Structure of stepper

a stepper and body technology, applied in the field of steppers, can solve the problems of limited exercised body parts, less effective, and inconvenient use of the structure of the conventional stepper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The features and the advantages of the present invention will be more readily understood upon a thoughtful deliberation of the following detailed description of a preferred embodiment of the present invention with reference to the accompanying drawings.

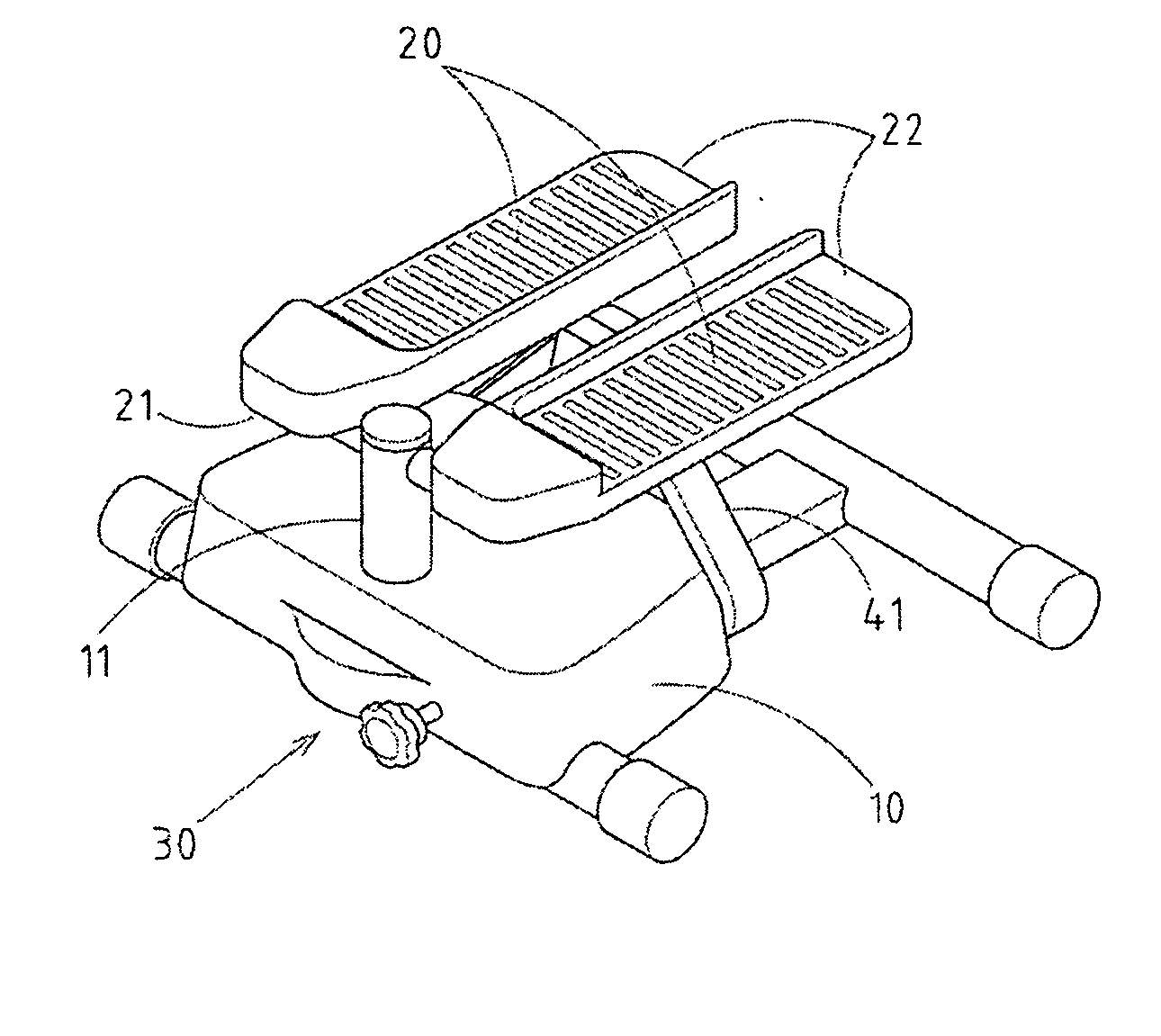

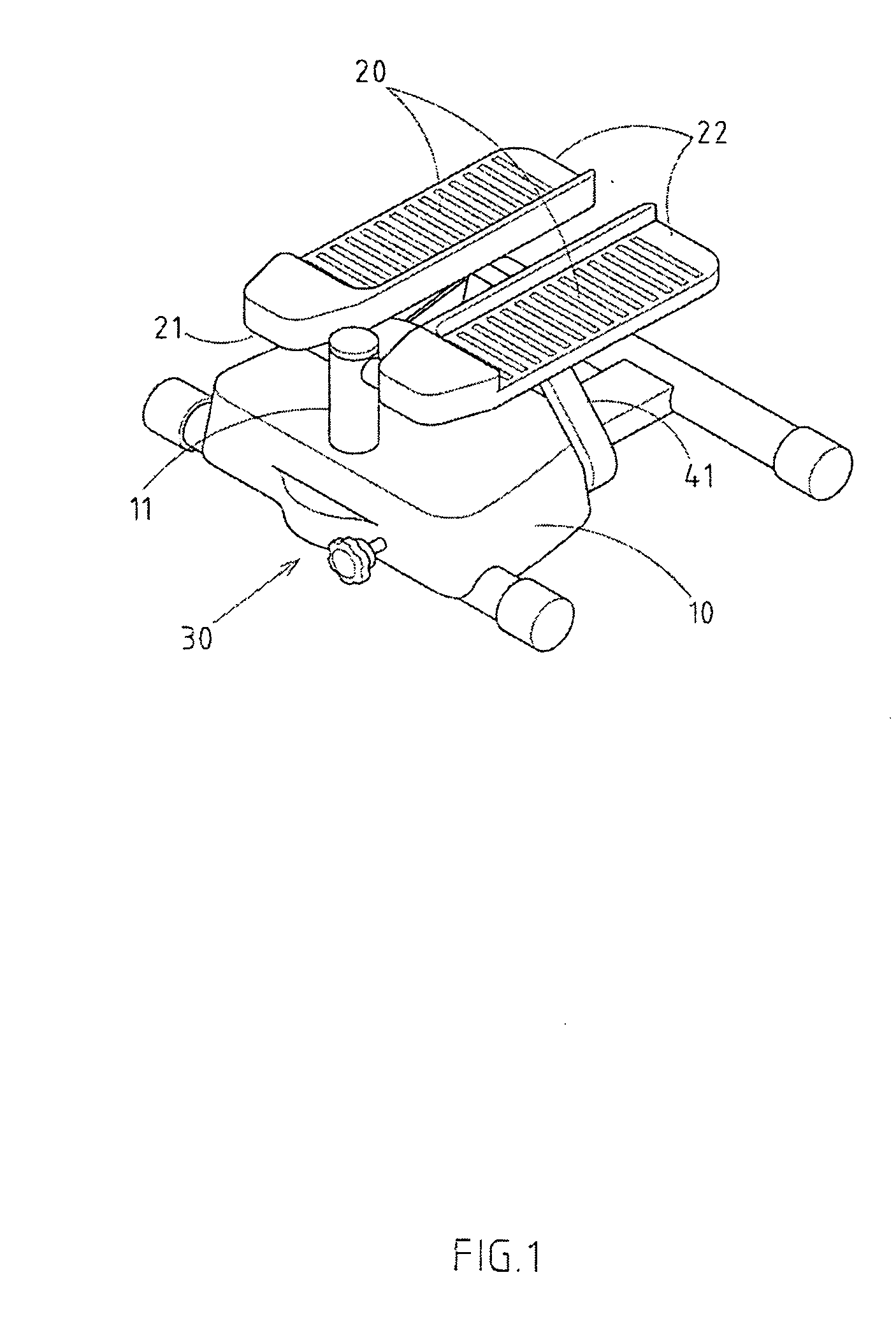

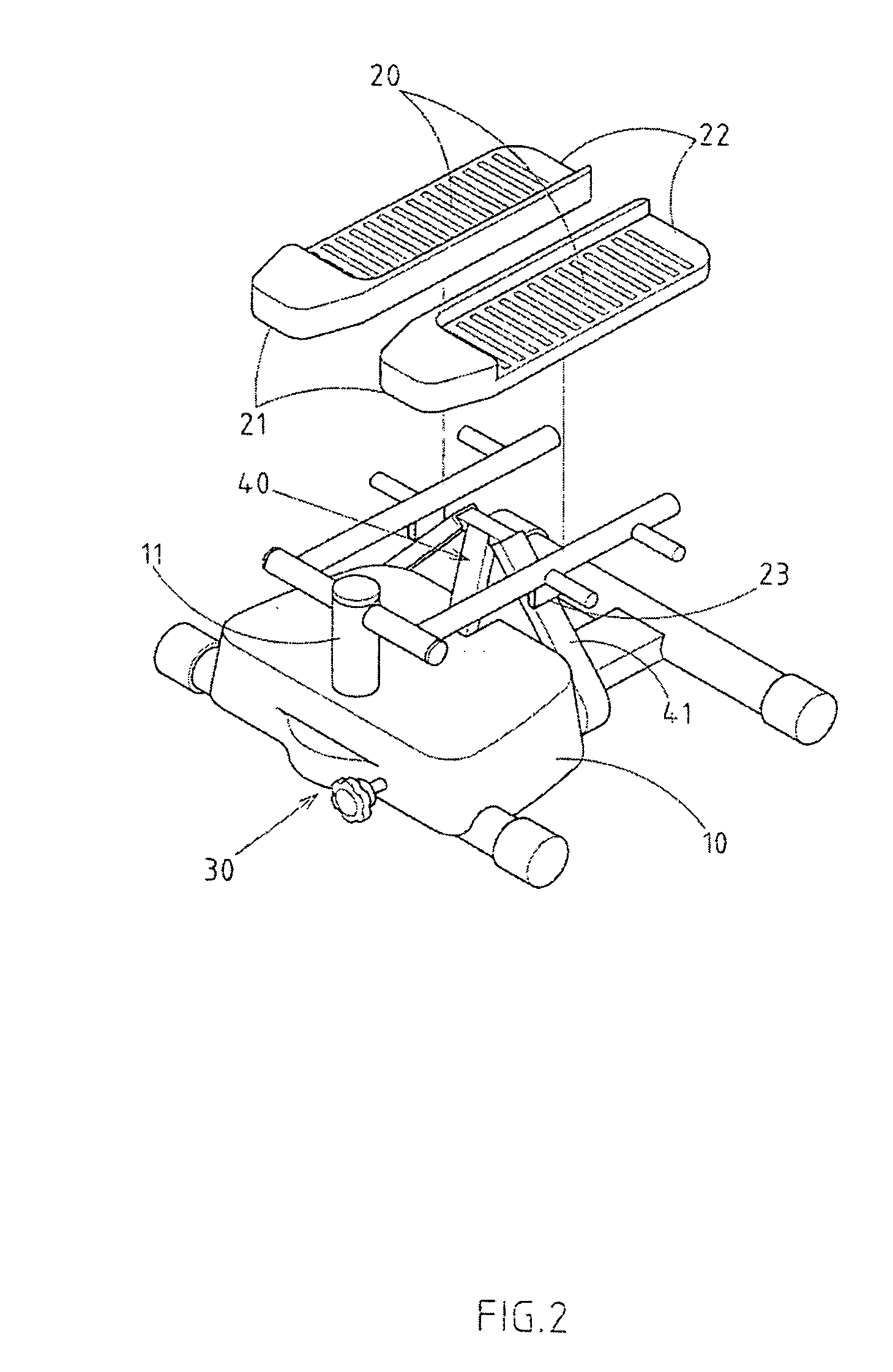

[0023] As shown in FIGS. 1-5, a stepper with improved structure embodied in the present invention comprises:

[0024] a base 10, two pedals 20 and the resistance device 30; whereas the front ends 21 of these two pedals 20 are pivoted respectively on the protruding prop 11 at the front of the base 10, which becomes the movable ends 22 for the two pedals 20 that provides the twisting motion in up and down directions, and forms a force of resistance when stepping provided by the resistance device 30; the features lie in:

[0025] the bottom of the protruding prop 11 is mounted on the base 10 pivotally, which puts the prop 11 in a revolvable position;

[0026] a triangular guide 40 mounted on the base 10, and its two oblique planes 41 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com