Patents

Literature

49results about How to "Improve stratification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

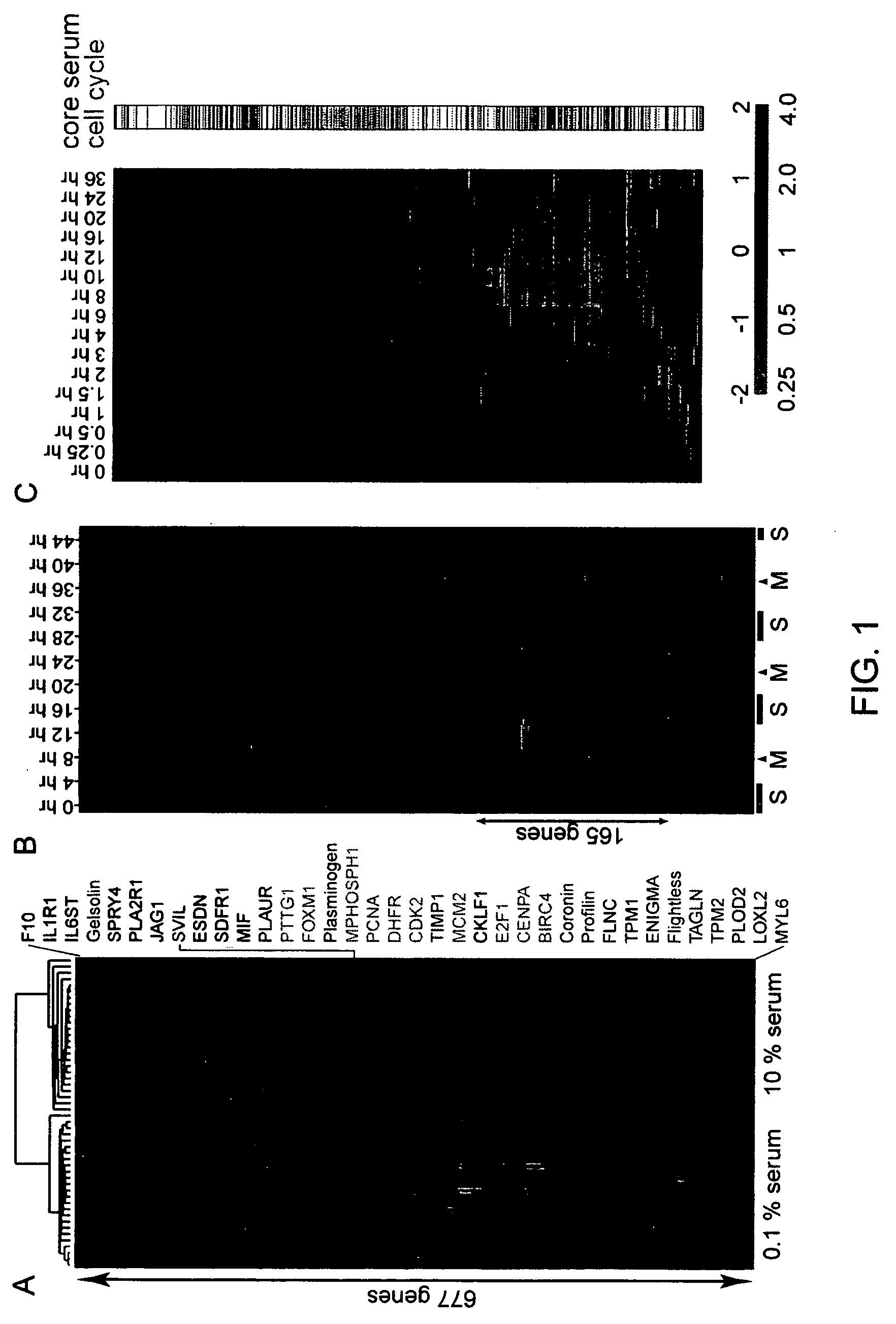

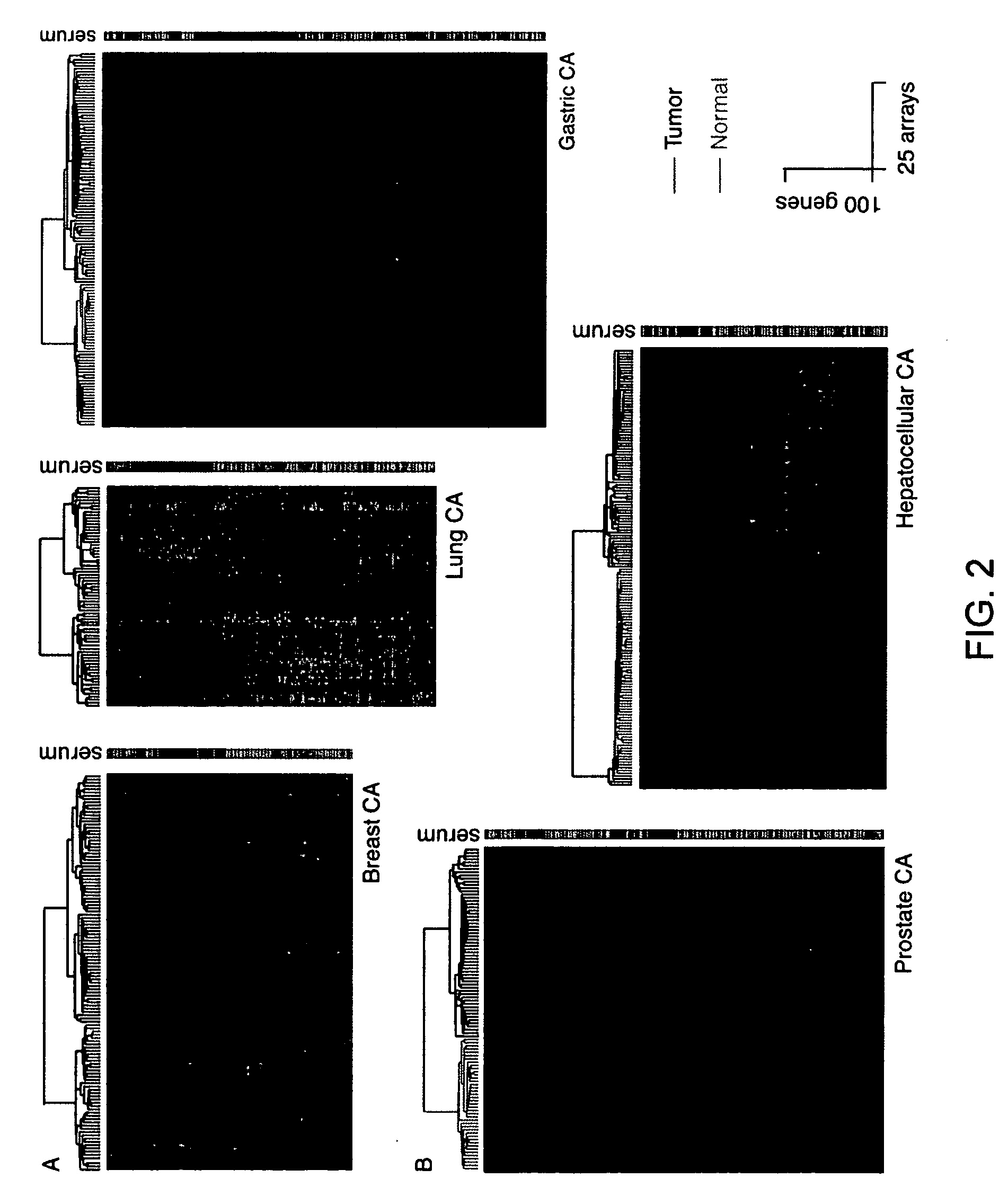

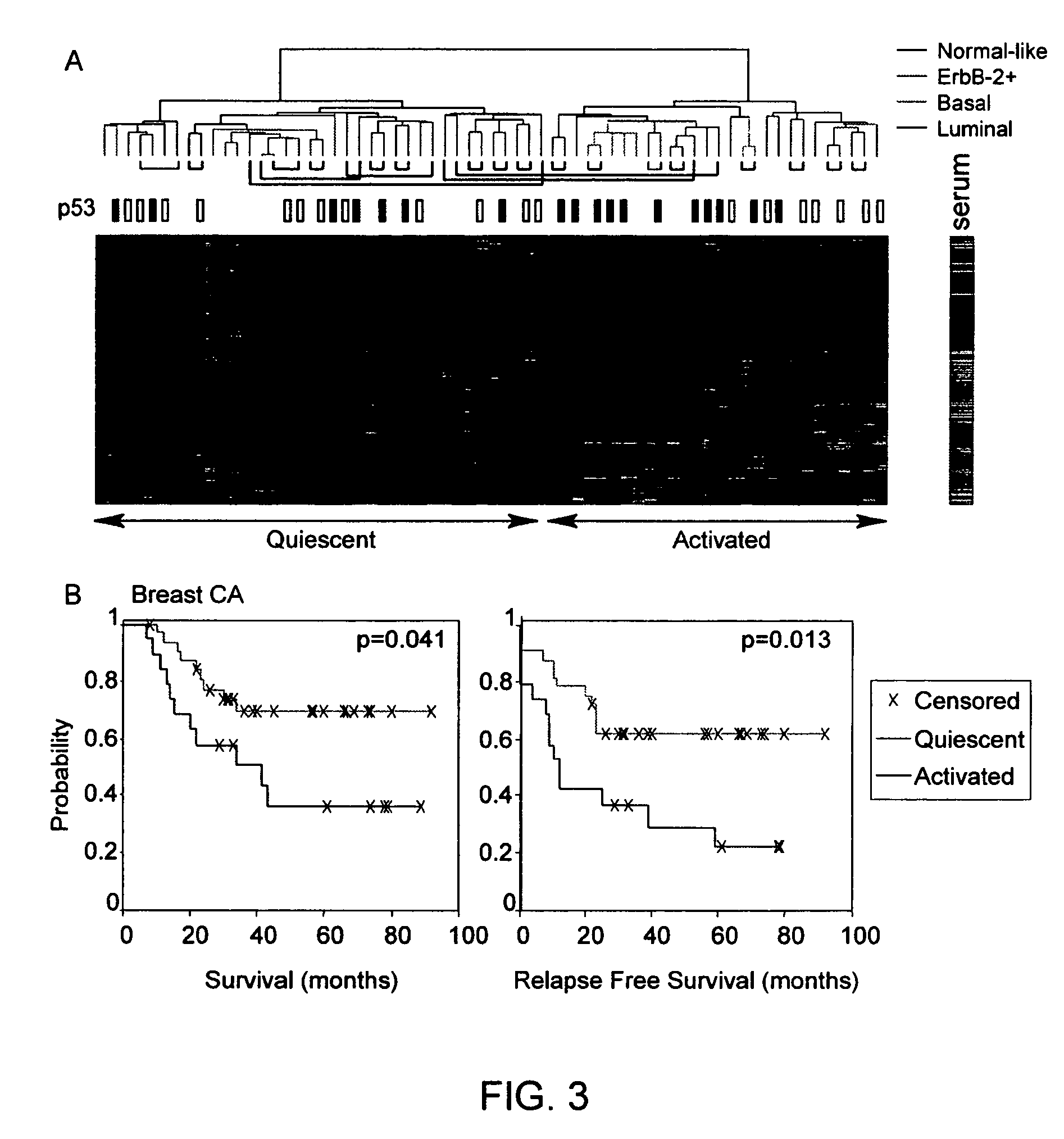

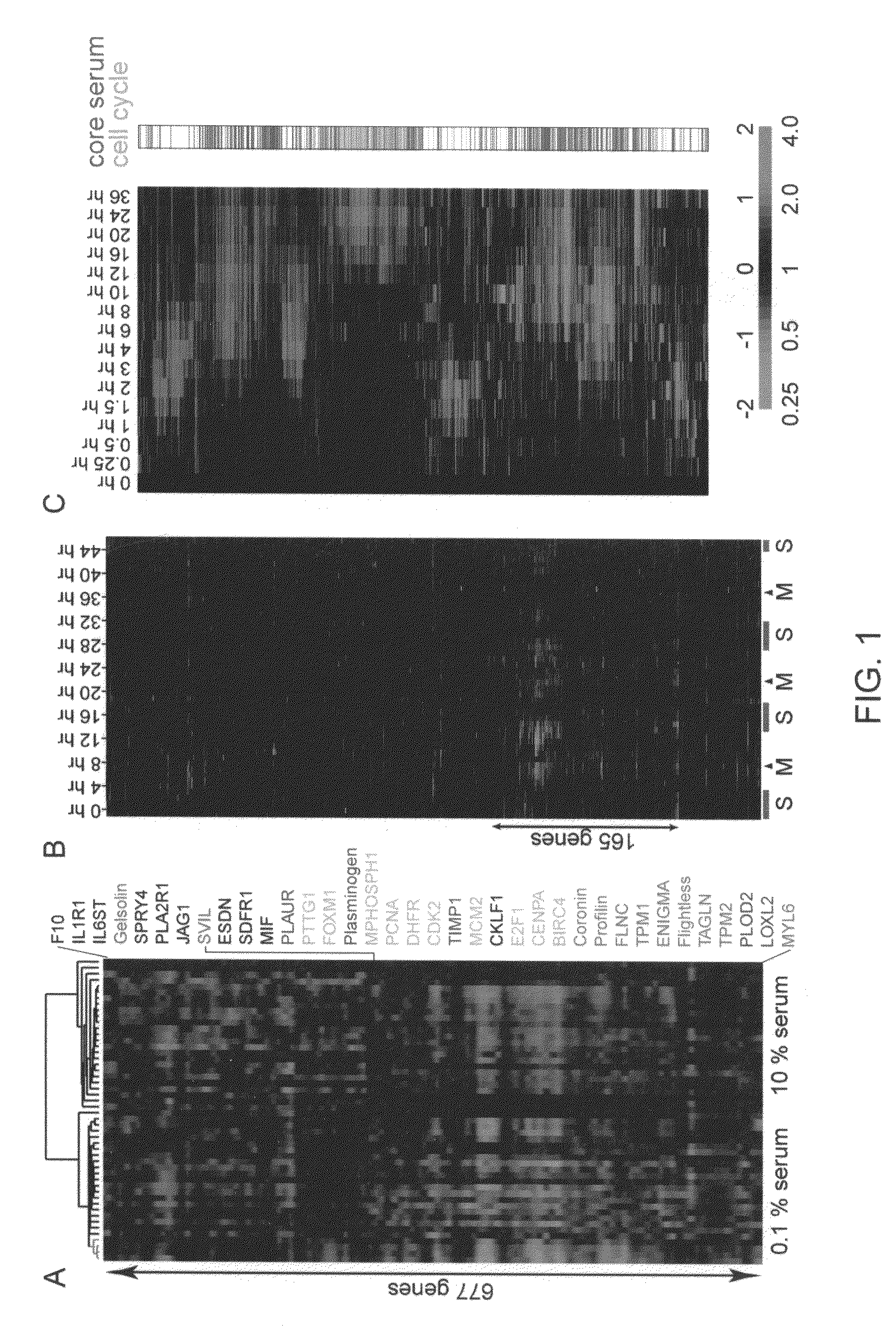

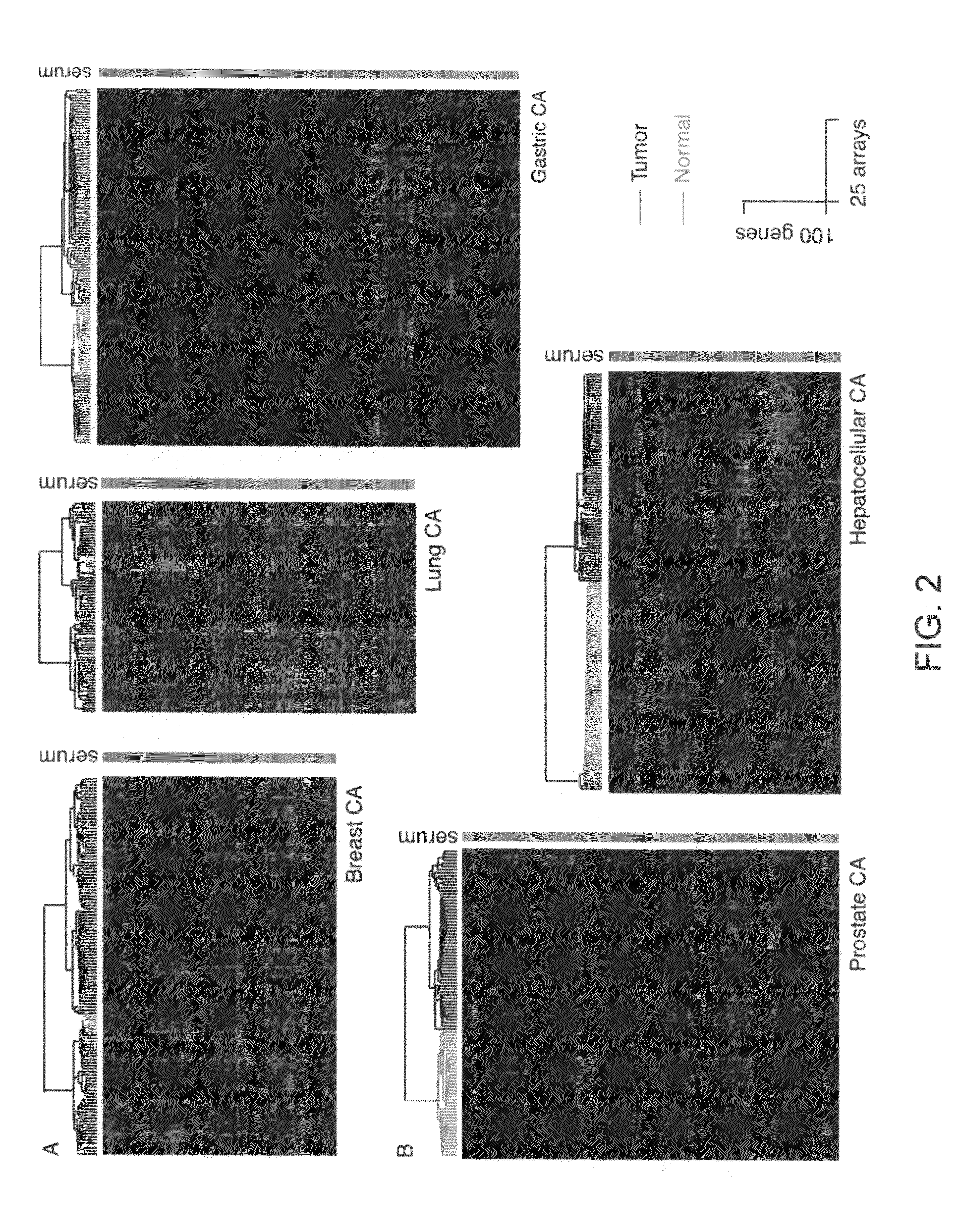

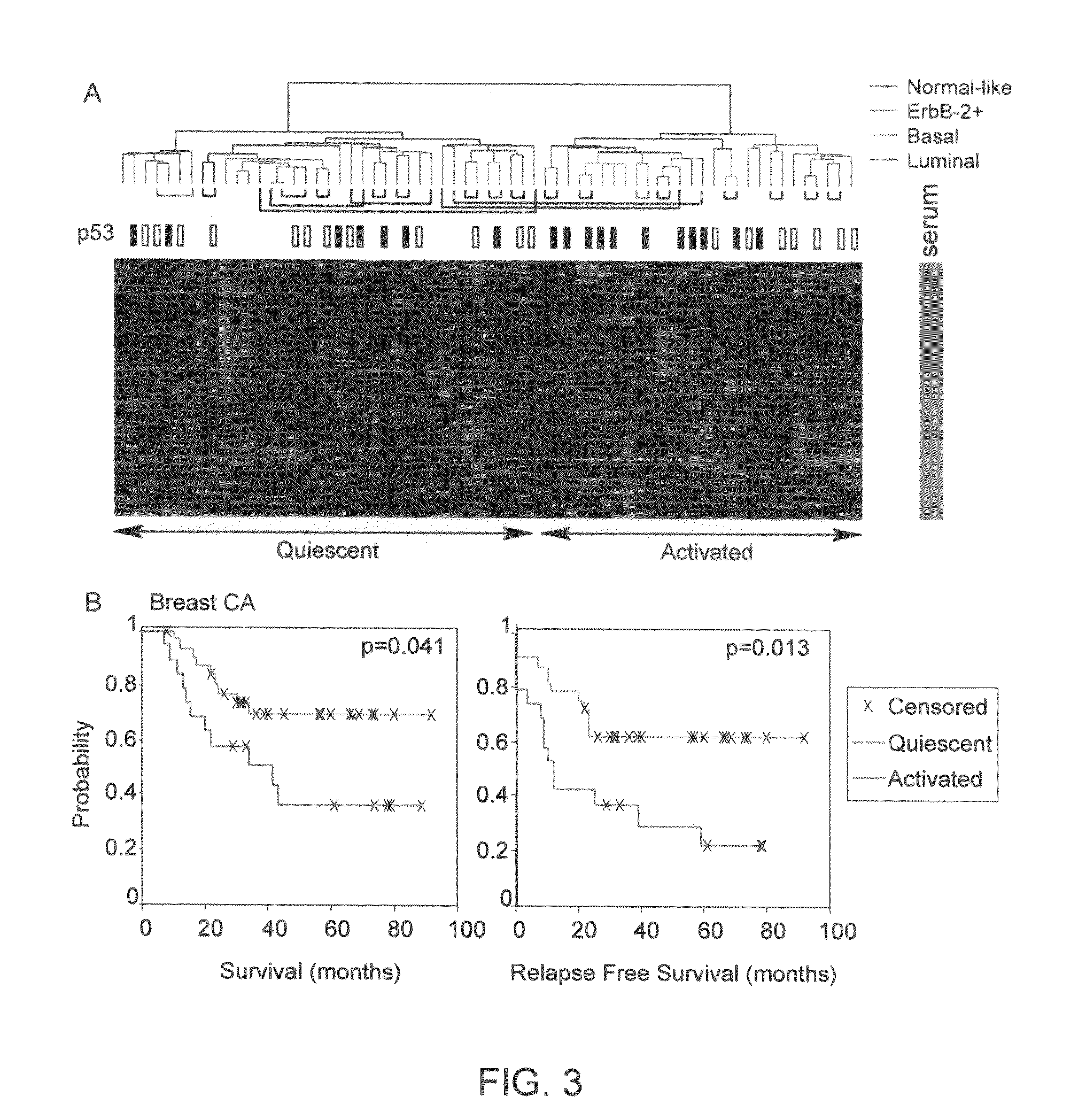

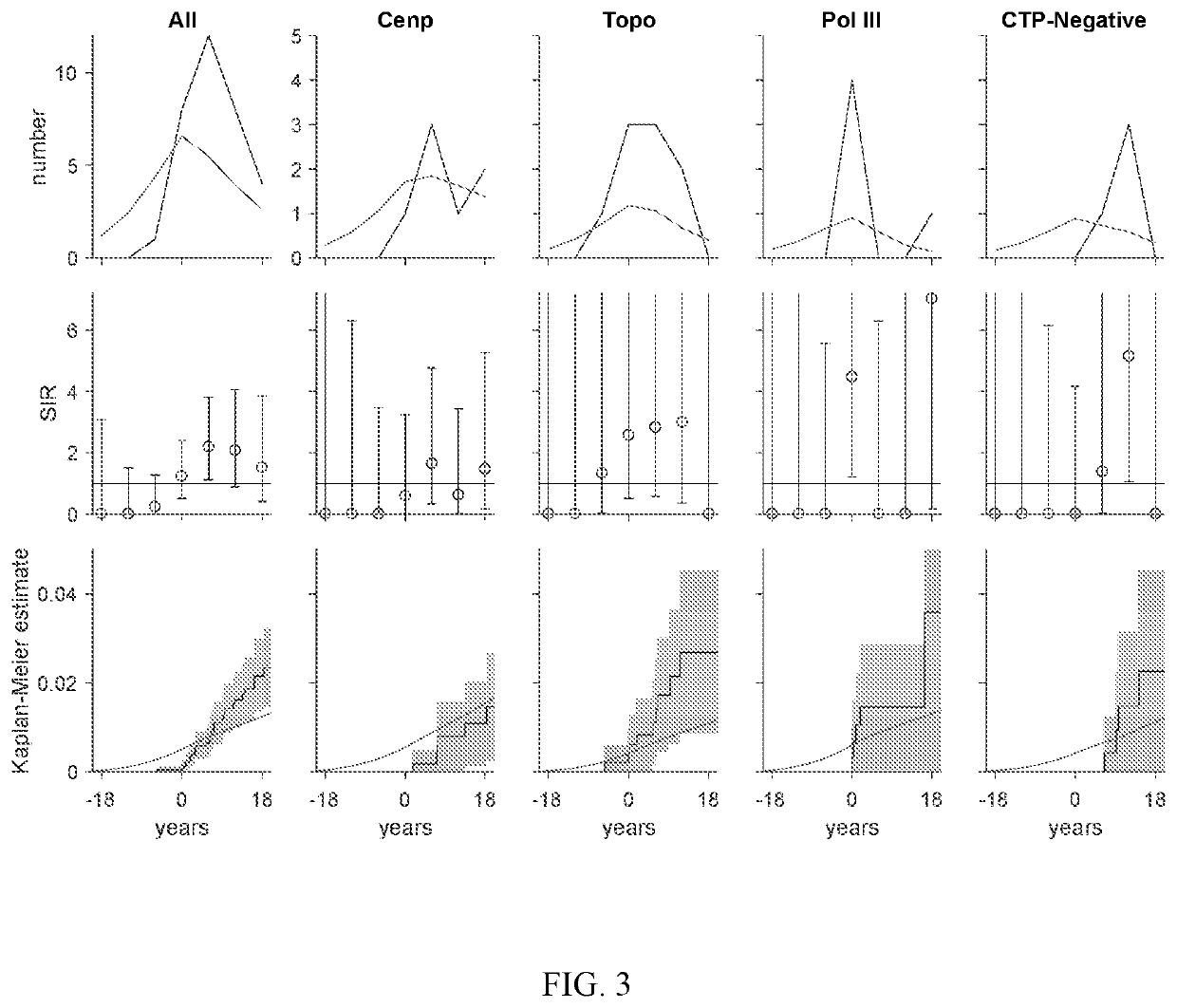

Gene expression signature for prediction of human cancer progression

InactiveUS20060183141A1Increase probabilityOptimize choiceSugar derivativesMicrobiological testing/measurementHuman cancerLymphatic Spread

Methods are provided for classification of cancers by the expression of a set of genes referred to as the core serum response (CSR), or a subset thereof. The expression pattern of the CSR in normal tissues correlates with that seen in quiescent fibroblasts cultured in the absence of serum, while cancer tissues can be classified as having a quiescent or induced CSR signature. Patients with the induced CSR signature have a higher probability of metastasis. Classification according to CSR signature allows optimization of treatment, and determination of whether on whether to proceed with a specific therapy, and how to optimize dose, choice of treatment, and the like.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

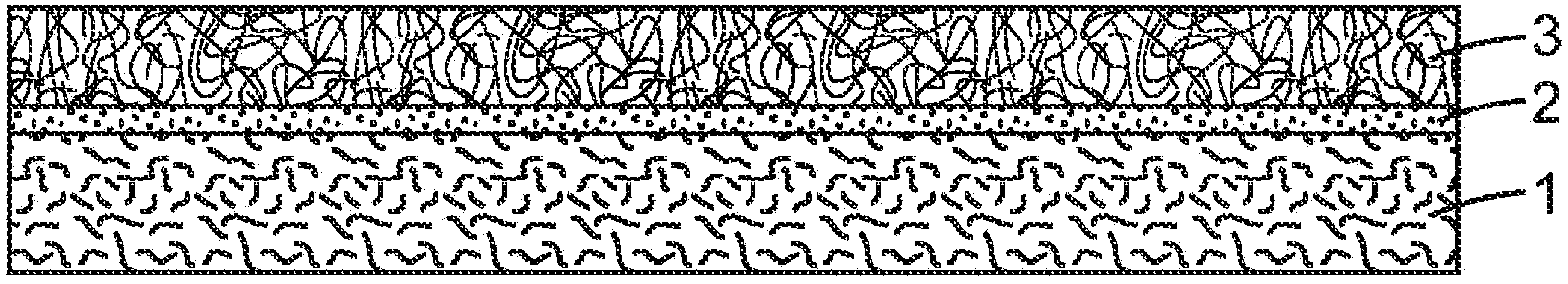

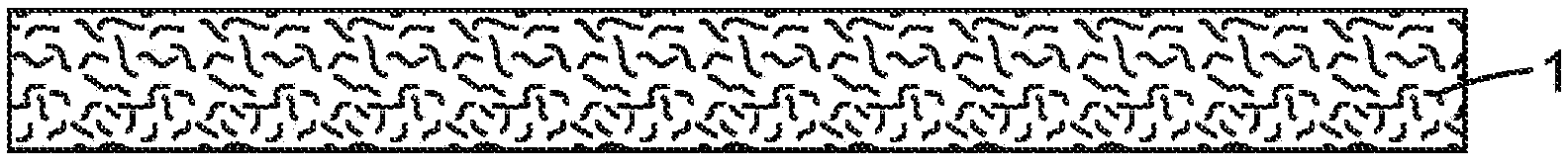

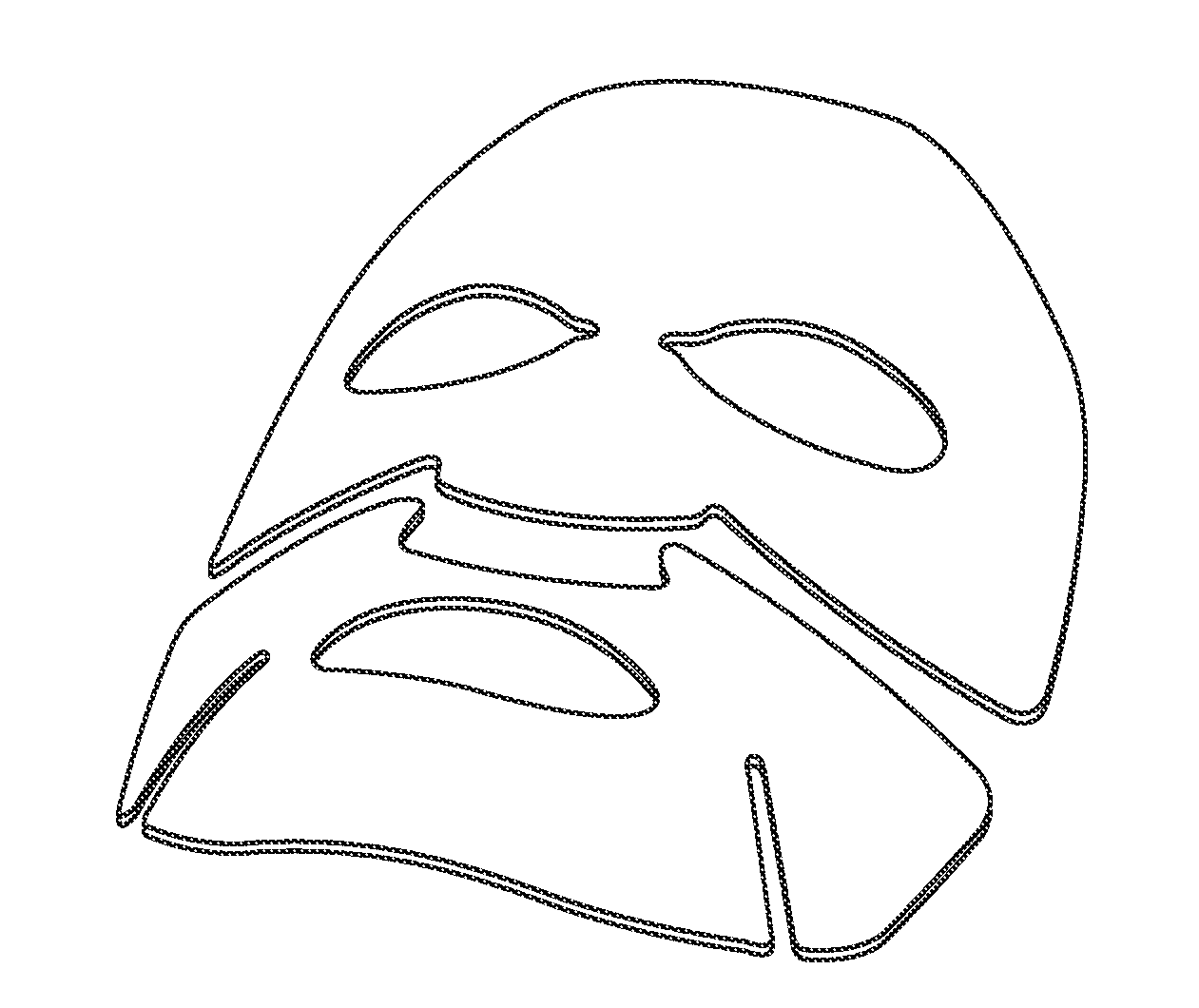

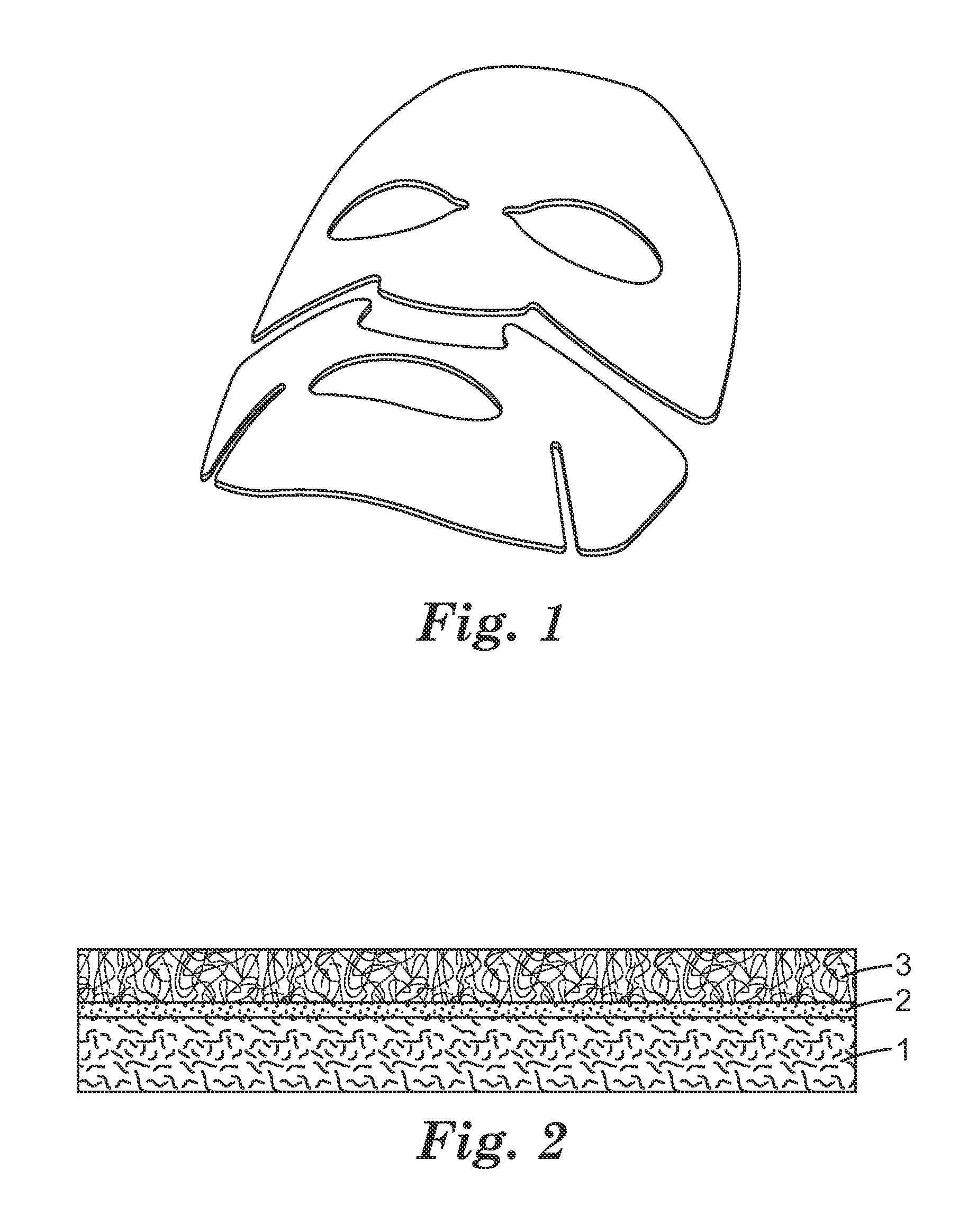

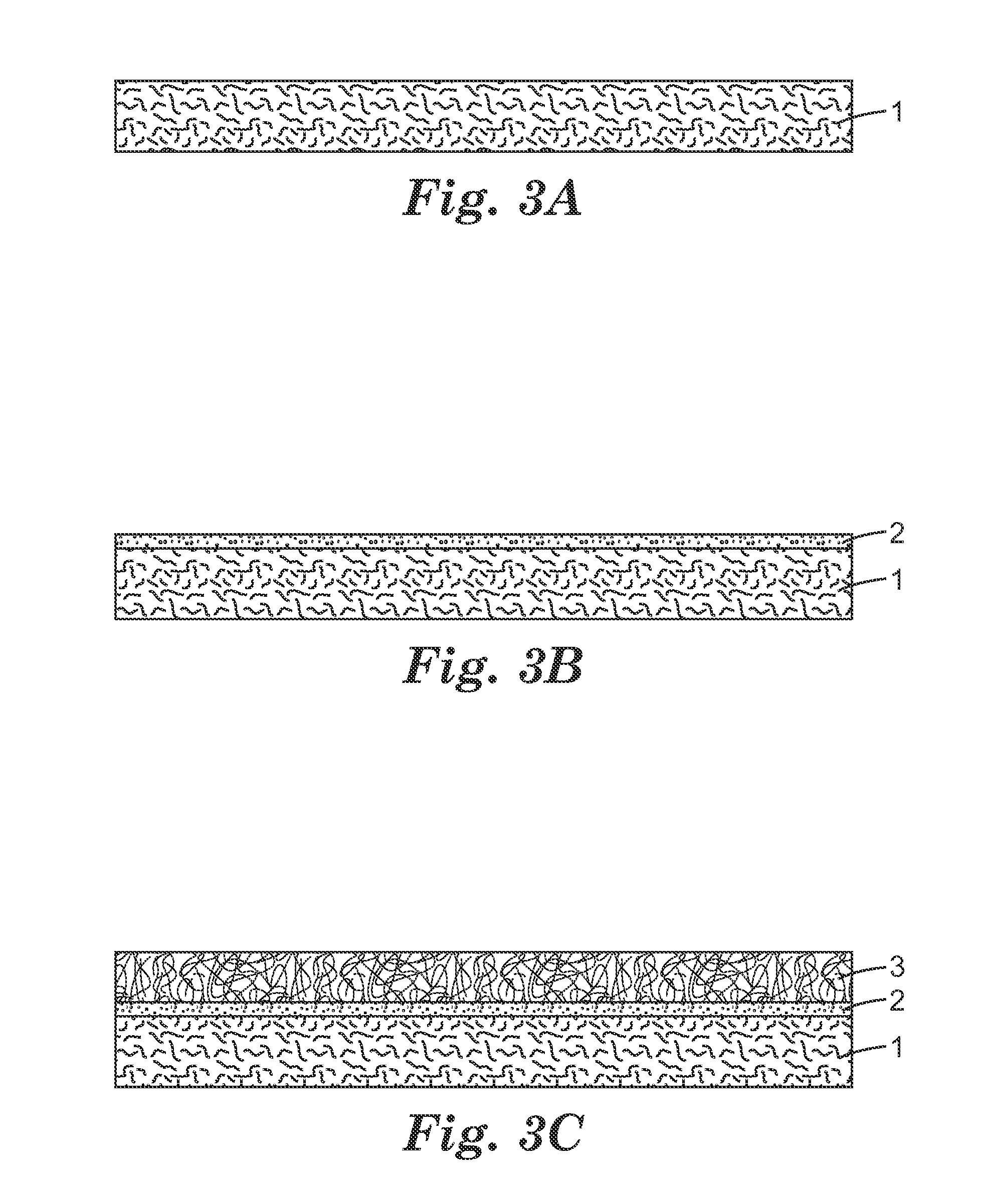

Mask pack

InactiveCN104114057AImprove stratificationStrong adhesionHead bandagesCosmetic preparationsHuman skinSkin surface

A mask pack impregnated with a liquid cosmetic preparation, being applied to a human skin surface, in particular a facial skin surface. The mask pack includes a nonwoven fabric layer and a nanofiber layer including a hydrophilic polymer, wherein said nanofiber layer is bonded to the nonwoven fabric layer.

Owner:3M INNOVATIVE PROPERTIES CO

Mask pack

InactiveUS20140352031A1Excellent impregnationImprove nanofiber delamination phenomenonHead bandagesCosmetic preparationsBiomedical engineeringNanofiber

A mask pack impregnated with a liquid cosmetic preparation, being applied to a human skin surface, in particular a facial skin surface. The mask pack includes a nonwoven fabric layer and a nanofiber layer including a hydrophilic polymer, wherein said nanofiber layer is bonded to the nonwoven fabric layer.

Owner:3M INNOVATIVE PROPERTIES CO

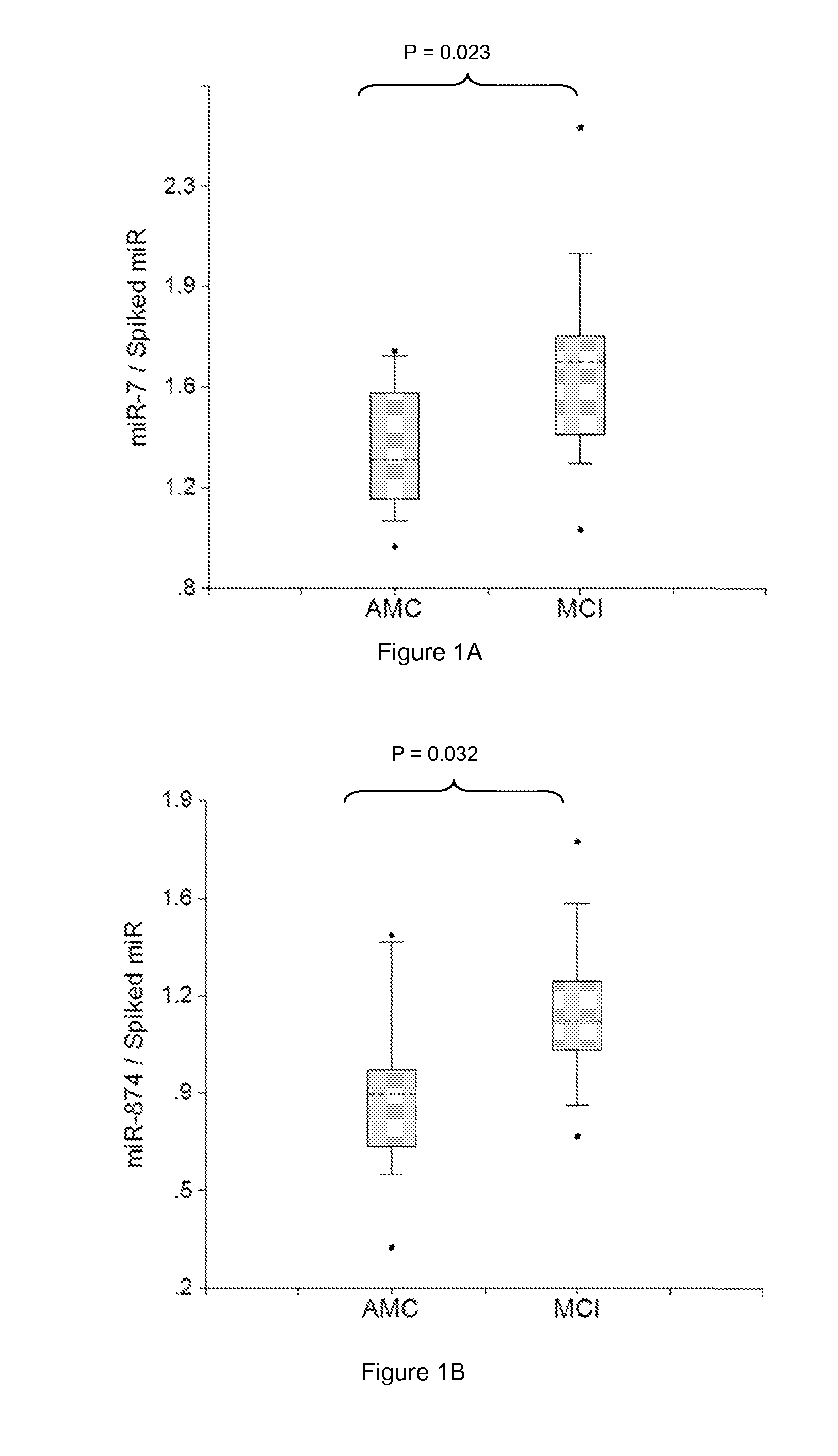

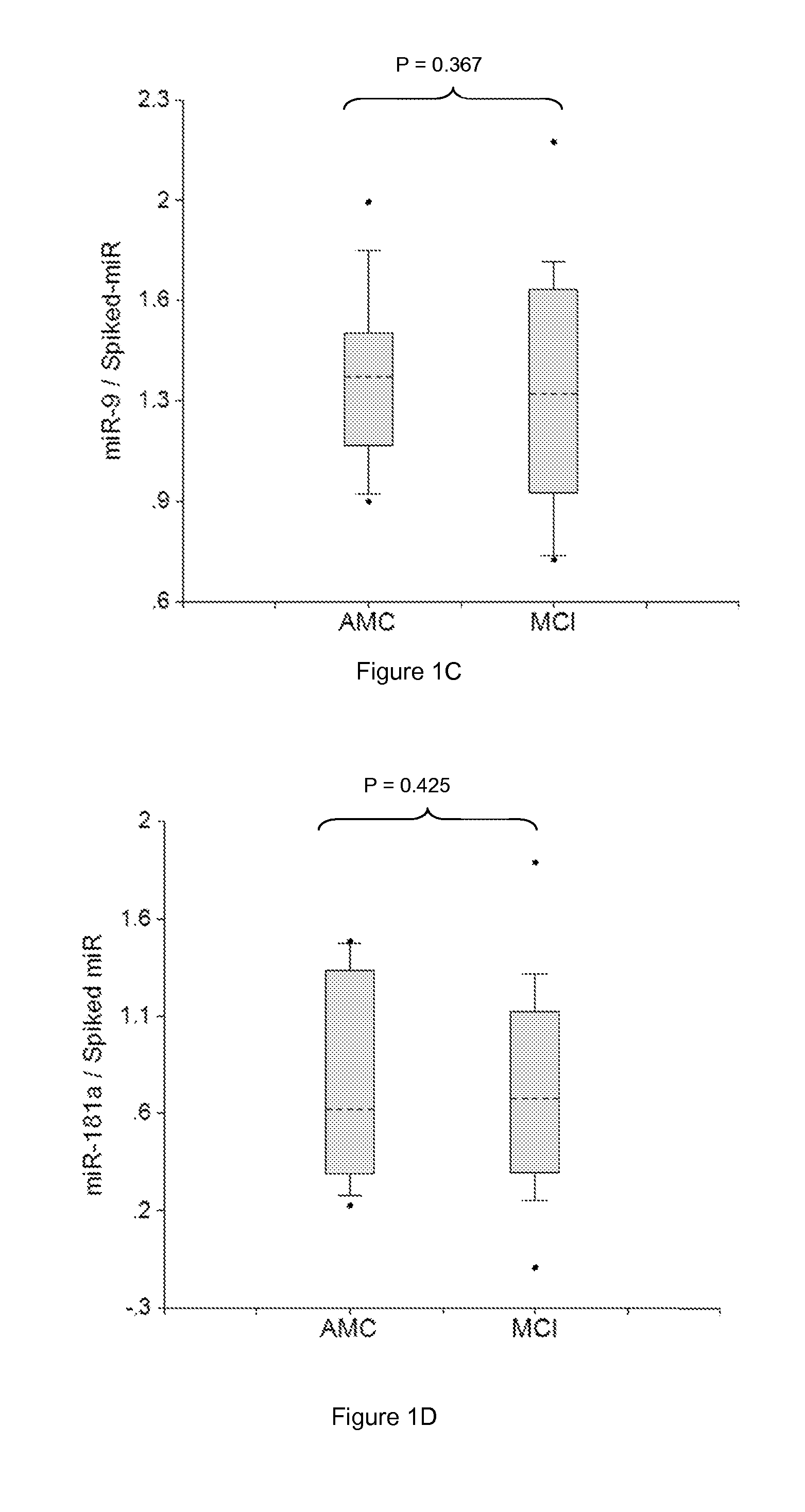

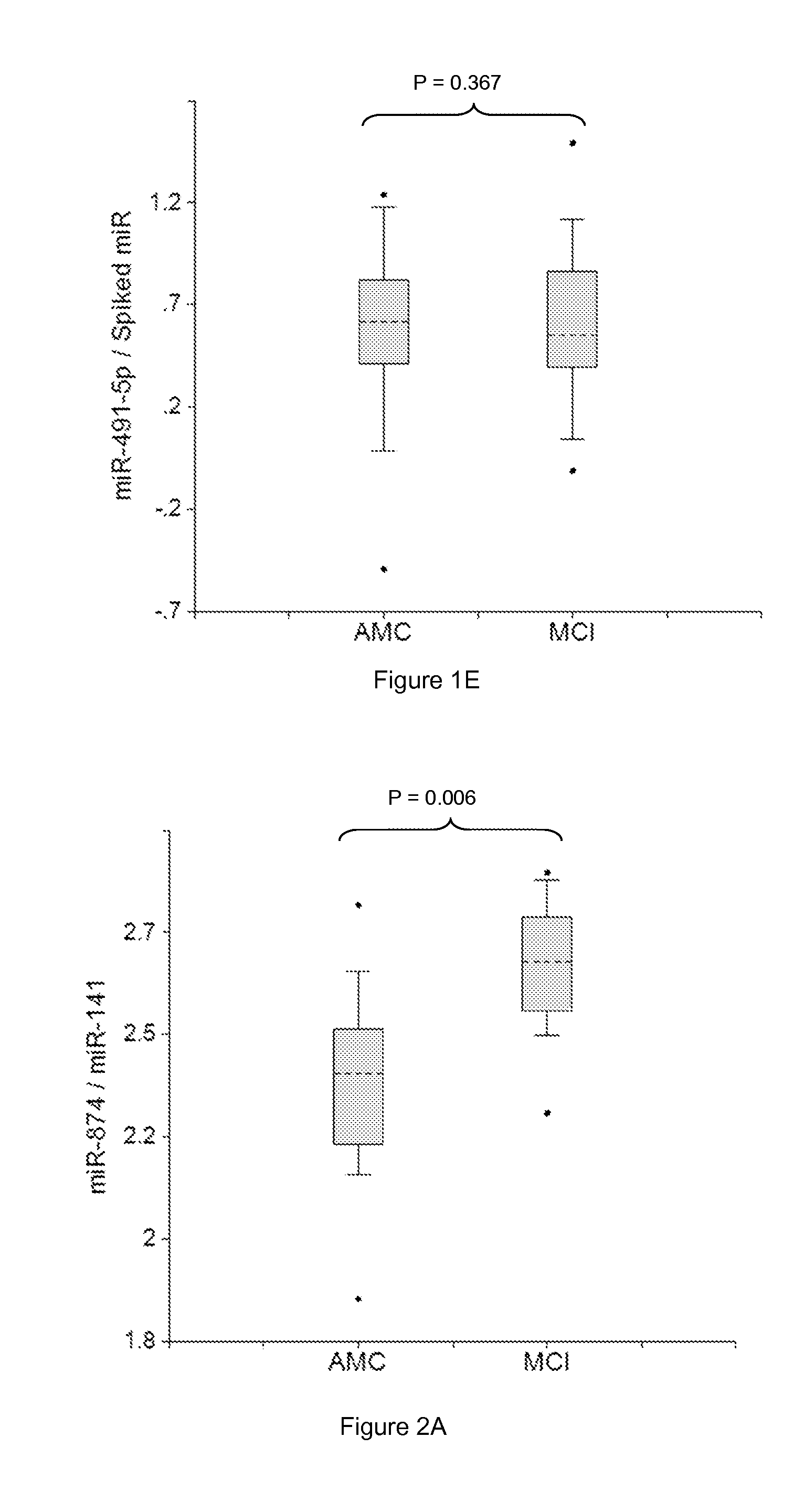

METHODS OF USING miRNA FROM BODILY FLUIDS FOR EARLY DETECTION AND MONITORING OF MILD COGNITIVE IMPAIRMENT (MCI) AND ALZHEIMER'S DISEASE (AD)

ActiveUS20140120545A1Improve efficiencyLow costNervous disorderMicrobiological testing/measurementMild cognitive impairment (MCI)Body fluid

Described are methods for early diagnosis and progression monitoring of Mild Cognitive Impairment (MCI) and Alzheimer's Disease (AD) by quantifying neurite and / or synapse miRNAs in bodily fluids.

Owner:DIAMIR

PMMA/ASA alloy material for PVC profile coextrusion surface layer and preparation thereof

InactiveCN101838435AImprove compatibilityImprove stratificationASA-polymerPolymethylmethacrylate resin

The invention discloses a PMMA / ASA alloy material for a PVC profile coextrusion surface layer and preparation thereof. The PMMA / ASA alloy material is prepared from the following raw materials in percentage by ,mass: 0.5 to 3 percent of chain extender, 0 to 5 percent of inorganic nano particle, coupling agent accounting for 0 to 3 percent of the mass of the inorganic nano particle, and the balance of PMMA resin and ASA resin, wherein the mass ratio of the PMMA resin to the ASA resin is 1:0.25-4; the PMMA resin is polymethylmethacrylate resin; the ASA resin is acrylonitrile-styrene-acrylate grafted copolymer; and the chain extender contains groups which can react with the carboxyl. The PMMA / ASA alloy material has excellent performance such as high intensity, high toughness, high glossiness, friction and abrasion resistance, and the like.

Owner:ZHEJIANG UNIV OF TECH

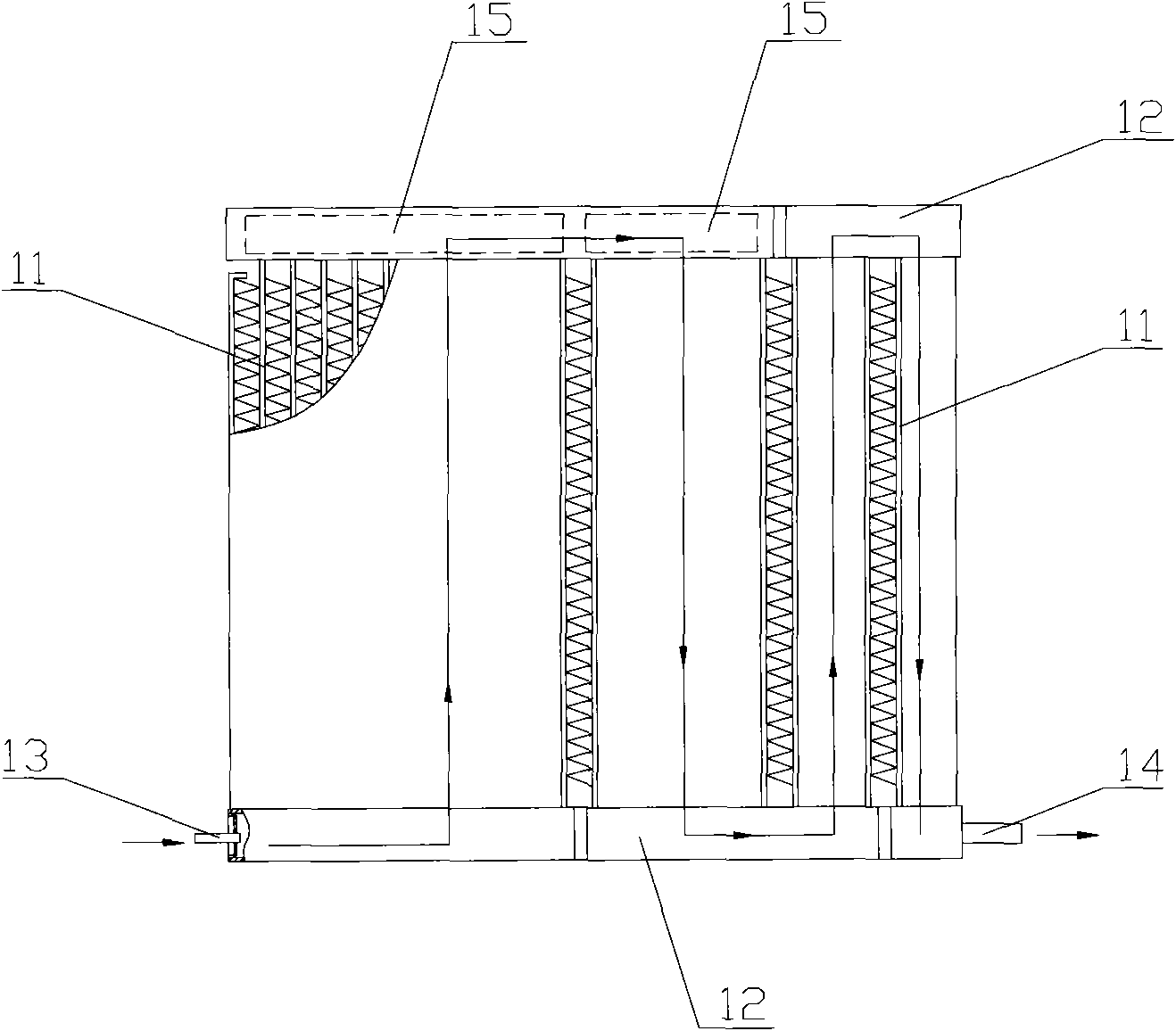

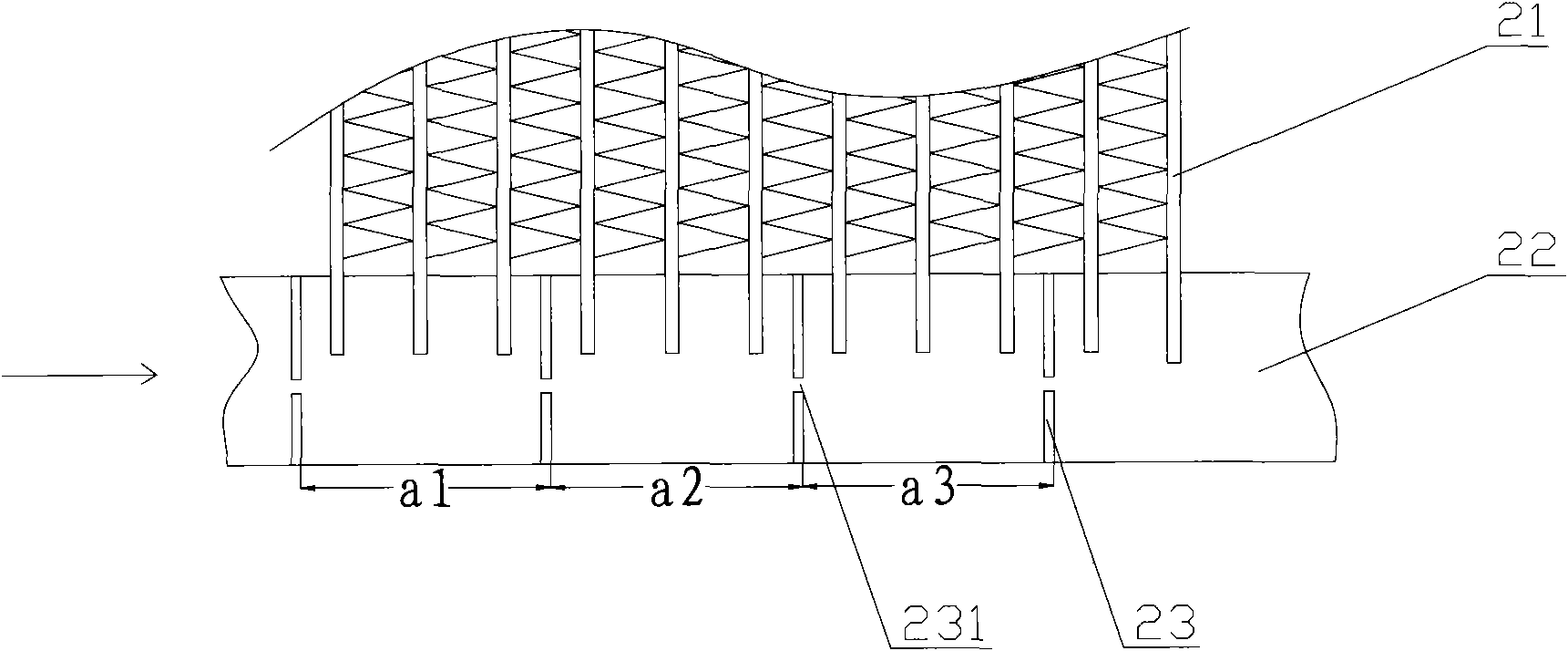

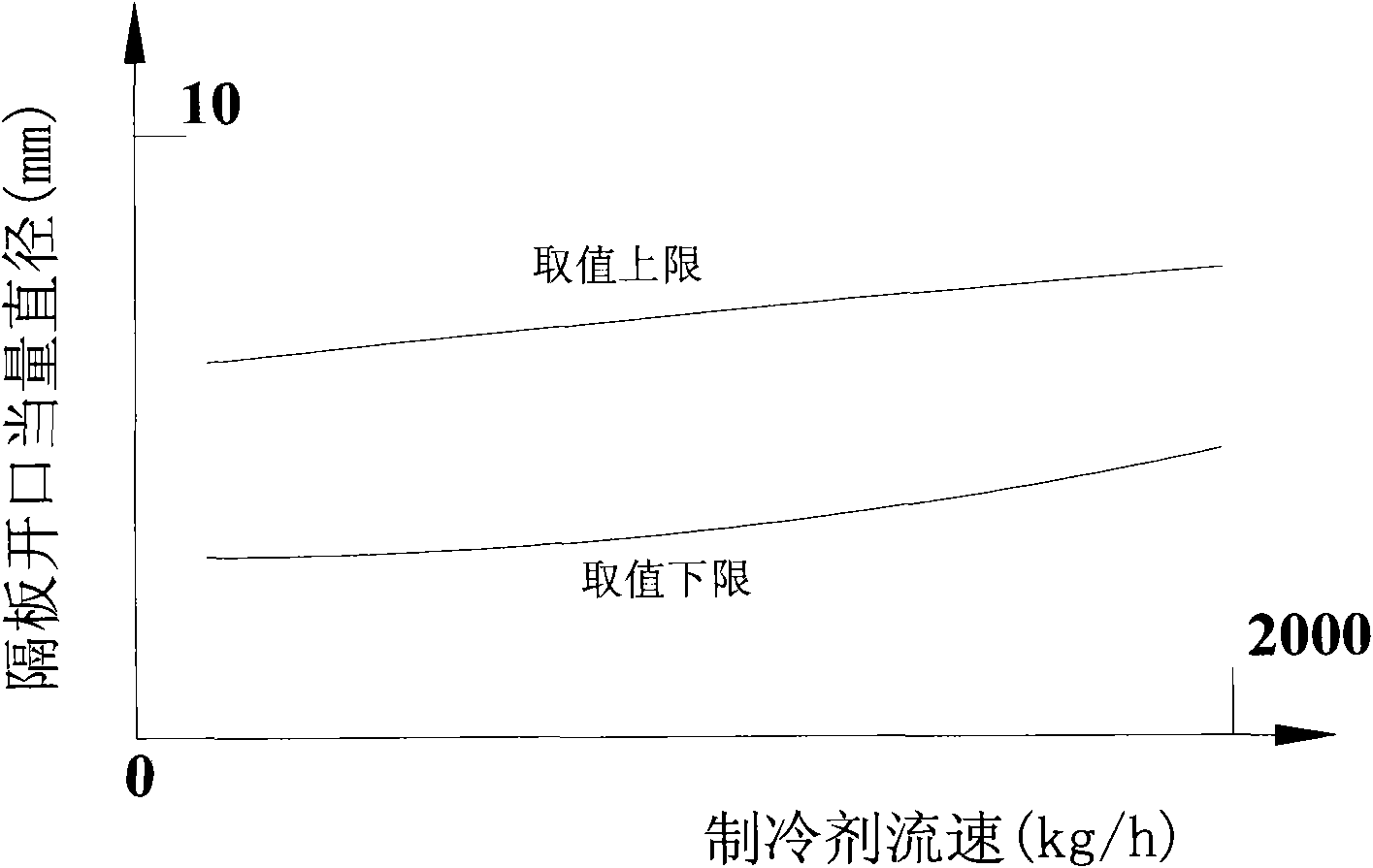

Heat exchanger and heat exchanging device including same

InactiveCN101639304AEvenly distributedImprove stratificationEvaporators/condensersHeat exchanger casingsEngineeringRefrigerant

The invention discloses a heat exchanger comprising a plurality of flat pipes (21), a collecting pipe (22) communicated with the flat pipe (21), an inlet pipe and an outlet pipe which are communicatedwith the collecting pipe (22). A plurality of clapboards (23) are arranged inside the collecting pipe (22) along the flowing direction of refrigerant, and a proper distance is left between the adjacent clapboards (23); and each of the clapboards (23) is provided with a passage (231) with a total equivalent diameter less than the geometric diameter of the collecting pipeline. The heat exchanger ensures that the refrigerant is mixed evenly inside the collecting pipe (22) and then evenly distributed into respective flat pipe (21) so as to improve the heat exchanging performance. Besides, the invention also discloses a heat exchanging device including the heat exchanger.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

PMMA/ASA alloy material for PVC profile coextrusion surface layer and preparation thereof

The invention discloses a PMMA / ASA alloy material for a PVC profile coextrusion surface layer and preparation thereof. The PMMA / ASA alloy material is prepared from the following raw materials in percentage by ,mass: 0.5 to 3 percent of chain extender, 0 to 5 percent of inorganic nano particle, coupling agent accounting for 0 to 3 percent of the mass of the inorganic nano particle, and the balanceof PMMA resin and ASA resin, wherein the mass ratio of the PMMA resin to the ASA resin is 1:0.25-4; the PMMA resin is polymethylmethacrylate resin; the ASA resin is acrylonitrile-styrene-acrylate grafted copolymer; and the chain extender contains groups which can react with the carboxyl. The PMMA / ASA alloy material has excellent performance such as high intensity, high toughness, high glossiness,friction and abrasion resistance, and the like.

Owner:ZHEJIANG UNIV OF TECH

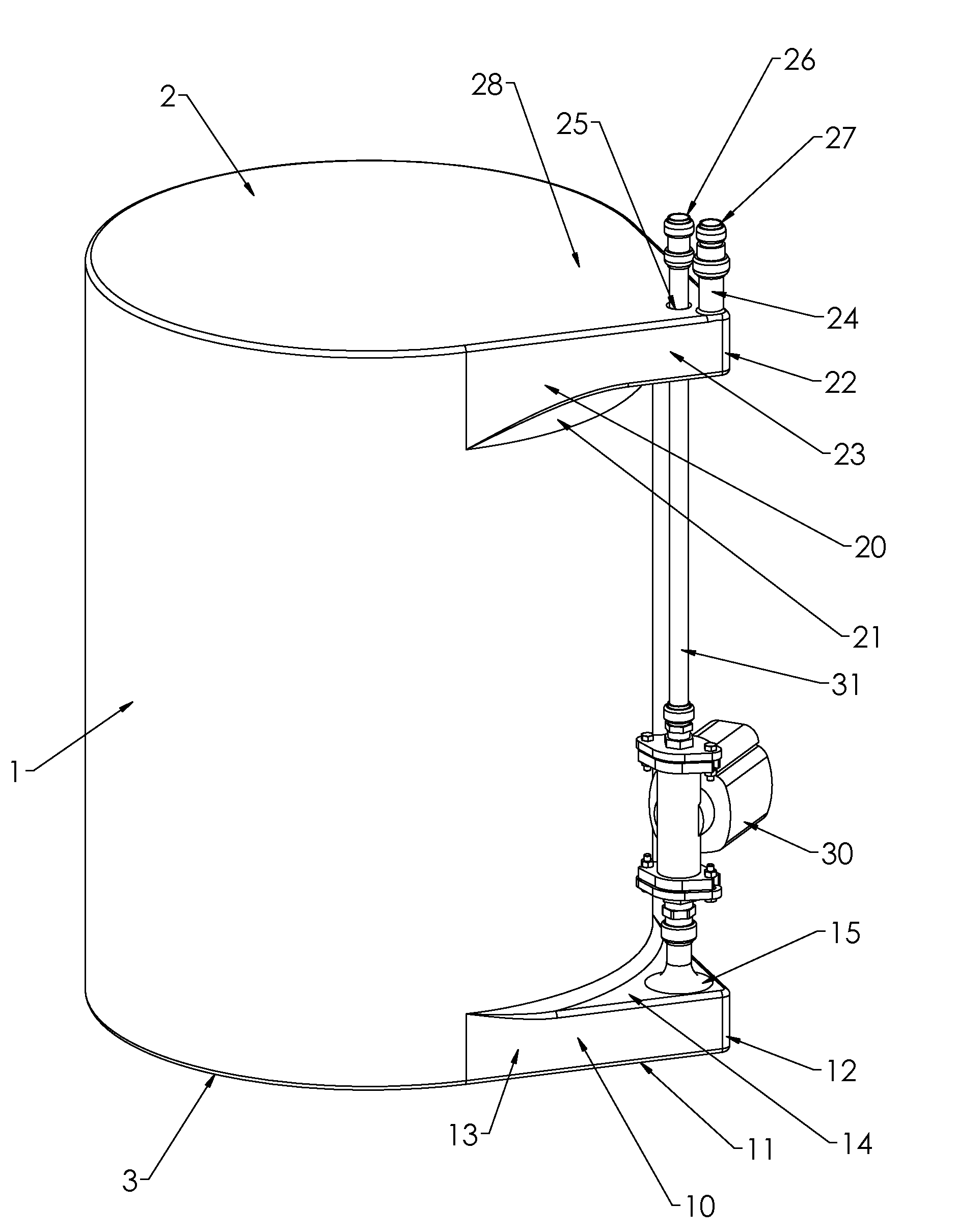

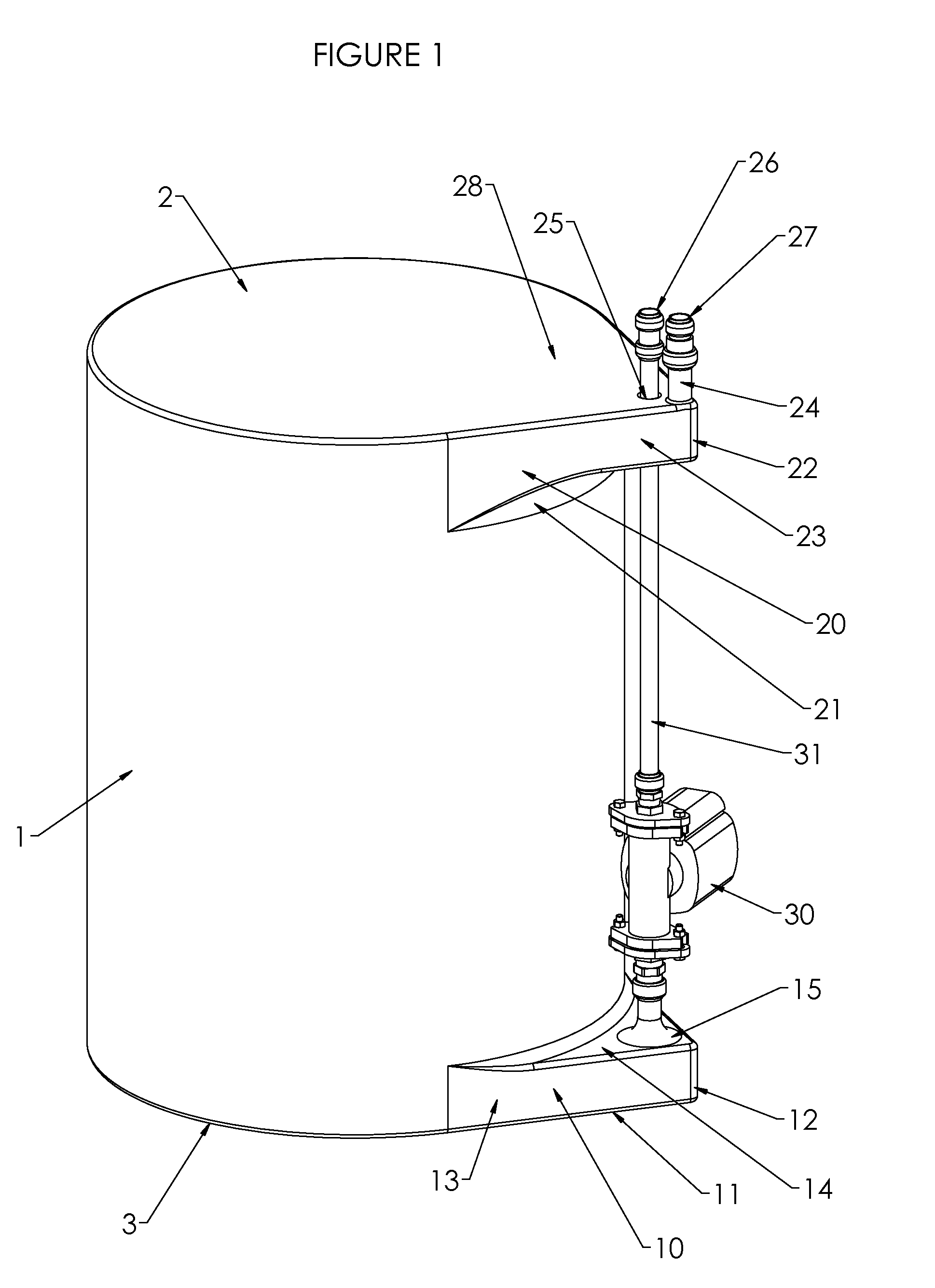

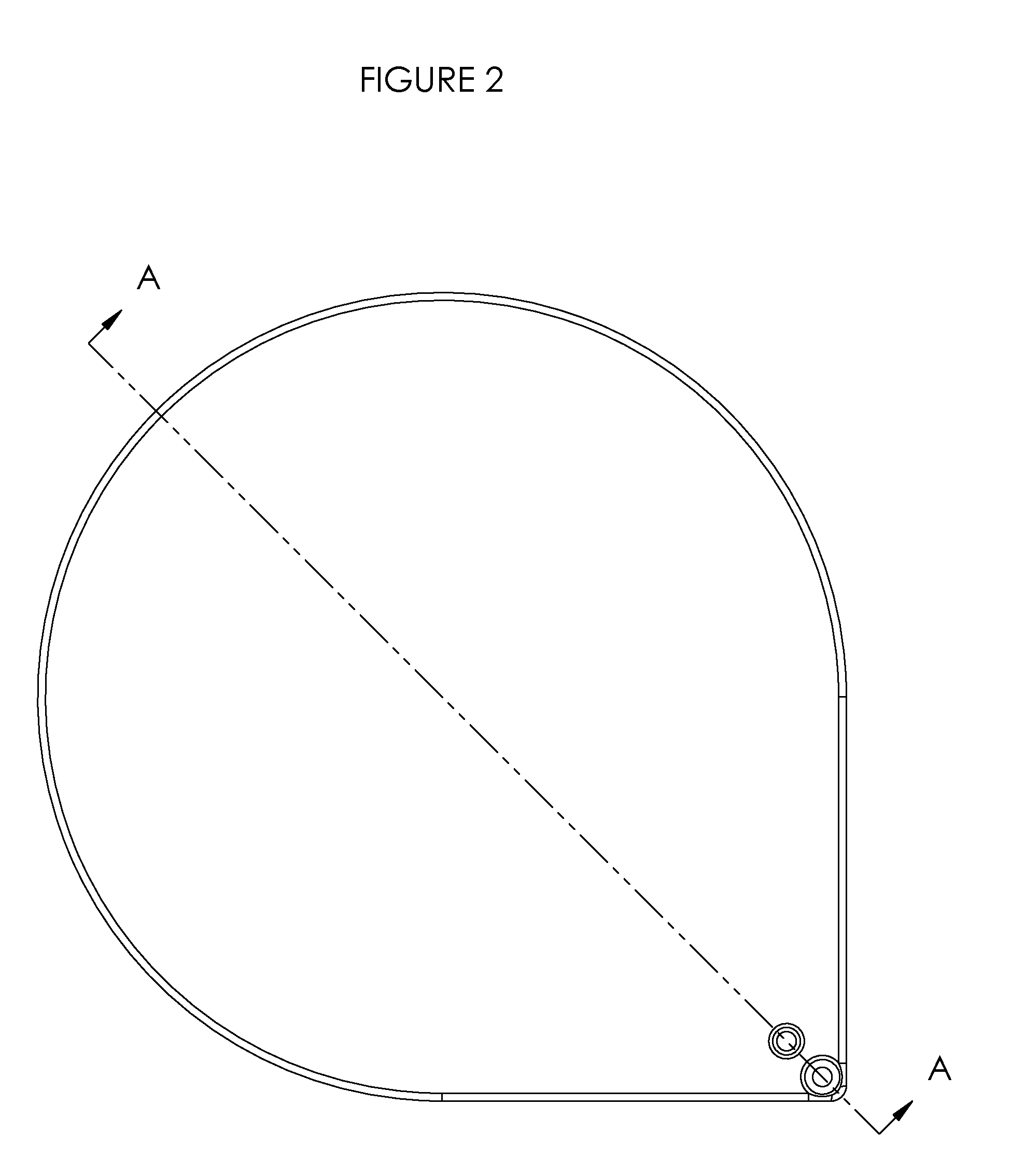

Horizontal Extraction and Return Extensions in liquid storage tanks

InactiveUS20120104003A1Facilitate transmissionMinimal stressSolar heating energyMechanical apparatusThermoclineCirculator pump

This invention is an improvement to the shape of liquid storage tanks, in particular to unpressurized molded polymer tanks used for thermal storage in solar systems. All aspects of this invention are well suited to solar storage tanks, and individual aspects are suited to other liquid tank applications.This invention provides a formed horizontal extension at the bottom of the tank. From the top of this lower extension, a hollow vertical stub provides a reliable connection to a circulator pump. Thermal performance is enhanced by ensuring the lowest and coolest water is delivered to the array of rooftop solar collectors without entraining debris from the bottom of the tank.At the top of the tank, a similar horizontal extension is used to distribute hot water returning from the solar collectors. Flow velocity is eliminated and a curving lower edge allows return water to find the matching thermocline to avoid de-stratifying.

Owner:LEE BRIAN ERIC +1

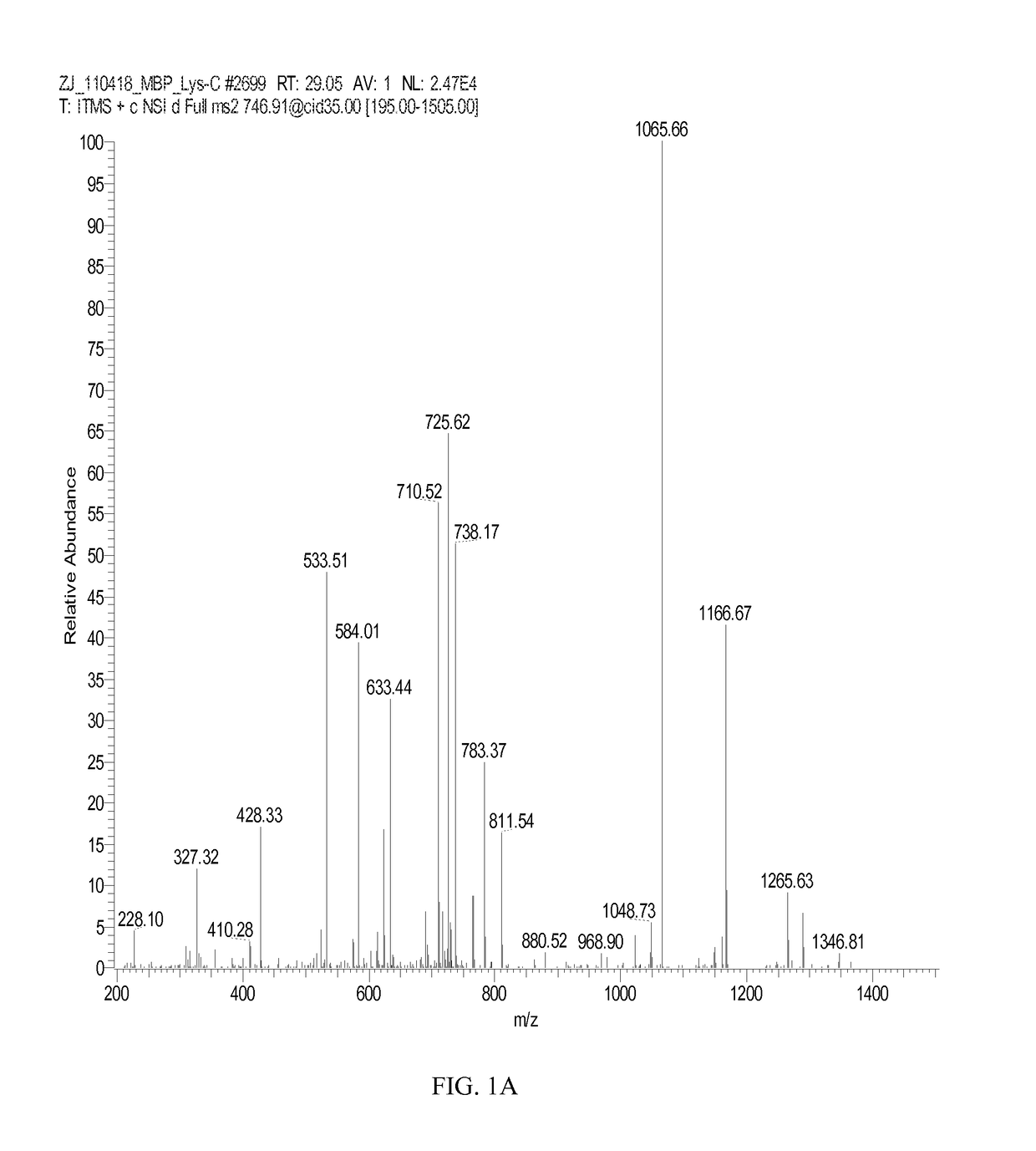

Citrullinated brain and neurological proteins as biomarkers of brain injury or neurodegeneration

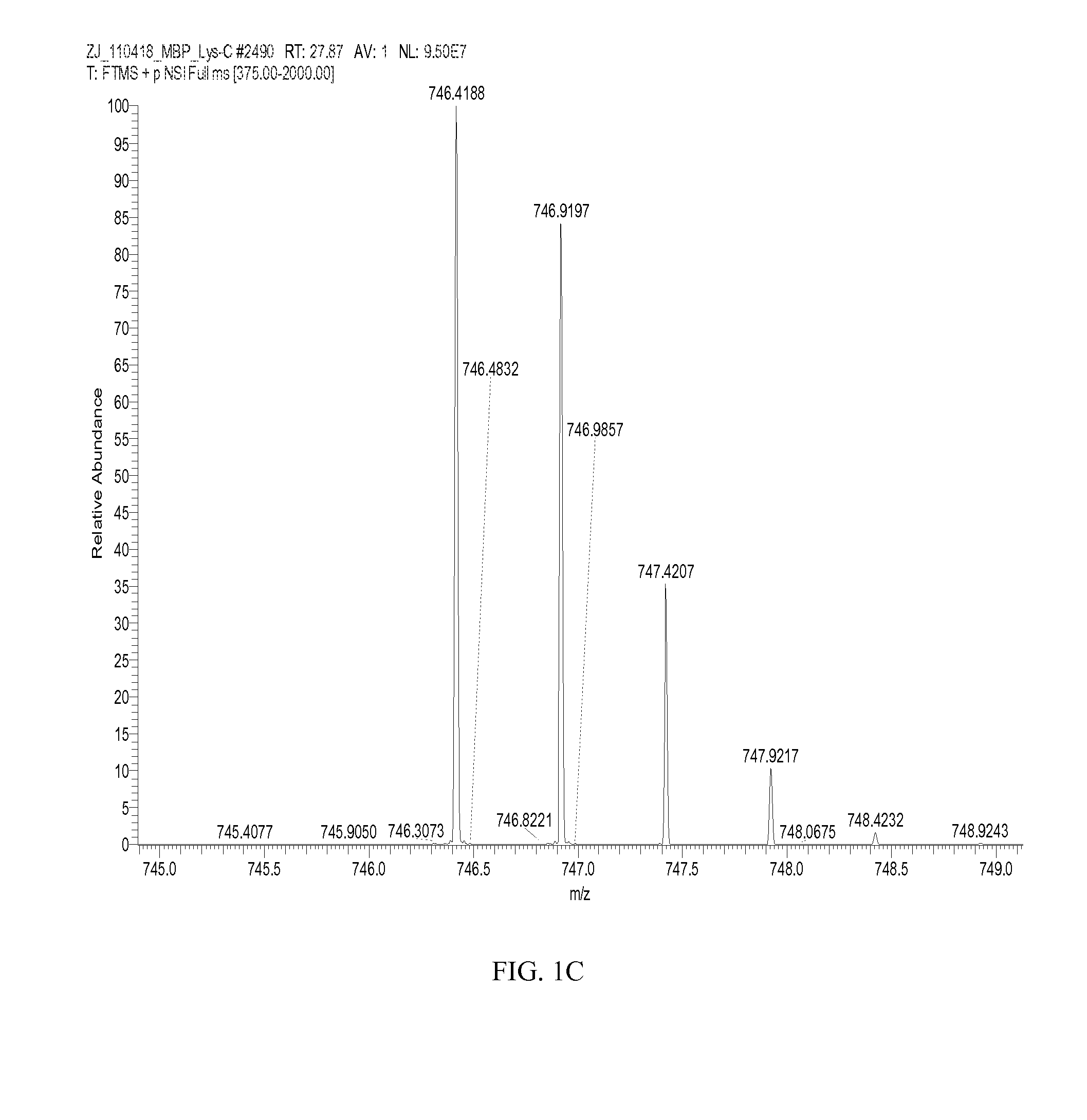

ActiveUS20150031048A1Improving immunogenicityImproved prognosisParticle spectrometer methodsIsotope separationInjury brainCerebral damage

The present invention relates to the field of biomarkers. More specifically, the present invention relates to biomarkers useful in diagnosing brain injury or neurodegeneration. In one embodiment, a method for diagnosing brain injury in a patient comprises the steps of (a) obtaining a sample from the patient; (b) determining the ratio of citrullinated to unmodified arginine residues at one or more arginine residues of one or more brain injury biomarker proteins; and (c) correlating the ratio to a patient having brain injury or to a patient not having brain injury, thereby providing the diagnosis.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Gene expression signature for prediction of human cancer progression

InactiveUS7943306B2Easy diagnosisImprove stratificationSugar derivativesMicrobiological testing/measurementHuman cancerLymphatic Spread

Methods are provided for classification of cancers by the expression of a set of genes referred to as the core serum response (CSR), or a subset thereof. The expression pattern of the CSR in normal tissues correlates with that seen in quiescent fibroblasts cultured in the absence of serum, while cancer tissues can be classified as having a quiescent or induced CSR signature. Patients with the induced CSR signature have a higher probability of metastasis. Classification according to CSR signature allows optimization of treatment, and determination of whether on whether to proceed with a specific therapy, and how to optimize dose, choice of treatment, and the like.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

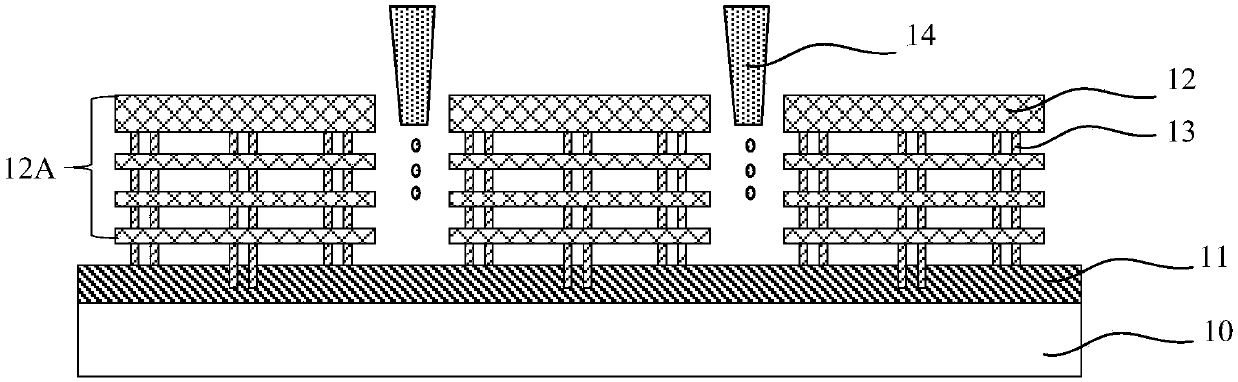

Chip package structure and method for forming same

InactiveCN109712966ASmall coefficient of thermal expansionReduced CTE mismatch differencesSemiconductor/solid-state device detailsSolid-state devicesWafer stackingColloid

The invention provides a chip package structure and a method for forming the same. By replacing all or a part of primer in a gap between two adjacent wafer stacks with a molding layer having a low thermal expansion coefficient, the amount of the primer is reduced and the thermal expansion coefficient of a packaging colloid composed of the molding layer and the primer is reduced, thereby reducing the CTE mismatch difference between the packaging colloid and the wafer stack and between the packaging colloid and a substrate, improving the warpage and the stratification of the substrate and the wafer stack, and improving packaging performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Device and method for clinical evaluation

PendingUS20200383647A1Overcome disadvantagesOvercome problemsEvaluation of blood vesselsSensorsPatient dataData mining

Systems and methods of evaluating a patient comprise the steps of obtaining temporal data of the patient after an event, monitoring a plurality of patient parameters, compiling patient data based on the temporal data and patient parameters, determining a state or change in state of the patient based on the compiled patient data, and alerting medical staff of the state or change in state.

Owner:RESPIRATORY MOTION

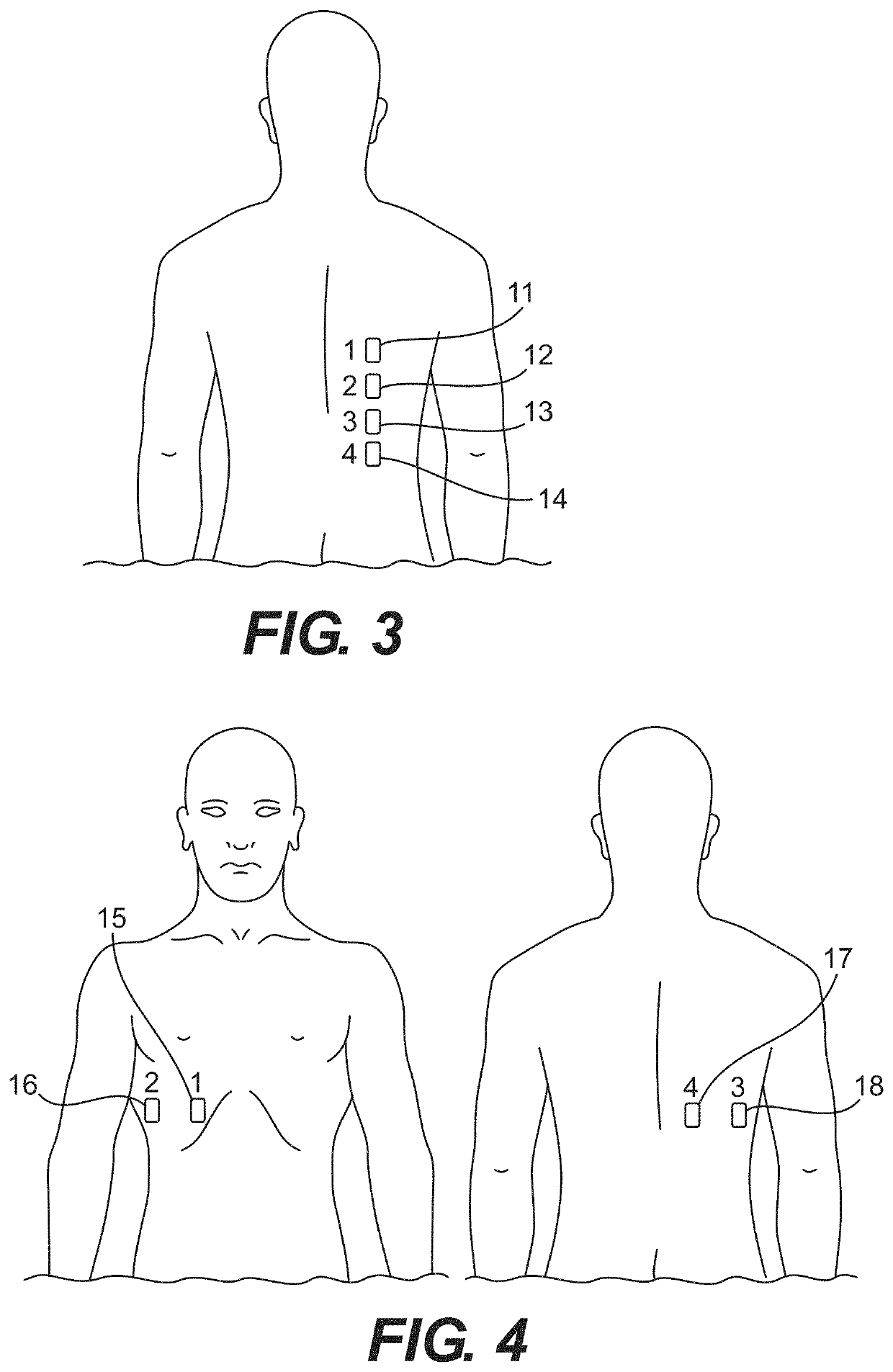

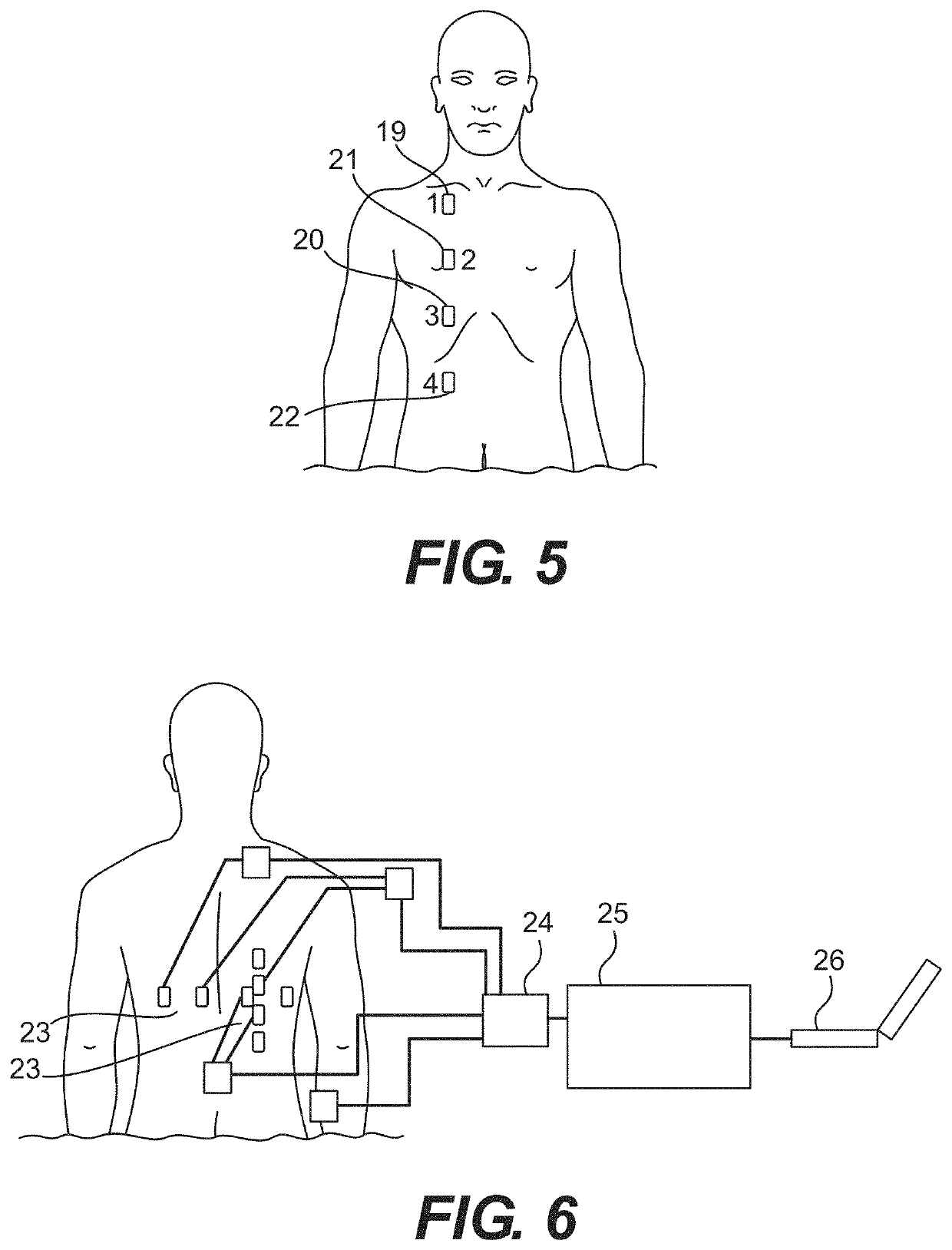

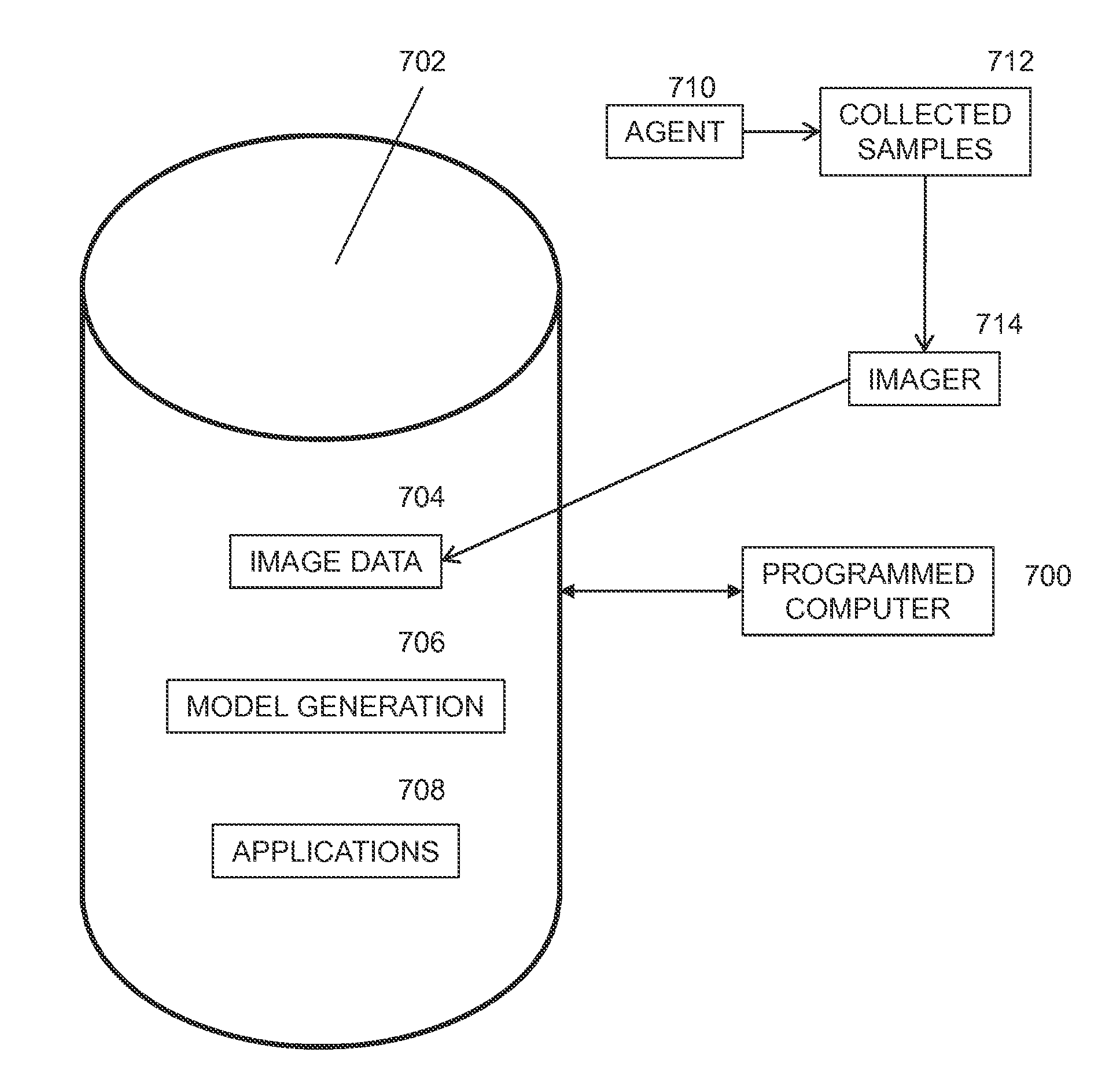

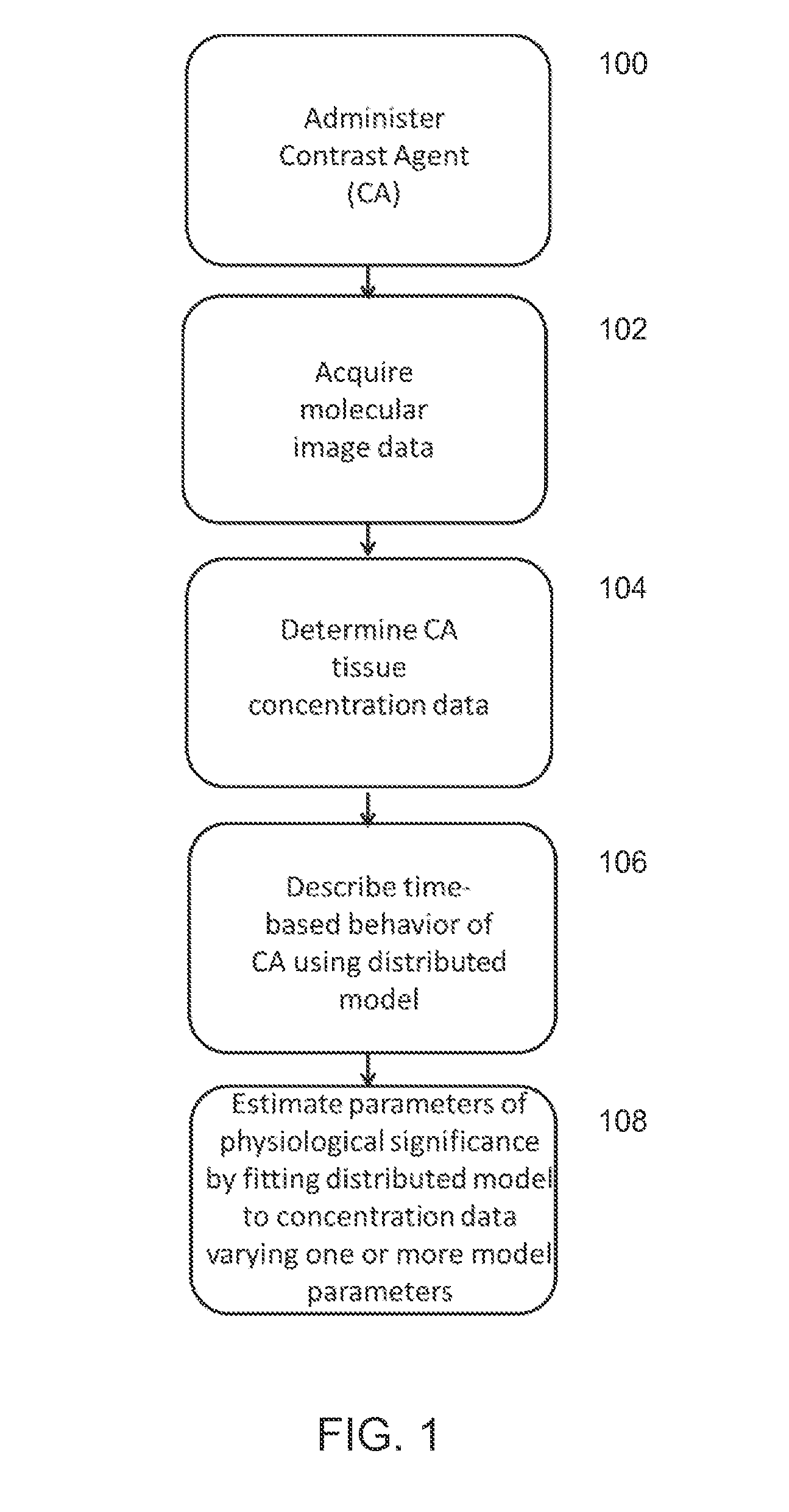

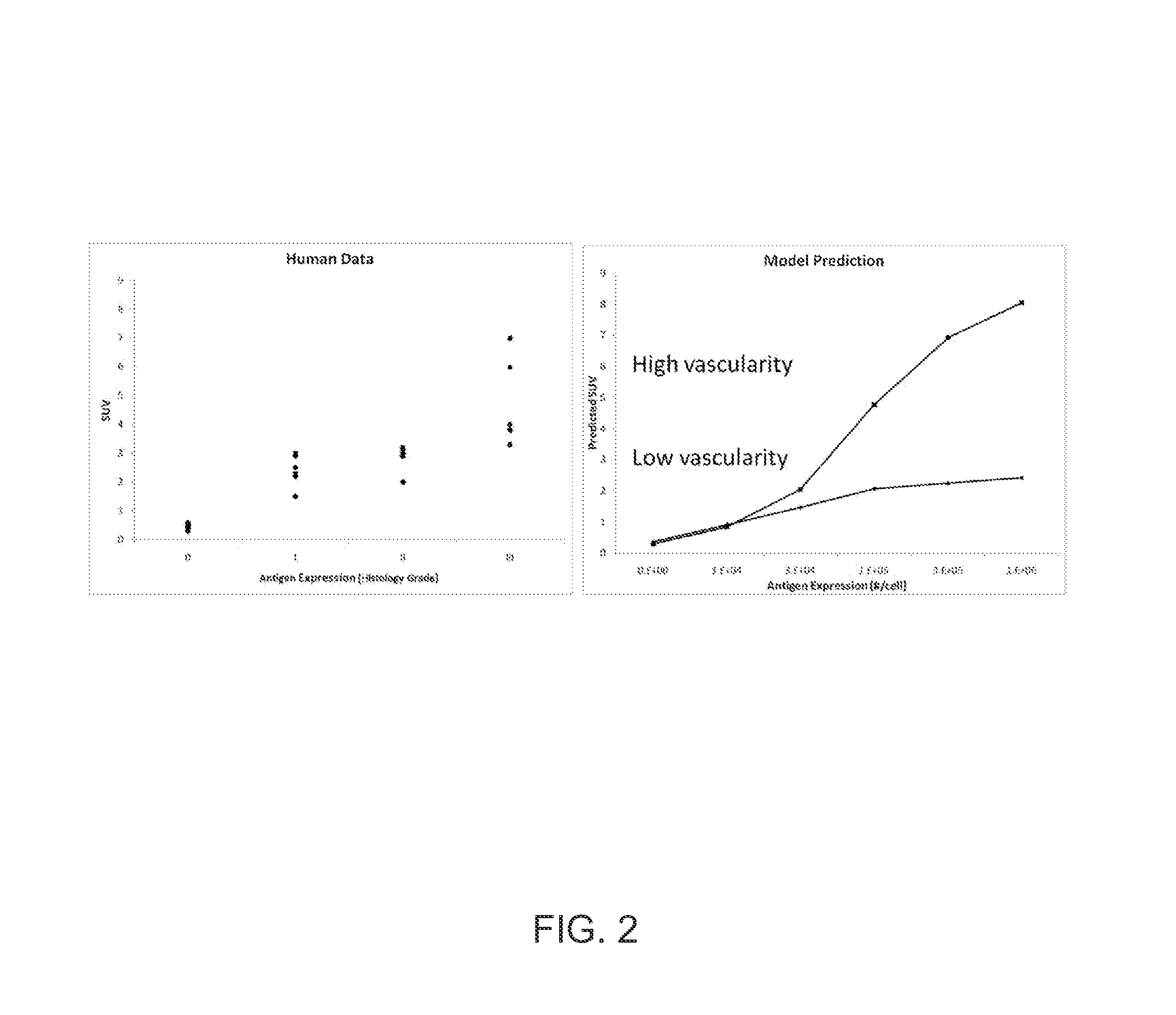

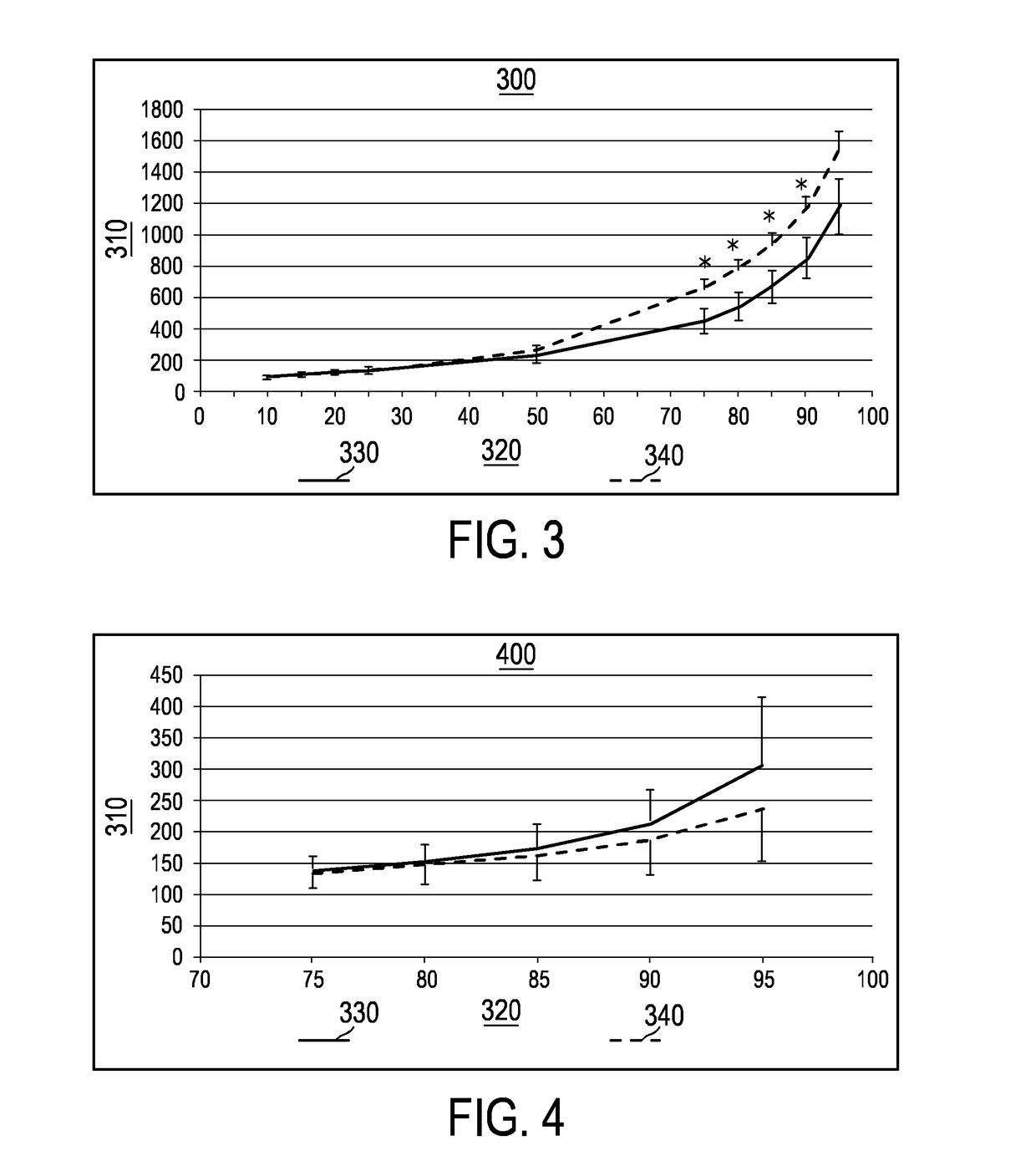

Estimating Pharmacokinetic Parameters in Imaging

ActiveUS20140321723A1Expand selectionImprove stratificationChemical property predictionImage enhancementImage processing softwarePharmacokinetic modeling

A method is provided for estimating a parameter of physiological significance. One or more images are provided of a tissue in a subject to whom a dose of a contrast agent (CA) has been administered, using a computer equipped with image processing software, the concentration or relative concentration of the agent in a region or regions of interest in the tissue is determined, thus generating concentration data. The time-based behavior of concentrations of CA within the tissue is determined using a pharmacokinetic model that is based on a set of pharmacokinetic model parameters. Using computer code, the pharmacokinetic model is fit to the concentration data, varying one or more parameters, such that a best fit estimate of a parameter of physiological significance is provided.

Owner:INVICRO

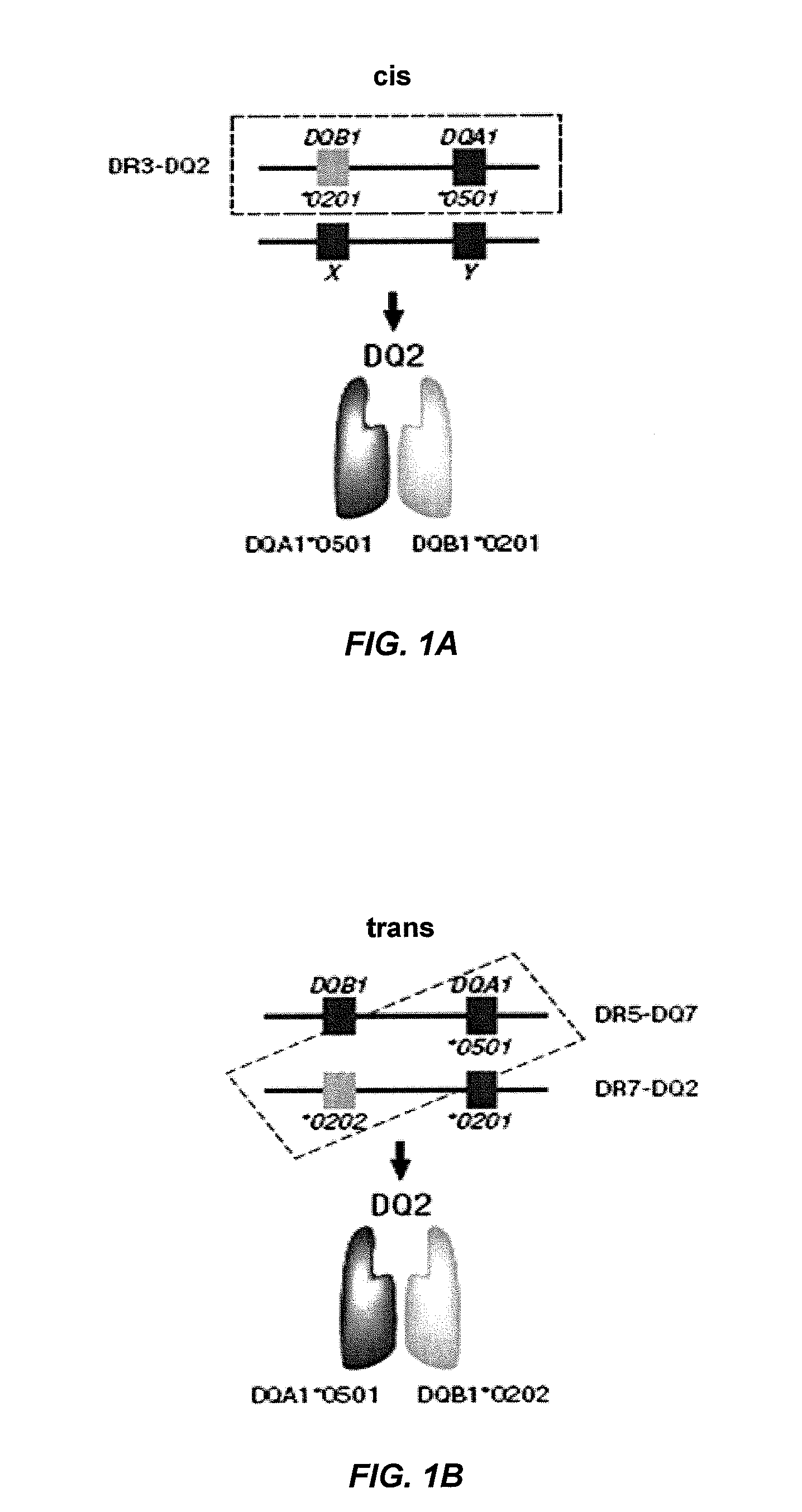

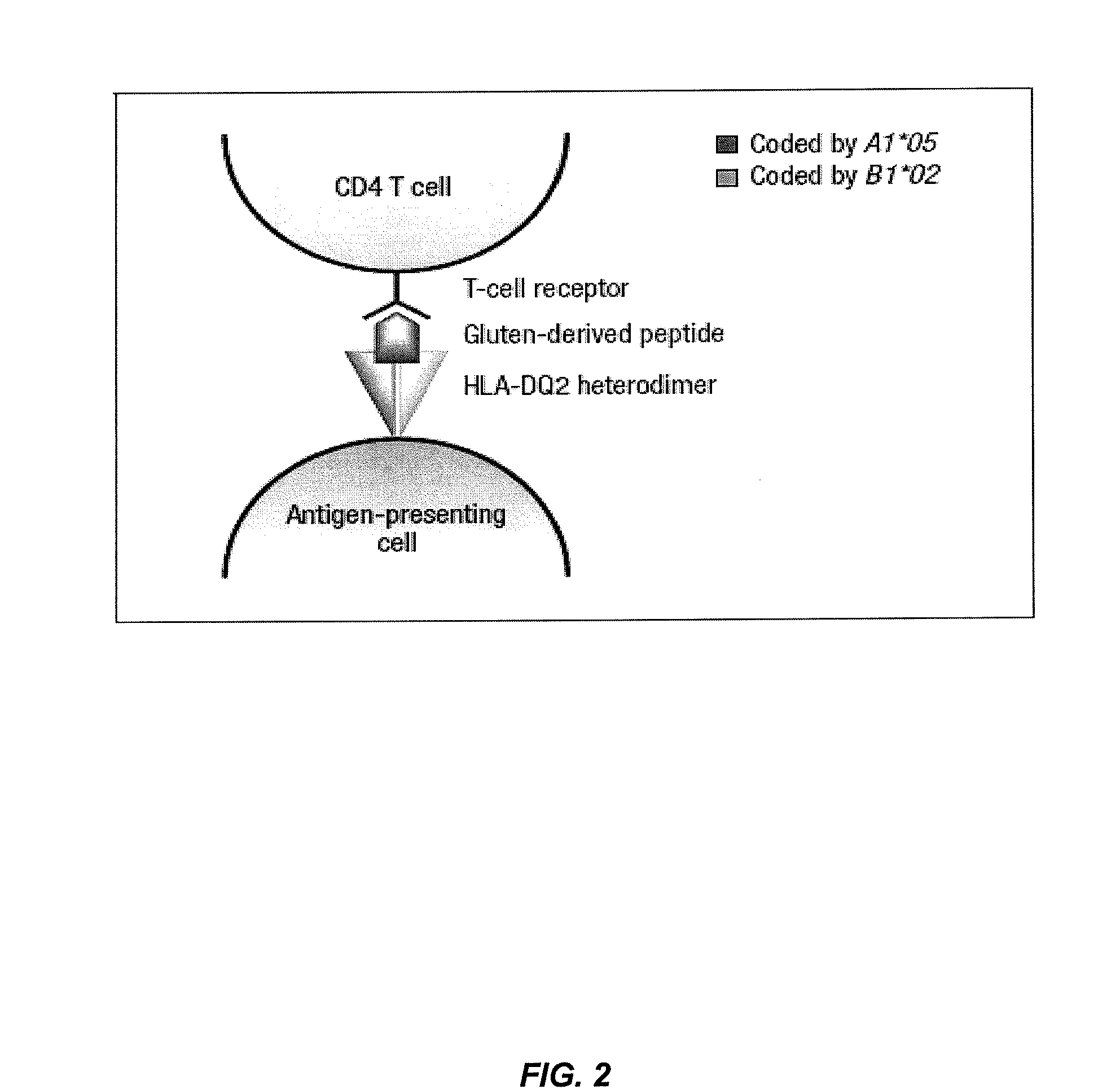

Methods to predict risk for celiac disease by detecting anti-flagellin antibody levels

InactiveUS8409819B1Effective predictionEffectively stratifyDisease diagnosisBiological testingGenotypeFlagellin

The present invention provides methods, assays, and kits for predicting or stratifying the risk of celiac disease (CD) based upon HLA-DQ genotype and / or anti-flagellin antibody levels. Such risk prediction or stratification can provide benefits to family members of CD patients, to a subset of patients who are being evaluated clinically for CD, and to researchers, who can utilize this strategy to establish inclusion criteria for participation in research studies investigating potential preventive interventions.

Owner:PROMETHEUS BIOSCI INC

M85 methanol gasoline and preparation method thereof

The invention relates to the technical field of methanol gasoline, in particular to an M85 methanol gasoline and a preparation method thereof. According to the preparation method, methanol, gasoline, sodium methoxide, pine oil, waste oil, glycerin, acetone and polyoxyethylene ether are mixed according to a proportion; the pine oil and the waste oil are separately treated through the combination of preparation process steps; the treated pine oil and waste oil are added for mixing; ultrasonic mixing treatment is performed during treatment processes, so that all raw materials are dispersed more uniformly, mutual concurrent effects among the methanol, gasoline, waste oil and other raw materials are further achieved, and then the quality of the methanol gasoline is improved. Particularly, the phenomenon that the methanol gasoline is easy to be subjected to stratification when the water content reaches 3% is avoided. Therefore, the water resistance of the methanol gasoline is improved, the guarantee period of the methanol gasoline is prolonged, and the storage difficulty of the methanol gasoline is lowered.

Owner:贵州大洋能源有限责任公司

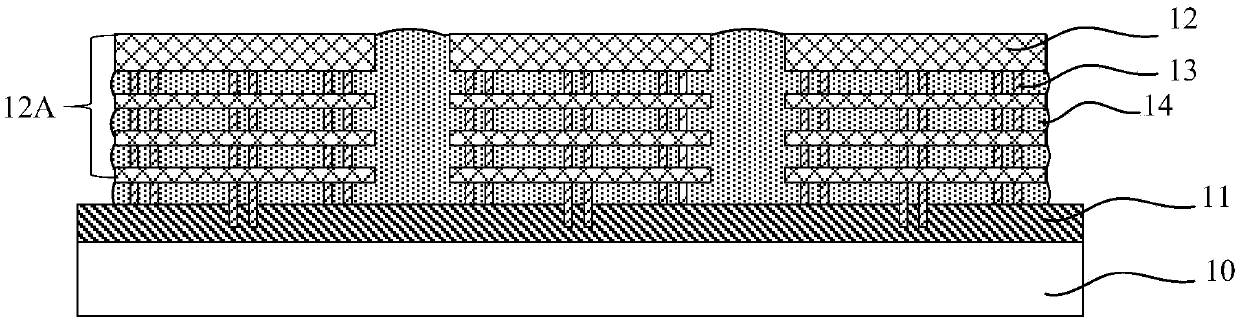

Apparatus, system, method and computer program for assessing the risk of an exacerbation and/or hospitalization

ActiveUS20170156681A1Reduce riskSmall differenceHealth-index calculationRespiratory organ evaluationAccelerometerIncreased risk

The present invention relates to an apparatus, a system (100), a method (200), and a computer program for assessing the risk of an exacerbation and / or hospitalization. A patient's physical activity is measured (e.g., by an accelerometer (110)) during an active period of time (e.g., during awake hours) and during a rest period of time (e.g., during sleep hours) to gather first and second activity data. A risk of exacerbation and / or hospitalization is assessed (e.g., by a risk assessment unit (120)) based on an expression involving the respective activity data during active and rest periods fulfilling a predetermined relationship with respect to a predetermined activity level. For instance, low activity data during active periods and high activity data during rest periods indicates an increased risk of exacerbation and / or hospital readmission for the patient.

Owner:KONINKLJIJKE PHILIPS NV

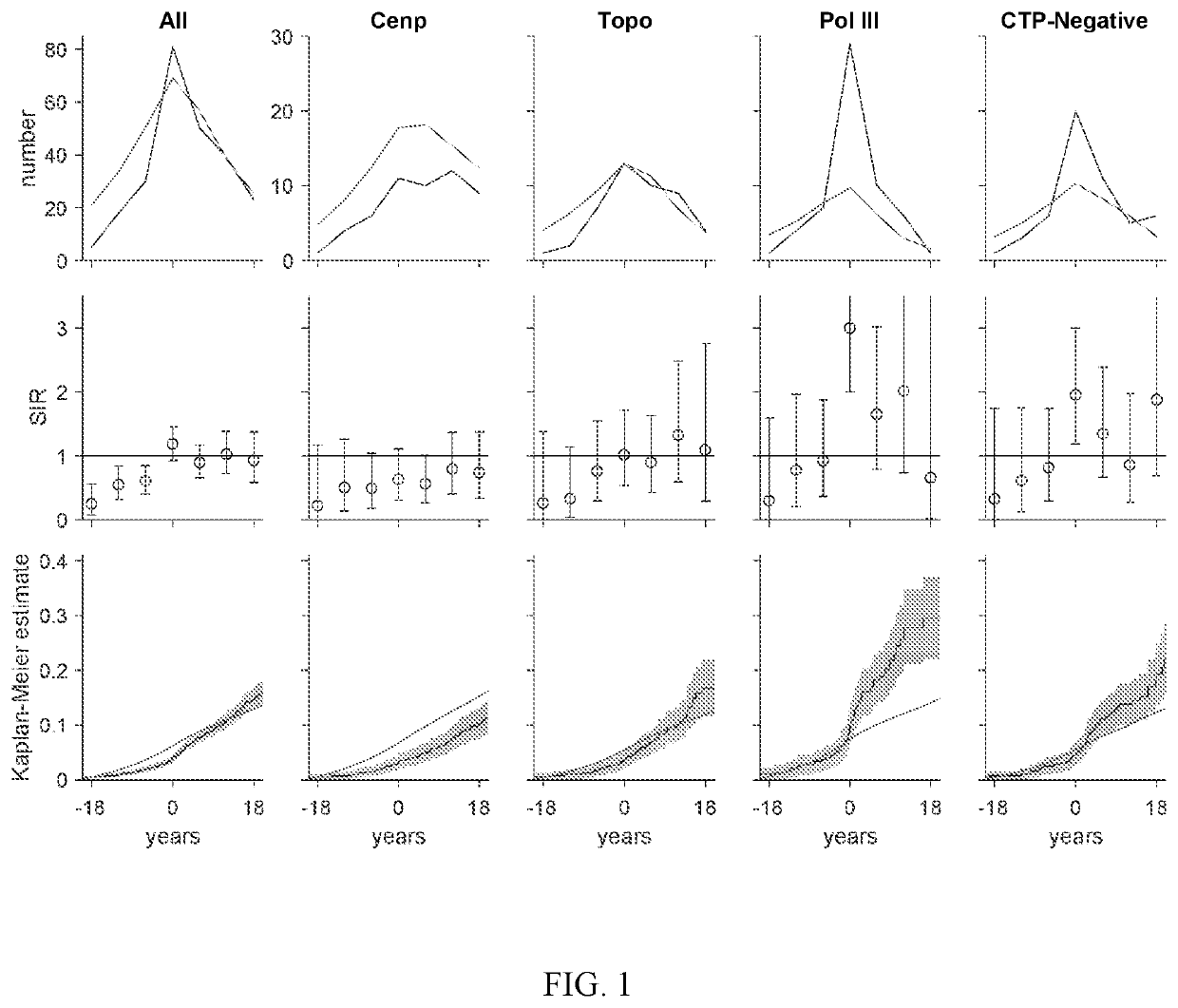

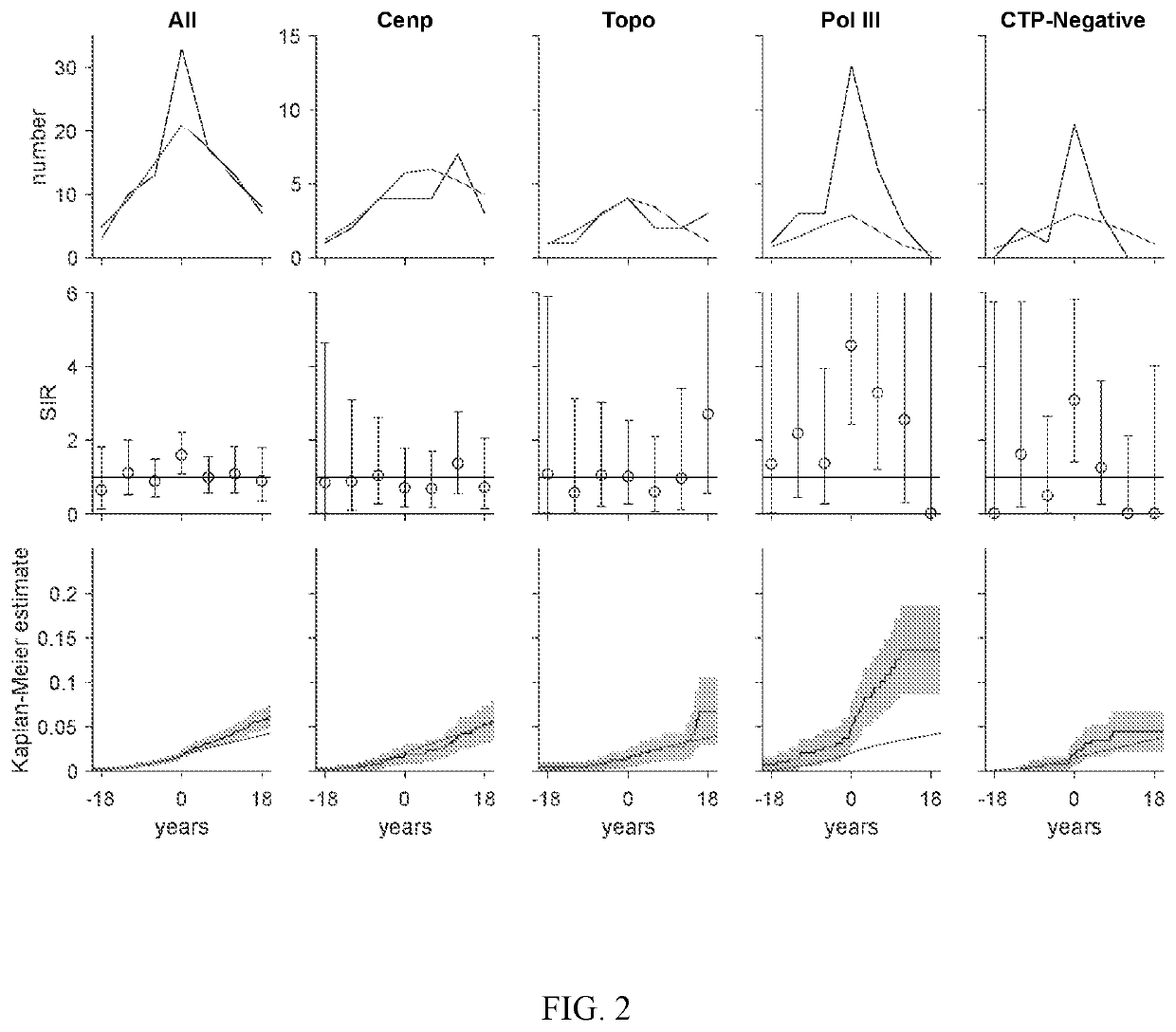

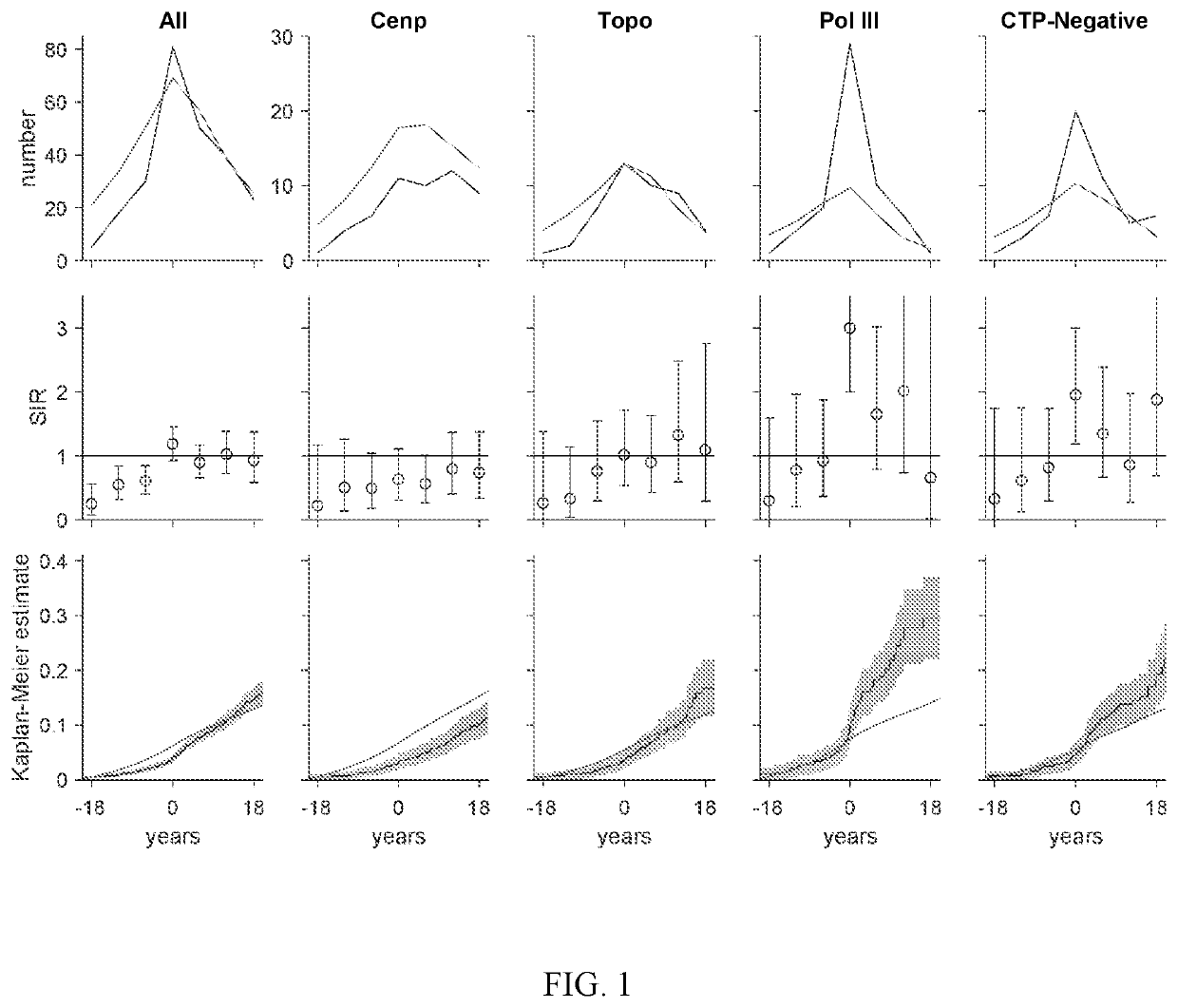

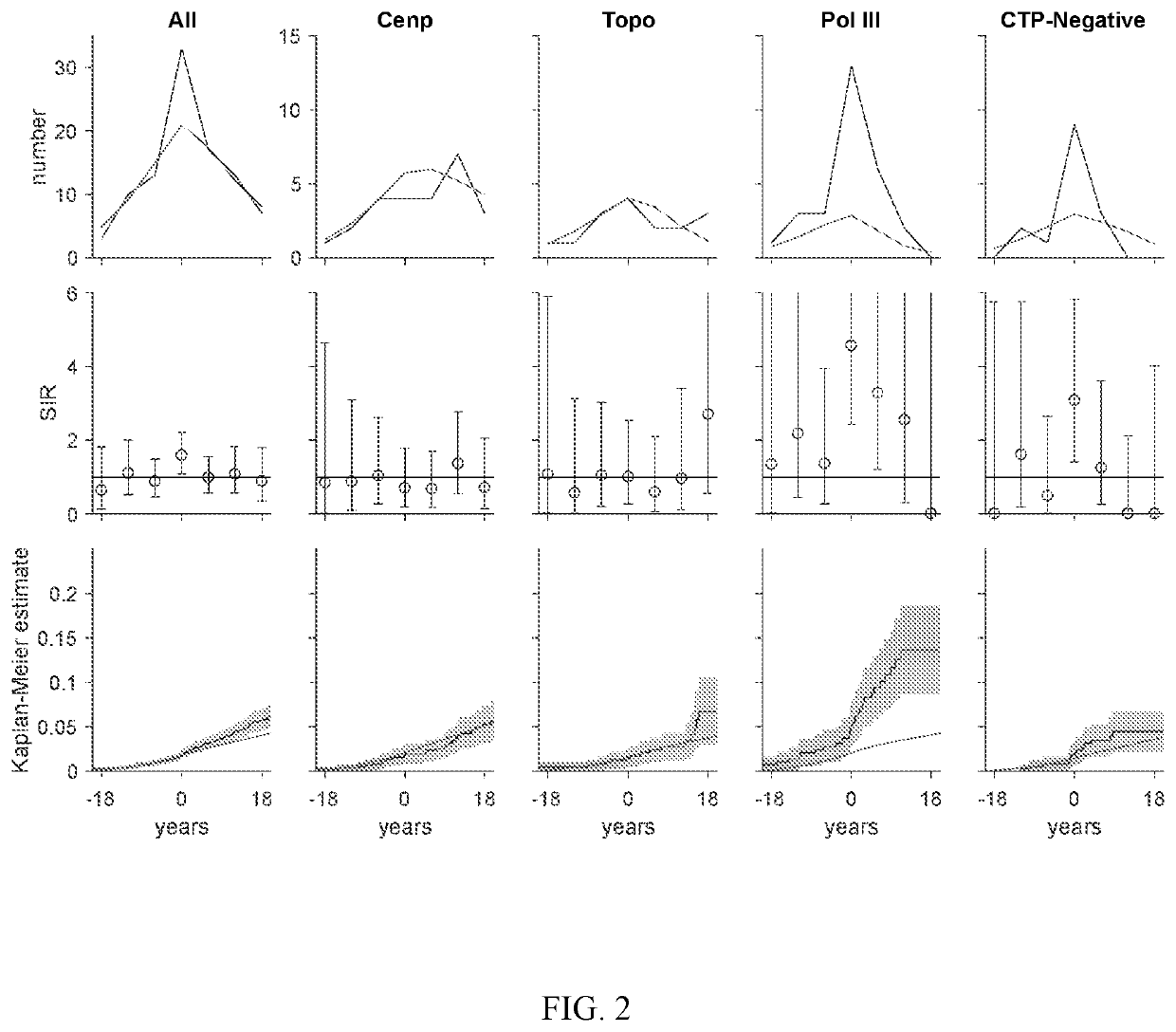

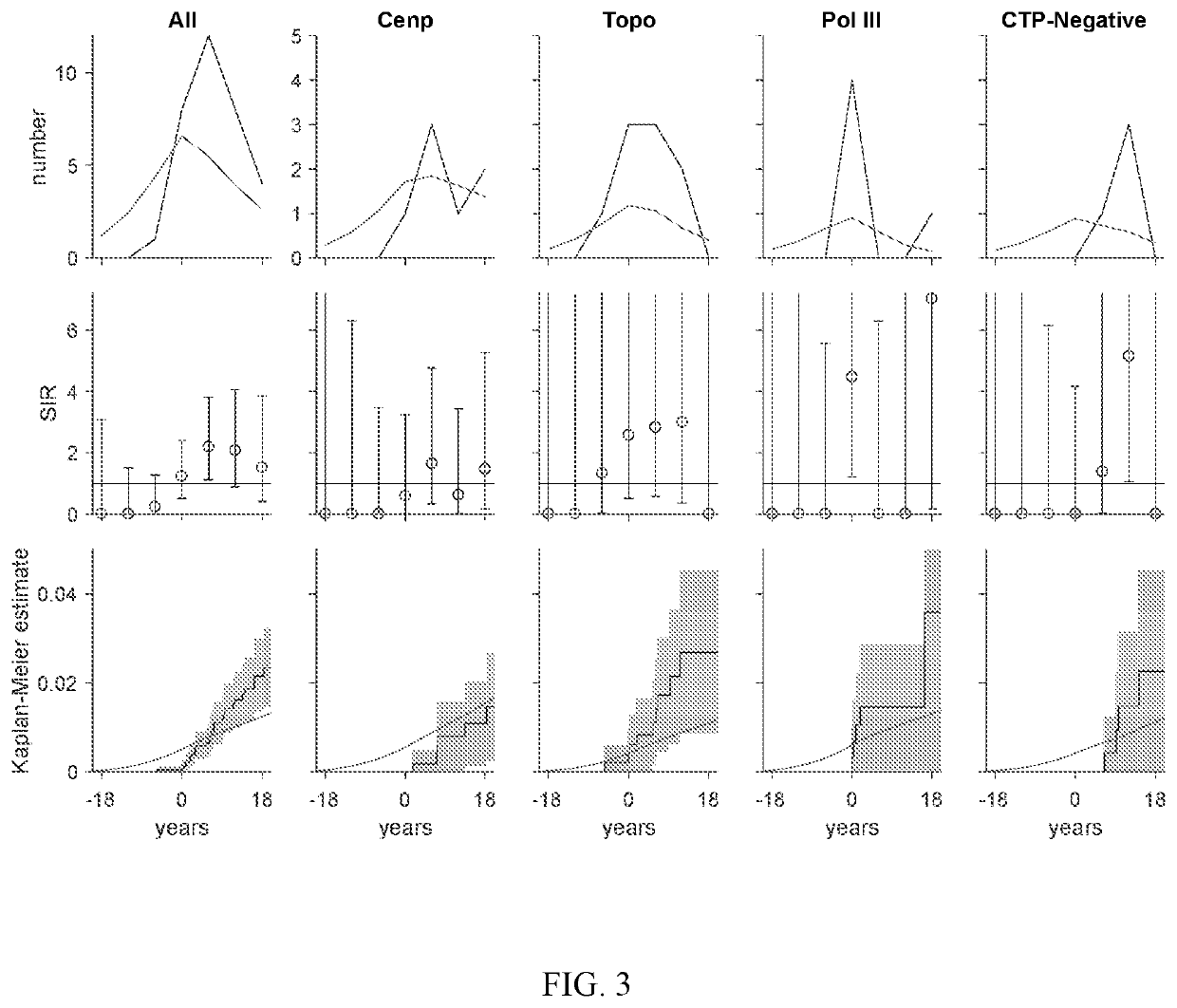

Materials and methods for assessing cancer risk and treating cancer

ActiveUS20200209245A1Reduce riskHigh riskSerum immunoglobulinsDisease diagnosisAutoimmune conditionAutoimmune disease

This document relates to materials and methods for assessing and / or treating subjects (e.g., subjects having autoimmune diseases). For example, materials and methods for determining if a subject (e.g., a human having an autoimmune disease) has one or more antibodies that can be used to identify the subject as having a lower risk of cancer or as having a higher risk of cancer are provided. Materials and methods for treating a subject (e.g., a human) identified as having a higher cancer risk for cancer are also provided.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

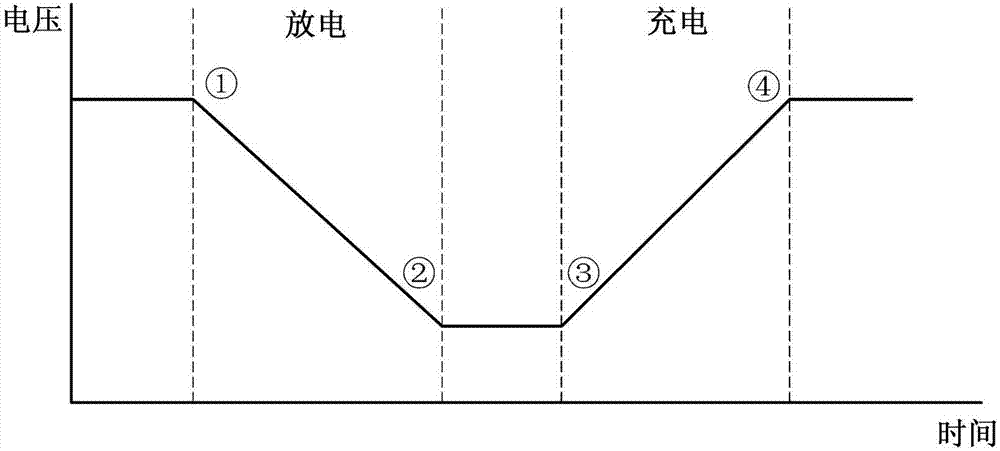

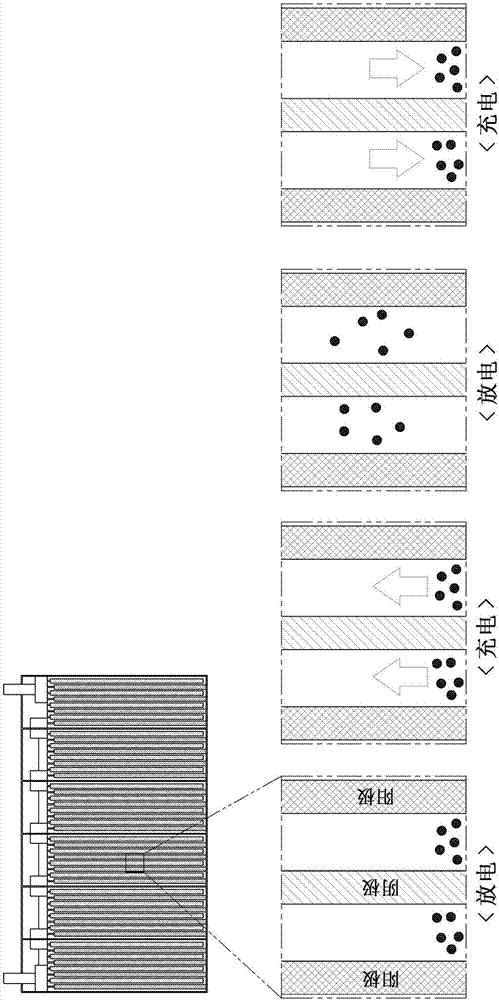

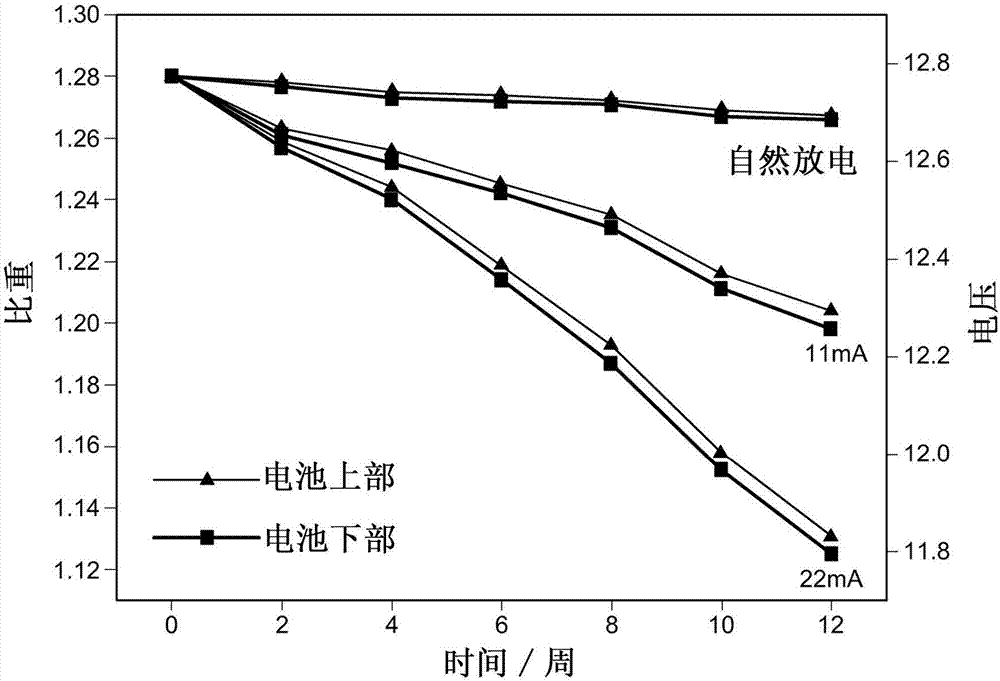

Electrolyte composition of lead storage battery and lead storage battery using the same

ActiveCN107959063AImprove stratificationIncreased durabilityFinal product manufactureLead-acid accumulators constructionMechanical componentsElectrical battery

An electrolyte composition for a lead storage battery and a lead storage battery using the same are provided. More particularly, the electrolyte composition of a lead storage battery and the lead storage battery using the same improve stratification of an electrolyte without use of a separate mechanical device by using a natural stirring effect caused by a specific gravity difference between a dispersant having a specific gravity of from about 1.02 to about 1.35 and an electrolyte including distilled water and sulfuric acid. Due to the reduction in mechanical components, the electrolyte composition for a lead storage battery and the lead storage battery which are disclosed herein have enhanced durability compared to conventional batteries.

Owner:HYUNDAI MOTOR CO LTD

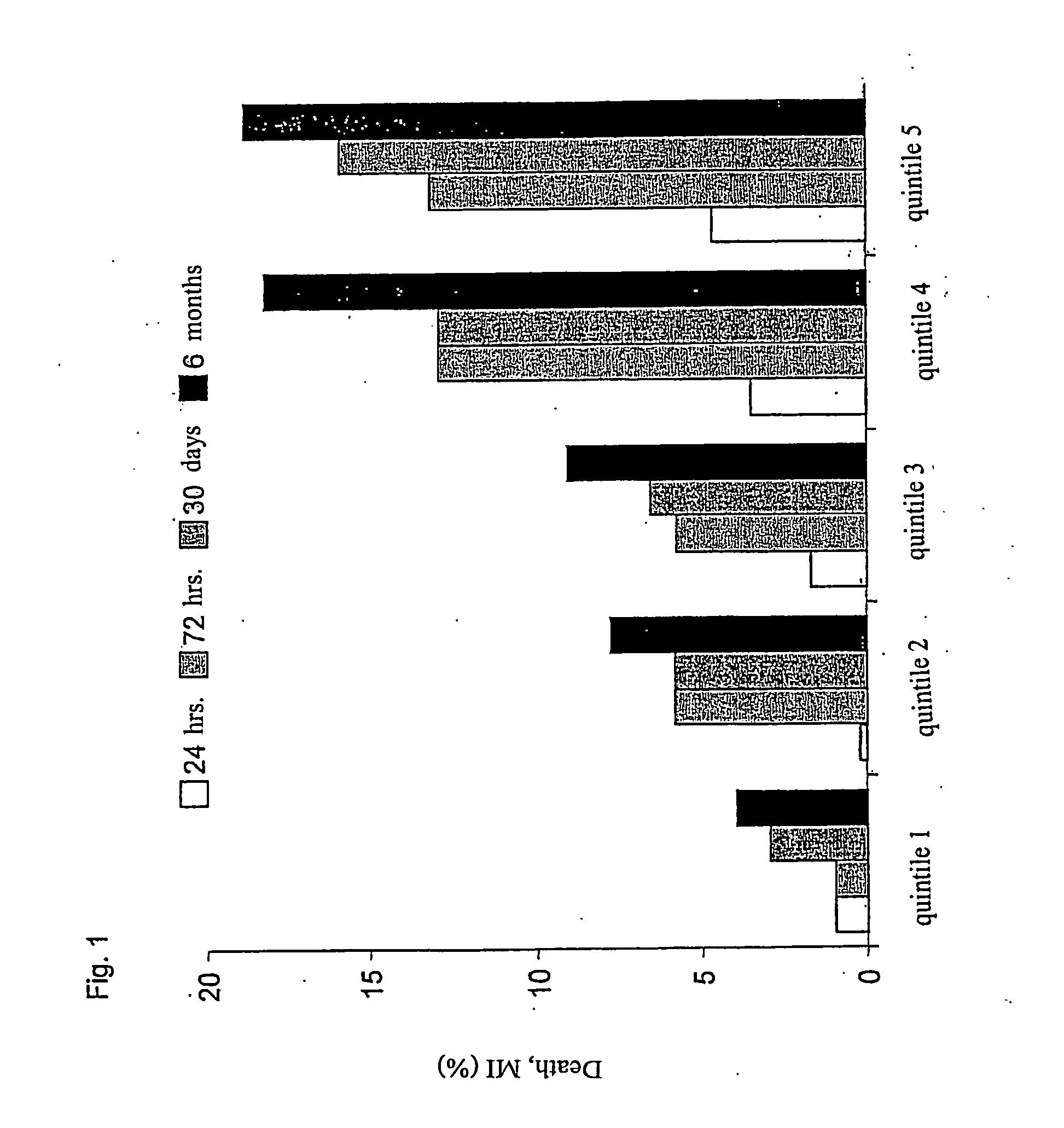

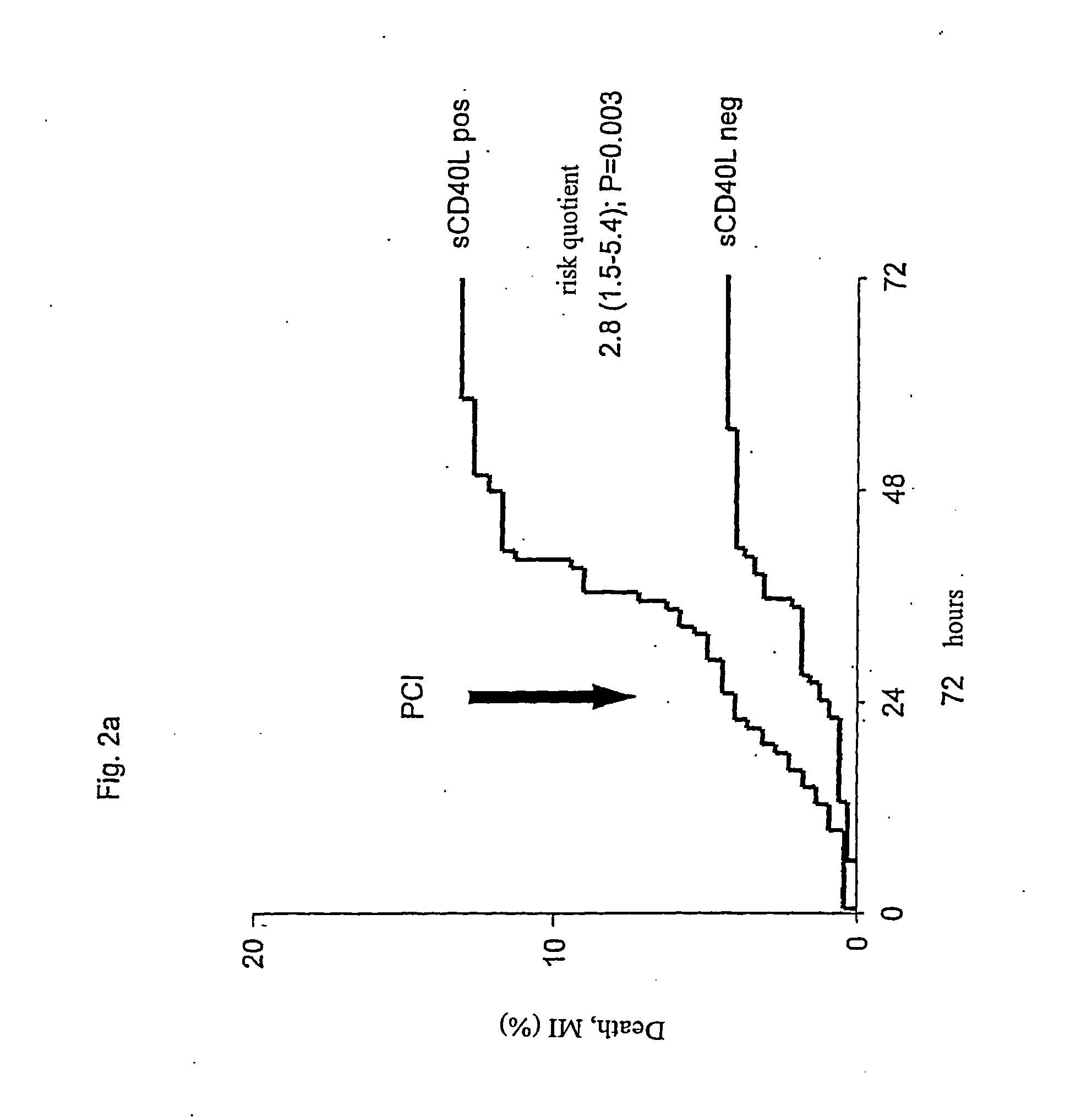

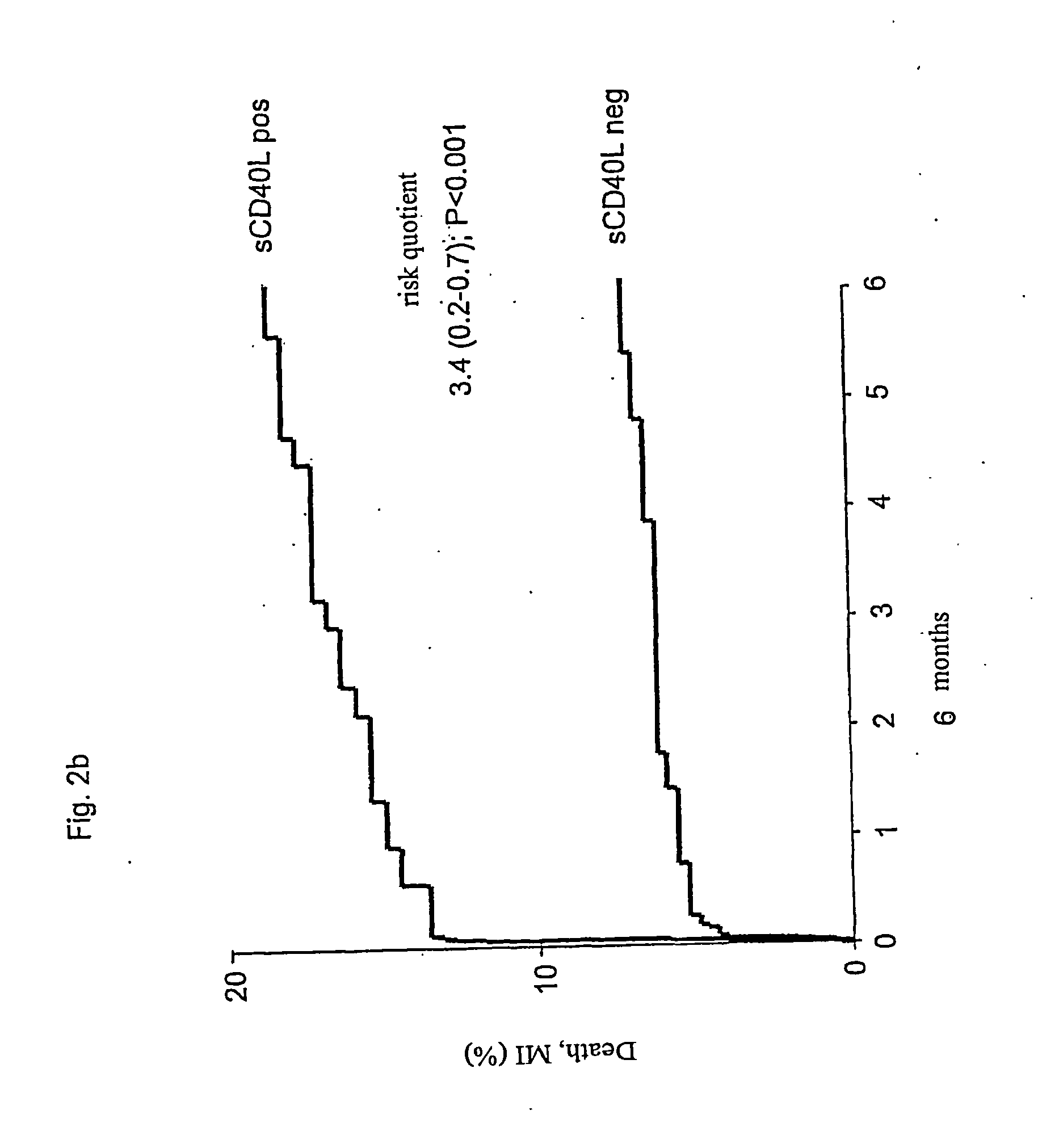

Scd40l and placental growth factor (PIGF) as biochemical marker combinations in cardiovascular diseases

InactiveUS20130004487A1Improve stratificationNone is in routine clinical useNGF/TNF-superfamilyAntibody ingredientsBULK ACTIVE INGREDIENTBiochemical markers

The invention relates to novel markers of vascular inflammation and combinations thereof as diagnostic and prognostic tools in patients with cardiovascular diseases. The markers also act as tools that facilitate the selection of active ingredients for the treatment of such diseases, and finally act as starting points for the treatment of cardiovascular diseases. Furthermore, the invention relates to the creation of an individual risk profile of negative events that are associated with the progression of arteriosclerosis.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS PRODS

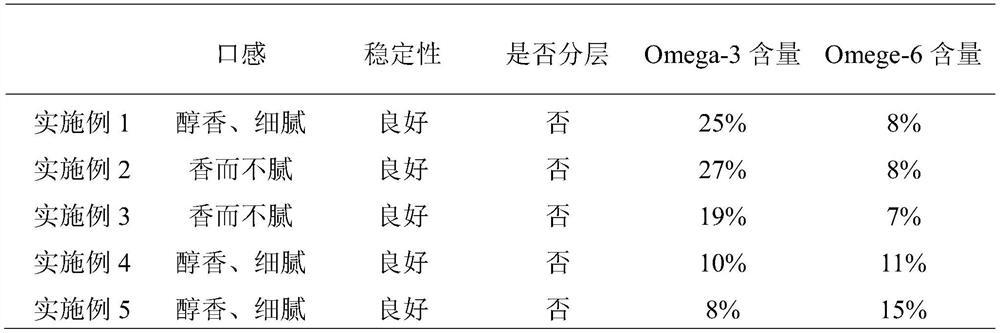

Nutritional flavored composite sauce and preparation method thereof

PendingCN112352938AGreat tasteAvoid clumpingFood ingredient as antioxidantFood preservationNutritive valuesVegetable oil

The invention discloses nutritional flavored composite sauce and a preparation method thereof, and belongs to the field of food processing. The method comprises the following steps: peeling and screening raw material seeds, carrying out ultrasonic soaking with a fructo-oligosaccharide solution with a certain concentration, carrying out microwave baking treatment, and carrying out sauce grinding toobtain a sauce material A; performing screening, superfine grinding and 80-100-mesh screening on the removed raw material skin to obtain raw material skin powder, then adding the raw material skin powder into vegetable oil preheated to 80 DEG C, and performing uniform stirring to obtain a sauce B; adding the sauce B into the sauce A, performing uniform stirring, performing homogenizing to obtaina sauce C, performing microwave sterilization, performing cooling, and performing filling so as to obtain the nutritional flavored composite sauce. The method is simple in process, low in energy consumption and low in cost. The obtained product is good in flavor, good in stability, free of layering, high in safety, high in nutritional value, rich in essential fatty acid and easy to digest and absorb.

Owner:SANMARK CORP

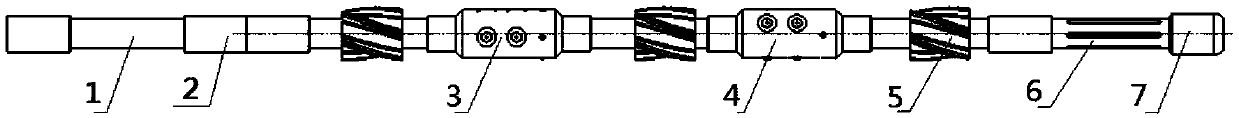

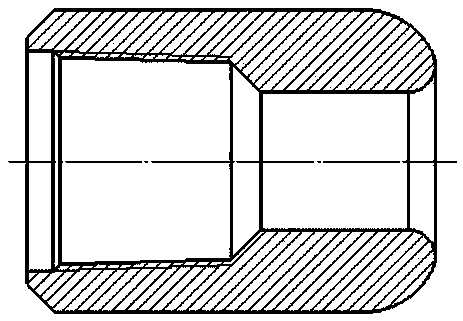

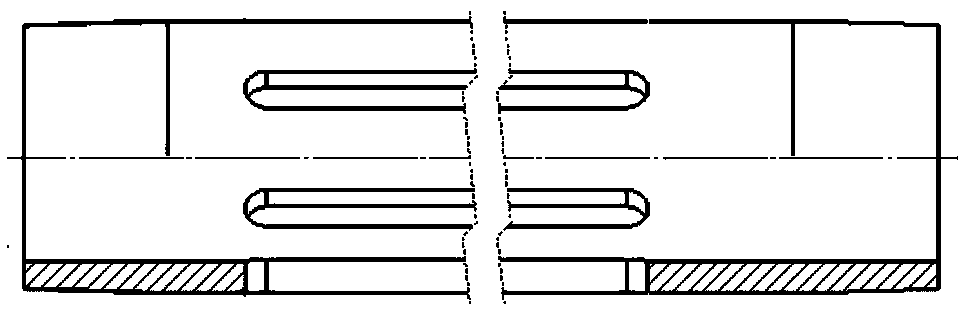

Composite acid fracturing construction pipe column and application method

ActiveCN110671086ASimple structureImprove stratificationFluid removalDrilling compositionAcid fracturingOil field

The invention provides a composite acid fracturing construction pipe column and an application method, and belongs to the technical field of underground fracturing operation technologies. The composite acid fracturing construction pipe column comprises at least one spray gun with a sliding sleeve, a slotted pipe and a hollow guide head, the spray guns with the sliding sleeves are connected in sequence, the lower end of the last spray gun with the sliding sleeve is connected with the upper end of the slotted pipe, and the lower end of the slotted pipe is connected with the hollow guide head. Bymeans of the method, subsection reconstruction of different construction modes such as large-scale acid fracturing, fixed-point jet perforation, jet fracturing and the like is sequentially completedon a long open hole section by one pipe column, the layering and subsection reconstruction effects of clastic rock in an oil field are improved, the swept volume and complexity of the reconstructed fracture of a clastic rock reservoir are improved, and the fracturing yield increasing effect is improved. Mechanical packing is not needed, the pipe column structure is simple, the tool reliability andsafety are high, the pipe column meets different functional requirements, the construction continuity is good, the construction time is saved, the construction cost is reduced, and the oil field development effect is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

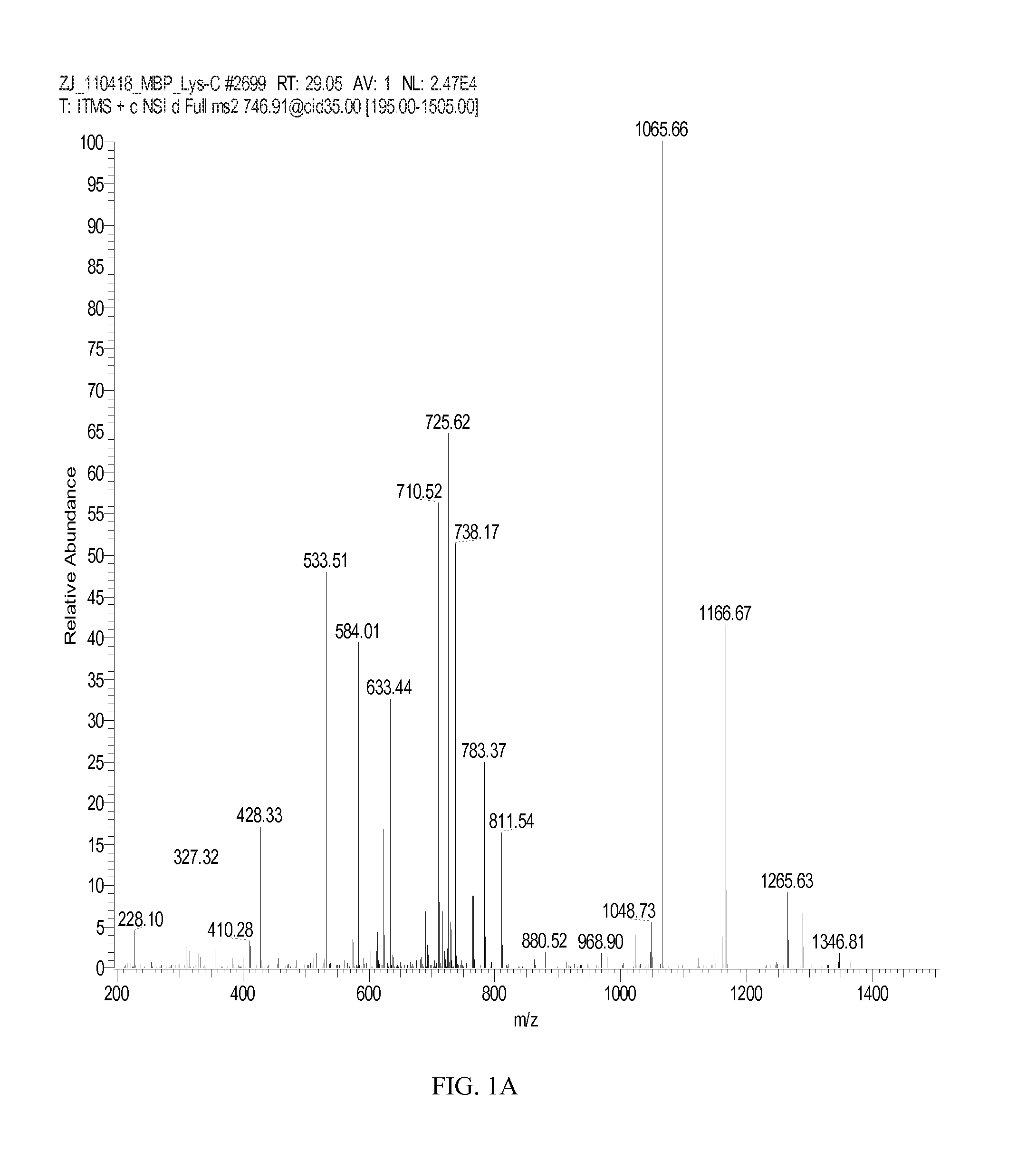

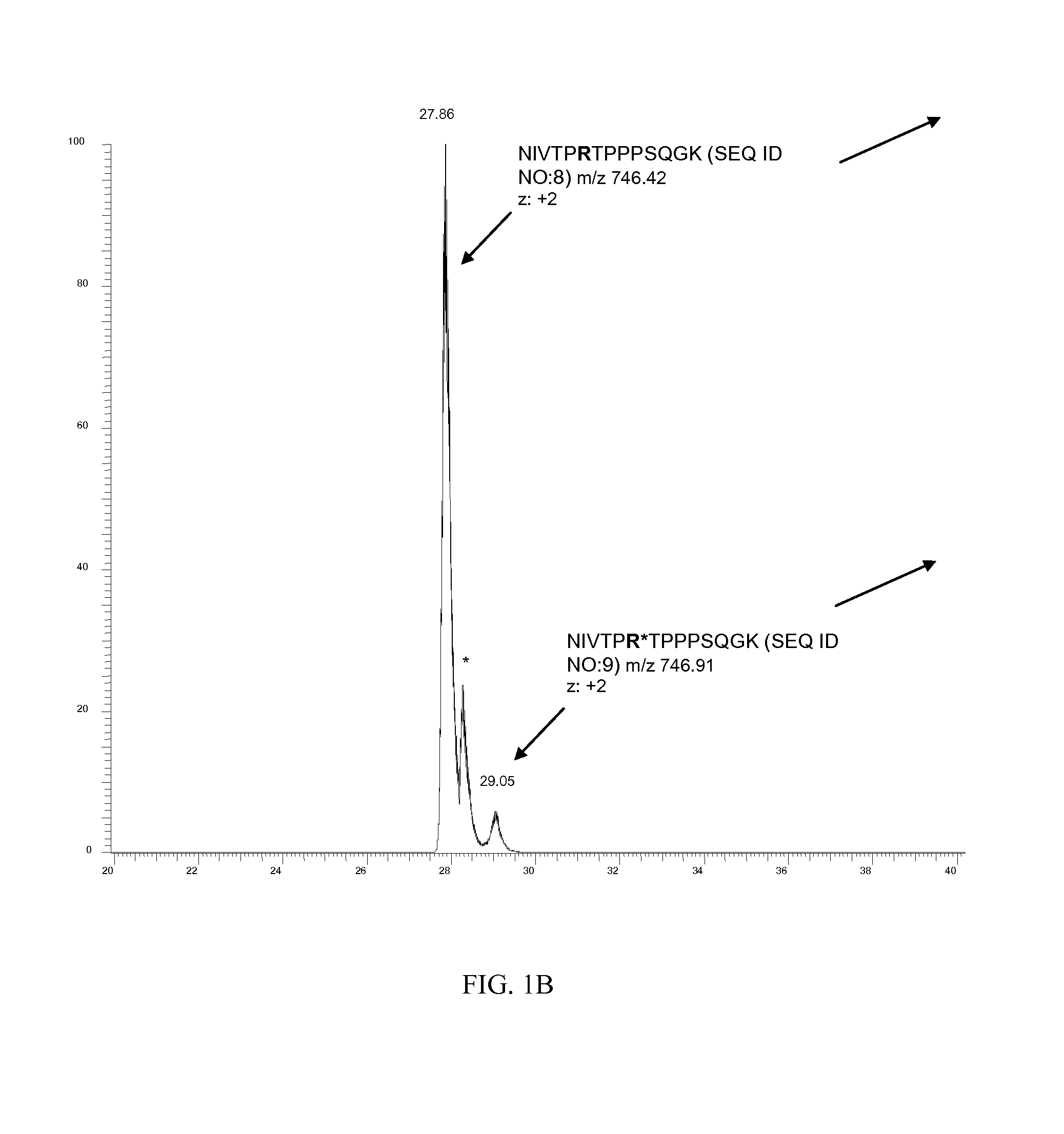

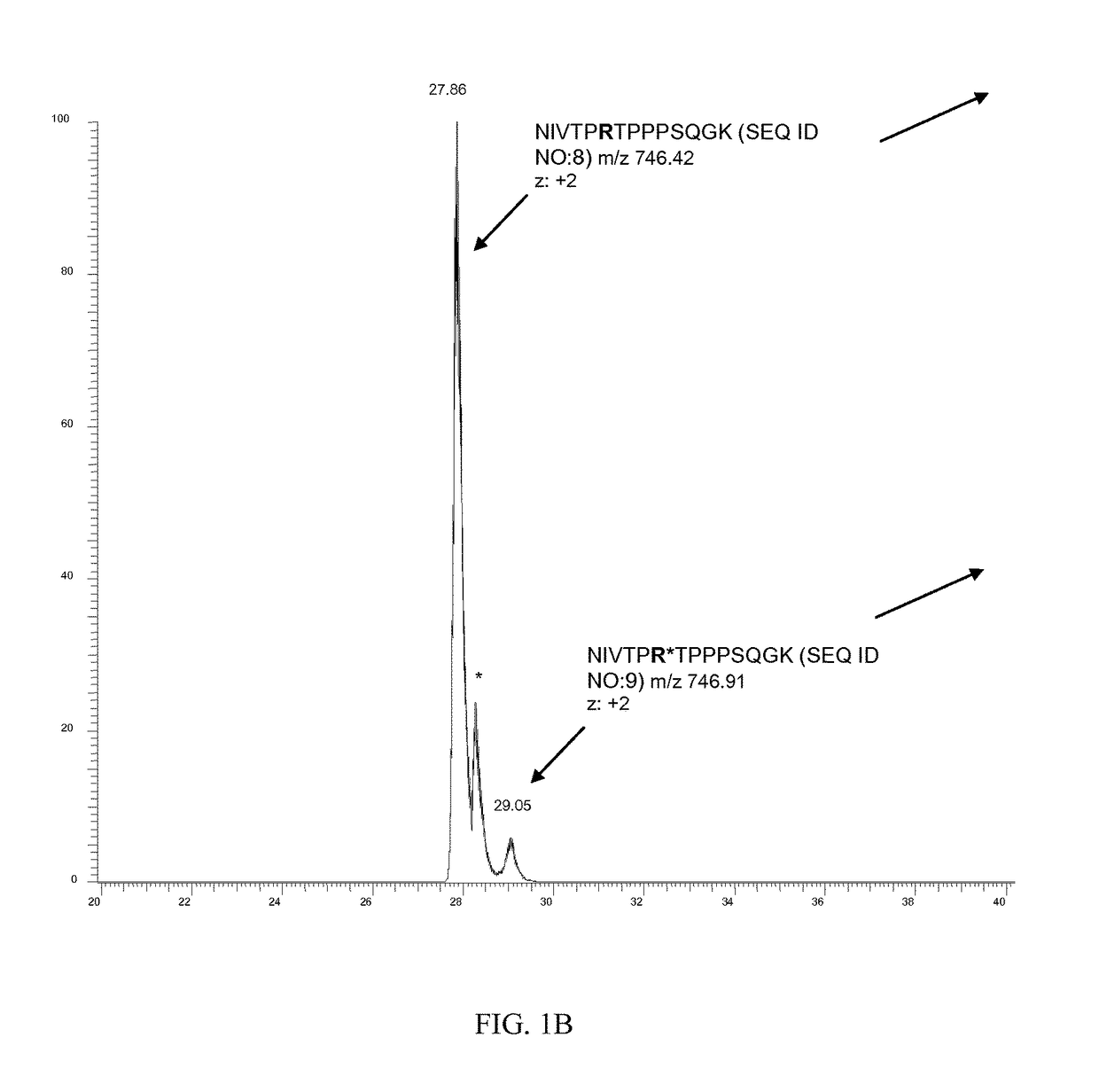

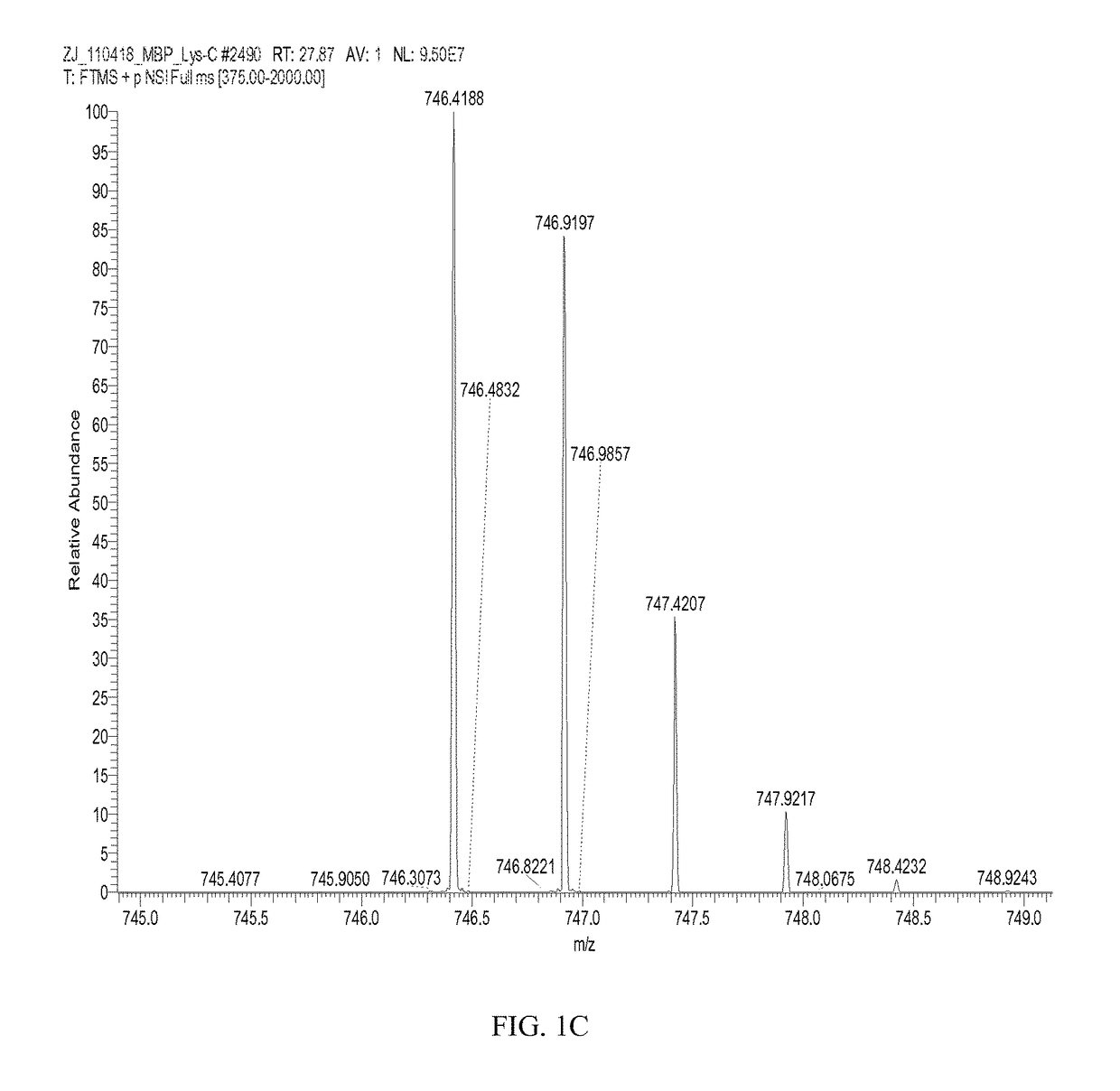

Citrullinated brain and neurological proteins as biomarkers of brain injury or neurodegeneration

ActiveUS9709573B2Fast and accurate diagnosisPromote resultsMicrobiological testing/measurementParticle spectrometer methodsInjury brainMedicine

The present invention relates to the field of biomarkers. More specifically, the present invention relates to biomarkers useful in diagnosing brain injury or neurodegeneration. In one embodiment, a method for diagnosing brain injury in a patient comprises the steps of (a) obtaining a sample from the patient; (b) determining the ratio of citrullinated to unmodified arginine residues at one or more arginine residues of one or more brain injury biomarker proteins; and (c) correlating the ratio to a patient having brain injury or to a patient not having brain injury, thereby providing the diagnosis.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

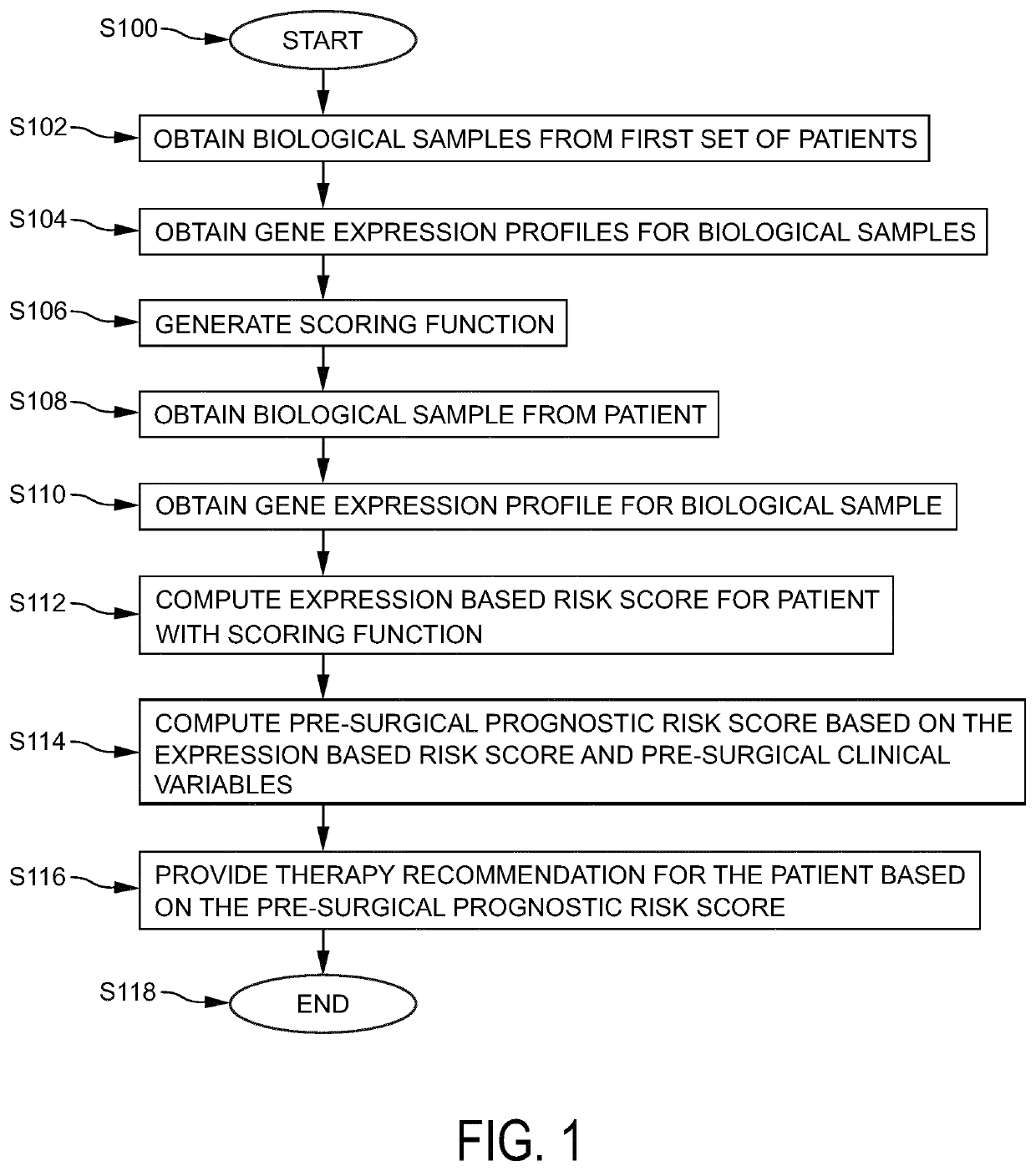

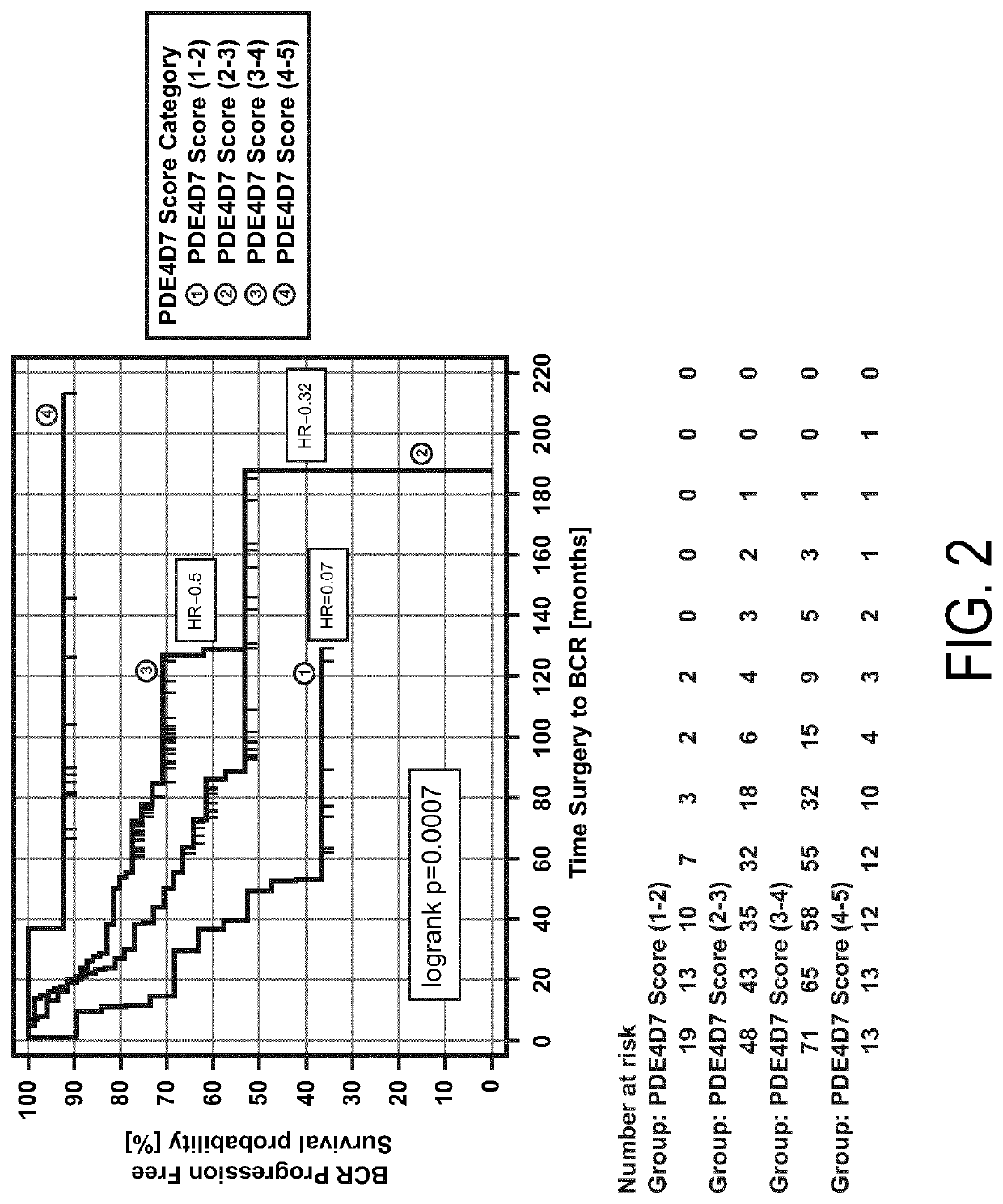

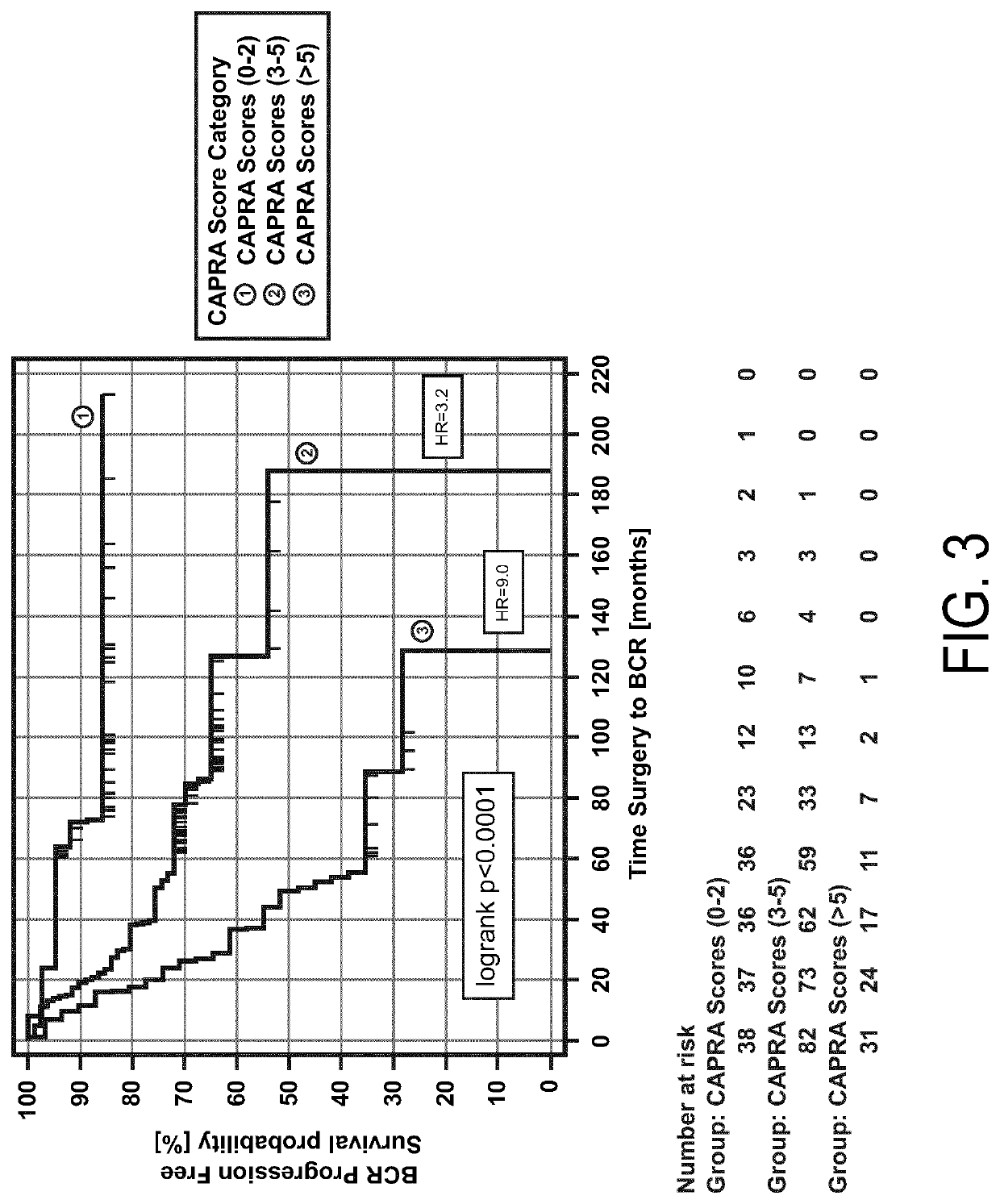

Pre-surgical risk stratification based on pde4d7 expression and pre-surgical clinical variables

PendingUS20200308654A1Reduce riskImprove stratificationHealth-index calculationMicrobiological testing/measurementSurgical riskSubtotal prostatectomy

The invention relates to a method of pre-surgical risk stratification of a prostate cancer subject, comprising determining a gene expression profile for phosphodiesterase 4D variant 7 (PDE4D7) in a biological sample obtained from the subject, determining gene expression profile, and determining a pre-surgical prognostic risk score for the subject based on the expression based risk score and pre-surgical clinical variables of the subject. This may allow for an improved stratification of the subject in a pre-surgical setting that may result in better primary treatment decisions. For instance, the pre-surgical prognostic risk score may allow to make better recommendation on whether to select active surveillance vs. active intervention, e.g., radical prostatectomy, for certain sub-populations of prostate cancer patients.

Owner:KONINKLJIJKE PHILIPS NV

Method for predicting the risk of late-onset alzheimer's diseases

InactiveUS20210230696A1Easy diagnosisImproved prognosisMicrobiological testing/measurementLate onsetOncology

A method for prognosis, risk assessment, risk stratification and / or diagnosis of a subject of developing late-onset Alzheimer's disease (LOAD), includes providing at least one sample isolated from the subject, and determining in the presence of ApoE4 and either rs1799931(G) or rs8192506(A), rs7653308(C), rs968529(C) and rs9658265(A). The presence or absence of these markers is indicative of a prognosis, a risk and / or a diagnosis of developing LOAD.

Owner:BIOTX AI GMBH

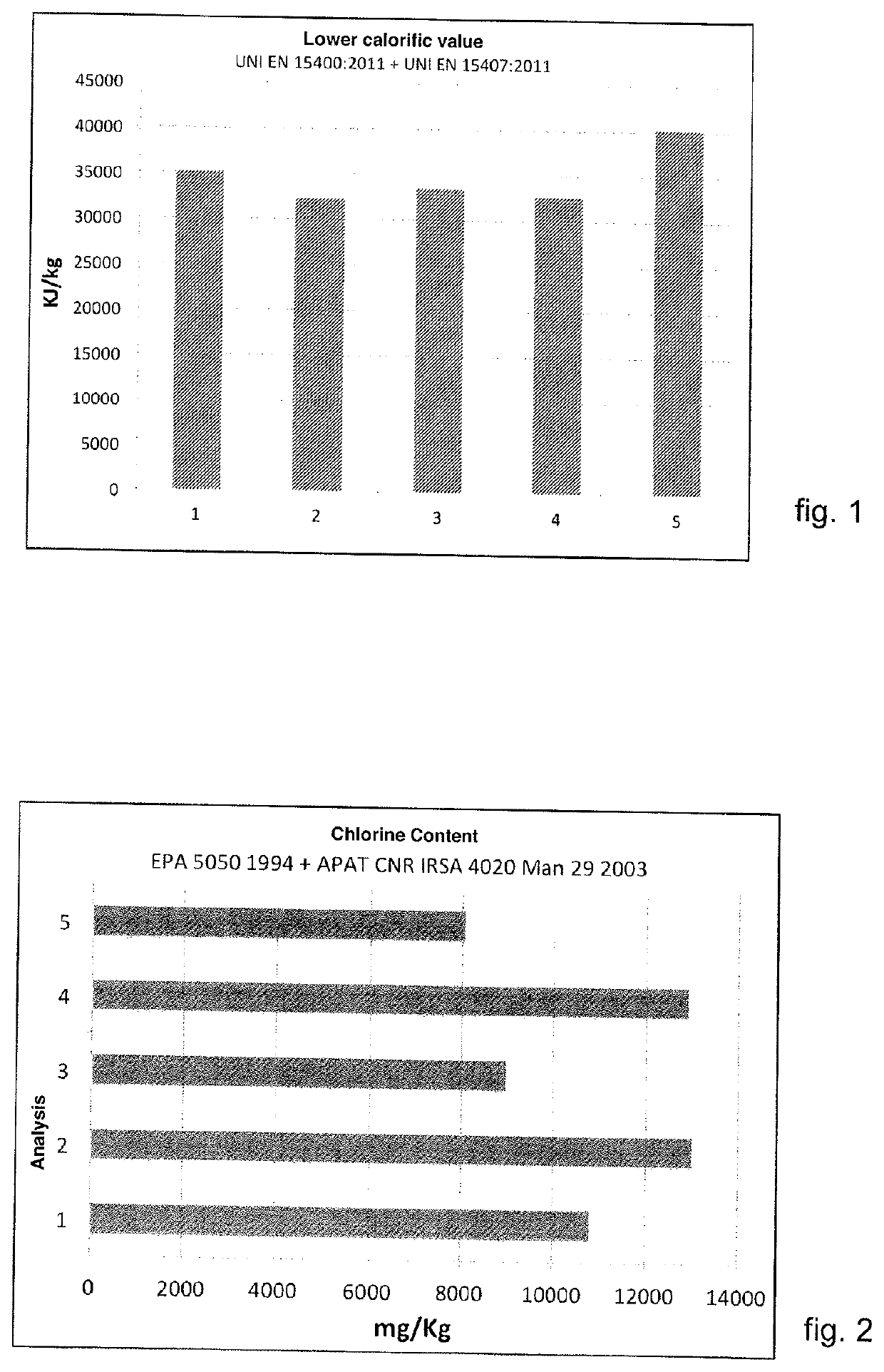

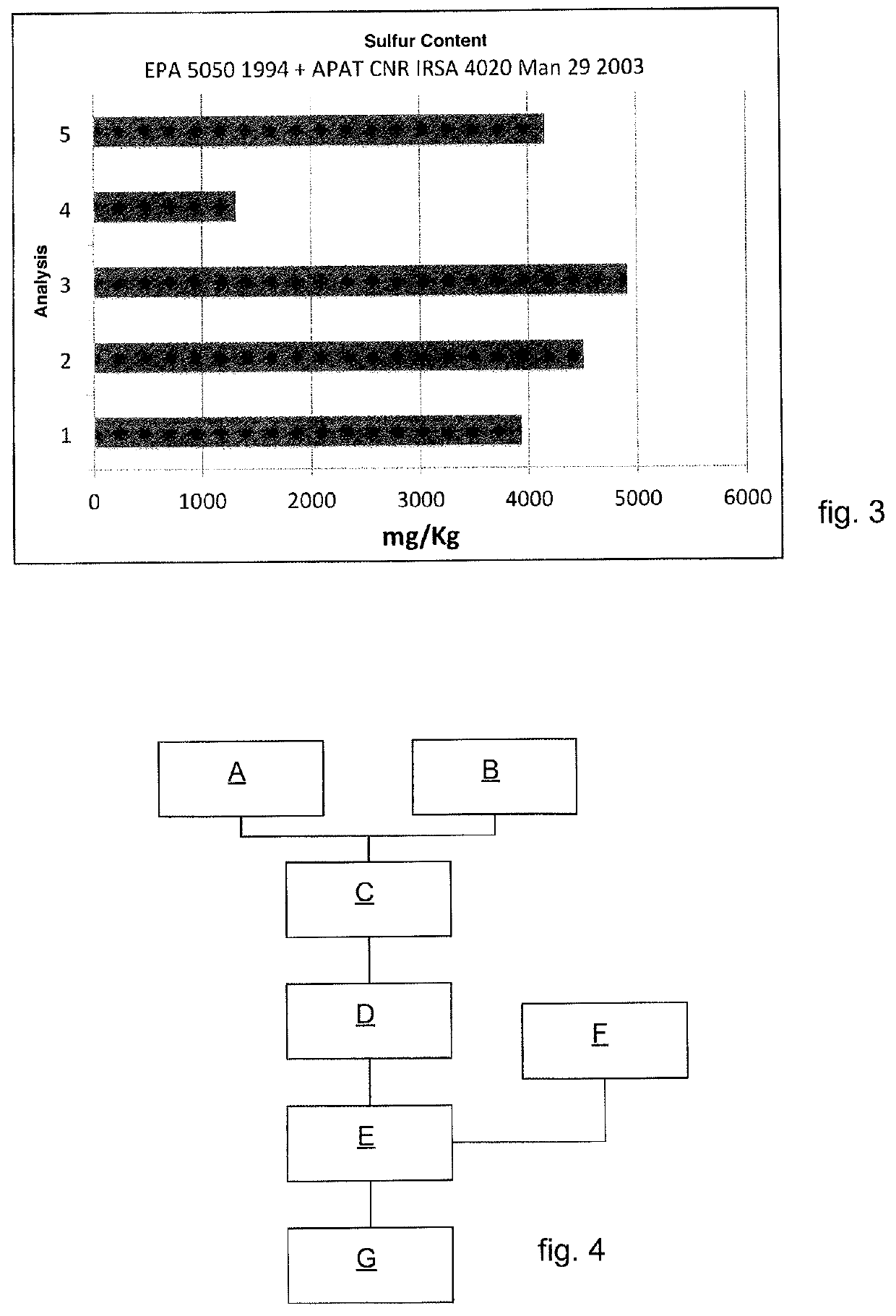

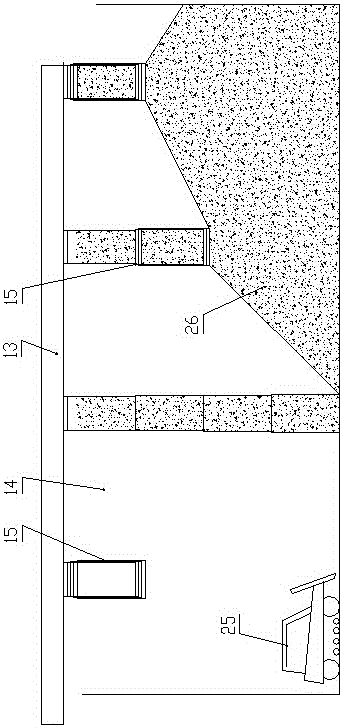

Method For The Production Of Metal Products Starting From Ferrous Material, By Means Of An Electric Arc Furnace

Method for the production of metal products starting from ferrous material, by means of an electric arc furnace.

Owner:I BLU SRL

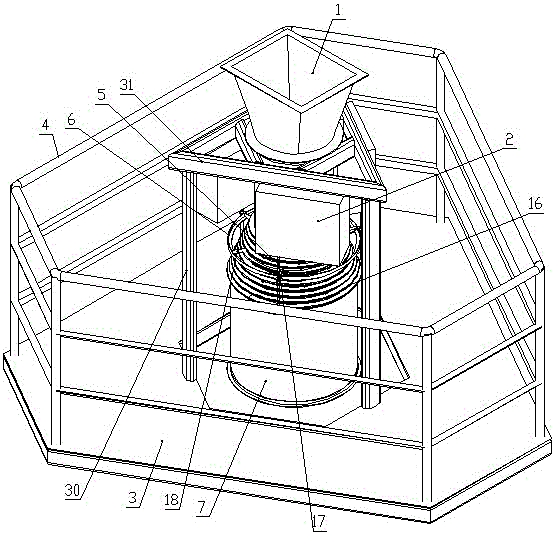

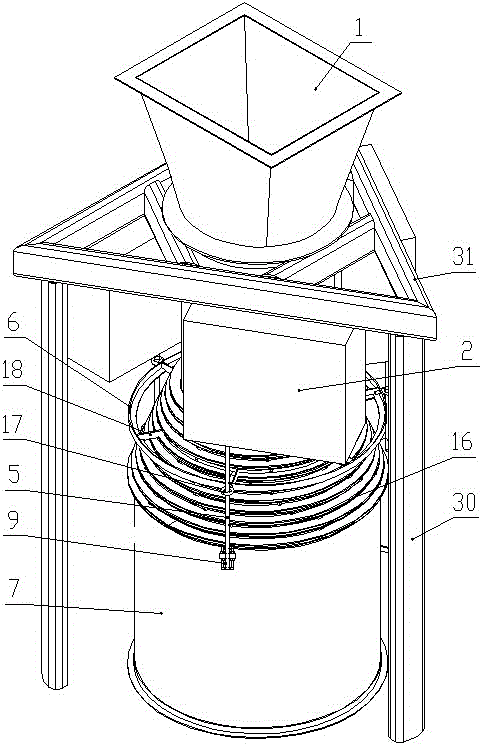

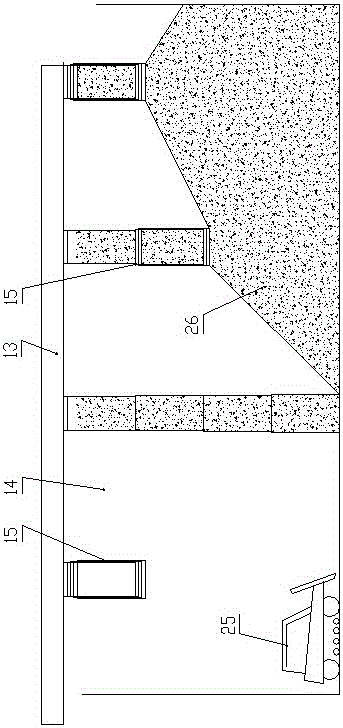

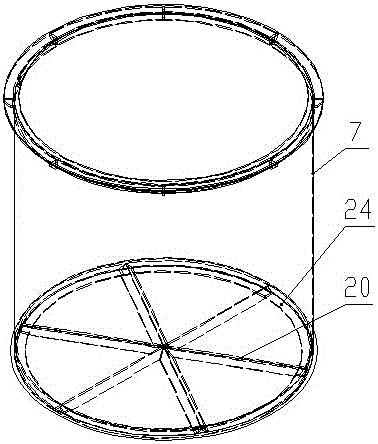

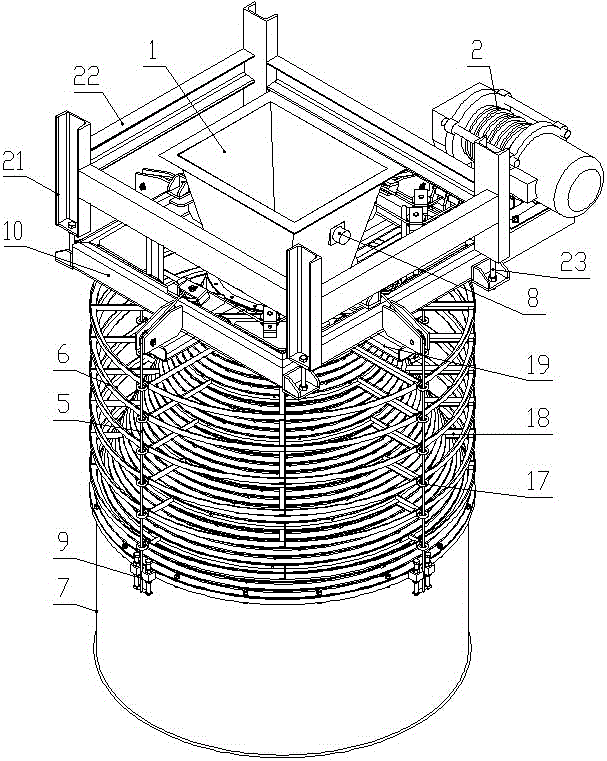

Electric hoist-driven discrete material anti-delamination storage system

InactiveCN104495409BAvoid stratificationImprove stratificationLoading/unloadingEngineeringStorage garage

An electric hoist driving type dispersive material layering-preventive warehousing system comprises a warehouse. A scraper conveyor is horizontally arranged at the top of the warehouse, a pipe extensible material distributing machine is arranged in the warehouse and comprises a maintenance platform, a guardrail is arranged at the outer edge of the upper surface of the maintenance platform, three uprights are vertically arranged on the maintenance platform, a triangular support is arranged among the upper ends of the uprights, three electric hoists are uniformly arranged on the triangular support, a steel wire rope is wound on each electric hoist, the lower end of each steel wire rope is connected with a tensioning connection member, and a diameter-variable feeding hopper with big end up and a plurality of sleeves positioned below the diameter-variable feeding hopper and different in outer diameter are arranged inside the triangular support. The electric hoist driving type dispersive material layering-preventive storage system is reasonable in design, high in automation level and easy to control and begins a new chapter in material layering prevention, and materials prone to layering are ensured not to being layered while simplified structure and reliability of an electric hoist lifting system are realized.

Owner:ZHENGZHOU SHENGMING GRAIN & OIL SCI & TECH CO LTD

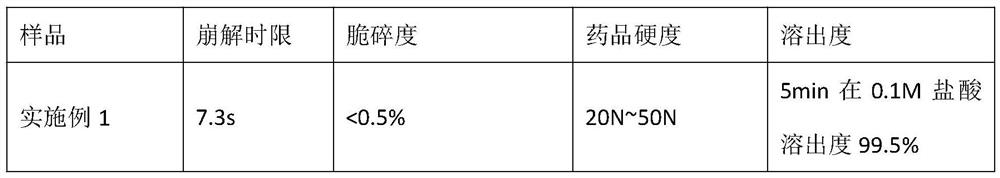

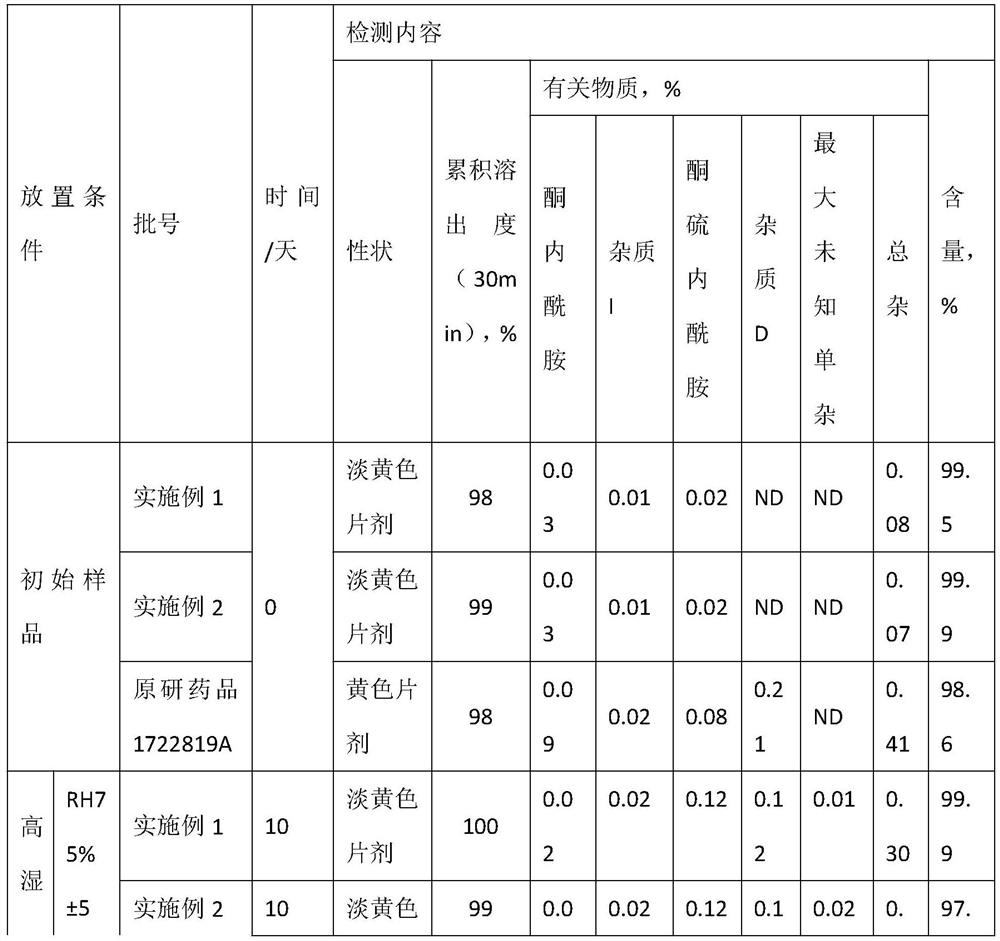

Olanzapine orally disintegrating tablet and preparation method thereof

PendingCN113730365AReduce adsorption lossImprove uniformityOrganic active ingredientsNervous disorderFructoseOrally disintegrating tablet

The invention provides an olanzapine orally disintegrating tablet. The olanzapine orally disintegrating tablet is composed of olanzapine, microcrystalline cellulose, mannitol, fructose, colloidal silicon dioxide, a disintegrating agent and a lubricant. The composition does not contain an aspartame flavoring agent. The olanzapine orally disintegrating tablet is low in weight (high in drug loading capacity of auxiliary materials), and has reduction of production procedures and production cost. The olanzapine orally disintegrating tablet has good mechanical strength in a low hardness range while achieving rapid disintegration and rapid action. The olanzapine orally disintegrating tablet meets requirements on hardness and friability in the processes of tablet preparation, production, transportation and use.

Owner:杭州新诺华医药有限公司

A kind of M85 methanol gasoline and preparation method thereof

The invention relates to the technical field of methanol gasoline, in particular to an M85 methanol gasoline and a preparation method thereof. According to the preparation method, methanol, gasoline, sodium methoxide, pine oil, waste oil, glycerin, acetone and polyoxyethylene ether are mixed according to a proportion; the pine oil and the waste oil are separately treated through the combination of preparation process steps; the treated pine oil and waste oil are added for mixing; ultrasonic mixing treatment is performed during treatment processes, so that all raw materials are dispersed more uniformly, mutual concurrent effects among the methanol, gasoline, waste oil and other raw materials are further achieved, and then the quality of the methanol gasoline is improved. Particularly, the phenomenon that the methanol gasoline is easy to be subjected to stratification when the water content reaches 3% is avoided. Therefore, the water resistance of the methanol gasoline is improved, the guarantee period of the methanol gasoline is prolonged, and the storage difficulty of the methanol gasoline is lowered.

Owner:贵州大洋能源有限责任公司

Materials and methods for assessing cancer risk and treating cancer

ActiveUS11454630B2Reduce riskHigh riskSerum immunoglobulinsDisease diagnosisAutoimmune conditionAutoimmune disease

This document relates to materials and methods for assessing and / or treating subjects (e.g., subjects having autoimmune diseases). For example, materials and methods for determining if a subject (e.g., a human having an autoimmune disease) has one or more antibodies that can be used to identify the subject as having a lower risk of cancer or as having a higher risk of cancer are provided. Materials and methods for treating a subject (e.g., a human) identified as having a higher cancer risk for cancer are also provided.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Hoist-driven discrete material anti-delamination storage system

The invention relates to a winch-drive type discrete material anti-layering warehousing system, which comprises a warehouse, wherein a scraper conveyer is horizontally arranged on the top part of the warehouse; a pipeline telescopic type distributing machine is arranged in the warehouse and comprises an installation frame; a reducing feed hopper and a plurality of sleeves with different external diameters located under the reducing feed hopper are arranged in the installation frame; the lower end of the reducing feed hopper stretches into the inner part of one sleeve on the innermost side; the sleeves are vertically run-through and have the same central line; the sleeve with the lesser external diameter of random every two adjacent sleeves is inserted into the sleeve with the larger external diameter; compression joint matching structures are formed between the outer edge of the lower end of the sleeve with the lesser external diameter and the edge of the upper end of the sleeve with the larger external diameter as well as between the outer edge of the upper end of the sleeve with the lesser external diameter and the edge of the upper end of the sleeve with the larger external diameter. The winch-drive type discrete material anti-layering warehousing system is reasonable in design, high in degree of automation and easy to control, initiates non-layering materials, ensures layering phenomenon not occurred on easy-to-layer materials, and meanwhile, realizes structure simplification and reliability brought by utilizing a winch lifting system.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com