Patents

Literature

581results about How to "Excellent impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

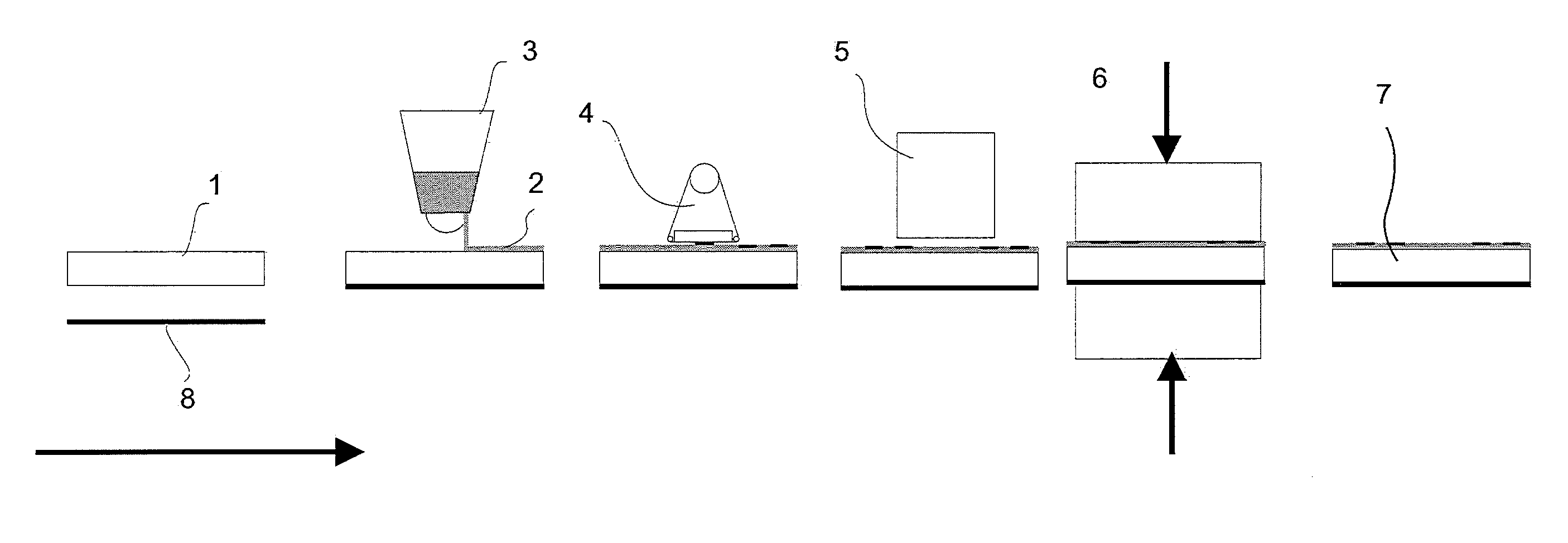

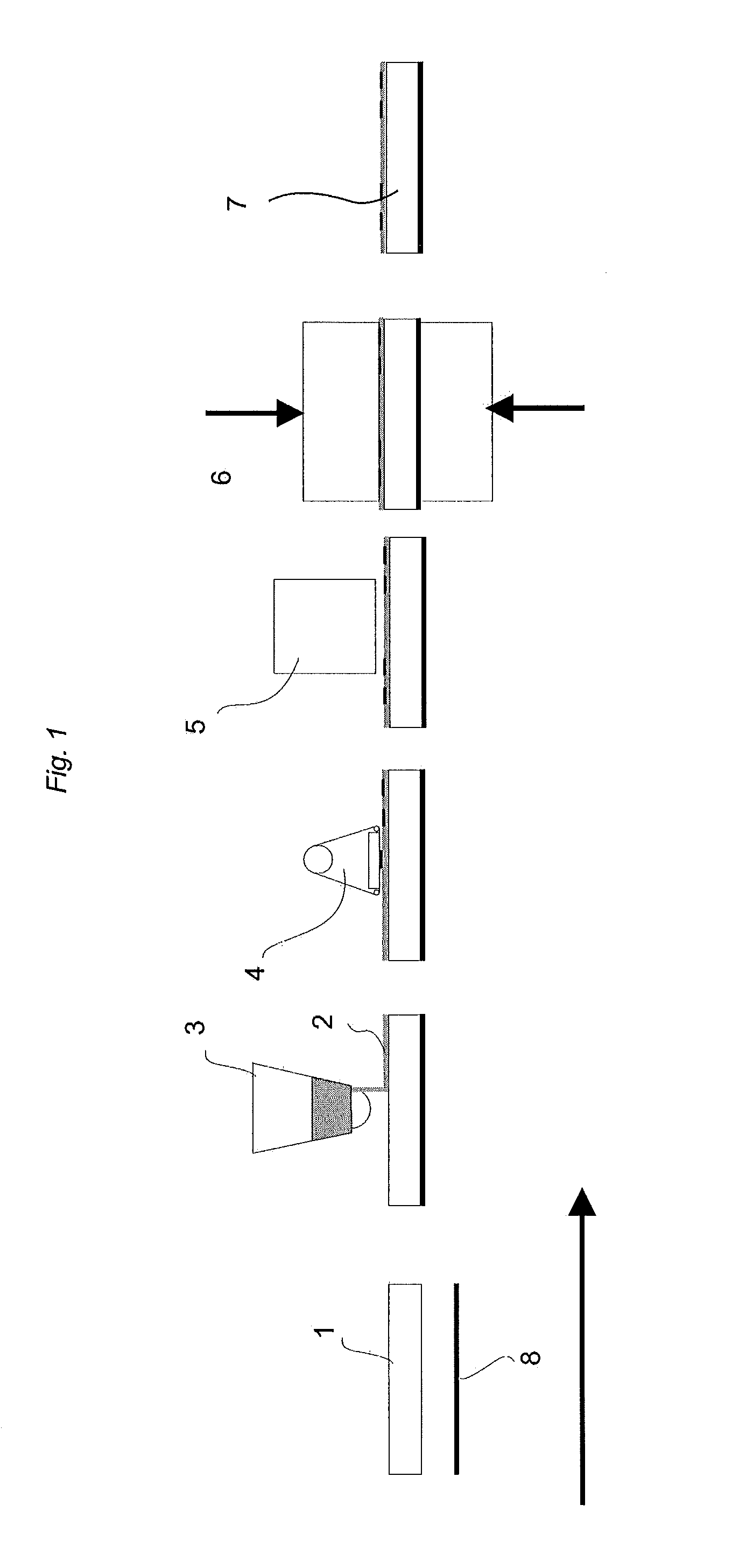

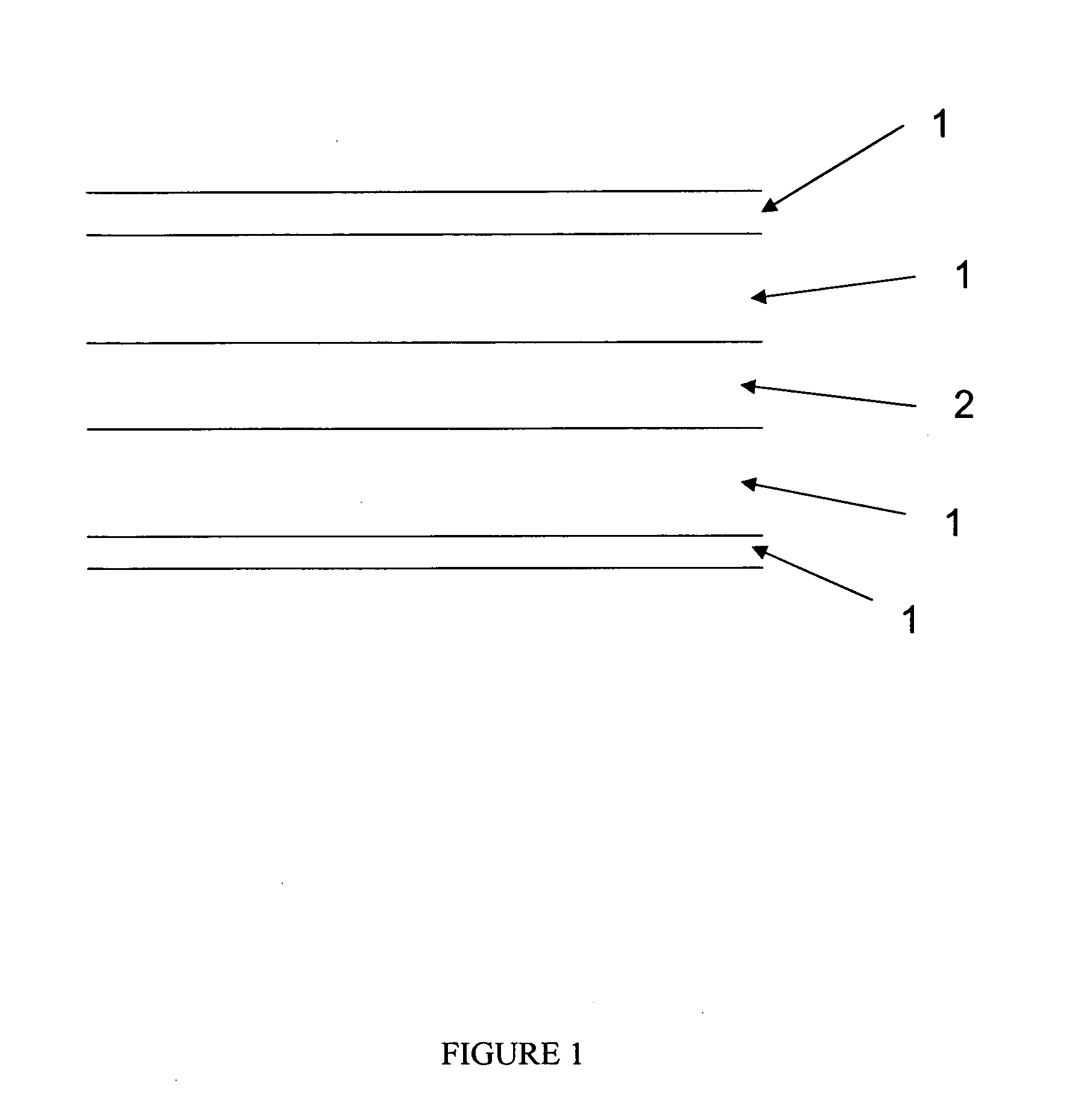

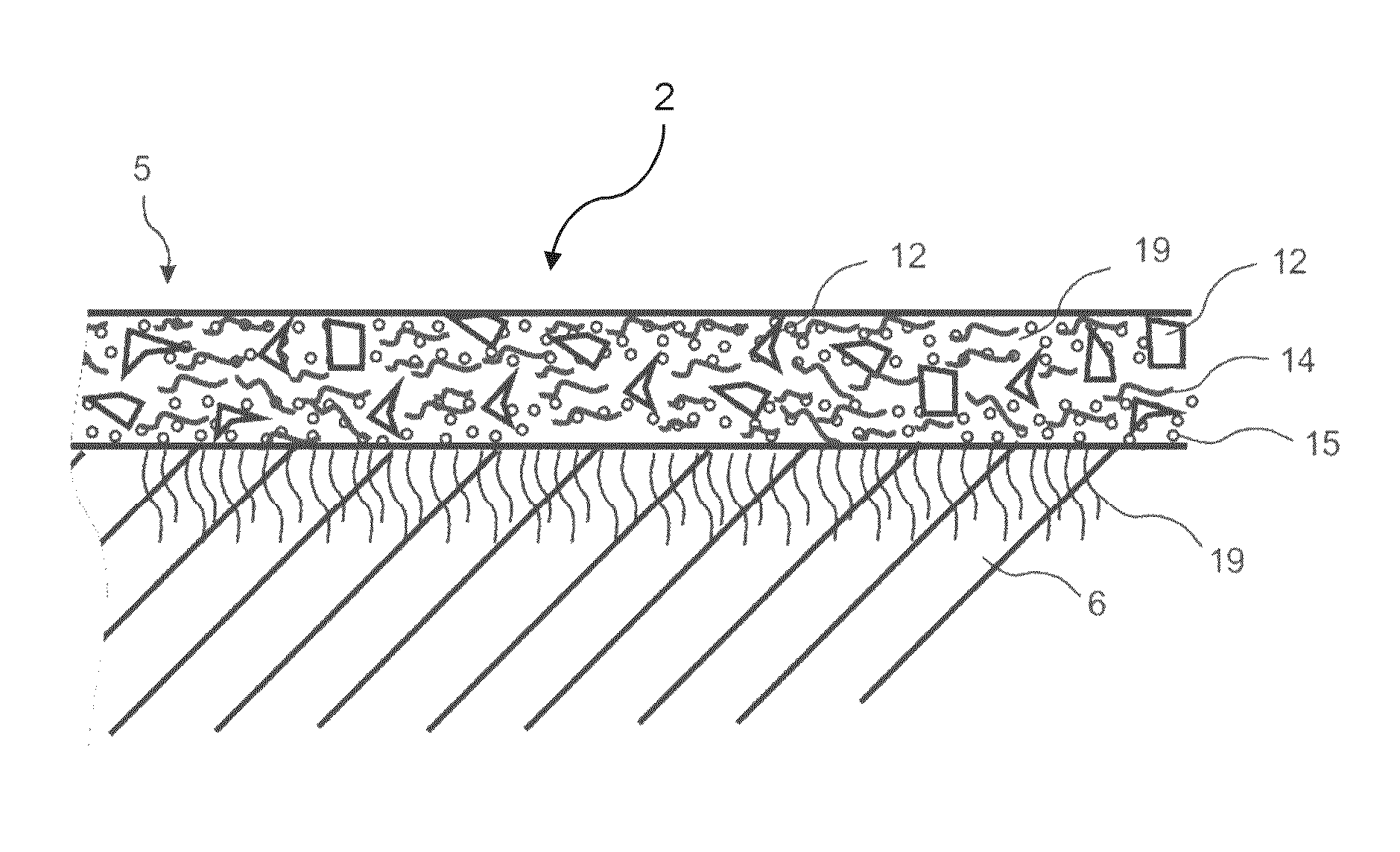

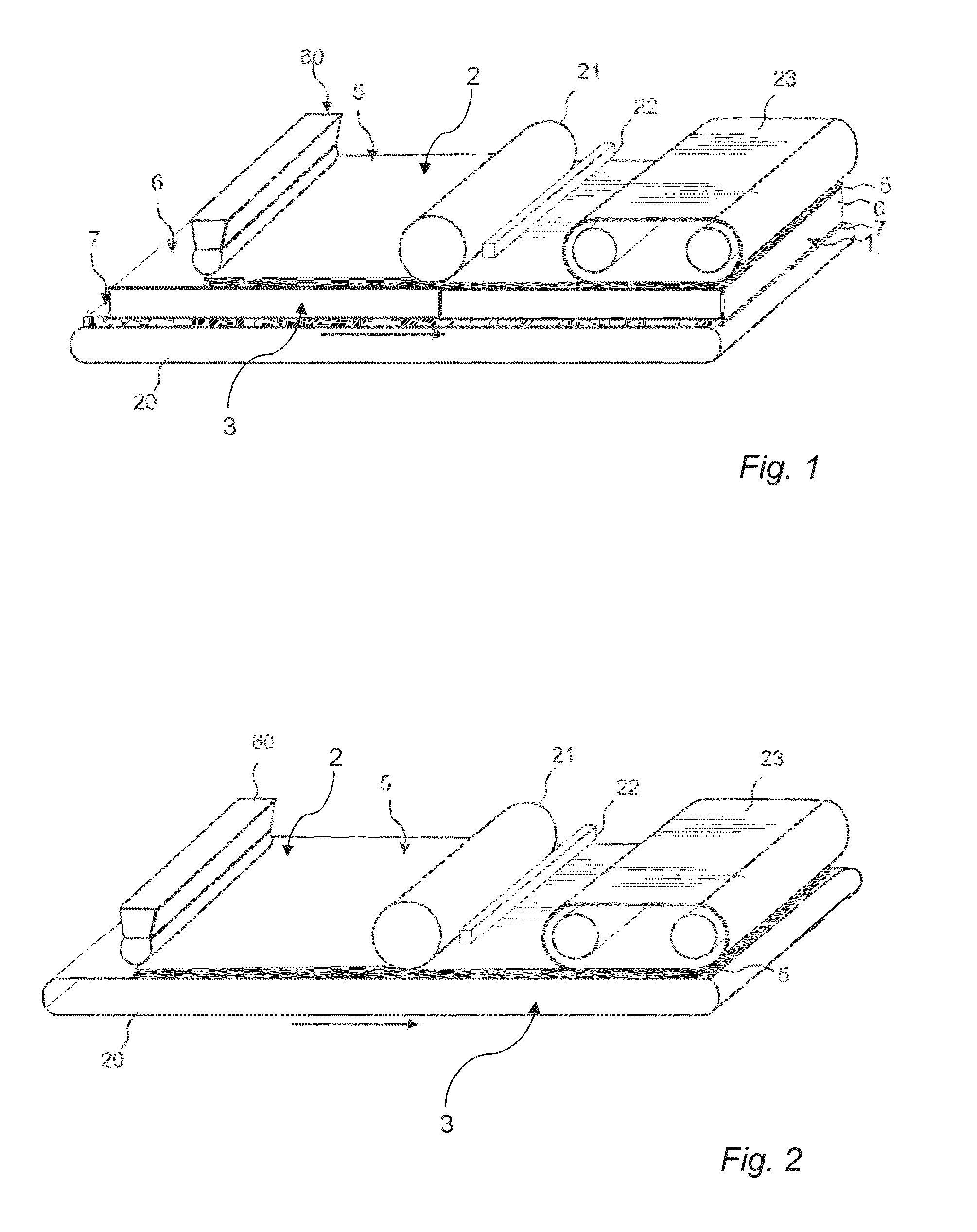

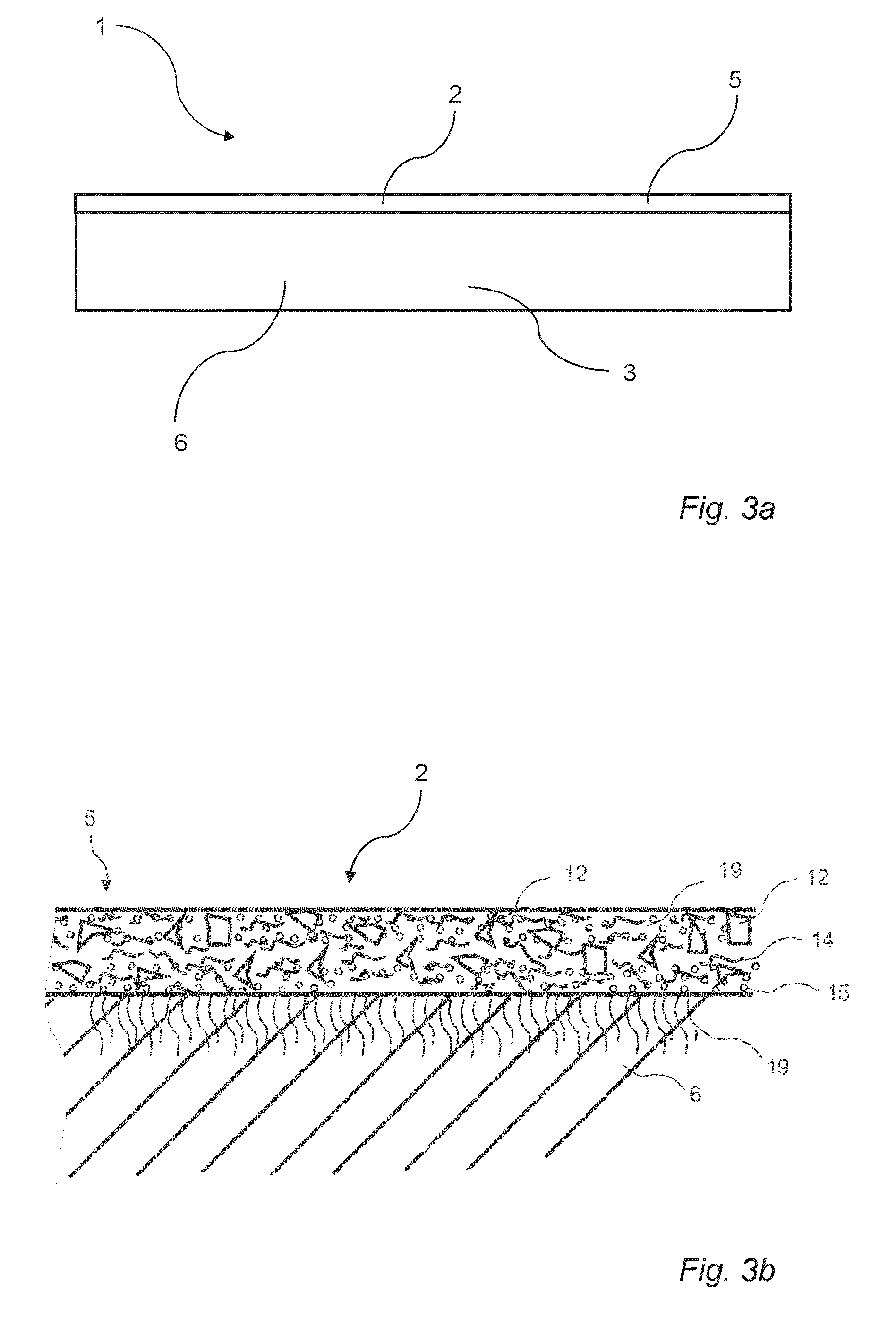

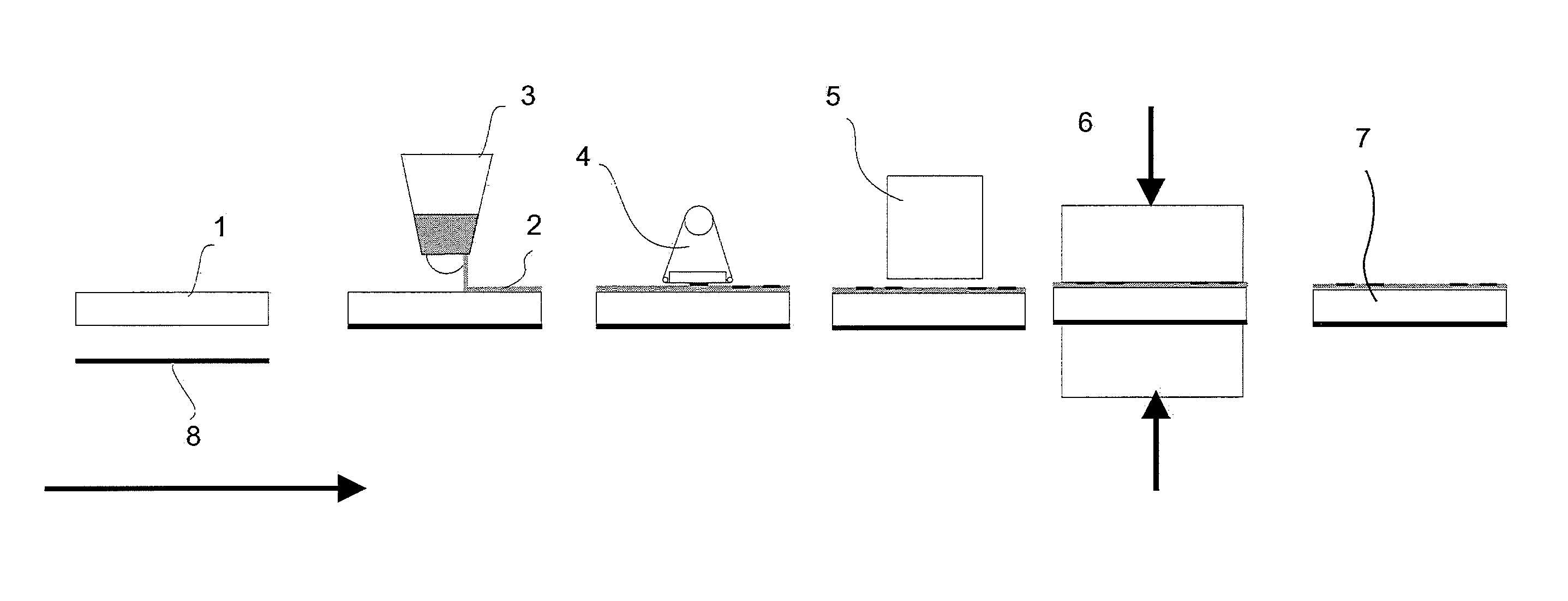

Method for producing a building panel

ActiveUS20130273244A1Simple technologyImprove the immunityLiquid surface applicatorsWood working apparatusMaterials science

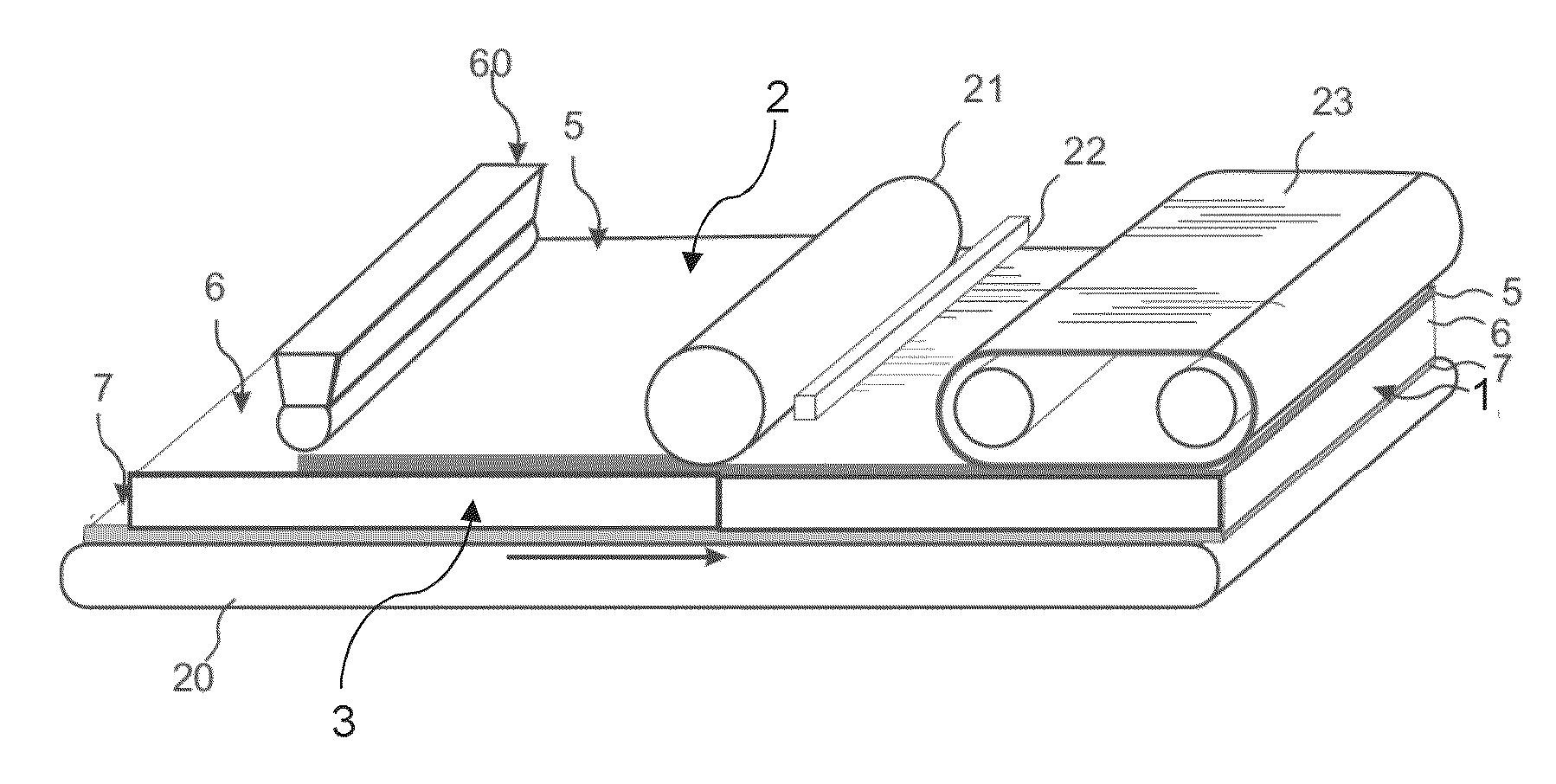

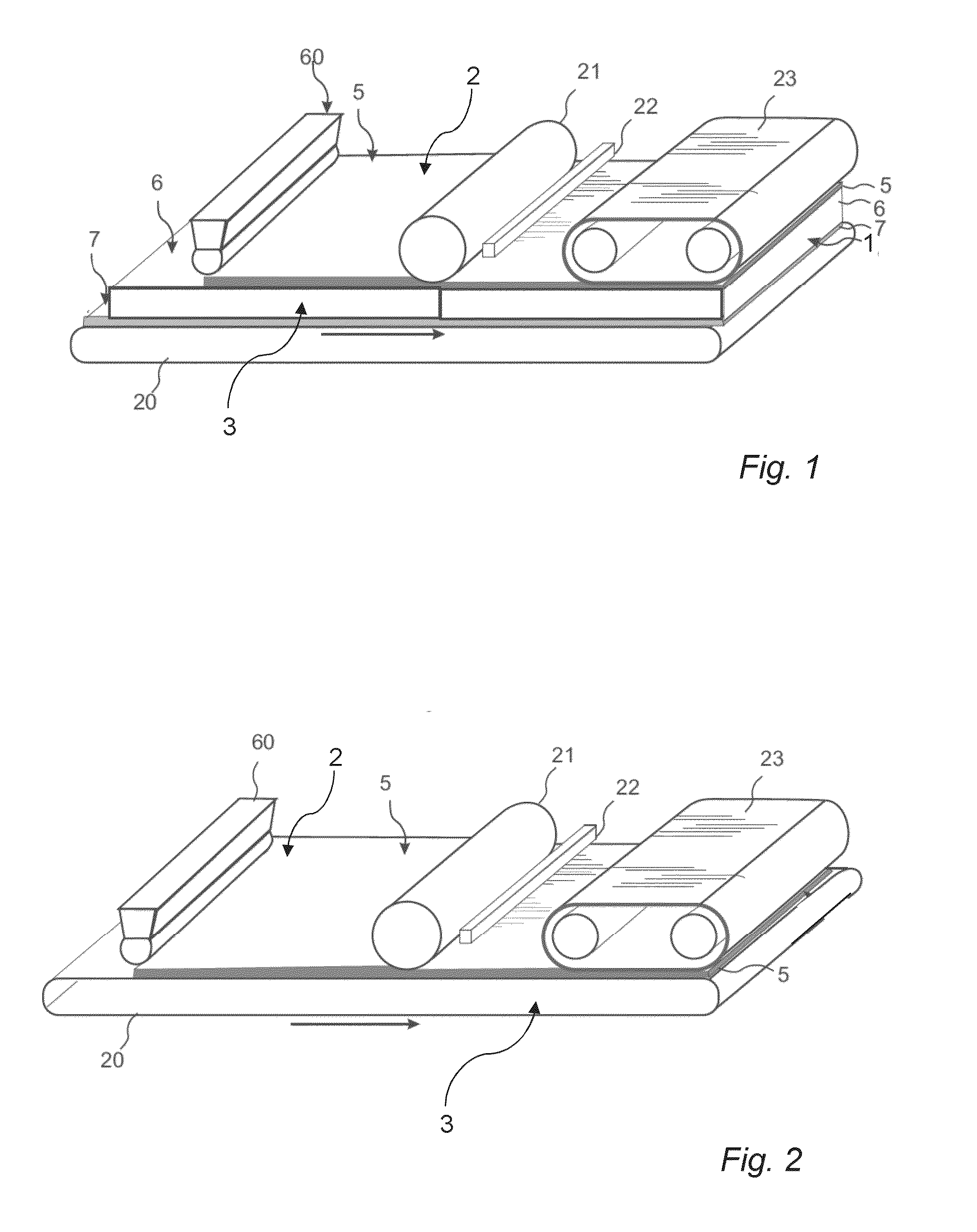

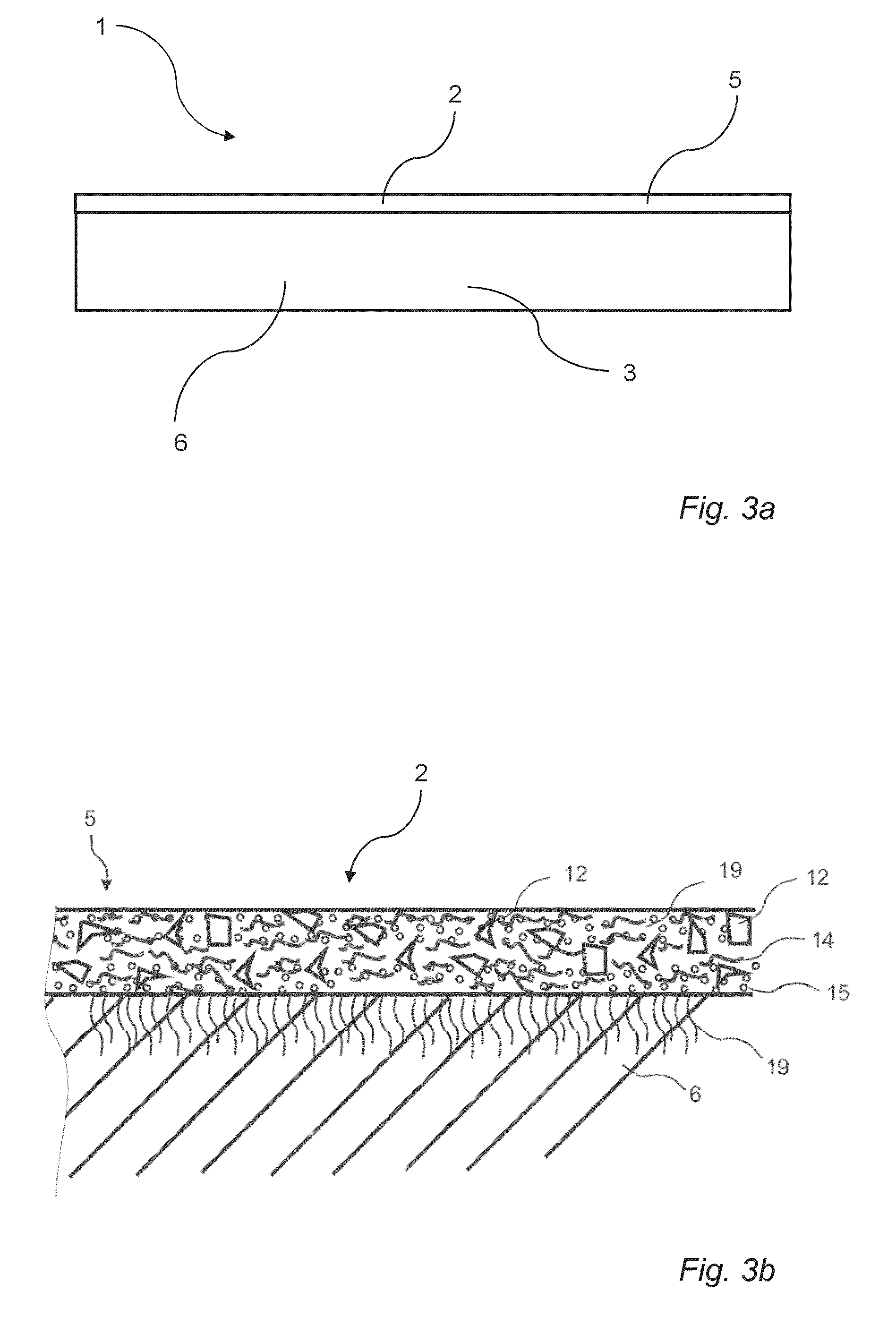

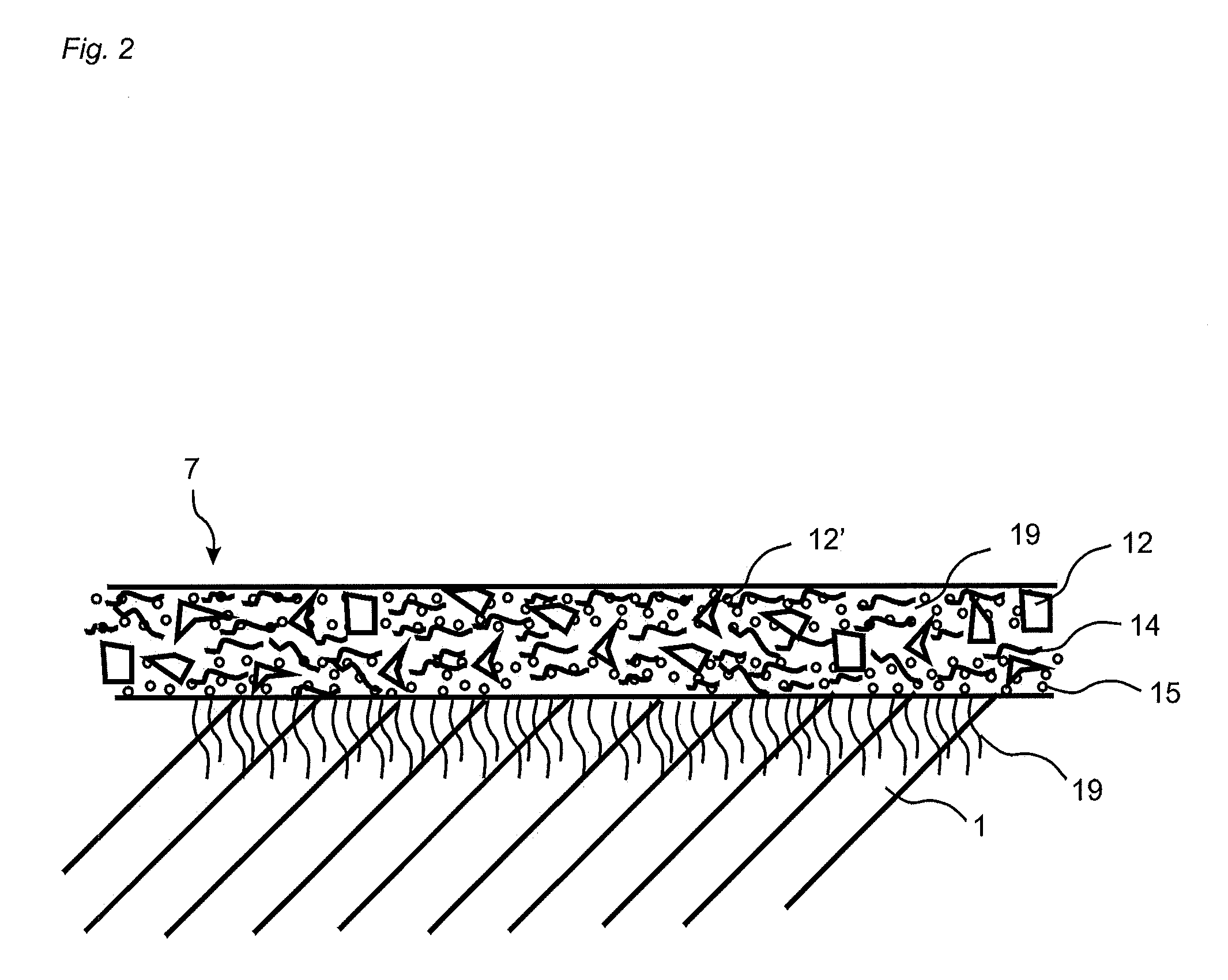

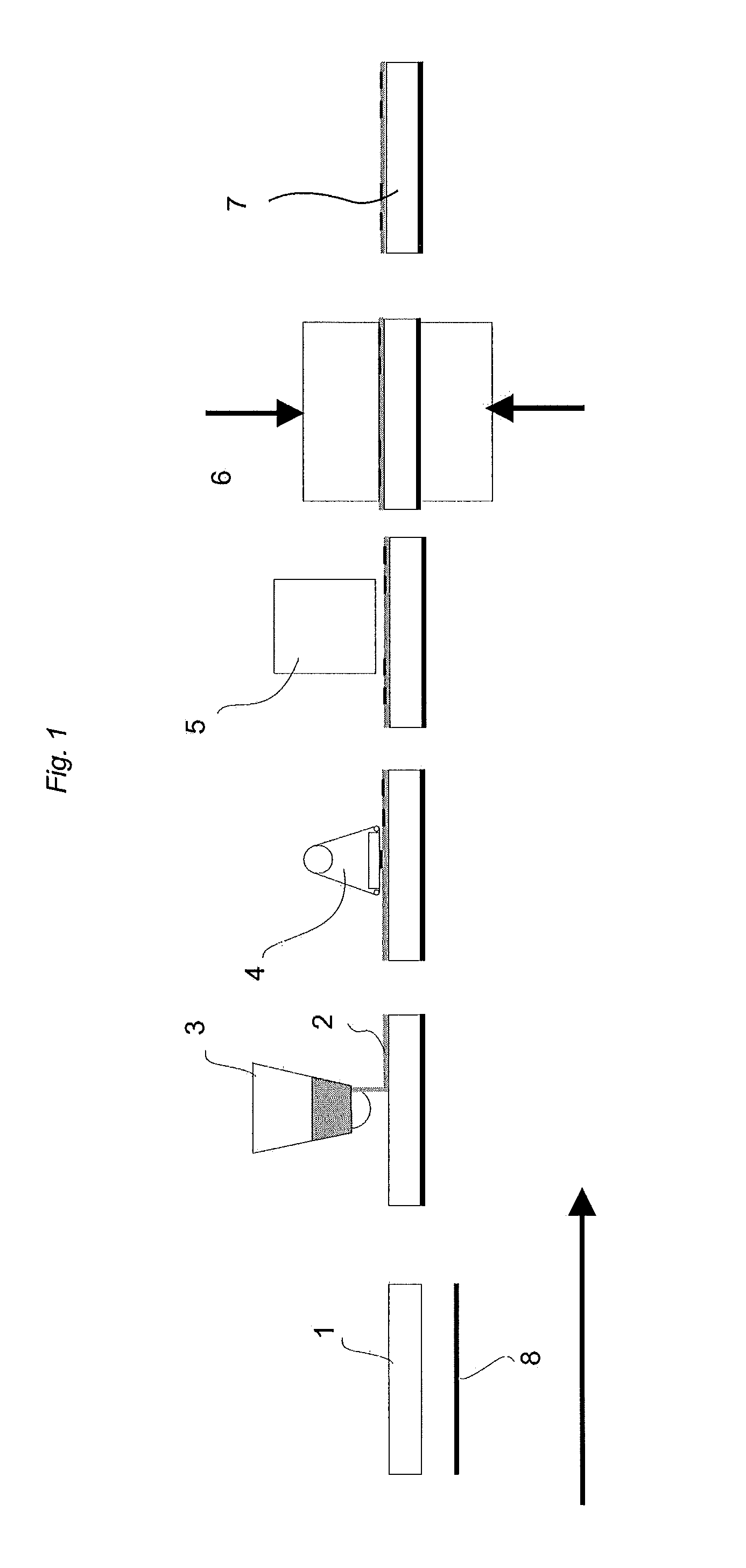

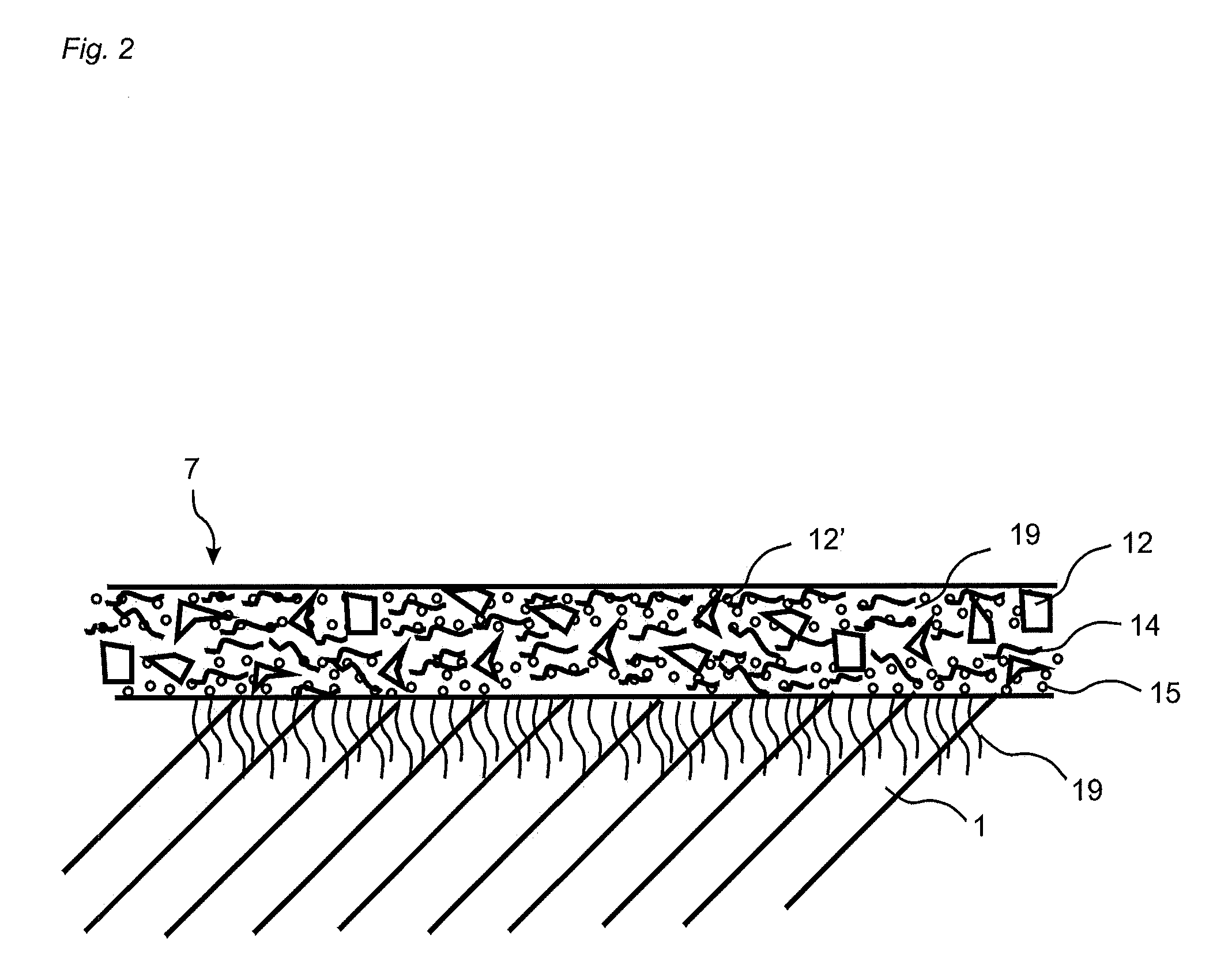

A method for producing a building panel. The method includes forming a mix (2) including wood particles (14), a solvent, a binder (19) and optionally at least one additive (15), wherein the binder (19) and optionally said at least one additive (15) are homogenously distributed in the mix (2) by means of the solvent and wherein the binder (19) impregnates the wood particles (14), drying the mix (2), applying the mix (2) on a substrate (3), and forming a layer (5) by applying heat and pressure to the mix (2).

Owner:VÄLINGE INNOVATION AB

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

Powder mix and a method for producing a building panel

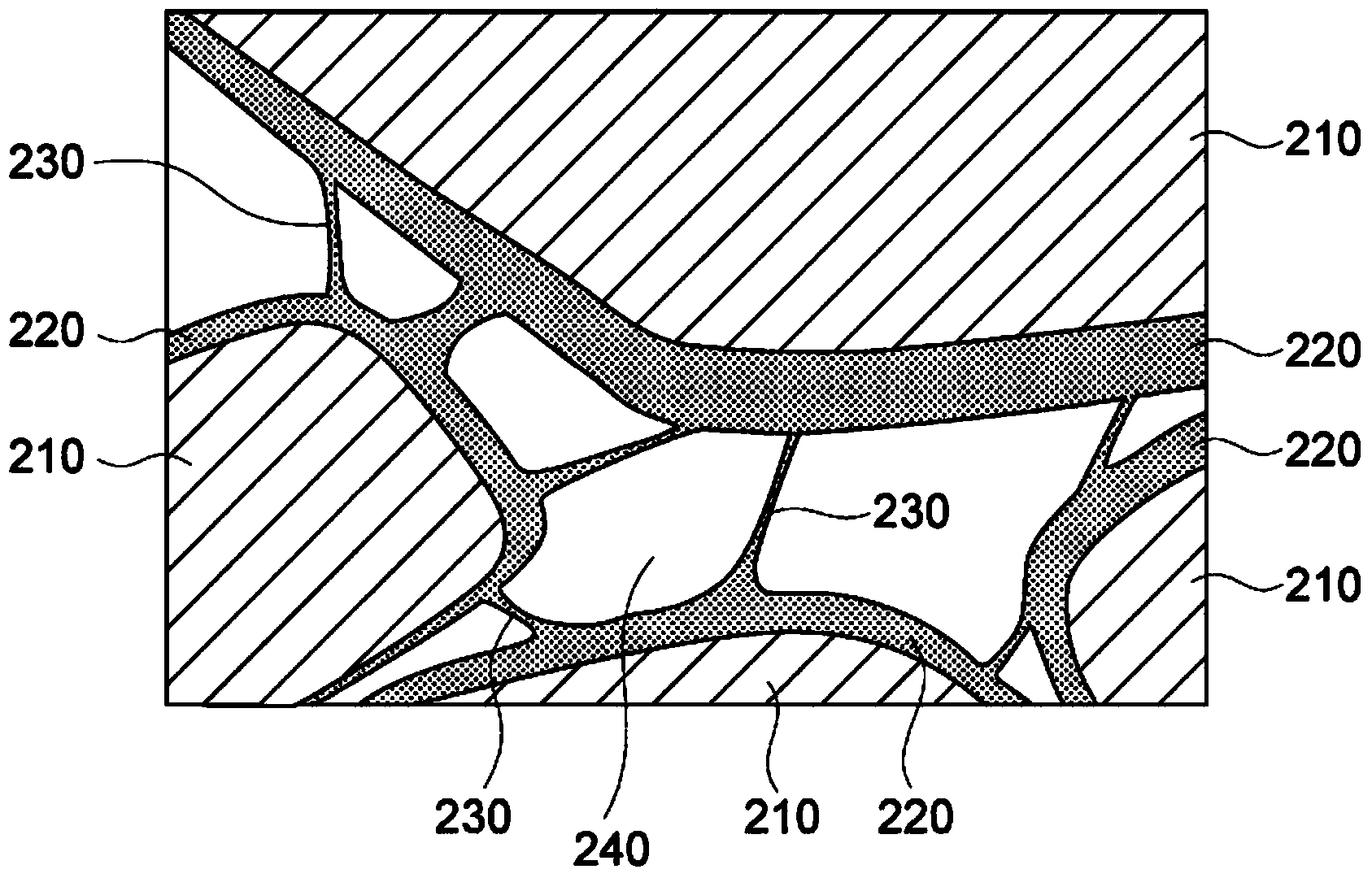

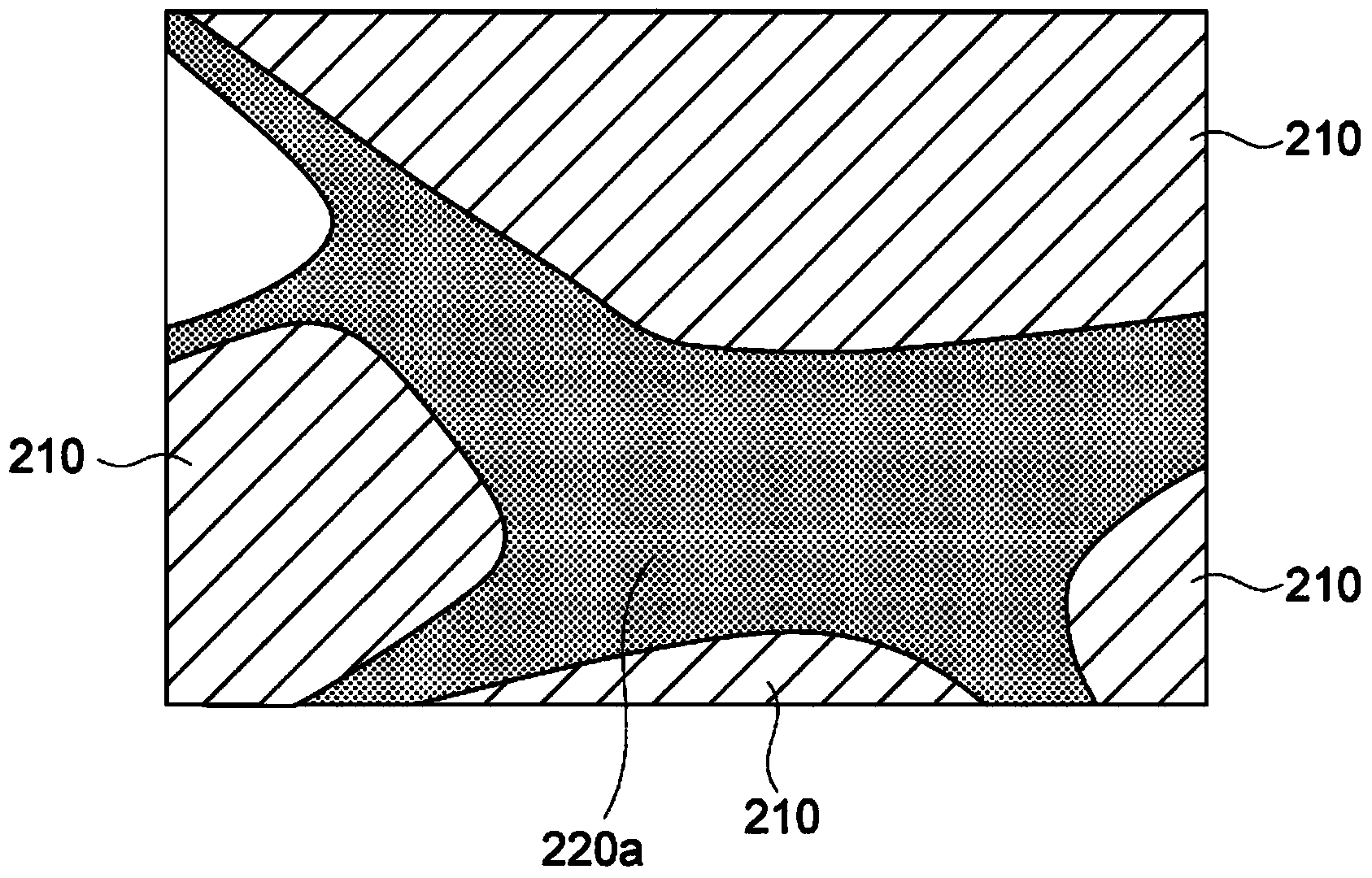

ActiveUS20120263878A1Enhanced control of lossEasy to controlPretreated surfacesWood working apparatusPowder mixtureComposite material

Owner:VÄLINGE INNOVATION AB

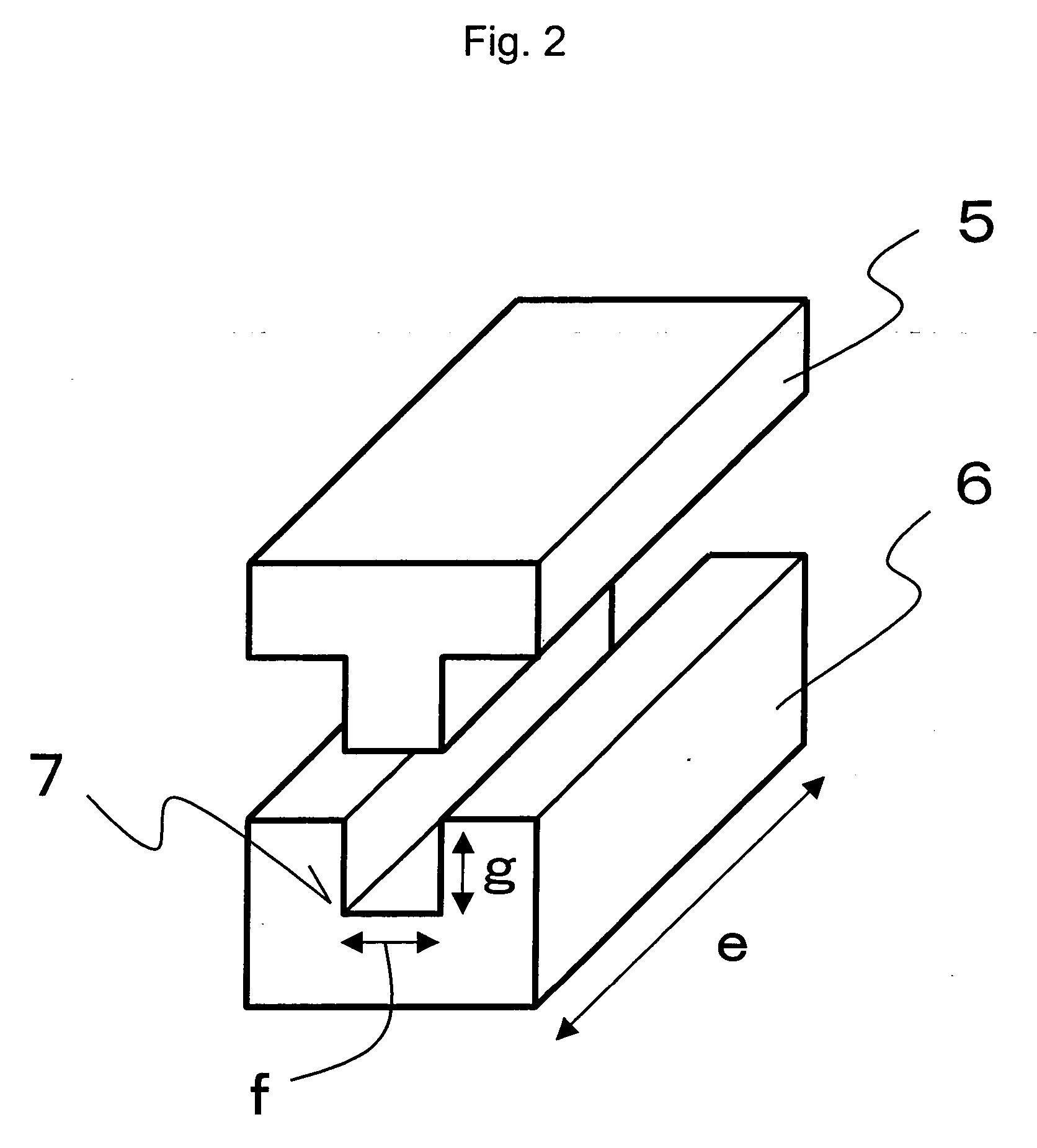

Method of rtm molding

ActiveUS20060125155A1Excellent impregnationImprove surface qualityLaminationLamination apparatusFiber

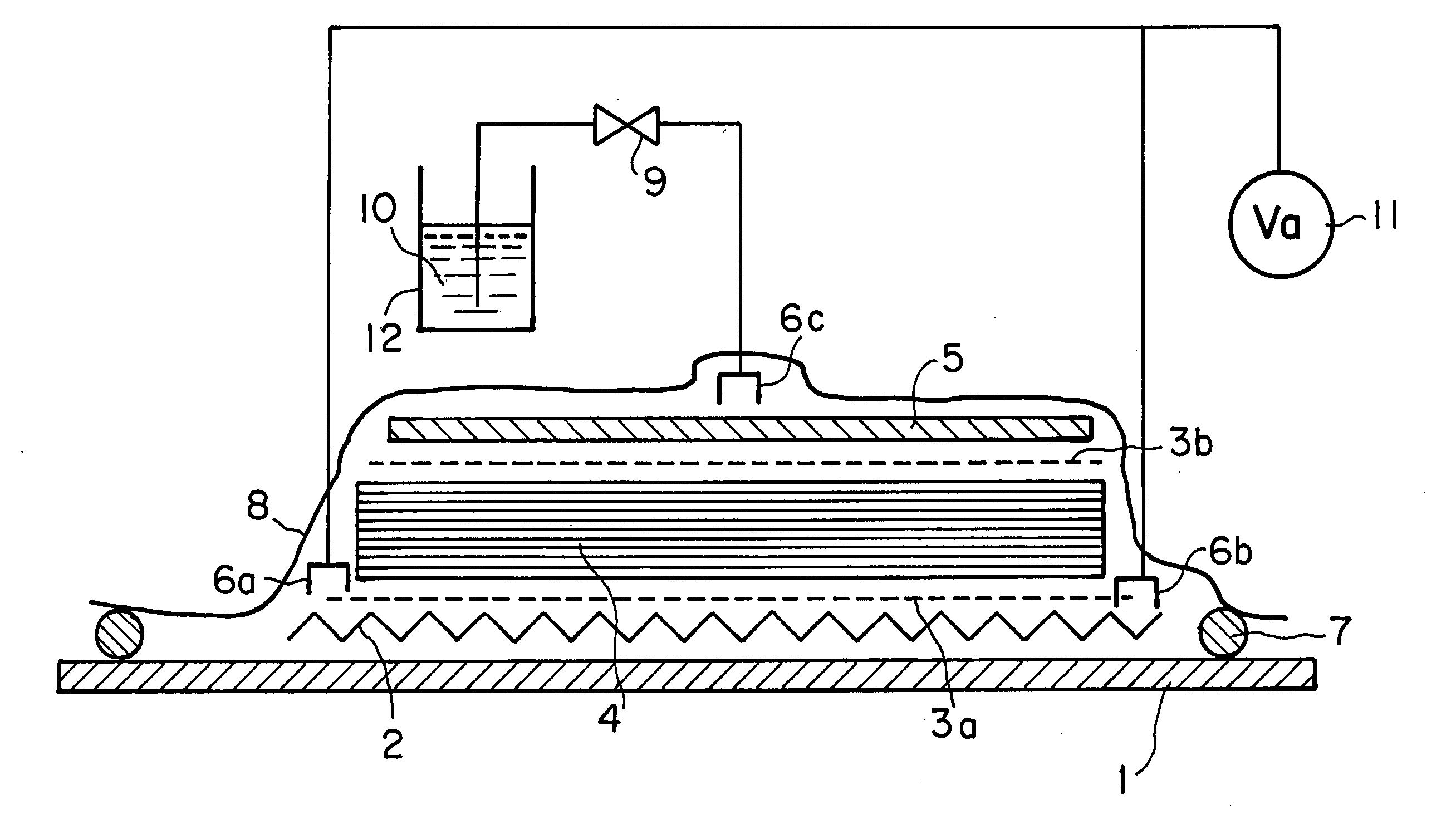

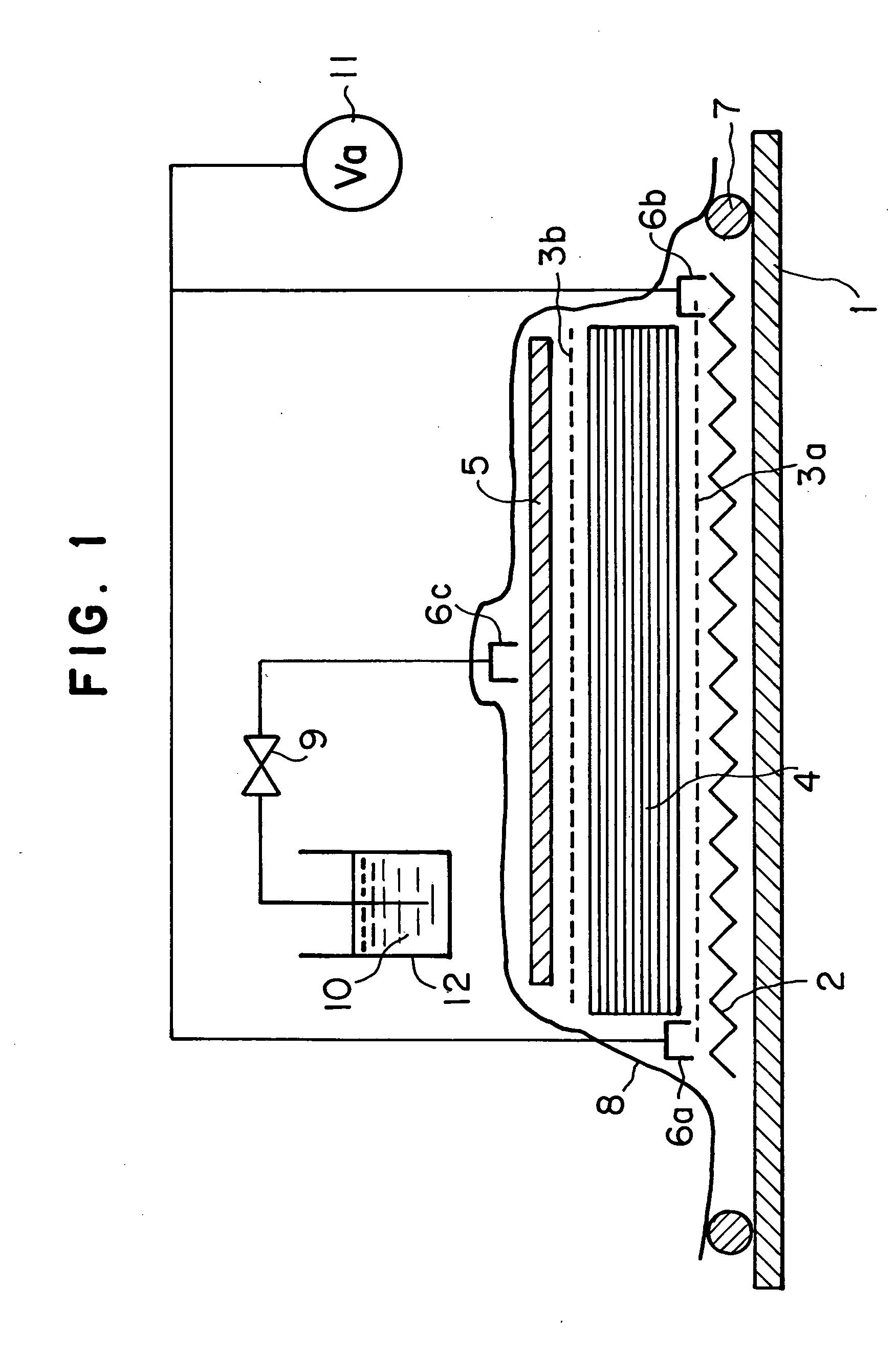

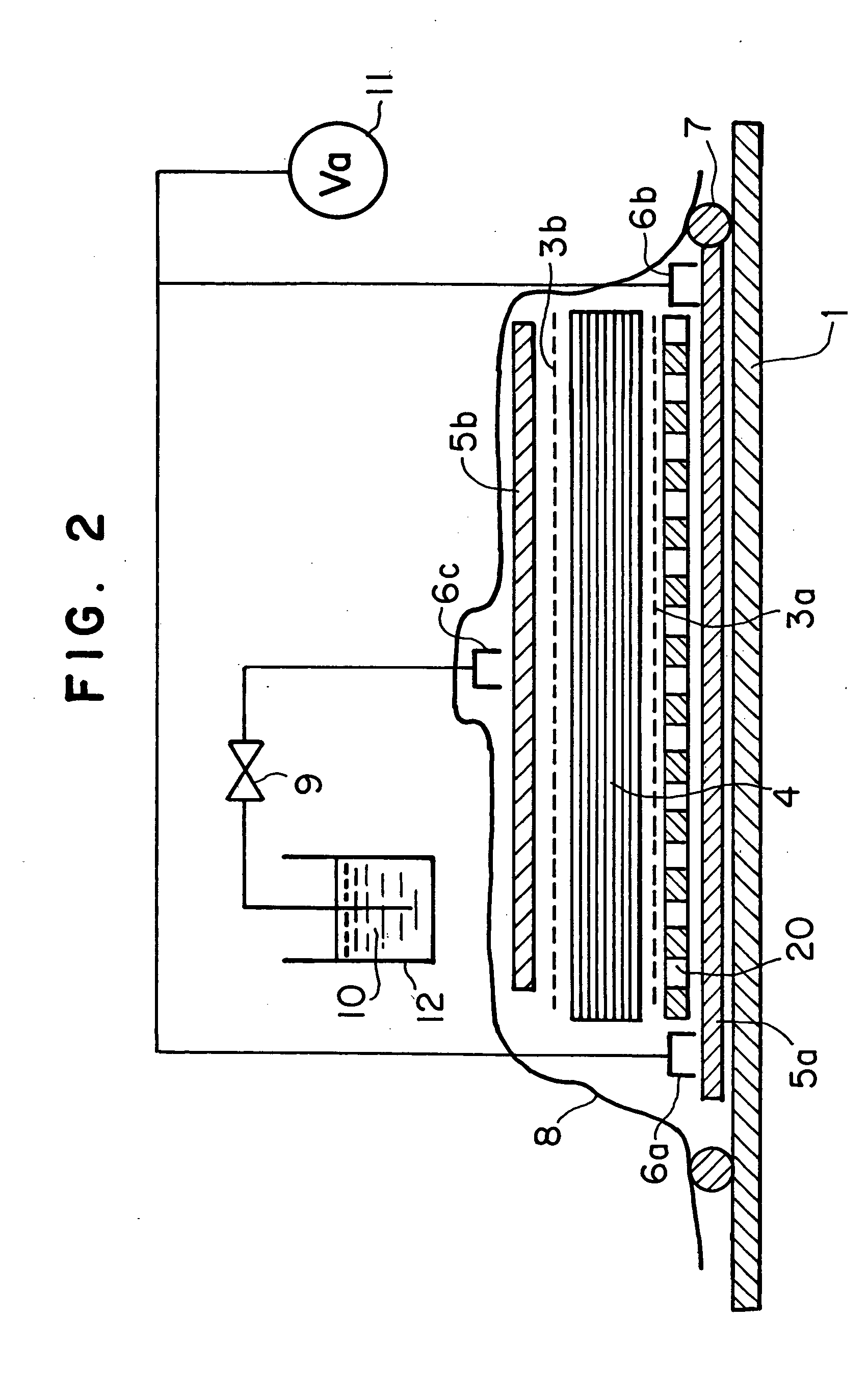

A method of RTM molding wherein a reinforcing fiber substrate is placed in a mold, each of a first and a second resin distribution media exhibiting a resin flow resistance lower than the resistance of the reinforcing fiber substrate is placed on each surface of the reinforcing fiber substrate, and the inside of the mold is evacuated and a resin is injected into the mold to thereby impregnate the reinforcing fiber substrate with the resin injected, characterized in that the first resin distribution medium exhibits a resin flow resistance lower than that of the second resin distribution medium, and the evacuation is carried out through the second resin distribution medium while the resin is injected through the first resin distribution medium. The method can be advantageously employed for producing, in particular, FRP structure which is thick and excellent in designability, lightweight property and / or strength.

Owner:TORAY IND INC +1

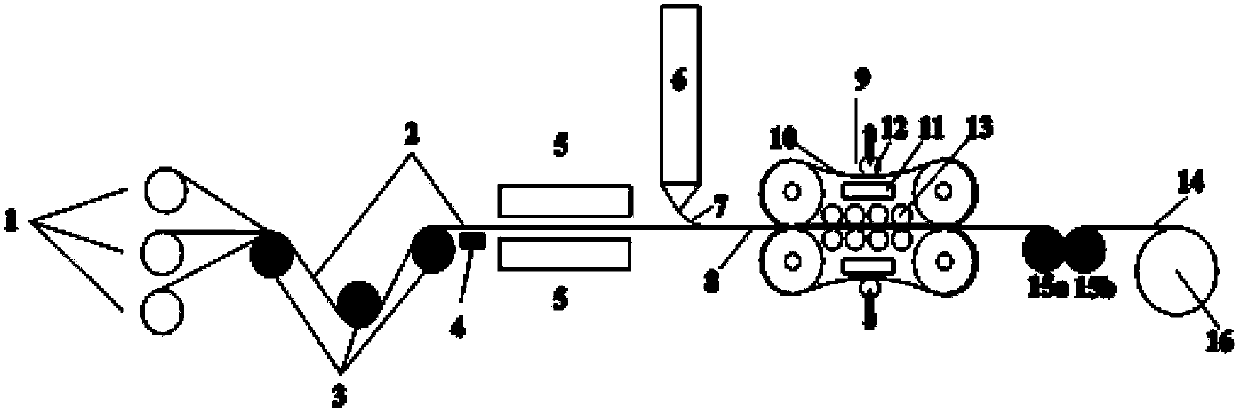

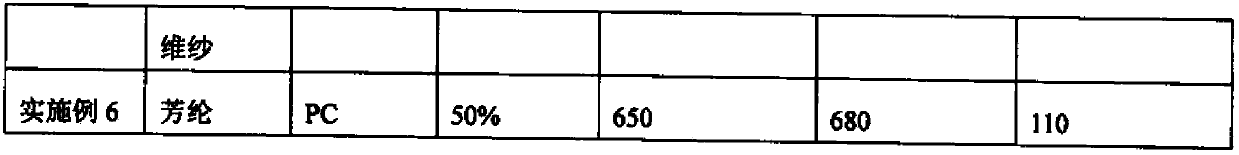

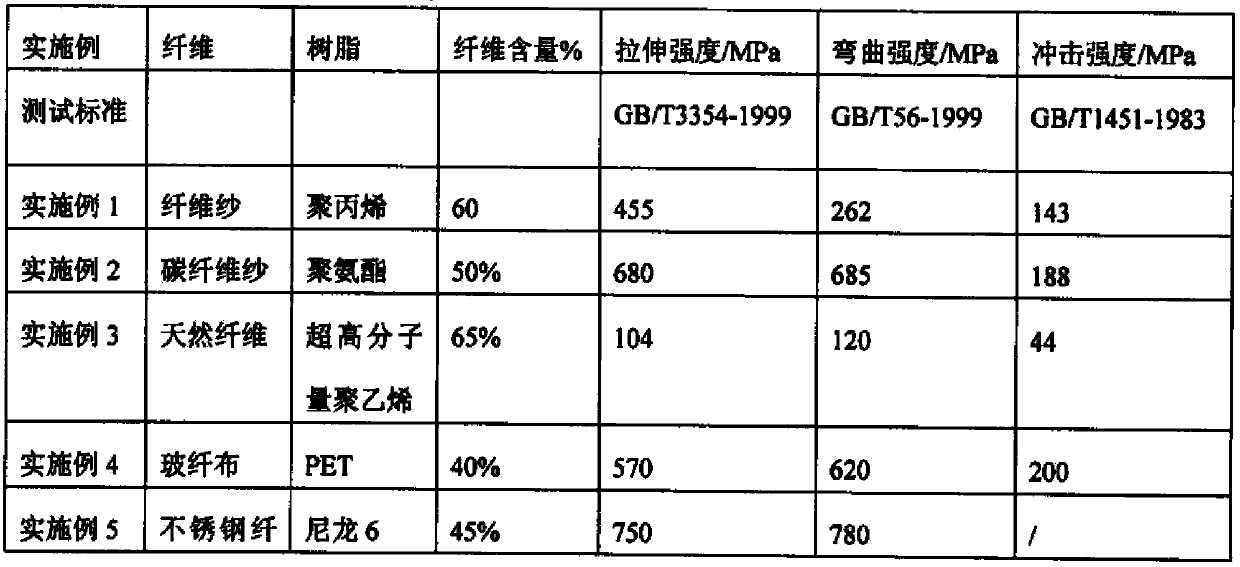

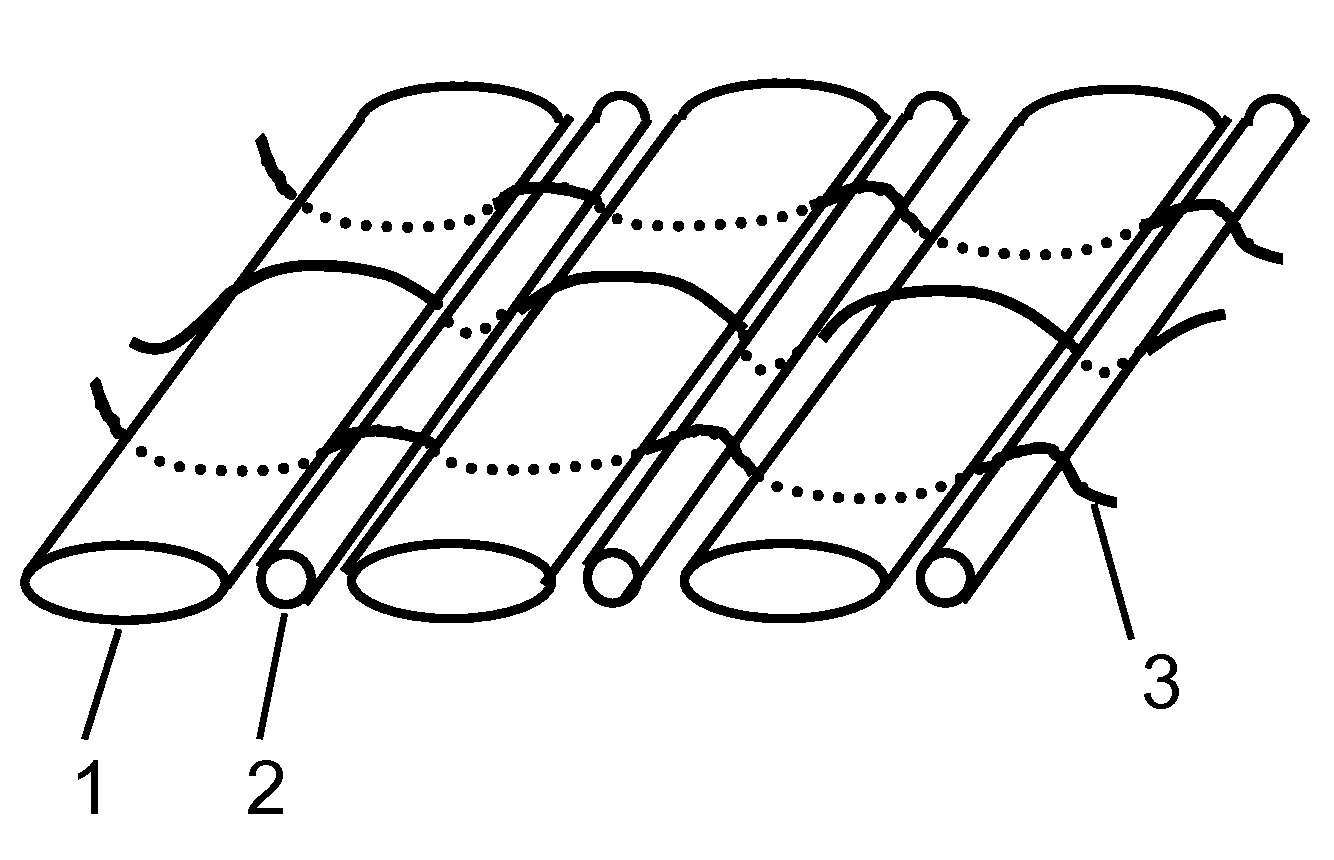

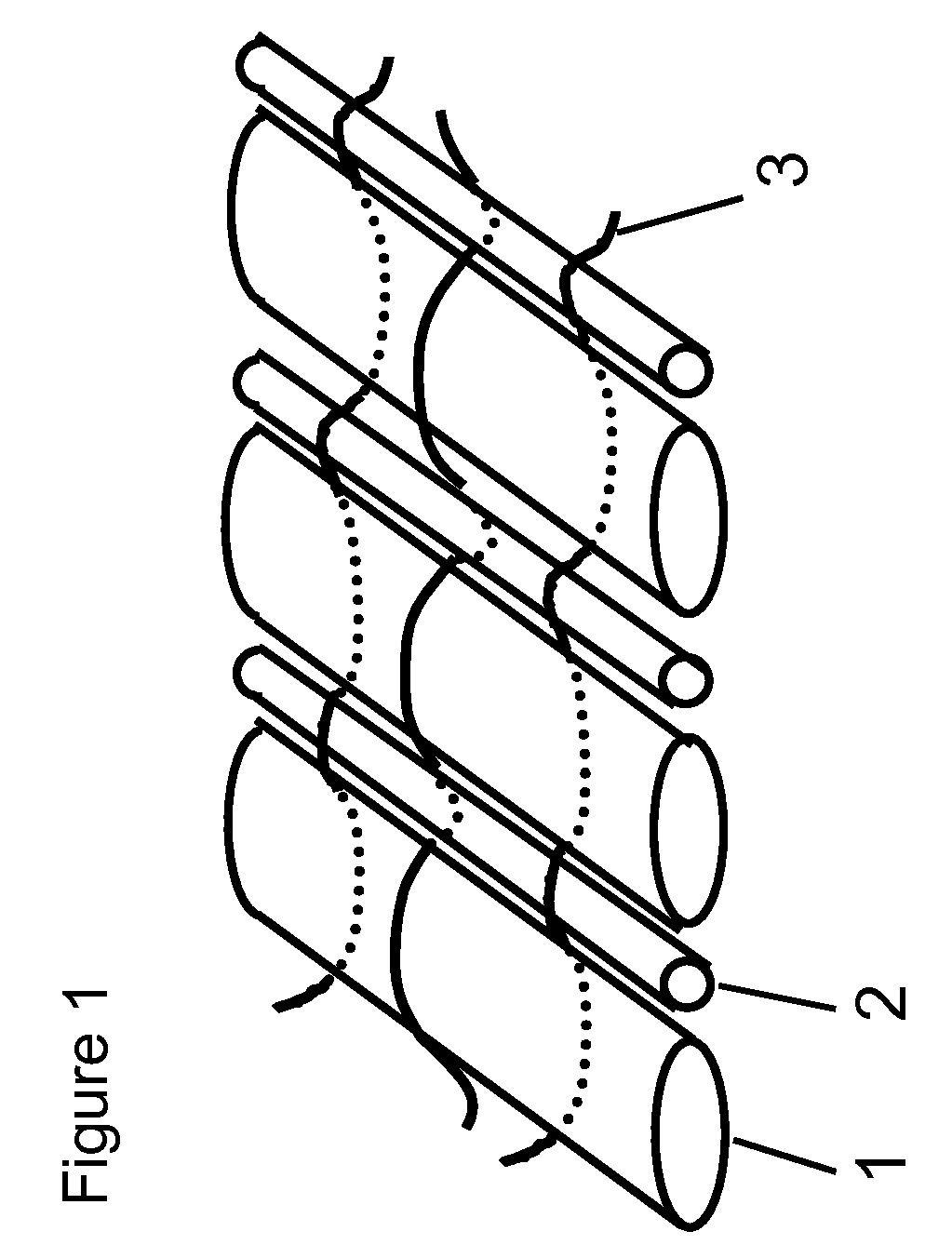

Continuous fiber fabric reinforced thermoplastic resin composite material and production method thereof

The invention relates to a continuous fiber fabric reinforced thermoplastic resin composite material and a production method thereof. The composite material is produced from continuous fiber through thermoplastic resin melting and impregnating, cooling and molding, with the thickness of 0.20mm-0.35mm, wherein the content of the continuous fiber reinforced fabric is 40wt%-65wt%, the continuous fiber fabric is uniformly spread out and subjected to tension adjustment and static electricity elimination, then enters thermoplastic resin for melting and impregnating, and finally is cooled in a cooling unit and wound and formed to obtain the continuous fiber fabric reinforced thermoplastic resin composite material. Compared with the prior art, the continuous fiber fabric reinforced thermoplastic resin composite material and the production method solve a series of problems caused by too high resin viscosity in the existing thermoplastic resin and fiber reinforcing process, such as complex equipment process, too high equipment cost, not environment-friendly technological operation process, dry gauze easily caused by poor impregnation and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

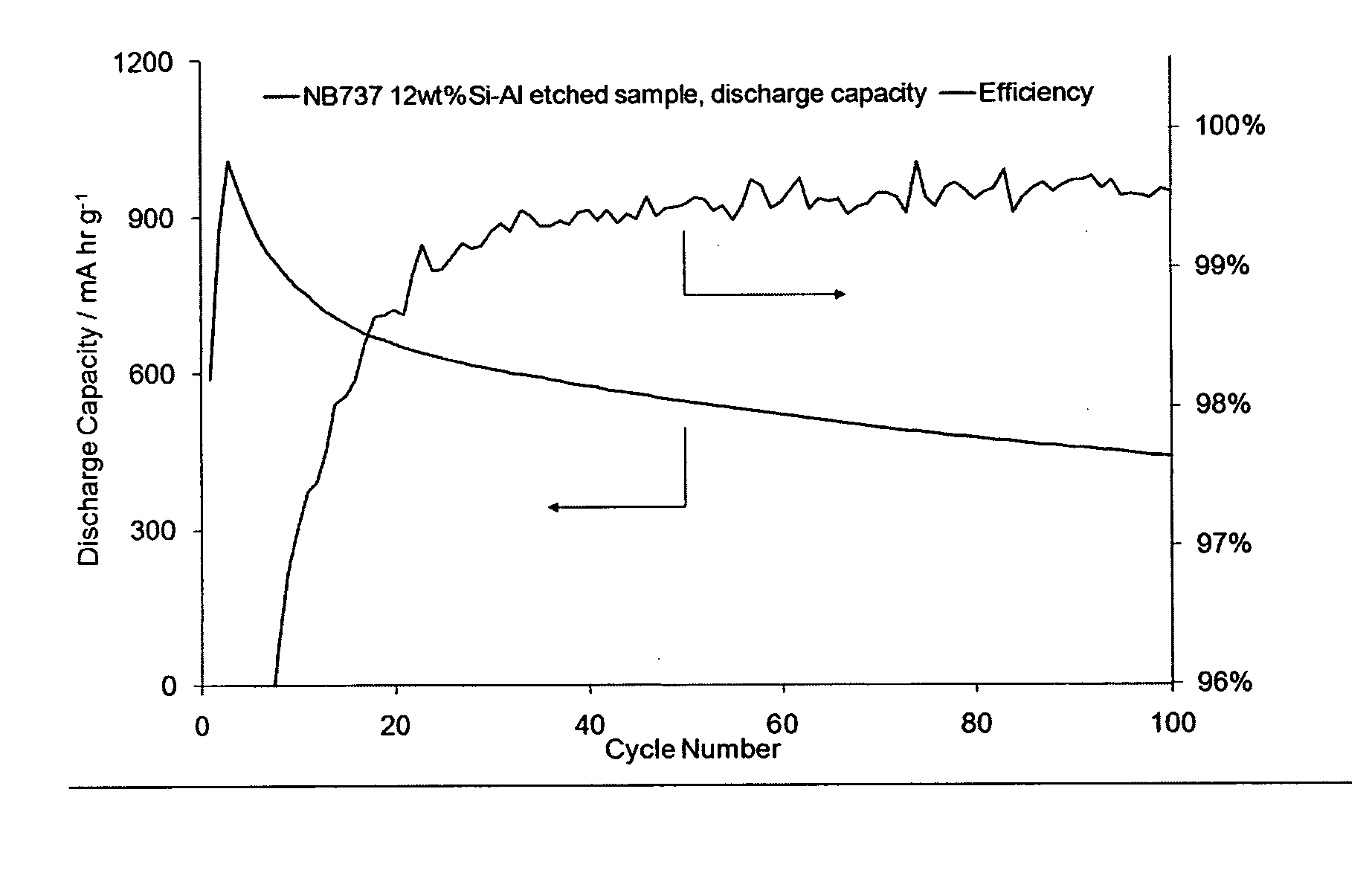

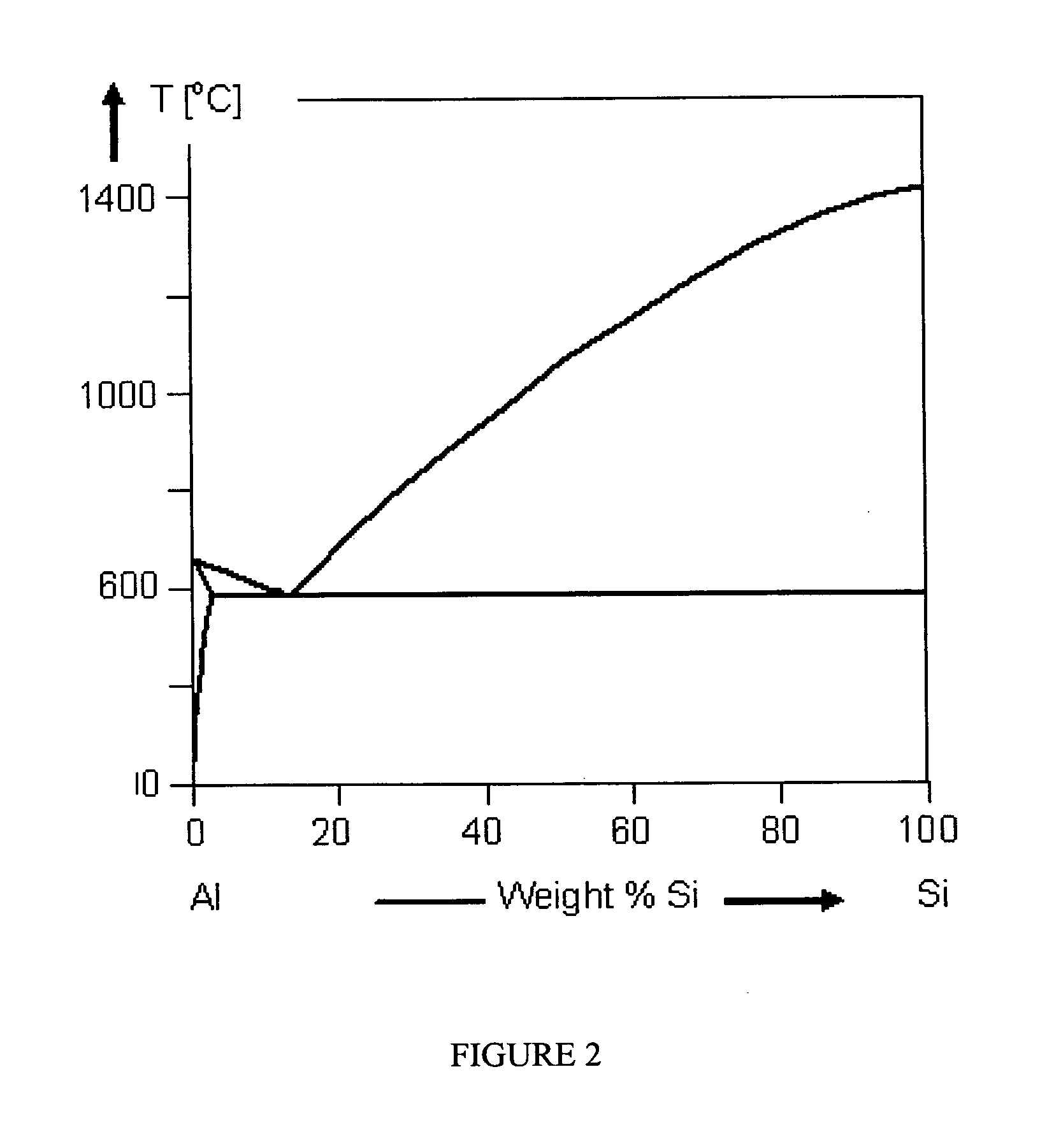

Method of making silicon anode material for rechargeable cells

ActiveUS20120129049A1Excellent cast-abilityExcellent weld-abilityElectrolysis componentsElectrode manufacturing processesRechargeable cellSilicon

Owner:NEXEON LTD

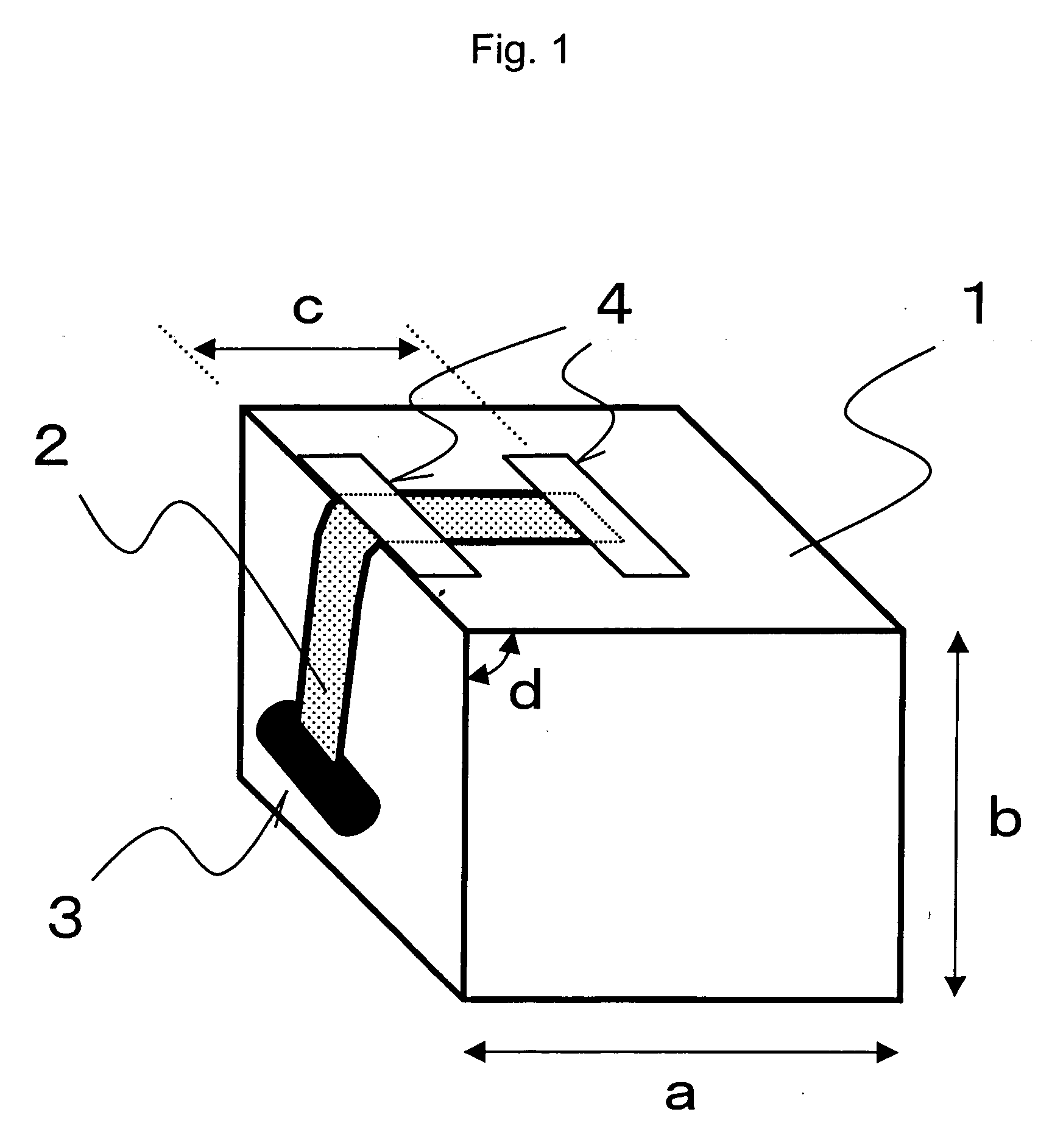

Method for producing a building panel

ActiveUS8920876B2Improve the immunityExcellent impregnationPretreated surfacesWood working apparatusSolventComposite material

A method for producing a building panel. The method includes forming a mix including wood particles, a solvent, a binder and optionally at least one additive, wherein the binder and optionally said at least one additive are homogenously distributed in the mix by means of the solvent and wherein the binder impregnates the wood particles, drying the mix, applying the mix on a substrate, and forming a layer by applying heat and pressure to the mix.

Owner:VÄLINGE INNOVATION AB

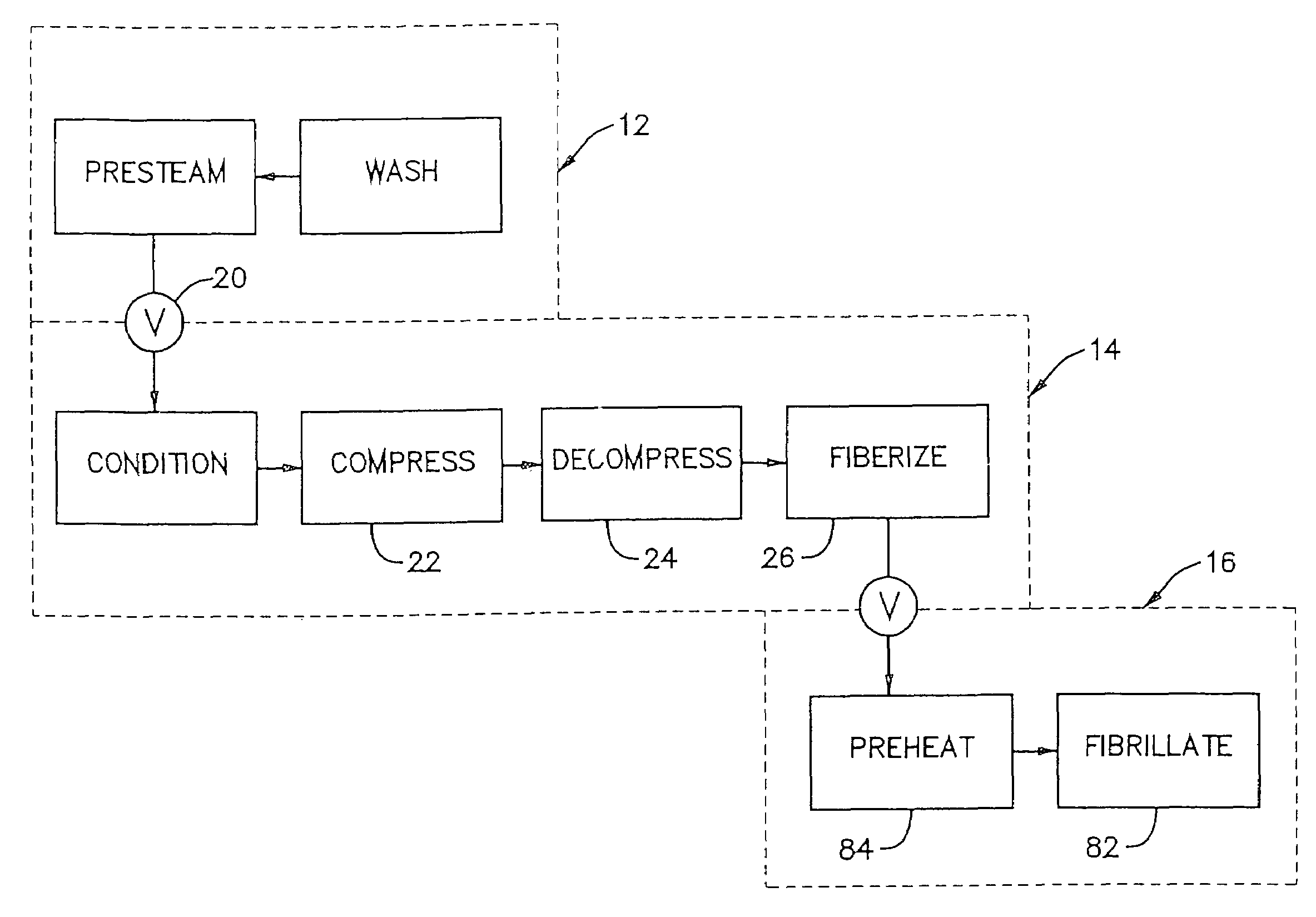

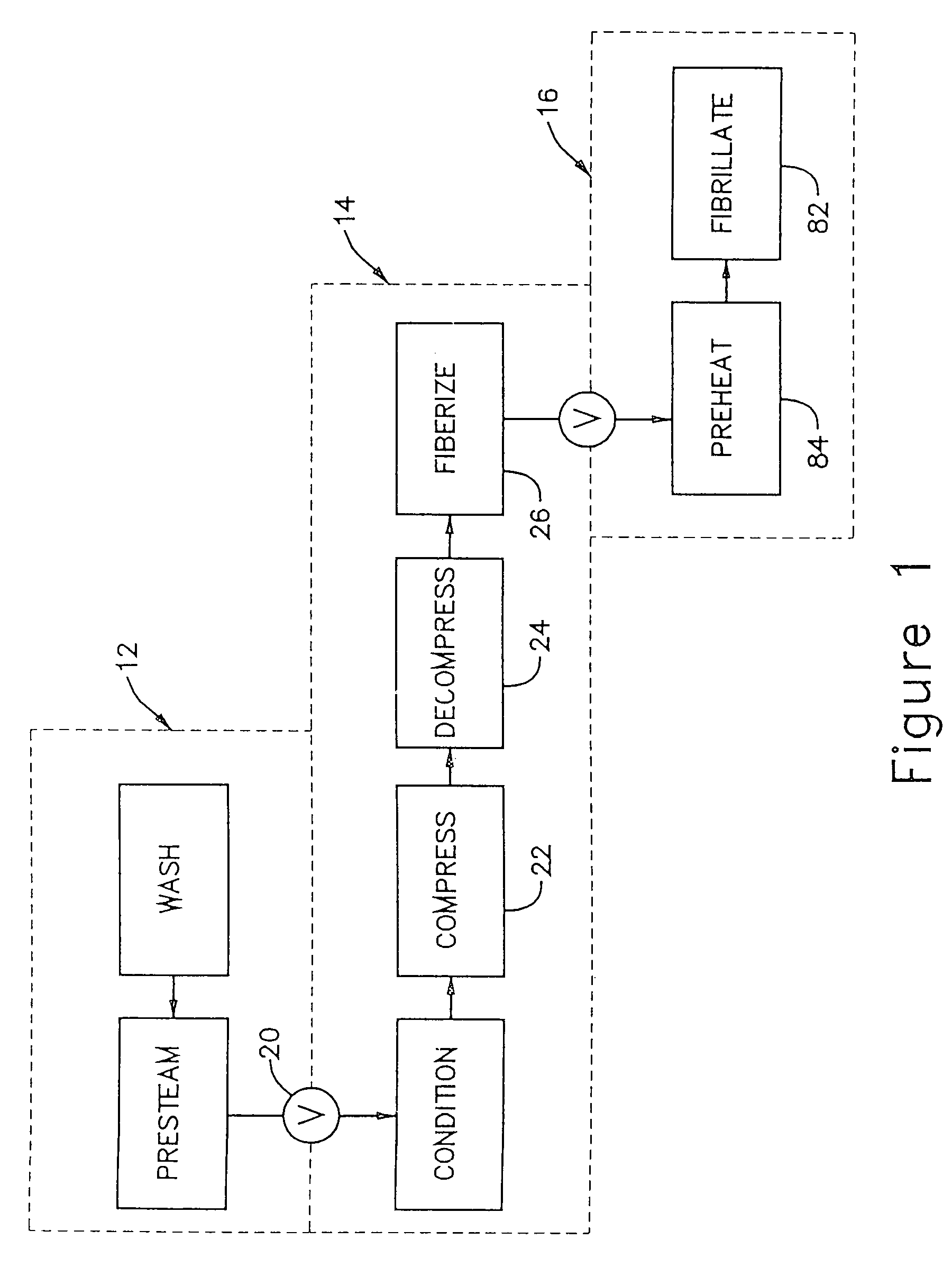

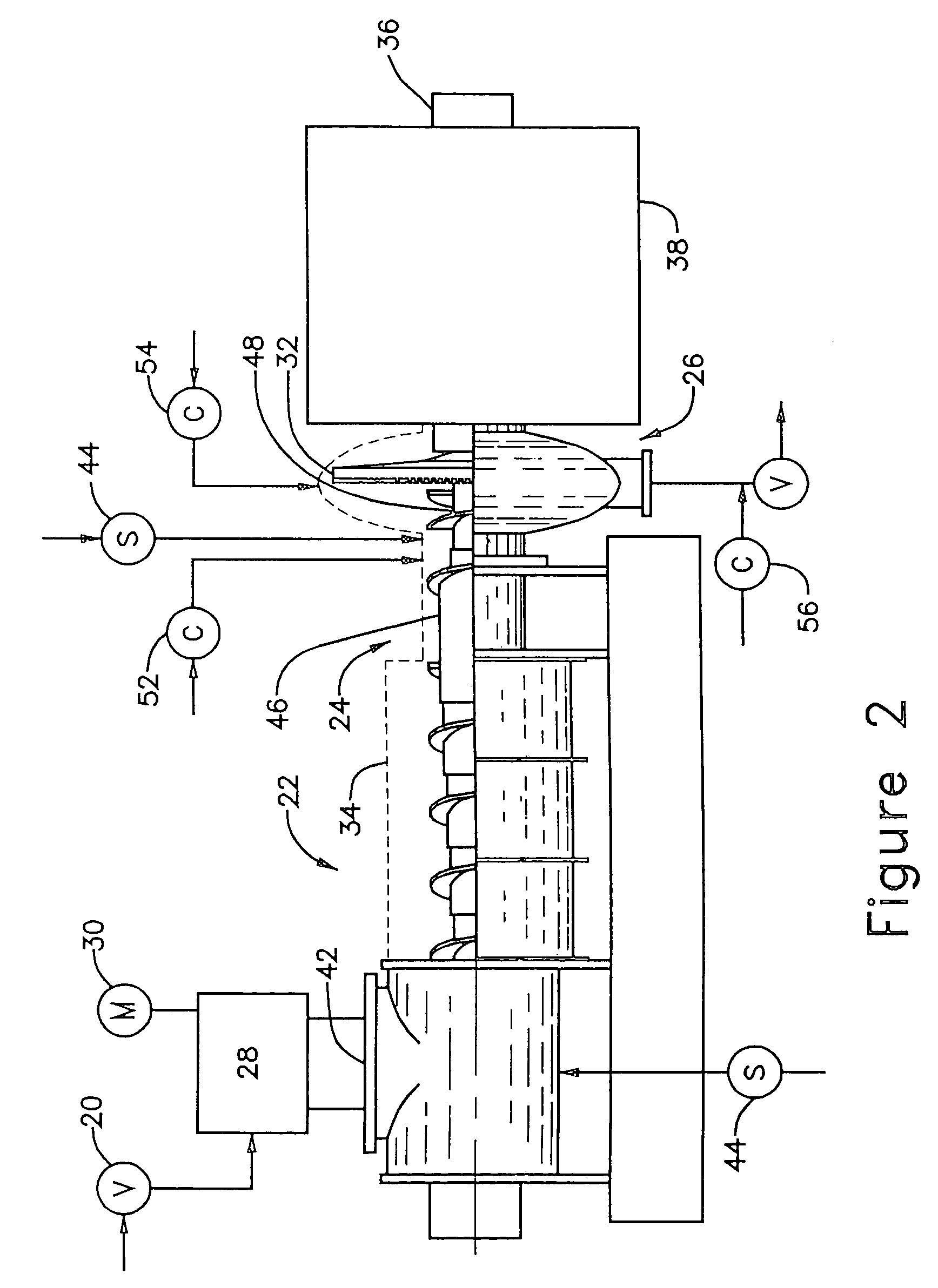

High defiberization chip pretreatment

ActiveUS7300541B2Reduce energy consumptionGood removal effectCellulosic pulp after-treatmentPretreatment with water/steamChemical treatmentFiber bundle

A chip pretreatment process which comprises conveying the feed material through a compression screw device having an atmosphere of saturated steam at a pressure above about 5 psig, decompressing and discharging the compressed material from the screw device into a decompression region, feeding the decompressed material from the decompression region into a fiberizing device, such as a low intensity disc refiner, where at least about 30 percent of the fiber bundles and fibers are axially separated, without substantial fibrillation of the fibers. Preferably, the fibers are axially separated with less than about 5 percent fibrillation, and subsequently the fiberized material is refined in a high intensity disc refiner until at least about 90 percent of the fibers are fibrillated. In another form the invention combines chip fiberizing with chemical treatments, for improving the pulp property versus energy relationships.

Owner:ANDRITZ INC

Powder mix and a method for producing a building panel

ActiveUS8728564B2Excellent impregnationIncrease resistancePretreated surfacesWood working apparatusPowder mixtureMaterials science

Owner:VÄLINGE INNOVATION AB

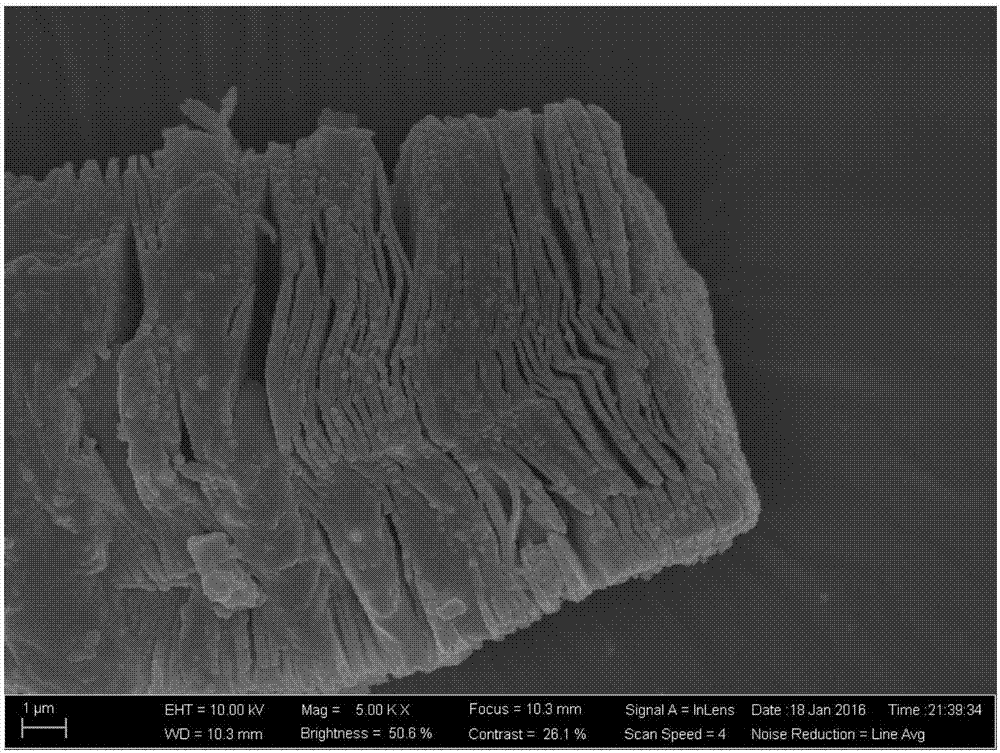

Preparation method of oxidized Mxene/S compound applied to lithium-sulphur battery cathode

ActiveCN107579235ALow costImprove adsorption capacityCell electrodesSecondary cellsWater bathsHigh conductivity

The invention discloses a preparation method of an oxidized Mxene / S compound applied to a lithium-sulphur battery cathode, relates to a preparation method of an S compound applied to the lithium-sulphur battery cathode, and aims to solve the technical problem of complex process of an existing Mxene / S compound preparation method. The preparation method disclosed by the invention comprises the following steps: 1, preparing Mxene powder; 2, oxidizing; 3, performing a water bath method. According to the preparation method, oxidized Mxene with high conductivity is taken as an S carrier, the preparation process is simple and safe, the production cost is low, large scale production is hopefully realized, and the oxidized Mxene / S compound as a lithium-sulphur battery cathode material has very highspecific capacity and cycling stability. The preparation method is applied to preparation of the lithium-sulphur battery cathode material.

Owner:HARBIN INST OF TECH

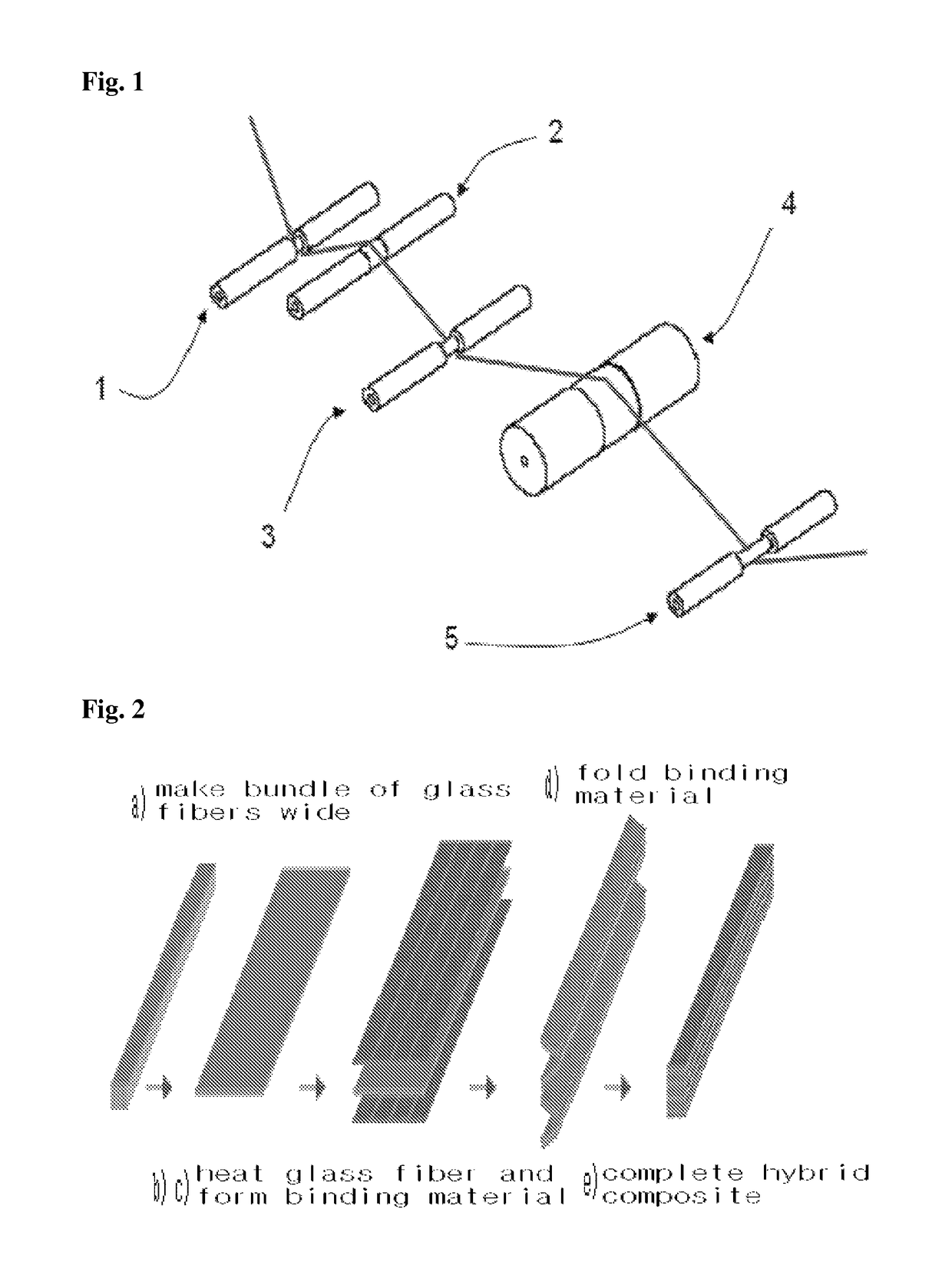

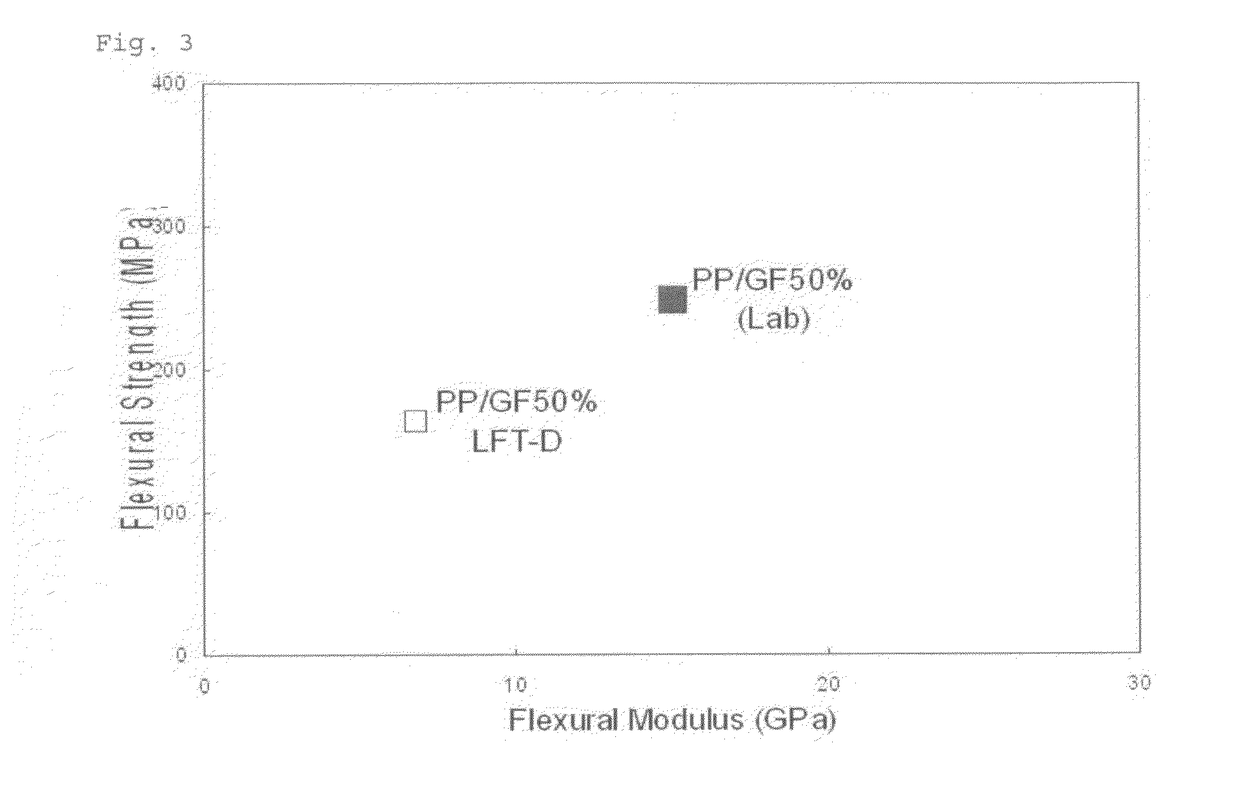

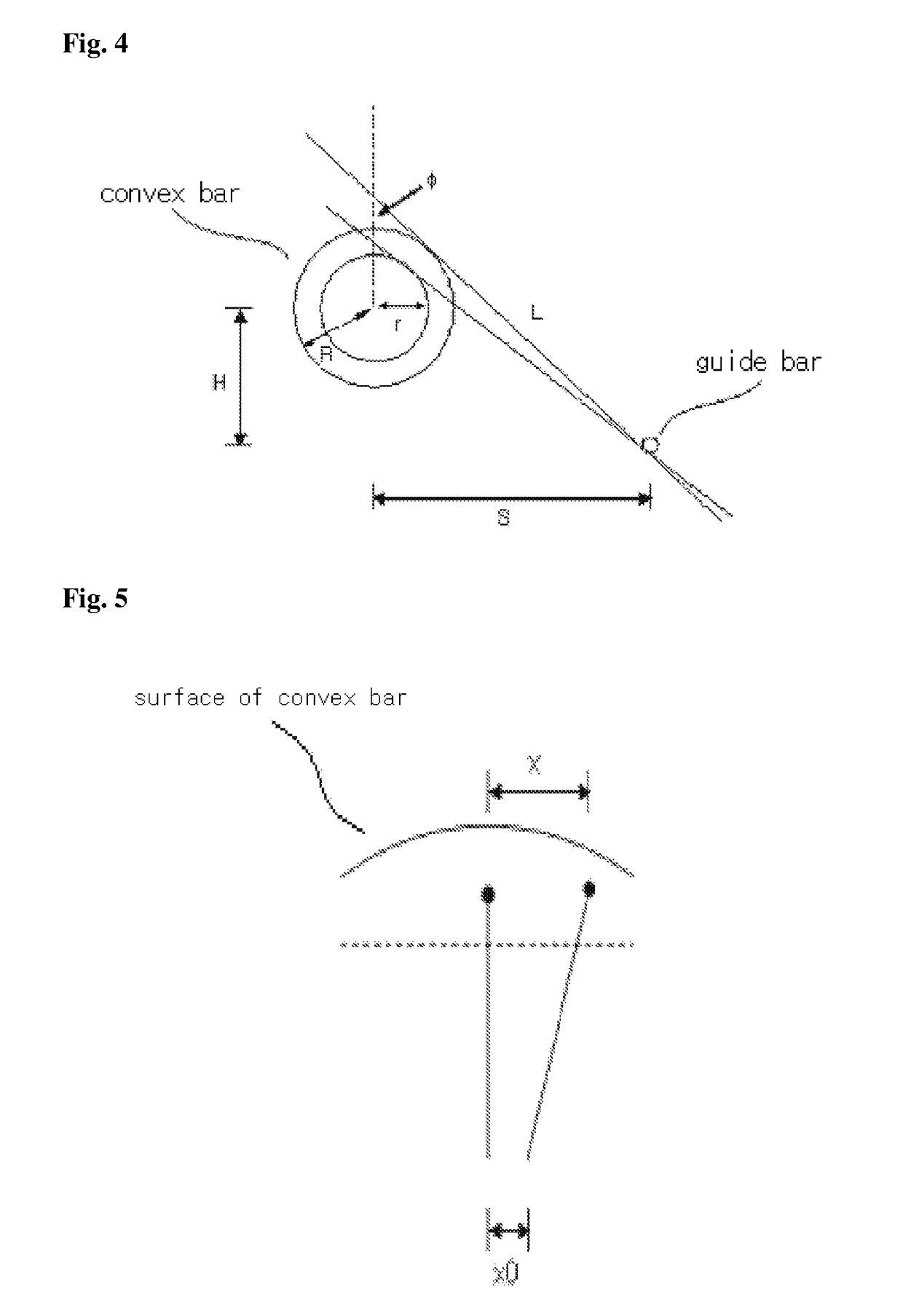

Method of preparing thermoplastics-continuous fiber hybrid composite

ActiveUS8470114B2Good flexibilityKnitting simpleSynthetic resin layered productsLaminationThermoplasticFiber

Provided is a method of preparing thermoplastics-continuous fiber hybrid composite, which is easily woven and has excellent uniformity and impregnation at the time of hot melt impregnation after the weaving, including: a) widely and uniformly stretching a bundle of glass fibers; b) heating the stretched glass fibers; c) preparing a thermoplastics-continuous fiber bonding material by binding the heated glass fiber with thermoplastics; d) preparing a multi-layered thermoplastics-continuous fiber bonding material by folding the bonding material in a shape of zigzag; and e) pressing the multi-layered thermoplastics-continuous fiber bonding material.

Owner:LARGE +1

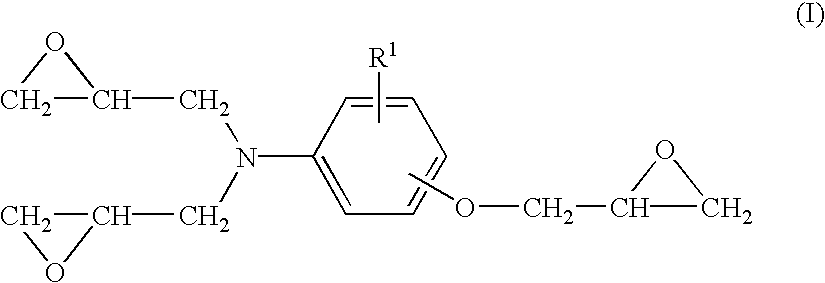

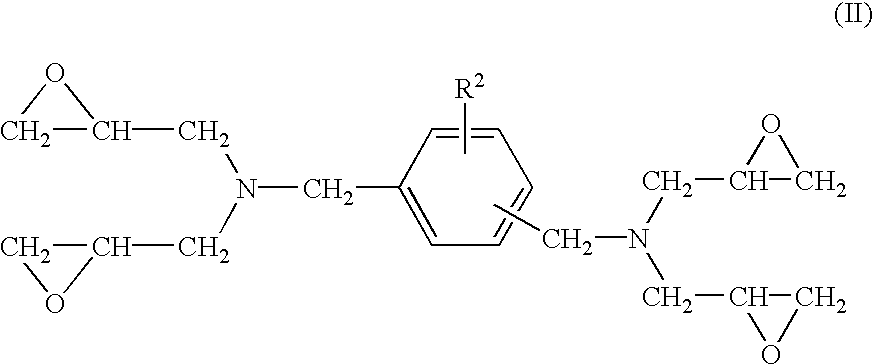

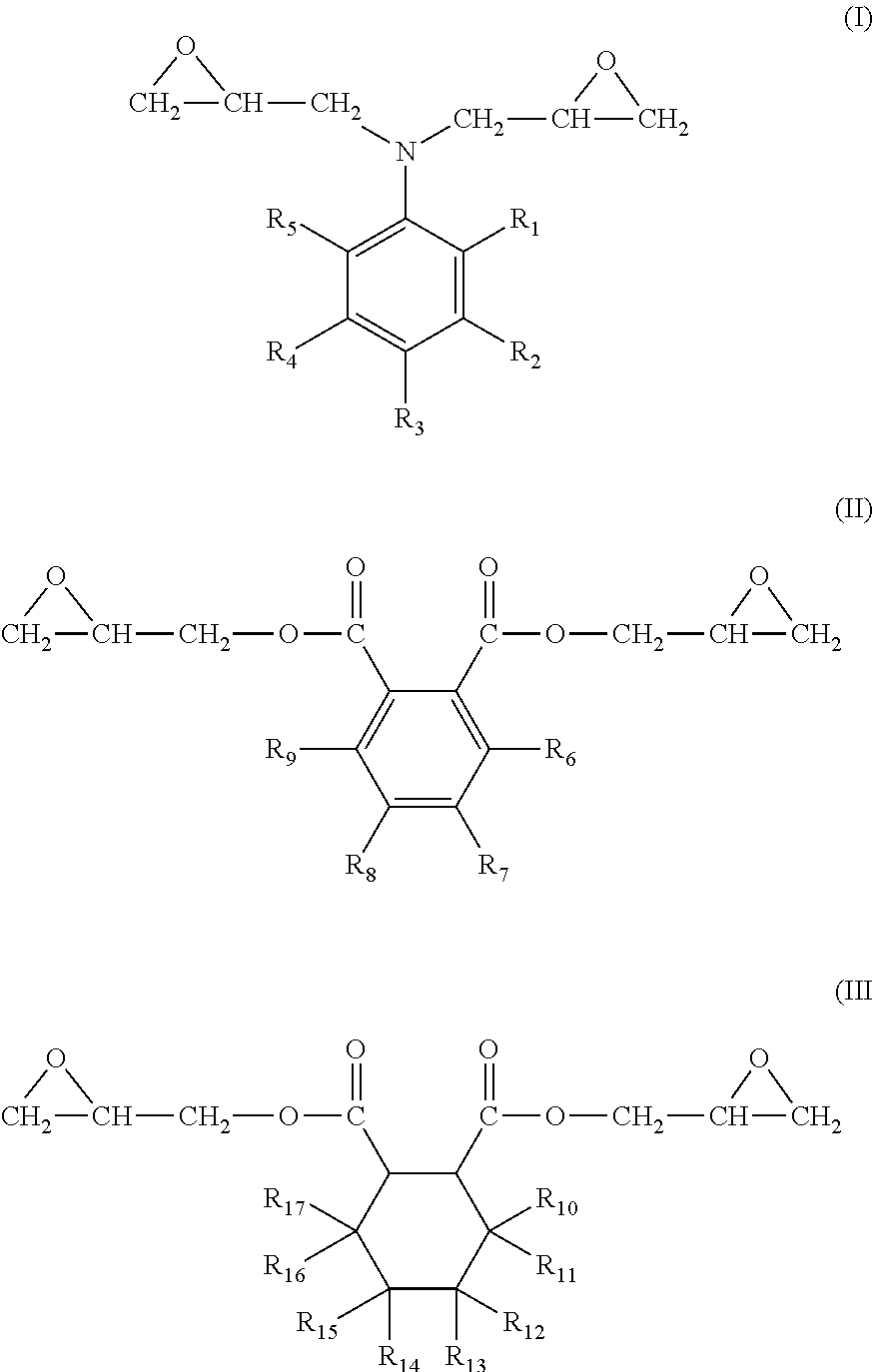

Epoxy resin composition, fiber-reinforced composite material, and method for producing the same

InactiveUS20110097568A1Low viscosityExcellent impregnationWoven fabricsThin material handlingEpoxyFiber-reinforced composite

Disclosed herein are an epoxy resin composition for fiber-reinforced composite materials which has low viscosity, high Tg, high elastic modulus, and excellent fracture toughness and a fiber-reinforced composite material using such an epoxy resin composition which has excellent thermal properties, compressive strength, impact resistance, fatigue resistance, and open-hole tensile strength and which is suitable for producing structural parts of aircraft and the like. The epoxy resin composition comprises at least a given bifunctional epoxy resin as a component (A), a liquid aromatic diamine curing agent as a component (B), and core-shell polymer particles as a component (C), wherein the core-shell polymer particles as the component (C) contain epoxy groups in their shell and have a volume-average particle size of 50 to 300 nm.

Owner:TORAY IND INC

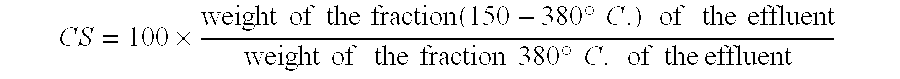

Catalyst comprising at least one zeolite chosen from ZBM-30, SM-48 EU-2 and EU-11 and at least one Y zeolite and process of hydroconversion of hydrocarbon charges using such a catalyst

InactiveUS20040232047A1Excellent impregnationHigh catalytic activityMolecular sieve catalystsHydrocarbon oil crackingZeoliteHydrocarbon

A hydrocracking catalyst containing at least one matrix, at least one zeolite chosen from the group formed by the zeolites ZBM-30, ZSM-48, EU-2, and EU-11, at least one Y zeolite, at least one hydro-dehydrogenating metal chosen from the group formed by the metals from Group VIB and Group VIII of the periodic table, optionally at least one element chosen from the group formed by phosphorus, boron and silicon, optionally at least one element from Group VIIA, and optionally at least one element from Group VIIB is used in a process of hydrocracking / hydroconversion of hydrocarbon charges.

Owner:INST FR DU PETROLE

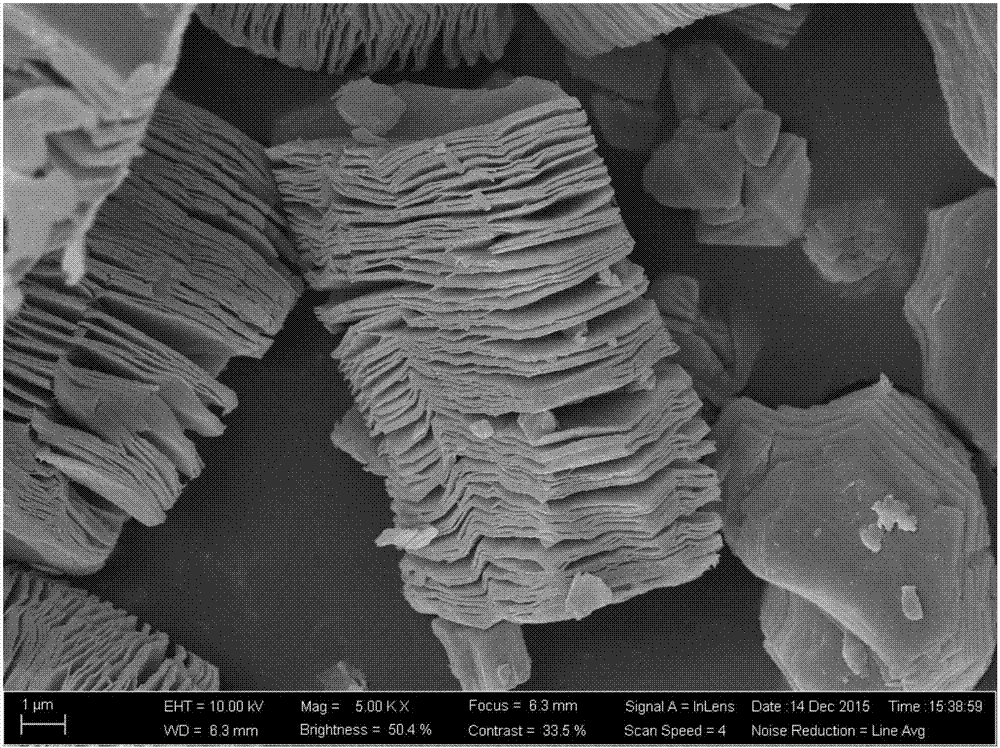

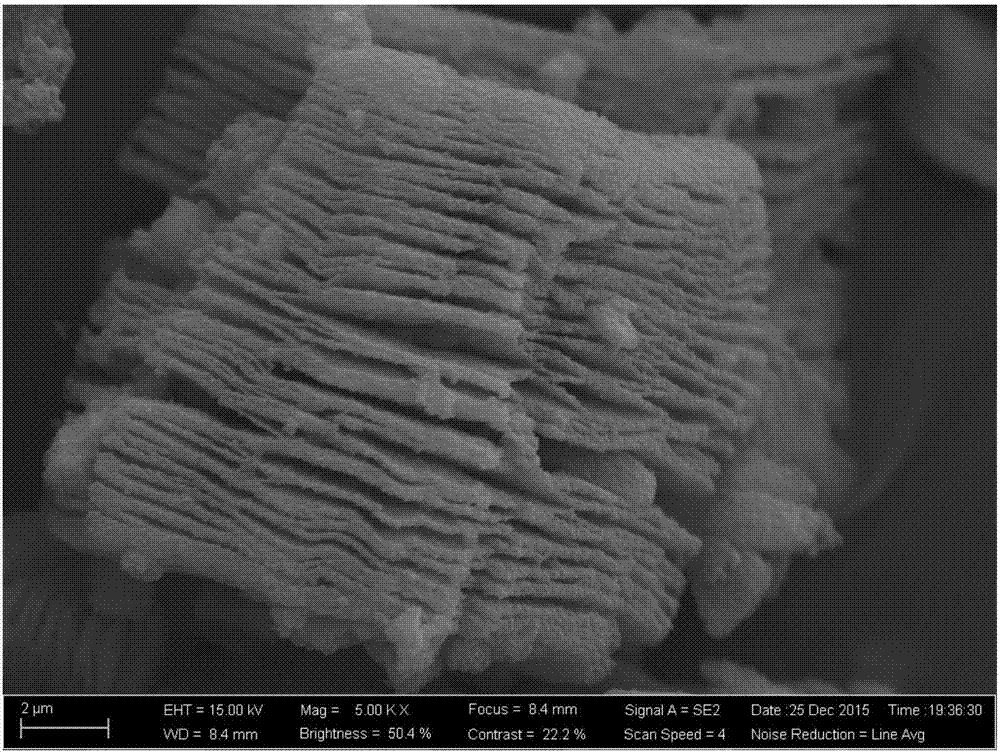

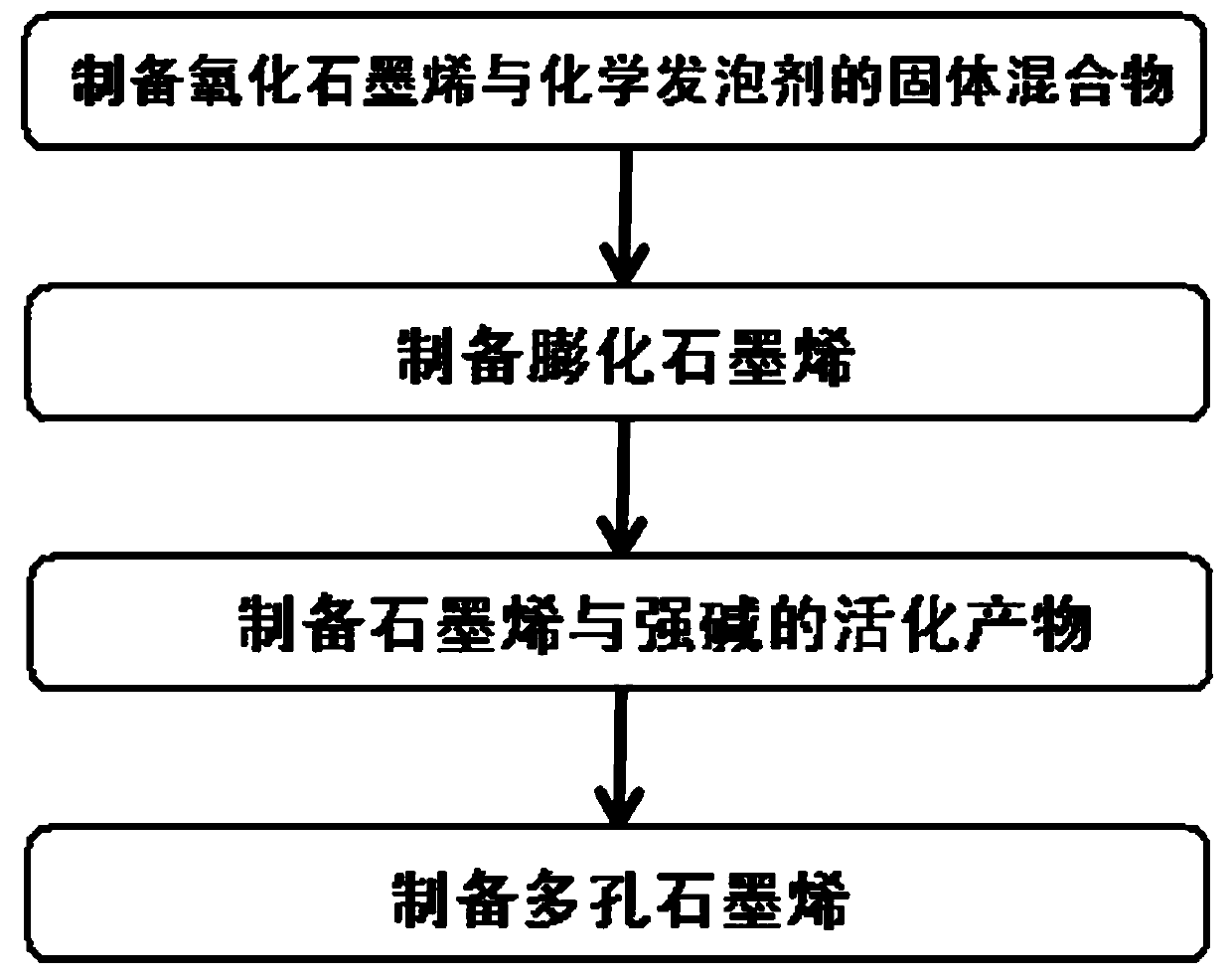

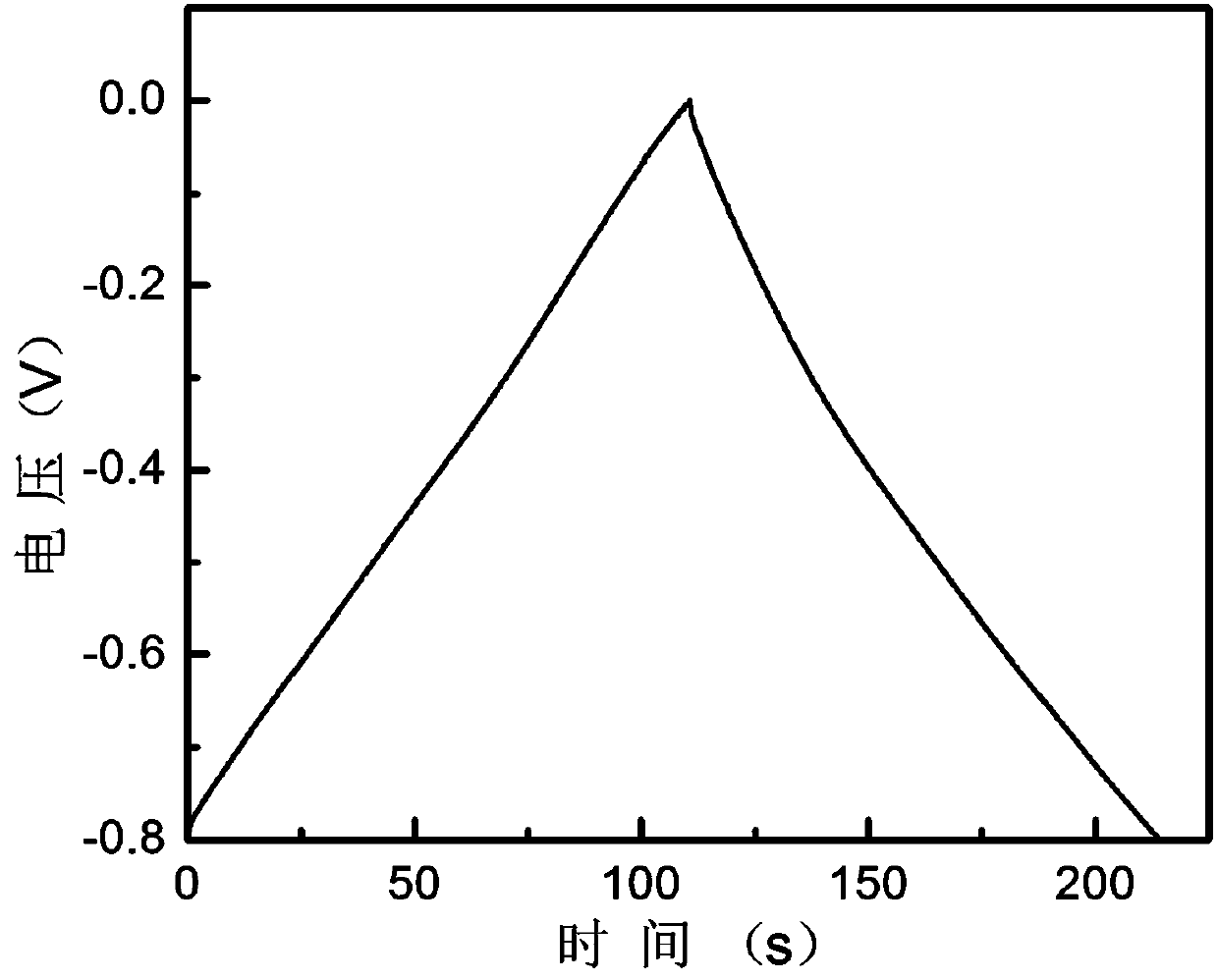

Preparation method of porous graphene

InactiveCN103466604AInhibit high temperature agglomeration effectHigh degree of peelingCarbon compoundsPorous grapheneCapacitance

The invention discloses a preparation method of porous graphene. The method comprises the steps of: (1) stripping graphite oxide in a water / ethanol mixed solution with pH of 9-10, adding a chemical foaming agent and mixing them uniformly, carrying out filtering and drying to obtain a solid mixture; (2) placing the mixture in a reducing atmosphere, and performing heating expansion reduction to obtain expanded graphene; (3) blending the expanded graphene with strong base, and conducting high temperature activation; and (4) washing the product with hydrochloric acid and deionized water, and performing drying so as to obtain porous grapheme. The porous graphene prepared by the method involved in the invention has a specific surface area up to 2075m<2> / g, a pore volume up to 1.8cm<3> / g, and an average pore size of 1-7nm. As a supercapacitor electrode material, the specific capacitance can reach 155F / g under a current density of 1Ag<-1>. As a porous graphene electrode, the specific capacitance can reach 84.4% along with the increase of current density from 0.2Ag<-1> to 20Ag<-1>. The porous graphene has high specific capacitance and cycle stability. The preparation method disclosed in the invention has the advantages of simple process, low cost, and easy scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

Electrode for electrochemical element

InactiveCN103907226AImprove adhesionExcellent impregnationElectrode manufacturing processesElectrolytic capacitorsEngineeringElectrochemistry

Owner:ZEON CORP

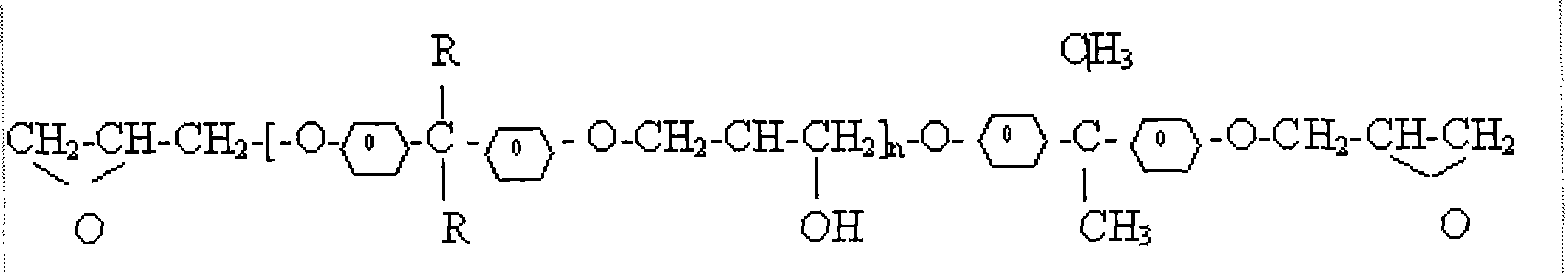

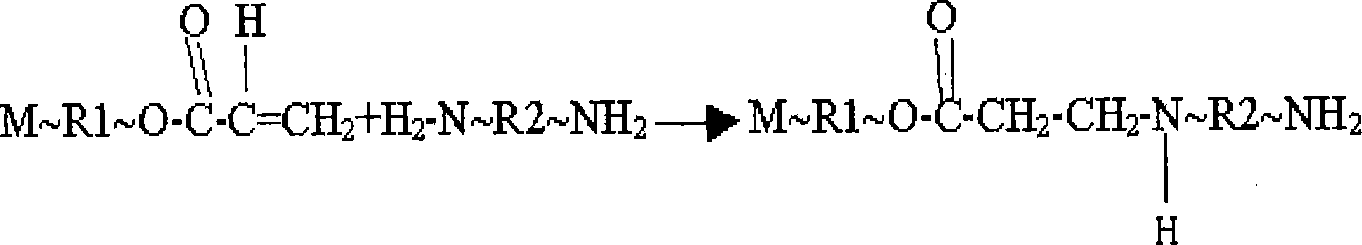

Epoxy resin and use thereof

The invention relates to an epoxide resin and the use. The epoxide resin comprises an epoxide, the reacting deflocculating agent and the curing agent, wherein the reacting deflocculating agent is a monomer or oligomer of acrylate and methacrylate with the low viscosity in the ambient temperature and a or a plurality of unsaturated double bond reactive function group, the reacting deflocculating agent is charged in the epoxide resin and is mixed uniformly in order to form the host crystal of the epoxide formulation, the host crystal comprises the reacting deflocculating agent 5-30 parts and agent B which forms epoxy resin formulation comprised by curing agent, the weight percentage of the agent B and the host crystal is 20-50 :100. The invention can improve the gel time, the temperature of exothermic peak and the processing operation characteristic of viscosity in the hardening process of the epoxide, which reduces the mechanical properties of the cured epoxide less, improves the tenacity of the epoxide, is suitable for manufacturing structural element of large scale composite material (air vane, craft, car and aerial craft and the like), and has good operation time, low exothermic peak temperature and fiber immersing property.

Owner:SWANCOR ADVANCED MATERIALS CO LTD

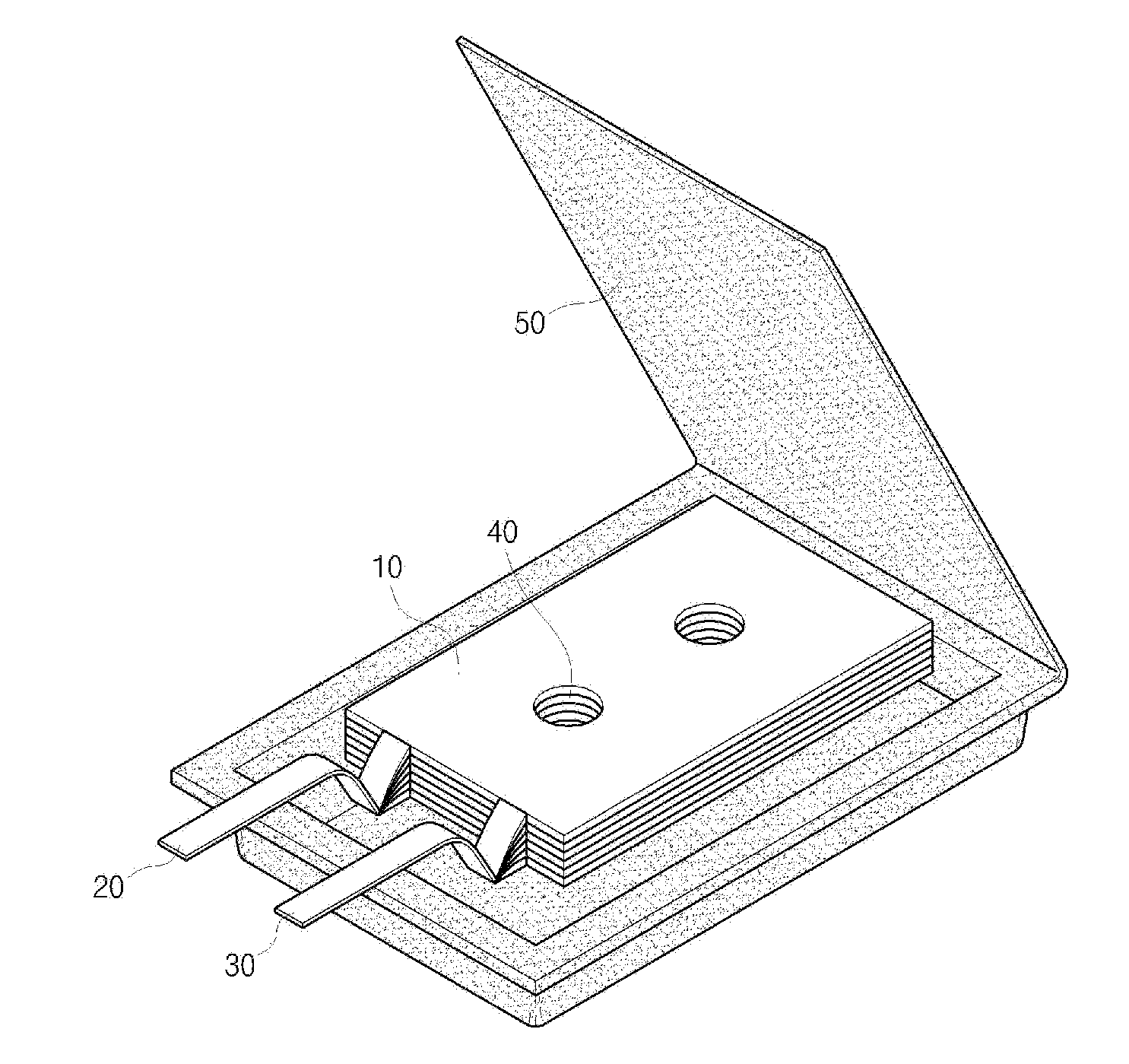

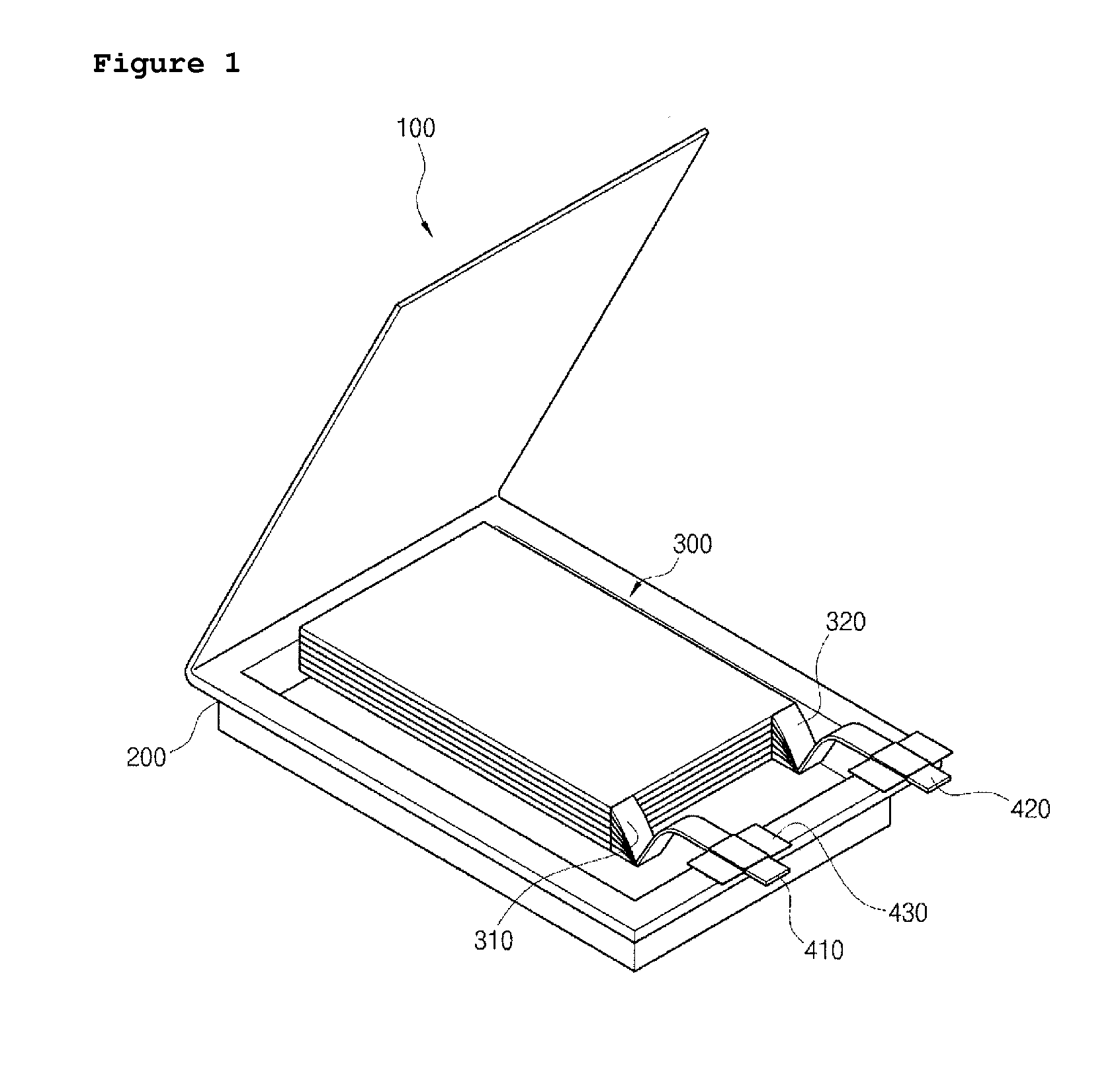

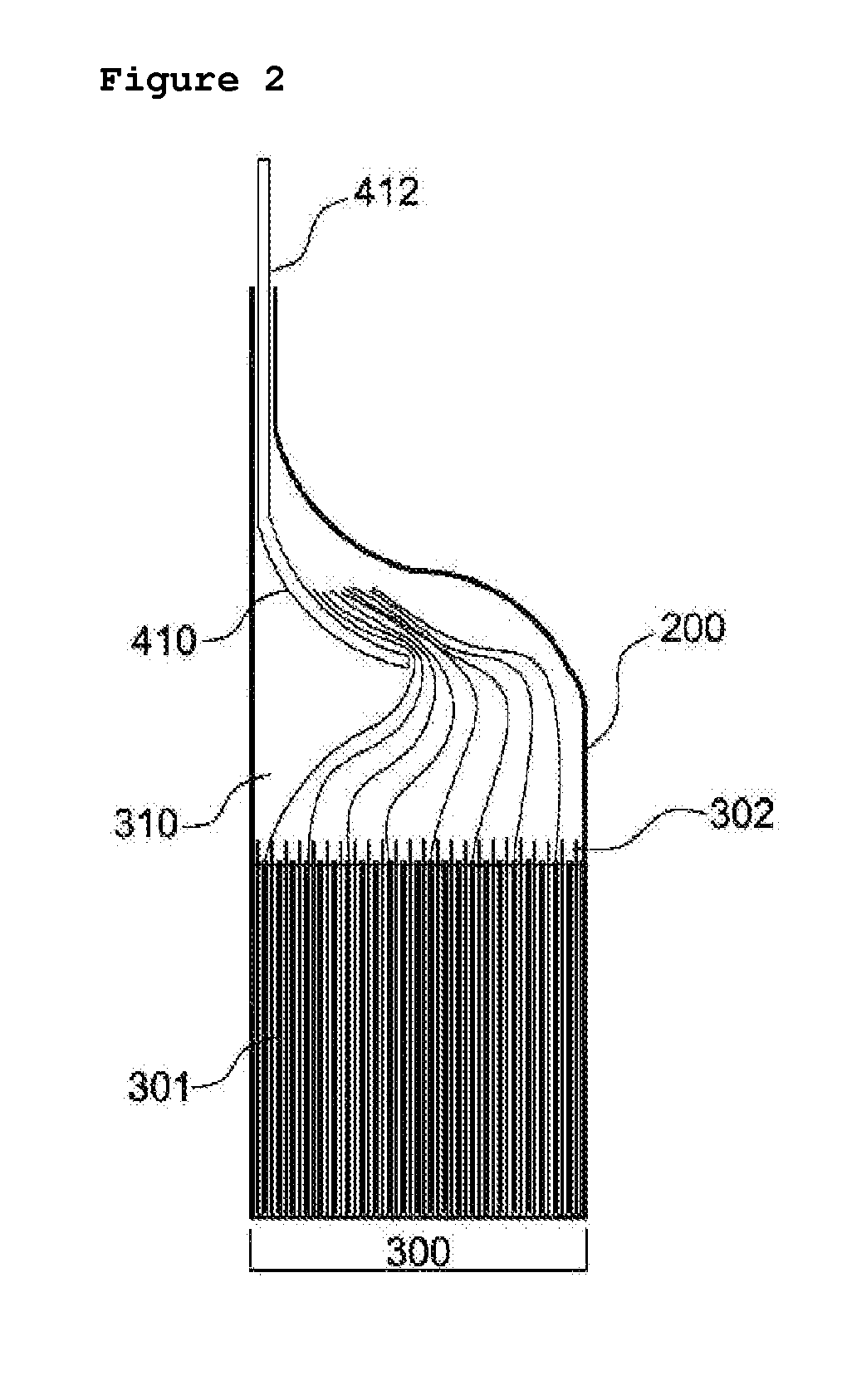

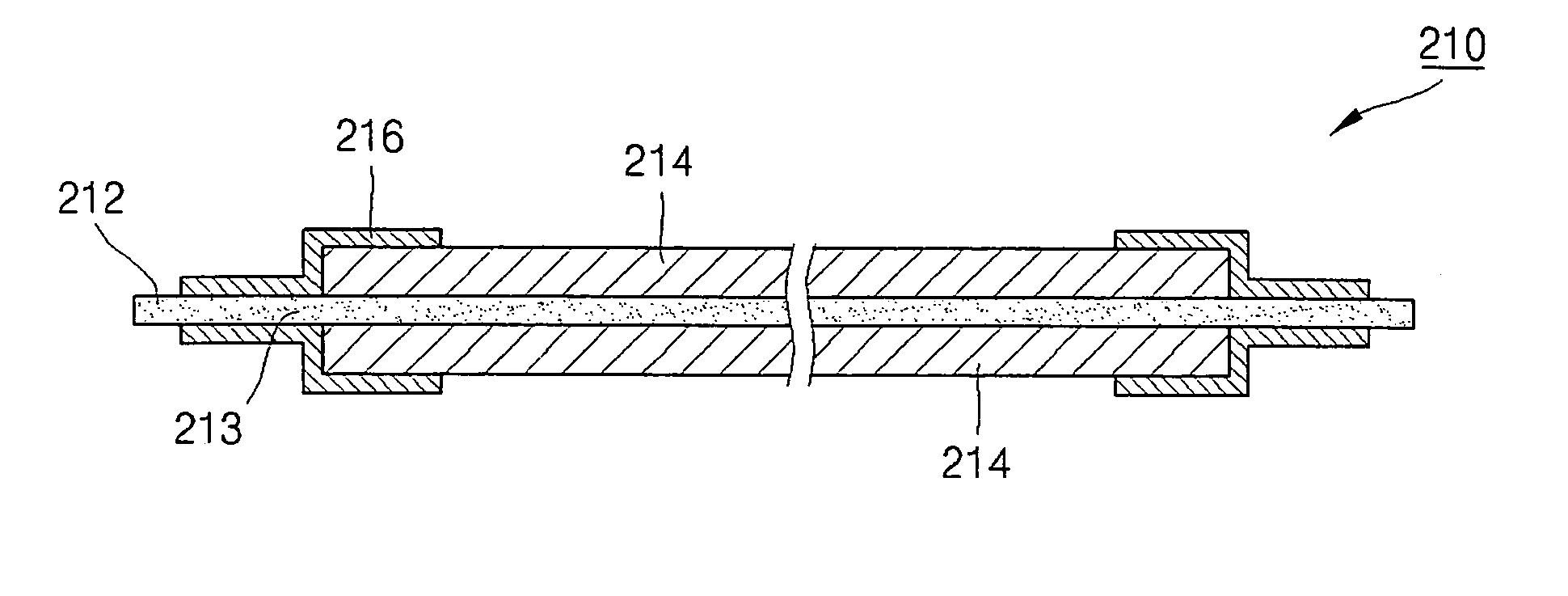

Electrode assembly with porous structure and secondary battery including the same

ActiveUS20140106193A1Improve securityEasy to fixLarge-sized flat cells/batteriesFinal product manufactureElectrical batteryBiomedical engineering

The present invention relates to an electrode assembly of a porous structure and a secondary battery including the same. In an electrode assembly including a plurality of anodes, cathodes, and separators, the present invention provides a secondary battery including an electrode assembly including one or more through holes, and a passing sealing portion supplementarily sealed on positions corresponding to the through holes. The secondary battery according to the present invention may prevent the inner short and increase safety by including the fused portion of an electrode assembly and a battery case, stably fixing them, and holding back the movement of the electrode assembly. In addition, the present invention has an effect of being capable of greatly enhancing impregnation on electrolyte since the electrode assembly has a porous structure.

Owner:LG ENERGY SOLUTION LTD

Prepreg, process for producing the same, and molded article

InactiveUS20050150593A1Increase production capacityEasy to shapeLamination ancillary operationsLaminationFiber bundleMechanical property

This invention provides a prepreg excellent in productivity, having the drapability to allow easy shaping according to a mold, excellent in resin impregnation, and excellent in handling convenience. This invention also provides a molded article with excellent mechanical properties obtained by molding the prepreg. The prepreg of this invention is a prepreg comprising reinforcing fibers and a thermoplastic resin, characterized in that an air-permeable layer (B) comprising the thermoplastic resin is laminated on a continuous reinforcing fiber bundle (A), and that the reinforcing fiber bundle (A) and the layer (B) comprising the thermoplastic resin are bonded at their interface.

Owner:TORAY IND INC

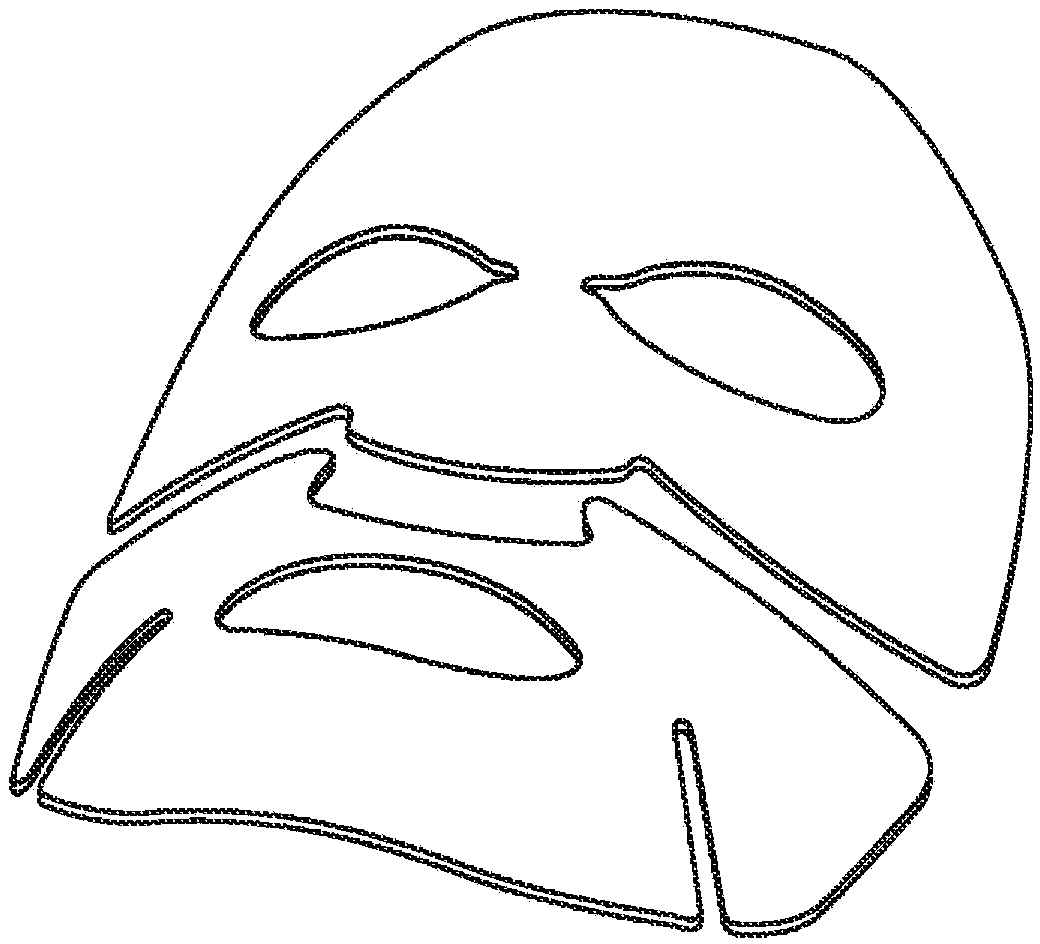

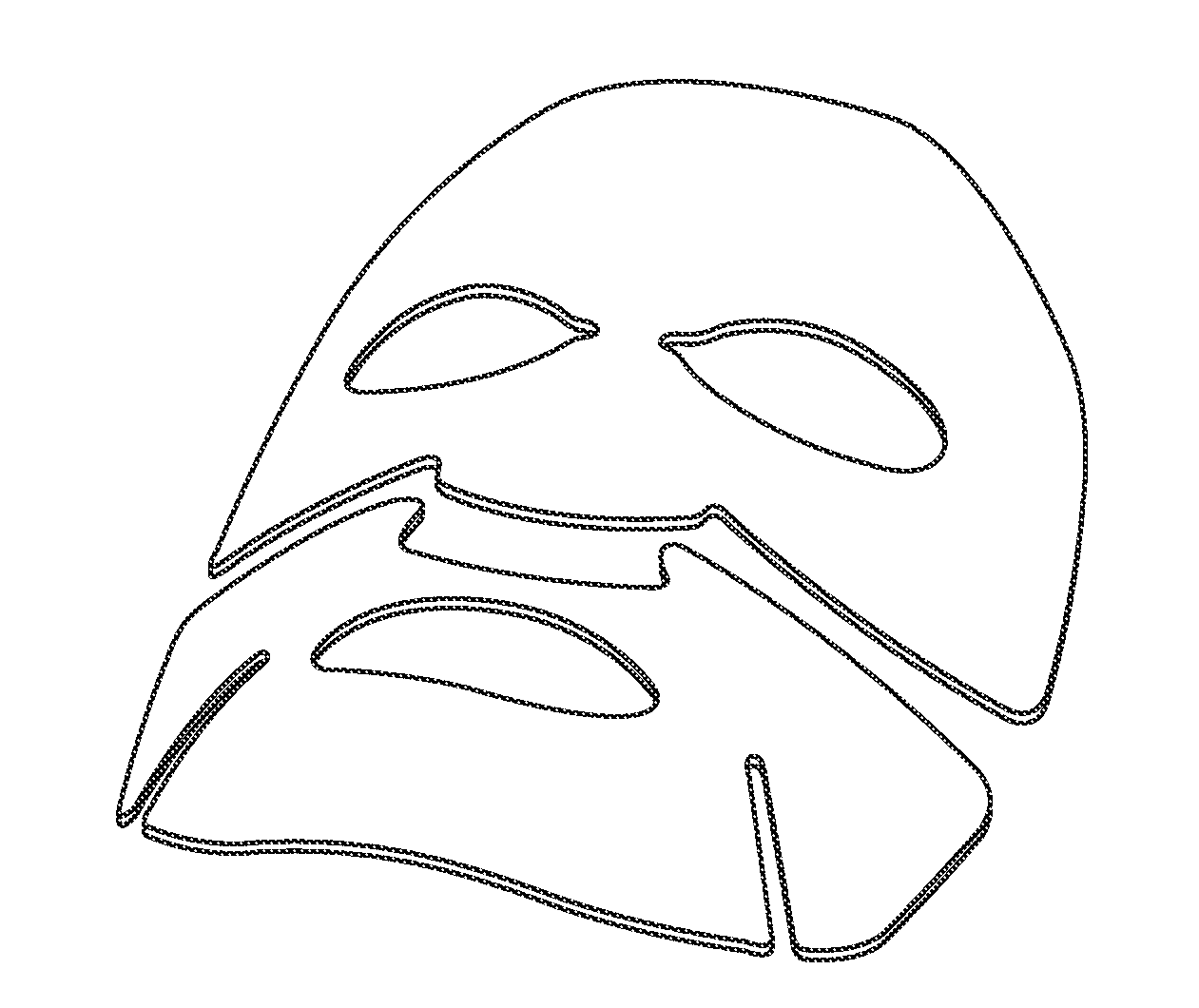

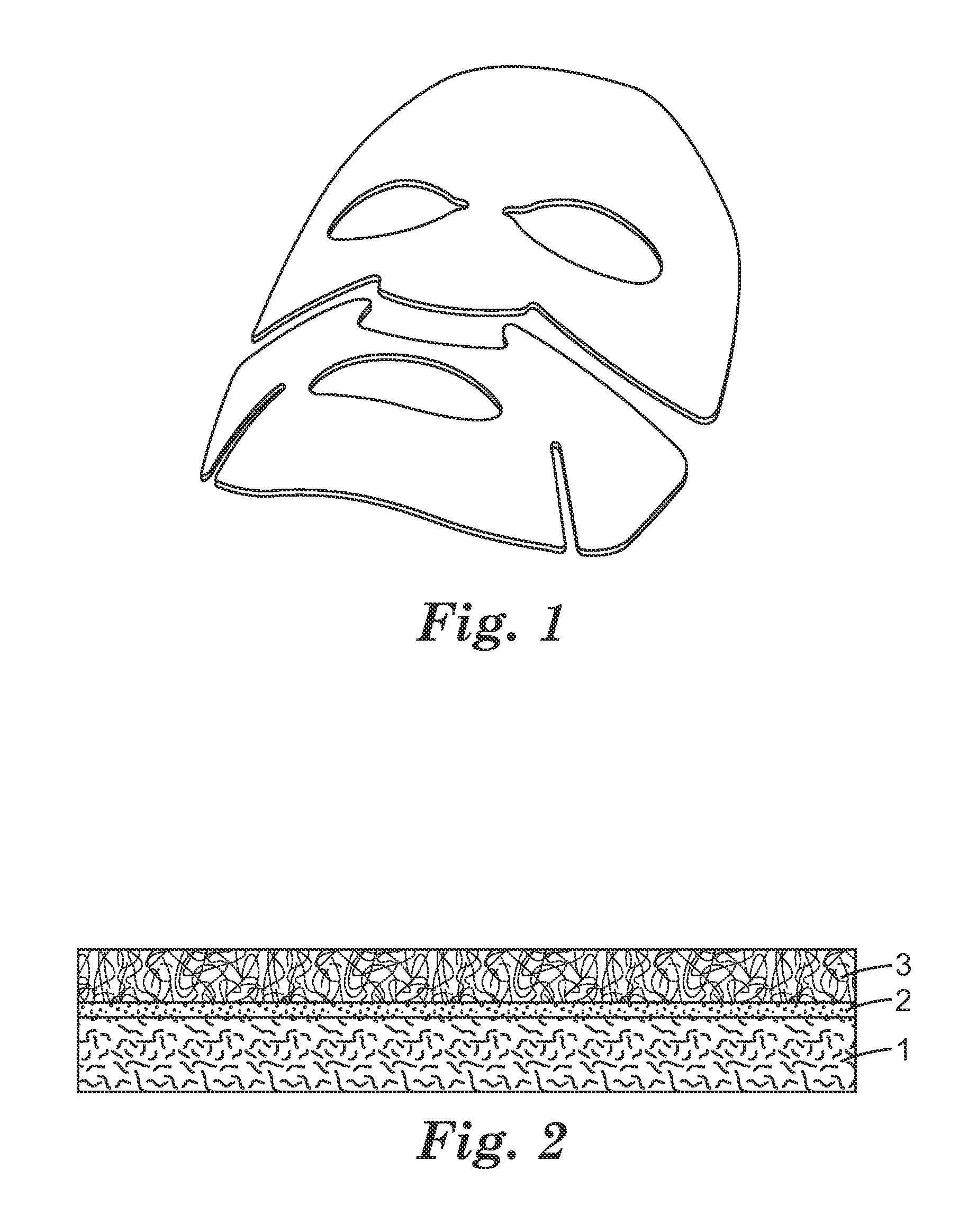

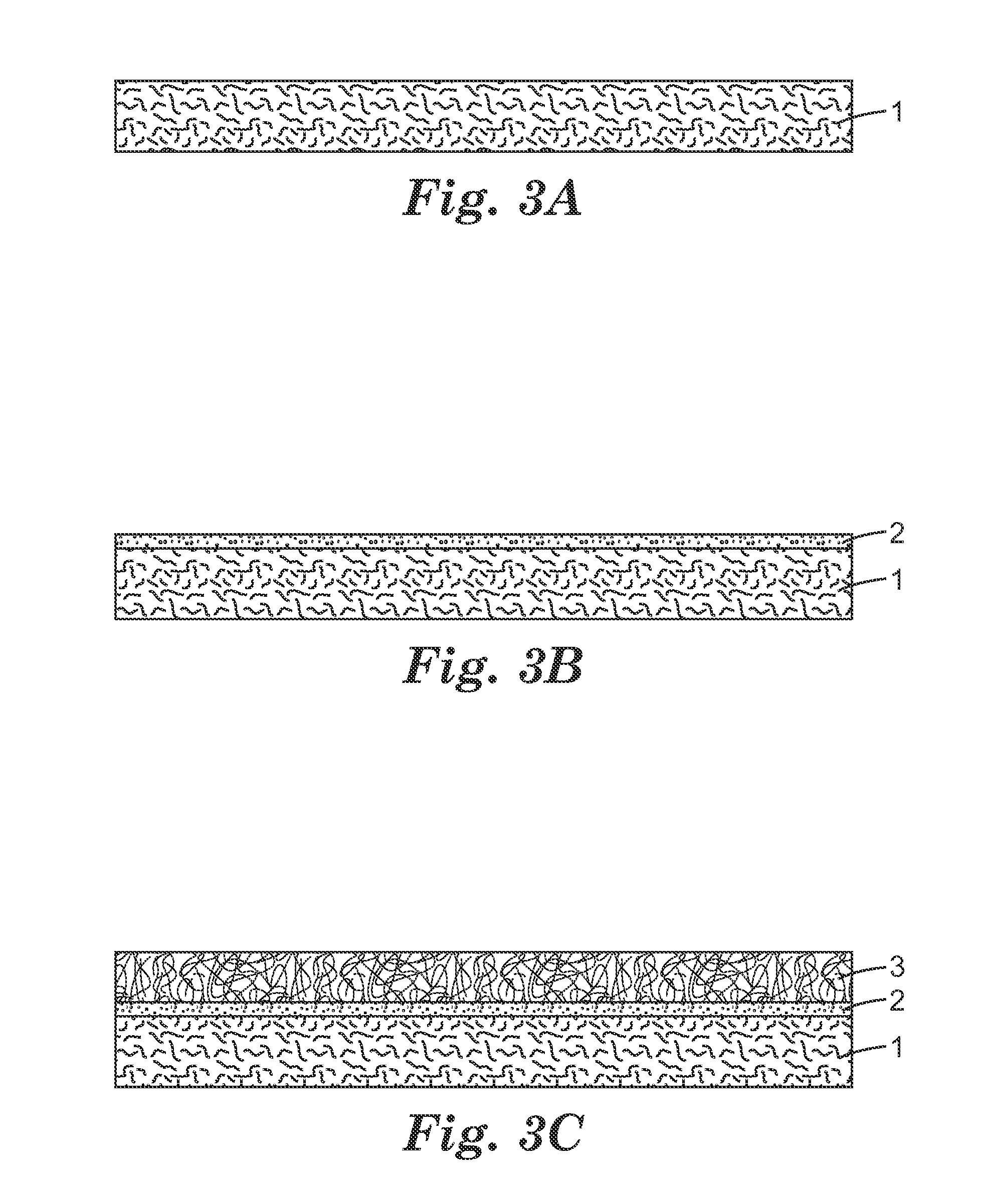

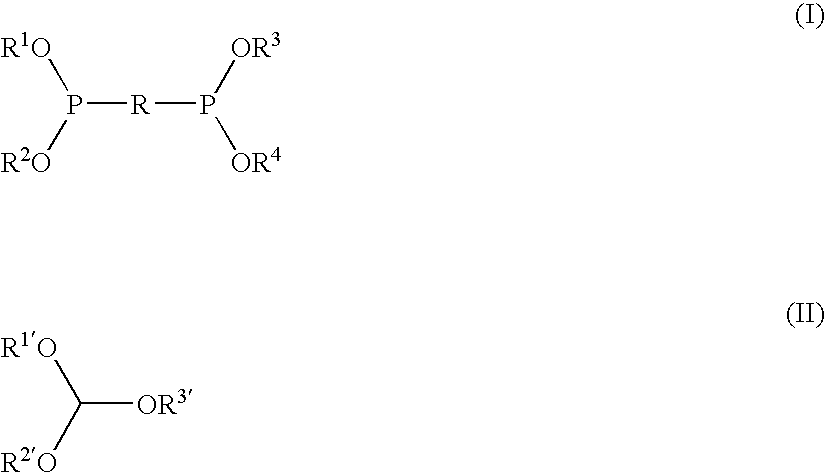

Mask pack

InactiveCN104114057AImprove stratificationStrong adhesionHead bandagesCosmetic preparationsHuman skinSkin surface

A mask pack impregnated with a liquid cosmetic preparation, being applied to a human skin surface, in particular a facial skin surface. The mask pack includes a nonwoven fabric layer and a nanofiber layer including a hydrophilic polymer, wherein said nanofiber layer is bonded to the nonwoven fabric layer.

Owner:3M INNOVATIVE PROPERTIES CO

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS7824770B2Excellent impregnationMaintain good propertiesSynthetic resin layered productsCoatingsFiber bundleShell molding

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

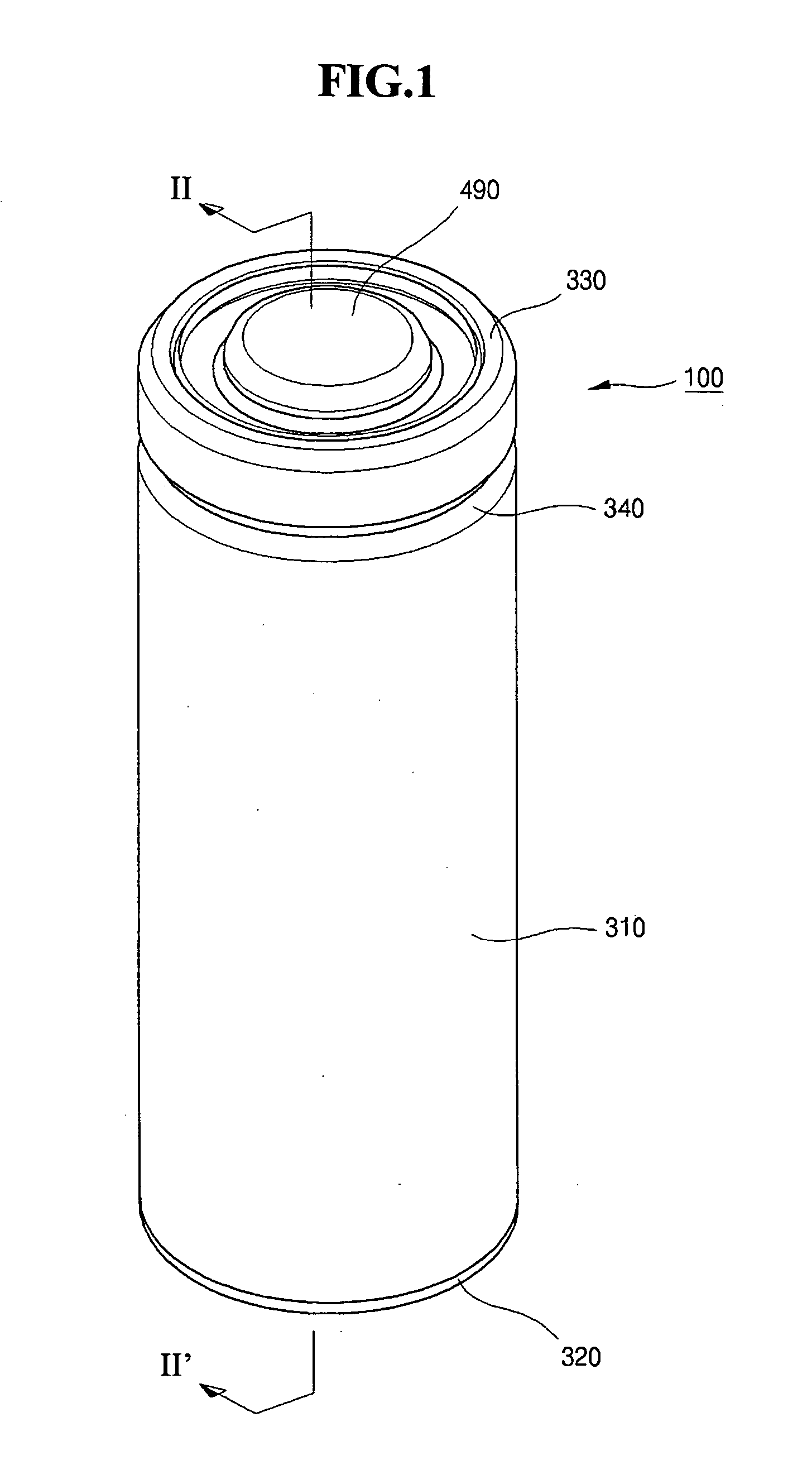

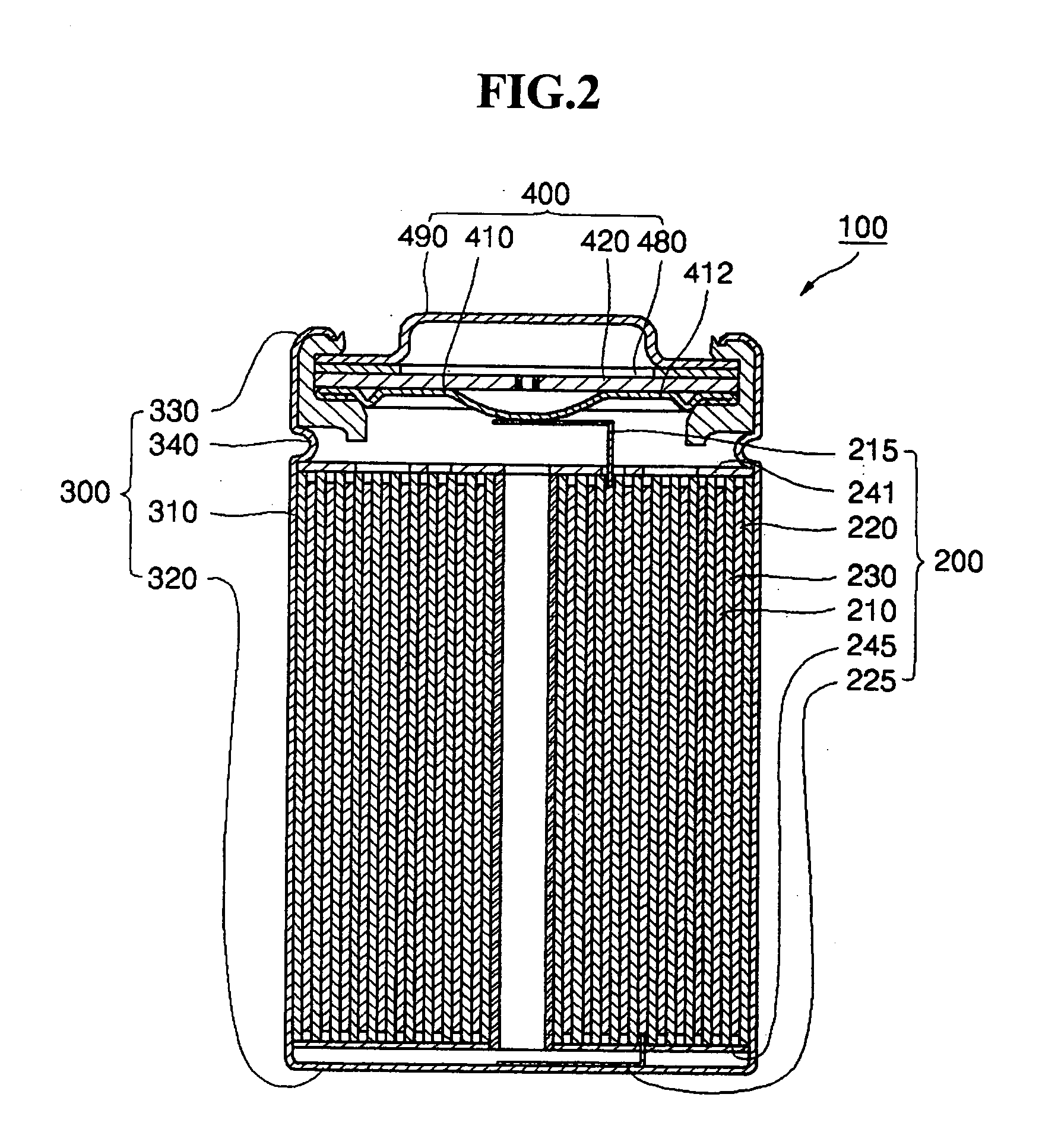

Lithium secondary battery

ActiveUS20070154788A1Improving impregnation of electrolyteExcellent impregnationFinal product manufactureElectrode carriers/collectorsLithiumAdditive ingredient

A lithium secondary battery, and more particularly, a lithium secondary battery which can improve the impregnation of an electrolyte solution either by modifying the material of a protection layer, such as a laminating tape and others, to be formed to protect the elimination of active materials, into a material with an affinity for the electrolyte solution, or by coating the material of an existing protection layer with an ingredient with an affinity for the electrolyte solution.

Owner:SAMSUNG SDI CO LTD

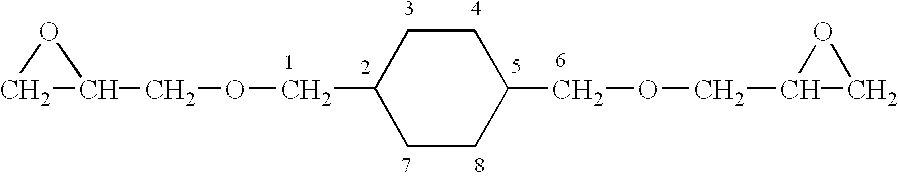

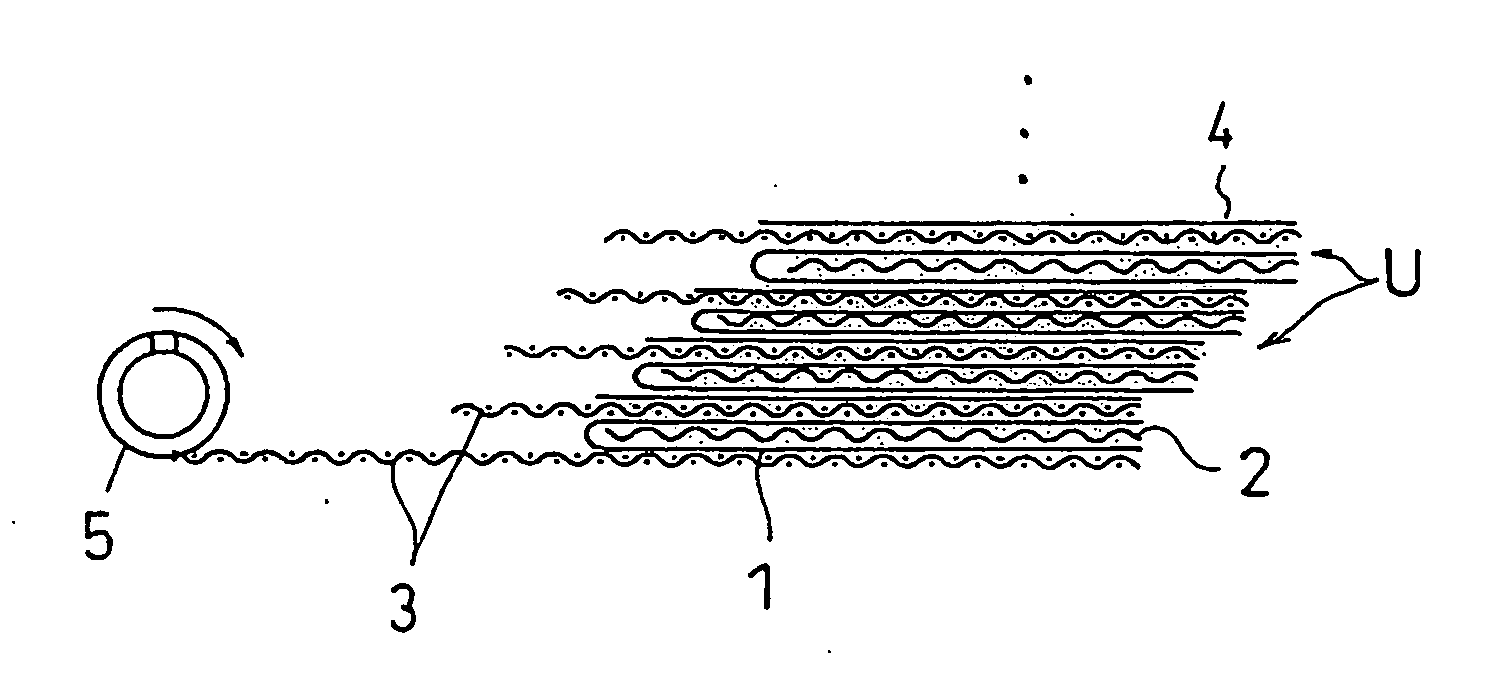

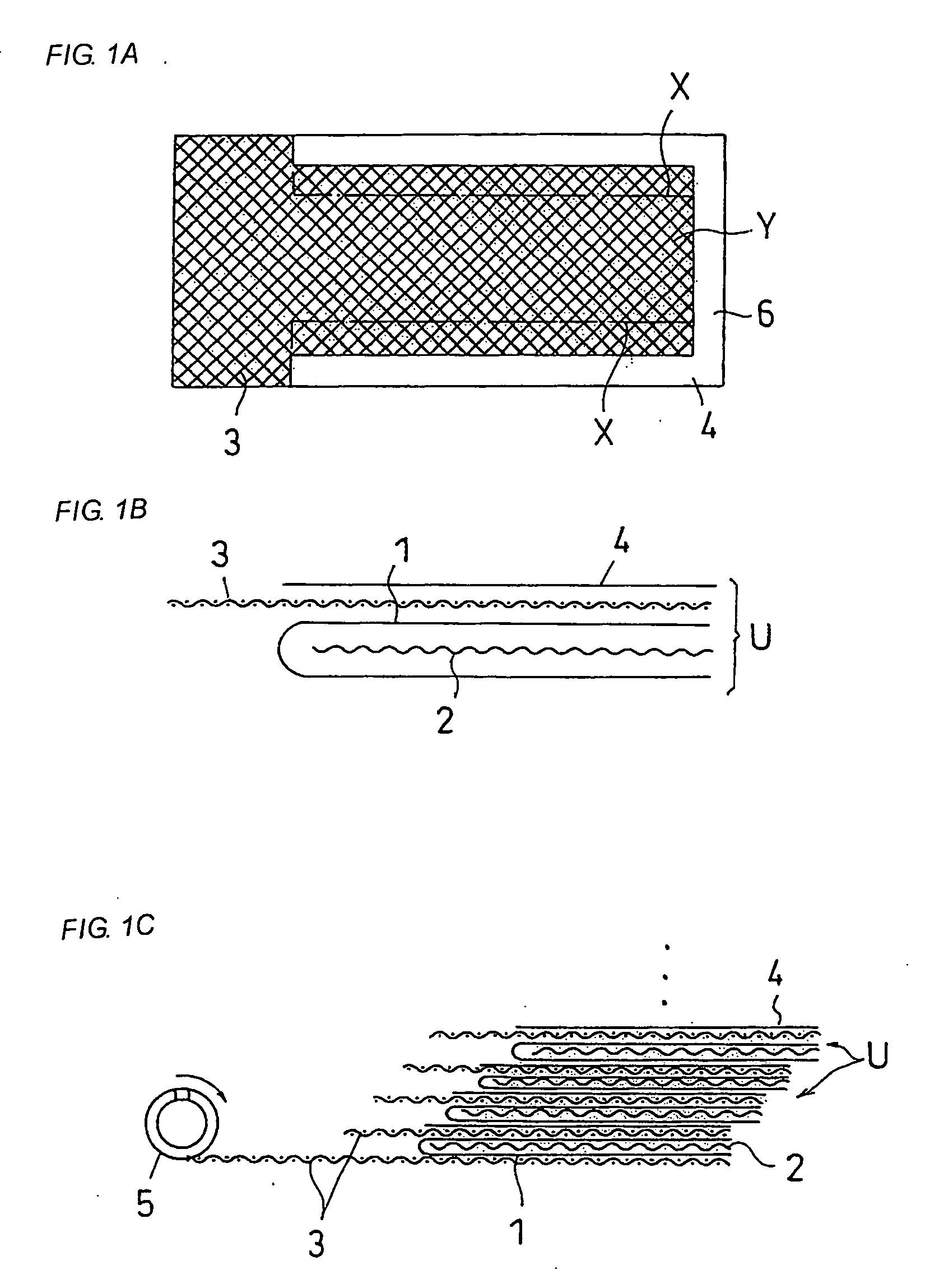

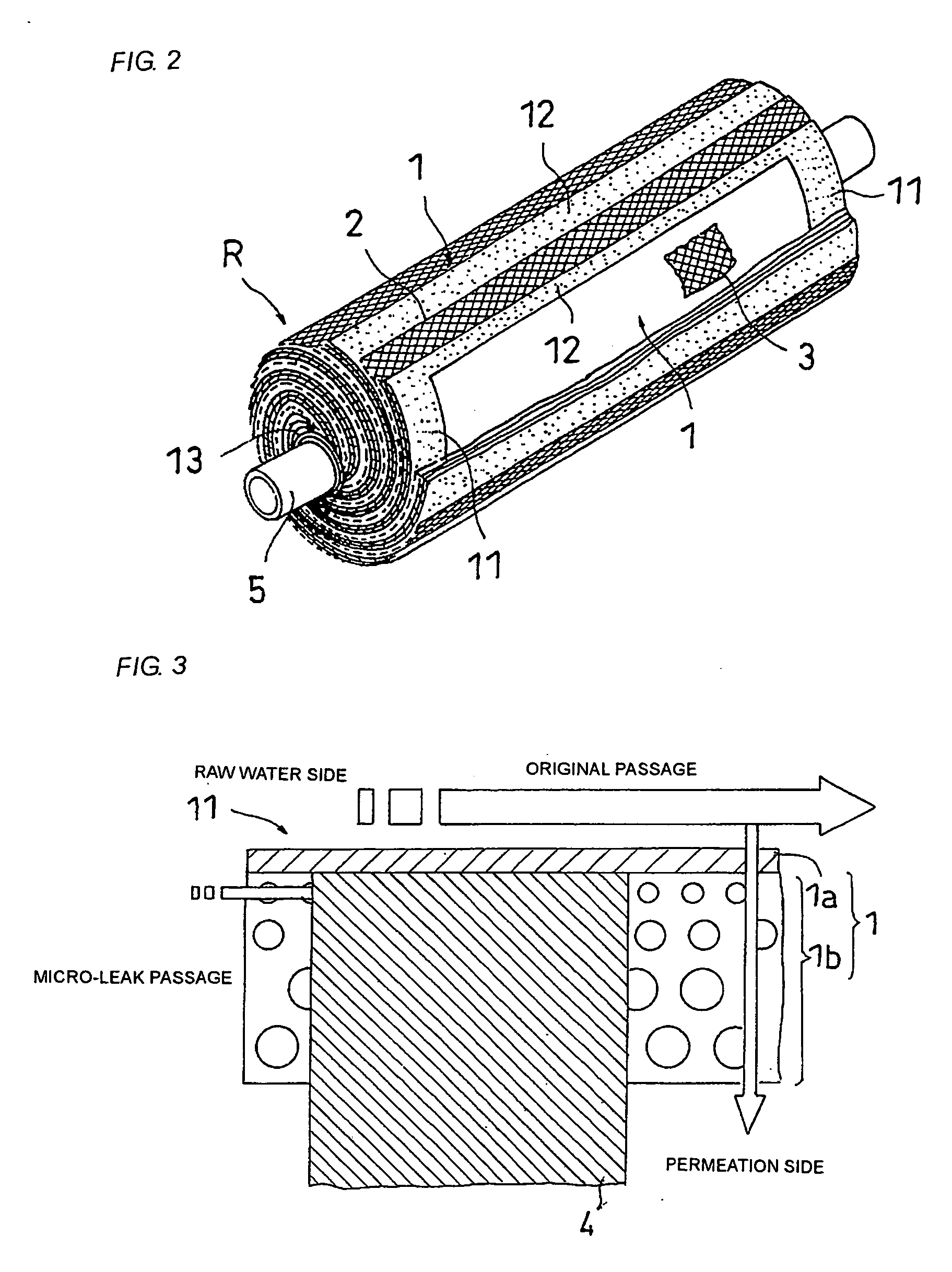

Spiral reverse osmosis membrane element, method of manufacturing the same, and its use method

ActiveUS20060043013A1Avoid dippingEasy to separateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisReverse osmosisPermeation

A spiral reverse osmosis membrane element that improves impregnation property of a sealing resin at edges of a membrane leaf and can effectively prevent micro-leaks, by using, for example, a porous support having a structure capable of sufficiently impregnating therein a sealing resin, a method for manufacturing the same, and a use method of the same are disclosed. The spiral reverse osmosis membrane element comprises a cylindrically wound body comprising a perforated core tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side liquid and a permeation-side liquid from being mixed together, wherein the separation membrane facing through the permeation-side passage material has a structure that a porous support and a skin layer are successively laminated on a non-woven fabric layer, and the sealing portion sealed with a sealing resin is provided at the edges of the separation membrane, wherein the separation membrane is impregnated with the sealing resin at least up to the vicinity of the skin layer through the porous support.

Owner:NITTO DENKO CORP

Mask pack

InactiveUS20140352031A1Excellent impregnationImprove nanofiber delamination phenomenonHead bandagesCosmetic preparationsBiomedical engineeringNanofiber

A mask pack impregnated with a liquid cosmetic preparation, being applied to a human skin surface, in particular a facial skin surface. The mask pack includes a nonwoven fabric layer and a nanofiber layer including a hydrophilic polymer, wherein said nanofiber layer is bonded to the nonwoven fabric layer.

Owner:3M INNOVATIVE PROPERTIES CO

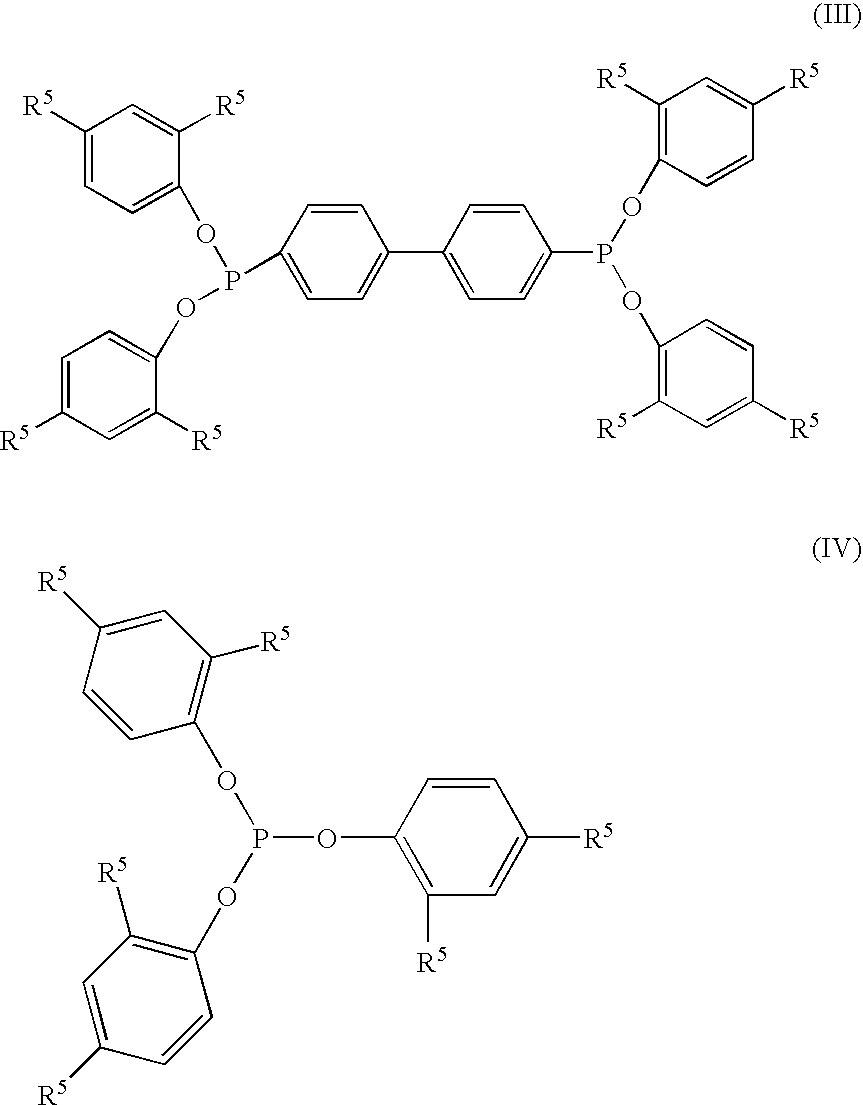

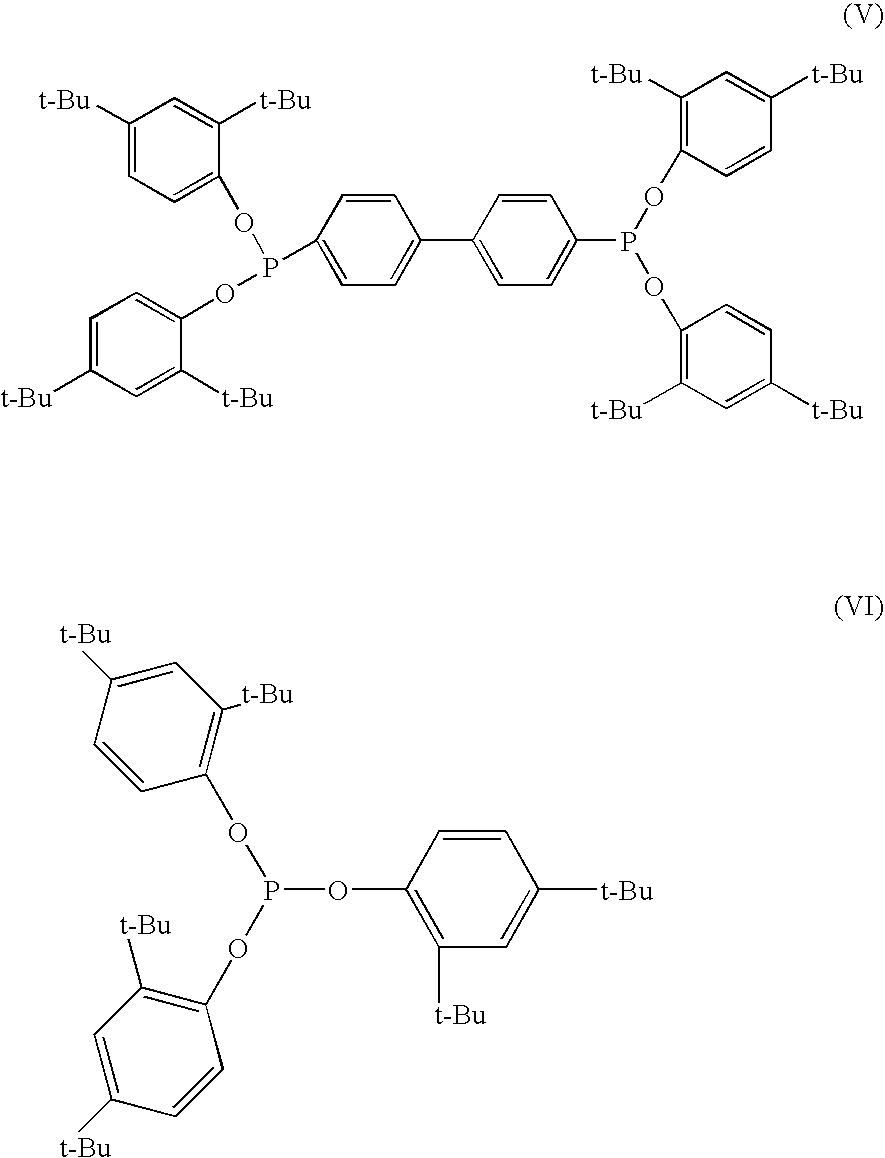

Single-component adhesive silicone elastomer composition which can be crosslinked by polyaddition

InactiveUS20060128881A1Well formedExcellent impregnationOther chemical processesGroup 5/15 element organic compoundsHydrosilylationSiloxane

Owner:BLUESTAR SILICONES FRANCE SAS

Boiling-resistant epoxy adhesive as well as preparation method and application thereof

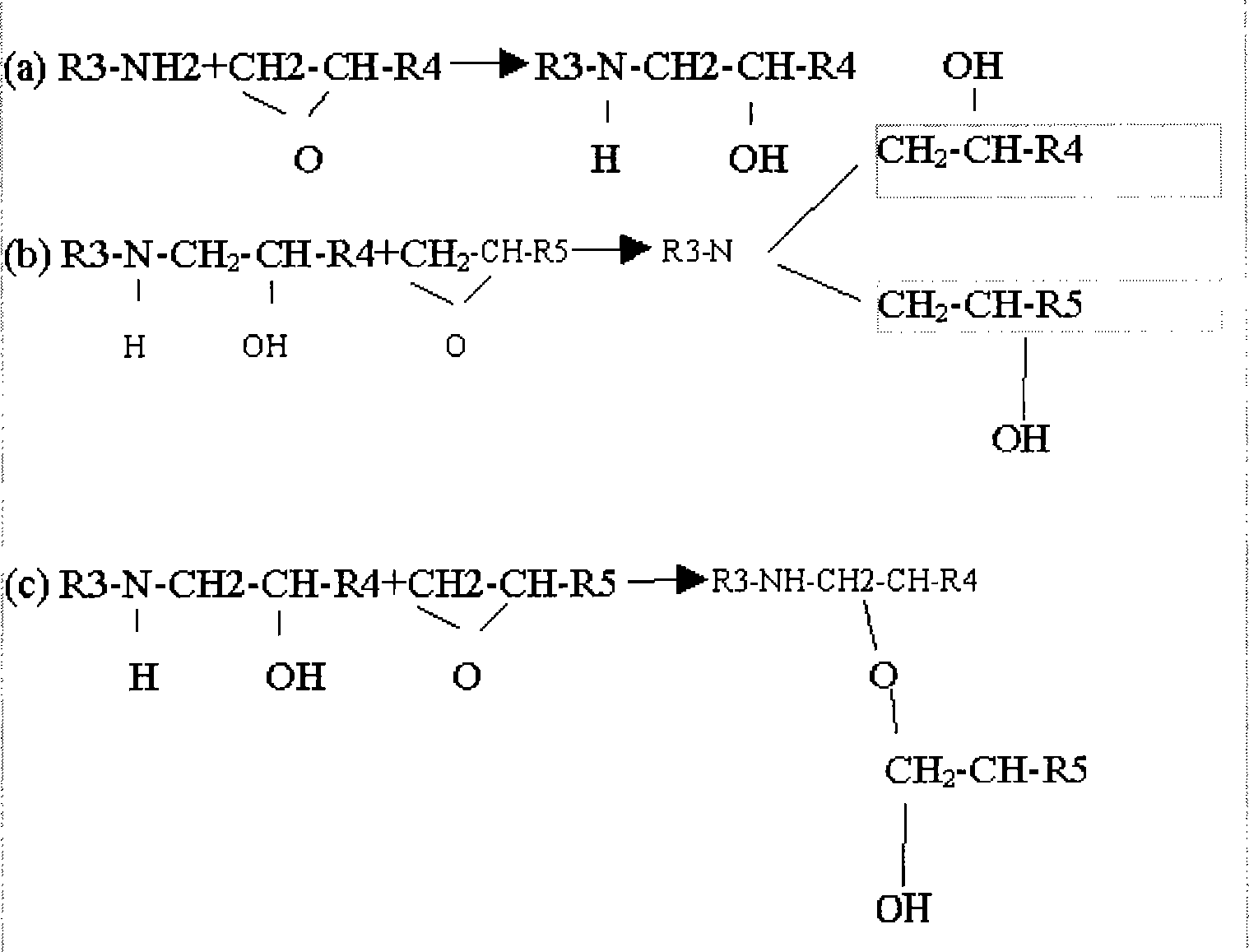

InactiveCN102329584AStrong adhesionEasy to useNon-macromolecular adhesive additivesOther chemical processesPolyolAlcohol

The invention relates to a boiling-resistant epoxy adhesive as well as a preparation method and application thereof. The boiling-resistant epoxy adhesive consists of a component A and a component B; epoxy resin, toughener and coupling agent are mixed, and are stirred and heated, activated inorganic filler and activated inorganic flame retardant are added, polyhydric alcohol or polyhydric phenol is then added, and thereby the component A is prepared; anhydride and catalyst are mixed and heated, activated inorganic filler and activated inorganic flame retardant are then added, and after depressurization for defoaming, the component B is prepared; when in use, the component A and the component B are uniformly mixed according to the proportion by weight of 1 to 3:1, and thereby the boiling-resistant epoxy adhesive is prepared. Compared with the prior art, the boiling-resistant epoxy adhesive has high adhesive force for electronic elements, is convenient to use, and has excellent high-temperature-resistant property, high strength and good weather fastness and impregnating property, the surface properties of solidified product is excellent, and the post-solidification phenomenon caused by cracking is prevented.

Owner:上海海鹰粘接科技有限公司

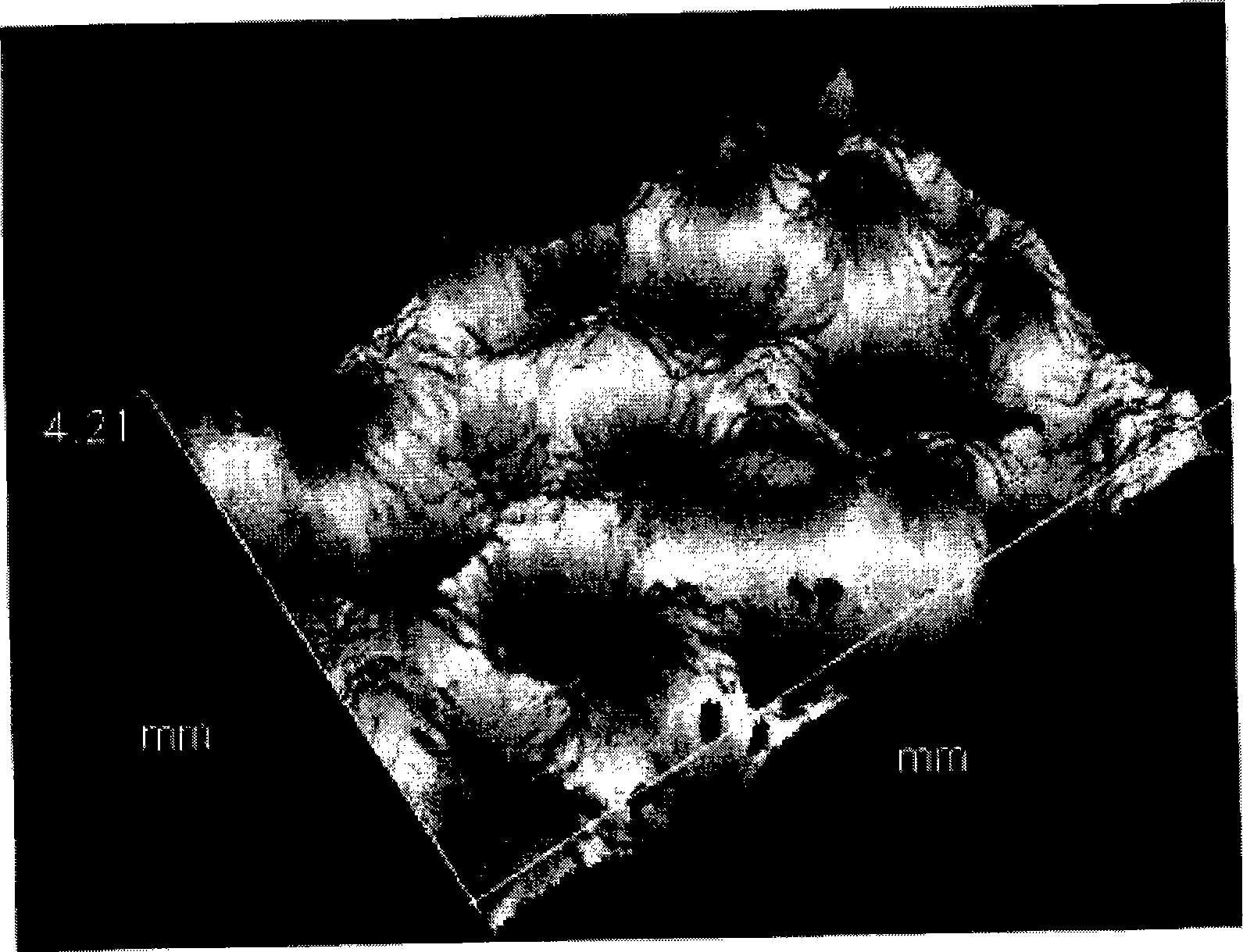

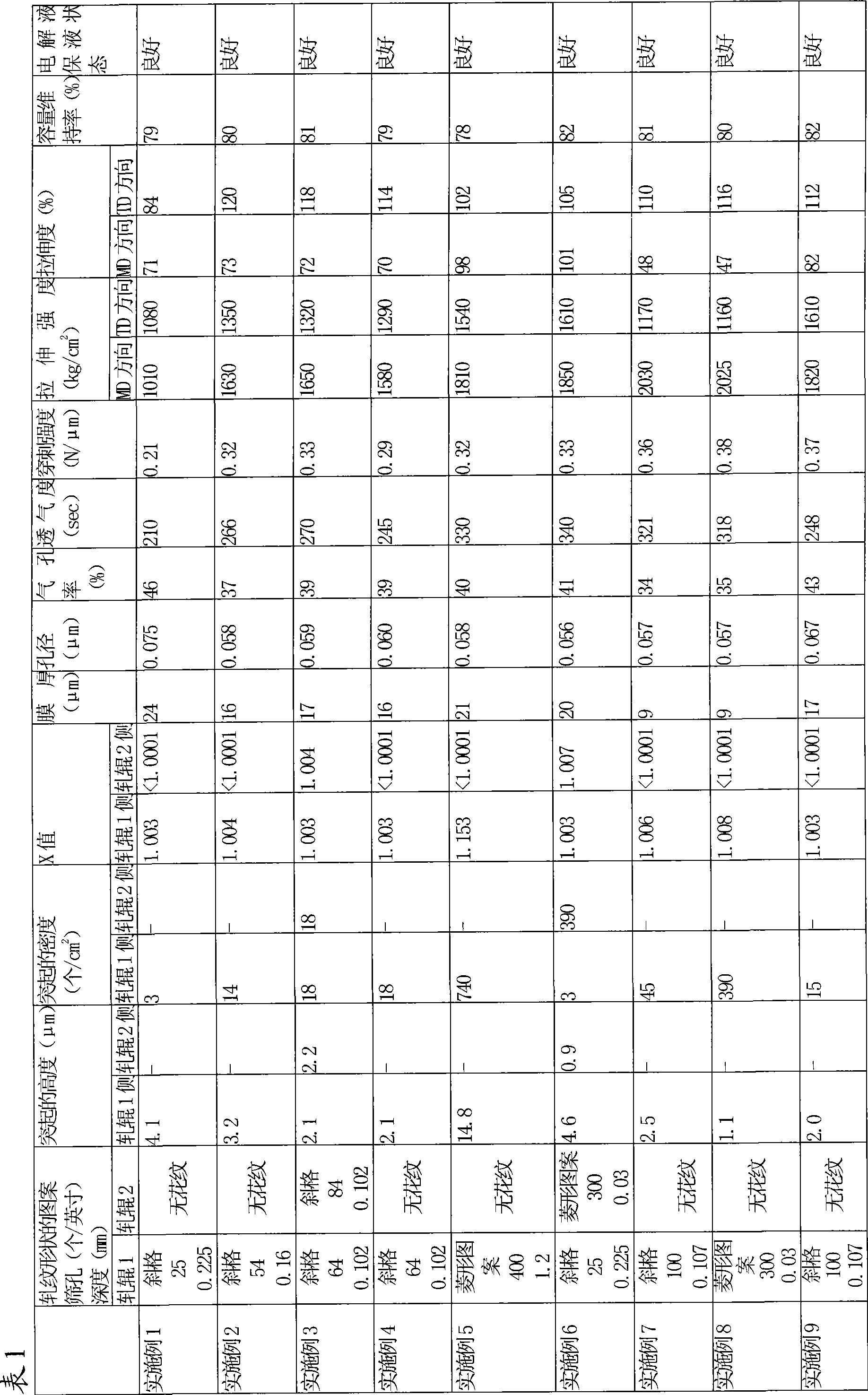

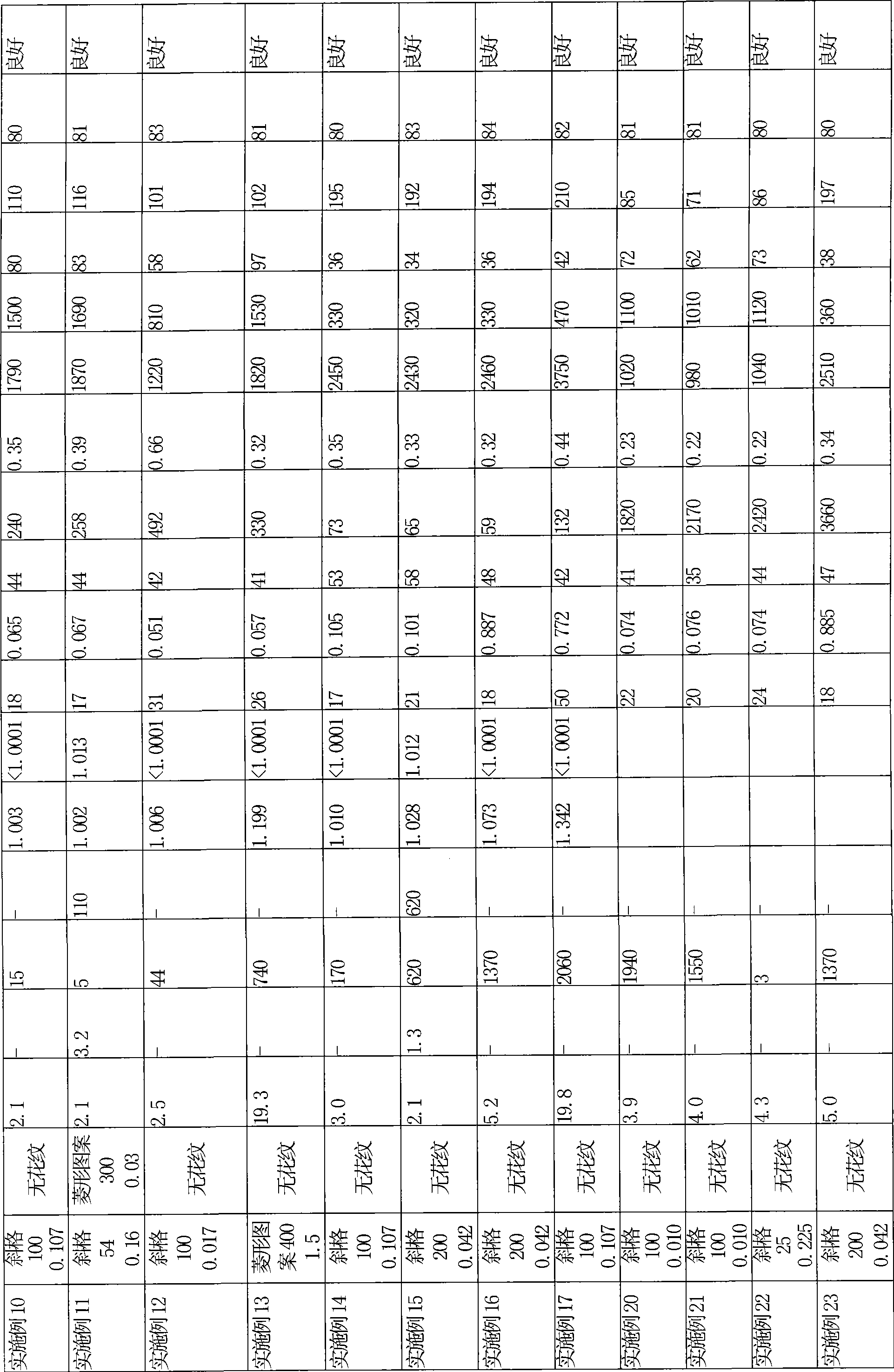

Polyolefin microporous membrane

ActiveCN101535386AAvoid compressionAvoid destructionSolid electrolytesCell seperators/membranes/diaphragms/spacersPolyolefinPolymer science

A polyolefin microporous membrane, which has a thickness of 1-100[mu]m, a pore diameter of 0.01-1[mu]m and a protrusion having a height of 0.5-30[mu]m arranged by embossing at least on one surface, is provided. A method for manufacturing the membrane and a battery separator made of the membrane are also provided.

Owner:ASAHI KASEI KK

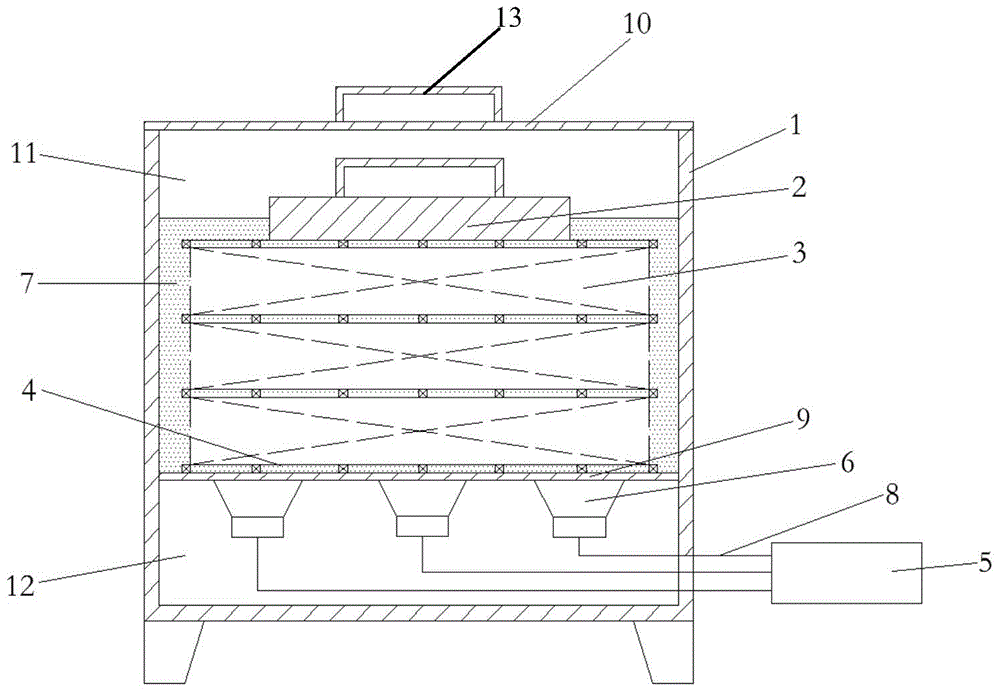

Pretreatment device for improving wood impregnation efficiency and wood impregnation treatment method

InactiveCN104416635AExpand the effective channel areaIncrease drug intakeWood treatment detailsWood impregnation detailsCavitationPre treatment

The invention discloses a pretreatment device for improving wood impregnation efficiency and a method for impregnating woods by utilizing the device. The device comprises a wood pretreatment chamber in which a cavity is formed, an ultrasonic treatment system and pretreatment liquid, wherein to-be-treated woods are subjected to ultrasonic pretreatment. The method disclosed by the invention comprises the following steps: pretreating to-be-impregnated woods by using ultrasonic waves under normal pressure, and getting through a liquid moving channel in the woods by utilizing a cavitation effect of the ultrasonic waves, so that the liquid permeability of the to-be-impregnated woods is enhanced, and the effective channel area inside the woods is enlarged; impregnating the woods, and impregnating a wood impregnation modifier into the woods, so that the absorption dose of the impregnated woods is improved, the agent penetration depth is increased, the impregnation period is shortened, and the impregnation effect is improved. The treatment device disclosed by the invention is simple, convenient to operate and is suitable for treating various woods, and process treatment conditions are controllable.

Owner:BEIJING FORESTRY UNIVERSITY

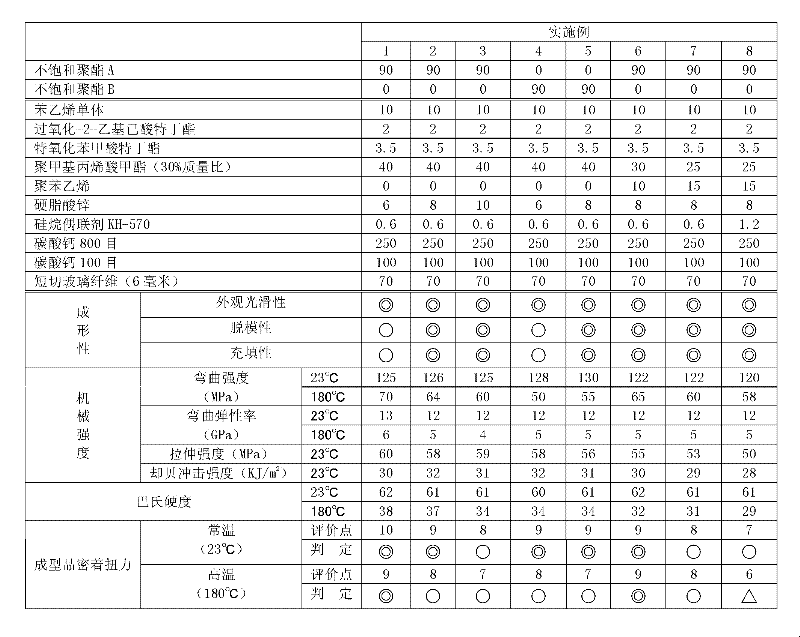

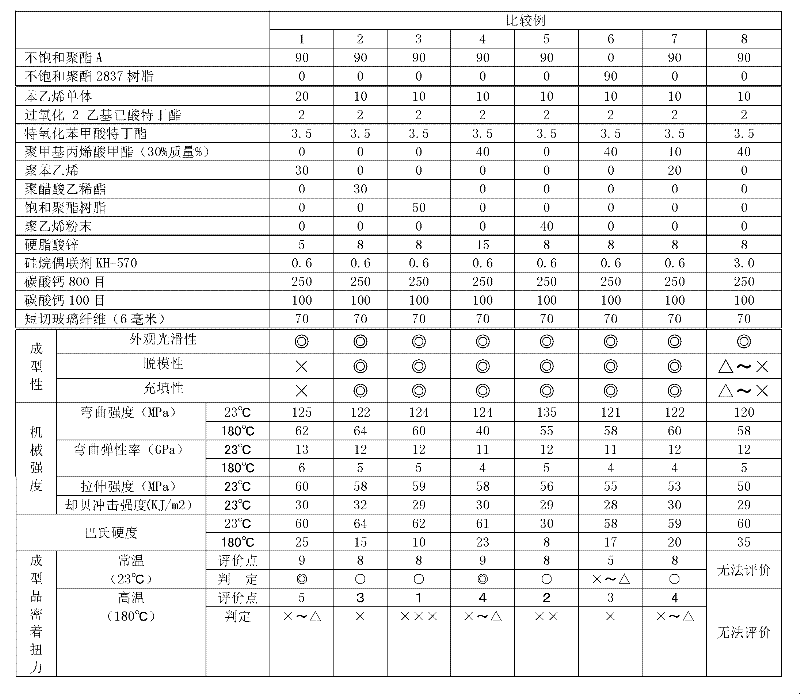

Unsaturated polyester bulk molding compound as well as method and application thereof

The invention relates to the technical field of a bulk molding compound for metal bonding, and specifically relates to an unsaturated polyester bulk molding compound as well as a method and application of the bulk molding compound. The bulk molding compound is prepared from the following raw materials in parts by weight: 8-20 parts of unsaturated polyester, 5-15 parts of low shrink agent, 55-70 parts of inorganic filler, 0.8-1.8 parts of internal demolding agent, 6-20 parts of fiber-reinforced material, 0.3-0.7 parts of curing agent, 0-3 parts of styrene, and 0.05-0.3 part of coupling agent. According to the invention, after the bulk molding compound (BMC) is molded, fast setting is realized and the appearance is excellent; and when used for electric tool and motor loop sealing and other fields, the bulk molding compound has excellent bonding property and torsion to the metal surface at normal temperature and high temperature, excellent resistance to impact, and excellent voltage withstand performance, conforms to the reliability required by product use, and fills up the blank of the field.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

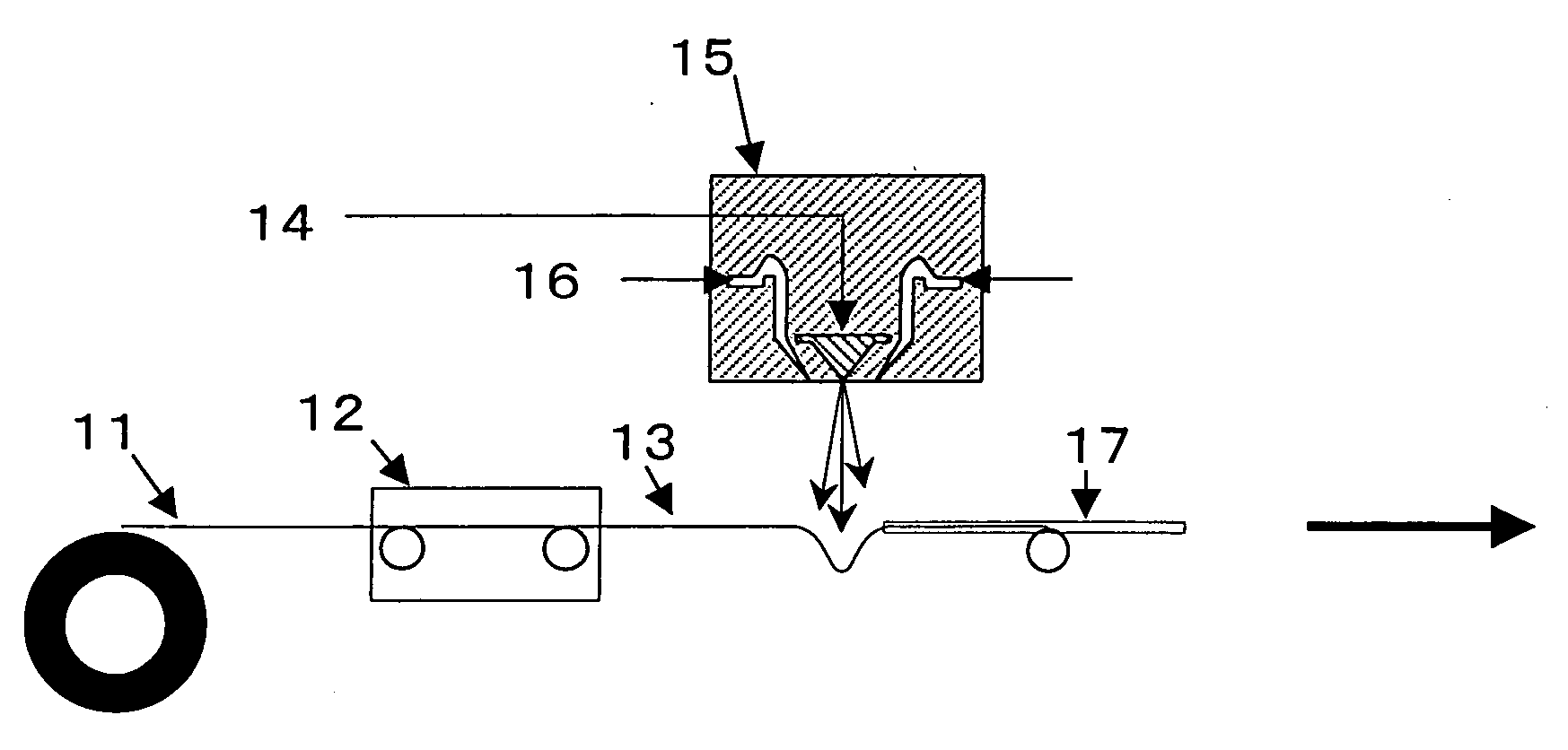

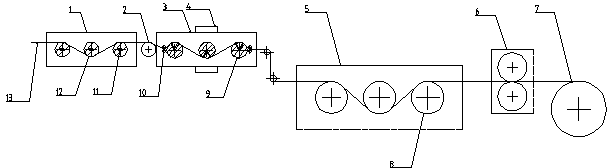

Molding method of continuous fiber reinforced thermoplastic resin sheet

The invention discloses a molding method of a continuous fiber reinforced thermoplastic resin sheet. An apparatus for realizing the method comprises a pre-dispersion device, a static elimination device, an extruder, a radiation melt impregnation device, a secondary impregnation device, a traction device and a rolling device. The method comprises the following steps: introducing continuous fiber yarns to the pre-dispersion device from a yarn rack, and dispersing, heating and drying the fibers by the pre-dispersion device to make the temperature of the surface of the fibers reach a temperature between the melting temperature of a melt resin and the destroy temperature of a surface conditioning agent in order to well impregnate; and allowing the preheated fibers to go through the static elimination device, introducing the yarns into the radiation melt impregnation device fed by the extruder, impregnating fiber bundles under the action of a tension roll, and introducing the fiber bundles into the secondary impregnation device to realize secondary impregnation in order to realize a secondary impregnation effect. The method has a substantial higher fiber bundle impregnation effect than the prior art, and the matched molding apparatus has the advantages of simple structure and convenient operation.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com