Optical system used for focusing and leveling

An optical system, focusing and leveling technology, which is applied in the field of focusing and leveling optical systems, can solve the problems of increasing the size of key parts, large reflection loss, and small working distance, so as to reduce design difficulty, reduce reflection loss, expand The effect of working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

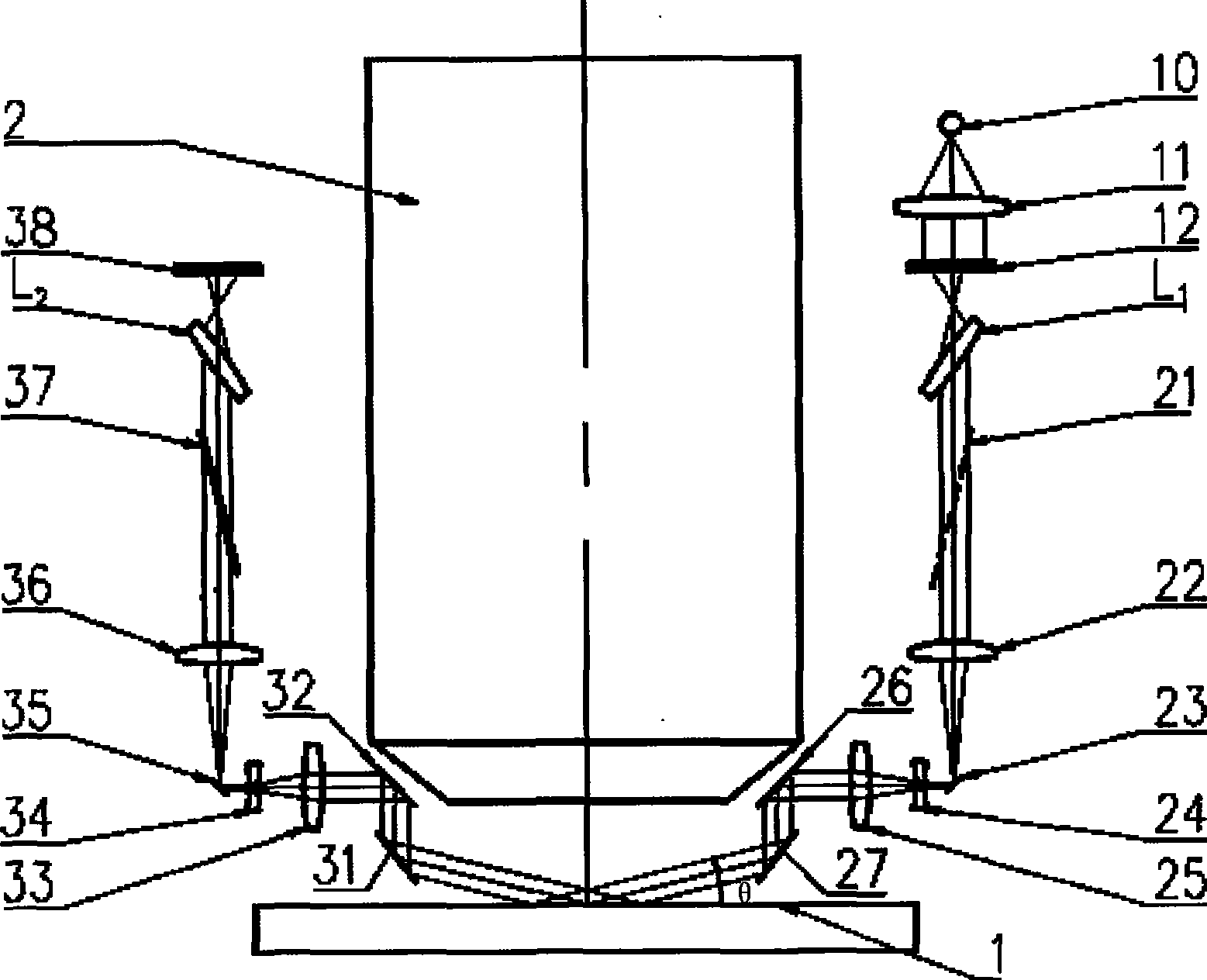

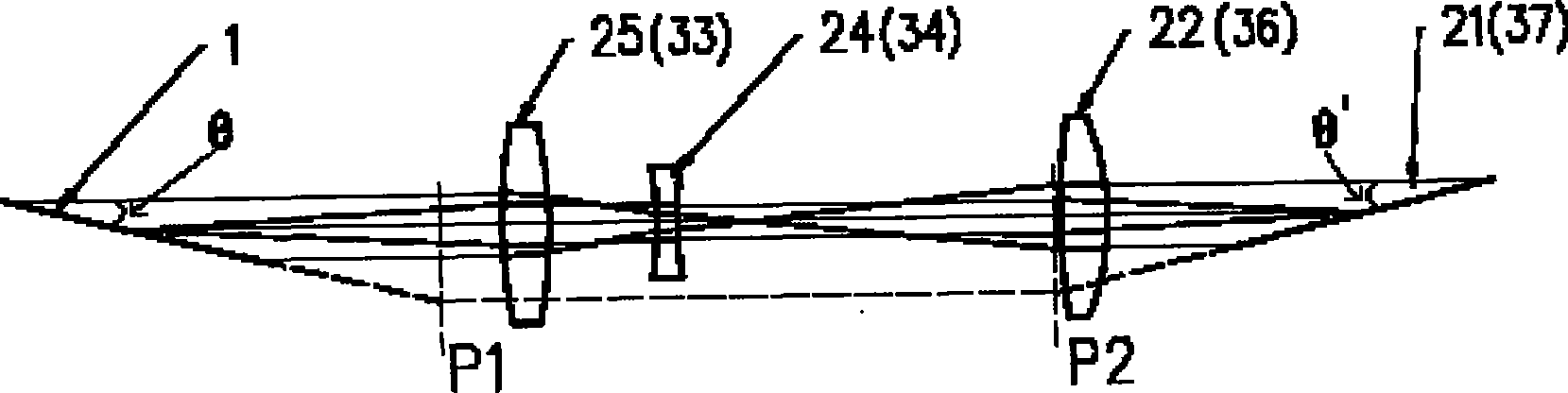

[0013] The optical structure of the present invention is composed of an illumination unit, a marking plate, an oblique imaging unit, a projection imaging unit, a receiving imaging unit, a correcting imaging unit and a detector. The illumination unit provides evenly illuminated broadband light, which illuminates the marking plate, and the marking plate forms an inclined marking image through the inclined imaging unit, and the inclined marking image is imaged on the surface of the silicon wafer by the projection imaging unit, and is received The imaging unit images the receiving mark, and then corrects the imaging unit to image the image on the detector. The position change of the silicon wafer will cause the position change of the receiving marker, so as to achieve the purpose of detecting the position of the silicon wafer.

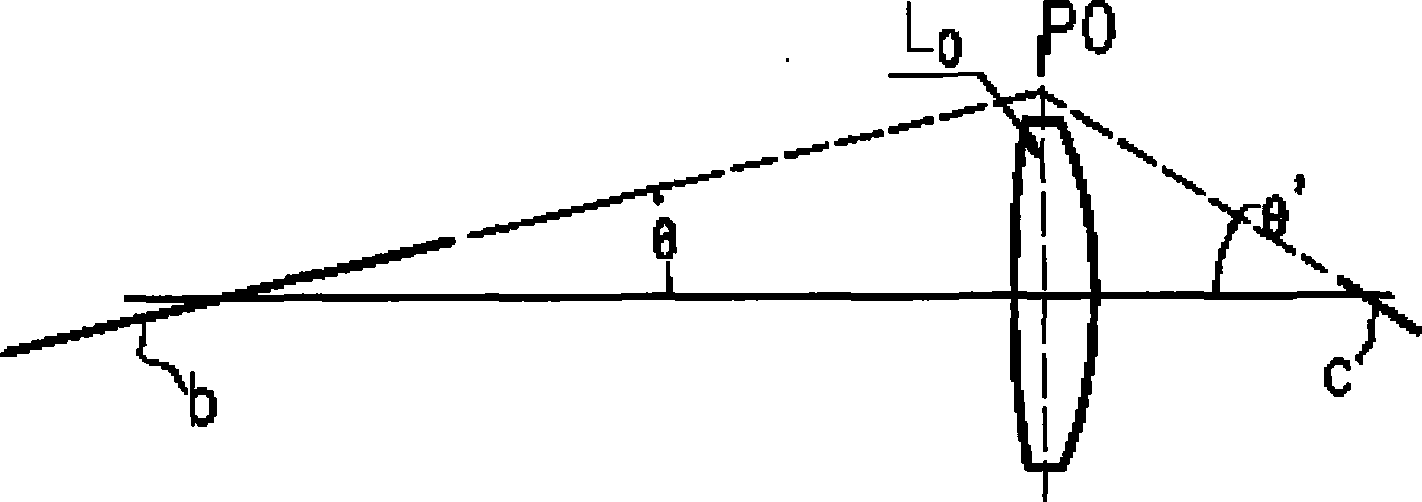

[0014] The structure of the above oblique imaging unit, projection and receiving imaging unit and correction imaging unit all satisfy the Scheimpflug condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com