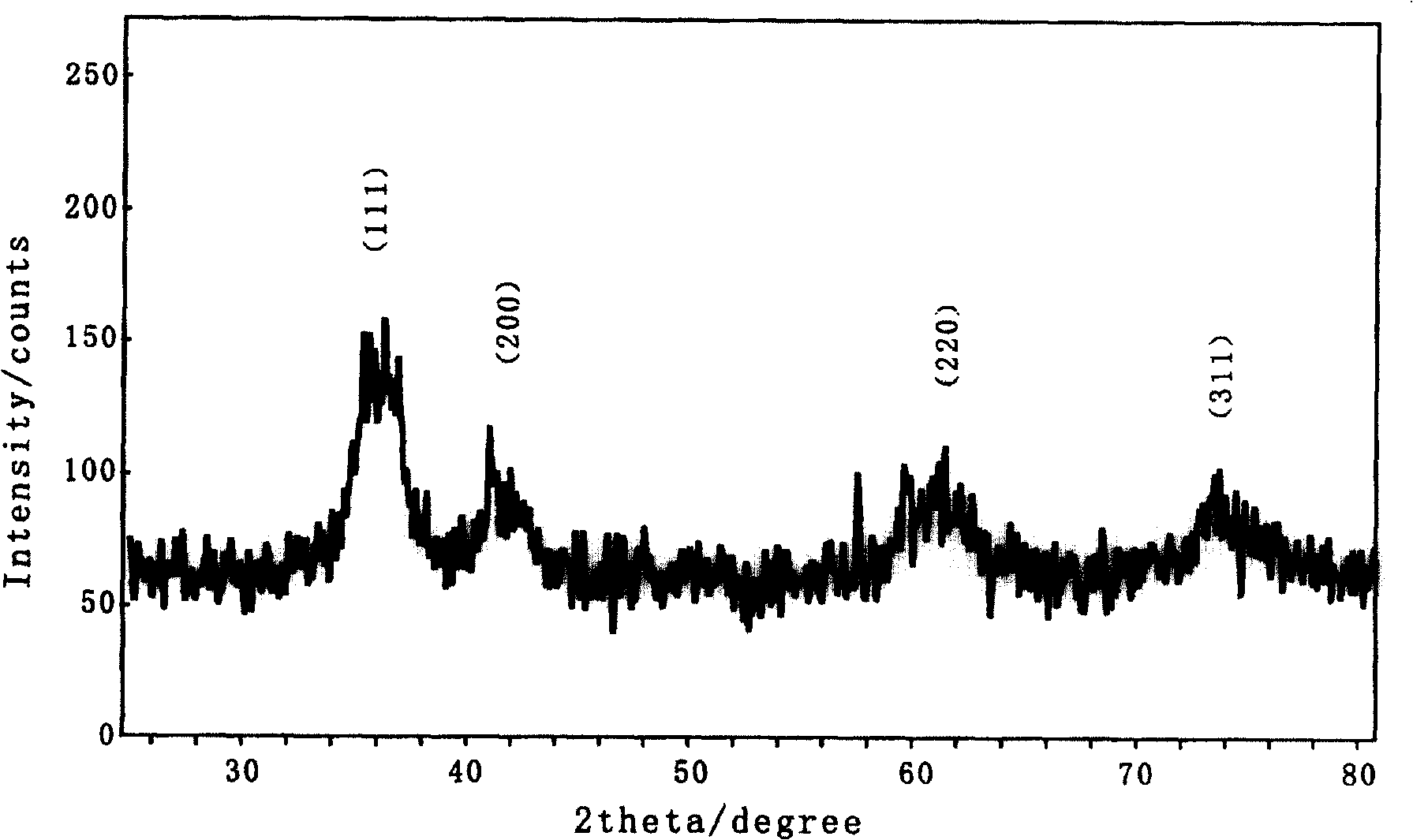

Preparing Nano Ag/CeO2 catalyst possessing catalytic activity of visible light

A catalytic activity, visible light technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problem of high investment in degradation equipment and degradation operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method of the present invention to prepare nano-Ag / CeO with visible light catalytic activity 2 The method of catalyst, its technique comprises following two parts:

[0018] (A) From Ce(NO 3 ) 3 ·6H 2 O to prepare CeO 2 Hydrosol part;

[0019] (B) with the above CeO 2 Preparation of Ag / CeO from Hydrosol as Feed Liquid 2 Catalyst part.

[0020] From Ce(NO 3 ) 3 ·6H 2 O to prepare CeO 2 For the hydrosol part, the process steps are as follows:

[0021] (A-1) with Ce(NO 3 ) 3 ·6H 2 O is the raw material, using the two-step precipitation method (see Document 3, B.Djuricic, S.Pickering.Nanostructured Cerium oxide preparation and properties of weakly-agglomerated powders.J.ofMater.Sci..34(1999), 1911~1919) Preparation of CeO 2 , namely: to Ce(NO 3 ) 3 Add H to the solution 2o 2 , and then dripped dilute ammonia water to obtain an orange precipitate, which was separated and washed to obtain CeO 2 precipitation;

[0022] (A-2) the gained CeO 2 Suspend in ...

Embodiment 2

[0042] A method of the present invention to prepare nano-Ag / CeO with visible light catalytic activity 2 The method of catalyzer, its material liquid and processing step are similar to embodiment 1, but in step (B-1) use hexamethylenetetramine instead as precipitant, in step (B-2) adopt simple impregnation method to prepare Ag / CeO 2 Sample, namely the hydrated cerium oxide product 5.80g (CeO 2 content is 58.3%) adding AgNO with a concentration of 0.05mol / L 3 In 10ml of the solution, after stirring for 1 hour in the dark, dry it in an oven at 110°C, and bake it in a muffle furnace at 500°C for 3 hours to obtain Ag / CeO with a silver content of 1.6%. 2 Sample 4#.

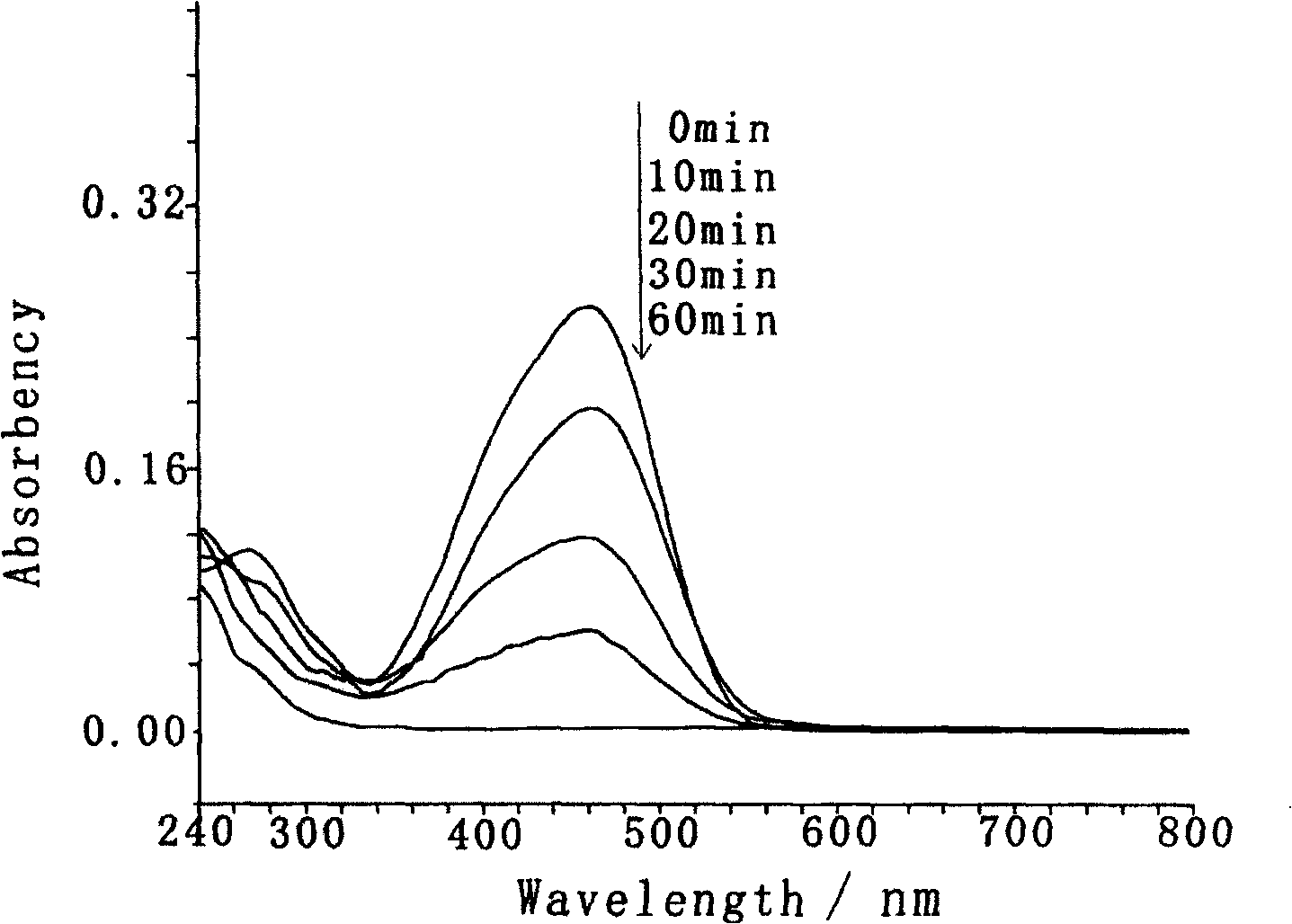

[0043] The sample 4# was used to degrade the dye methylene blue under sunlight irradiation, the degradation conditions were the same as in Example 1, and the degradation rate was 46.4% in 3 hours.

Embodiment 3

[0045] A method of the present invention to prepare nano-Ag / CeO with visible light catalytic activity 2 The method of catalyst, with the aqueous solution of mixed rare earth chloride containing cerium (III) and non-cerium rare earth as starting material, in the mixed rare earth chloride solution that mixed rare earth oxide content is 100 g / liter, add equivalent rare earth oxide Ammonia water of 1.2 times of the total amount (denoted as TREO) is used to precipitate mixed rare earth chlorides as mixed hydroxides, and then add hydrogen peroxide equivalent to 0.37TREO to oxidize cerium (III) in mixed rare earth hydroxides to cerium (IV) , and then heat the resulting reddish-brown suspension to turn it into yellow, then slowly add hydrochloric acid under stirring to selectively dissolve the hydroxides of non-cerium rare earths, make the suspension clear, and obtain CeO 2 Hydrosol. To the above CeO 2 Add urea equivalent to 0.08TREO into the hydrosol, and heat the system. After abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com