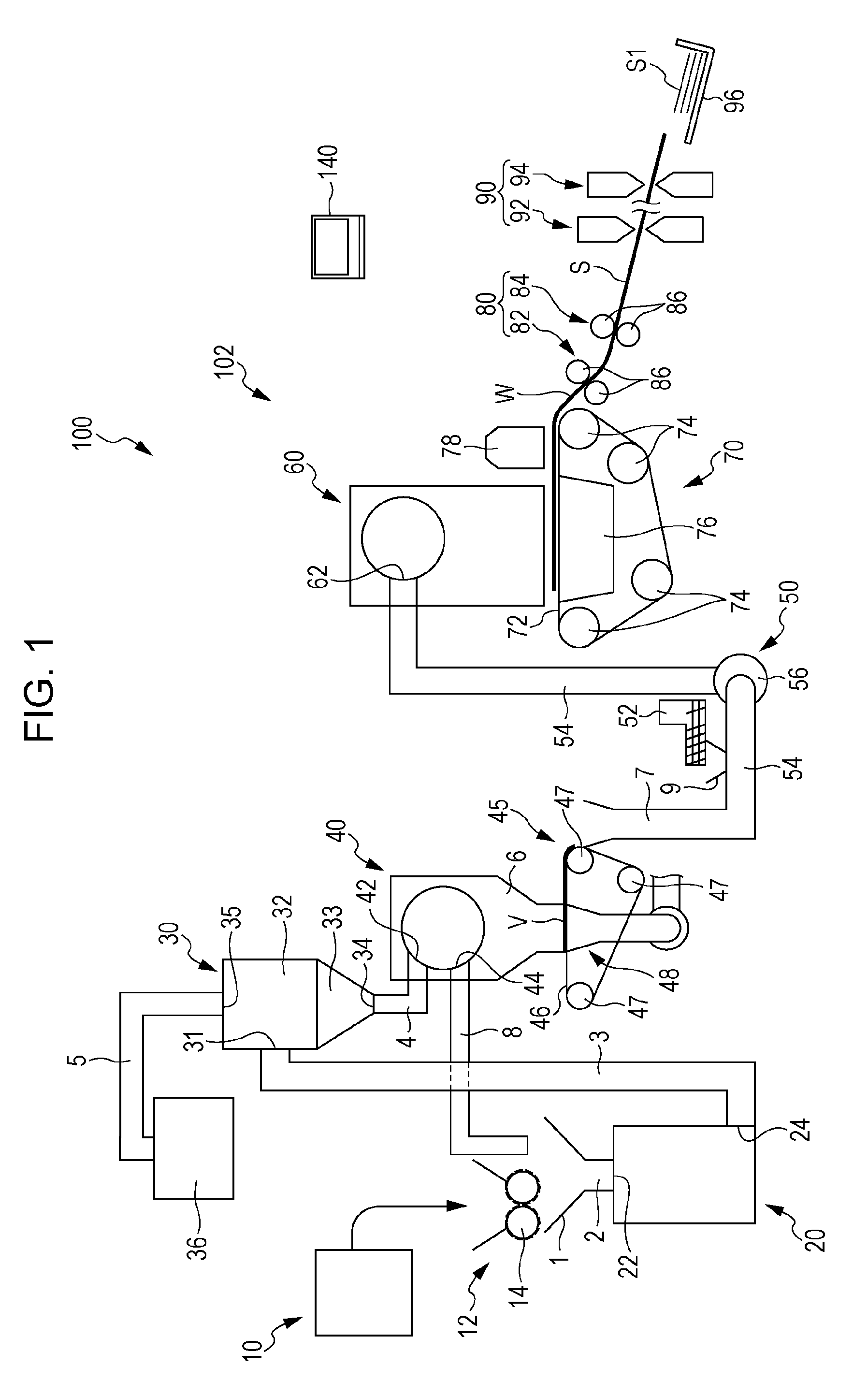

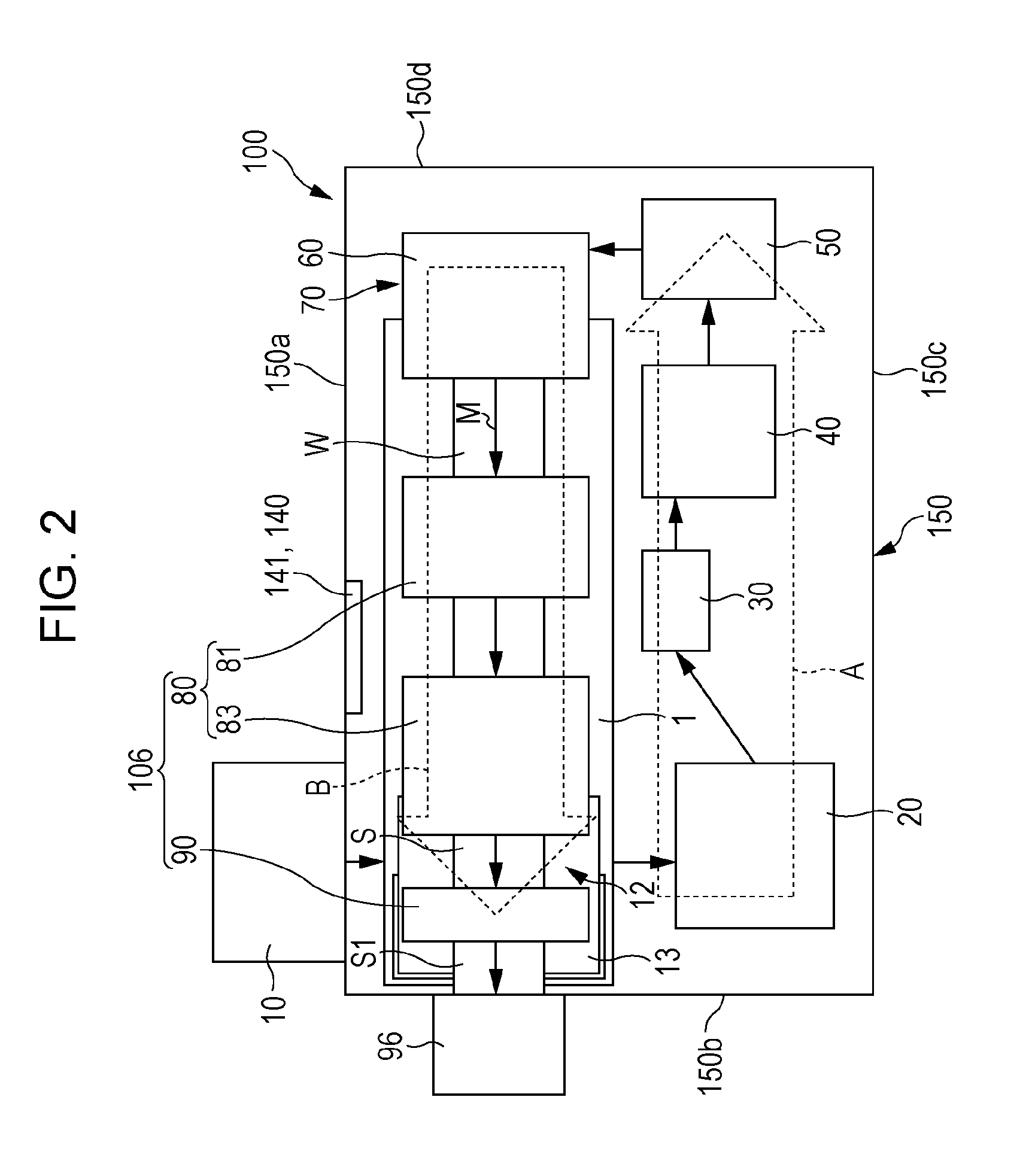

Sheet manufacturing apparatus

ActiveUS20160258112A1Increased ease of installationWasted spacePaper recyclingPress sectionManufactured apparatusCrusher

A sheet manufacturing apparatus includes a crusher unit, a defibrator unit, a second web forming unit, and a shaping unit. The crusher unit coarsely crushes a raw material that contains fibers into coarsely crushed pieces. The defibrator unit defibrates coarsely crushed pieces into defibrated material. The second web forming unit forms a web by accumulating defibrated material. The shaping unit forms a sheet from the web. The crusher unit is positioned vertically below the shaping unit.

Owner:SEIKO EPSON CORP

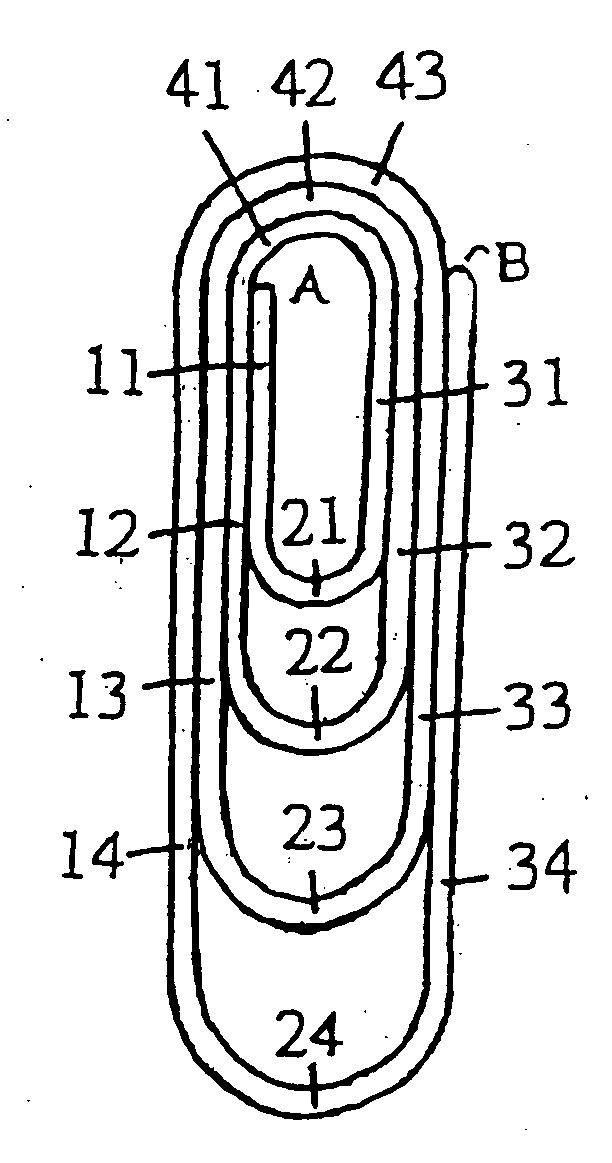

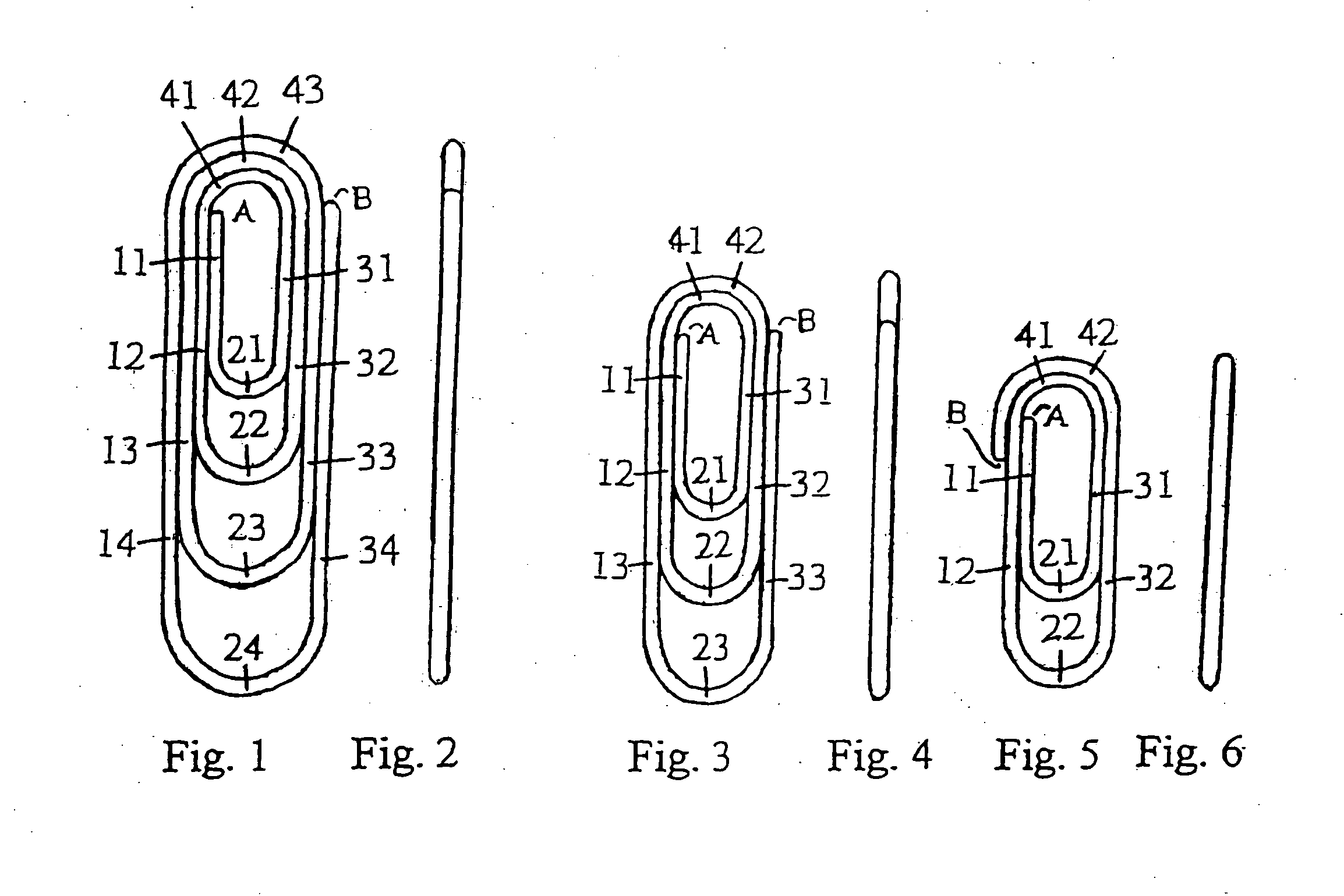

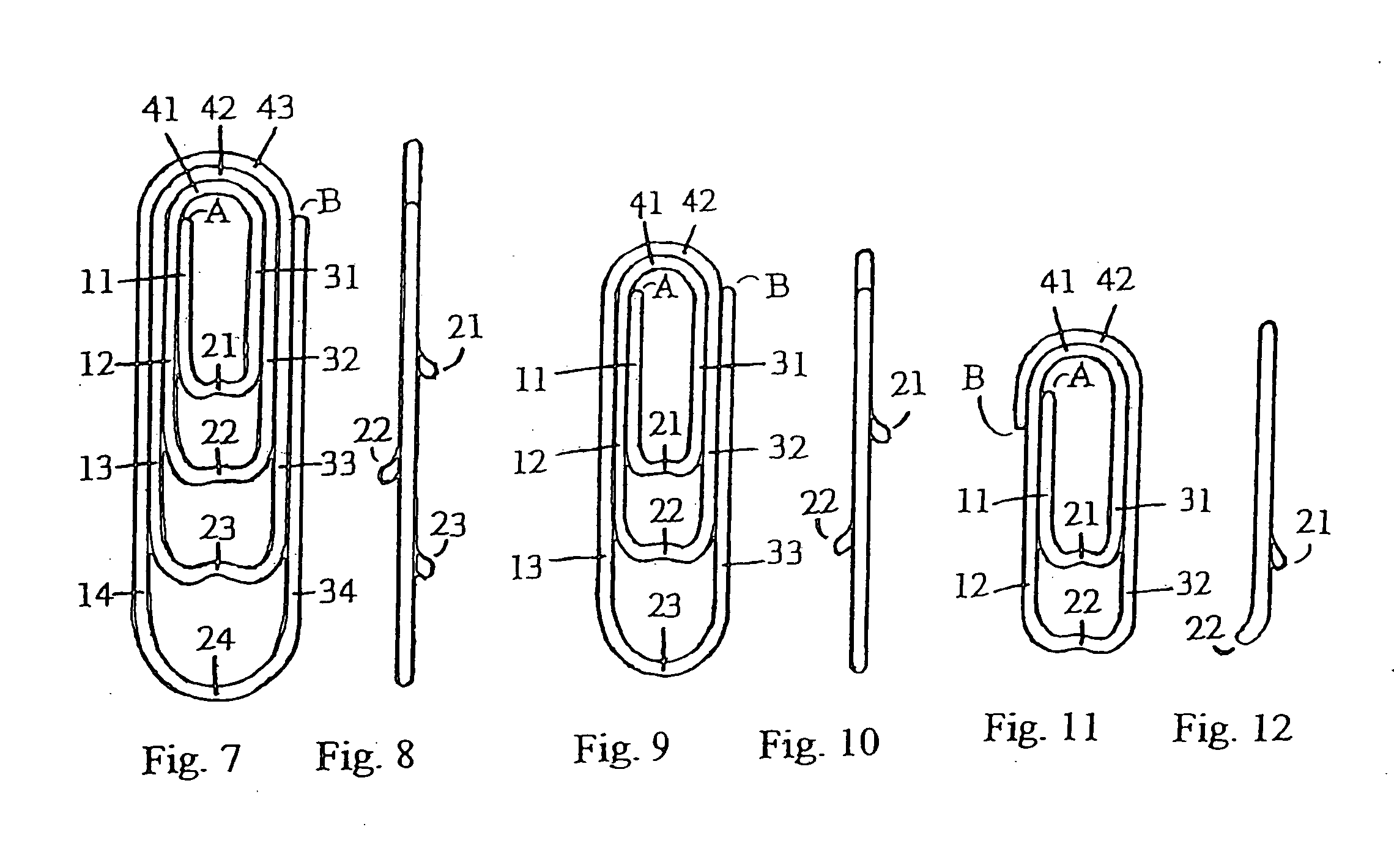

Paper clip

InactiveUS20110258813A1Increase pressureWasted spaceSnap fastenersClothes buttonsGrip forceMechanical engineering

A novel and improved paper clip is formed from a single length of resilient metal wire bent into a configuration, having additional series of re-entrant loops. The upper loops are closely grouped together reducing the length of the arms, which allow stronger gripping force to be concentrated on the clamping jaws. The lower loops interconnecting the length-reduced arms form additional number of clamping jaws, which significantly add further holding strength. These particular features result in practical advantages in that the paper clip of the present invention provides a firm gripping force to effectively hold sheets of paper together without slipping or shifting; and does not create a large bulk in one area to make the pile unmanageable due to its flat form, and does not waste space in drawers and boxes as the upper loops are closely grouped together, and is simple and inexpensive to manufacture.

Owner:LU KAI CHEN

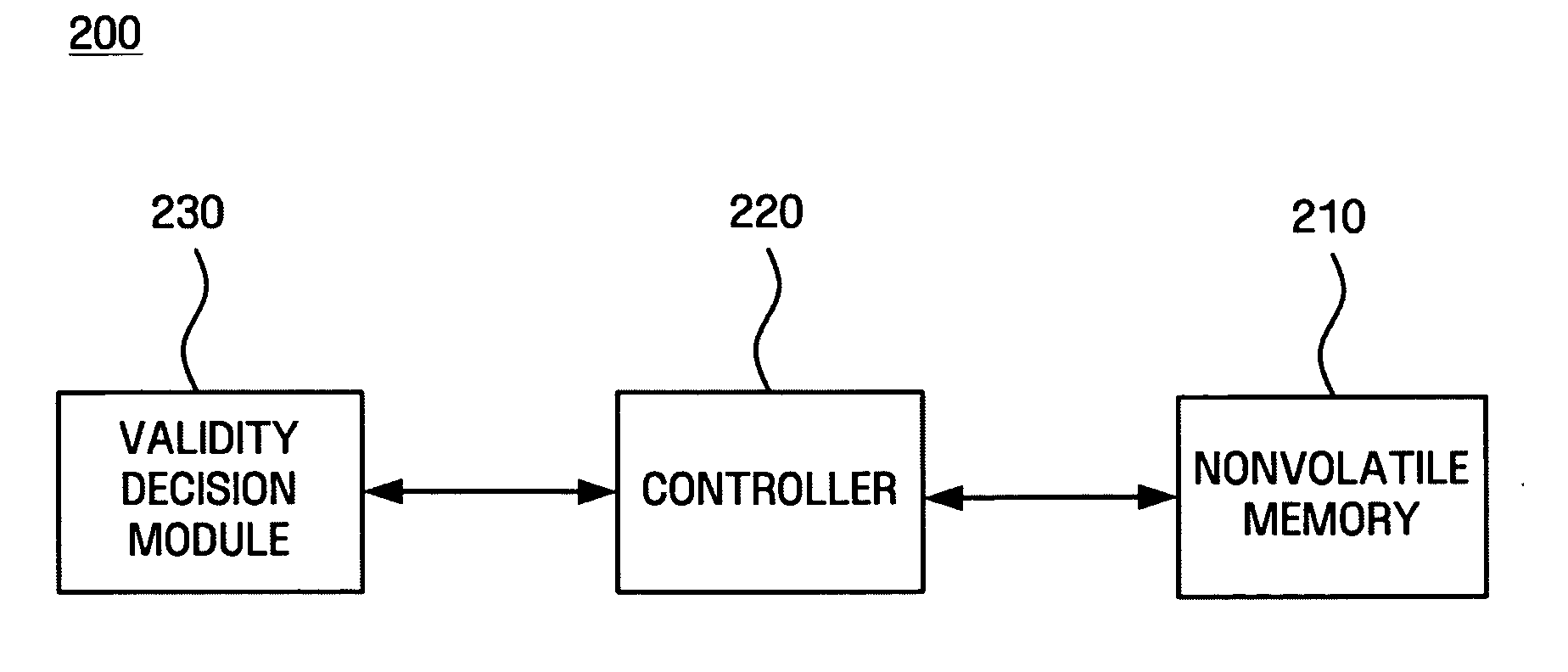

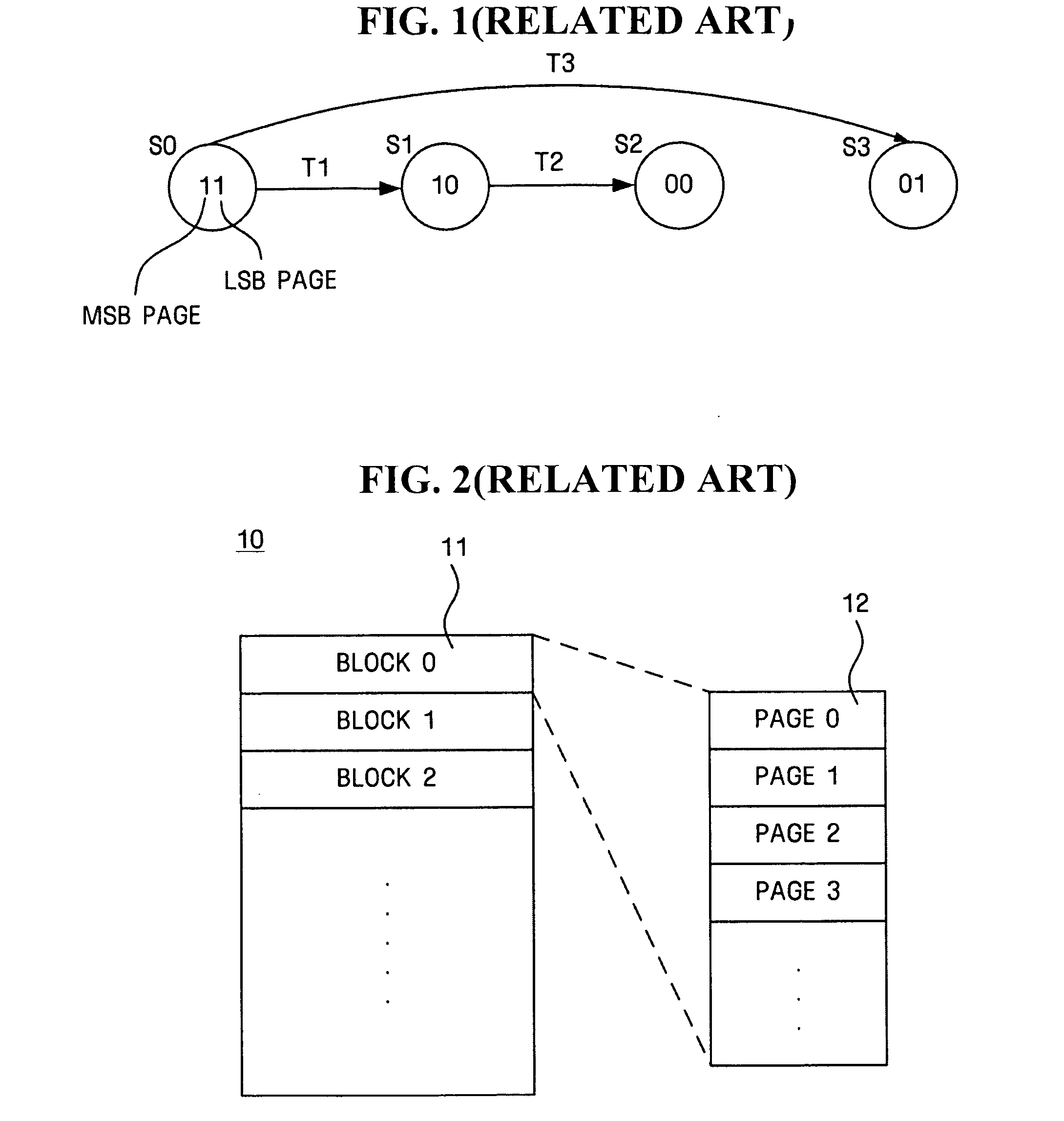

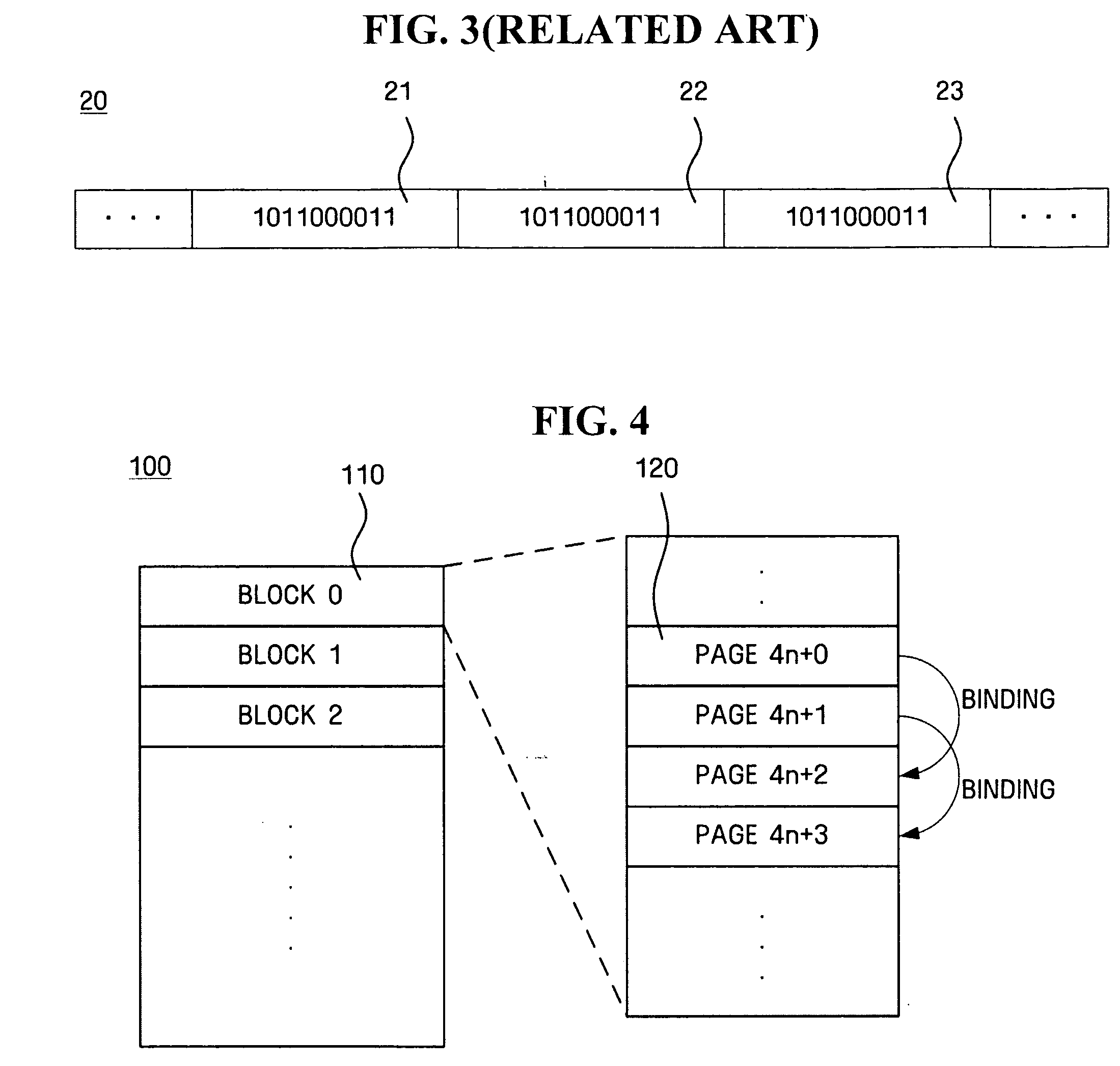

Nonvolatile memory and apparayus and method for deciding data validity for the same

ActiveUS20070189107A1Wasted spaceAvoid wastingError detection/correctionRead-only memoriesData storingData store

Provided are a nonvolatile memory and an apparatus and method for deciding data validity for the same, in which validity of data stored in the nonvolatile memory can be decided. The nonvolatile memory includes a memory cell storing data bits in a plurality of pages included in a predetermined block through a plurality of states realized by at least two bits. The block includes a first page in which data bits for determining validity of data bits written by a user are stored, and a second page in which the data bits written by the user are stored.

Owner:SAMSUNG ELECTRONICS CO LTD

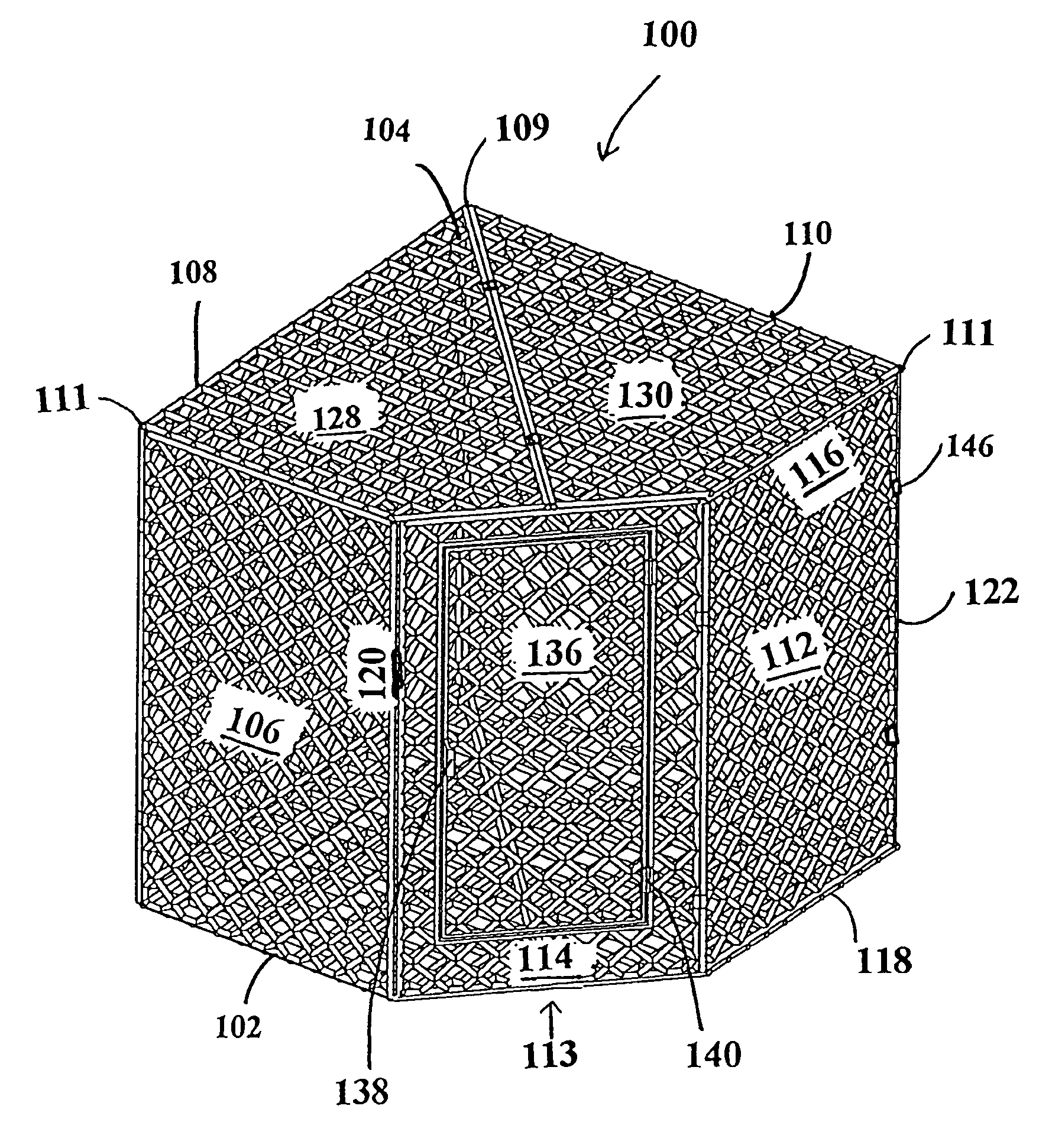

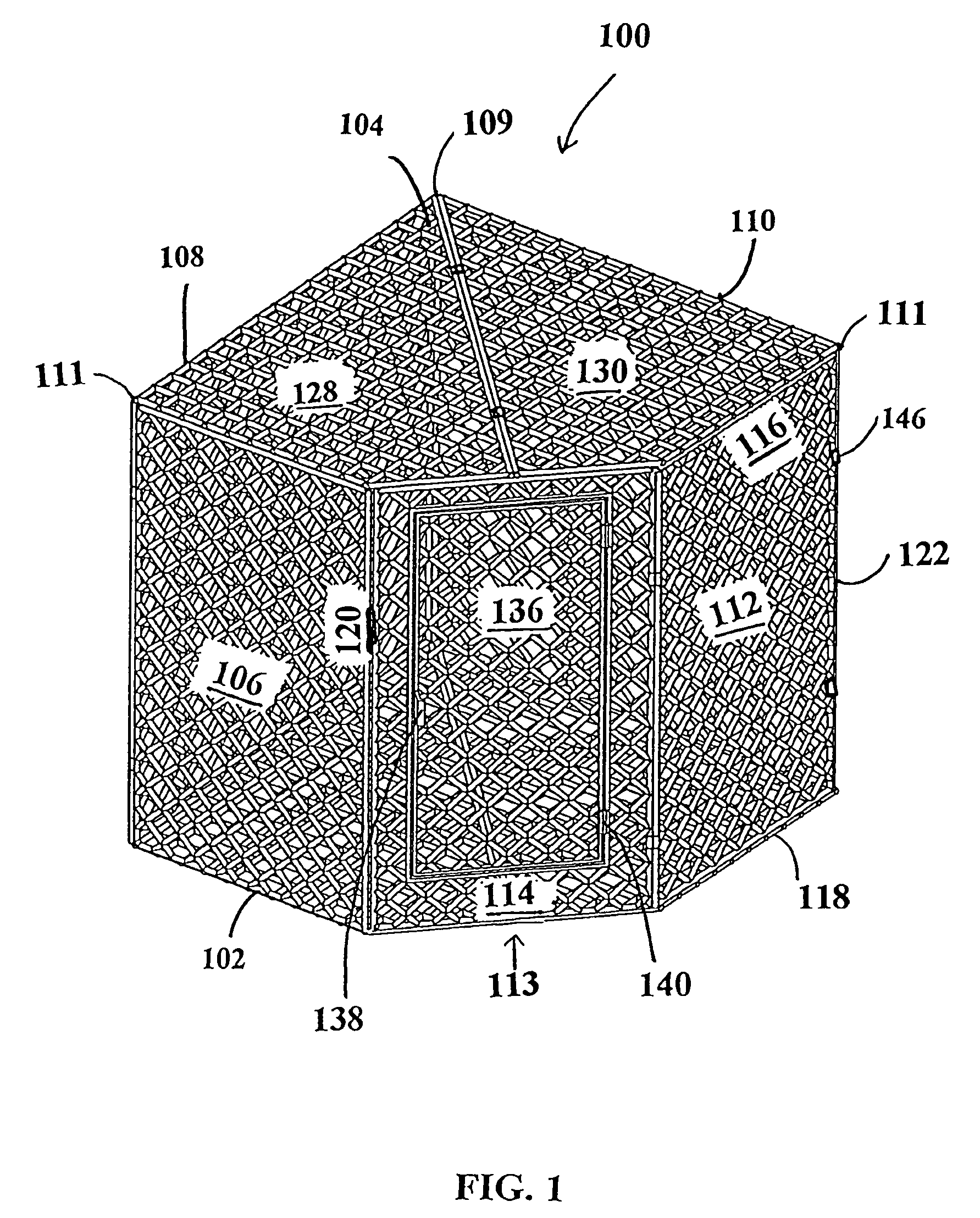

Collapsible corner animal cage

A collapsible corner animal cage is provided. The collapsible cage comprises a first set of side walls fastened together to define the rear corner of the cage; a second set of side walls fastened to the first set of side walls to define the side corners of the cage; a door panel fastened to the second set of side walls to define the front of the cage, the door panel positioned diametrically opposite the rear corner of the cage; a floor fastened to the side walls and the door panel; and a roof fastened to the side walls and the door panel; wherein the side walls, door panel, floor and roof are fastened together to define a collapsible structure for use in a corner. The cage may also be collapsed into a one-piece, substantially flat unit with a carrying handle for transport.

Owner:FRISBEE LINDA SUSAN

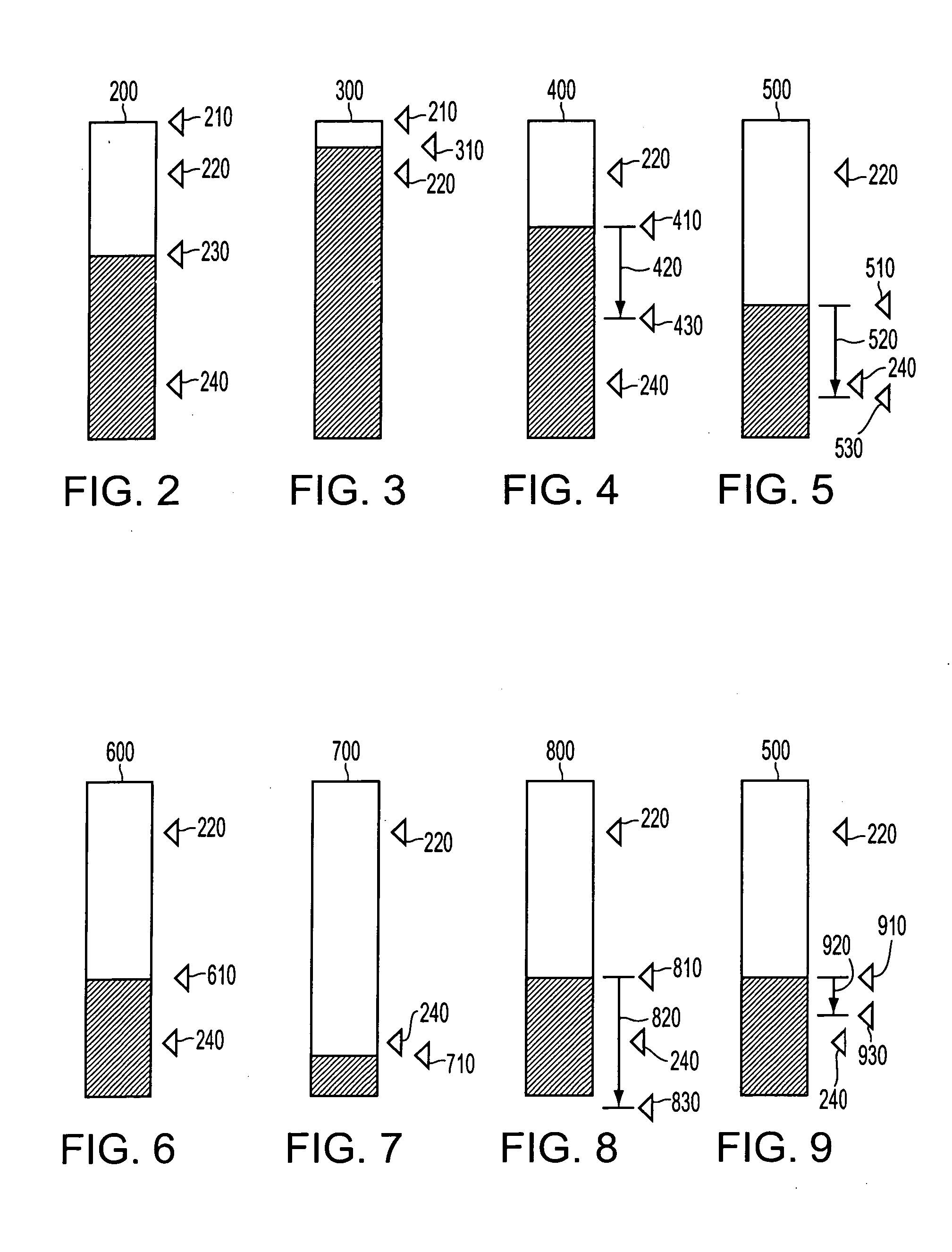

Liquid container and method of manufacturing the same

ActiveUS20090237475A1Fast chargingAvoid breakingWriting implementsMetal-working apparatusEngineeringLiquid storage

The liquid container has substantially rectangular parallelepiped shape having a bottom face that is situated at bottom when the liquid container is attached to the liquid consuming apparatus, and a first side face that is substantially orthogonal to the bottom face. The liquid container pertaining the second mode comprises a liquid storage portion that stores a liquid, a liquid feed portion that is situated downstream from the liquid storage portion and that feeds the liquid to the liquid consuming apparatus, and an air introduction portion that is situated upstream from the liquid storage portion and that introduces air into the liquid storage portion from an upstream side in association with feed of the liquid to the liquid consuming apparatus. The liquid storage portion includes a first liquid storage chamber having a first storage chamber bottom face situated at bottom, a first upstream opening situated along the first storage chamber bottom face, and a first downstream opening situated along the first storage chamber bottom face, a second liquid storage chamber that is situated further downstream from the first liquid storage chamber and that includes a second storage chamber bottom face situated at bottom, a second upstream opening situated along the second storage chamber bottom face, and a first downstream opening situated along the second storage chamber bottom face, and a connecting flow channel disposed between the first downstream opening and the second upstream opening so as to connect the first liquid storage chamber with the second liquid storage chamber. The first upstream opening, the first downstream opening, the second upstream opening, and the second downstream opening are juxtaposed in proximity to the bottom face of the liquid container. The first storage chamber bottom face slopes so as to be lower towards the juxtaposed first upstream opening and first downstream opening with the container attached to the liquid consuming apparatus. The second storage chamber bottom face slopes so as to be lower towards the juxtaposed second upstream opening and second downstream opening with the container attached to the liquid consuming apparatus.

Owner:SEIKO EPSON CORP

Motorcycle with a rear frame portion having a reduced-width portion

ActiveUS8453781B2Reduce widthWithout wasting spaceMotorcyclesCycle containersVehicle frameEngineering

In a vehicle body frame including a front frame portion extending rearward from a head pipe, and a rear frame portion extending downward or rearward from a rear end of the front frame portion, a forward portion of the rear frame portion, for example, a lumbar frame, includes a reduced-width portion overlapping with a vehicle body center line extending in a forward and rearward direction when viewed from above, and having a shape in which a width in a rightward and leftward direction is smaller than a length in an upward and downward direction. Devices incorporated into the motorcycle, such as a canister, a battery, an ABS unit, and a suspension unit, are laid out in spaces lateral relative to the reduced-width portion. Thus, the devices can be mounted to the vehicle body frame easily and efficiently.

Owner:KAWASAKI MOTORS LTD

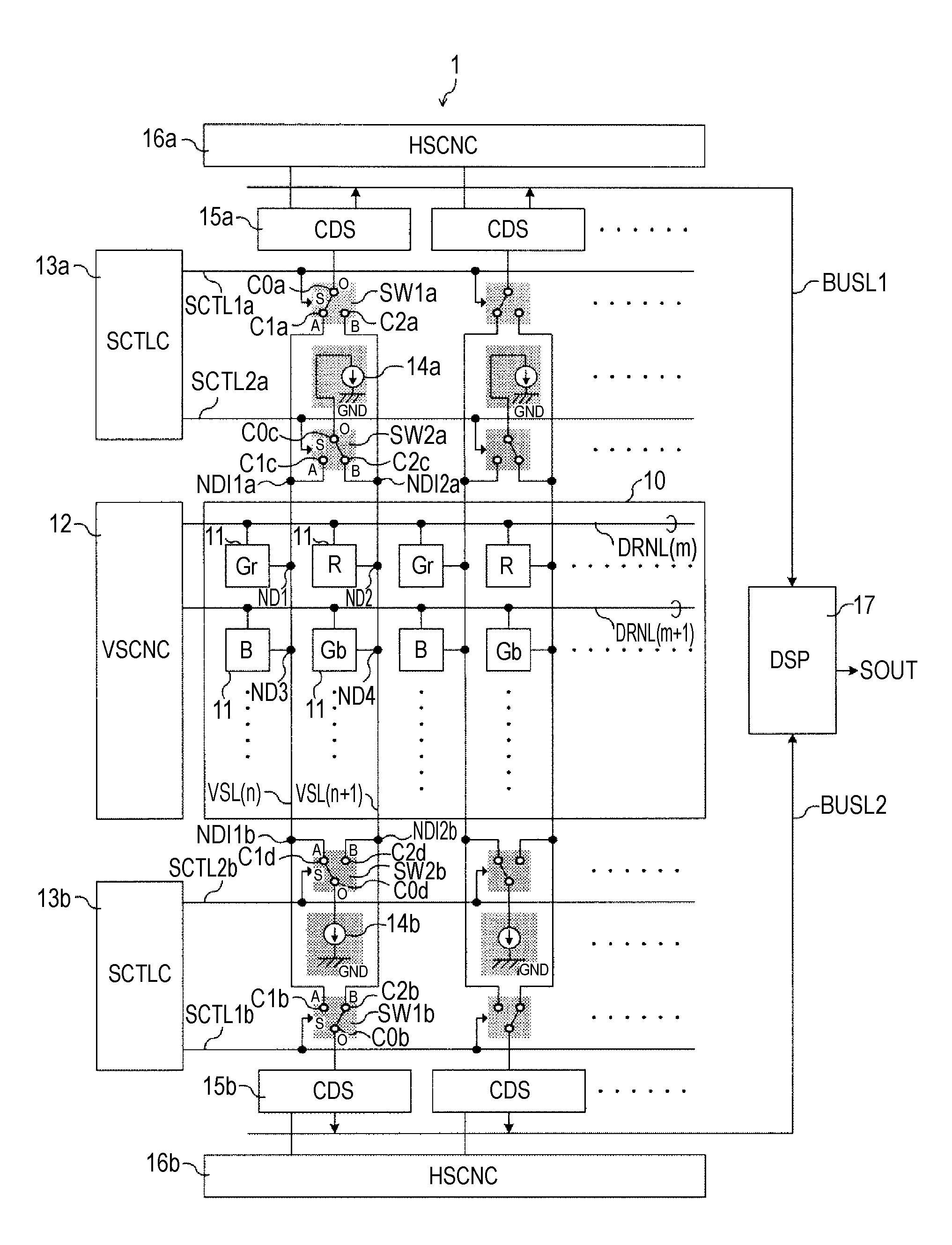

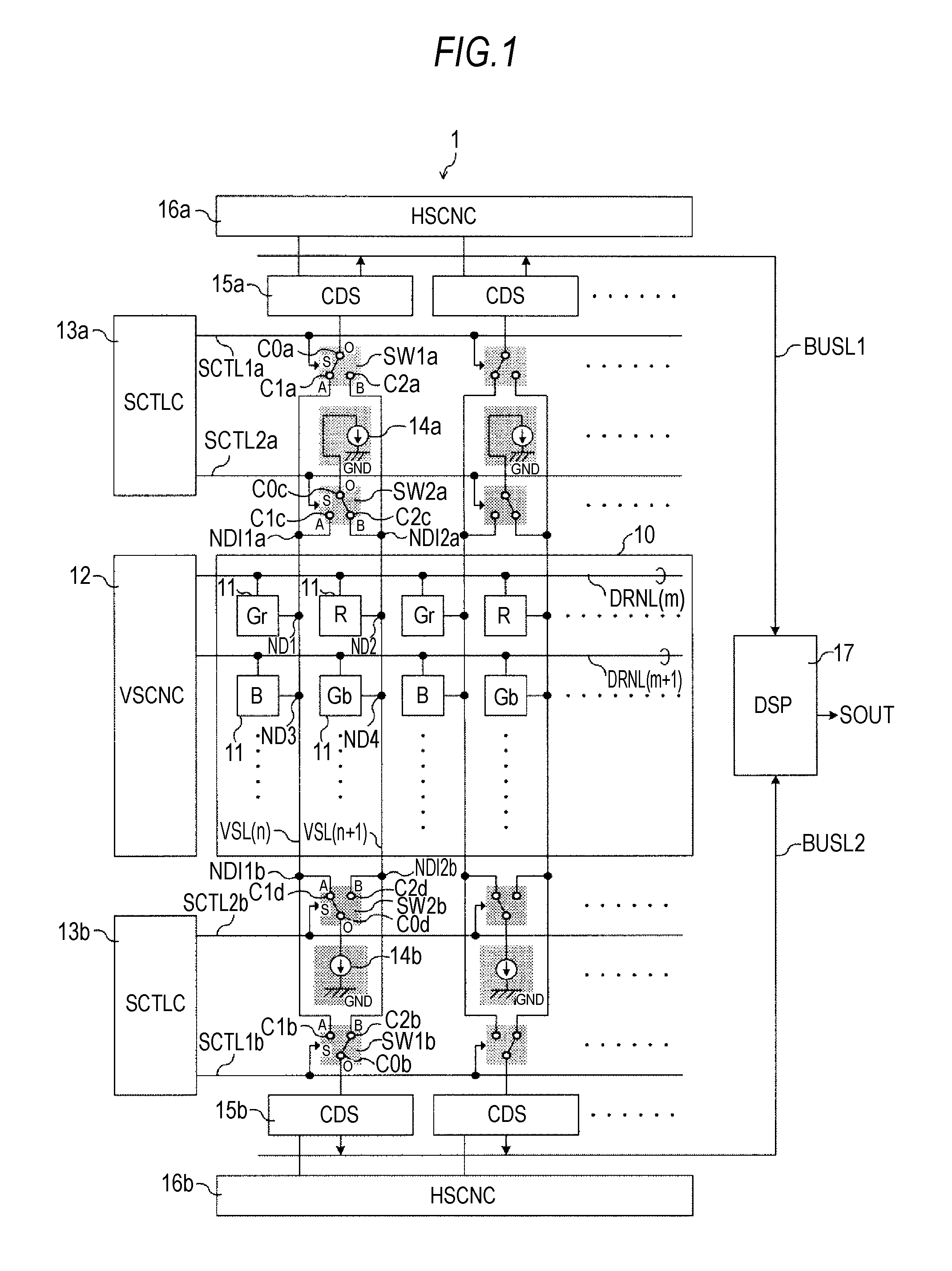

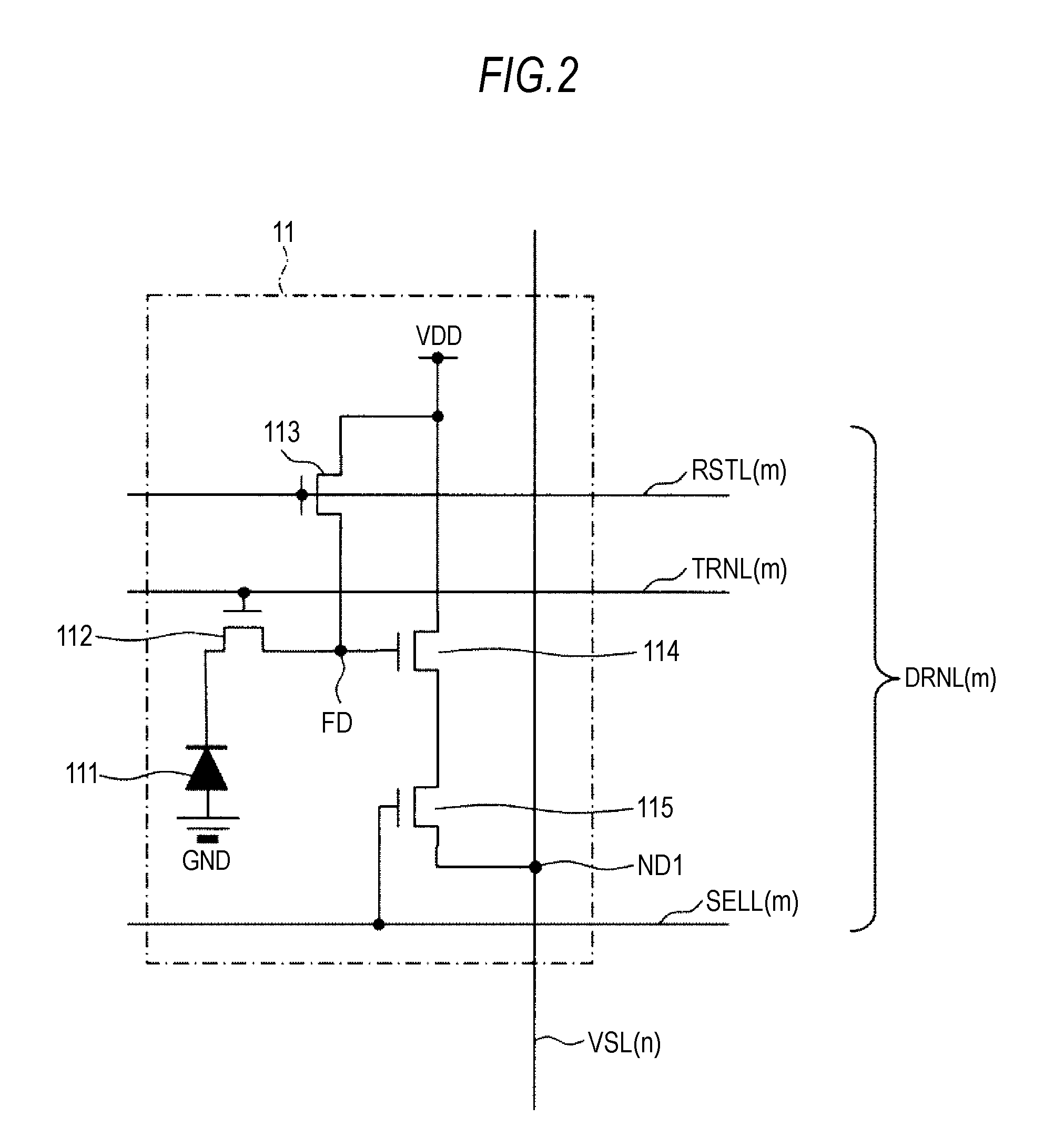

Imaging device, control method therefor, and camera

InactiveUS20100182472A1Reduce vertical noiseReduce shadingTelevision system detailsTelevision system scanning detailsSignal processing circuitsComputer science

An imaging device includes: a pixel section having a plurality of pixel circuits arranged in a matrix form; and a signal processing section that processes an output signal read from the pixel section. The pixel section includes a first output signal line, at least one first color pixel circuit connected to the first output signal line, a second output signal line, and at least one second color pixel circuit adjacent to the first color pixel circuit in a row direction thereof and connected to the second output signal line. The signal processing section includes a first signal processing circuit, a second signal processing circuit, a selection circuit, a first current source, a second current source, a current source selection circuit, a first connection node, and a second connection node.

Owner:SONY CORP

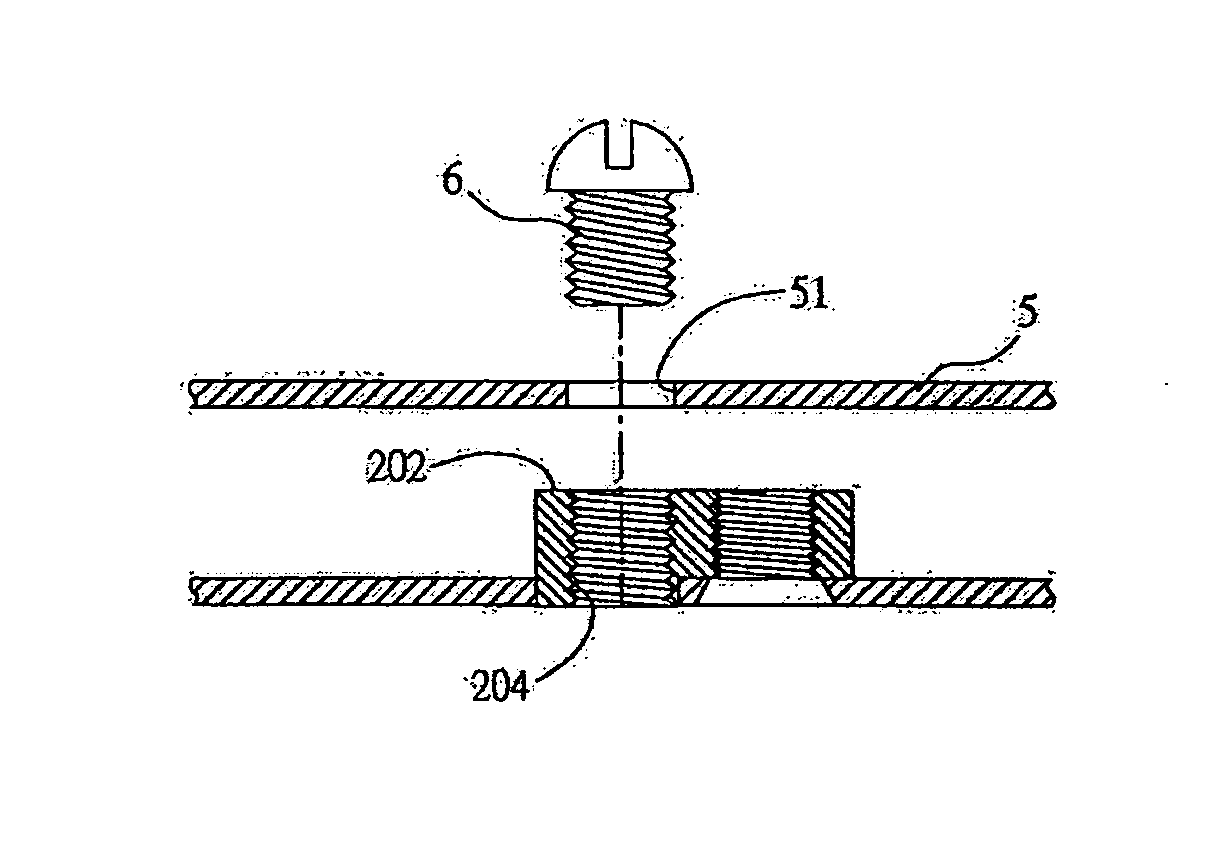

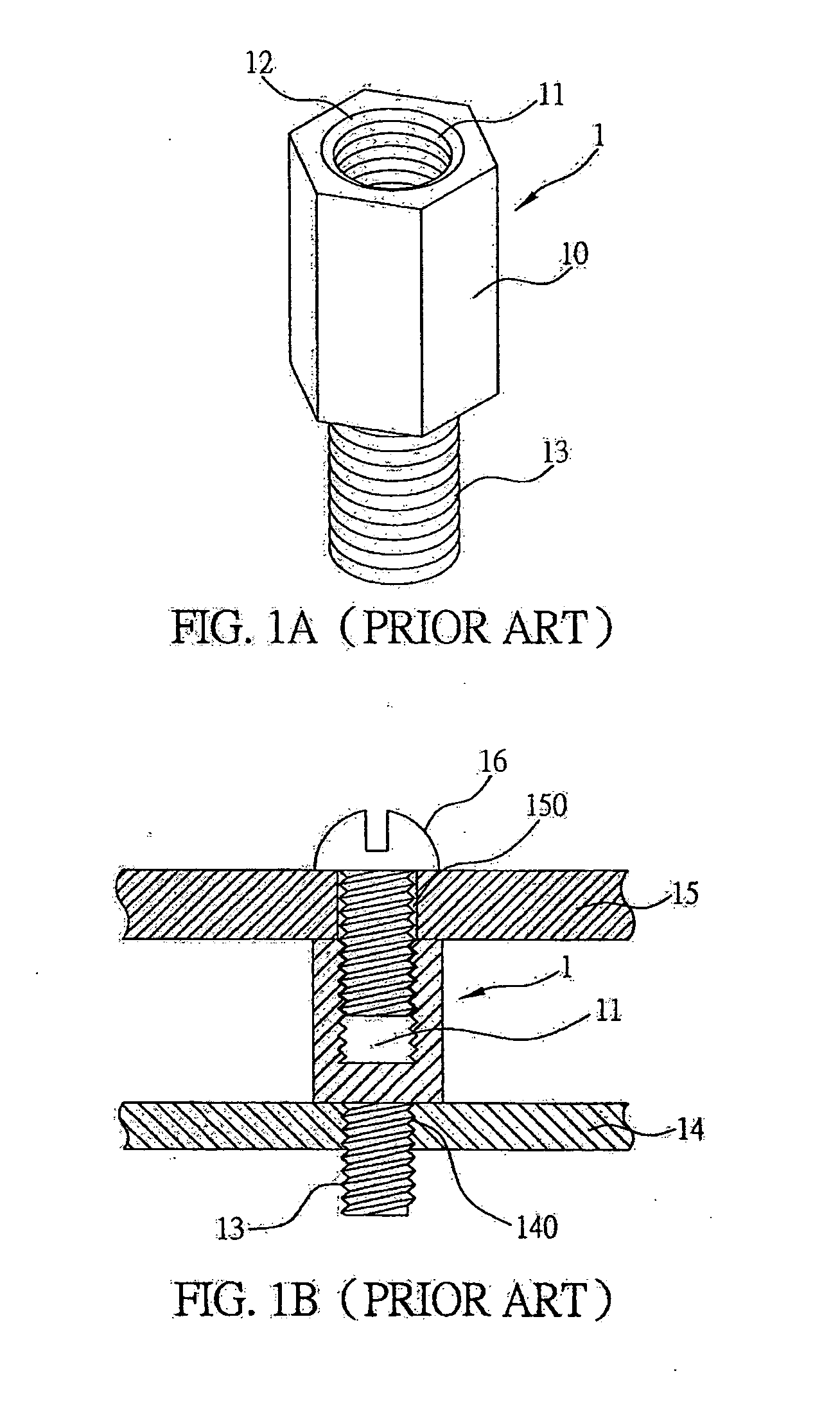

Installation element

An installation element is proposed, which includes a body, a coupling portion, an installation hole, and a coupling hole. The body includes a first surface and an opposing second surface. The coupling portion extends outward from the first surface. The installation hole and the coupling hole, whose axes are parallel, are installed in the body. The installation hole penetrates the body, whereas the coupling hole penetrates both the body and the coupling portion. The coupling portion may be positioned on a board having a positioning opening, such that the coupling portion positionally corresponds to the positioning opening. The board further includes an installation opening connected and aligned with the installation hole, such that not only is the installation element fixed on the board by a coupling element which penetrates both the installation opening and the installation hole, but another board is fixed to the installation element by the coupling hole.

Owner:INVENTEC CORP

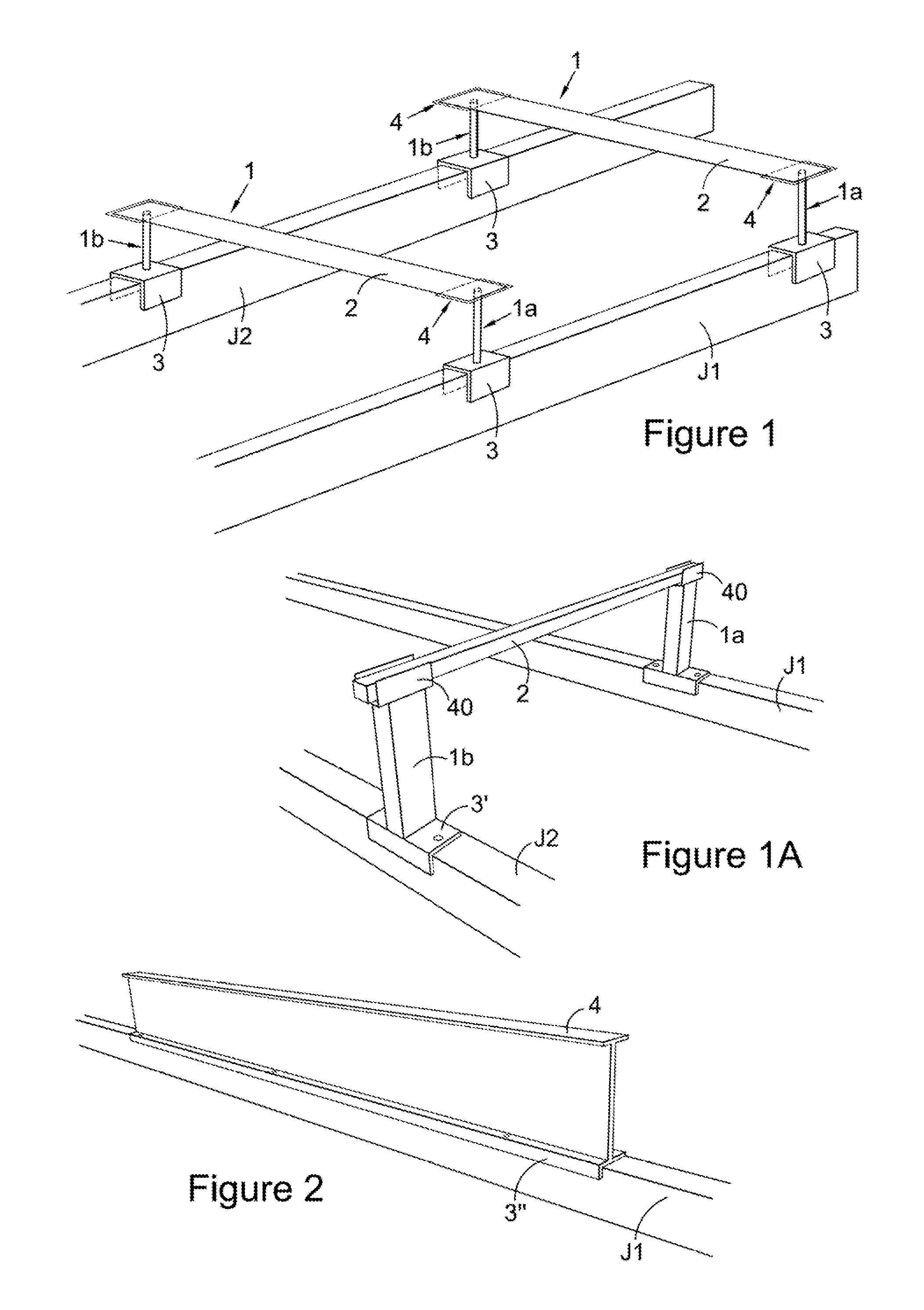

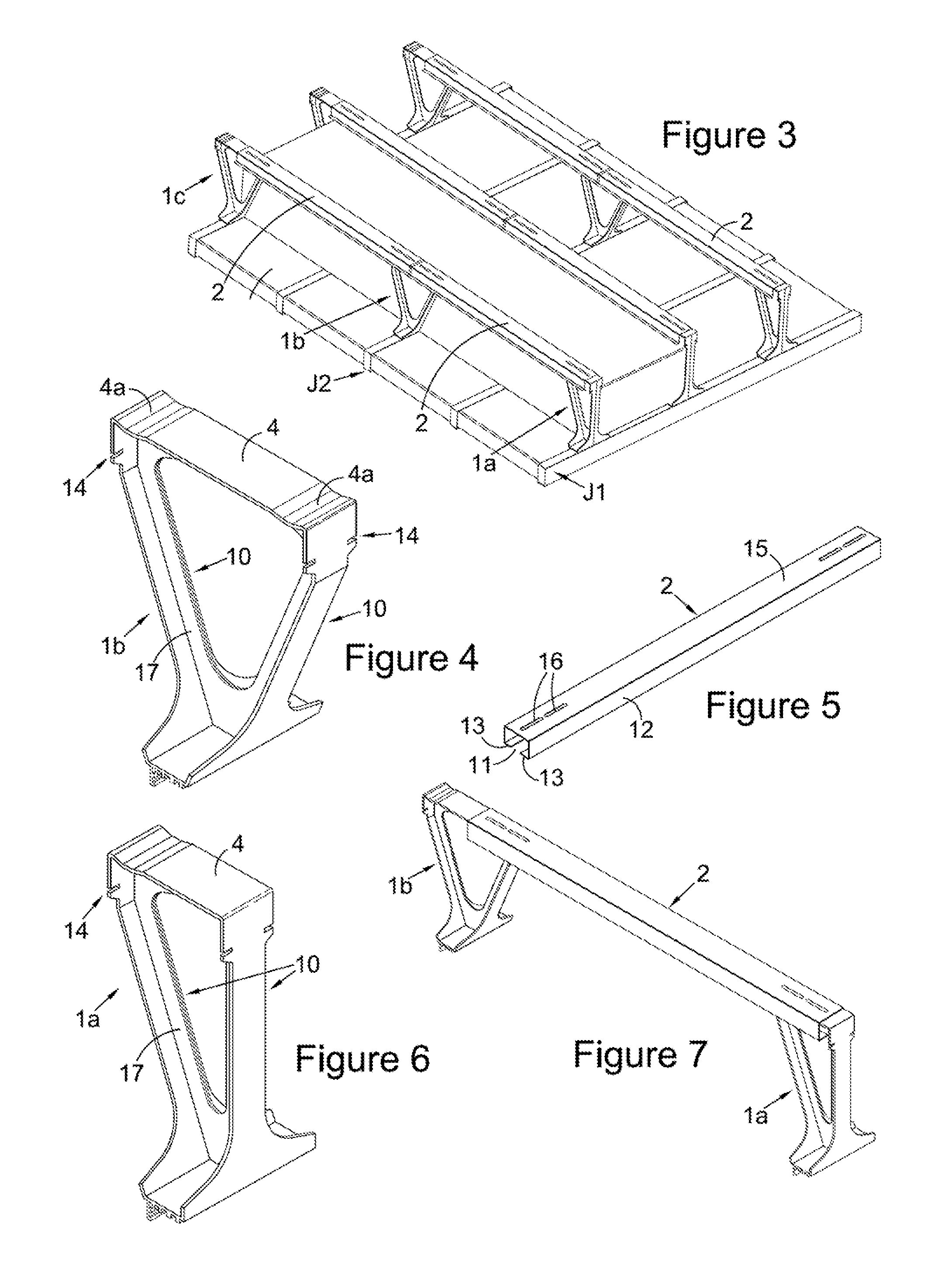

Loft flooring system

The present invention provides a loft flooring system that, inter alia, comprises: a plurality of bridging supports each adapted to bridge between a substantially parallel pair of joists of a loft floor and having a first upright leg with a foot to mount onto a first of the joists and having, in use, a second upright leg with a foot to mount onto a second of the joists, and a spanning element therebetween defining a flooring surface or onto which flooring boards or flooring panels are laid, wherein each leg is initially separate and the spanning element is an initially separate beam that is mounted to the legs to span between the joists. The system is comparatively straightforward and efficient to install and, where needed, uninstall and also is robust and stable. With special support arms on the legs or hung from the spanning element it can also greatly facilitate discrete management of pipe-work and cabling below the raised floor too.

Owner:NOMINAL SUM

Multi-colored crayons with associated packaging

Owner:FAMILY HOSPITALTY GRP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com