Transparent Ce:YAG microcrystalline glass and application of transparent Ce:YAG microcrystalline glass in white LED

A technology of glass-ceramics and glass, applied in the field of inorganic materials, to achieve the effect of matching refractive index, saving heat treatment process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] will analyze pure SiO 2 、Al 2 o 3 , Y 2 o 3 , PbO, CeF 3 , B 2 o 3 , by 20 parts SiO 2 : 19.5 Al 2 o 3 : 9.5 parts Y 2 o 3 : 46 parts PbO: 0.5 parts CeF 3 : 5 copies of B 2 o 3 (mol fractions) of the proportion of accurate weighing and placed in an agate mortar, mixed in the agate mortar and ground evenly, then placed in a corundum crucible, placed in a resistance furnace, heated to 1450 ° C, and then kept for 2 hours to make it After melting, the glass melt is taken out and quickly poured into a cast iron mold with a temperature of 650°C, then placed in a muffle furnace for annealing, kept at 800°C for 3 hours, and then cooled to 20°C with the furnace to form spontaneous crystallization Transparent Ce:YAG glass-ceramics.

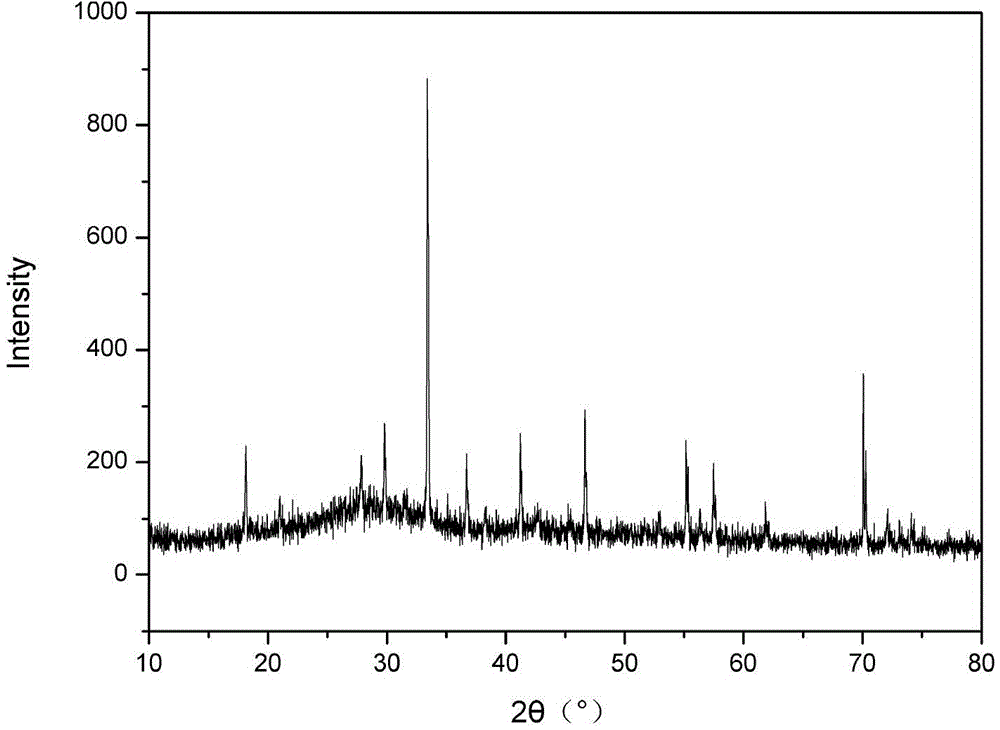

[0044] The prepared Ce:YAG glass-ceramic was tested for spectral properties, and its XRD pattern is as follows figure 2 As shown, the XRD diffraction peaks of the glass-ceramic sample are consistent with the main diffraction peaks of...

Embodiment 2

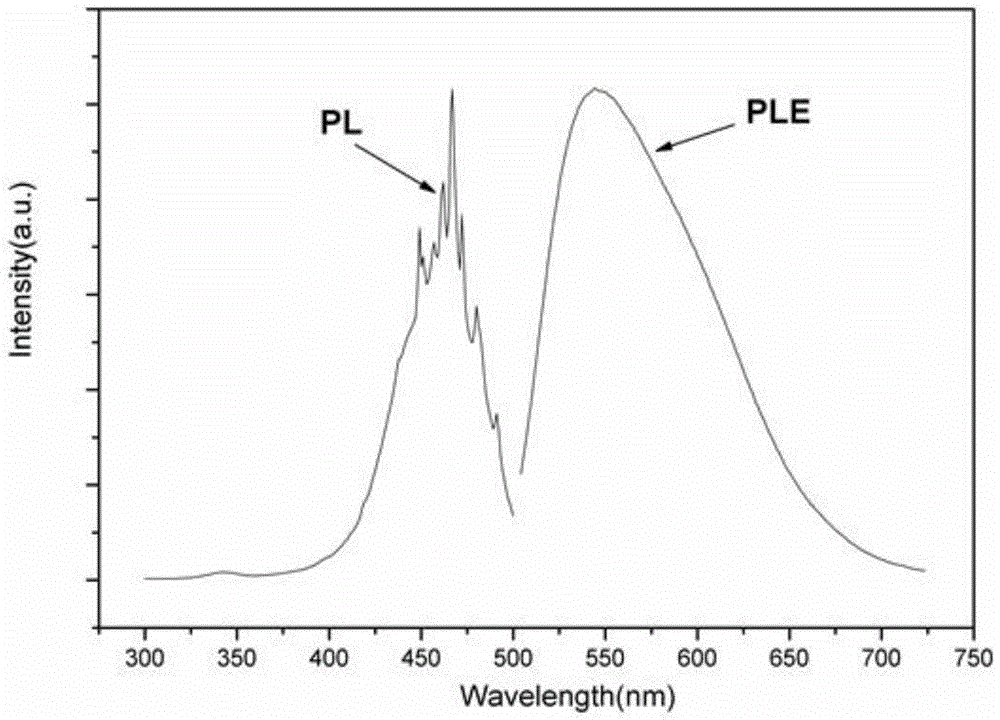

[0046] will analyze pure SiO 2 、Al 2 o 3 , Y 2 o 3 , PbO, CeF 3 , B 2 o 3 , by 23 parts SiO 2 : 19 Al 2 o 3 : 9 copies of Y 2 o 3 : 45 parts PbO: 0.5 parts CeF 3 : 4 copies of B 2 o 3 (mol fractions) of the proportion of accurate weighing and placed in an agate mortar, mixed in the agate mortar and ground evenly, then placed in a corundum crucible, placed in a resistance furnace, heated to 1500 ° C and kept for 2 hours to make After melting, the glass melt is taken out and quickly poured into a cast iron mold with a temperature of 650°C, then placed in a muffle furnace for annealing, kept at 800°C for 3 hours, and then cooled to 20°C with the furnace to form spontaneous crystallization Transparent Ce:YAG glass-ceramics. Coupling glass-ceramics with a 460nm blue light chip can emit bright white light under blue light excitation. The obtained glass-ceramic is excited by a wavelength of 460nm, the maximum wavelength can reach 534nm, and the luminous efficiency can...

Embodiment 3

[0048] will analyze pure SiO 2 、Al 2 o 3 , Y 2 o 3 , PbO, CeF 3 , B 2 o 3 , by 25 parts SiO 2 : 20 Al 2 o 3 : 10 copies of Y 2 o 3 : 43 parts PbO: 0.5 parts CeF 3 : 3 copies of B 2 o 3 (mol fractions) of the proportion of accurate weighing and placed in an agate mortar, mixed in the agate mortar and ground evenly, then placed in a corundum crucible, placed in a resistance furnace, heated to 1600 ° C, and then kept for 2 hours to make it After melting, the glass melt is taken out and quickly poured into a cast iron mold with a temperature of 650°C, then placed in a muffle furnace for annealing, kept at 800°C for 3 hours, and then cooled to 20°C with the furnace to form spontaneous crystallization Transparent Ce:YAG glass-ceramics. Coupling glass-ceramics with a 460nm blue light chip can emit bright white light under blue light excitation. The obtained glass-ceramic is excited by a wavelength of 460nm, the maximum wavelength can reach 532nm, and the luminous effi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com