LED based on photonic crystal-single-layer graphene structure

A single-layer graphene and photonic crystal technology, used in semiconductor devices, electrical components, circuits, etc., can solve problems such as expensive, high preparation temperature, lack of flexibility, etc., to reduce high costs, improve heat dissipation, and improve light extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

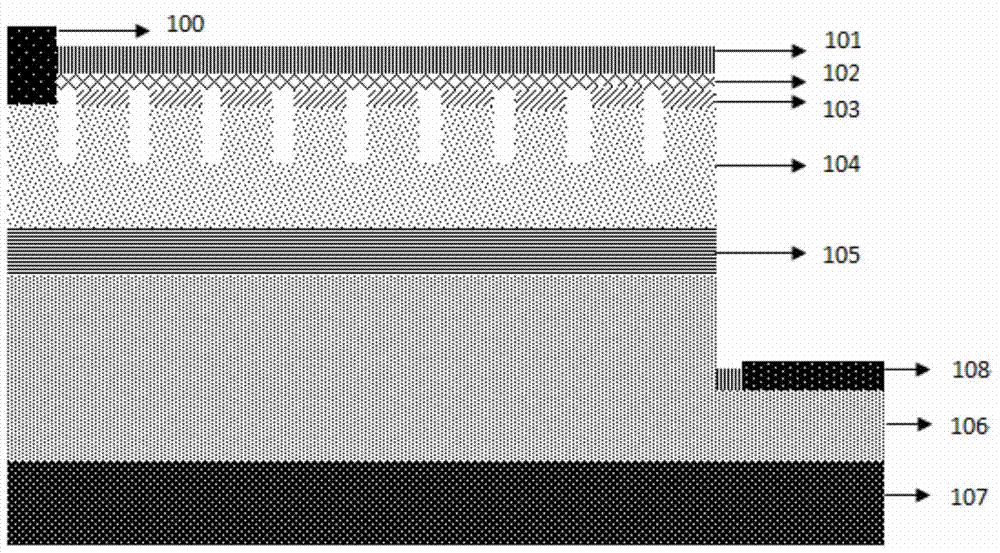

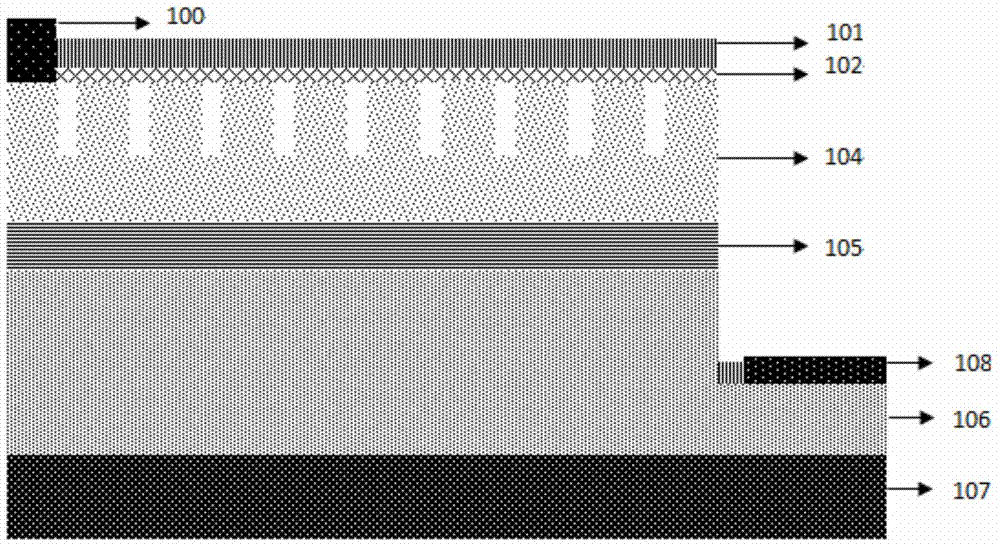

[0033] LEDs based on photonic crystal-single-layer graphene structures such as figure 1 Shown, wherein the preparation method process can be found in Figure 4 . First, a 1 nm thick contact layer is deposited on p-GaN using electron beam evaporation.

[0034] Use inductively coupled plasma etching (ICP) to carve the negative electrode part, with a depth of 1.2um.

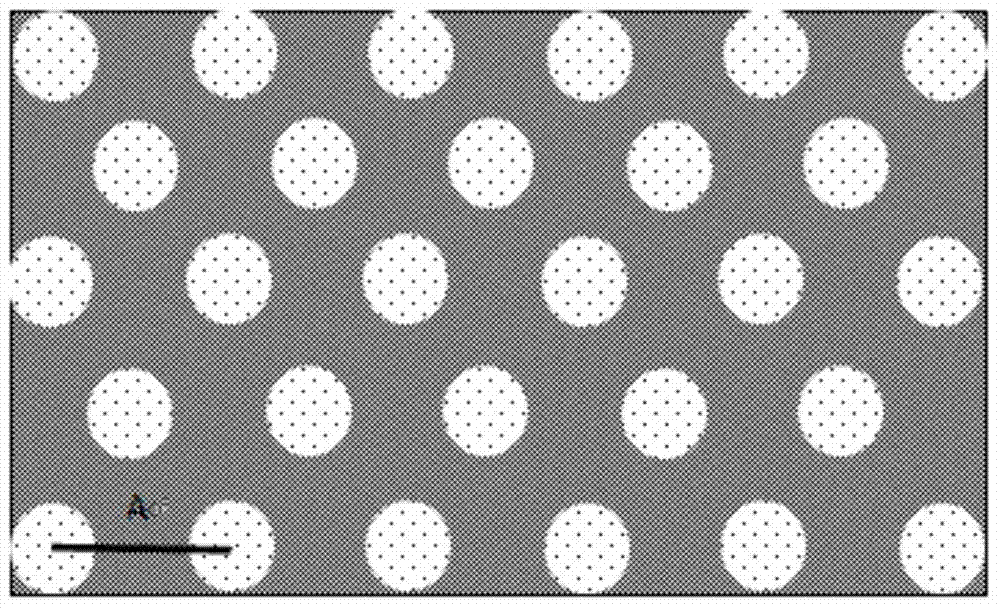

[0035] The photonic crystal structure was fabricated by inductively coupled plasma etching (ICP) in the p-GaN counterpart, see image 3 , the distance between adjacent circle centers is A=460nm, the radius of the circle is r=210nm, and the depth of the circular hole is h=120nm.

[0036] Transfer of single-layer graphene onto LEDs.

[0037] Sputtered titanium gold electrode (50nm).

[0038] A protective layer of silicon dioxide (300nm) was deposited by PECVD.

[0039] Compared with traditional GaN-LEDs, the light extraction efficiency of the present invention can be increased by more than 40%.

[0040] Above,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com