Unsaturated polyester bulk molding compound as well as method and application thereof

A bulk molding compound and unsaturated technology, which is applied in the field of unsaturated polyester bulk molding compound, can solve the problems of insulation degradation and achieve the effect of improved molding performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0038] Synthesis Example 1: In a device with stirring and heating, in a device with nitrogen protection and temperature indication, put in 100 moles of propylene glycol, 50 moles of isophthalic acid, and 50 moles of maleic anhydride, according to the normal reaction method React at 190-210°C until the acid value is below 40, then cool down to 160°C, pour into a solution containing diallyl phthalate and 250ppm hydroquinone for dilution, and keep the dilution temperature at 60-80°C , to obtain an unsaturated polyester A with an acid value of 20 or less and a solid content of 70%. The heat distortion temperature of the molded resin body of A was 146°C.

Synthetic example 2

[0039] Synthesis Example 2: In a device with stirring and heating, pass into a device with nitrogen protection and temperature display, drop in 25 moles of propylene glycol, 75 moles of neopentyl glycol, 60 moles of maleic anhydride, and phthalic anhydride 40 moles, according to the normal reaction method, react at 190~210℃ until the acid value is below 40, then cool down to 160℃, pour into a solution containing styrene and 250ppm hydroquinone for dilution, and keep the dilution temperature at 60~ 80°C, an unsaturated polyester B with an acid value of 25 or less and a solid content of 67% was obtained. The thermal deformation temperature of the molded resin body of B was 132°C.

Embodiment 1~8

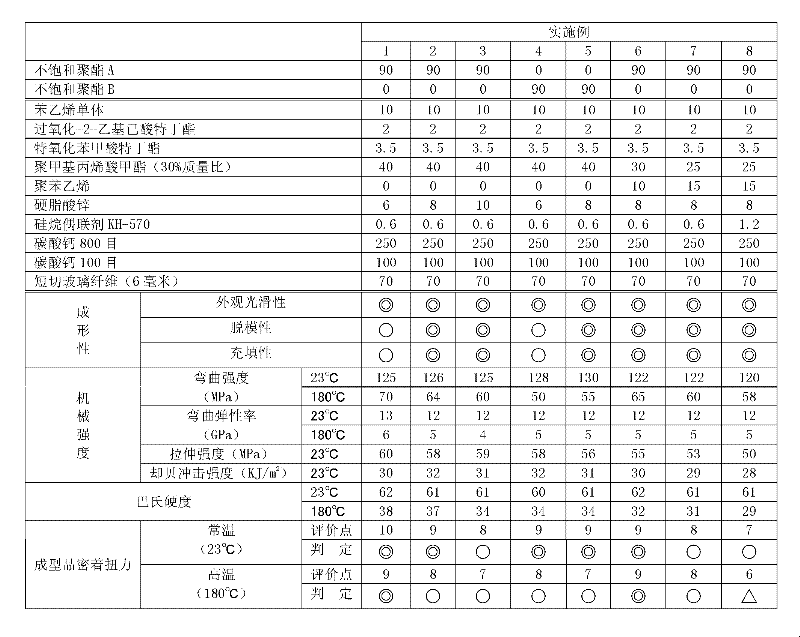

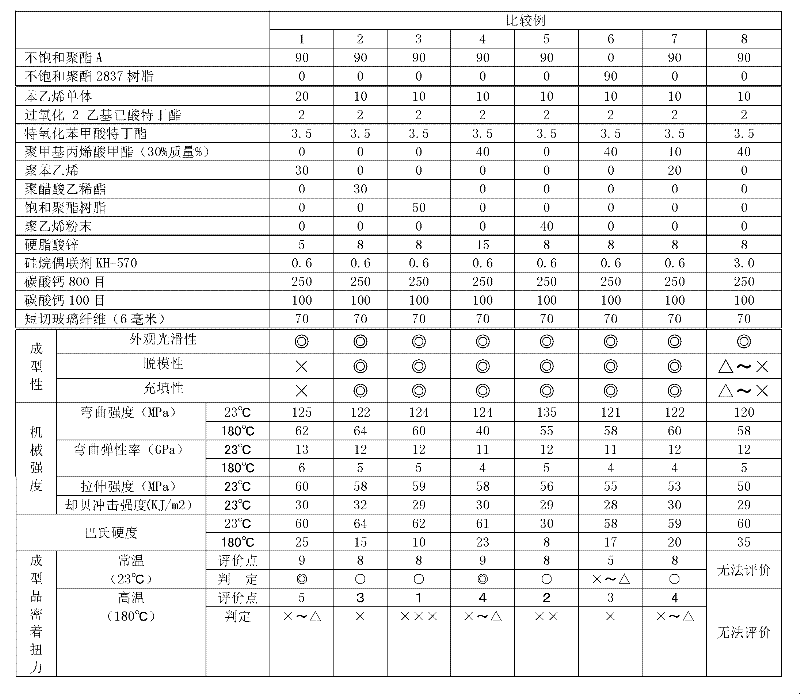

[0041] The formula ingredients shown in Table 1 are added to the double-wrist kneader according to the specific ratio, and the temperature of the kneader jacket is kept at 30 ° C. Add resin, styrene, curing agent, low shrinkage agent and filler in order. During the kneading process During the process, the adhered materials on the container wall should be cleaned continuously, and the materials around the blades and the dead corners around the machine should be cleaned in time. After about 30 to 40 minutes of full mixing and uniformity, slowly add the chopped glass fiber in a predetermined proportion. , take it out after fully kneading, place it in a special bag that can prevent the volatilization of cross-linking monomers such as styrene and seal the package, and then you can get the BMC material designed according to the predetermined ratio.

[0042] The bulk molding compound BMC obtained as a trial was evaluated for molding appearance, mold release, mechanical strength at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com