Patents

Literature

192results about How to "Escape smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

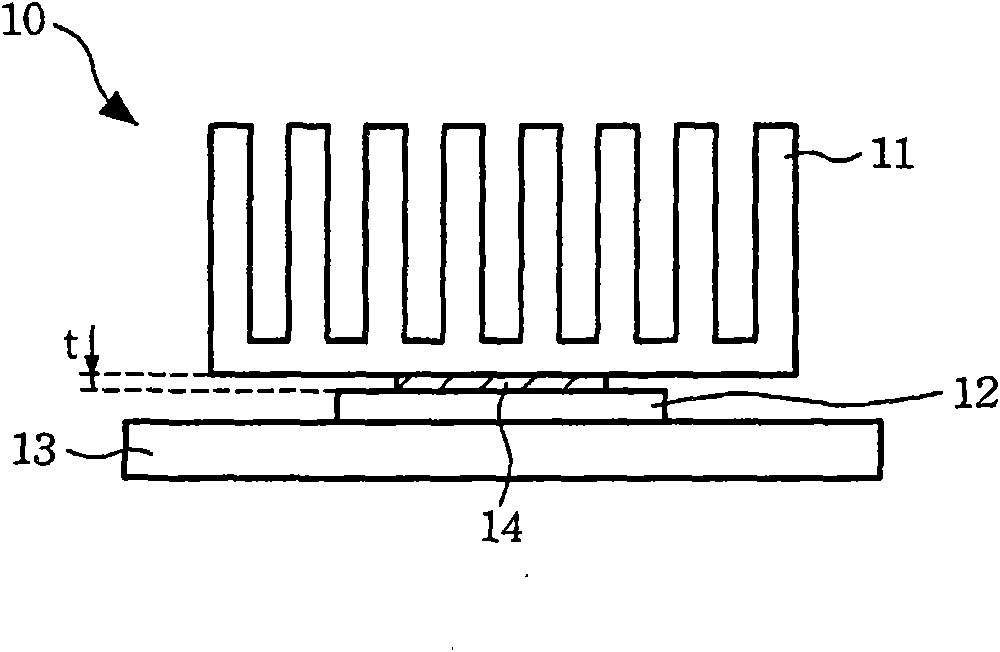

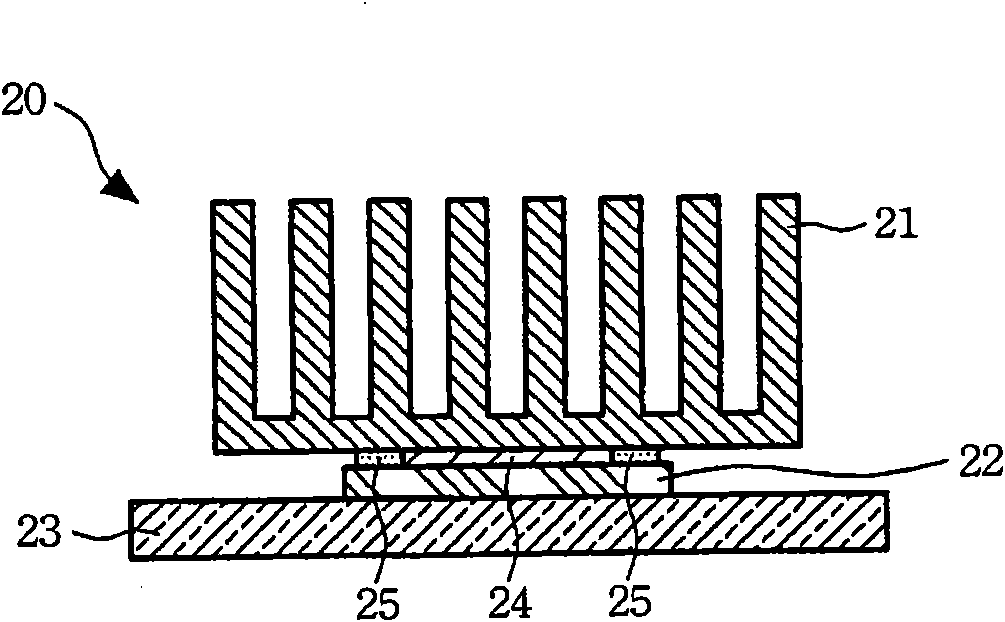

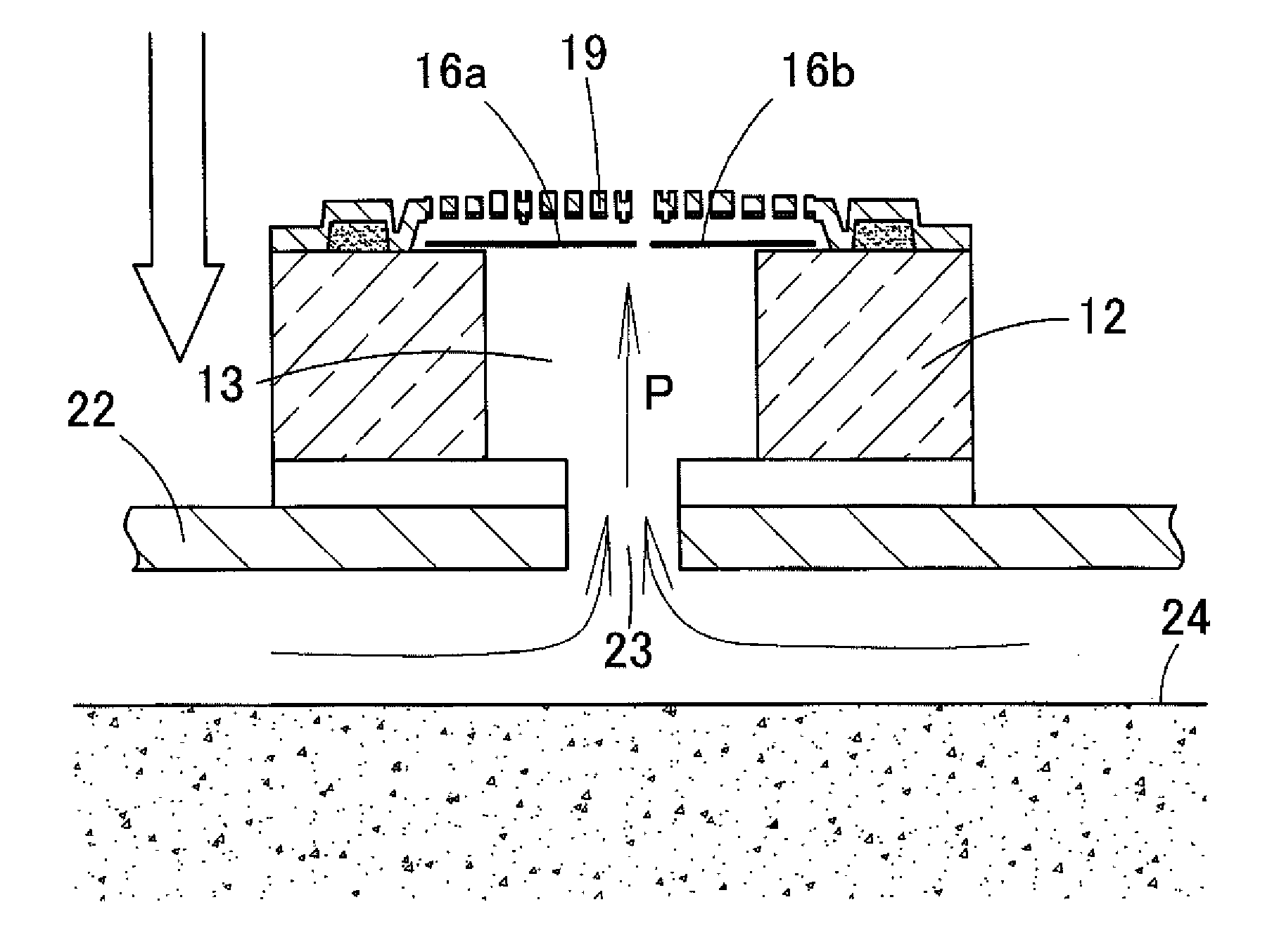

Heat radiation die set and radiation system applying phase change metal thermal interface material

InactiveCN101557697AAvoid the problem of liquid phase spillageAvoid spillingSemiconductor/solid-state device detailsSolid-state devicesElectronic componentPhase change

The invention relates to a heat radiation die set and a radiation system applying a phase change metal thermal interface material. The heat radiation die set and the heat radiation system can ensure that heat generated by the operation of an electronic element can be rapidly transmitted to outside environments. The heat radiation die set comprises a radiator and a phase change metal thermal interface material (TIM), wherein the radiator is arranged above the electronic element, and the bottom surface of the radiator is at least provided with a slot. The phase change metal thermal interface material is arranged between the electronic element and the bottom surface of the radiator, and is used as a thermal interface material between the electronic element and the radiator. When the phase change metal thermal interface material is melted by heating, part of hot melting liquid can flow into the slot so as to prevent the superfluous hot melting liquid from leaking out of a thermal interface.

Owner:萧复元

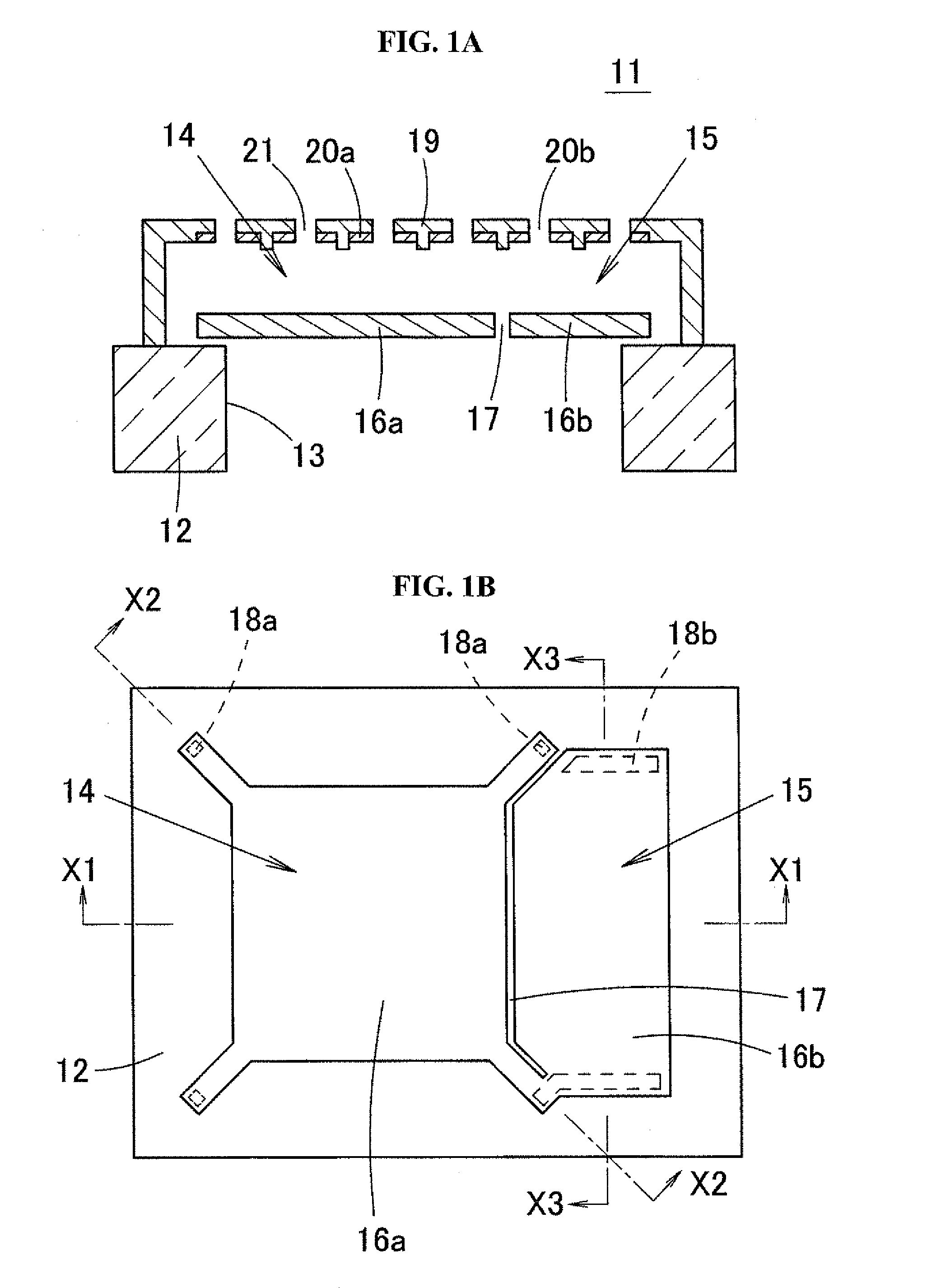

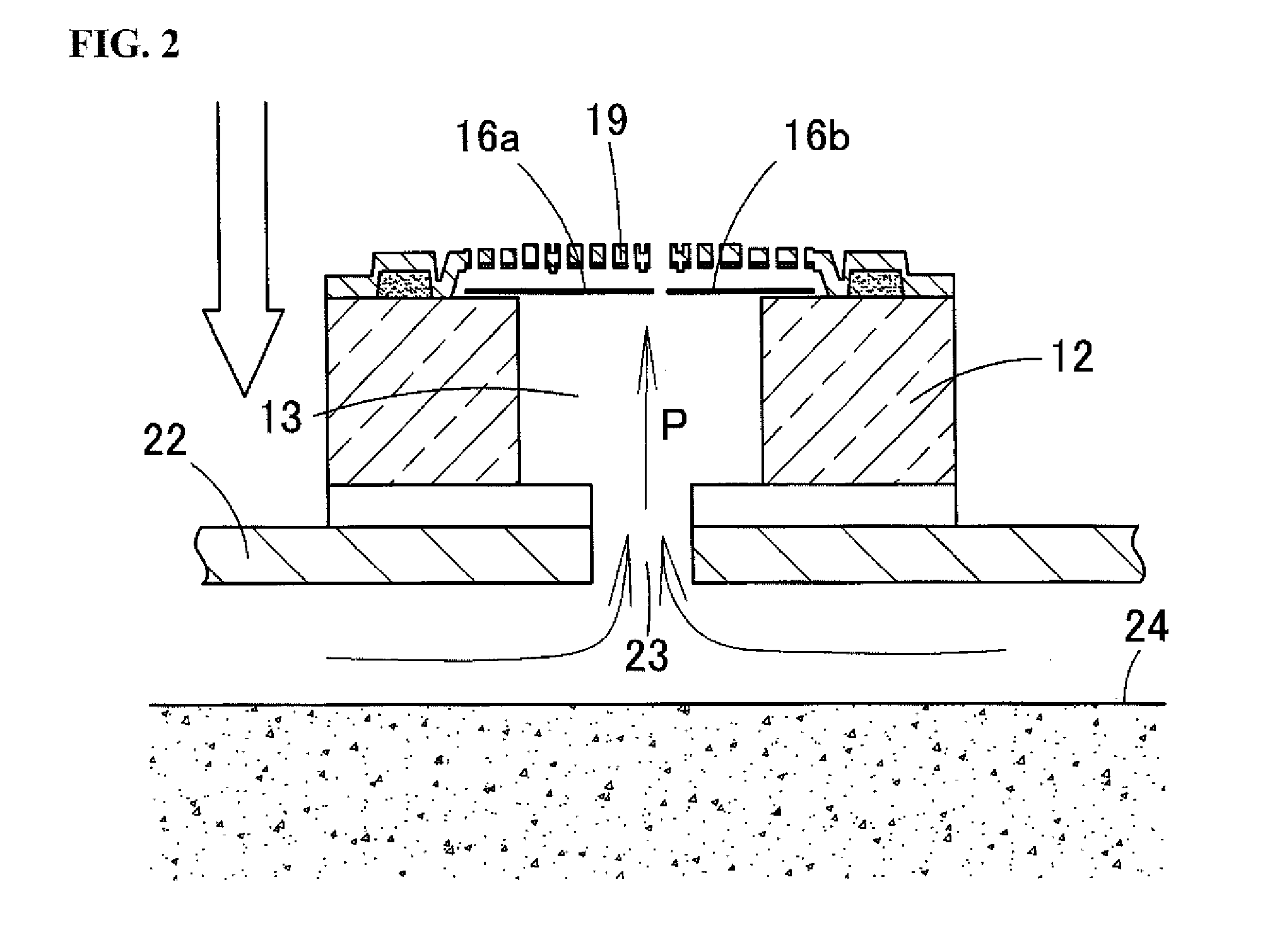

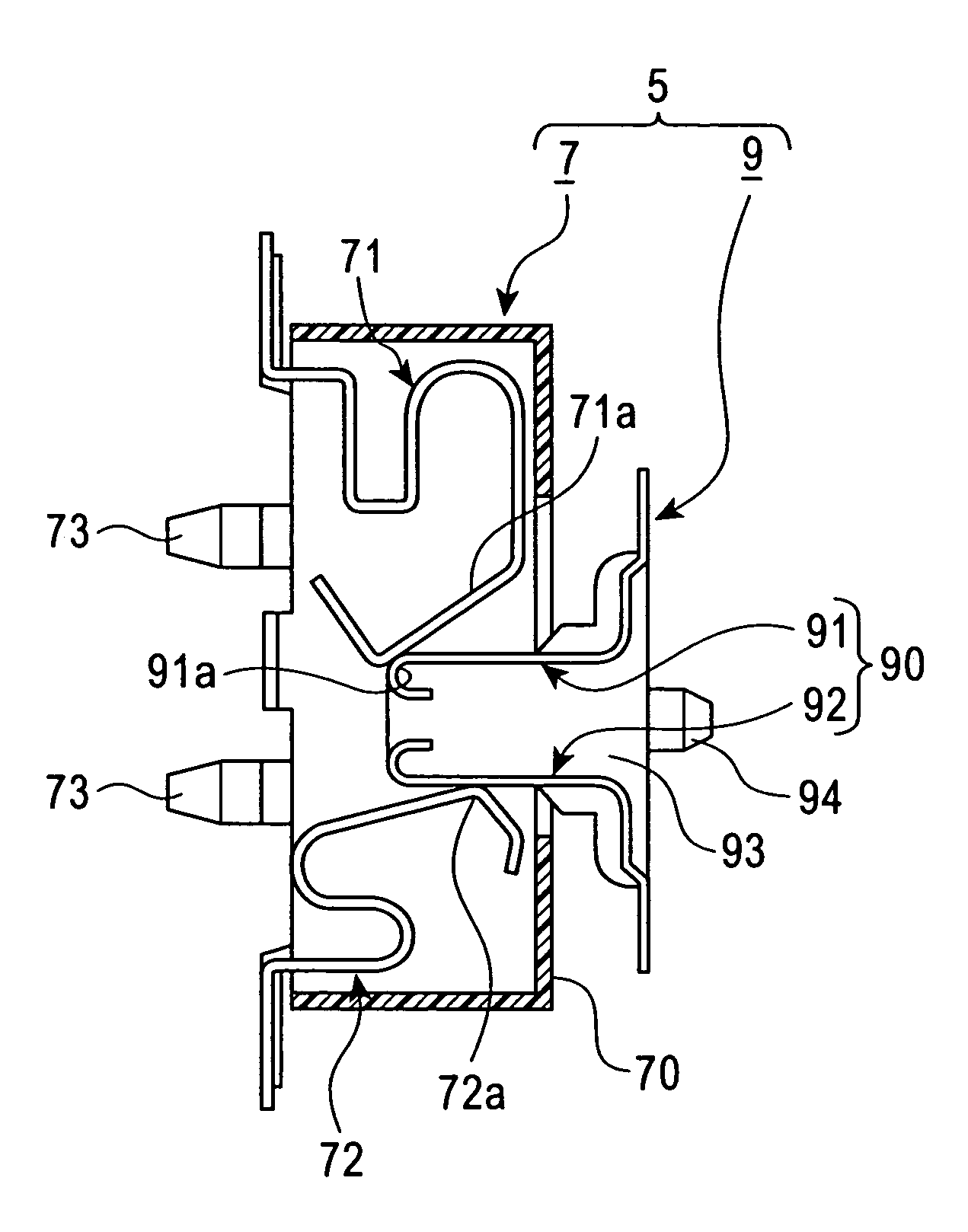

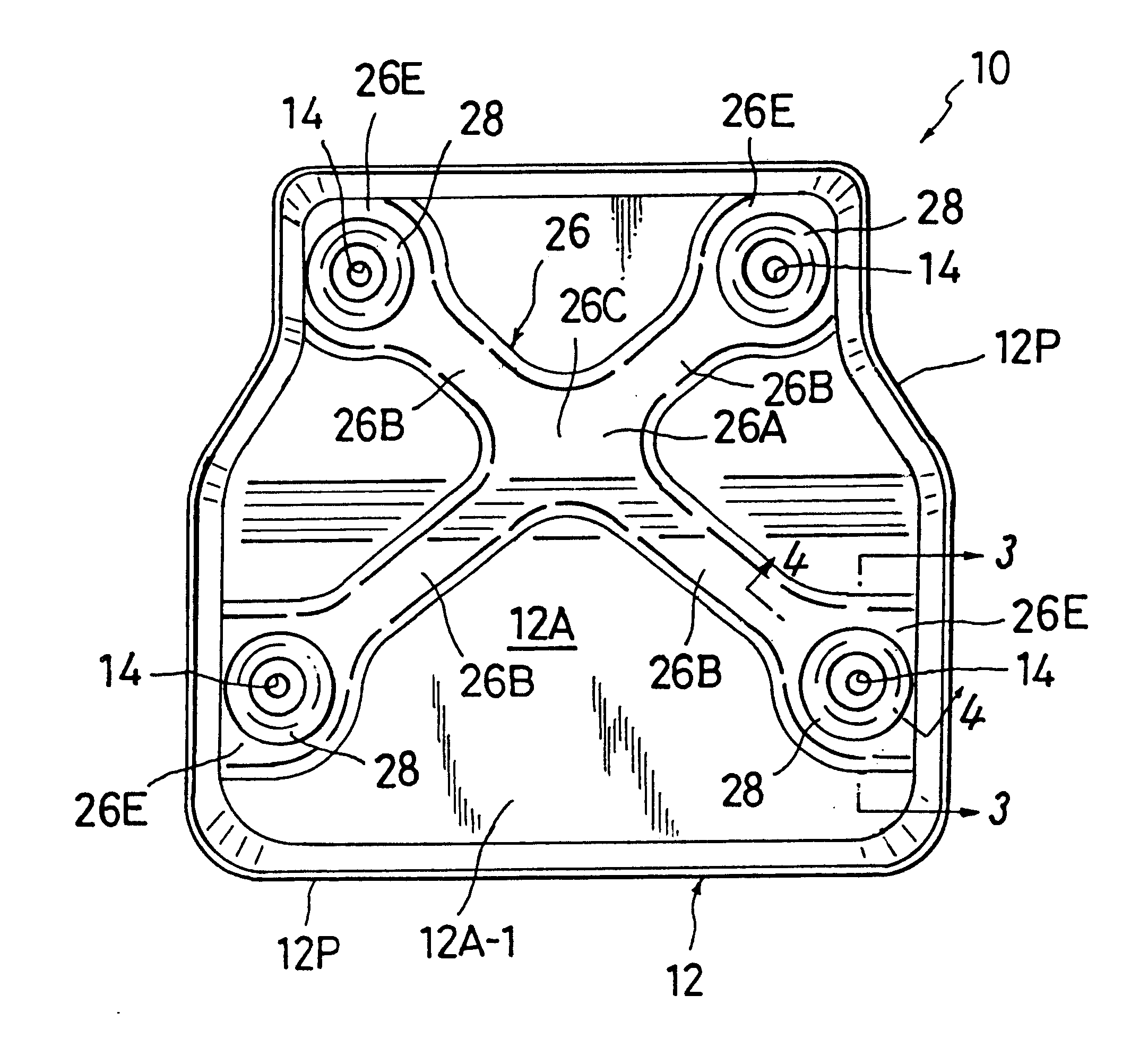

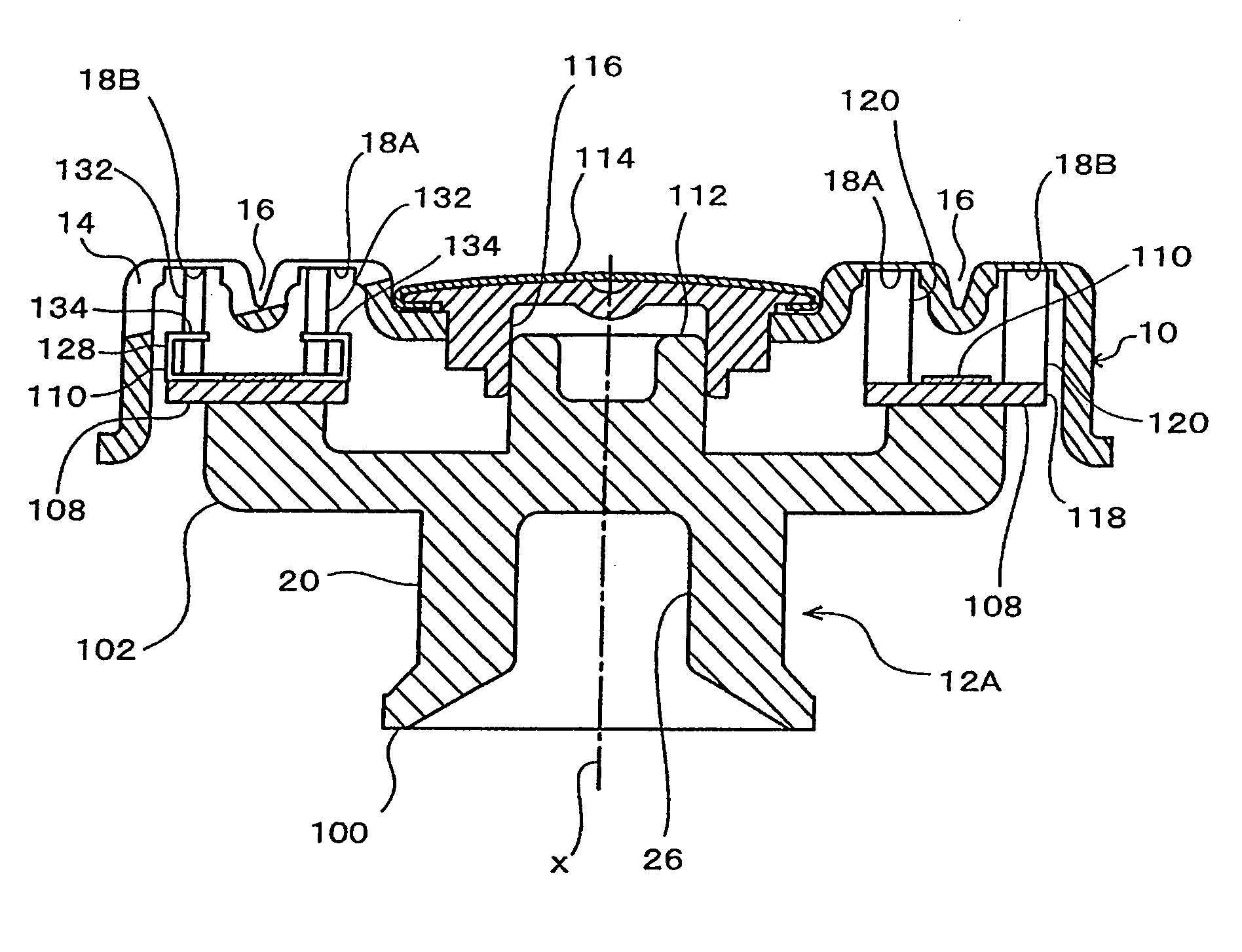

Acoustic transducer and microphone

ActiveUS20150078593A1Short pathEscape smoothlySemiconductor electrostatic transducersSolid-state devicesMicrophoneTransducer

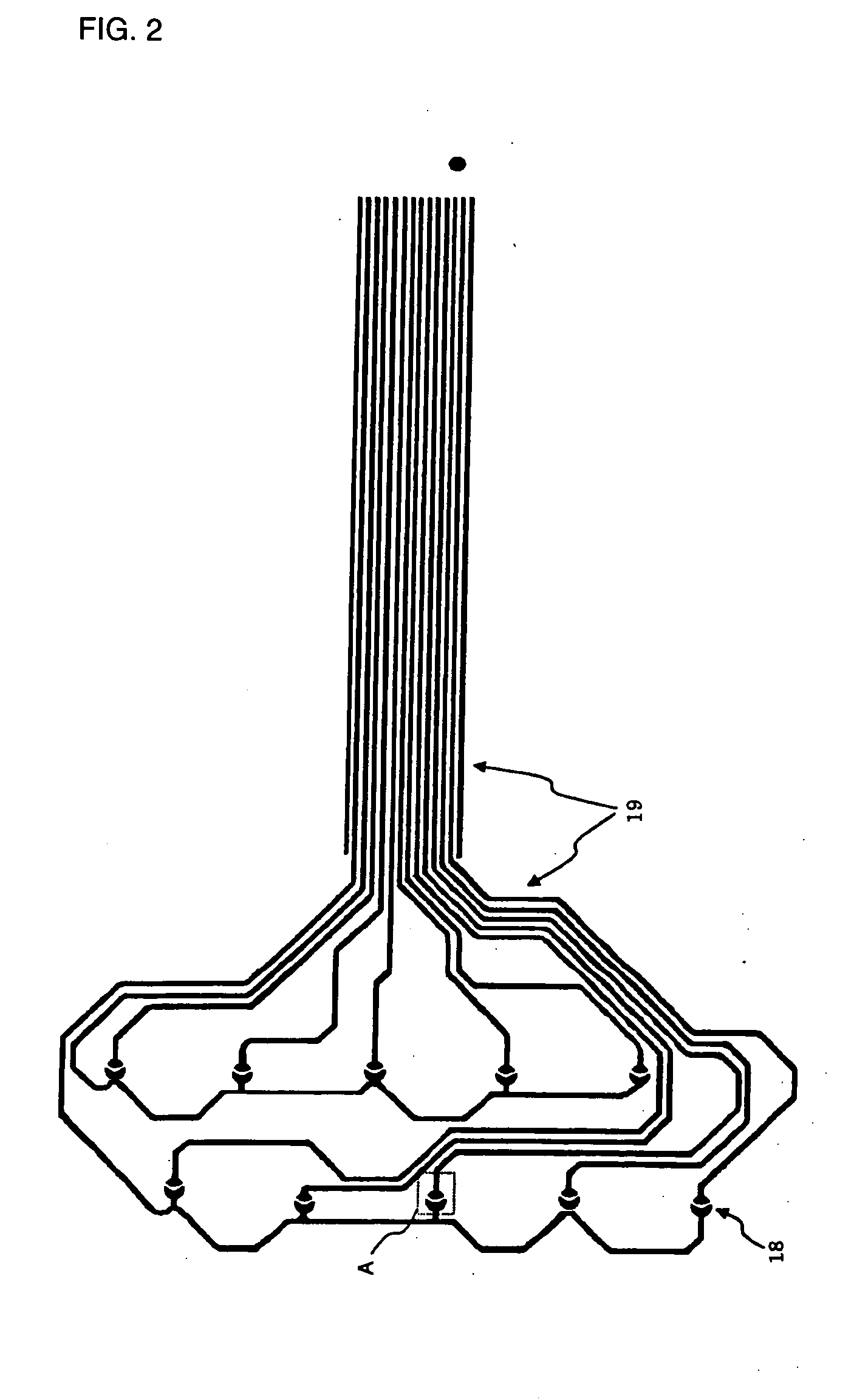

An acoustic transducer has a substrate having a cavity, a vibrating electrode plate disposed above the substrate and having a void portion that allows pressure to escape, a fixed electrode plate disposed above the substrate opposite the vibrating electrode plate, a plurality of sensing portions configured by the vibrating electrode plate and the fixed electrode plate, at least one of the vibrating electrode plate and the fixed electrode plate being divided into a plurality of regions, and a sensing portion being configured by the vibrating electrode plate and the fixed electrode plate in each of the divided regions, and a leak pressure regulation portion that hinders leakage of air pressure passing through the void portion when the vibrating electrode plate is not undergoing deformation.

Owner:MMI SEMICON CO LTD

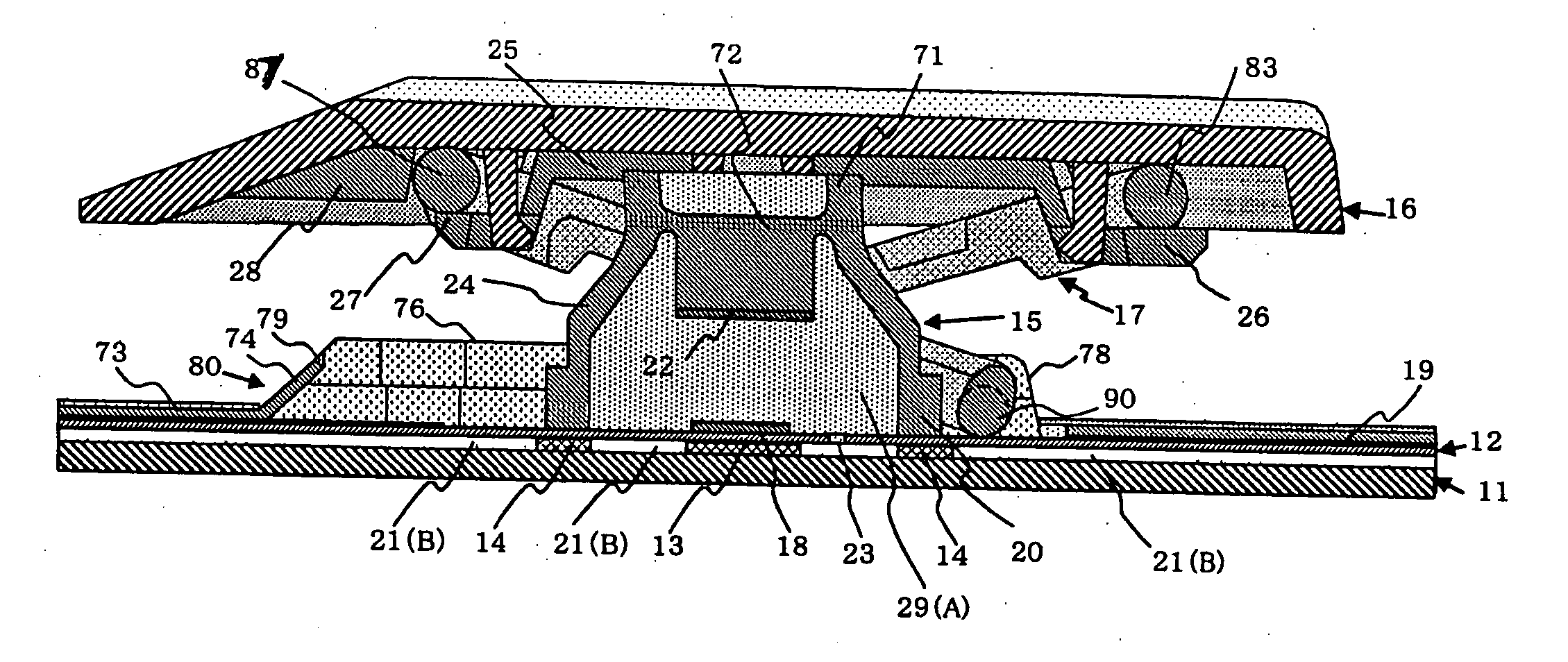

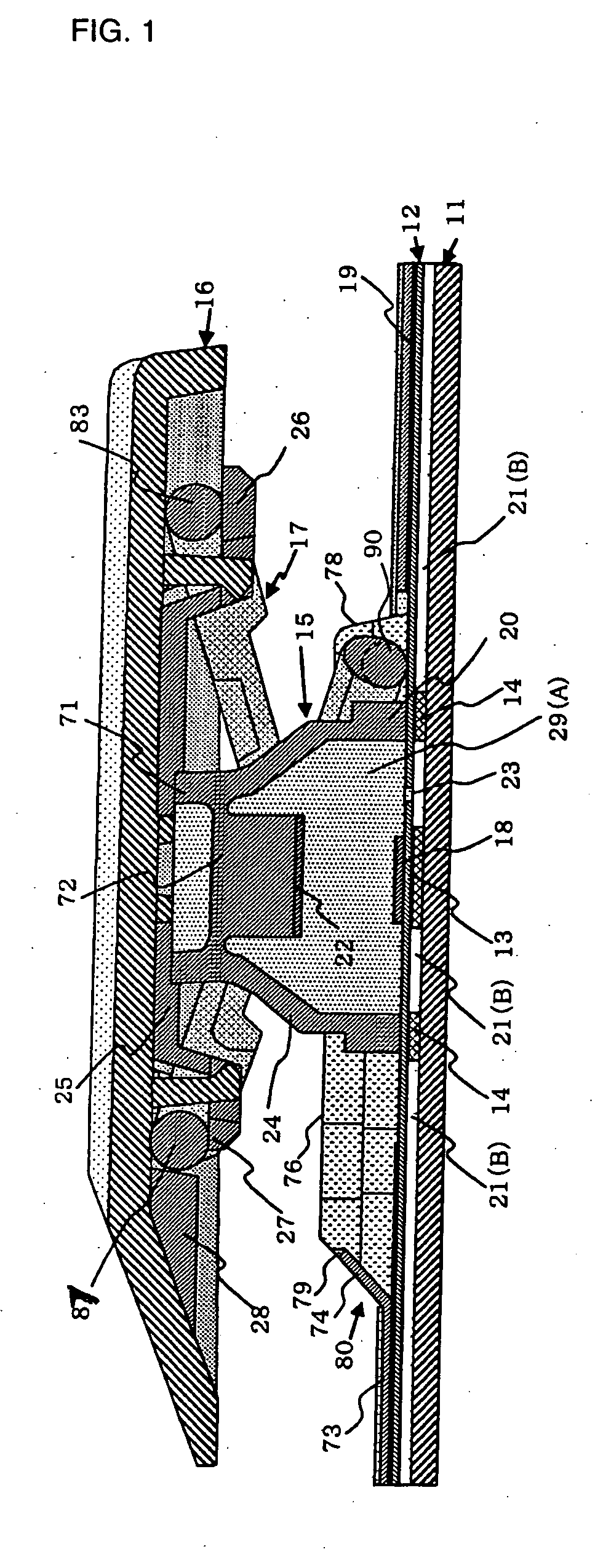

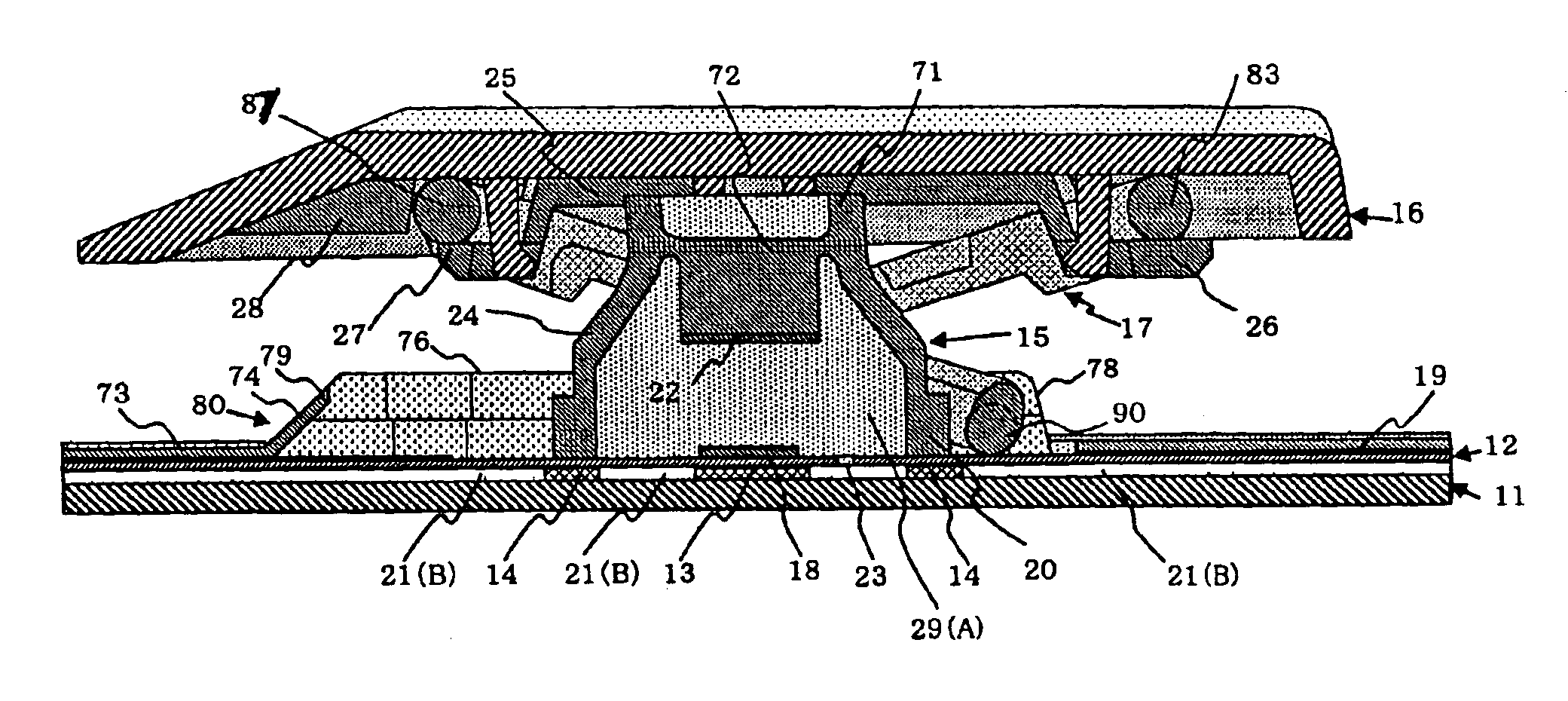

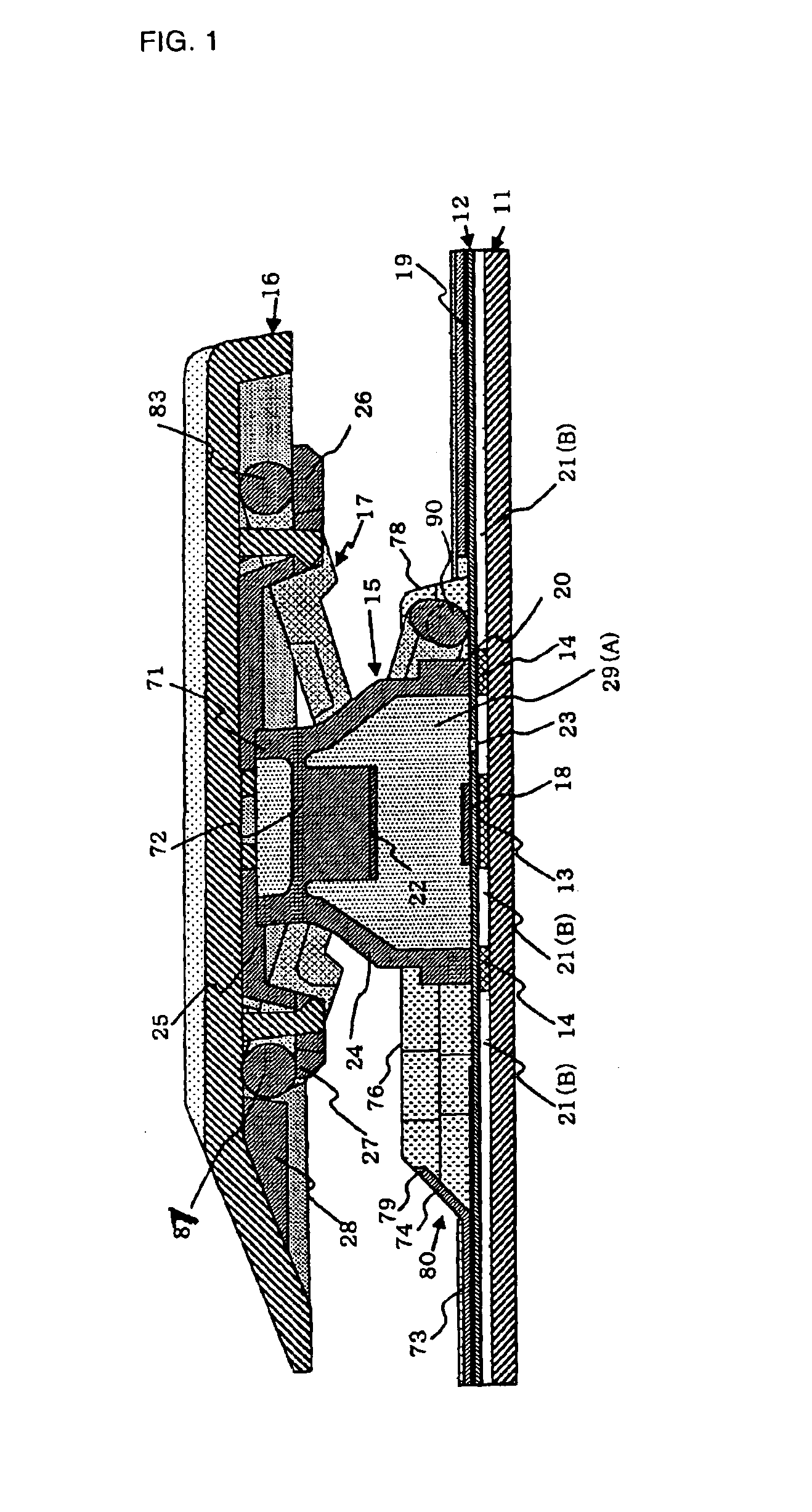

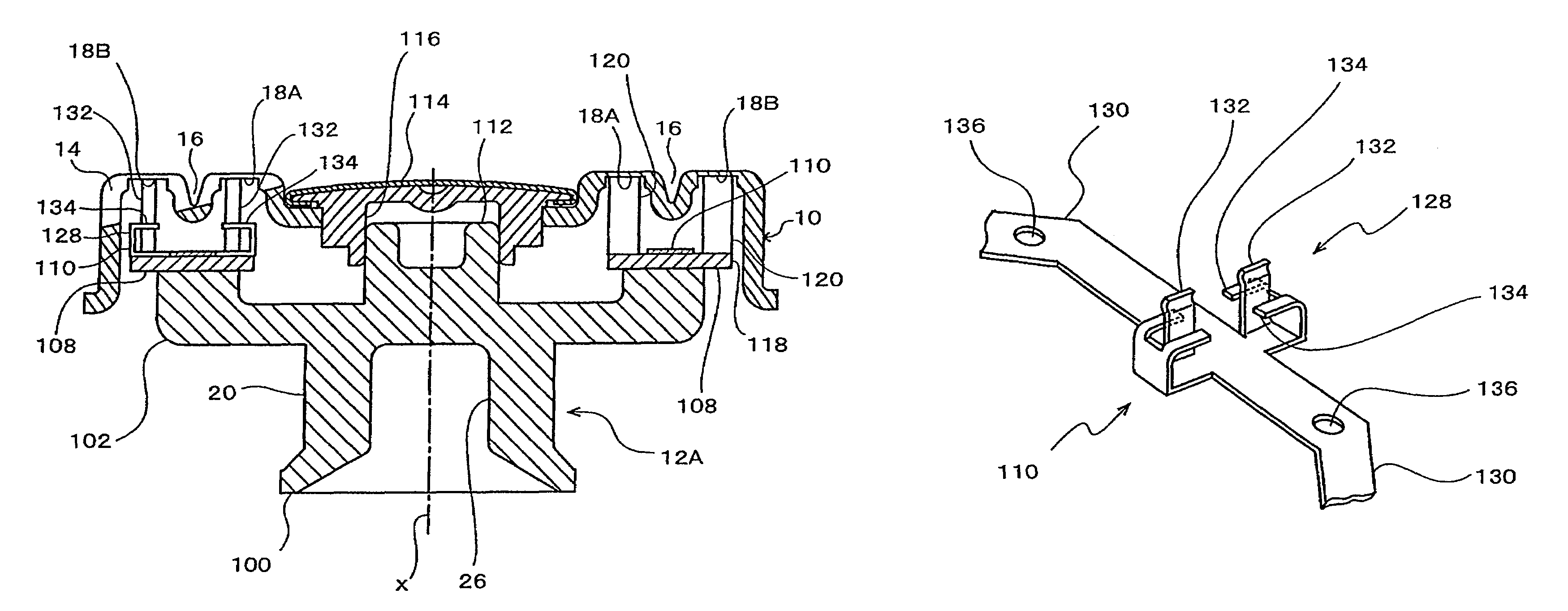

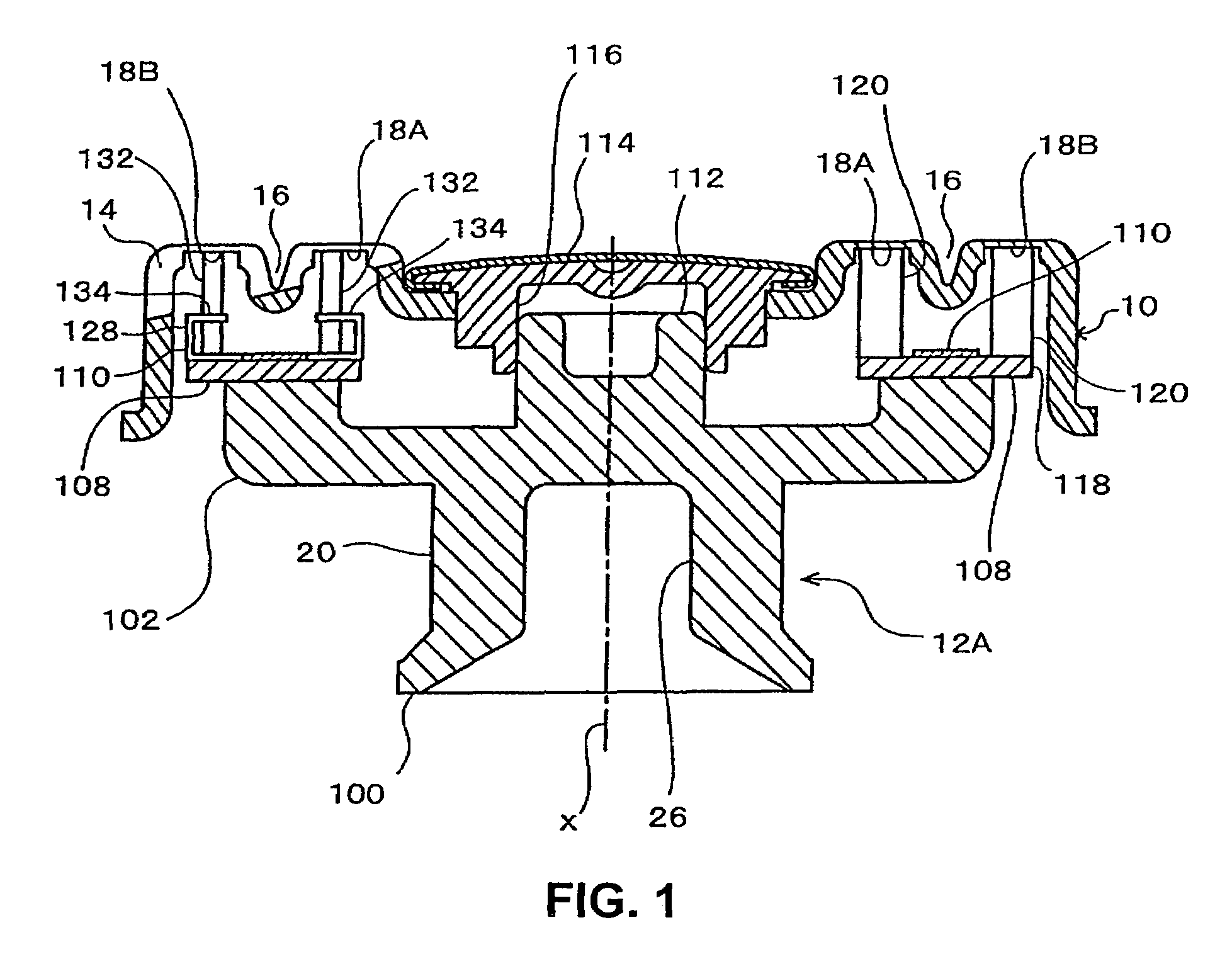

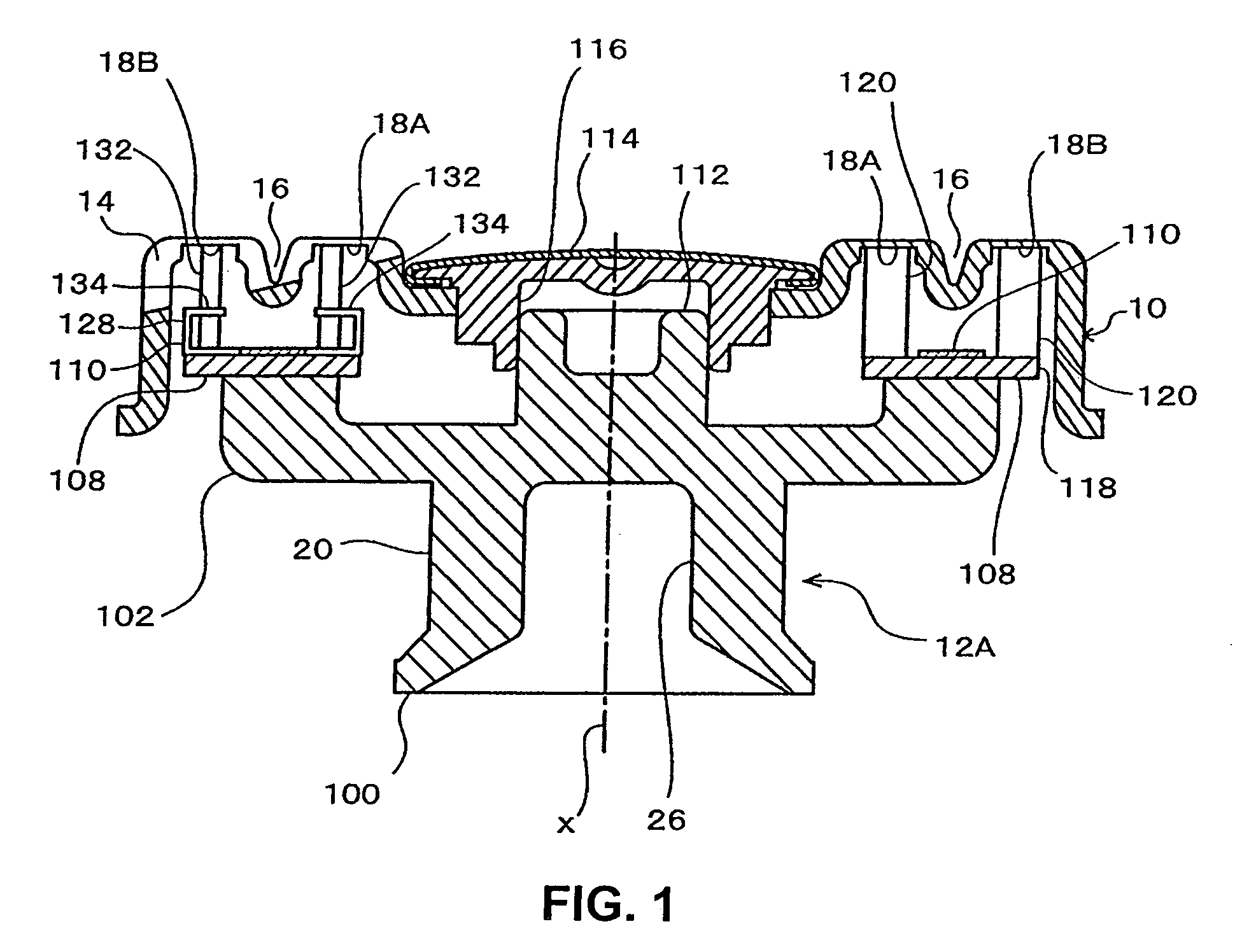

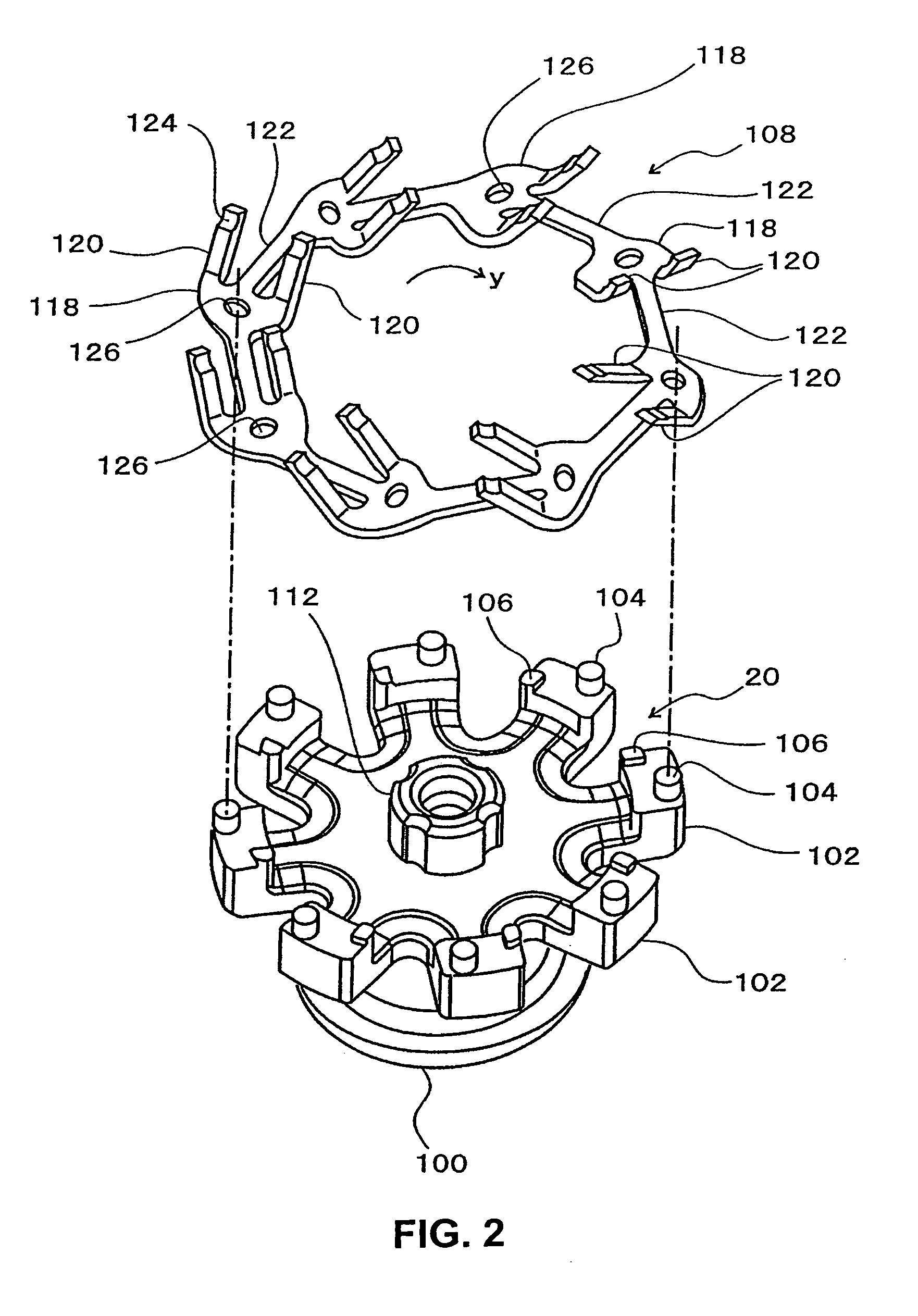

Keyboard switch with internal fluid containment network

ActiveUS20050000789A1Operation feeling can be improvedImprove operationContact surface shape/structureContact operating partsEngineeringElectrical and Electronics engineering

Owner:LITE ON SINGAPORE PTE LTD

Extrusion forming method for magnesium alloy housing type component ring ribs

The invention discloses an extrusion forming method for magnesium alloy housing type component ring ribs. The extrusion forming method comprises the following steps of: (1), placing a processed hollow blank in a barrel-shaped hollowing block; (2), symmetrically arranging at least two split terrace dies in an inner tube of the hollow blank, moving the split terrace dies in the radial direction, respectively extruding the inner tube wall surface of the hollow blank by extrusion bulges of the split terrace dies, forming a certain vacancy between the extrusion bulges of the two split terrace dies, enabling un-extruded part of the inner wall of the hollow blank to plastically flow towards the vacancy between the extrusion bugles to form radial bulges, and automatically returning the split terrace dies; and (3), rotating the split terrace dies by a certain angle to reach positions at which the extrusion bulges of the split terrace dies correspond to the radial bulges, circulating the extrusion operation in the step (2), retracting the extruded split terrace dies, extruding the ring ribs at the periphery, repeating the operations when the split terrace dies reach the position of the next ring rib, and finally forming the qualified housing component with the ring ribs.

Owner:ZHONGBEI UNIV

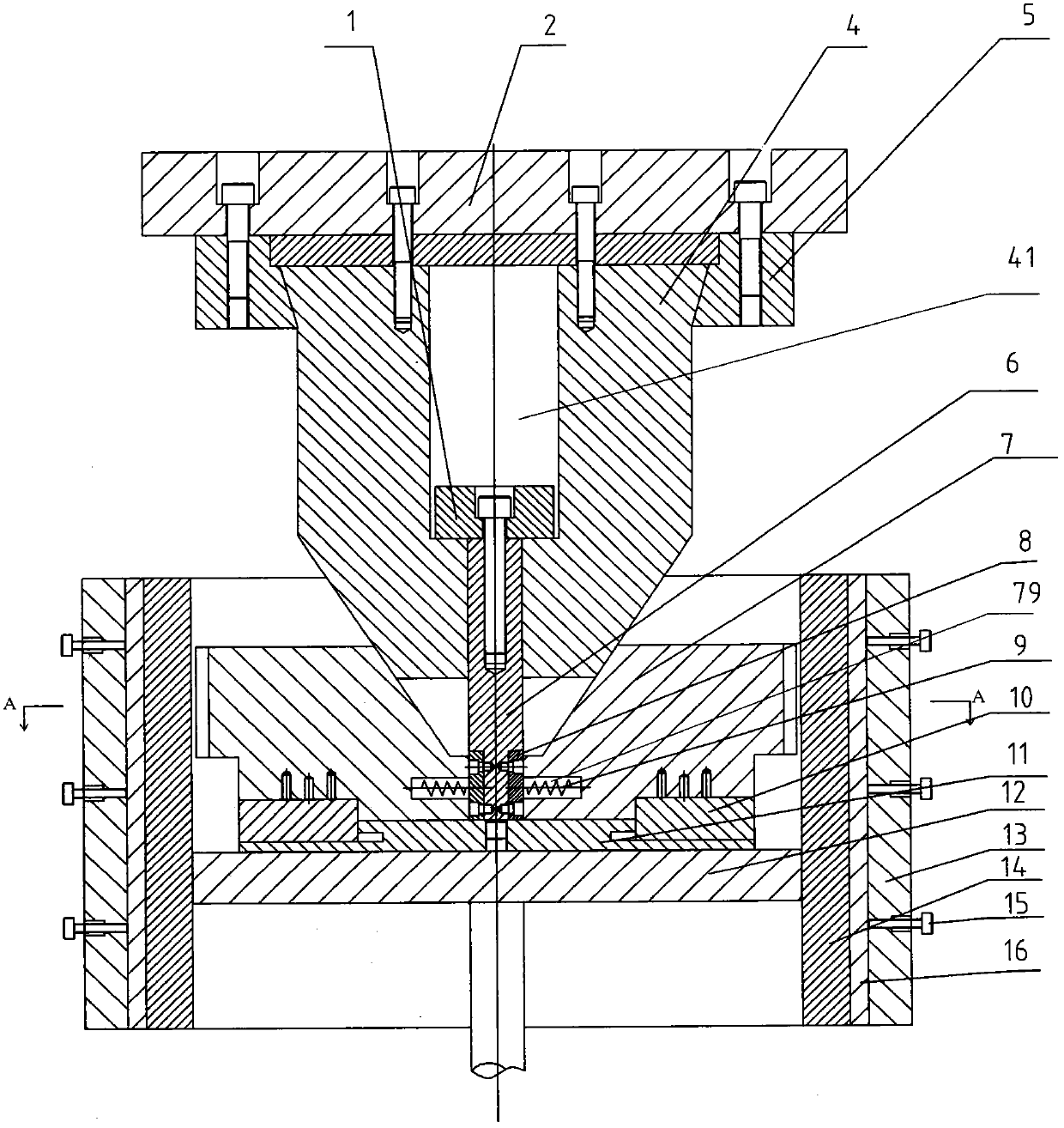

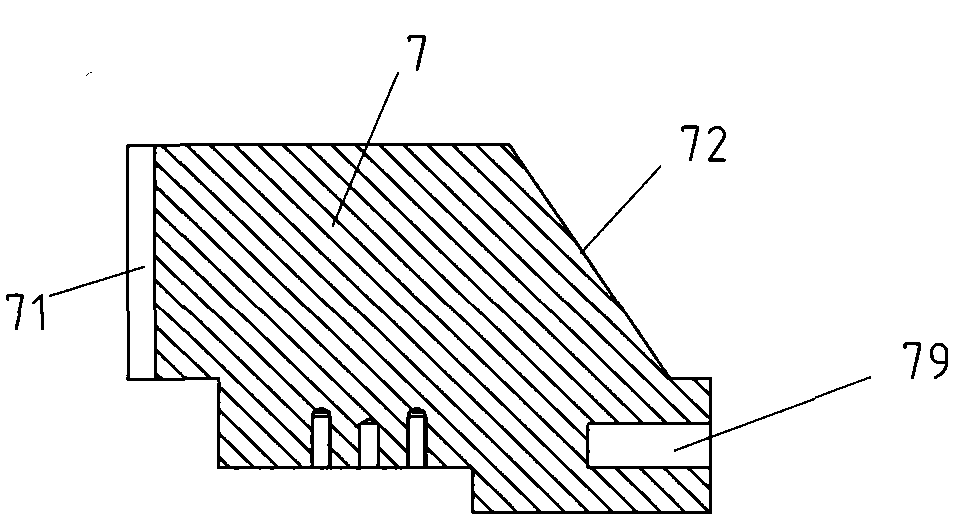

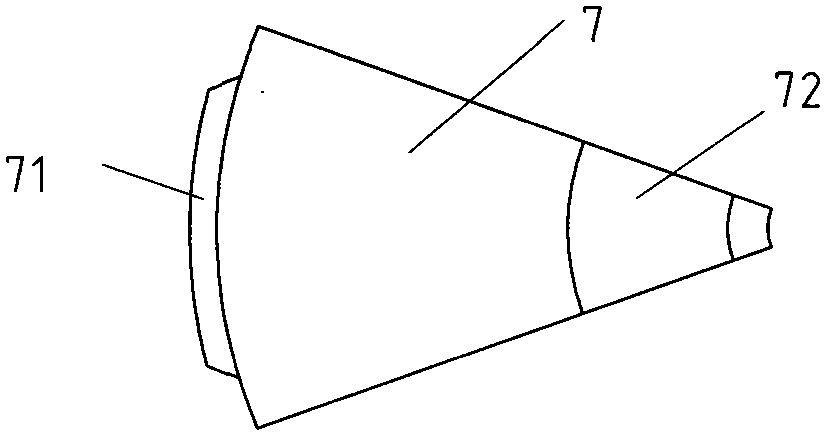

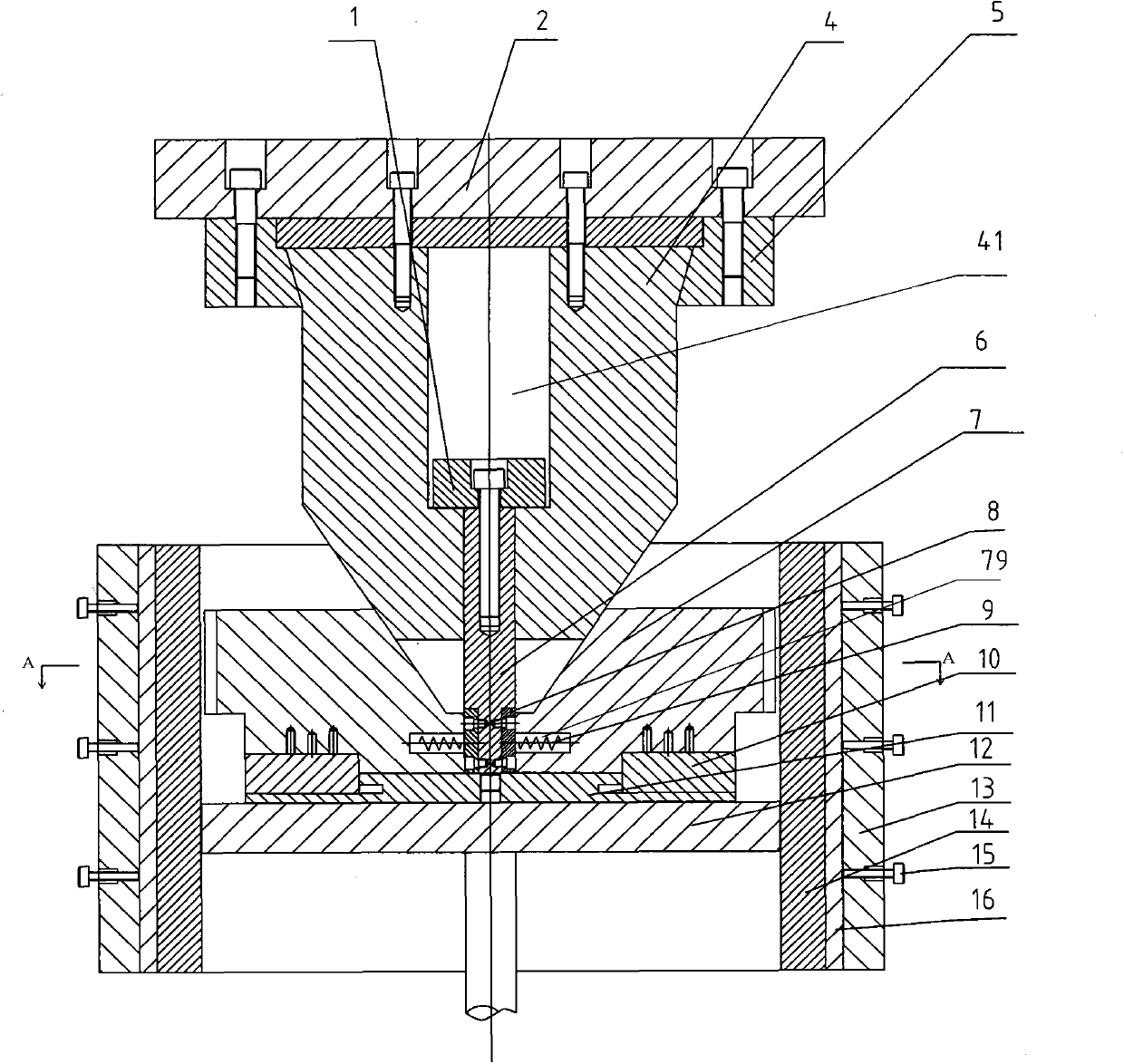

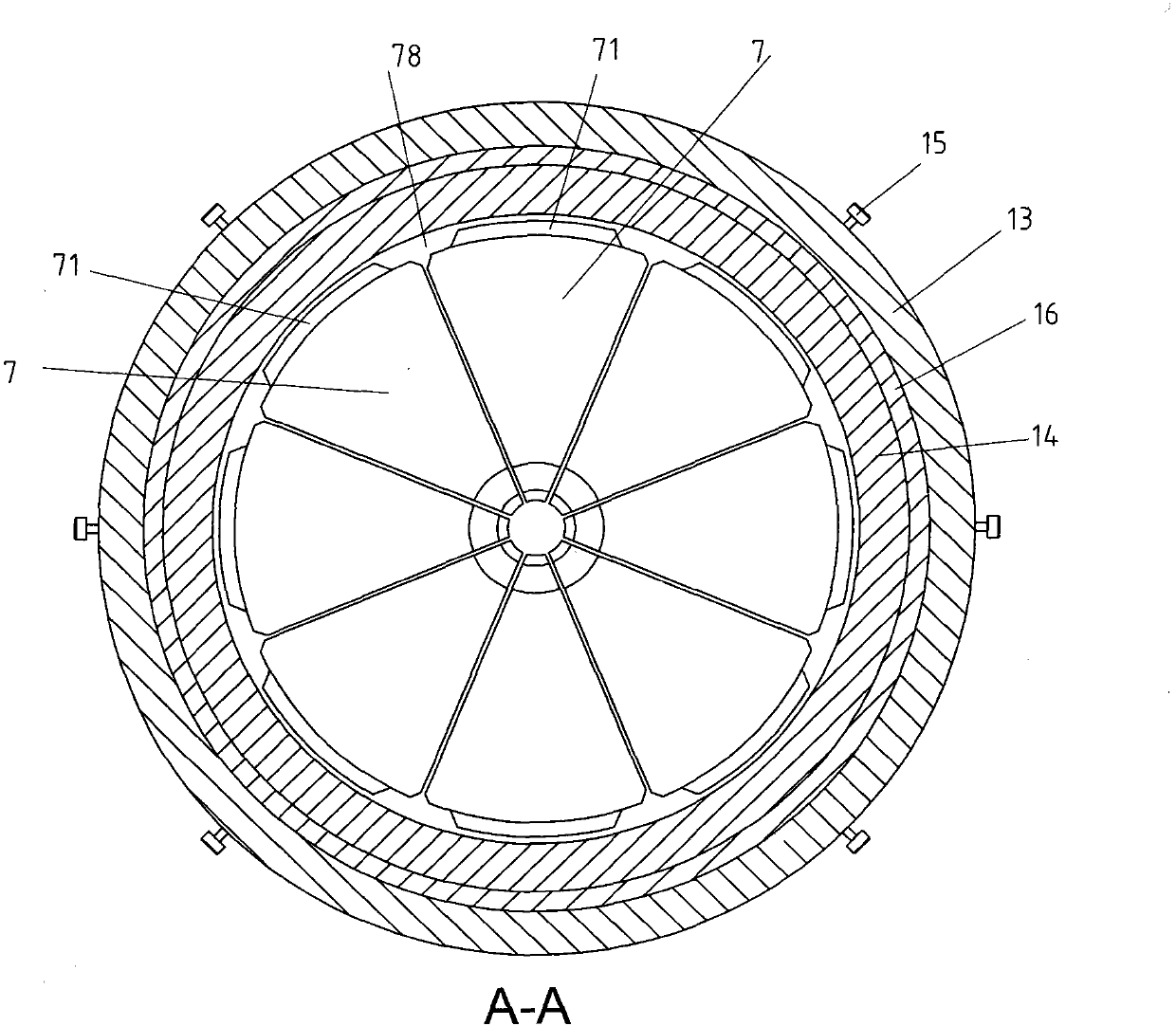

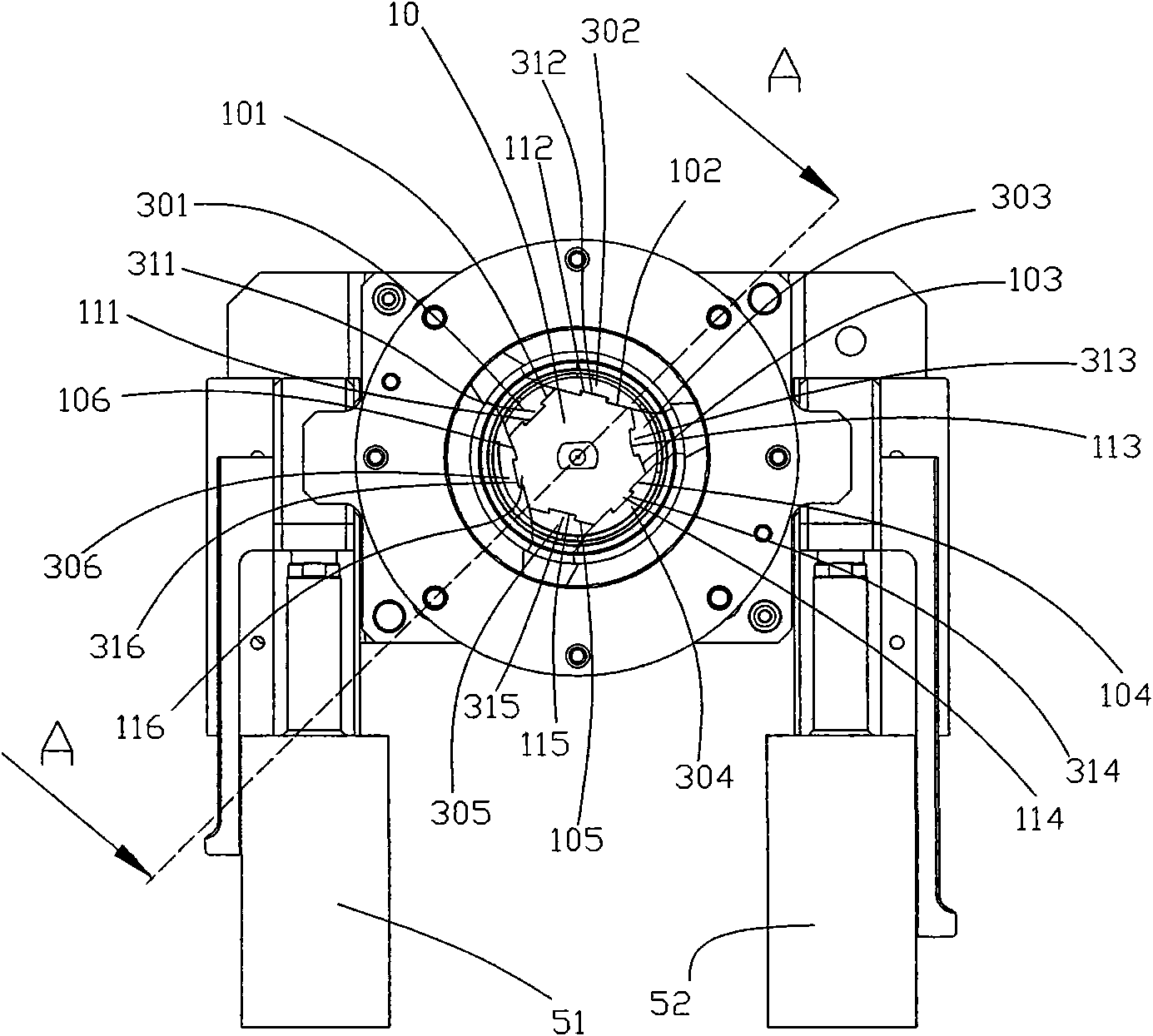

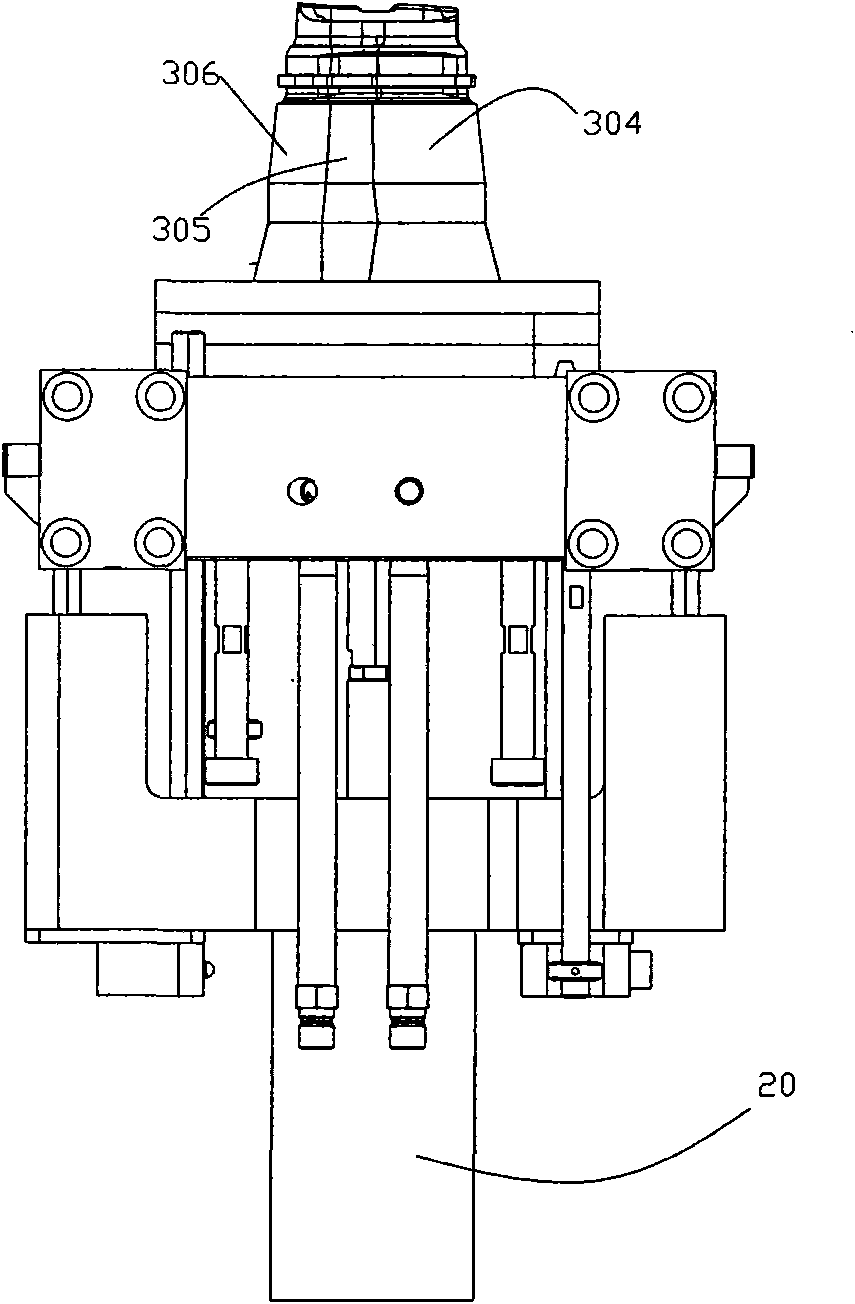

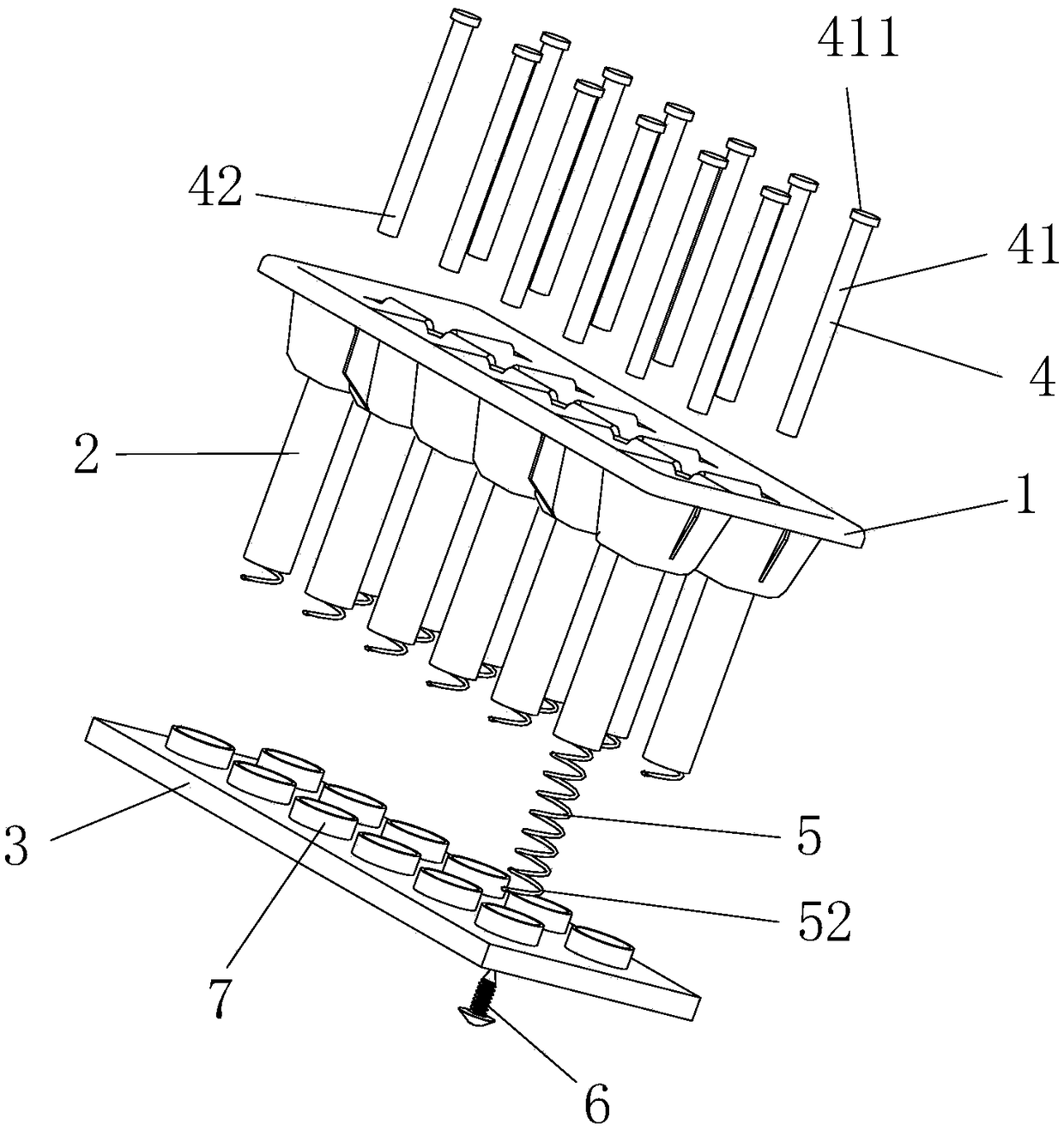

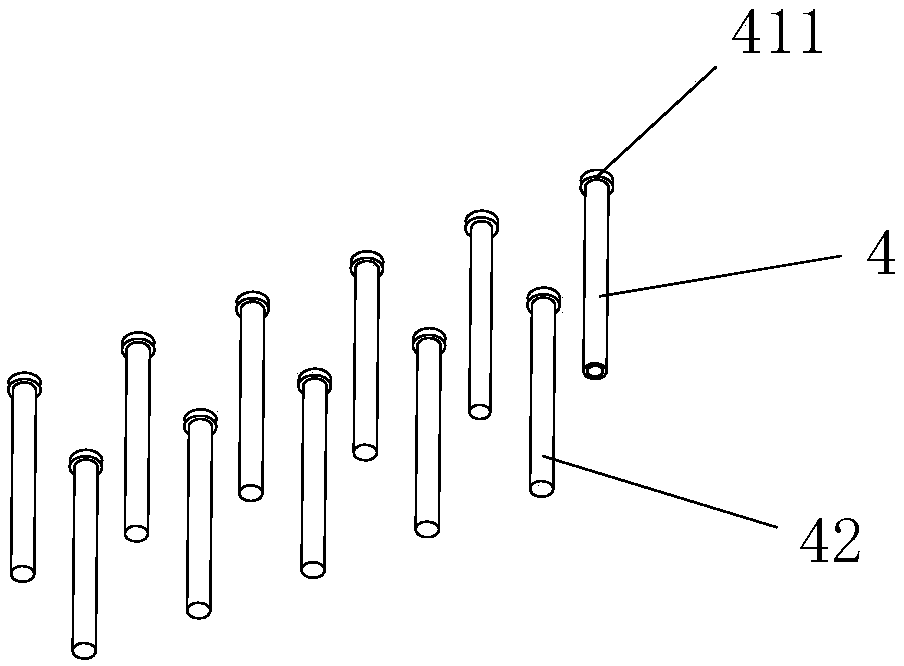

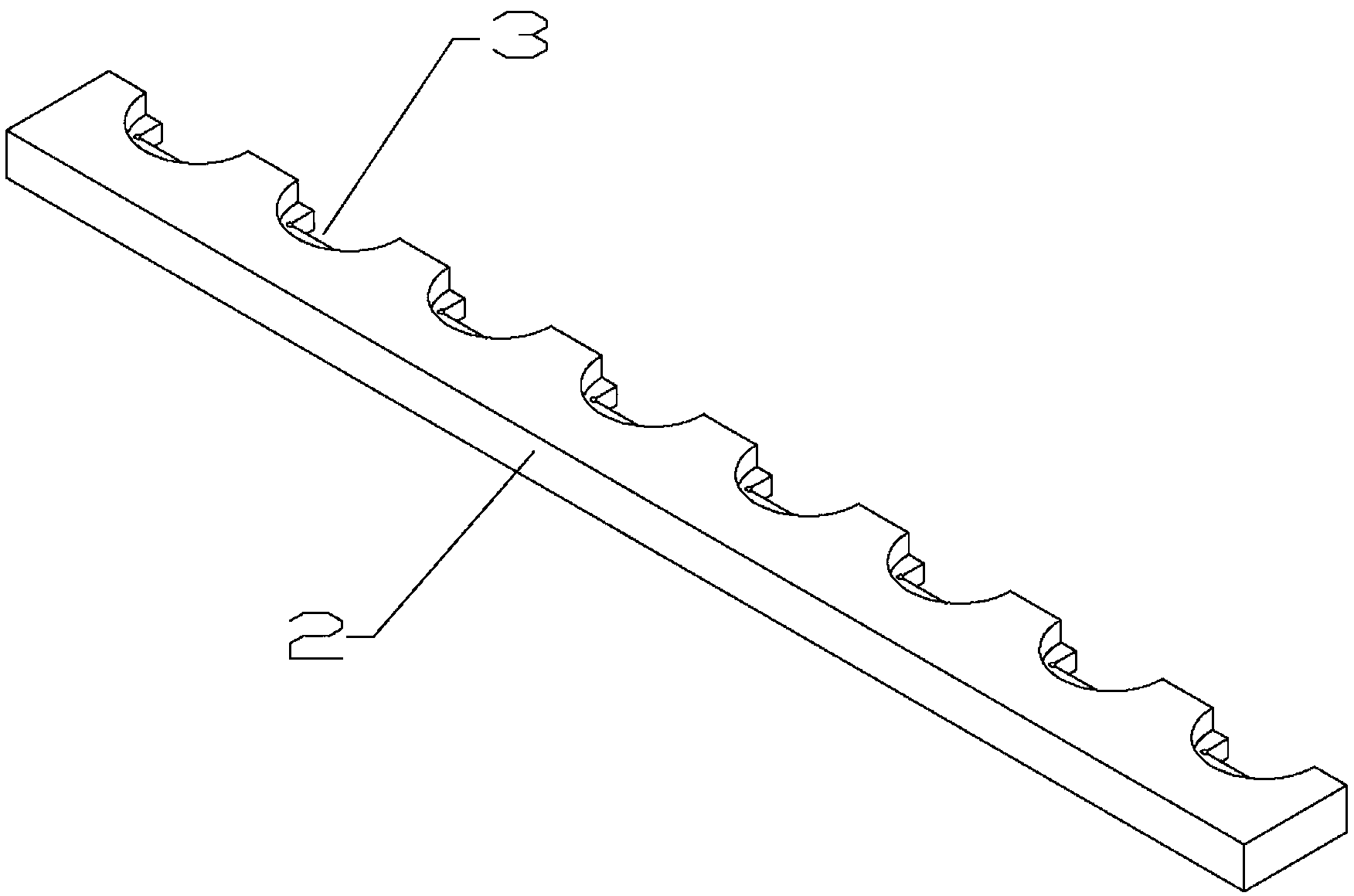

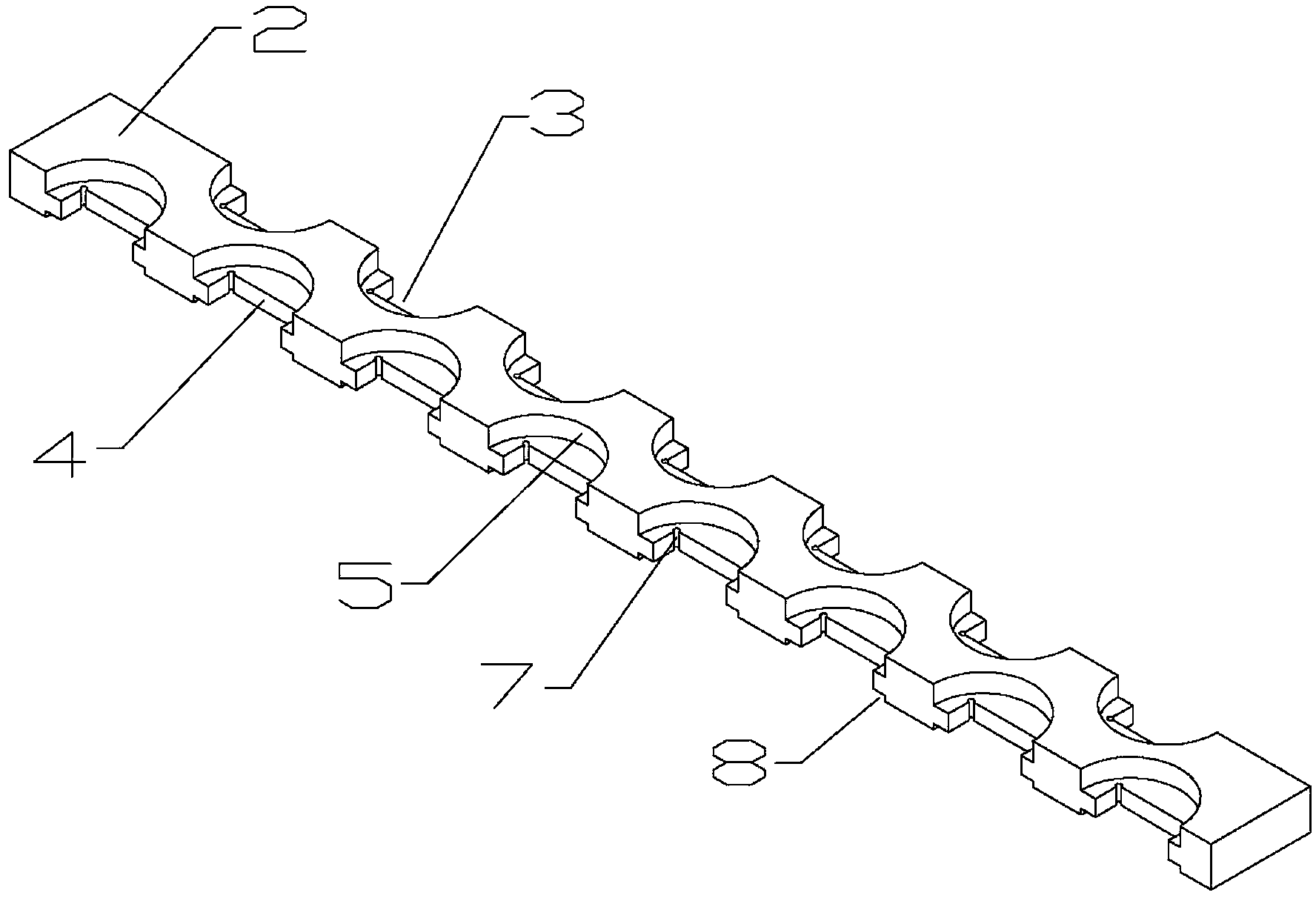

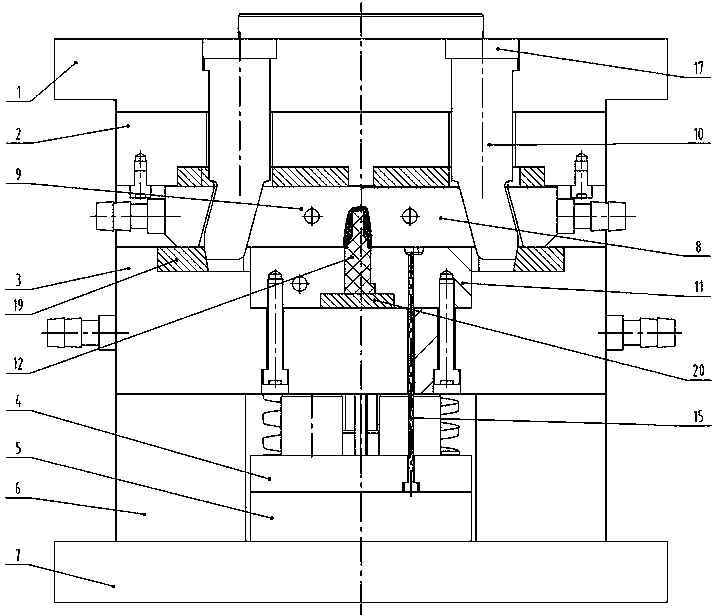

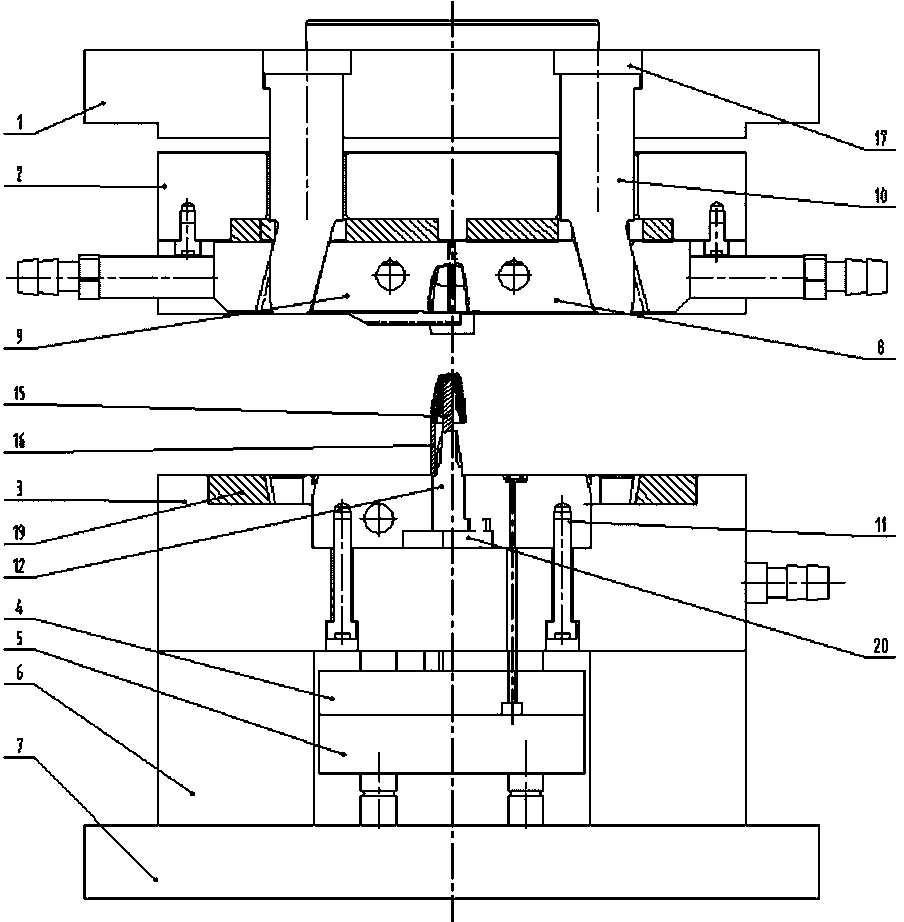

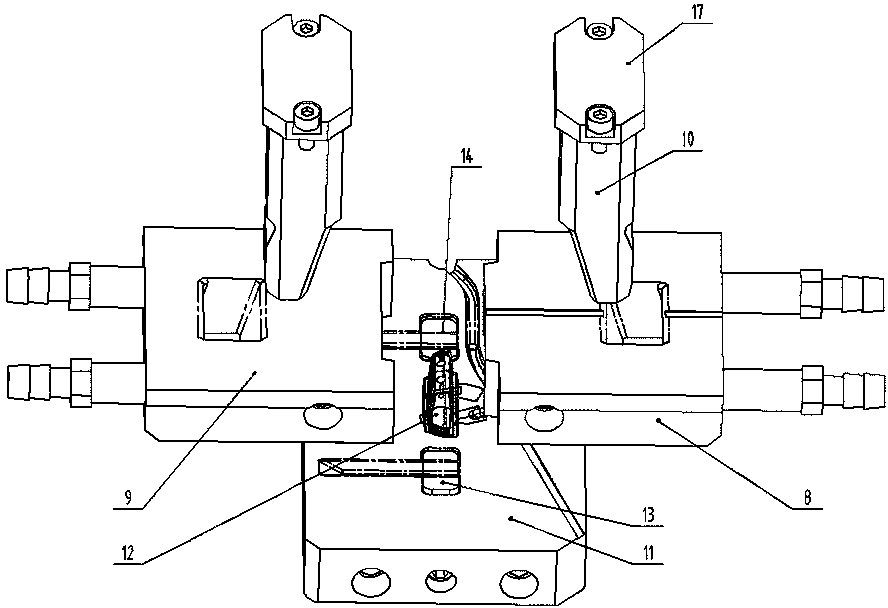

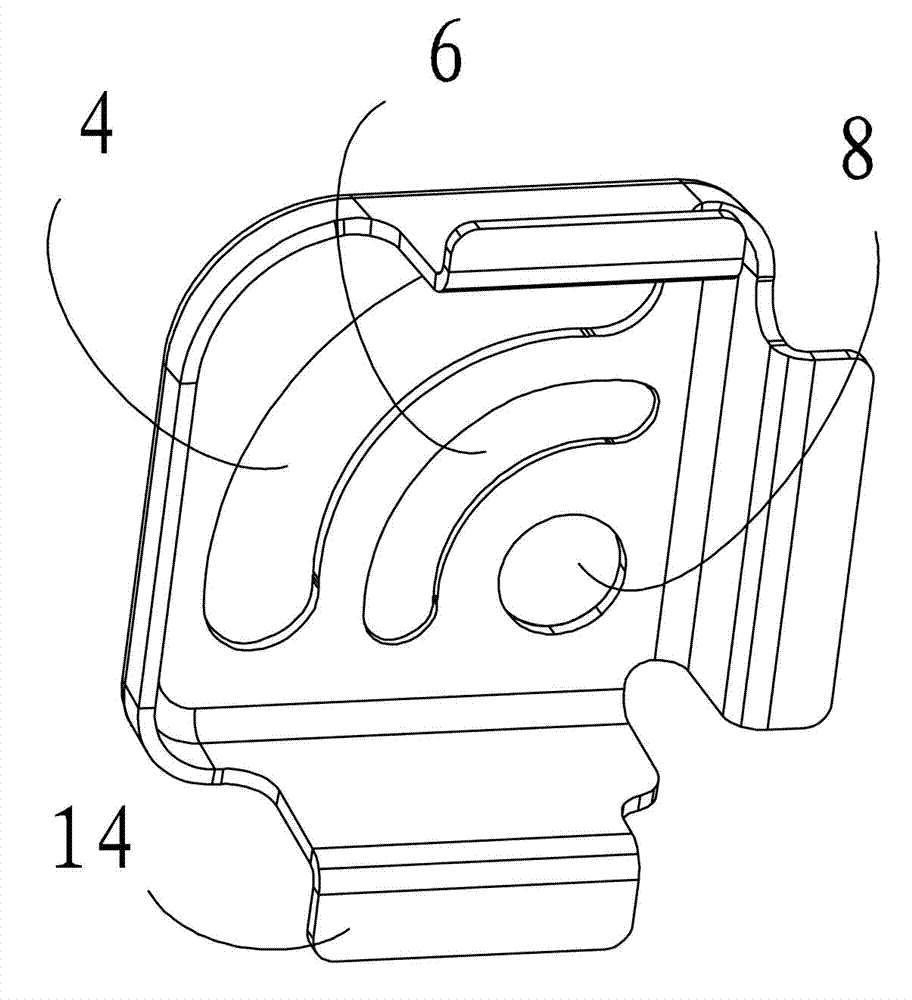

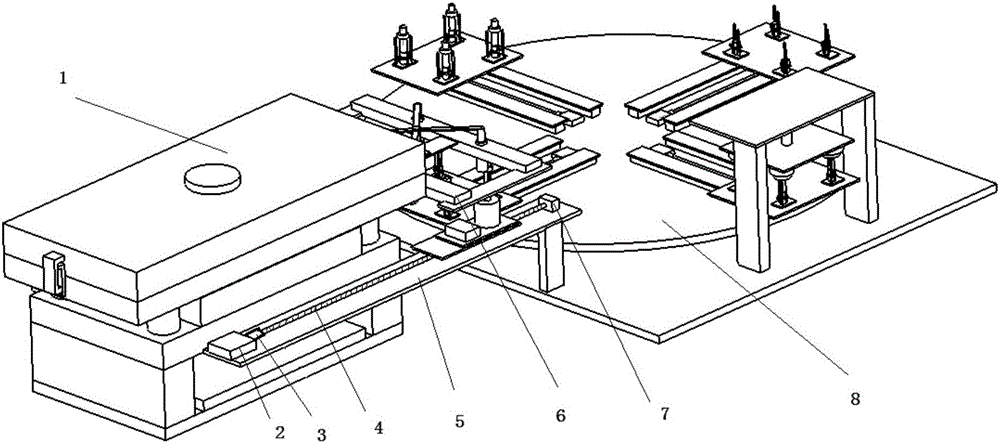

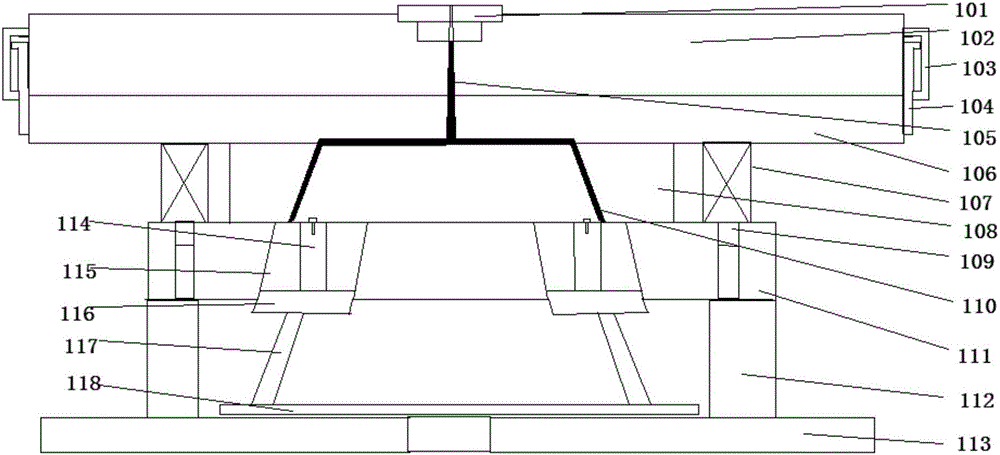

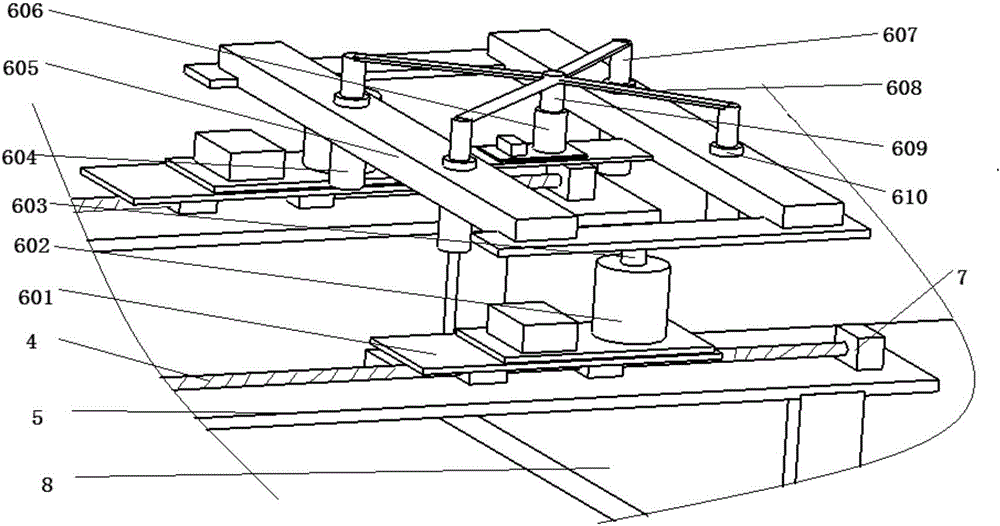

Extrusion forming mould for annular ribs of magnesium alloy shell parts

The invention discloses an extrusion forming mould for annular ribs of magnesium alloy shell parts. The extrusion forming mould mainly comprises an upper mould plate, a mandrel, a split male mould pull rod, split male moulds, tension springs, a male mould sliding guide rail, a split male mould sliding bottom plate, a supporting plate and a cylindrical female mould, wherein the head part of the mandrel is conical, a center hole is formed in the axial direction of the mandrel, one end of the split male mould pull rod is inserted in the center hole, the other end of the split male mould pull rod is fixed on the split male mould sliding bottom plate, the at least two split male moulds are symmetrically arranged around the split male mould pull rod, are fixedly connected with the split male mould pull rod through the tension springs and are arranged in a radial sliding groove of the split male mould sliding bottom plate through the male mould sliding guide rail, a wedge-shaped inclined plane adapting to the conical head part of the mandrel is arranged at the inner side of each split male mould, an arc-shaped extruding bulge is arranged at the arc-shaped wall surface of the outer side of each split male mould, and the arc length of each extruding bulge is more than the distance between each two adjacent extruding bulges. According to the extrusion forming mould, all the split male moulds do radial movement by virtue of the axial movement of the mandrel, metal flows in the radial direction, and thus the annular ribs are generated.

Owner:ZHONGBEI UNIV

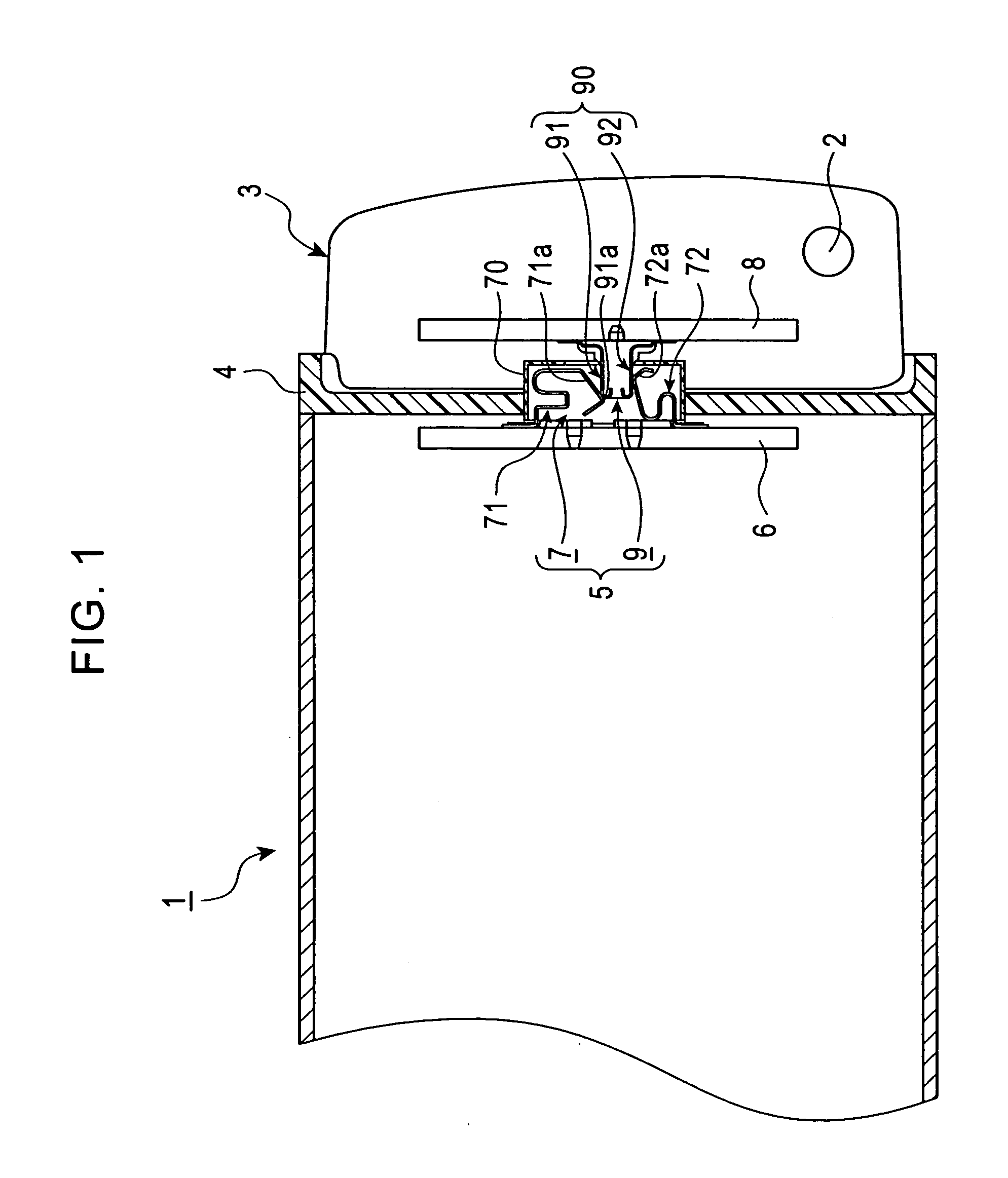

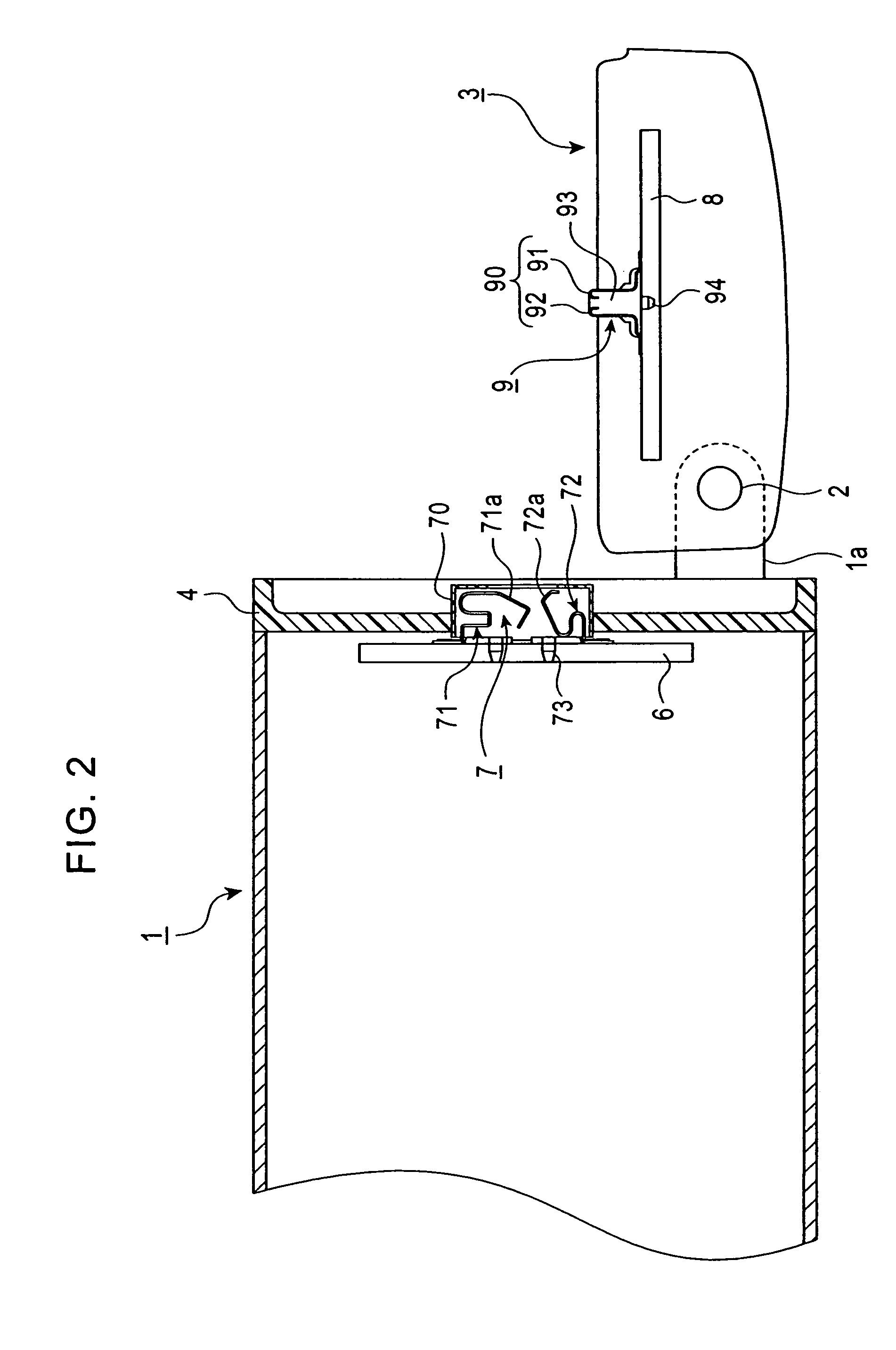

Detachable connector and front-panel device including same

ActiveUS7168991B2Avoid damageMaintain pressureEngagement/disengagement of coupling partsElectric discharge tubesEngineeringElectrical and Electronics engineering

Owner:ALPINE ELECTRONICS INC

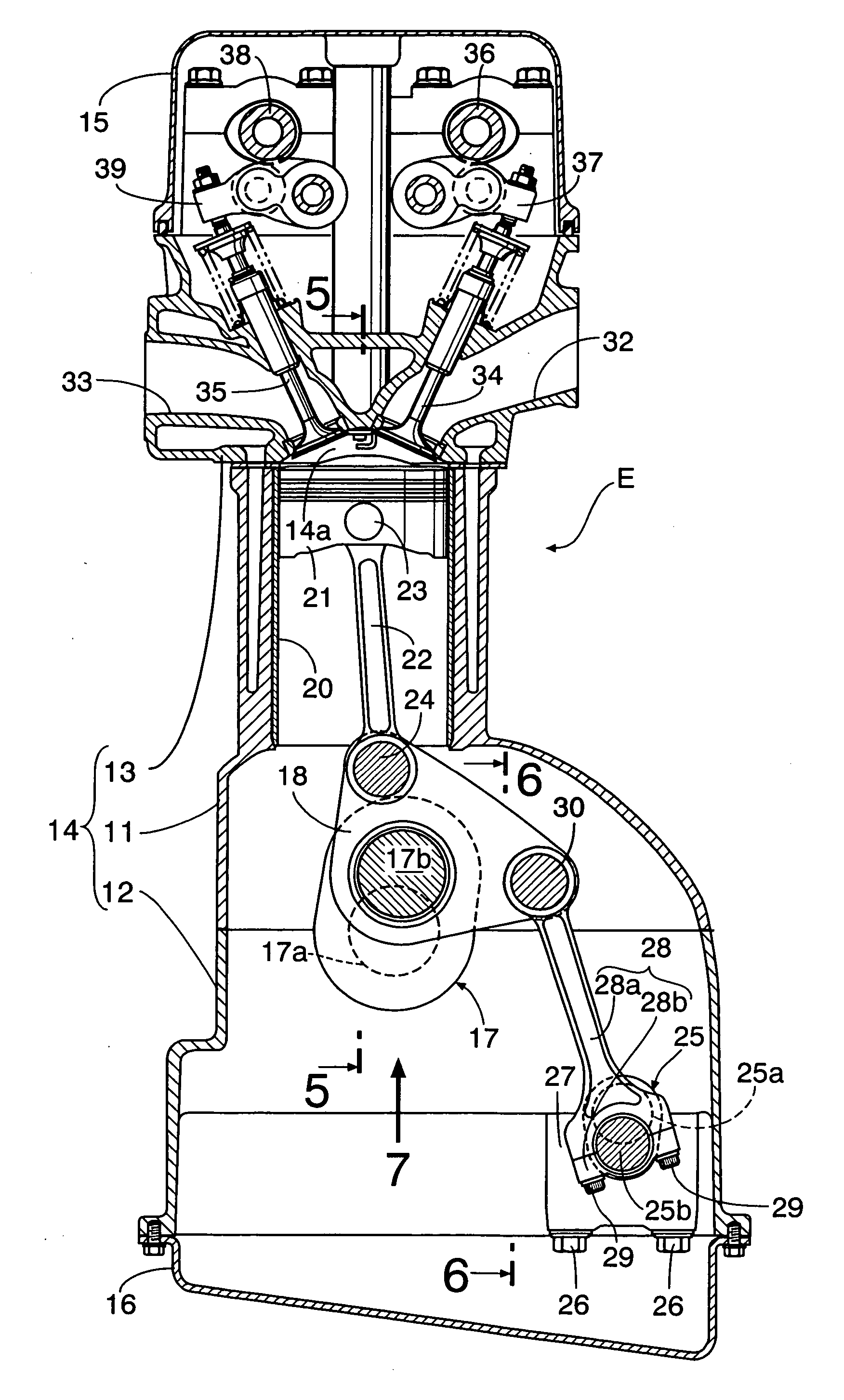

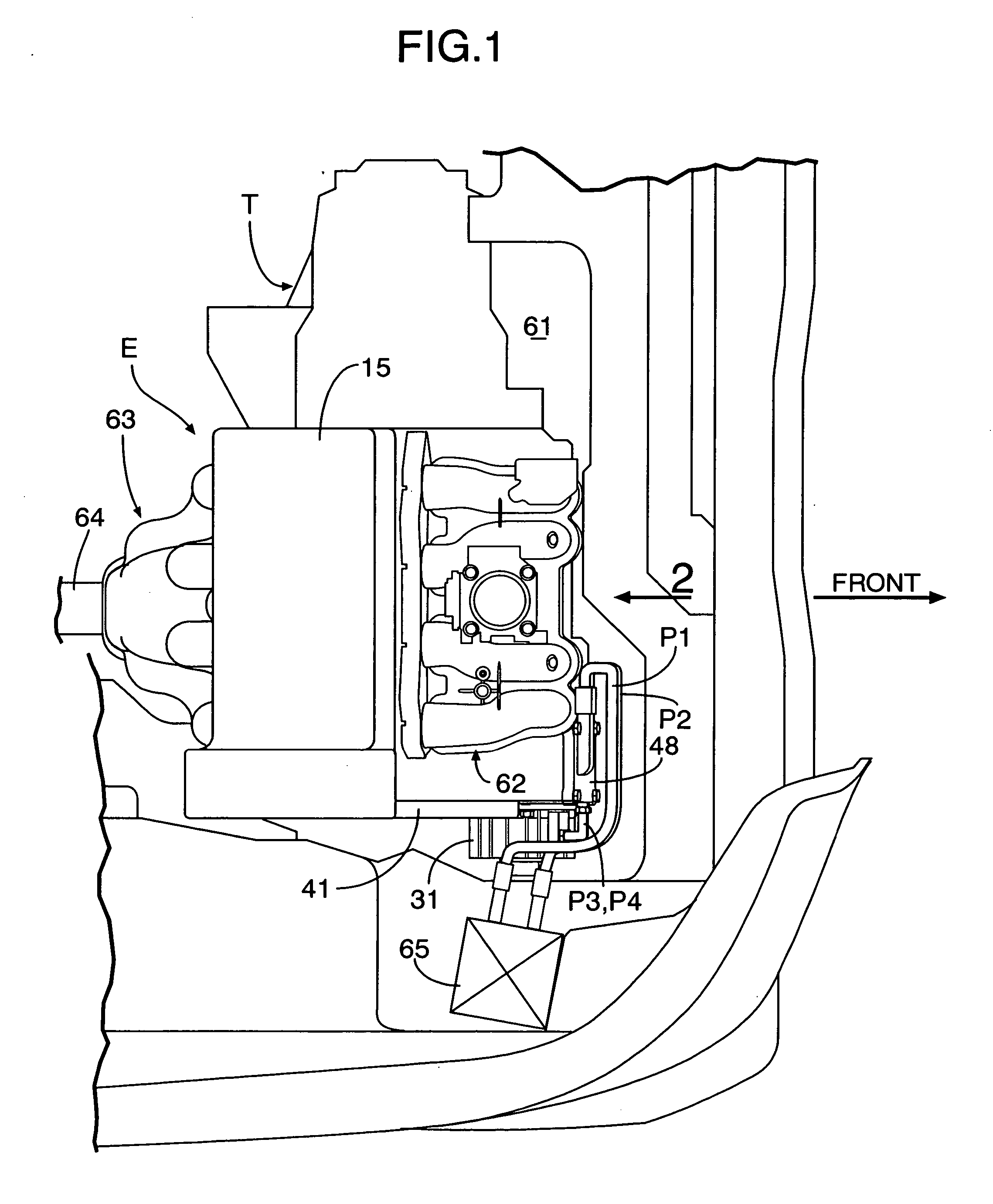

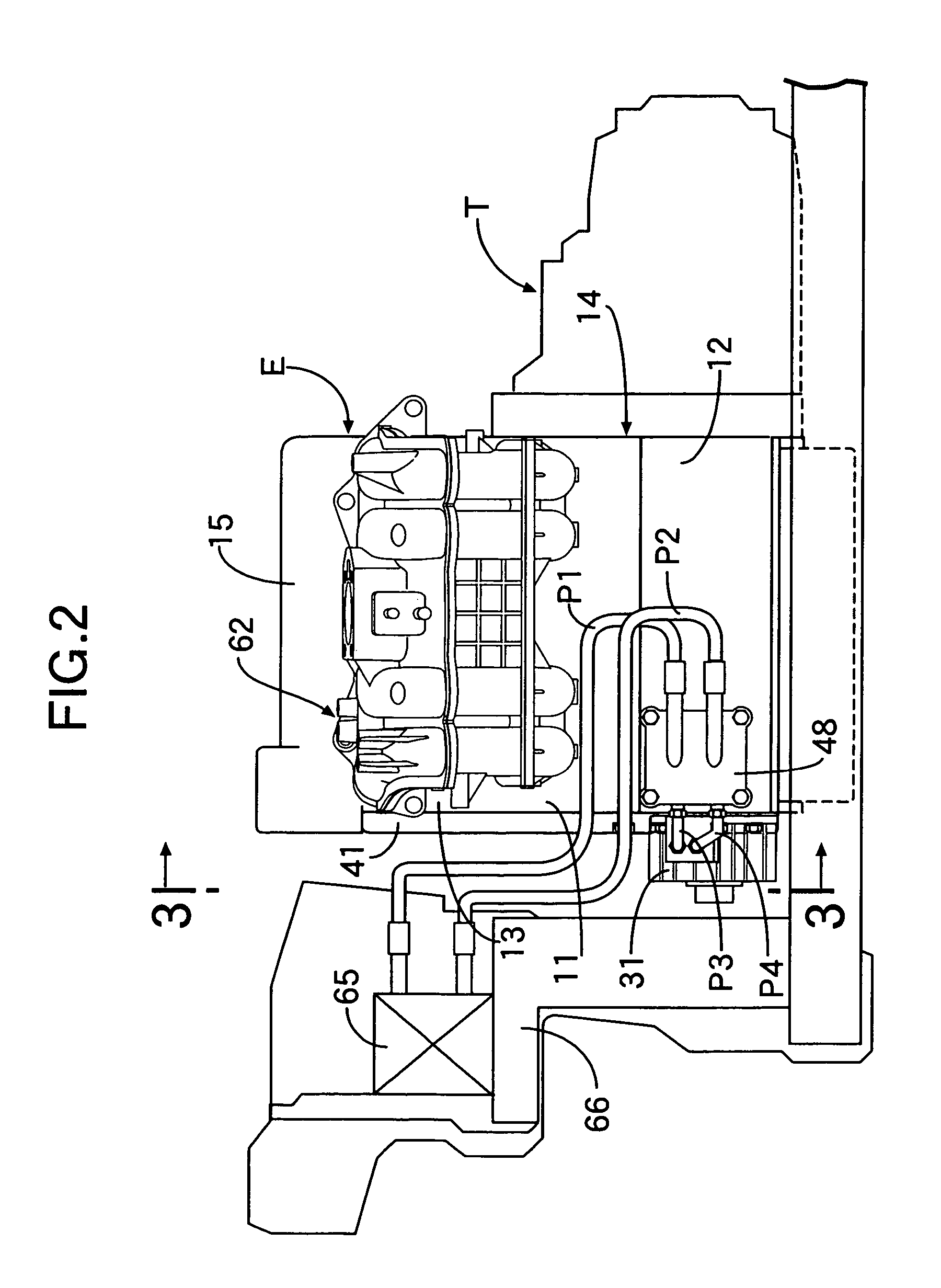

Variable stroke-characteristic engine for vehicle

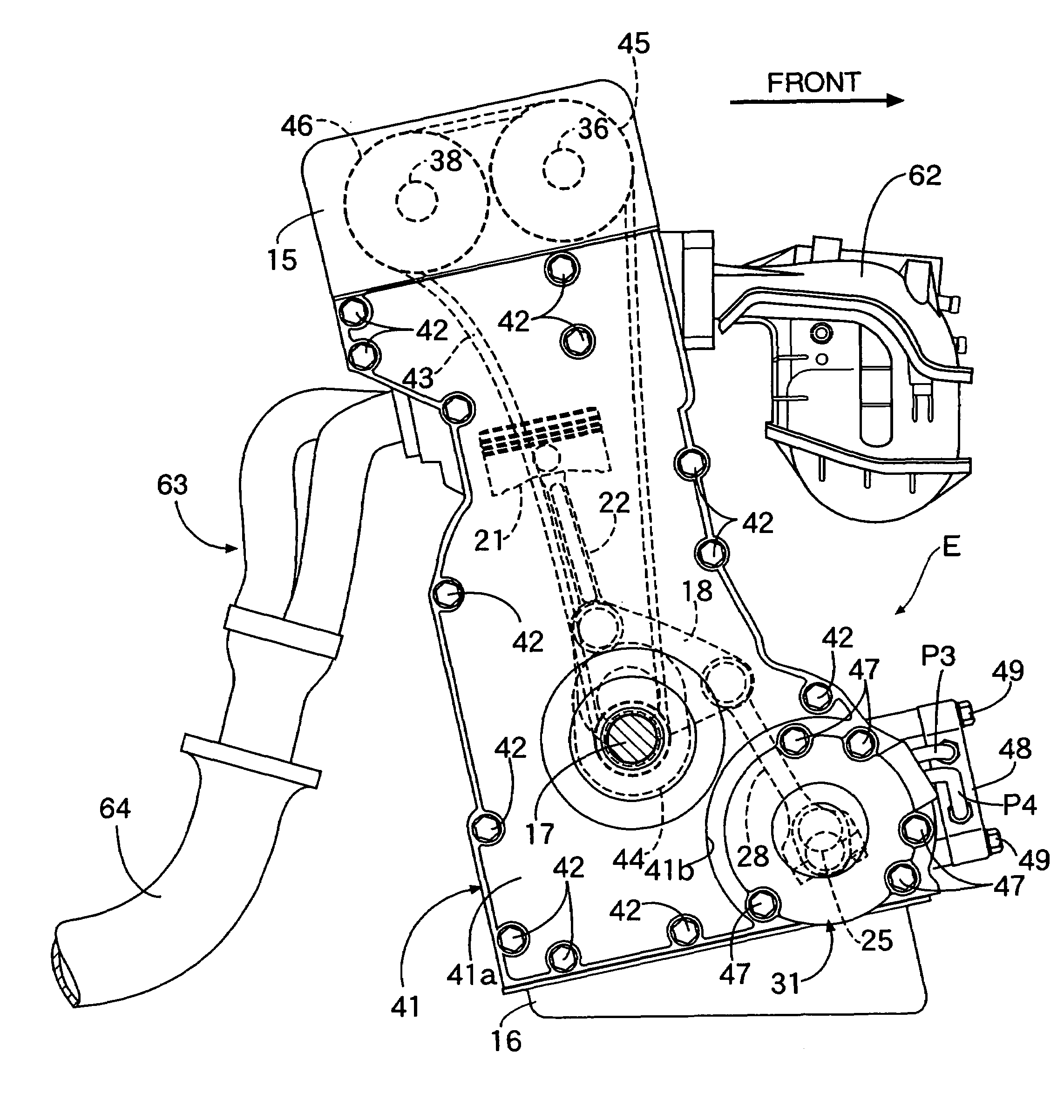

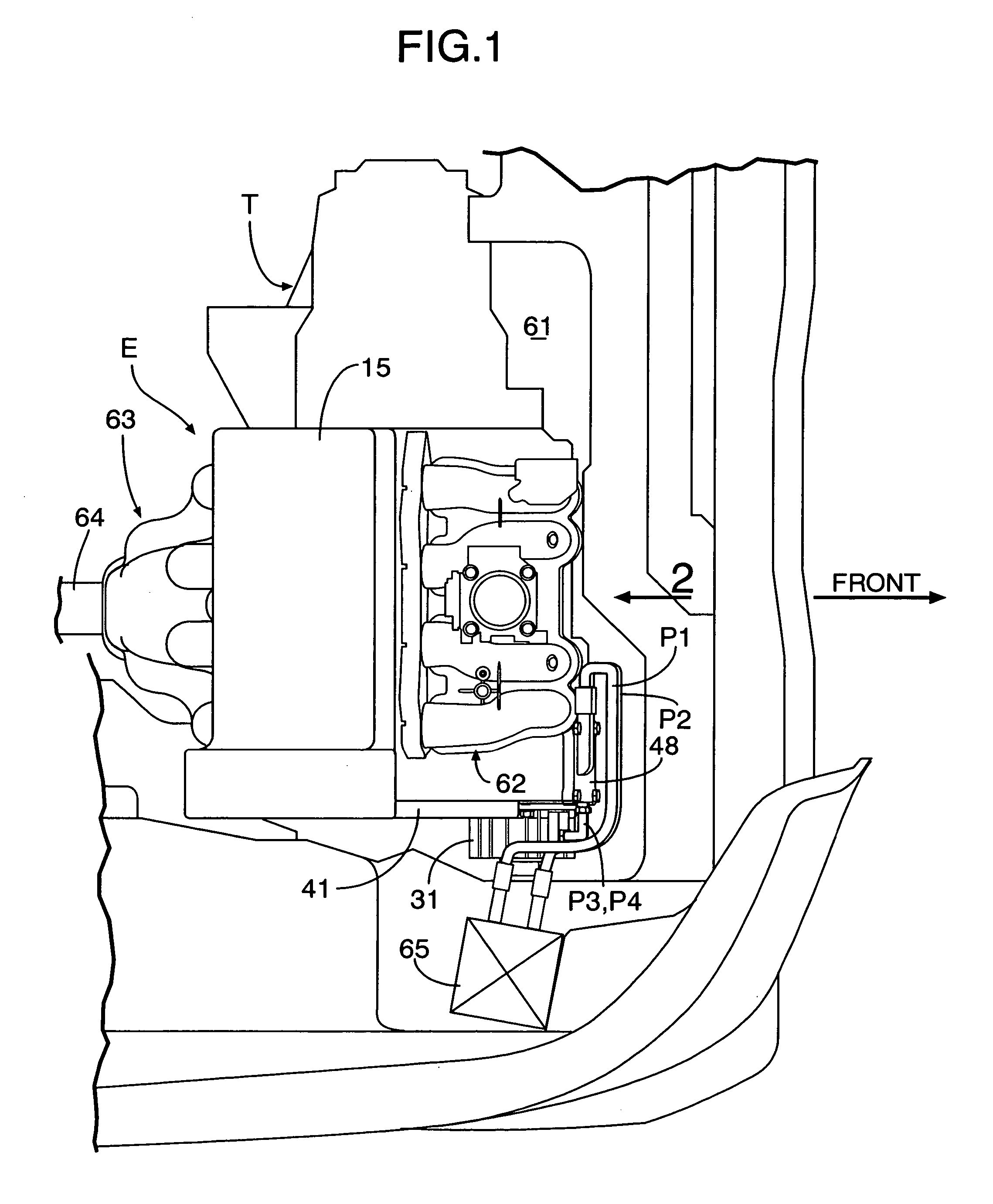

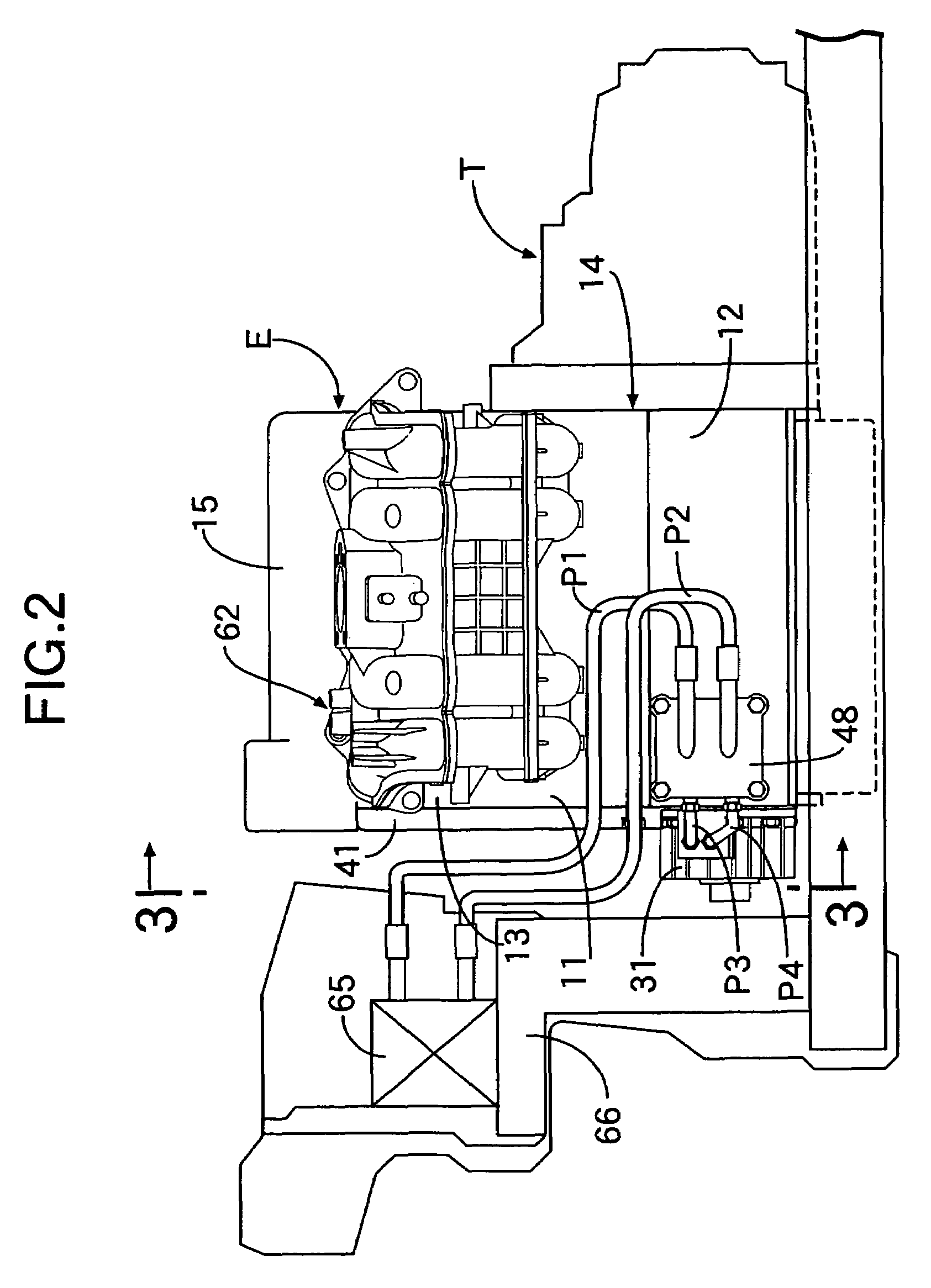

InactiveUS20060144354A1Improve cooling effectIncrease temperatureEngine controllersMachines/enginesAutomotive engineeringCylinder block

In a variable stroke-characteristic engine for a vehicle, a control shaft and a control link are disposed on a front side of a vehicle body with respect to a crankshaft. An actuator for driving the control shaft is disposed on an outer surface of an engine block on the front side of the vehicle body. Thus, the actuator projects as much as possible from a position of the engine block toward the front side of the vehicle body so that traveling wind from ahead of the vehicle is effectively applied to the actuator to enhance the cooling effect. Hence, any temperature increase of the actuator is suppressed. Moreover, the actuator is disposed as far as possible from an exhaust manifold that is heated to a high temperature by the heat of an exhaust gas.

Owner:HONDA MOTOR CO LTD

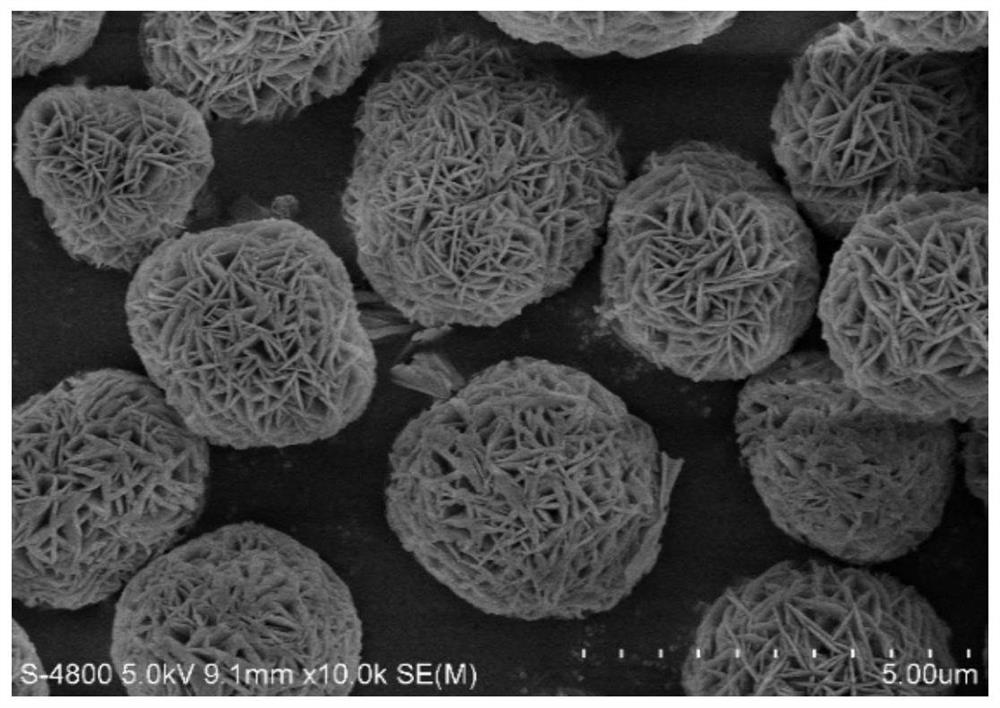

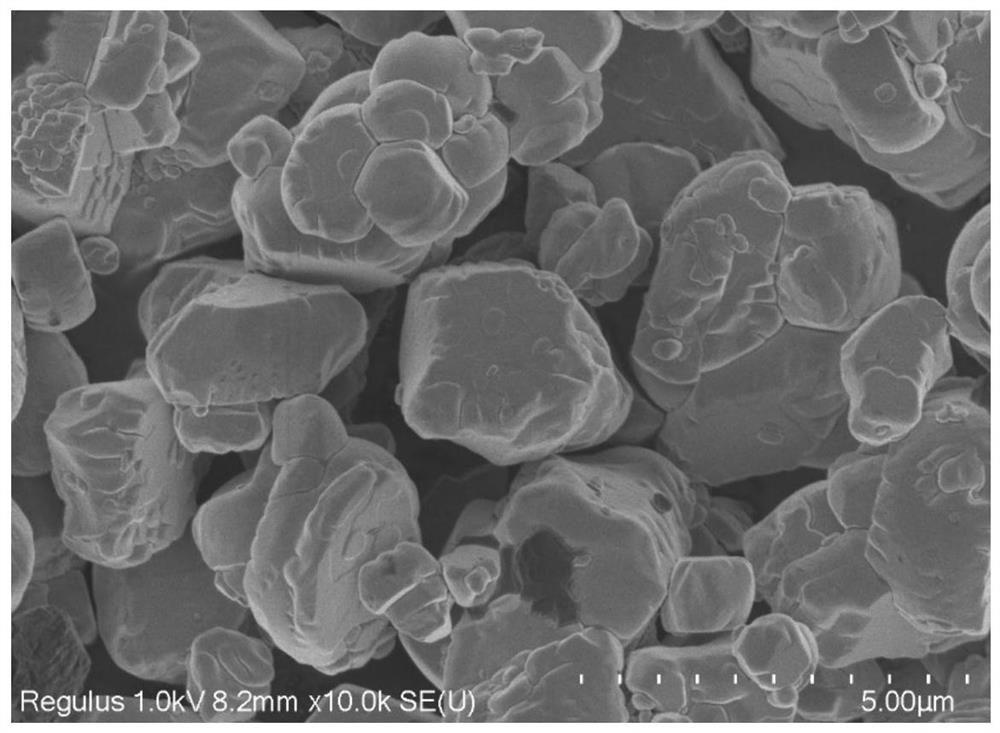

Positive electrode material, preparation method thereof and lithium ion battery

ActiveCN112750999ALow costUniform coating effectMaterial nanotechnologyPolycrystalline material growthPhysical chemistryManganese

The invention relates to the technical field of lithium ion batteries, and discloses a positive electrode material, a preparation method thereof and a lithium ion battery. The positive electrode material comprises a high-nickel cobalt-free multi-element positive electrode material intermediate and a cobalt-containing compound coating the outer surface of the high-nickel cobalt-free multi-element positive electrode material intermediate, and the total mole number of nickel and manganese in the high-nickel cobalt-free multi-element positive electrode material intermediate is taken as a reference, the content of the cobalt-containing compound in terms of cobalt element is 0.5-5 mol%. The positive electrode material is stable in structure, high in energy density, good in rate capability, high in capacity retention ratio, simple in preparation method and low in cost.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Demolding mechanism for full circle internal reverse clamp of automotive air inlet pipe

The invention relates to a demolding mechanism for a full circle internal reverse clamp of an automotive air inlet pipe. The demolding mechanism comprises a core shaft, a core-pulling device, a plurality of slanted slide blocks and a slanted slide block seat, wherein the core shaft is provided with even-numbered slant planes (at least 6); each slant plane comprises a first slant plane and a second slant plane; the first slant plane and the second slant plane are arranged at intervals; an included angle between the first slant plane and the axis of the core shaft is larger than that between the second slant plane and the axis of the core shaft; the number of the slant slide blocks is the same as that of the slant planes; each slant slide block comprises a first slant slide block matched with the first slant plane and a second slant slide block matched with the second slant plane; the slant slide blocks and the slant planes are provided with sliding connection mechanisms which are matched with one another; and when the core-pulling device drives the core shaft to be pulled out, the slant slide blocks are driven by the matched slant planes to move towards the center of the core shaft. The demolding mechanism for the full circle internal reverse clamp of the automotive air inlet pipe has the advantages of smart action principle, simple and compact structure and contribution to manufacturing and popularization.

Owner:SHENZHEN KUNDA PRECISION MOULD CO LTD

Mold release agent

The invention discloses a mold release agent which comprises the following components in parts by weight: 5-13 parts of paraffin, 2-6 parts of stearic acid, 3-7 parts of potassium hydroxide, 4-8 parts of fatty alcohol polyethenoxy ether, 5-9 parts of aluminum dihydrogen phosphate, 2-7 parts of graphene, 3-9 parts of epoxy resin, 8-15 parts of zinc dialkyl dithiophosphate and 2-5 parts of coupling agent. The mold release agent has the advantages of simple preparation process and high isolation performance; and the mold release agent has certain adhesive, but can release the product smoothly.

Owner:南通优尼科化工有限公司

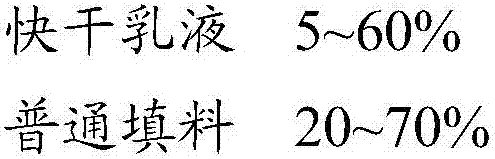

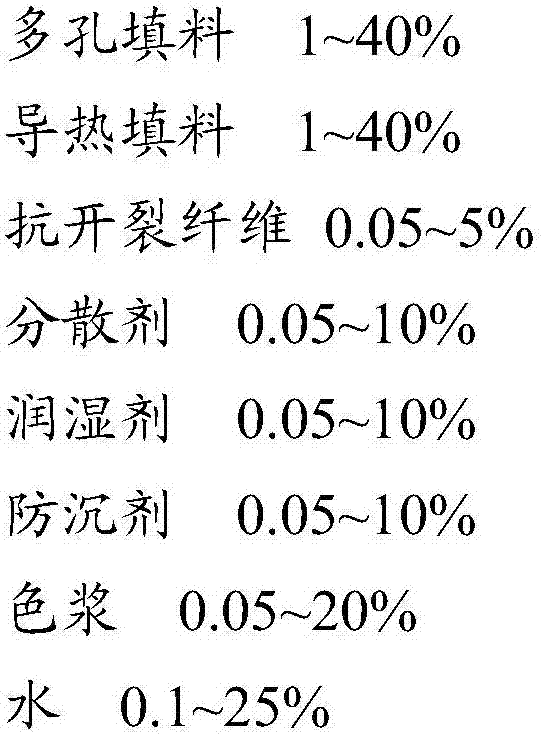

High-temperature-baking resistant and water-based paint

ActiveCN107880654AConvenient and quick escapeEscape smoothlyConjugated diene hydrocarbon coatingsChloropene polymer coatingsEmulsionHeat conducting

The invention provides high-temperature-baking resistant and water-based paint. The provided high-temperature-baking resistant and water-based paint utilizes the molecular design of quick drying emulsion, water in a coating thus quickly escapes, and the purpose of quick drying is achieved; by adding heat conducting filler, the difference between the inside temperature and the outside temperature of the paint is adjusted, and the gasification speed and escaping speed of the water are controlled; meanwhile by using the microporous foaming technology of the porous filler, the inside and outside of the paint form an interpenetrating microporous network system, steam in the paint thus can be smoothly led out, and key problems that a formed film is cracked and bulging occurs in the high-temperature baking process of water-based damping paint and other problems are solved fundamentally. The experimental results show that when the provided high-temperature-baking resistant and water-based paint is 2 mm, after being braked at 140 DEG C for 30 min, the film is not cracked, no bulging occurs, and the adhesion of the paint to a substrate is good.

Owner:湖南金利源新材料科技有限公司

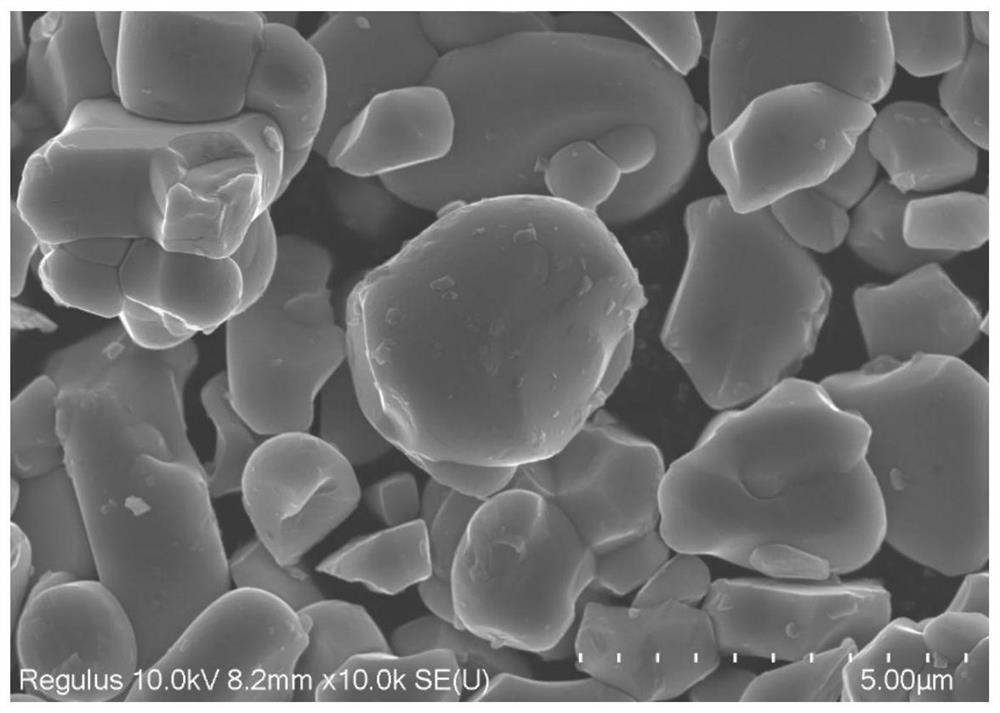

Preparation method of composite MnO2 anode material for chargeable Li-Mn battery

InactiveCN101746829AHigh purityImprove product qualityCell electrodesManganese oxides/hydroxidesElectrolysisElectrical battery

The invention provides a preparation method of composite MnO2 anode material for a chargeable Li-Mn battery and relates to a manufacturing method of electrode material; finished products are manufactured by the steps of purification of raw material, calcining and refining and reactive sintering; the method comprises the following steps: merchant electrolysis MnO2 material is acid-dipped and then is filtered and cleaned, and the washed material is ground finely; and then nonionic surface active agents with 0.3-0.5 percent of weight ratio are added, the mixture is heated to 120-140 DEG C in a sealing agitated reactor, and the temperature is kept for 3-5 hours, after the temperature is reduced, the reaction material is filtered and dried, and the dried material is placed in an electric furnace for calcining; the calcined MnO2 and chemically pure lithium nitrate are mixed with 1:(0.3-0.4) of molar ratio, the mixture is ground in a dry state, and then is sintered for 10-24 hours at 260-400DEG C under atmosphere, and then dry ball-milling and sieving are carried out to obtain the needed composite MnO2 material.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Keyboard switch with internal fluid containment network

ActiveUS6946611B2Improve operationImprove user experienceContact surface shape/structureContact operating partsEngineeringElectrical and Electronics engineering

Owner:LITE ON SINGAPORE PTE LTD

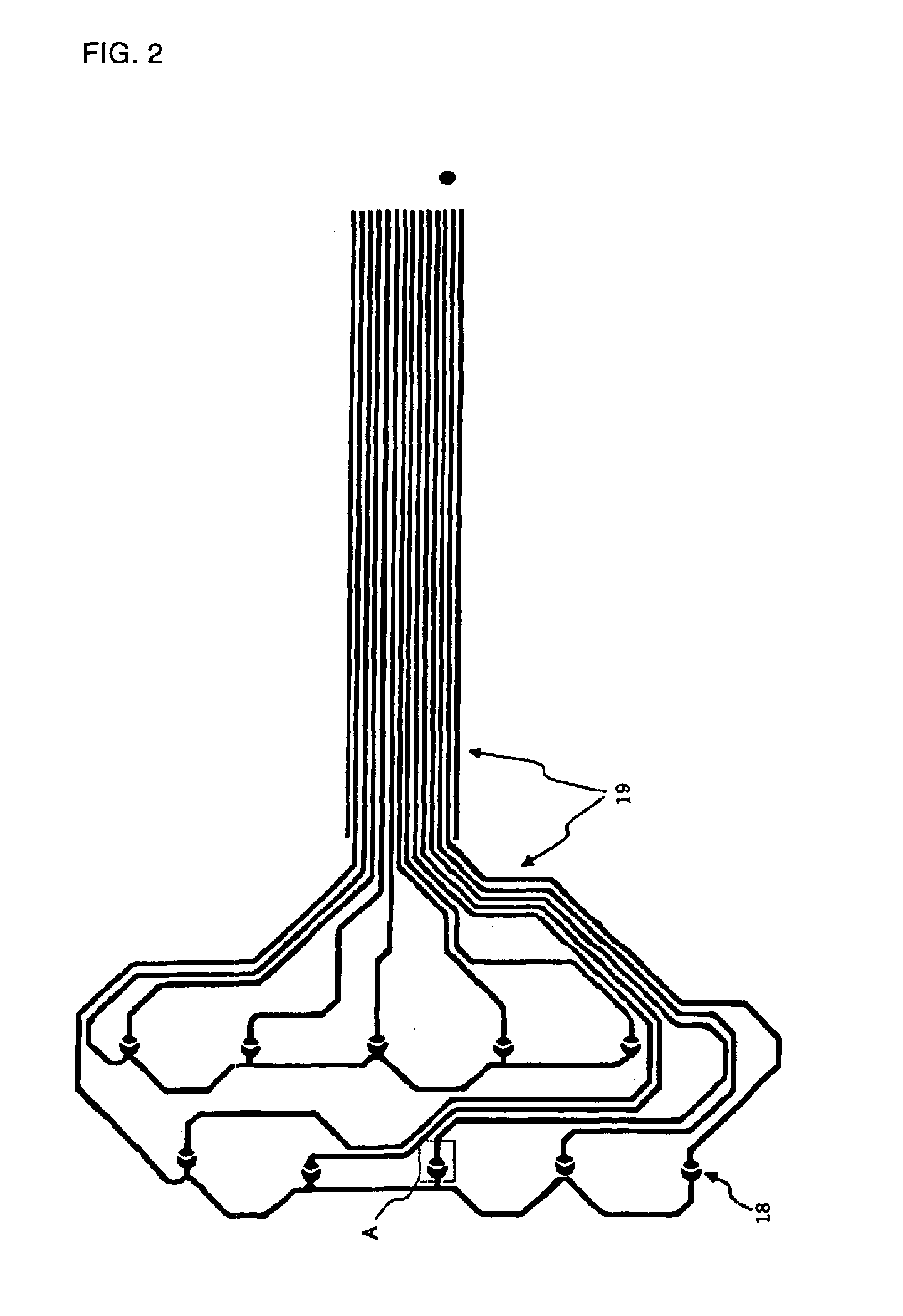

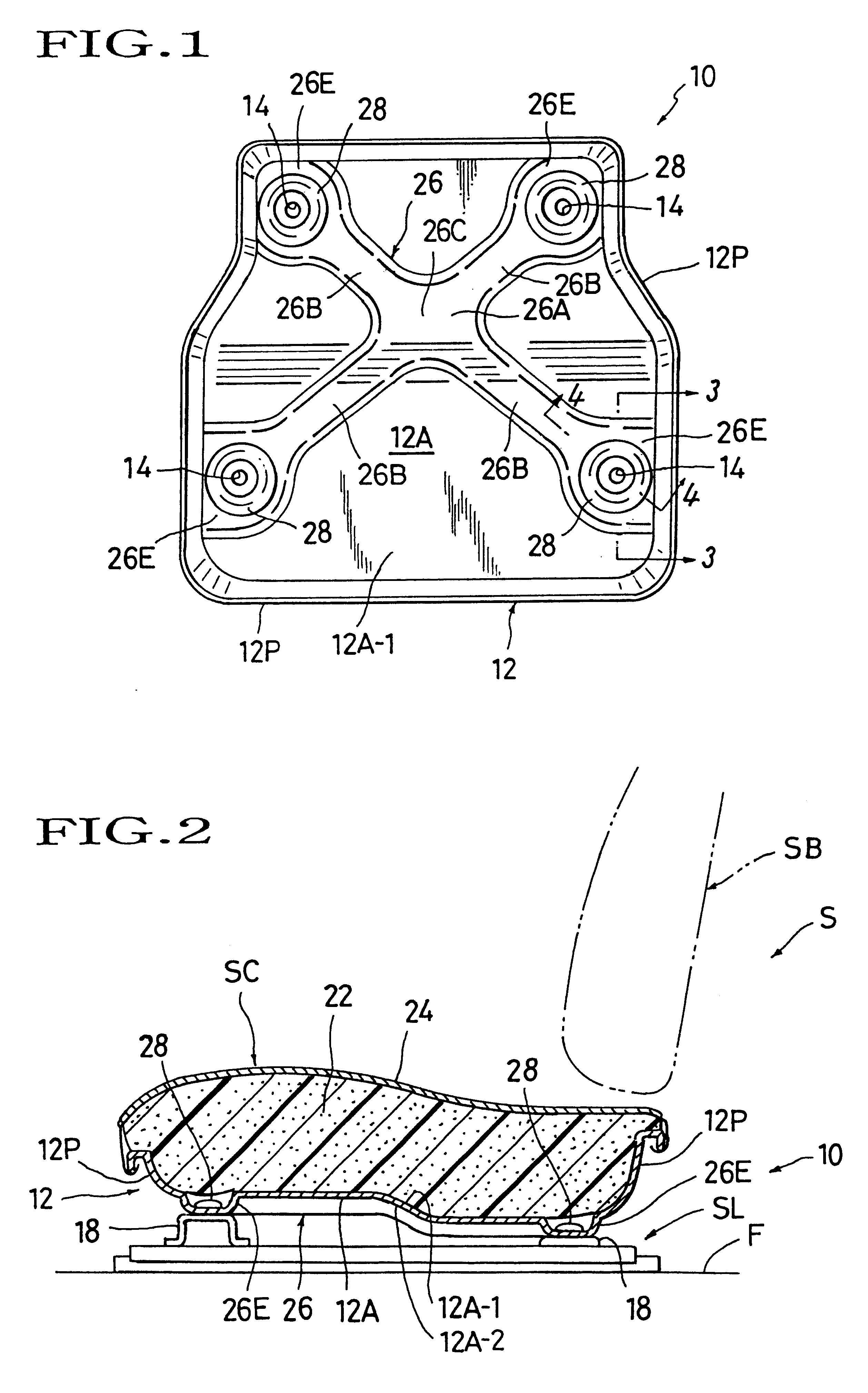

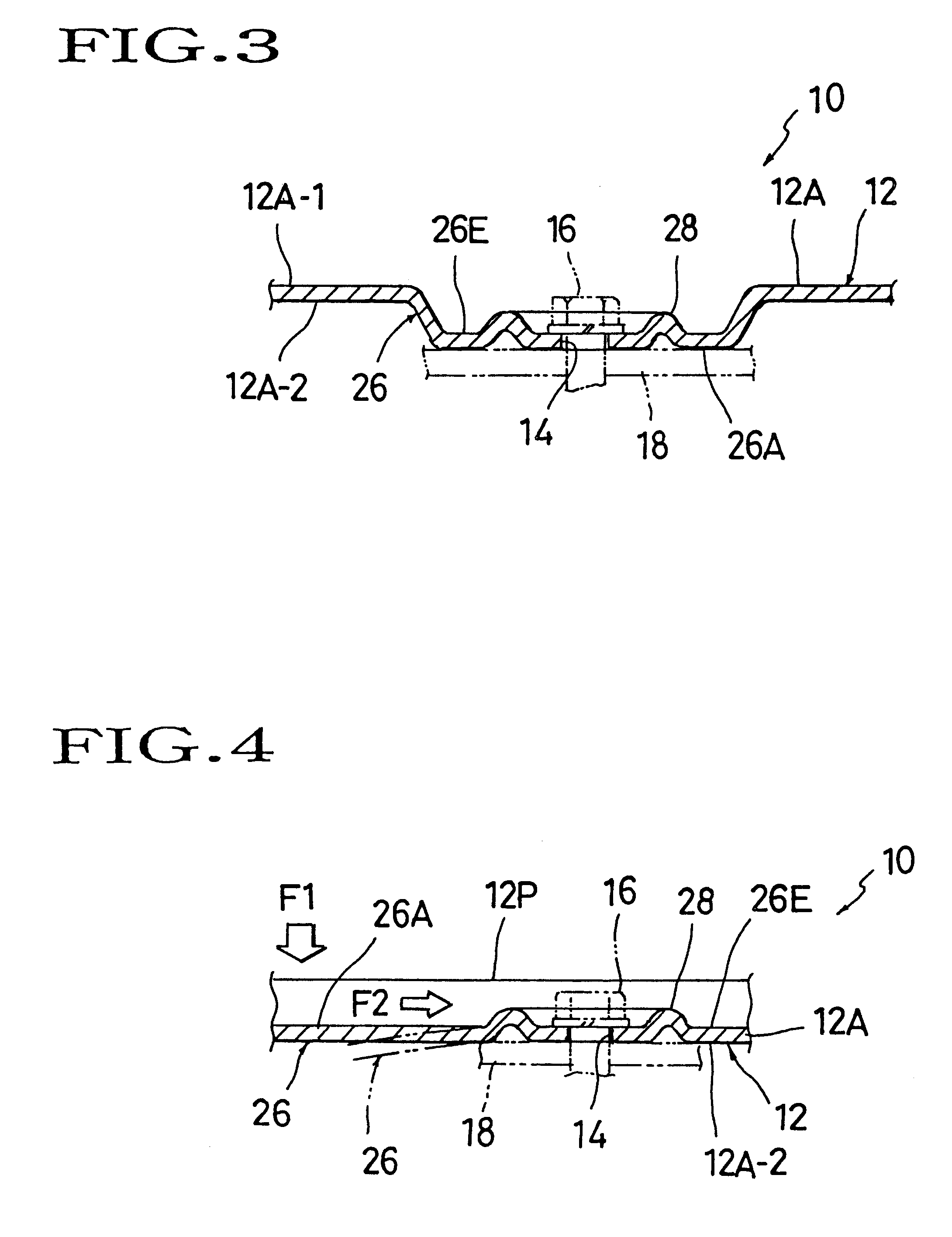

Pan frame structure of seat cushion of a vehicle seat

A structure of the so-called "pan frame" of seat cushion for use with a vehicle seat, which includes a primary reinforcing pattern press formed therein. The primary reinforcing pattern has a flat bottom region defined on its top and protrudes from the bottom wall of the seat-cushion pan frame. The primary reinforcing pattern further communicates with the securing areas where the frame is to be secured to a floor side of the vehicle. Hence, most of a load applied to the pan frame is dispersed via such pattern toward the securing areas, while being absorbed thereby. An auxiliary reinforcing pattern is press formed in the primary reinforcing pattern such as to surround each of the securing areas, thereby blocking further transmission of the load thereto. The primary reinforcing pattern may be of a generally X-shaped channel configuration which communicates its four channel sections with the securing areas, whereas the auxiliary reinforcing pattern be of an annularly protruded configuration that surrounds each of the securing areas.

Owner:TACHI S CO LTD

Novel coating for canned luncheon meat inner wall and production method thereof

ActiveCN1990798AStrong adhesion and impact resistanceImprove compactnessLinings/internal coatingsEpoxy resin coatingsSolventChemistry

The invention discloses a method for preparing coating material for luncheon meat cans inner wall. It comprises following steps: synthesing epoxy phenolic resin coatings A with high chemical resistant and mechanical property that meets food sanitary requirement; adding zinc oxide powder into A to mill for slurry B; immersing aluminum into solvent to form C; adding synthetic rap into A to form D after high- speed dispersion; putting A, B, C and D according to a certain proportion into reraction autoclave, stirring for 60 minutes and getting final product. The material A possesses sound chemical and mechanical resistant property, and strong adhesion and anti-impacting property with tinplate; the zinc oxide in B can react with sulfur released from meat, so the coating material can prevent the generation of ferrous sulfide and sulfue spot; the aluminum powder in C can cover the can and intensifies the compactness, and reduces corrison of sulfur to tinplate; the synthetic rap in D can increase the slippery of coating layer and demoulding effect, which enables smooth getting out for meat from can. The invention is characterized by simple and controllable process, lower cost and energy saving, and reduced waste discharge.

Owner:SHANGHAI MEILIN FOODS

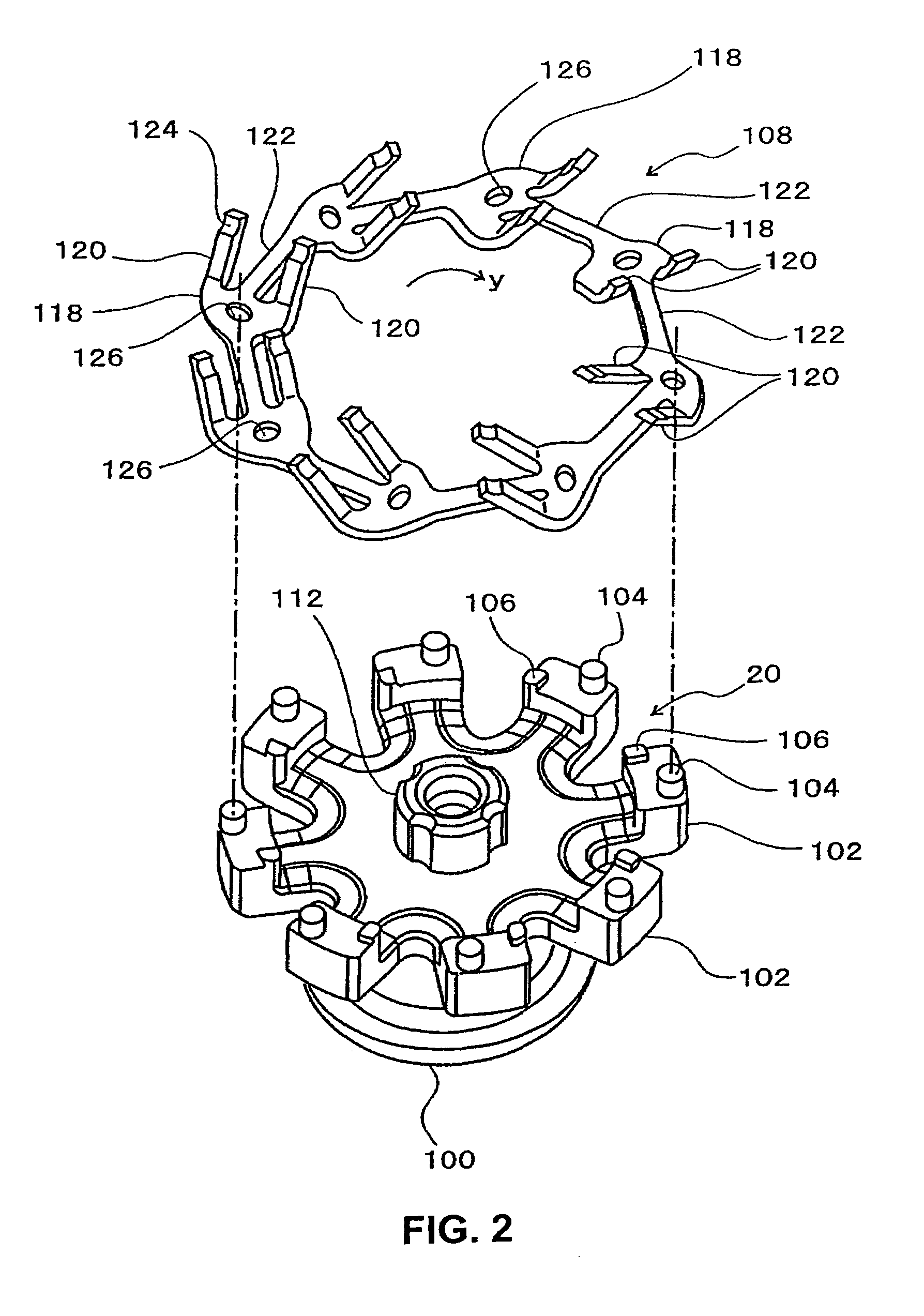

Rotary electric shaver

InactiveUS7665214B2Quality improvementImprove rigidityMetal working apparatusElectric razorsRazor Blade

Owner:IZUMI PROD CO

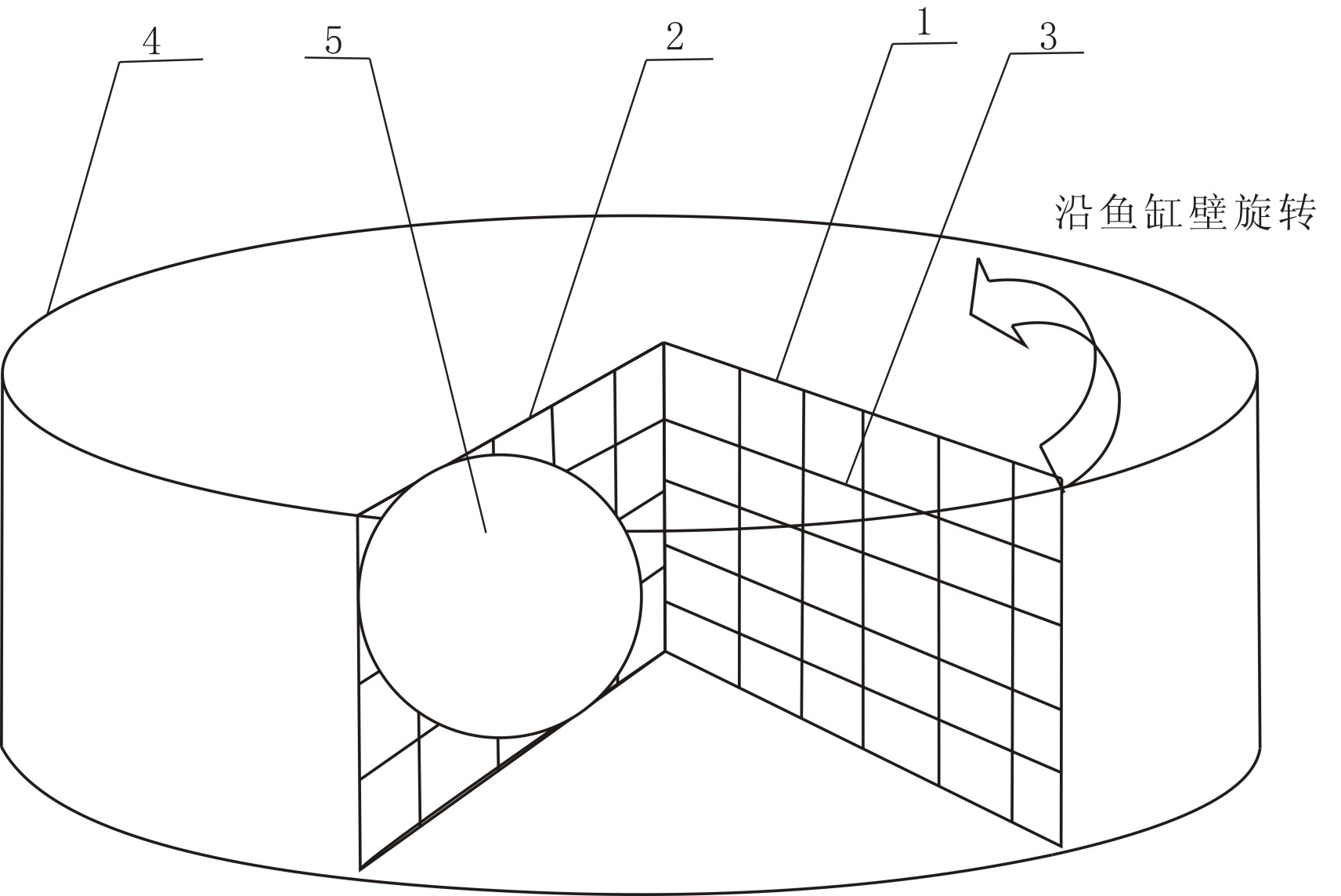

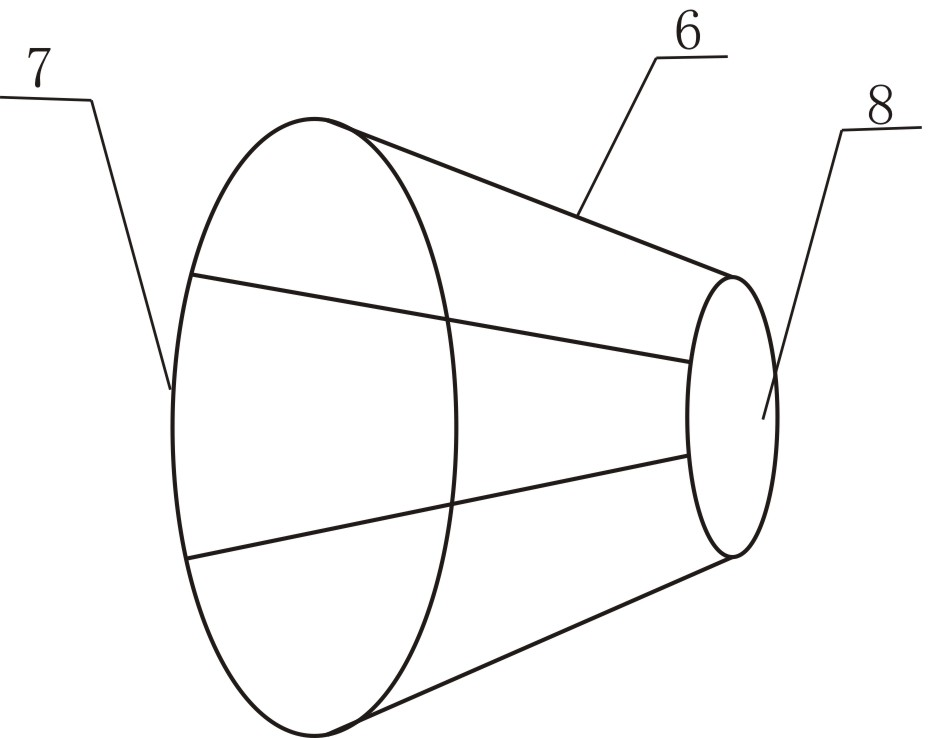

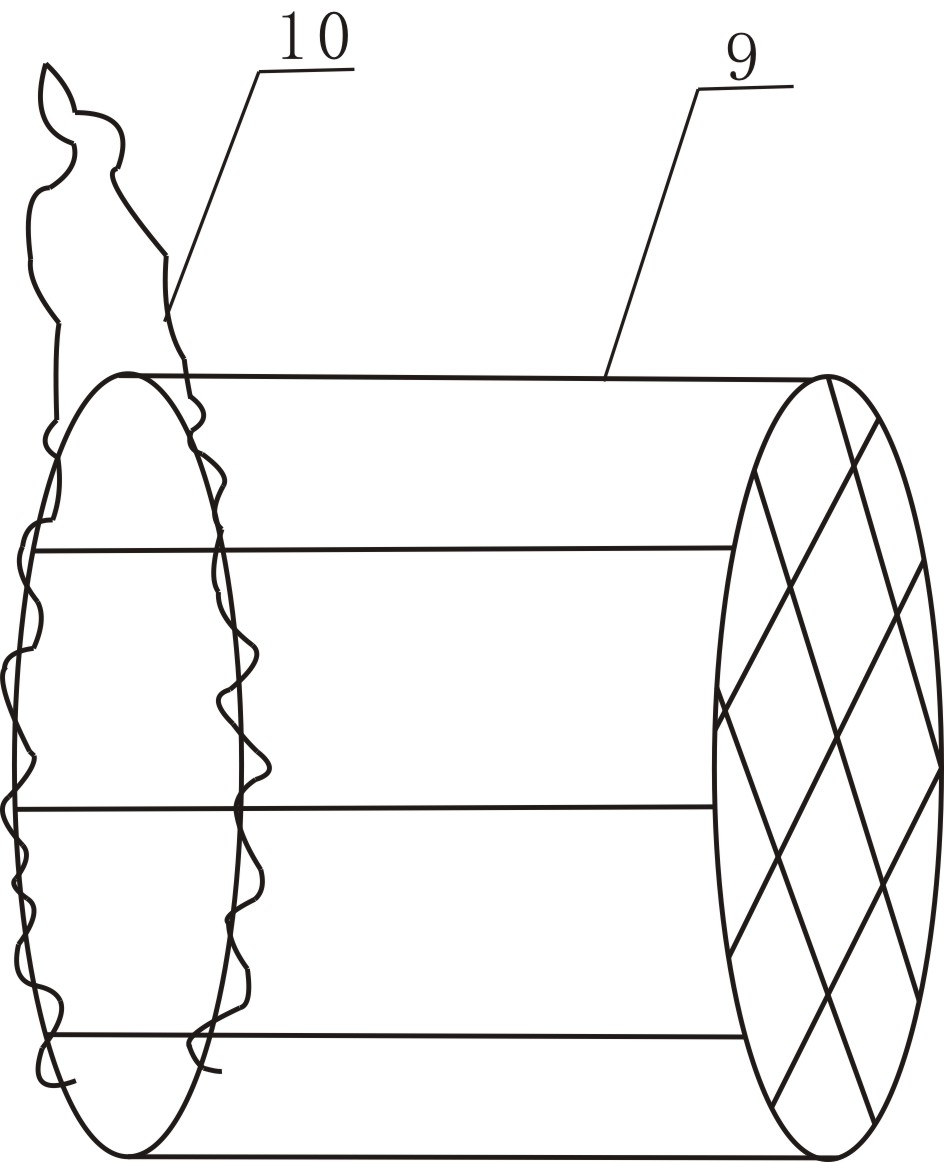

High-efficient harmless fishing device for fish tank

The invention relates to a high-efficient harmless fishing device for a fish tank. The high-efficient harmless fishing device comprises a driving mechanism, a fish passage mechanism and a fish collecting mechanism, wherein, in the driving mechanism, a fishing net is laid in a first rectangular frame and a second rectangular frame, one end of the first rectangular frame is articulated with one end of the second rectangular frame, and a round hole with the diameter which is consistent with the height of the second rectangular frame is formed on the fishing net in the second rectangular frame; in the fish passage mechanism, the diameter of a big port part of a conical cylinder is consistent with that of the round hole in the driving mechanism, and the diameter of a small port part of the conical cylinder is slightly larger than the average body height of a fish stock in the fish tank; and the fish collecting mechanism is of a mesh bag with one closed end, the open end of the mesh bag is matched with the big port part of the conical cylinder, and a lifting rope is arranged at the open end of the mesh bag by penetration. The high-efficient harmless fishing device for the fish tank, provided by the invention, can overcome the defects of the existing fishing way from the fish tank, realize fast-speed and high-efficient fishing and prevent harming fish during fishing, and further has extensive using value.

Owner:CHINA THREE GORGES UNIV

Variable stroke-characteristic engine for vehicle

InactiveUS7234424B2Improve cooling effectIncrease temperatureEngine controllersMachines/enginesActuatorCylinder block

In a variable stroke-characteristic engine for a vehicle, a control shaft and a control link are disposed on a front side of a vehicle body with respect to a crankshaft. An actuator for driving the control shaft is disposed on an outer surface of an engine block on the front side of the vehicle body. Thus, the actuator projects as much as possible from a position of the engine block toward the front side of the vehicle body so that traveling wind from ahead of the vehicle is effectively applied to the actuator to enhance the cooling effect. Hence, any temperature increase of the actuator is suppressed. Moreover, the actuator is disposed as far as possible from an exhaust manifold that is heated to a high temperature by the heat of an exhaust gas.

Owner:HONDA MOTOR CO LTD

Push-out type ice cube tray structure and refrigerator with push-out type ice cube tray structure

InactiveCN108981253AStable supportEscape smoothlyLighting and heating apparatusIce productionMarine engineeringRefrigerated temperature

The invention relates to the technical field of household appliance manufacturing and discloses a push-out type ice cube tray structure and a refrigerator with the push-out type ice cube tray structure. The push-out type ice cube tray structure comprises an ice cube tray, a base plate, a push-out part and an elastic support part, wherein a through hole is formed on a bottom wall of the ice cube tray; a barrel which extends downward is constructed on an edge of the through hole; the push-out part is arranged in the barrel; the through hole is plugged by the upper end of the push-out part; the lower end of the push-out part is fixedly connected with the base plate; the elastic support part is arranged between the barrel and the push-out part and is used for keeping the lower end of the barrel under a free suspending state; a first end of the elastic support part is resisted against the bottom wall of the ice cube tray; a second end of the elastic support part is resisted against the baseplate. The push-out type ice cube tray structure has the advantage that ice can be conveniently and quickly taken off.

Owner:HUBEI MIDEA REFRIGERATOR CO LTD

Marine escape door

InactiveCN105350881AImprove sealingEscape smoothlyPower-operated mechanismWar-like protectionDetonatorSolid nitrogen

The present invention discloses a marine escape door. The marine escape door comprises a door frame installed on a cabin, notches being disposed at all four corners of the door frame; an escape door installed inside the door frame and equipped with a lock, a baffle plate being installed at a side face of the escape door, a ring of air sac being installed at one side of the baffle plate and being internally equipped with solid nitrogen particles, and electric detonators being installed at four corners inside the air sac; and a switch being installed in the center of an inner surface of the escape door and connected with the four electric detonators. Through the above method, the marine escape door provided by the present invention is used inside the cabin, a conventional escape door is hard for escape because the cabin door has the characteristics of being excellent in leakproofness, and with adoption of the air sac of the marine escape door, the door and the door frame can be separated, thereby ensuring smooth escape of people.

Owner:SUZHOU JINYE MARINE MACHINERY PLANT

Rotary electric shaver

InactiveUS20070113408A1Improve rigidityImprove sound qualityMetal working apparatusEngineeringElectric razors

Owner:IZUMI PROD CO

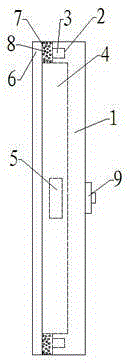

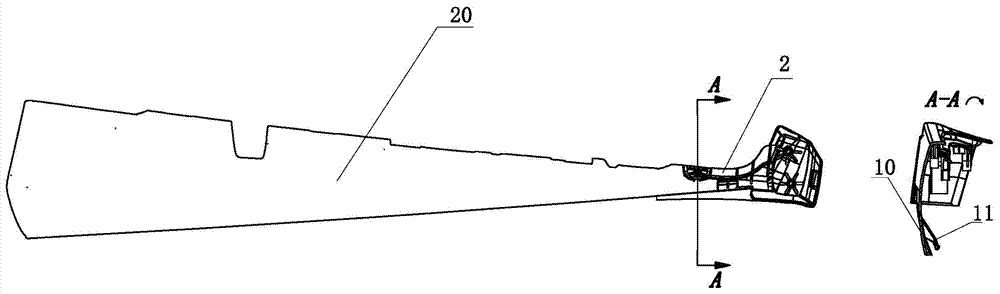

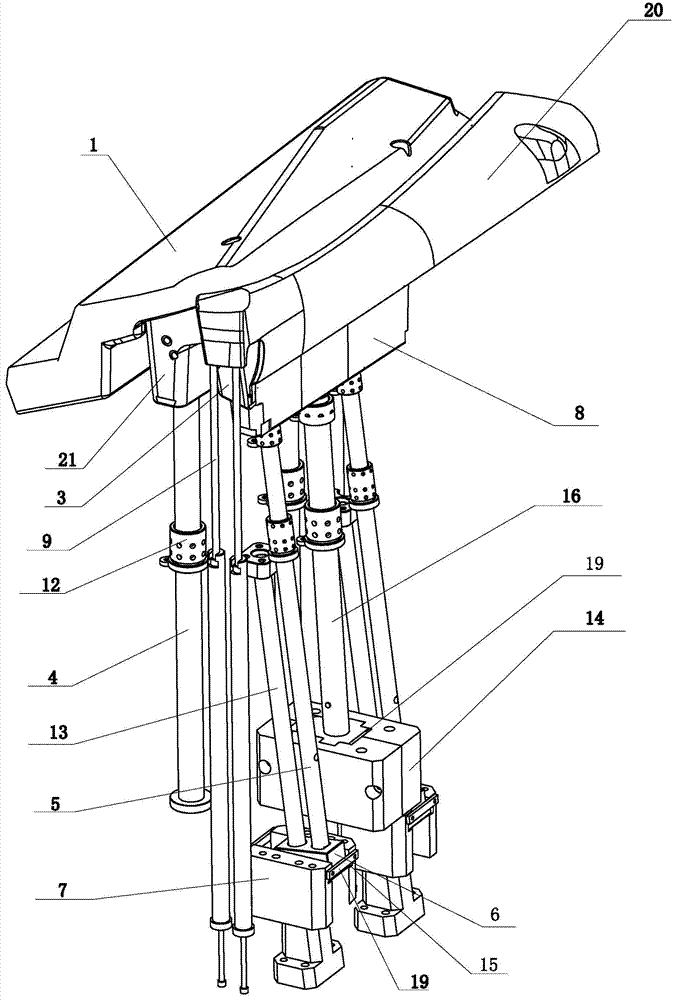

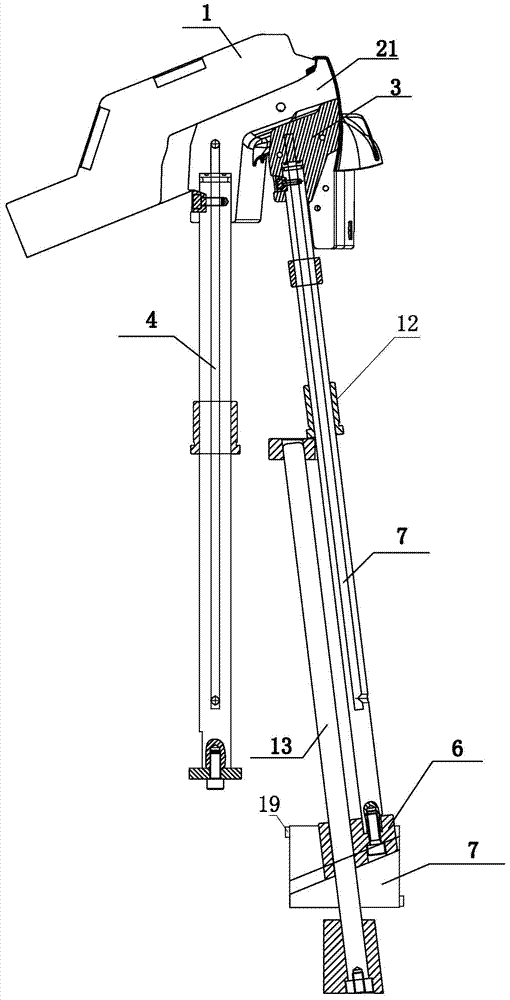

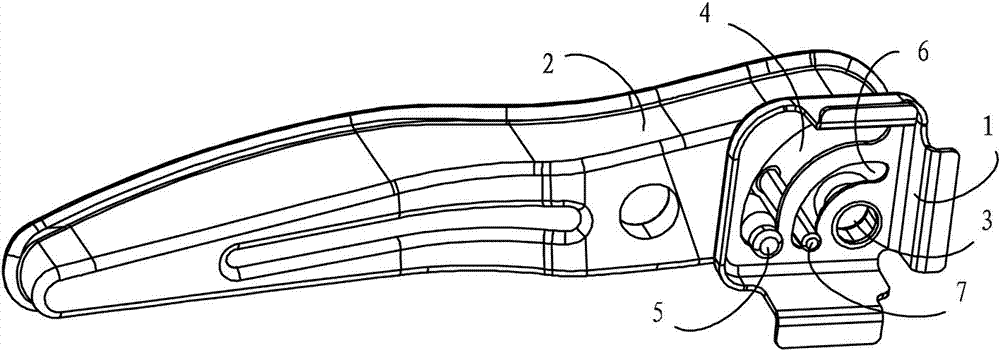

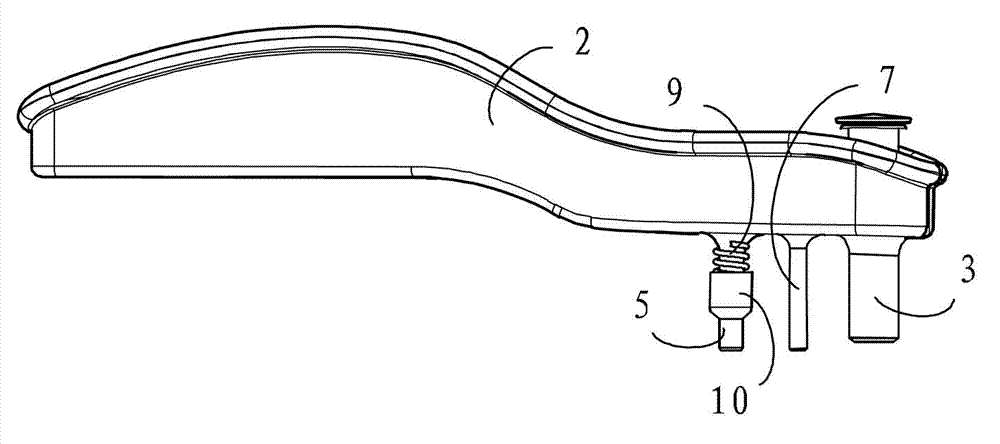

Core pulling mechanism of automobile front door upper framework

The invention discloses a core pulling mechanism of an automobile front door upper framework. The core pulling mechanism comprises a product (20), wherein the product (20) comprises a small end (2); the lower part of the small end (2) is provided with a warped surface (10); the inner side of the warped surface (10) is provided with an inverted buckle (11); an included angle between the inverted buckle (11) and the vertical direction is 50 degrees-65 degrees; the product (20) also comprises a core pulling mechanism for pulling a core of the small end (2); the core pulling mechanism comprises a slide block (1), a straight ejector (21), an oblique ejector (3), an oblique ejector body (8), a first oblique ejector slide base (7) and a second oblique ejector slide base (14), wherein the straight ejector (21) is positioned on the inner side of the upper part of the small end (2); the lower end of the straight ejector (21) is provided with a straight ejector bar (4); the slide block (1) is matched with the oblique surface of the upper end surface of the straight ejector (21). The invention provides the core pulling mechanism of the automobile front door upper framework, which is large in oblique ejector walking angle, can guarantee no seizing and self-locking in the walking process, and is beneficial to core pulling.

Owner:NINGBO FANGZHENG TOOL

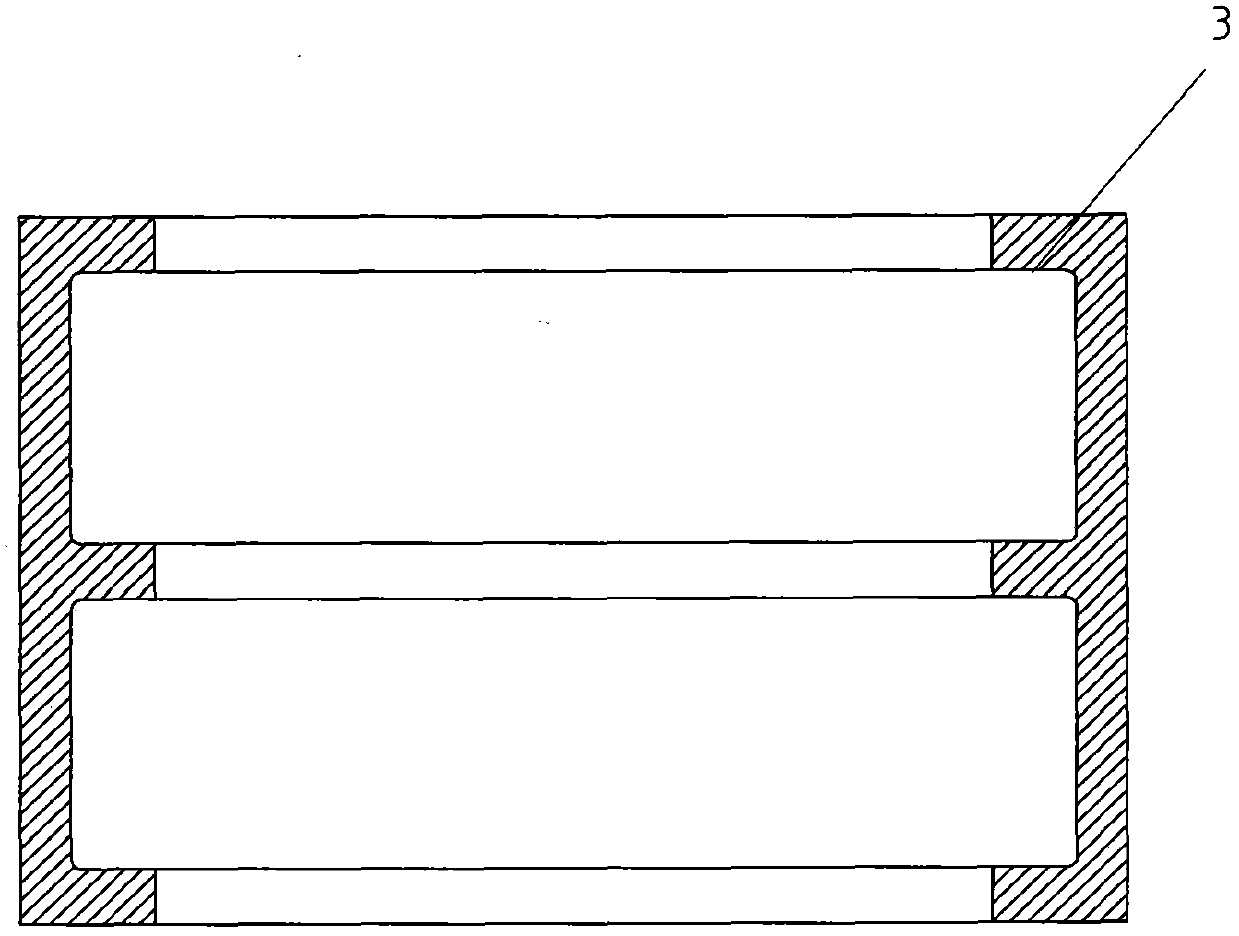

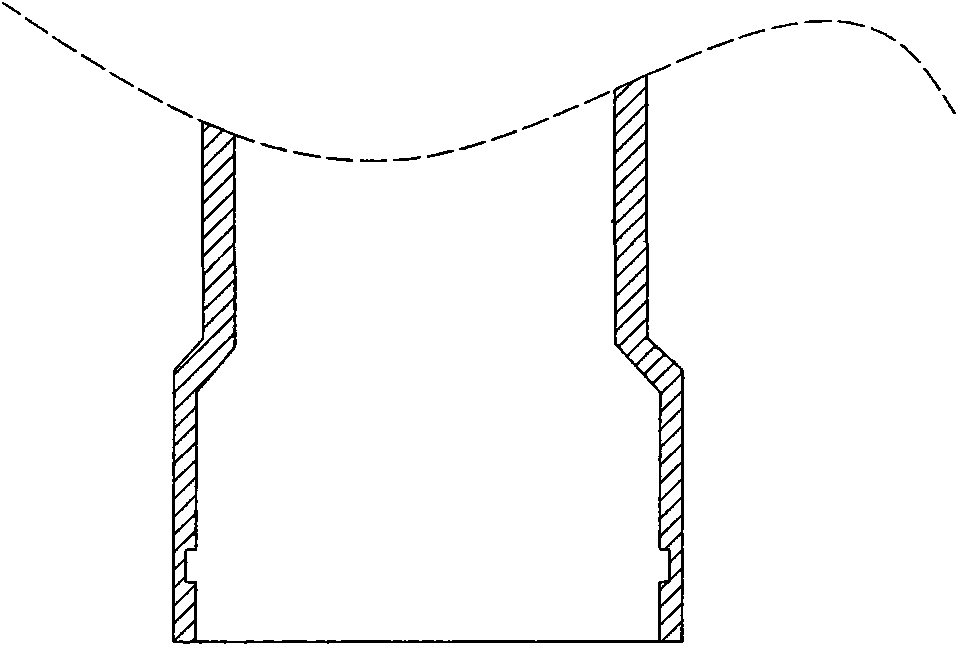

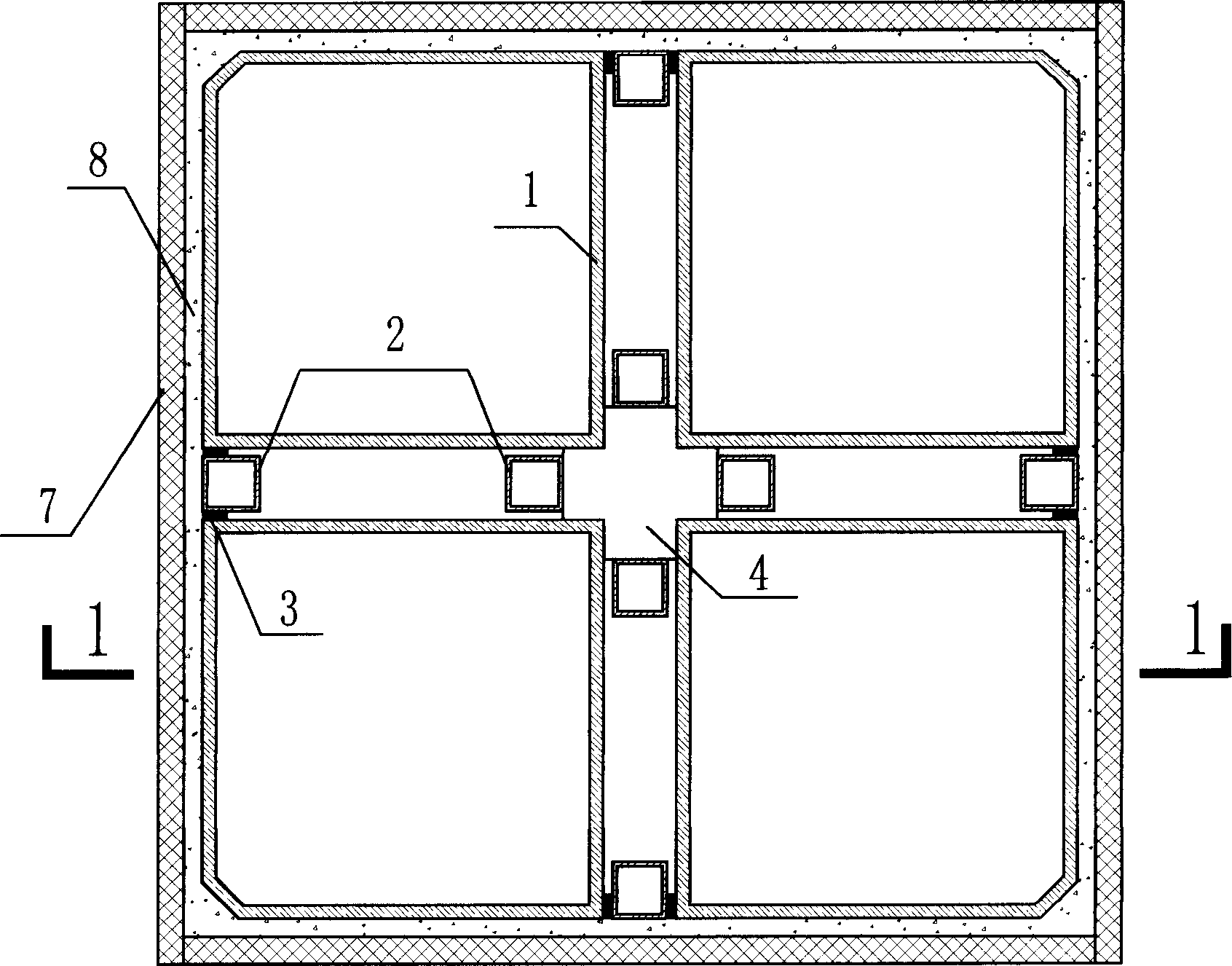

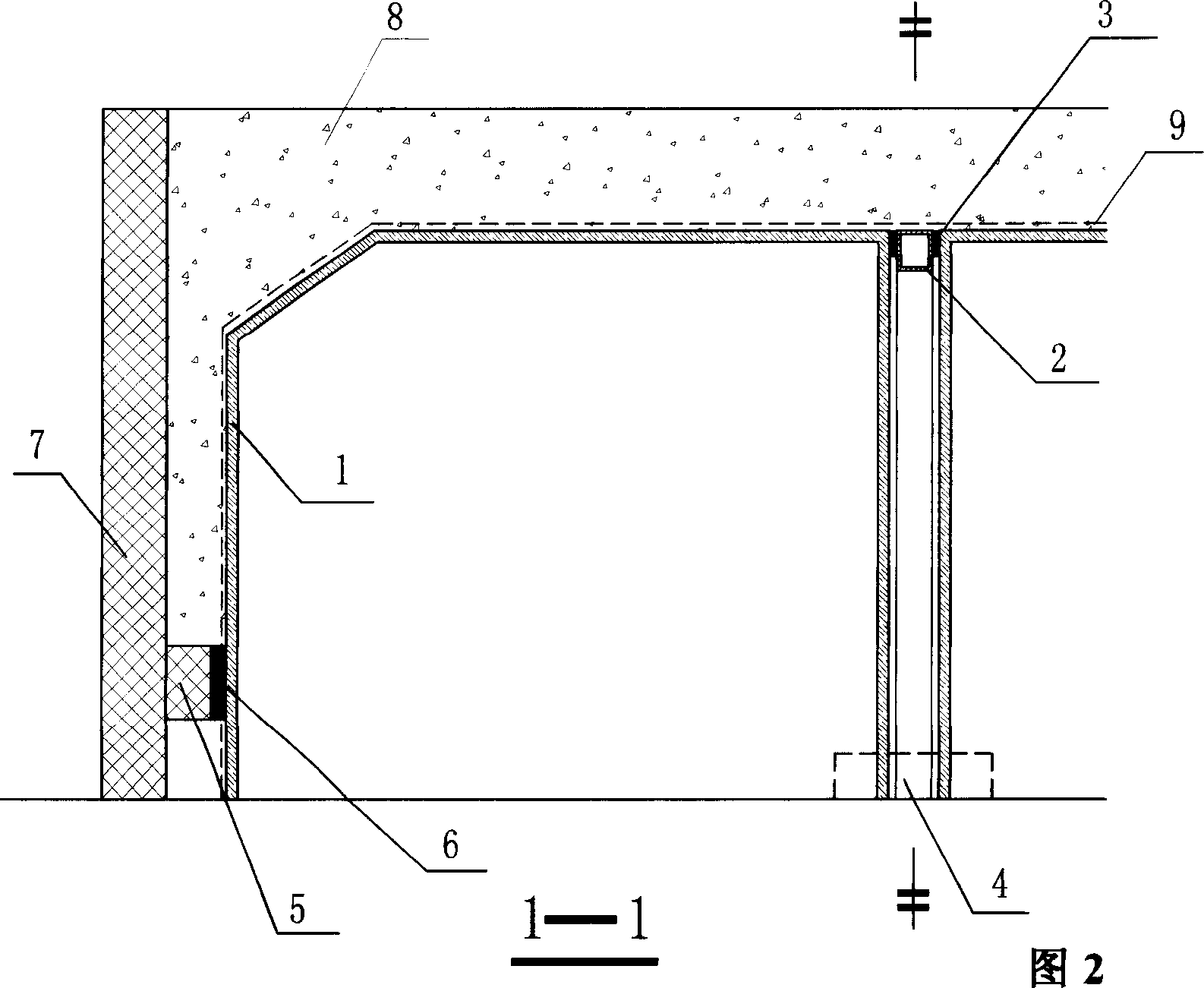

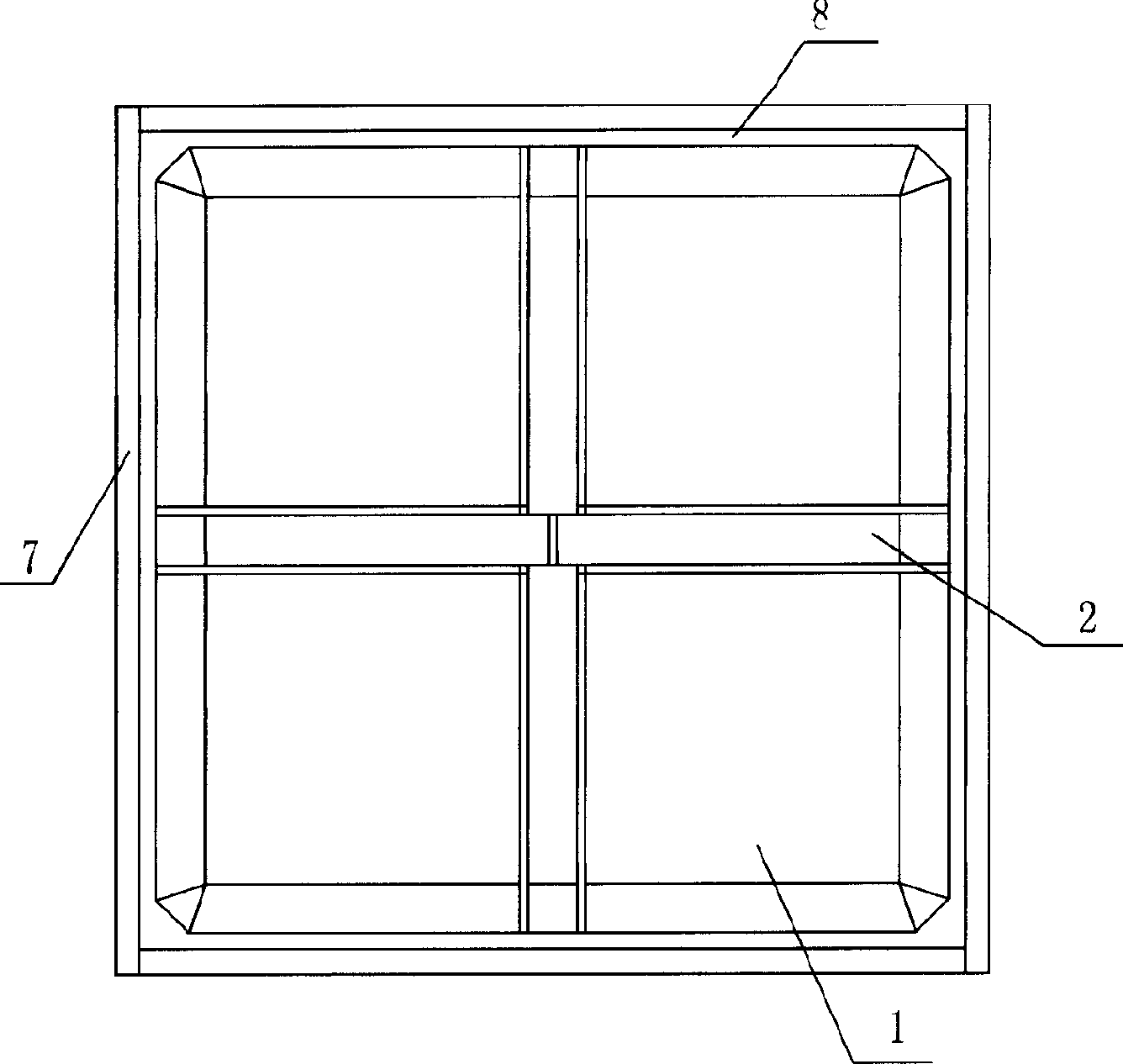

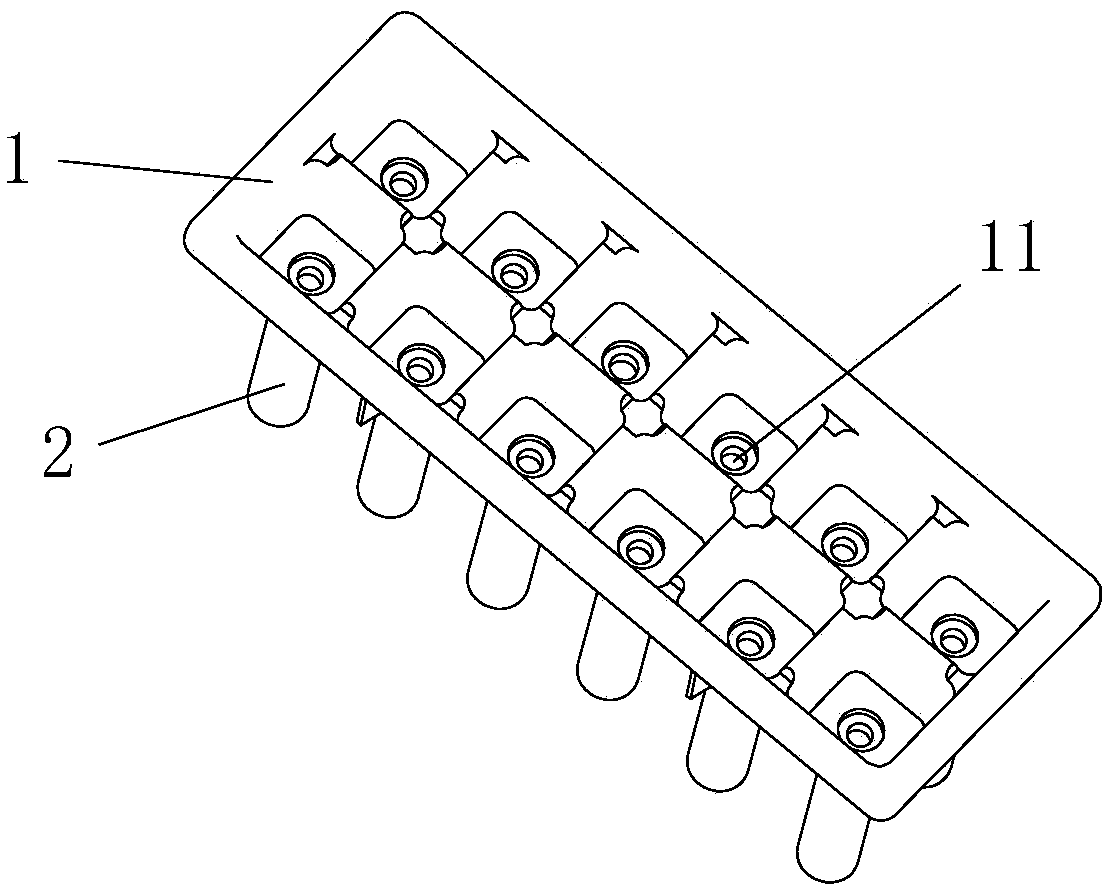

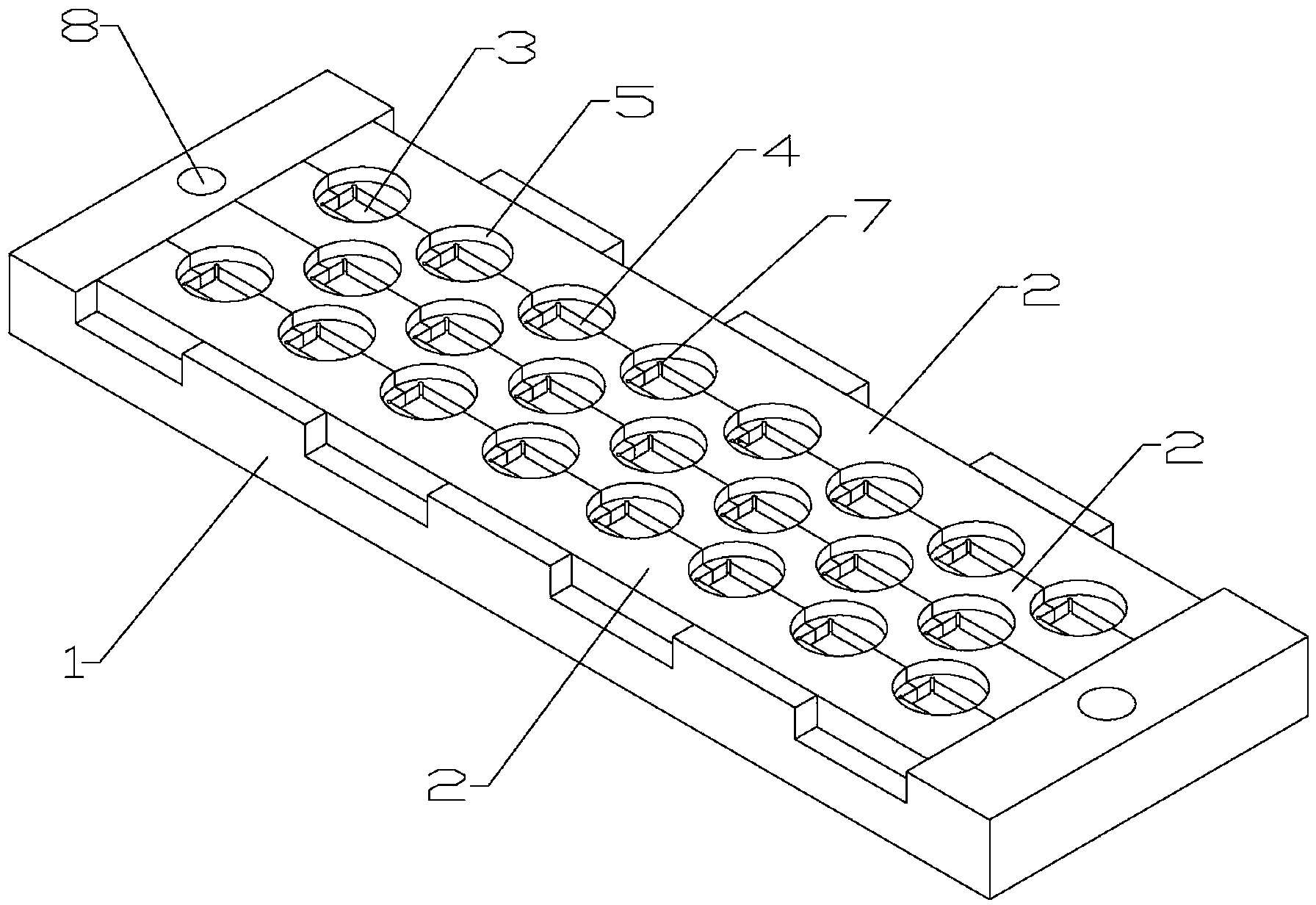

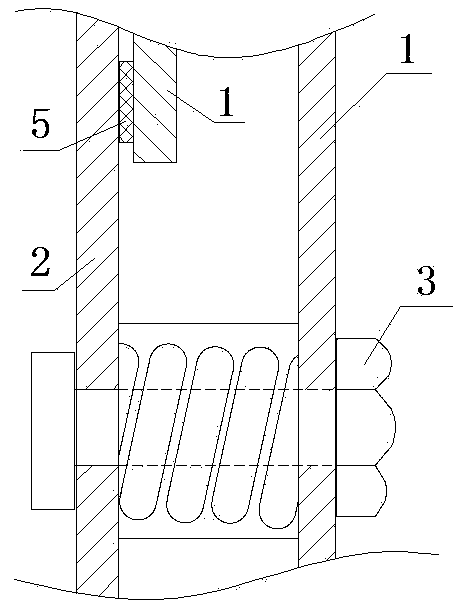

Graphite die for sintering multichip

InactiveCN103077912AEscape smoothlyTo achieve the purpose of assembly and sinteringSemiconductor/solid-state device manufacturingGraphiteSintering

The invention discloses a graphite die for sintering a multichip. The graphite die comprises a graphite bottom plate (1) and a graphite assembling strip (2); a sintering groove (3) with an opening is formed on the side part of the graphite assembling strip (2); the sintering groove (3) comprises a sintering chamber (4), an upper sintering groove (5) and a lower sintering groove (6), wherein the upper sintering groove (5) and the lower sintering groove (6) are formed on the upper side and the lower side of the sintering chamber (4) and are communicated with the sintering chamber (4); the dimension of the sintering chamber (4) in the length direction and the width direction of the graphite assembling strip (2) is smaller than the dimensions of the upper sintering groove (5) and the lower sintering groove (6) along the length direction and the width direction of the graphite assembling strip (2). According to the graphite die for sintering the multichip, disclosed by the invention, the structure of each part of the upper sintering groove of the graphite assembling strip is designed according to the structure of a design product, so that the chip in each position can be matched with different positions on the sintering grooves, and the chips can be prevented from collapsing during being assembled and sintered; and the graphite die has the characteristics of being simple in structure and convenient to use, and is suitable for popularization and application.

Owner:YIXING HUANZHOU MICRO ELECTRONICS

Mechanism for separating plastic products from slide blocks on four sides

The invention discloses a mechanism for separating plastic products from slide blocks on four sides, belonging to the field of a thermoplastic forming mould. The mechanism is characterized in that during mould opening, a fixed mould seat plate and a fixed molding board are bounced off under action of tension of a spring; an inclined wedge fixed on the fixed mould seat plate drives the fixed mould slide blocks to move, so that the fixed mould slide blocks are separated to get out of inverted buckle parts outside the plastic products; meanwhile, the fixed mould slide blocks are used for limiting, inserting and separating movable mould internal-drawing slide blocks, so that the movable mould internal-drawing slide blocks are internally core-pulled under the action of the tension of the spring to get out of the inverted buckle parts inside the plastic products; during mould closing, the inclined wedge guides the fixed mould slide blocks to move, so that the fixed mould slide blocks at the two sides are in surface contact; meanwhile, tapered bosses of the fixed mould slide blocks contact with tapered slots in the tops of the movable mould internal-drawing slide blocks to complete mould closing. The fixed mould slide blocks and the movable mould internal-drawing slide blocks move, so that the products are got out of the inverted buckle parts in four directions, and therefore, a mould structure is simplified, and production efficiency is improved.

Owner:DALIAN LUANYI PRECISION ENG

Seat armrest support structure

Owner:GREAT WALL MOTOR CO LTD

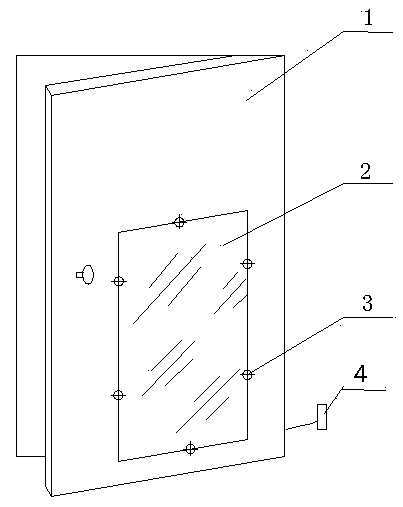

Explosion fire door

InactiveCN104343356AOpen the escape method quicklySimple and fast operationFireproof doorsPeep-holesEngineeringFire door

The invention provides an explosion fire door. The explosion fire door comprises a door sheet (1), a fire-resisting glass (2) mounted onto the door sheet (1), and explosive bolts (3) electrically connected with an initiation button (4) through an initiation circuit, wherein the circumference of the fire-resisting glass (2) is connected with the door sheet (1) through the explosive bolts (3). Fire doors are wide in application range, and most of the fire doors are made of steel and are hard in texture, consequently, when fire breaks, the fire doors cannot be opened or artificially sabotaged for escape, and further people can miss optimal escape opportunities to result in accidents and life losses and injuries. The explosion fire door is high in escape speed and simple and quick in operation.

Owner:XIAN DASHENG FIRE DETECTION

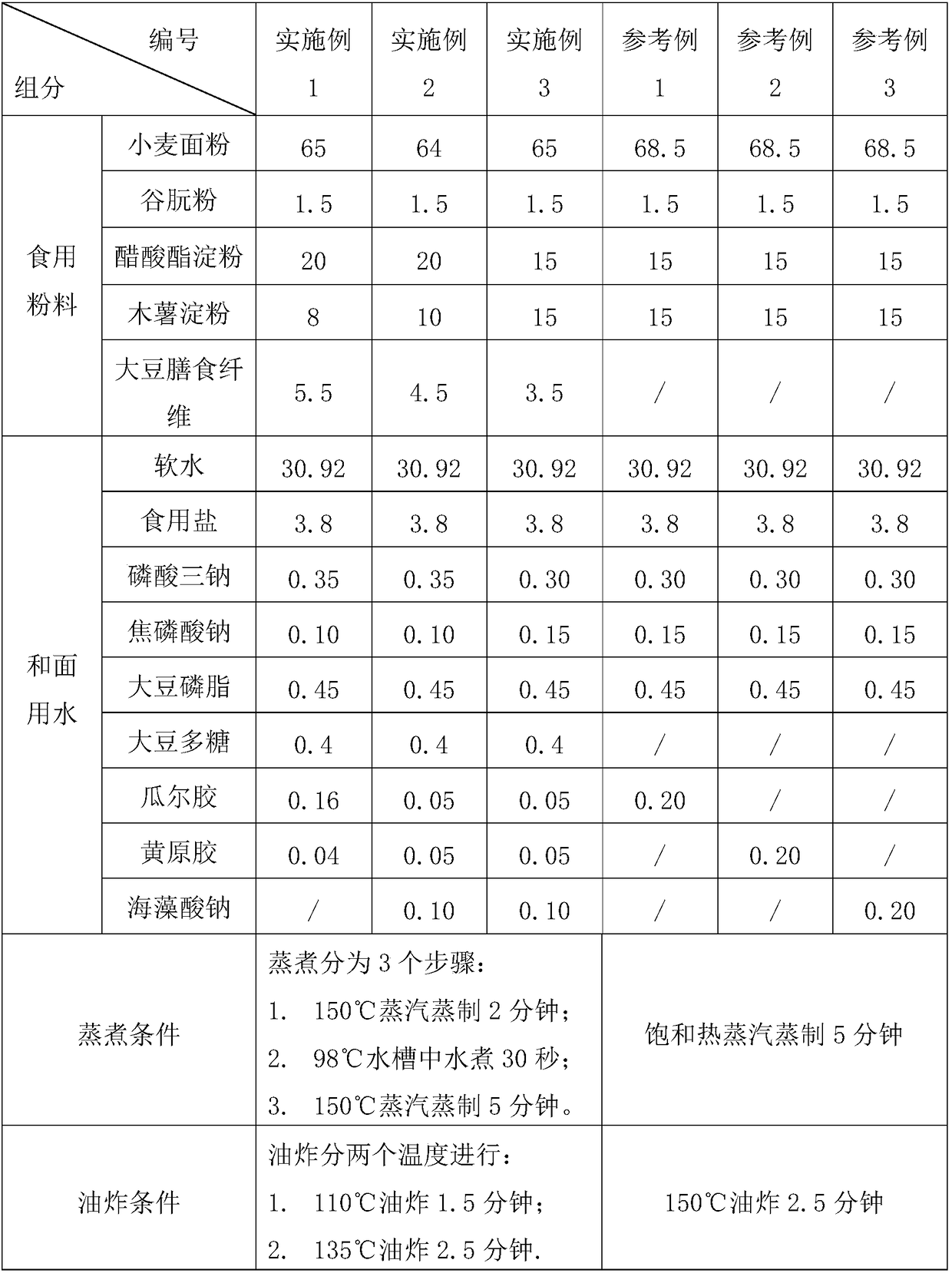

Oil-fried Udon noodles and processing method thereof

InactiveCN108208578AExcellent extension performanceExcellent pasting propertiesFood scienceWater solubleWater use

The invention discloses a processing method of oil-fried Udon noodles. The processing method of the oil-fried Udon noodles comprises the following steps of uniformly dissolving edible salt, compound phosphates, an emulsifier, a thickening agent and water-soluble soybean polysaccharides in weakly alkaline soft water so as to obtain water used for making dough; adding the water used for making doughinto edible flour, and carrying out vacuum stirring so as to make dough; performing 1-time compounding on the dough by utilizing a composite rolling machine so as to obtain a dough band, and performing curing treatment on the dough band; rolling the dough band by using a rolling machine so as to obtain dough sheet; cutting the dough sheet into stripes by using a cutter, and carrying out preliminary shaping by performing knurling by using a baffle so as to obtain noodles; sending the shaped dough noodles into a staged steaming box via a conveyor belt; stretching the steamed noodles, carrying out quantitative cutting, and carrying out oil-frying in a pan so as to carry out dewatering, and thus, oil-fried noodle blocks are prepared. The noodles are oil-fried by adopting two-stage oil-frying,wherein the first stage is low-temperature frying and the second stage is high-temperature frying. By optimizing raw material formula and processing method, the oil-fried Udon noodles prepared according to the processing method are chewy, soft and smooth in taste, as well as good in tenacity. And thus, a new idea and direction of noodle product industry is provided. The oil-fried Udon noodles andthe processing method thereof have wide market prospects and market benefits.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

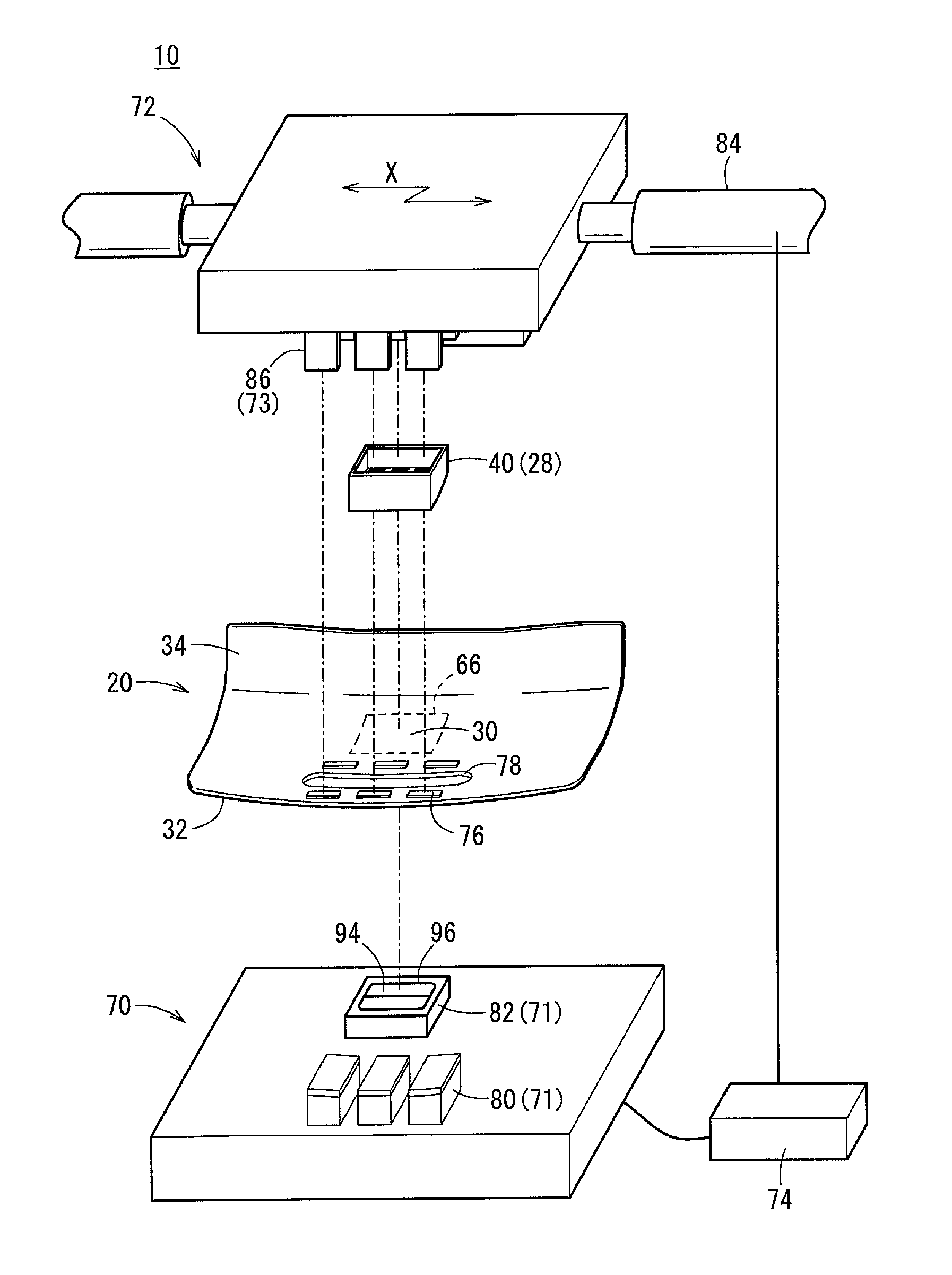

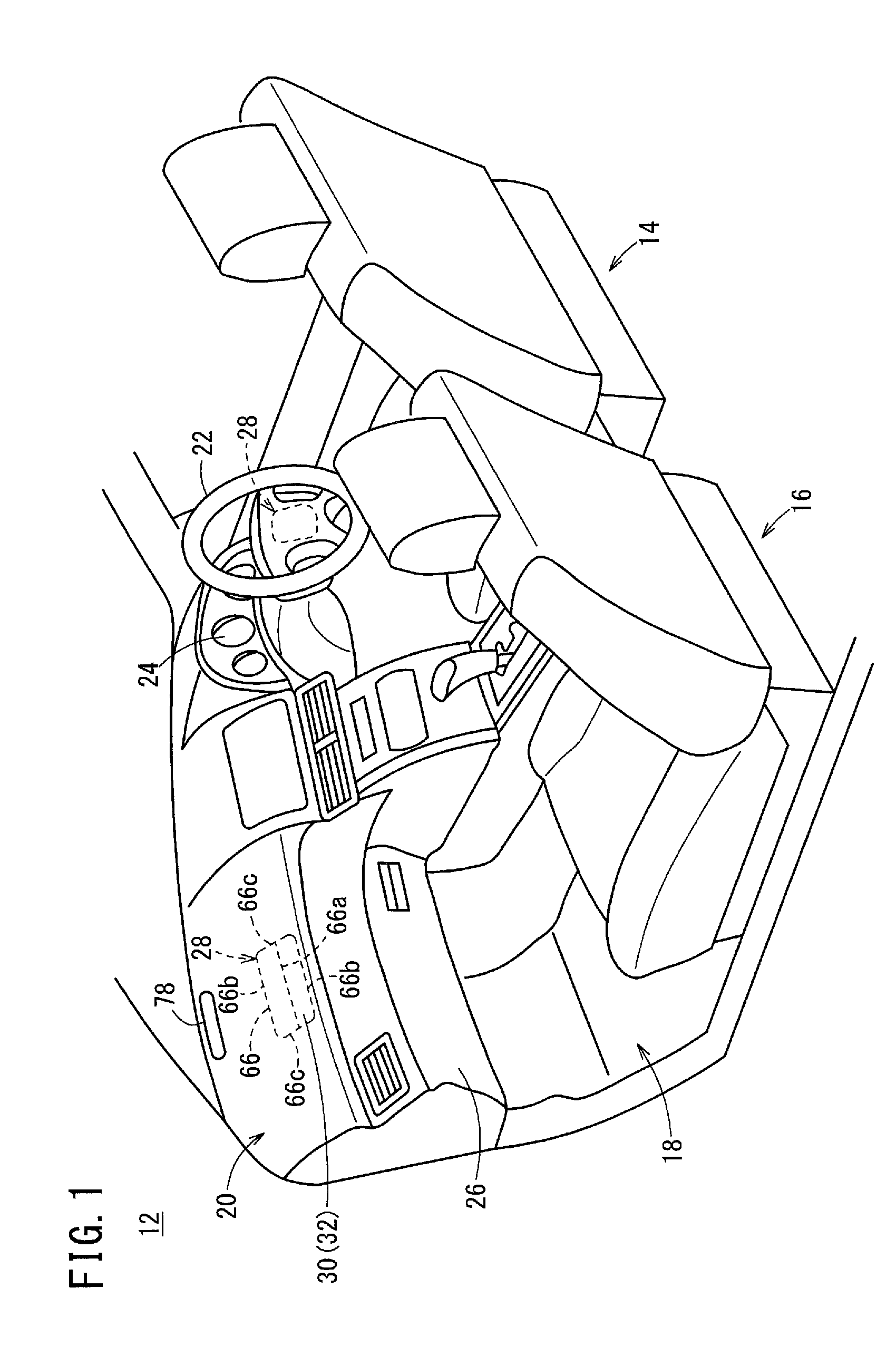

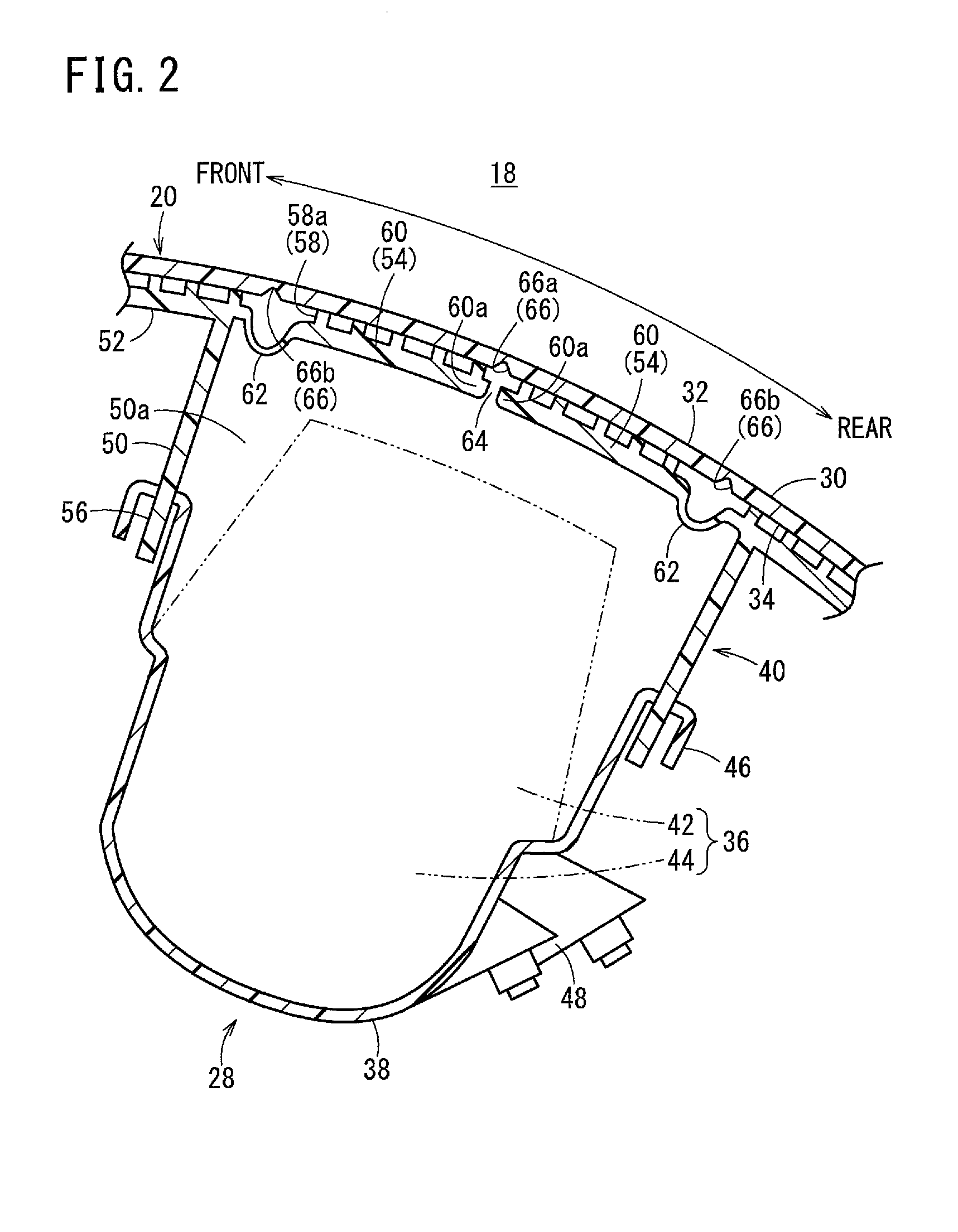

Vibration welding device and vibration welding method

ActiveUS20160144557A1Improve workpiece qualityImprove product qualityPedestrian/occupant safety arrangementWelding/cutting auxillary devicesEngineeringThermal expansion

This vibration welding device is a device that vibration welds an airbag holding box and an installment panel having a tear line. The vibration welding device is provided with a support jig that carries and affixes the installment panel during vibration welding. The support jig is provided with a groove that permits thermal expansion during vibration welding of the installment panel at a position differing from the tear line.

Owner:HONDA MOTOR CO LTD

Injection mold for forming assembly

InactiveCN106584774AGuaranteed successful separationWon't hurtDomestic articlesEngineeringMechanical engineering

The invention provides an injection mold for forming assembly. The injection mold comprises a lower mold base, a pad foot, a fixed template, a movable template, a fixed plate and an upper mold base; an ejector plate is arranged between the lower mold base and the fixed template; four inclined ejector rods are uniformly distributed on the ejector plate; ejector blocks are fixed at the head parts of the ejector rods; multiple molding cores are uniformly distributed at the bottom of the movable template; a sprue sleeve is arranged in the center of the upper mold base; a runner is formed in the center of the sprue sleeve; and the runner includes a main runner for penetrating through the fixed plate along the center of the sprue sleeve, and a branch runner positioned between the fixed template and the fixed plate. The injection mold for forming assembly realizes secondary mold opening thereof through use of two simple structures of an elastic block and a pull rod, totally separates workpieces from wastes during mold opening, is flat in section, is easy to take out the wastes, is convenient to machine, and is higher in forming rate.

Owner:天津格林特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com