Airfoil type axial-flow stirrer

An axial flow, agitator technology, applied in mixers with rotary stirring devices, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc., can solve the problem of increasing agitator vibration, large fluid resistance, Less specifications, etc., to achieve the effect of strengthening axial circulation and flow, optimizing hydraulic performance, and improving flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

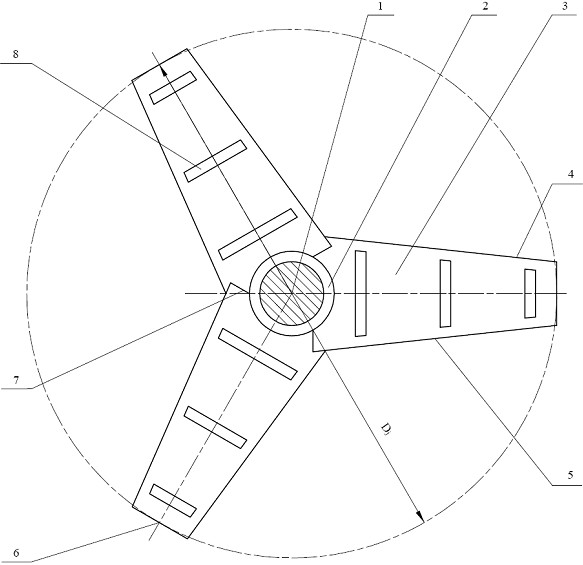

[0020] A nitration reaction kettle with an effective volume of 50 L, the inner diameter of the reaction kettle is 500 mm, and the height-to-diameter ratio of the kettle body is 1. The airfoil axial flow agitator designed by the present invention is used for the nitration reaction. The structure of the agitator is shown in the attached figure 1 to attach Figure 5 .

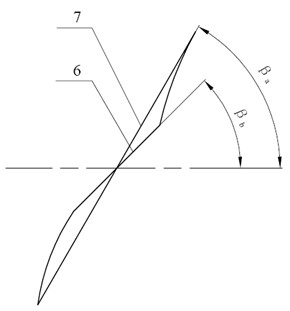

[0021] The diameter of the airfoil impeller D j The ratio to the inner diameter of the reactor is 0.5, and the pitch angle β at the end of the blade b is 45°, the pitch angle β at the blade root a is 60°, the pitch angle β of any section at different radii from the blade tip to the blade root i Designed according to equal pitch structure, pitch angle β i It increases continuously from the tip of the blade to the root of the blade. The ratio of the arc height h to the chord length a of an arc of any cross section is 0.06. The blade width of the paddle blade gradually increases from the blade end to the blade ...

Embodiment 2

[0024] A nitration reaction kettle with an effective volume of 200 L and an inner diameter of 700 mm uses the airfoil axial flow agitator designed by the present invention for nitration reaction. For the structure of the agitator, see the attached figure 1 to attach Figure 5 .

[0025] The diameter of the airfoil impeller D j The ratio to the inner diameter of the reactor is 0.4, D j =280 mm. The pitch angle β at the tip of the blade b is 45°, the pitch angle β at the blade root a is 60°, the pitch angle β of any section at different radii from the blade tip to the blade root i Designed according to equal pitch structure, pitch angle β i It increases continuously from the tip of the blade to the root of the blade. The ratio of the arc height h to the chord length a of an arc of any cross section is 0.06. The blade width of the paddle blade gradually increases from the blade end to the blade root, and the width B of the blade end b is 35 mm, the width B of the blade r...

Embodiment 3

[0028] The nitrification reaction kettle with an effective volume of 700 L, the inner diameter of the reaction kettle is 1000 mm, and the airfoil axial flow agitator designed by the present invention is used for the nitrification reaction. The structure of the agitator is shown in the appendix. figure 1 to the attached Figure 5 .

[0029] The diameter D of the airfoil stirring paddle j The ratio to the inner diameter of the reactor is 0.45, D j =450mm. The pitch angle β of the blade end b is 45°, the pitch angle β at the root of the blade a is 60°, the pitch angle β of any section at different radii from the end of the blade to the root of the blade i Designed according to the equal pitch structure, the pitch angle β i It increases continuously from the tip of the blade to the root of the blade. The ratio of the arc height h to the chord length a of any cross-sectional arc is 0.06. The blade width of the paddle blade gradually increases from the blade end to the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com