ce 3+ 、tb 3+ : Preparation method of yag glass-ceramics

A technology of glass-ceramics and lead glass, which is applied in the preparation of terbium-doped yttrium-aluminum-garnet glass-ceramics and in the field of cerium, which can solve the complex and difficult production process, and the difficulty in precise control of the crystal type, quantity and size of YAG glass-ceramics and other problems, to achieve good economic benefits, simple preparation process, and good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

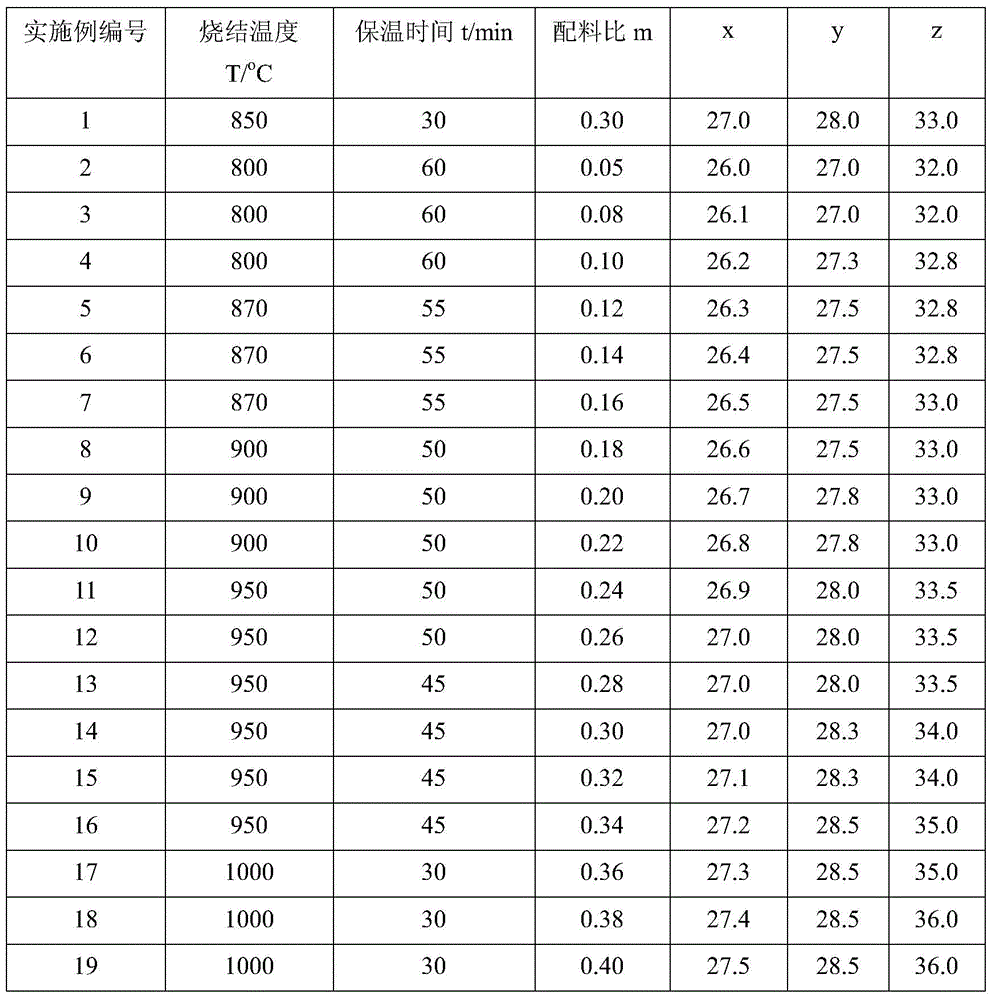

[0018] The preparation method of the present embodiment is as follows:

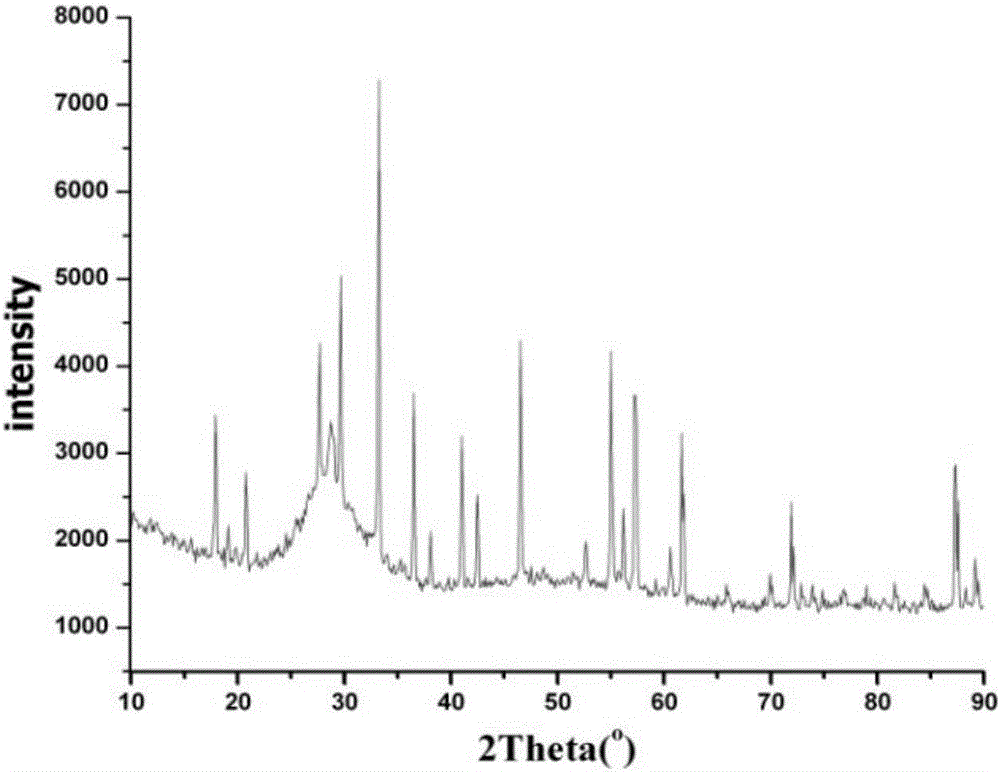

[0019] First, determine the mole percentage composition of lead glass when the refractive index of lead glass is n=1.82 through the software "Inorganic Glass Engineer": 27PbO-28PbF 2 -12Al 2 o 3 -33B 2 o 3 , where PbO uses Pb(NO 3 ) 2 Introduce, B 2 o 3 with HBO 3 The purity of all raw materials is analytically pure, and 100g of powder is prepared according to the above molar percentage, put into an alumina crucible, melted in a silicon carbide rod furnace at 1000°C for 45min, and then directly pour the molten liquid into cold water for rapid cooling to obtain shattered lead glass;

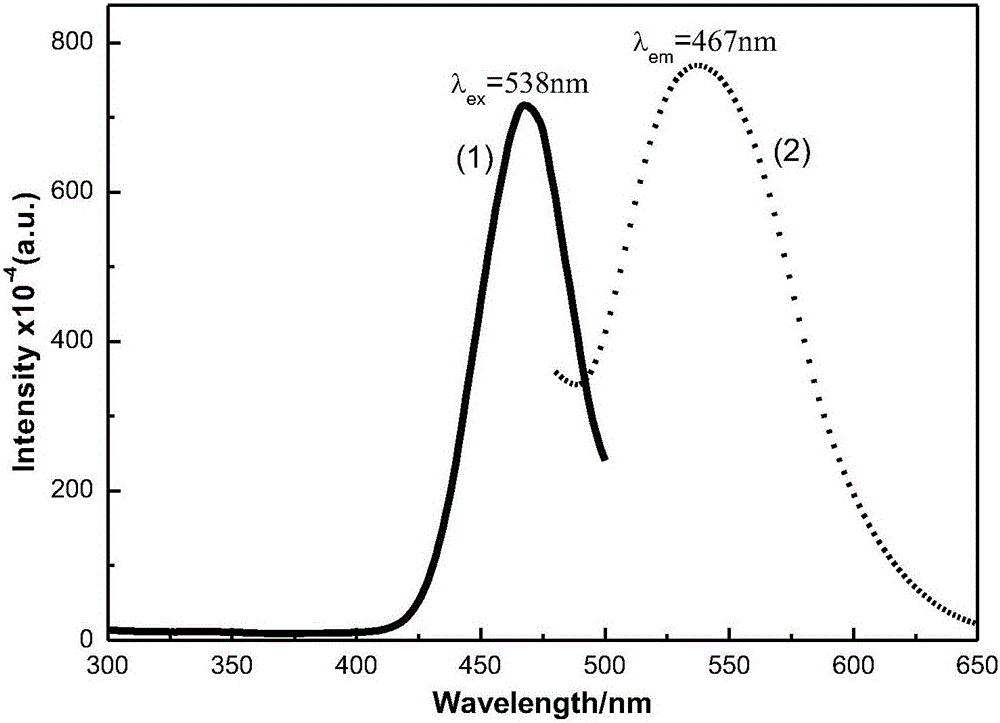

[0020] Press Ce with Analytical Balance 3+ , Tb 3+ : YAG crystal and described broken lead glass mass ratio are 0.3, take the Ce of 20g 3+ , Tb 3+ : YAG crystal and lead glass as raw materials, the Ce 3+ , Tb 3+ : 85% of the YAG crystal particle size is distributed in 1um, and the purity is 99.0%. The raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com