Patents

Literature

1866 results about "Oblique plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oblique plane (plural oblique planes) A plane which declines from the zenith, or inclines toward the horizon.

Catheter tracking with phase information

ActiveUS20050245814A1Precise positioningTrack positionCatheterDiagnostic recording/measuringLaparoscopesBiopsy

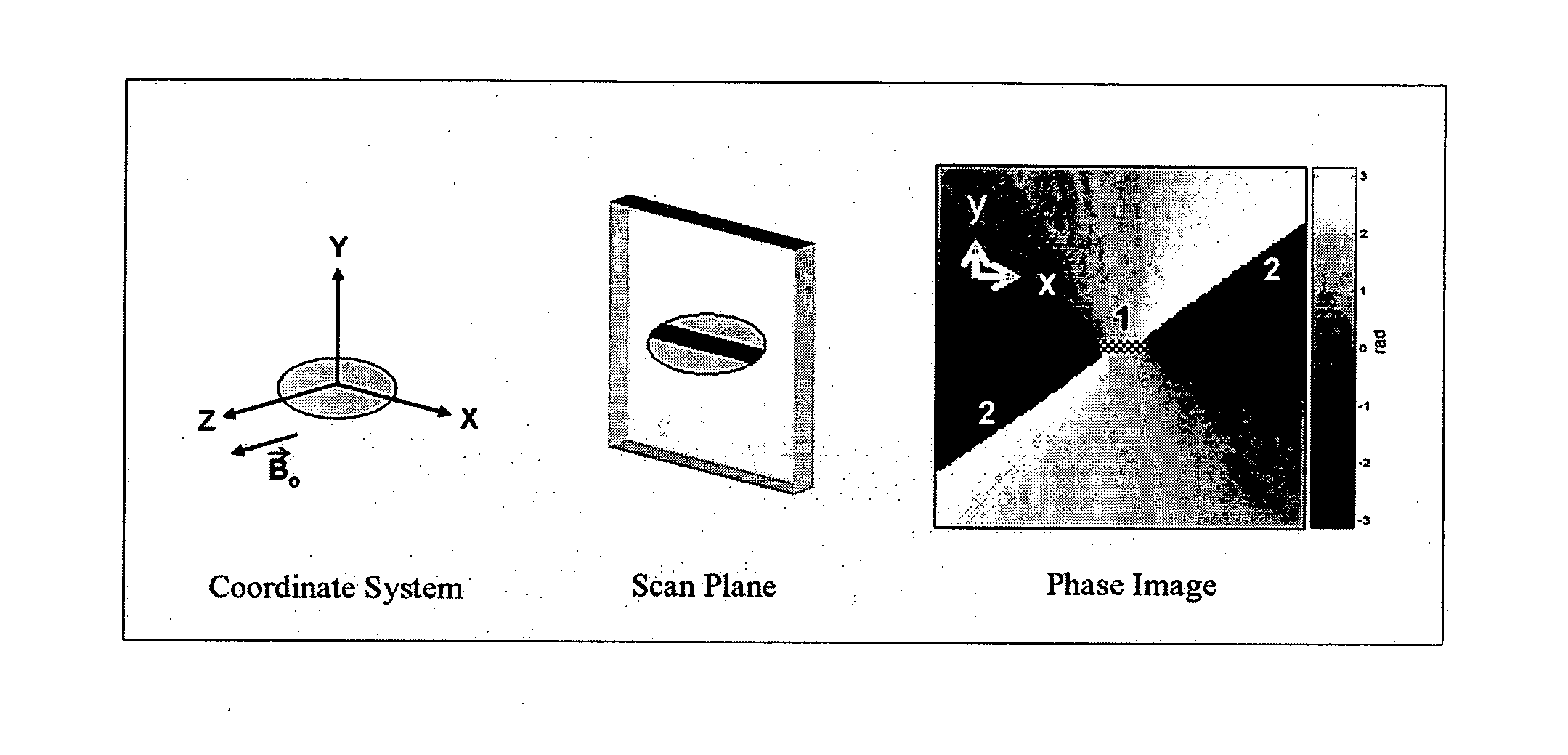

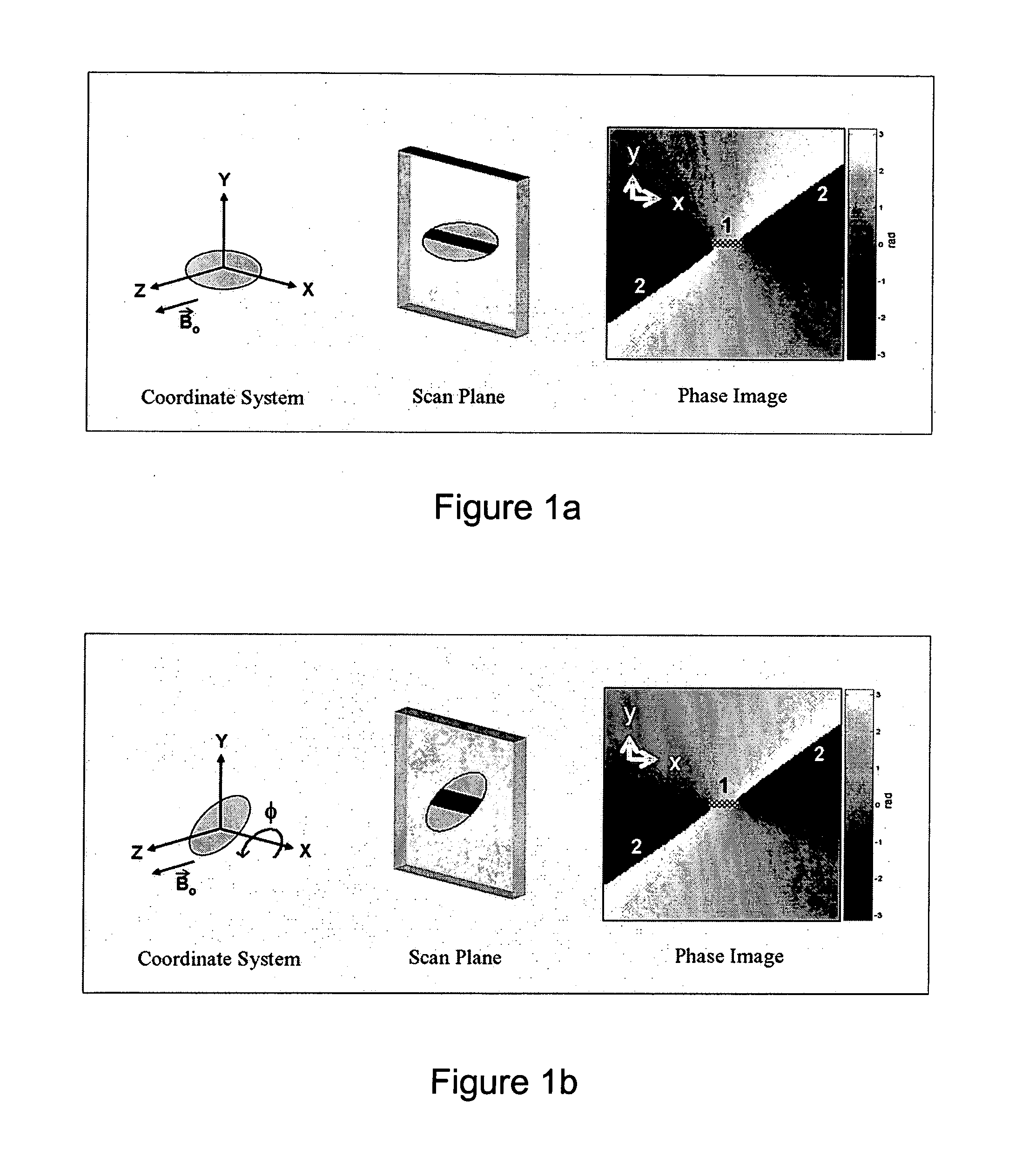

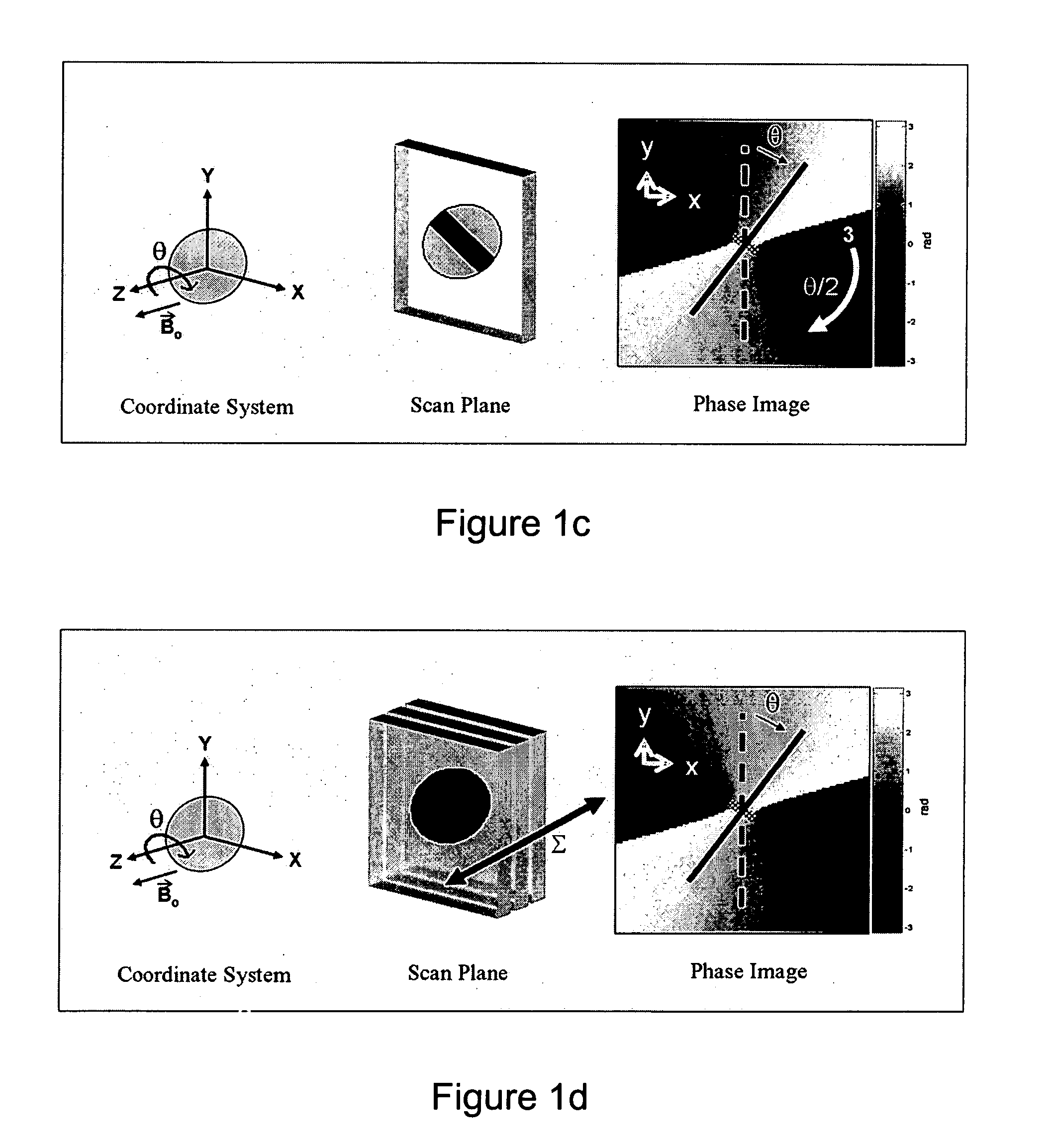

The present invention discloses a method for determining the position and / or orientation of a catheter or other interventional access device or surgical probe using phase patterns in a magnetic resonance (MR) signal. In the method of the invention, global two-dimensional correlations are used to identify the phase pattern and orientation of individual microcoils, which is unique for each microcoil's position and orientation. In a preferred embodiment of the invention, tracking of interventional devices is performed by one integrated phase image projected onto the axial plane and a second image in an oblique plane through the center of the coil and normal to the coil plane. In another preferred embodiment, the position and orientation of a catheter tip can be reliably tracked using low resolution MR scans clinically useful for real-time interventional MRI applications. In a further preferred embodiment, the invention provides real-time computer control to track the position of endovascular access devices and interventional treatment systems, including surgical tools and tissue manipulators, devices for in vivo delivery of drugs, angioplasty devices, biopsy and sampling devices, devices for delivery of RF, thermal, microwave or laser energy or ionizing radiation, and internal illumination and imaging devices, such as catheters, endoscopes, laparoscopes, and related instruments.

Owner:SUNNYBROOK HEALTH SCI CENT +1

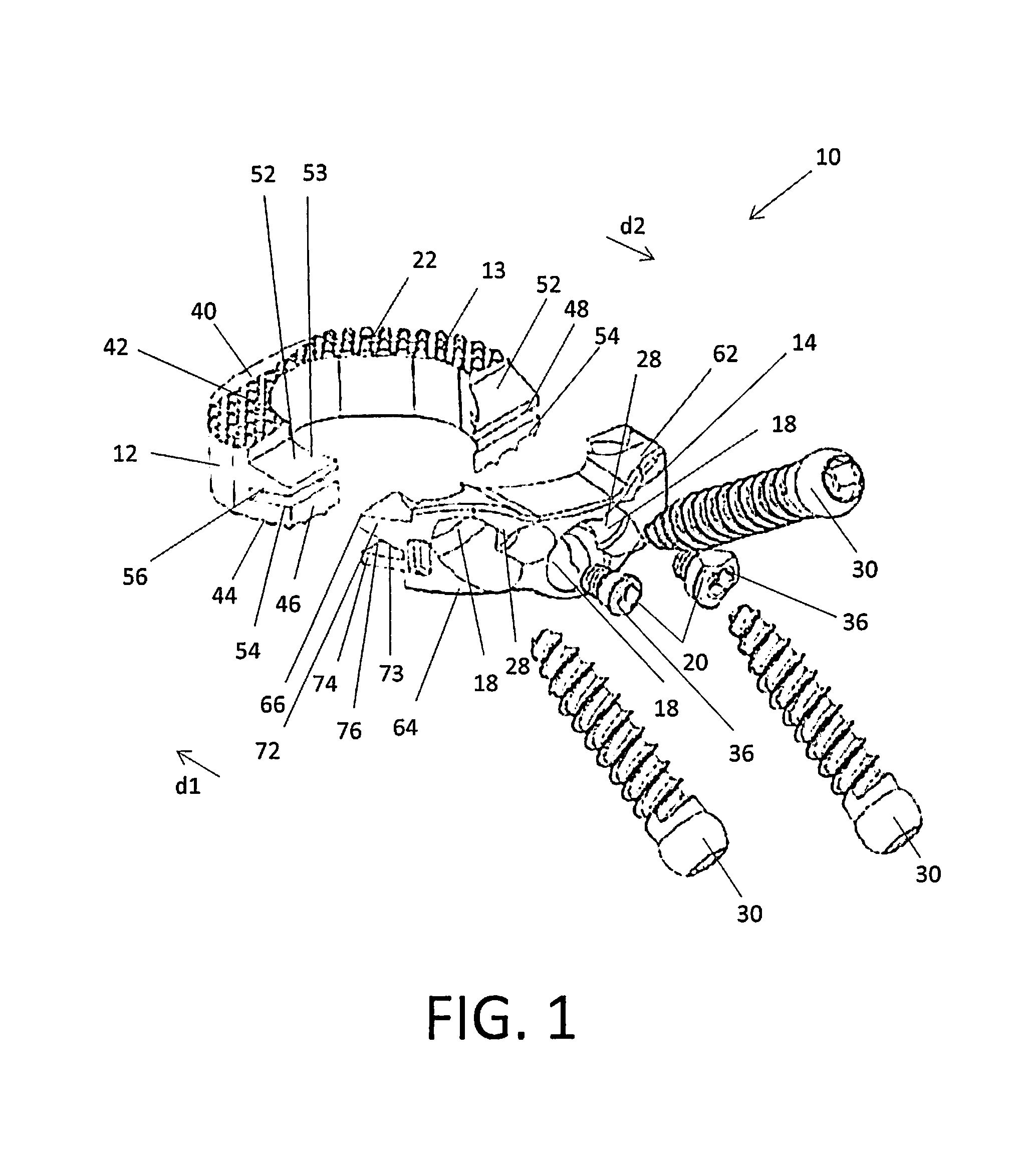

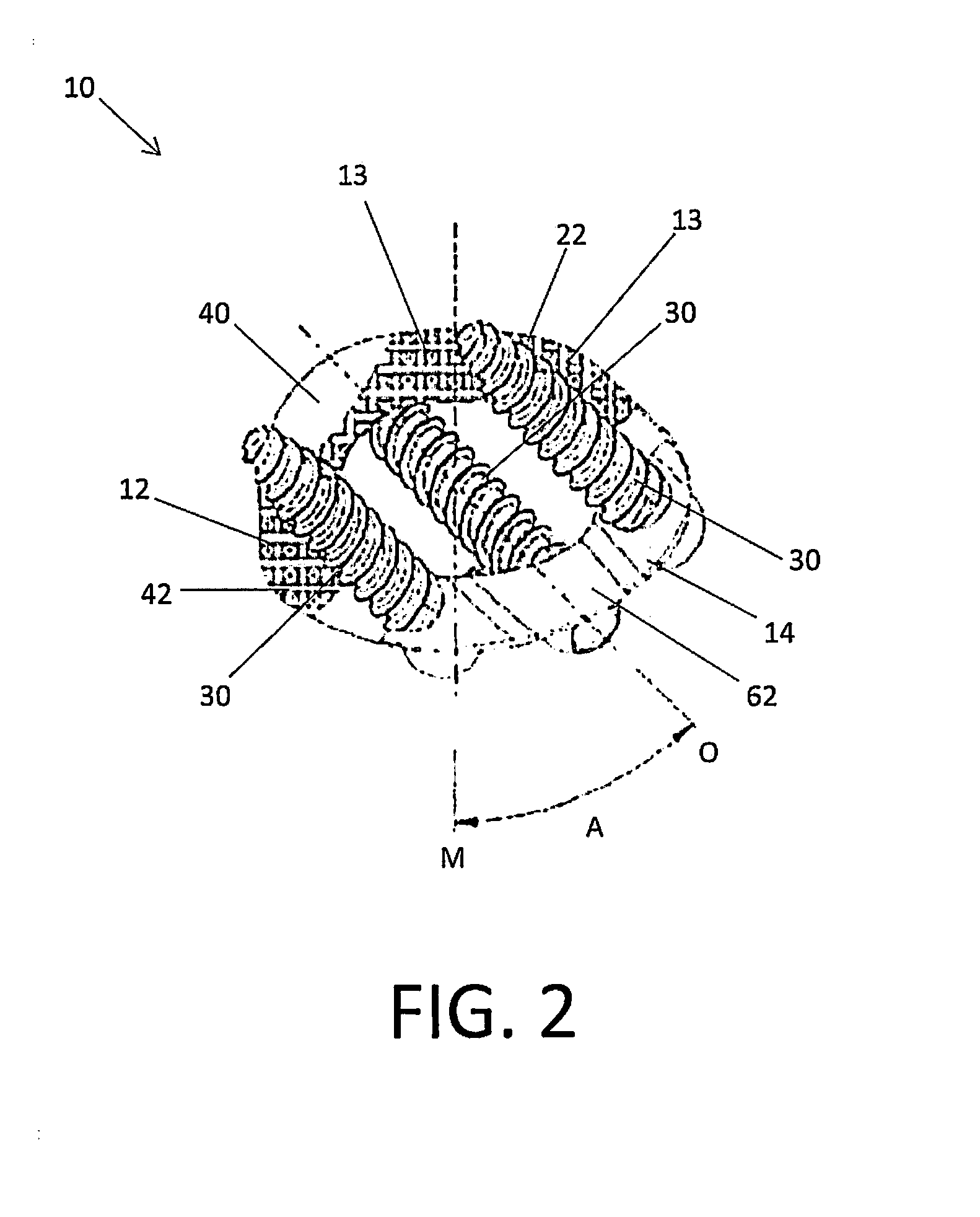

Interbody Standalone Intervertebral Implant

ActiveUS20140277497A1Vascular anatomy of the patient may be avoidedSpinal implantsSpinal cageCorpectomy

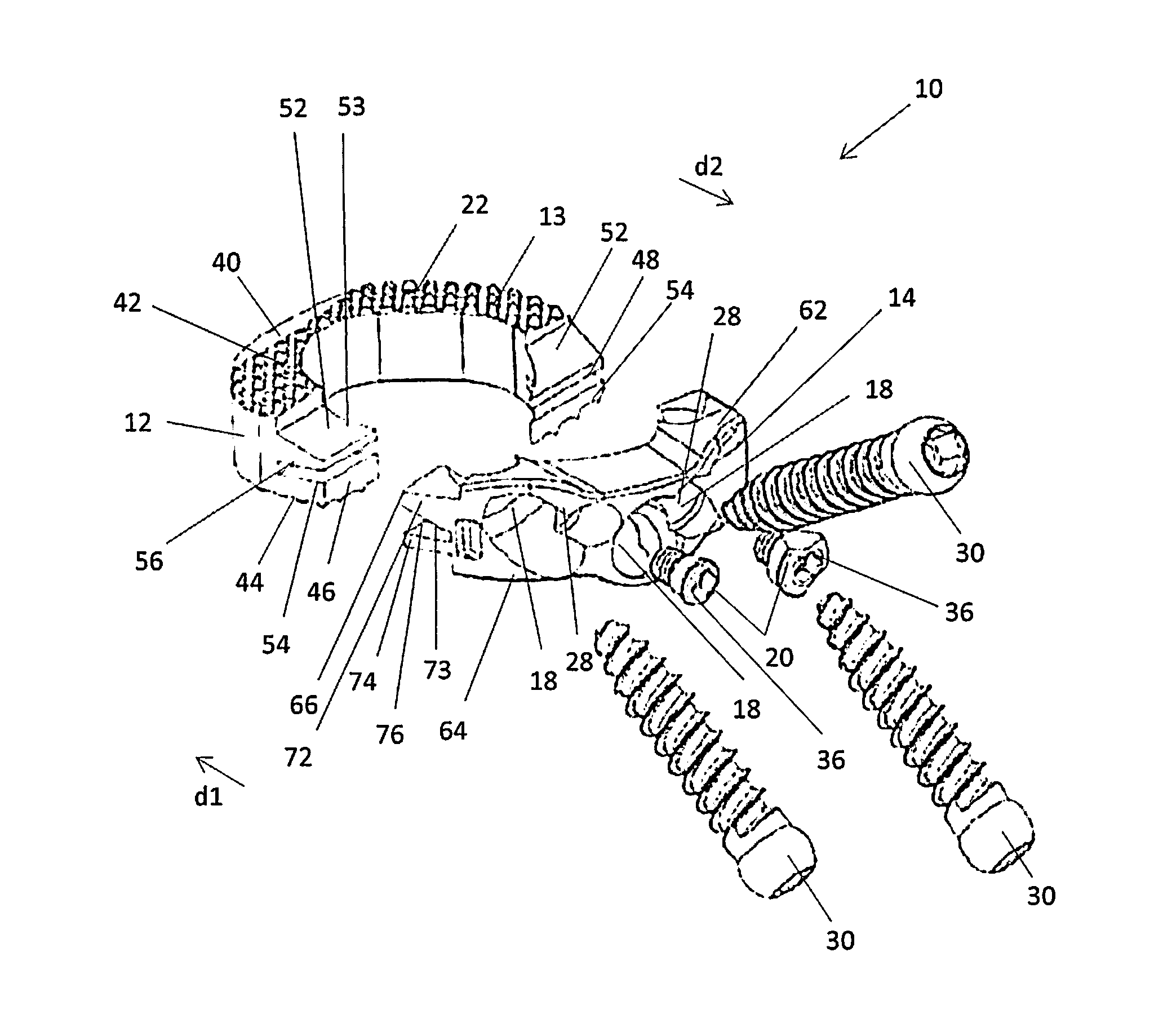

Stand-alone interbody fusion devices and corpectomy devices suitable for use with an oblique implantation. The stand-alone interbody fusion devices may include a spacer having a substantially U-shaped body and a plate coupled to the spacer. The overall shape of the implant is asymmetrical such that a median plane, an oblique plane, or both planes divide the spacer and the plate into two asymmetrical halves. The implants are shaped and configured to allow for an oblique or anterolateral approach to the spine or an oblique corpectomy.

Owner:GLOBUS MEDICAL INC

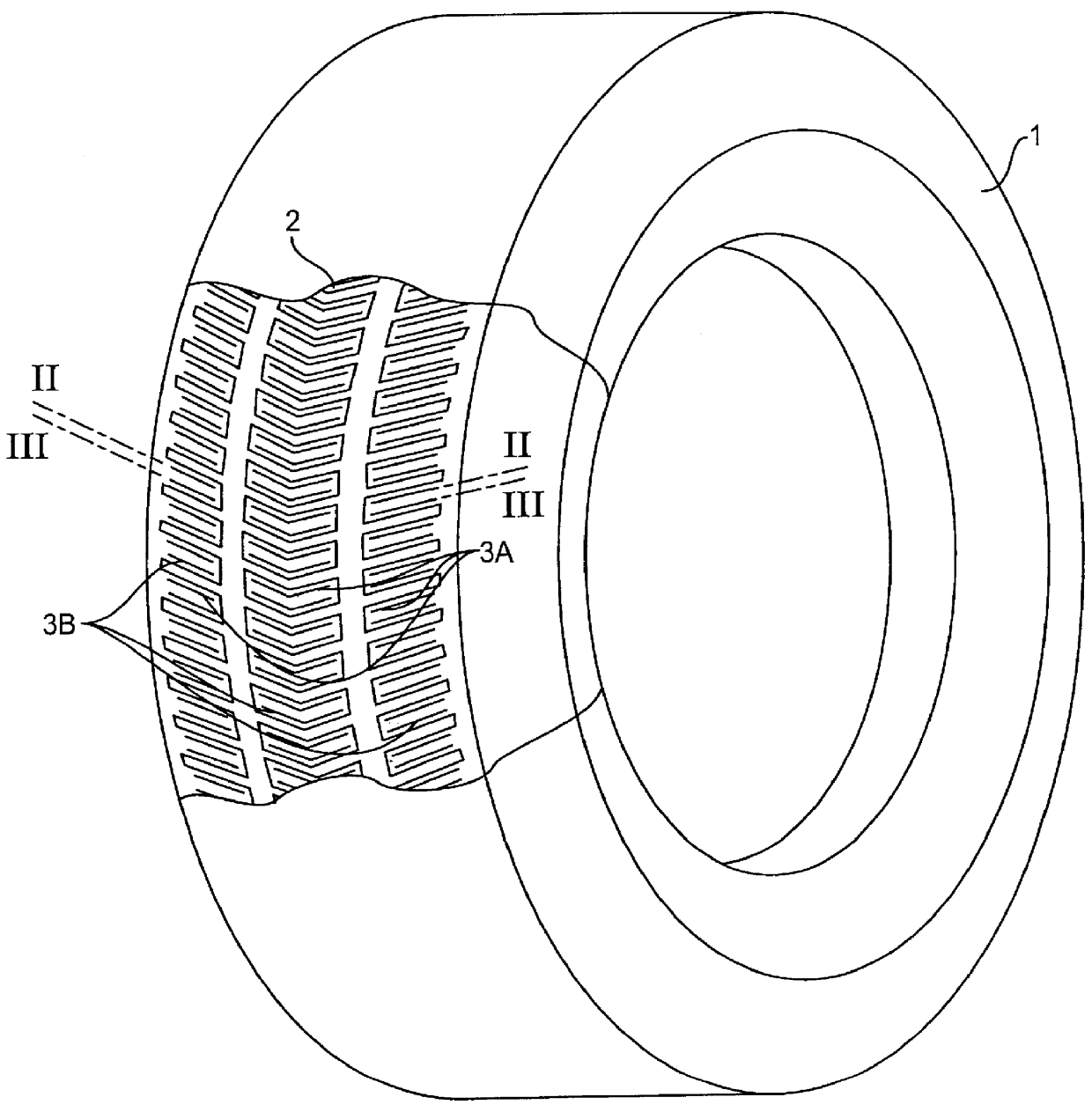

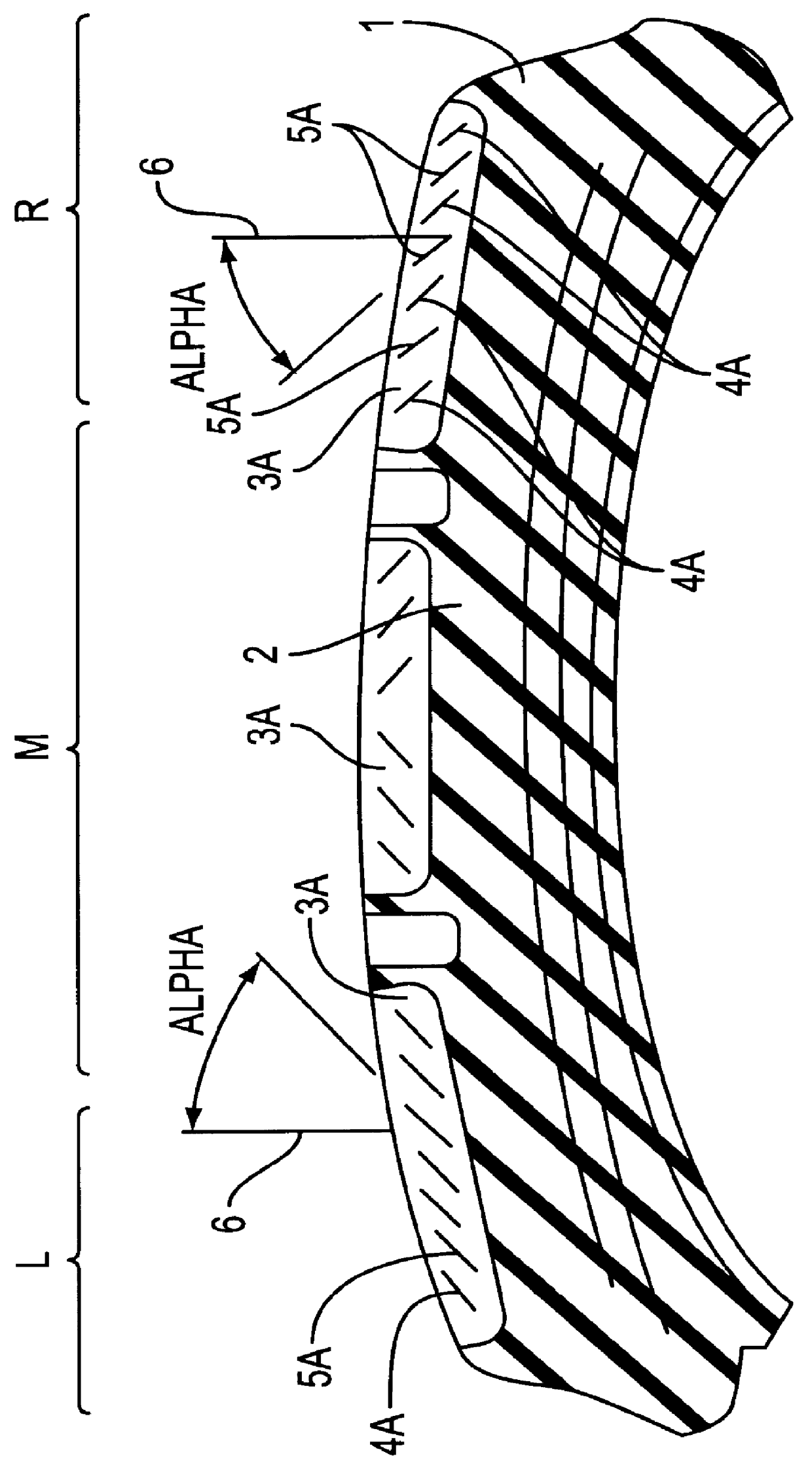

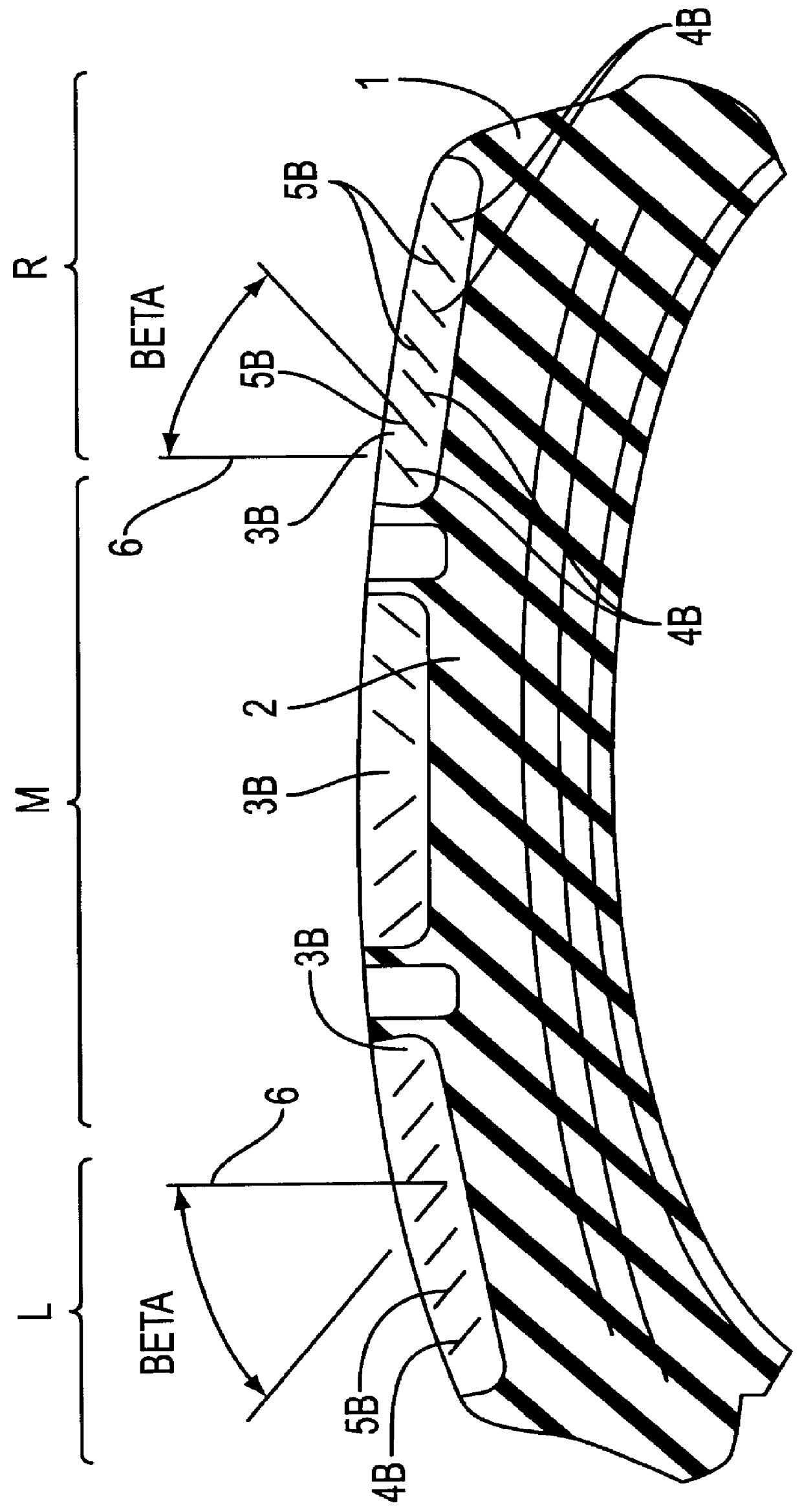

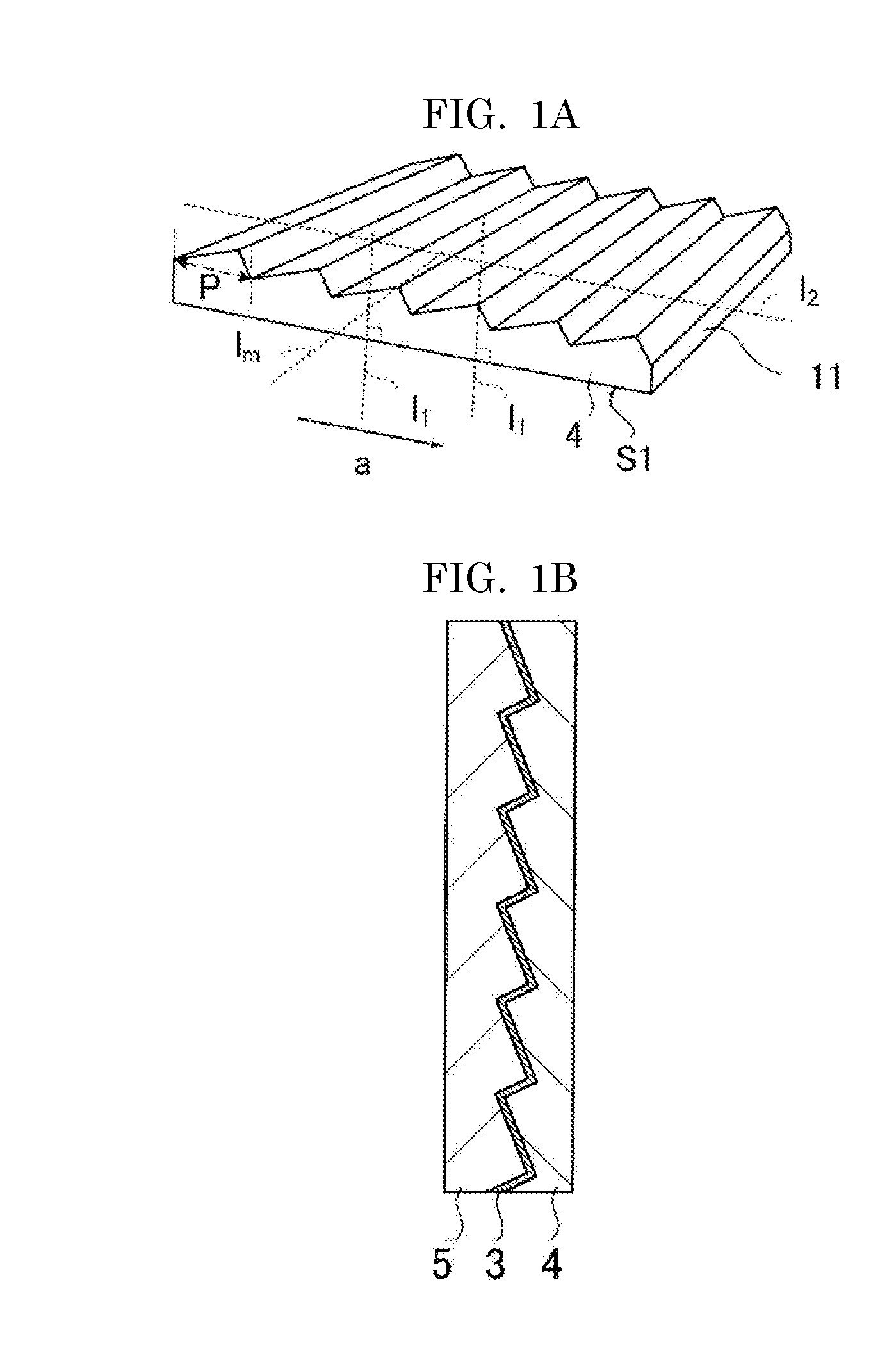

Vehicle tire with a tread exhibiting sipes substantially running in the axial direction

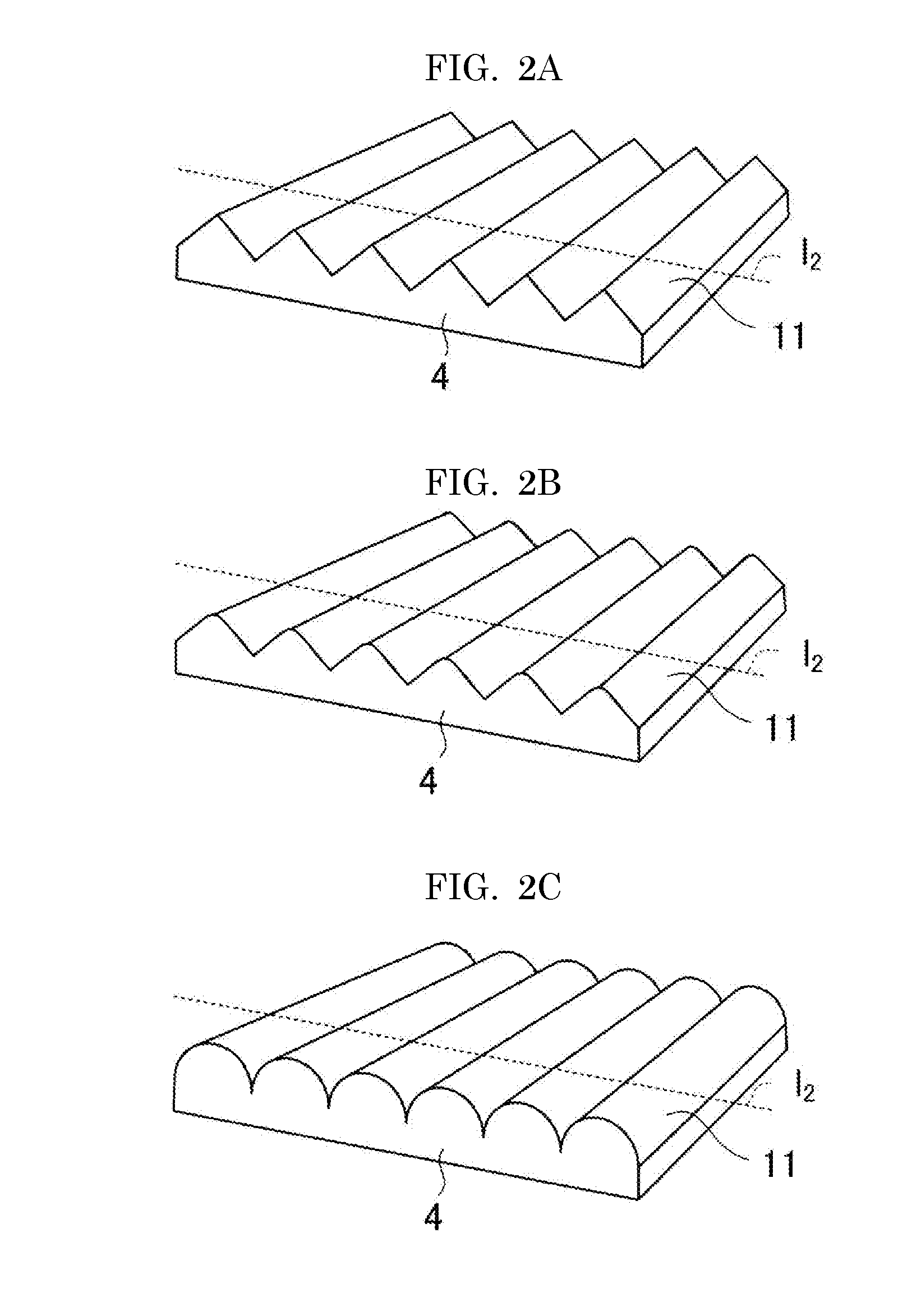

InactiveUS6026875ATerminal end bending is further reducedImprove efficiencyTyresTyre tread bands/patternsMetal sheetTread

Vehicle tire and a metal sheet mold plate for forming the vehicle tire having at least one axial end section includes a tread that includes sipes running substantially axially in at least one of the axial end sections when viewed from the top (i.e., perpendicular to the tread surface). The sipes are corrugated to form corrugated ridges and valleys that are substantially straight lines diagonally inclined in an oblique plane parallel to the substantially axially running sipes. The substantially axially running sipes may include a first set of sipes and a second set of sipes. The corrugated ridges and valleys of the first set of sipes are oriented, with regard to a radially outward direction, to extend axially inwardly toward (i.e., toward a axial center of the tire). Conversely, the corrugated ridges and valleys of the second set of sipes are oriented, with regard to the radially outward direction, to extend axially outwardly (i.e., away from the axial center of the tire). At least one joint track is also provided that includes the corrugated sipes of the first and second sets of sipes.

Owner:CONTINENTAL AG

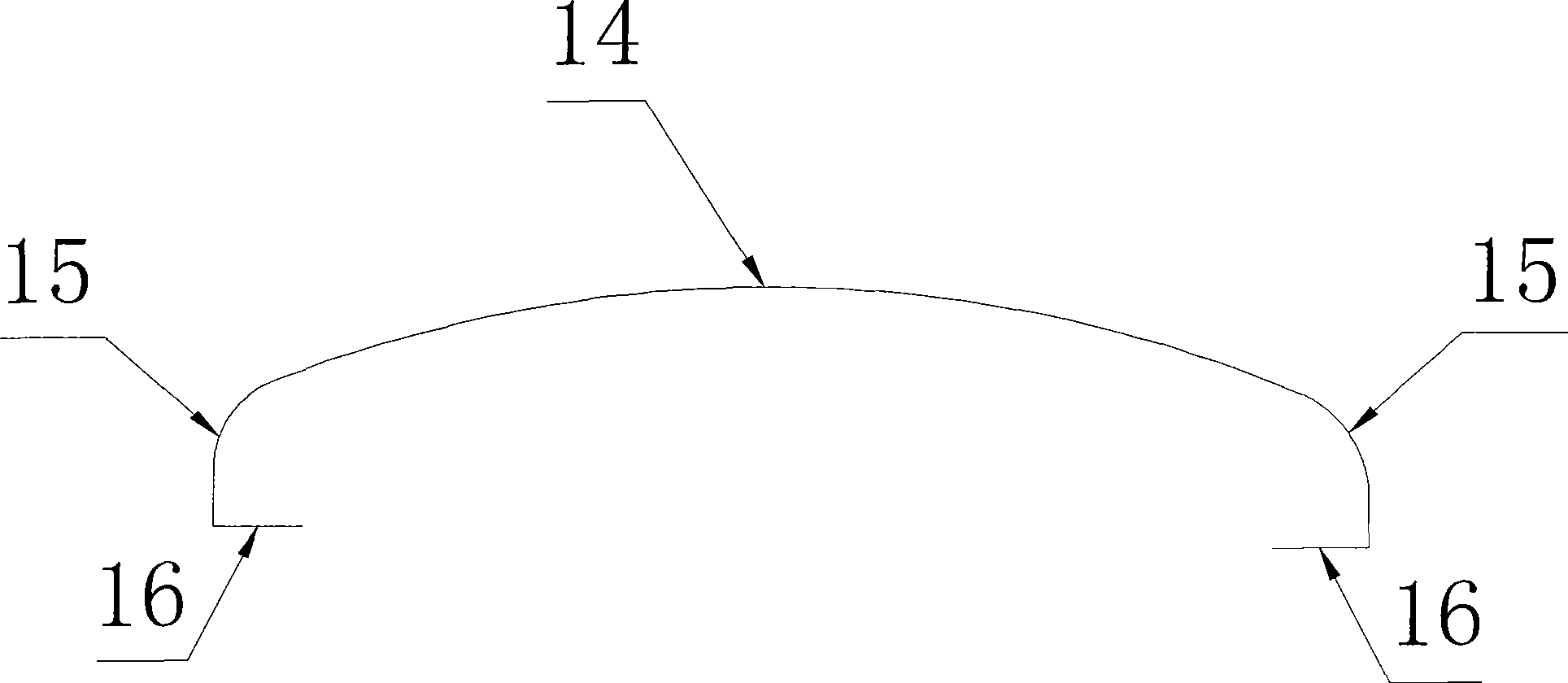

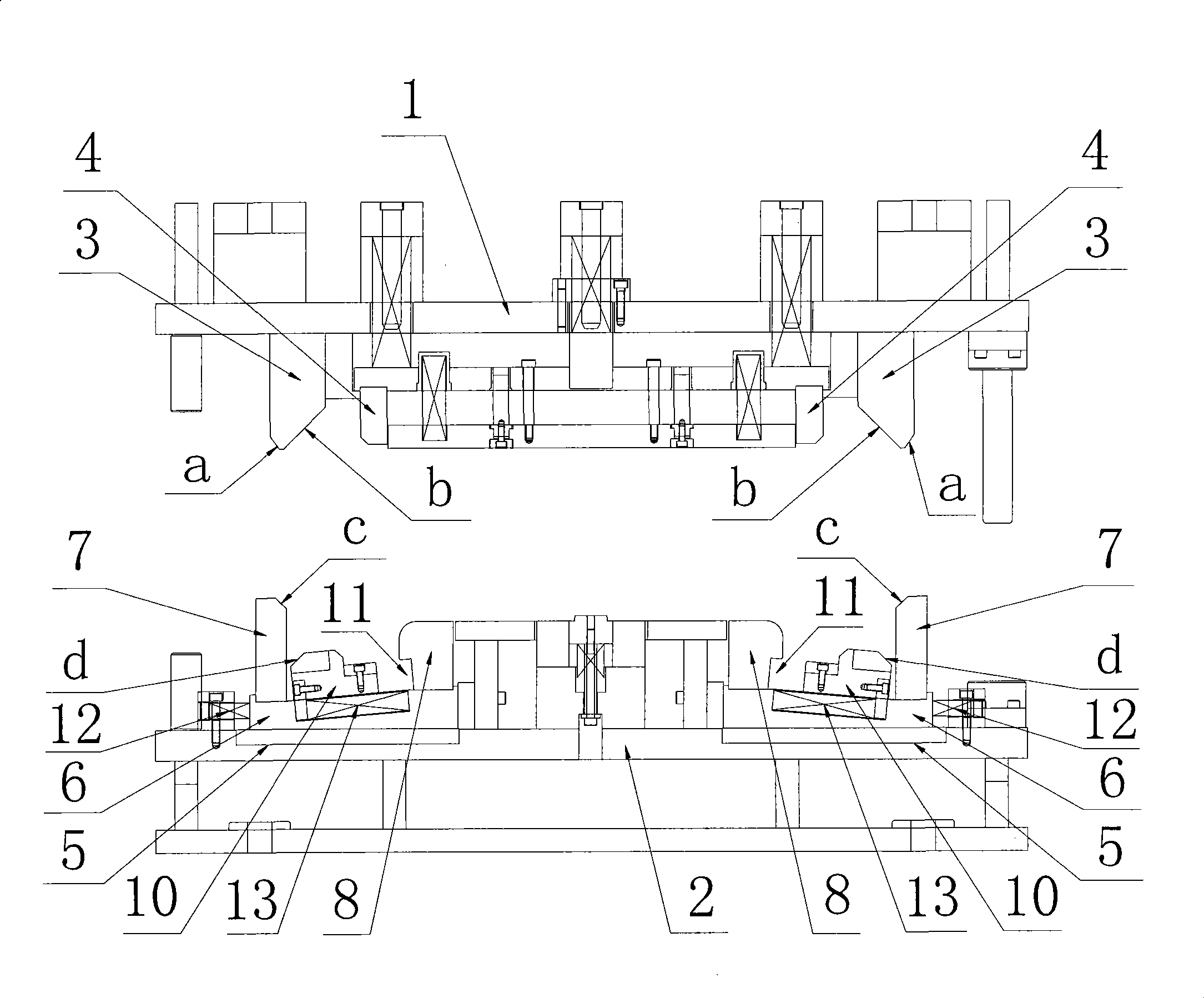

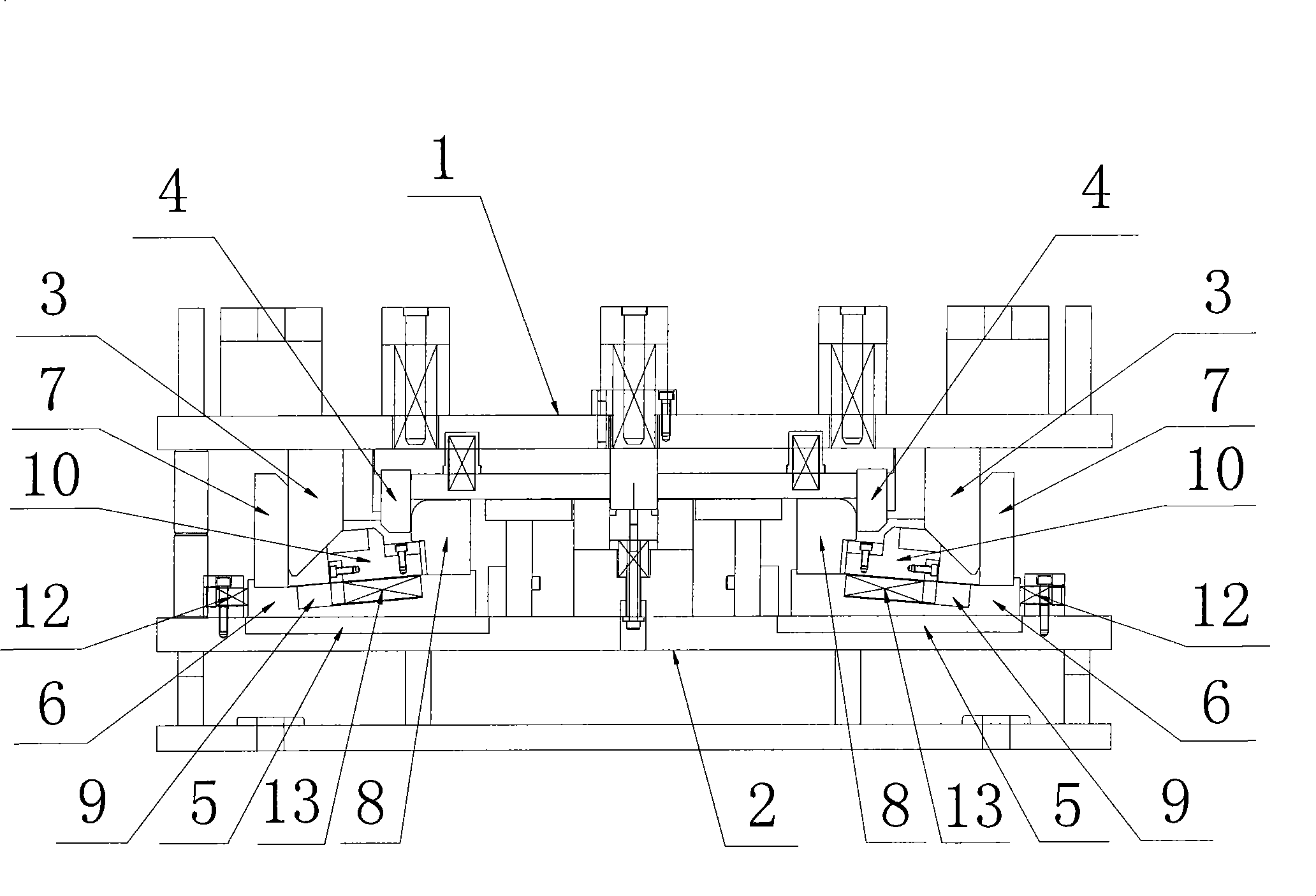

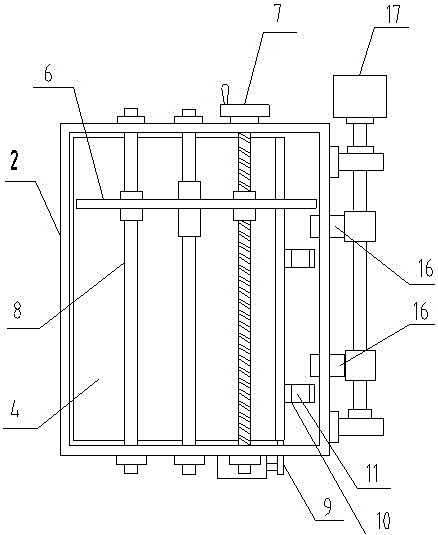

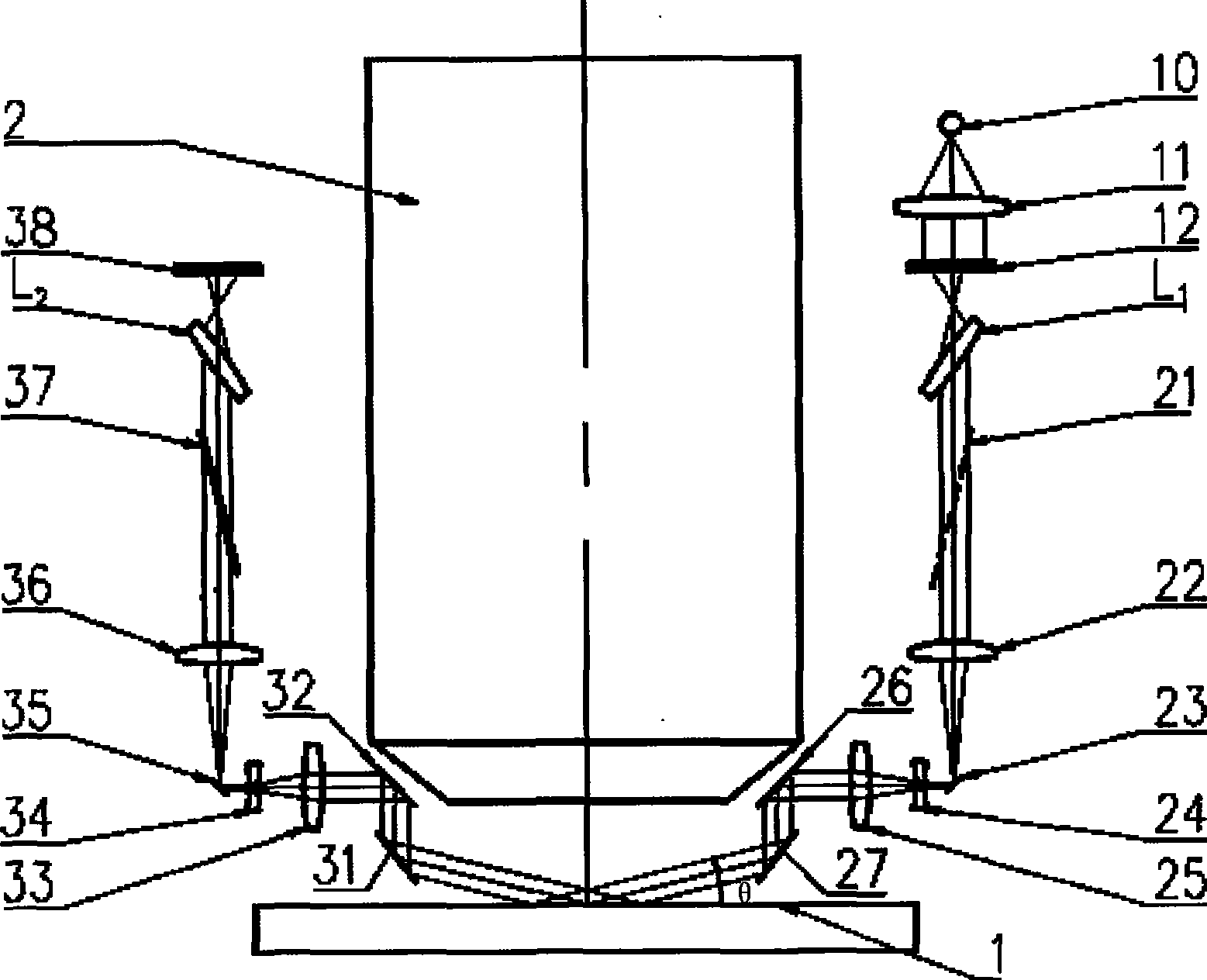

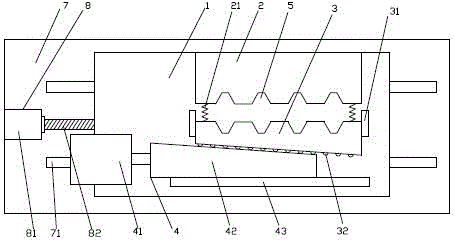

Brake forming mold for door casing of refrigerator

InactiveCN101474655ASimple structureEasy to manufactureShaping toolsRefrigerated temperatureMechanical engineering

The invention discloses an electric refrigerator door shell bending forming die. The bending forming die comprises an upper die plate and a lower die plate; the upper die plate is symmetrically fixed with two upper drive blocks and two upper die bending strips from the outside to the inside, and the outside surface and the inside surface of each drive block are respectively provided with a first oblique plane and a second oblique plane which are arranged downwards; the lower die plate is symmetrically provided with two sliders which are slidably arranged in a main slideway, each slider is fixed with lower drive blocks and lower die bending strips from the outside to the inside, and the inside surface of each lower drive block is provided with a third oblique plane which is arranged upwards and opposite to the first oblique plane; meanwhile, each slider is also provided with a sub-slideway which is positioned between the lower drive block and the lower die bending strip, the sub-slideway is internally and slidably provided with a bending strip, the outside surface of which is provided with a fourth oblique plane which is arranged upwards and opposite to the second oblique plane, and side surfaces of the lower die bending strips are provided with bending concave parts which are matched with the bending strips. The bending forming die can once complete the bending forming of the electric refrigerator door shell, thus improving the production efficiency.

Owner:昆山市三建模具机械有限公司

Three-dimensional gesture action recognition method based on depth images

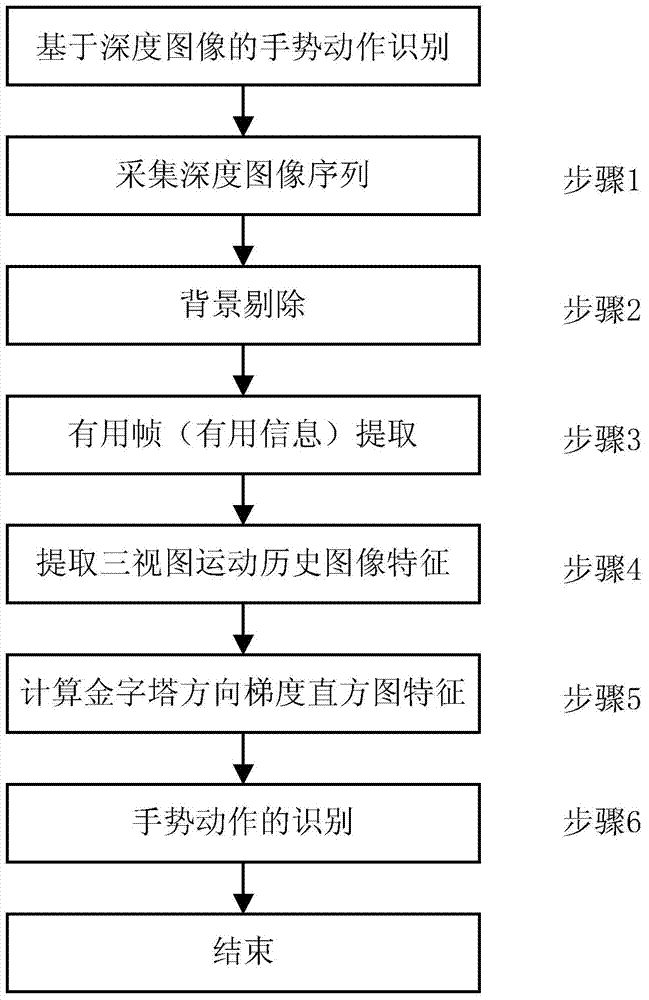

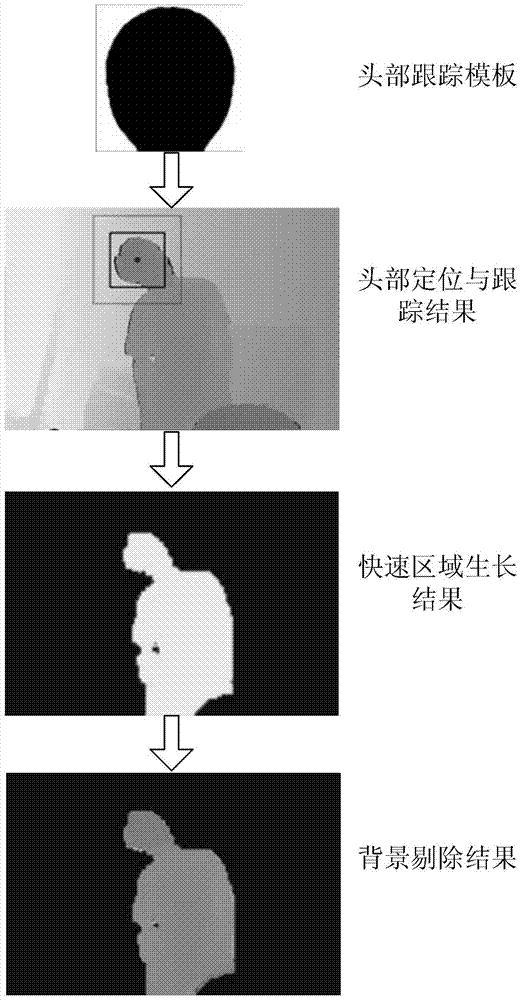

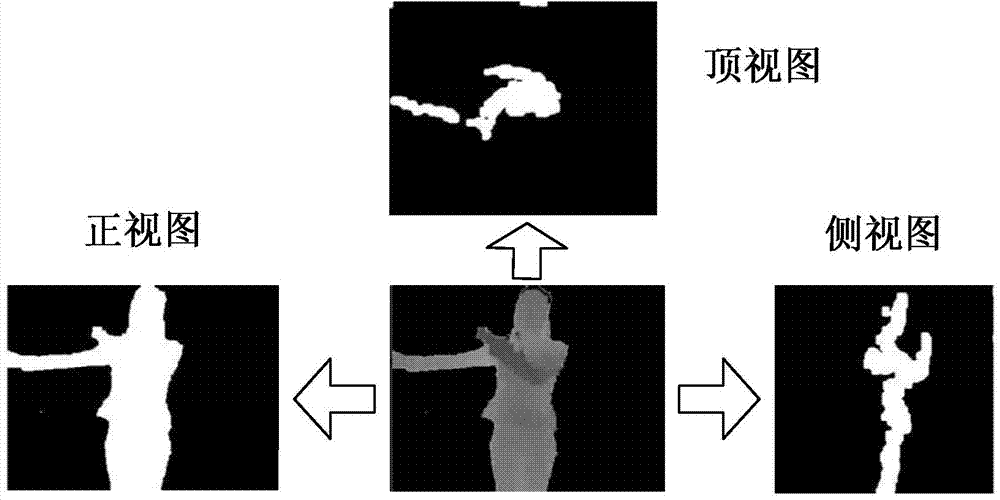

InactiveCN103679154AImprove recognition rateDisambiguationImage analysisCharacter and pattern recognitionObject motionHistogram of oriented gradients

The invention provides a three-dimensional gesture action recognition method based on depth images. The three-dimensional gesture action recognition method comprises the steps of acquiring the depth images including gesture actions; dividing a human body region corresponding to the gesture actions from the images through tracking and positioning based on quick template tracking and oblique plane matching to obtain a depth image sequence after the background is removed; extracting useful frames of the gesture actions according to the depth images after the background is removed; calculating three-view drawing movement historical images of the gesture actions in the front-view, top-view and side-view projection directions according to the extracted useful frames; extracting direction gradient histogram features corresponding to the three-view drawing movement historical images; calculating relevance of combination features of the obtained gesture actions and gesture action templates stored in a pre-defined gesture action library; using a template with largest relevance as a recognition result of a current gesture action. Therefore, three-dimensional gesture action recognition can be achieved by adopting the three-dimensional gesture action recognition method, and the three-dimensional gesture action recognition method can be applied to recognition of the movement process of simple objects.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Single-component thickly-coated anti-sagging polyurethane waterproof coating and preparation method thereof

InactiveCN106189798ASuitable for mechanical sprayingShorten the construction periodPolyurea/polyurethane coatingsPolyolPlasticizer

The invention relates to a single-component thickly-coated anti-sagging polyurethane waterproof coating and a preparation method thereof. The waterproof coating comprises the following raw materials in percentage by weight: 21-27% of polyether polyol, 5-8% of isocyanate, 15-22% of plasticizer, 0.03-0.1% of dispersant, 35-50% of filler, 0.05-0.2% of dehydrating agent, 0.5-2% of thixotropic agent, 0.03-0.2% of catalyst, 0.2-1% of defoaming agent and 0-15% of solvent. Vertical and oblique planes can be thickly coated with the waterproof coating; the coating thickness of the coating on the vertical and oblique planes at one time can reach 1mm-1.5mm without obvious sagging; the requirement that specific waterproof required thickness is realized by coating for one time is met; the construction period is reduced; the waterproof coating is extremely suitable for mechanical spraying.

Owner:JIANGSU CANLON BUILDING MATERIALS

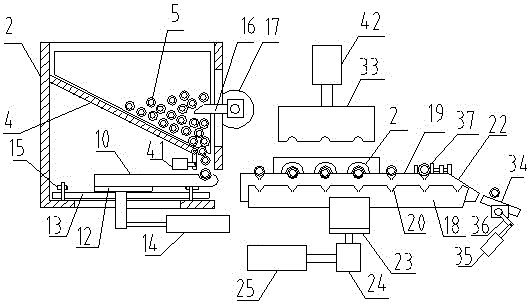

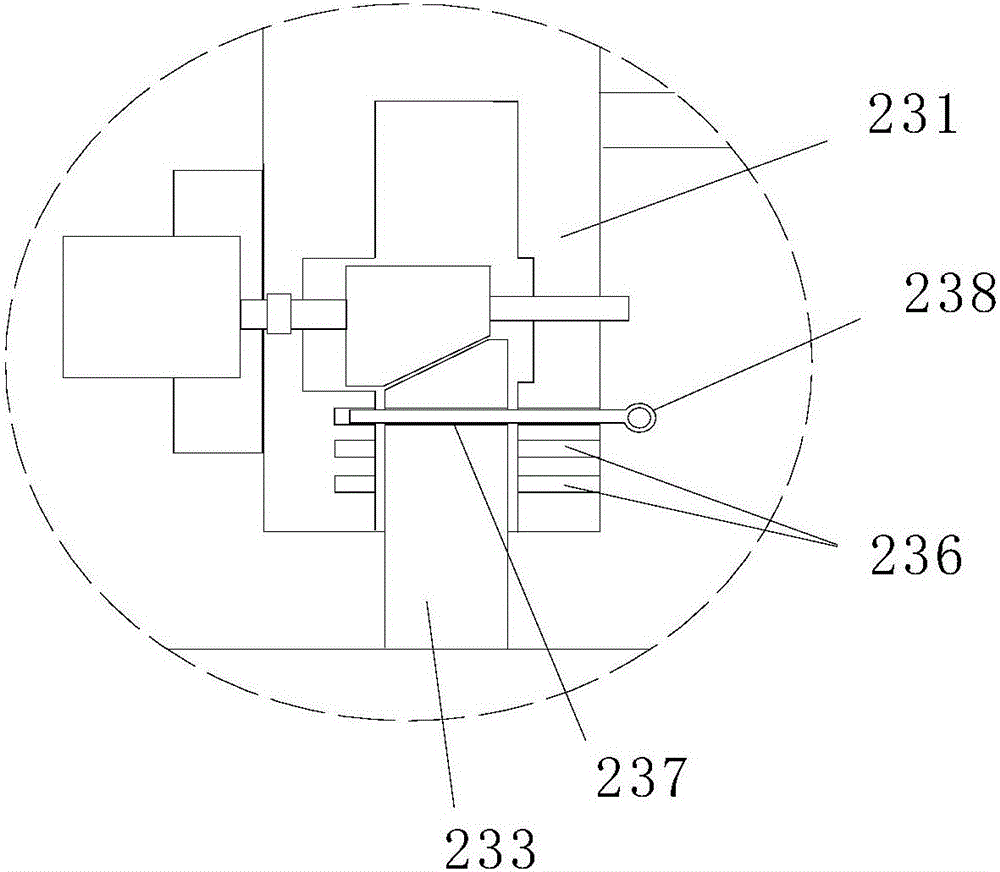

Full-automatic necking machine

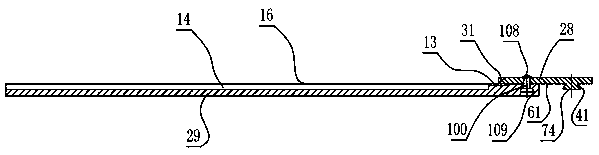

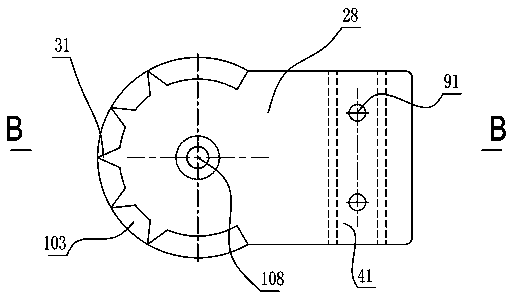

InactiveCN106111826AImprove diameter reduction efficiencyReduce labor costsMetal-working feeding devicesMetal working apparatusEngineeringPipe support

The invention provides a full-automatic necking machine and belongs to the technical field of automatic machines. By the adoption of the full-automatic necking machine, the problem that in the prior art, the steel pipe necking efficiency is low is solved. The full-automatic necking machine comprises a machine frame, a hopper and a necking mold. A movable steel pipe supporting frame and a fixed steel pipe supporting frame are arranged between the feeding side and the discharging side of the necking mold device, wherein the moving direction of the movable steel pipe supporting frame is the same as the moving direction of a feeding pull frame, and the fixed steel pipe supporting frame and the movable steel pipe supporting frame are arranged side by side in the same direction. The fixed steel pipe supporting frame and the movable steel pipe supporting frame are each provided with a plurality of grooves distributed at equal intervals. A discharging guide plate is arranged corresponding to an unfilled-corner oblique plane and provided with a rotating mechanism used for controlling the guide plate to rotate. The full-automatic necking machine is simple in structure and low in cost, and the steel pipe necking efficiency can be greatly improved.

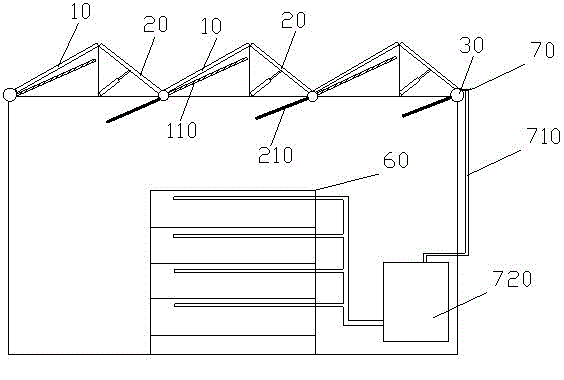

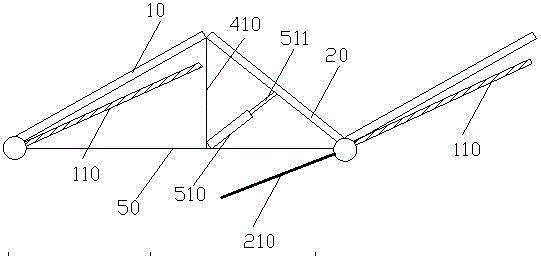

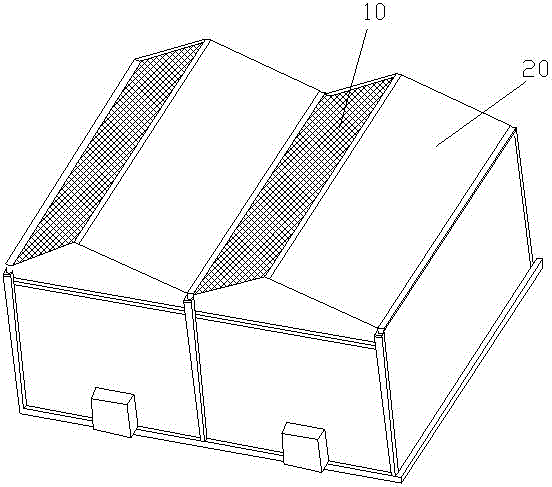

Ecological roof

ActiveCN104429714AGuaranteed efficiencyGuaranteed light transmittancePhotovoltaic supportsBuilding roofsLandscape designThe Internet

The invention relates to an ecological roof. The ecological roof comprises a corrugated roof body arranged on the top of a greenhouse. The continuous wave crests of the roof body are composed of solar panels and heat insulation light-permeating plates, the tops of the solar panels and the heat insulation light-permeating plates lean on one another and are obliquely arranged. Semitransparent scattering plates are correspondingly arranged below the oblique planes of the roof body composed of the heat insulation light-permeating plates, and incident light is evenly distributed in the greenhouse to overcome the shadow formed by the solar panels. In addition, a distribution type photovoltaic power generation system, a rainwater collecting system, an automatic sprinkling irrigation system with the energy conversion function and a plant planting system photovoltaic greenhouse are integrated, the rainwater collecting system, the automatic sprinkling irrigation system, the photovoltaic power generation system, a plant planting system and the like can run in a coordinated mode according to the user requirements, and remote control is achieved through the Internet. The integrated design of a photovoltaic building and the greenhouse is adopted, and the ecological roof can provide service for the urban art landscape design and the green building design.

Owner:杭州驭光科技有限公司

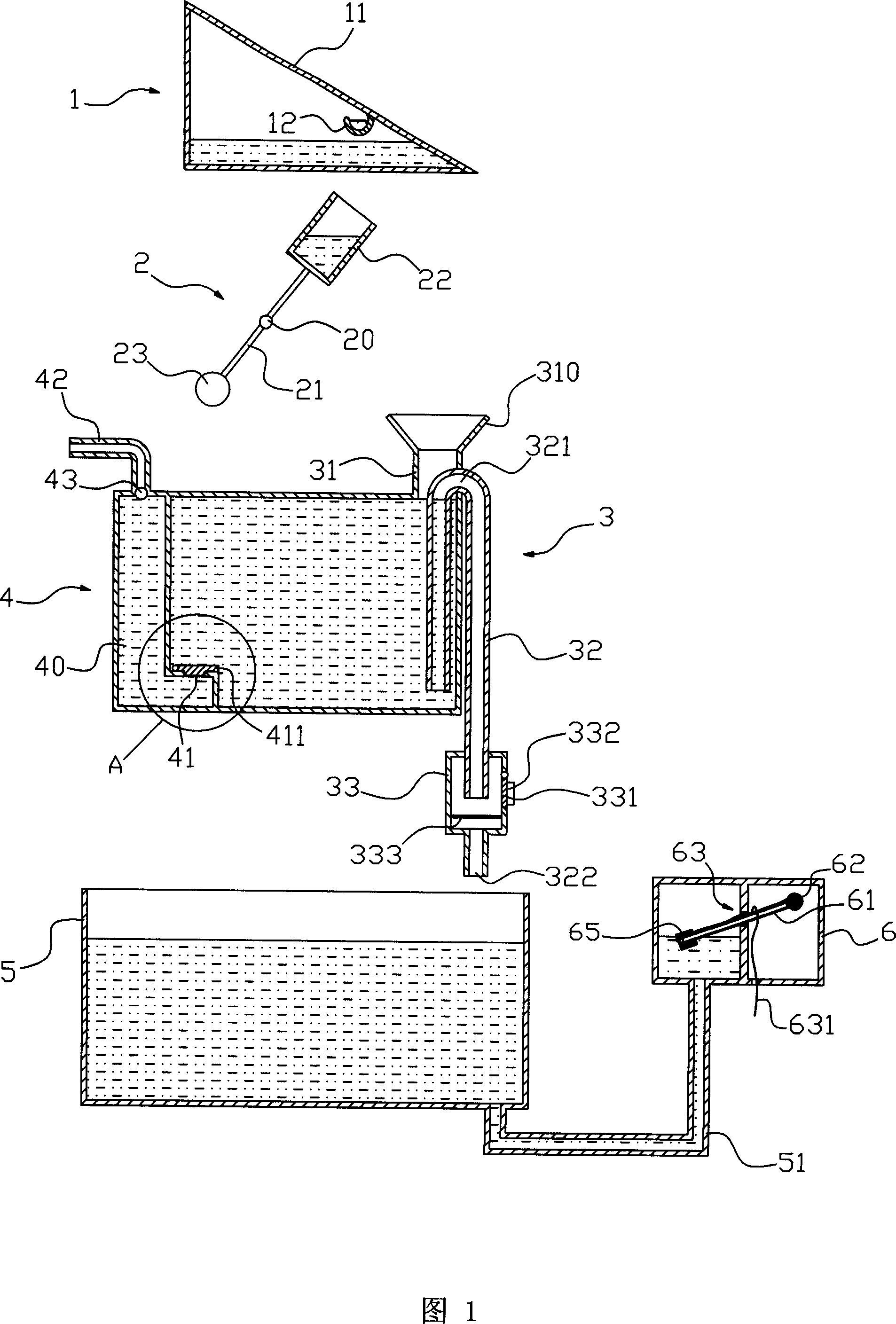

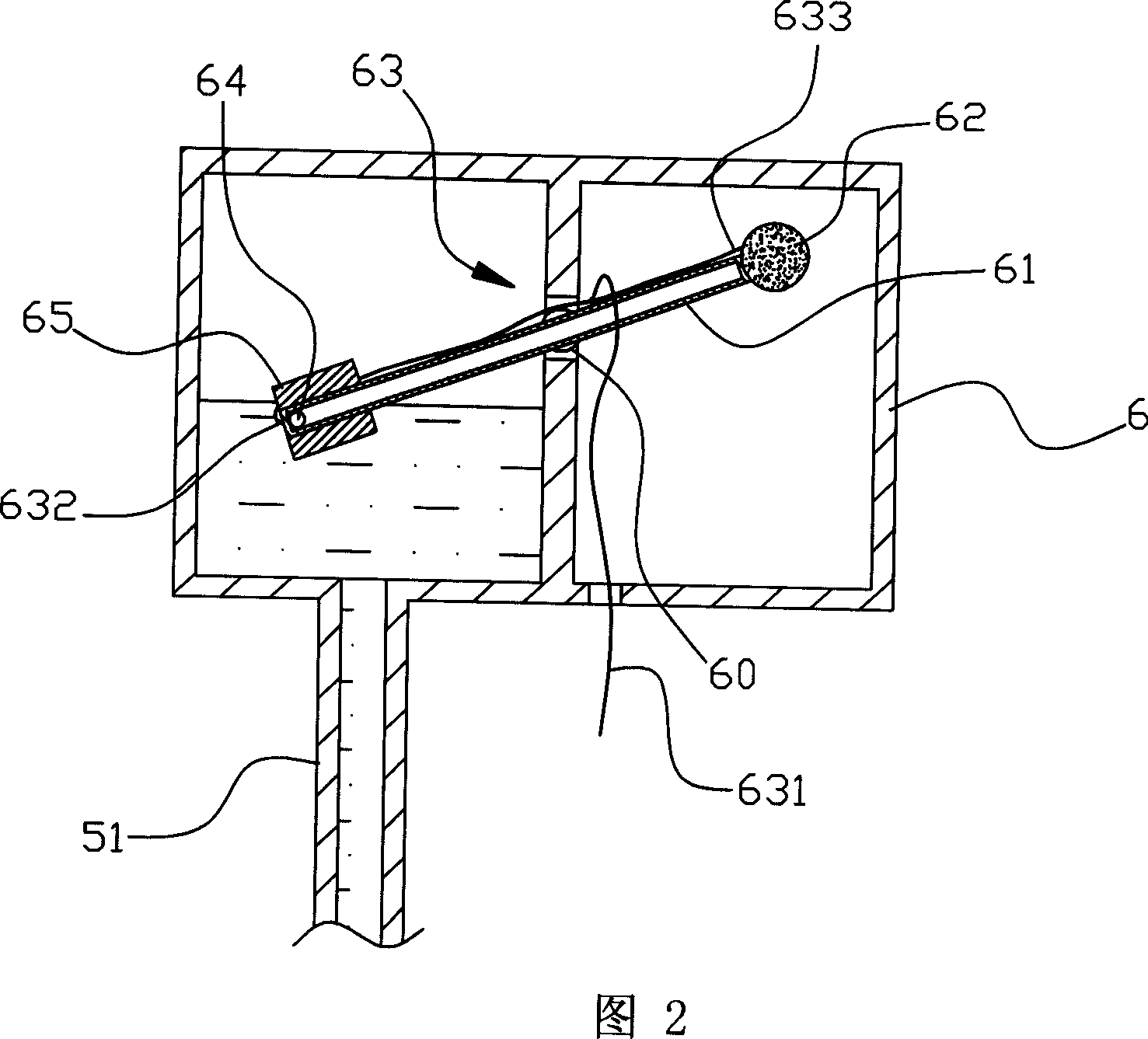

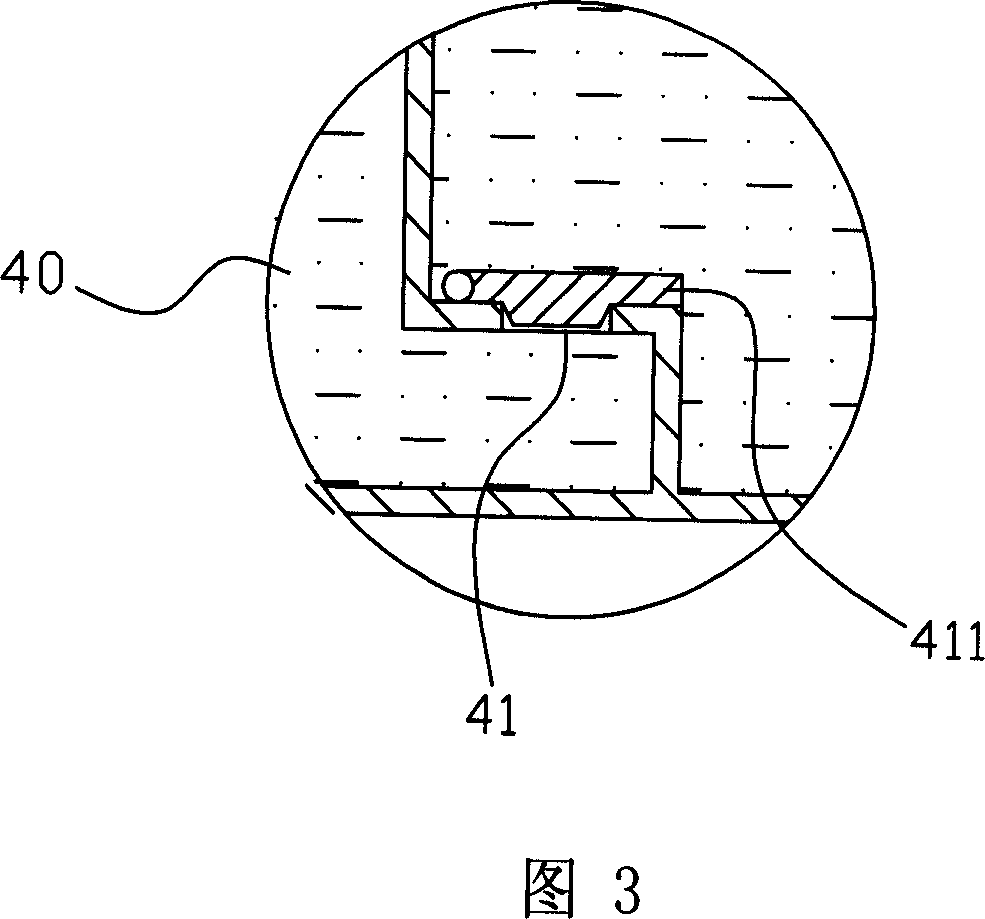

Vegetation automatic irrigation device

InactiveCN1918969ALow costIrrigation activities are more in line with natural lawsSelf-acting watering devicesVegetationSiphon

The invention discloses a plant self-irrigating device, which comprises the following parts: evaporating device, which concludes container, oblique plane on the container and collecting groove under the oblique plane, pouring device, which consists of collecting barrel with opening under the collecting groove and lever device to pour water in the collecting barrel, irrigating tank under the pouring device, which contains siphon pipe with one end in the irrigating tank and bending part on the initial level of irrigating tank and the other end forming outlet of self-irrigating device.

Owner:官辅忠

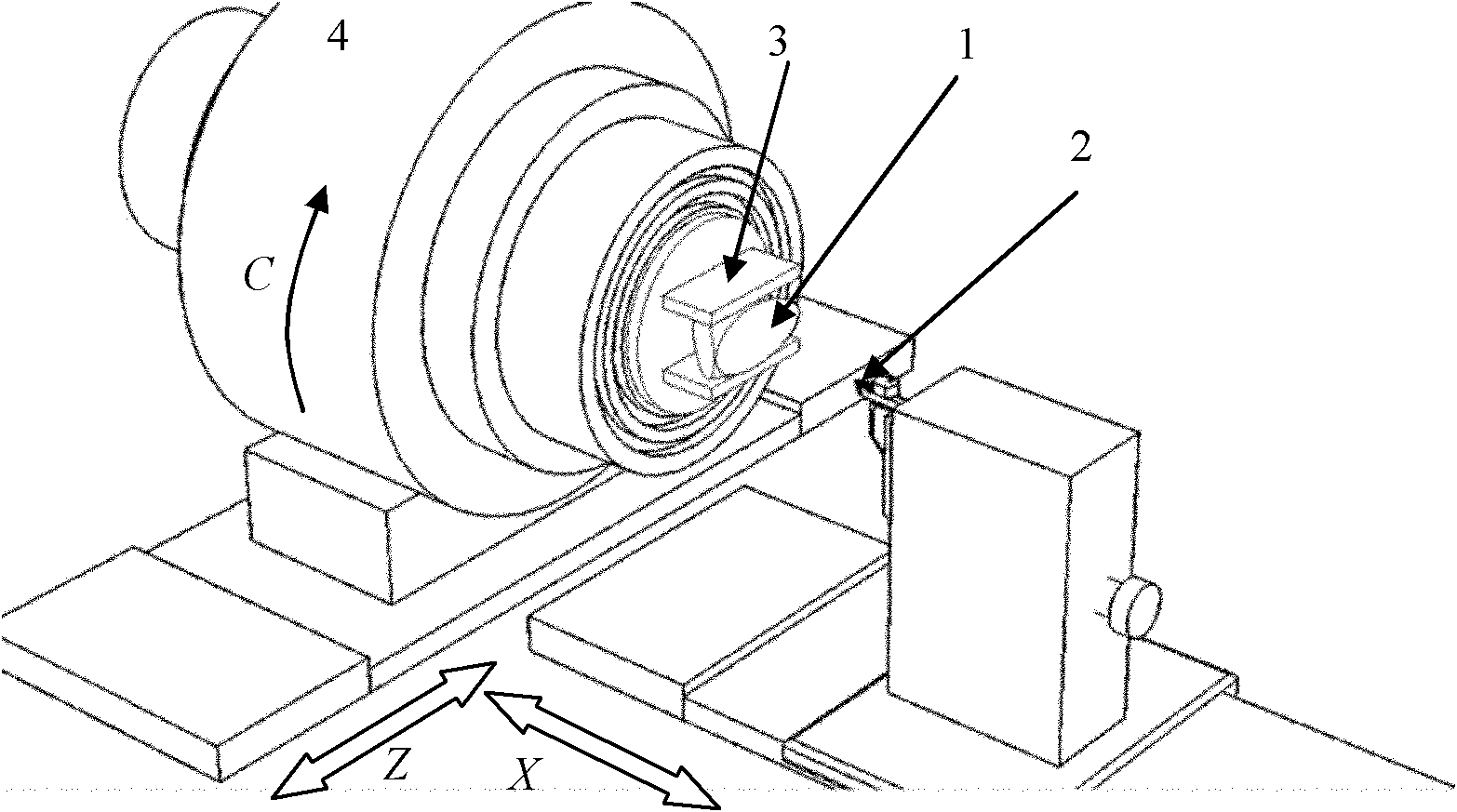

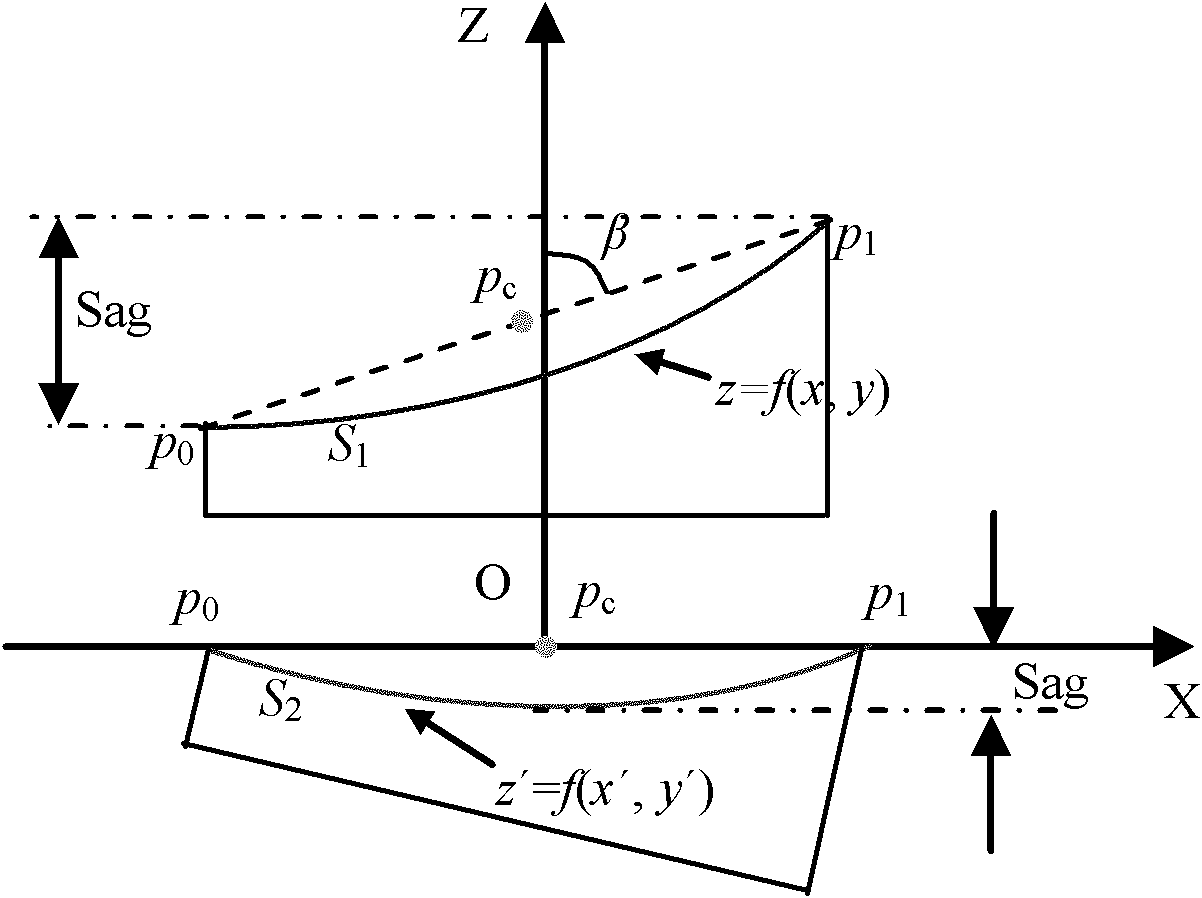

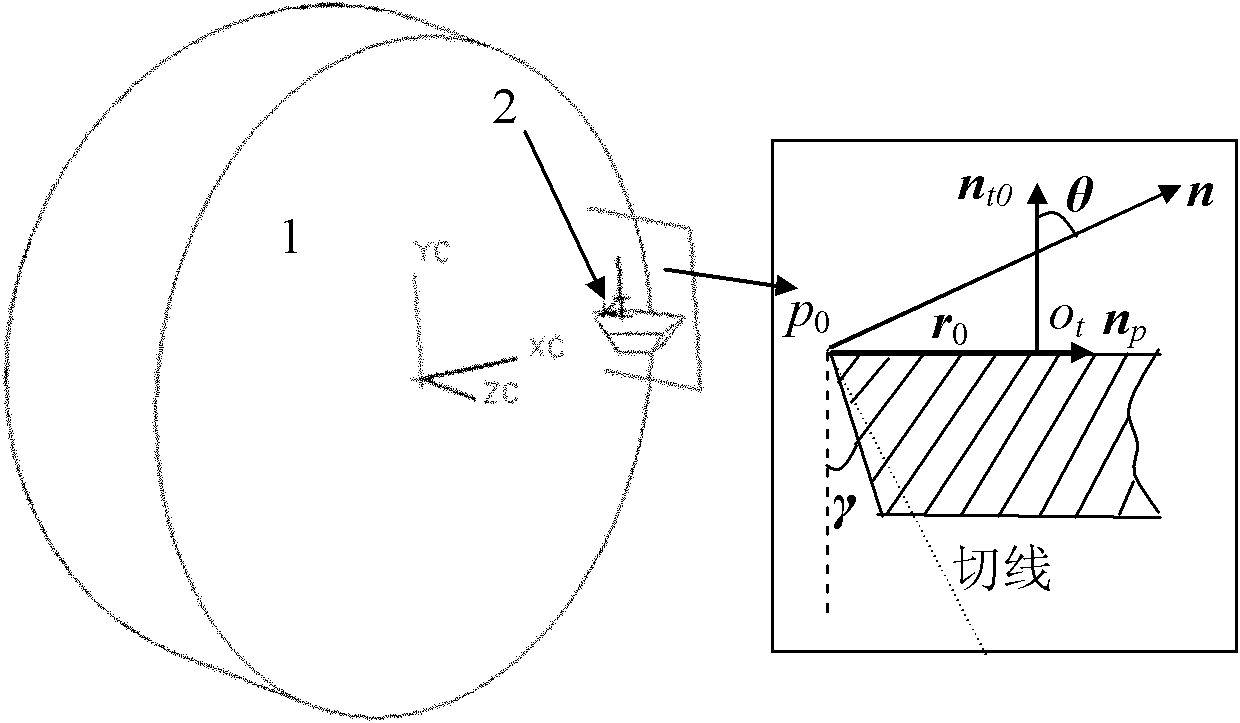

Ultraprecise turning method of optical lens with incline

The invention belongs to the technical field of manufacture and ultraprecise processing of optical elements, and relates to an ultraprecise turning method of an optical lens with an incline, which comprises the steps of: taking two datum points on the incline, determining a workpiece initial plane, roughly processing on the incline to be processed; making a fixture and assembling the workpiece on the end face of a processing lathe, regulating the workpiece initial plane to be vertical to the z axis, regulating a workpiece center to be coincide with a main shaft center; and carrying out coordinate conversion to obtain a connecting line of two end points to be coincide with the x axis, calculating a normal angle of the whole curved surface with center coordinates of the two datum points as a new curved surface of the original point, determining a diamond tool rear angle required by processing the curved surface, selecting a proper tool to be assembled on the lathe, carrying out NURBS (Non-Uniform Rational B-Spline) curved surface fitting on the curved surface subjected to the coordinate conversion, and determining the processing path according to a spiral drive line method. The lens surface is leveled by the coordinate conversion, and the tool rear angle required by processing the curved surface is reduced, thus the processing efficiency and the size of the processing workpiece can be increased, and the method is suitable for processing the large-incline optical lens with any gradient and Sag value.

Owner:TIANJIN UNIV

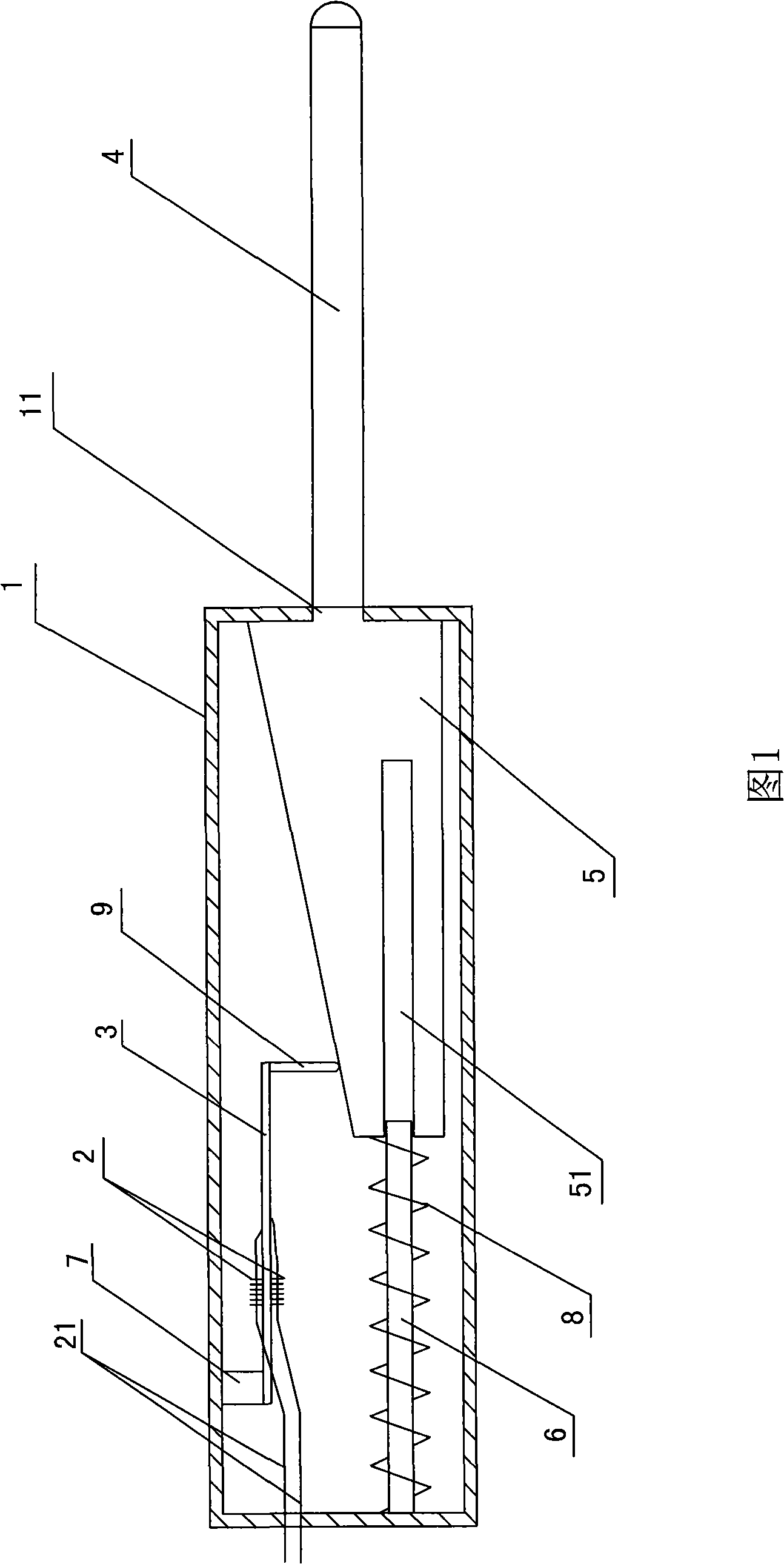

Optical fibre displacement transducer

ActiveCN101290214AImprove performanceImprove anti-interference abilityUsing optical meansConverting sensor output opticallyFiberObservational error

The invention discloses a fiber grating displacement sensor which comprises a shell, fiber gratings, an equal-strength beam and a measurement probing rod. One end of the measurement probing rod extends into the shell, the shell is provided with a wedge block, a connecting rod and a cushion block, wherein the measurement probing rod is in fixed connection with the cushion block, the cushion block is provided with a cavity, the length of the connecting rod is larger than the length of the cavity, one end of the connecting rod is fixed on the shell, the other end of the connecting rod extends to the cavity, a pulling spring whose aperture is large than the width of the cavity is arranged on the connecting rod, one end of the equal-strength beam is fixed on the cushion block, the other end of the equal-strength beam is connected with a supporting rod, one end of the supporting rod is held against the oblique plane of the wedge block, the fiber gratings are boned on the upper and the lower surfaces of the equal-strength beam in symmetry, the fiber gratings are connected with tail fibers, one end of each tail fiber extends out of the shell. The characteristics of the fiber grating displacement sensor are that the fiber gratings are used to carry out displacement detection, prevents electromagnetic interference, is good in durability and high in measurement precision; the symmetrical bonding of the fiber gratings on the upper and the lower surfaces of the equal-strength beam eliminates the measurement error which may be caused due to temperature change.

Owner:NINGBO SHANGONG CENT OF STRUCTURAL MONITORING &CONTROL ENG +1

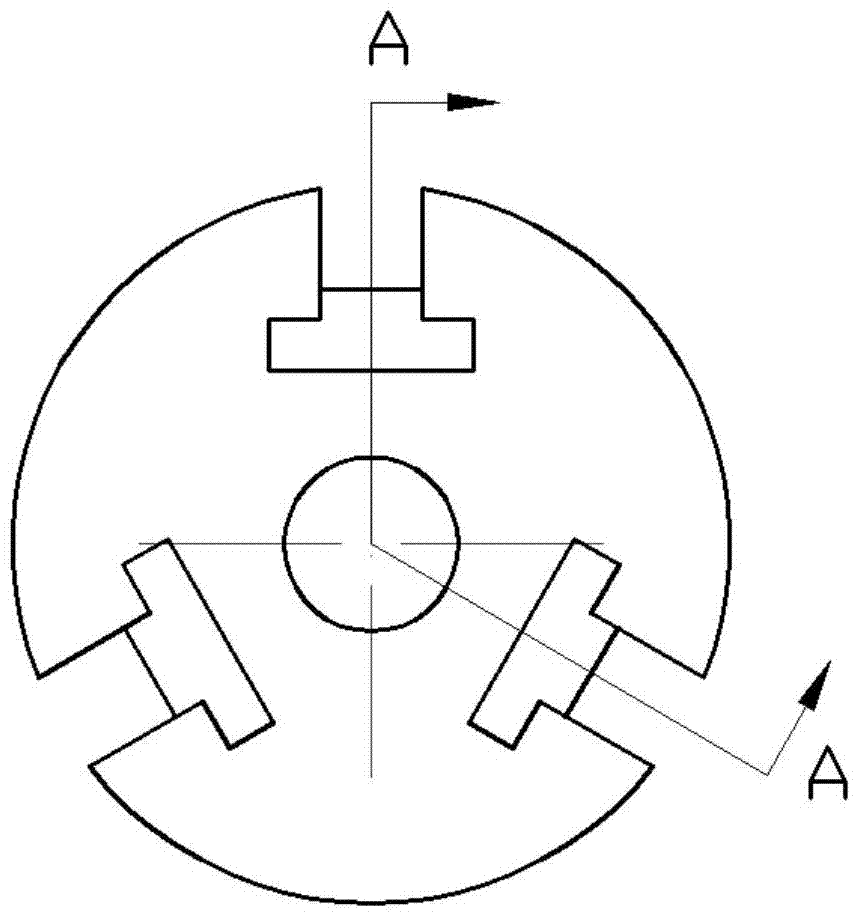

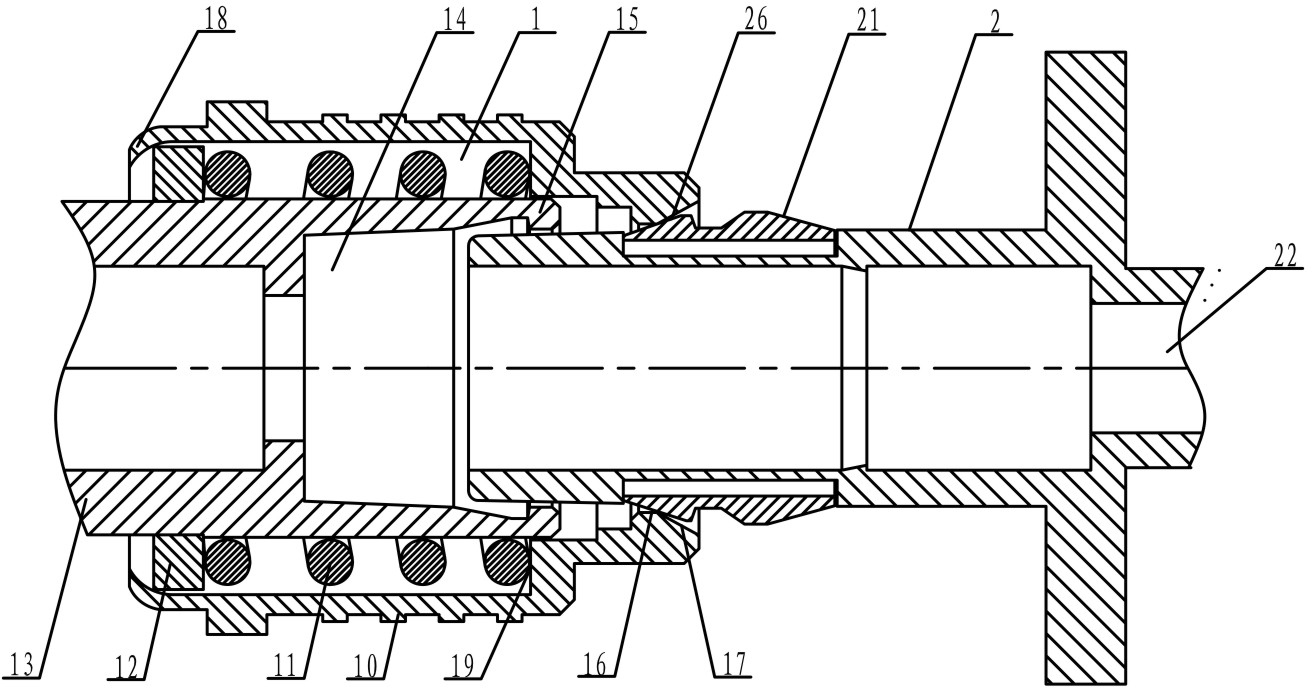

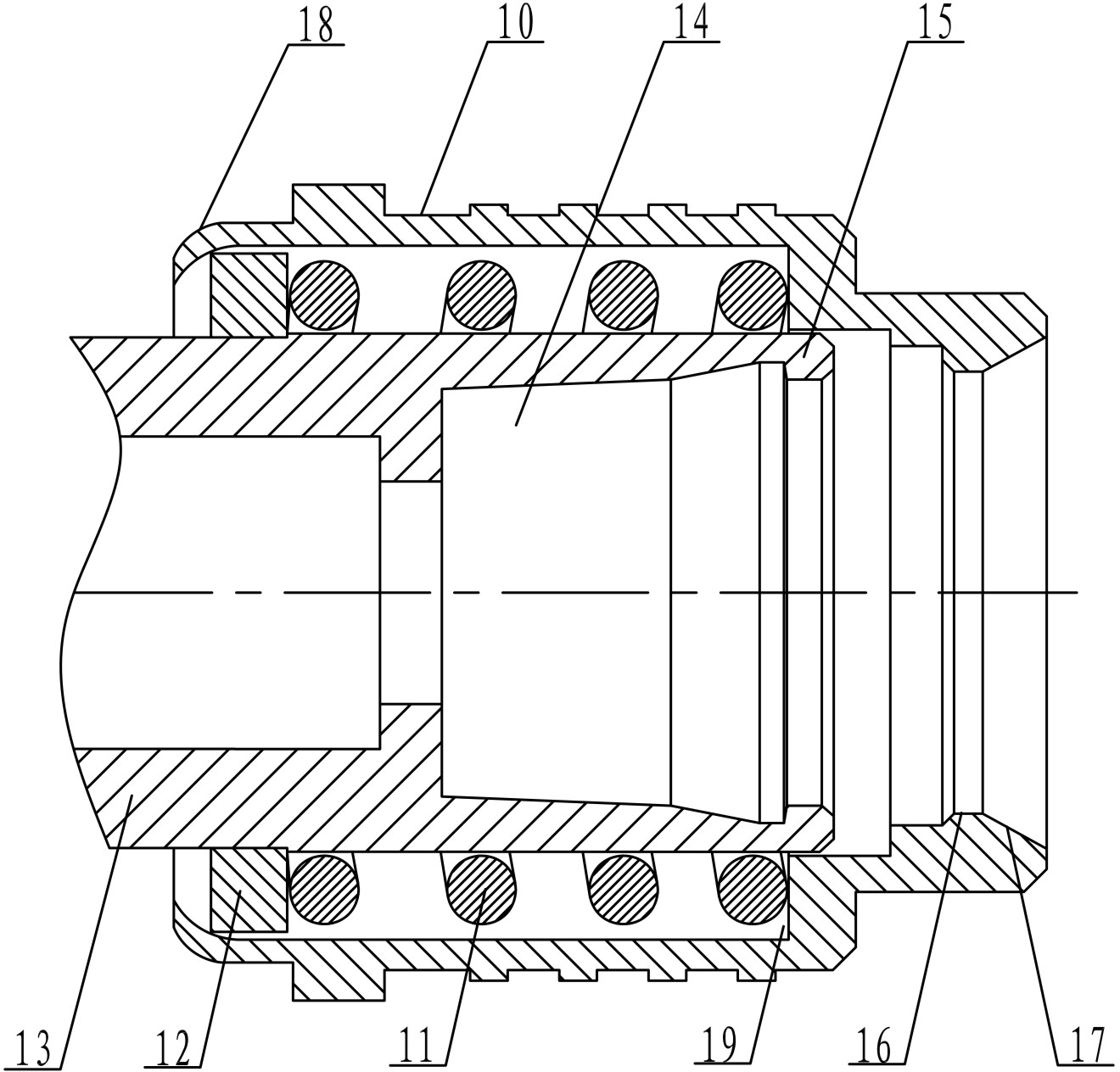

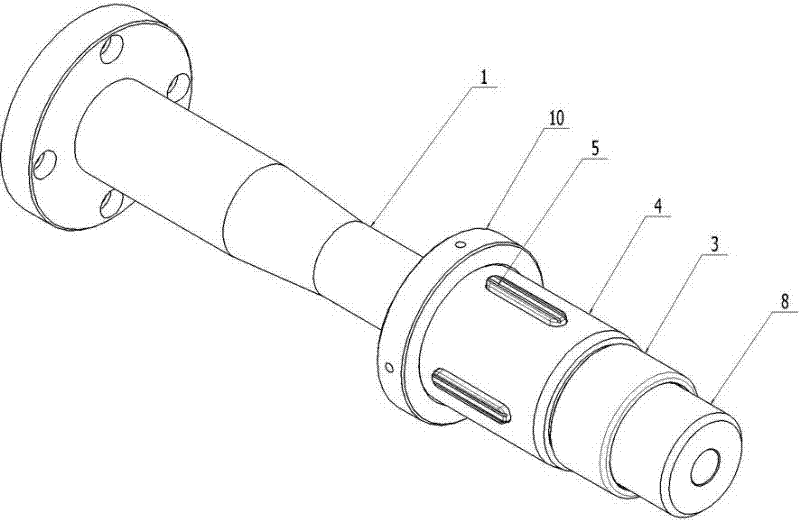

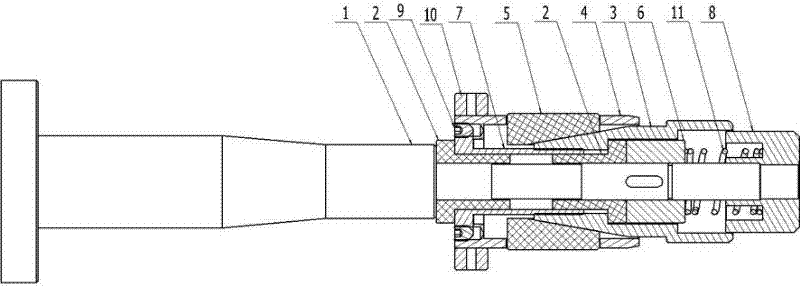

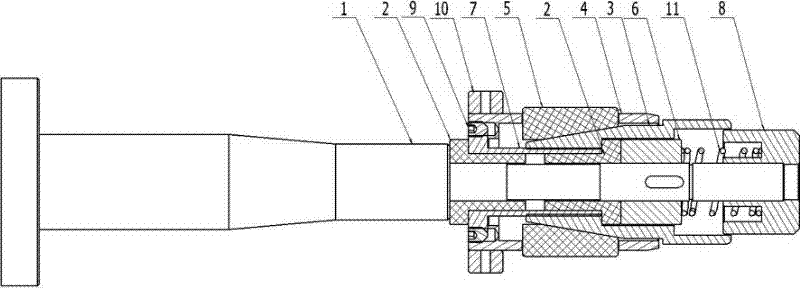

Opposite roller spin forming device

The invention discloses an opposite roller spin forming device which comprises a frame, an outer spinning roller device and an inner spinning roller device. One end of a flange supporting cylinder is connected with a chuck, the other end of the flange supporting cylinder is fixed to an opposite roller top end, the opposite roller top end is connected with a bearing block, rear bearings are arranged at the center of the bearing block, the rear end of a lead screw is fixed to the rear bearings and connected with a first servo motor, the lead screw penetrates the opposite roller top end and the flange supporting cylinder, the front end of the lead screw is connected with three wedge blocks through lead screw nuts, inner spinning rollers are mounted on inner clamping jaws through bearings, the inner clamping jaws are connected with the wedge blocks, the three wedge blocks are uniformly distributed in T-shaped guide-track grooves in a 120-degree manner, an oblique angle is formed between each guide-track groove and the axis of the corresponding wedge block, the inner clamping jaws are provided with T-shaped sliders with oblique planes having the same angle, and three outer spinning rollers are positioned on the peripheries of the three inner spinning rollers. The opposite roller spin forming device is simple and reliable in structure and high in control precision and machined workpiece quality.

Owner:SOUTH CHINA UNIV OF TECH

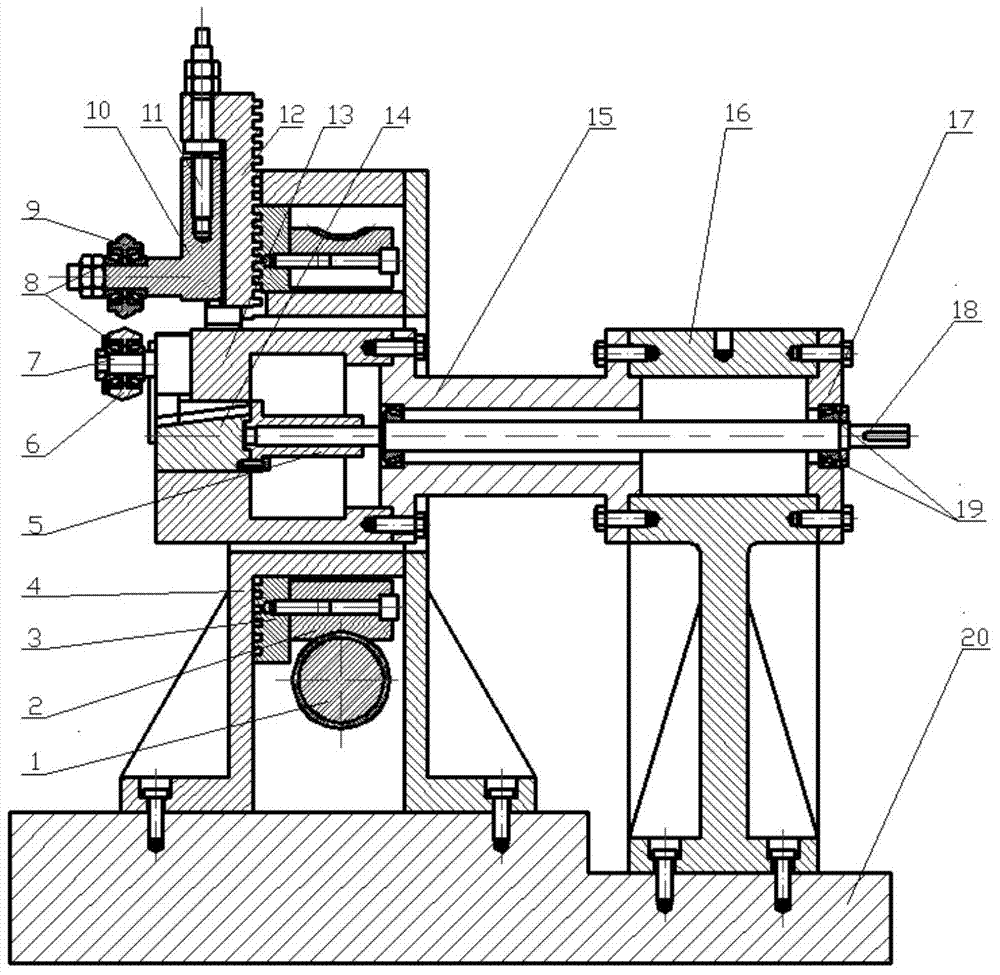

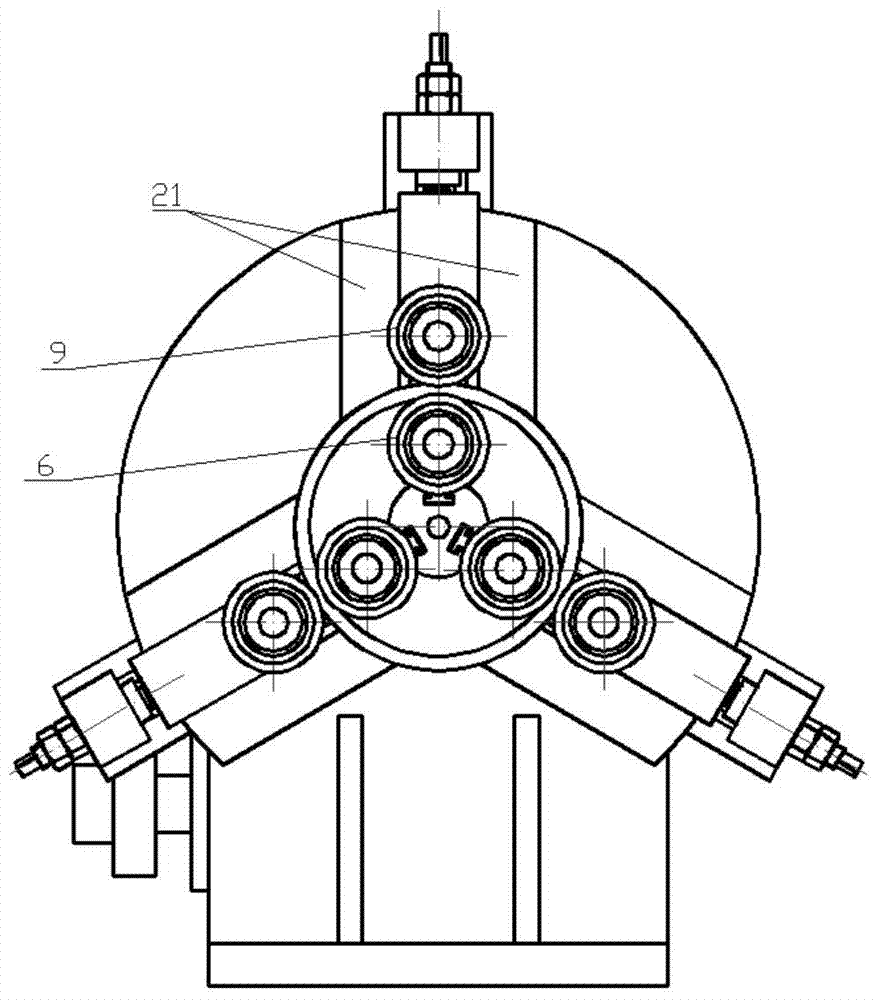

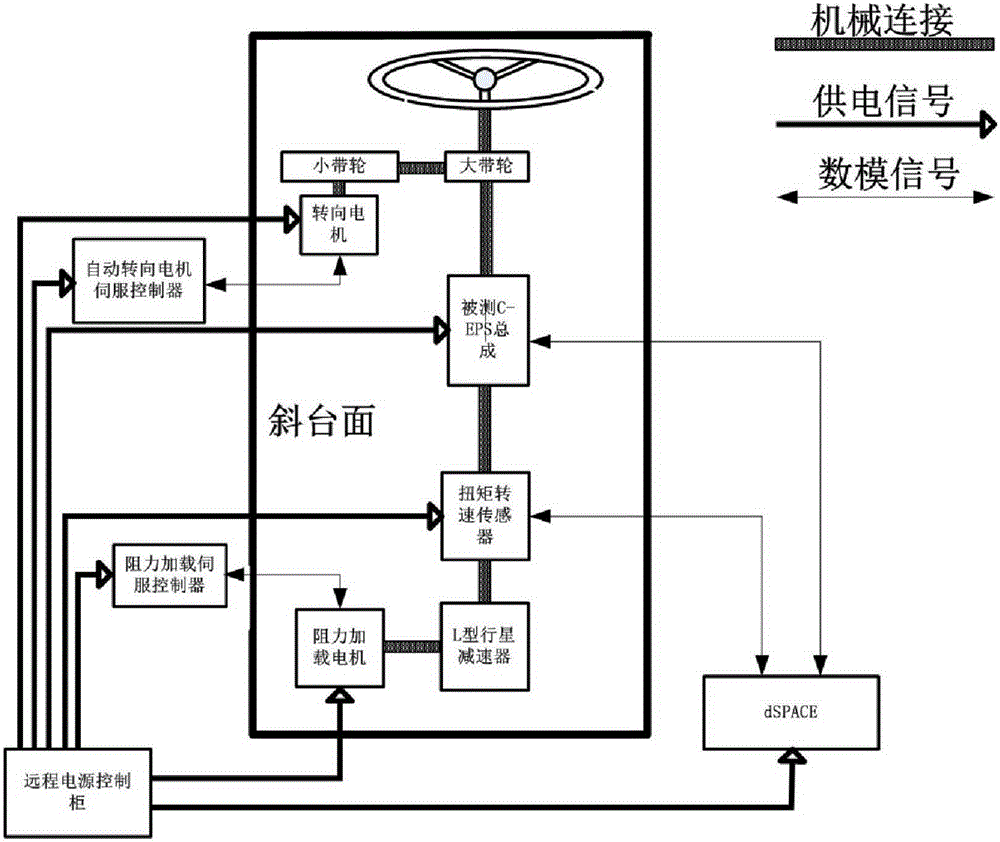

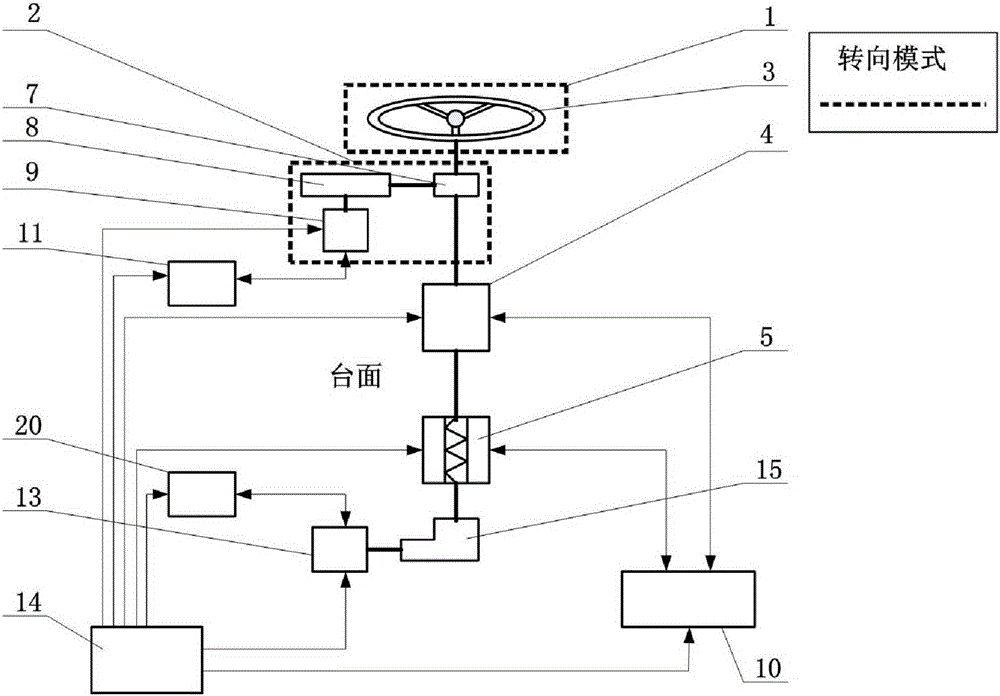

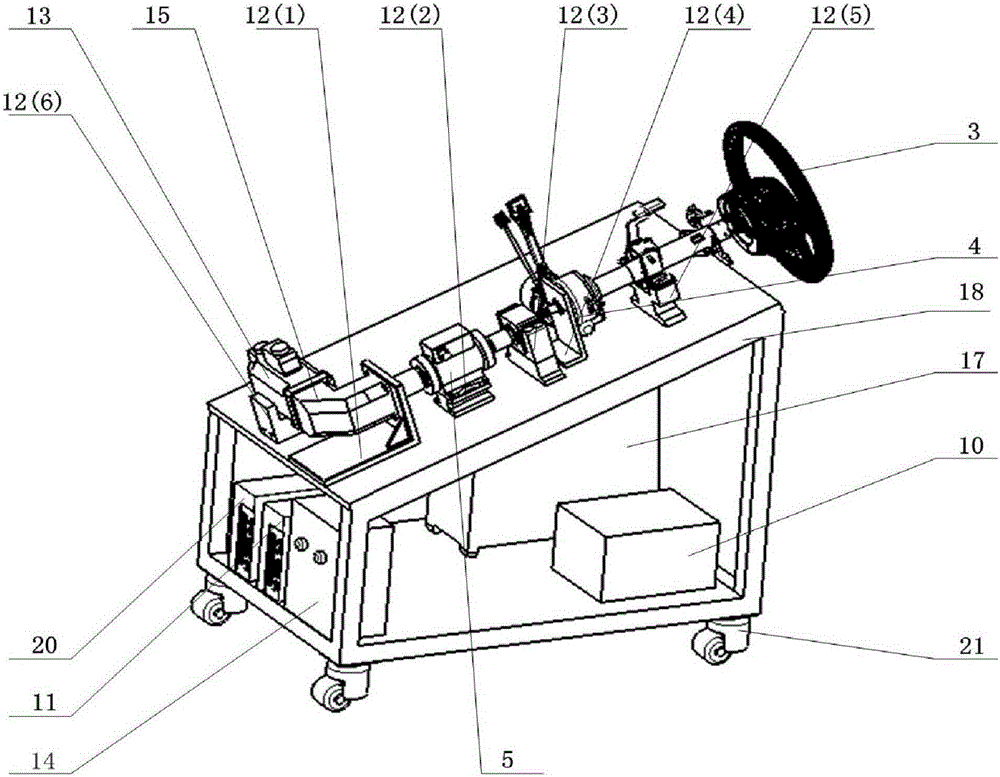

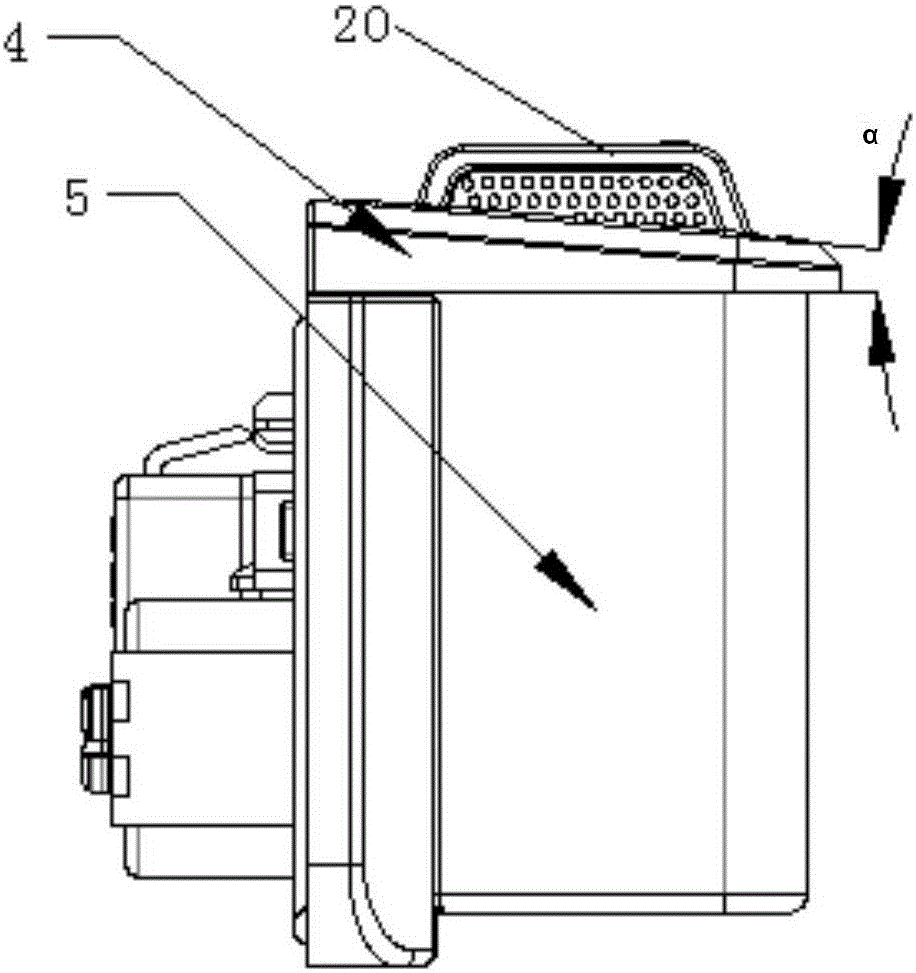

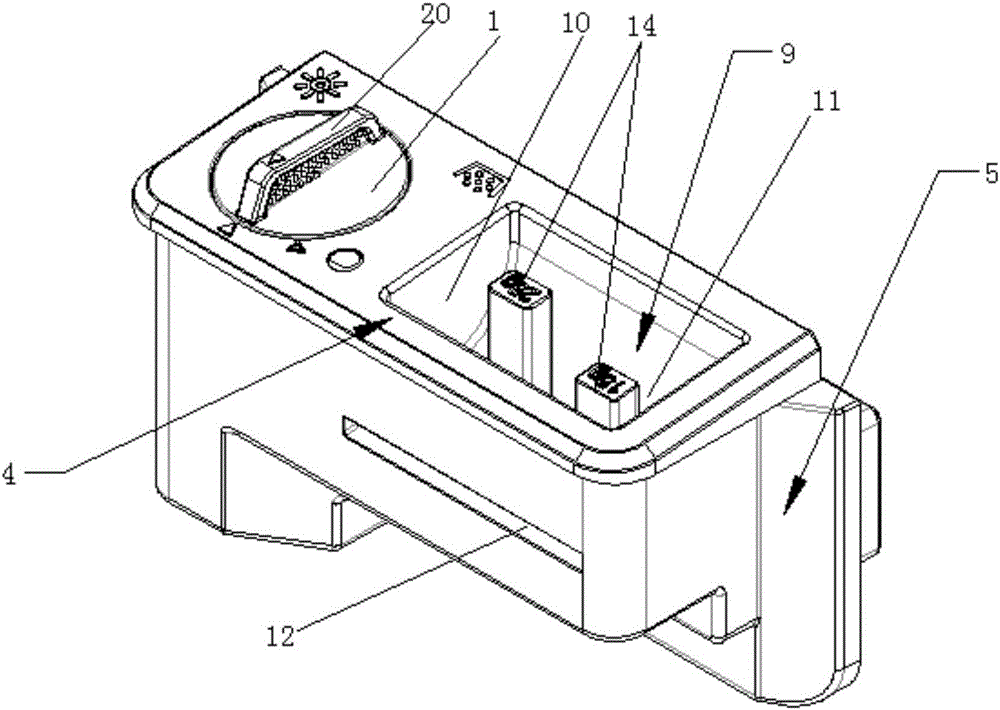

Hardware-in-loop performance testing stand suitable for automobile C-EPS system

InactiveCN105182968AReduce volumeEasy to adjust the installation positionElectric testing/monitoringElectric power steeringAutomatic steering

The present invention provides a hardware-in-loop performance testing stand suitable for an automobile C-EPS system. The hardware-in-loop performance testing stand includes an oblique plane support platform, a steering wheel mounted above the stand face, a C-EPS steering column assembly, a steering resisting simulator, an automatic steering motor, a measurement and control system based on a dSPACE real-time simulation platform, a remote control main power box, support ground castors and the like. A lower inertia AC servo motor is used to initiatively load the C-EPS steering system on the hardware-in-loop performance testing stand through a L type planetary reducer. The automatic steering motor can replace a tester for testing in part of open-loop tests. The influences, such as friction, damp and inertia existed in the L type planetary reducer, on the resistance load is considered and the corresponding compensation control is performed during the simulation process of the steering resisting torque. Compared to other electric power steering testing stands, the hardware-in-loop performance testing stand can realize the development and performance testing of an EPS control system by utilizing the precious steering resistance simulation, and the hardware-in-loop performance testing stand is compact in structure and is movable.

Owner:JILIN UNIV

Adjustable lifting textile machine

ActiveCN106352213AHeight adjustableEasy height adjustmentNon-rotating vibration suppressionStands/trestlesEngineeringOblique plane

The invention discloses an adjustable lifting textile machine. The adjustable lifting textile machine comprises a textile machine body and a textile machine rack, wherein the textile machine rack is arranged at the bottom of the textile machine body; the textile machine rack comprises a supporting mounting seat, a lifting driving device and lifting adjusting foot devices; the lifting driving device is arranged in a mounting groove of the supporting mounting seat; the lifting driving device is in transmission connection with a push block fixed at the bottom of the textile machine body so as to drive the textile machine body to move up and down; each lifting adjusting foot device comprises a lifting footstand, an oblique plane push block, a push block driving device and a lifting foot, each oblique plane push block is movably arranged in an internal cavity of the corresponding lifting footstand, oblique planes matched with each other are arranged on the top of each oblique plane push block and the top of the corresponding lifting foot respectively, each push block driving device comprises a servo motor and a lead screw, each push block driving device is in transmission connection with the corresponding oblique plane push block so as to drive the corresponding oblique plane push block to move transversely, and each oblique plane push block drives the corresponding lifting foot to move up and down through oblique plane sliding. The adjustable lifting textile machine is simple in structure, the height of the textile machine rack can be conveniently adjusted, and the textile machine is high in applicability and practicability.

Owner:江苏福安特纺织机械制造有限公司

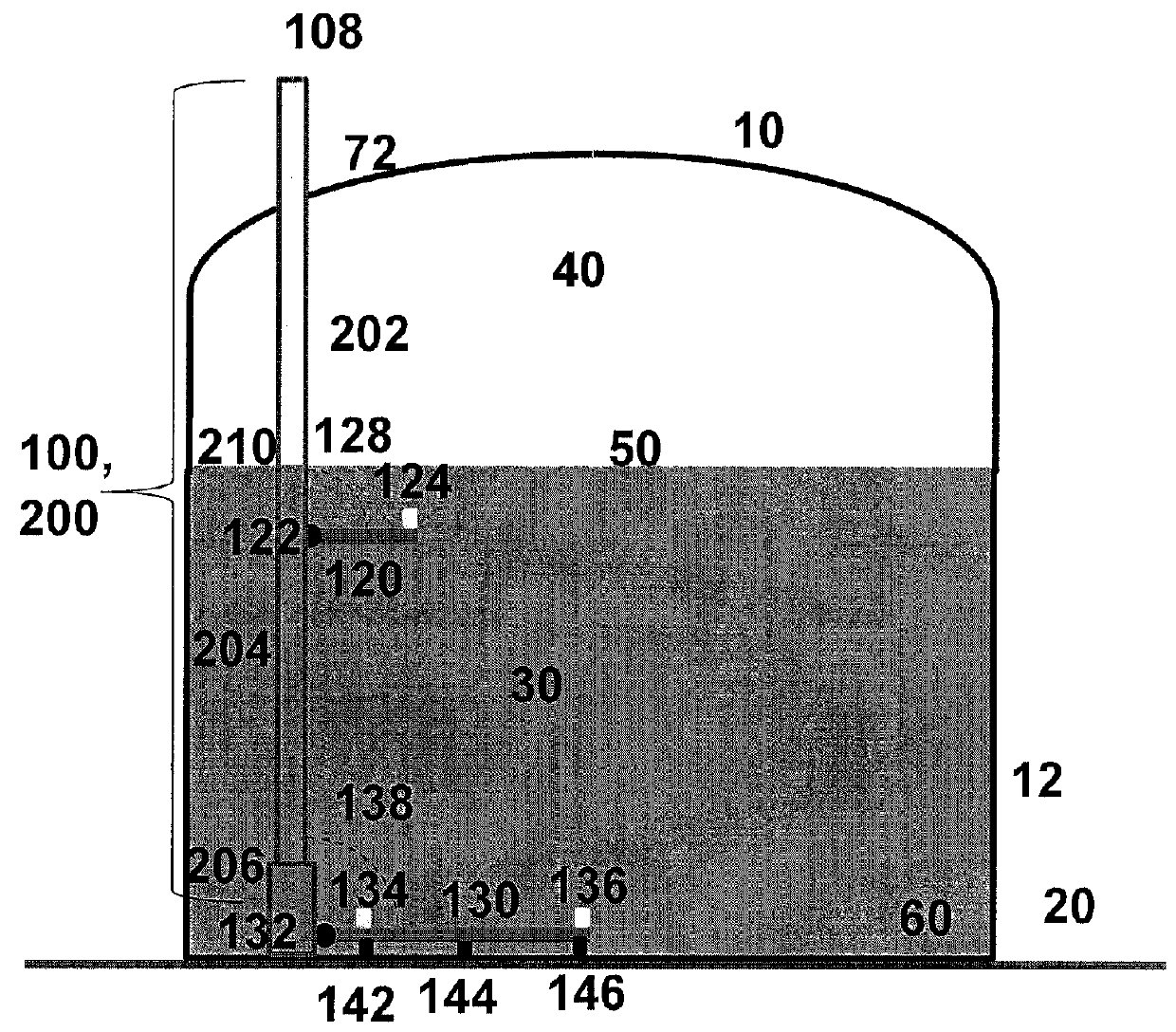

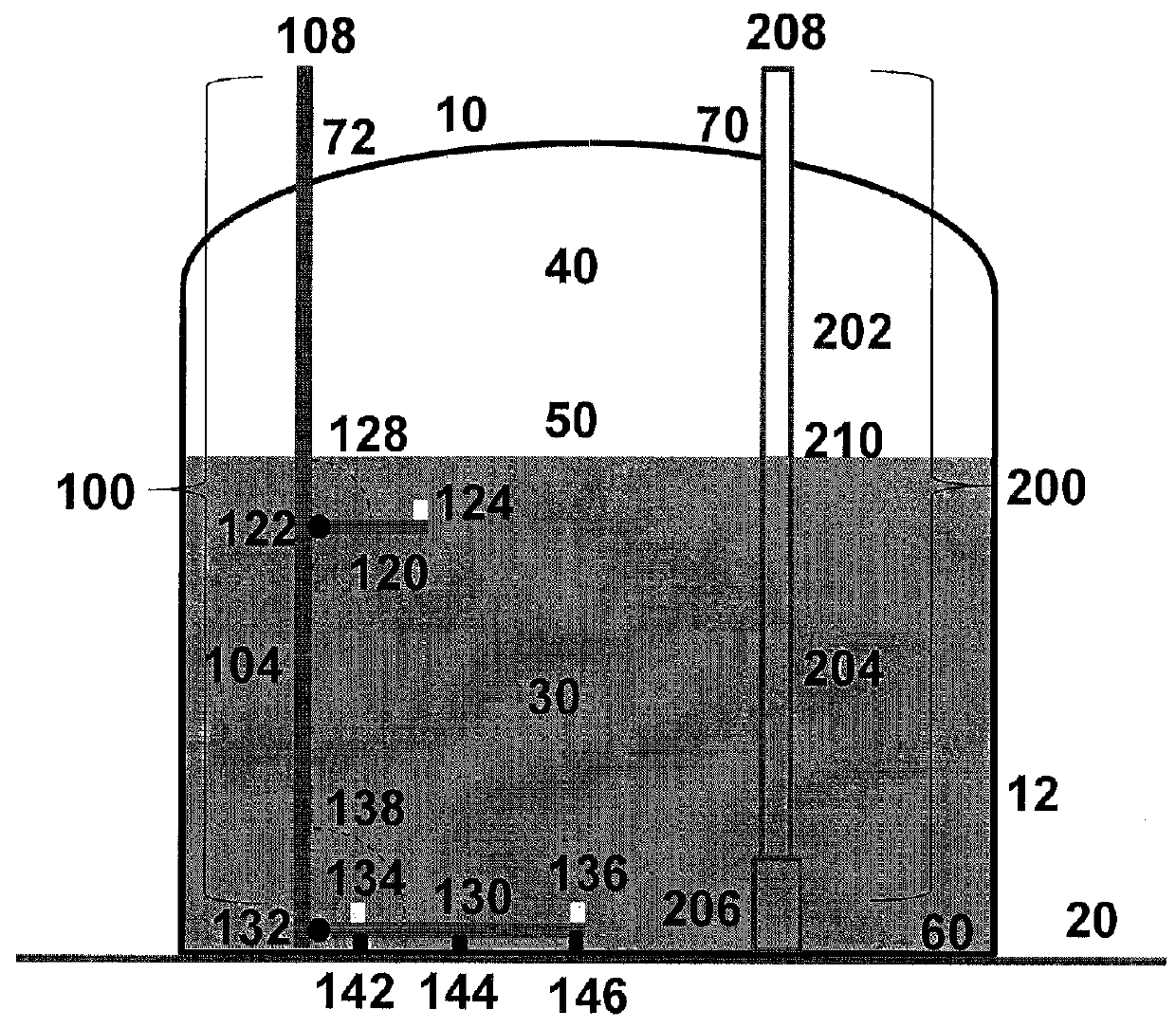

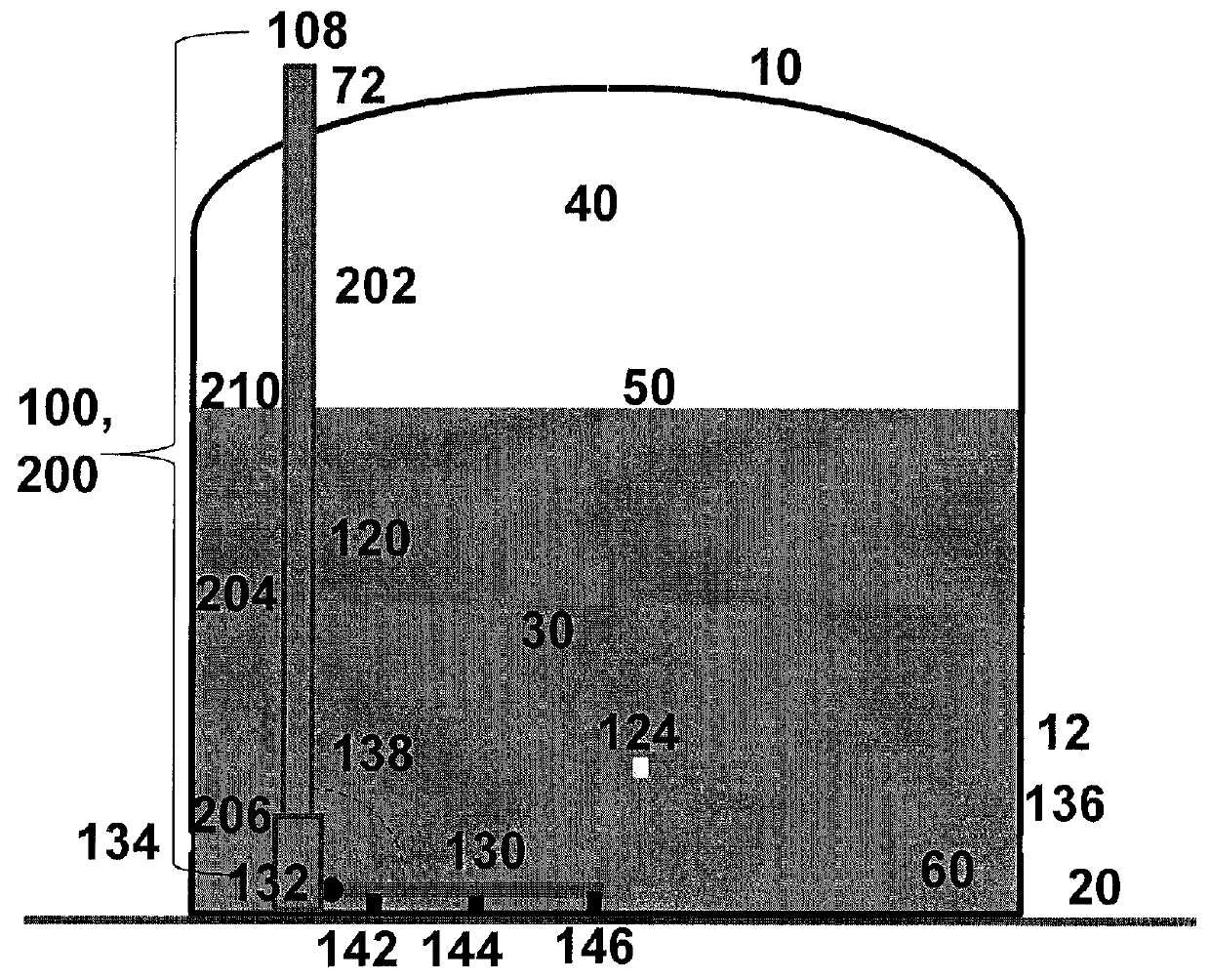

Method and apparatus for extending the time between out-of-service, in-tank inspections

ActiveUS9228932B1Safely extendedSafely extending timeDetection of fluid at leakage pointMaterial analysis using acoustic emission techniquesAcoustic emissionStructure of Management Information

A method and apparatuses to extend the time interval between out-of-service, in-tank inspections while insuring structural integrity using a risk-based, Bayesian statistical approach comprised of a passing leak detection test and the using the results from (1) tank floor thickness measurements, (2) prior out-of-service tank floor inspection results, and / or (3) acoustic emission corrosion maps of the tank floor to estimate the minimum thickness and maximum corrosion rate of the tank during the extension period. The present invention uses an in-tank, mass-based leak detection system to establish tank integrity, three or more ultrasonic (UT) thickness measurement sensors for measurements of the tank floor at one location, and to establish the spatial distribution of corrosion of the tank floor, one or more prior API 653 / 12R1 or STI SP001 tank floor thickness inspections and / or three or more in-tank AE sensors mounted inside the tank with vertical and horizontal locations in an oblique plane relative to the tank floor.

Owner:VISTA RES INC

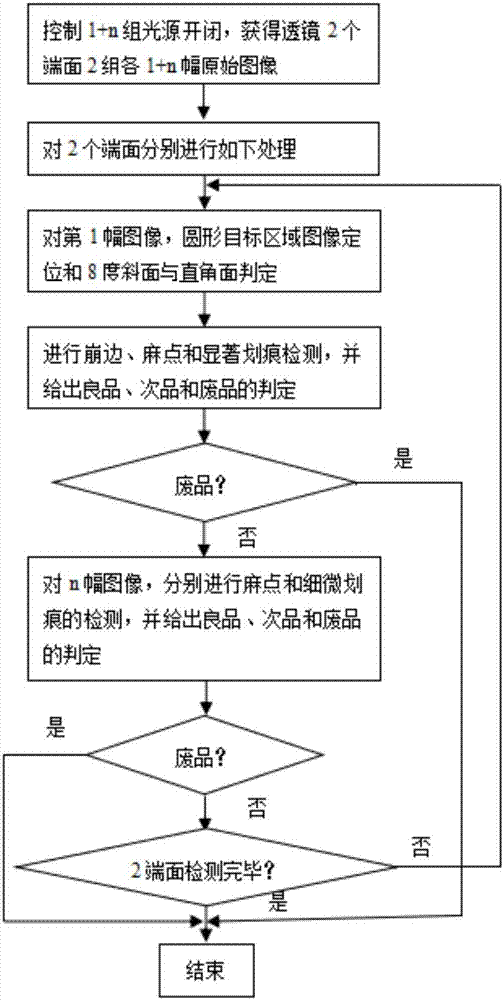

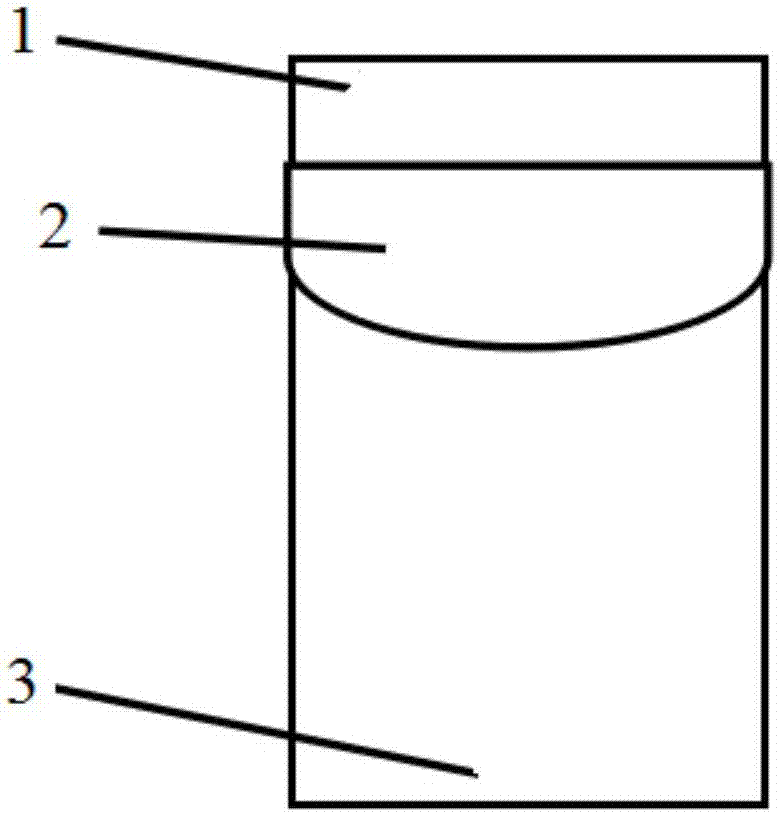

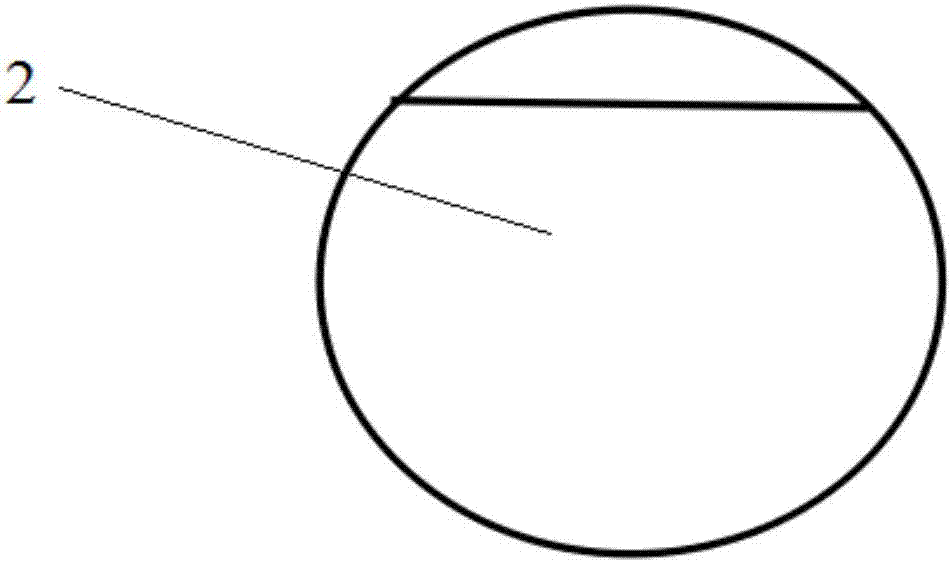

Method for machine vision detection in allusion to self-focusing lens surface defect

ActiveCN107255641AHigh degree of automationImprove detection efficiencyMaterial analysis by optical meansMachine visionSelf-focusing

The invention discloses a method for machine vision detection in allusion to a self-focusing lens surface defect. The method comprises the following steps: 1, controlling open and close of 1+n groups of light sources, to obtain 1+n original images of two end faces of a self-focusing lens; 2, using the first image, executing the circular target area image location and 8-degree slope and right-angle surface judgment, using dynamic threshold segmentation to obtain a binary image, extracting the suspected defect area feature, and giving out the product qualified or unqualified judgment; 3, if the judgment is a qualified product, dividing the target image on n rest images according to the circular target area position, executing median filtering differential treatment to the target mage, and executing pit detection, executing the scratch detection on the divided target image by using the shape feature of the tiny scratch, and giving out a detection result; and 4, executing the defect detection to 1+n images of two end faces, and executing the comprehensive judgment to the product. The method is capable of solving the problem in the prior art that the artificial detection efficiency is low and the detection quality is unstable.

Owner:XIAN UNIV OF TECH

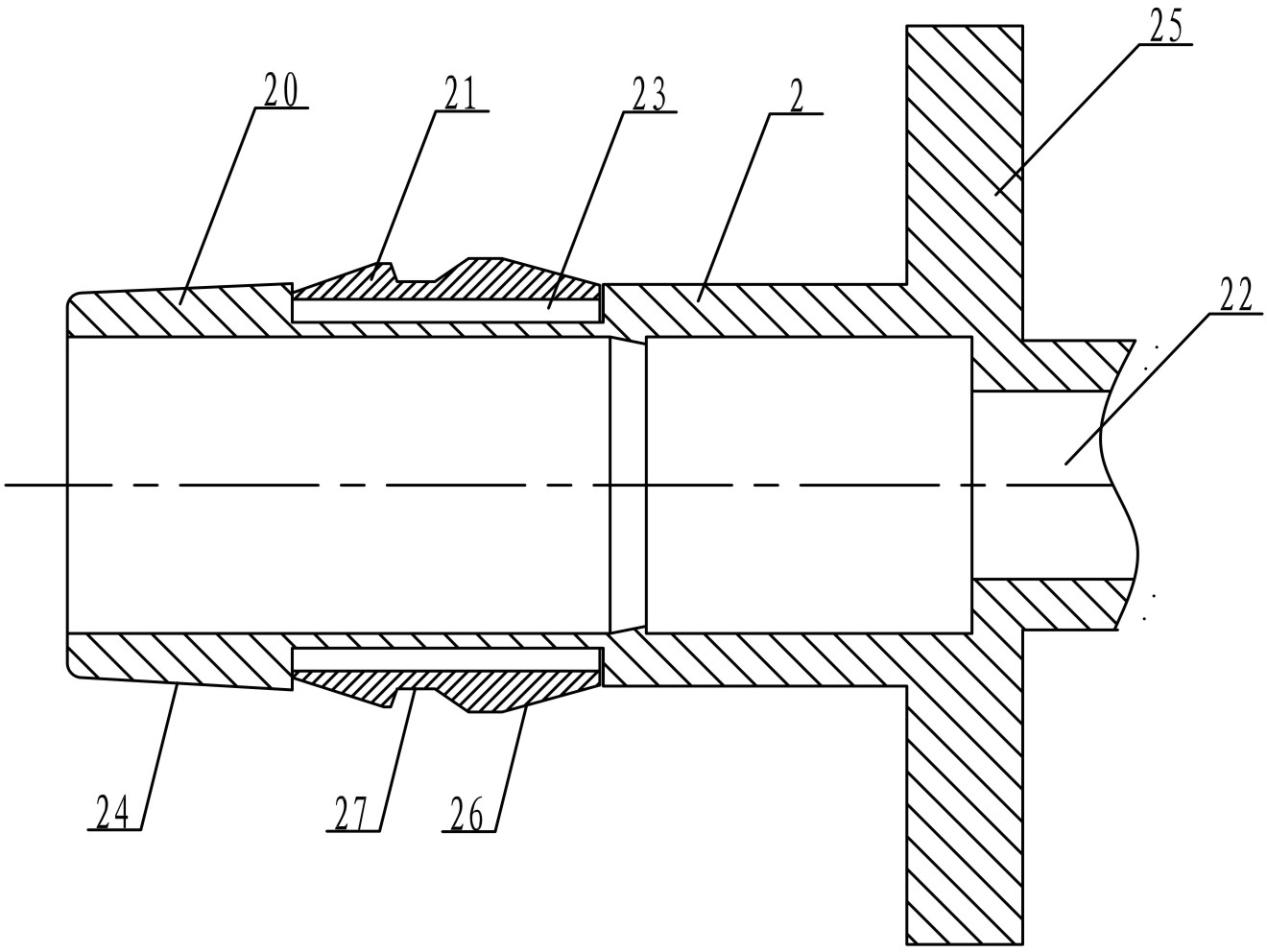

Rapid locking coaxial connector

ActiveCN102646894ASimple structureQuick butt lockCoupling device detailsElectrical conductorClamp connection

The invention discloses a rapid locking coaxial connector, which comprises a plug and a socket and is characterized in that the plug is formed by assembling a screw sleeve with an outer conductor which is sleeved by springs and pressing retaining rings, and the outer conductor of the plug is a connection piece provided with a clamping jaw and a plug-in hole; one end of the screw sleeve is provided with a guiding oblique plane and an unlock plane, the other end of the screw sleeve is provided with a sleeve which has a bending structure; the socket is composed of an outer casing and a clamping ring, and the clamping ring is an elastic sleeve ring which is provided with guiding slopes, a clamping groove and an axial cutting groove and is sleeved on the outer casing to be in clamping connection with a groove; and the plug and the socket are connected in an inserting mode, and the clamping jaw enters into the clamping groove by means of an axial thrust and is locked in the clamping groove by means of the springs, so that rapid connection and locking between the plug and the socket are achieved. Compared with coaxial connectors in prior art, the rapid locking coaxial connector is simple in structure, rapid and convenient in butting locking and disassembling, reliable in connection, good in vibration resistance and impact resistance, convenient to install and low in production cost.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

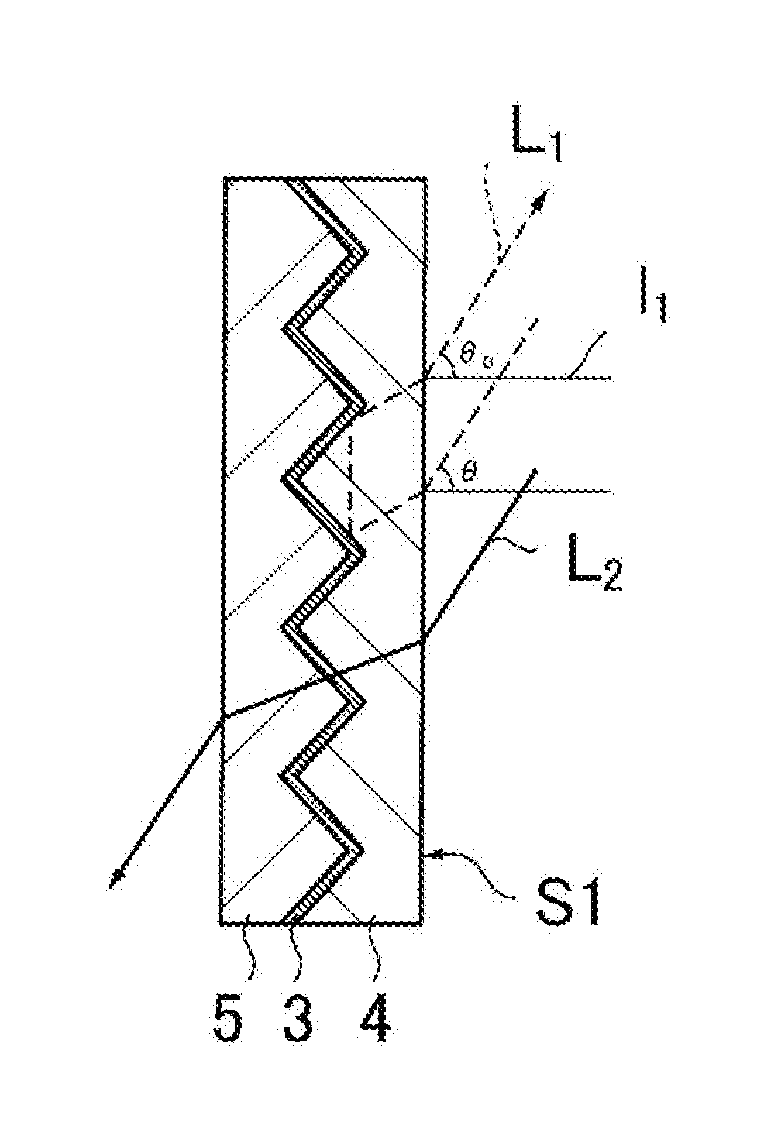

Optical member, production method therefor, window material, and fixture

InactiveUS20170052295A1Increased durabilityComplex structureLiquid surface applicatorsOptical filtersReflective layerMetal

An optical member including a first optical layer having convex shapes, and a reflective layer, which is formed on the convex shapes of the first optical layer and is configured to reflect light including at least infrared light, wherein the reflective layer includes at least a metal layer, wherein a maximum height roughness Rz (nm) of inclined planes of the convex shapes is 3.0 times or less an average thickness (nm) of the metal layer, and wherein the average thickness of the metal layer is 40 nm or less.

Owner:DEXERIALS CORP

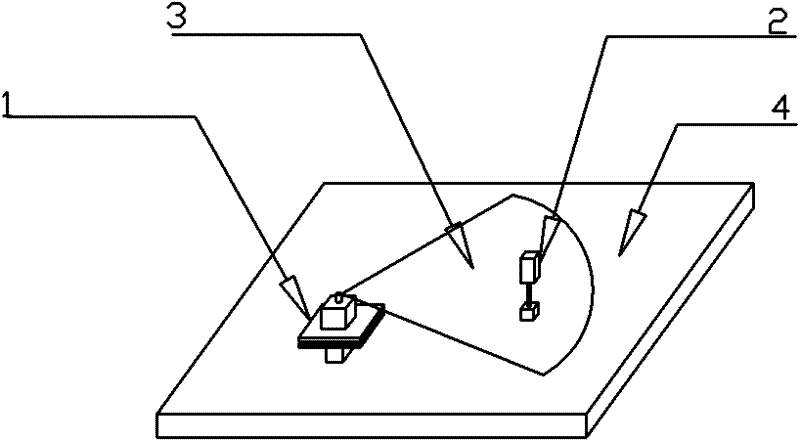

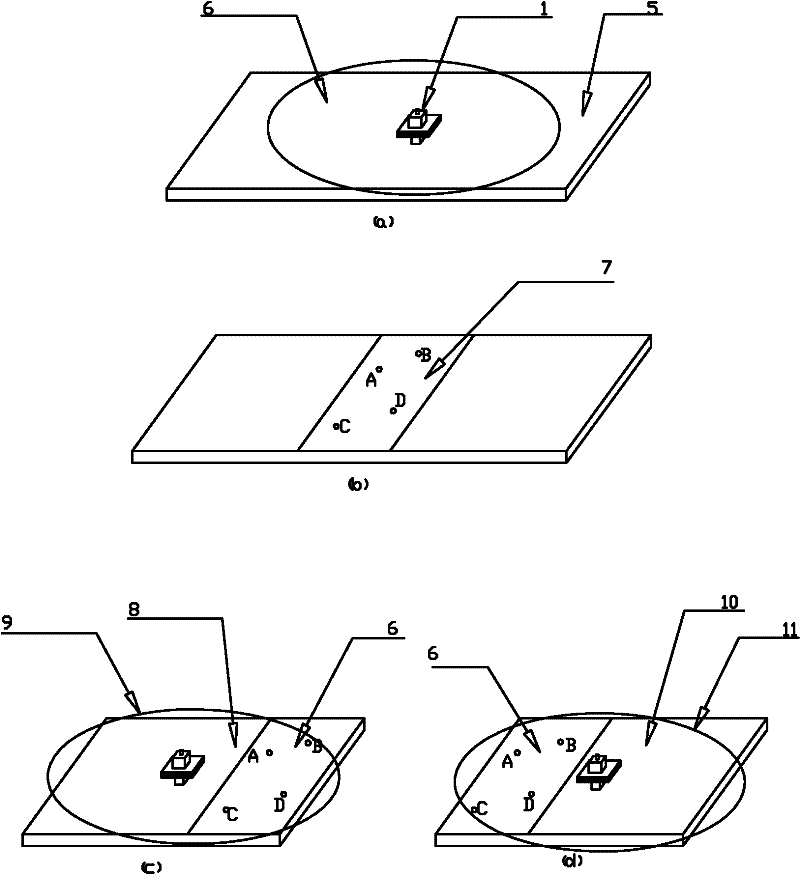

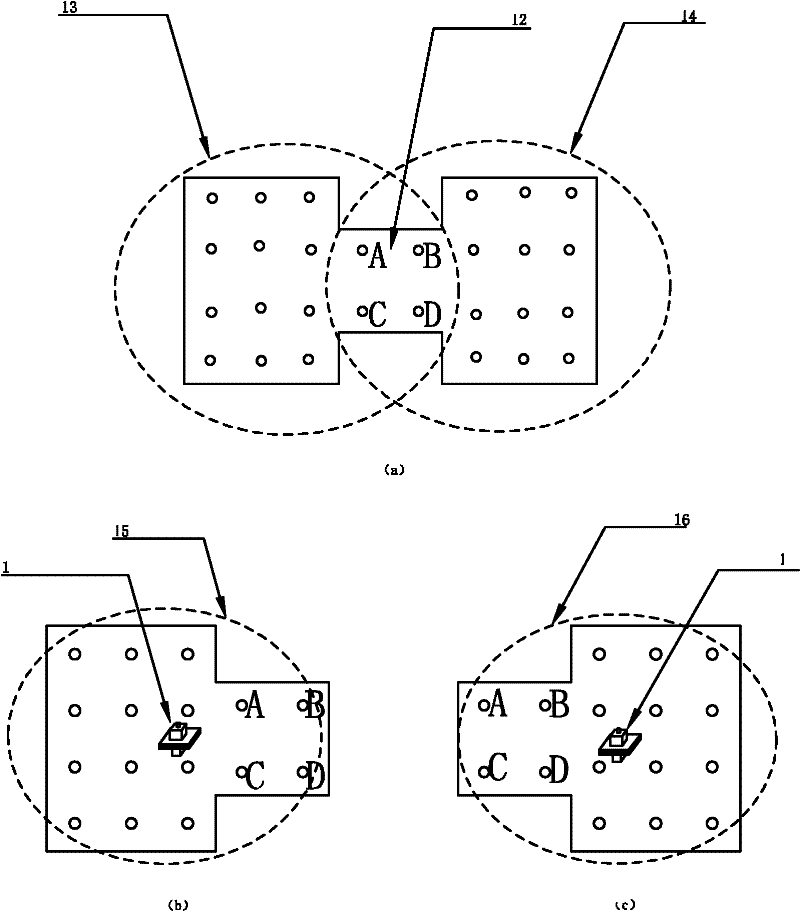

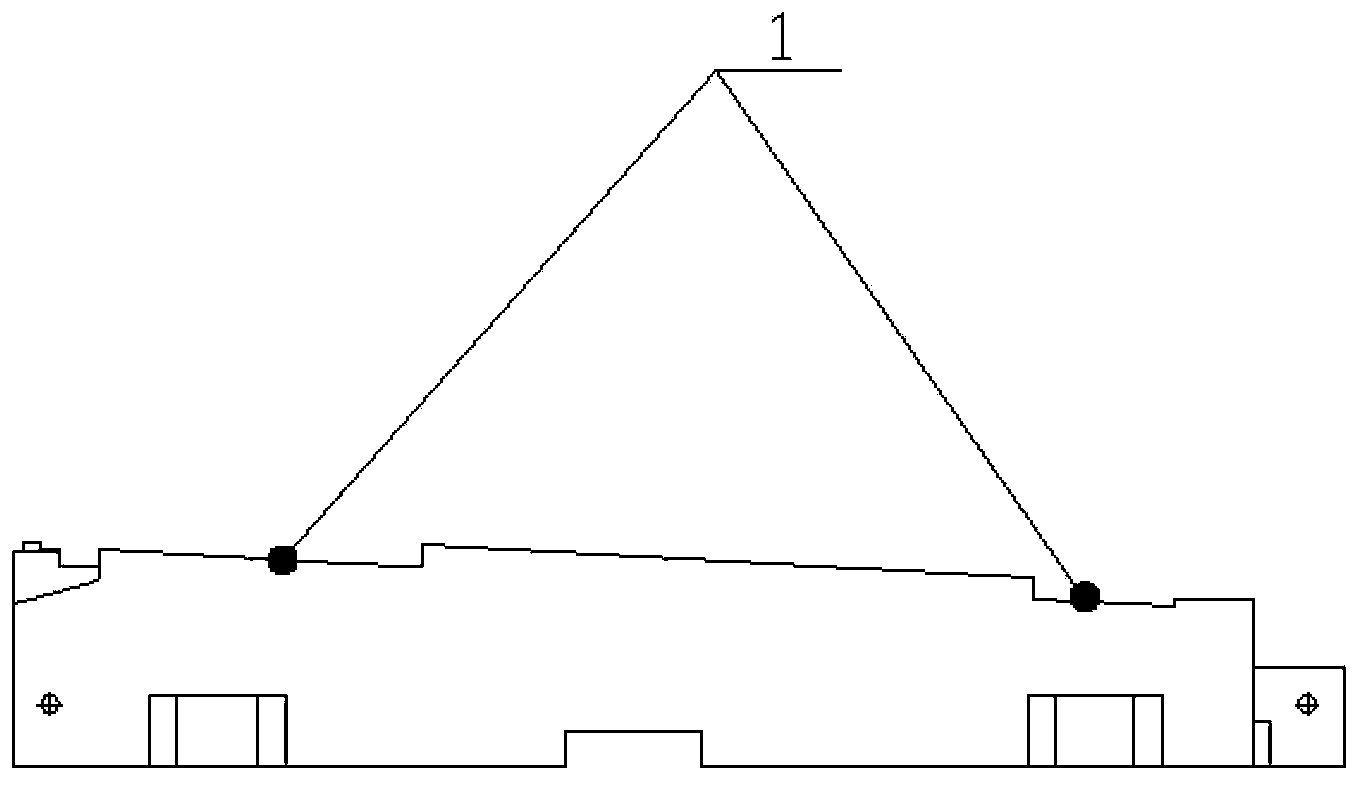

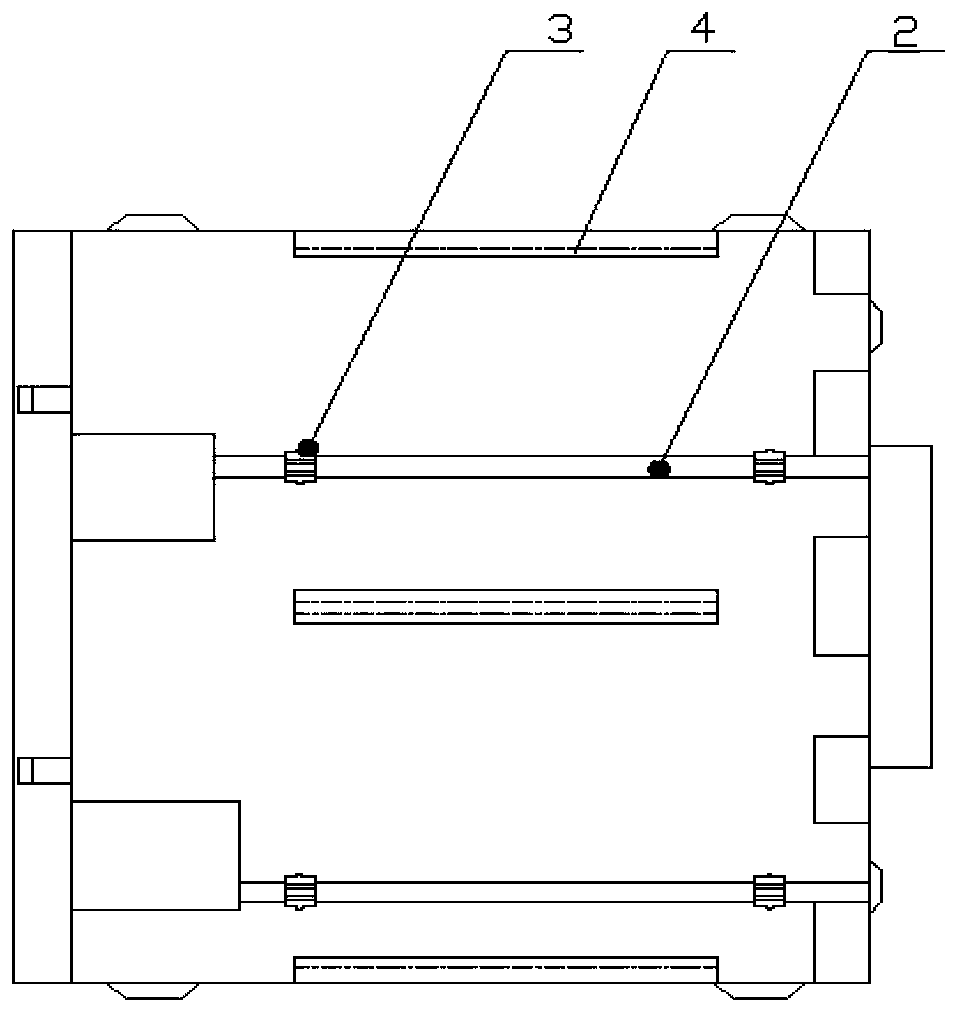

Data splicing technology for measuring flatness of super large plane

The invention relates to a data splicing technology for measuring the flatness of a super large plane. Based on a laser alignment scanning method, a measured plane with an obstacle or the super large plane is partitioned into a plurality of sub areas with a common area and then the sub areas are measured, the measurement result is processed by using a data splicing method, the flatness error is evaluated according to the evaluation criteria and methods of the flatness error, and the flatness error value of the whole plane can be acquired, so that quick measurement of the super large plane and the plane with the obstacle is realized. The method comprises the following steps of: 1, dividing the measured plane into the plurality of sub areas with the common area; 2, measuring the sub areas by using the laser alignment scanning method respectively; and 3, after all the sub areas are measured, normalizing the measurement data. By the technology, the flatness measurement of the large plane and the plane with the obstacle is realized, the defects of long measurement time, incapability of measuring the flatness of an inclined plane and the like in a liquid level method are overcome, and the measurement speed is improved.

Owner:DALIAN MARITIME UNIVERSITY

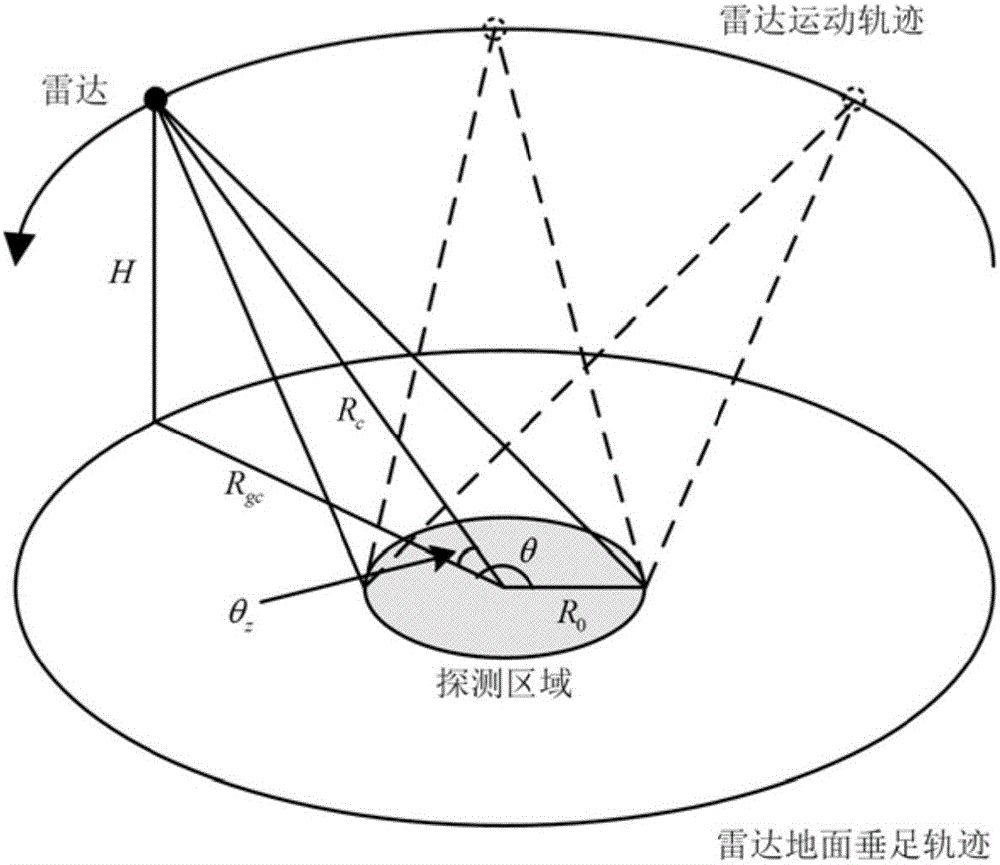

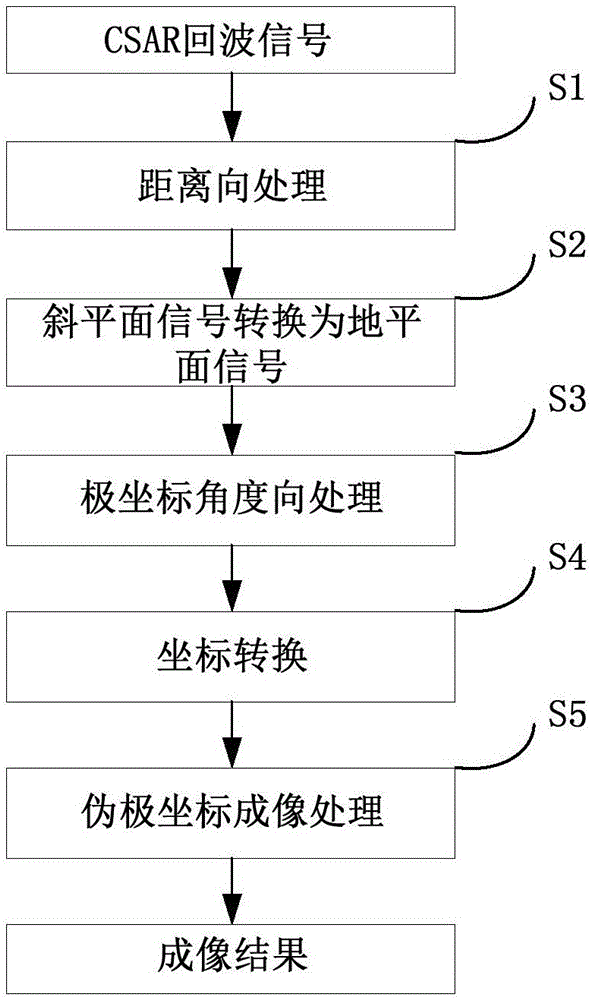

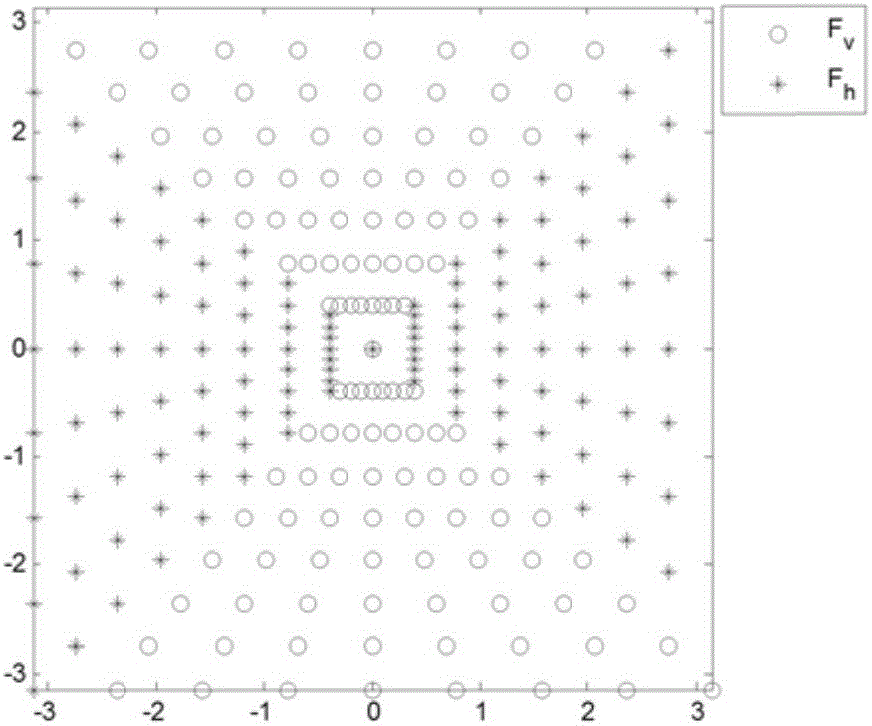

Circular synthetic aperture radar imaging method

InactiveCN106772380AHigh resolutionHigh resolution imagingRadio wave reradiation/reflectionInformation processingRapid imaging

The invention discloses a circular synthetic aperture radar imaging method, belonging to the technical field of electronic signal processing. The invention relates to a spatial remote sensing and air-to-ground observation information processing technology, in particular to an onboard circular synthetic aperture radar imaging technology. According to the imaging method, an original oblique plane echo is mapped to the ground plane by solving the inverse of a system kernel function, and the distribution of signals in a wave number domain is obtained by multiplying an azimuth frequency domain with a reference function, so that plane wave approximation is avoided, the problem that the size of an imaging area of the traditional polar format algorithm is limited can be solved, and the imaging of a large imaging scene can be realized; pseudo-polar coordinates are used for replacing rectangular coordinates as an intermediate interpolation transition matrix, and the distribution density characteristic of the signals in the wave number domain is considered, so that the interpolation precision is higher, the obtained image resolution is higher, and the high resolution imaging can be realized; the imaging process only involves one-dimensional interpolation, and fast algorithms such as chirp z transform (CZT) and inverse fast Fourier transform (IFFT) are adopted, so that the method has very high computational efficiency and can realize rapid imaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

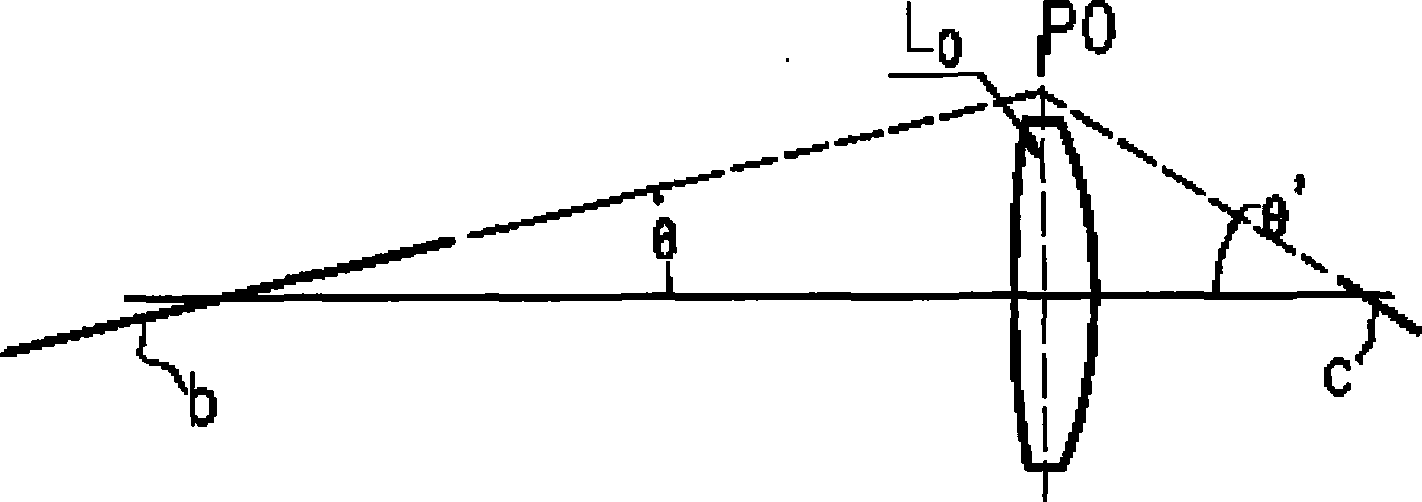

Optical system used for focusing and leveling

ActiveCN101477319AReduce reflection lossReduce design difficultyPhotomechanical exposure apparatusMicrolithography exposure apparatusCamera lensReflection loss

The invention discloses an optical system for focusing and leveling, which comprises an illumination unit, a marking plate, an oblique imaging unit, a projection imaging unit, an accept imaging unit, a correction imaging unit and a detector, wherein the illumination unit provides broadband light for uniform illumination and illuminates the marking plate; the marking plate forms an oblique mark image through the oblique imaging unit; the oblique mark image is imaged on a silicon slice surface by the projection imaging unit and reflected by the silicon slice surface, and forms an accept mark through the accept imaging unit; and the accept mark is transmitted to the detector through the correction imaging unit. The novel proposal for the focusing and leveling system provided on the basis of Scheimpflug condition comprises that: a vertical plane is changed into an oblique plane in an imaging mode so as to reduce reflection loss and design difficulty. Simultaneously, the aim of reducing the focal length and increasing the operating distance is achieved by adoption of a telephoto structure on a near measuring plane of a telecentric optical system.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Solid-state fermentation preparation method for gamma-aminobutyric acid

InactiveCN101240301AIncrease productionHigh purityMicroorganism based processesFermentationBiotechnologyGamma-Aminobutyric acid

The invention discloses a method for solid fermentation preparing Gamma-aminobutyric acid comprising the following steps firstly filtering red aspergillus from beancurd preserved, putting the red aspergillus MP1104 on oblique plane culture medium and culturing for 7 days to activate the fungus, then transferring the fermentation fungus into culture medium at 30 DEG C, at rotating speed of 150r / min and culturing the activating fungus rocketing bed for 2 says to prepare fermentation seed, optimizing solid fermentation condition and culture medium, at last culturing and preparing GABA on the condition of optimizing culture medium and culture condition. The fermentation raw material is rice and the fungus is red aspergillus. The product of the invention is safe in edibility and also can be used as health care food. The GABA field and purity in the method are high. In optimum fermentation condition and culture medium, the GABA field can be improved from 0.21mg / g to 0.35mg / g and the final purity can be up to 45, and can be prepared continuously in industrialization in low cost.

Owner:GUIZHOU UNIV

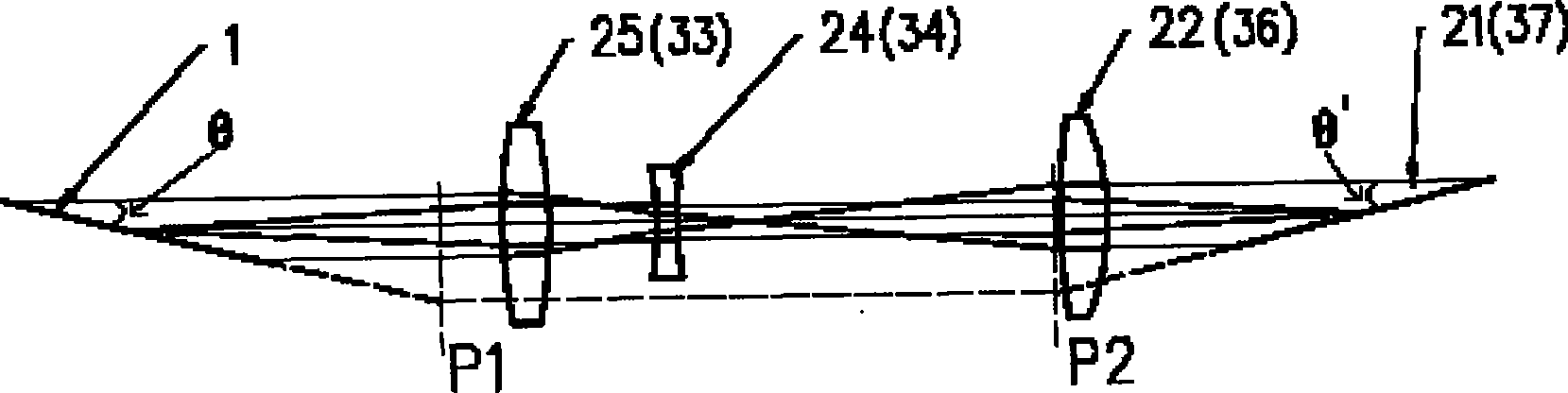

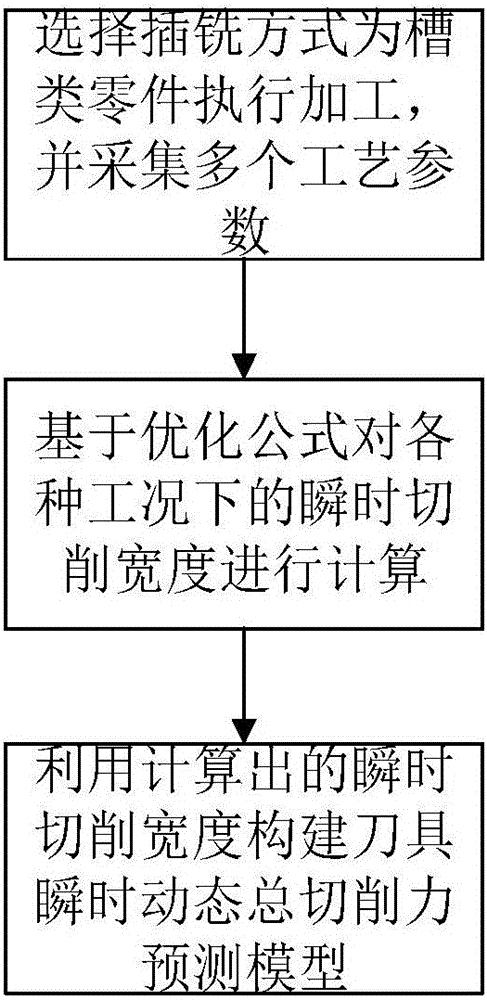

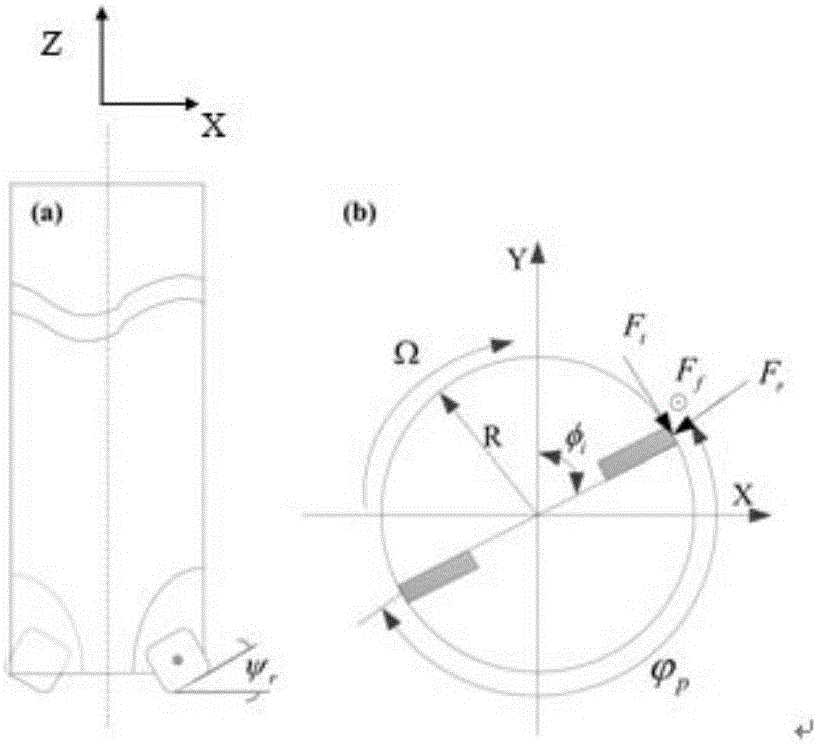

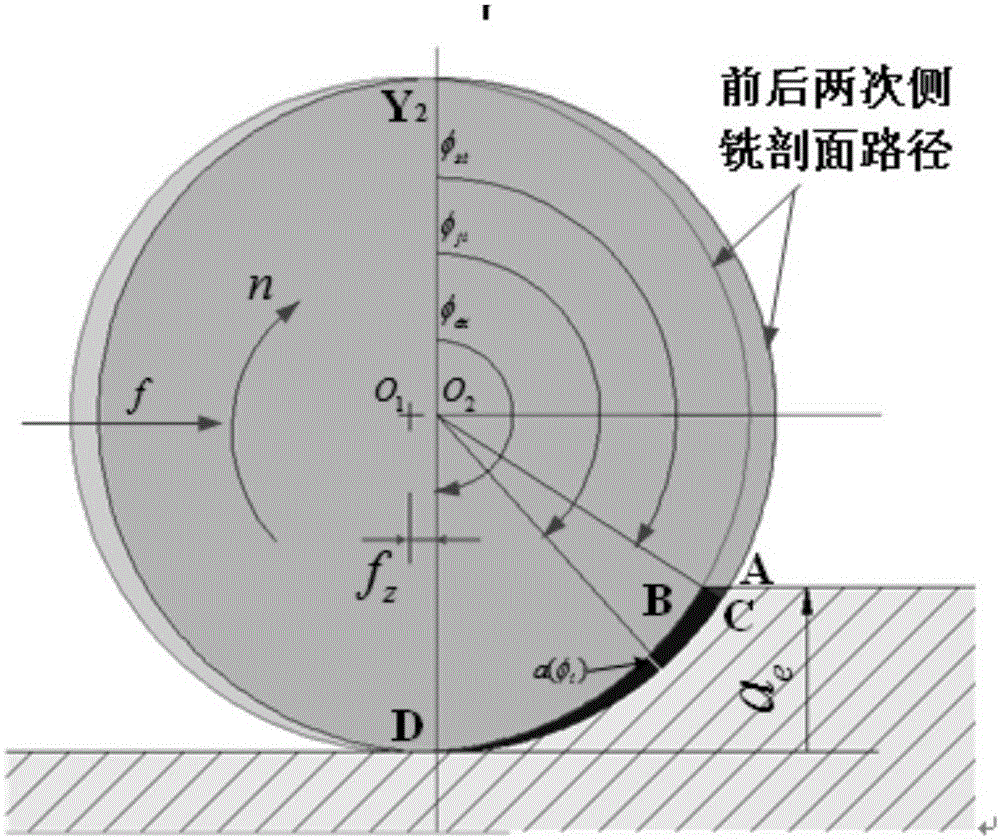

Plunge milling machining cutting force predicting and modeling method

InactiveCN105701323AComprehensive responseAccurate responseGeometric CADSpecial data processing applicationsImpellerModel method

The invention belongs to the related technical field of metal cutting machining and discloses a compound oblique plane milling machining method for high-precision surface roughness control.The method comprises the steps that (a) a workpiece is machined in a plunge milling mode, and multiple process parameters are acquired; (b) instantaneous cutting widths under the different plunge milling machining conditions are respectively calculated according to an optimizing formula; (c) the calculated instantaneous cutting widths are utilized to establish a required cutter instantaneous dynamic total cutting force prediction model, and corresponding guidance is provided according to the model to complete the plunge milling machining process.By the adoption of the method, comprehensive and accurate prediction on the cutting force in the plunge milling machining process can be achieved under the condition that technical machining requirements are strictly met, and accordingly the process guidance is provided for the high-quality efficient plunge milling control process.Therefore, the method is especially suitable for the plunge milling machining occasions of impellers, casings and other grooved parts.

Owner:HUAZHONG UNIV OF SCI & TECH

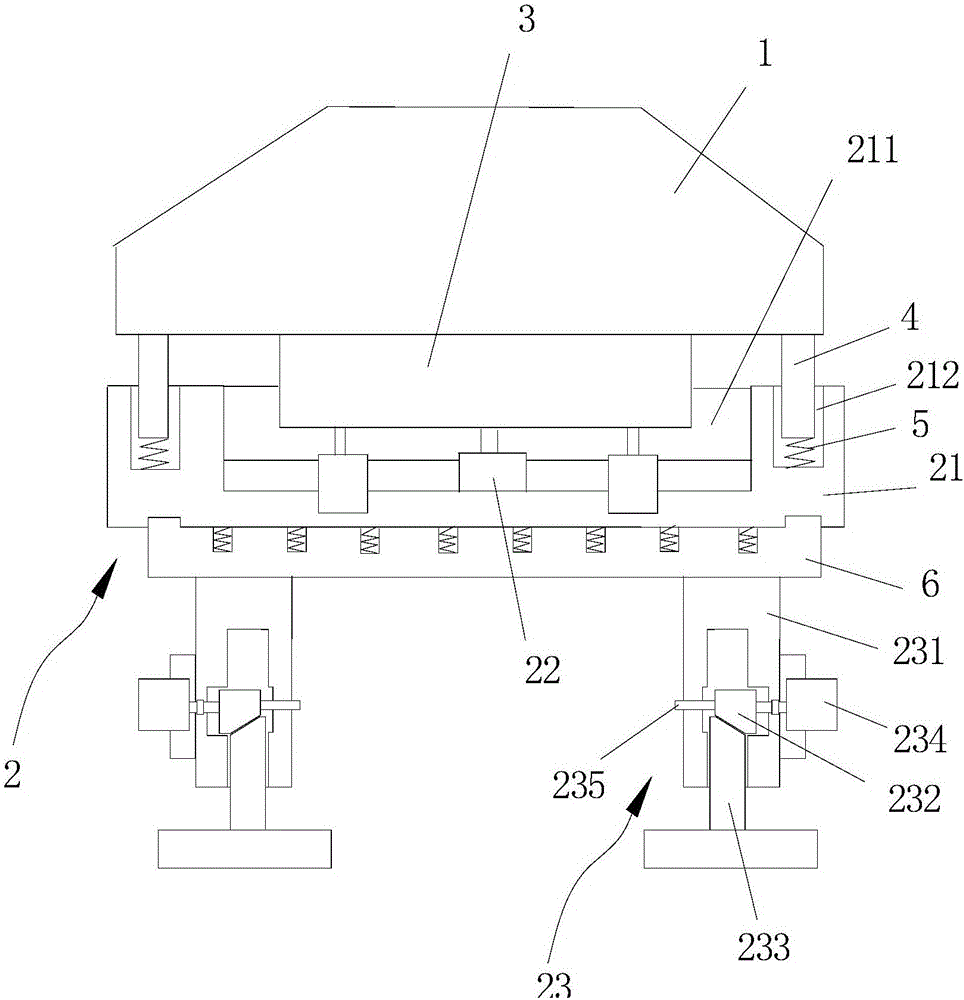

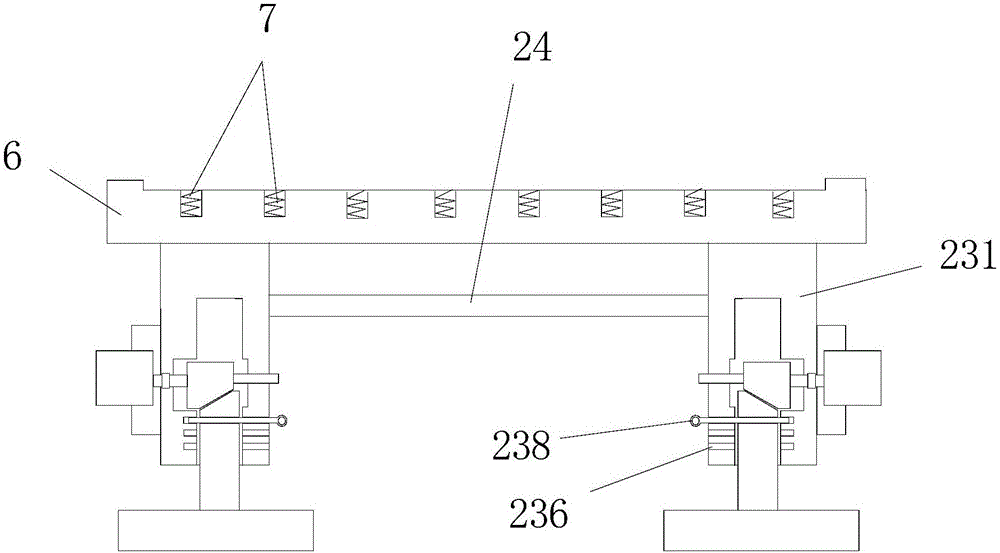

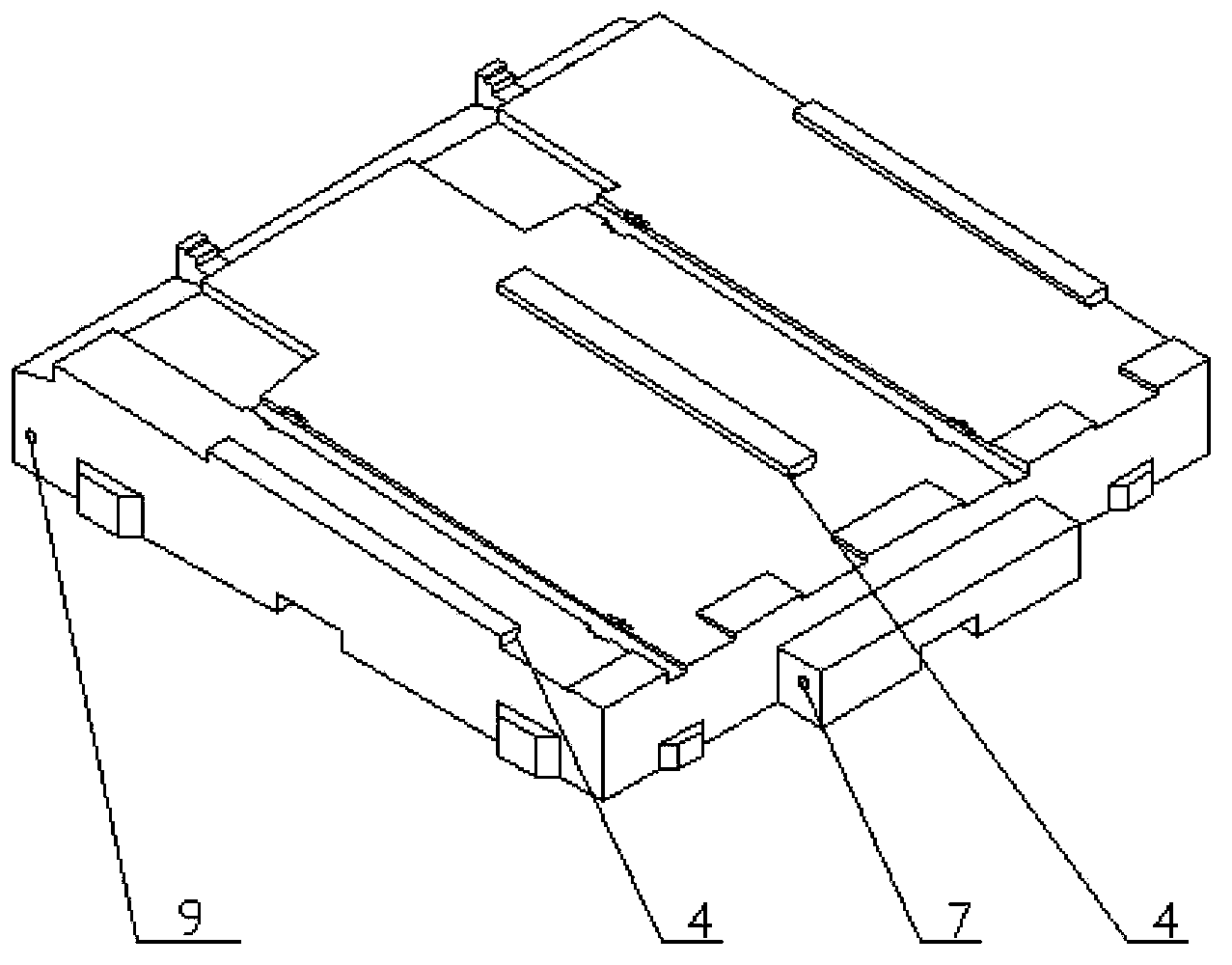

Floating platform used for waterborne photovoltaic power generation system

InactiveCN103986409AIncrease power generationReduce construction costsPhotovoltaic supportsSolar heating energySupporting systemWorking environment

The invention relates to a floating platform used for a waterborne photovoltaic power generation system and belongs to the field of photovoltaic power generation systems. The floating platform is an integrated shell-shaped hollow structure which is sealed inside. The upper surface of the floating platform is an oblique plane capable of placing at least one photovoltaic assembly. At least one through groove used for water drainage, ventilation and / or wiring is arranged in the oblique plane. The floating platform is capable of adapting to a special work environment: water surface and has all functions of a support system and also has the characteristics of being low in cost, convenient to build up, easy to maintain and adjust and high in environment adaptability and the like.

Owner:HANERGY NEW MATERIAL TECH CO LTD

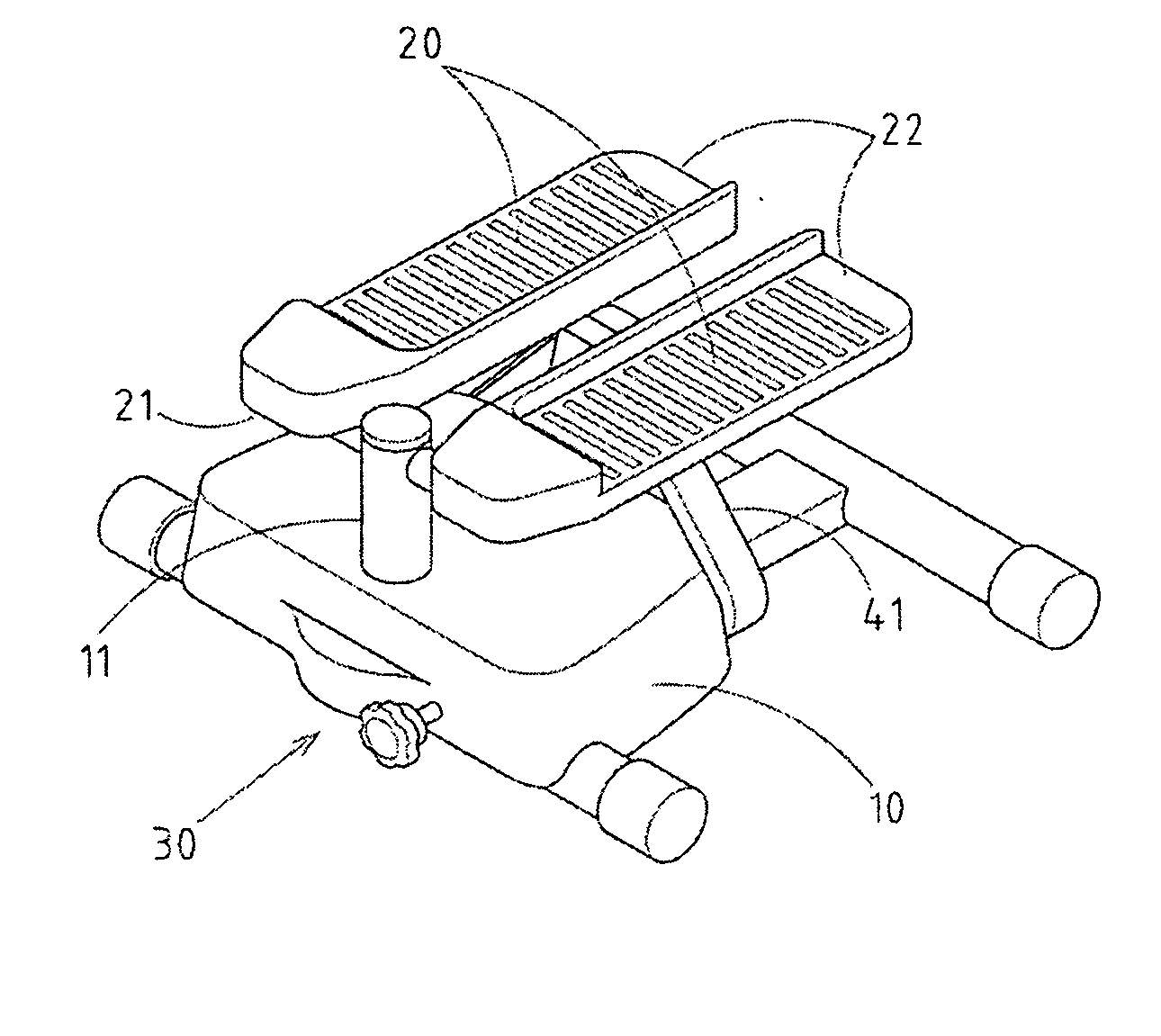

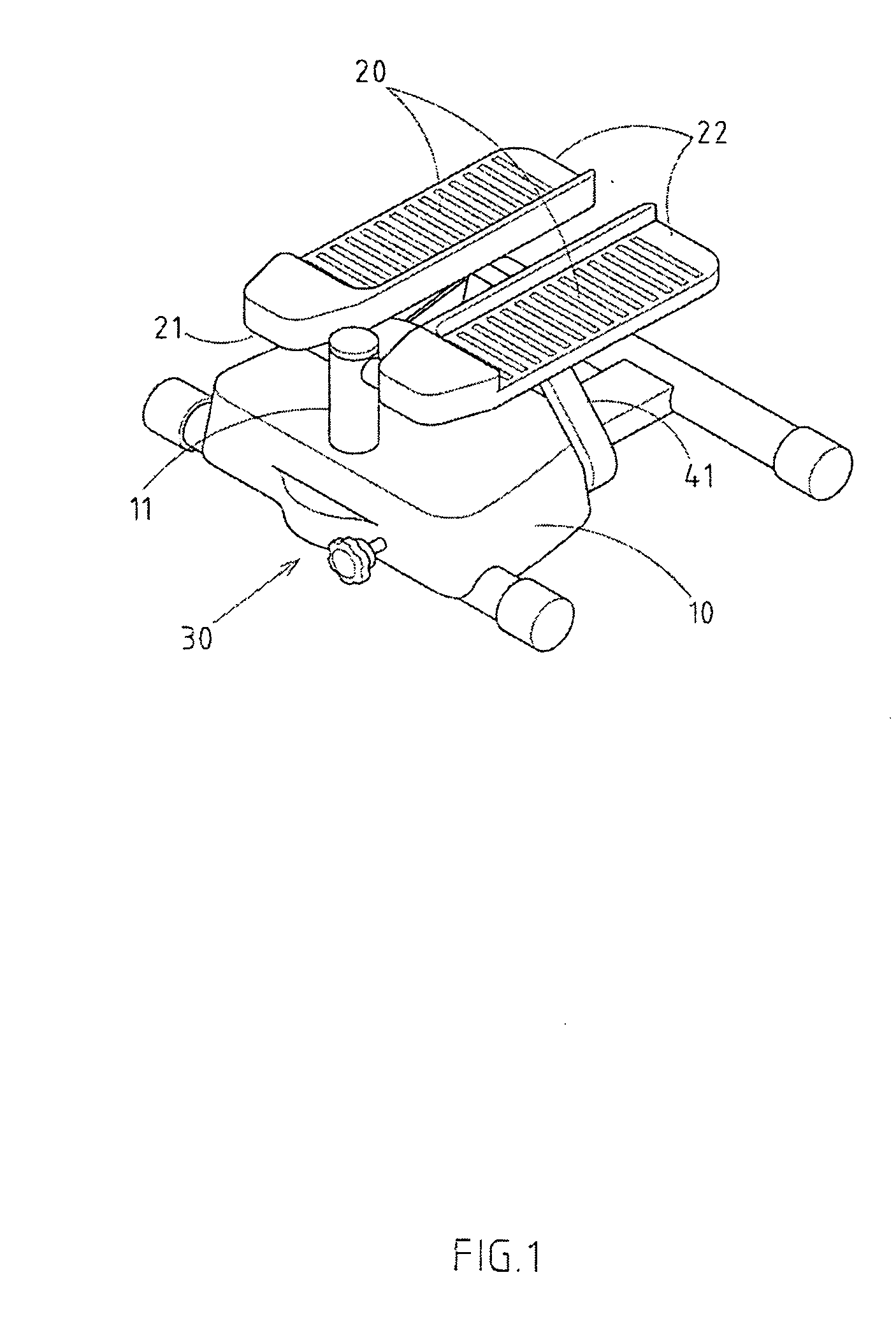

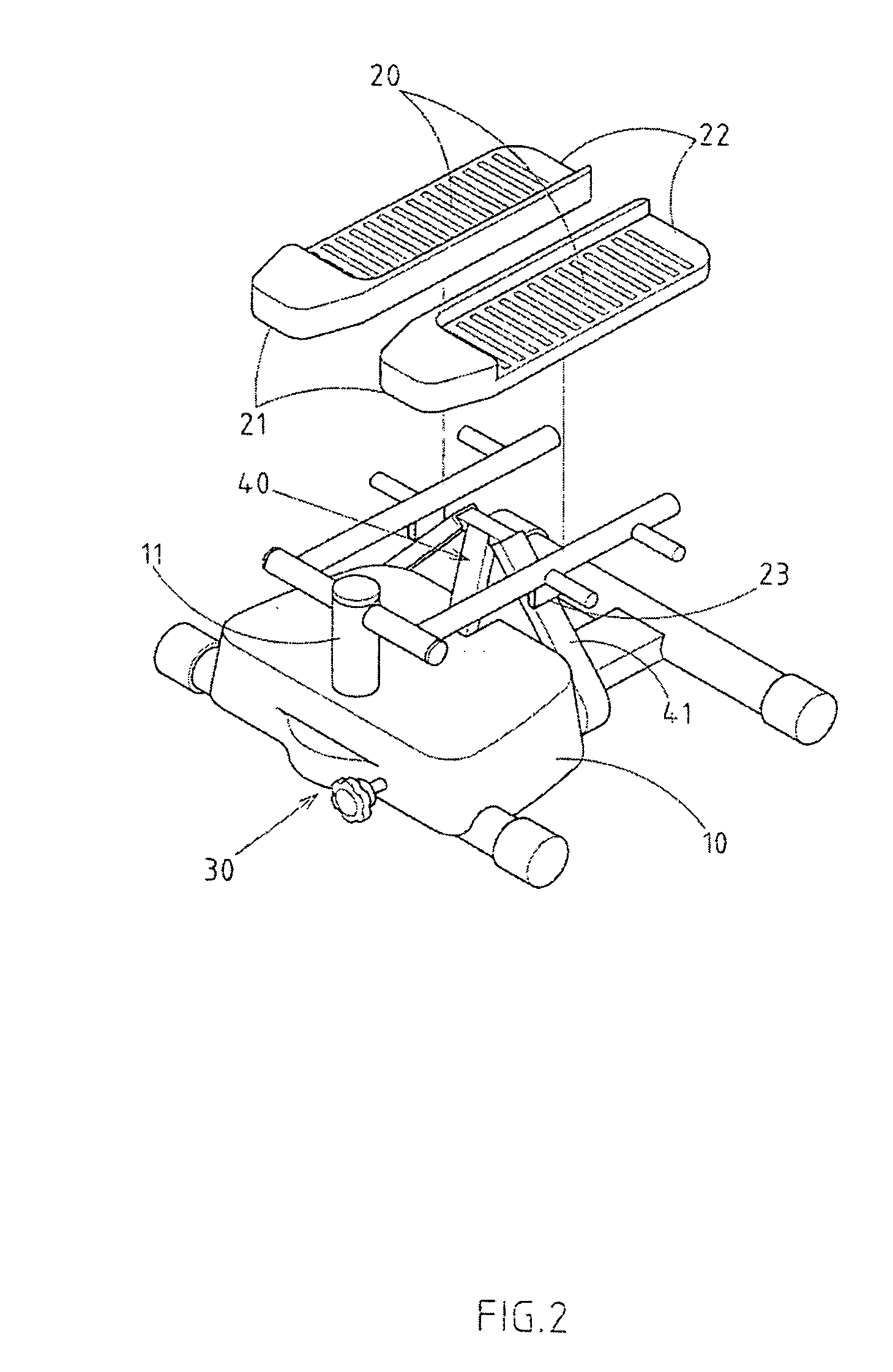

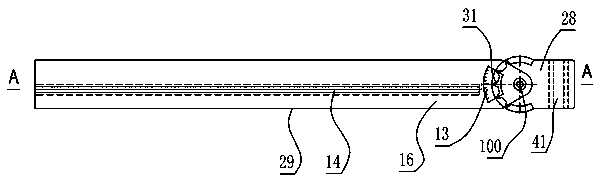

Structure of stepper

InactiveUS20060019801A1Movement coordination devicesCardiovascular exercising devicesEngineeringMechanical engineering

The stepper with improved structure has a base, two pedals and the resistance device. The front ends of these two pedals are pivoted respectively on the protruding prop at the front of the base, which becomes the movable ends for the two pedals that provides the twisting motion in up and down directions, and forms a force of resistance when stepping provided by the resistance device. The bottom of the protruding prop is mounted on the base pivotally, which puts the prop in a revolvable position; a triangular guide mounted on the base, and its two oblique planes sets correspondingly and relatively to the movable ends of the two pedals, and on the bottoms of the movable ends of the pedals are the sliding part that are mounted pivotally on the oblique planes of the triangular guides. When the pedals are stepped down, they generate the motion that twists left and right downward diagonally as well.

Owner:ZENG CIAN CHANG

Inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers

InactiveCN105547820AAchieve fixationAvoid stickingStrength propertiesIsosceles trapezoidInterference fit

The invention relates to fixing rest pliers for glass detection, and in particular relates to a pair of inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers. The pair of inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers has following improvement: one end of an upper clamping plane is provided with an inclined-plane groove the bottom surface of which is provided with a bottom plane of the groove; the cross section of the inclined-plane groove is isosceles trapezoid; a lower slipping plane is provided with a rotary through hole; a rotary plate chamber arc surface is arranged at one side of the rotary through hole; the turn angle chamber arc surface is provided with a turn angle arc surface protruding pointer; an inclined-plane convex rail is positioned on the lower slipping plane; the cross section of the inclined-plane convex rail is also isosceles trapezoid; the lower slipping plane is provided with two plane screw holes; the inclined-angle convex rail is also provided with two convex rail stepped holes; convex rail screws pass through the convex rail stepped holes and are fit with the plane screw holes in a spirally fastening mode so as to fix the convex rail contact surface on the lower slipping plane; inclined planes at two sides of anti-falling raised lines and inclined planes at two sides of anti-falling grooves are in interference fit so as to generate extrusion and expansion force and prevent falling accidents caused by glue aging; heights of the anti-falling raised lines and depths of the anti-falling grooves are in clearance fit for the convenience of installation and binding.

Owner:张志雄

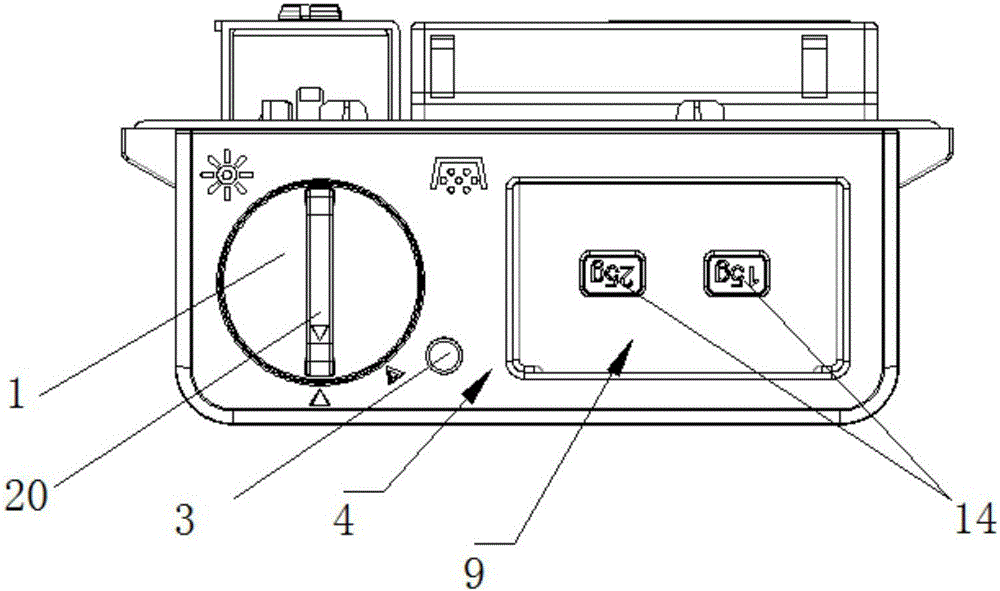

Distributor for dish-washing machine and dish-washing machine

PendingCN106466169ASave spaceImprove space utilizationTableware washing/rinsing machine detailsEngineeringDistributor

The invention provides a distributor for a dish-washing machine. The distributor is fixed to the side wall of an inner container and comprises a cavity and an upper shell fixed to the cavity. The upper shell is provided with an open-type dishwasher powder containing chamber, a user can directly put dishwasher powder into the top of the containing chamber, and a dishwasher powder outlet is formed in the bottom of the dishwasher powder containing chamber. According to the open-type dishwasher powder containing chamber, when the cavity is fixed to the side wall of the inner container, the use of the space inside the dish-washing machine is optimized; the bottom of the dishwasher powder containing chamber is an oblique plane, and by means of the characteristics of the structure, the dishwasher powder can automatically flow into the inner container without other auxiliary structures and control devices. The structure is simple, cost is low and the safety performance is high.

Owner:QINGDAO HAIER DISHWASHER

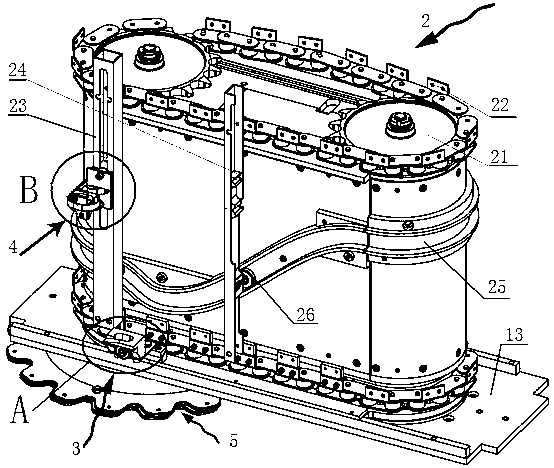

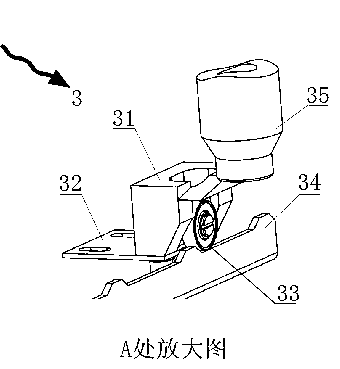

Automatic doffing trolley of spinning machine

The invention relates to an automatic doffing trolley of a spinning machine. The automatic doffing trolley comprises a doffing trolley body and an automatic doffing device. The automatic doffing device is arranged on a bottom plate located on the upper portion of the doffing trolley body. A pre-loosening mechanism of the automatic doffing device is arranged on the bottom plate of the doffing trolley body through a spring steel plate. A pre-loosening block is fixed on the spring steel plate. When the trolley moves forwards, the pre-loosening block moves forwards along with the trolley, is inserted into the lower end of a bobbin, and enables the lower end of the bobbin to ascend along an oblique plane of the pre-loosening block. Then, under the action of a plane cam, the pre-loosening block abuts against the lower end of the bobbin, moves upwards in the direction parallel to the axis of a spindle blade and enables the full bobbin to break away from the spindle blade under the blocking action of a spindle hook. The bobbin bounced upwards enters a manipulator device. The upper ends of claws of the manipulator device clamp the upper end, without yarn, of the full bobbin and then pull the full bobbin out. The pre-loosening force of the pre-loosening mechanism is parallel to the axis of the spindle blade and has little influence on a spindle bearing. The manipulator device clamps the upper end, without the yarn, of the bobbin, and the quality index of the yarn can not be influenced.

Owner:SHANXI JINXIN CARD CLOTHING

Wedge-block-type unwinding shaft used in production line of disposable hygienic products

The invention relates to a wedge-block-type unwinding shaft used in a production line of disposable hygienic products. In the invention, a fixed shaft is a stepped shaft, a small-diameter section of the fixed shaft is sequentially sheathed with two guide sleeves, a spacer bush and a compression spring, and an end part of the small-diameter section of the fixed shaft is in threaded connection witha hand wheel; one end of the compression spring is positioned in a circular groove of the hand wheel, and the other end of the compression spring is in contact with an end face of the spacer bush; locking sleeves are sheathed on small-diameter sections of the two guide sleeves, sleeves are sheathed outside the locking sleeves, four axial expansion pin grooves are uniformly distributed on each sleeve, and each expansion pin groove is internally equipped with an expansion pin; each expansion pin is in the shape of a wedge block, and an oblique plane of each expansion pin corresponds to each locking sleeve; and a taper sleeve is inserted between the locking sleeve and the sleeve which are positioned at one end adjacent to the spacer bush, a conical tube is arranged at one side of the taper sleeve, a cylindrical tube is arranged at the other side of the taper sleeve, and the conical surface of the conical tube of the taper sleeve is in contact with the oblique planes of the four expansionpins in a fit manner. The wedge-block-type unwinding shaft has the advantages of compact and delicate structure and reasonable design, and is convenient in use; unwinding resistance can be controlledby adjusting the hand wheel; and material coils can be fixed, assembled and disassembled quickly through the expansion pins.

Owner:ANQING HENG CHANG MACHINERY

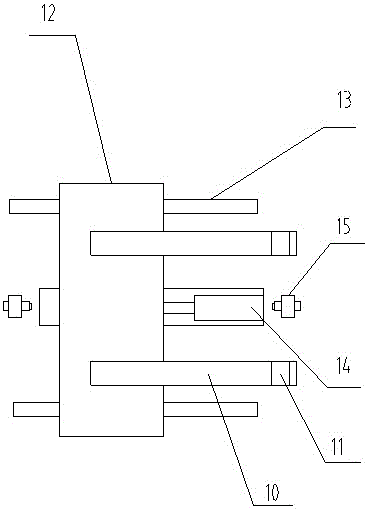

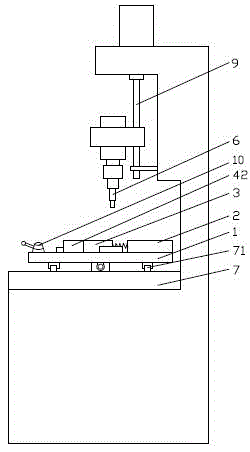

Multi-workpiece drilling equipment with movable fixture

InactiveCN104475808AMeet the clamping positioning requirementsAvoid replacementWork clamping meansPositioning apparatusSelf lockingEngineering

The invention discloses multi-workpiece drilling equipment with a movable fixture, and belongs to the technical field of machining equipment. The multi-workpiece drilling equipment comprises a framework and the fixture. The fixture is positioned on the framework; a drill bit is arranged on the upper side of the framework and corresponds to the fixture; a slide table is further arranged on the framework, and slide rails are arranged on the surface of the slide table; the fixture comprises a fixture bottom plate, a positioning block, a clamping block and a clamping block driving device, the positioning block and the clamping block are positioned on the fixture bottom plate and are opposite to each other, and the clamping block driving device can drive the clamping block to slide towards the positioning block; a return spring is arranged between the positioning block and the clamping block in a connected manner; V-shaped grooves which correspond to one another are formed in opposite surfaces of the positioning block and the clamping block; the clamping block driving device comprises a cylinder and a wedge block, the wedge block is connected with a piston rod of the cylinder, and an oblique plane is arranged on the surface, which is opposite to the corresponding V-shaped grooves, of the clamping block and is matched with an oblique plane of the wedge block; rollers are arranged and supported on the oblique plane of the clamping block, and the oblique plane of the wedge block is tangential to the surfaces of the rollers. The multi-workpiece drilling equipment has the advantages that the machining efficiency can be improved, self-locking effects can be realized after workpieces are clamped, the multi-workpiece drilling equipment can be automatically reset after the workpieces are completely machined, and drilling procedures can be reliably and accurately carried out.

Owner:CHENGDU FANXINJIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com