Tail gas collecting system of silicon carbide smelting furnace

A technology for exhaust gas collection and smelting furnace, applied in silicon carbide, carbide and other directions, can solve the problems of inability to collect gas, environmental pollution, waste, etc., to reduce CO pollution to the environment and harm to workers' health and investment costs Low cost and the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below by means of the accompanying drawings and specific embodiments.

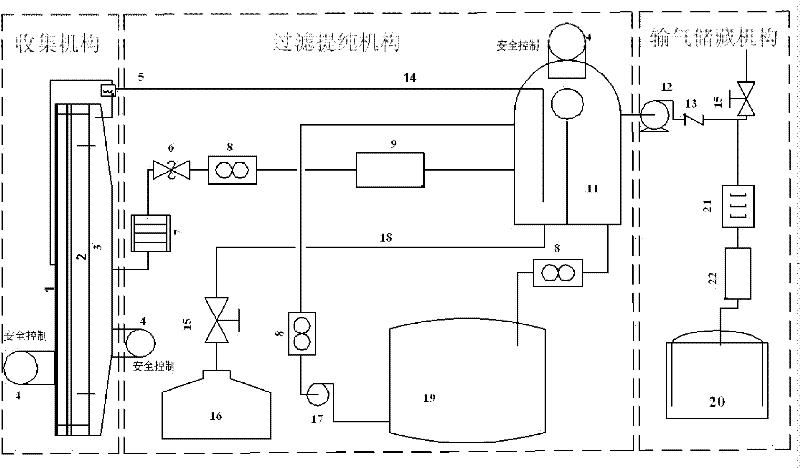

[0030] Such as figure 1 As shown, the silicon carbide smelting furnace exhaust gas collection system includes three interconnected collection mechanisms, filtration and purification mechanisms, and gas transmission and storage mechanisms. Among them: the collection mechanism is connected with the smelting furnace wall of the system, and the collection mechanism is in turn connected with the filtration and purification mechanism It is connected with the gas transmission and storage mechanism; the collection mechanism and the filtration and purification mechanism are respectively equipped with safety control mechanisms.

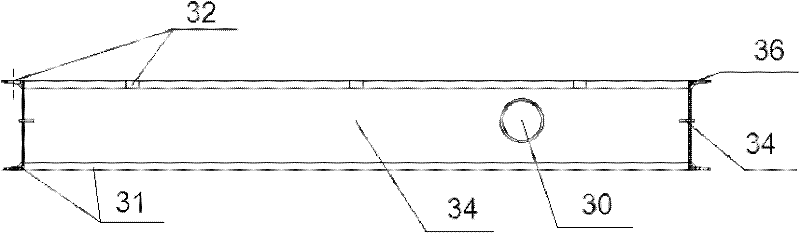

[0031] The collection mechanism includes a collection cover base 1, a collection cover 3 and shutters 2. The collection cover base 1 is fixedly connected to the furnace wall of the smelting furnace, and the collection cover 3 is connected to on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com