Patents

Literature

54results about How to "Index matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

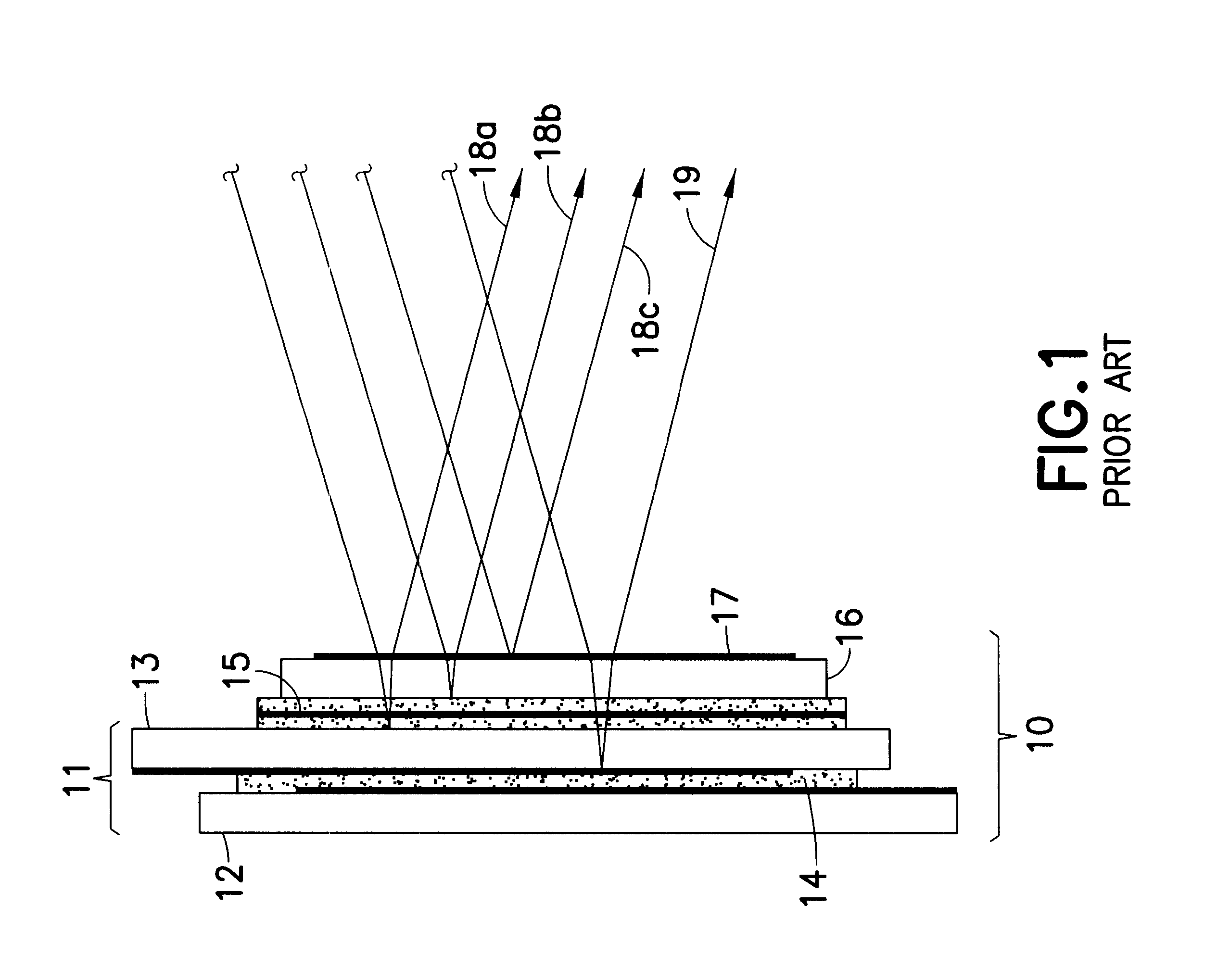

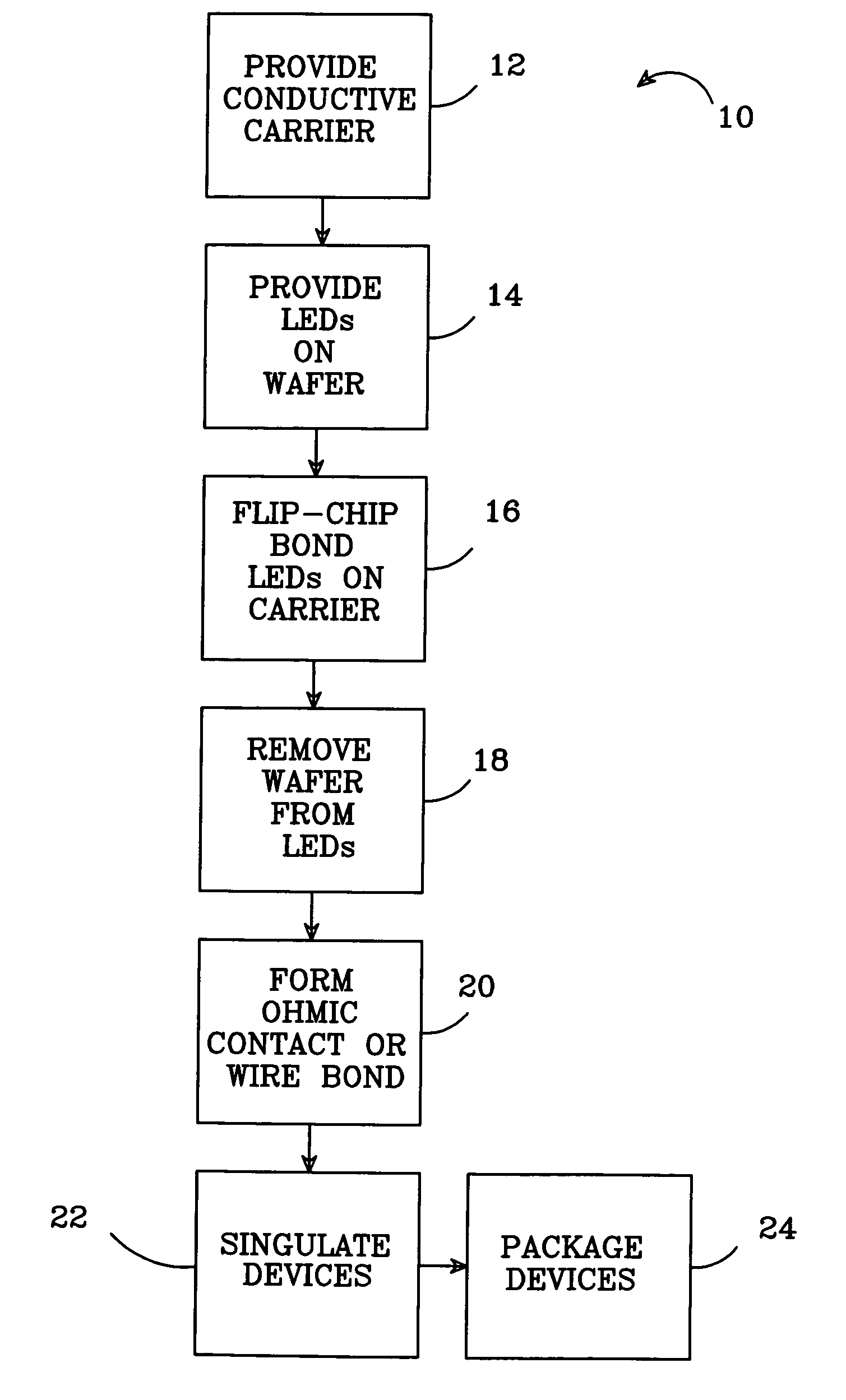

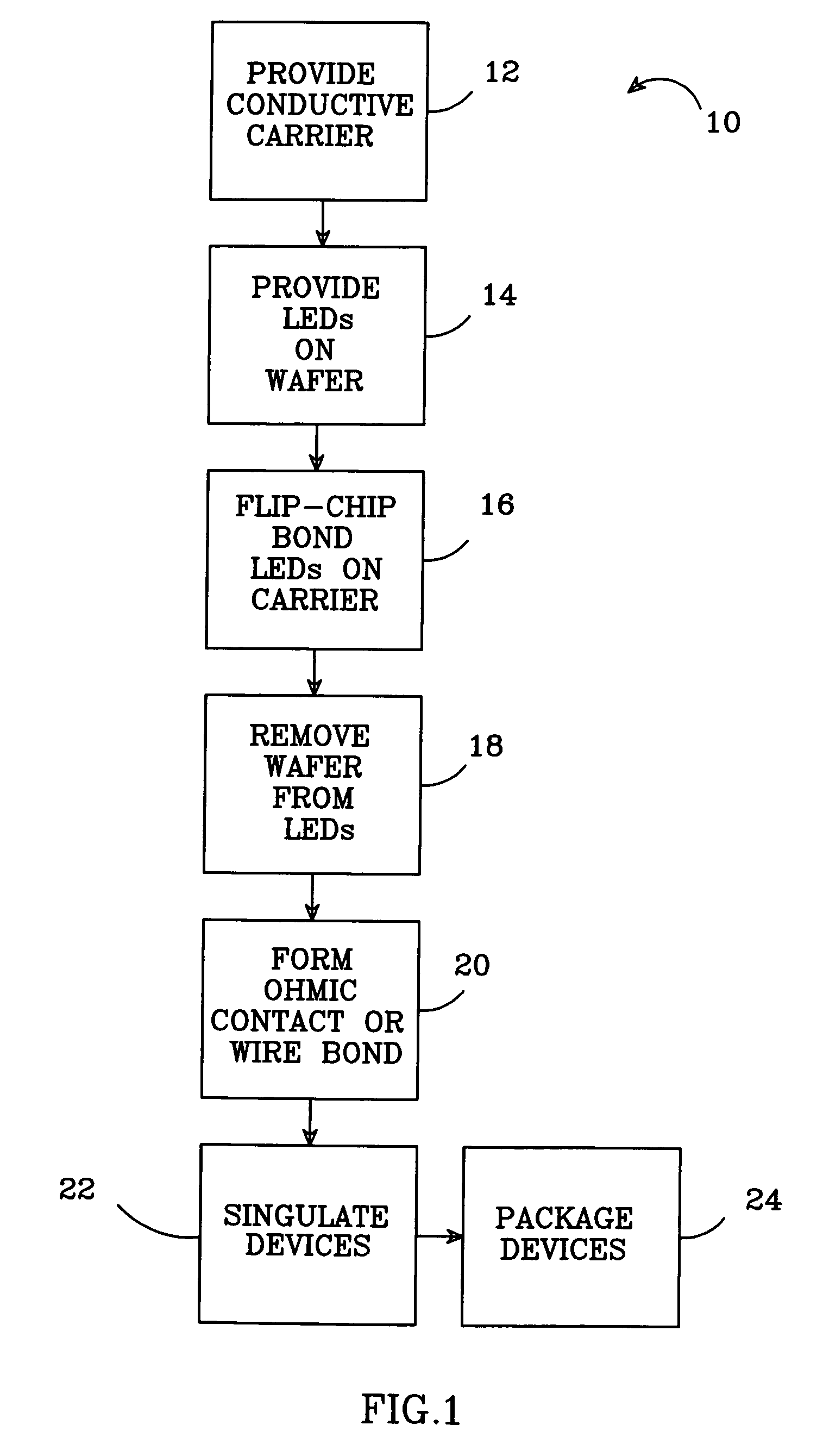

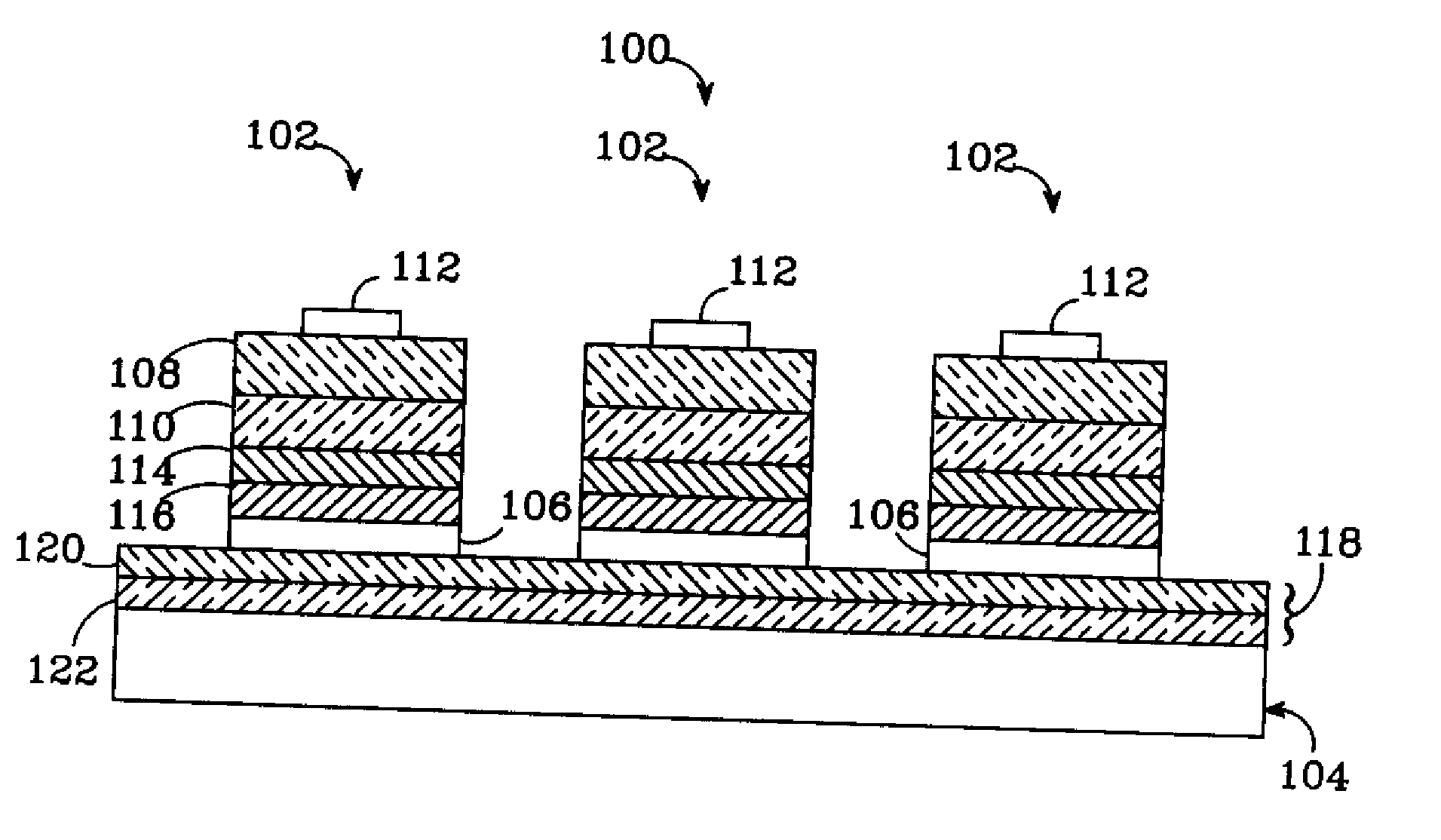

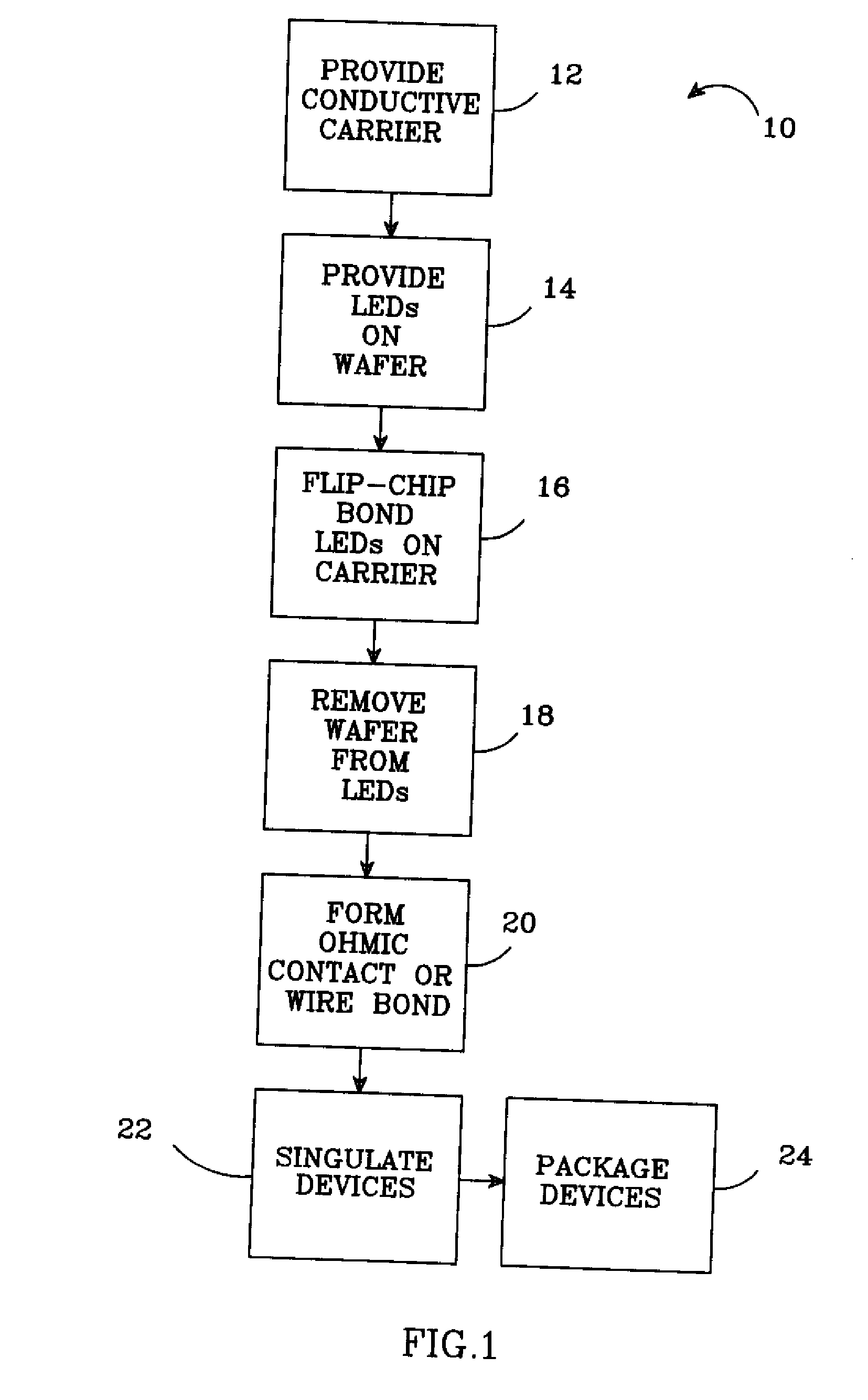

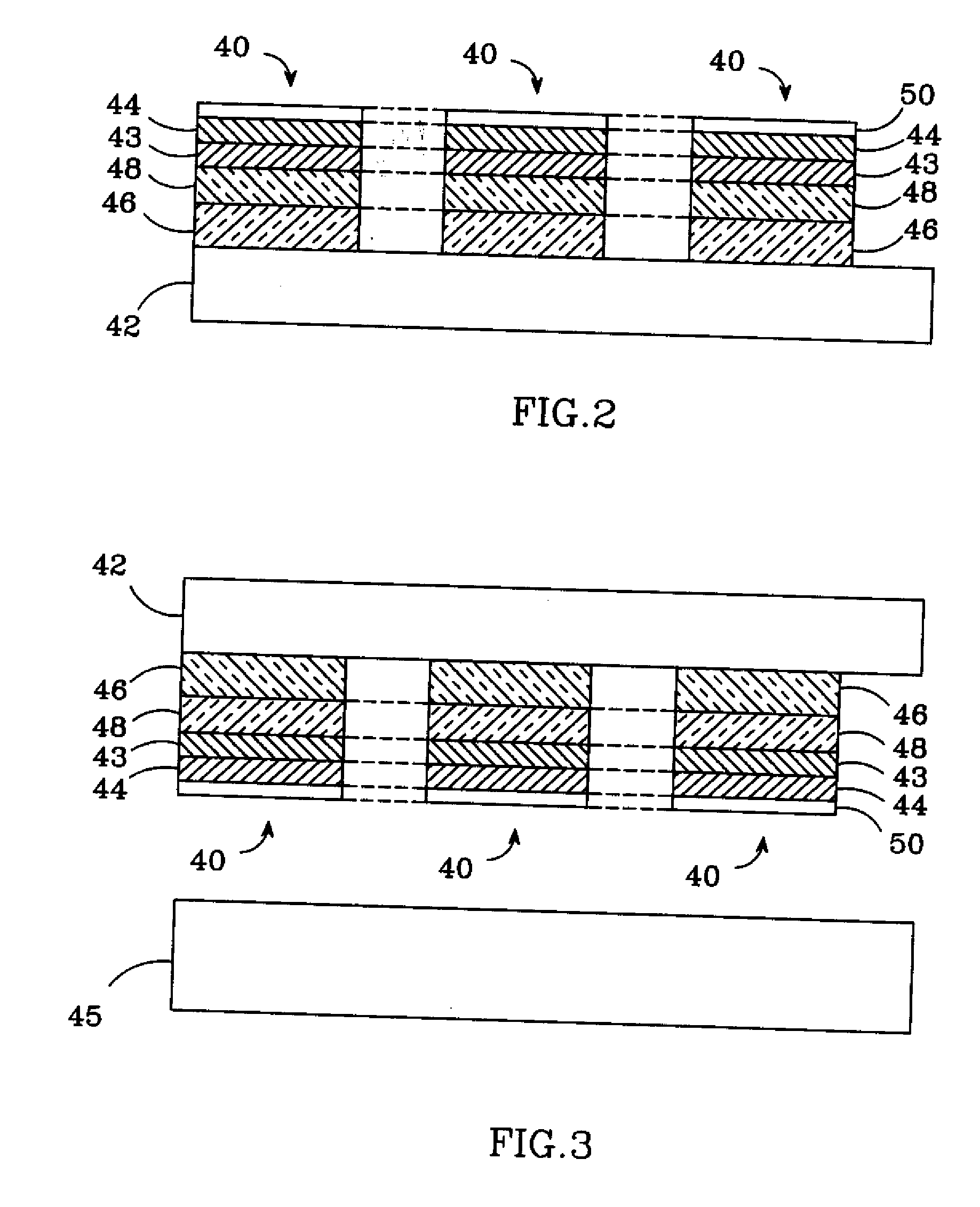

Substrate removal process for high light extraction LEDs

ActiveUS20060189098A1Index matchingImprove light extractionSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideLight-emitting diode

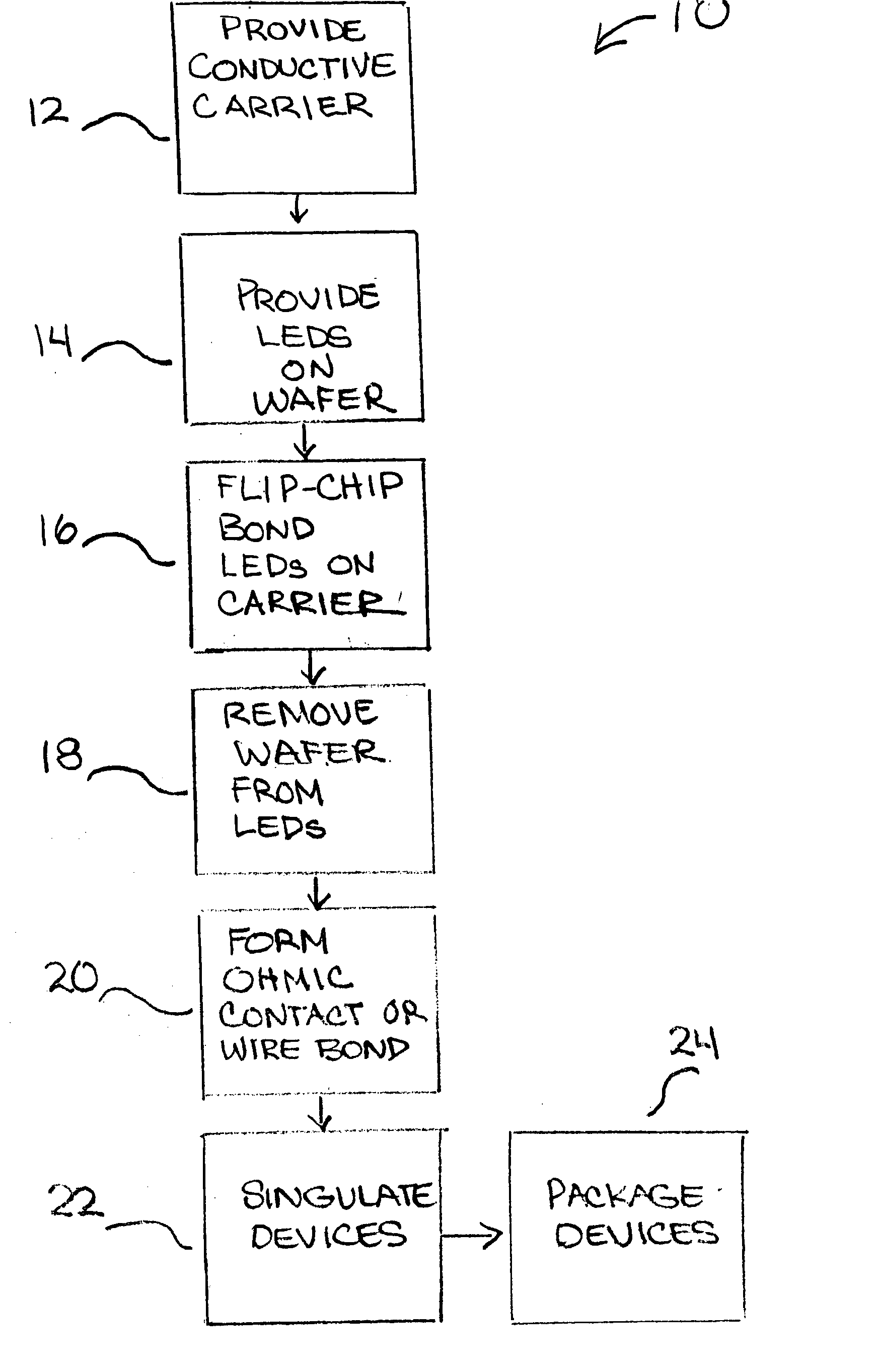

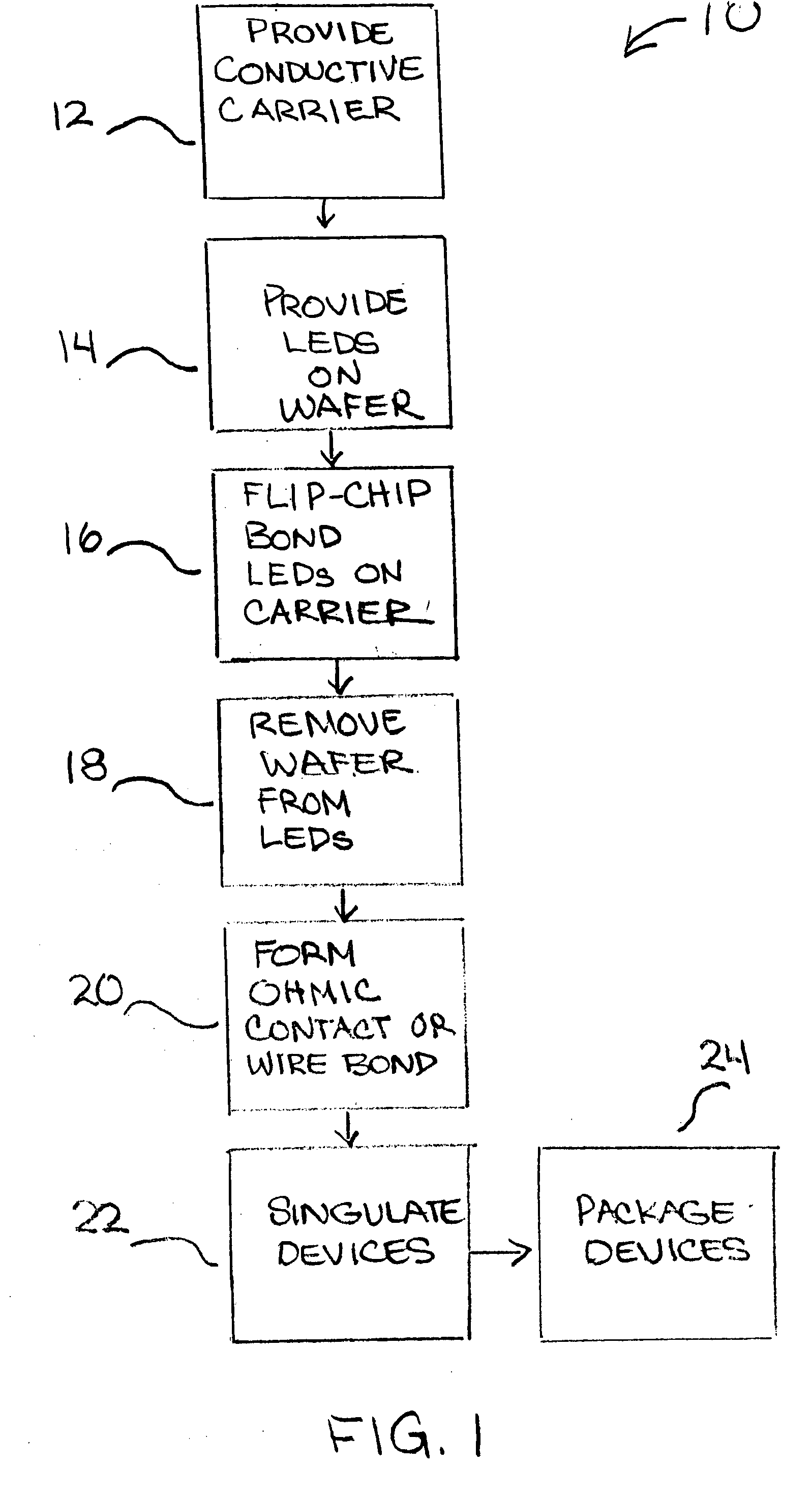

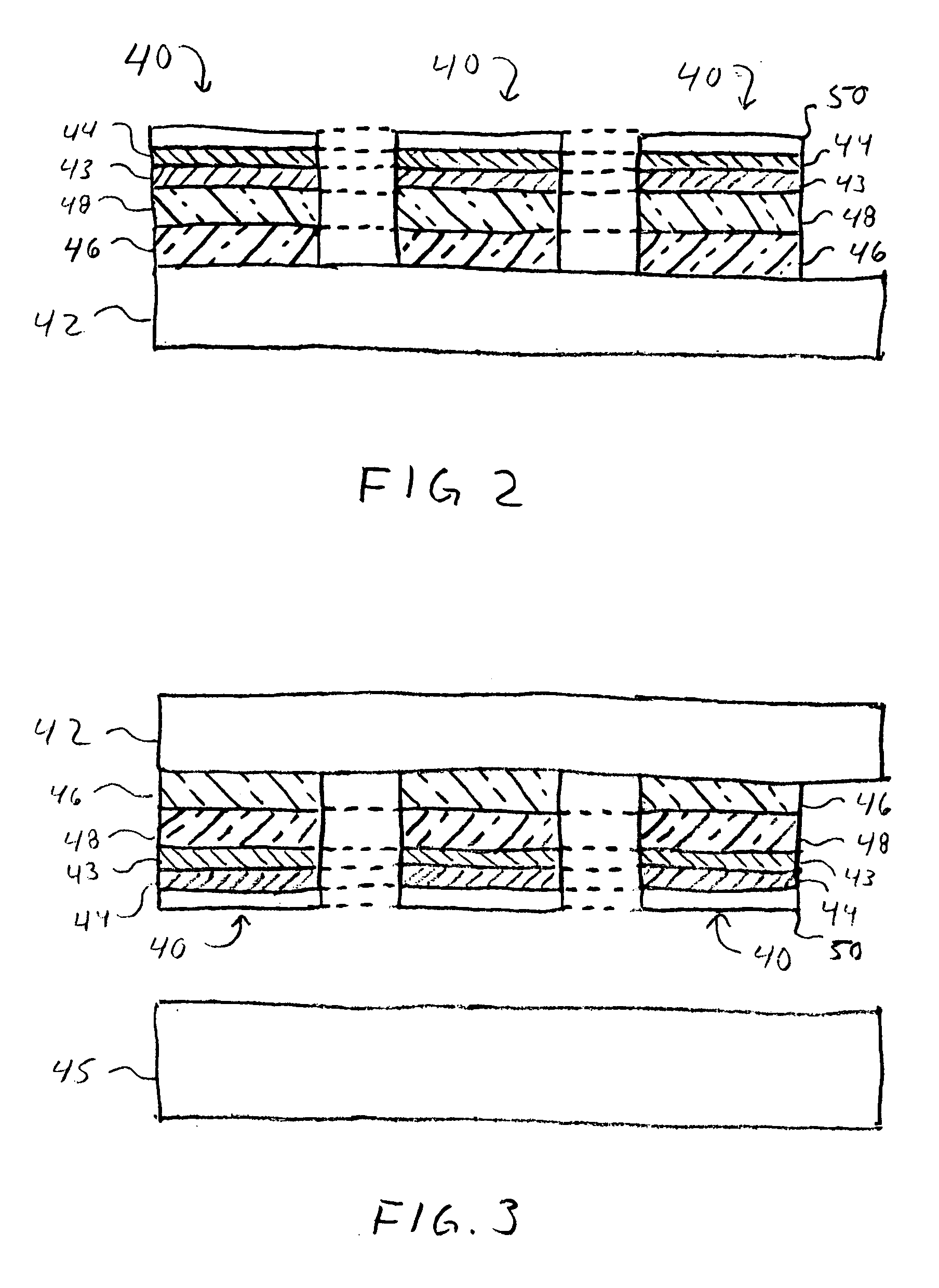

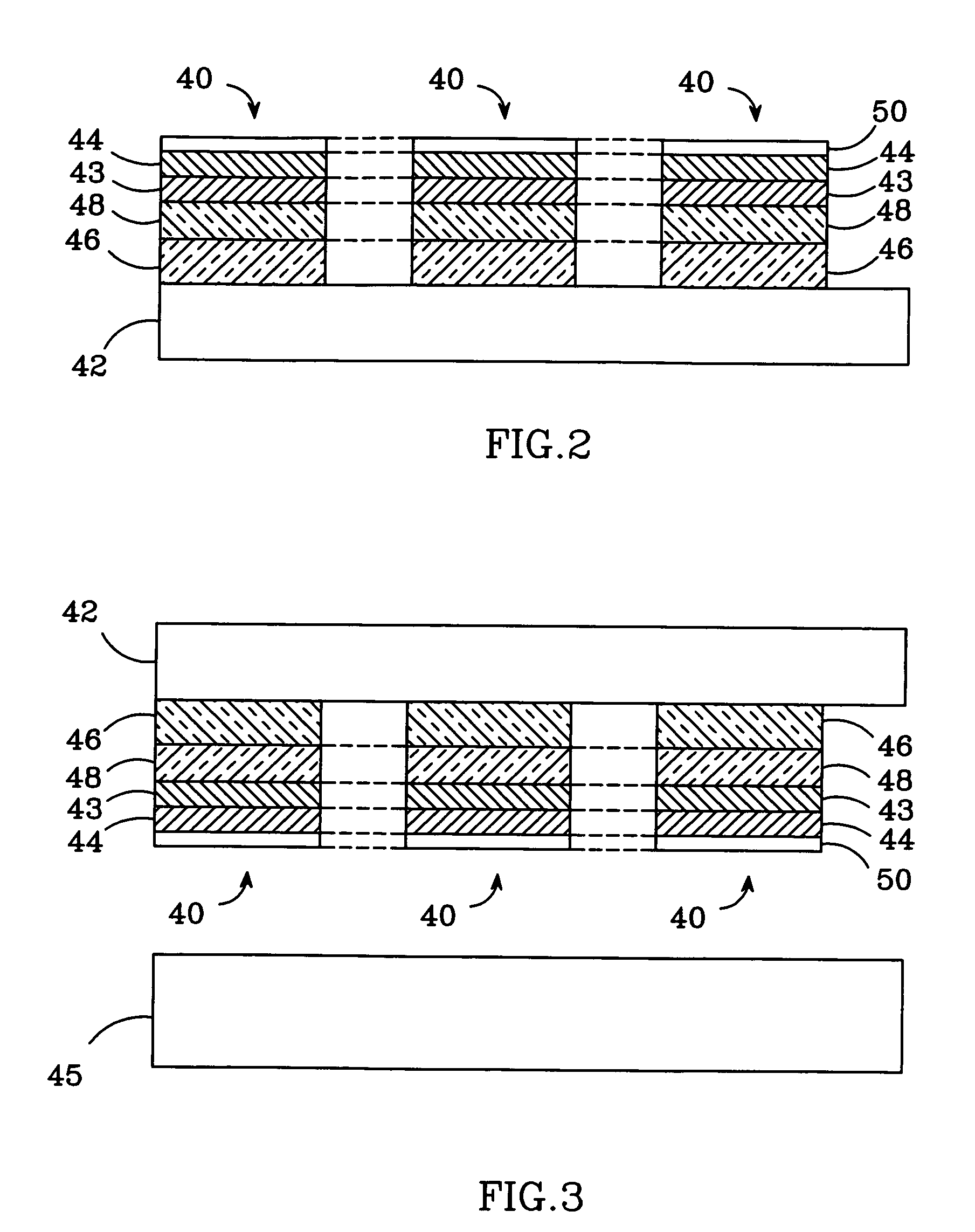

A method for fabricating light emitting diode (LEDs) comprises providing a plurality of LEDs on a substrate wafer, each of which has an n-type and p-type layer of Group-III nitride material formed on a SiC substrate with the n-type layer sandwiched between the substrate and p-type layer. A conductive carrier is provided having a lateral surface to hold the LEDs. The LEDs are flip-chip mounted on the lateral surface of the conductive carrier. The SiC substrate is removed from the LEDs such that the n-type layer is the top-most layer. A respective contact is deposited on the n-type layer of each of the LEDs and the carrier is separated into portions such that each of the LEDs is separated from the others, with each of the LEDs mounted to a respective portion of said carrier.

Owner:CREELED INC

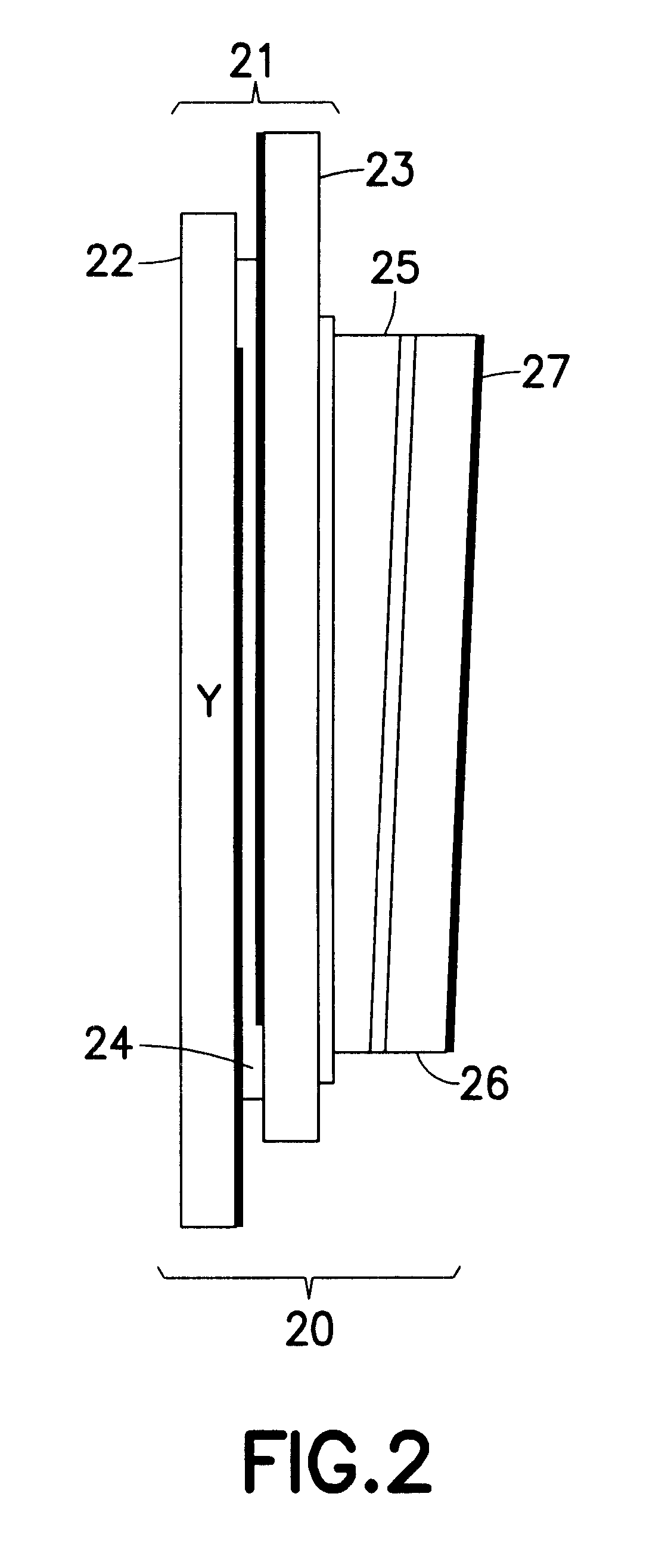

Liquid crystal cell for use in coherent beams

InactiveUS6535257B2Eliminating high-order interferenceImprove matchStatic indicating devicesCoupling light guidesOptical coatingLight beam

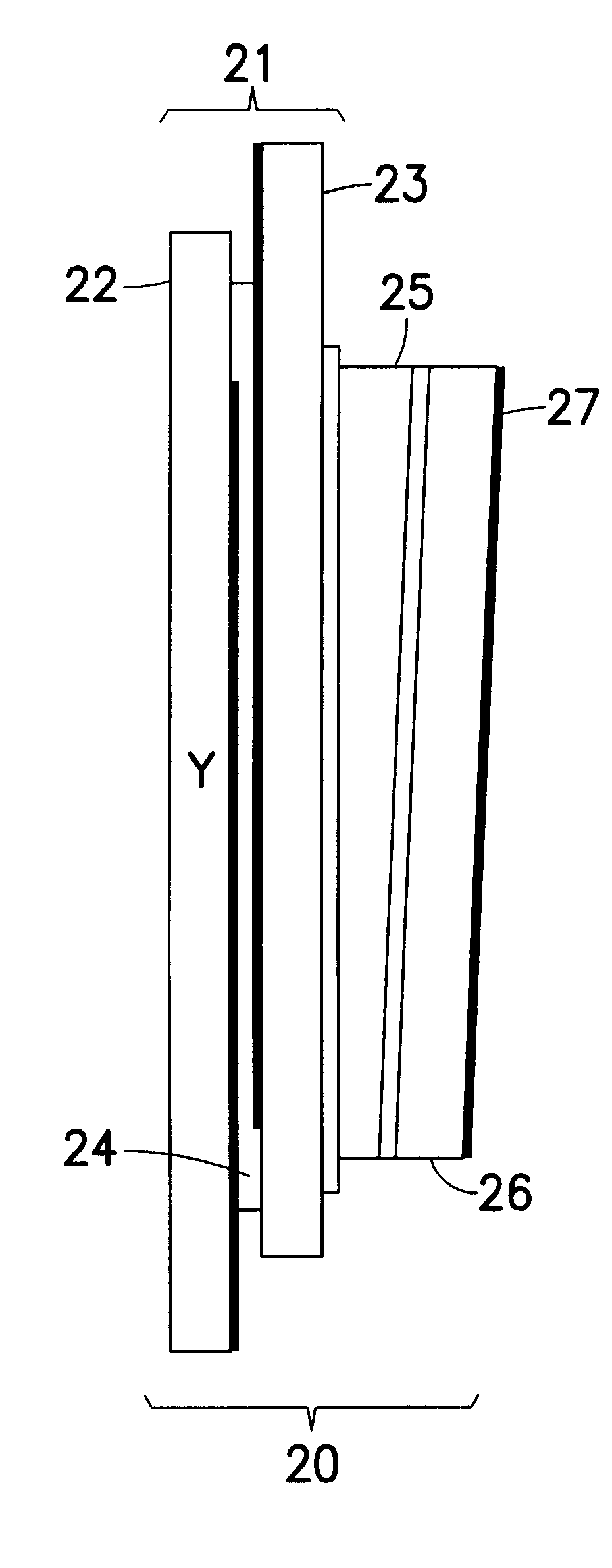

A liquid crystal cell assembly is described which eliminates high-order multiple-beam interference from reflections at the interfaces between the various elements. It can incorporate fixed retarders for compensation or production of high retardances. The invention enables standard, economical methods to be used in making the liquid crystal cell, retarder elements, optical coatings, and overall assembly. Transmissive and reflective embodiments are shown.

Owner:CAMBRIDGE RES & INSTR

Substrate removal process for high light extraction LEDs

ActiveUS7932111B2Index matchingImprove light extractionSemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeNitride

A method for fabricating light emitting diode (LEDs) comprises providing a plurality of LEDs on a substrate wafer, each of which has an n-type and p-type layer of Group-III nitride material formed on a SiC substrate with the n-type layer sandwiched between the substrate and p-type layer. A conductive carrier is provided having a lateral surface to hold the LEDs. The LEDs are flip-chip mounted on the lateral surface of the conductive carrier. The SiC substrate is removed from the LEDs such that the n-type layer is the top-most layer. A respective contact is deposited on the n-type layer of each of the LEDs and the carrier is separated into portions such that each of the LEDs is separated from the others, with each of the LEDs mounted to a respective portion of said carrier.

Owner:CREELED INC

Composition for providing an abrasion resistant coating on a substrate with a matched refractive index and controlled tintability

InactiveUS20010056157A1Improve stabilityControl the extent of tint absorptionFilm/foil adhesivesMixingColloidal silicaRefractive index matching

The present invention discloses compositions as well as methods of making and using said compositions, having improved stability which, when applied to a variety of substrates and cured, form transparent coatings which have abrasion resistant properties, a matched refractive index to that of the substrate, and which can be tailored to control the extent of tint absorption (vide infra). The compositions comprise an aqueous-organic solvent mixture containing a mixture of hydrolysis products and partial condensates of an epoxy-functional silane, a carboxylic acid functional compound selected from the group consisting of carboxylic acids, multifunctional carboxylic acids, anhydrides, and combinations thereof, a metal oxide composite colloid, and a disilane. The coating compositions may further include a mixture of hydrolysis products and partial condensates of one or more silane additives, a colloidal silica material, and a tetrafunctional silane.

Owner:SDC TECHNOLOGIES INC

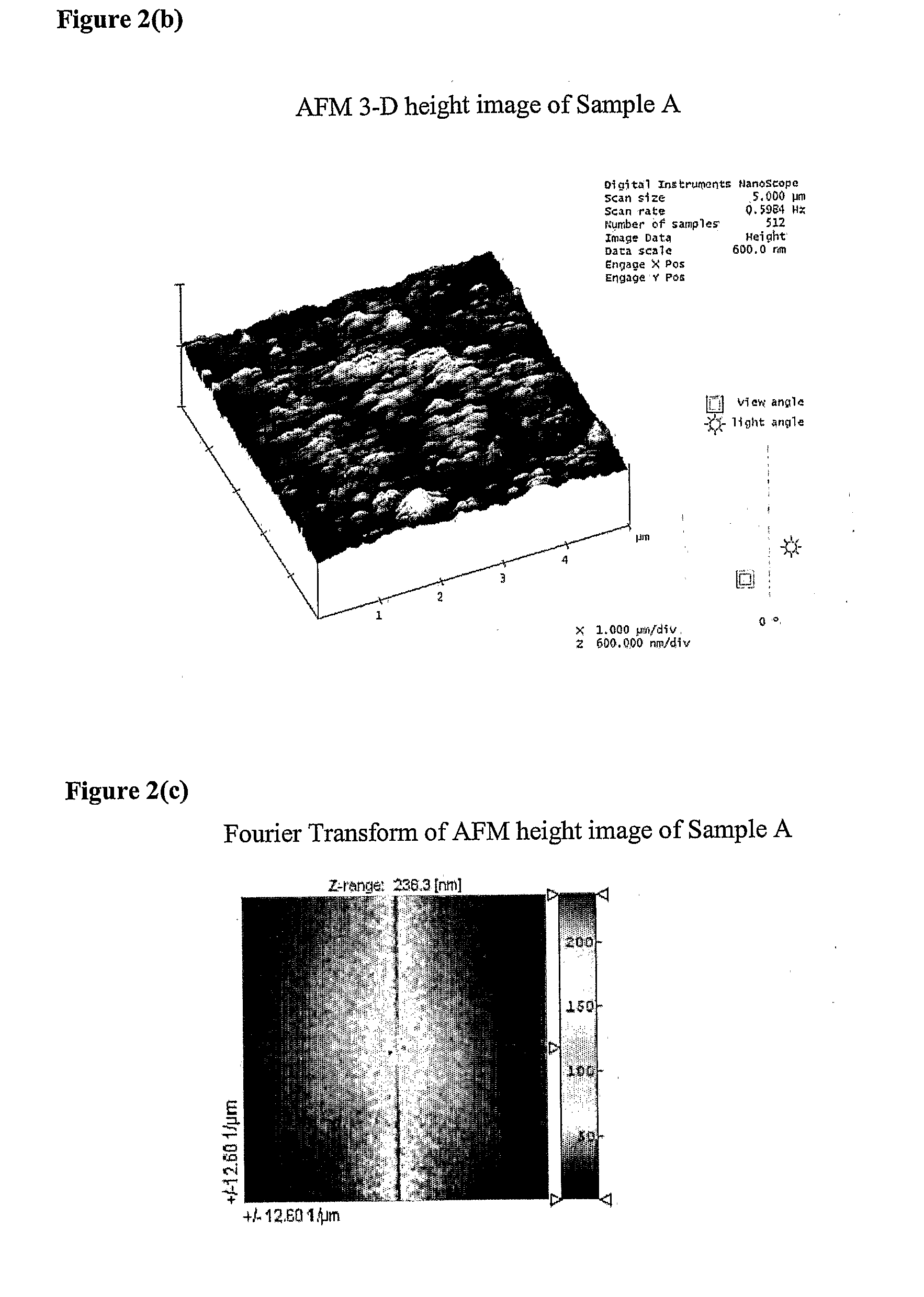

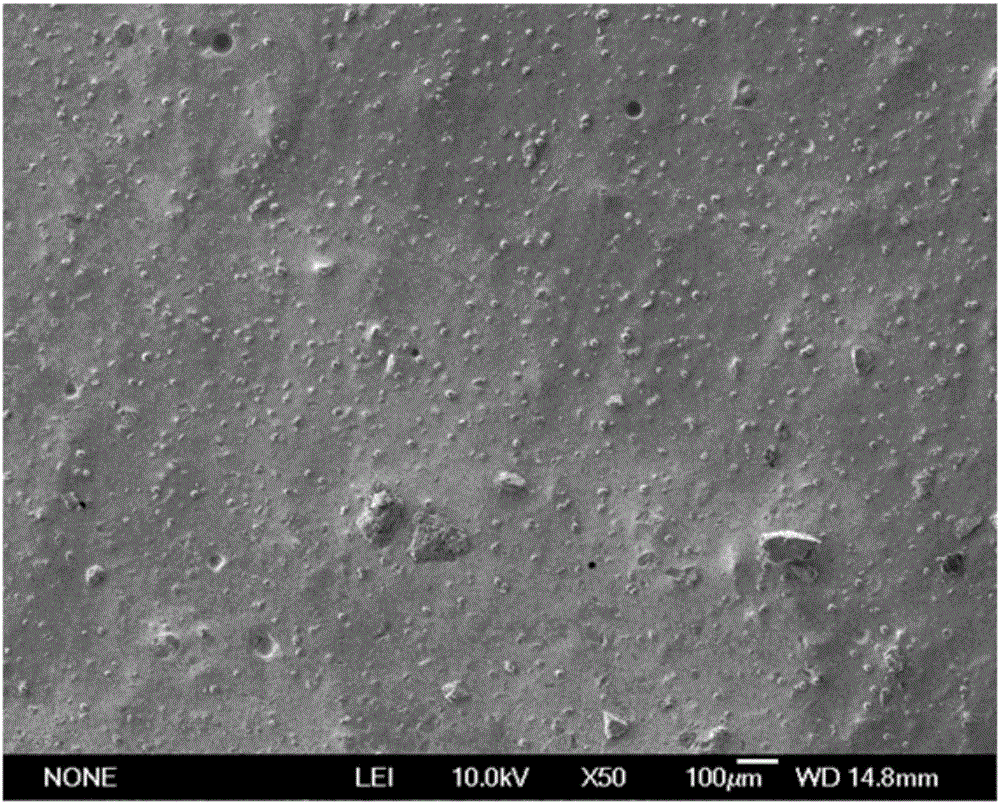

Optical Thin Films with Nano-Corrugated Surface Topologies by a Simple Coating Method

InactiveUS20080157665A1Improve lighting efficiencyLight extraction efficiency of lightMaterial nanotechnologyDischarge tube luminescnet screensStainingNanoparticle coating

Embodiments of the invention relate to functionalized nanoparticle coating compositions. These coating can improve the light extraction efficiency of light emitting devices, including LEDs and OLEDs. In some embodiments, the coating can improve other properties such as anti-staining, abrasion and / or scratch resistance.

Owner:OPTIMAX TECHNOLOGY CORPORATION

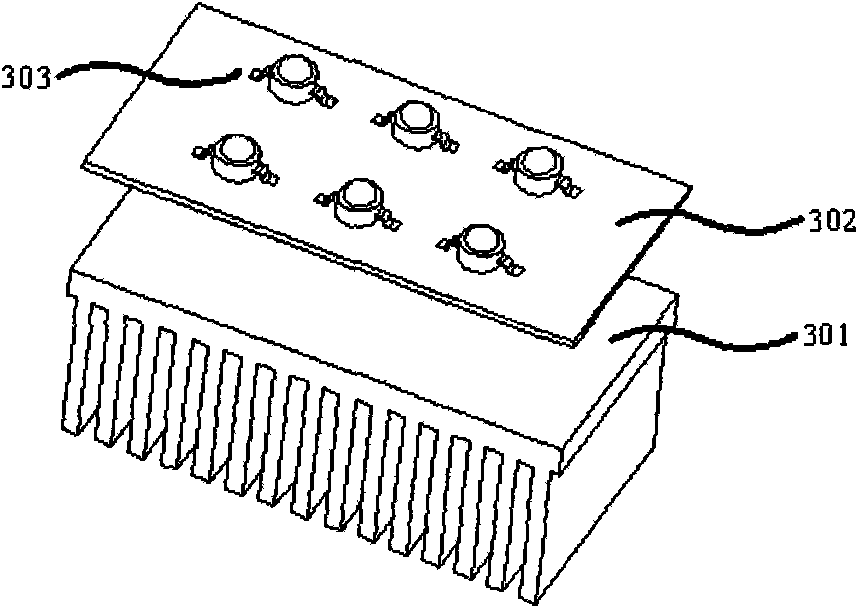

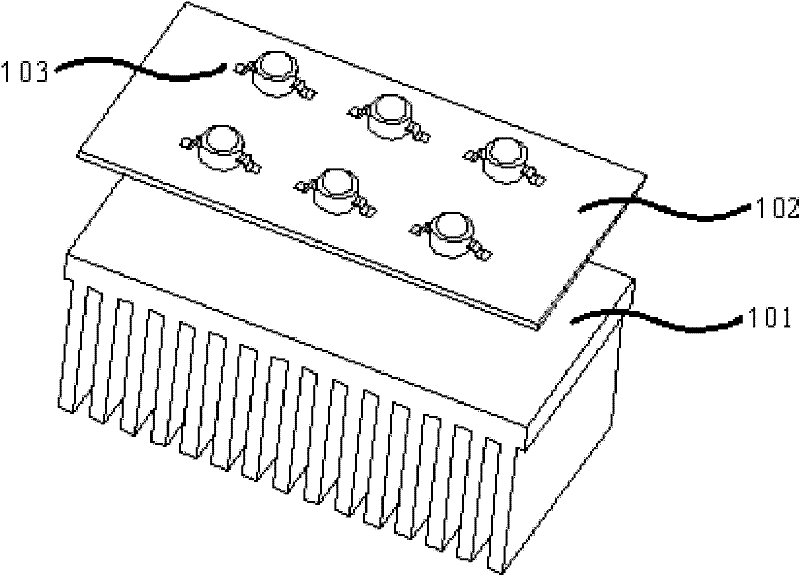

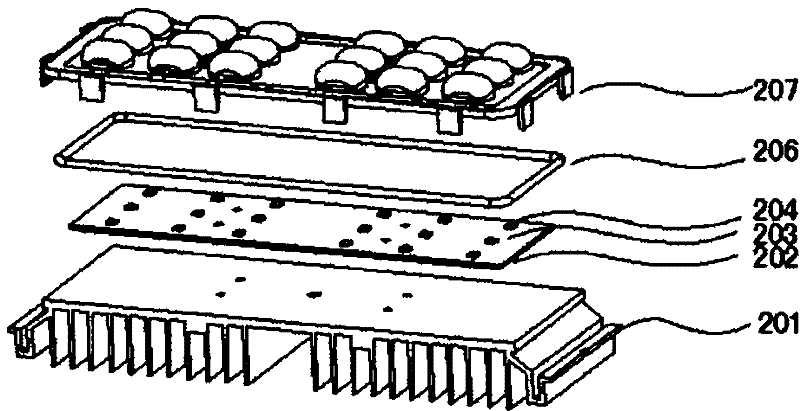

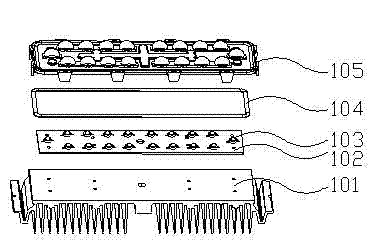

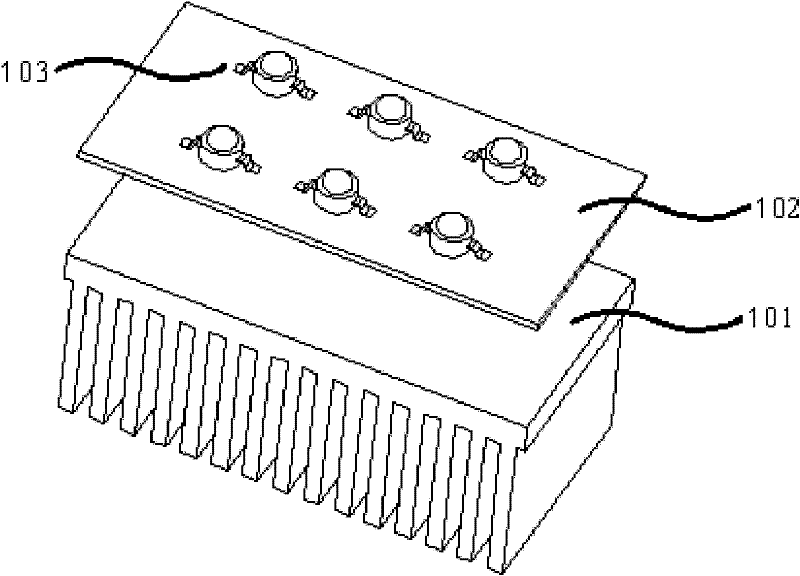

LED module and manufacturing process thereof

InactiveCN101980387AImprove cooling effectIndex matchingSemiconductor devicesReflection lossEngineering

The invention discloses an LED module, which comprises a radiator, a circuit board, an LED chip, an intraconnection track, filling colloid and a lens module, wherein the LED chip is fixed on the circuit board coated with a prime coat; the intraconnection track bridges the LED chip and the pad of the corresponding circuit board; the filling colloid is poured to embed the LED chip and the intraconnection track; the circuit board and the radiator are tightly jointed by faces; and the lens module is covered on the LED chip, the circuit board and the radiator. The LED chip is solidified on the circuit board directly, so the conventional LED packaging process is not used; and a bracket with a heat sink is not used, so that the heat of the LED chip is dissipated to the circuit board and the radiation, which have high heat conductivity, without passing through a heat skink intermediate layer, so the heat dissipation effect is improved. As only the filling colloid is filled between the lens module and the LED chip, light passes through fewer mediums and the transmissivity is high; and the refractive index of the filling colloid and the refractive index of the lens module are matched, so the reflection loss is little and the light rate of the LED module is improved.

Owner:ZHEJIANG XIZI OPTOELECTRONICS TECH

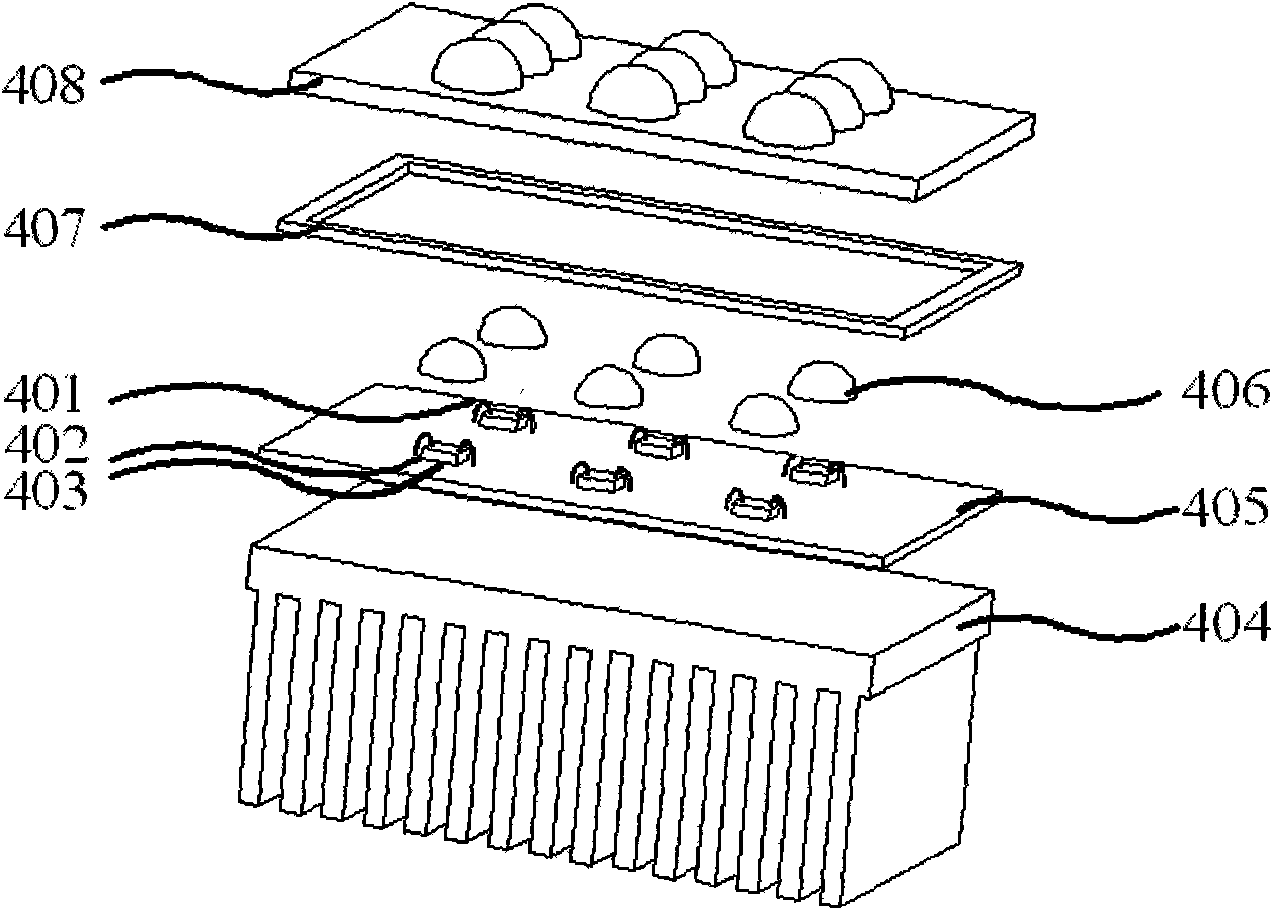

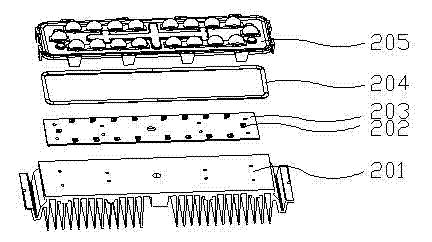

Lead-free LED (Light-Emitting Diode) module and manufacturing process thereof

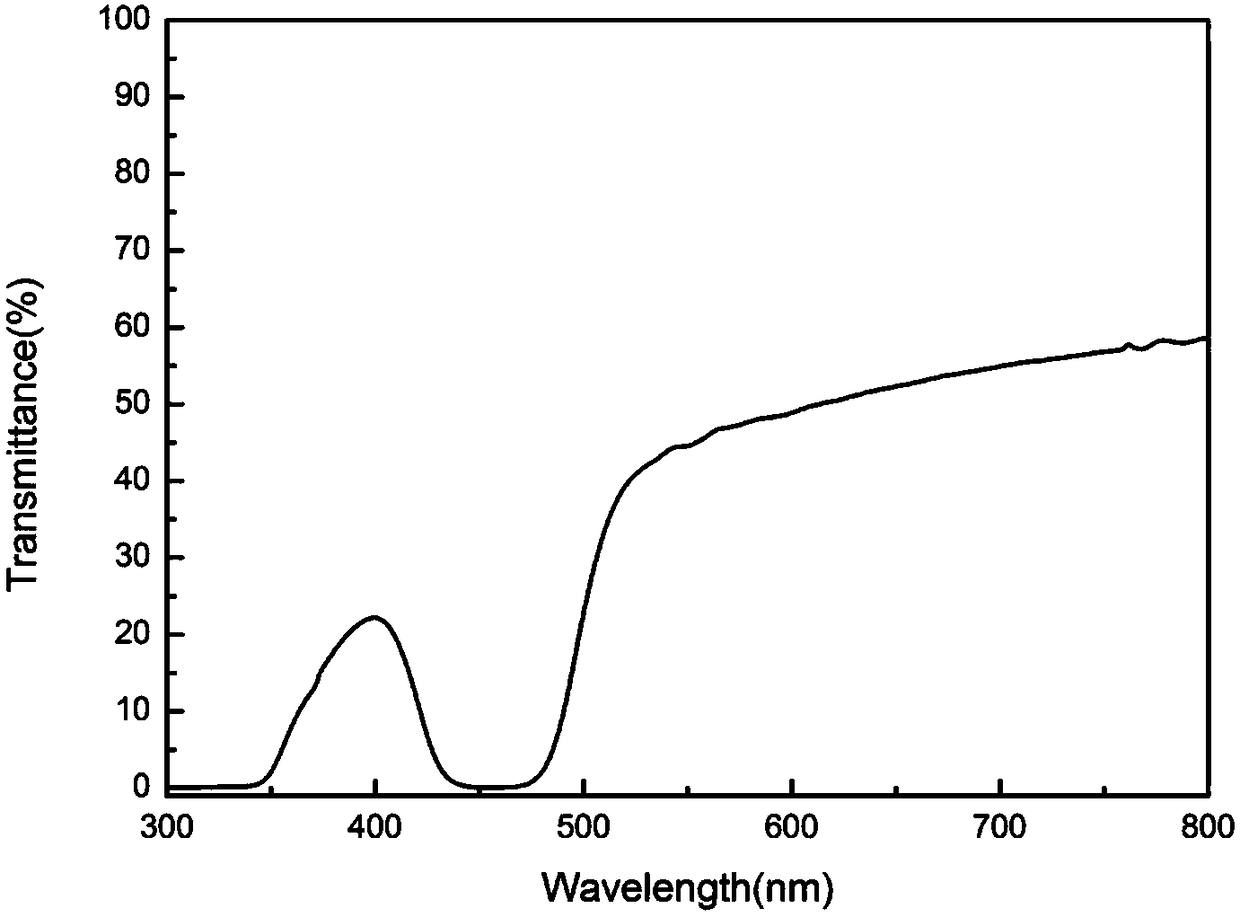

InactiveCN102364685AImprove cooling effectIndex matchingSolid-state devicesSemiconductor devicesReflection lossTransmittance

The invention relates to a lead-free LED (Light-Emitting Diode) module and a manufacturing process thereof. The LED module comprises a radiator, a PCB (Printed Circuit Board), an LED chip, an encapsulating colloid, sealing silica gel and a lens module, wherein the LED chip is welded on the PCB; the anode and cathode of the LED chip are welded on corresponding electrode pads respectively; the PCB is jointed with the radiator; and the lens module is arranged above the LED chip, and is filled with the encapsulating colloid. The LED chip is directly welded on the circuit board, so that the conventional LED encapsulating process is eliminated, a bracket comprising a heat sink is eliminated, heat of the LED chip is directly diffused to the high-heat-conductivity circuit board and the radiator, and the radiating effect is enhanced. Only the sealing colloid is arranged between the lens module and the LED chip, so that light rays pass through a small quantity of media, and the transmittance is high; and the filling colloid is matched with the refractive index of the lens module, so that the reflection loss is small, and the light emitting rate of the LED module is increased.

Owner:HANGZHOU HPWINNER OPTO CORP

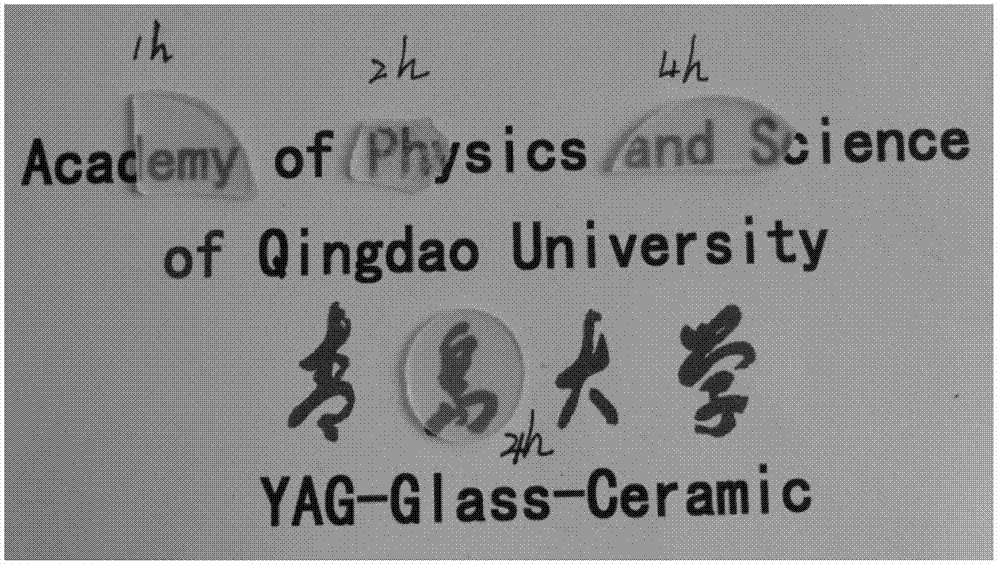

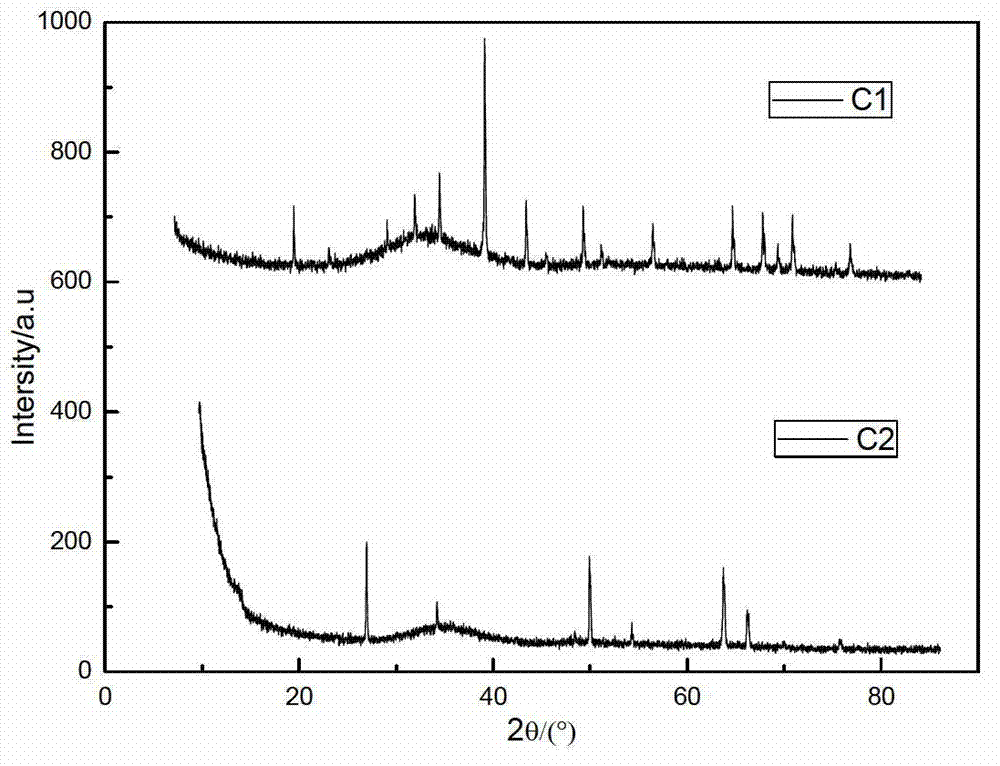

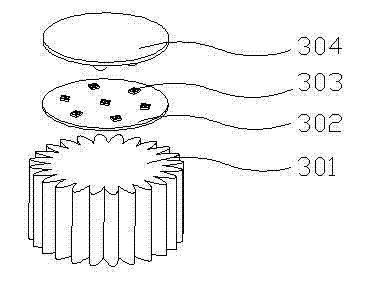

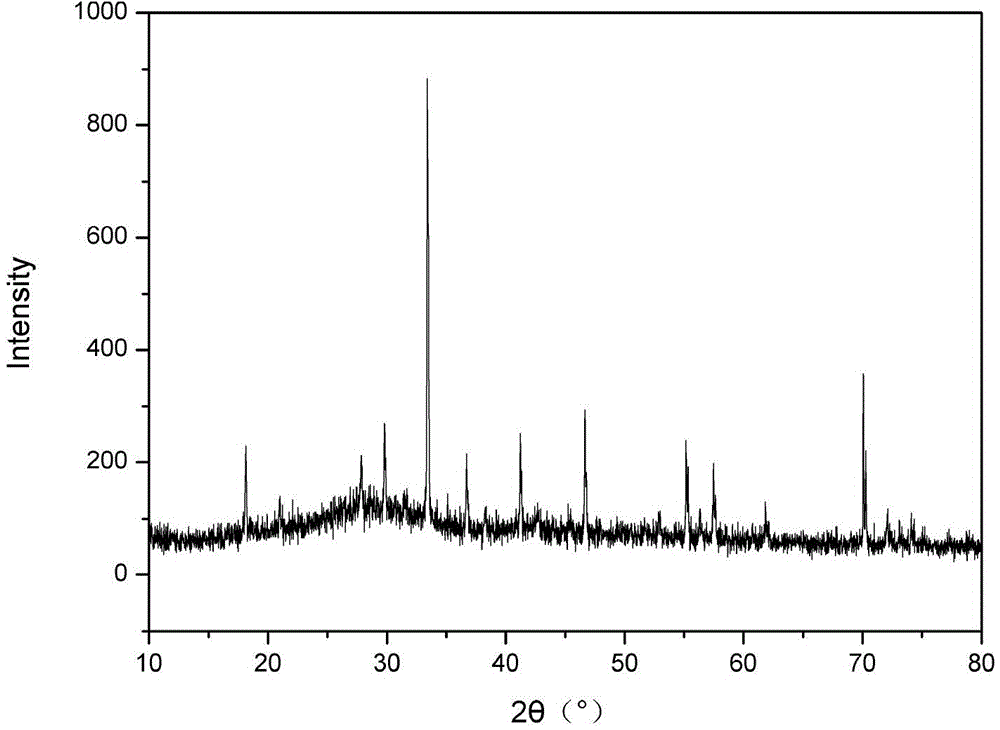

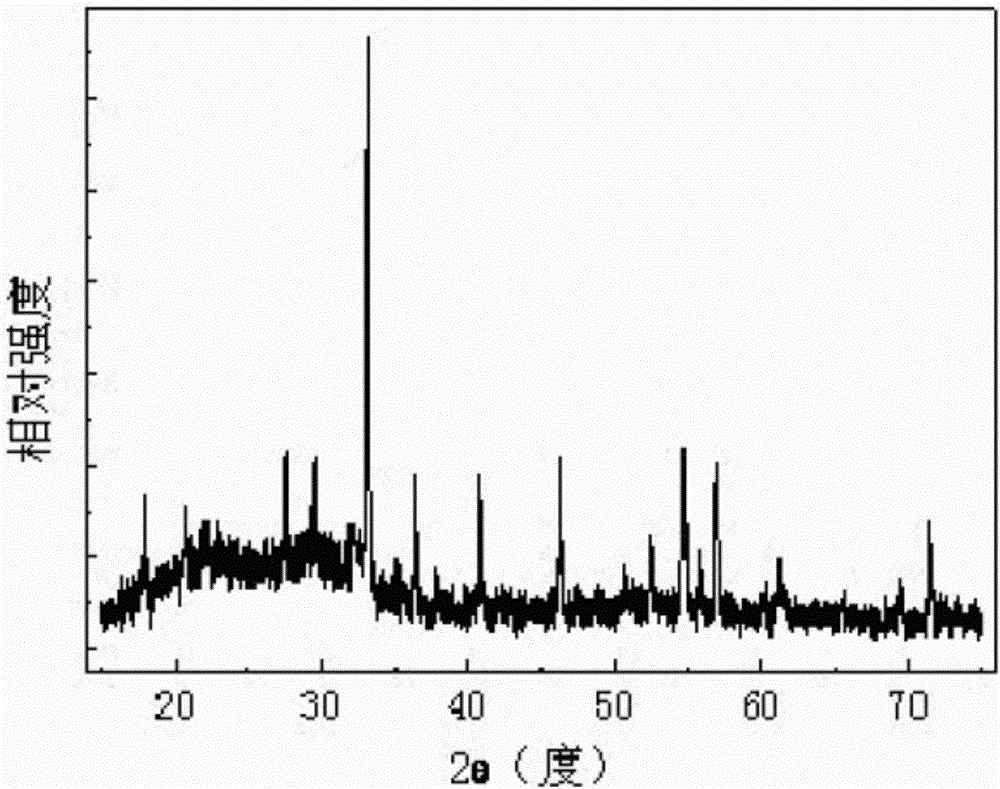

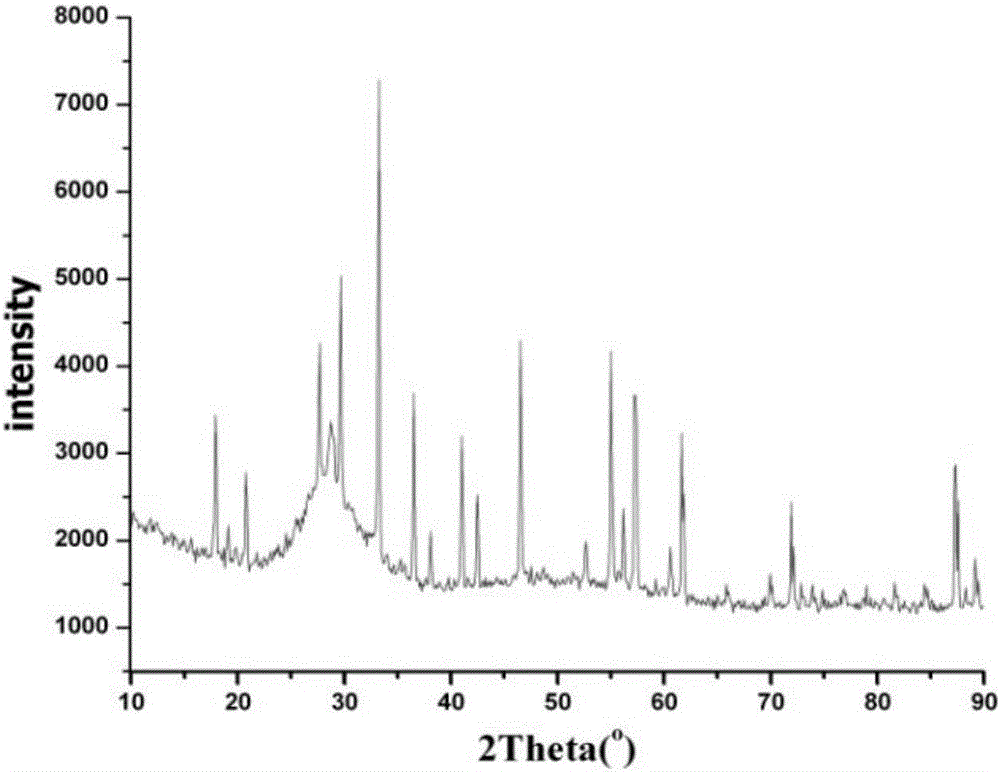

Preparation method of YAG microcrystalline glass

The invention belongs to the technical field of inorganic material preparation and relates to a preparation method for a piece of YAG (Yttrium Aluminum Garnet) microcrystalline glass. The method comprises the following steps: mixing materials to form mixed materials to be filled into a ball milling pot, then adding agate balls with equal quality but different sizes, and allowing the mixed materials to be subjected to ball milling in a ball milling machine for 2 hours so as to obtain mixed glass materials; placing the mixed glass materials in an alumina crucible after being pressed to be cylinder-shaped in an oil press, and melting the cylindric glass materials in a muffle furnace so as to obtain molten glass materials after temperature reduction; maintaining 2 hours after the temperature of the molten glass materials is reduced to 1,250 DEG C in 15 minutes, and maintaining 1-20 hours after the temperature is regulated to 1,000 DEG C; and maintaining 6 hours after the temperature is reduced to 600 DEG C with the cooling of the furnace, and obtaining the piece of transparent YAG microcrystalline glass after the temperature is reduced to a room temperature through natural cooling. The preparation method has the advantages of simple preparation process, easiness in obtaining raw material, low cost, larger product size, complex shapes, good transparency, easiness in adjusting spectral quality, good applicability and environmental friendliness.

Owner:QINGDAO UNIV

Composition for providing an abrasion resistant coating on a substrate with a matched refractive index and controlled tintability

InactiveUS7001642B2Improve stabilityIndex matchingGroup 4/14 element organic compoundsFilm/foil adhesivesColloidal silicaOrganic solvent

Owner:SDC TECHNOLOGIES INC

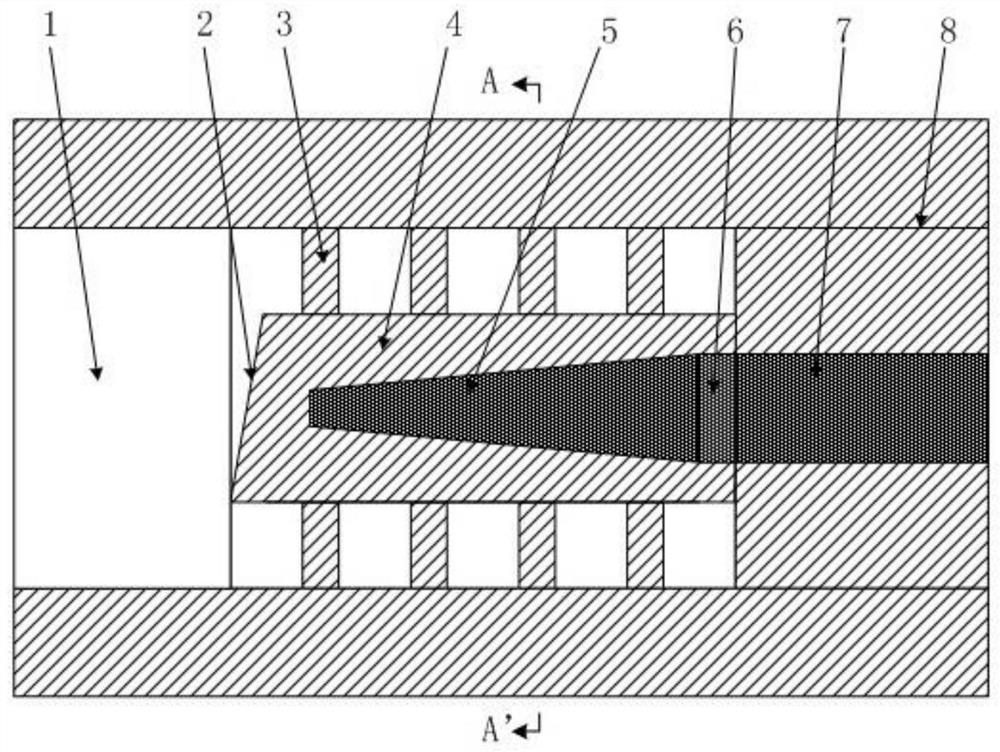

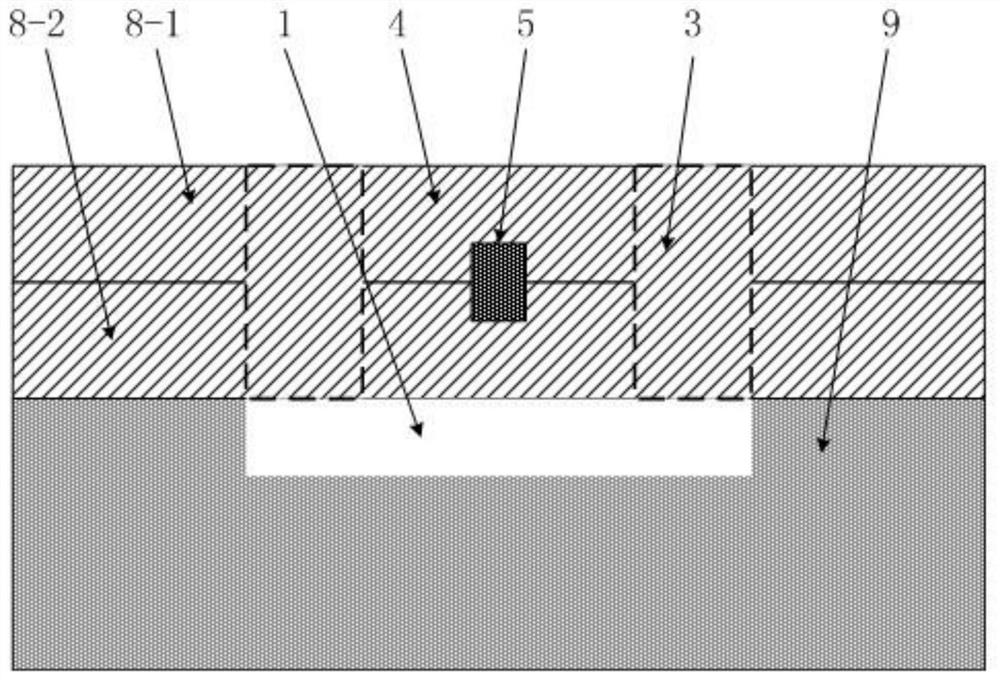

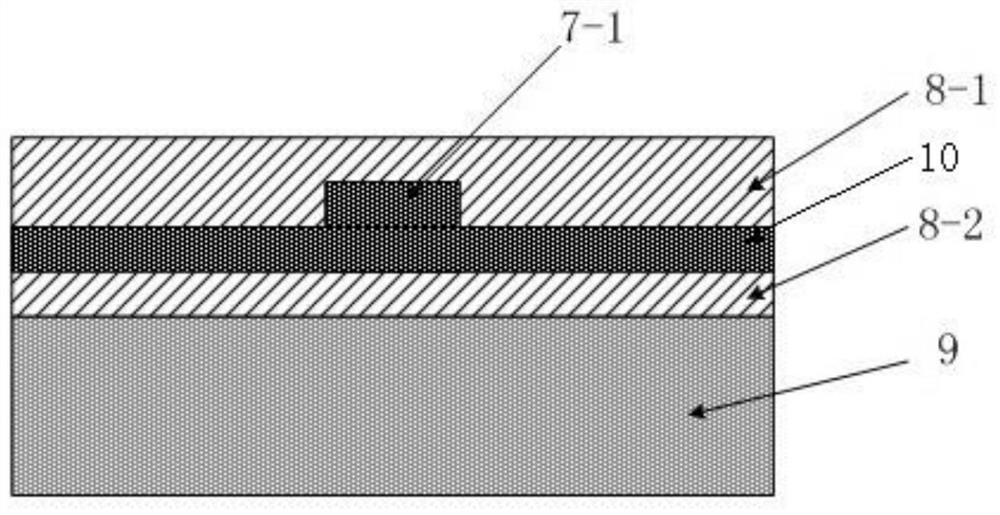

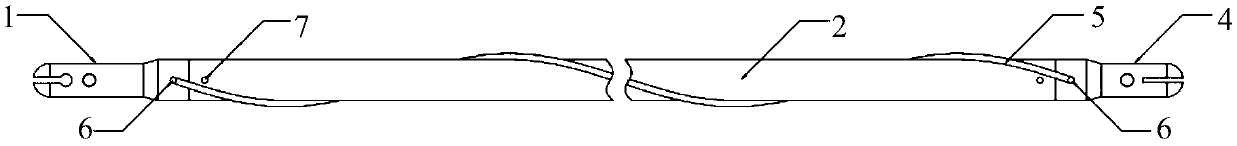

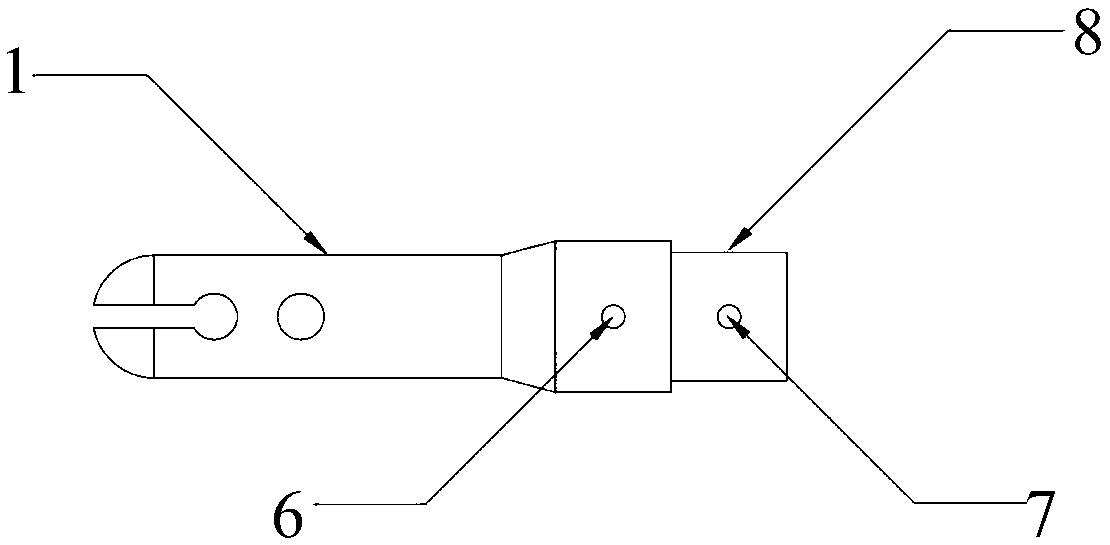

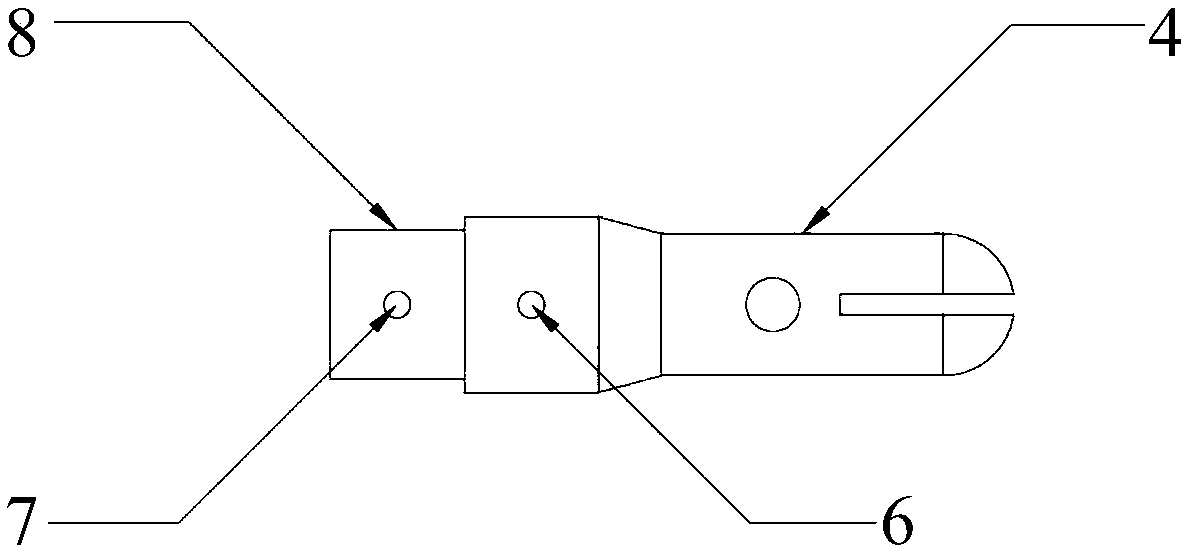

LNOI suspended spot size converter and process implementation method thereof

ActiveCN111665592AMeet matching needsReduce reflectionOptical waveguide light guideCantilevered beamConverters

The invention discloses an LNOI (Lithium Niobate on Insulator) suspended spot size converter and a process implementation method thereof. The LNOI suspended spot size converter comprises an optical fiber fixing groove, an optical coupling end face, a SiO2 cantilever beam supporting structure, a SiO2 suspended optical waveguide, an LNOI conical core layer, a transition structure, an LNOI optical waveguide core layer, a SiO2 cladding and a chip substrate. The LNOI conical core layer is embedded in the middle of the SiO2 suspended optical waveguide, and the LNOI optical waveguide core layer is located in a space defined by the transition structure and the SiO2 cladding; the SiO2 suspended optical waveguide, the transition structure and the SiO2 cladding are connected in sequence, and the embedded LNOI conical core layer is in accurate butt joint with the LNOI optical waveguide core layer. According to the converter, transverse and longitudinal simultaneous conversion of the optical mode size in the LNOI optical waveguide is achieved, the requirement for matching a submicron LNOI optical waveguide with the optical fiber mode size can be met, and the mode converter is suitable for botha ridge-shaped LNOI optical waveguide and a rectangular LNOI optical waveguide.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Substrate removal process for high light extraction leds

ActiveUS20110198626A1Index matchingImprove light extractionSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeNitride

Owner:CREELED INC

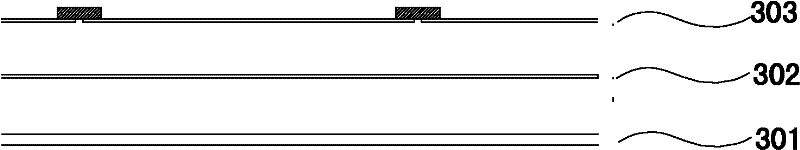

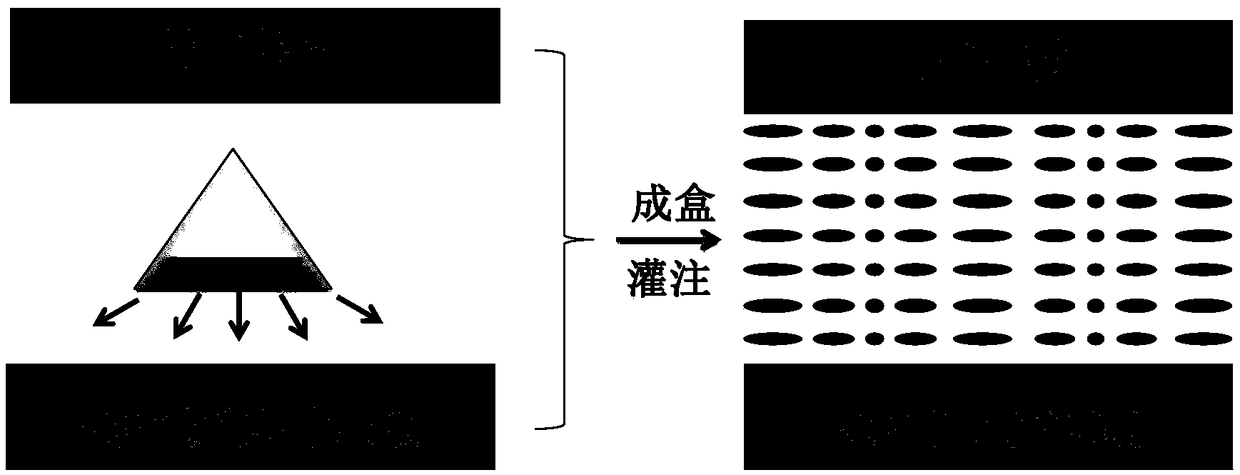

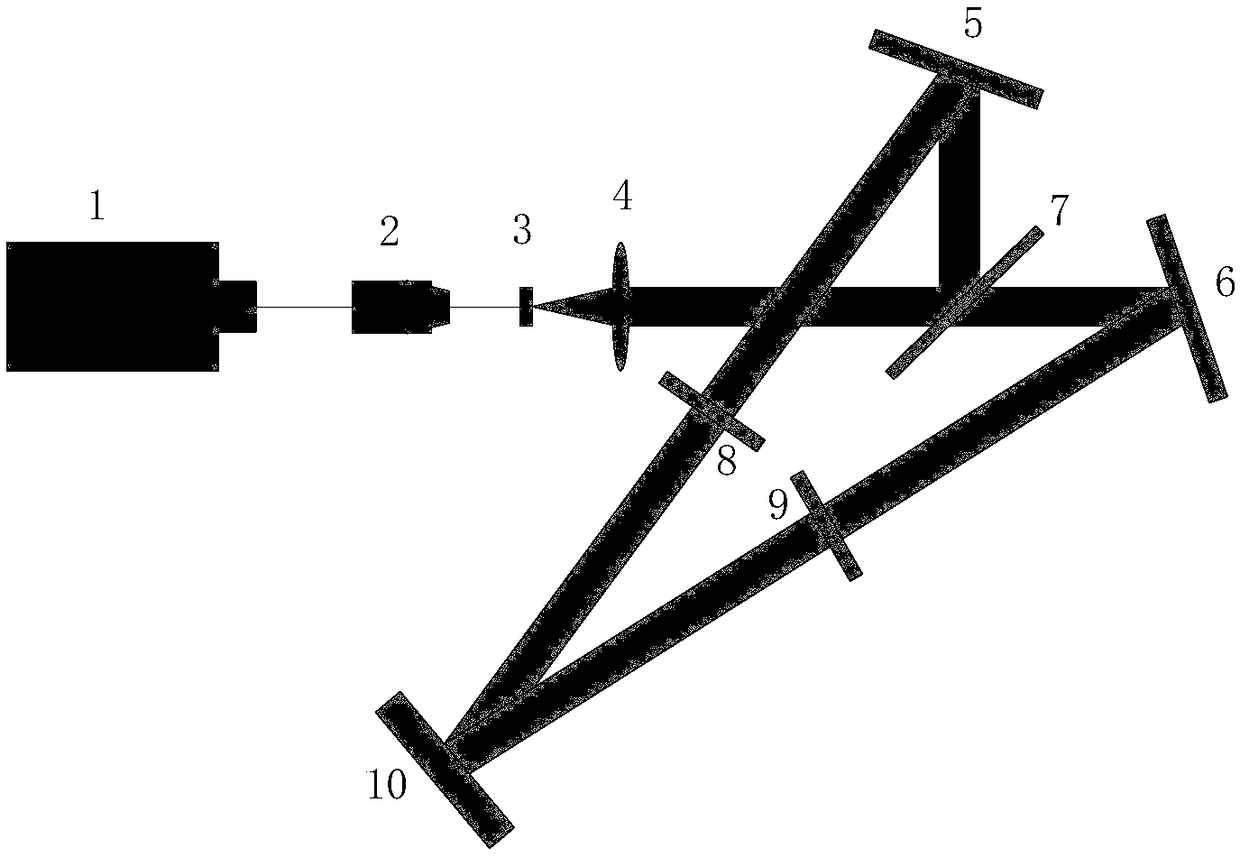

Active liquid crystal polarized optical grating structure with one-sided orientation mode and preparing method thereof

ActiveCN109375426AReduce in quantityIndex matchingNon-linear opticsOptical elementsGratingLight beam

The invention discloses an active liquid crystal polarized optical grating structure with a one-sided orientation mode and a preparing method thereof, belongs to the technical field of non-mechanicallight beam deflection in driving optoelectronic systems, and mainly aims at solving the problems in the prior art that the number of active liquid crystal polarized optical grating substrates is large, the energy loss is large, and the light leakage problem is serious. The preparing method of the active liquid crystal polarized optical grating structure breaks the traditional sequence of box formation and exposure orientation, and the one-sided orientation mode of firstly conducting substrate exposure orientation and then conducting pressing box formation is adopted. By means of the active liquid crystal polarized optical grating structure and the preparing method thereof, the box formation uniformity of active liquid crystal polarized optical gratings can be improved, the light leakage isreduced, and the contrast ratio is increased. By means of the method, liquid crystal polarized optical grating and wave plate combination and integration box formation technology also becomes reality.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

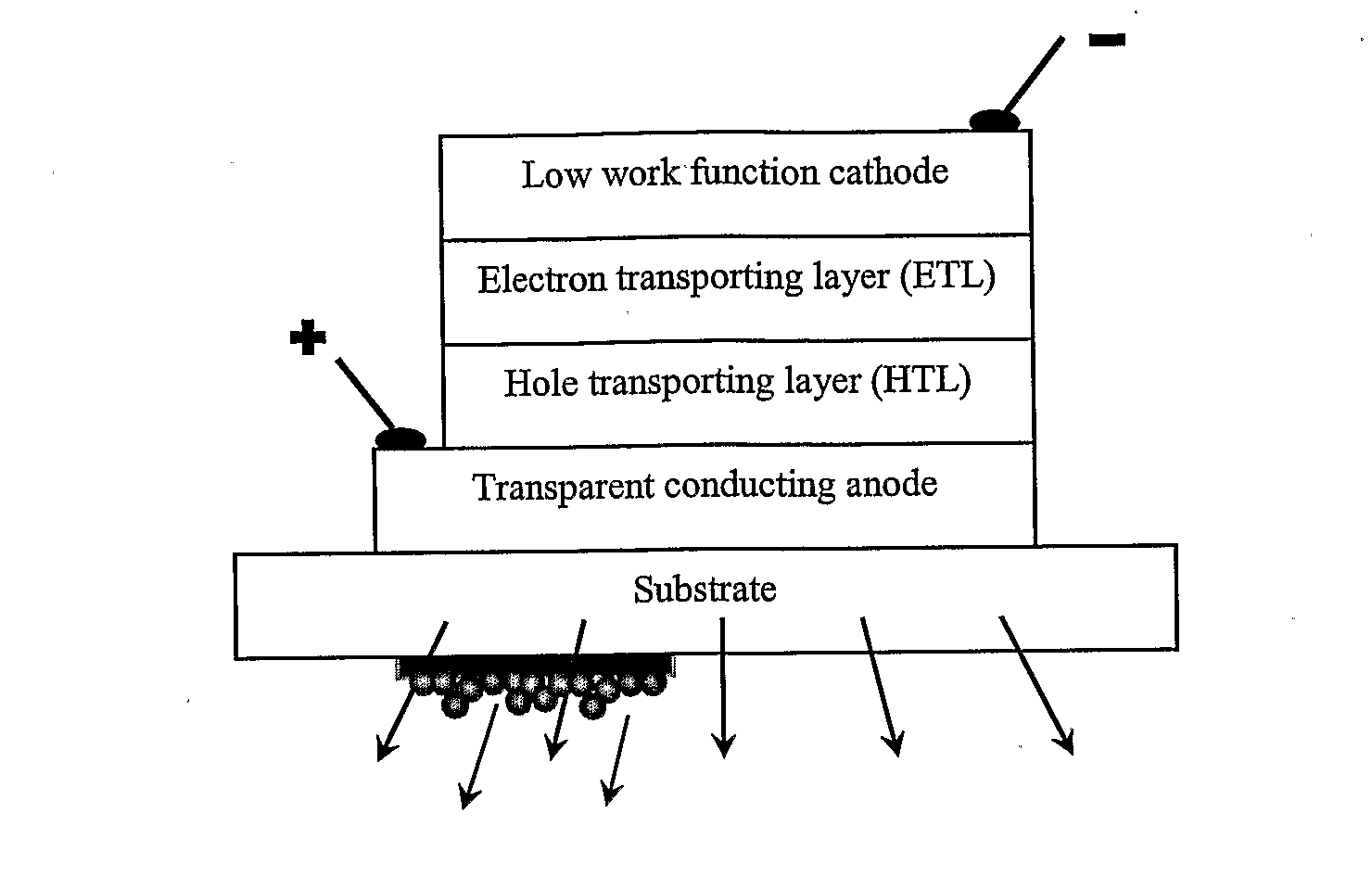

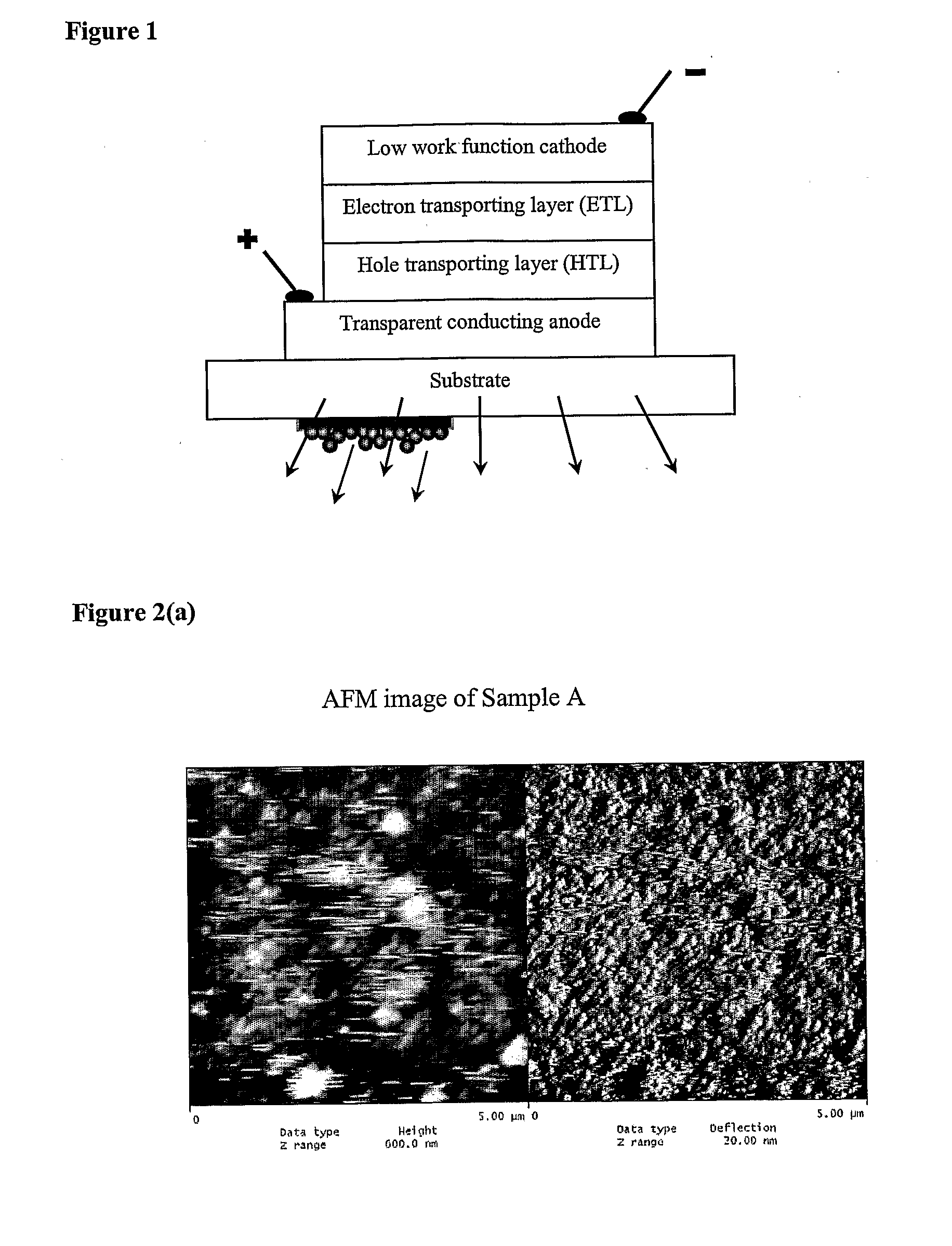

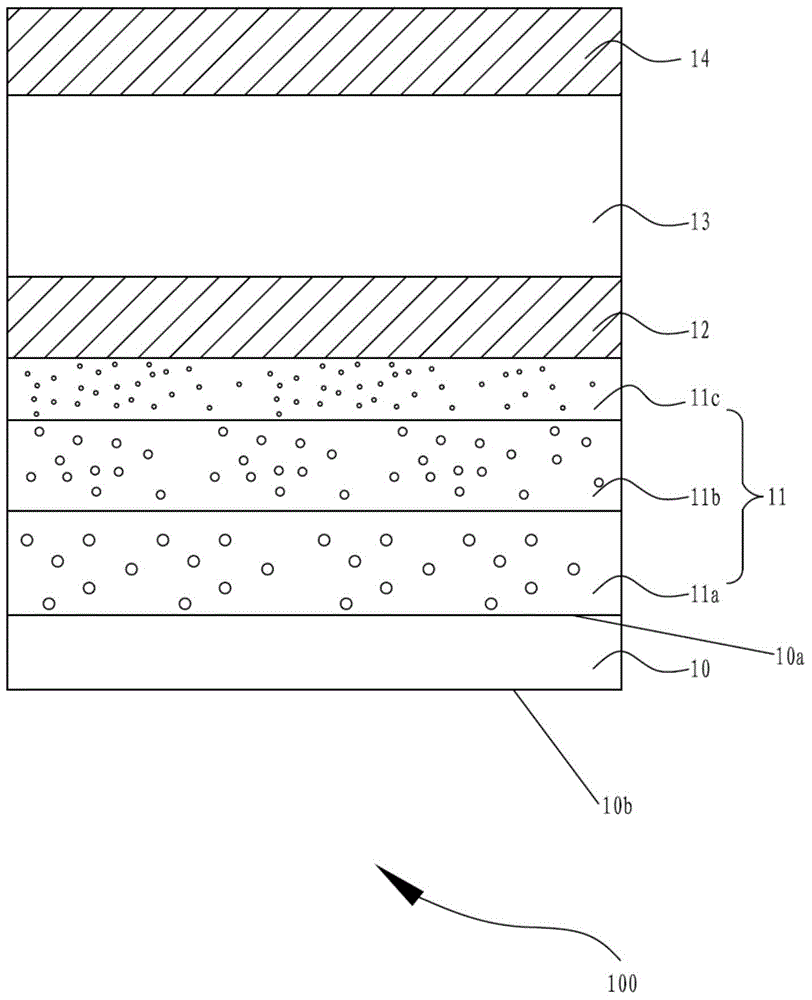

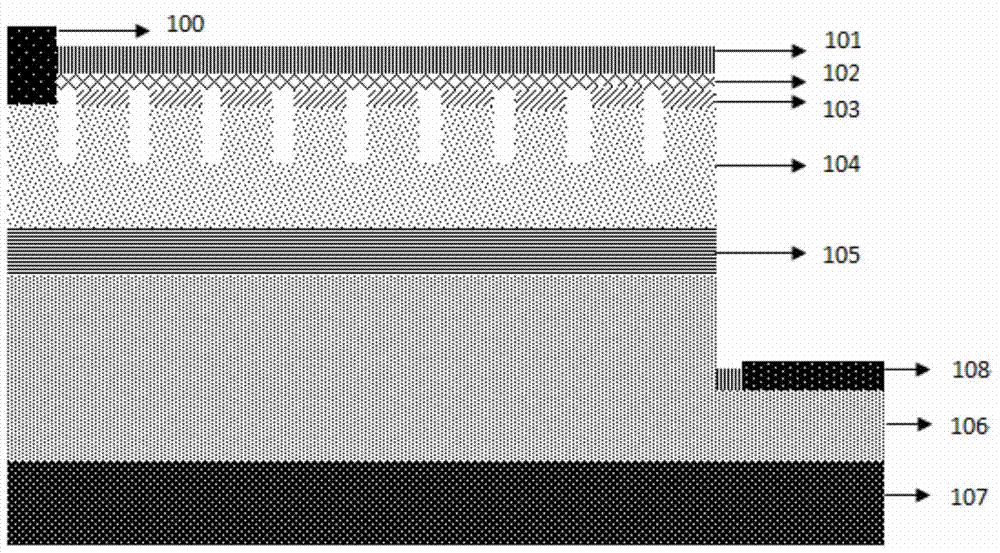

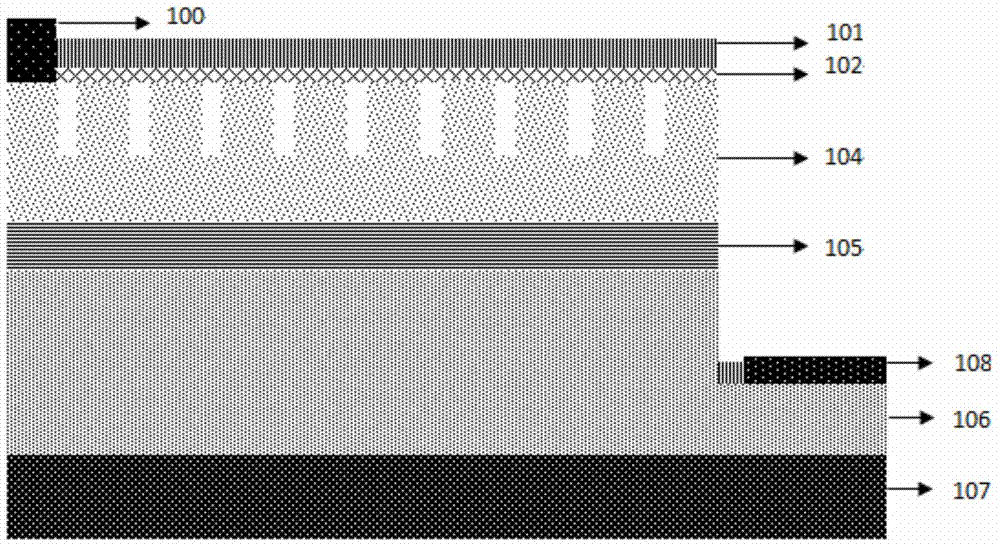

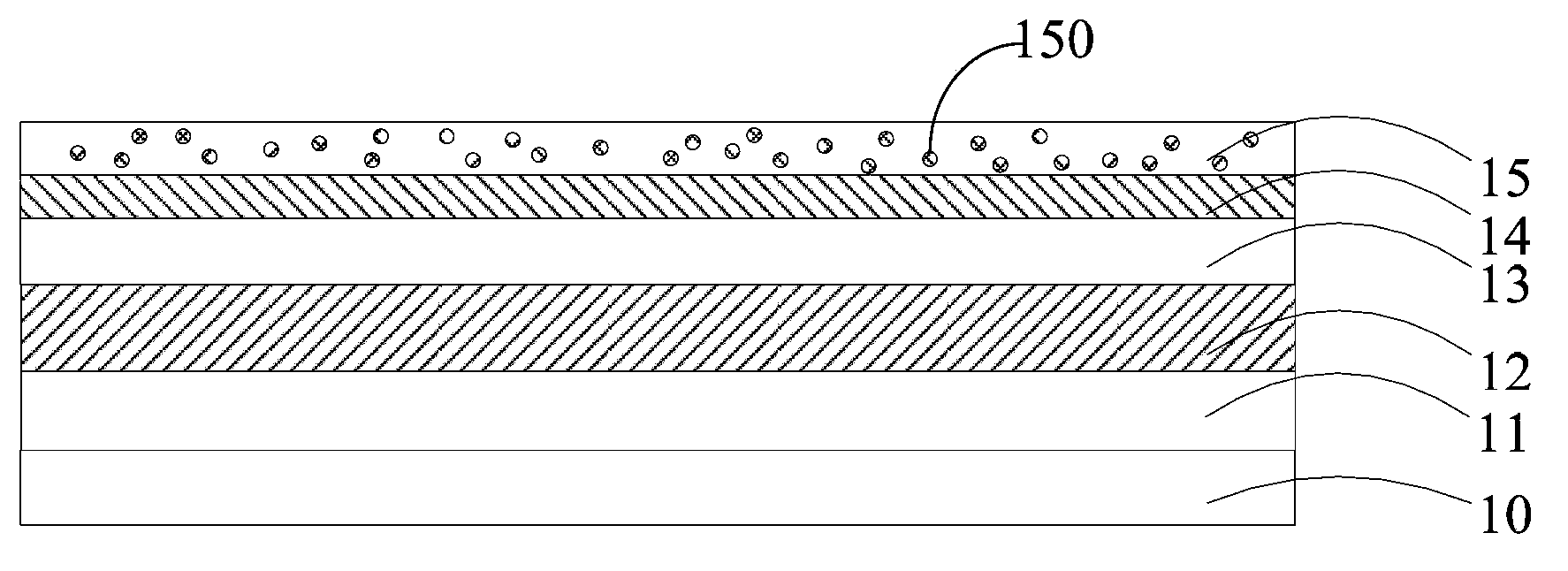

Organic light-emitting diode device and preparation method thereof

InactiveCN104465995AIndex matchingSolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereNanoparticle

The invention provides an organic light-emitting diode device comprising a substrate, a light extraction layer, a conductive anode, a light-emitting function layer and a conductive cathode. The substrate, the light extraction layer, the conductive anode, the light-emitting function layer and the conductive cathode are successively laminated. The light-emitting function layer emits light through the substrate under the voltage drive. The light extraction layer is characterized in that a polymer material is doped with a nanoparticle material and includes a plurality of light-transmitting layers with different nanoparticle contents; and the multiple light-transmitting layers with different nanoparticle contents are laminated along the direction from the substrate to the conductive anode. Because of the different nanoparticle contents in the light-transmitting layers, the body refractive index of the light extraction layer can be changed; and the more the contents, the larger the refractive index. Therefore, the light-transmitting layer approaching the conductive anode has the higher refractive index and the light-transmitting layer approaching the substrate has the lower refractive index, thereby realizing refractive index matching of the light extraction.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

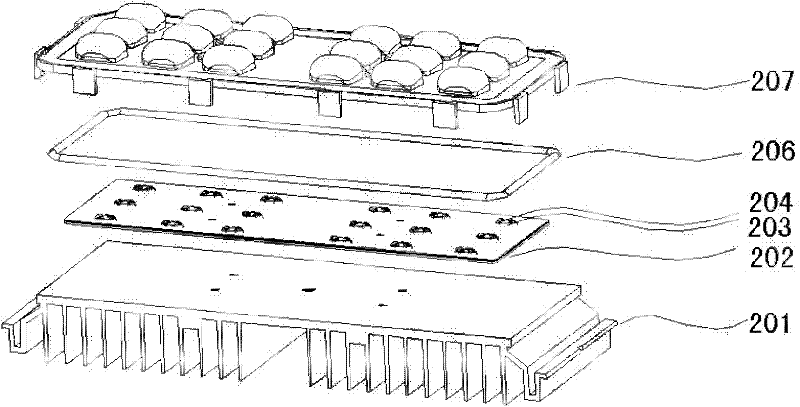

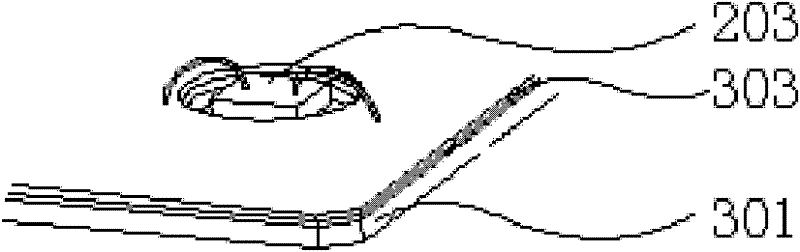

Manufacturing process of light emitting diode (LED) module group and LED module group

InactiveCN103094425AEasy to produceReduce manufacturing costSemiconductor devicesReflection lossTransmittance

A manufacturing process of a light emitting diode (LED) module group includes the following steps: (1), LED components without light-out lenses are welded on a circuit board; (2), the circuit board of the step one is fixed on a radiator, and the bottom of the circuit board is tightly attached to the radiator to form surface contact; (3), molding gel is filled in each concaved pit in the inner surface of an inverted lens module group and matched with the light refraction index of the lens module group; (4), the radiator of the step two is buckled on the lens module group in an inverted mode, the concaved pits filled with the gel correspond to the LED components and then is pressed tightly, and the LED components are completely coated with the molding gel and air is not residual between the LED components and the molding gel; (5), and the lens module group and the radiator are fixed to form the LED module group. Only the molding gel exists between the lens muddle group and an LED light source, the air is not included, light rays pass through a few media, transmittance is high, the filled gel is matched with the refraction index of the lens module group, reflection losses are few, and the light-out rate of the LED module group is improved. In addition, the LED light source only comprises a chip and an encapsulation support, the light-out lens is not included, and the cost is reduced.

Owner:HANGZHOU HPWINNER OPTO CORP

Scintillation microcrystalline glass embedded with YAG microcrystalline phase and preparation method of scintillation microcrystalline glass

InactiveCN108147669ASize limitGuaranteed uniformityMaterial analysis using wave/particle radiationDevitrificationFluorescence

The invention relates to scintillation microcrystalline glass embedded with a YAG microcrystalline phase and a preparation method of the scintillation microcrystalline glass. The scintillation microcrystalline glass and the preparation method thereof are characterized in that the microcrystalline phase is YAG, activation ions are one or two of Ce<3+> and Tb<3+>, the activation ions are evenly doped into the YAG microcrystalline phase, and the YAG microcrystalline phase is evenly distributed in the scintillation microcrystalline glass; the chemical components of matrix glass are only yttrium oxide and aluminum oxide, the matrix glass is doped with the rare-earth ions Ce<3+> and Tb<3+>, transparent glass is prepared by a container-free solidification method or a flame floatation method, thetransparent glass is subjected to thermal treatment under Tg temperature, and the YAG microcrystalline phase is spontaneously separated out without devitrification; the YAG microcrystalline glass is high in crystallinity and transparency, short in fluorescence service life, excellent in scintillation performance, capable of emitting green light, green and yellow light or yellow light under X-ray excitation and capable of being used as an X-ray detection scintillation material.

Owner:WUHAN UNIV OF TECH

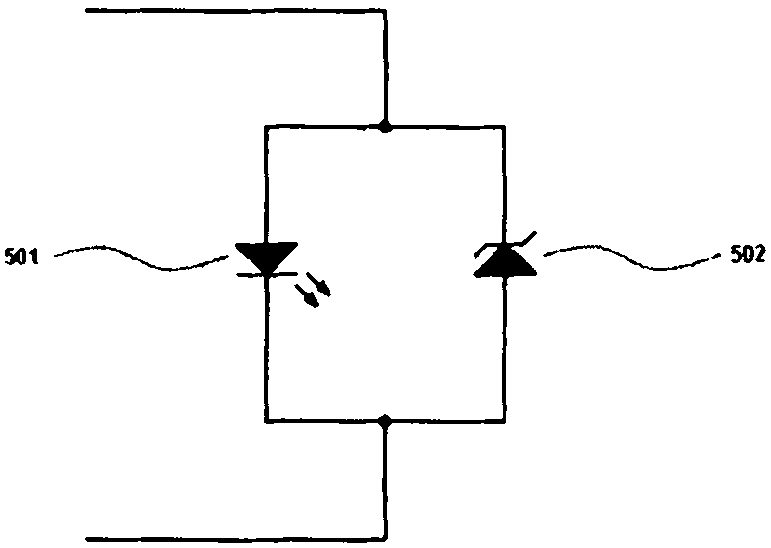

LED based on photonic crystal-single-layer graphene structure

InactiveCN103489982AIndex matchingEquivalent Index MatchingSemiconductor devicesQuantum wellPhotonic crystal structure

The invention discloses an LED based on a photonic crystal-single-layer graphene structure, and belongs to the technical field of LEDs. The LED sequentially comprises a silicon dioxide protective layer, monoatomic-layer graphene, a contact layer (not essential), an LED chip p-GaN layer, an LED chip multi-quantum well light emitting layer, an LED chip n-GaN layer and a sapphire substrate from top to bottom, wherein the LED chip p-GaN layer is of a photonic crystal structure, and the protective layer covers all the portions except for a positive electrode and a negative electrode. The structure of combining the photonic crystal and the single-layer graphene is adopted, so that the aim of greatly improving the light emitting efficiency and being free of using an ITO at the same time is achieved.

Owner:BEIJING UNIV OF TECH

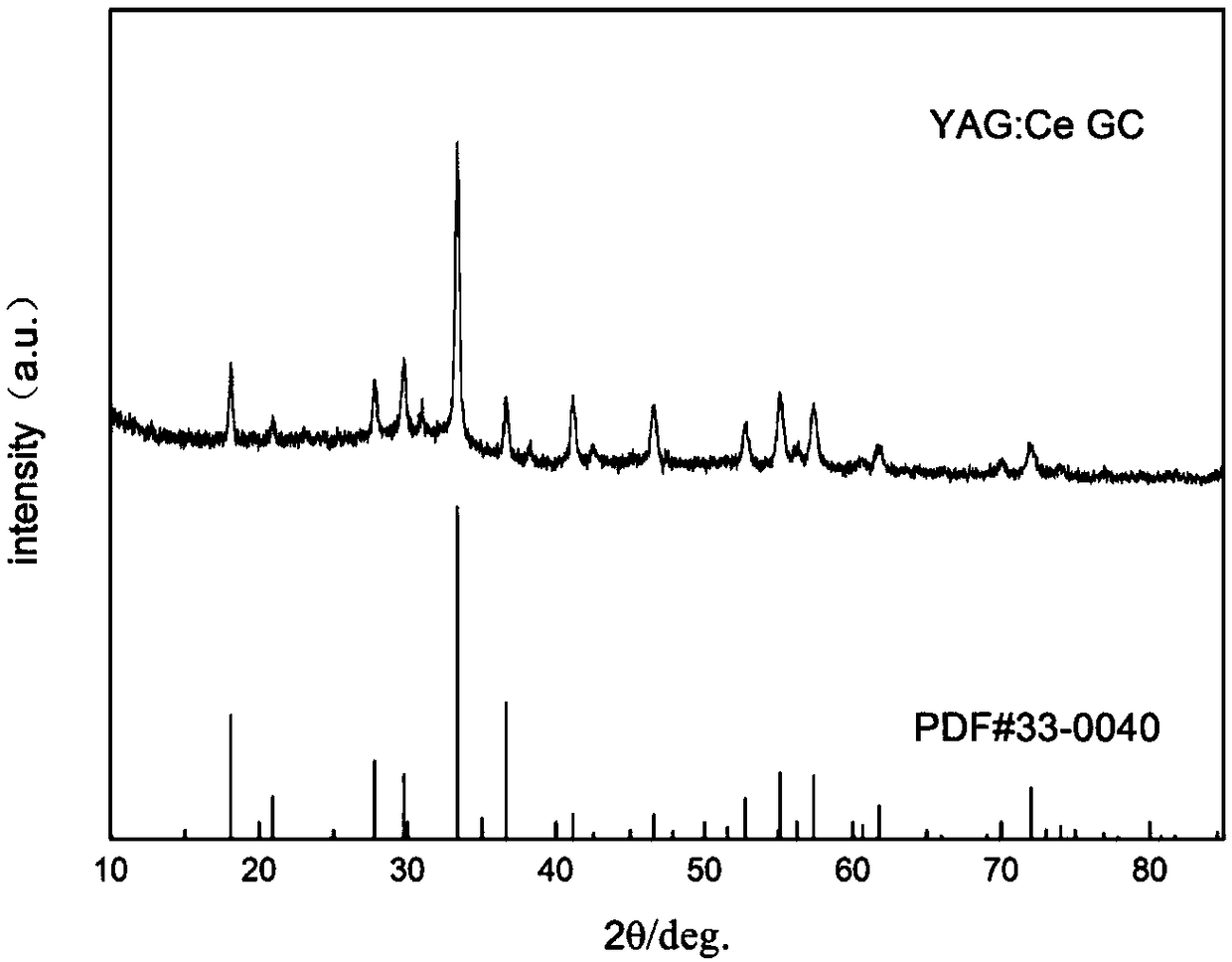

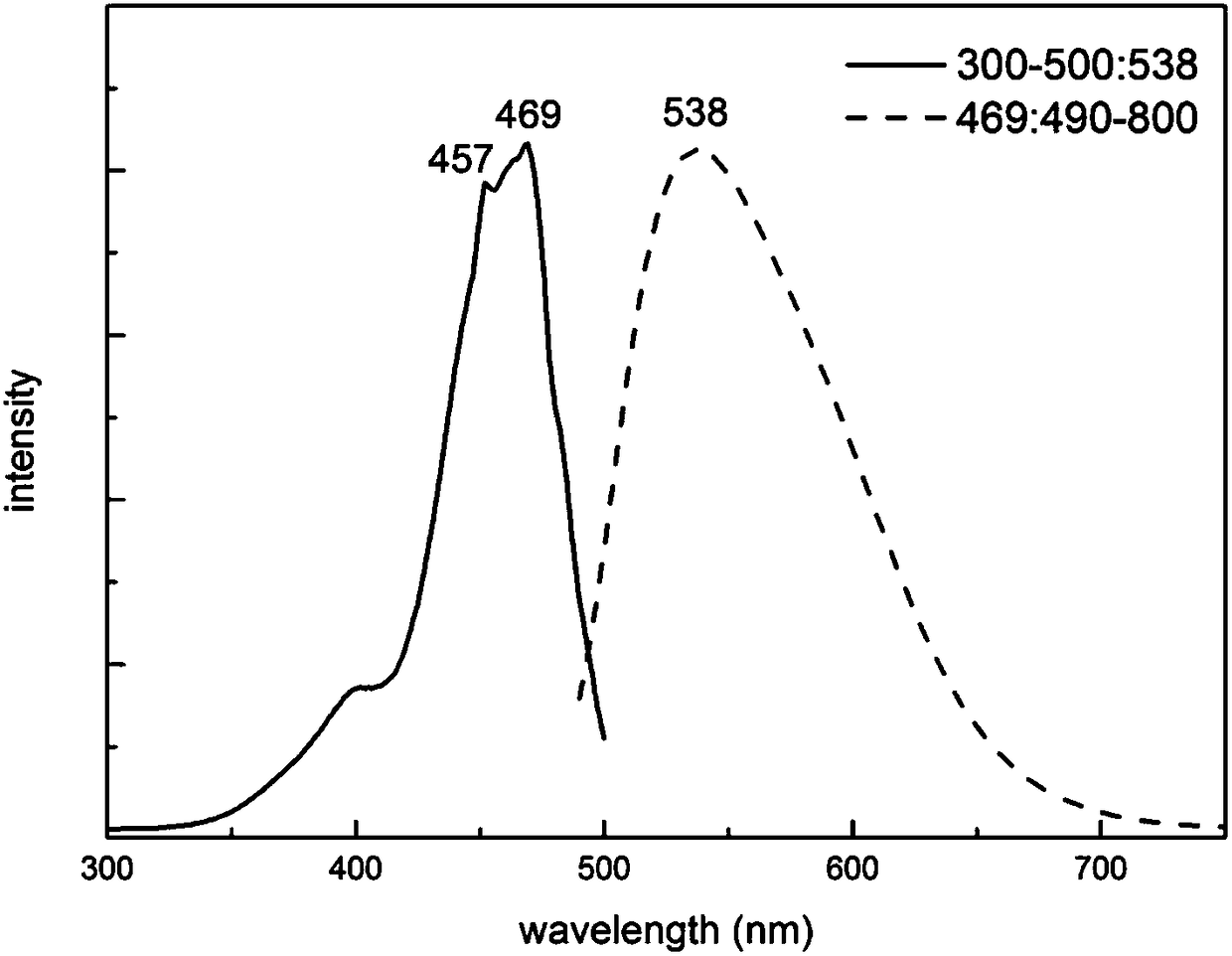

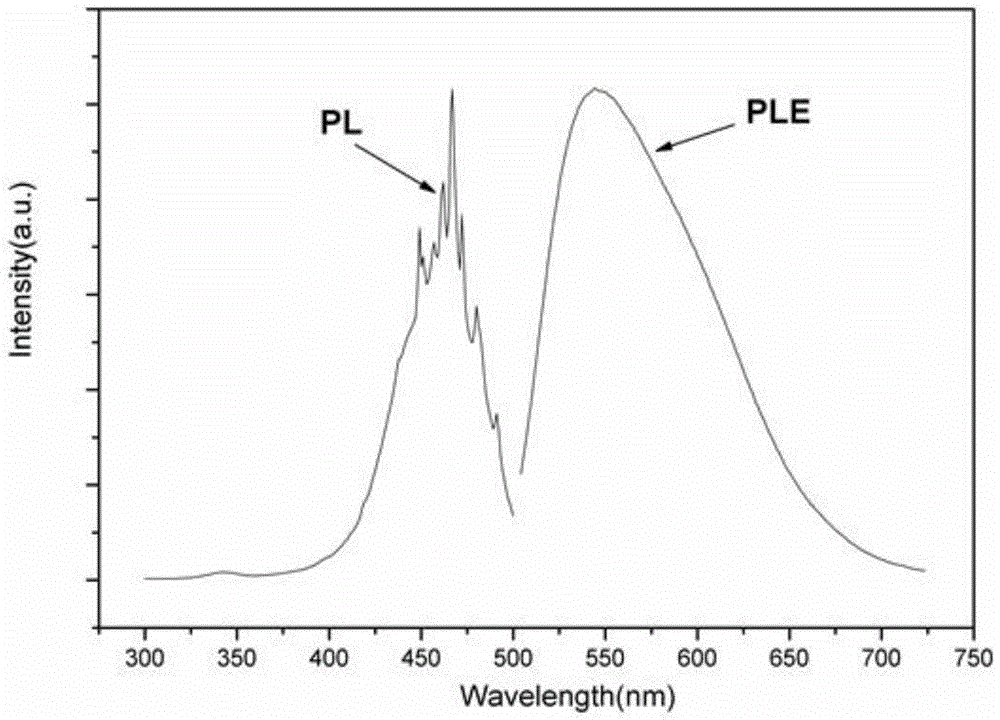

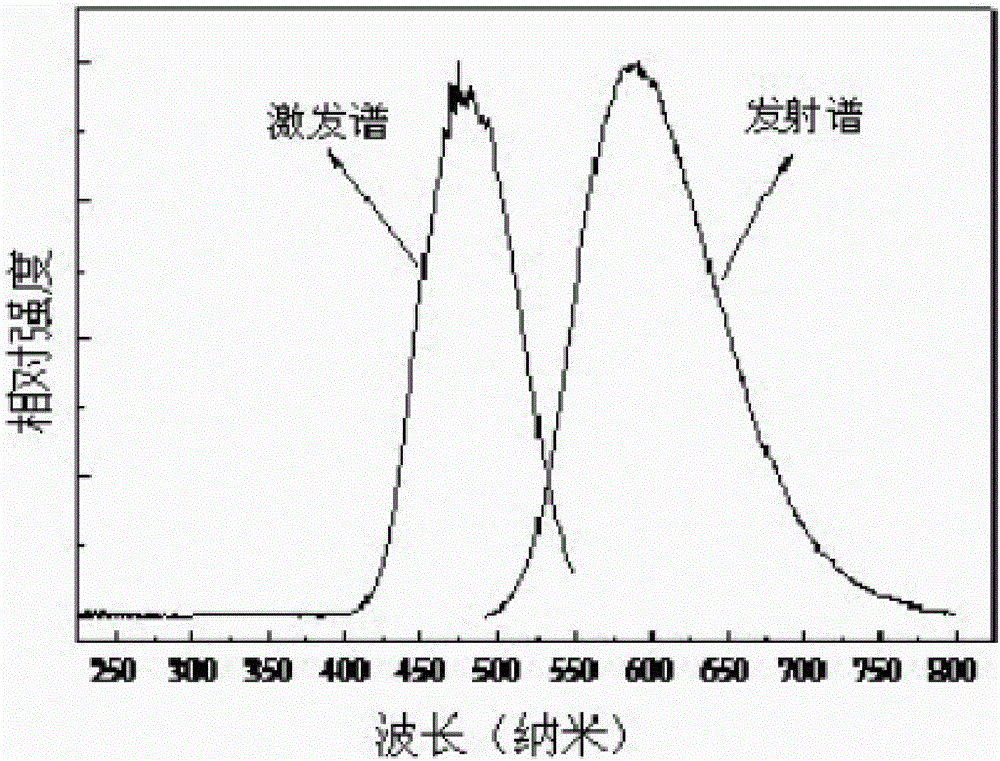

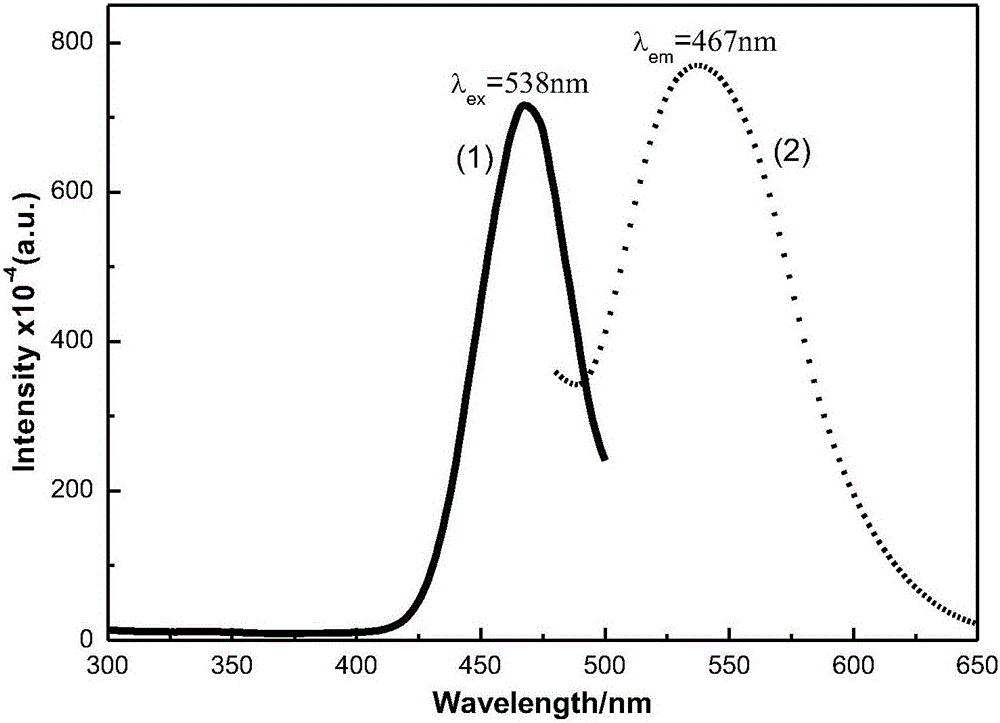

Transparent Ce:YAG microcrystalline glass and application of transparent Ce:YAG microcrystalline glass in white LED

The invention discloses transparent Ce:YAG microcrystalline glass and application of the transparent Ce:YAG microcrystalline glass in a white LED. The microcrystalline glass is self-crystallized, and is prepared from the following active materials in percentage by mole: 19-30mol% of SiO2, 15-30mol% of Al2O3, 5-20mol% of Y2O3, 40-60mol% of PbO, 0.5-5mol% of CeF3 and 2-10mol% of B2O3, wherein the sum of the mole percentage of the components is 100 percent. The Ce:YAG microcrystalline glass disclosed by the invention meets the requirements that the glass melting temperature is low, a preparation method is simple, the raw materials are readily available, the production cycle is short, the batch production is easily realized, and the glass is stable in physicochemical properties, high in uniformity, long in service life and high in heat conductivity; and moreover, the Ce:YAG microcrystalline glass emits bright yellow light under blue light excitation of 465nm, the yellow light and blue light are combined to generate strong white light, and the microcrystalline glass can be used for preparing the white LED.

Owner:WENZHOU UNIVERSITY

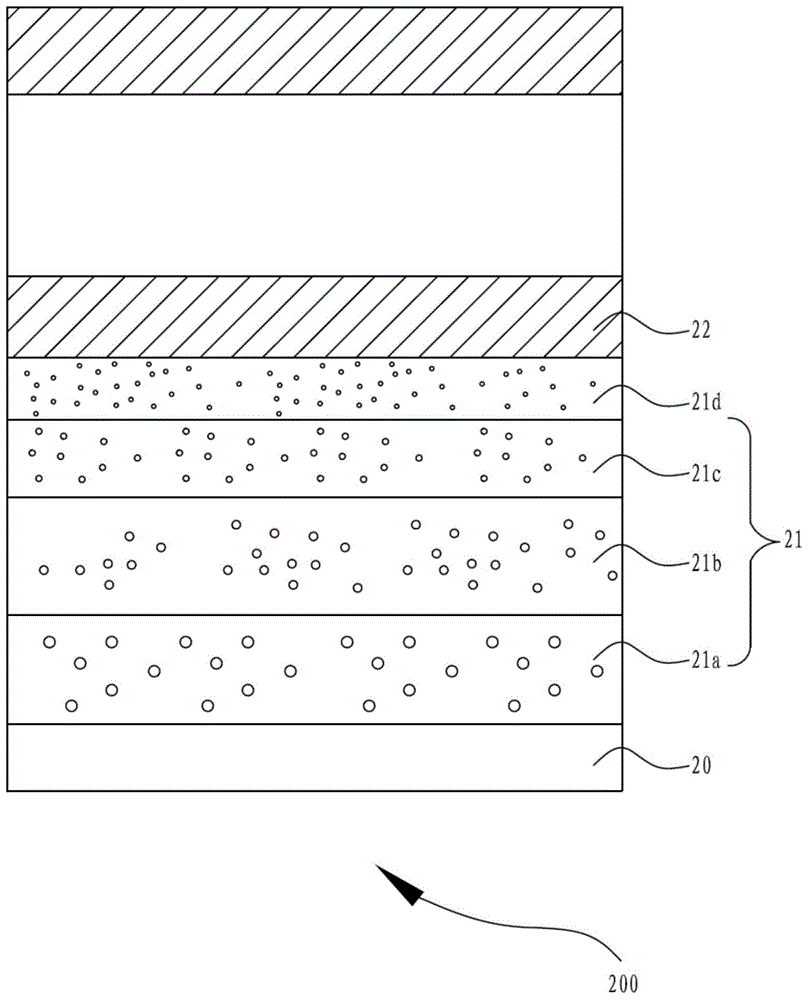

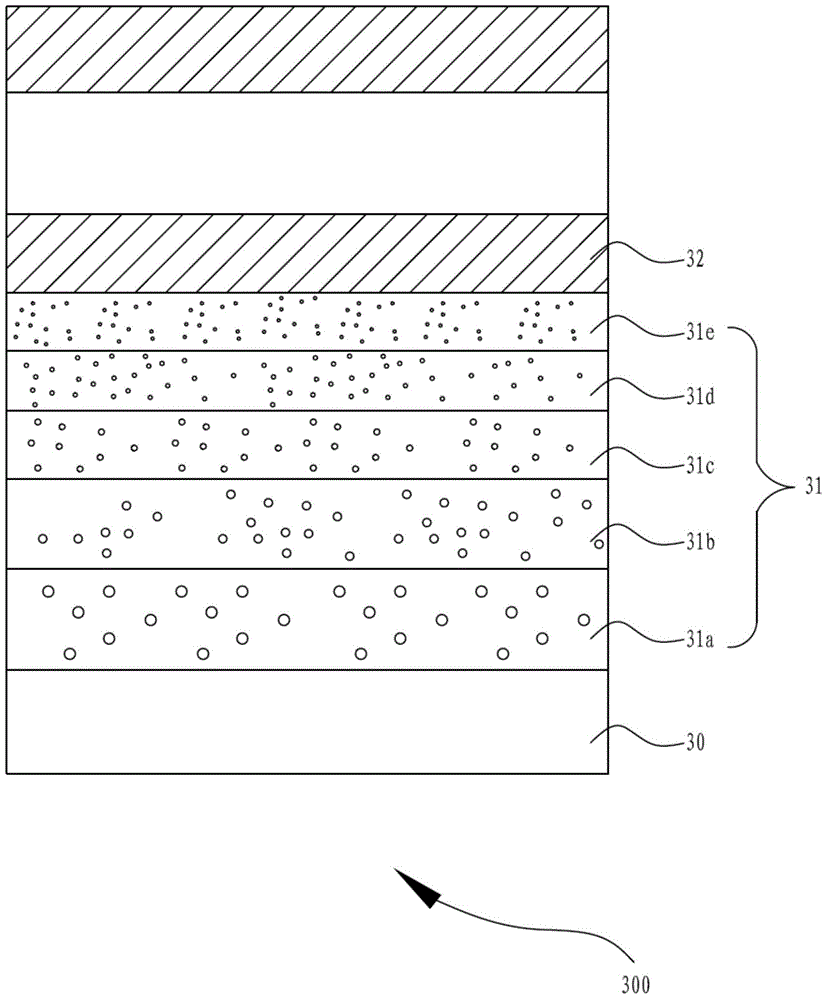

Organic light emission diode device and fabrication method thereof

InactiveCN104218173AImprove light extraction efficiencyGood light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereMixed materials

The invention provides an organic light emission diode device. The organic light emission diode device comprises a substrate and an anode, a light emission functional layer and a cathode which are sequentially laminated on the substrate, a light matching layer and a light extraction layer are sequentially arranged on the surface of the cathode, the material of the light extraction layer comprises nanoparticles and a polymer material, the nanoparticles are ceramic or high-polymer material particles with the grain size of 50 to 1,500 nanometers, the polymer material is a heat cured polymer or photo cured polymer material, the thickness of the light extraction layer is 10 to 100 micrometers, the material of the light matching layer is a mixed material formed by metal and an organic material, the metal is silver, aluminum or magnesium, and the organic material is N,N'-diphenyl-N,N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-diamine, copper phthalocyanine or 8- hydroxyquinoline aluminum. The luminous efficiency of the cathode of the organic light emission diode device is high, so that the luminous efficiency of the device is improved. The invention also provides a fabrication method of the organic light emission diode device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

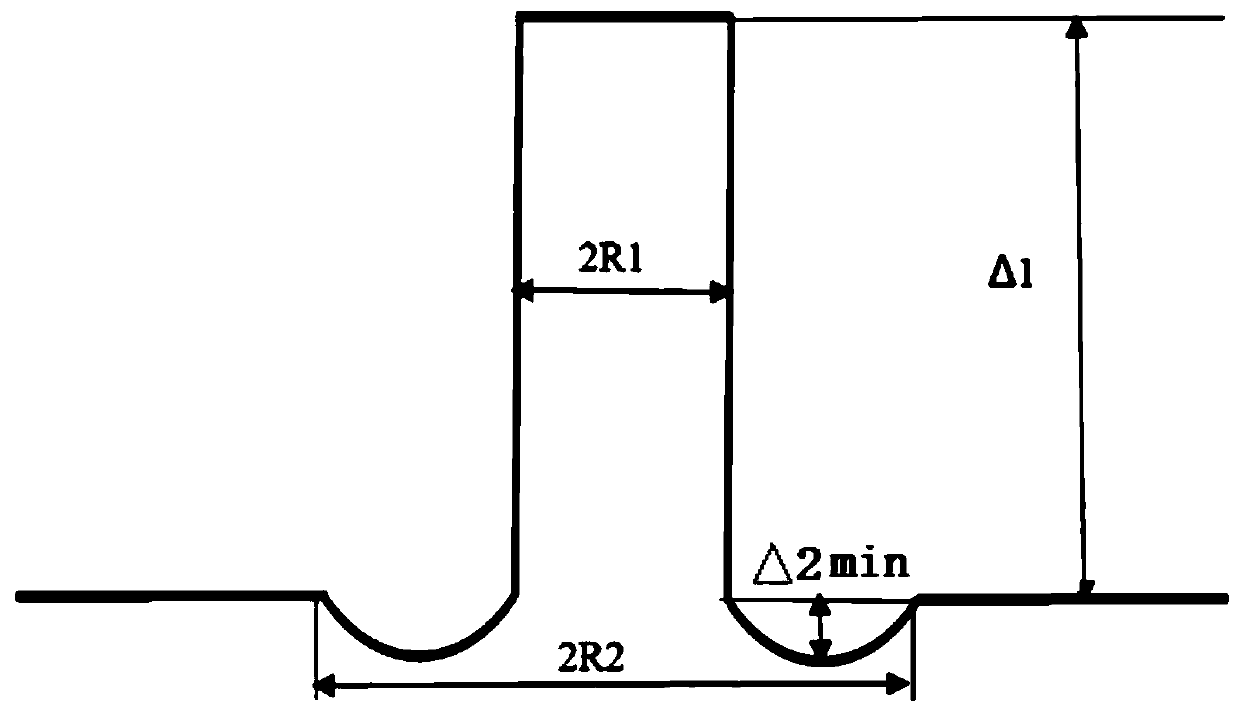

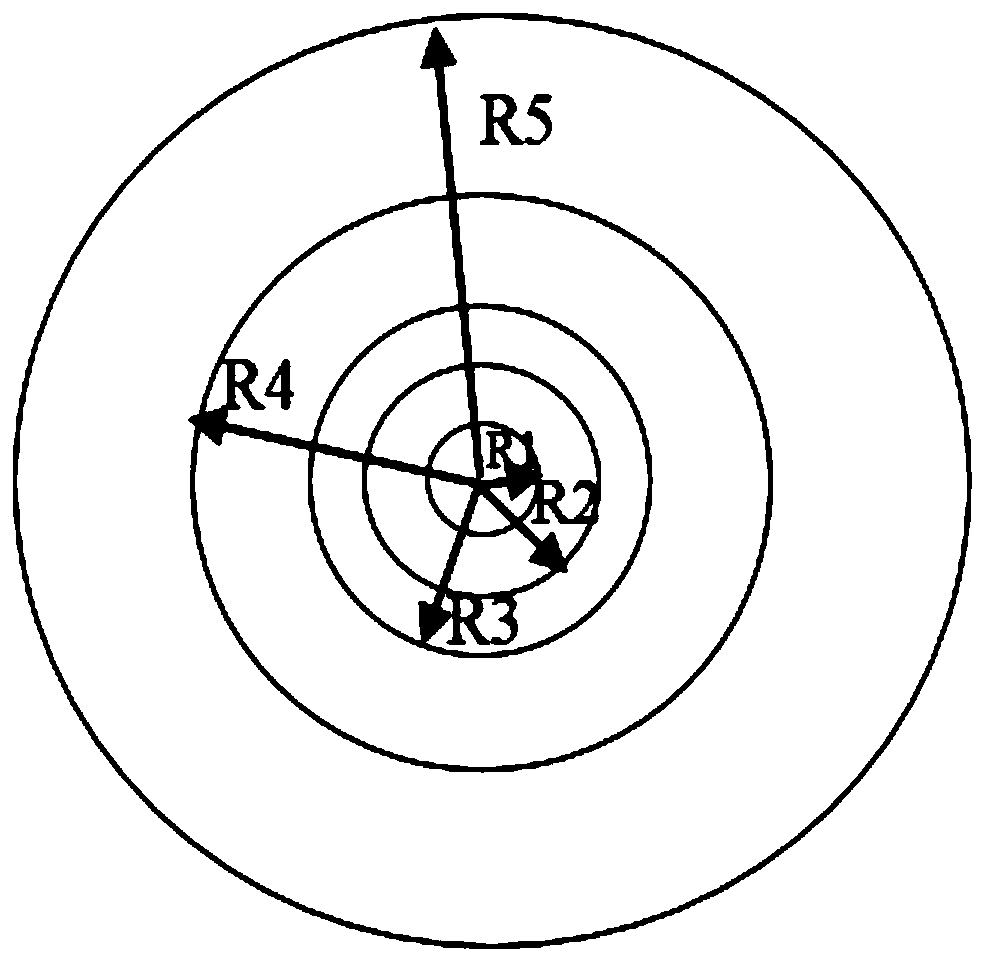

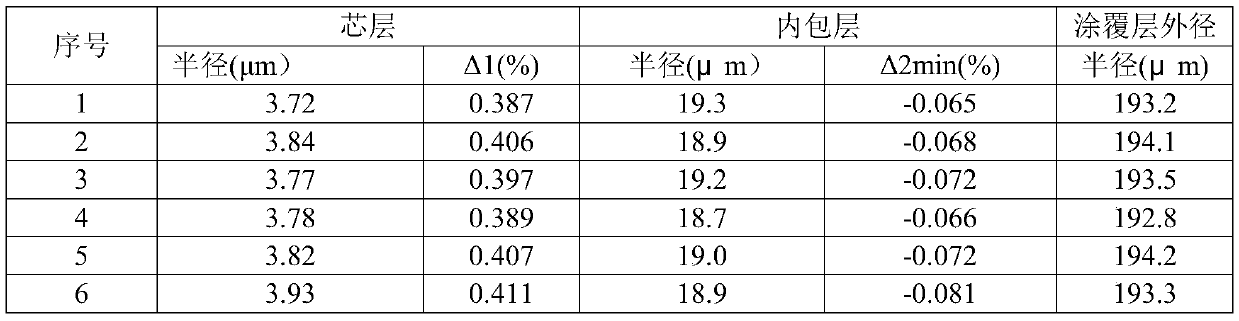

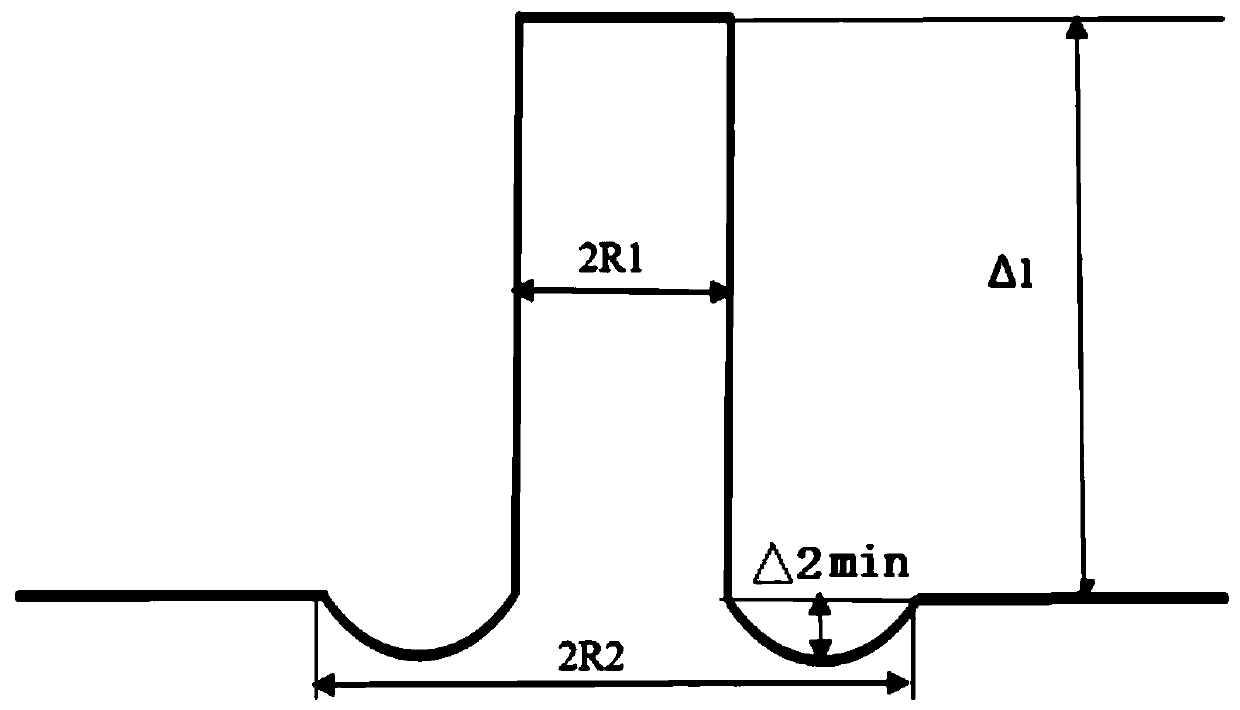

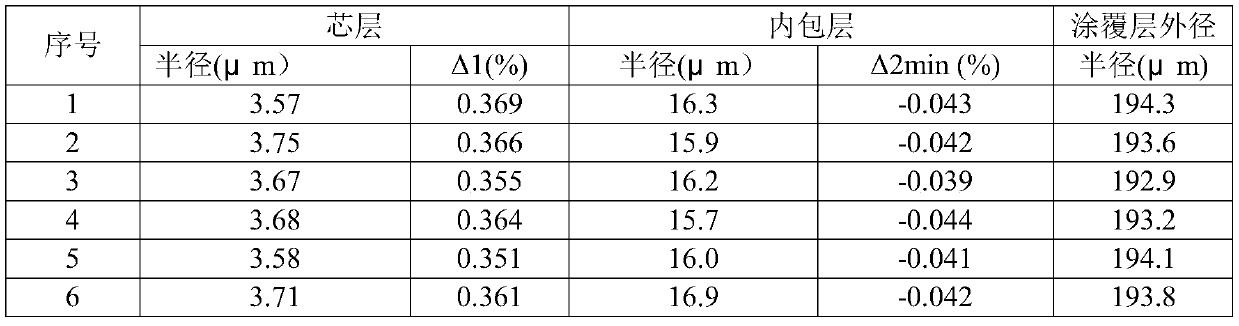

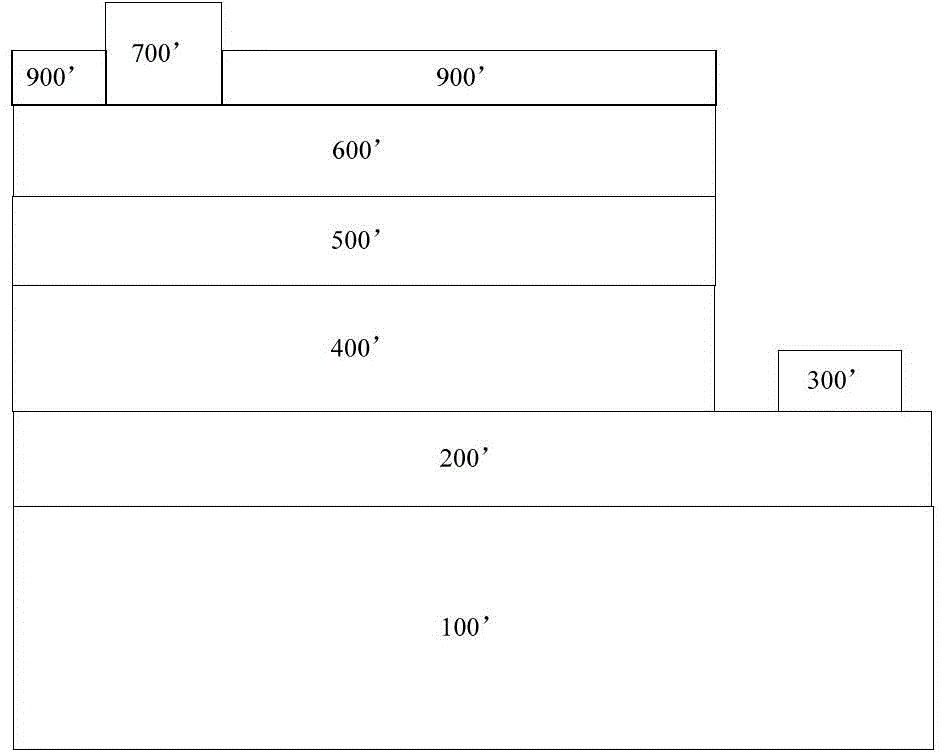

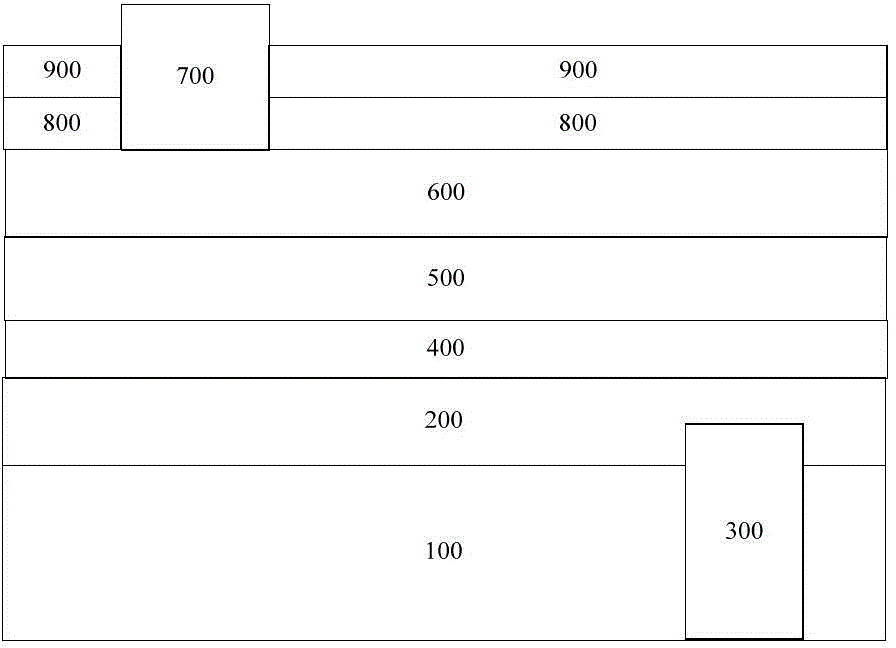

Small-outer-diameter bending insensitive single-mode optical fiber

ActiveCN111399113ALow bending lossImprove bending performanceGlass making apparatusOptical fibre with graded refractive index core/claddingRelative refractive indexSilicon dioxide

The invention relates to a small-outer-diameter bending insensitive single-mode optical fiber. The optical fiber comprises a core layer and a cladding layer, the diameter 2R1 of the core layer is 7.4to 7.8 mu m; the relative refractive index difference is delta 1; the cladding sequentially comprises a sunken inner cladding and an outer cladding from inside to outside; the diameter 2R2 of the sunken inner cladding is 34-40 [mu] m; the refractive index of the sunken inner cladding is distributed in a sunken shape; the minimum relative refractive index difference is delta 2 min; the refractive index difference delta total between the core layer and the inner cladding is equal to delta 1-delta 2 min; the range of delta total is 0.44%-0.52%, and the range of delta total is 0.44%-0.52%; and therelative refractive index difference distribution relationship between the core layer and the sunken inner cladding meets the following condition: the relative refractive index difference distribution relationship is shown in the specification. The absolute value of delta 1 / delta 2 min is 4.5-6.5; wherein the outer cladding is a pure silicon dioxide outer cladding, the relative refractive index difference delta 3 of the outer cladding is 0%, the diameter 2R3 of the outer cladding is 123-125 [mu] m, the outer cladding is coated with the inner coating layer and the outer coating layer, the diameter 2R4 of the inner coating layer is 163-170 [mu] m, and the diameter 2R5 of the outer coating layer is 190-195 [mu] m. Through optimization of a section structure and a coating process, the opticalfiber not only has a large mode field diameter, but also has low bending loss and good micro-bending performance.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Visual fuel rod

ActiveCN109659042AMeet the requirements of mechanical strengthEasy collimation installationOptical rangefindersFuel elementsAutomotive engineeringMeasuring equipment

The invention provides a visual fuel rod. The visual fuel rod is characterized in that the visual fuel rod includes a lower plug (1), a fuel shell (2), a liquid column (3), an upper plug (4) and a positioning winding wire (5). The liquid column (3) is arranged in the fuel shell (2). The refractive index deviation of the liquid column (3) and the fuel shell (2) is within a range of 1%. The lower plug (1) and the upper plug (4) are connected to the two ends of the fuel shell (2) so as to seal the liquid column (3) in the fuel shell (2). The positioning winding wire (5) wraps and is fixed to theouter surface of the fuel shell (2). Through the arrangement of liquid with the same or similar refractive index with the fuel shell (2) in the fuel shell (2), the requirements of optical velocity measuring equipment for refractive index matching and transmittance can be satisfied, and the requirements of mechanical strength can be satisfied. The visual fuel rod can be used for studying a velocityfield, a pressure field and the like inside a fuel assembly.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

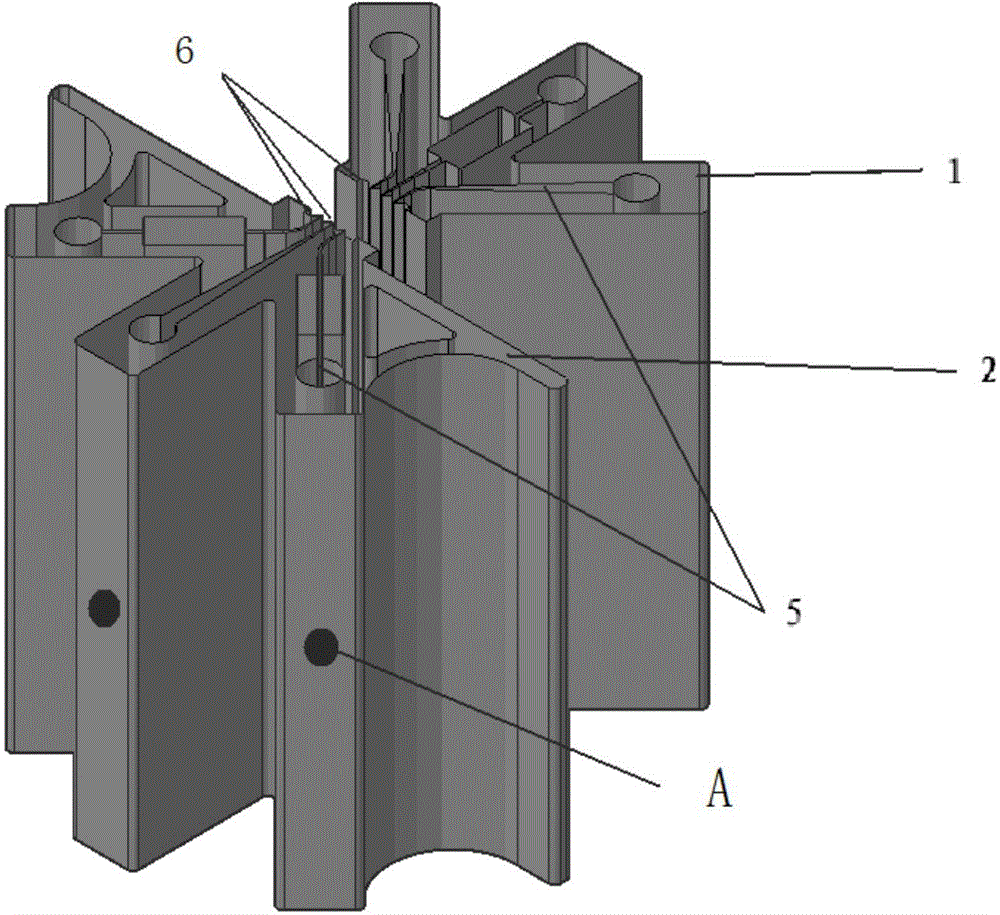

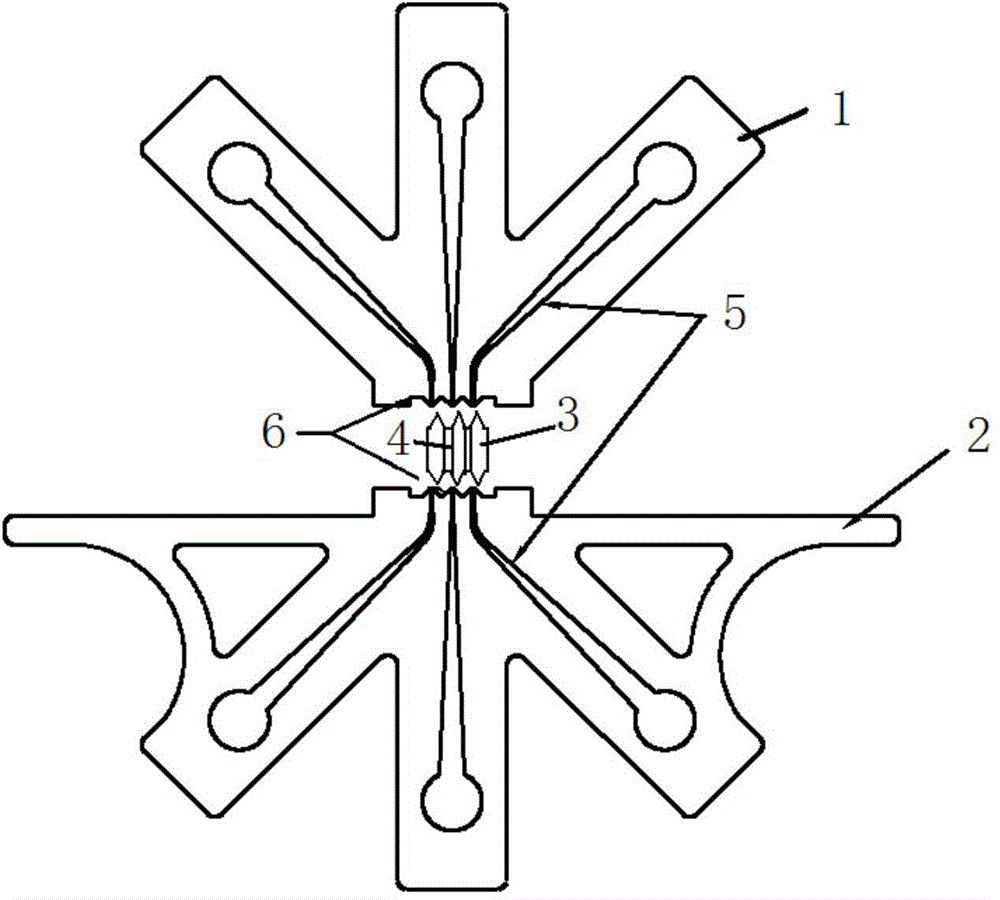

Novel diode-pumping immersion-type liquid-cooling solid laser gain pool

The invention relates to the technical field of novel lasers, more specifically, a novel diode-pumping immersion-type liquid-cooling solid laser gain pool. The gain pool can solve problems that an immersion-type liquid-cooling solid laser is difficult in uniform heat dissipation, and poor in light beam quality. The gain pool consists of an upper support (1), a lower support (2), a quartz window (3), a gain medium (4), and two end cover plates. The gain pool ingeniously employs a technical route of single-cavity oscillation, and prolongs an optical path while guaranteeing the compact structure of a laser. The gain pool achieves the uniform cooling of two surfaces of the gain medium (4) through the laminar flow of high-pass liquid, ingeniously builds the technology of heat management, and improves the light beam quality of the laser.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

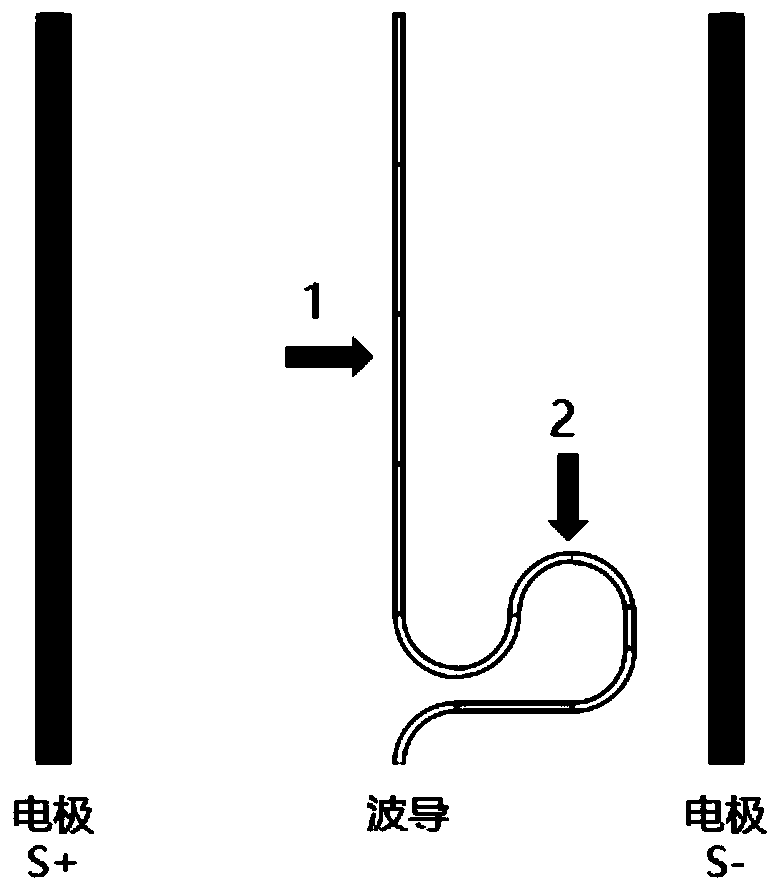

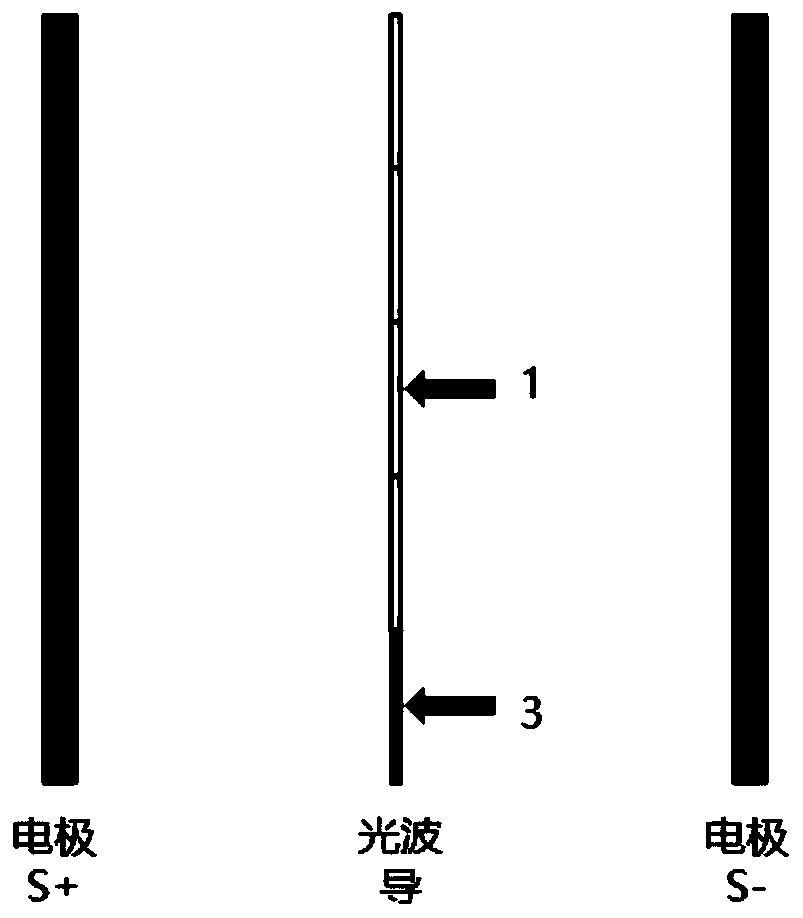

Electrooptical modulator with electrodes and waveguide groups matched in refractive index and design method thereof

The invention discloses an electrooptical modulator with electrodes and waveguide groups matched in refractive index and a design method of the electrooptical modulator, and relates to the technical field of optical communication devices. The electrooptical modulator comprises a plurality of periodically repeated electro-optical modulation units, the electrodes of the electro-optical modulation units and the waveguides are equal in equivalent length, and each electro-optical modulation unit comprises a radio frequency electrode and a waveguide. The length of each radio frequency electrode is one cycle length L of the electro-optical modulator, and the waveguide comprises a first part and a second part which are connected in sequence. The first part is an optical waveguide of the modulator,and the second part is a photonic crystal waveguide with a delay function. Meanwhile, the length of the photonic crystal waveguide needs to meet the following condition that X * Np + (L-X) * No = L *Ne. The electrooptical modulator with the electrodes and the waveguide groups matched in refractive index is simple in structure, can effectively achieve the refractive index matching of the electrodes and the waveguide groups, is easy to achieve and is lower in cost.

Owner:WUHAN POST & TELECOMM RES INST CO LTD +1

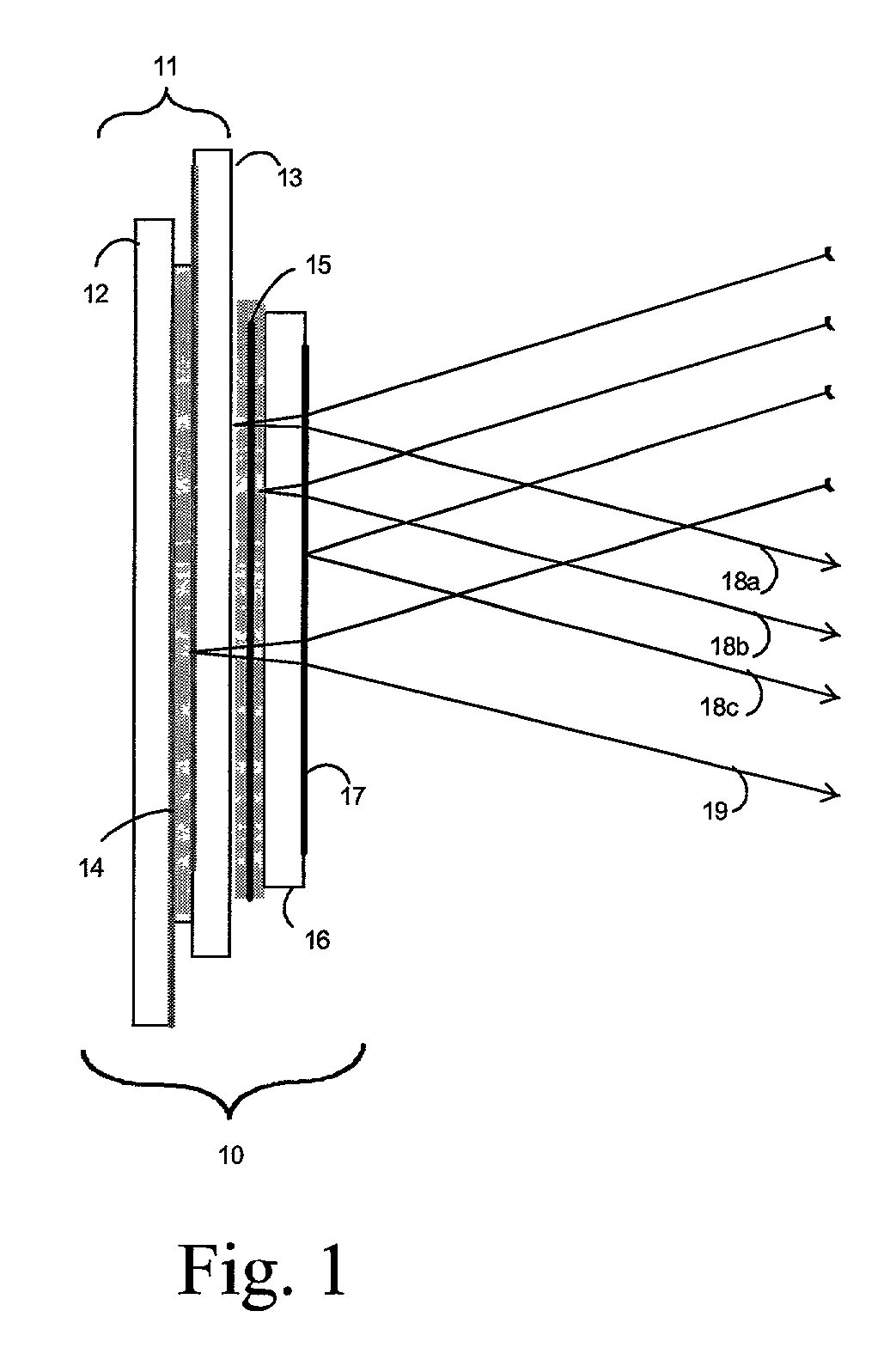

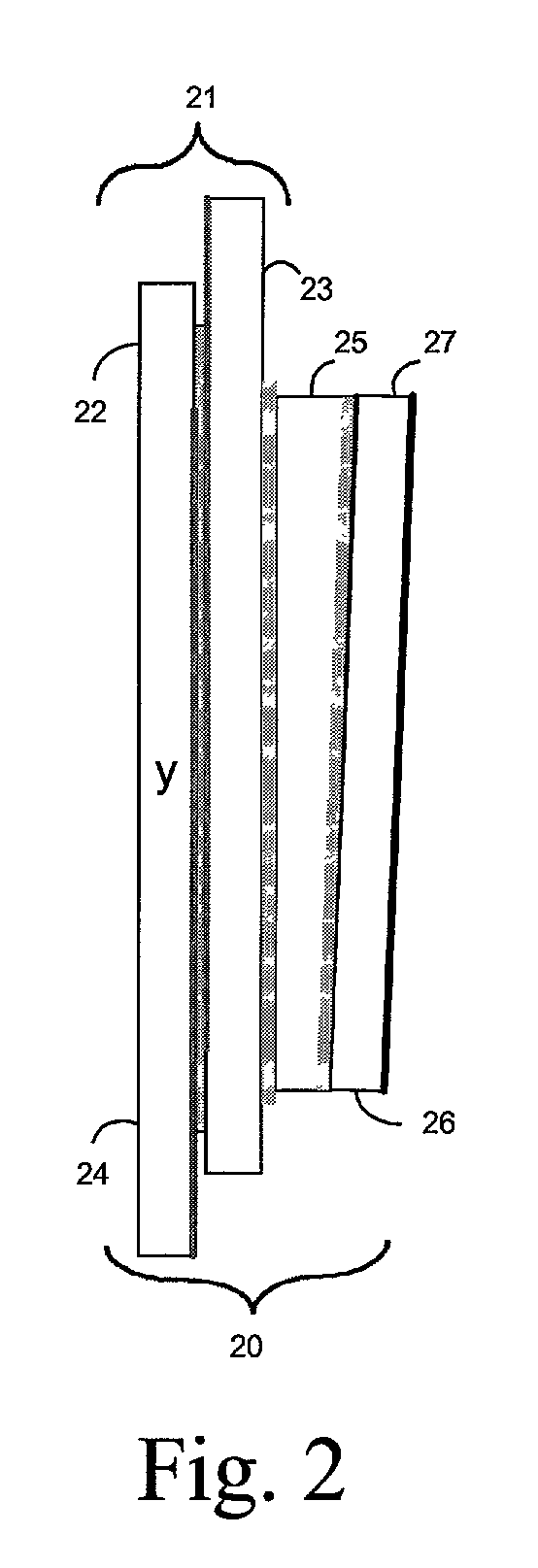

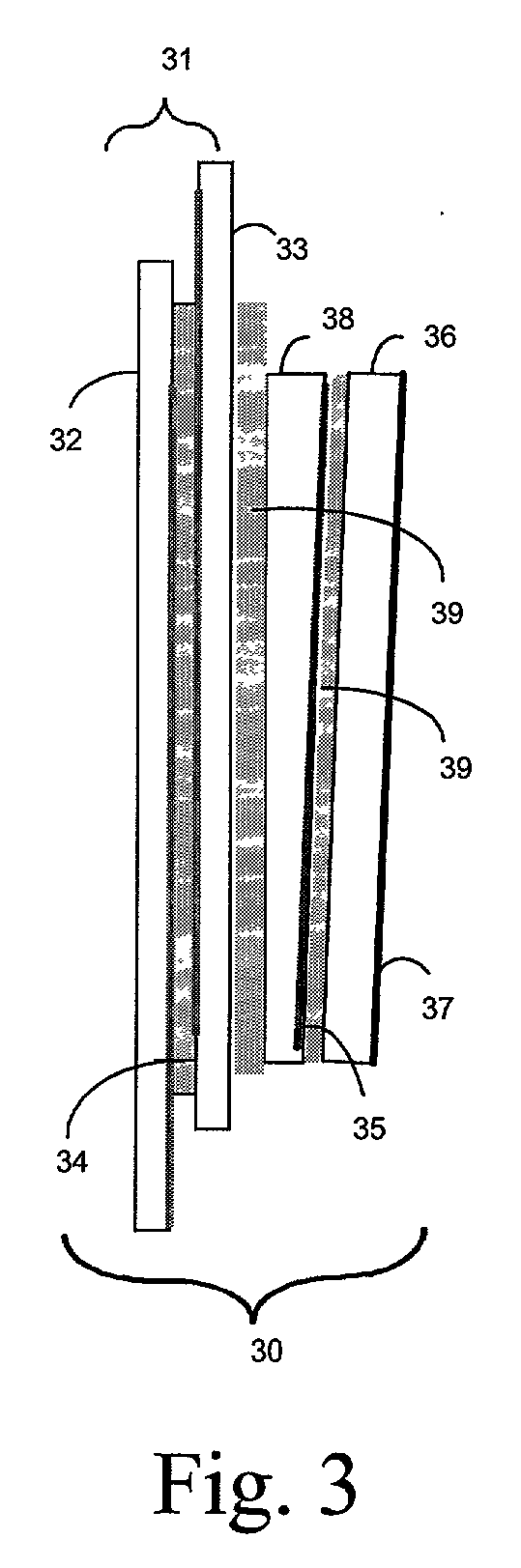

Liquid crystal cell for use in coherent beams

InactiveUS20010050738A1Eliminating high-order interferenceImprove matchCoupling light guidesNon-linear opticsOptical coatingLight beam

A liquid crystal cell assembly is described which eliminates high-order multiple-beam interference from reflections at the interfaces between the various elements. It can incorporate fixed retarders for compensation or production of high retardances. The invention enables standard, economical methods to be used in making the liquid crystal cell, retarder elements, optical coatings, and overall assembly. Transmissive and reflective embodiments are shown.

Owner:CAMBRIDGE RES & INSTR

LED (Light Emitting Diode) module based on ceramic-based PCB (Printed Circuit Board) and manufacturing process thereof

InactiveCN102376699AImprove cooling effectIndex matchingPrinted circuit detailsSolid-state devicesColloidEngineering

The invention relates to an LED (Light Emitting Diode) module based on a ceramic-based PCB (Printed Circuit Board) and a manufacturing process thereof. The LED module comprises a heat radiator, the ceramic-based PCB, an LED chip, a package colloid, a sealing silicon rubber and a lens module, wherein the LED chip is coated by fluorescent powder, is loaded on the ceramic-based PCB and is welded to an electrode bonding pad of an electrical layer of the ceramic-based PCB through a lead; the ceramic-based PCB is attached to the heat radiator; the lens module is arranged above the LED chip; and a lens concave pit on the lens module is filled with the package colloid. The LED chip is directly welded on a circuit board, so that the heat of the LED chip is directly diffused to the circuit board with high conductivity and the heat radiator and the heat radiating effect is improved. The package colloid is only arranged between the lens module and the LED chip; media through which the light passes are fewer; in addition, the refractive index of the filled colloid is matched with that of the lens module, so that the light emitting rate of the LED module is improved.

Owner:HANGZHOU HPWINNER OPTO CORP

Glass ceramics, process for preparing same and remote warm white-light LED device

ActiveCN106277799AEffective adjustment of refractive indexIndex matchingSemiconductor devicesGlass matrixToxicity

The invention relates to the technical field of LED white-light illumination, in particular to glass ceramics, a process for preparing the same and a remote warm white-light LED device. The glass ceramics, the process and the remote warm white-light LED device have the advantages that the transparent glass ceramics with Y3Mg2AlSi2O12:Ce, Re crystal grains which are uniformly inlaid in oxide glass matrixes can be obtained by the aid of the process; raw material ratios are adjusted, so that the refractive index of glass can be effectively regulated, the refractive index of the Y3Mg2AlSi2O12:Ce, Re crystal grains and the refractive indexes of the glass matrixes can be matched with one another, scattering can be reduced, and the transparency of the glass ceramics can be improved; the process for preparing the glass ceramics is simple, is low in cost, free of toxicity or pollution and excellent in thermal and chemical stability, and reaction conditions are easy to control; bright orange light can be emitted by the remote warm white-light LED device with the glass ceramics when the remote warm white-light LED device is excited by nanometer blue light, and the orange light and blue light of chips can be combined with each other to form warm white light.

Owner:福建省德化县腾兴陶瓷有限公司

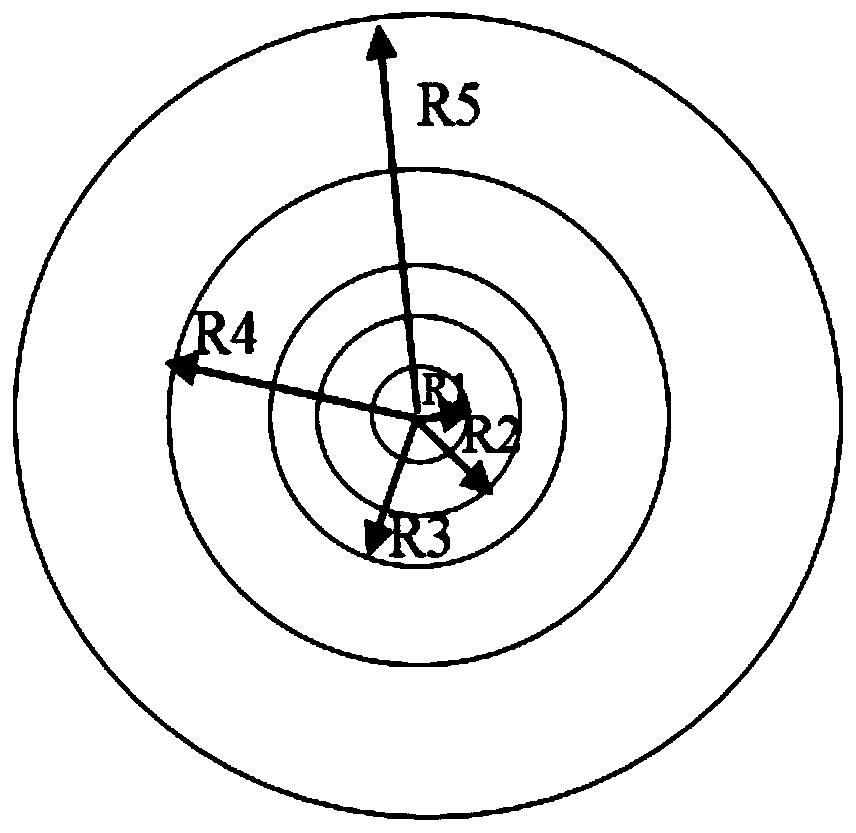

Small-outer-diameter single-mode optical fiber

ActiveCN111381314ALow bending lossImprove bending performanceGlass optical fibreOptical fibre with graded refractive index core/claddingRelative refractive indexSilicon dioxide

The invention relates to a small-outer-diameter single-mode optical fiber, which comprises a core layer and a cladding, and is characterized in that the diameter 2R1 of the core layer is 7.0-7.4[mu]m,the relative refractive index difference is [delta]1, the cladding sequentially comprises a sunken inner cladding and an outer cladding from inside to outside, the diameter 2R2 of the sunken inner cladding is 26-34[mu]m, the refractive index of the sunken inner cladding is distributed in a sunken shape, the minimum relative refractive index difference is [delta]2min, the refractive index difference [delta]total between the core layer and the inner cladding is equal to ([delta]1-[delta]2min), the range of [delta]total is 0.37-0.44%, and the relative refractive index difference distribution relationship between the core layer and the sunken inner cladding meets the following condition: the absolute value of [delta]1 / [delta]2min ranges from 7.5 to 10, the outer cladding is a pure silicon dioxide outer cladding, the relative refractive index difference [delta]3 of the outer cladding is 0%, the diameter 2R3 of the outer cladding is 124-126[mu]m, the outer cladding is coated with an inner coating and an outer coating, the diameter 2R4 of the inner coating is 150-170[mu]m, and the diameter 2R5 of the outer coating is 180-220[mu]m. Through optimization of a section structure and a coatingprocess, the optical fiber not only has a large mode field diameter, but also has low bending loss and good micro-bending performance.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

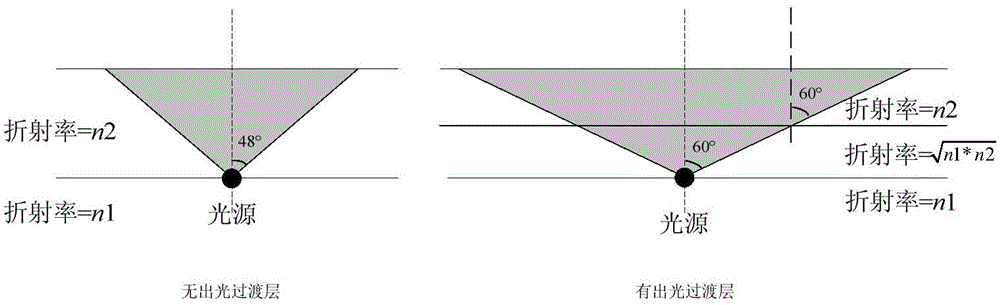

LED chip and forming method thereof

ActiveCN104659161AGood shotBroaden the light output angleSemiconductor devicesMultiple quantumRefractive index matching

The invention discloses an LED chip and a forming method thereof. The LED chip comprises a substrate, a first doped semiconductor layer, a first electrode, multiple quantum wells, a second doped semiconductor layer, a current diffusion layer, a second electrode, a light-exiting transition layer and a passivation layer, wherein the first doped semiconductor layer is arranged on the substrate; the first electrode is in contact with the first doped semiconductor layer; the multiple quantum wells are arranged on the first doped semiconductor layer; the second doped semiconductor layer is arranged on the multiple quantum wells; the current diffusion layer is arranged on the second doped semiconductor layer; the second electrode is arranged on the first region of the current diffusion layer; the light-exiting transition layer is arranged on the second region of the current diffusion layer; the passivation layer is arranged on the light-exiting transition layer; the refractive indexes of the current diffusion layer, the light-exiting transition layer and the passivation layer are matched. The LED chip disclosed by the invention has the advantages of large light-exiting angle and the like.

Owner:BYD SEMICON CO LTD

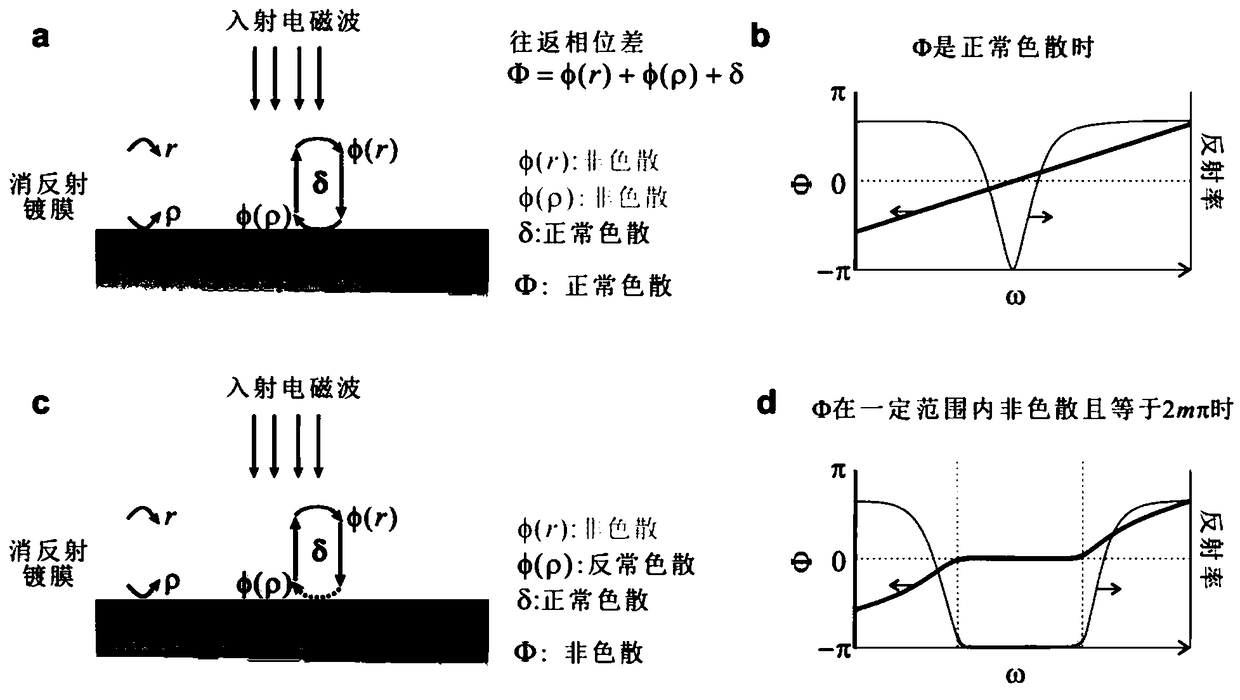

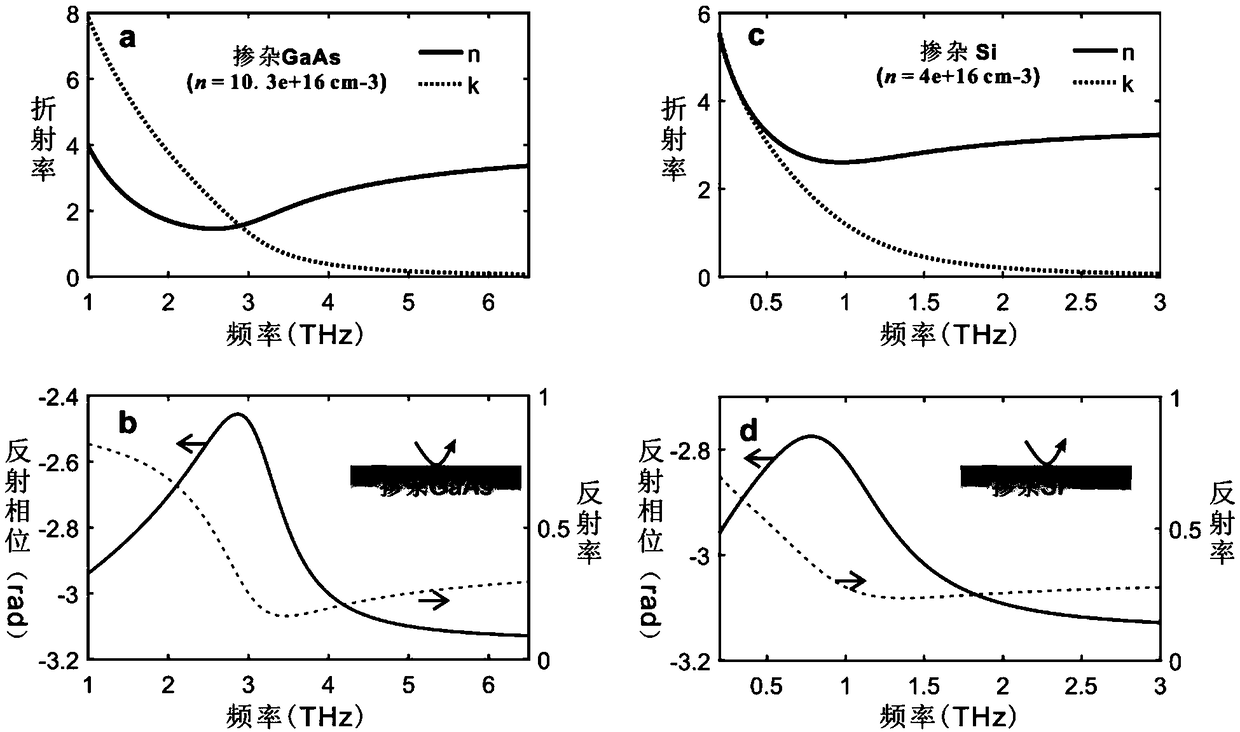

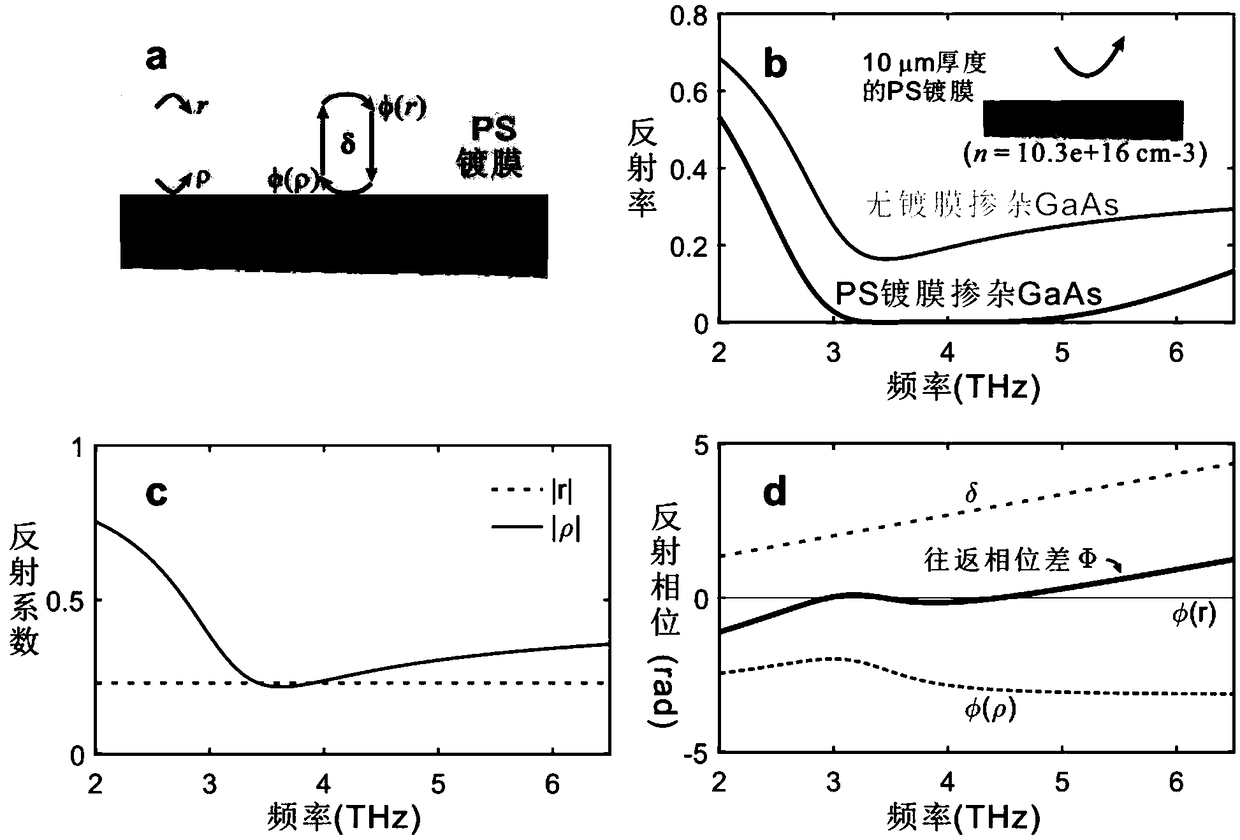

Terahertz broadband absorber based on doped semiconductor with coating film

ActiveCN108761587AStrong absorption propertiesSatisfy the amplitude condition of the reflectionOptical elementsHigh absorptionRefractive index

The present invention relates to a Terahertz broadband absorber based on a doped semiconductor with a coating film. The Terahertz broadband absorber comprises a doped semiconductor layer and a coatingfilm layer, the coating film layer is arranged at the upper portion of the doped semiconductor layer, the doped semiconductor has high absorption features at the Terahertz waveband and has a refractive index showing Drude dispersion, and the reflection phase of the doped semiconductor has anomalous dispersion at some frequencies of the Terahertz, namely, the reflection phase is reduced with the increasing of the frequency. The Terahertz broadband absorber employs the anomalous dispersion of the doped semiconductor in the Terahertz waveband reflection phase to perform coating film on the dopedsemiconductor to allow the anomalous dispersion of the doped semiconductor reflection phase to be mutually offset with the normal dispersion of a propagation phase in the coating film and meet the absent reflection phase condition in a wide frequency range so as to achieve Terahertz broadband absent reflection and approximate perfect absorption. Besides, the doping concentration and the coating film thickness are changed to regulate the frequency range of generation of the broadband absent reflection and the approximate perfect absorption.

Owner:SOUTH CHINA NORMAL UNIVERSITY

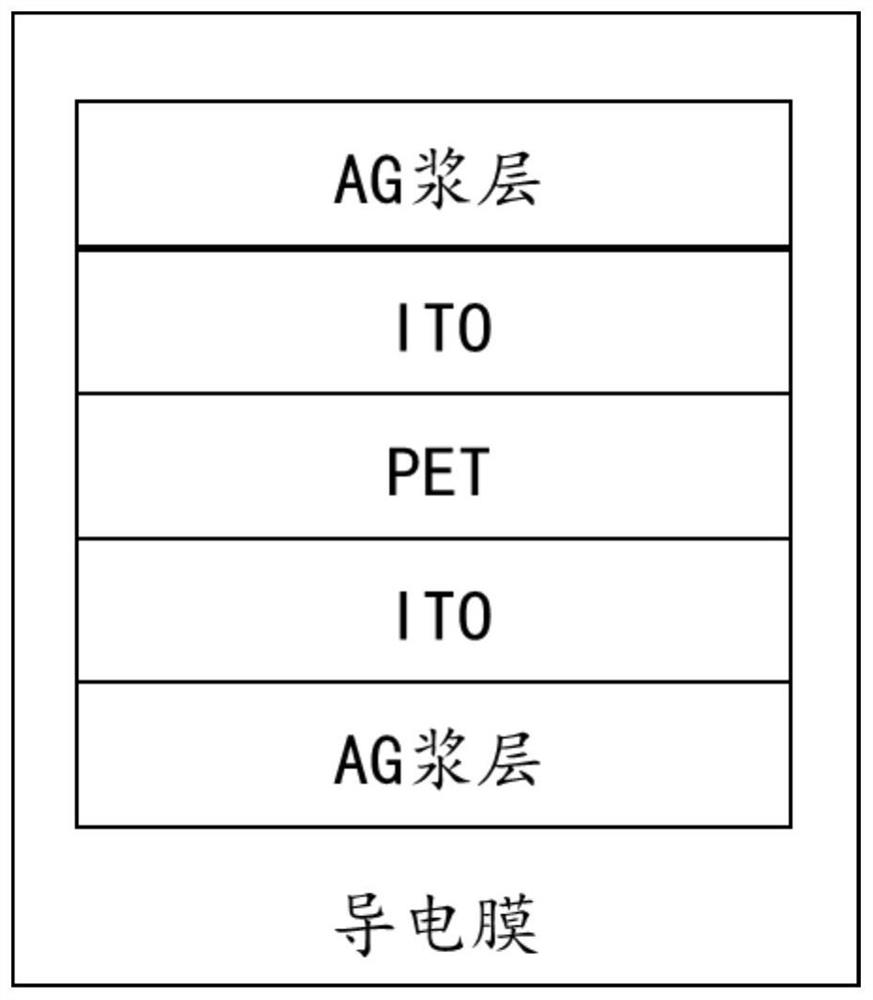

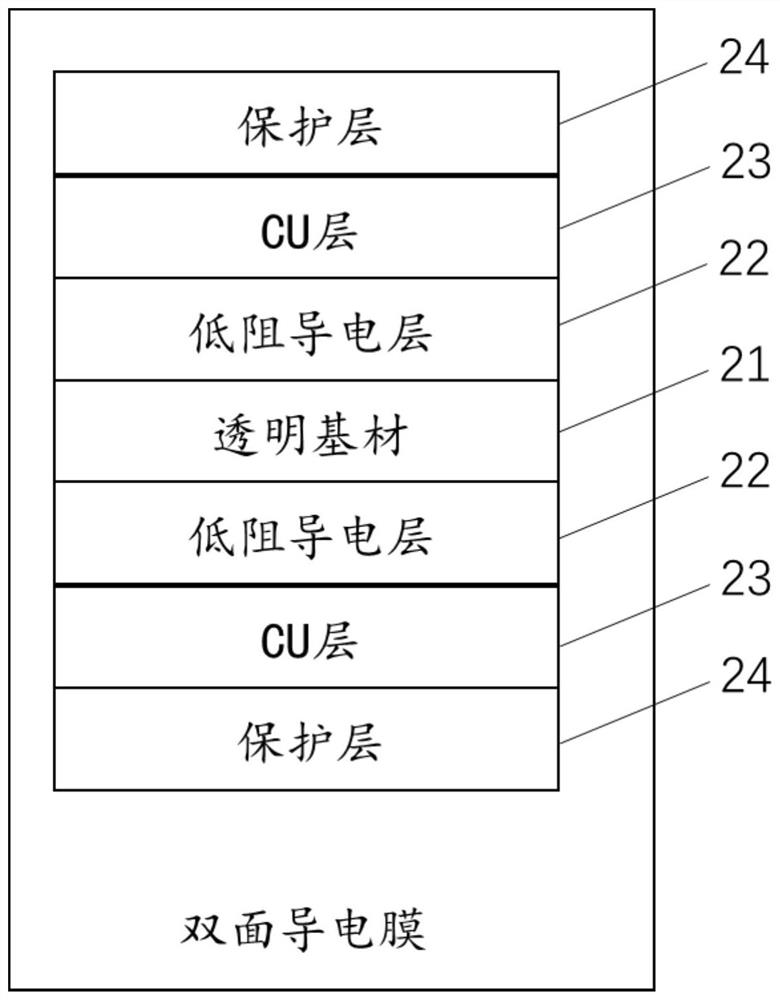

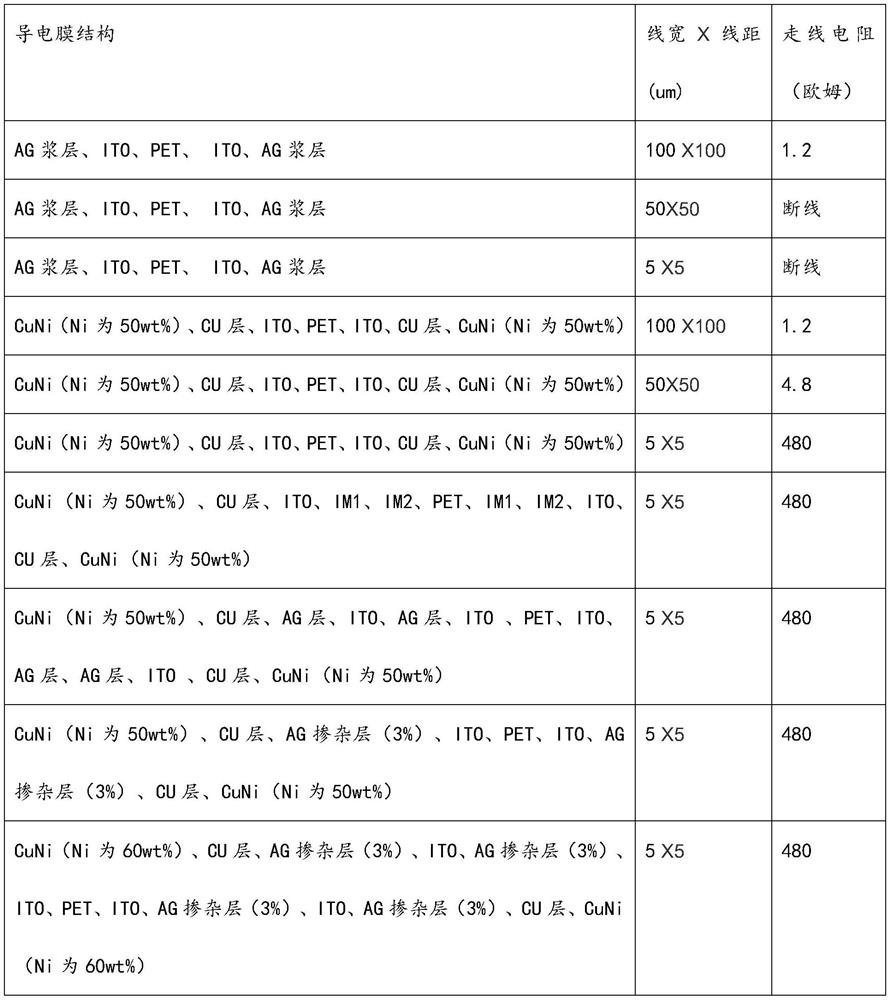

Double-sided conductive film, film coating method and touch screen

PendingCN111883284AGuaranteed electrical conductivityNarrow bezel spacingConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersSilver pasteElectrical resistance and conductance

The embodiment of the invention discloses a double-sided conductive film, a film coating method and a touch screen. The conductive film comprises a transparent base material, and a low-resistance conductive layer, a Cu layer and a protective layer which are sequentially laminated on two sides of the transparent base material, the protective layer is a Cu alloy layer or an Mo alloy layer; the low-resistance conducting layer is used for conducting electricity, and the resistance of the low-resistance conducting layer is not larger than 100 ohms. According to the technical scheme, the Cu is usedfor replacing silver paste, the Cu alloy is used as the protective layer, and through experimental verification, the conductivity of the Cu alloy can be guaranteed even if the line width * the line distance is 5 microns * 5 microns after etching.

Owner:BEIJING ZENITHNANO TECH CO LTD

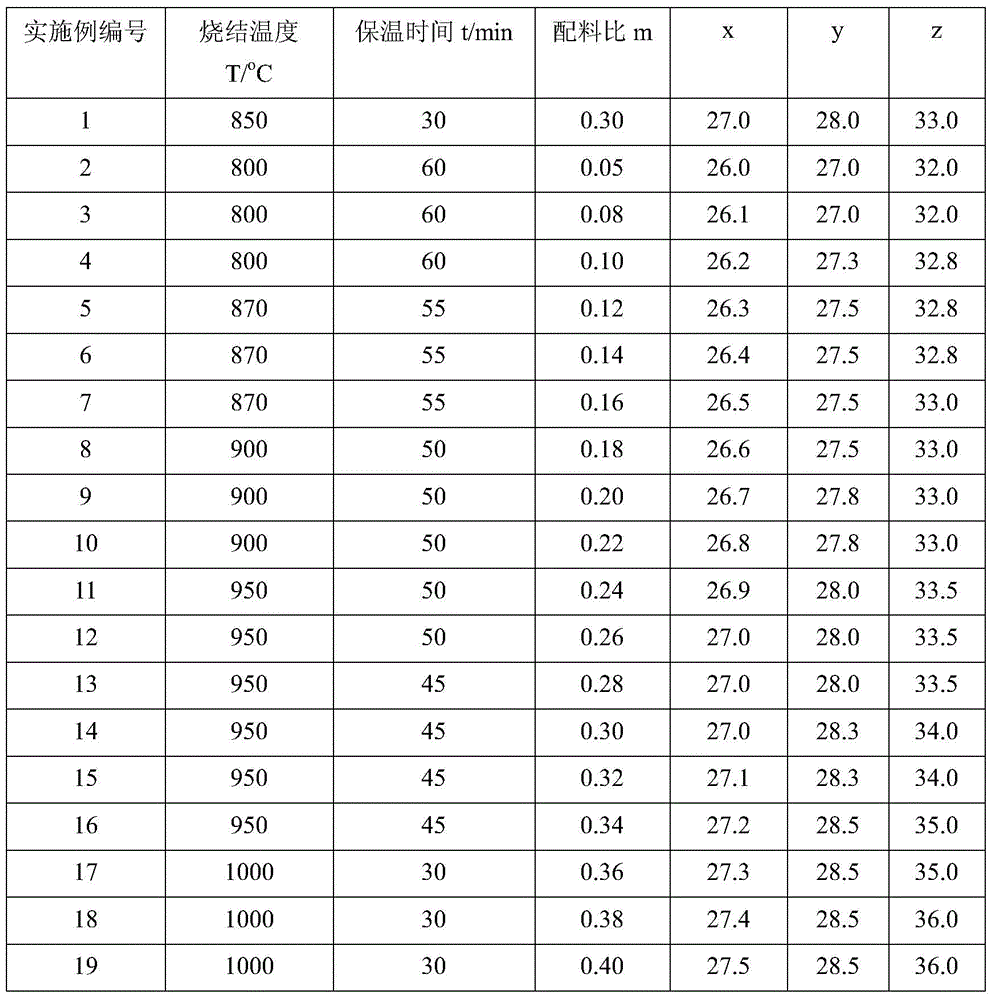

ce 3+ 、tb 3+ : Preparation method of yag glass-ceramics

A preparation method of Ce<3+>, Tb<3+>: YAG microcrystalline glass comprises three steps of preparation of scrap lead glass, mixing and drying of ingredients, and temperature control sintering. Sintering is performed after the glass is softened under temperature control by utilizing an excellent luminescence characteristic of a Ce<3+>, Tb<3+>: YAG crystal and a high refractive index and low softening temperature of lead glass, to prepare a composite material with crystal particles uniformly dispersed in the glass. The method of the invention has characteristics of being low in preparation temperature, easy in control of crystallization, and simple in process without heat post-treatment. The obtained Ce<3+>, Tb<3+>: YAG microcrystalline glass realizes white light output under the excitation of a 450 nm LD semiconductor laser.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com