Mask pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

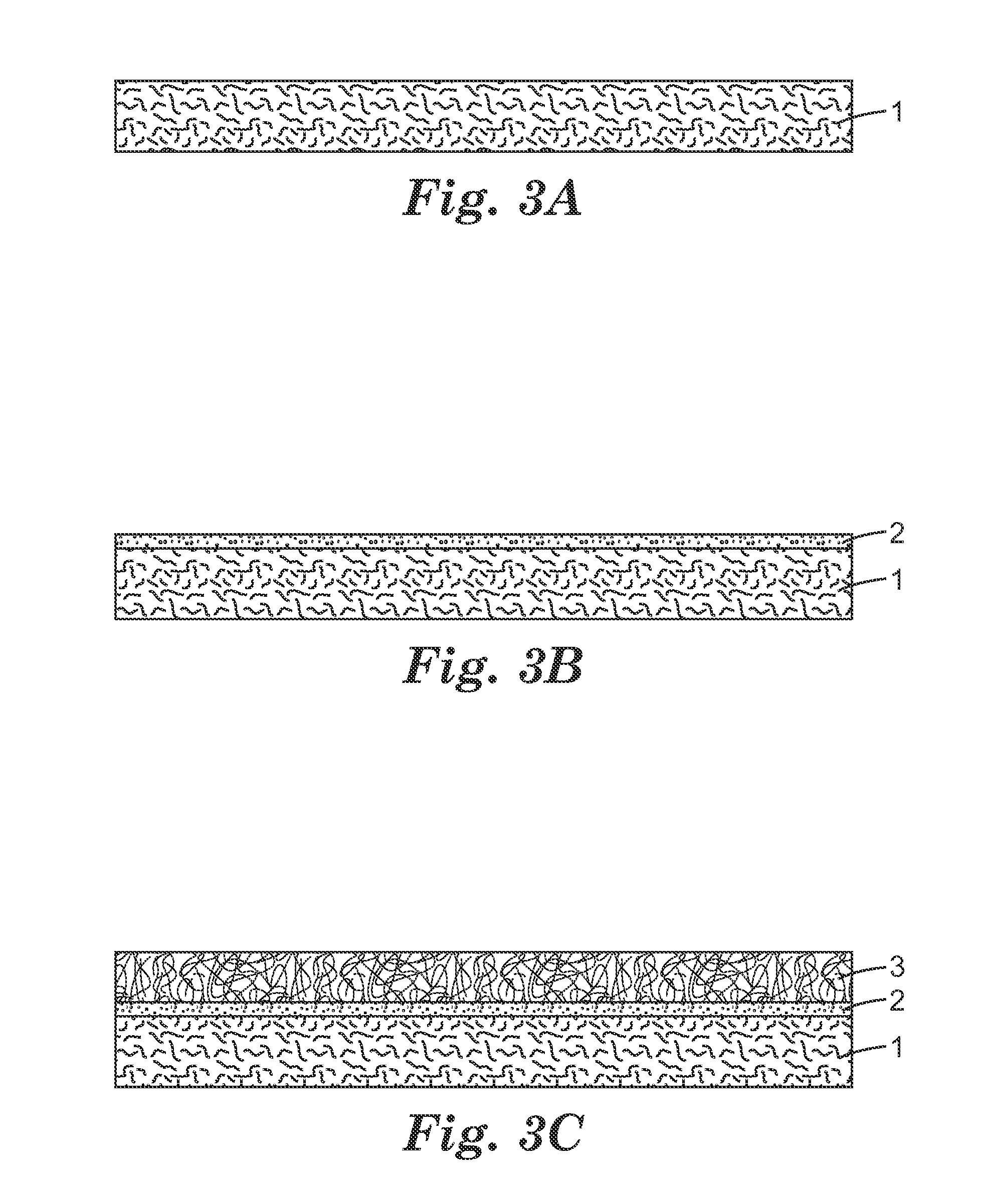

[0042]First, a rayon-PET spunlace (60 gsm) including viscose rayon and PET (weight ratio 8:2) (Namyang Textile Co., Ltd.) was prepared as nonwoven fabric.

[0043]A polyurethane adhesive (0.3 g) was coated on the nonwoven fabric to form a polyurethane adhesive-coated rayon-PET spunlace nonwoven fabric.

[0044]A solution of PAN (6.30 g), hydrophilic PU (3.15 g), hot-melt PU (1.04 g) and a pigment (0.01 g) in dimethylacetamide (89.5 g) was applied onto the adhesive-coated nonwoven fabric by an electrospinning process to thereby complete a nanofiber-coated nonwoven fabric. At this time, the mass per unit area of the nanofiber layer was adjusted to be 0.4, 0.8 or 1.1 gsm.

[0045]The nanofiber-coated nonwoven fabric was cut, and the resultant nonwoven fabric samples were folded twice and placed into cases for mask packs. A liquid cosmetic preparation (22 g, HongSam (C&Tech)) was then incorporated into the cases. The resultant packages were sealed and stored at room temperature for 3 days, 7 day...

example 2

[0046]Nowoven fabric samples obtained in the same procedure as in Example 1 except that the mass per unit area of nanofibers was 0.3 or 1.3 gsm were folded twice and placed into cases for mask packs. Then, a liquid cosmetic preparation (22 g, HongSam (C&Tech)) was then incorporated into the cases.

[0047]The resultant packages were sealed and stored at room temperature for 30 minutes to prepare desired mask pack samples.

example 3

[0048]Nonwoven fabric samples obtained in the same procedure as in Example 1 were folded twice and placed into cases for mask packs. Then, a liquid cosmetic preparation (22 g, HongSam (C&Tech)) was then incorporated into the cases. The resultant packages were sealed and stored at room temperature for one day to prepare desired mask pack samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Weight ratio | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com