Method for preparing nano-catalyst of Cu2+/TiO2-SiO2

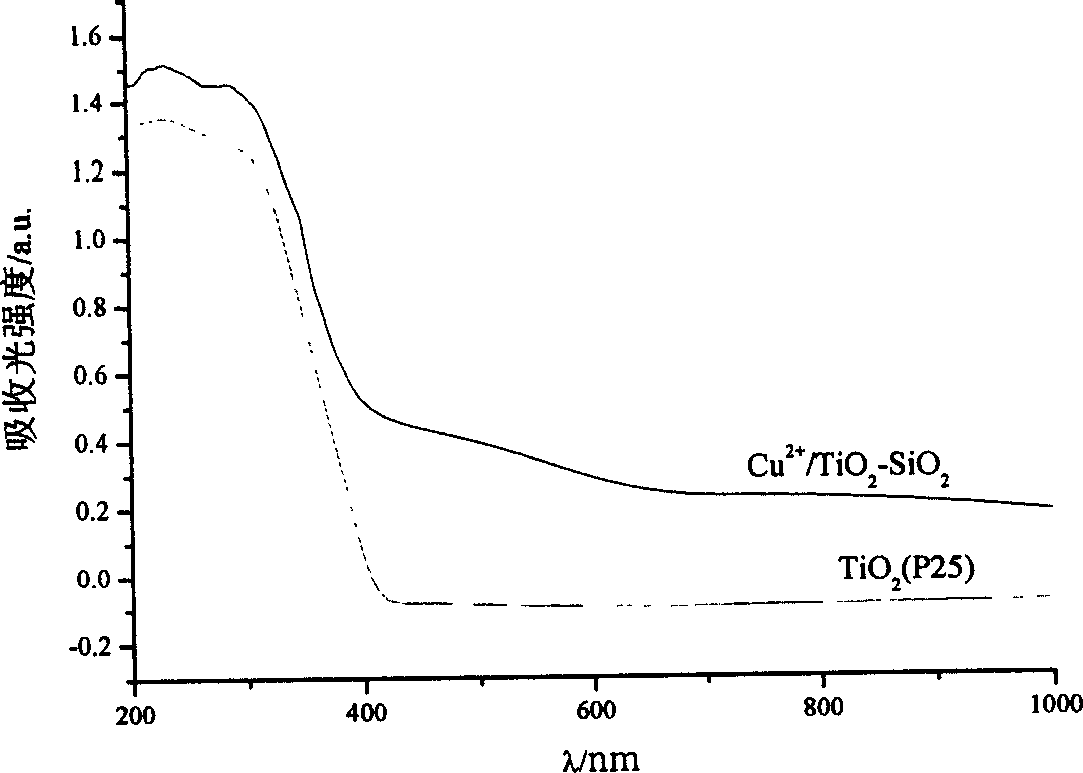

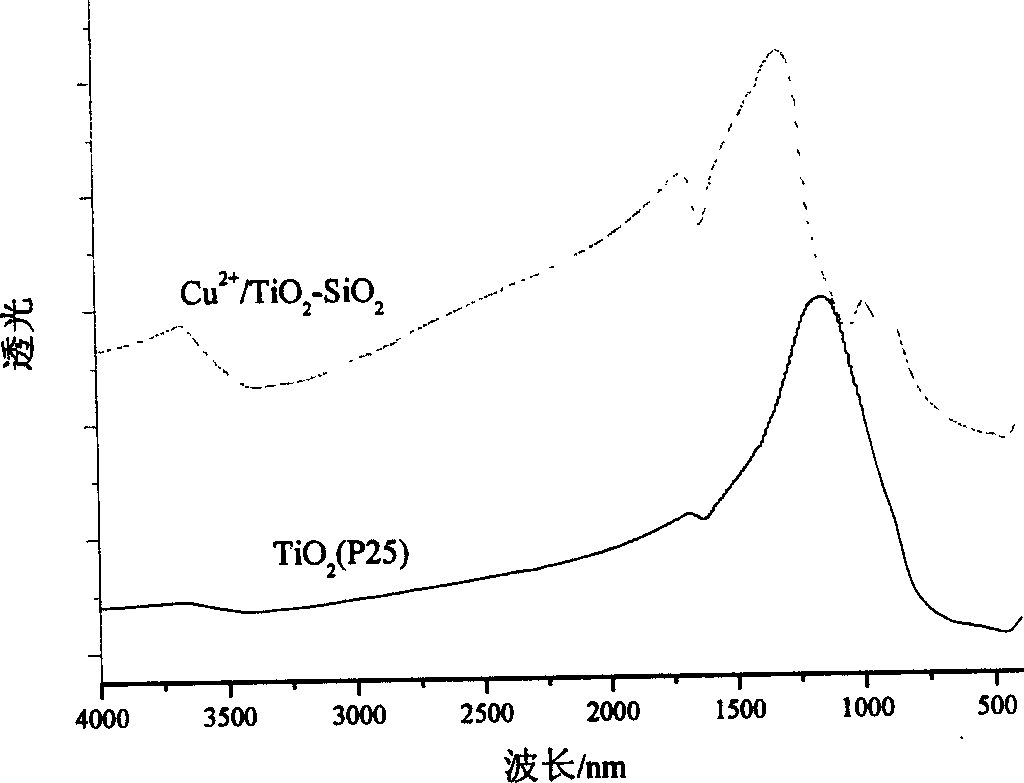

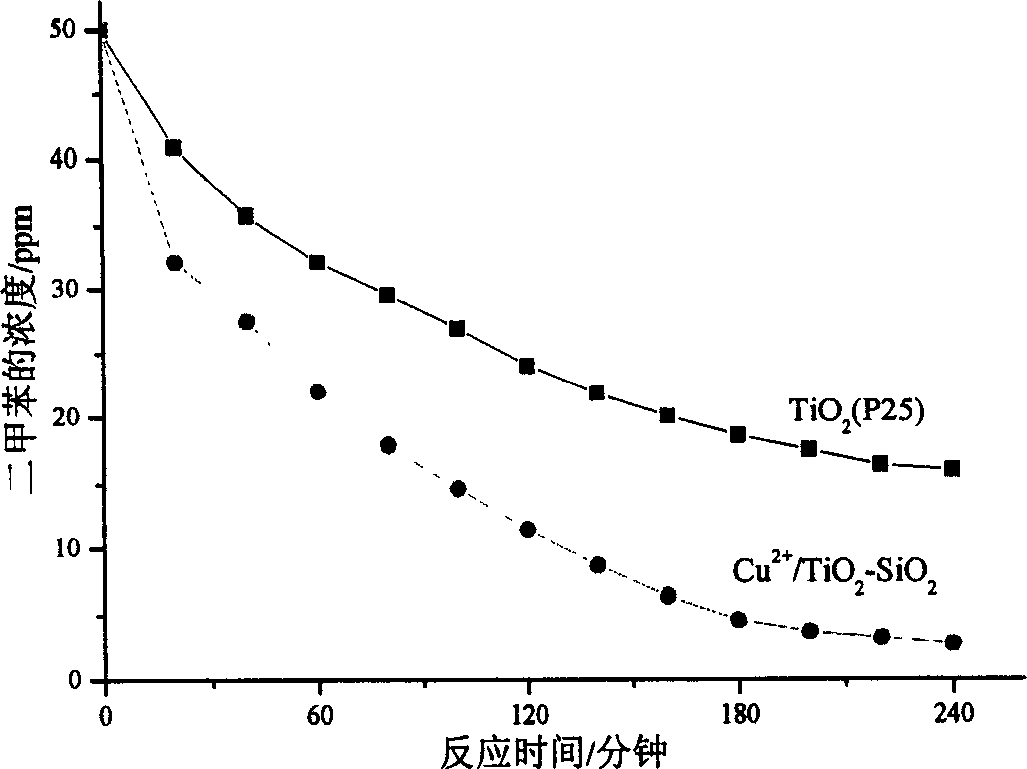

A nano-catalyst, sol technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of complex photodeposition process, low activity and expensive equipment and other problems, to achieve the effect of reasonable process, low production cost and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Measure 20ml of absolute ethanol, 15ml of glacial acetic acid and 1.64ml of ethyl orthosilicate into the conical flask, mix evenly at 25°C, drop 8ml of deionized water into the conical flask at a rate of 5 drops / min, After dropping, stir at 60 rpm for 15 min to obtain transparent SiO 2 Sol. Weigh 10ml of butyl titanate and add SiO at a rate of 8 drops / min 2 In the sol, TiO was obtained after stirring at 60 rpm for 15 minutes after dropping. 2 -SiO 2 Sol. Then 2.94ml of copper nitrate solution (concentration is 0.5mol / L) was dripped into TiO at a rate of 5 drops / min. 2 -SiO 2 After the sol was dropped and stirred at 60 rpm for 40 minutes, the sol was allowed to stand in a natural state to obtain translucent Cu 2+ / TiO 2 -SiO 2 The gel was dried at room temperature for 48 hours, and then dried in a drying oven at 80°C for 36 hours. Finally, the dried Cu 2+ / TiO 2 -SiO 2 The dry gel is heated to 500°C in a muffle furnace, the heating voltage is 110V, the heatin...

Embodiment 2

[0019] Measure 18ml of absolute ethanol, 14ml of glacial acetic acid and 1.64ml of ethyl orthosilicate into the conical flask, mix evenly at 30°C, drop 7ml of deionized water into the conical flask at a rate of 5 drops / min, After dropping, stir at 80 rpm for 20min to obtain transparent SiO 2 Sol. Weigh 10ml of butyl titanate and add SiO at a rate of 8 drops / min 2 In the sol, after dropping and stirring for 20min, TiO 2 -SiO2 Sol. Then 2.94ml of copper nitrate solution (concentration is 0.5mol / L) was dripped into TiO at a rate of 5 drops / min. 2 -SiO 2 Sol, after dropping and stirring for 60min, leave the sol in a natural state to obtain translucent Cu 2+ / TiO 2 -SiO 2 The gel was dried at room temperature for 72 hours, and then dried in a drying oven at 80°C for 48 hours. Finally, the dried Cu 2+ / TiO 2 -SiO 2 The dry gel is heated to 500°C in a muffle furnace, the heating voltage is 110V, the heating rate is 5°C / min, and the temperature is kept at a constant tempera...

Embodiment 3

[0021] Measure 40ml of absolute ethanol, 30ml of glacial acetic acid and 3.28ml of ethyl orthosilicate into the conical flask, mix evenly at 20°C, drop 15ml of deionized water into the conical flask at a rate of 5 drops / min, After dropping, stir at 100 rpm for 10 min to obtain transparent SiO 2 Sol. Weigh 20ml of butyl titanate and add SiO at a rate of 8 drops / min 2 In the sol, TiO was obtained after stirring for 10 minutes after dropping 2 -SiO 2 Sol. Then 5.88ml of copper nitrate solution (concentration is 0.5mol / L) was dripped into TiO at a rate of 5 drops / min. 2 -SiO 2 Sol, after dropping and stirring for 30min, let the sol stand in a natural state to obtain translucent Cu 2+ / TiO 2 -SiO 2 The gel was dried at room temperature for 64 hours, and then dried in a drying oven at 80°C for 42 hours. Finally, the dried Cu 2+ / TiO 2 -SiO 2 The dry gel is heated to 500°C in a muffle furnace, the heating voltage is 110V, the heating rate is 5°C / min, and the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com