Patents

Literature

92results about How to "Workability is degraded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

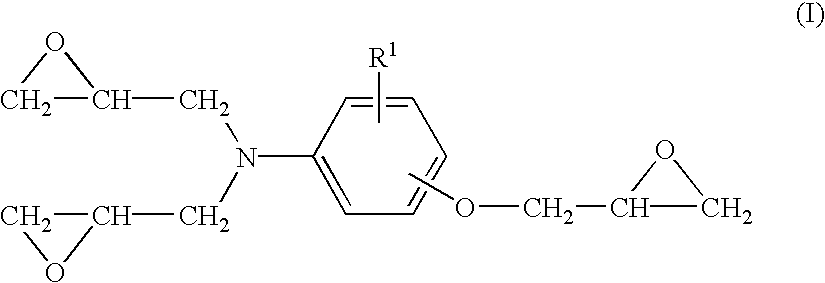

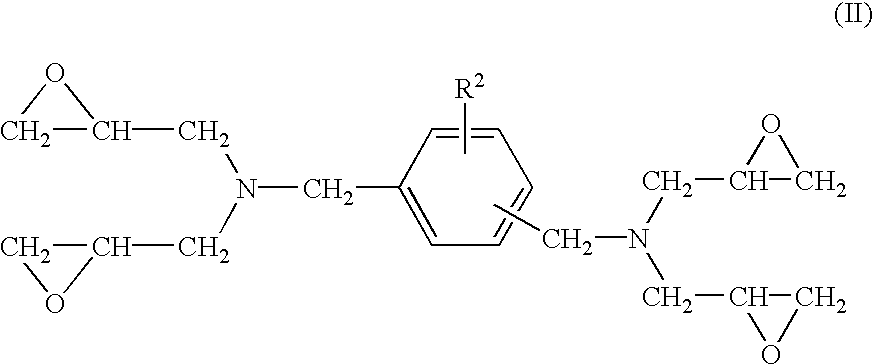

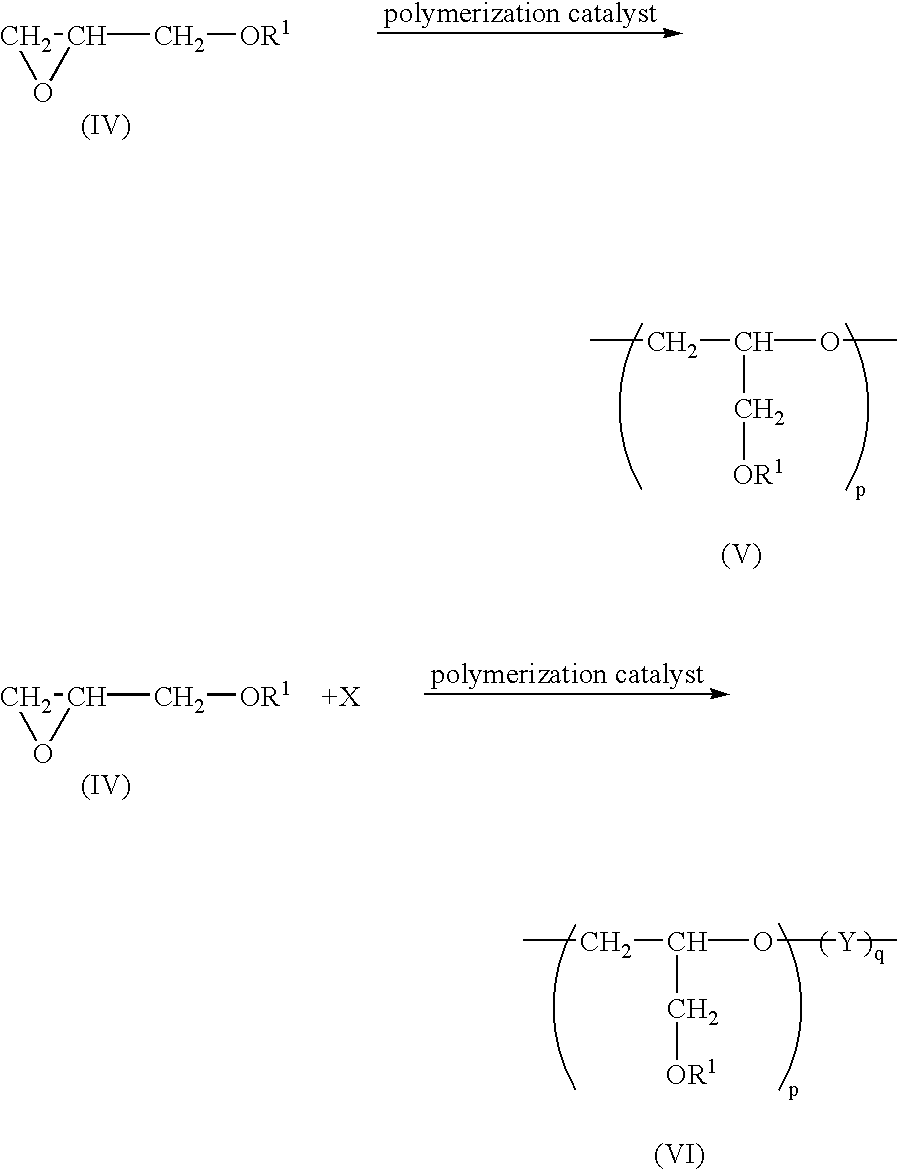

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

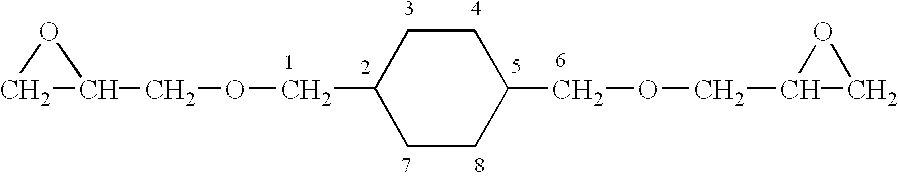

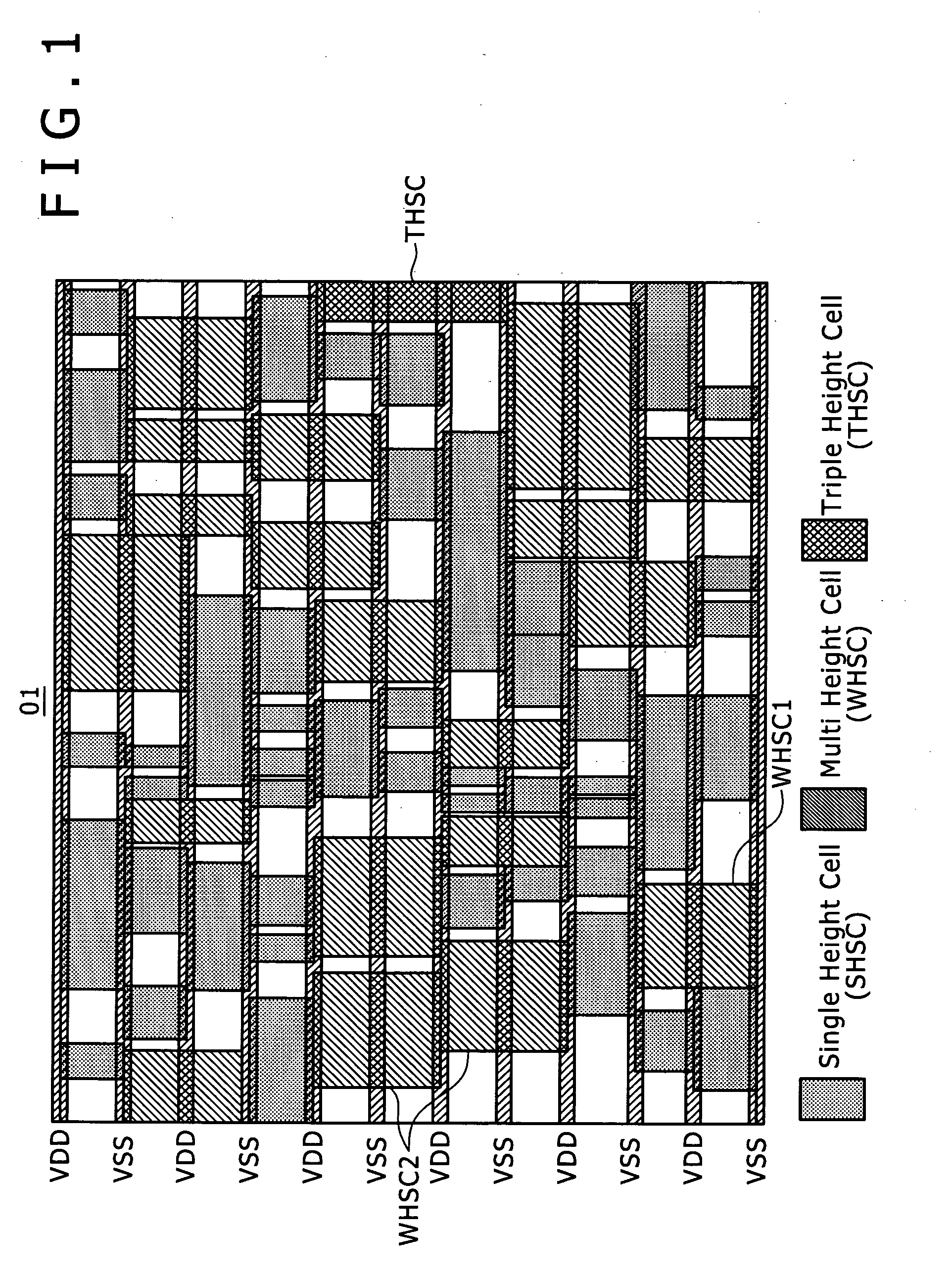

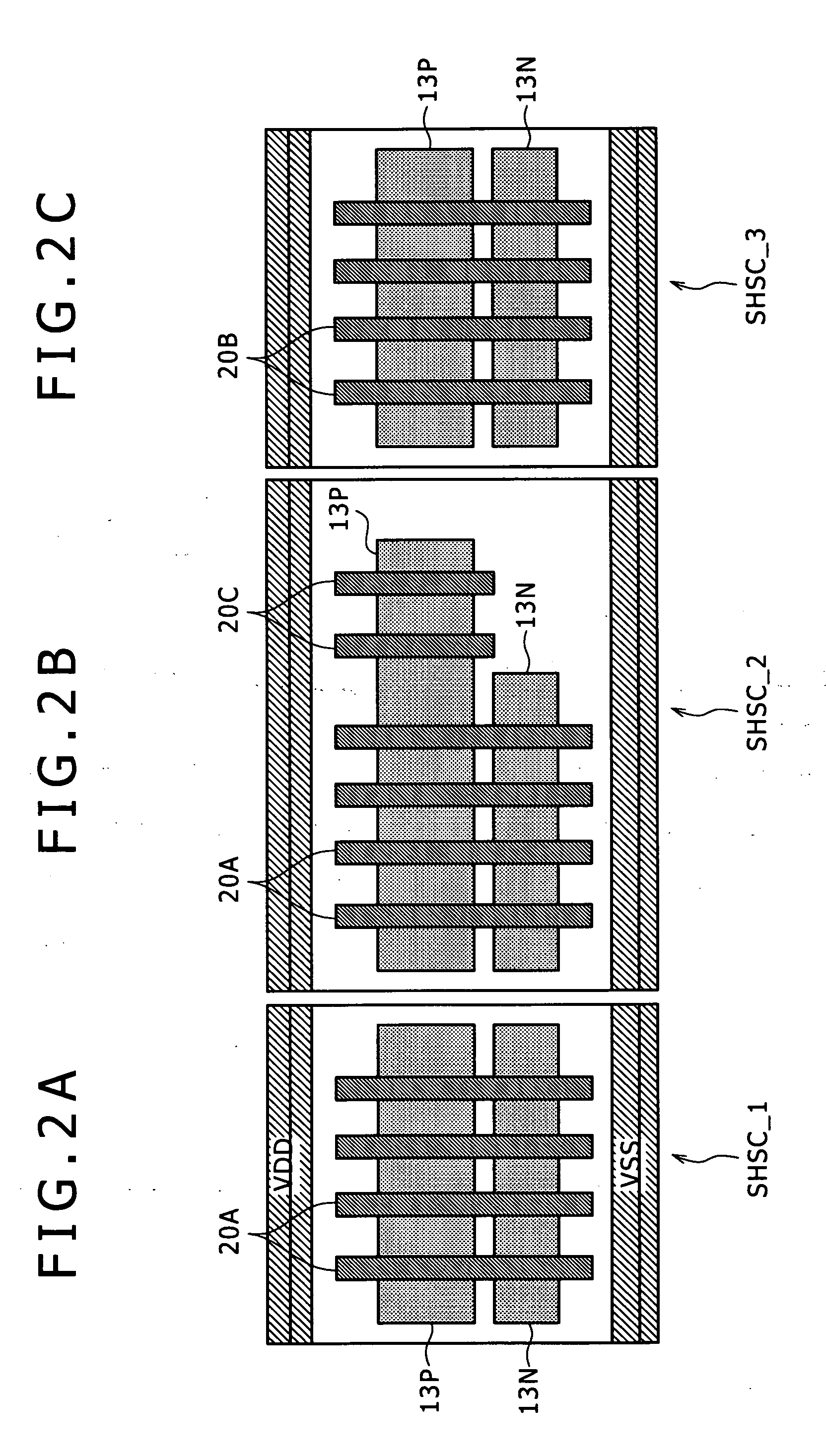

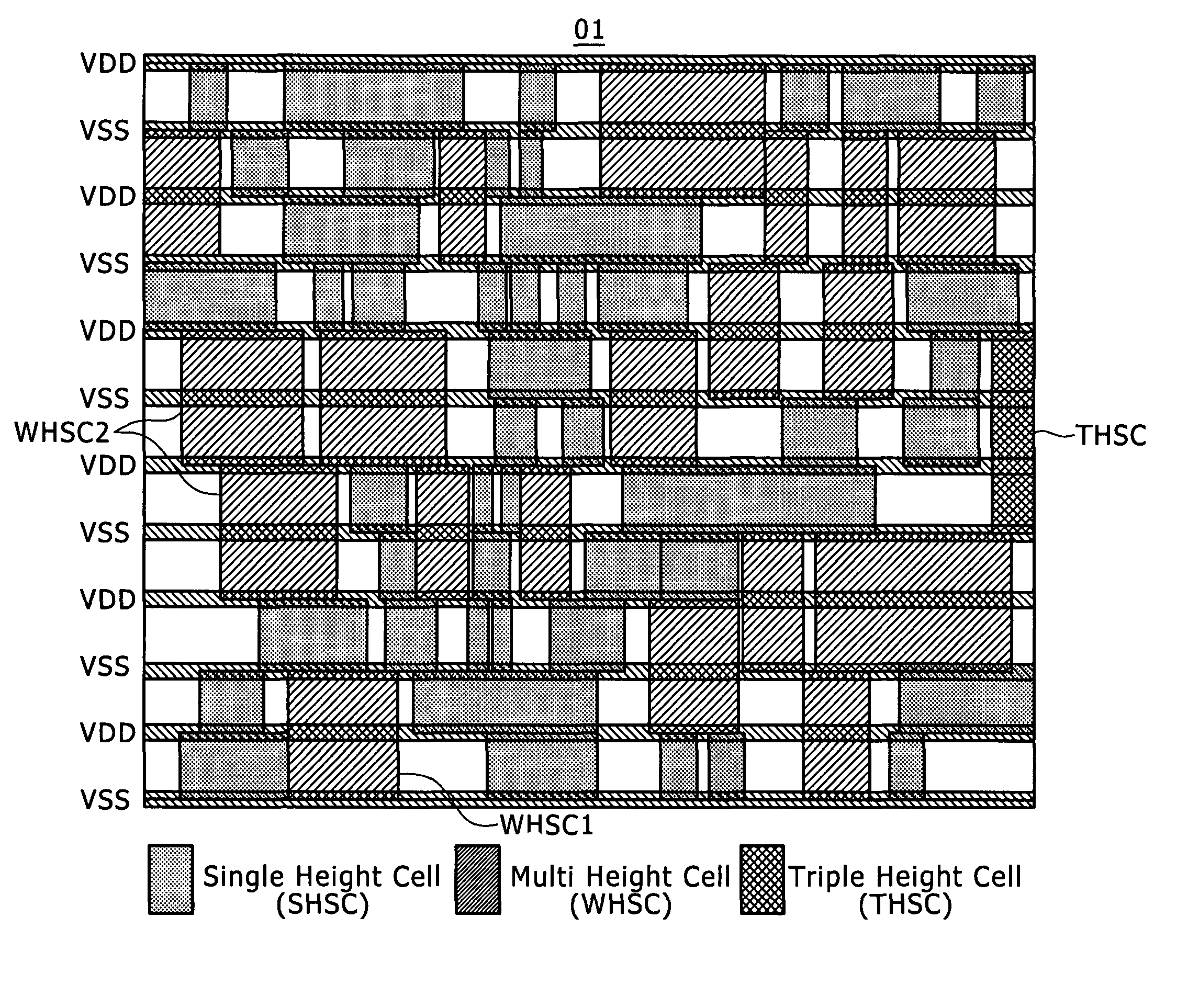

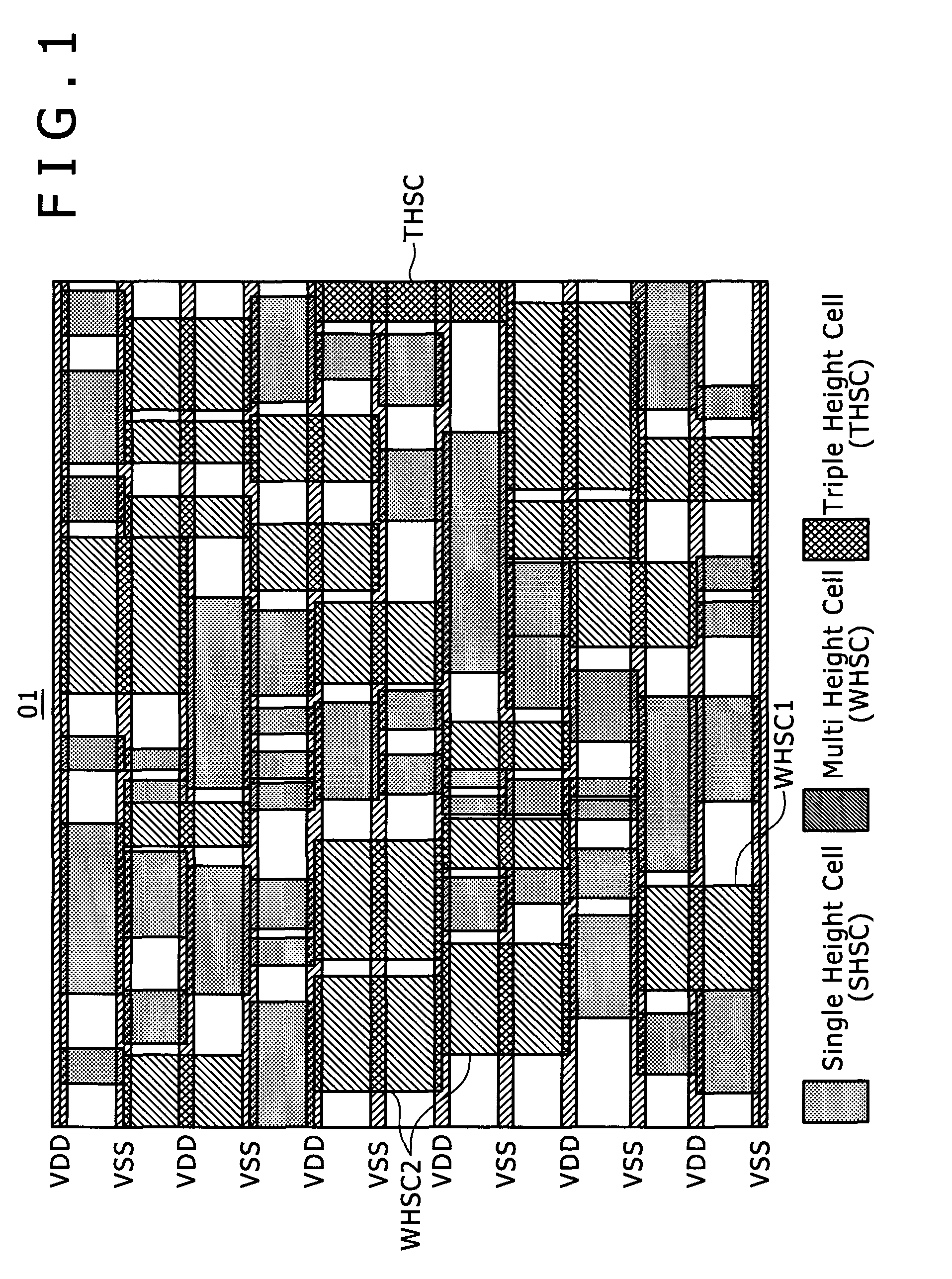

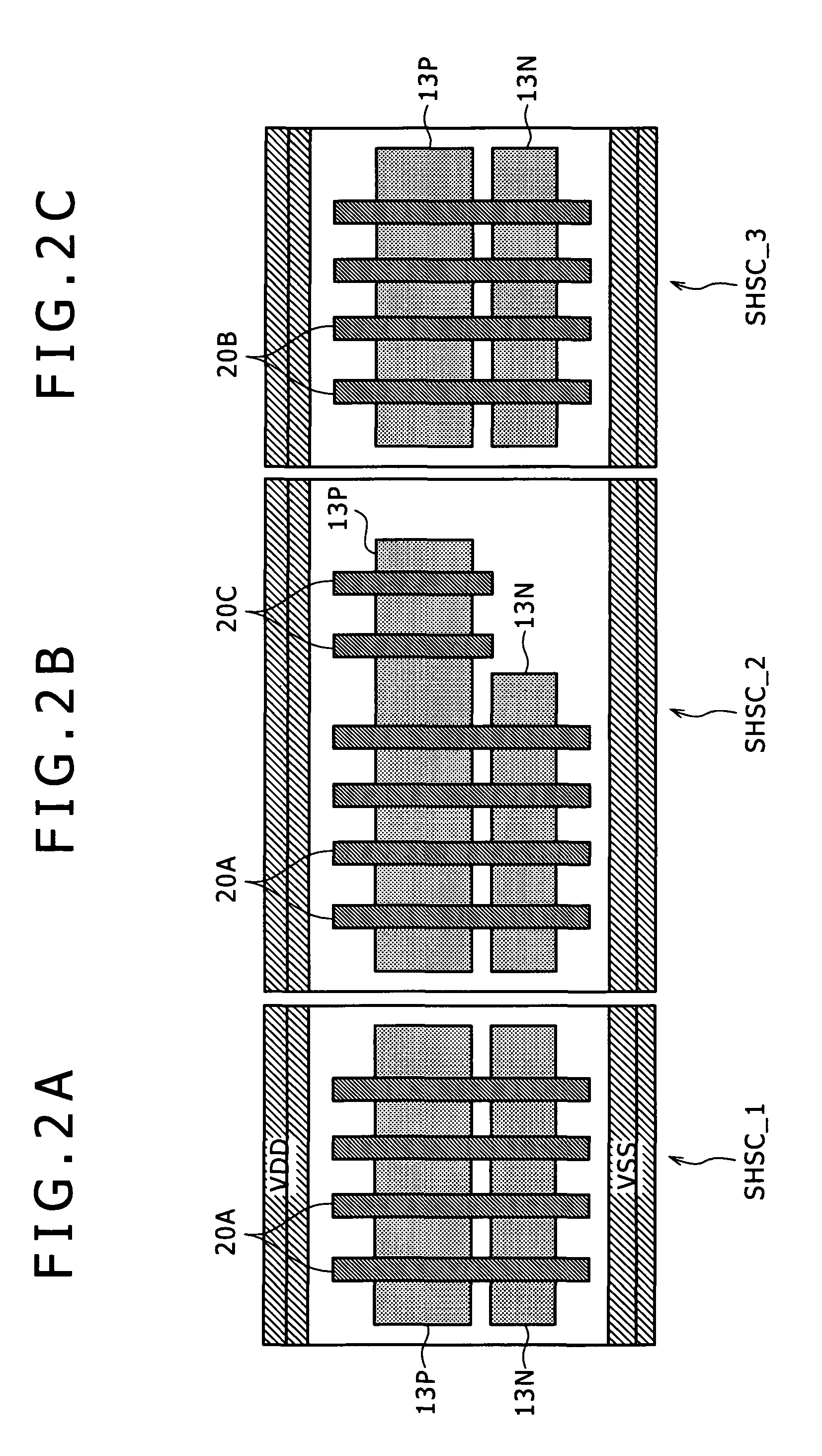

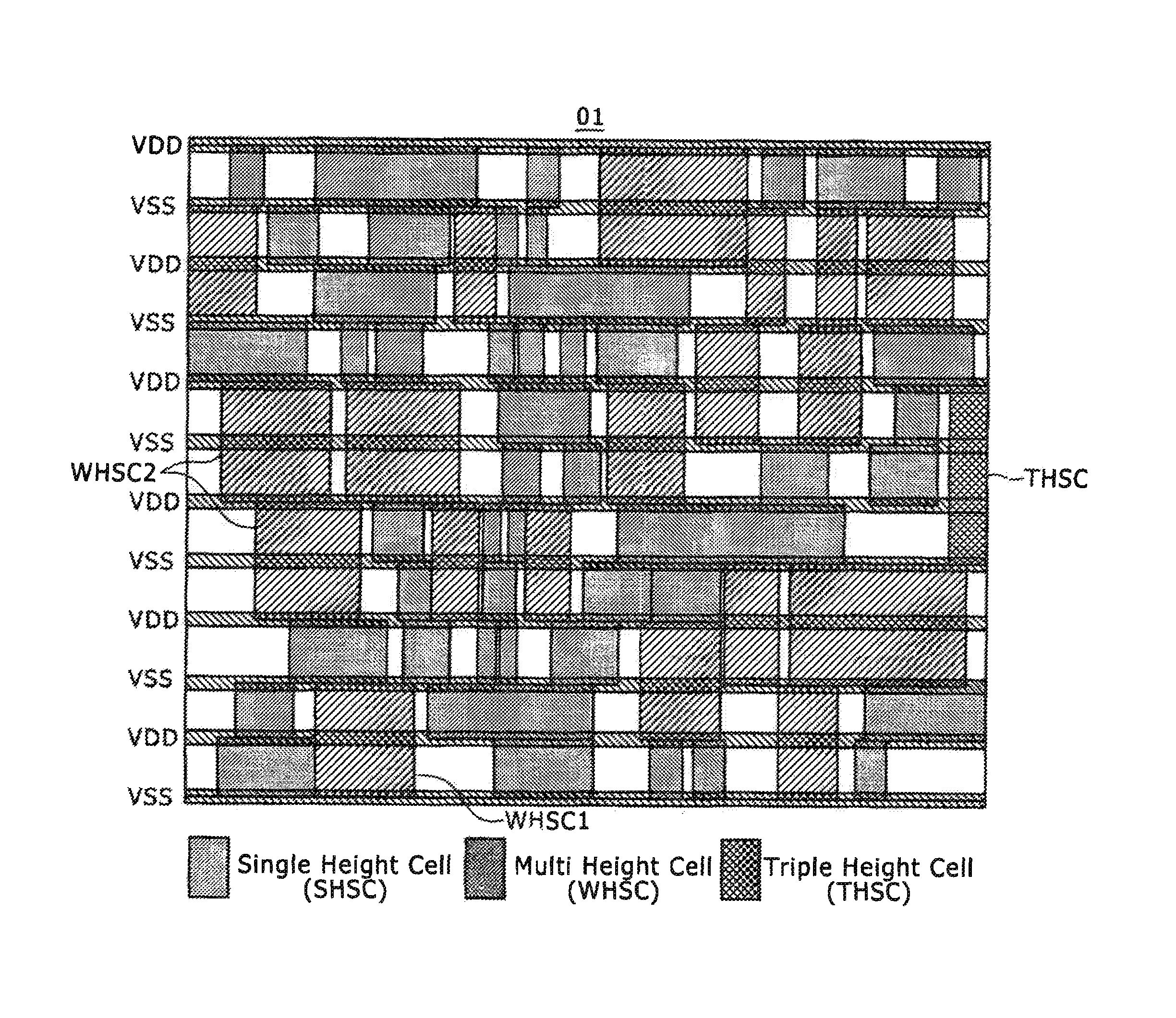

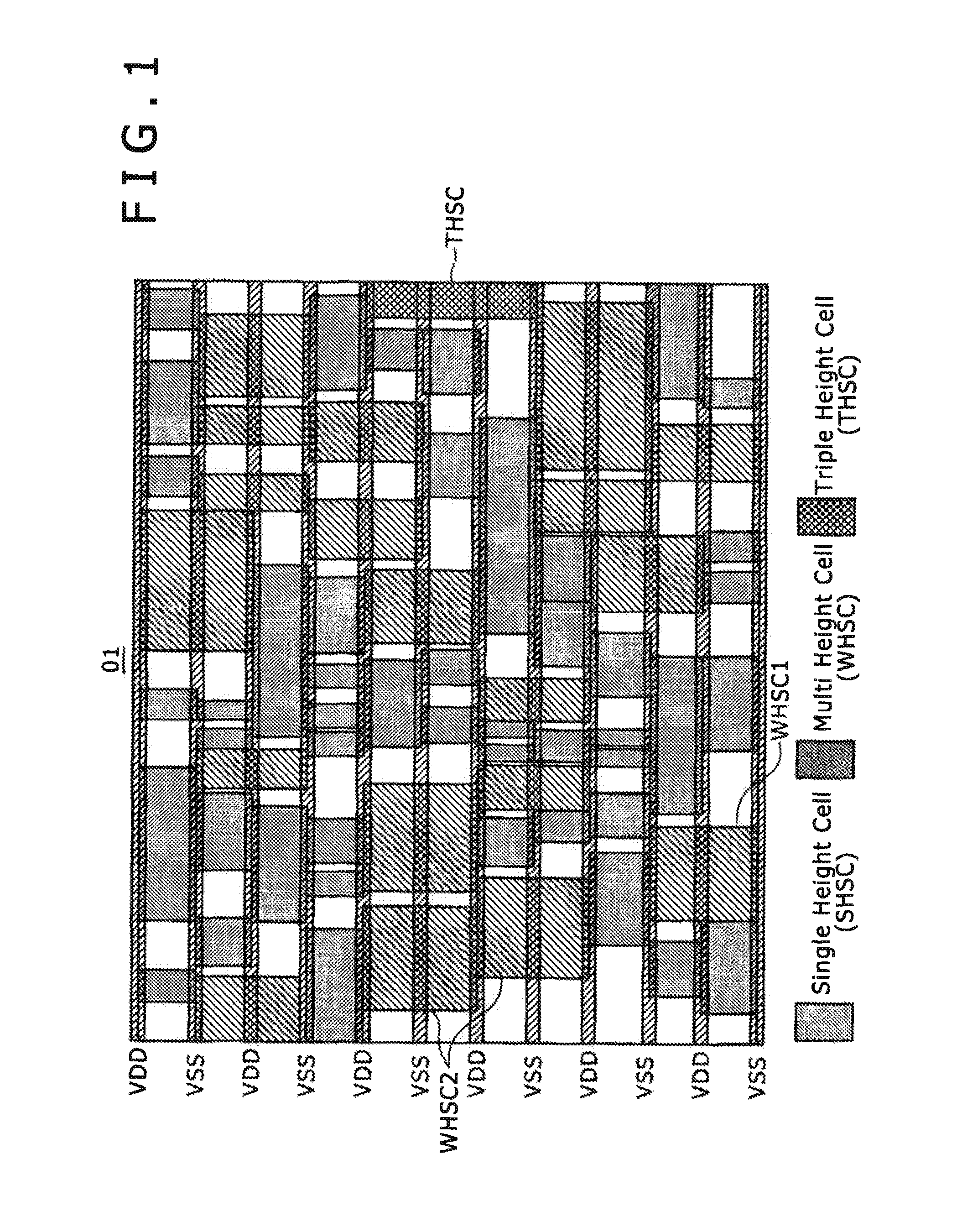

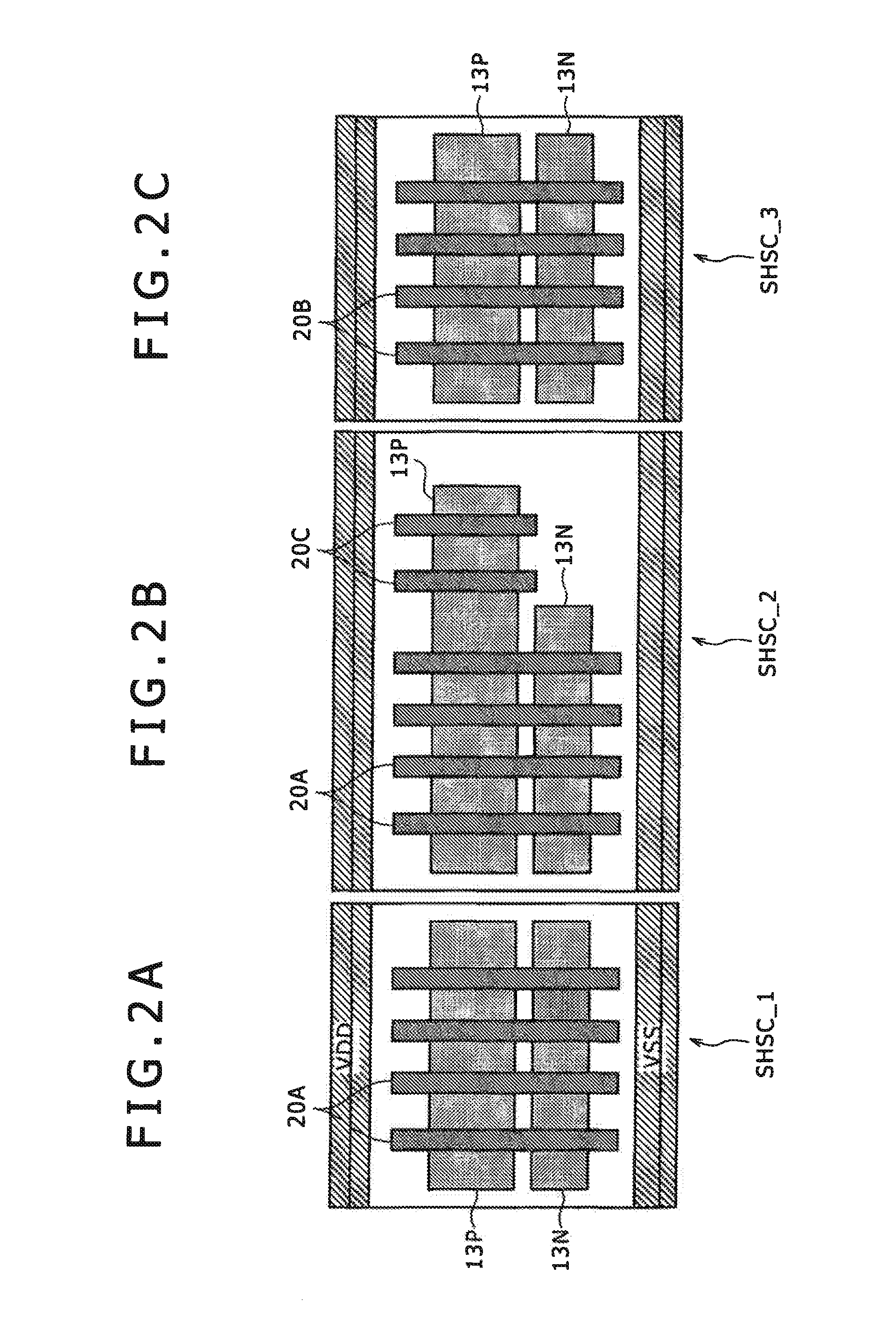

Semiconductor integrated circuit

ActiveUS20110049575A1Eliminating wasted spaceReduce in quantitySolid-state devicesLogic circuitsEngineeringSemiconductor

Disclosed herein is a semiconductor integrated circuit, wherein a desired circuit is formed by combining and laying out a plurality of standard cells and connecting the cells together, of which the cell length, i.e., the gap between a pair of opposed sides, is standardized, the plurality of standard cells forming the desired circuit include complementary in-phase driven standard cells, each of which includes a plurality of complementary transistor pairs that are complementary in conductivity type to each other and have their gate electrodes connected together, and N (≧2) pairs of all the complementary transistor pairs are driven in phase, and the size of the standardized cell length of the complementary in-phase driven standard cell is defined as an M-fold cell length which is M (N≧M≧2) times the basic cell length which is appropriate to the single complementary transistor pair.

Owner:SONY CORP

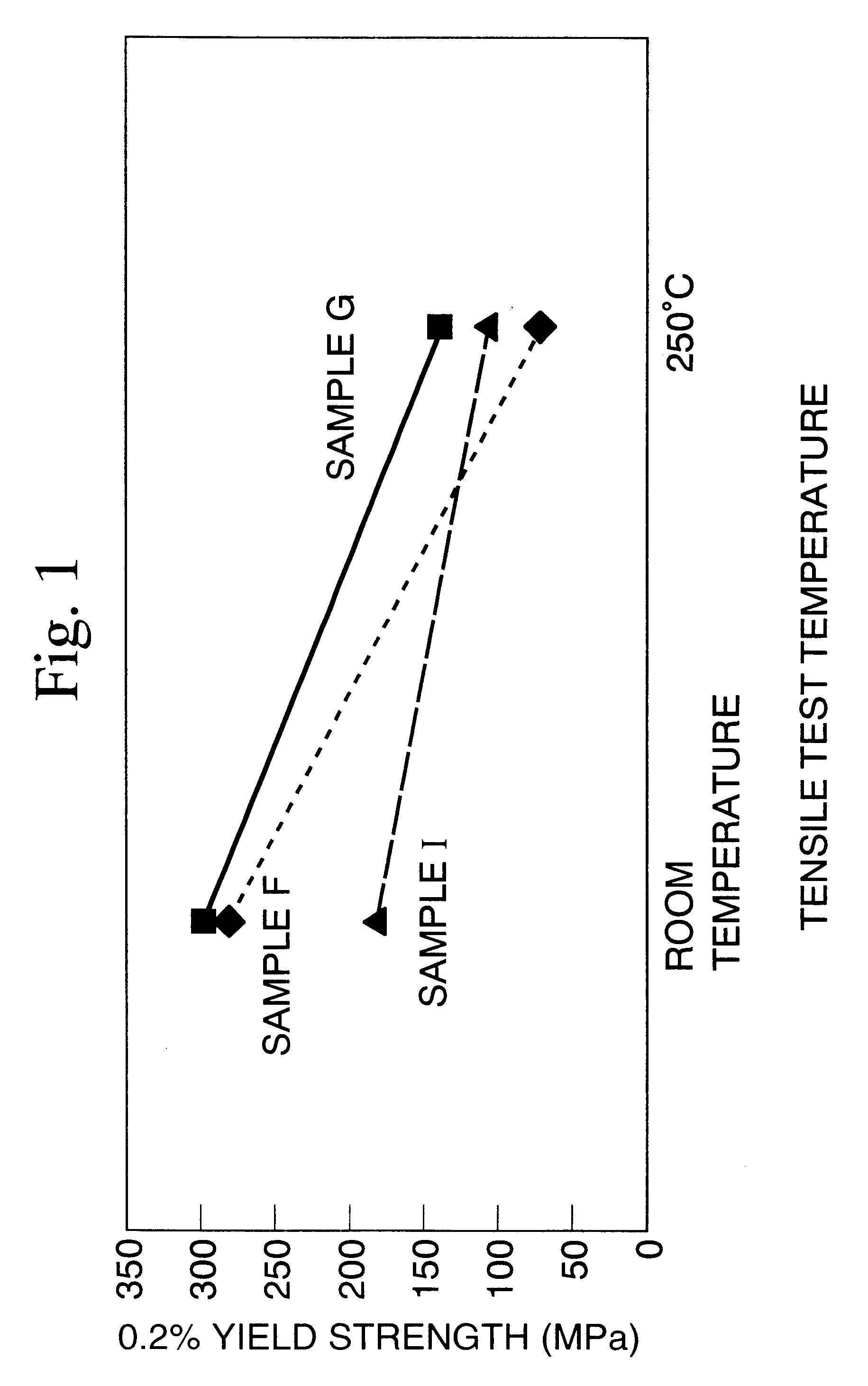

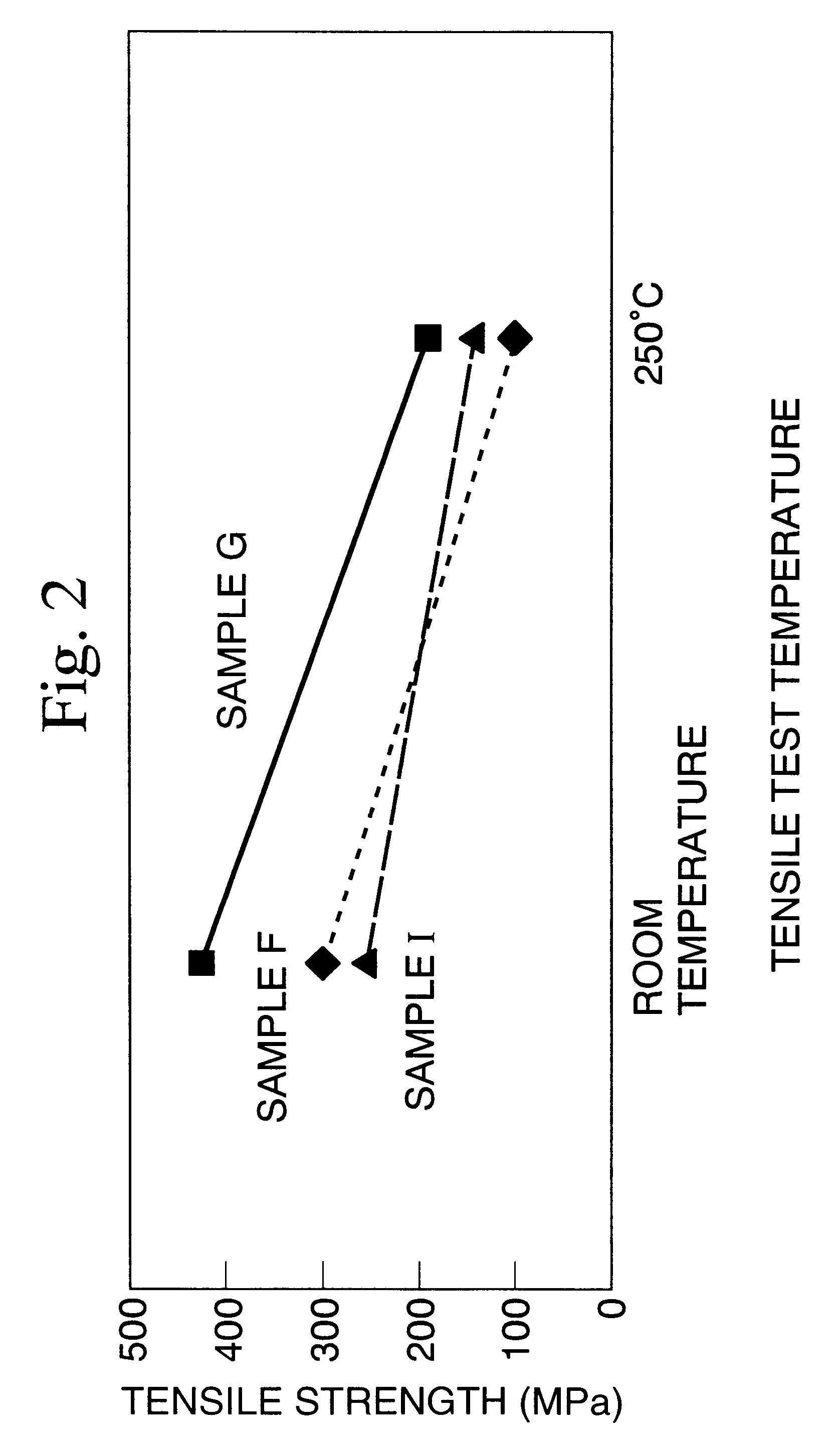

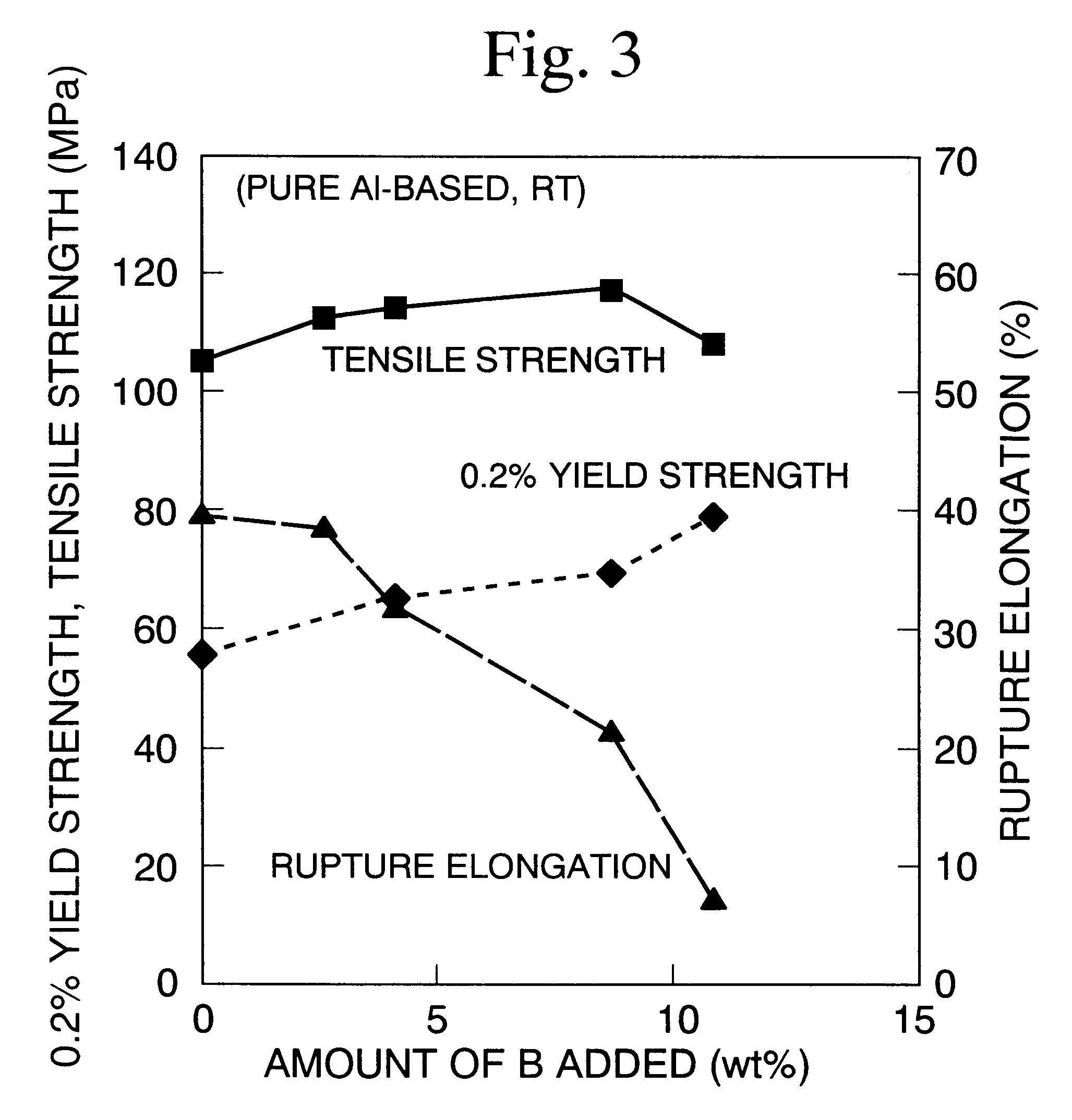

Aluminum composite material having neutron-absorbing ability

InactiveUS6602314B1Improve mechanical propertiesImprove workabilityNuclear engineering problemsNuclear engineering solutionsAlloyAbsorbed power

The present invention provides an aluminum composite material having neutron absorbing power that improves the ability to absorb neutrons by increasing the content of B, while also being superior to materials of the prior art in terms of mechanical properties and workability. The aluminum composite material having neutron absorbing power contains in Al or an Al alloy matrix phase B or a B compound having neutron absorbing power in an amount such that the proportion of B is 1.5% by weight or more to 9% by weight or less, and the aluminum composite material has been pressure sintered.

Owner:MITSUBISHI HEAVY IND LTD

Semiconductor integrated circuit

ActiveUS8357955B2Workability is degradedLow costSolid-state devicesLogic circuitsEngineeringSemiconductor

Disclosed herein is a semiconductor integrated circuit, wherein a desired circuit is formed by combining and laying out a plurality of standard cells and connecting the cells together, of which the cell length, i.e., the gap between a pair of opposed sides, is standardized, the plurality of standard cells forming the desired circuit include complementary in-phase driven standard cells, each of which includes a plurality of complementary transistor pairs that are complementary in conductivity type to each other and have their gate electrodes connected together, and N (≧2) pairs of all the complementary transistor pairs are driven in phase, and the size of the standardized cell length of the complementary in-phase driven standard cell is defined as an M-fold cell length which is M (N≧M≧2) times the basic cell length which is appropriate to the single complementary transistor pair.

Owner:SONY CORP

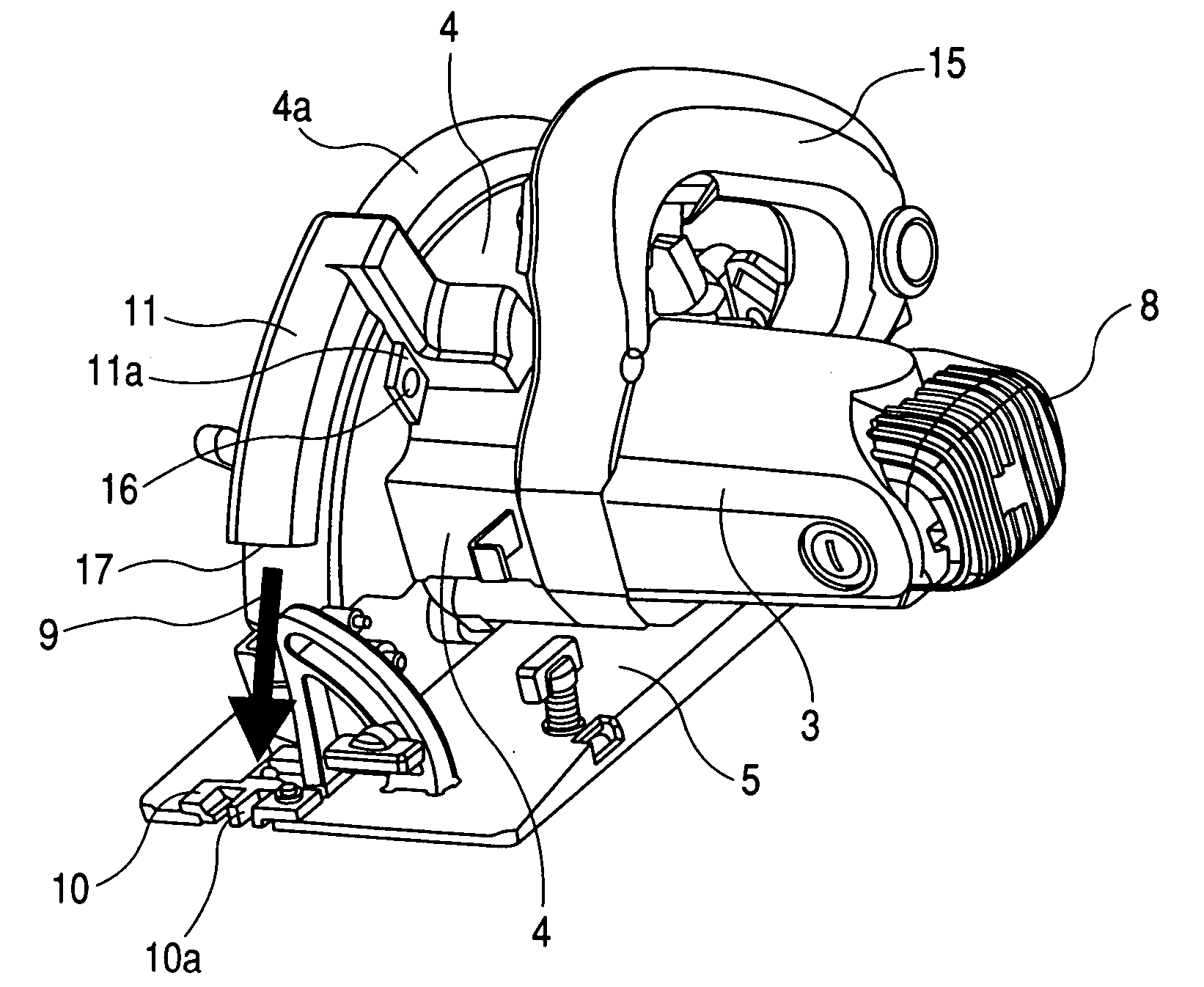

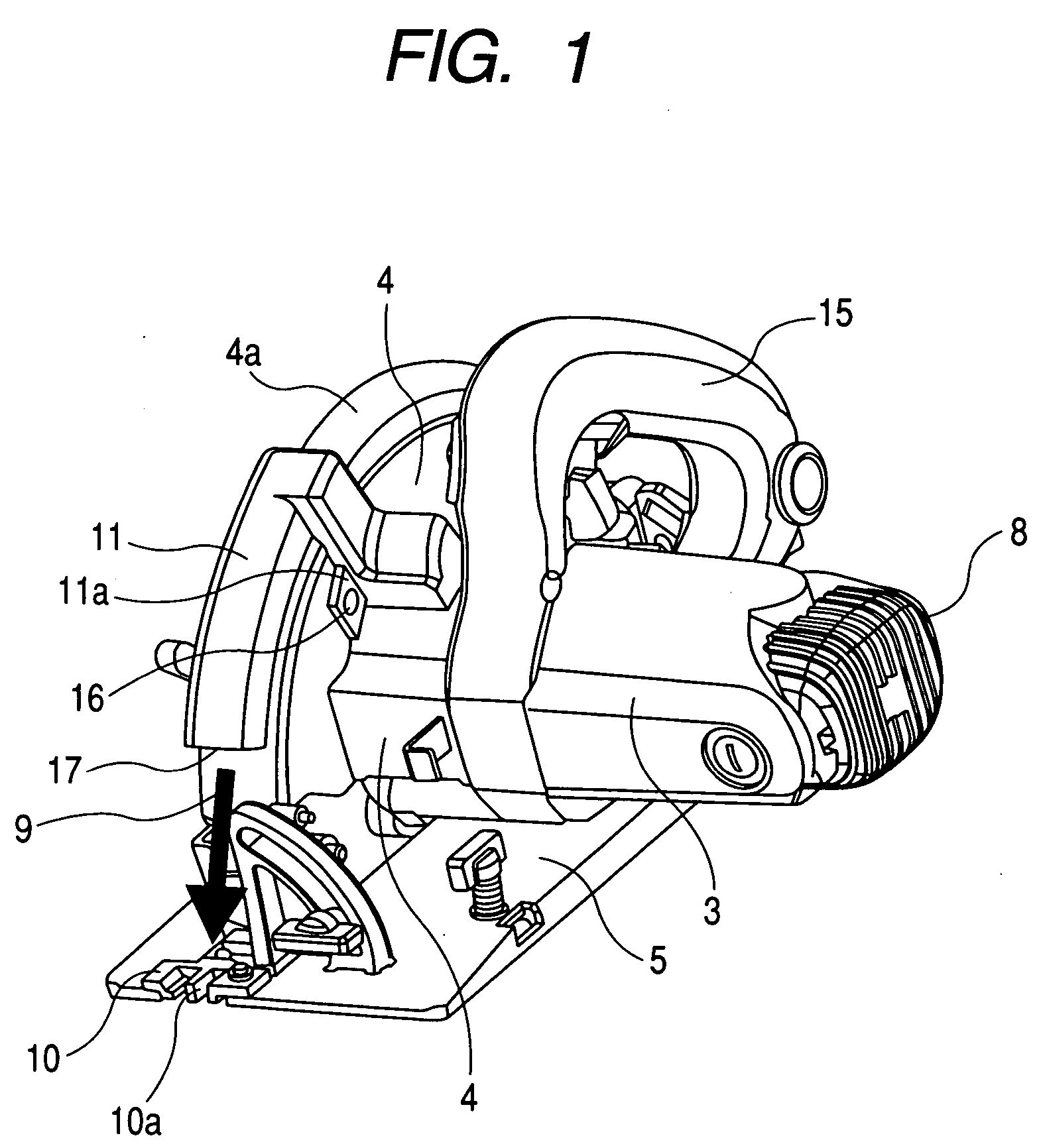

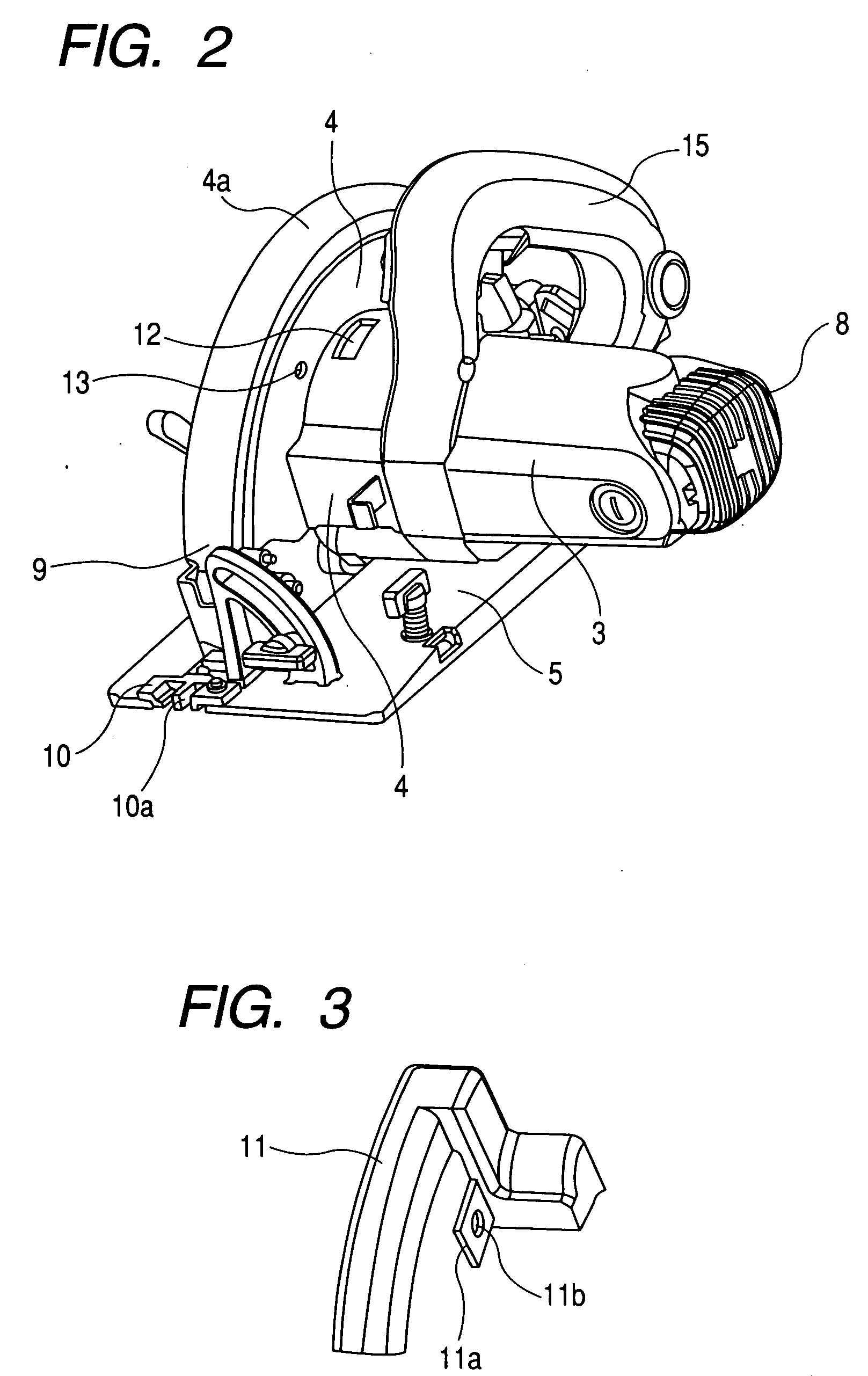

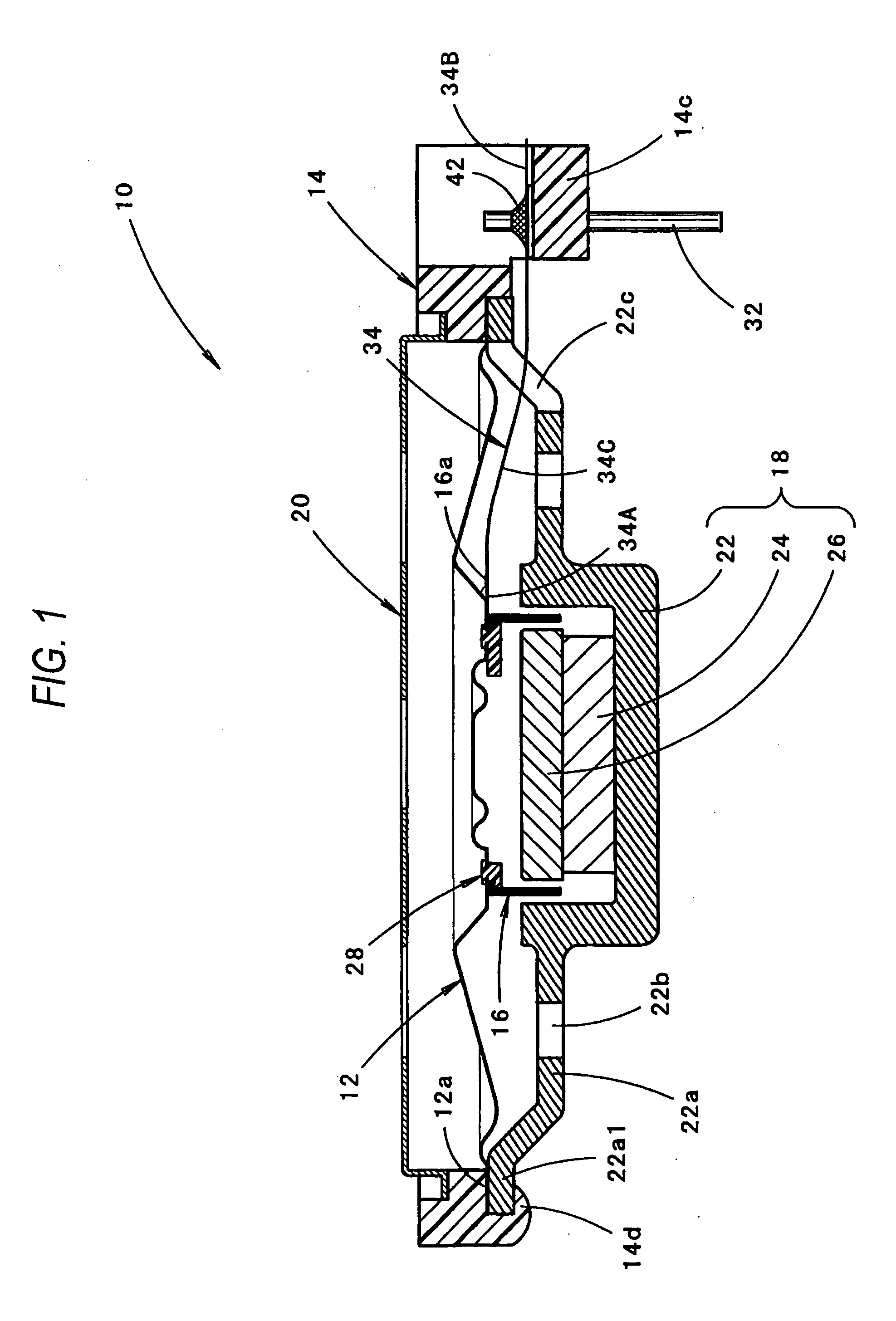

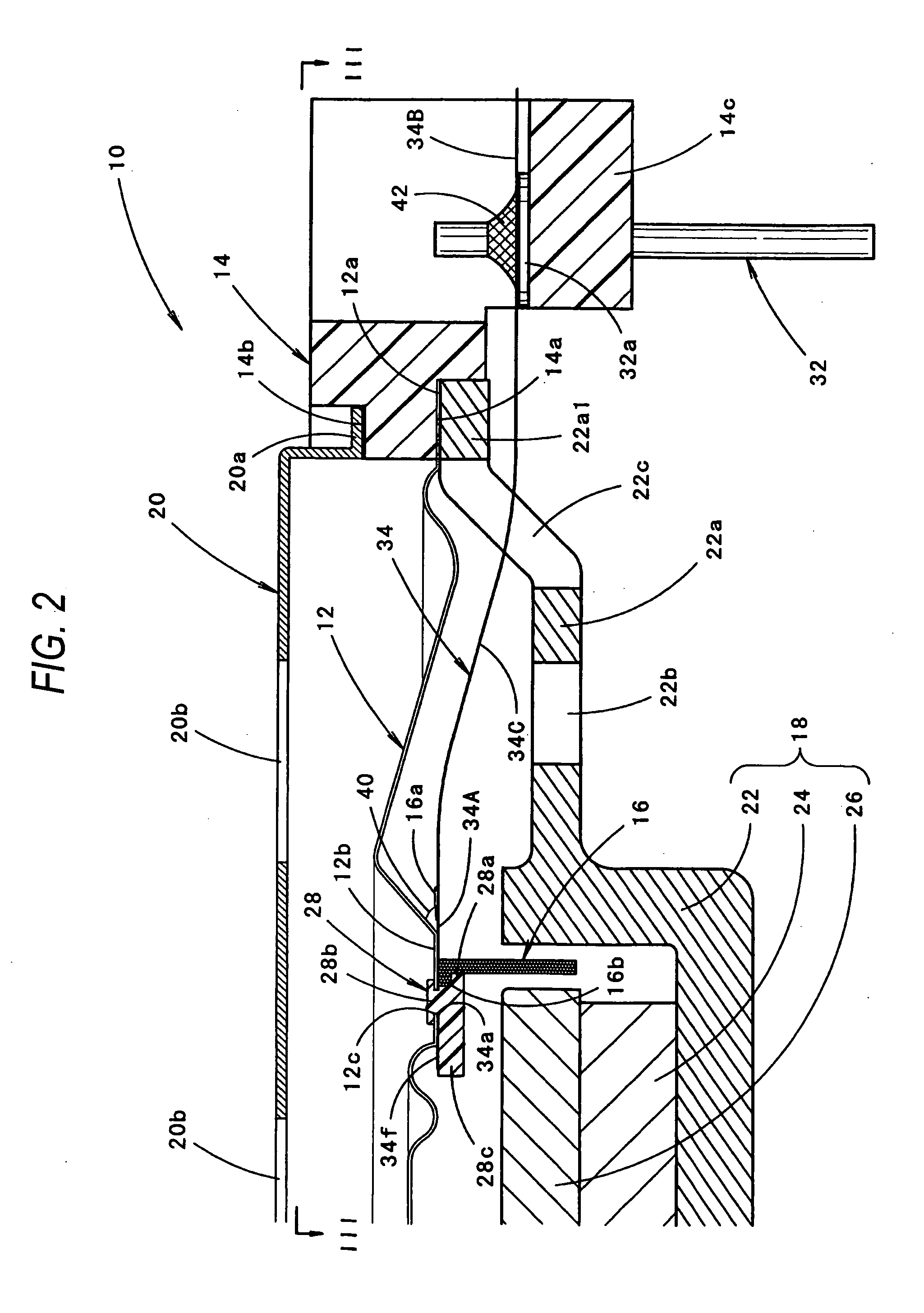

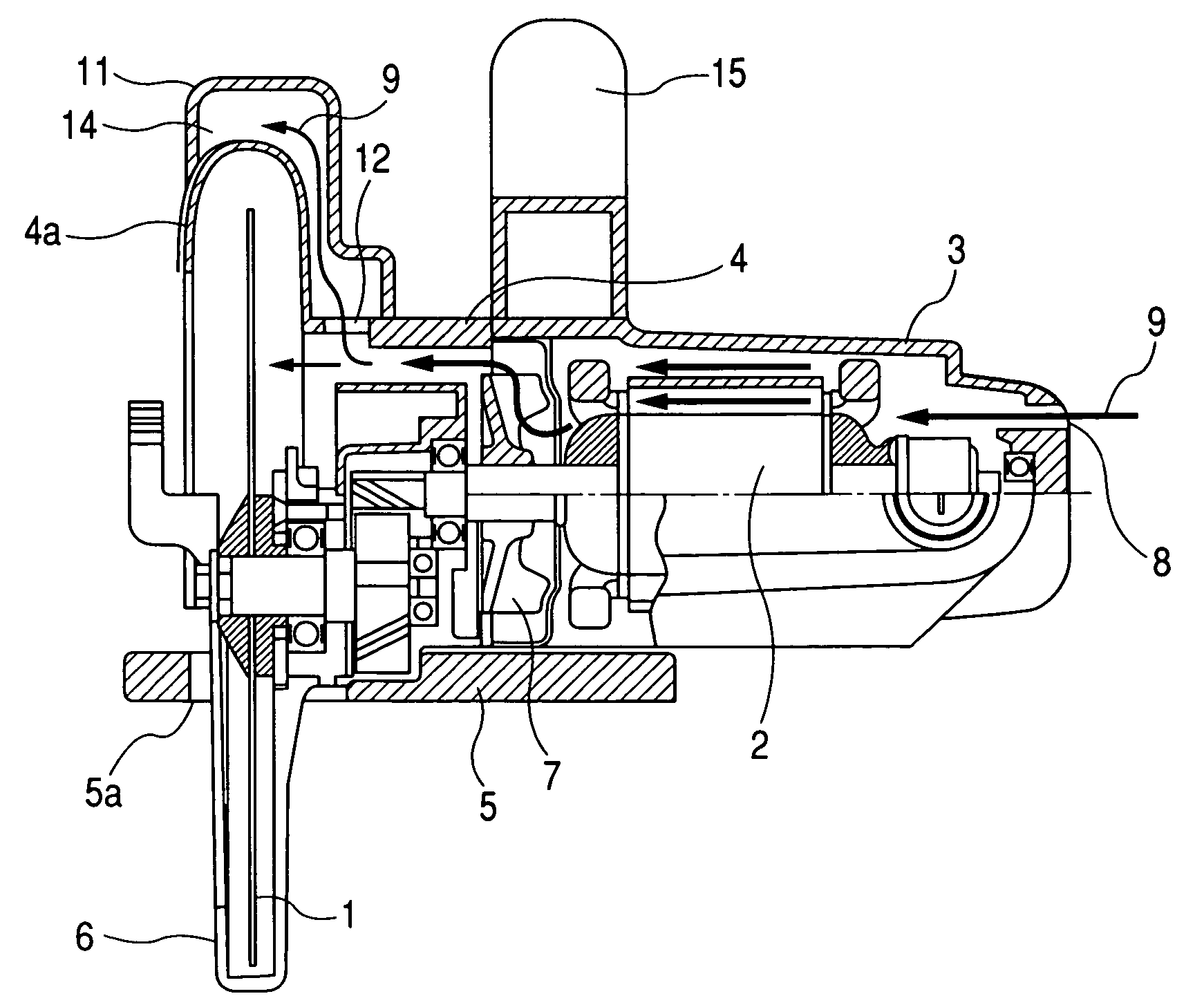

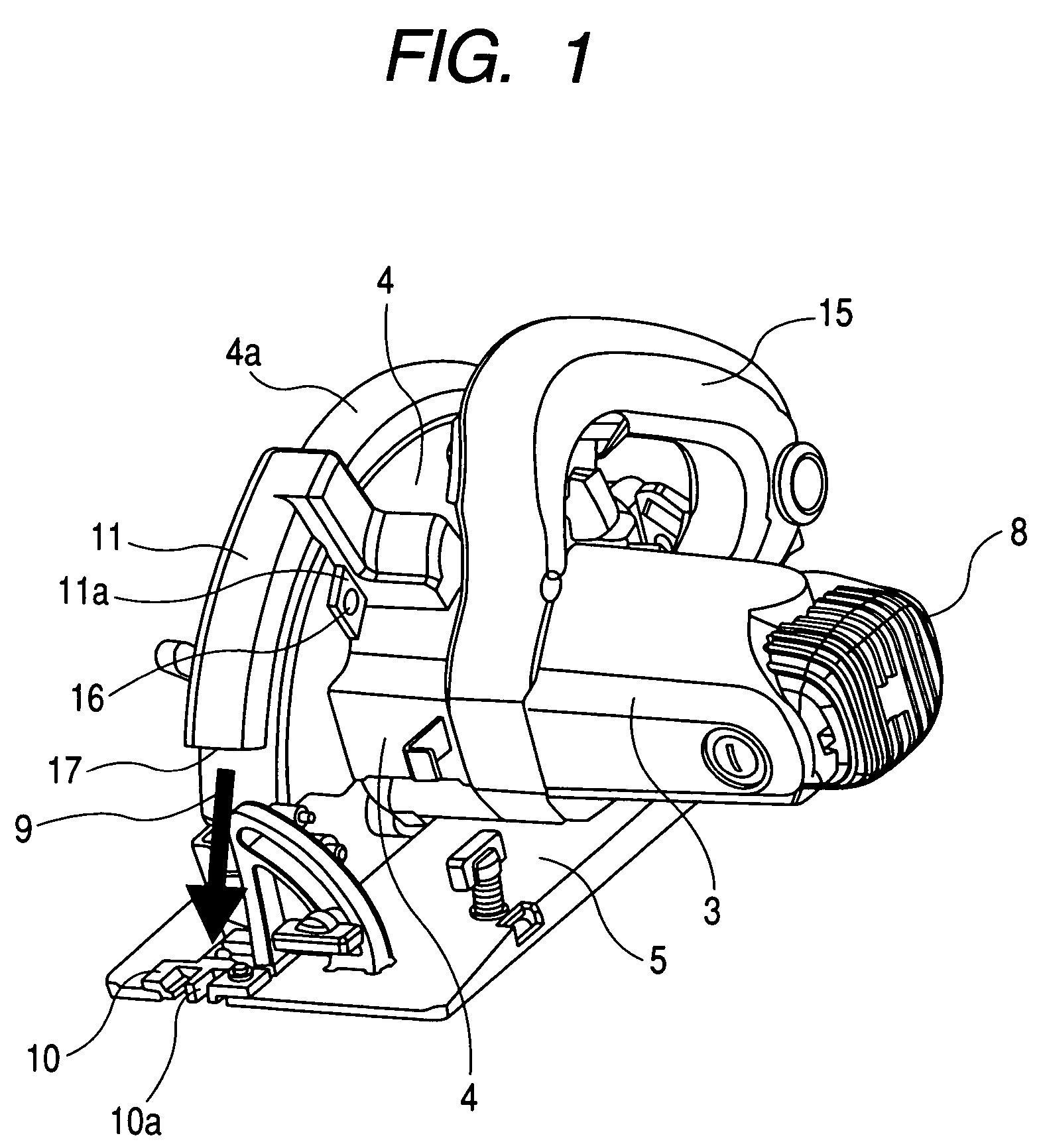

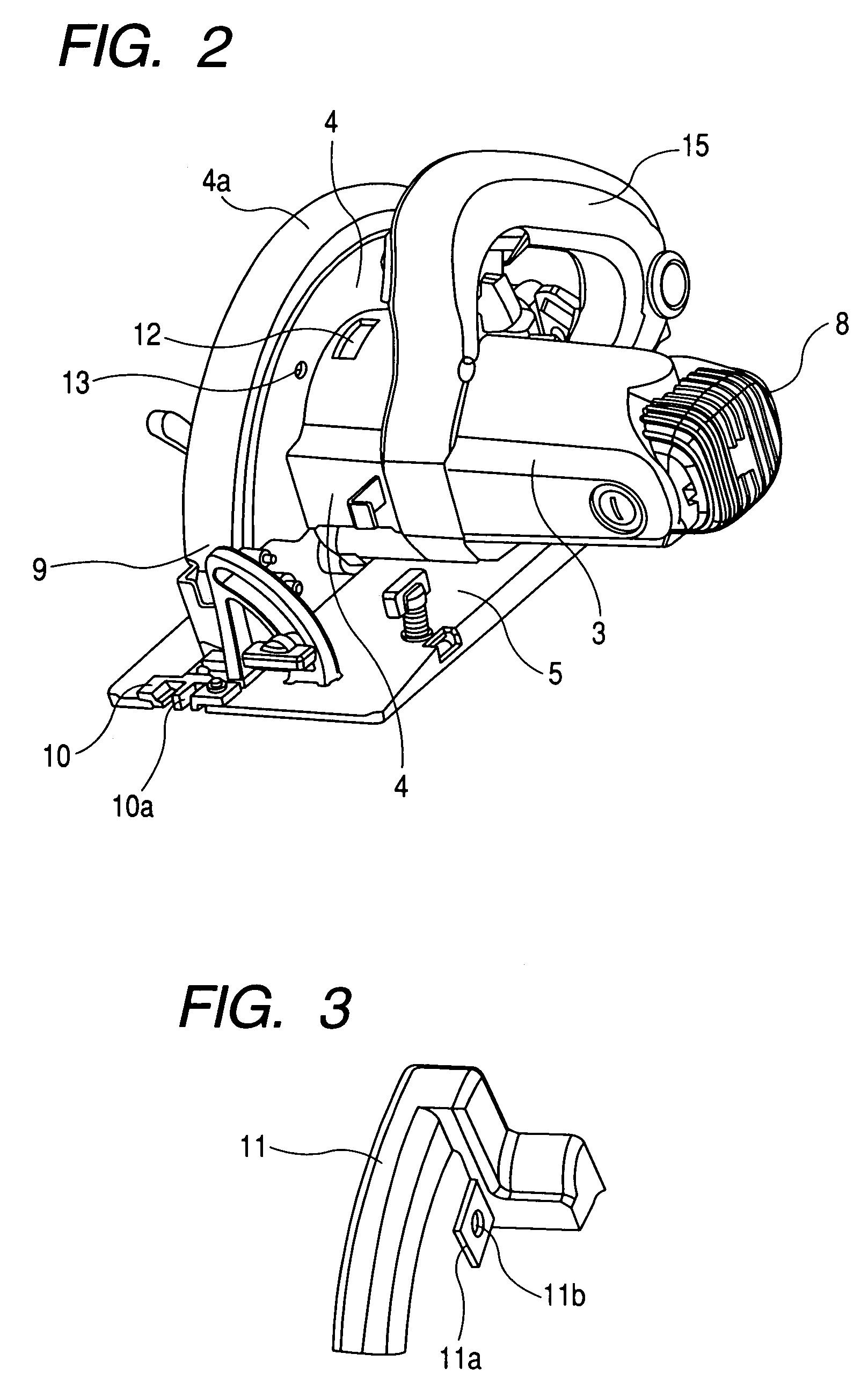

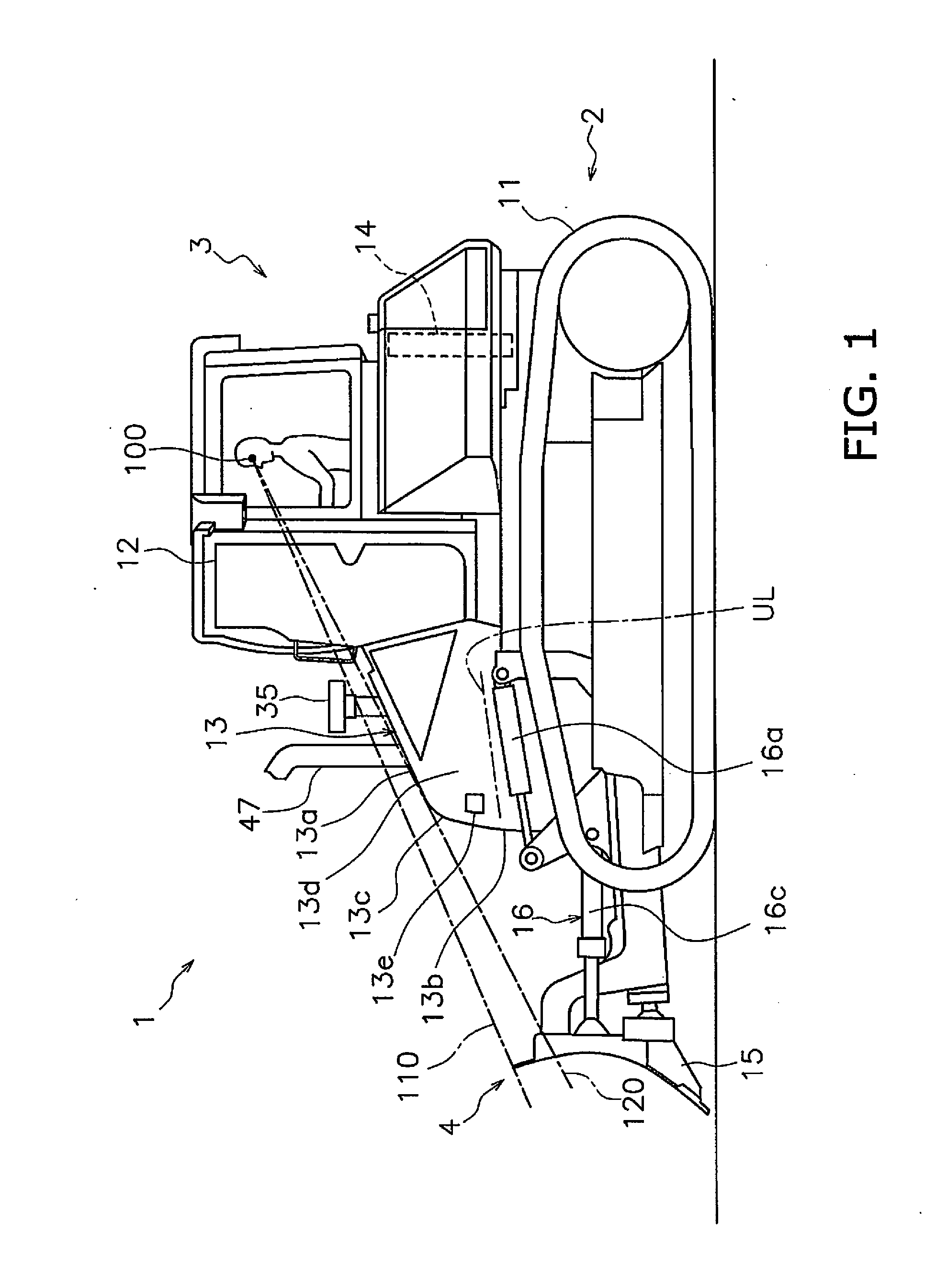

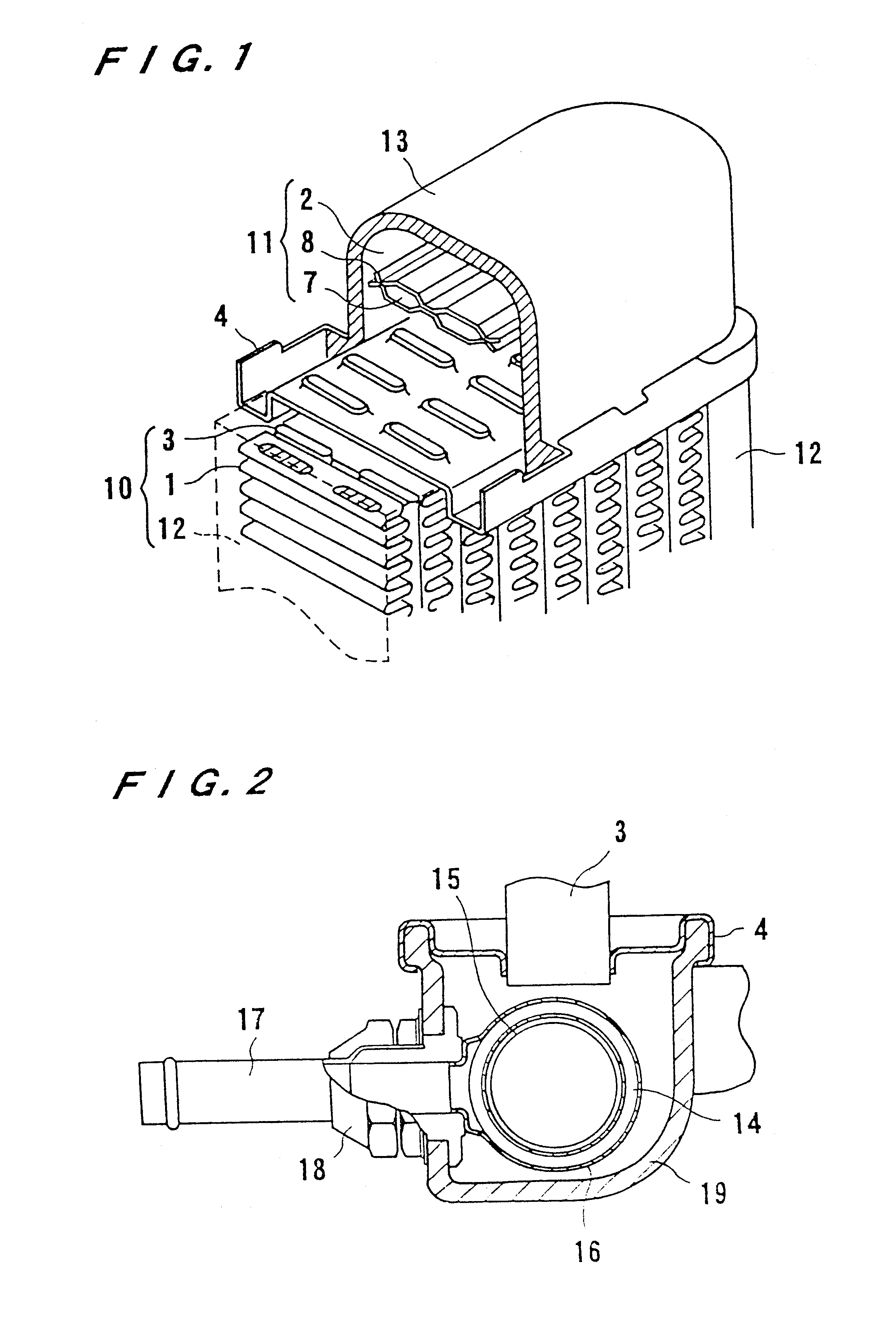

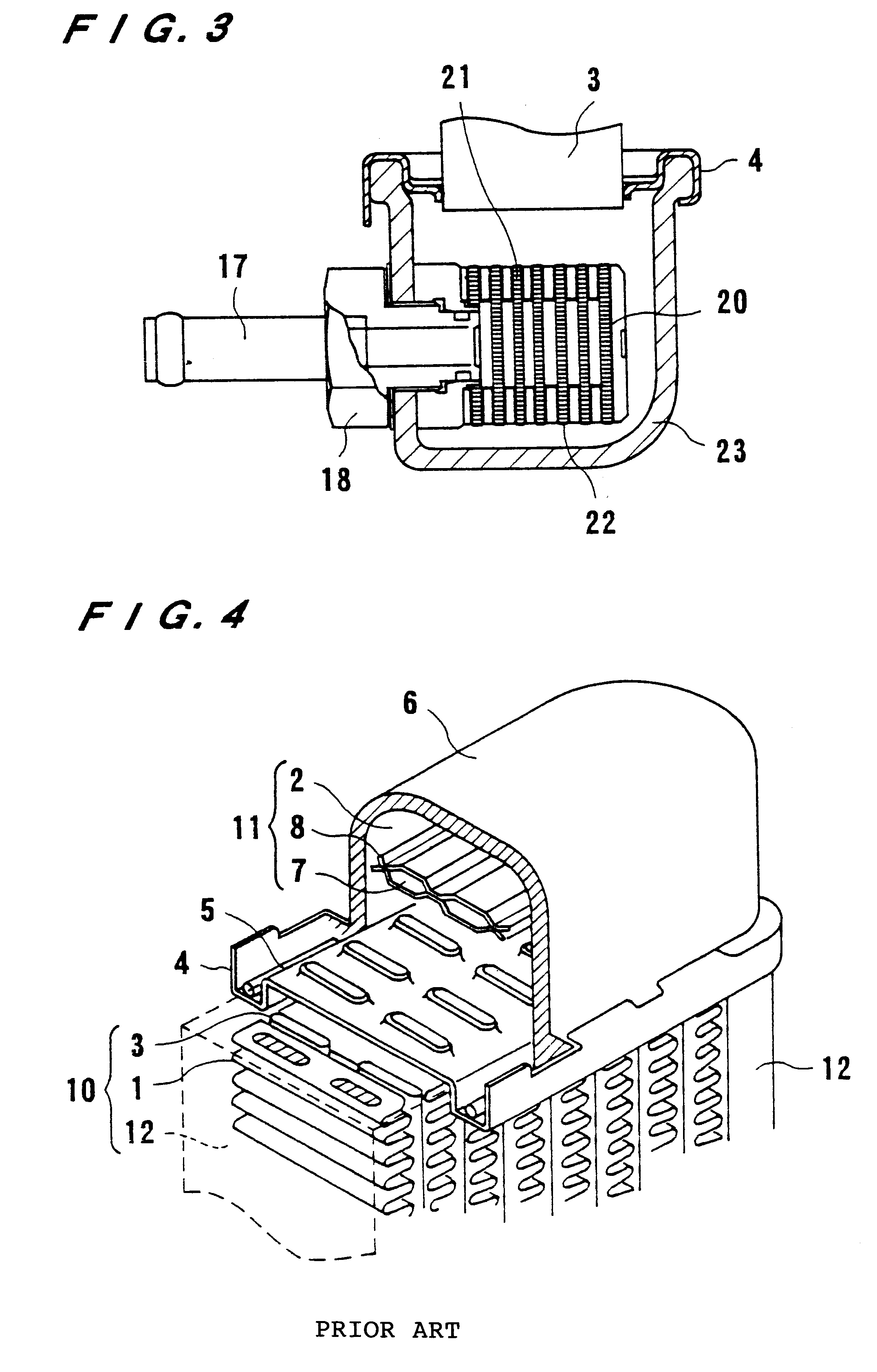

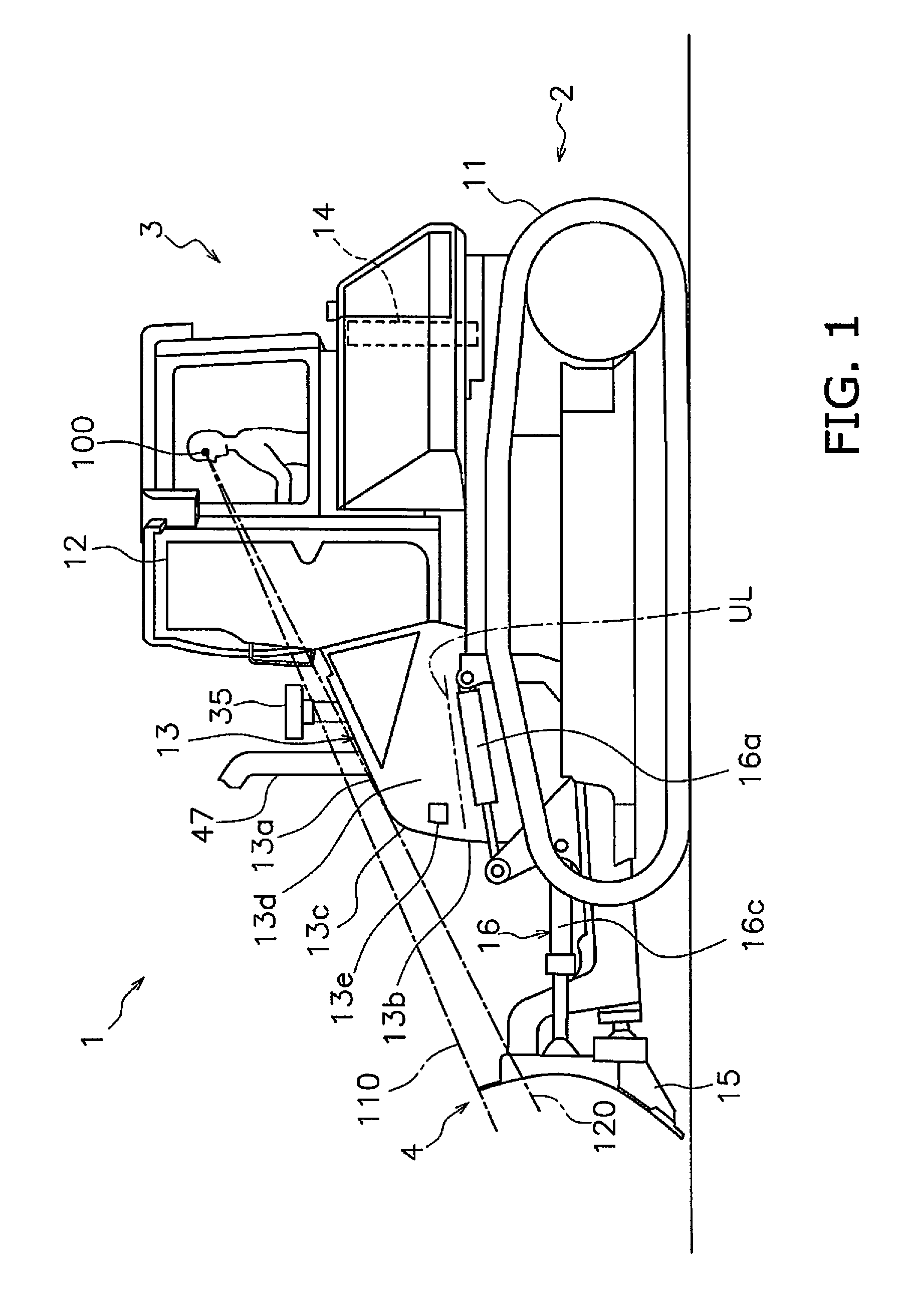

Portable electric cutting apparatus

ActiveUS20050160608A1High rectilinear propagation propertyCut easily and preciselyMetal sawing devicesMetal sawing accessoriesElectric motorEngineering

A portable electric cutting apparatus includes a housing for housing an electric motor for rotating a saw blade a fan provided in the housing and driven by the electric motor, a saw cover attached to the housing and having a saw blade housing part having a shape to cover an upper half of the outer periphery of the saw blade for housing a part of the saw blade, a base formed with an opening for allowing the saw blade to project downward from a bottom face which is slidable on a cut material. A discharge passage for discharging a fan wind produced by driving the fan is formed along an outer periphery of the saw cover. The fan wind is discharged through the discharge passage toward a front side of the base in the cutting direction.

Owner:HITACHI KOKI CO LTD

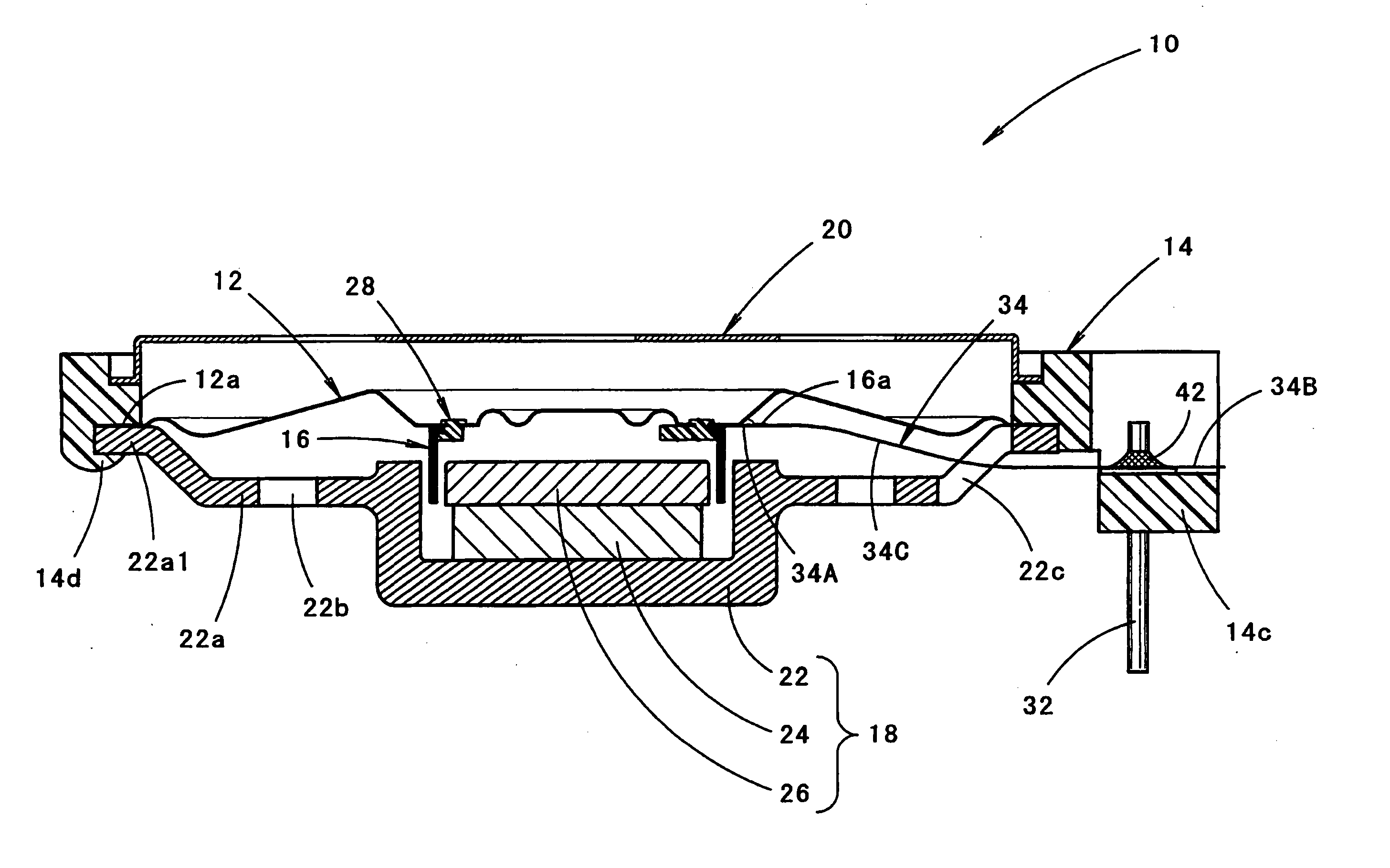

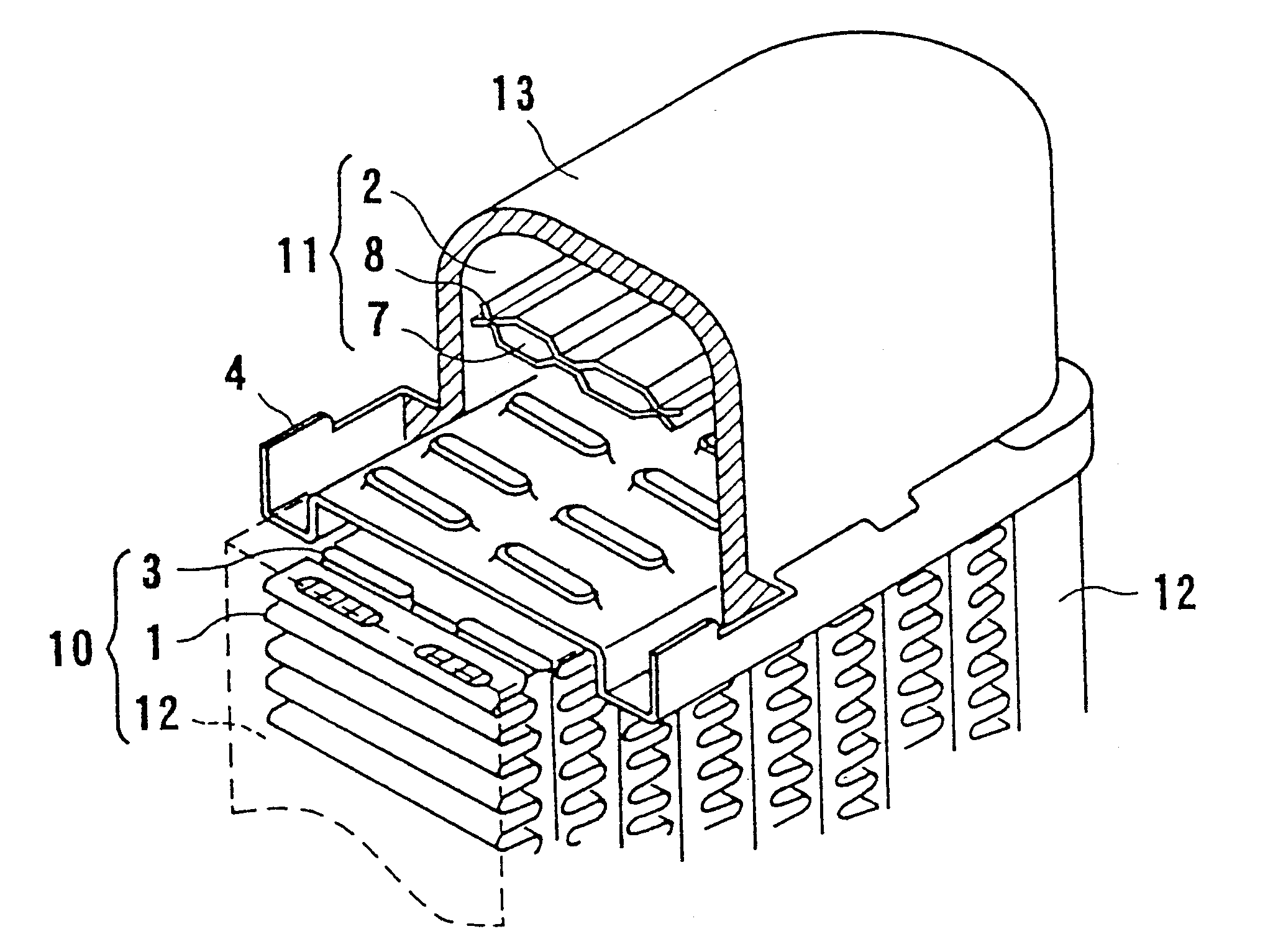

Electroacoustic transducer

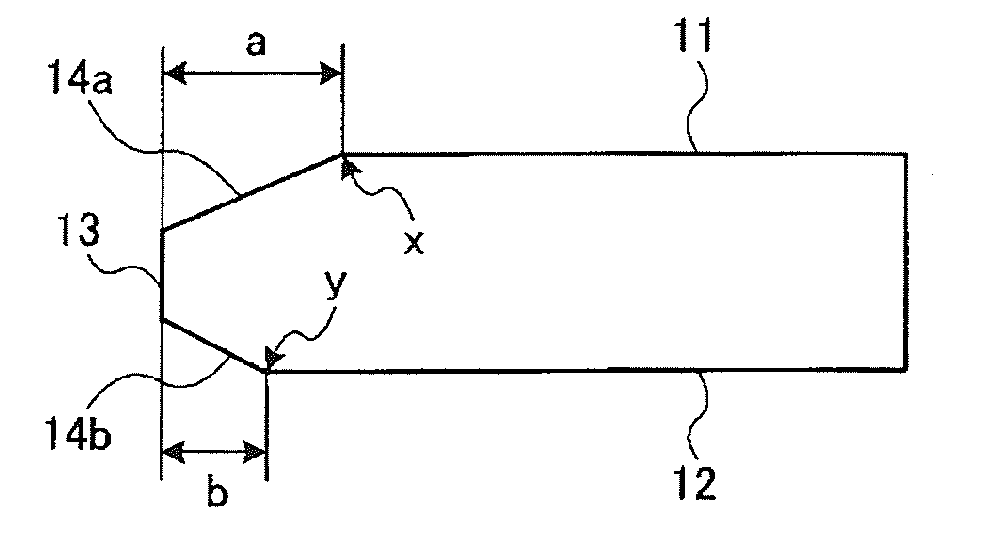

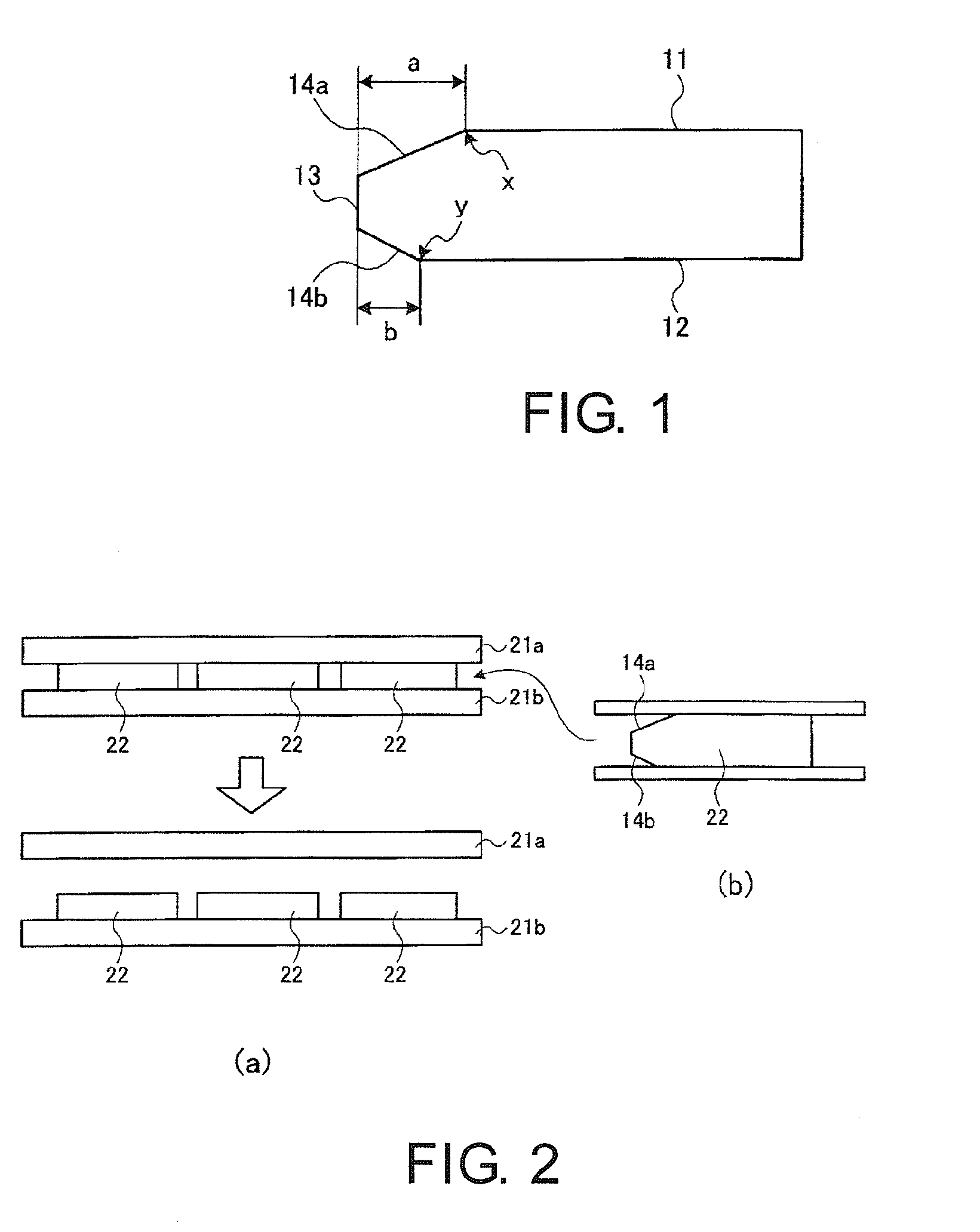

InactiveUS20050254680A1Avoid stress concentrationUniform stress distributionPrinted circuitsCircuit lead arrangements/reliefStress concentrationTransducer

In an electroacoustic transducer, a pair of coil terminals elongating from a voice coil are electrically connected to a pair of terminal members attached to a frame via a flexible printed circuit board, respectively. According to the configuration, even in a case where an electroacoustic transducer is used at a high sound pressure, breakage of the coil terminals hardly occurs. In the flexible printed circuit board, the width of an intermediate portion is set to be smaller than the widths of an end portion on the side of the coil terminals and an end portion on the side of the terminal members. Therefore, the flexibility of the intermediate portion can be enhanced, whereby transmission of characteristic vibration of the flexible printed circuit board to a diaphragm, and stress concentration in the vicinity of the end portions are effectively suppressed.

Owner:STAR MICRONICS

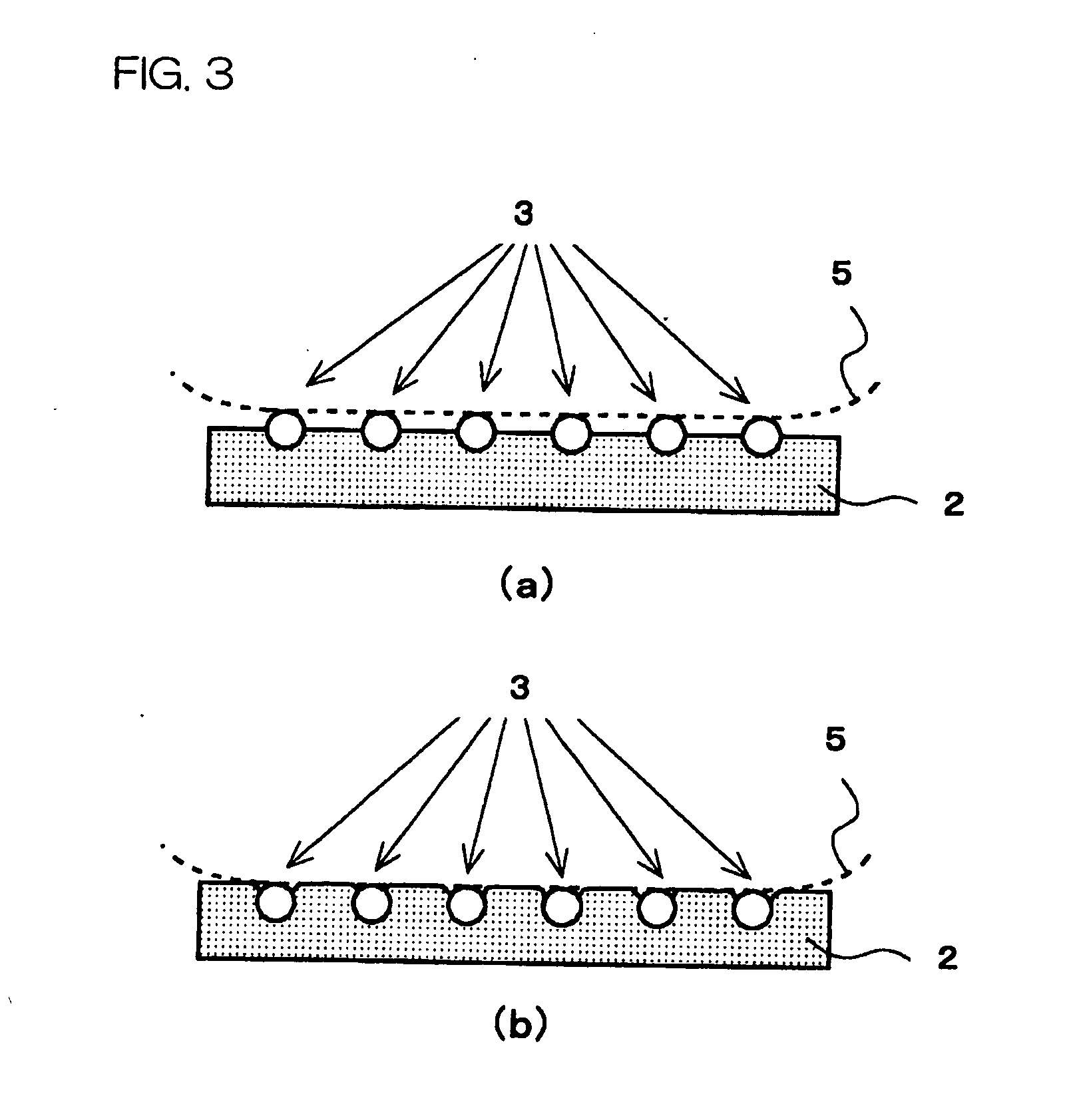

Adhesive seal material for end portion of solar cell panel, sealed structure of end portion of solar cell panel, sealing method, solar cell module, and producing method thereof

InactiveUS20110088756A1Easy to processEasy to stickPhotovoltaic supportsPV power plantsEngineeringSolar cell

An adhesive seal material for an end portion a solar cell panel is an adhesive seal material which is bonded to an end portion of a solar cell panel. The adhesive seal material includes a rubber-based adhesive layer, and a non-adhesive layer partially covering a surface of the rubber-based adhesive layer.

Owner:NITTO DENKO CORP

Subastrate for a magnetic disk and method of manufacturing the same

InactiveUS20100247977A1Improve smoothnessWorkability is degradedMagnetic materials for record carriersBase layers for recording layersEngineeringMechanical engineering

Owner:HOYA CORP

Portable electric cutting apparatus

ActiveUS7275326B2Workability is degradedAvoid accumulationMetal sawing devicesMetal sawing accessoriesElectric motor

Owner:KOKI HLDG CO LTD

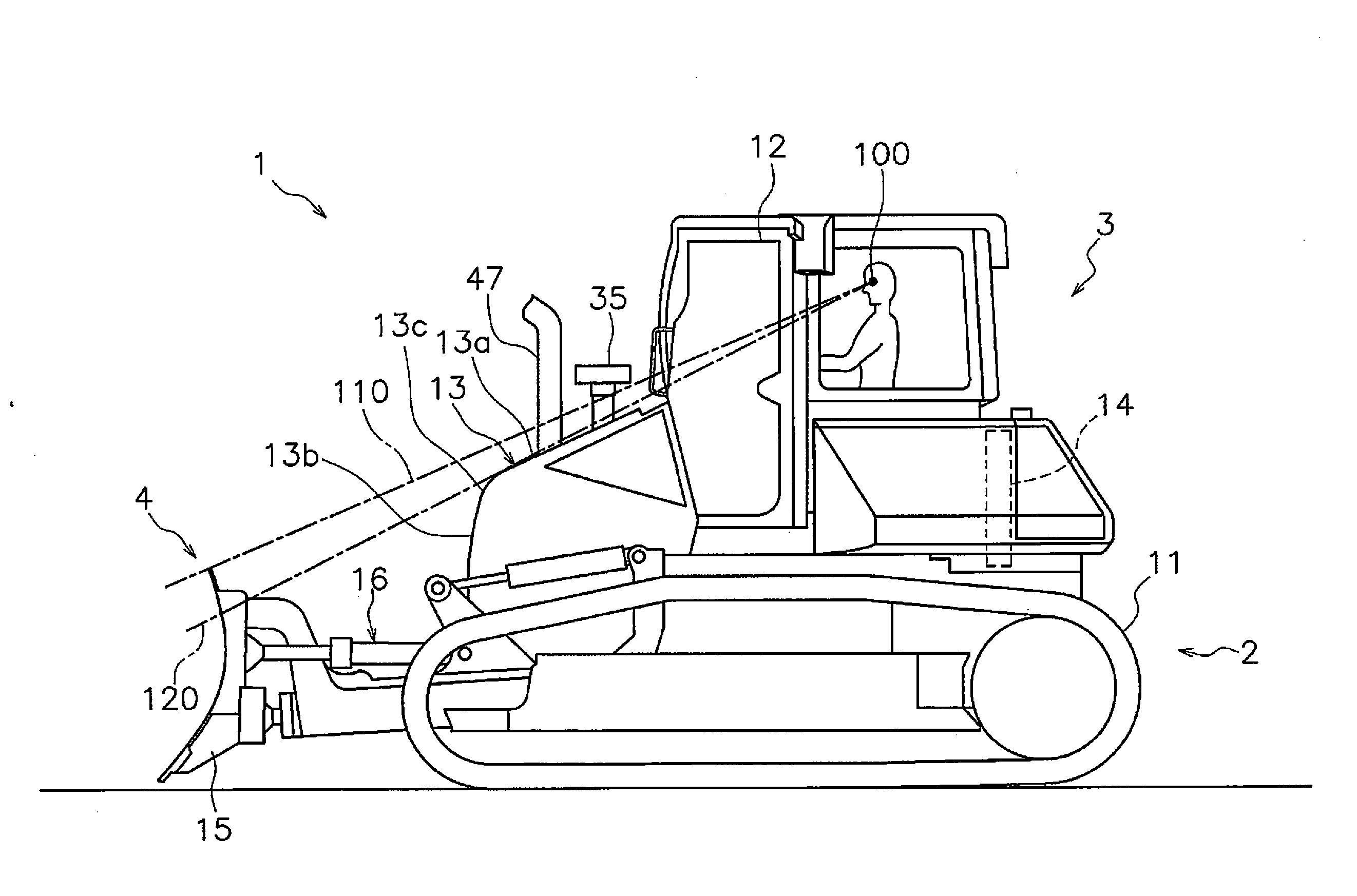

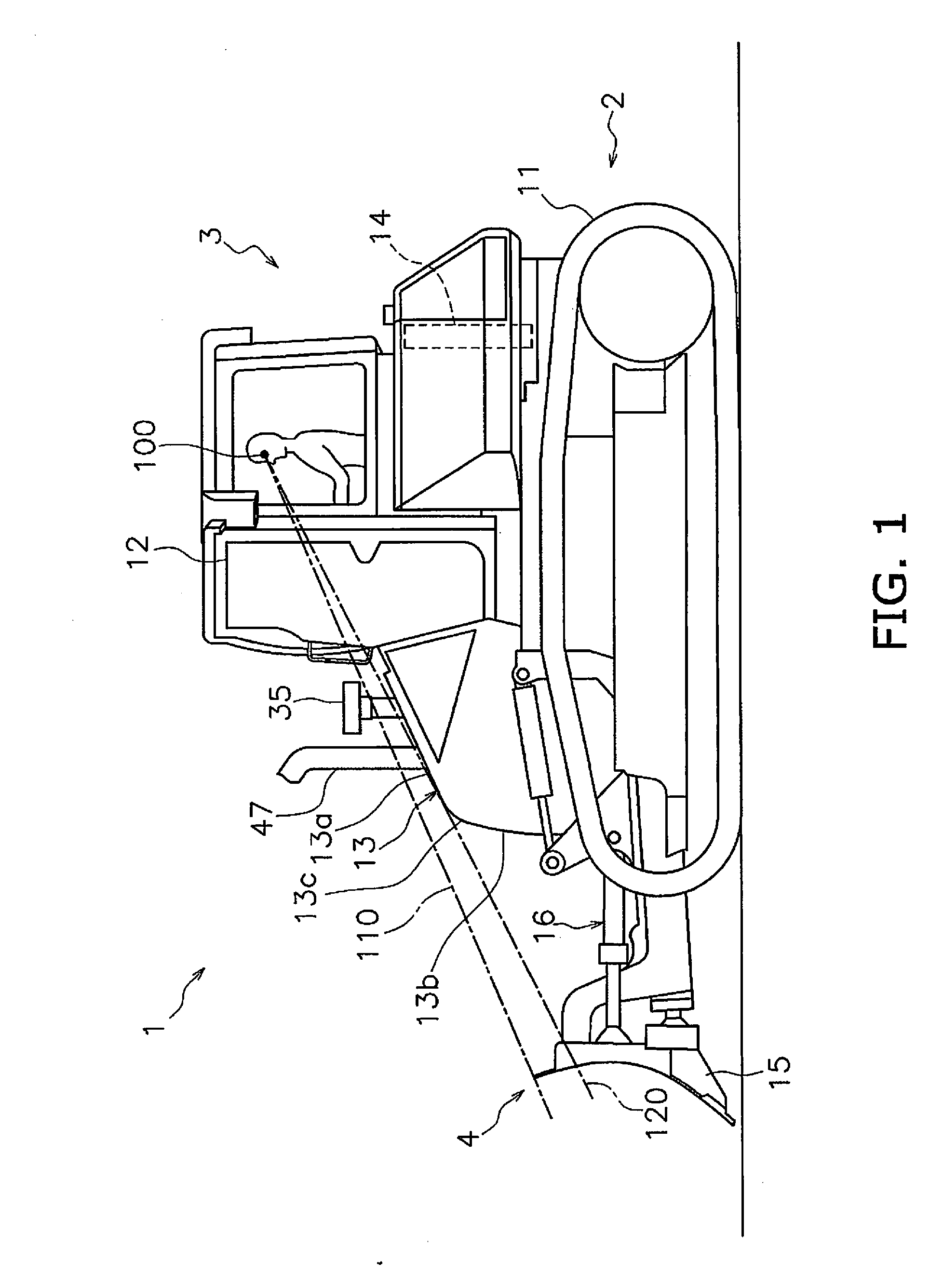

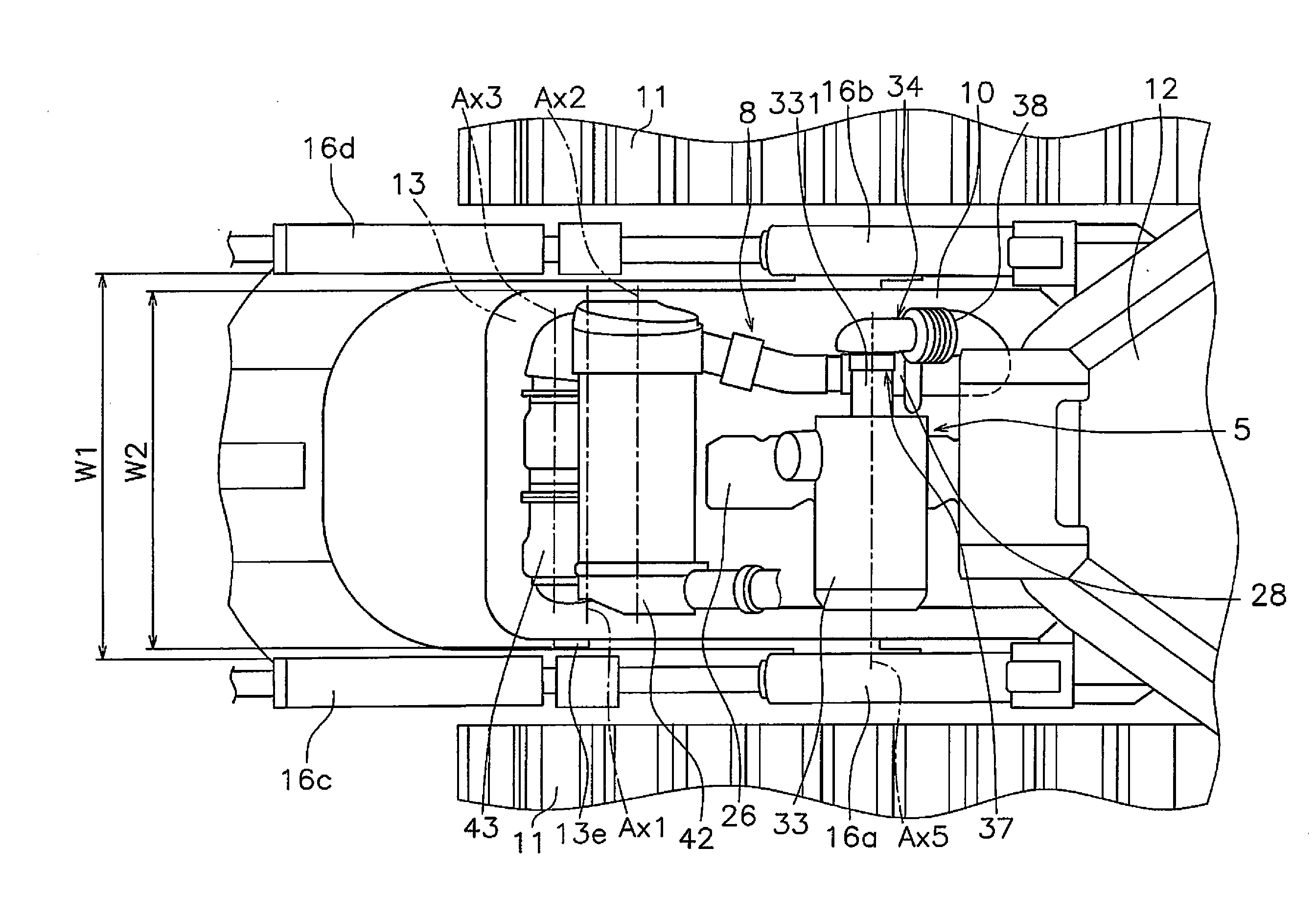

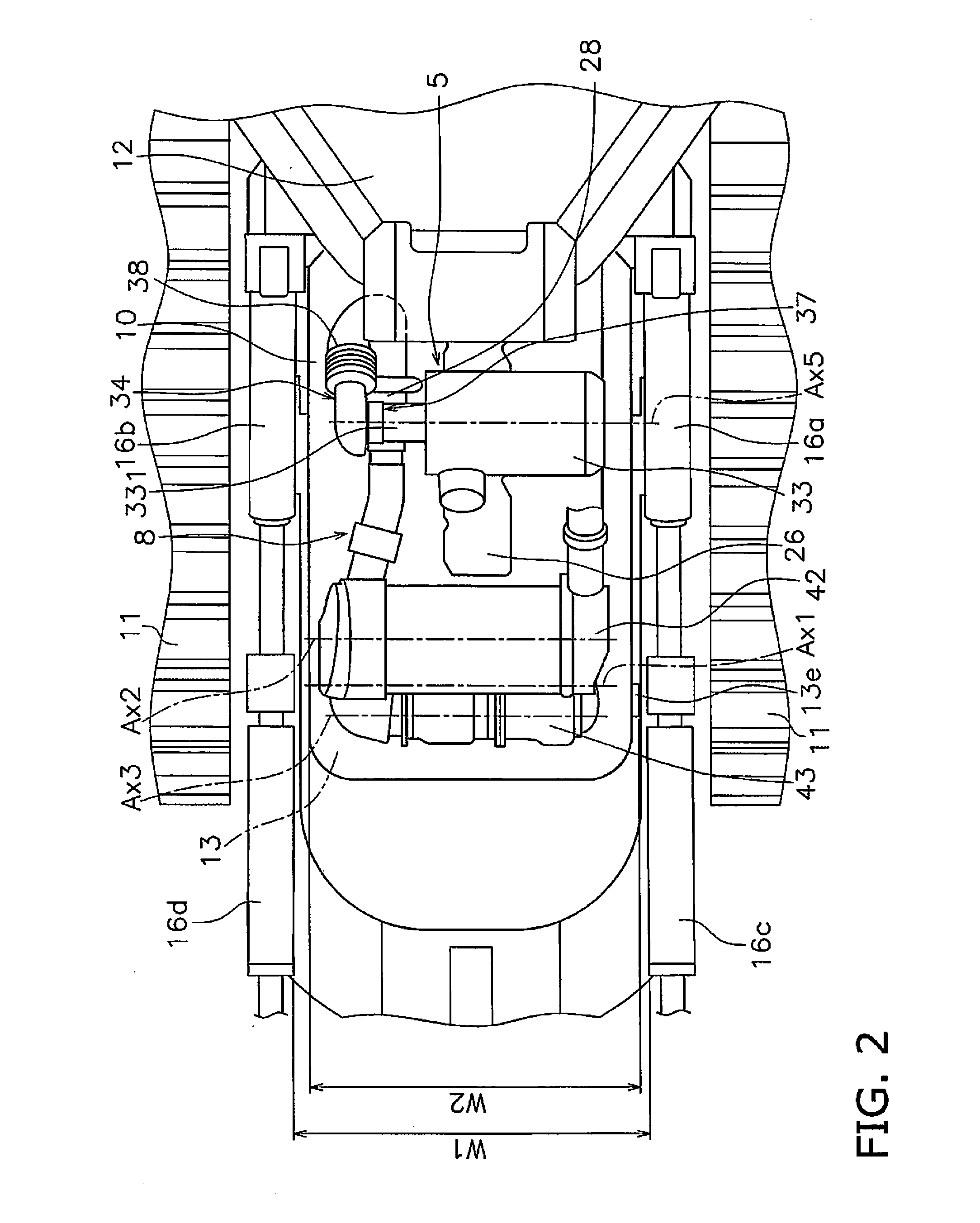

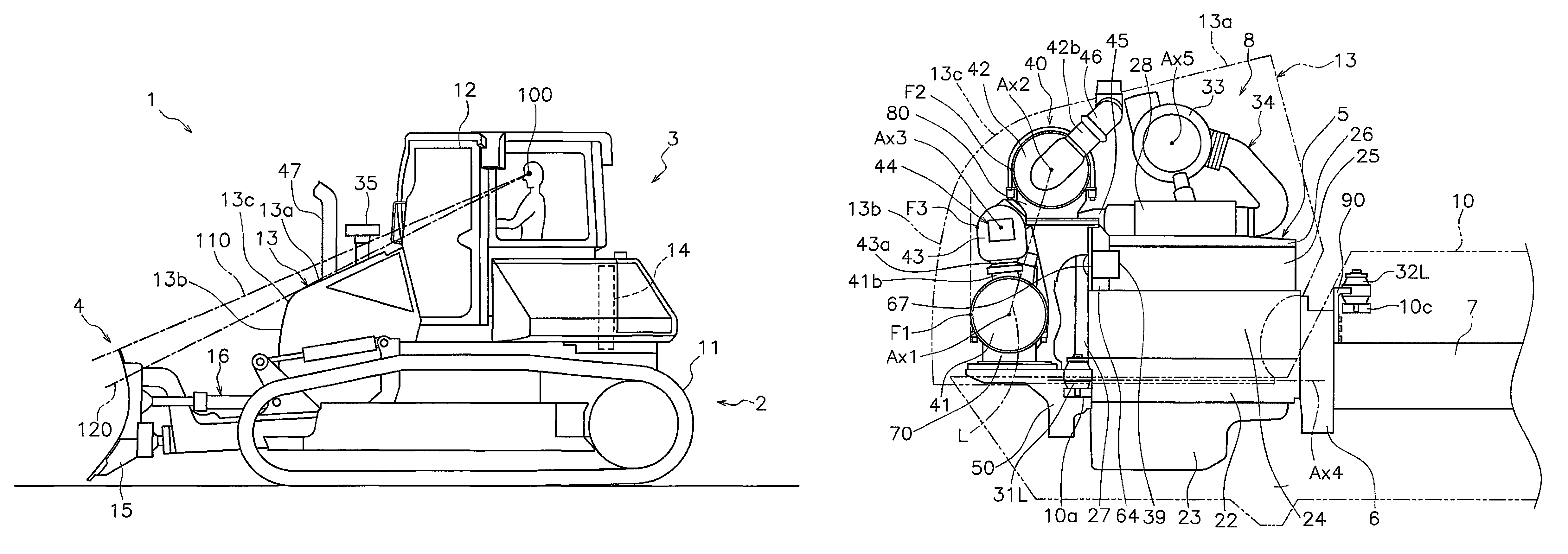

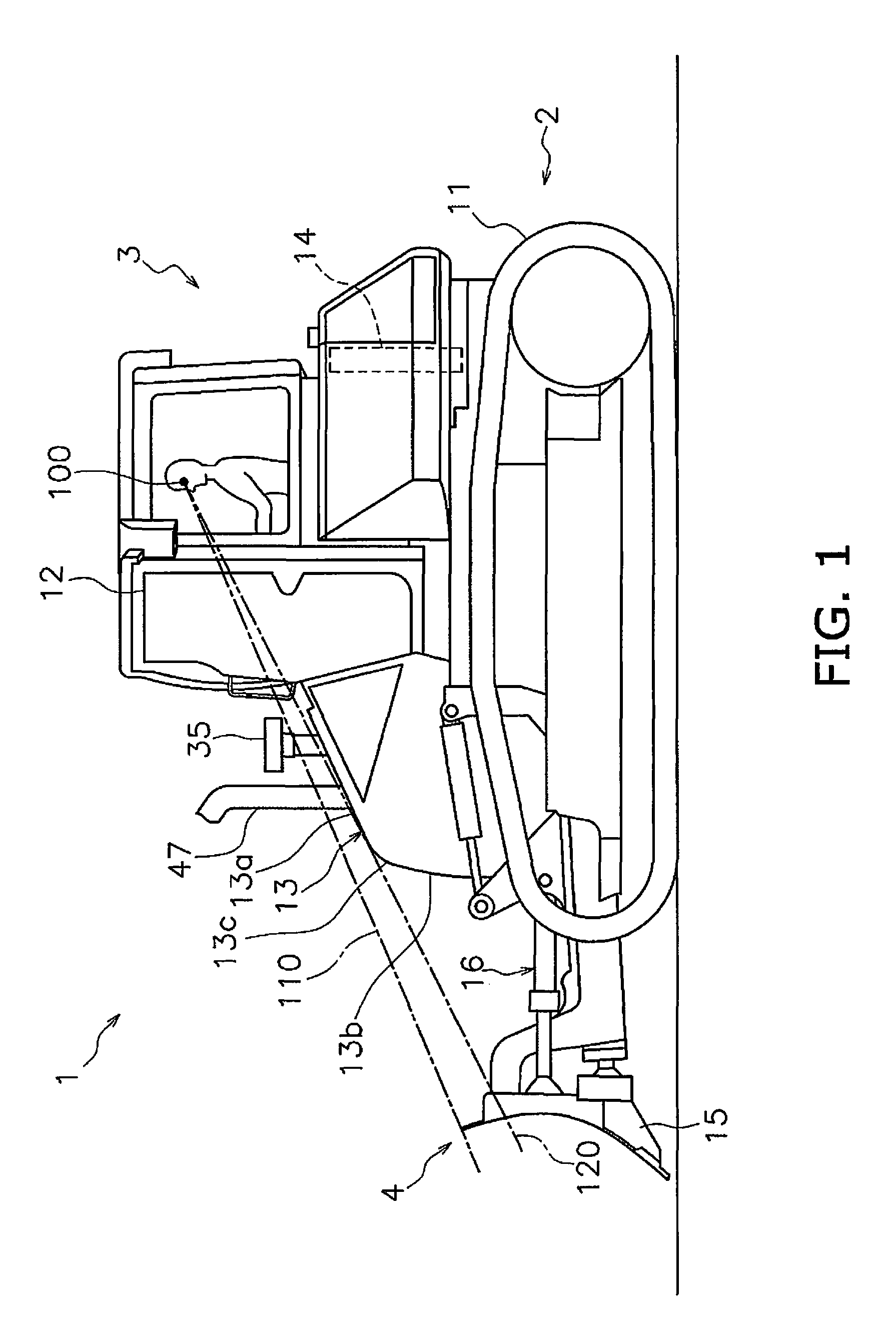

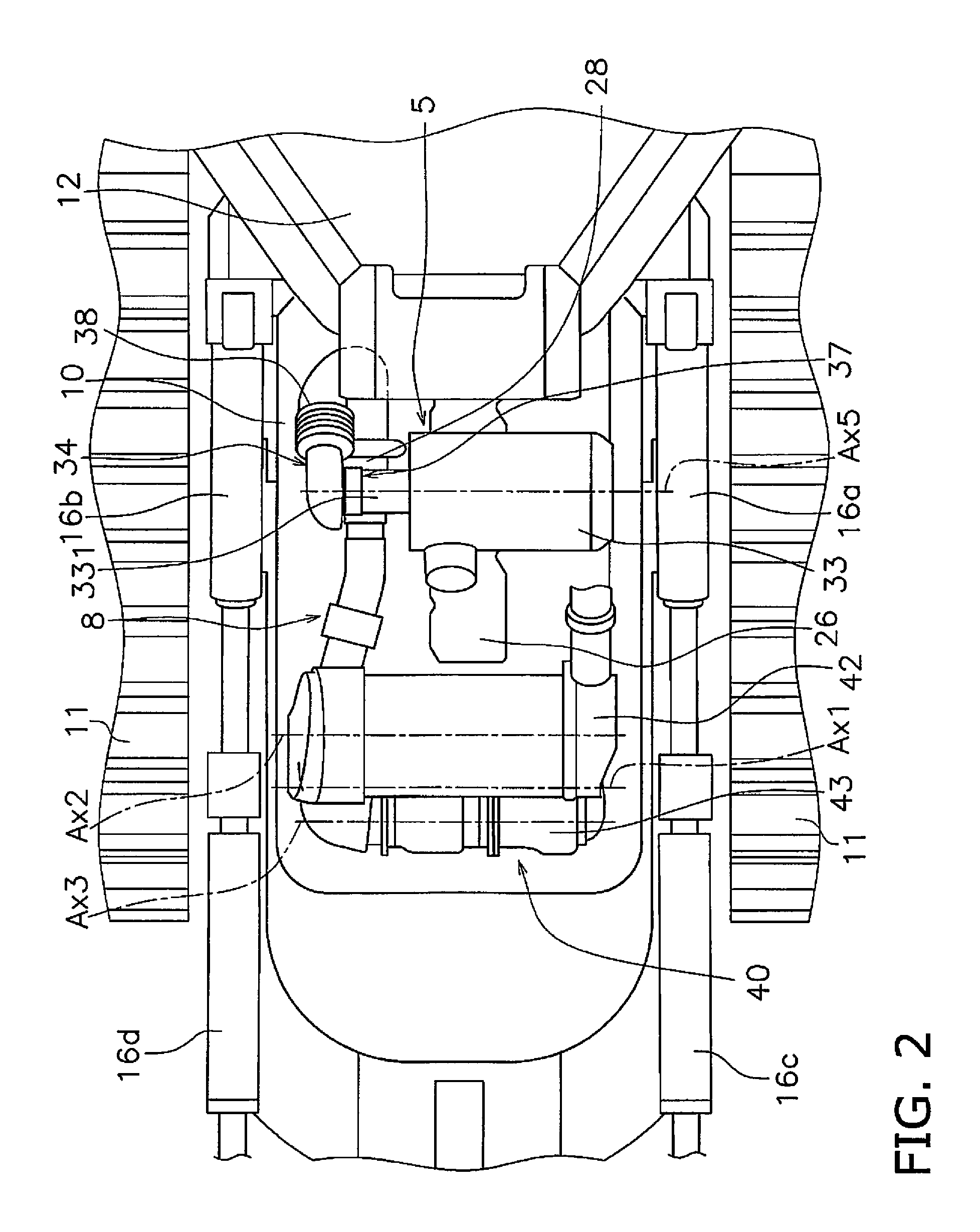

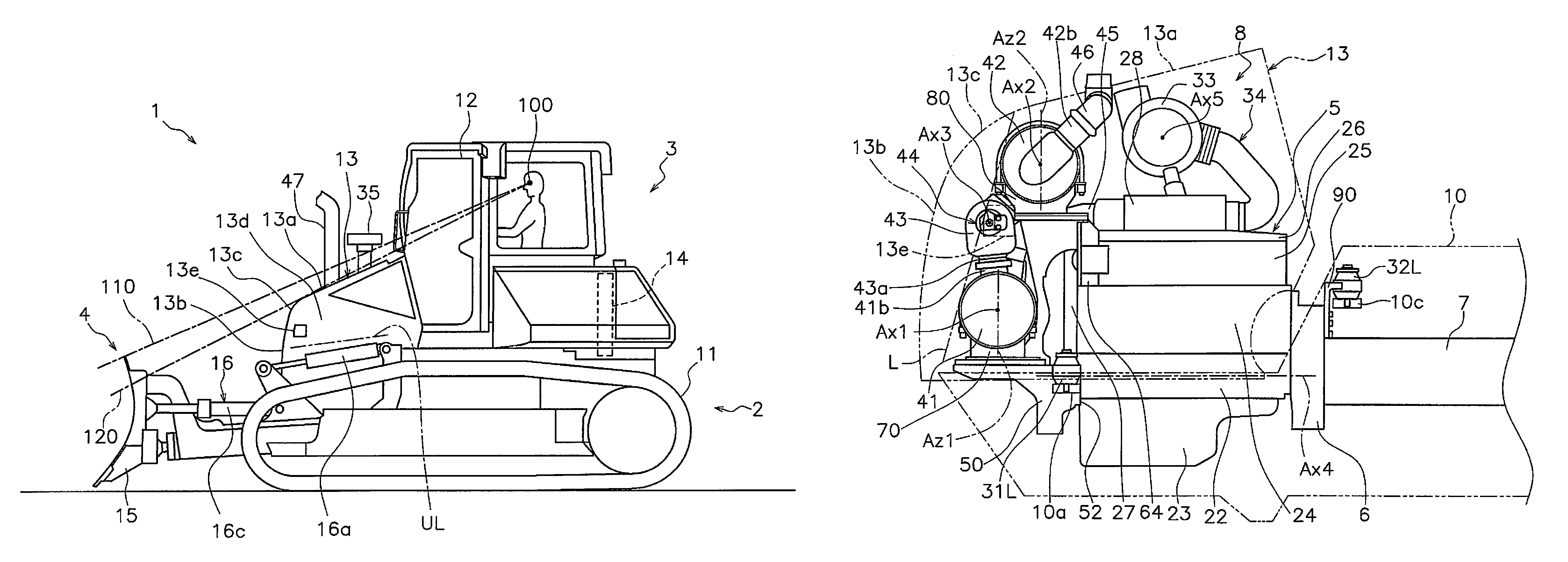

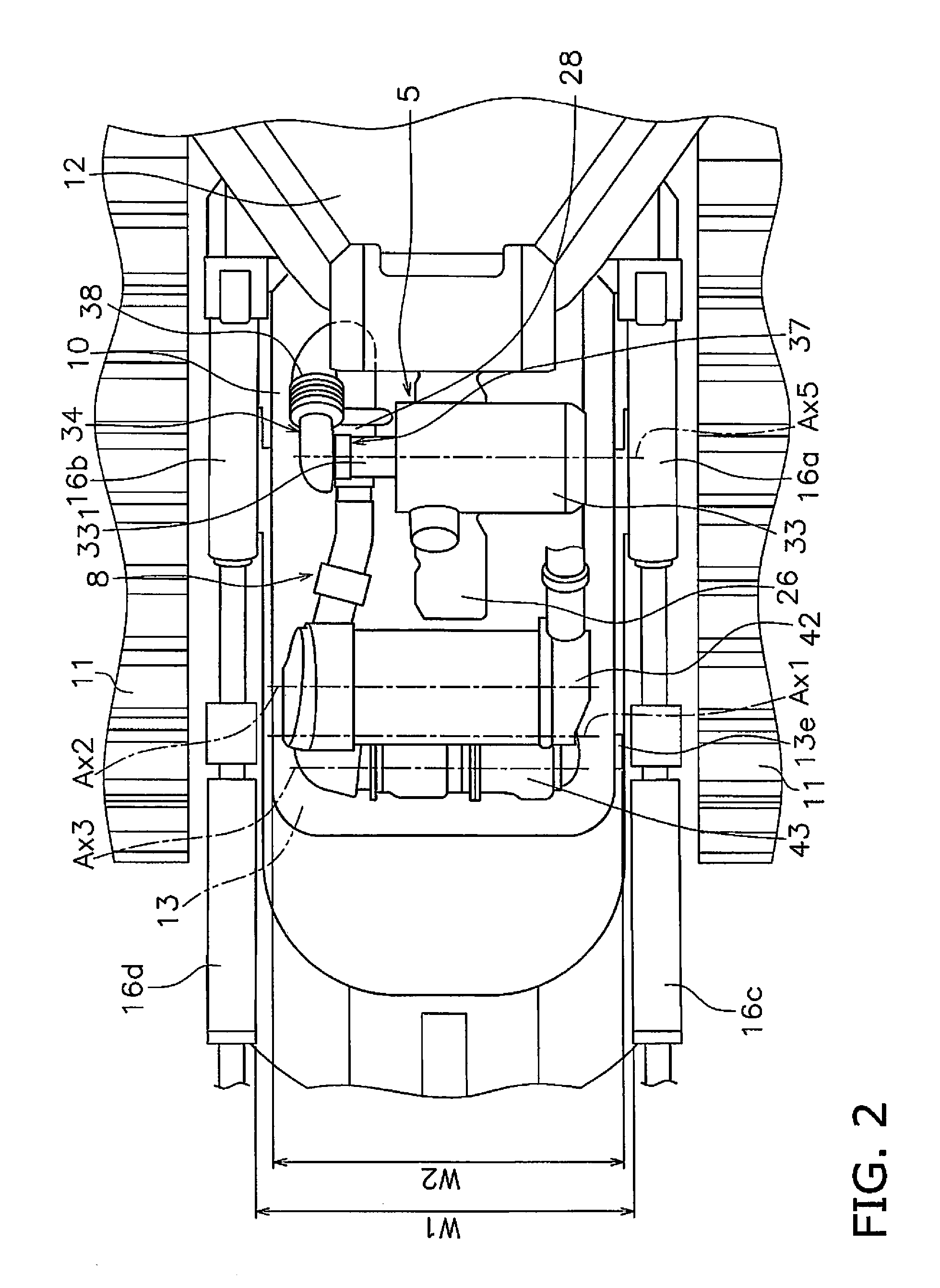

Bulldozer

ActiveUS20150275476A1Workability be deteriorateWorkability is degradedExhaust apparatusMechanical machines/dredgersEngineeringFront edge

A bulldozer includes a blade, an engine, a first exhaust treatment device, a second exhaust treatment device, a relay connection pipe, and an engine cover. The first exhaust treatment device is disposed in front of the engine and lower than the upper surface of thereof. The second exhaust treatment device is disposed above the first exhaust treatment device. The relay connection pipe is disposed above the first exhaust treatment device and below the second exhaust treatment device. The longitudinal directions of the first and second exhaust treatment devices extend along the vehicle lateral direction. As seen from the top of the vehicle, the second exhaust treatment device overlaps at least a part of the first exhaust treatment device. As seen from the side of the vehicle, the front edge of the first exhaust treatment device is positioned forward of the front edge of the second exhaust treatment device.

Owner:KOMATSU LTD

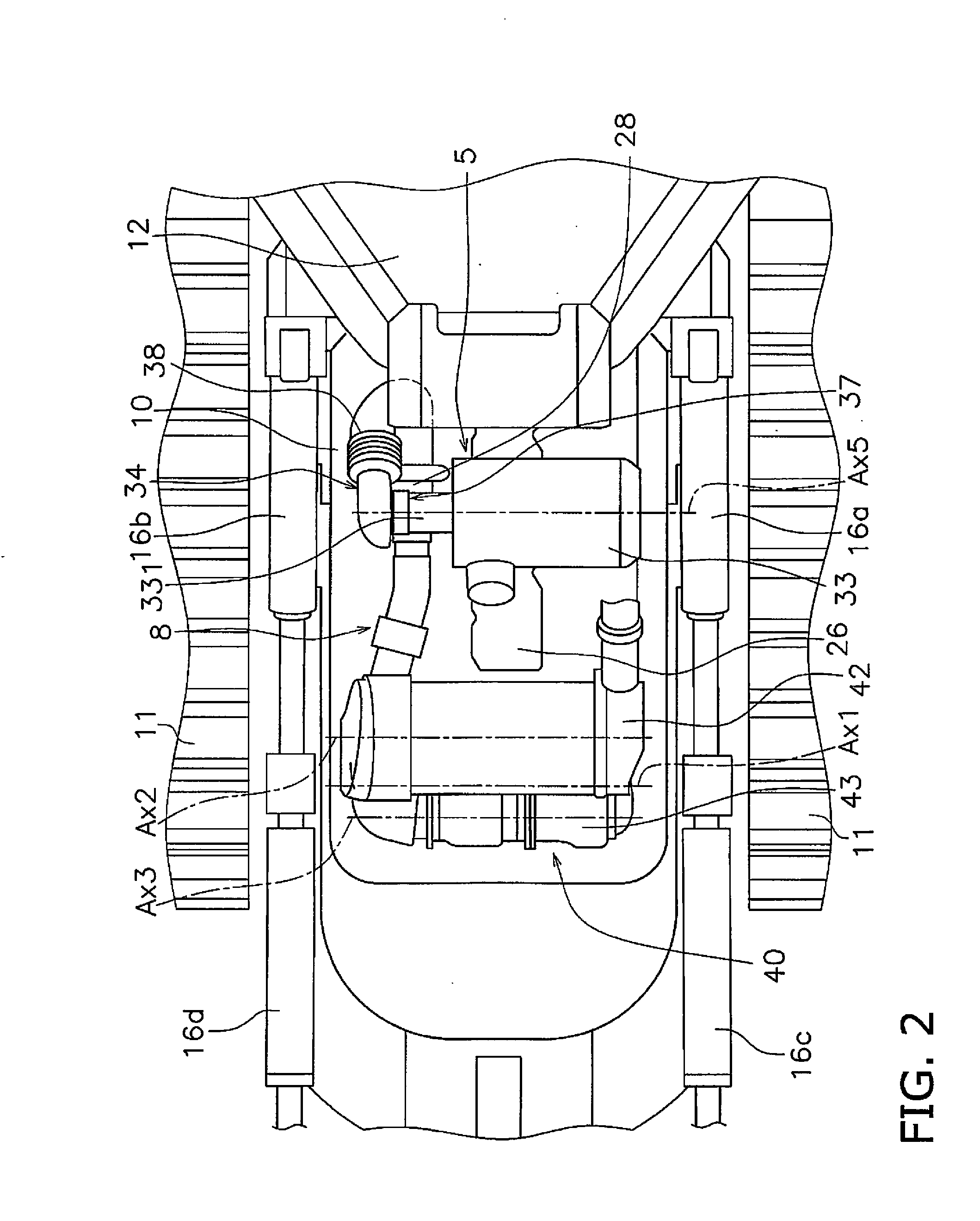

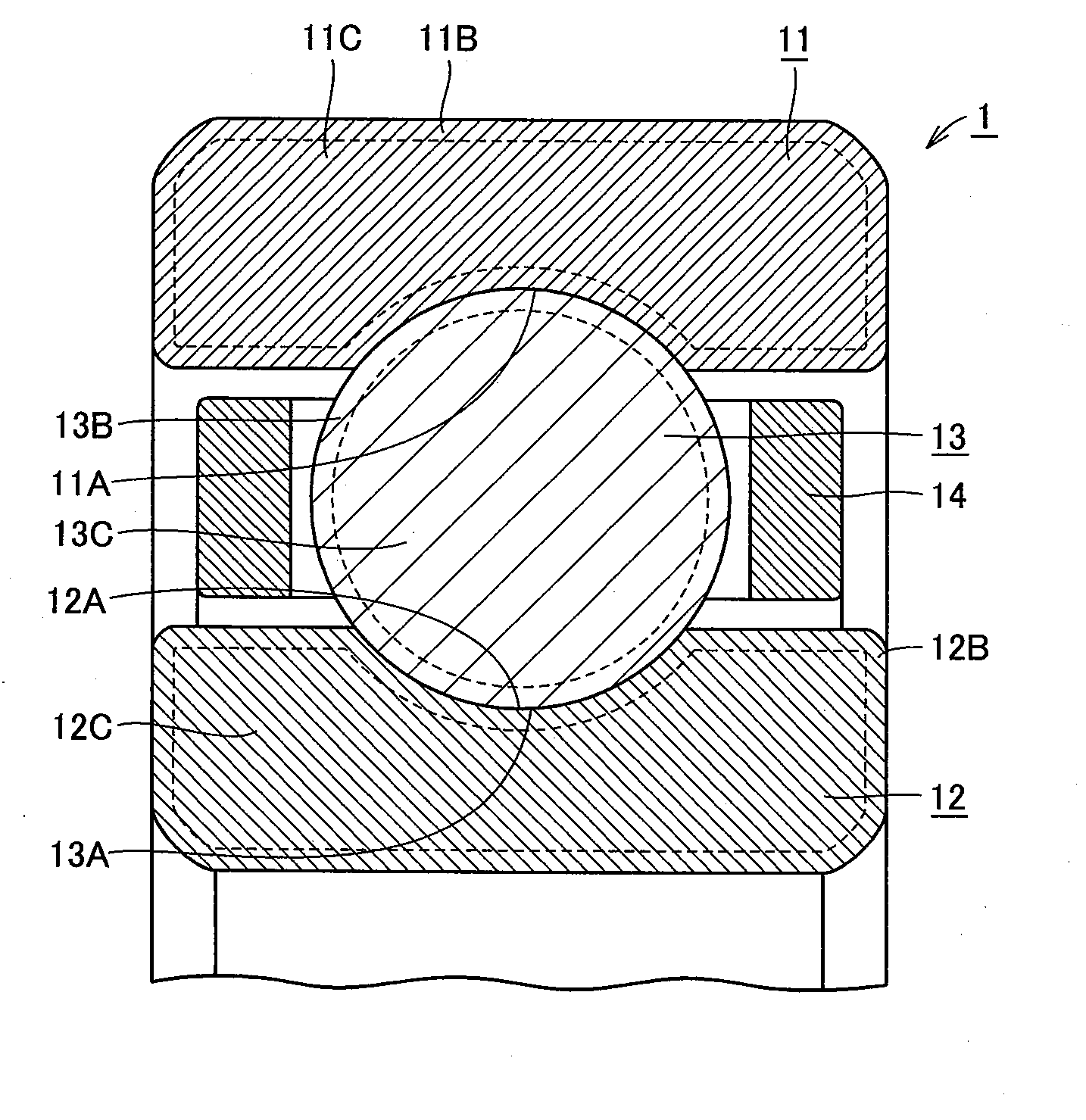

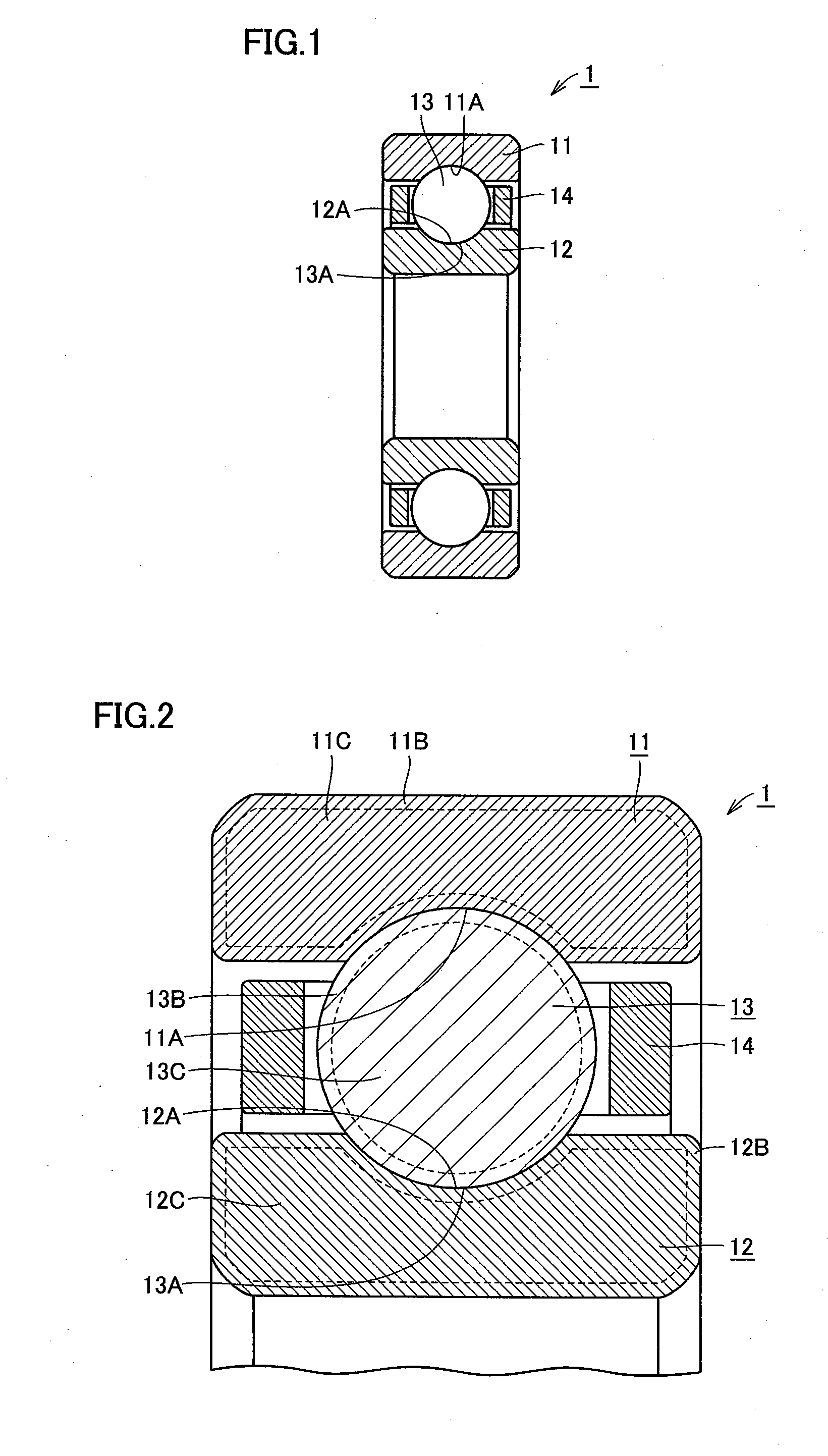

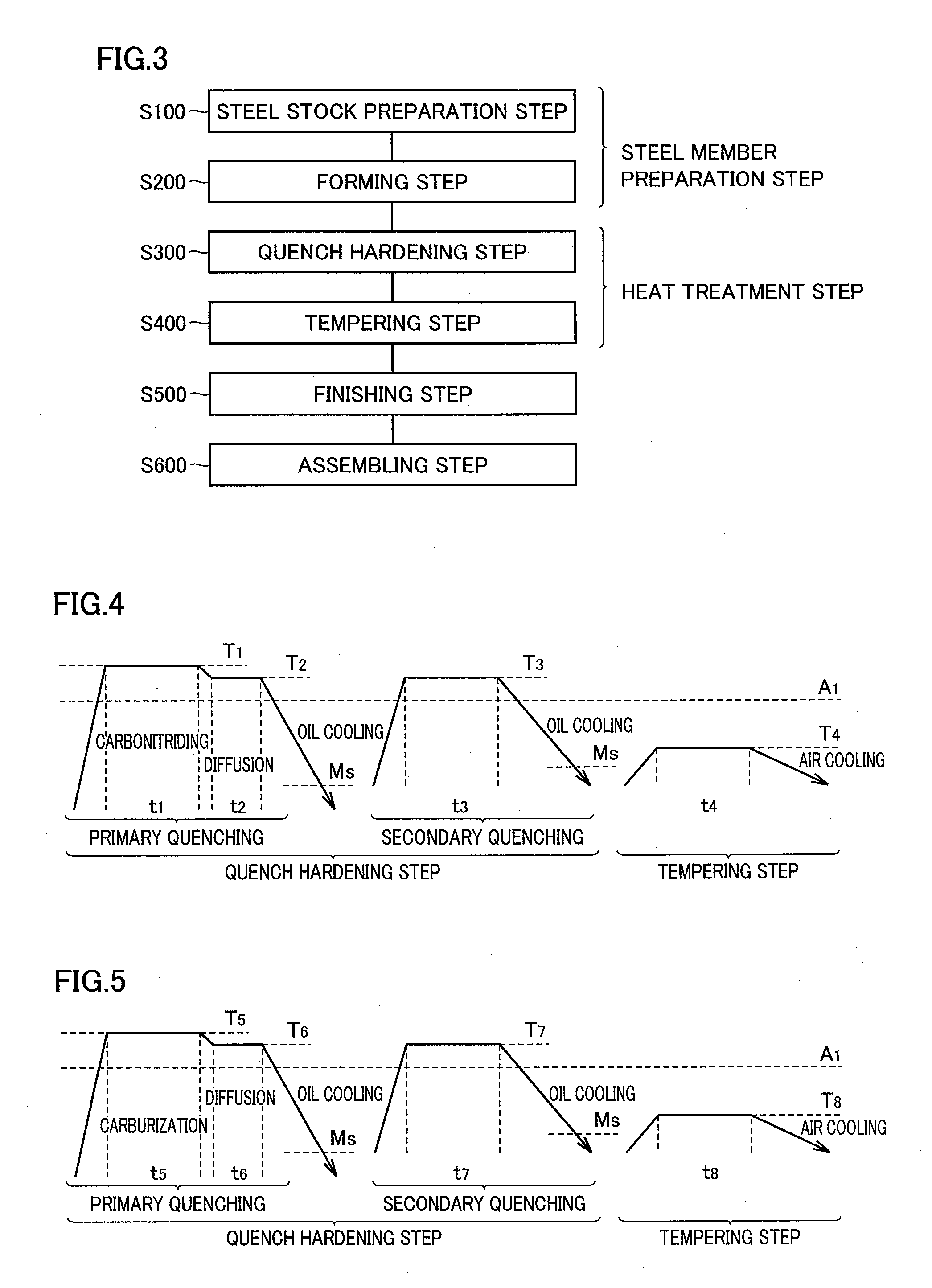

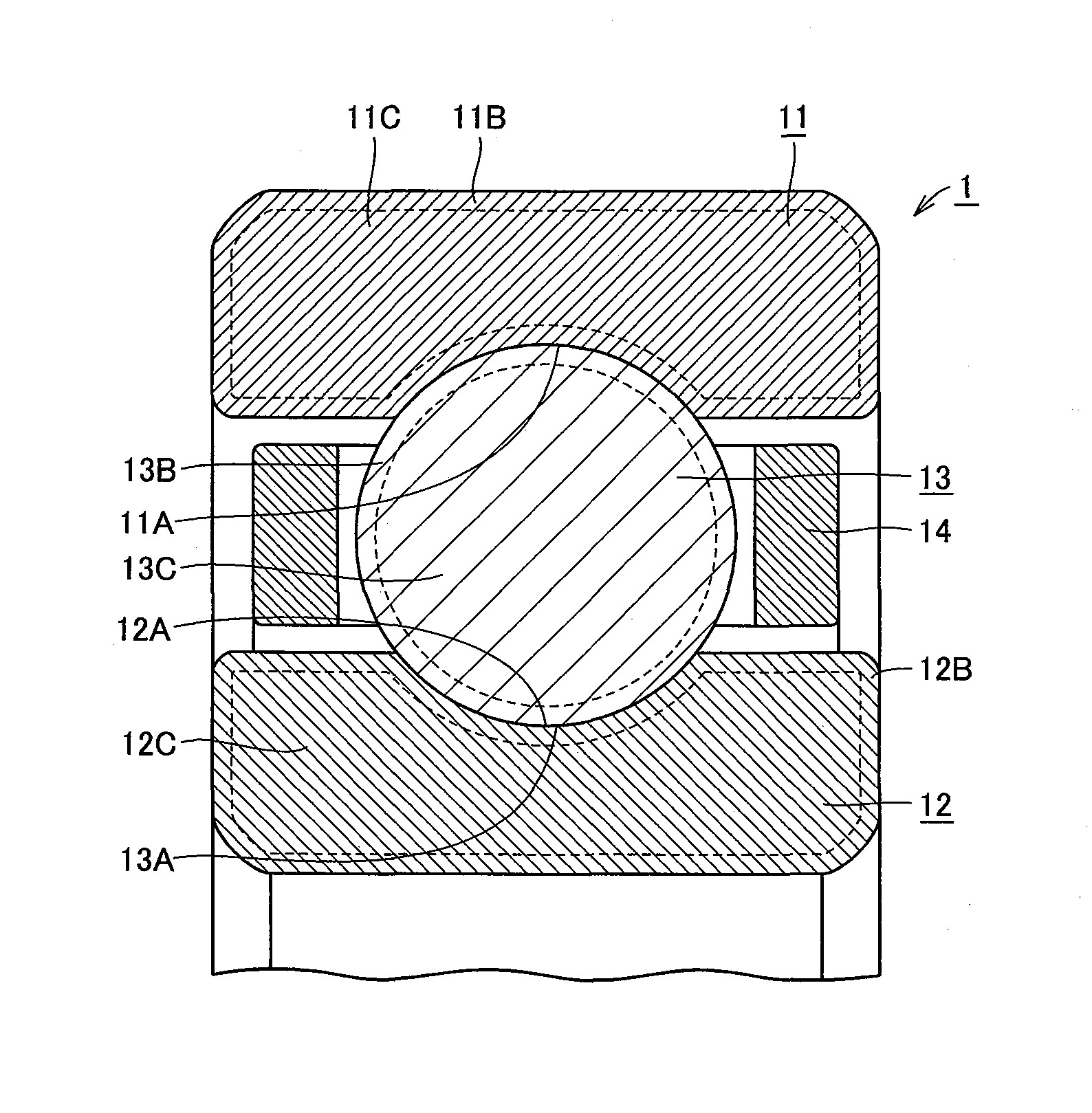

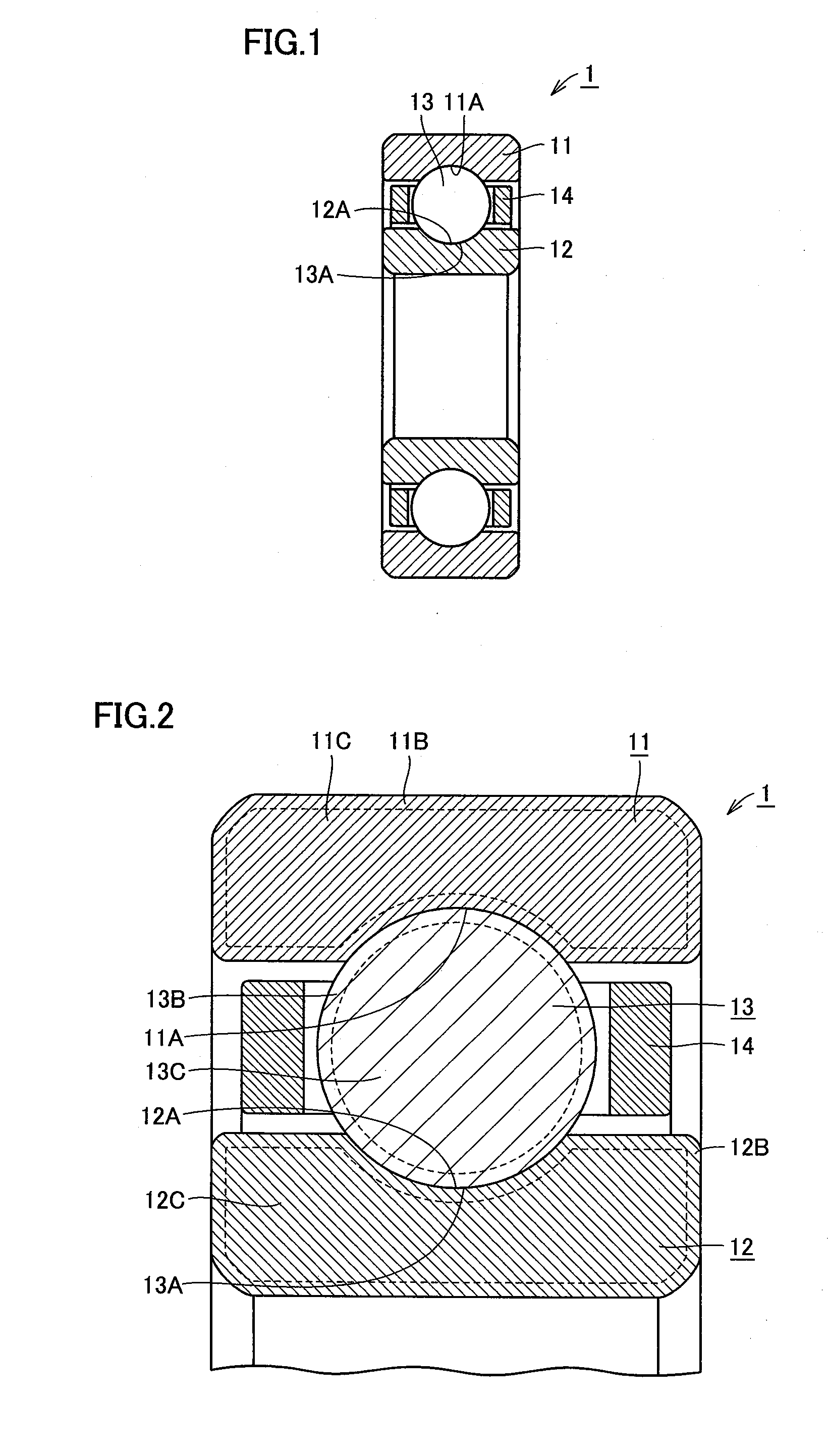

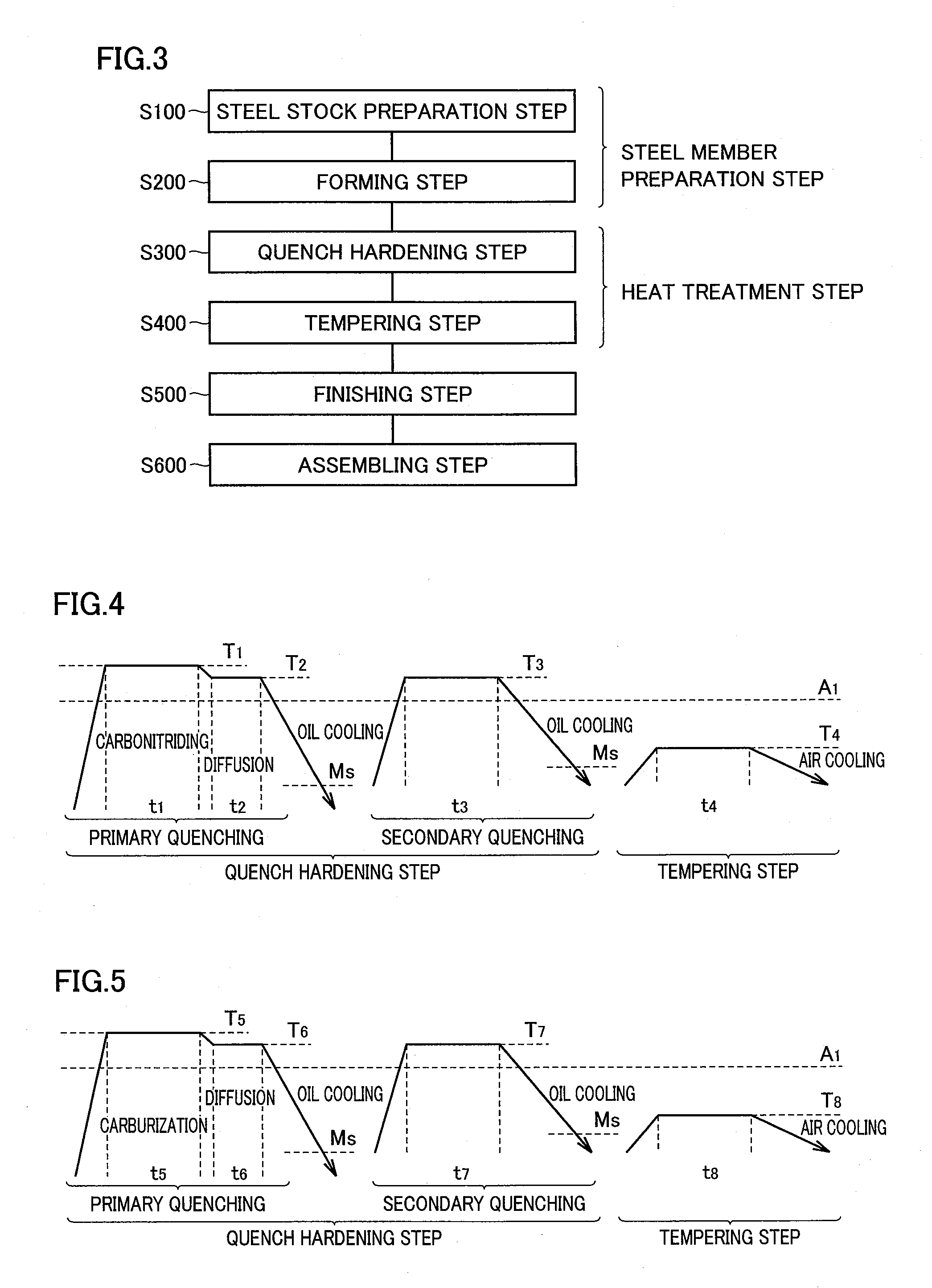

Rolling member, rolling bearing and process for manufacturing rolling member

ActiveUS20100150489A1Workability is degradedSolution to short lifeToothed gearingsBearing componentsBall bearingManganese

The invention provides a deep groove ball bearing which exhibits a long life even in a high-temperature environment or an environment involving the penetration of water in spite of its low alloying element content. The outer race, inner race and ball constituting the bearing are made of a steel which contains 0.3 to 0.4% of carbon, 0.3 to 0.7% of silicon, 0.3 to 0.8% of manganese, 0.5 to 1.2% of nickel, 1.6 to 2.5% of chromium, 0.1 to 0.7% of molybdenum and 0.2 to 0.4 of vanadium with the balance consisting of iron and impurities and in a total content of silicon and manganese of 1.0% or below, a total content of nickel and chromium of 2.3% or above and a total content of chromium, molybdenum and vanadium of 3.0% or below. Surface hardened layers are formed in the outer race, inner race and ball respectively and the surface hardened layers exhibit hardness of 725 to 800 HV, while the maximum particle size of carbides dispersed in the surface hardened layers is 10 μm or below and the area ratio thereof is 7 to 25%. Further, the inner parts exhibit hardness of 450 to 650 HV.

Owner:NTN CORP

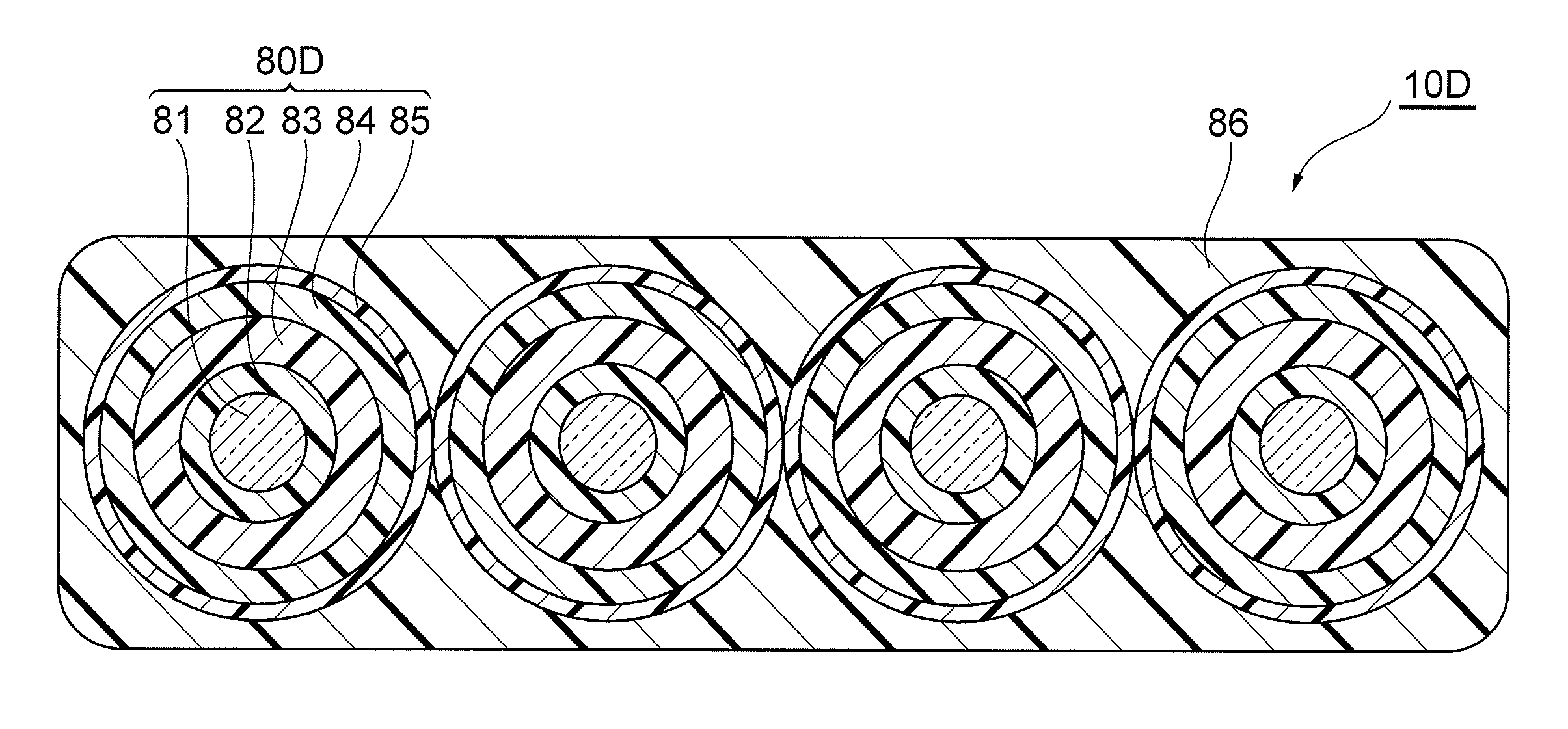

Copper alloy twisted wire, method for manufacturing same, and electric wire for automobile

InactiveUS20160368035A1High strengthHigh elongationApparatus for heat treatmentConductive materialChemical compositionImpurity

A cast material is formed, the cast material having a chemical component composition that contains at least one additional element selected from the group consisting of Fe, Ti, Sn, Ag, Mg, Zn, Cr, and P in an amount of at least 1.0 mass % and not more than 2.0 mass % in total, and in which a remaining portion includes Cu and inevitable impurities. An expanded material is formed by subjecting the cast material to plastic forming. An intermediate wire material is formed by wiredrawing the expanded material. The intermediate wire material is annealed. A single wire is formed by wiredrawing the annealed intermediate wire material at a cold deformation degree in a range of at least 77% and less than 99%. A twisted wire is formed by twisting a plurality of single wires, and the twisted wire is heated. Accordingly, a copper alloy twisted wire is obtained.

Owner:AUTONETWORKS TECH LTD +2

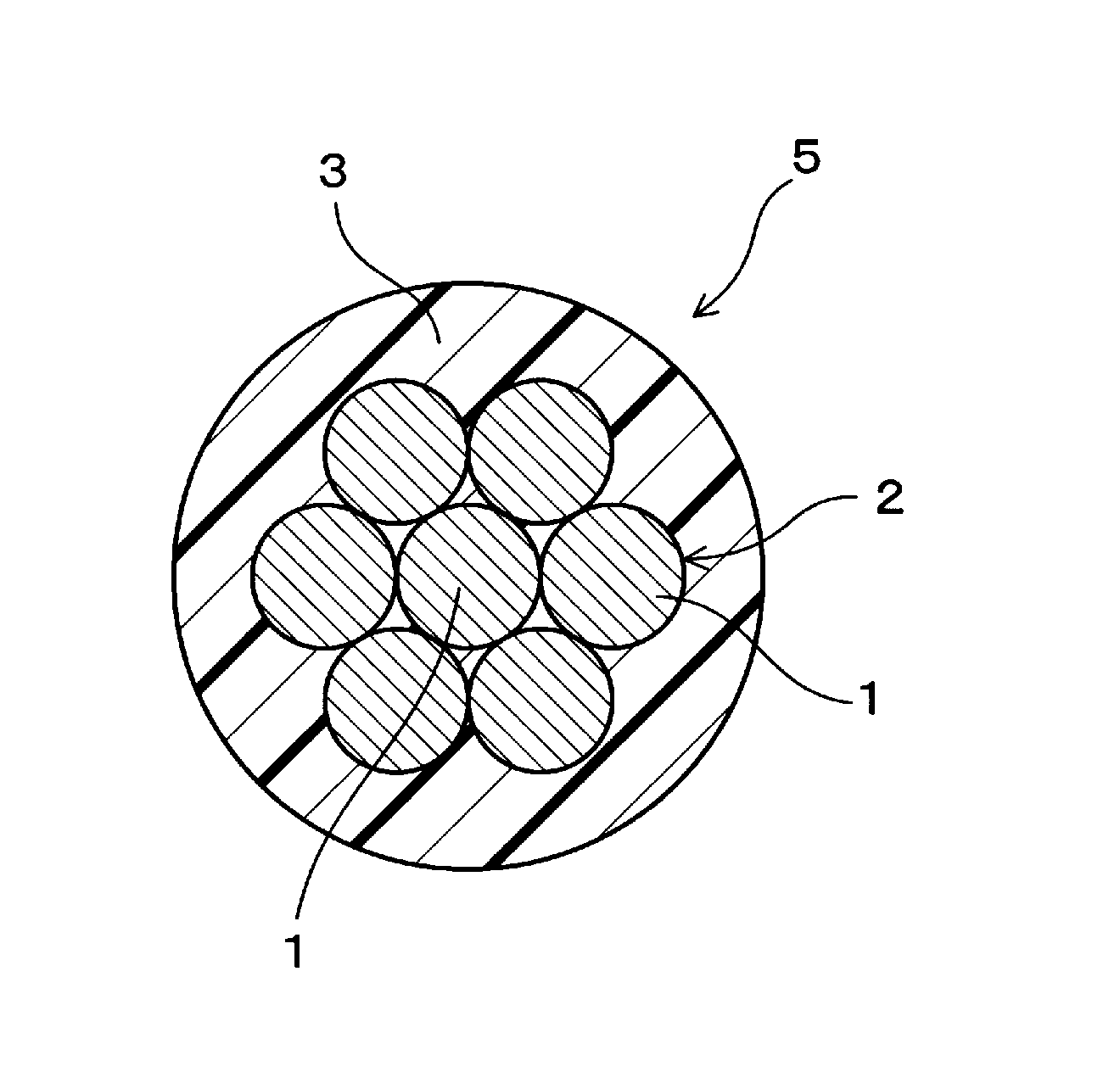

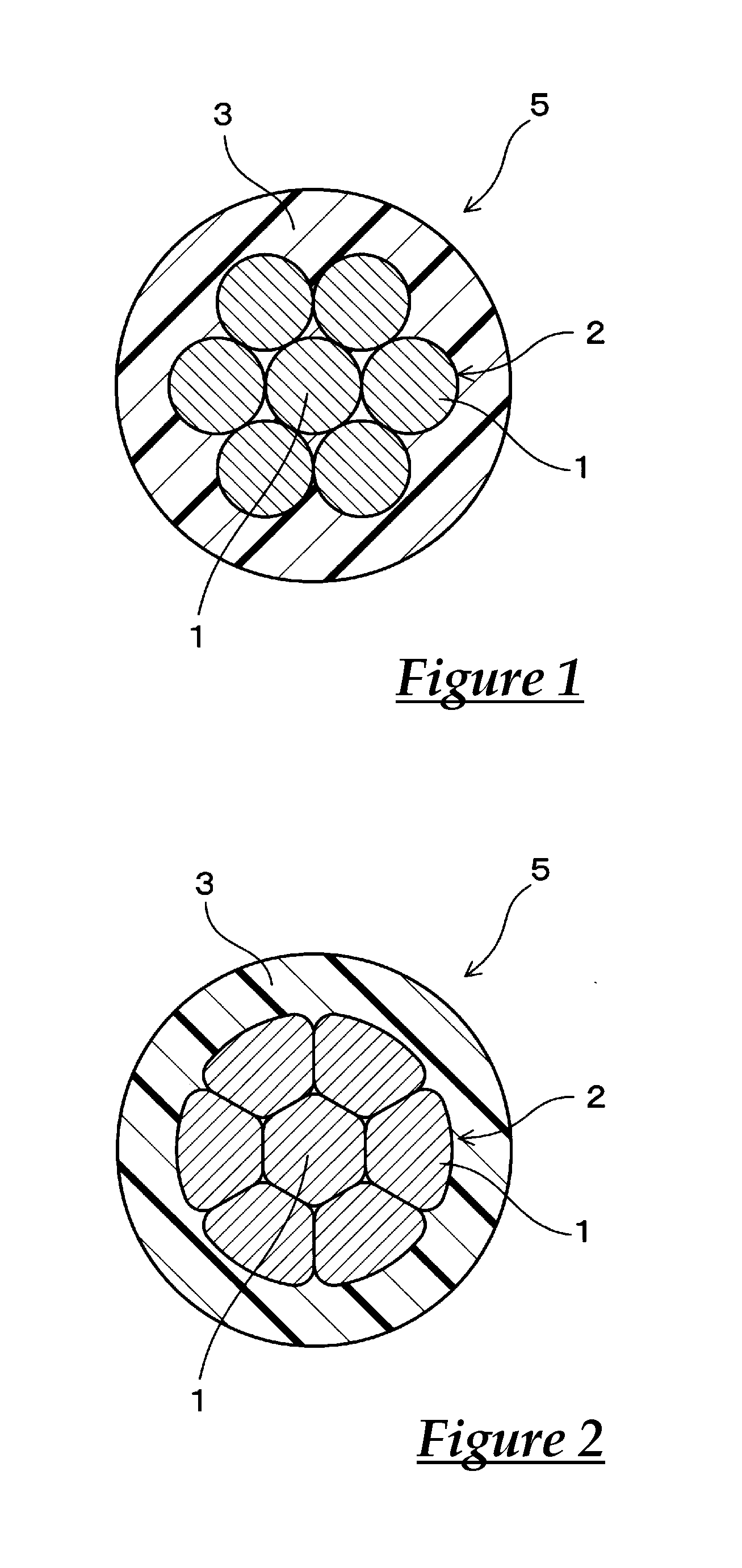

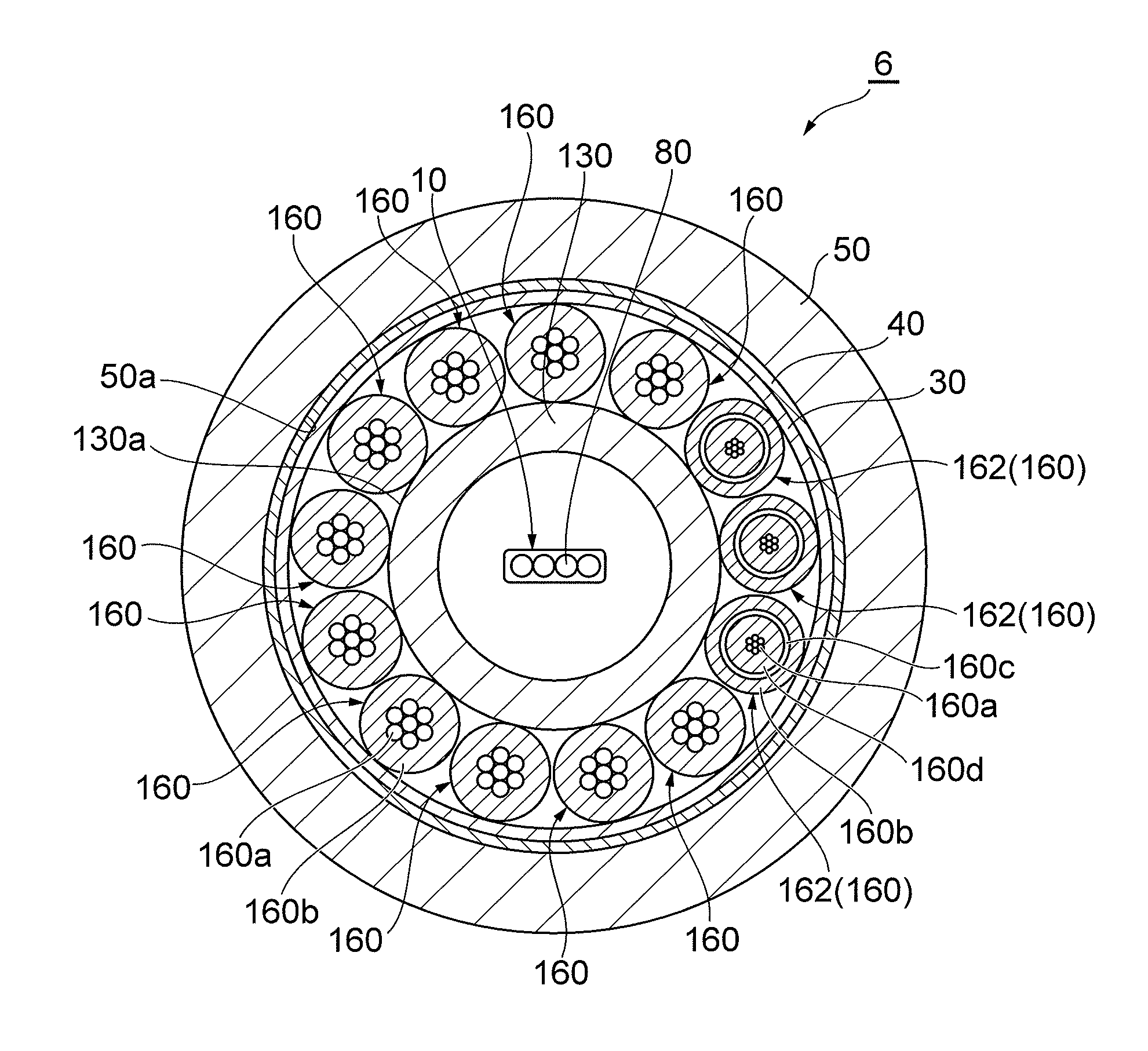

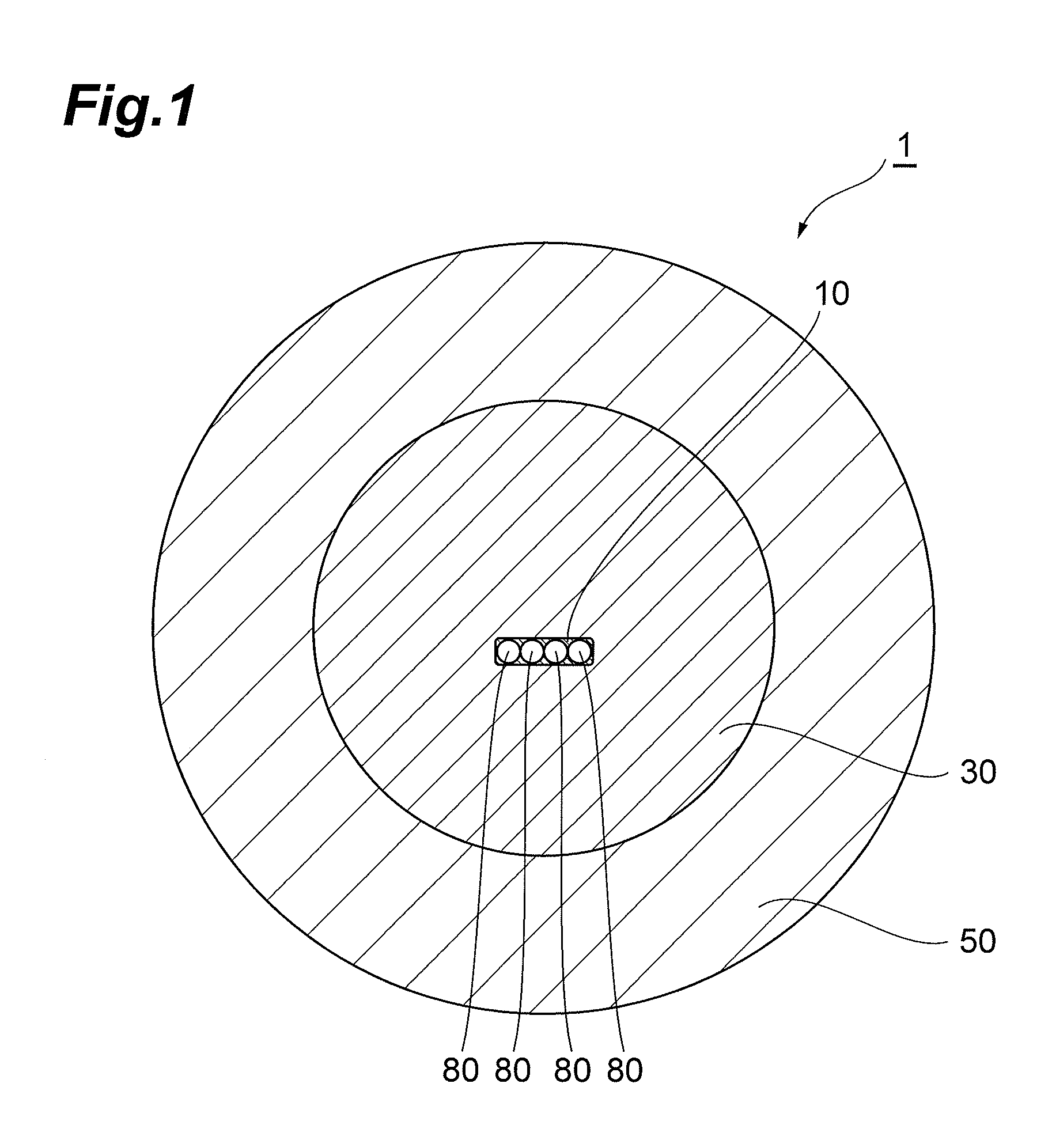

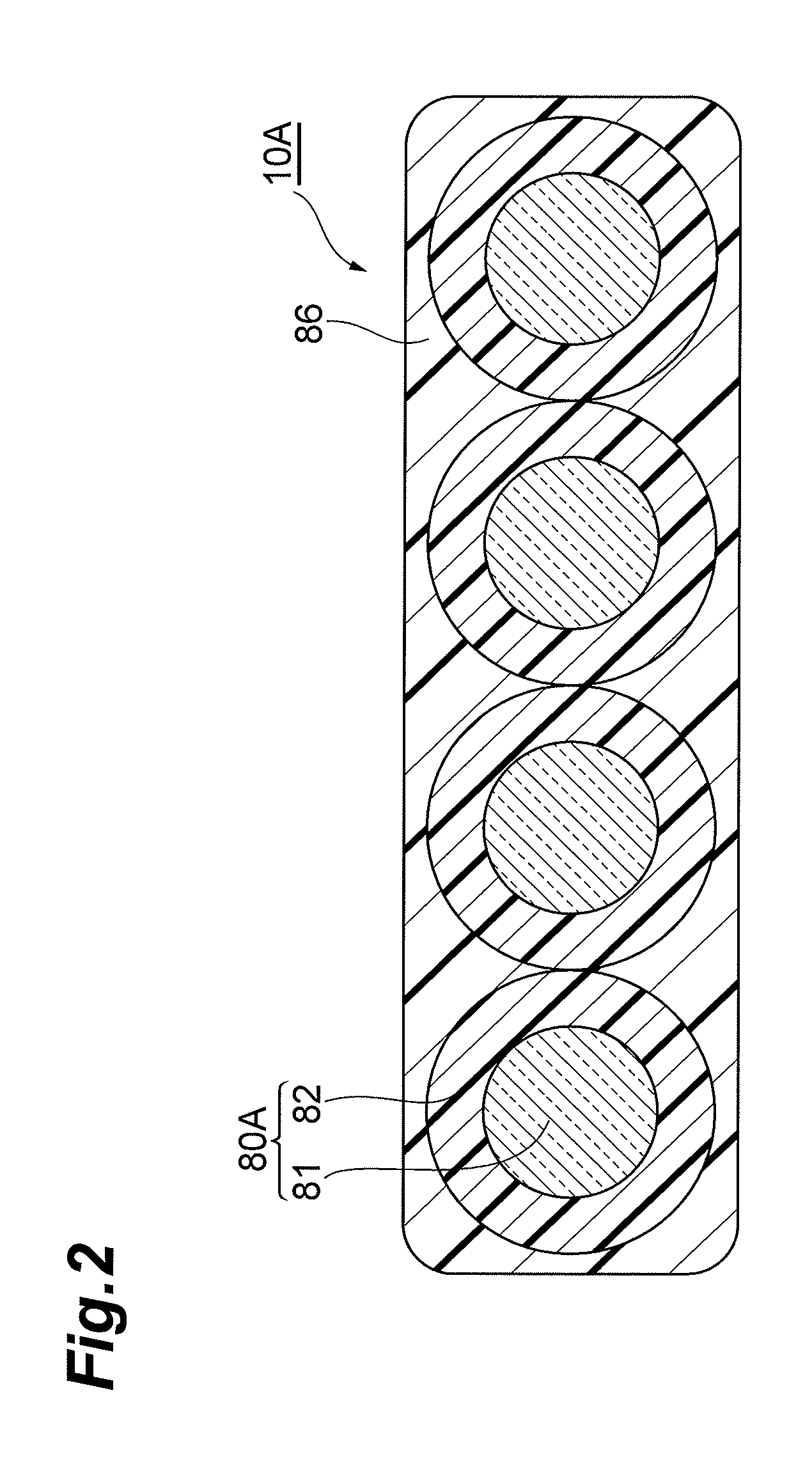

Optical cable

InactiveUS20130129288A1Reduced flexibilityNot easy to bendFibre mechanical structuresEngineeringTension member

An optical cable comprises an optical fiber ribbon, a tension member and a sheath. The optical fiber ribbon is constructed by integrating a plurality of optical fibers arranged in parallel. The sheath is provided so as to surround the optical fiber ribbon. The sheath is used for protecting the optical cable. One optical fiber ribbon is arranged twistably within an inner space surrounded by the sheath.

Owner:SUMITOMO ELECTRIC IND LTD

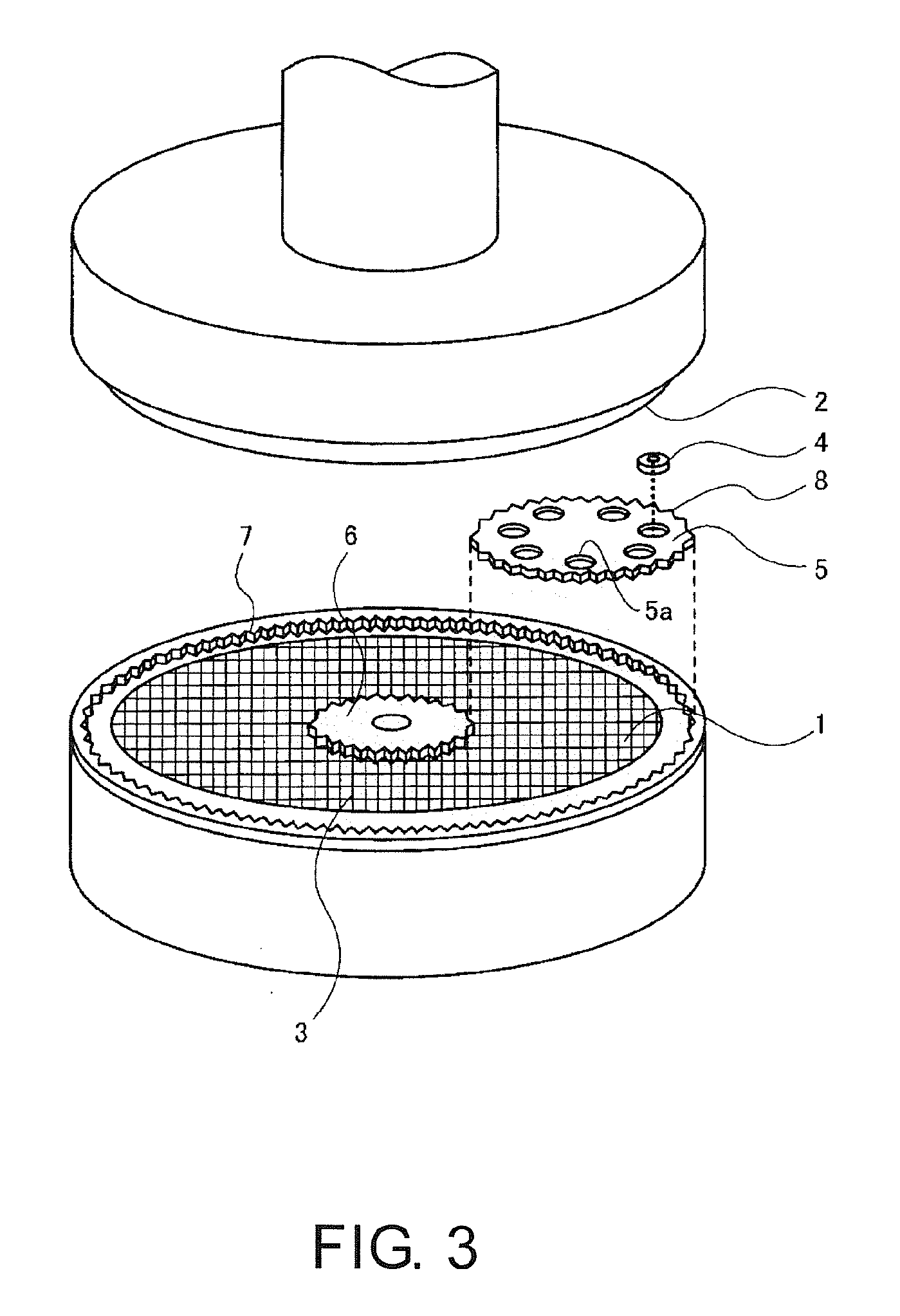

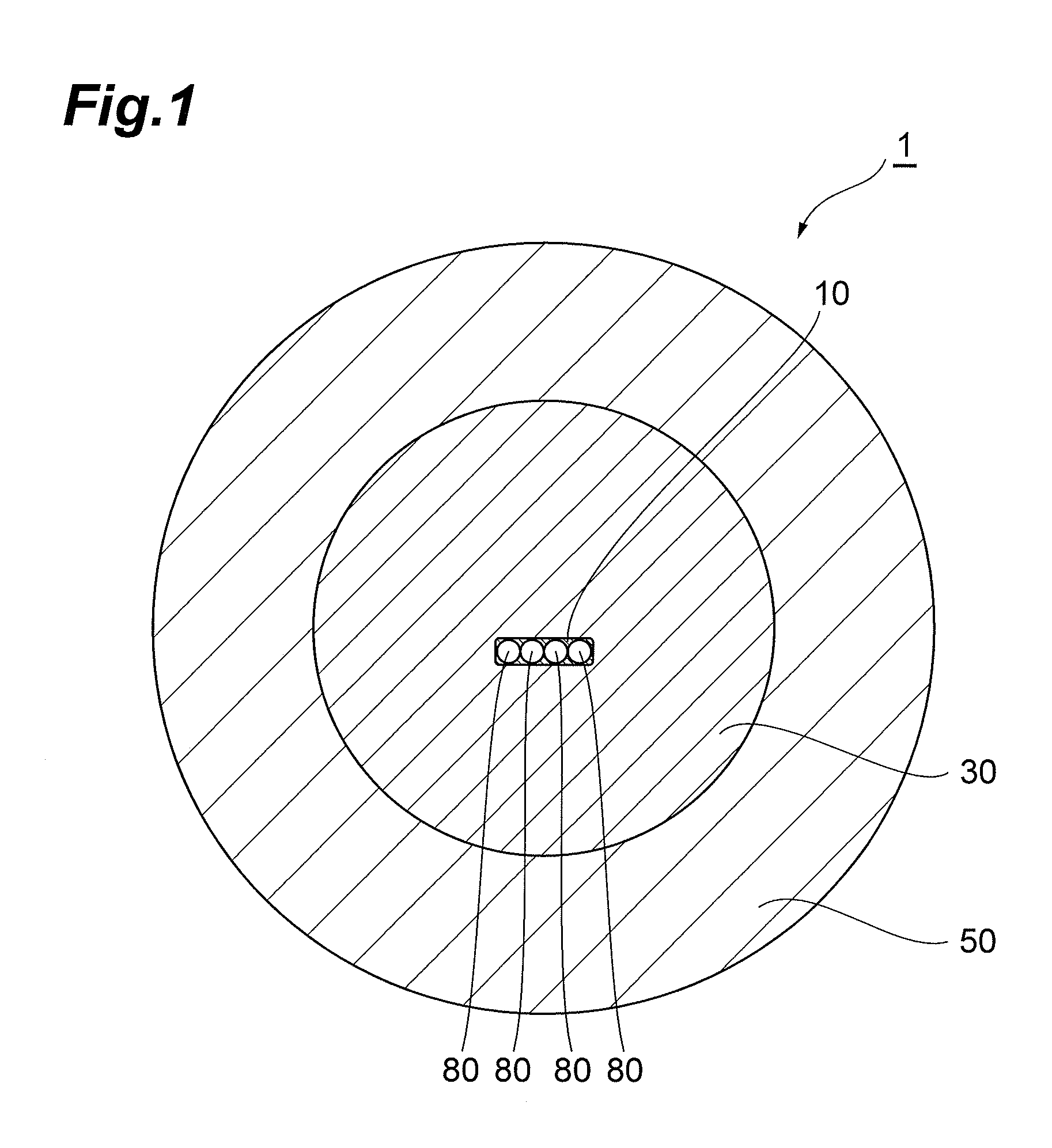

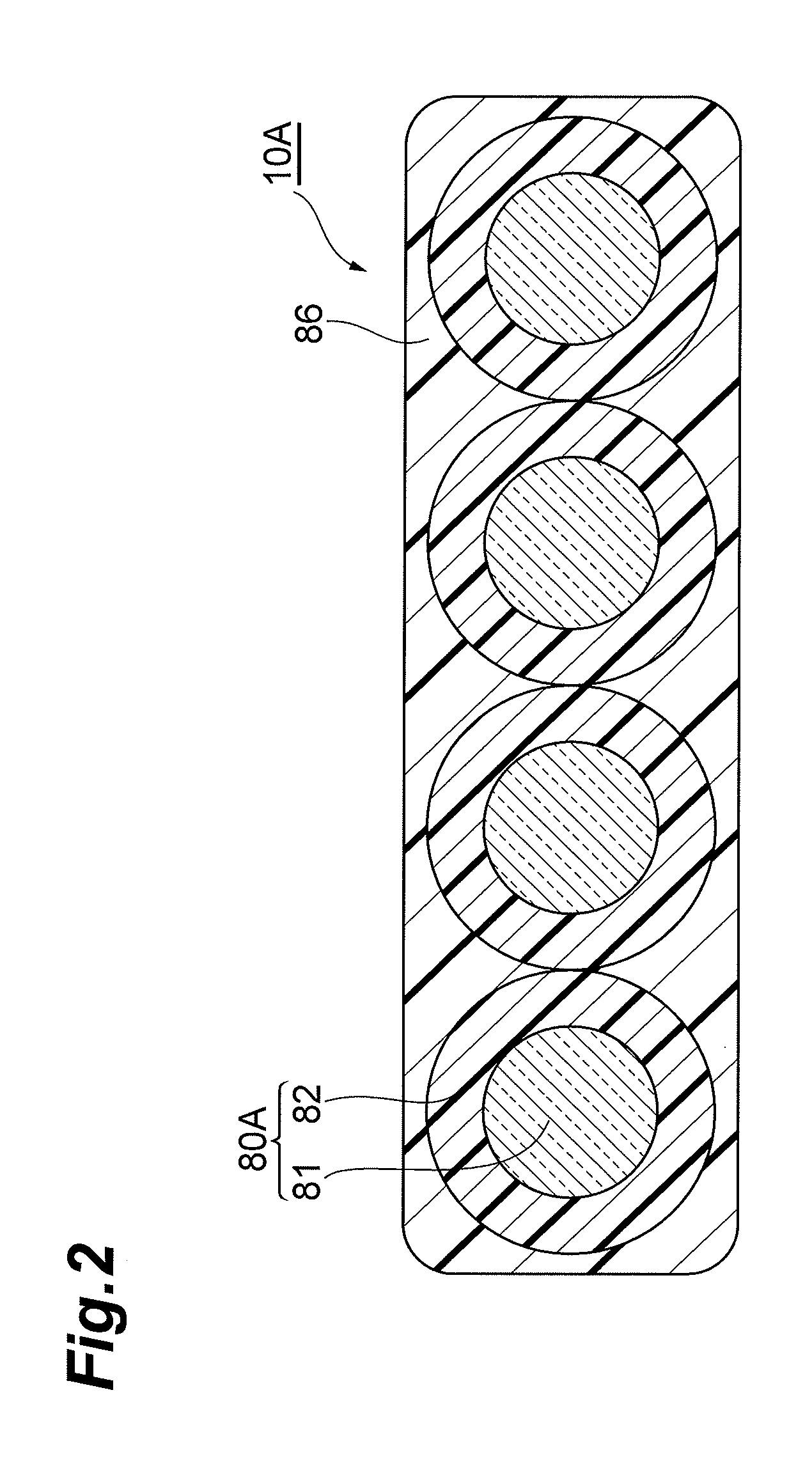

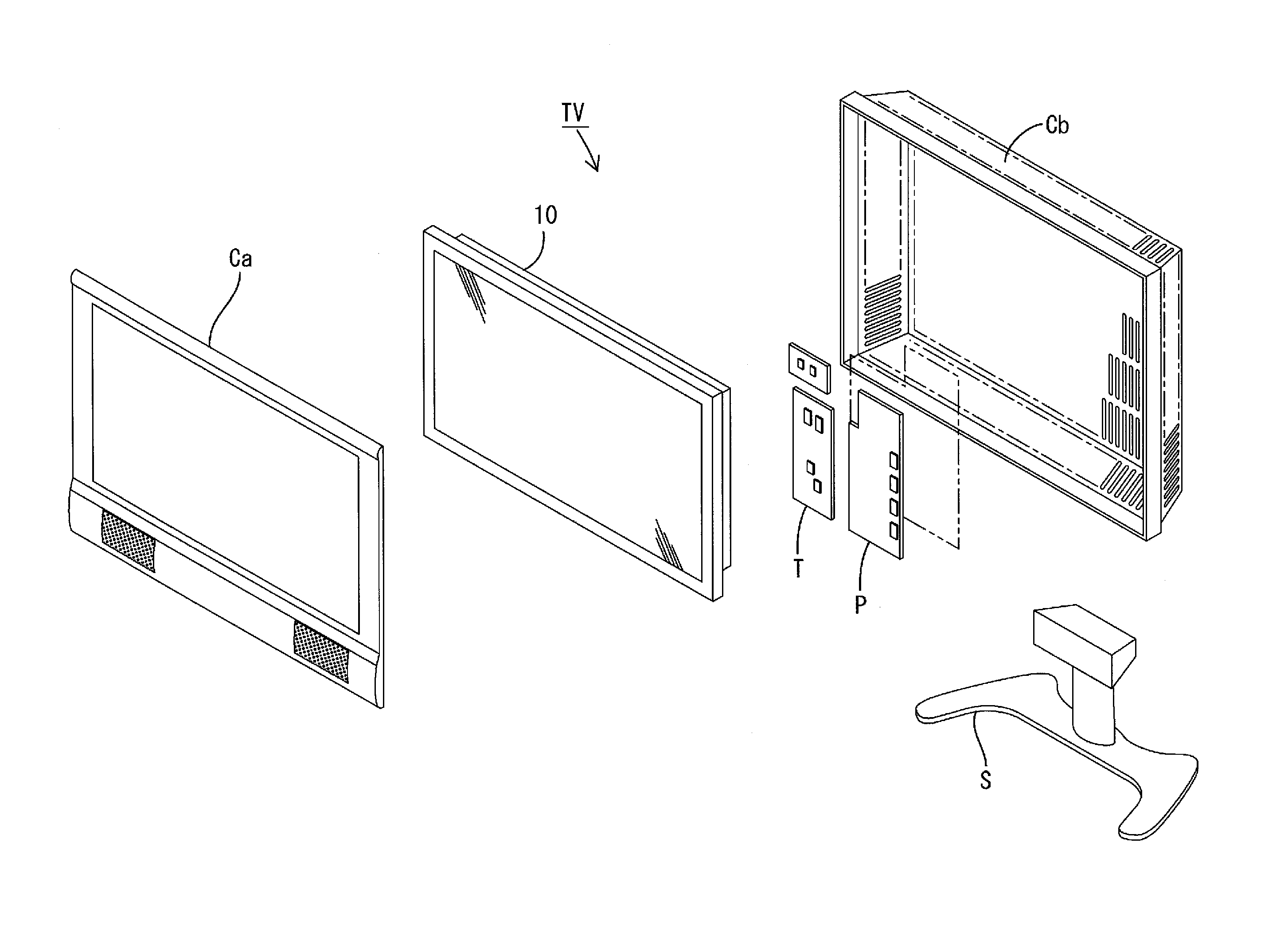

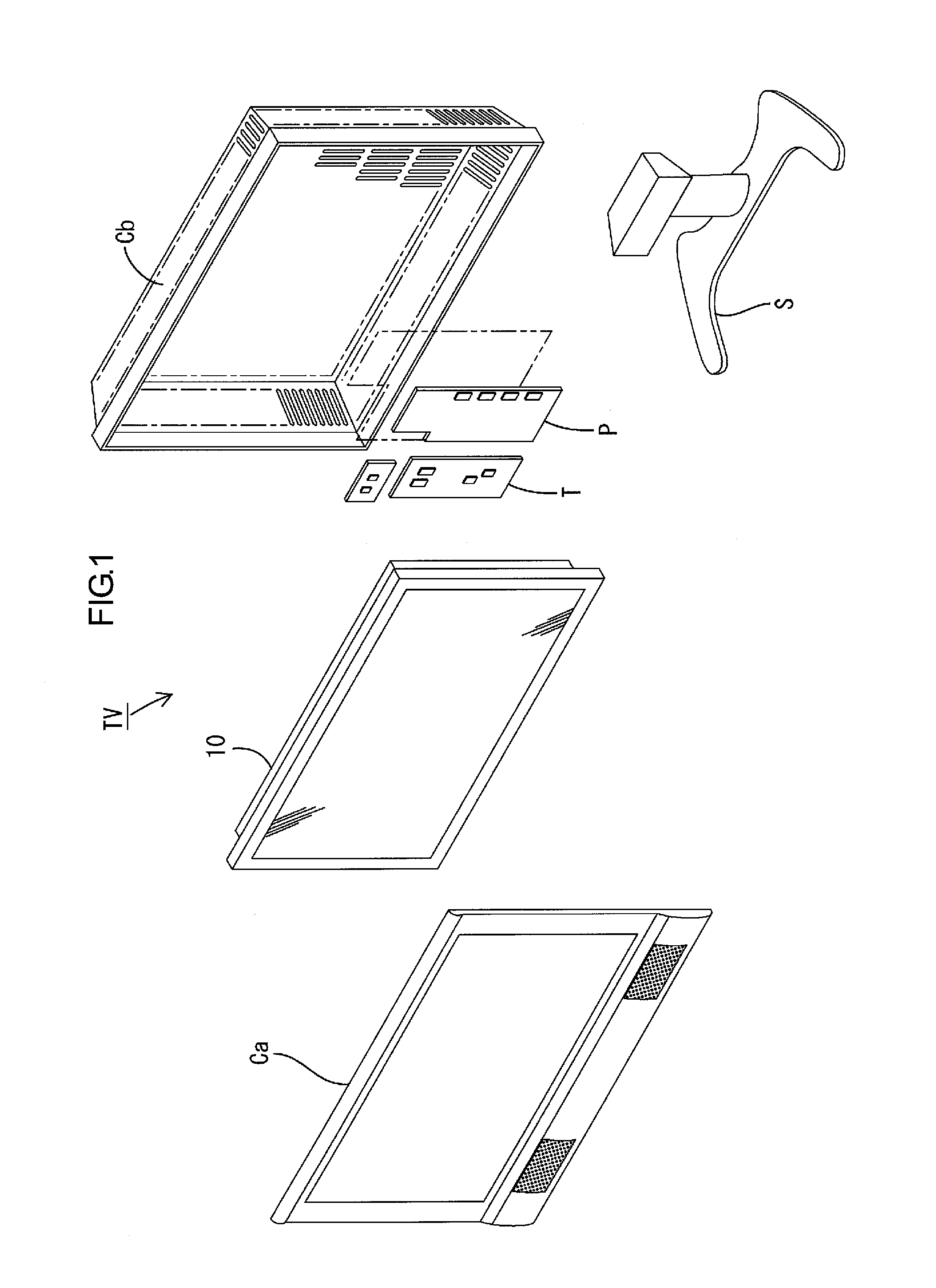

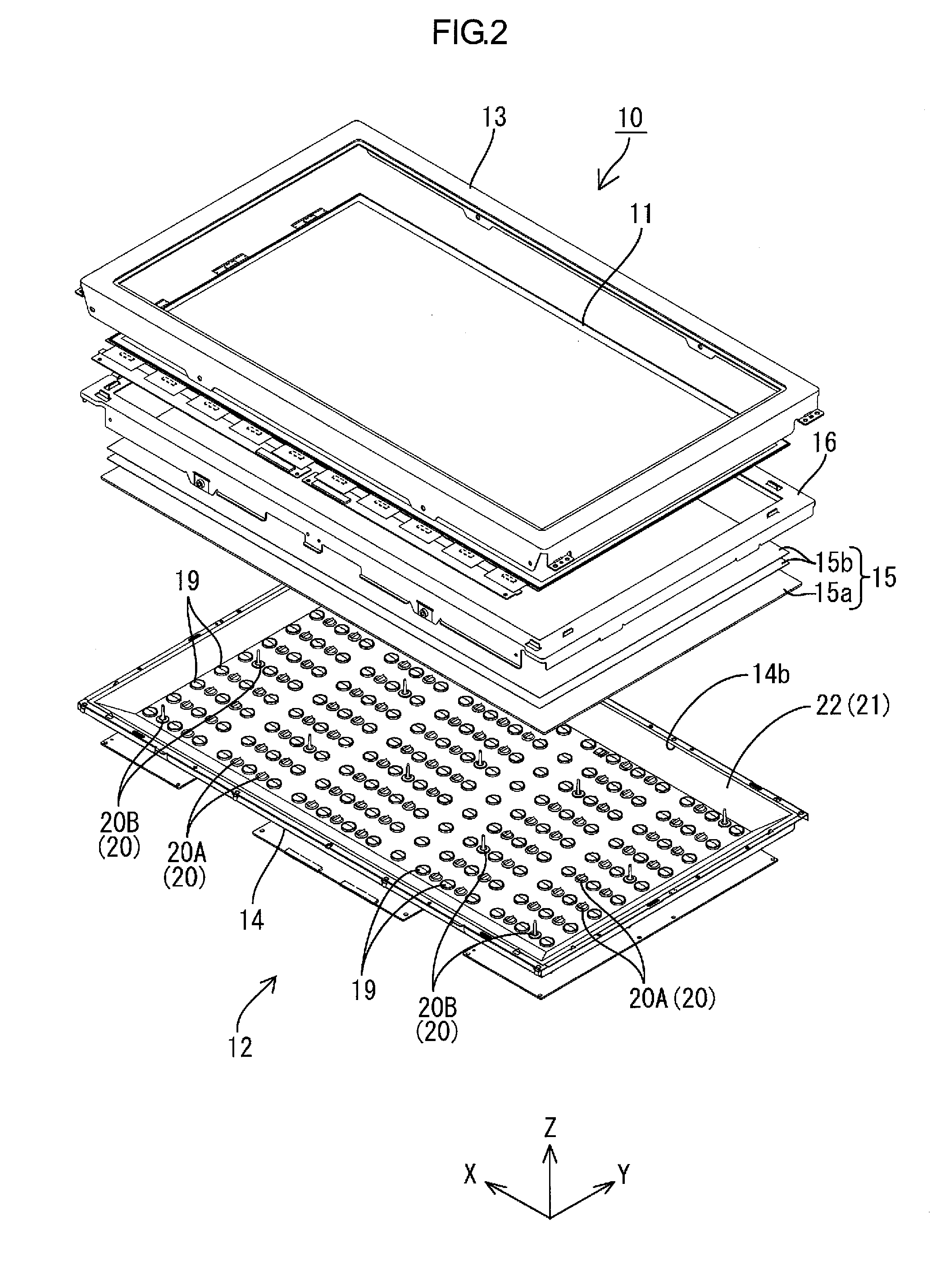

Lighting device, display device and television receiver

InactiveUS20120120324A1Avoid operating efficiencyWorkability in poorTelevision system detailsPoint-like light sourceTelevision receiversDisplay device

A backlight unit 12 according to the present invention includes LEDs 17 as light sources, an LED board 18 mounting the LEDs 17 thereon, a chassis 14 that stores the LED board 18 therein and includes an attachment hole 14e, a body portion 24 that sandwiches the LED board 18 between the body portion 24 and the chassis 14 and holds the LED board 18, and a board holding member 20 including an attachment portion 25 that is protruded from the body portion 24 toward the chassis 14 to be inserted into the attachment hole 14e, and the board holding member 20 is configured to be rotatable along a plate surface of the chassis 14 between a holding position at which the attachment portion 25 overlaps with an edge of the attachment hole 14e in a plan view and sandwiches the edge of the attachment hole 14e between the attachment portion 25 and the body portion 24 and a non-holding position at which the attachment portion 25 does not overlap with the edge of the attachment hole 14e in a plan view and attaching and detaching of the attachment portion 25 from the attachment hole 14e is allowed.

Owner:SHARP KK

Liquid resin composition and cured product using the liquid resin composition

ActiveUS20100204404A1Low viscosityImprove grafting efficiencyAdditive manufacturing apparatusLiquid stateVolume average

An object of the invention is to provide a liquid resin composition with low viscosity while containing polymer particles. Further, another object of the invention is to provide a liquid resin composition containing a large quantity of polymer particles without increasing the viscosity of the liquid resin composition. A liquid resin composition of the invention is comprising a liquid resin component and polymer particles each having an elastic core layer, an intermediate layer formed with a monomer having two or more double bonds and coated on the core layer, and a shell layer coated on the intermediate layer; wherein the polymer particles are dispersed at a ratio of their volume average particle diameter (Mv) to their number average particle diameter (Mn) of 3 or lower.

Owner:KANEKA CORP

Bulldozer

ActiveUS20160115671A1Reduce the overall heightDeterioration of workability can be preventedInternal combustion piston enginesExhaust apparatusEngineeringInjector

A first exhaust treatment device, a second exhaust treatment device, and a relay connection pipe are disposed in front of an engine of a bulldozer. A relay connection pipe connects the first and second exhaust treatment devices. An injector assembly is attached to the relay connection pipe. The first exhaust treatment device, the relay connection pipe, and the second exhaust treatment device are arranged in sequence such that longitudinal directions thereof extend along the vehicle lateral direction. An attachment surface for the injector on the relay connection pipe is provided on an offset portion of the relay connection pipe at a connection portion between the first exhaust treatment device and the relay connection pipe. The distance between the injector assembly and a first side surface of the engine cover closest to the injector assembly is substantially equal to the distance between the first side surface and the first exhaust treatment device.

Owner:KOMATSU LTD

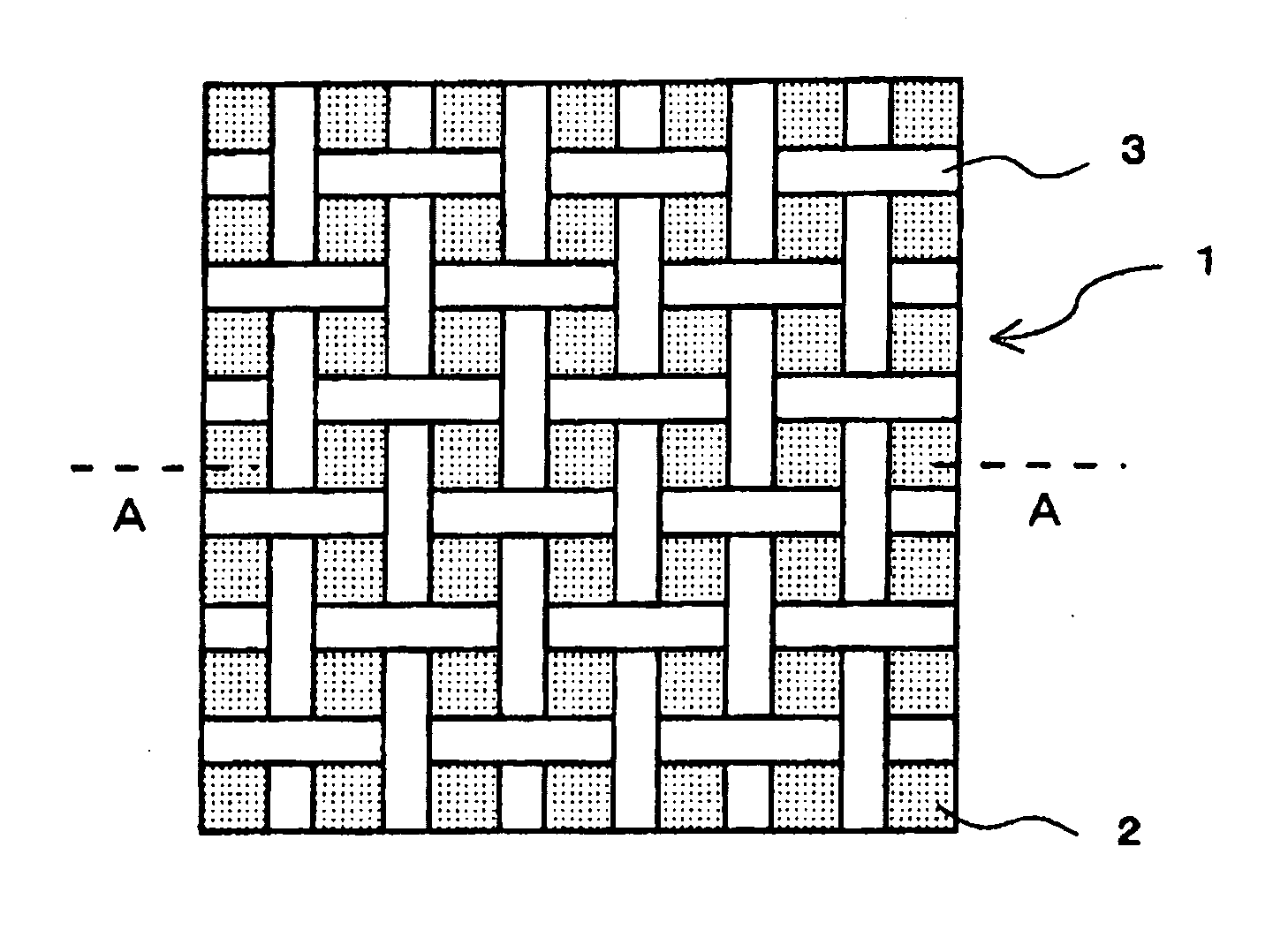

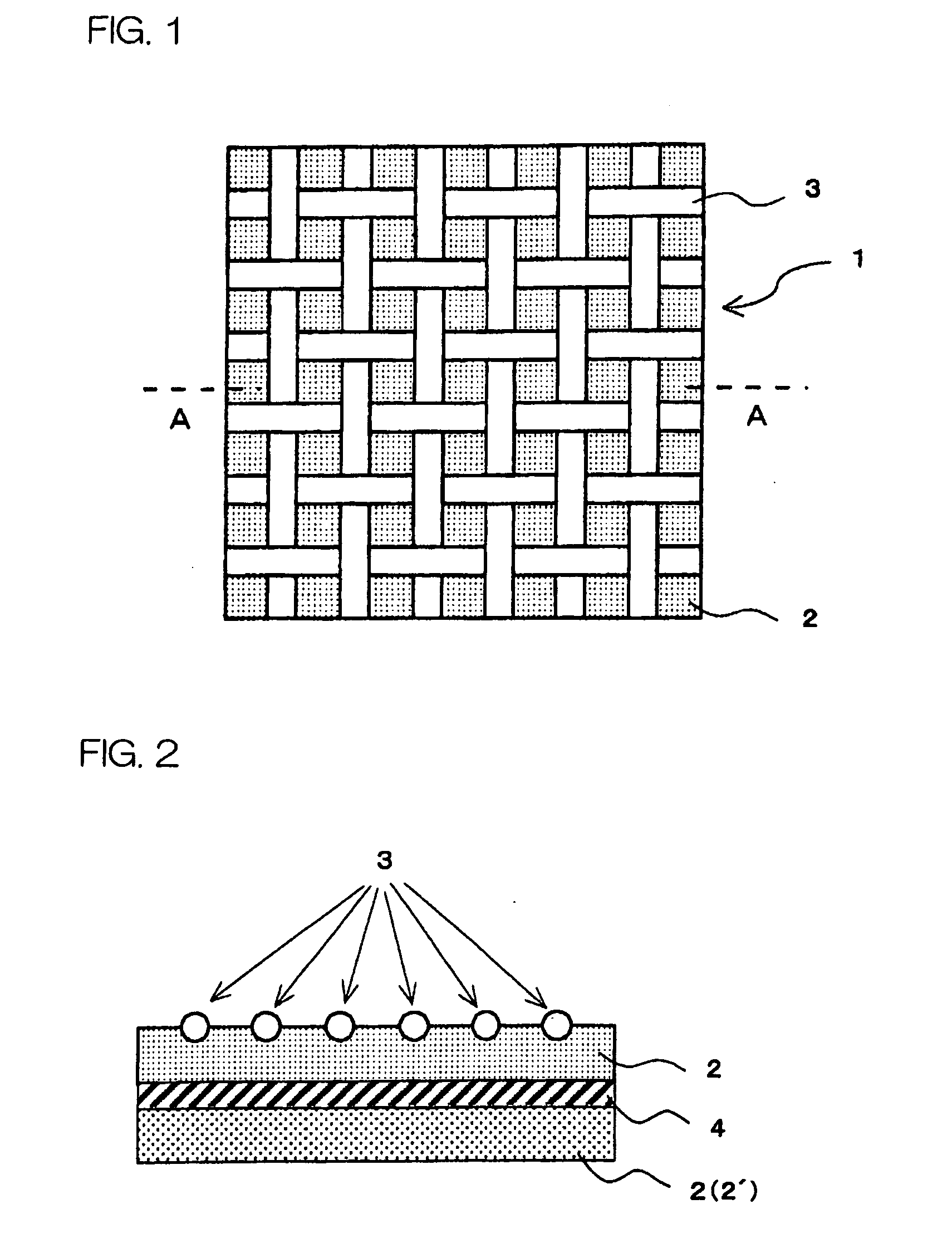

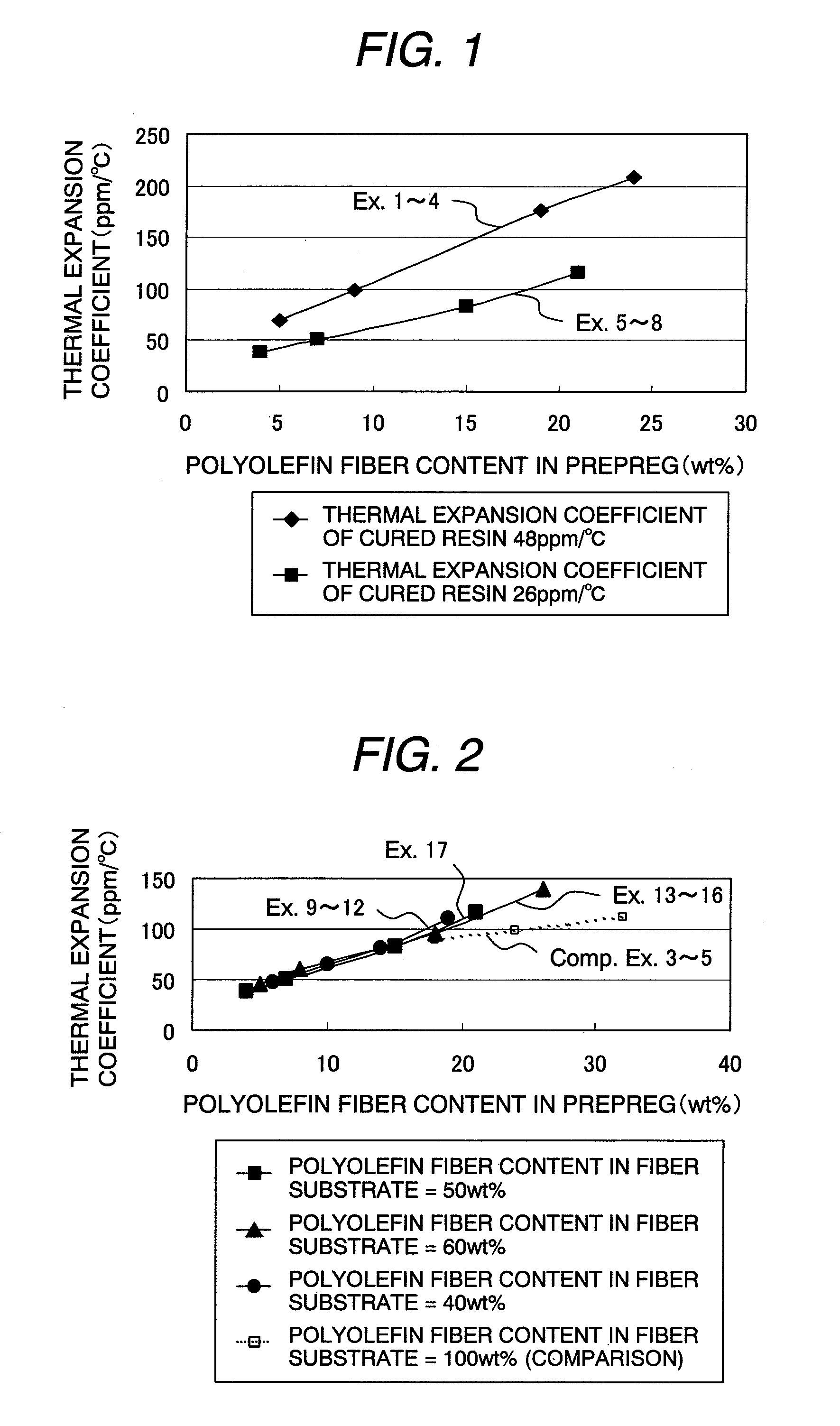

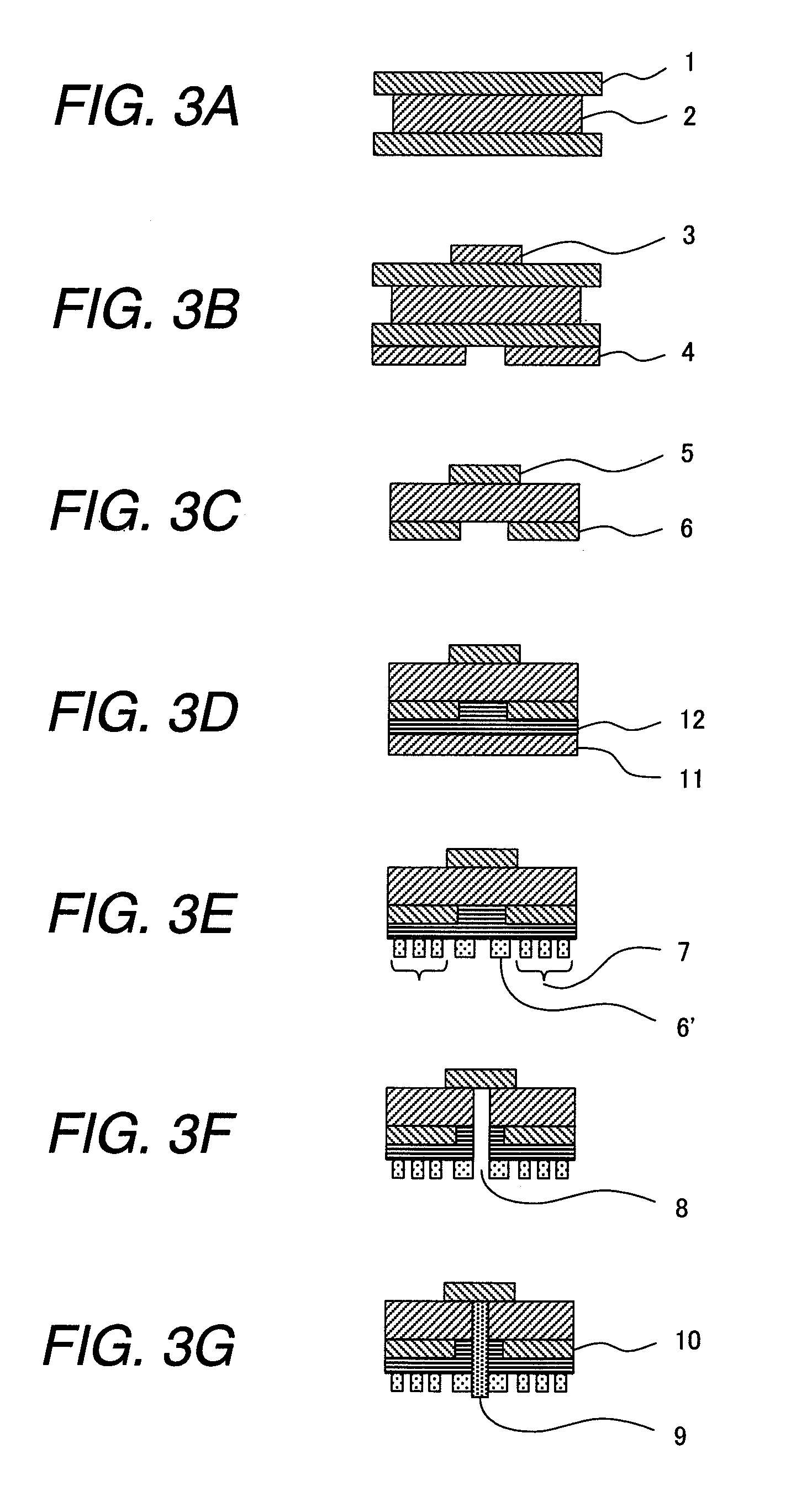

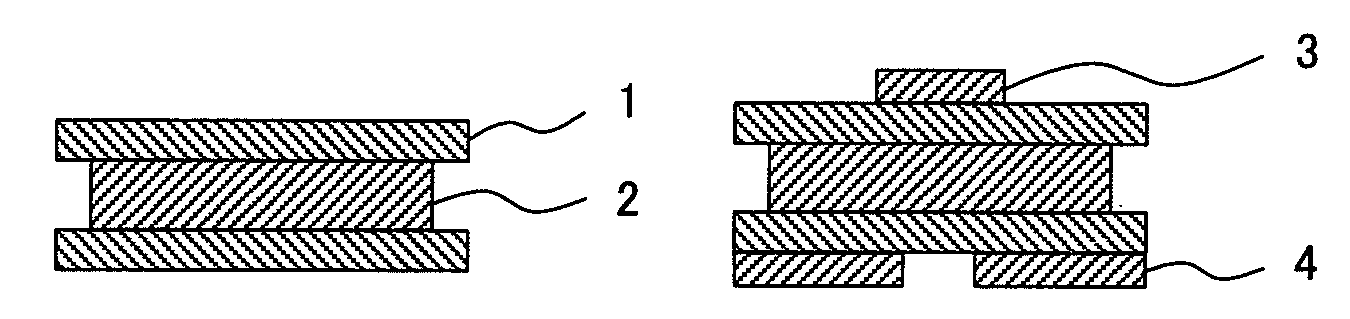

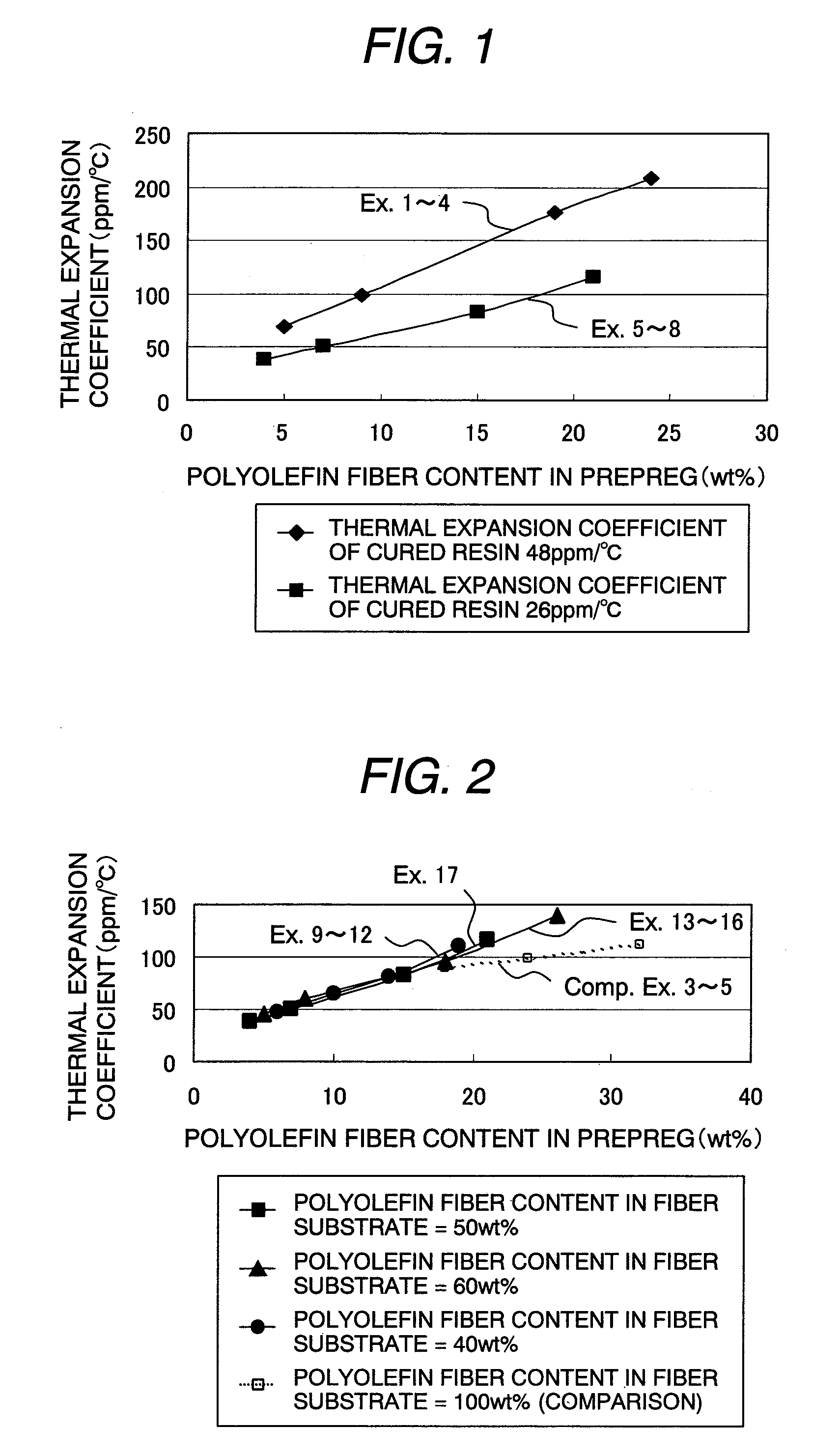

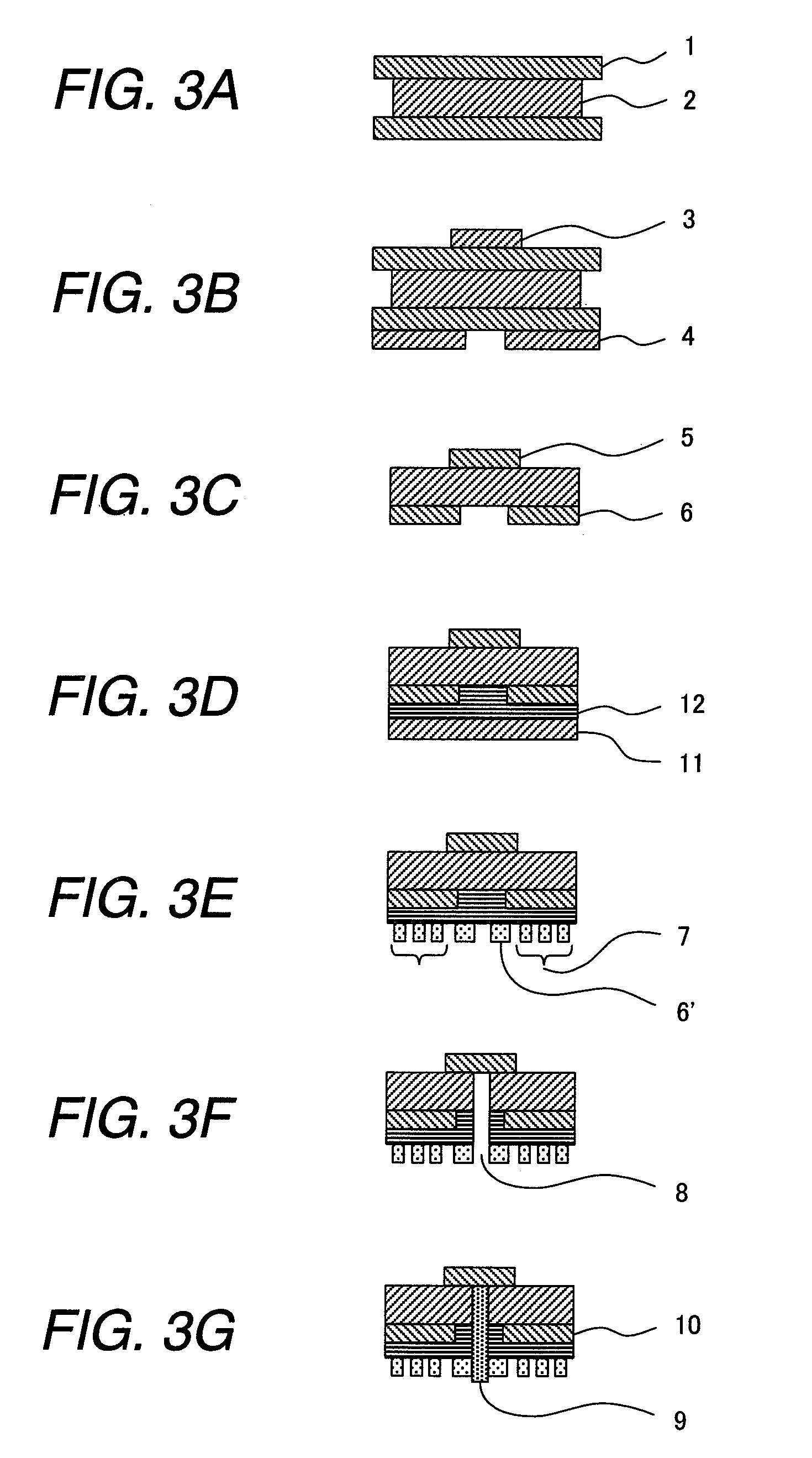

Prepreg and its application products for low thermal expansion and low dielectric tangent

ActiveUS20090178832A1Reduction factorIncrease material costSynthetic resin layered productsPrinted circuit manufactureGlass fiberPolyolefin

A prepreg comprising composite woven cloth or non-woven cloth composed of glass fiber and polyolefin fiber that are a main part of the cloth and a thermosetting resin composition that gives a cured product having a low thermal expansion coefficient, wherein the thermal expansion coefficient of the cured resin composition at 50 to 100 ° C. is 50 ppm / ° C. or less. A printed circuit board, multi layered circuit board, and electronic part are disclosed.

Owner:HITACHI CHEM CO LTD

Optical cable

InactiveUS8989543B2Reduced flexibilityNot easy to bendFibre mechanical structuresEngineeringTension member

Owner:SUMITOMO ELECTRIC IND LTD

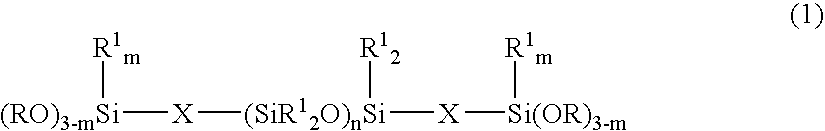

Room temperature-curable organopolysiloxane composition

A room temperature-curable organopolysiloxane composition is provided. The composition comprises(A) 100 parts by weight of a organopolysiloxane represented by the following general formula (1):wherein R is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, R1 is independently a substituted or unsubstituted monovalent hydrocarbon group containing 1 to 10 carbon atoms; n is an integer of at least 10; X is oxygen atom or an alkylene group containing 2 to 5 carbon atoms, and m is independently an integer of 0 or 1; or a mixture of such organopolysiloxane;(B) 50 to 150 parts by weight of a colloidal calcium carbonate having a specific surface area measured by BET method of at least 10 m2 / g;(C) 100 to 200 parts by weight of a heavy calcium carbonate having a specific surface area measured by BET method of up to 8 m2 / g;(D) 1 to 25 parts by weight of an organosilicon compound having at least 3 hydrolyzable groups bonded to silicon atom in one molecule represented byR2aSi(OR3)4-a wherein R2 is a monovalent hydrocarbon group containing 1 to 12 carbon atoms, R3 is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, and a is 0 or 1; or its partial hydrolysate; and(E) 0.01 to 10 parts by weight of a curing catalyst. The mass ratio of the component (B) to the component (C) is less than 1.

Owner:SHIN ETSU CHEM IND CO LTD

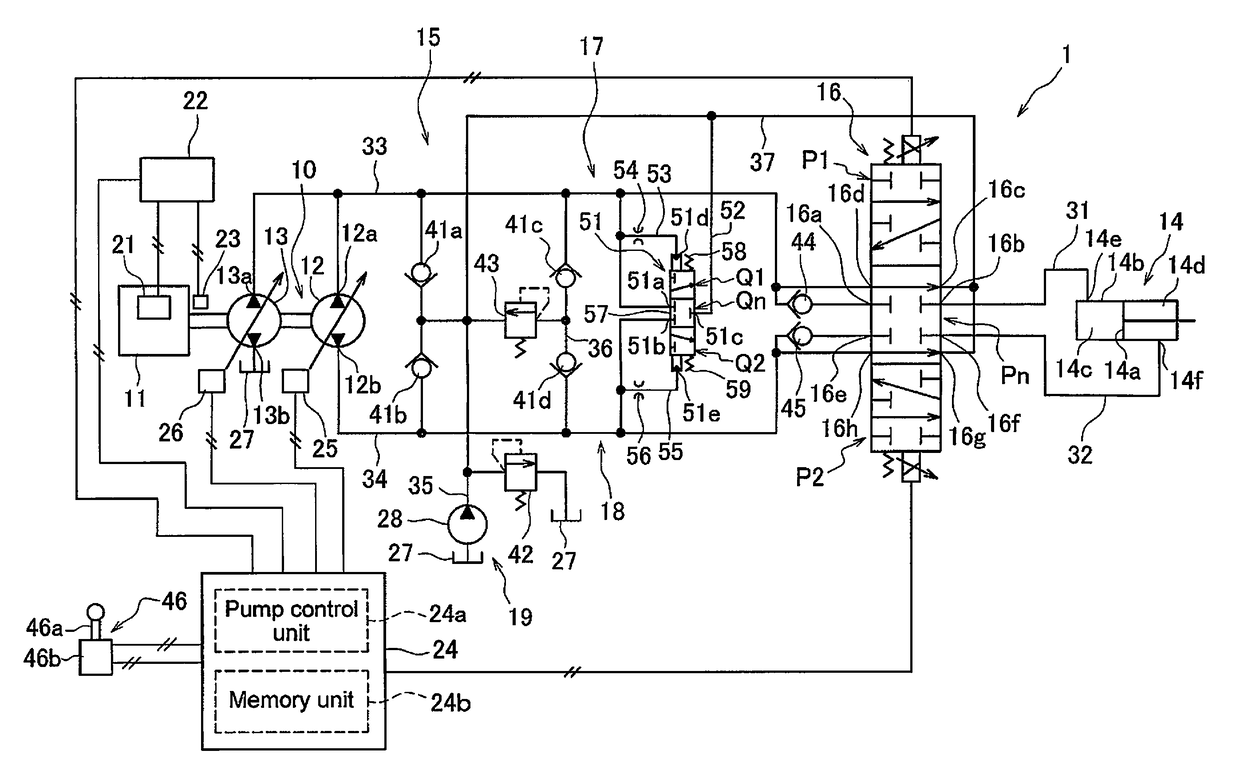

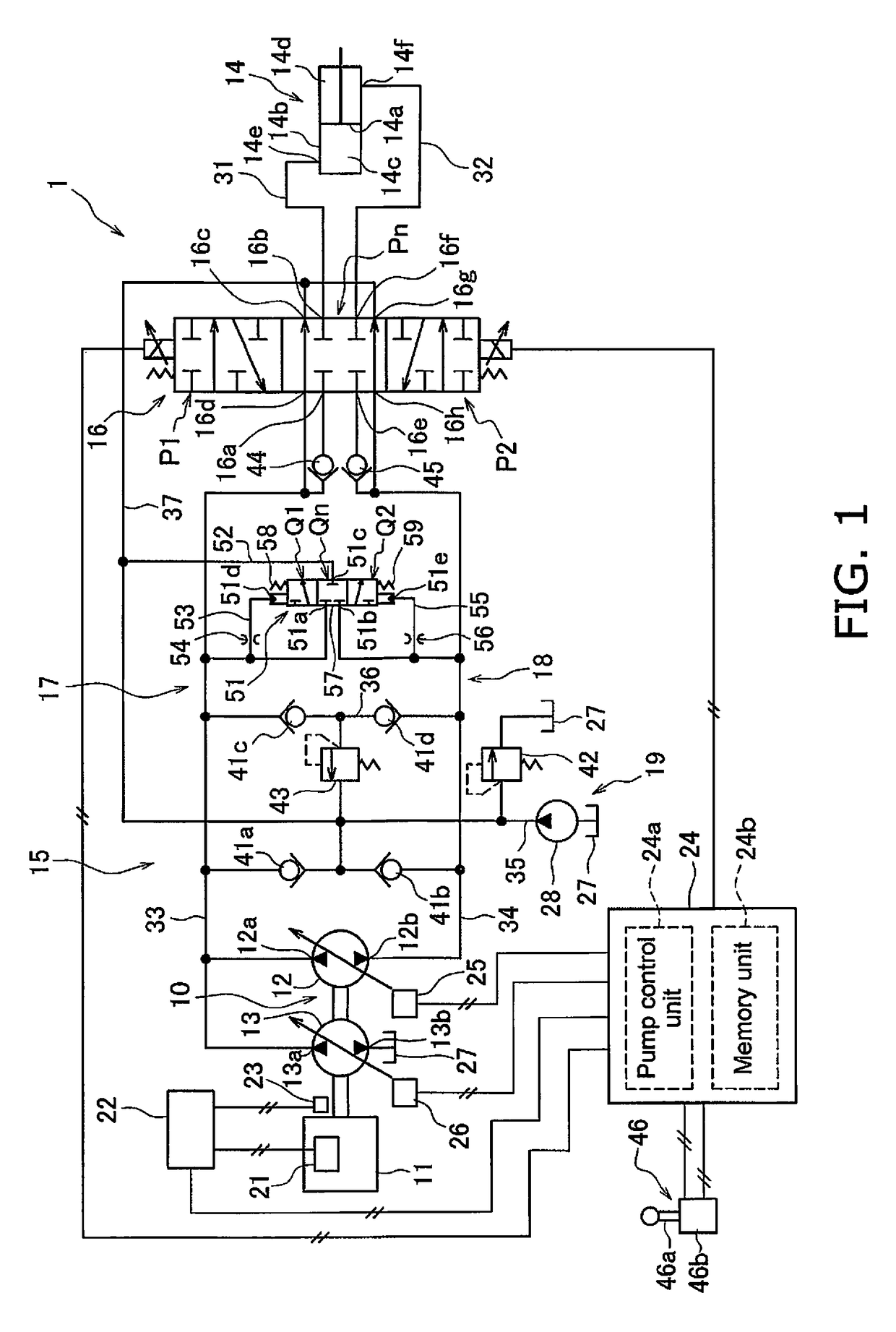

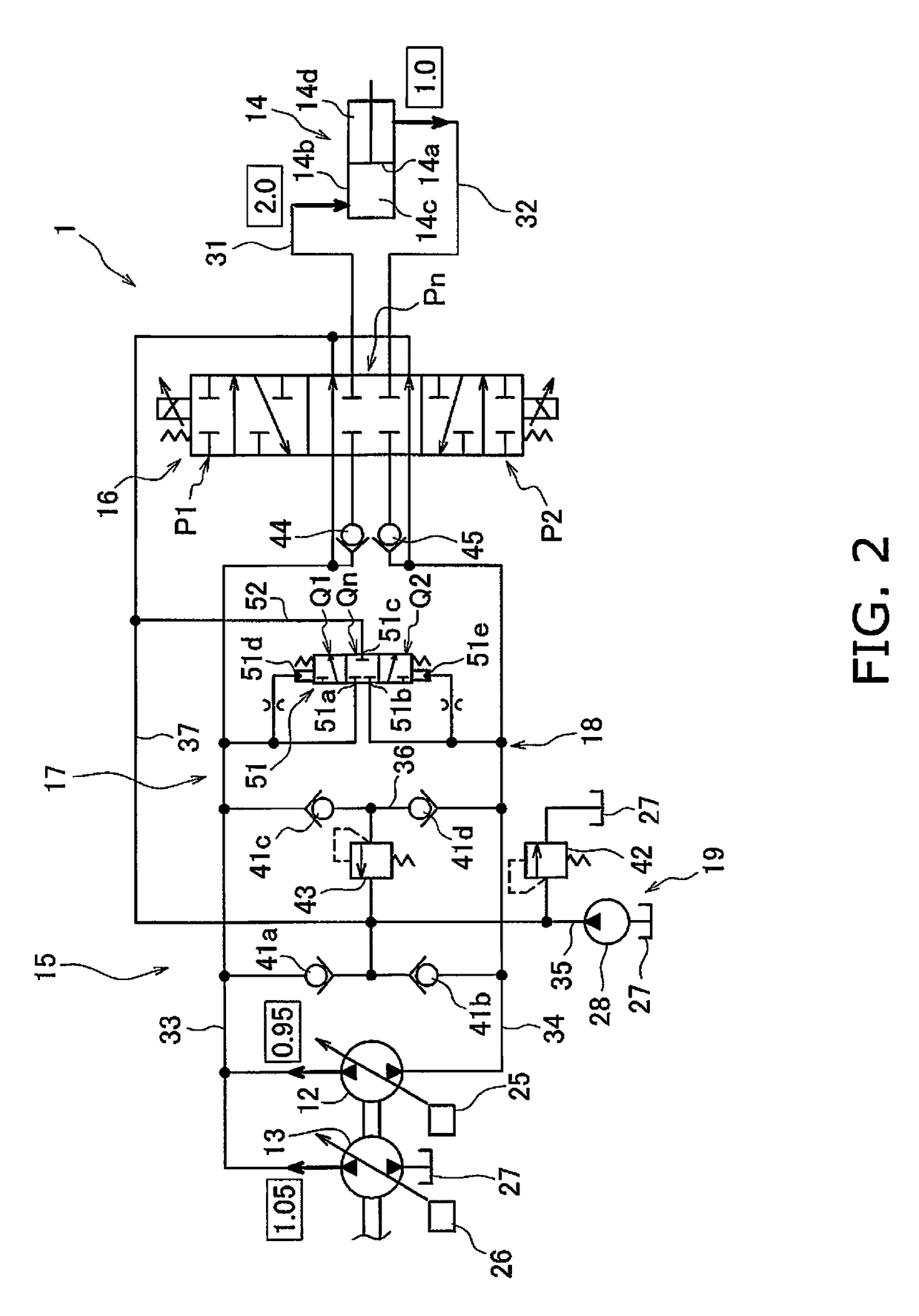

Hydraulic drive system

InactiveUS9790966B2Reduce stepsWorkability is degradedServomotorsSoil-shifting machines/dredgersShuttle valveMechanical engineering

A shuttle valve connects a second flowpath and a drain flowpath when the hydraulic pressure in a first flowpath is greater than the hydraulic pressure in the second flowpath. The shuttle valve connects the first flowpath and the drain flowpath when the hydraulic pressure in a second flowpath is greater than the hydraulic pressure in the first flowpath. The ratio between the pressure receiving area of a first pressure section and the pressure receiving area of a second pressure section is the same as the ratio between the pressure receiving area of a first chamber side and the pressure receiving area of a second chamber side of a cylinder rod.

Owner:KOMATSU LTD

Bulldozer

ActiveUS9175455B2Workability is degradedDeterioration of workability is preventedExhaust apparatusSilencing apparatusEngineeringFront edge

A bulldozer includes a blade, an engine, a first exhaust treatment device, a second exhaust treatment device, a relay connection pipe, and an engine cover. The first exhaust treatment device is disposed in front of the engine and lower than the upper surface thereof. The second exhaust treatment device is disposed above the first exhaust treatment device. The relay connection pipe is disposed above the first exhaust treatment device and below the second exhaust treatment device. The longitudinal directions of the first and second exhaust treatment devices extend along the vehicle lateral direction. As seen from the top of the vehicle, the second exhaust treatment device overlaps at least a part of the first exhaust treatment device. As seen from the side of the vehicle, the front edge of the first exhaust treatment device is positioned forward of the front edge of the second exhaust treatment device.

Owner:KOMATSU LTD

Heat exchanger made of an aluminum alloy

InactiveUS6523605B2Improve corrosion resistanceWorkability is degradedCorrosion preventionHeat exchanger casingsPlate heat exchangerFilling materials

Owner:FURUKAWA SKY ALUMINUM CORP

Liquid resin composition and cured product using the liquid resin composition

ActiveUS8742014B2Low viscosityImprove grafting efficiencyAdditive manufacturing apparatusLiquid stateDouble bond

Owner:KANEKA CORP

Semiconductor integrated circuit

ActiveUSRE45988E1Workability is degradedLow costSolid-state devicesSemiconductor devicesSemiconductorFolded cell

Disclosed herein is a semiconductor integrated circuit, wherein a desired circuit is formed by combining and laying out a plurality of standard cells and connecting the cells together, of which the cell length, i.e., the gap between a pair of opposed sides, is standardized, the plurality of standard cells forming the desired circuit include complementary in-phase driven standard cells, each of which includes a plurality of complementary transistor pairs that are complementary in conductivity type to each other and have their gate electrodes connected together, and N (≧2) pairs of all the complementary transistor pairs are driven in phase, and the size of the standardized cell length of the complementary in-phase driven standard cell is defined as an M-fold cell length which is M (N≧M≧2) times the basic cell length which is appropriate to the single complementary transistor pair.

Owner:SONY GRP CORP

Rolling member, rolling bearing and process for manufacturing rolling member

ActiveUS8535457B2Workability is degradedSolution to short lifeToothed gearingsBearing componentsBall bearingManganese

The invention provides a deep groove ball bearing which exhibits a long life even in a high-temperature environment or an environment involving the penetration of water in spite of its low alloying element content. The outer race, inner race and ball constituting the bearing are made of a steel which contains 0.3 to 0.4% of carbon, 0.3 to 0.7% of silicon, 0.3 to 0.8% of manganese, 0.5 to 1.2% of nickel, 1.6 to 2.5% of chromium, 0.1 to 0.7% of molybdenum and 0.2 to 0.4 of vanadium with the balance consisting of iron and impurities and in a total content of silicon and manganese of 1.0% or below, a total content of nickel and chromium of 2.3% or above and a total content of chromium, molybdenum and vanadium of 3.0% or below. Surface hardened layers are formed in the outer race, inner race and ball respectively and the surface hardened layers exhibit hardness of 725 to 800 HV, while the maximum particle size of carbides dispersed in the surface hardened layers is 10 μm or below and the area ratio thereof is 7 to 25%. Further, the inner parts exhibit hardness of 450 to 650 HV.

Owner:NTN CORP

Pressure sensitive adhesive for optical film, pressure sensitive adhesive layer for optical film, method for manufacturing the same, pressure sensitive adhesion type optical film, and image display

InactiveUS20090233102A1Increased durabilityEasy to handlePolyureas/polyurethane adhesivesConductive materialMeth-Display device

The invention relates to a pressure-sensitive adhesive for an optical film, comprising 0.02 to 2 parts by weight of a peroxide (B) and 0.01 to 5 parts by weight of an isocyanate-based compound (C) contained in 100 parts by weight of a (meth)acrylic polymer (A) consisting primarily of an alkyl(meth)acrylate and not containing a functional group reactive with an isocyanate group. By using the invented pressure-sensitive adhesive for an optical film, there can be obtained a pressure sensitive adhesion type optical film that can suppress warping and light leakage caused by a stress accompanying a dimensional change of members such as an optical film, has high durability, is excellent in handling ability in the manufacturing process and is excellent in quality.

Owner:NITTO DENKO CORP

High tensile cold-rolled steel sheet excellent in ductility and in strain aging hardening properties, and method for producing the same

InactiveUS20030047258A1High strengthPromote formationFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention provides a high tensile cold-rolled steel sheet having superior ductility, strain age-hardening characteristics, and crash resistance properties, and also provides a manufacturing method therefor. As a particular means, a thin cold-rolled steel sheet containing 0.05% to 0.30% of C, 0.4% to 2.0% of Si, 0.7% to 3.0% of Mn, 0.08% or less of P, 0.02% or less of Al, and 0.0050% to 0.0250% of N on a mass % basis is manufactured in which N / Al is 0.3 or more. This thin cold-rolled steel sheet is heated to a temperature between (an Ac1 transformation point) and (an Ac3 transformation point+50° C.), is cooled at a cooling rate of 5 to 150° C. / second in the range of at least 600 to 500° C., and is held in the temperature range of 350 to 500° C. This steel sheet has superior ductility, strain age-hardening characteristics having a DELTATS of 50 MPa or more, and crash resistance properties.

Owner:JFE STEEL CORP

Prepreg and its application products for low thermal expansion and low dielectric tangent

ActiveUS8115105B2Low thermal expansionLow dielectric tangentPrinted circuit manufactureElectrical equipmentGlass fiberPolyolefin

A prepreg comprising composite woven cloth or non-woven cloth composed of glass fiber and polyolefin fiber that are a main part of the cloth and a thermosetting resin composition that gives a cured product having a low thermal expansion coefficient, wherein the thermal expansion coefficient of the cured resin composition at 50 to 100° C. is 50 ppm / ° C. or less, is disclosed. A printed circuit board, multi layered circuit board, and electronic part are disclosed.

Owner:HITACHI CHEM CO LTD

Bulldozer

ActiveUS9394668B2Workability is degradedLarge lateral widthInternal combustion piston enginesExhaust apparatusEngineeringInjector

A first exhaust treatment device, a second exhaust treatment device, and a relay connection pipe are disposed in front of an engine of a bulldozer. A relay connection pipe connects the first and second exhaust treatment devices. An injector assembly is attached to the relay connection pipe. The first exhaust treatment device, the relay connection pipe, and the second exhaust treatment device are arranged in sequence such that longitudinal directions thereof extend along the vehicle lateral direction. An attachment surface for the injector on the relay connection pipe is provided on an offset portion of the relay connection pipe at a connection portion between the first exhaust treatment device and the relay connection pipe. The distance between the injector assembly and a first side surface of the engine cover closest to the injector assembly is substantially equal to the distance between the first side surface and the first exhaust treatment device.

Owner:KOMATSU LTD

Rubber composition for tire tread and pneumatic tire using the same

InactiveUS7338999B2Improve wet grip performanceGood dispersionPigmenting treatmentSpecial tyresRolling resistancePolymer science

To provide a rubber composition having excellent wet grip performance while maintaining low heat build-up characteristics without lowering processability, abrasion resistance and rolling resistance. The rubber composition of the present invention comprises, based on 100 parts by weight of a diene rubber (A), 5 to 150 parts by weight of particular inorganic filler (B), 5 to 150 parts by weight of carbon black (C) having a nitrogen adsorption specific surface area of 70 to 300 m2 / g, and 1 to 20 % by weight of a silane coupling agent (D). The pneumatic tire of the present invention is obtained by using the rubber composition for the tread rubber.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com