Method for preparing surface patterned SiO2 high molecular composite microsphere

A technology of silicon dioxide and composite microspheres, applied in the field of chemistry or physics, can solve the problems of complex preparation process of layer-by-layer assembly method, difficult to form single type particles, difficult to form structural composite materials, etc., and achieves feasible process and low quality. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

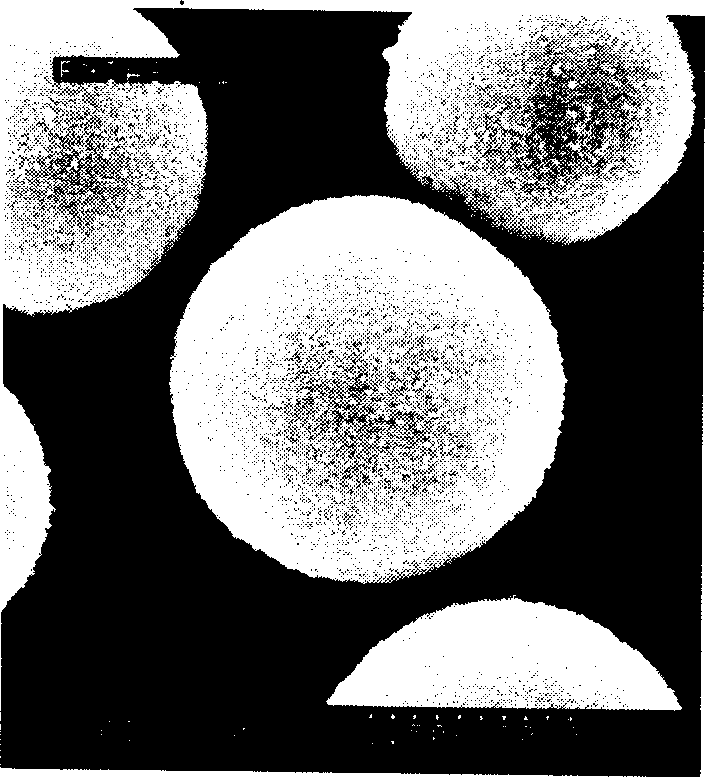

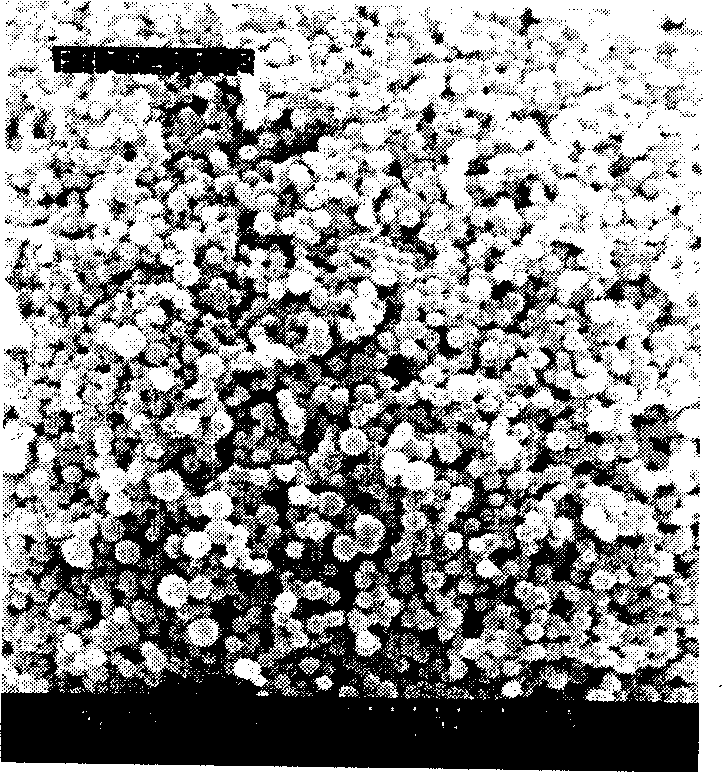

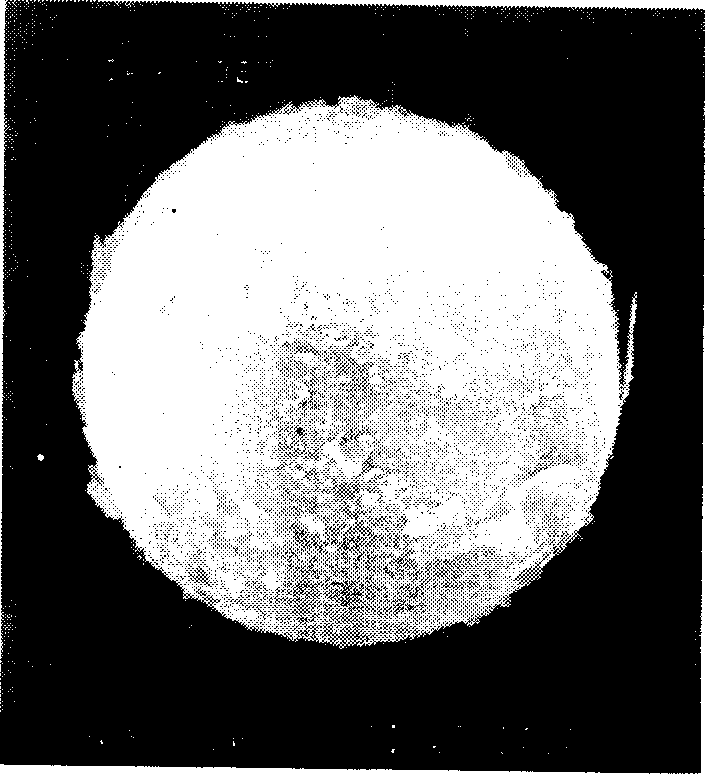

Image

Examples

Embodiment 1

[0040] 1. Preparation of mixed surfactants

[0041] Mix Span-80 and Tween-80 at a weight ratio of 5:1 to prepare a mixed surfactant.

[0042] 2. Preparation of synthetic template oil phase

[0043] Add the mixed surfactant prepared in step 1 into a three-necked flask filled with n-heptane, and mix the mixed surfactant and n-heptane at a weight ratio of 1:122 to prepare a synthetic template oil phase.

[0044] 3. Preparation of emulsion

[0045] Put the synthetic template oil phase prepared in step 2 into a three-necked flask, stir with a stirrer at a stirring speed of 360-400 rpm, and inject N at a flow rate of 2-3 mL / min. 2 , emulsified at 25°C for 40-60 minutes to make an emulsion.

[0046] 4. Preparation of water phase

[0047] Mix N,N'-methylene dienamide, ammonium persulfate, and N-isopropylacrylamide in a molar ratio of 1:1.17:28.3, stir evenly, and prepare solution A. The molar ratio of acrylic acid and NaOH is 1:0.6 to prepare acrylic acid aqueous solution with a ...

Embodiment 2

[0057] In this embodiment, in step 2 of the process of preparing the synthetic template oil phase, the mixed surfactant and n-heptane were mixed at a weight ratio of 1:115 to prepare the synthetic template oil phase. In the process step 3 of preparing the emulsion, the emulsification temperature is 18°C. In step 4 of the preparation of the aqueous phase, the molar ratio of acrylic acid and NaOH is 1:0.3 to prepare an aqueous acrylic acid solution with a concentration of 23%. In Step 6 of the process for preparing the swollen copolymerized microgel, the microgel was swelled with ammonia water at a concentration of 9%. In step 8 of the process of preparing surface-patterned silica polymer composite microspheres, the reaction temperature is 18°C. Other processing steps are identical with embodiment 1.

Embodiment 3

[0059] In this embodiment, in step 2 of the process of preparing the synthetic template oil phase, the mixed surfactant and n-heptane were mixed at a weight ratio of 1:130 to prepare the synthetic template oil phase. In the process step 3 of preparing the emulsion, the emulsification temperature is 30°C. In step 4 of the preparation of the aqueous phase, the molar ratio of acrylic acid and NaOH is 1:1 to prepare an aqueous acrylic acid solution with a concentration of 23%. In step 6 of the process of preparing the swollen copolymerized microgel, the microgel was swollen with ammonia water at a concentration of 28%. In step 8 of the process of preparing surface-patterned silica polymer composite microspheres, the reaction temperature is 34°C. Other processing steps are identical with embodiment 1.

[0060] In order to determine the best processing step of the present invention, the inventor has carried out a large amount of laboratory research tests, and various test situatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com