Rapid locking coaxial connector

A technology of coaxial connectors and quick locks, applied in the direction of connections, parts of connection devices, coupling devices, etc., can solve the problems of low installation density, high manufacturing cost, low production efficiency, etc., and achieve anti-vibration and impact resistance Good, low manufacturing cost, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

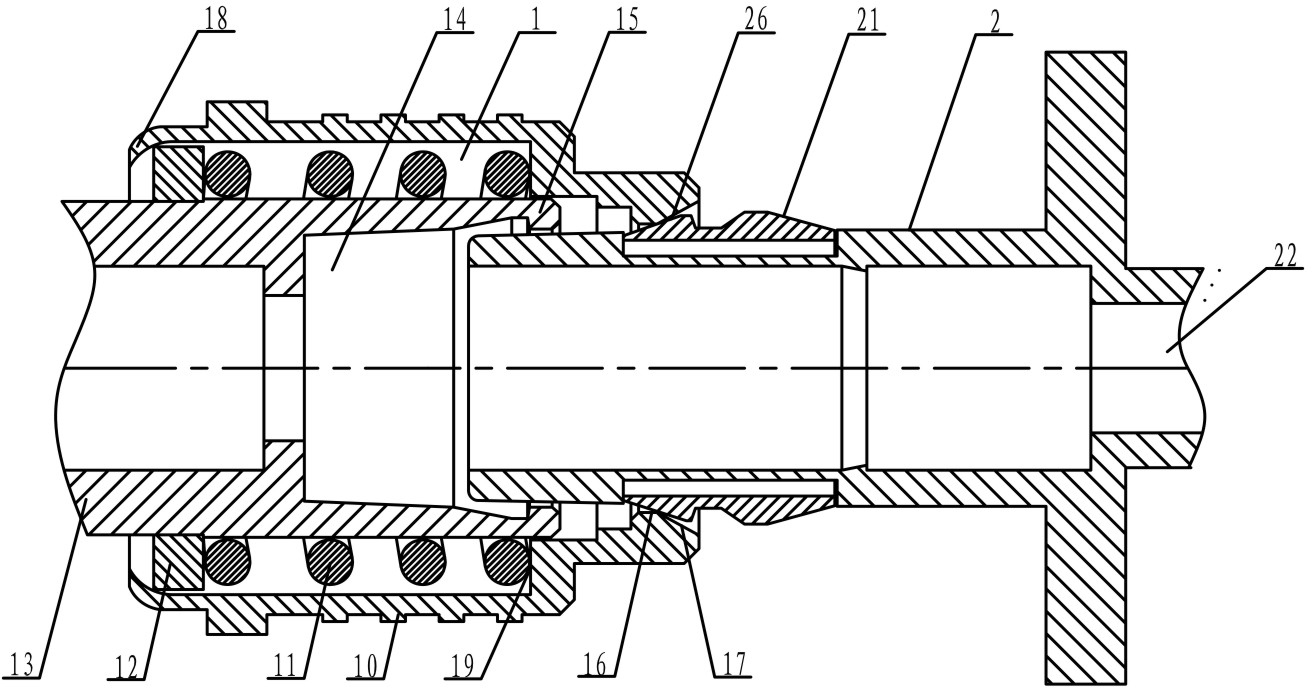

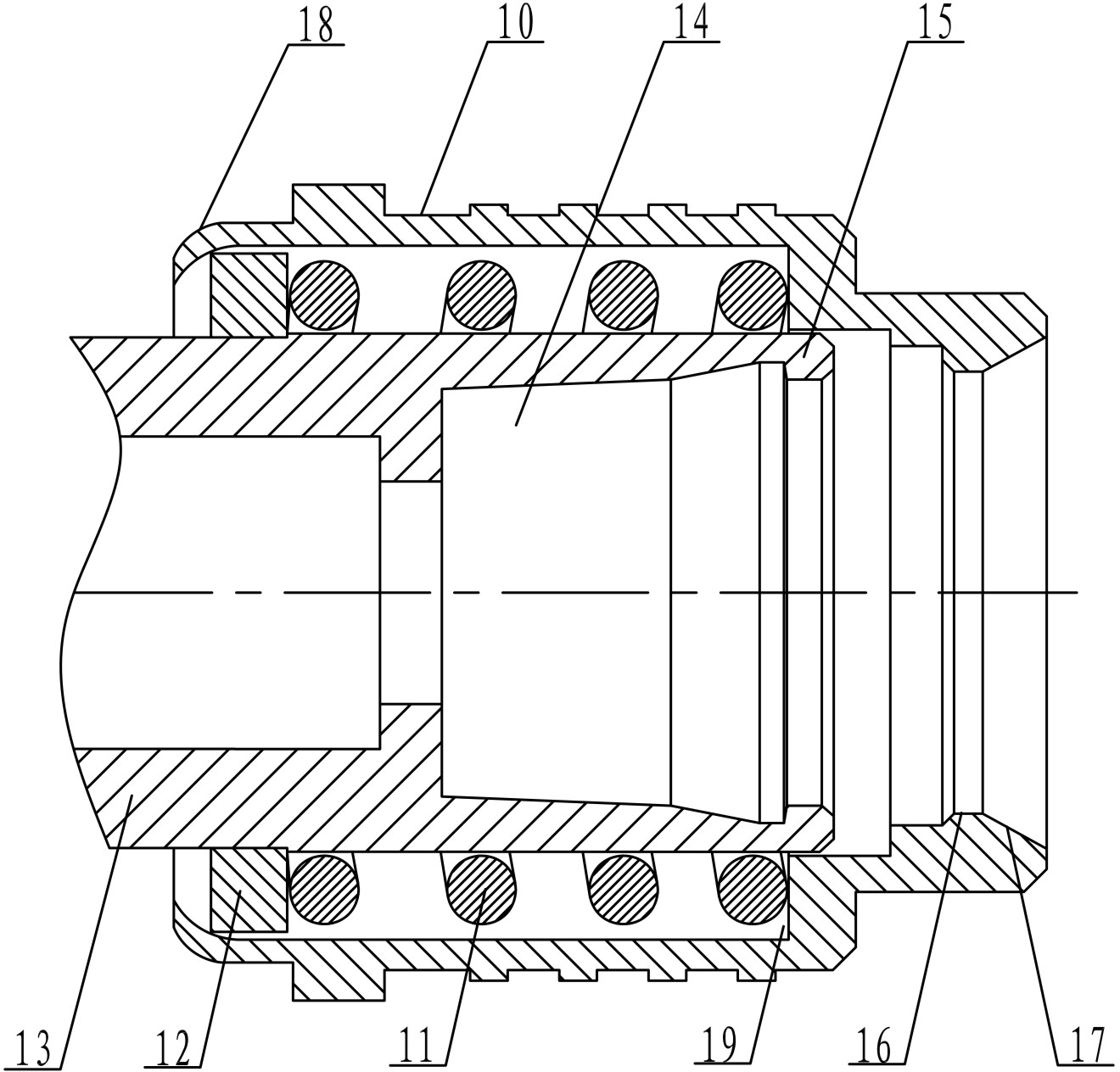

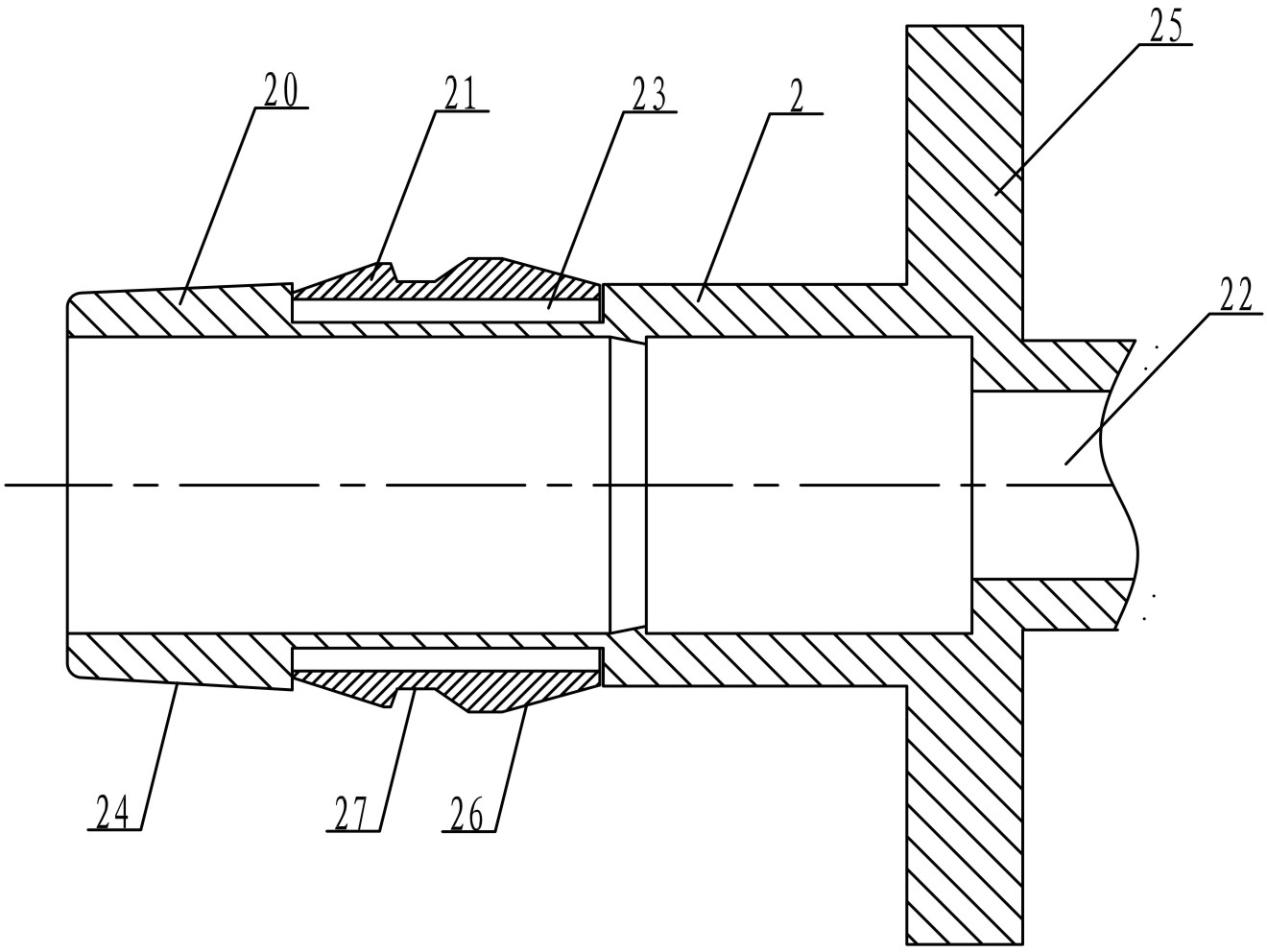

[0016] See attached figure 1 , the present invention is composed of a plug 1 and a socket 2. The plug 1 is assembled with a screw sleeve 10 after the outer conductor 13 is fitted with a spring 11 and a pressure-fit retaining ring 12. The outer conductor 13 is provided with claws 15 and socket holes 14. The connector, the claw 15 is set at the port of the socket hole 14; the socket 2 is composed of a clasp ring 21 set on the shell 20, and the clasp ring 21 is an elastic sleeve provided with a guide slope 26, a clamping groove 27 and an axially cut groove 28 The card slot 27 is a trapezoidal slot with slopes 29 on both sides; the docking of the plug 1 and the socket 2 is firstly that the guide slope 17 on the screw sleeve 10 contacts the front guide slope 26 on the collar 21. This process makes the card While the ring 21 is radially centered, the compression collar 21 radially shrinks to a diameter smaller than the inner diameter of the insertion hole 14, and the claw 15 enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com