Patents

Literature

94 results about "Normal reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal reaction. The force exerted by a surface on an object in contact with it which prevents the object from passing through the surface; the force is perpendicular to the surface, and is the only force that the surface exerts on the object in the absence of frictional forces.

Efficient ceramic core removal device for hollow blade

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

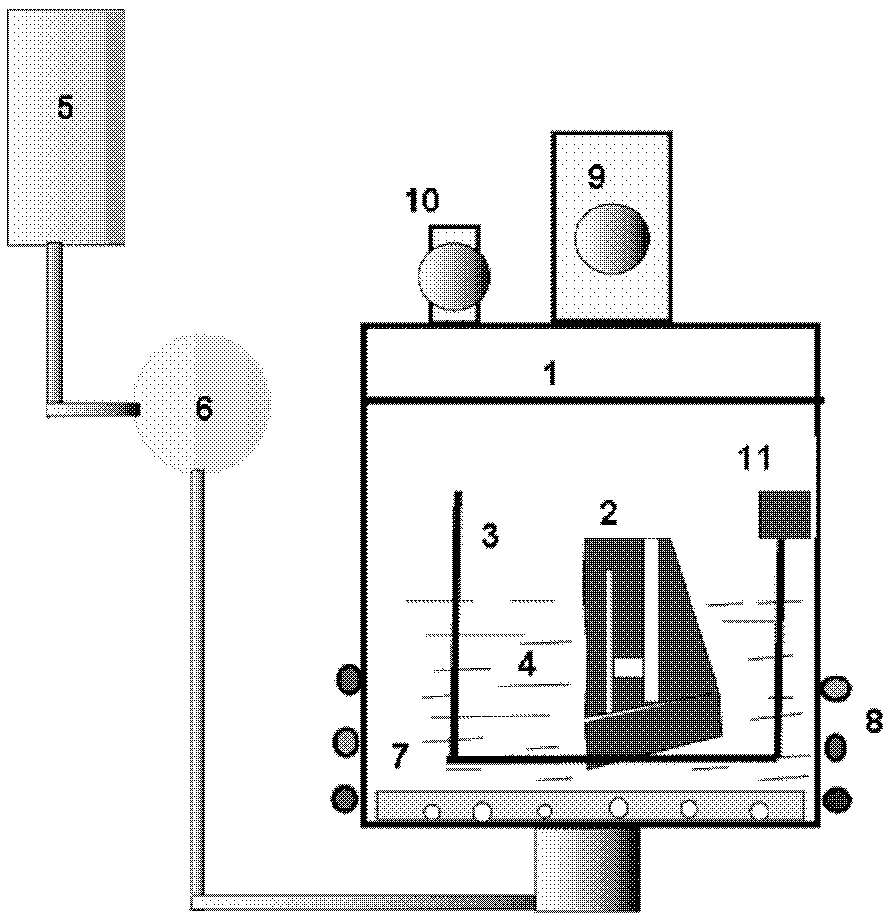

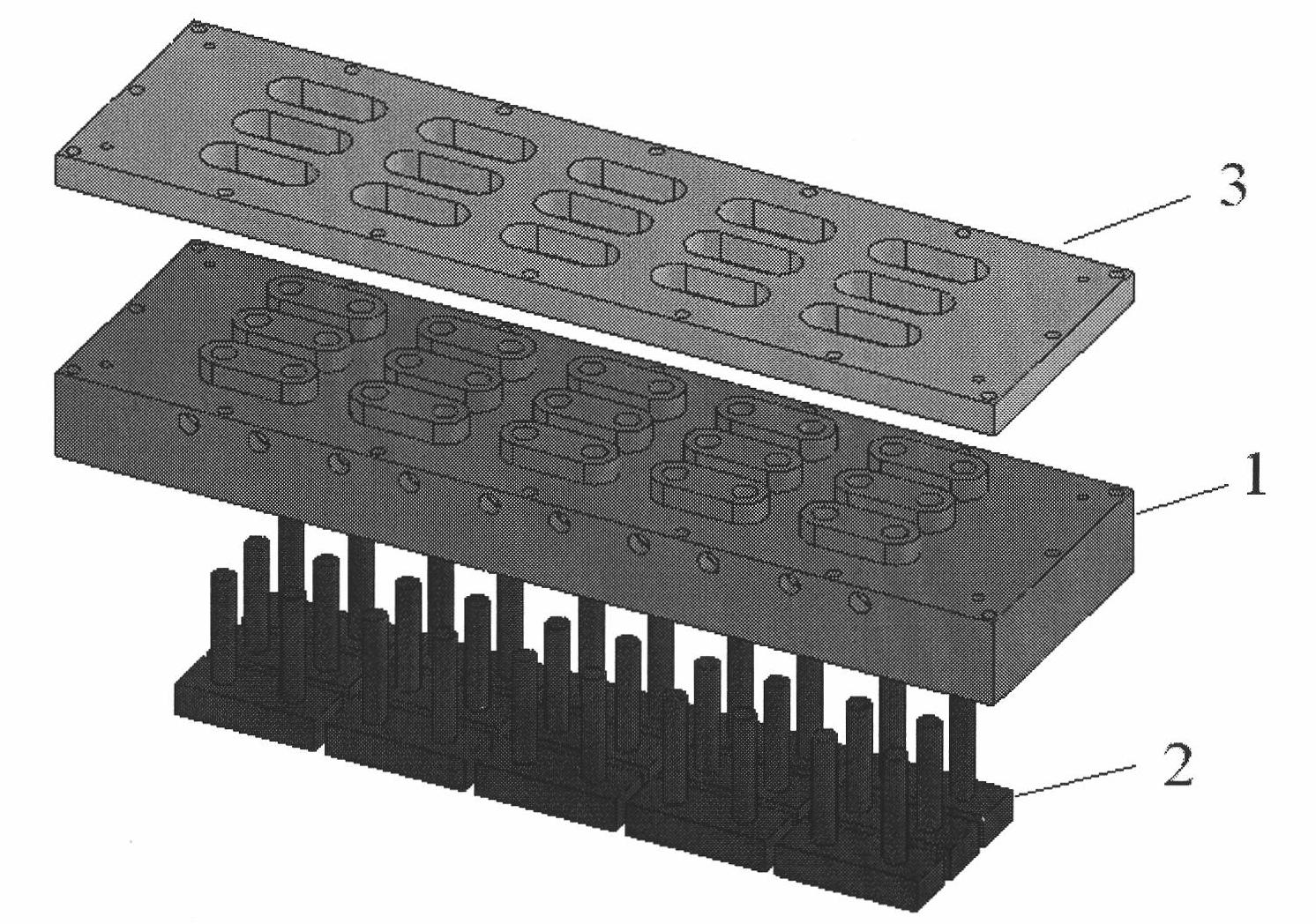

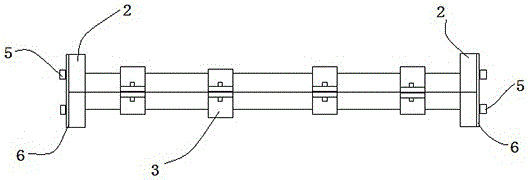

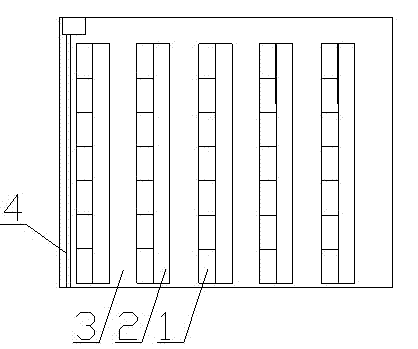

Block type end plate structure for measuring current distribution of PEMFC

ActiveCN102110818AGuaranteed a high degree of similarityEasy to meet corrosion resistanceCell electrodesFuel cell auxillariesPower flowCurrent distribution

The invention relates to a block type end plate structure of a PEMFC (Proton Exchange Membrane Fuel Cell). The structure comprises an insulating motherboard and n sub collector blocks (n is a positive integer equal to or larger than 2); grooves are formed on the insulating motherboard, the sub collector blocks are embedded in the grooves on the insulating motherboard, and after the surface on oneside of the insulating motherboard, on which the sub collector blocks are embedded, is integrally flatten-milled, a normal reaction gas flow field is curved; conductive metal collector bars vertically penetrating through the insulating motherboard are arranged on the sub collector blocks; one end of each collector bar penetrating through the insulating motherboard is connected with a current output conducting wire of the PEMFC; and a current mutual induction element is arranged on the conducting wire. Compared with the prior art, the invention has the distinguished advantage that the cell temperature can be flexibly controlled through circulating water, and the flow field is curved after tensioning and flatten-milling are performed, so that a similarity to a normal flow field plate is guaranteed. Anyhow, the design of the end plate realizes the blocking structure while a flow field plate, a cooling plate and a collector plate are integrated, and is a novel block type end plate structure for measuring current distribution.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polymers in a solid state

Owner:SIKA TECH AG

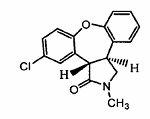

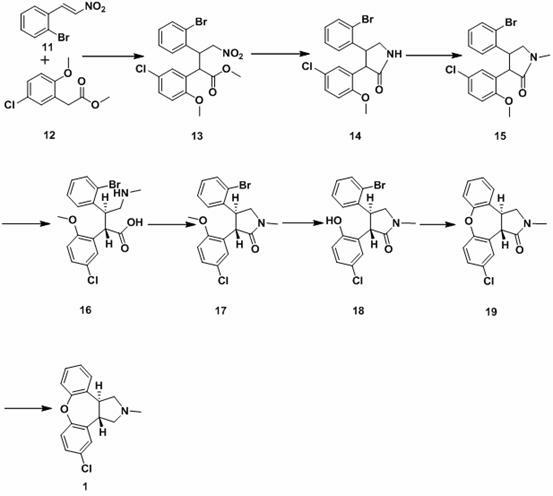

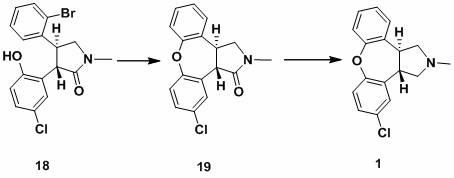

New process for synthesis of asenapine

ActiveCN102229613AReaction transposition effect is goodHigh yieldOrganic chemistryLoop closingMethyl group

The invention discloses a process for synthesis of asenapine. The asenapine is prepared through adopting a compound (18) as a key intermediate and carrying out the following steps that: 1.1, the compound 18 is subjected to a Ullmann reaction under a alkaline condition through adopting copper powder as a catalyst to generate a ether (19); 1.2, the ether (19) is subjected to a carbonyl reduction to obtain the target compound of the asenapine (1). The process has the following advantages that: cheap and available 2-bromobenzaldehyde is adopted as an initial raw material and is subjected to acondensation, a addition, a reductive amination and a intramolecular cyclization reaction, a aminomethylation, a open loop transposition and then loop closing, a demethylation and a Ullmann loop closing reaction to synthesize of the asenapine (1); cis-trans-isomer is subjected to a delicate transposition to obtain a trans-product, such that the process is simplified and easy to be operated; the raw material is easy to be obtained and has cheap price; each reaction is a normal reaction, and reaction conditions are mild; a total yield is substantially improved; production cost is reduced; a purity of the product is more than 99% through a detection by HPLC.

Owner:安庆润科生物医药科技有限公司

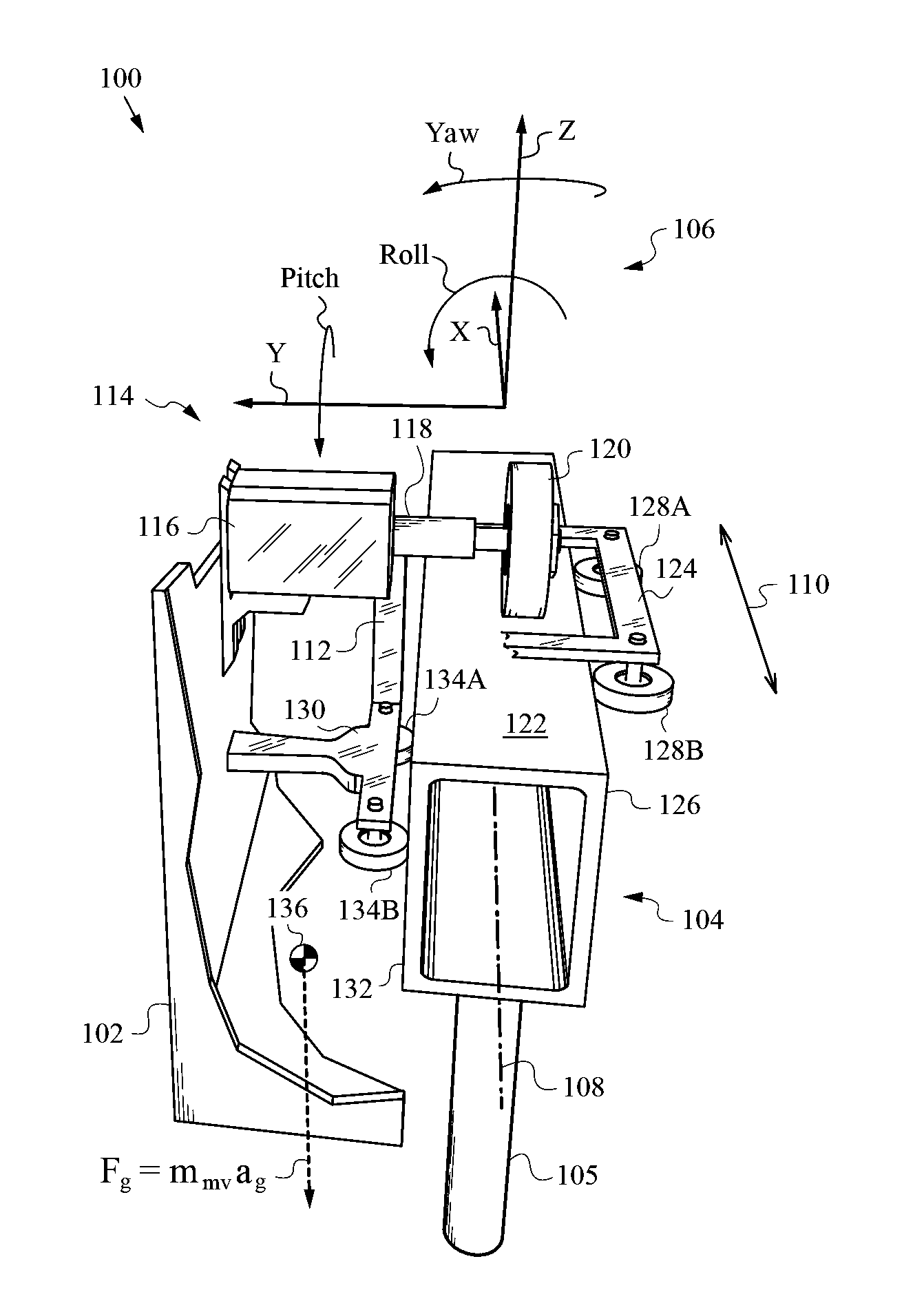

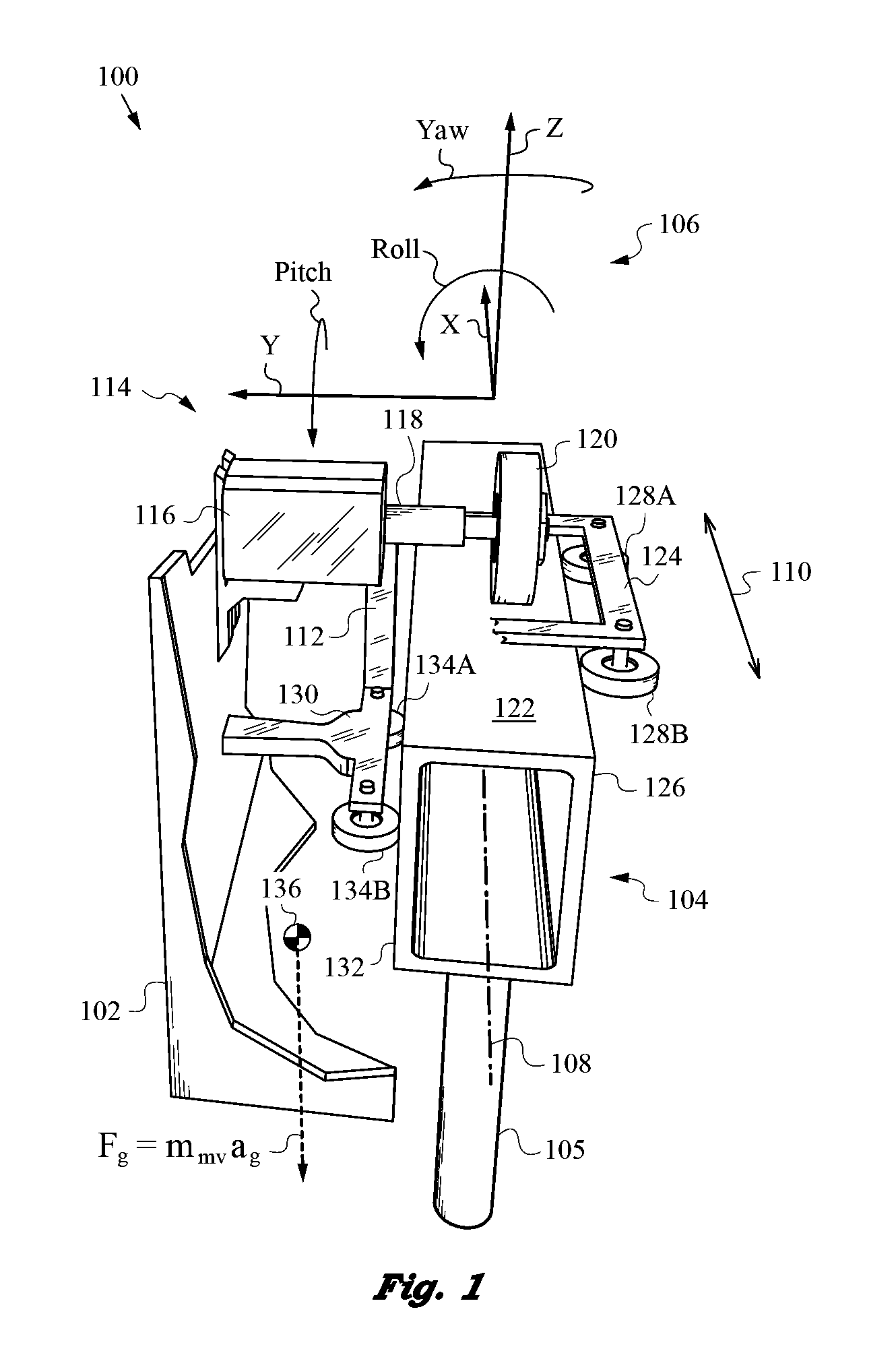

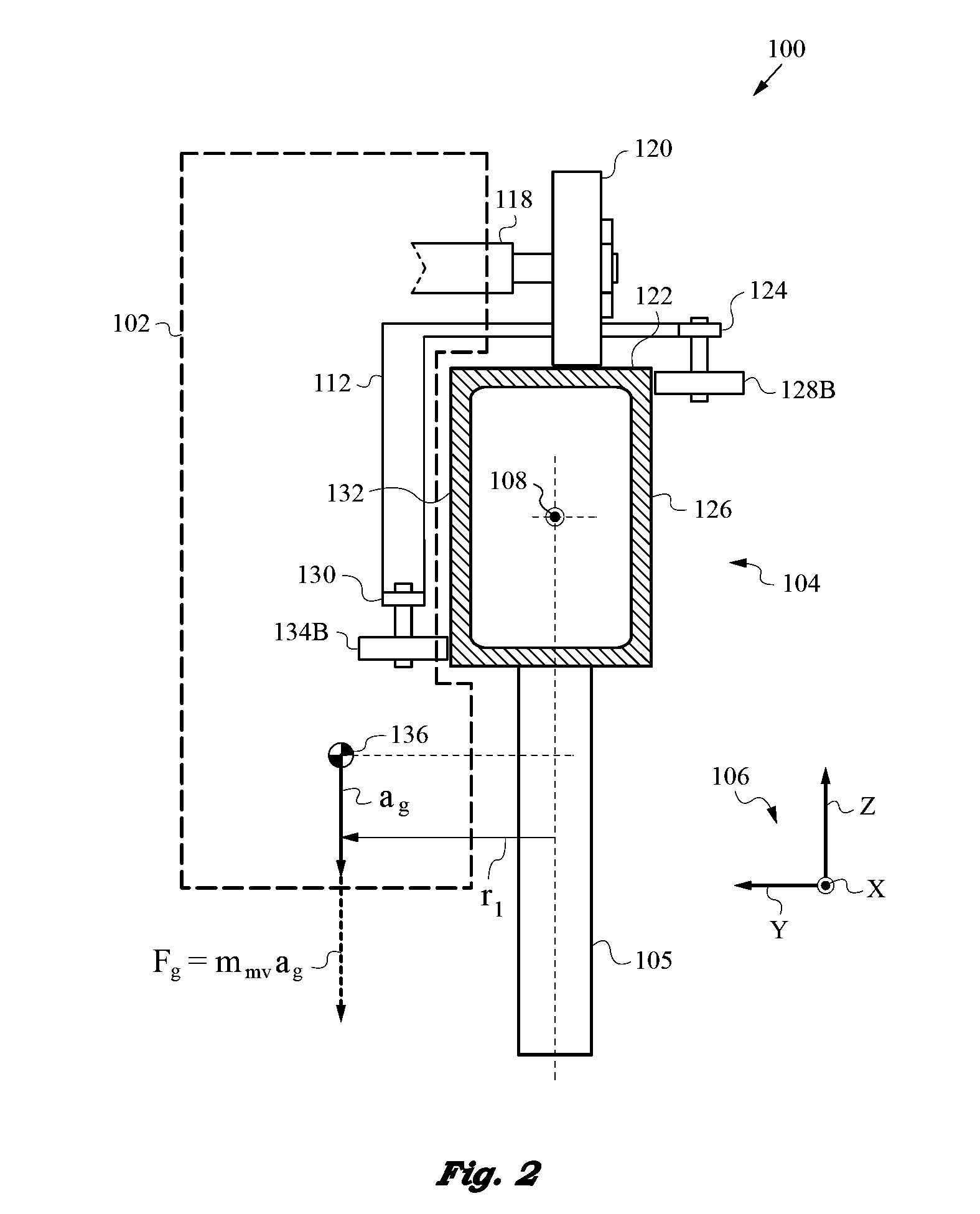

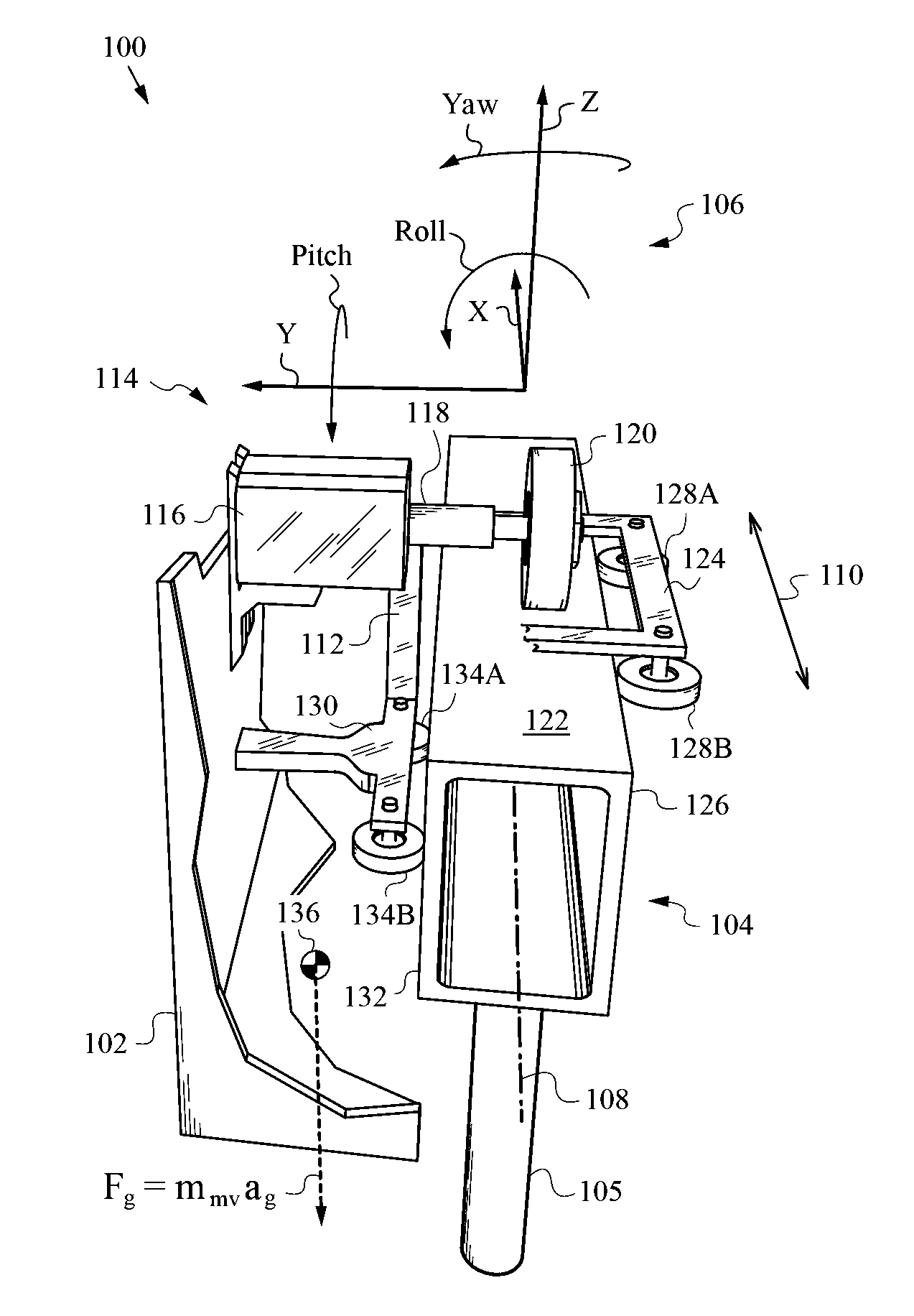

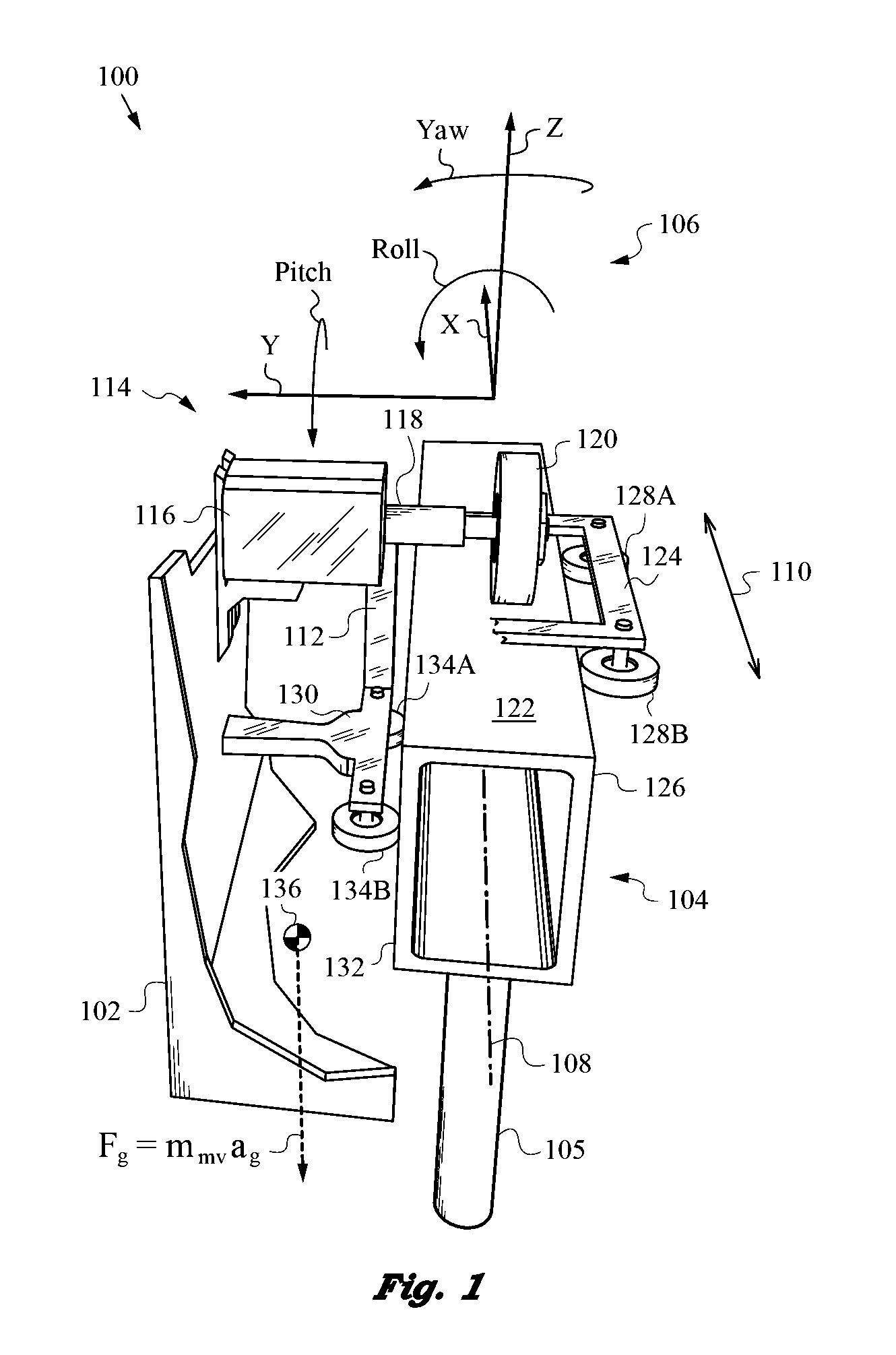

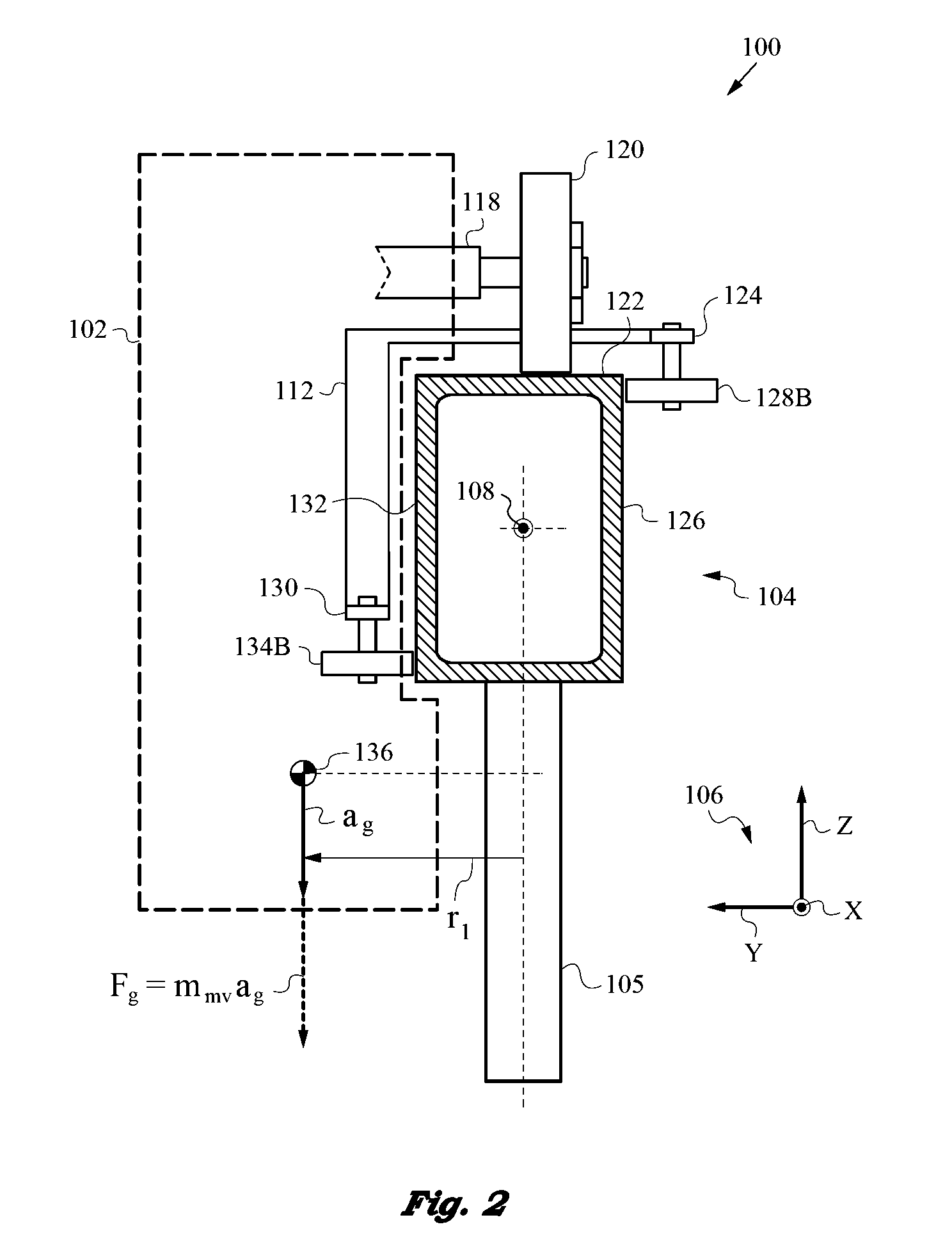

Monorail Vehicle Apparatus with Gravity-Controlled Roll Attitude and Loading

InactiveUS20140174315A1Significant changeConstant contact forceMonorailsRailway componentsBogieRolling moment

Monorail vehicle that travels on a non-featured rail with substantial profile variation and controls roll attitude, lateral location, and loading through judicious placement of the vehicle's center of gravity without using springs or suspensions. The vehicle has a bogie for engaging the non-featured rail so the center of gravity has a lateral offset r1 from the rail centerline to produce a roll moment Nr determined by vehicle's mass and value of r1. The center of gravity also has a vertical offset r2. The bogie uses first and second assemblies for engaging the rail to produce a pair of surface normal reaction forces to thus control roll attitude and loading by the placement of the center of gravity, thereby enabling accurate alignment of the monorail vehicle.

Owner:SOLARCITY

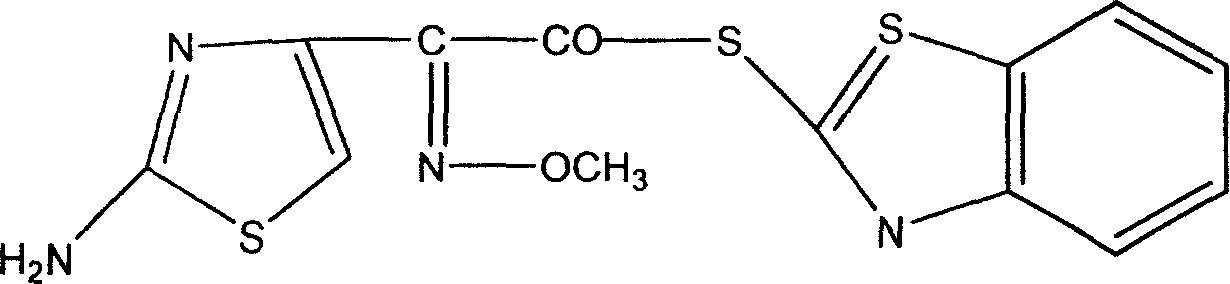

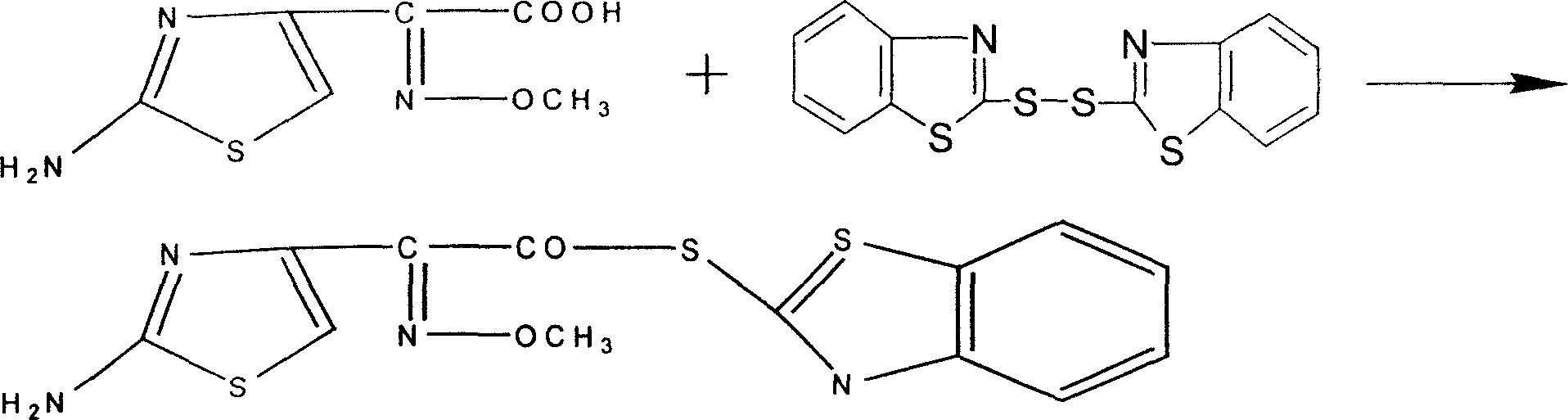

New technique for catalytic synthesis of AE active ester

ActiveCN101096364AHigh yieldMild operating conditions for productionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTriethylphosphiteDistillation

The invention discloses a new technology for synthesizing AE-active ester with accelerant, which is made by condensation reaction in the triethyl phosphate and triethylamine solvent. The invention is characterized by the following: introducing pyridine with high hydroscopicity as the accelerant in order to accelerate the reaction proceeding according to the forward direction based on the original technology; changing the reaction solvent system (the mixed solvent which is comprised by acetonitrile and carrene according to (0.9-1.0):1); avoiding the problem of water content which is introduced by the new solvent; improving the normal reaction temperature; reducing the operation difficult; reducing the strength; improving the product efficient to more than 92%. The invention also achieves the recycling of the solvent by distillation.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD +1

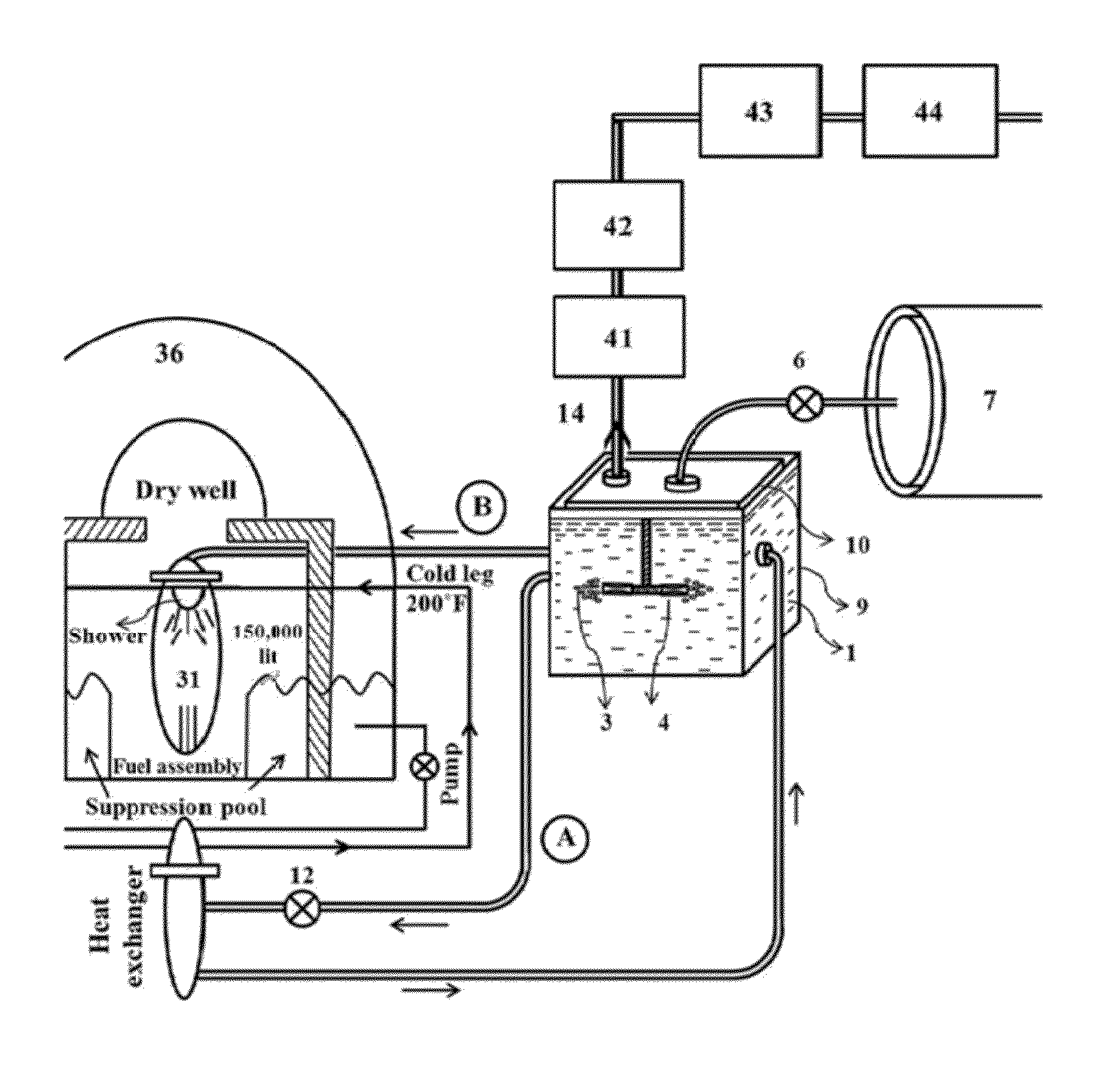

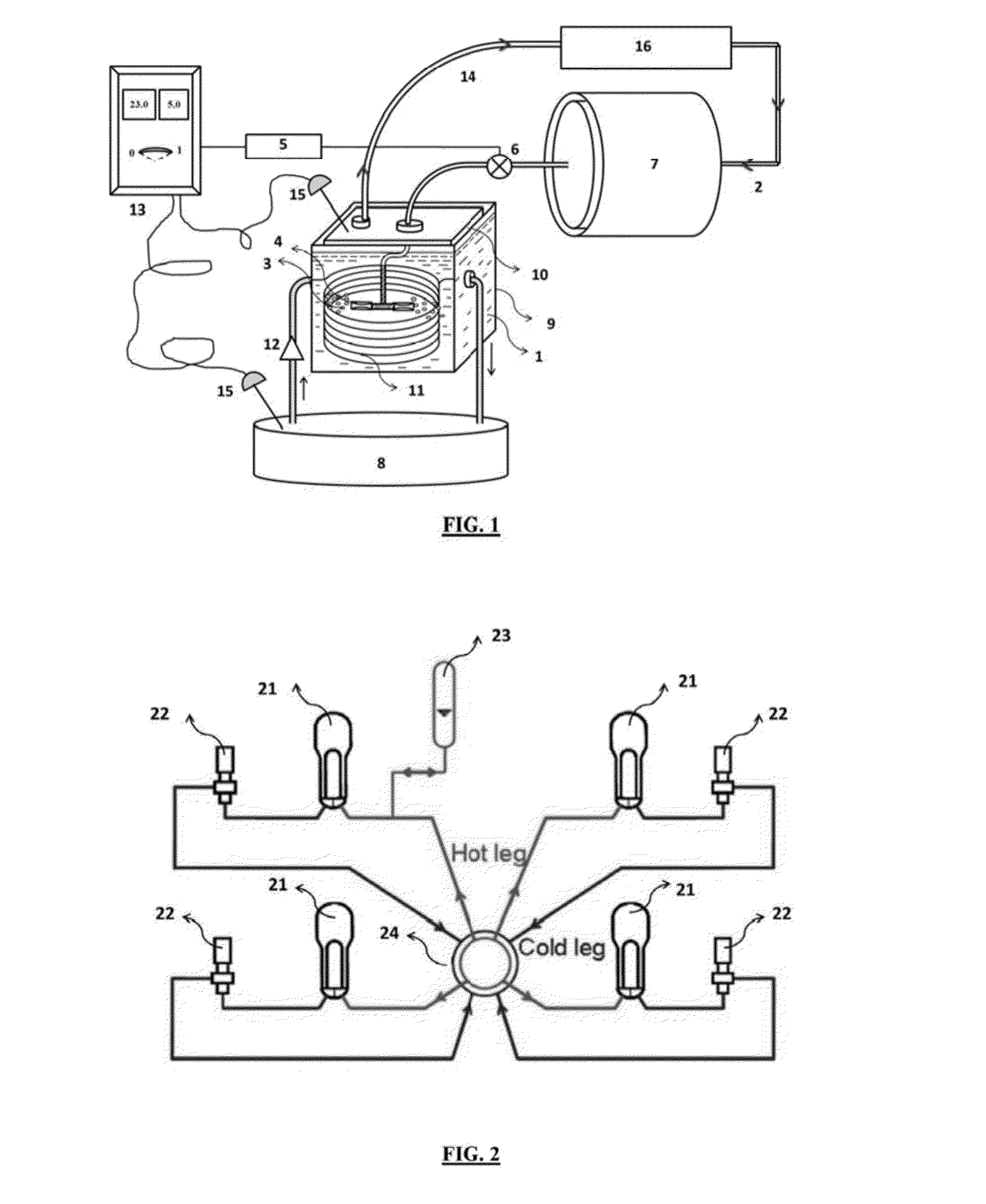

Modified dry ice heat exchanger for heat removal of portable reactors

InactiveUS20130301781A1Increase in sizeEffective temperaturePower plant safety arrangementLighting and heating apparatusReactor pressure vesselSlurry

A novel heat exchanger (FIG. 1) designed and fabricated based on dry ice-ethylene glycol (DIEG) bath 1 as the coolant mixture for the emergency core cooling system (ECCS) of the nuclear power systems to avoid core meltdown during the normal reactor shutdown or reactor scram in the emergency conditions.This method is proposed to upgrade the safety systems including modified ECCS which utilizes fast non-water coolant emergency system by fast cooling of reactor pressure vessel (RPV) 31 based on dry ice+ethylene glycol slurry 1.

Owner:PARVIN PARVIZ +1

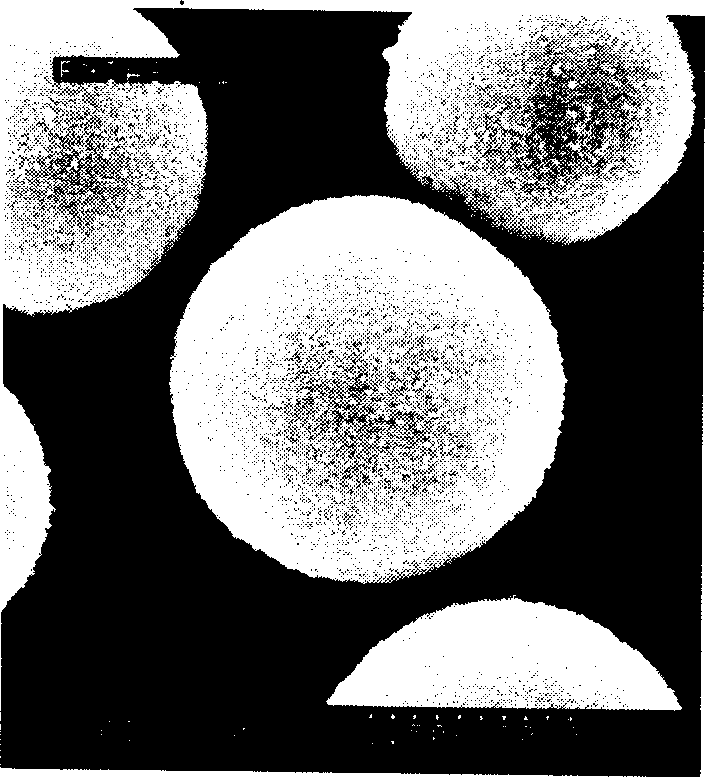

Method for preparing copper nanometer granules

InactiveCN102114545AImprove performanceLow reaction temperatureNanotechnologyCopper nitrateReaction temperature

The invention discloses a method for preparing copper nanometer granules, which comprises the following steps: respectively preparing clear copper nitrate solution with concentration of 0.1-0.9 g / L, clear ethanolamine solution with concentration of 2-8g / L, and clear polyvinylpyrrolidone solution with concentration of 3-9g / L by taking low-molecular alcohol as solvent, mixing the three solutions into reaction liquid at the temperature of 60 DEG C to 80 DEG C for reaction until presenting a stable bronze color, and carrying out cooling, evaporation and drying to obtain copper nanometer granules;in the method, the reaction temperature is lower, the normal reaction can be carried out even at the temperature lower than 70 DEG C, the production cost is lower, the equipment is simple, the production is convenient, the average granule diameter of the obtained copper nanometer granules is no more than 10nm, and the copper nanometer granules are uniform monodisperse granules without binding, therefore, the material performance is better.

Owner:NINGBO UNIV

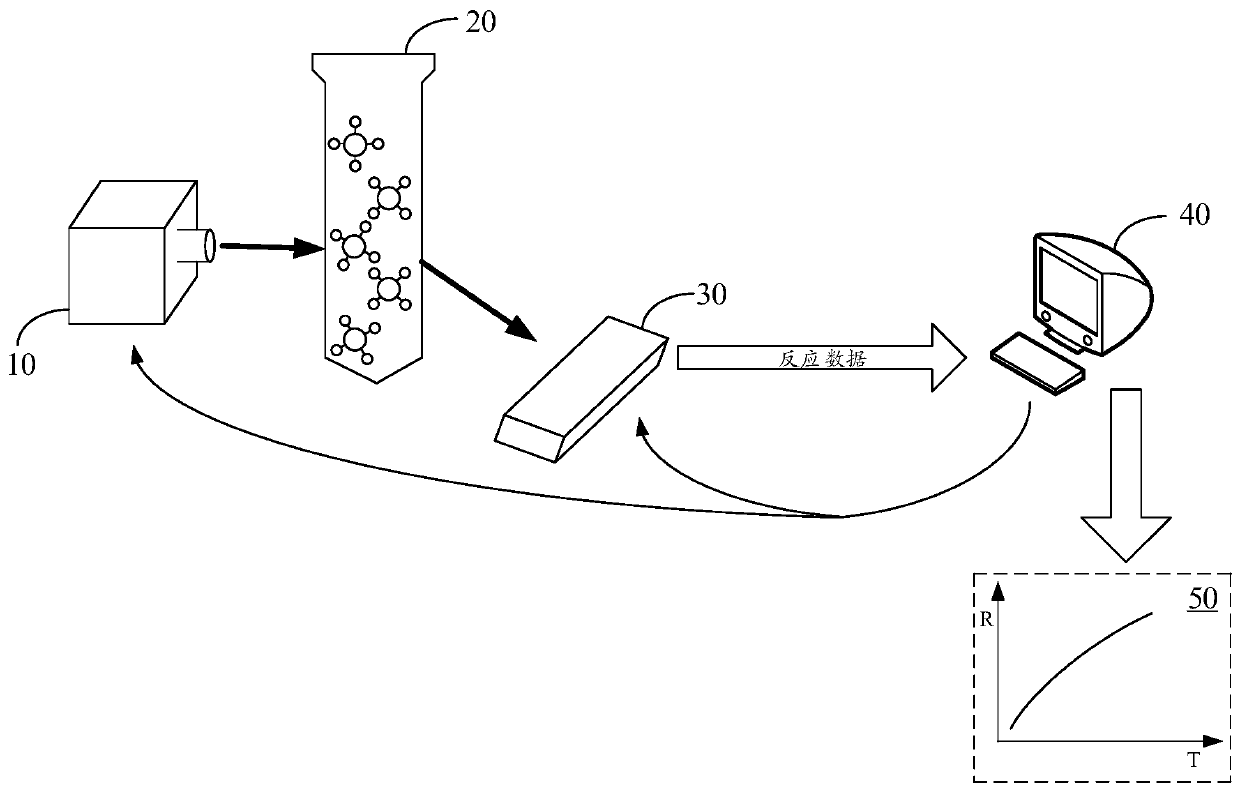

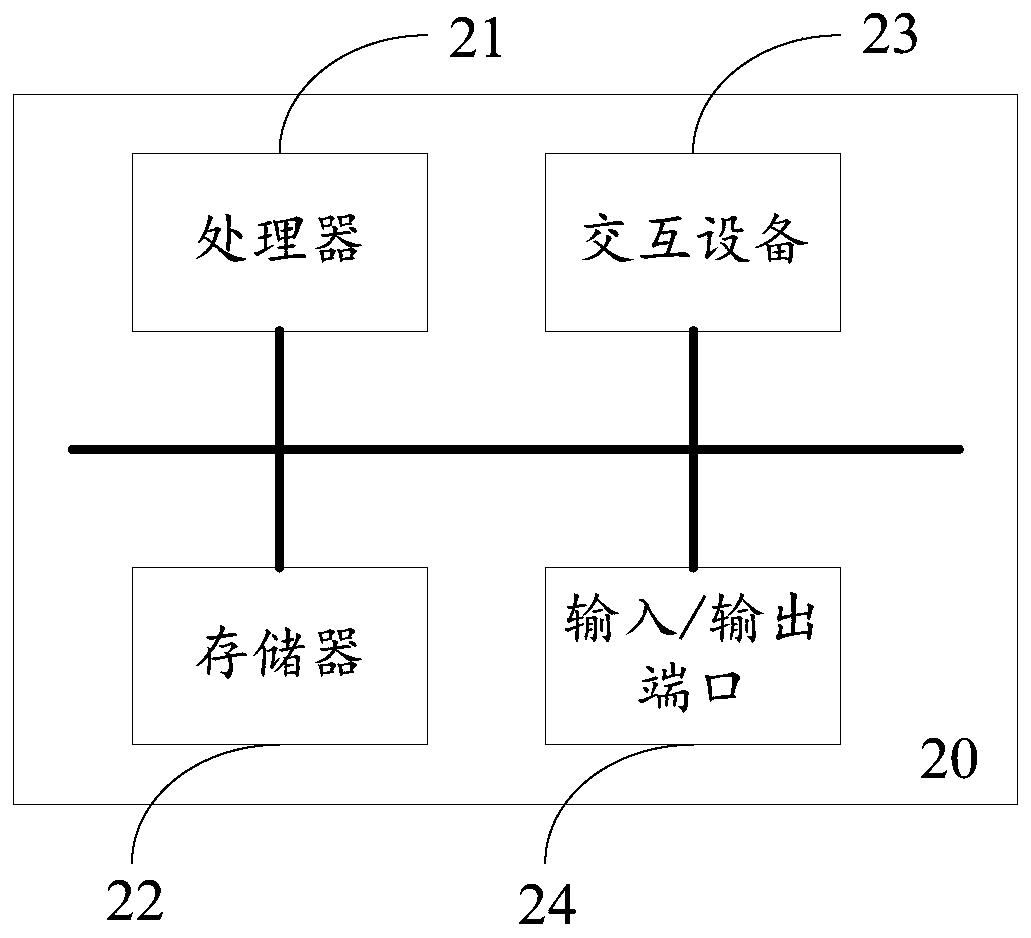

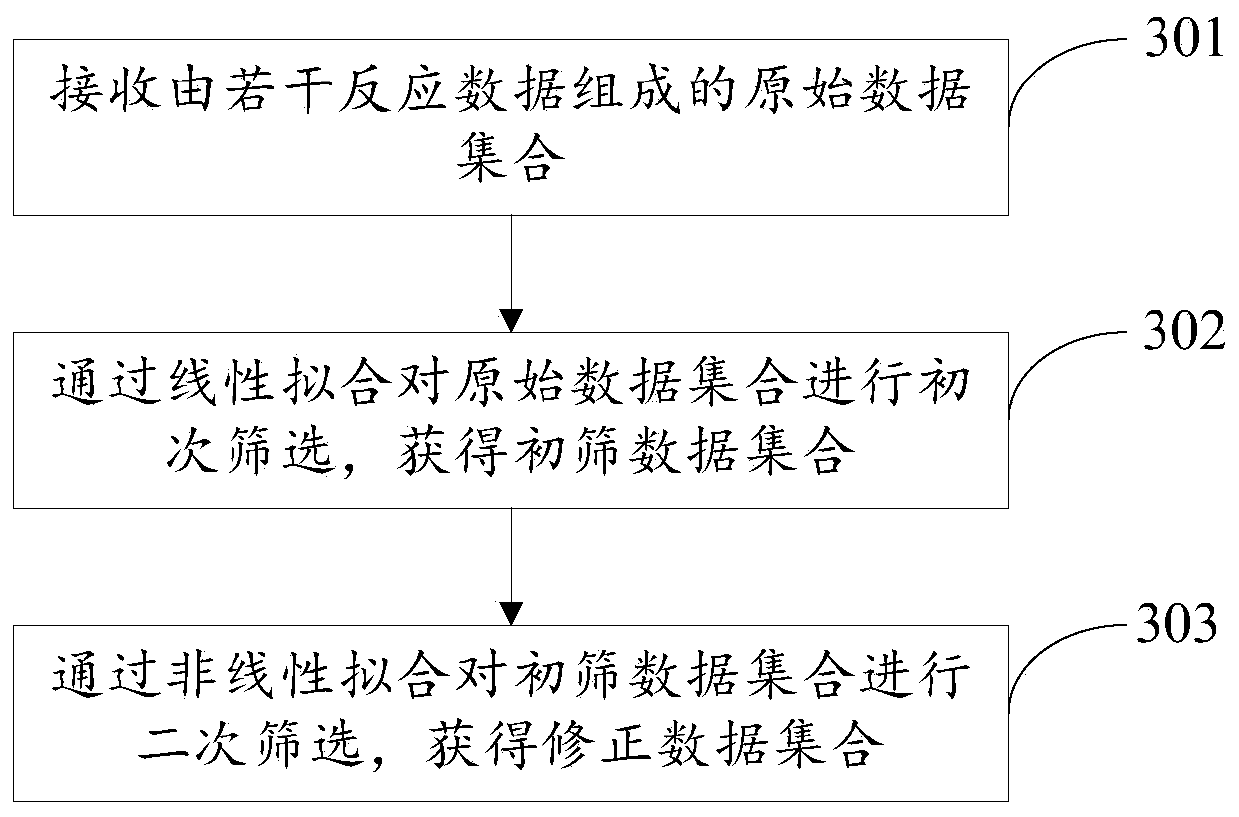

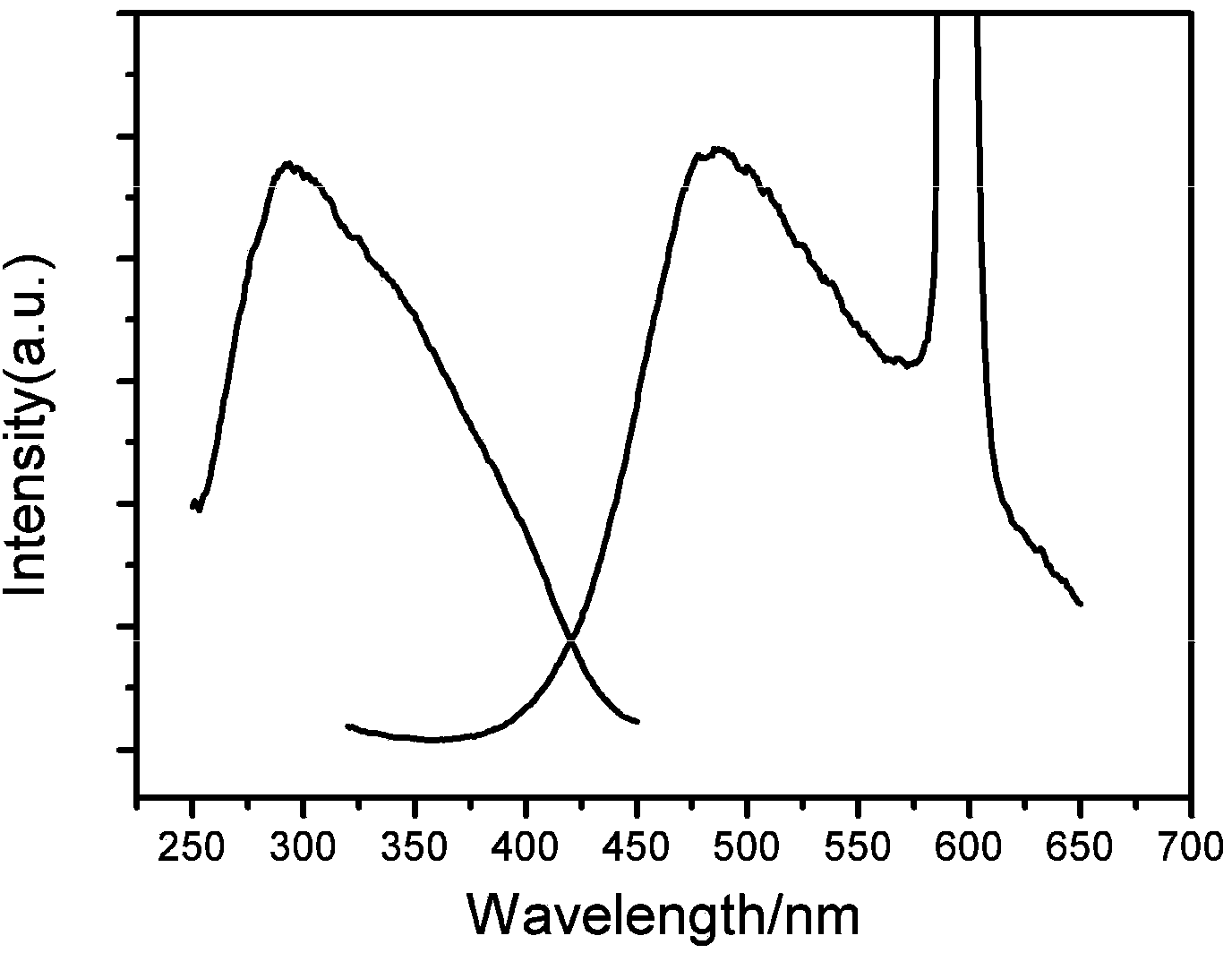

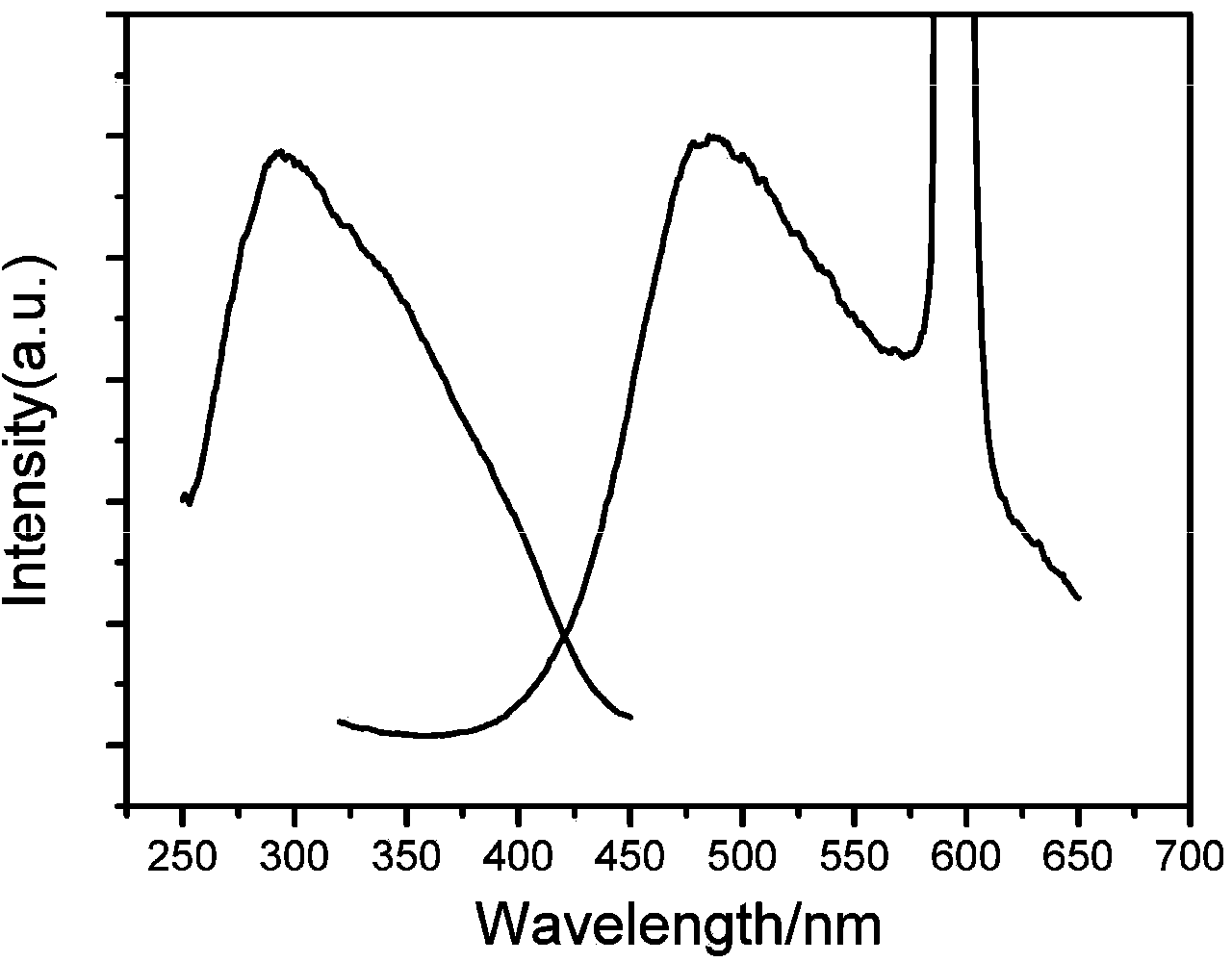

Calibration data correction method and electronic equipment thereof

ActiveCN110082319AAvoiding Misfit SituationsGuaranteed accuracyScattering properties measurementsTransmissivity measurementsOriginal dataPrimary screening

The embodiment of the invention relates to a calibration data correction method and electronic equipment thereof. The calibration data correction method comprises the following steps that: receiving an original dataset formed by multiple pieces of reaction data; through linear fitting, carrying out primary screening on the original dataset to obtain a primary-screening dataset; and through nonlinear fitting, carrying out secondary screening on the primary-screening dataset to obtain a corrected dataset. By use of the method, an original reaction curve dataset is subjected to coarse screening and fine screening in sequence, two fitting ways are used for iteratively removing and rejecting exceptional data which does not conform to a reaction tendency and a normal reaction rule, and the accuracy of a final calibration result is guaranteed.

Owner:GENRUI BIOTECH INC

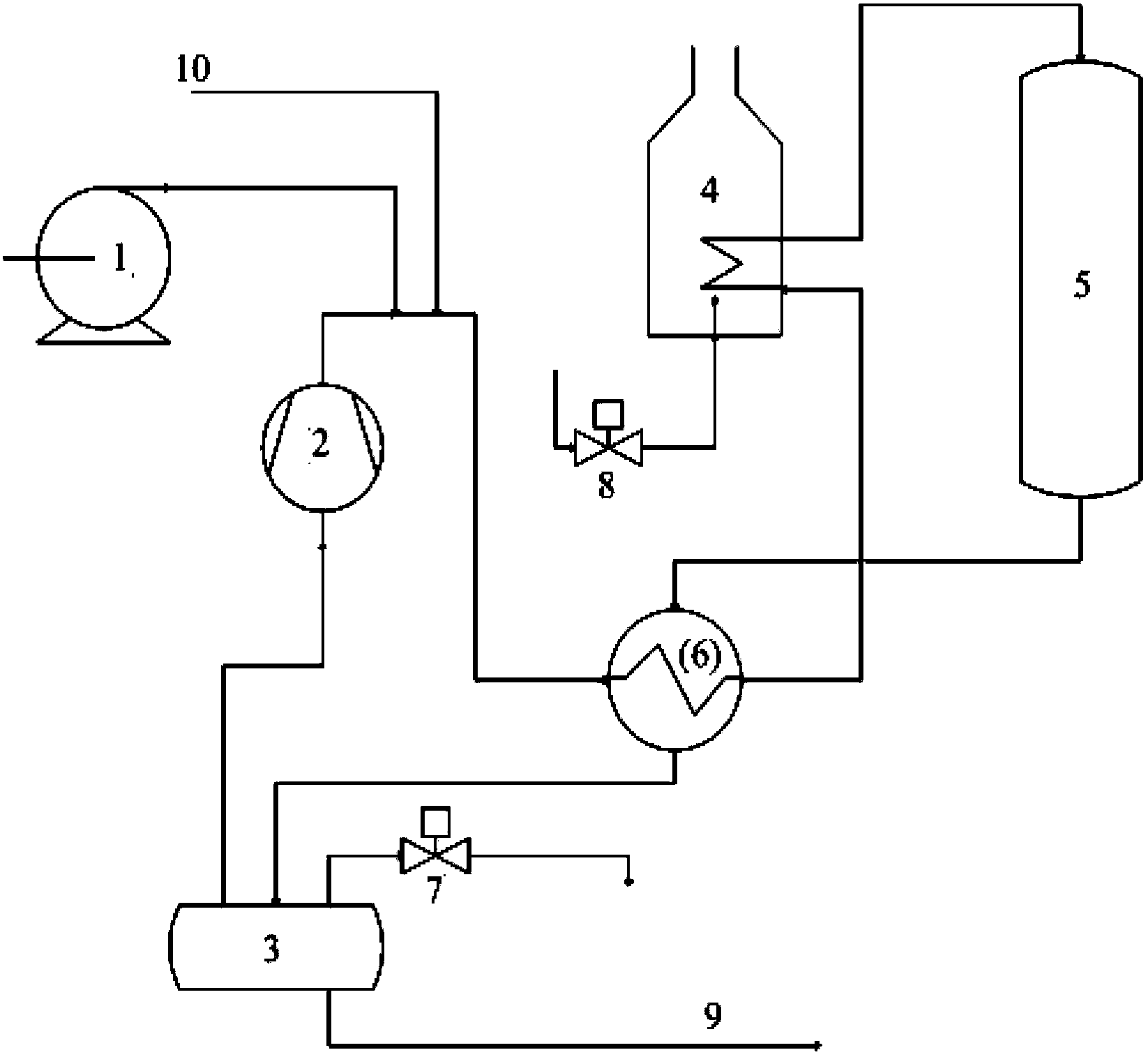

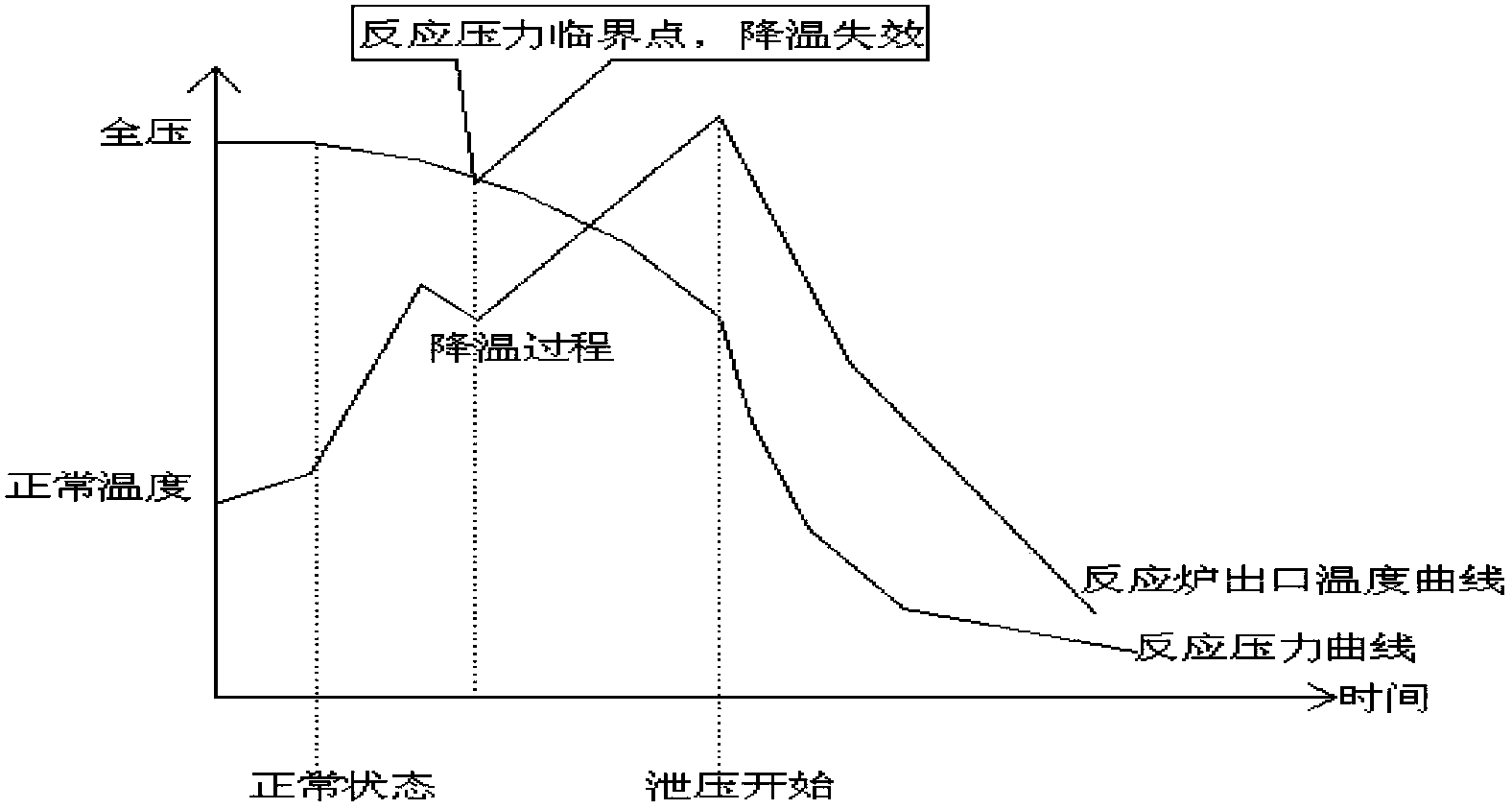

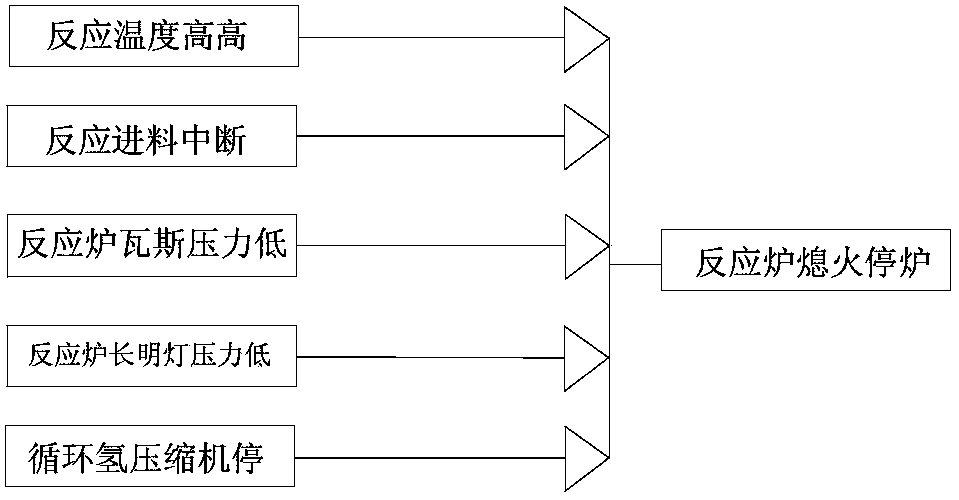

Method for inhibiting hydrocracking temperature runaway by using reaction pressure

InactiveCN103484153ARunaway suppression and avoidanceHydrocarbon oil crackingTemperature controlProcess engineering

The invention relates to a method for inhibiting hydrocracking temperature runaway by using reaction pressure. According to the present invention, before temperature runaway of a reactor bed layer is generated, reduction of the key parameter reaction pressure is utilized to timely interlock stopping of reaction material feeding and main gas of a heating furnace so as to reduce the temperature of reactor materials from the source, and achieve in advance braking of reactor temperature control, such that the heavy temperature runaway and pressure relief interlock caused by the reaction bed layer is avoided, wherein the reaction pressure is set at 80-88% of the normal reaction pressure; and the reaction furnace is directly stopped in the interlock manner when the reaction pressure is close to the critical point, such that temperature reduction on the feeding material of the reactor is achieved so as to inhibit temperature runaway possibly generated by the reactor bed layer.

Owner:PETROCHINA CO LTD

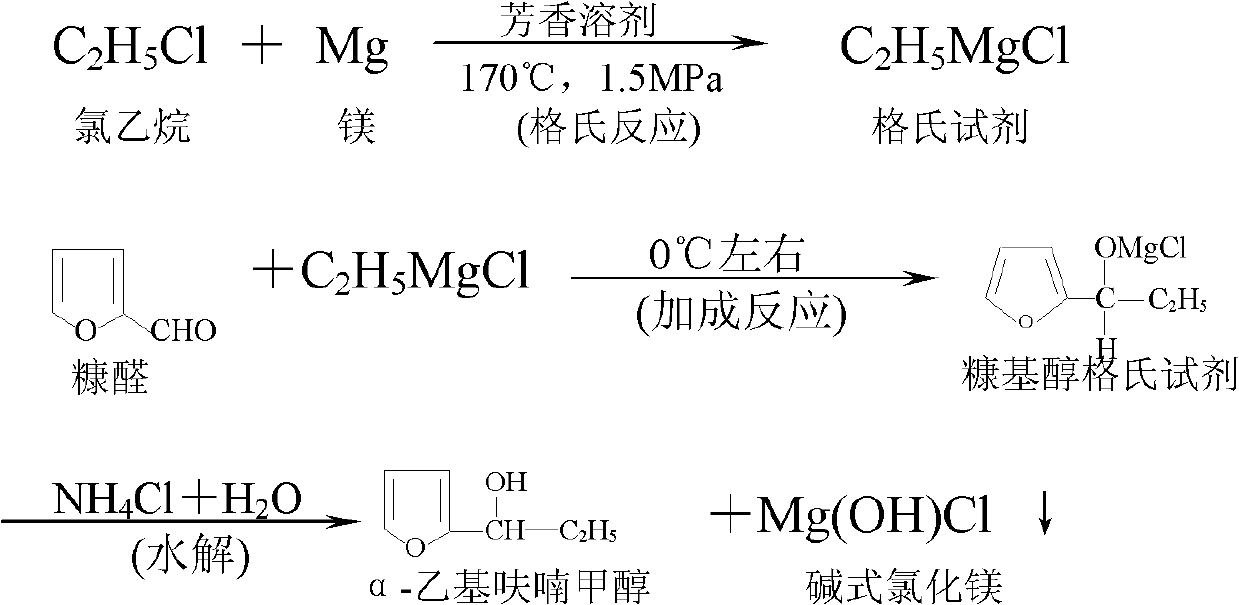

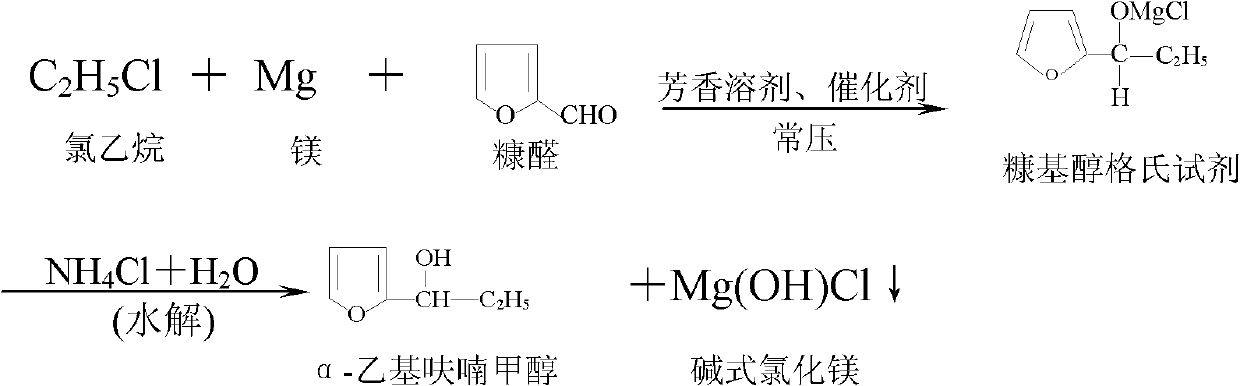

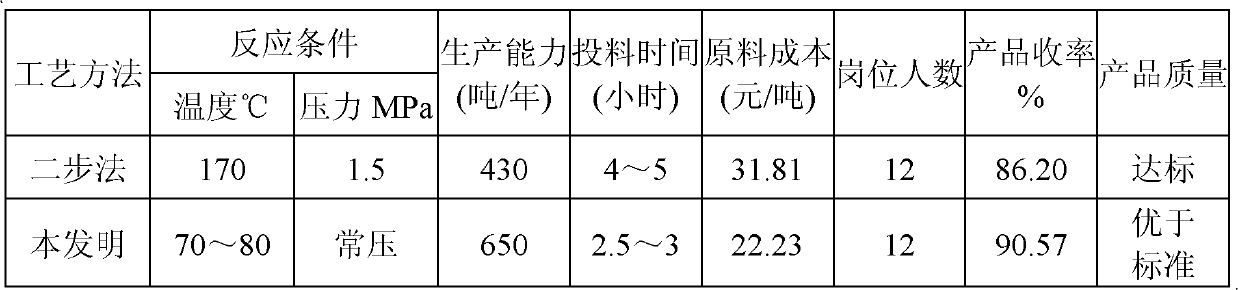

Preparation method of alpha-ethyl furan carbinol

The invention discloses a preparation method of alpha-ethyl furan carbinol, comprising the following order steps in sequence: (1) preparing furfuryl alcohol Grignard reagent by the catalytic reaction of chloroethane, magnesium and furfural; and (2) preparing the alpha-ethyl furan carbinol via the hydrolysis reaction of the furfuryl alcohol Grignard reagent. The method of the invention has the advantages of short process route, short feeding time, low raw material cost, high production capacity, good and stable product quality, normal reaction pressure, low reaction temperature, reliable and safe production and the like and is especially suitable for large-scale industrial production.

Owner:广东省肇庆香料厂有限公司

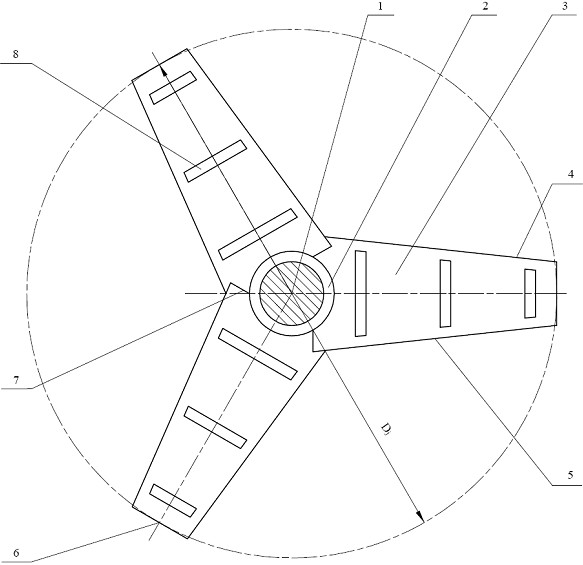

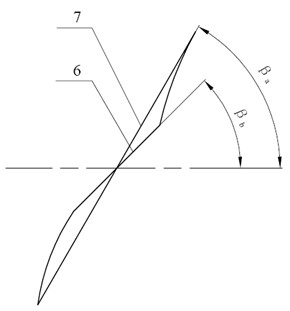

Airfoil type axial-flow stirrer

InactiveCN102179227AReduce resistanceReduce vibrationTransportation and packagingRotary stirring mixersIsosceles trapezoidPropeller

The invention discloses an airfoil type axial-flow stirrer, which comprises a stirring shaft, a hub and a propeller blade, wherein the hub is mounted on the stirring shaft; the propeller blade can be mounted on the hub removably or irremovably; the propeller blade of the stirrer has a smooth special distortion face, the cross section at any radius position is in an airfoil shape, the angle of pitch and blade width increase continuously from the end part to root part of the blade, and the design is based on a uniform pitch structure; and a plurality of isosceles trapezoid-shaped channels, which are vertical to the central line of the blade, are formed on the blade and are symmetrically distributed on the blade. The airfoil type axial-flow stirrer has the advantages that: the impact force applied by a fluid on the back of the stirring propeller blade face is reduced; the vibration of the stirrer is reduced; the axial circulation and flowing are reinforced; the flowing property of fluid in the reaction kettle is improved obviously; the liquid and solid phases are well separated; the stirring of the materials in the kettle is uniformly; and gases formed by reaction can be conveyed and allowed to escape smoothly to guarantee a normal reaction. In addition, the stirring power of the airfoil type stirrer is smaller than common airfoil propeller, so the energy consumption is low.

Owner:ZHEJIANG UNIV

Normal-temperature continuous production technology for cetane number improver

InactiveCN101633620AReduce consumptionReduce energy consumptionLiquid carbonaceous fuelsNitric acid ester preparationHigh energyReaction rate

The invention discloses normal-temperature continuous production technology for a cetane number improver, which belongs to the technical field of the preparation of organic nitrate ester compounds, and comprises the steps of using nitramine or nitric acid and isooctanol to react under the action of a catalyst. The normal-temperature continuous production technology for the cetane number improver is characterized by changing concentrated sulfuric acid as the catalyst, using different proportions of the concentrated sulfuric acid, concentrated nitric acid and water to control different reaction temperatures and realize continuous production, returning waste acid to an acid distribution post for acid mixing according to the content of the acid, then circularly utilizing the waste acid, finally selecting a normal reaction temperature of between 8 DEG C below zero and 40 DEG C in order to the safety and the control of the purity and the yield of energy consumption and the like, and utilizing the proportion of acid mixing to control reaction rate to achieve optimum process conditions such as continuous recycling of the waste acid, continuous feeding nitrification and the like. The technology overcomes the disadvantages of unsteady quality of products, large potential safety hazard, high energy consumption and material consumption and the like, improves the yield, ensures that the quality of the products entirely and steadily reaches that of high-class products, and greatly improves the utilization efficiency of equipment.

Owner:SHANDONG LIANHE CHEM

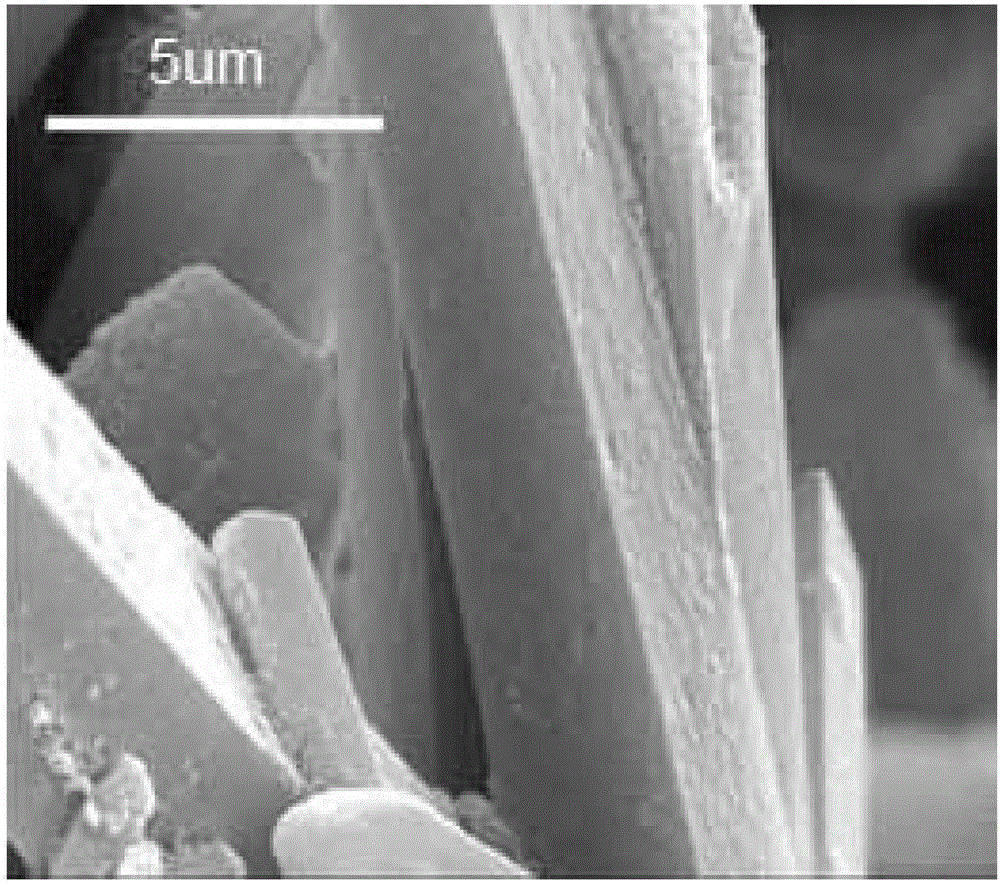

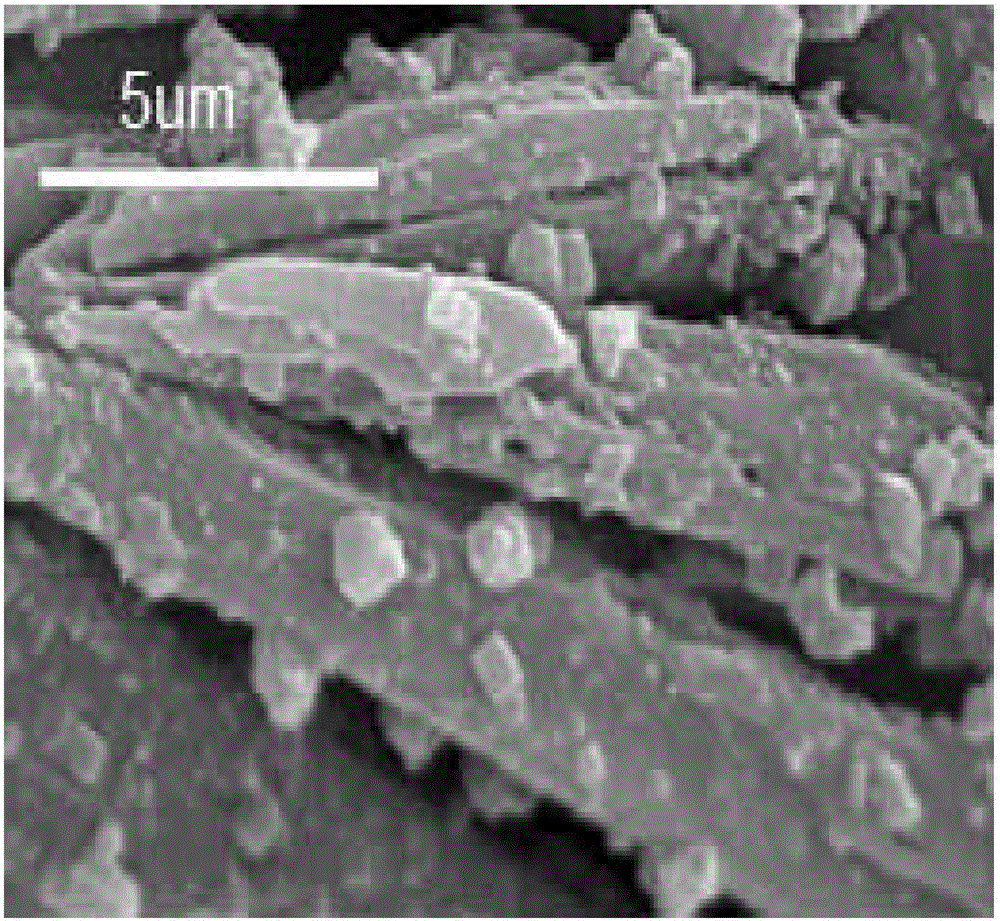

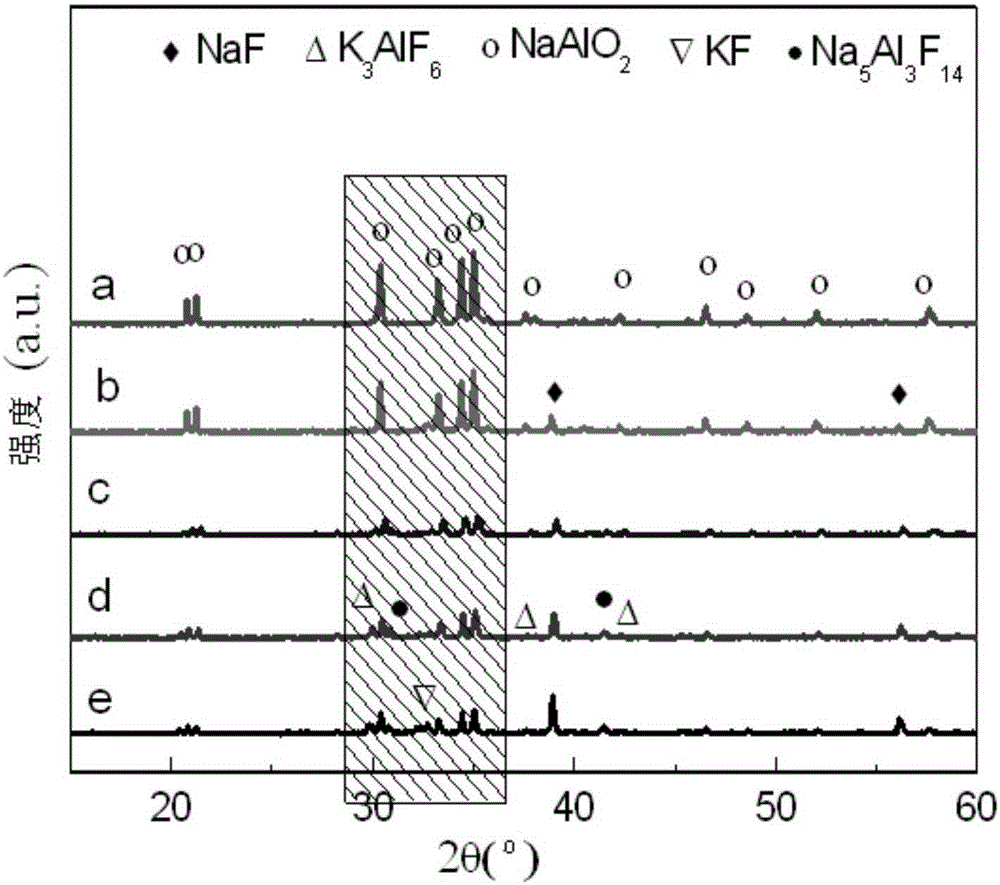

Supported solid base catalyst, preparation method and appliance thereof for compounding novel biological diesel oil

ActiveCN105195181AEvenly dispersedHigh activityPhysical/chemical process catalystsFatty acid esterificationPotassium fluoridePotassium

The invention discloses a supported solid base catalyst, a preparation method and an appliance thereof for compounding novel biological diesel oil, which relate to a solid base catalyst, a perpetration method and a method for catalyzing and preparing novel biological diesel oil, and aim to solve the problems that existing homogeneous base catalysts are not high in reaction activity, can not be recycled, are complex in post-processing process, need to neutralize and wash reaction products, and leads to discharge a lot of waste water and pollute environment. The supported solid base catalyst comprises sodium aluminate, potassium fluoride, sodium fluoride, potassium fluoroaluminate and sodium fluoroaluminate. The preparation method comprises steps: 1 x-KF / NaAlO2 precursors are prepared; and 2 drying and calcining, thereby obtaining the supported solid base catalyst. The method for catalyzing and preparing the novel biological diesel oil is that reaction materials and catalysts are added into a reactor with a reflux condensation device, are stirred and reacted in normal reaction pressure and protection of nitrogen, and then are centrifugally separated, decompressed and distilled. The supported solid base catalyst can be used to catalyze and compound the novel biological diesel oil.

Owner:中德晨晰环保工程有限公司

1,5-dinaphthylamine electrochemical synthesis method

InactiveCN101187031AShort reaction timeReduce energy consumptionOrganic chemistryElectrolysis componentsSupporting electrolyteSynthesis methods

Provided is an electrochemical synthetic method of 1,5-diaminonaphthalene, which includes four steps that firstly the electrochemical synthetic of diaminonaphthalene is performed in an electrolytic cell which contains a cathode chamber and an anode chamber which are separated by a cation-exchange membrane which is taken as a permeable membrane, copper sheets and a calomel electrode which are installed in the cathode chamber are respectively taken as working electrodes and a saturated reference electrode, and ruthenium-plated iron screens which are arranged inside the cathode chamber are taken as auxiliary electrodes. Secondly catholyte is mixed solution of solvent N, N-dimethyl formamide, sulfuric acid solution supporting electrolyte and substrate 1, 5-diaminonaphthalene, and anolyte is sulfuric acid solution of which the volume is equal to the volume of the catholyte. Thirdly electrolyzation is performed at room temperature and under the condition that the working electrodes are driven by a certain constant potential relative to the saturated reference electrode. Fourthly after the electrolyzation is finished, the electrolytic solution is post-processed to obtain the product of 1, 5-diaminonaphthalene. The method has the advantages of simple requirement, easy preparation of the electrodes, ready availability of raw material, greening synthetic process, normal reaction temperature, small energy consumption, high yield and suitability to industrial production.

Owner:EAST CHINA NORMAL UNIV

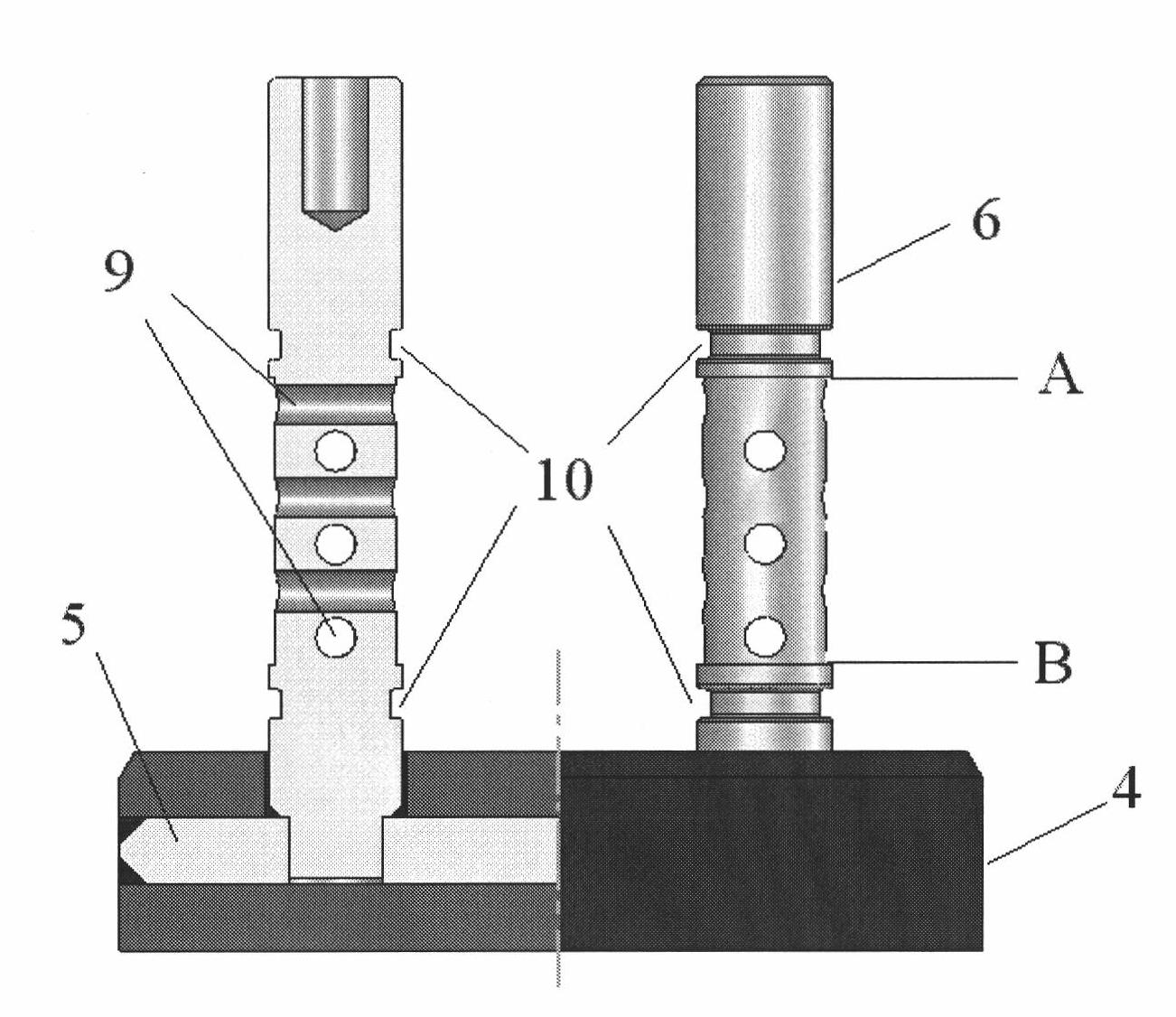

Monorail vehicle apparatus with gravity-controlled roll attitude and loading

InactiveUS8950336B2Accurate constraintAccurate translationMonorailsRailway componentsBogieEngineering

Monorail vehicle that travels on a non-featured rail with substantial profile variation and controls roll attitude, lateral location, and loading through judicious placement of the vehicle's center of gravity without using springs or suspensions. The vehicle has a bogie for engaging the non-featured rail so the center of gravity has a lateral offset r1 from the rail centerline to produce a roll moment Nr determined by vehicle's mass and value of r1. The center of gravity also has a vertical offset r2. The bogie uses first and second assemblies for engaging the rail to produce a pair of surface normal reaction forces to thus control roll attitude and loading by the placement of the center of gravity, thereby enabling accurate alignment of the monorail vehicle.

Owner:SOLARCITY

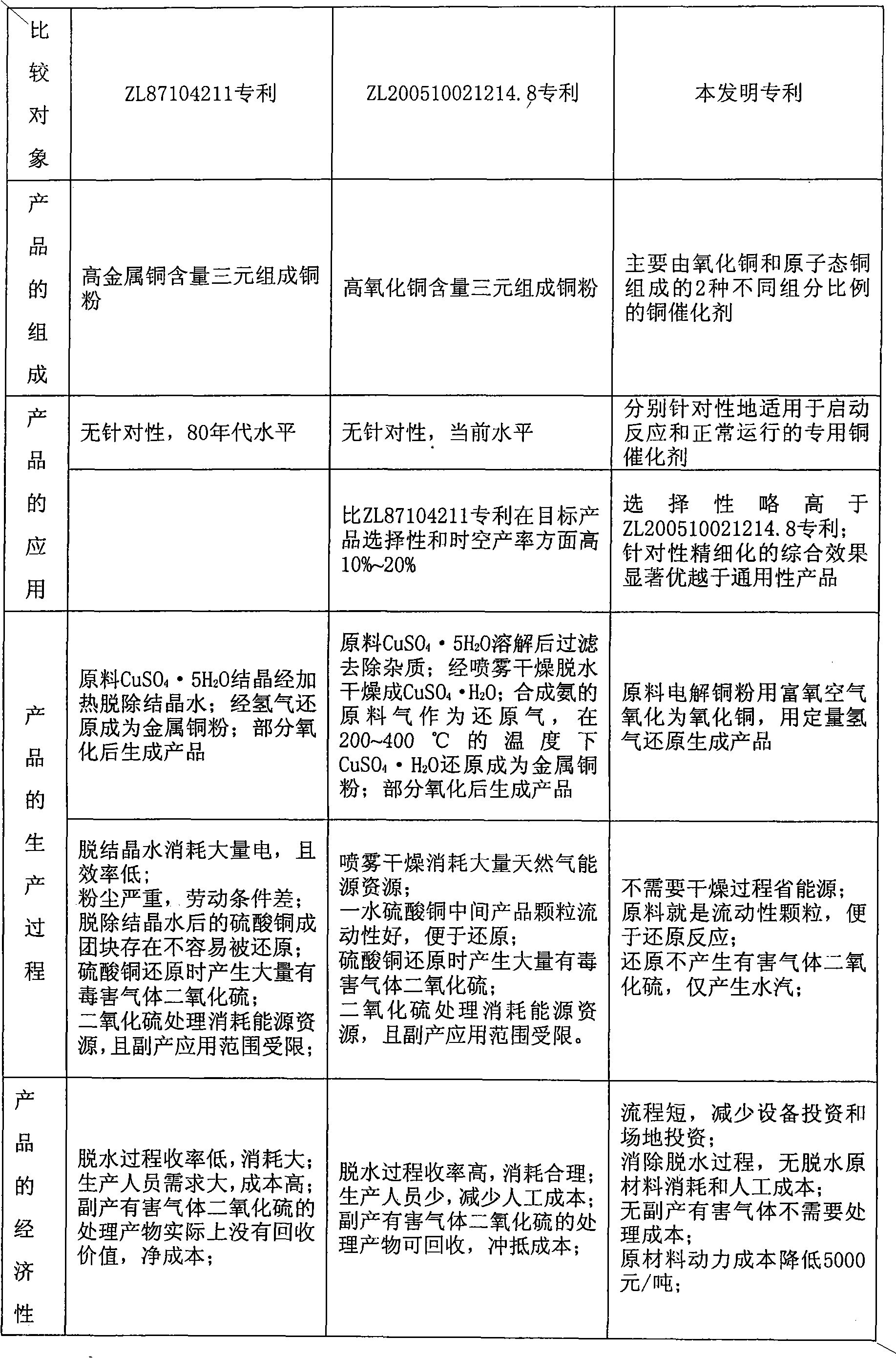

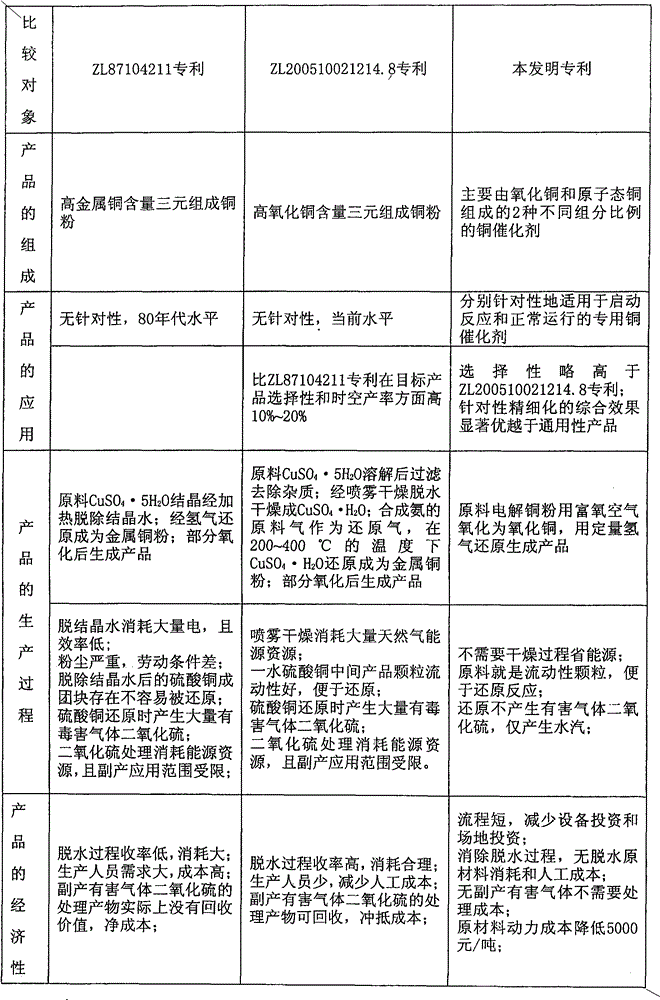

Two types of catalysts for synthesizing methyl chlorosilane and preparation method thereof

ActiveCN102059117AReduce solubilityReduce energy consumptionGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper oxideImpurity

Owner:成都隆盛新材料股份有限公司

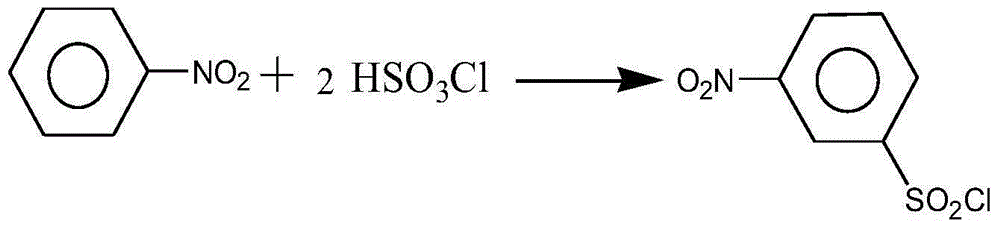

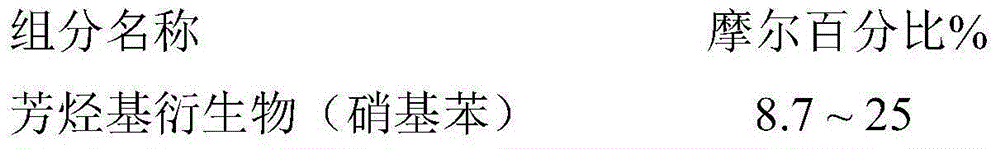

Preparation method for aryl sulfonyl chloride derivative

InactiveCN105111111AReduce generation riskHigh yieldSulfonic acid preparationSulfonyl chlorideChlorosulfuric acid

The invention discloses a preparation method for an aryl sulfonyl chloride derivative. The aryl sulfonyl chloride derivative is prepared through the following steps that firstly, an aryl derivative is slowly added in a mixture of chlorosulfonic acid and sulfur trioxide, 1-2 drops of acetic acid is dropwise added, the temperature is increased to 50-140 DEG C and is kept invariable, and a reaction is performed for 6-8 h; secondly, the temperature is lowered to 40-60 DEG C, phosphorus oxychloride is dropwise added, then the temperature is increased to 60-120 DEG C, and a heat preservation reaction is performed for 2-4 h; thirdly, after the complete reaction is achieved, the temperature is lowered below 20 DEG C, and the mixture is added into ice water for dilution; finally, solvent is added, and the aryl sulfonyl chloride derivative is prepared after distillation and filtration are performed. According to the preparation method, the reaction is stable, the demand quantity for the chlorosulfonic acid is little, the product yield is high, and the problem that in a normal reaction, sulphur is generated due to the fact that a disproportionated reaction takes place between the added phosphorus trichloride and sulfuric acid is solved; meanwhile, no hydrogen chloride gas is generated, aftertreatment is convenient, and pollution to the environment is little.

Owner:TAIXING ZHENQING CHEM CO LTD

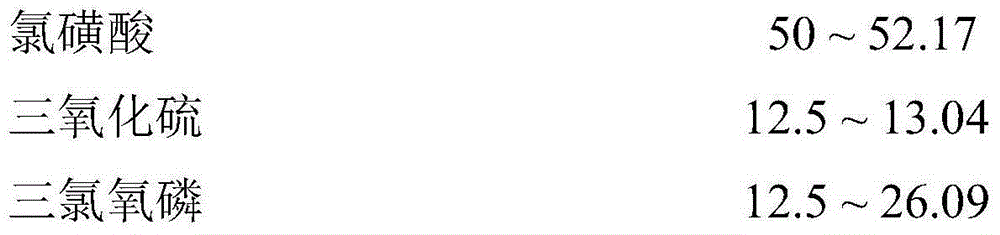

Method for preparing surface patterned SiO2 high molecular composite microsphere

InactiveCN1864845AImprove stabilityEasy to controlMicroballoon preparationMicrocapsule preparationSurface patternMicrosphere

The invention relates to a method for preparing silica dioxide hollow microsphere with pattern on surface, comprising process of preparing mixed surface active agent, composite mould oil phase, emulsion, water phase, cogelled, swelling cogelled, mixing liquid of tetraethoxysilane and skellysolve C, silica dioxide high molecular compound microsphere with pattern on surface. The invention is characterized by rational design, feasible process, simple operation, normal reaction temperature and short reaction time. The prepared high molecular compound microsphere is characterized by rigid and stable inorganic material, flexible organic material, large specific surface area and smaller quantity, and wide application on biological medicine, damping of vibration, carrying catalyst, fast concentration and separation, sensing technology, environmental protection and ocean mining.

Owner:SHAANXI NORMAL UNIV

Method for manufacturing pipeline through reaction injection-rotation moulding, pipeline die and pipeline moulding device

InactiveCN106553300ASimple structureEasy to assembleCoatingsTubular articlesEngineeringInjection moulding

The invention relates to a method for manufacturing a pipeline through reaction injection-rotation moulding, a pipeline die and a pipeline moulding device. The method comprises injecting reaction injection moulding raw materials in a pipeline die with a closed cylindrical die cavity, rotating the pipeline die around an axis of the cylindrical die cavity, allowing the reaction injection moulding raw materials to spread on an inner wall of the closed cylindrical die cavity, forming a tube structure, performing curing and performing demoulding to obtain the pipeline. According to the method, the characteristic that the normal reaction injection moulding raw materials are low in viscosity is used, the curing reaction is controlled to be performed in a rotation condition, and the raw materials can be uniformly spread inside the die cavity for a curing reaction, so that the manufactured pipeline is good in pipeline uniformity. Since shrinkage happens after curing and no die core is used, the final pipeline product can be conveniently demoulded from the die.

Owner:张航

Two types of catalysts for synthesizing methyl chlorosilane and preparation method thereof

ActiveCN102059117BReduce solubilityReduce energy consumptionGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper oxideImpurity

The invention discloses two types of catalysts for synthesizing methyl chlorosilane and a preparation method thereof. The two types of catalysts are prepared by taking metal copper powder as a raw material through the steps of oxidizing to remove surface impurities, deeply oxidizing to change substance structures, partially reducing and regulating product constituents, the catalyst I comprises the following constituents in percentage by weight: 15-30% of metal copper, 20-30% of cuprous oxide and 40-65% of copper oxide, and is used during normal reaction after a synthesis reaction is started, and the catalyst II comprises the following constituents in percentage by weight: 50-65% of metal copper, 25-35% of cuprous oxide and 5-20% of copper oxide, and is used during driving starting reaction in the early stage of synthesis reaction. The method disclosed by the invention has the advantages of low energy consumption, high efficiency, environmental friendliness, effectively reduced production cost, and more stable and complete reduction reaction; meanwhile, the prepared copper catalysts have the characteristics of high catalytic activity and selectivity, strong raw material adaptability and good overall indicators.

Owner:成都隆盛新材料股份有限公司

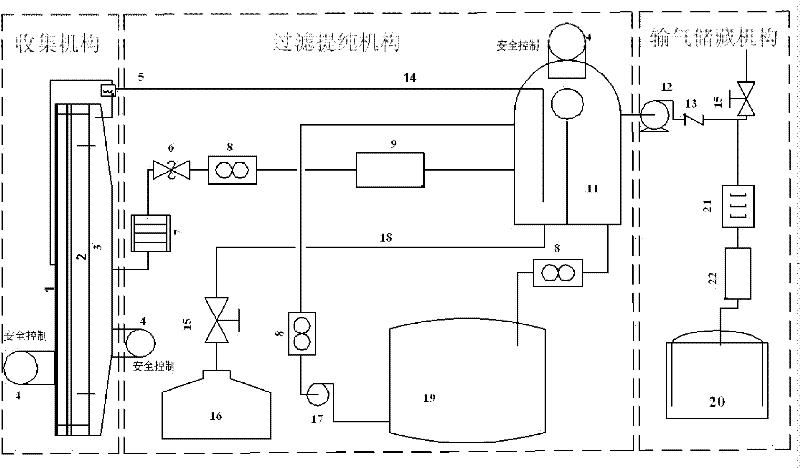

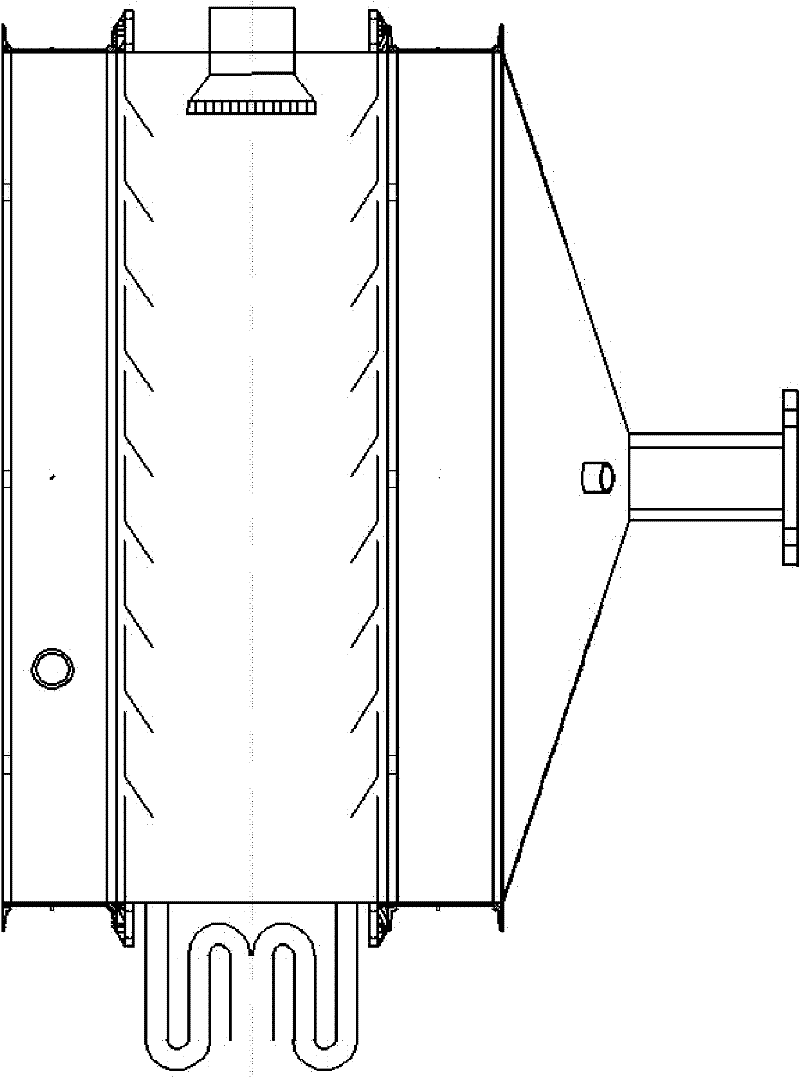

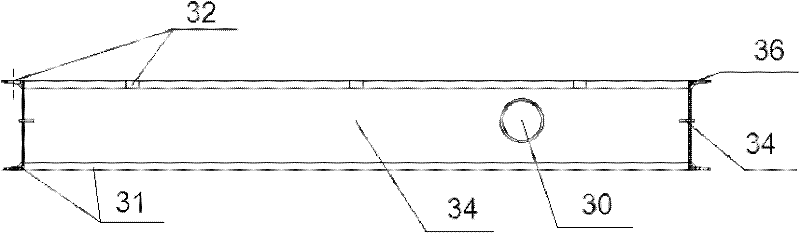

Tail gas collecting system of silicon carbide smelting furnace

The invention discloses a tail gas collecting system of a silicon carbide smelting furnace, which comprises a collecting mechanism, a filtering and purifying system and a gas transmission storage mechanism which are mutually connected, wherein the collecting mechanism is connected with a furnace wall of the smelting furnace of the system, and is then sequentially connected with the filtering and purifying mechanism and the gas transmission storage mechanism; the collecting mechanism and the filtering and purifying mechanism are respectively provided with a safety control mechanism; the collecting mechanism comprises a collecting cover base, a collecting cover and a shutter; the filtering and purifying mechanism comprises a gas separator, an oil storage tank and a water tank which are connected respectively through a pipeline; the gas separator is connected with the gas transmission storage mechanism through a pipeline; the gas transmission storage mechanism comprises a gas storage tank connected with the gas separator. The system can fully utilize the additional value of tail gases such as CO generated in the silicon carbide smelting process, and the environment pollution is reduced; and the danger of CO gas gathering and explosion is reduced, and the normal reaction conditions of silicon carbide can not be damaged.

Owner:XIAN UNIV OF SCI & TECH

Method for improving selectivity of catalyst

ActiveCN104549556ADecreased Hydrogen SaturationReduced activityCatalyst regeneration/reactivationCatalyst activation/preparationHydrogenation reactionAtmosphere

The invention relates to a method for improving selectivity of a catalyst. A catalyst selectivity regulation and control process is increased between a desulfurization process and a normal production process, and the catalyst selectivity regulation and control process is that activity catalytic raw materials are in contact with the catalyst for 24-96h in an atmosphere of activity catalytic gas under activity catalytic reaction conditions, wherein the activity catalytic gas comprises hydrogen gas and hydrogen sulfide, and based on the whole activity catalytic gas, the volume fraction of the hydrogen gas is not less than 70%, and the volume fraction of hydrogen sulfide is 0.2%-5%; and the normal production process is that gasoline raw material is in contact with the catalyst in the atmosphere which is rich in the hydrogen gas under normal reaction conditions to be in hydrogenation reaction. By adopting the method provided by the invention, the selectivity of the catalyst can be improved. Compared with the prior art, under the situation that the sulfur content in a gasoline product is the same, the olefin saturation rate is lower and the loss in octane number of a product is smaller.

Owner:CHINA PETROLEUM & CHEM CORP +1

Charged microporous filtration membrane and affinity base membrane preparing method

InactiveCN1579599AEvenly distributedImprove connectivitySemi-permeable membranesFiltration membraneCellulose acetate

The invention relates to a microporous membrane, concretely speaking, an approach of producing charge microporous membrane and its affinity basement membrane. By weight, use cellulose acetate of 5-9 percent as basic material. Mix polycation compound of 0-15 percent in acetone / dimethyl formamide of 45-70 percent. Use polyisocyanate of 0-0.8 percent as crosslinking agent to react. Add glycerin as additive. After knifing, absorb moisture in temperature of 30-70deg.C and relative humidity of over 95 percent and volatilize impregnant misphasing gel for 1-30 minutes. Finally form membrane and solidify. Merits of the invention lie in wide applied range, stable performance and normal reaction condition.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing rare earth doped aluminum nitride based blue fluorescent powder

InactiveCN103525410AShort preparation timeReduce energy consumptionLuminescent compositionsRare earthEuropium

The invention provides a method for preparing a rare earth doped aluminum nitride based blue fluorescent powder. Cheap aluminum powder, silicon powder and europium oxide powder are used as raw materials; in the process of sintering and heating, aluminum and silicon respectively melt into balls at 660 and 1400 DEG C, and the balls block the N atoms from entering into the metal, resulting in incomplete nitridation. The invention creatively uses ammonium fluoride to decompose and produce hydrogen fluoride and ammonia in the heating process, so as to destroy agglomerates formed by melted aluminum and silicon and ensure normal reaction; and the sintering temperature is greatly reduced, and the generated gas will volatile, without introducing impurities.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Efficient metallurgical rotary kiln for treating lead-zinc oxide ore

PendingCN106766870AGuaranteed reduction temperatureNormal responseRotary drum furnacesMetallurgical industryFuel gas

The invention relates to an efficient metallurgical rotary kiln for treating lead-zinc oxide ore and belongs to the field of structural designs and application of non-ferrous metallurgical industry equipment. The efficient metallurgical rotary kiln for treating lead-zinc oxide ore comprises a rotary kiln body, a feed opening, air blasting equipment, an air inlet pipe, a heat exchanger, a hot air adding opening, a discharge opening, an exhaust gas outlet, a rotary kiln support roller, a rotary kiln mechanical transmission component and a hot air pipe. As the heat exchanger is added to the outside of a reduction area to heat air produced by the air blasting equipment up to about 500 DEG C, air required for in-kiln reaction is provided while an in-kiln material is heated up, accordingly, the temperature of the reduction area reaches 1,200-1,300 DEG C, and normal reaction is guaranteed. Besides, a gas nozzle is arranged at the head part of the rotary kiln, and if the temperature of the reduction area does not reach 1,200-1,300 DEG C, the gas nozzle can be ignited for heating, so that the temperature of the reduction area is guaranteed, effective volatile reaction of the material in the reduction area is ensured, meanwhile, in-kiln material coking is reduced, and the production cycle of the rotary kiln is prolonged.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

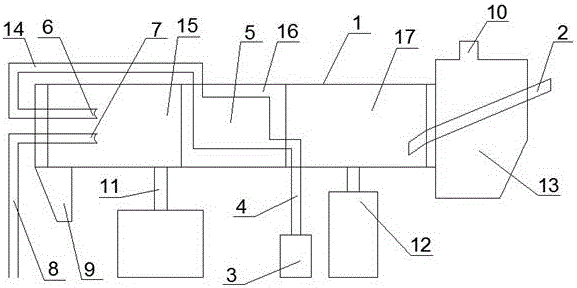

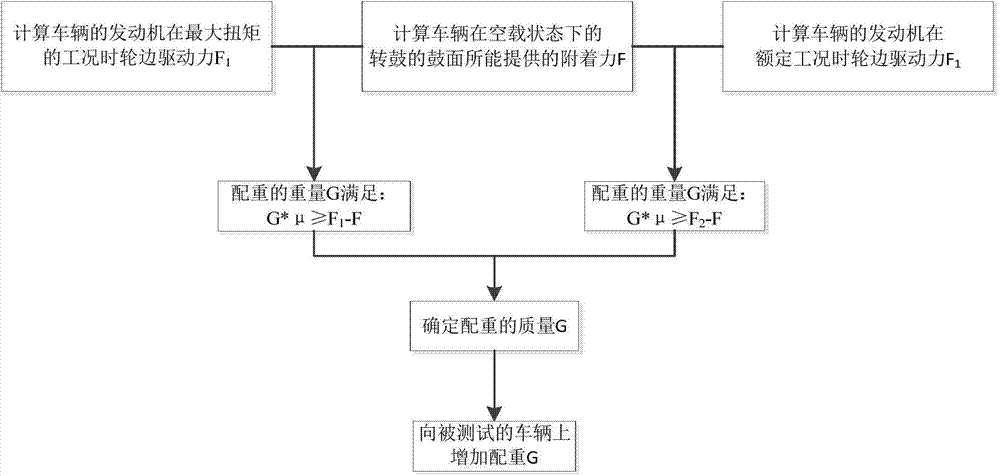

Vehicle test method employing chassis dynamometer and drum adhering force adjusting method

InactiveCN104849064APrevent slippingGuaranteed adhesionVehicle wheel testingDrive wheelChassis dynamometer

The invention discloses a drum adhering force adjusting method for a chassis dynamometer for a vehicle. The adjusting method includes adding weight on the vehicle to be tested. The invention also provides a vehicle test method employing the chassis dynamometer. According to the invention, the drum adhering force can be adjusted in a condition that the drum surface adhering indexes of the drum remains unchanged. By adopting the technical scheme of adding weight on the to-be-tested vehicle, namely, by adding the normal reaction on a driving wheel of the vehicle for guaranteeing the adhering force on the surface of the drum, slippage of the wheel on the drum during a test process is avoided.

Owner:BEIQI FOTON MOTOR CO LTD

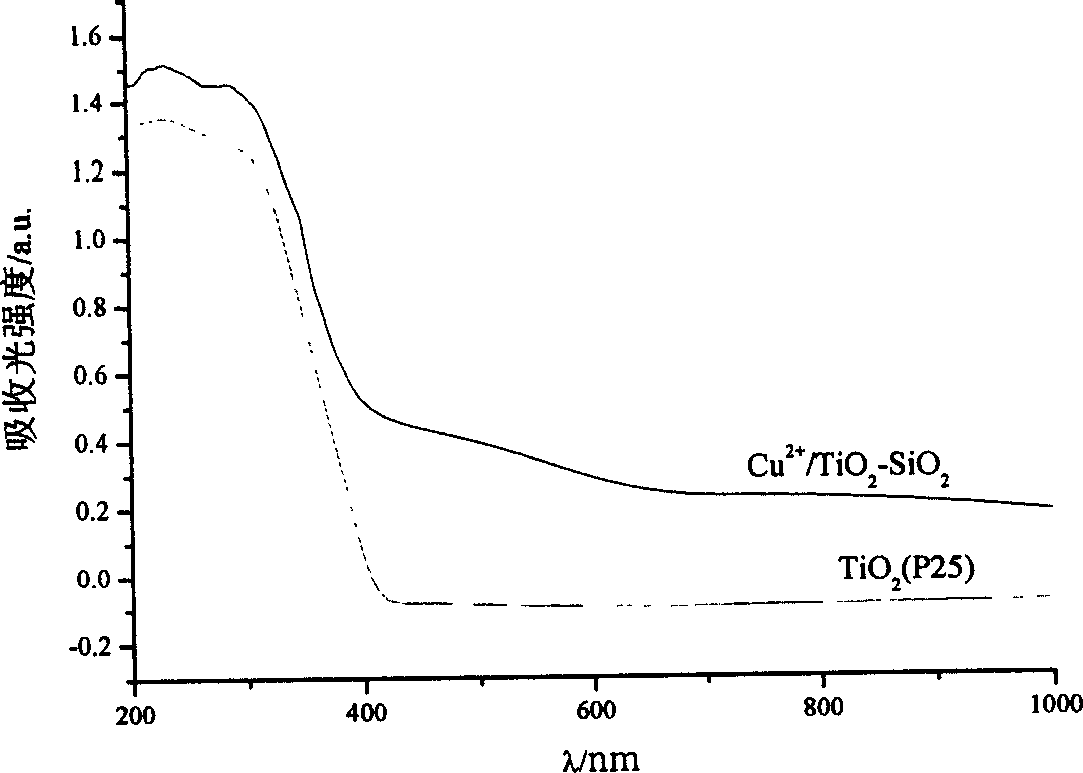

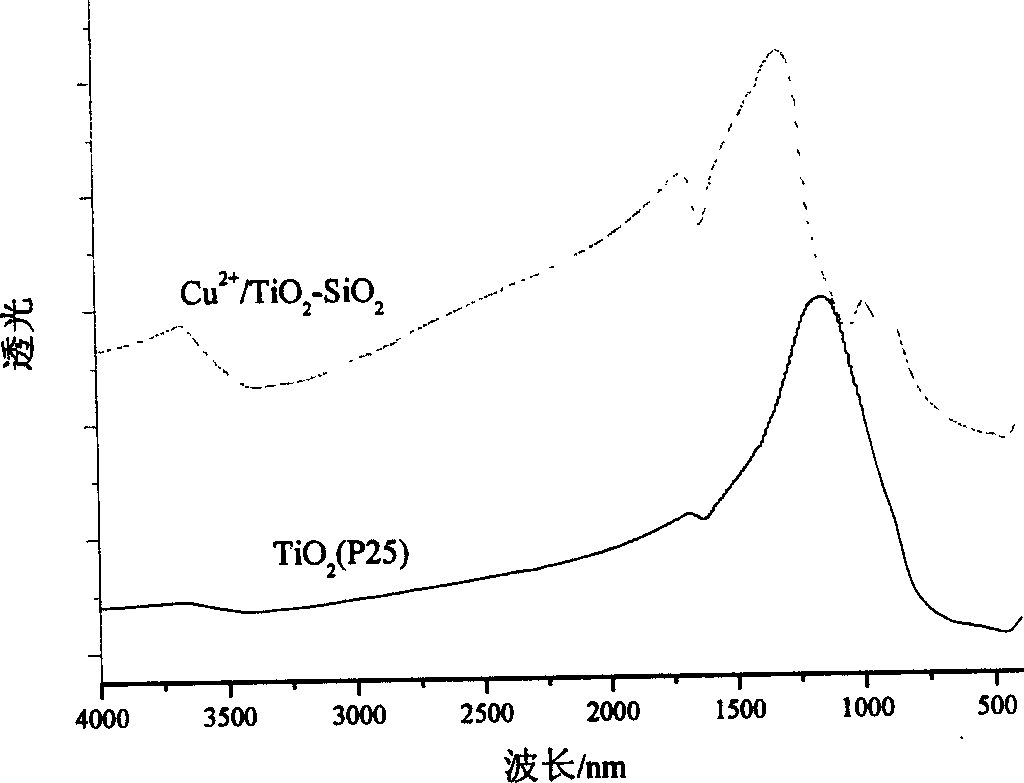

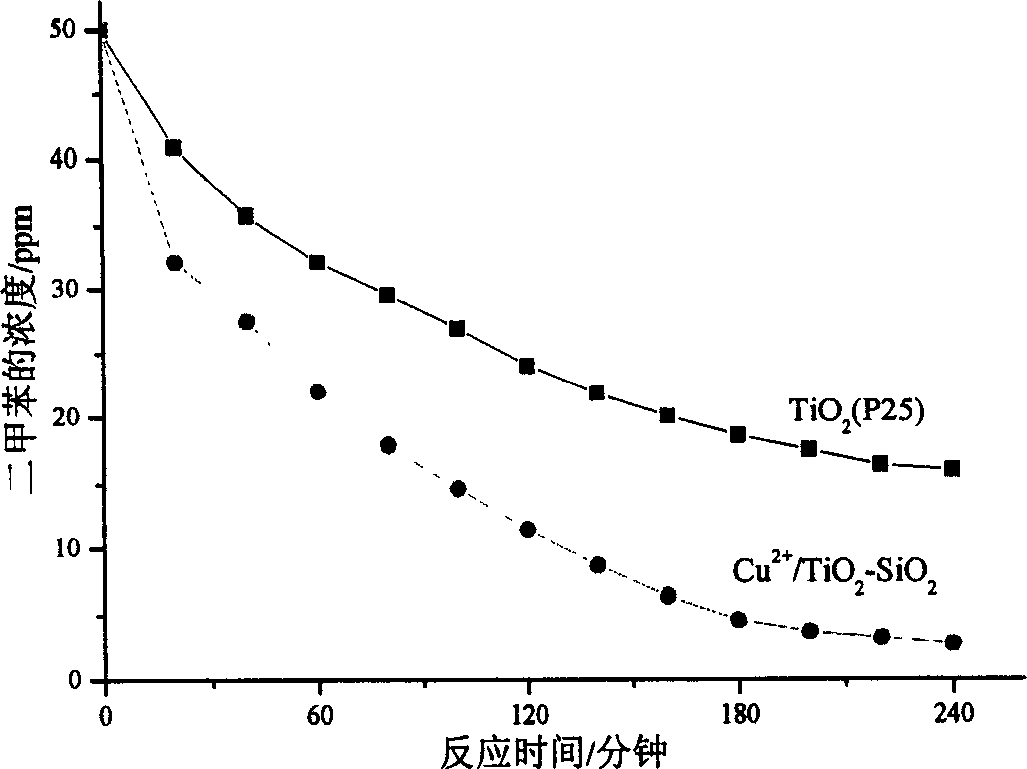

Method for preparing nano-catalyst of Cu2+/TiO2-SiO2

InactiveCN1768931AAchieve full frequency absorptionHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano catalystSilicic acid

The invention discloses a method for preparing nanometer catalyst of Cu2+ / TiO2-SiO2, belonging to the vapor phase photo-catalyst technique. Said method comprises: adding de-ionized water into the mixture of silicic acid n-hexanoic, alcohol, and acetic acid to be mixed and attaining the SiO2 sol; adding butyl titanate into SiO2 sol to be mixed to attain the TiO2-SiO2 sol; adding cupric nitrate solution to be mixed to attain the Cu2+ / TiO2-SiO2 sol, which is processed by drying, sintering and milling to attain the Cu2+ / TiO2-SiO2 catalyst at 10-15nm. The inventive Cu2+ / TiO2-SiO2 can realize the full-frequency absorption of visible light, to improve the optical quantum efficiency significantly, while the degradation rate of photo-catalysis dimethoxybenzene can reach more than 95%, with anatase crystal structure with high purity, uniform particle distribution, and larger specific surface. And the invention has reasonable process, simple producing processes, normal reaction conditions, and lower producing cost.

Owner:TIANJIN UNIV

Method for processing sludge from papermaking and pulping by using earthworms, method for separating sludge and earthworms

ActiveCN102229461APromote circulationImprove fertilityClimate change adaptationSewage/sludge fertilisersLoop closingSludge

The invention discloses a new process for synthesis of asenapine. The asenapine is prepared through adopting a compound (18) as a key intermediate and carrying out the following steps that: 1.1, the compound 18 is subjected to a Ullmann reaction under a alkaline condition through adopting copper powder as a catalyst to generate a ether (19); 1.2, the ether (19) is subjected to a carbonyl reduction to obtain the target compound of the asenapine (1). The process has the following advantages that: cheap and available 2-bromobenzaldehyde is adopted as an initial raw material and is subjected to a condensation, a addition, a reductive amination and a intramolecular cyclization reaction, a aminomethylation, a open loop transposition and then loop closing, a demethylation and a Ullmann loop closing reaction to synthesize of the asenapine (1); cis-trans-isomer is subjected to a delicate transposition to obtain a trans-product, such that the process is simplified and easy to be operated; the raw material is easy to be obtained and has cheap price; each reaction is a normal reaction, and reaction conditions are mild; a total yield is substantially improved; production cost is reduced; a purity of the product is more than 99% through a detection by HPLC.

Owner:GUIZHOU CHITIANHUA

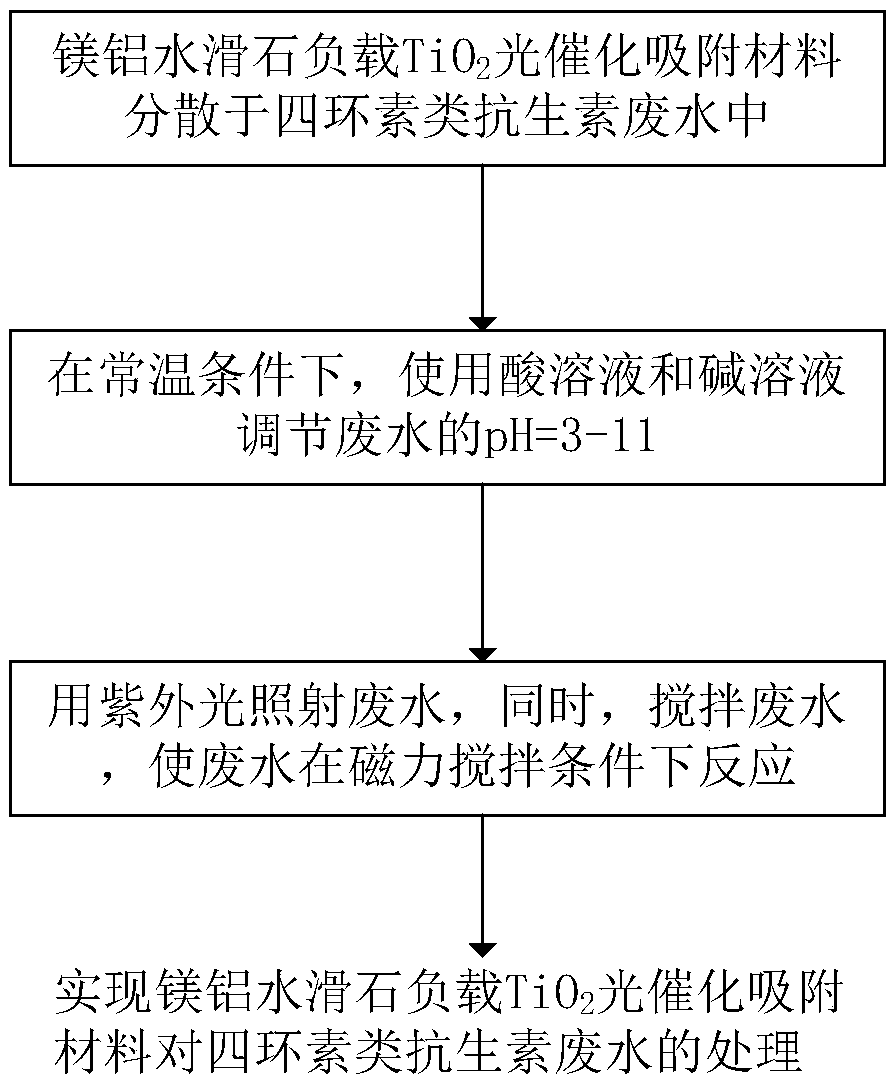

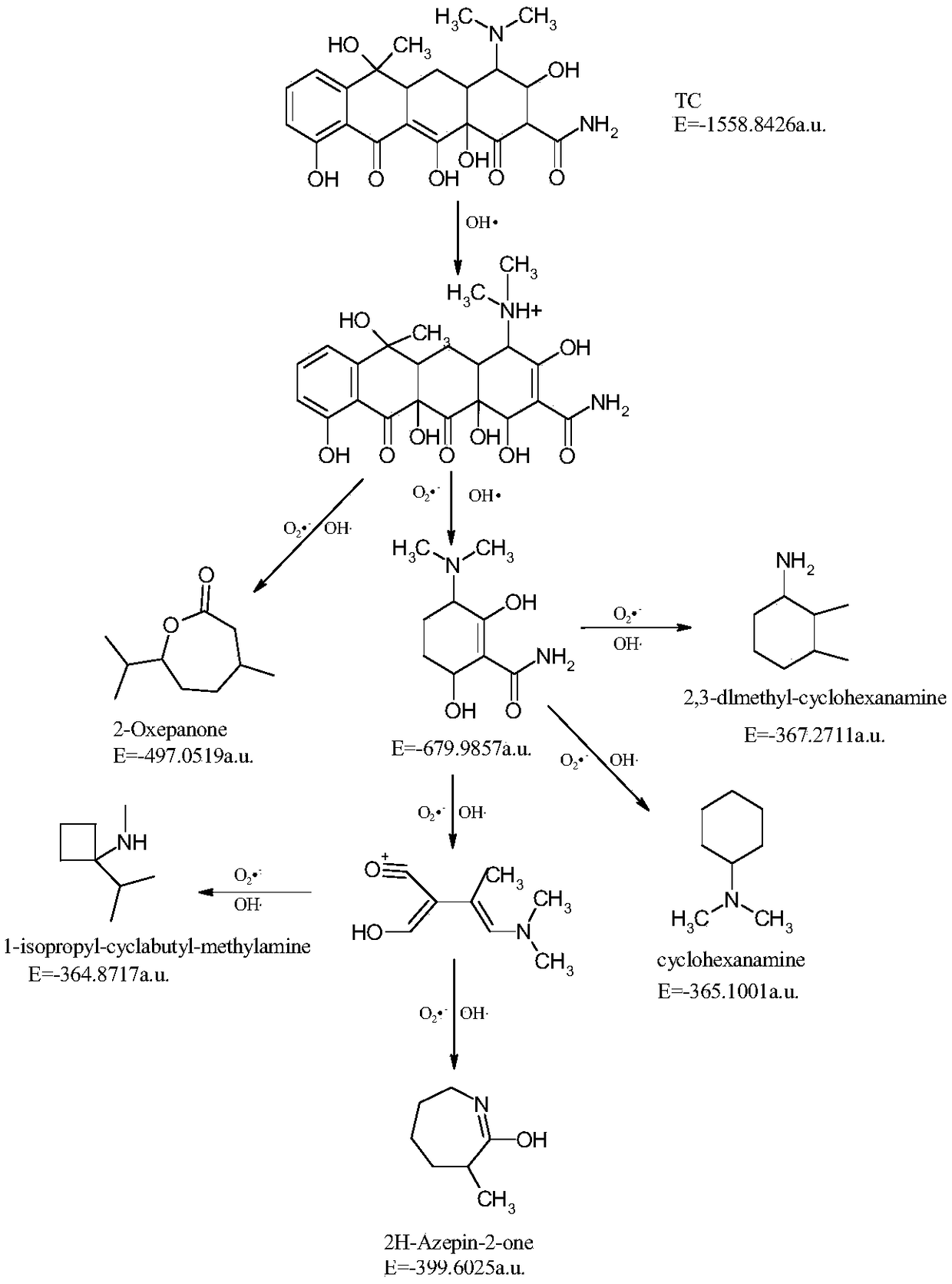

Method for treatment of tetracycline antibiotic wastewater by magnesium-aluminum hydrotalcite loaded TiO2 photocatalytic adsorption material

ActiveCN109133452ALow ring-opening toxicityPromote degradationWater/sewage treatment by irradiationWater treatment compoundsDisinfection by-productHydrotalcite

The invention discloses a method for treatment of tetracycline antibiotic wastewater by a magnesium-aluminum hydrotalcite loaded TiO2 photocatalytic adsorption material. The method includes: weighingthe magnesium-aluminum hydrotalcite loaded TiO2 photocatalytic adsorption material, and dispersing into the tetracycline antibiotic wastewater; under normal-temperature conditions, adopting acid solution and alkaline solution to regulate pH of the wastewater to 3-11; subjecting the wastewater to ultraviolet irradiation while stirring the wastewater to enable reaction of the wastewater under the condition of magnetic stirring. The method has advantages of short reaction time, normal reaction temperature, wide applicable pH range, low energy consumption, high degradation rate of tetracycline antibiotics in the wastewater, high mineralization degree, low ring-opening toxicity of disinfection by-products and the like and has great practical significance and market competitiveness. In addition,photocatalytic and adsorption synergistic effects on the tetracycline antibiotics in the wastewater are achieved.

Owner:湖北昌硕环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com