Demolding mechanism for full circle internal reverse clamp of automotive air inlet pipe

A demoulding mechanism and air intake pipe technology, which is applied in the field of automobile air intake pipe injection molds, can solve the problems of insufficient compact structure and difficult manufacturing, and achieve the effect of simple structure, ingenious action principle, and easy manufacture and popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

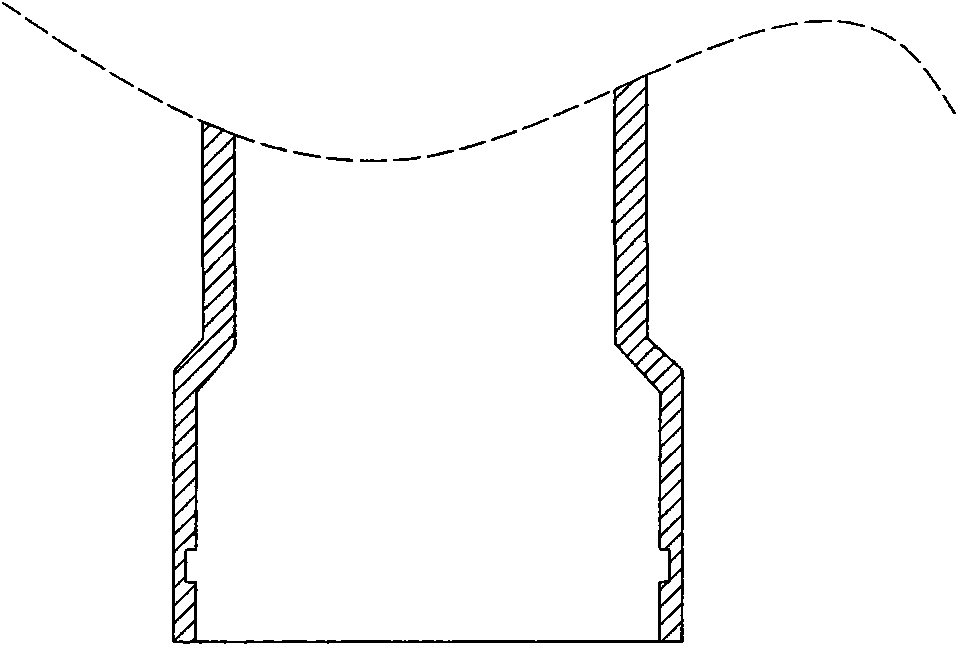

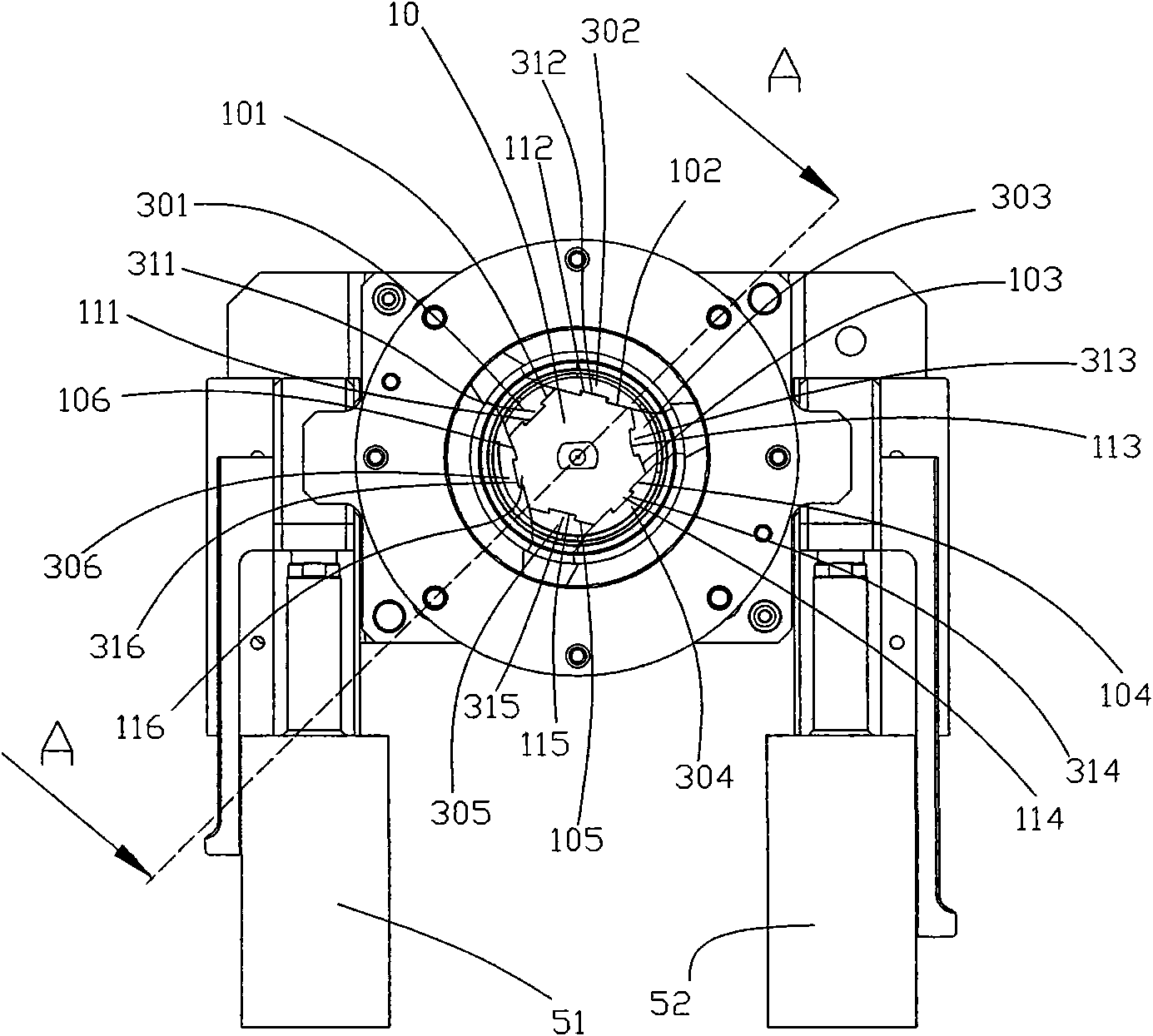

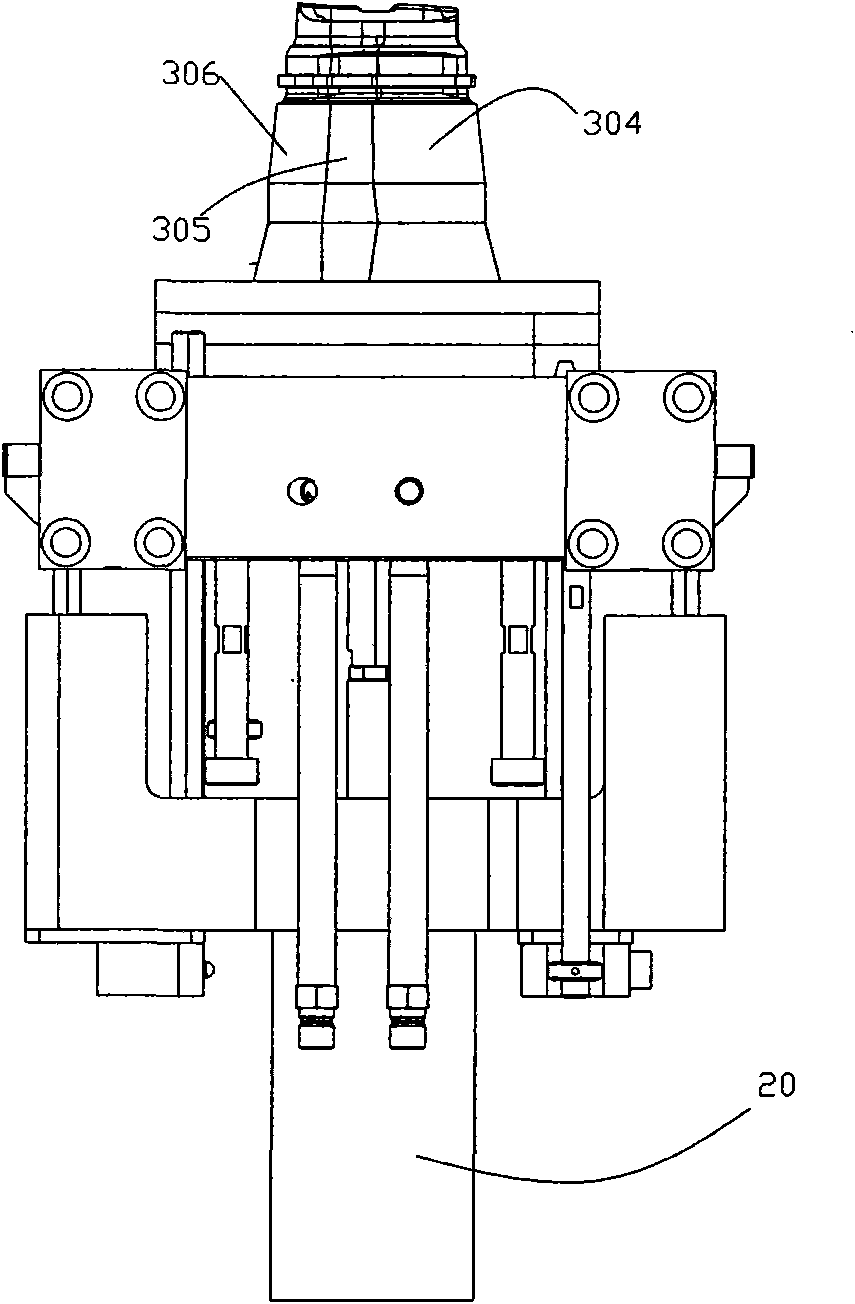

[0022] like figure 2 , image 3 , Figure 4 and Figure 5 As shown, in one embodiment of the demoulding mechanism for the full-circle inner undercut of the automobile intake pipe of the present invention, it includes a mandrel 10, a core-pulling device 20 connected to the mandrel, and the core-pulling device 20 can be a hydraulic cylinder Or other commonly used core-pulling structures. In this embodiment, the core-pulling device 20 is a hydraulic cylinder, and the mandrel 10 has six inclined surfaces 101, 102, 103, 104, 105 and 106, wherein the inclined surfaces 101, 103 and 105 are The first slope, the slopes 102, 104 and 106 are the second slope, the first slope and the second slope are arranged at intervals, the angle between the first slope and the axis of the mandrel 10 is greater than the angle between the second slope and the axis of the mandrel 10 ; The demoulding mechanism also includes six oblique sliders 301, 302, 303, 304, 305 and 306, wherein the oblique slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com