Lead-free LED (Light-Emitting Diode) module and manufacturing process thereof

A technology for LED modules and manufacturing processes, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of low thermal conductivity of intermediate layers, low optical transmittance, poor heat dissipation performance, etc., and achieve transmittance. High, low cost, the effect of improving the light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

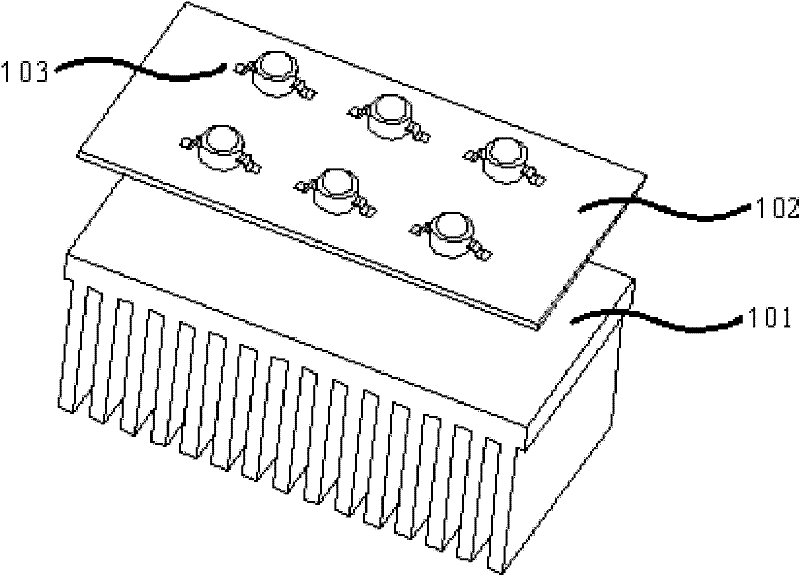

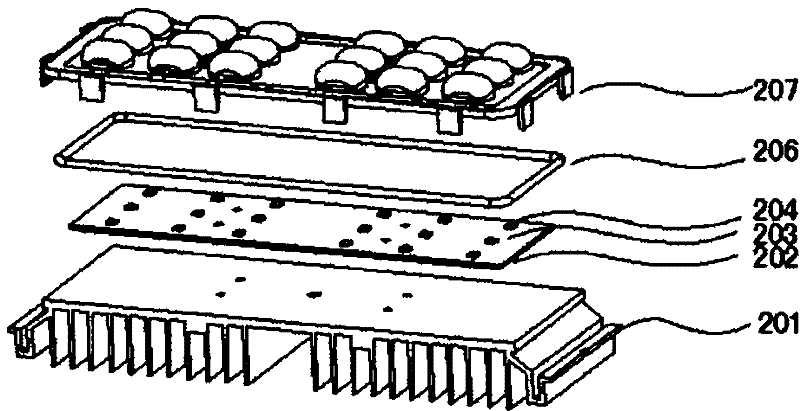

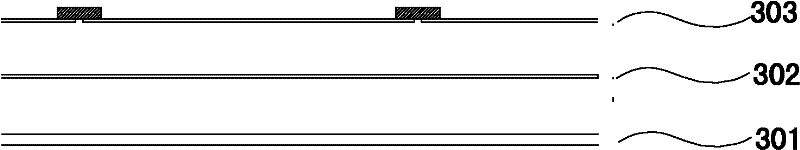

[0076] like figure 2 As shown, an LED module includes: a heat sink 201 , a PCB board 202 , an LED chip 203 , an LED open circuit protector 204 , encapsulating colloid, sealing silicone 206 , and a lens module 207 . In this embodiment, the LED open circuit protector 204 is a Zener diode. The sealing silicone 206 includes a solid silicone ring installed on the lens module 207, and a gel silicone ring formed by liquid silicone coated on the side of the solid silicone ring. On the position corresponding to the plane of the lens module 207 on the side of the solid silicone ring, there is a groove for coating liquid silicone. In the present embodiment, the lens module 207 has an overall plane, on the plane, it is obvious that each convex is a lens (if you look upside down, it is a lens pit), and the edge position around the plane is first attached with a Solid silicone ring, the outer or inner position of the solid silicone ring, corresponding to the plane of the lens module 207,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com