Opposite roller spin forming device

A technology of spinning forming and wheel alignment, which is applied in the field of powerful spinning devices, can solve the problems of poor adaptability of core molds, uneven deformation of inner and outer surfaces of spinning parts, etc., achieve uniform deformation, reduce residual stress, and improve dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the structure of the present invention will be described in detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

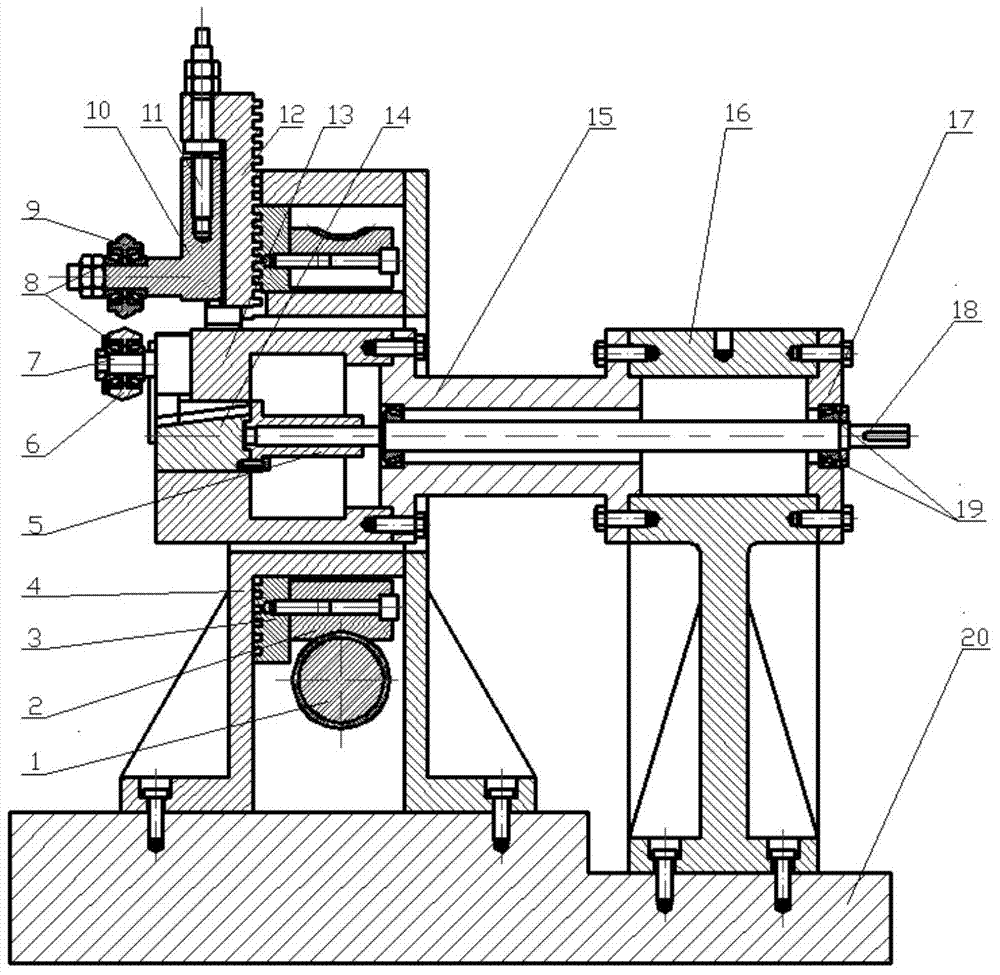

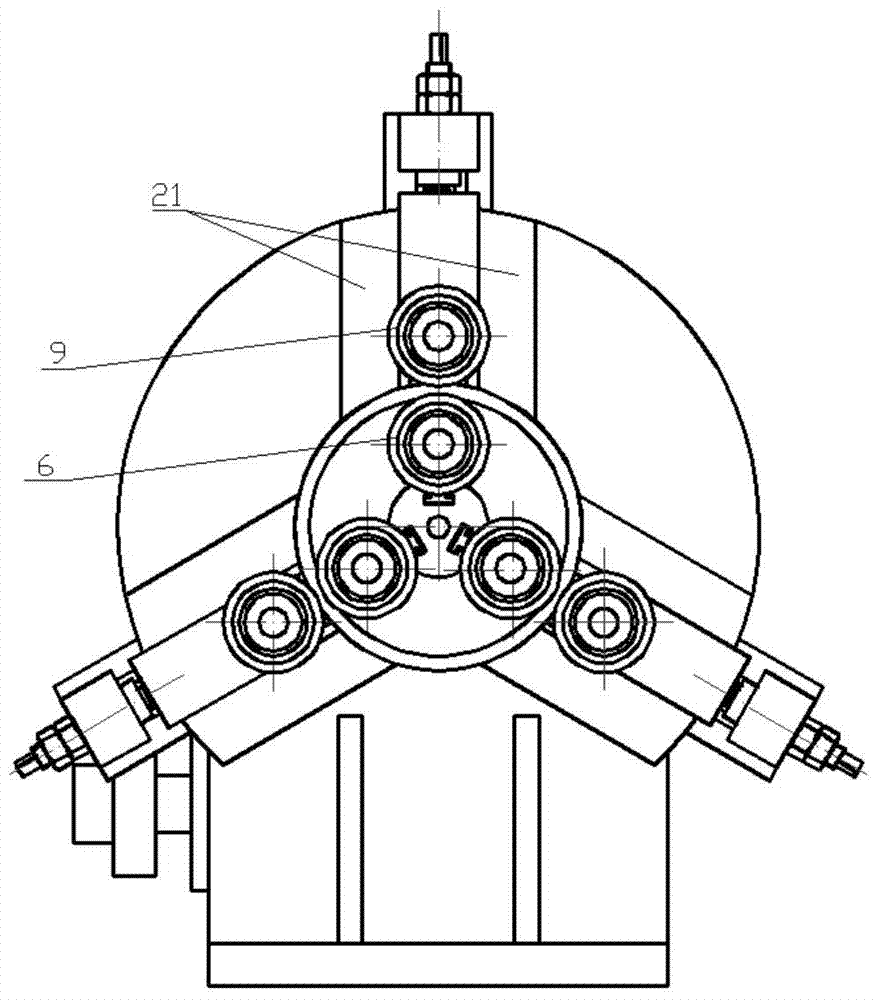

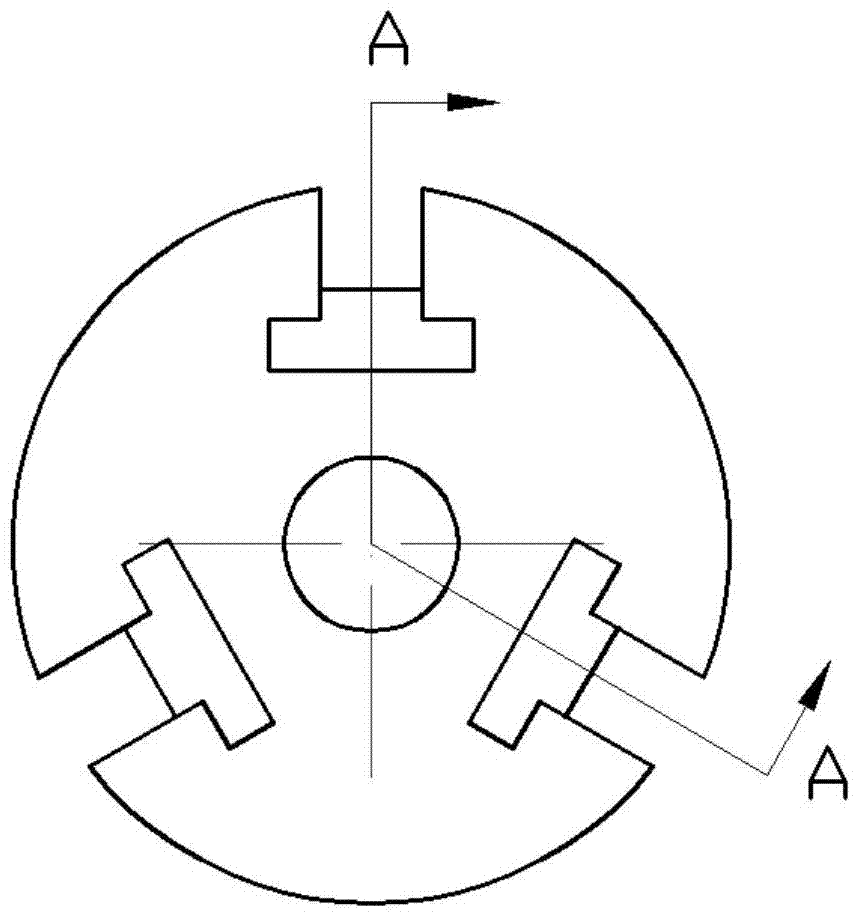

[0019] like figure 1 , 2 As shown, a counter wheel spinning forming device includes a frame 20, an outer wheel device and an inner wheel device; wherein the frame 20 is mainly composed of a frame, a pressing plate 21 and a back cover; the pressing plate 21 and the back cover are fixed on the frame superior.

[0020] The inner wheel device is mainly composed of inner wheel 6, inner jaw 7, bearing 8, chuck body 13, wedge block 14, flange support tube 15, counter wheel tail top 16, bearing seat 17 and screw rod 18; One end of the blue support cylinder 15 is connected to the chuck body 13, and the other end is fixed to the tail top 16 of the pair of wheels, and the tail top 16 of the pair of wheels is connected to the bearing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com