Preparation method of YAG microcrystalline glass

A technology of yttrium aluminum garnet and glass-ceramic, which is applied in the field of preparation of yttrium aluminum garnet glass-ceramic, can solve the problems of devitrification, high cost, low transparency and the like, and achieves the effects of complex shape, low cost and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

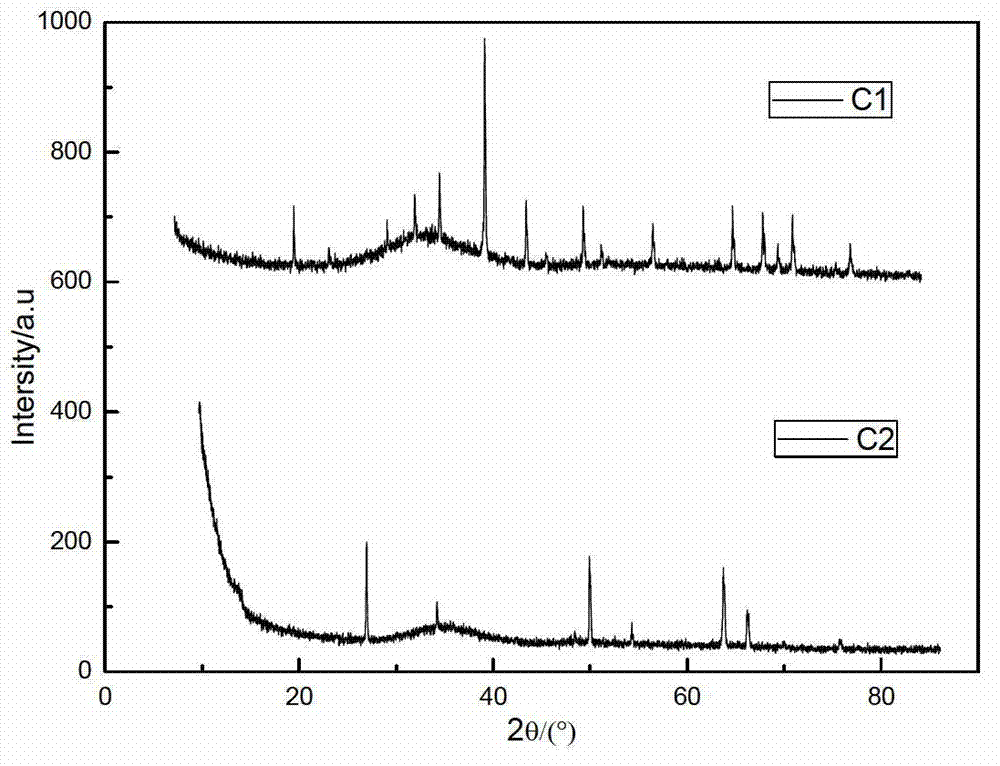

[0014] The specific implementation process of this embodiment includes three steps of glass frit mixing, glass frit melting and heat preservation treatment:

[0015] (1) Glass frit mixing: chemically pure raw materials are mixed according to the molar ratio, among which Al 2 o 3 10~20mol%; Y 2 o 3 6~14mol%; SiO 2 20~50mol%; PbO is 30~70mol%; B 2 o 3 0~3mol%, after mixing, put it into a ball mill jar, add agate balls with the same quality and uneven size as the mixture, put them on a ball mill and mill them for more than 2 hours to obtain a mixed glass frit;

[0016] (2) Glass frit melting: Press the mixed glass frit into a column under the condition of 10GPa in a hydraulic press, put it into an alumina crucible, put it into a 1600°C muffle furnace for melting, and set the electric furnace temperature to 1400°C for 1 hour 10 minutes after melting, drop to 1350°C and keep warm for 2 hours to obtain molten glass frit;

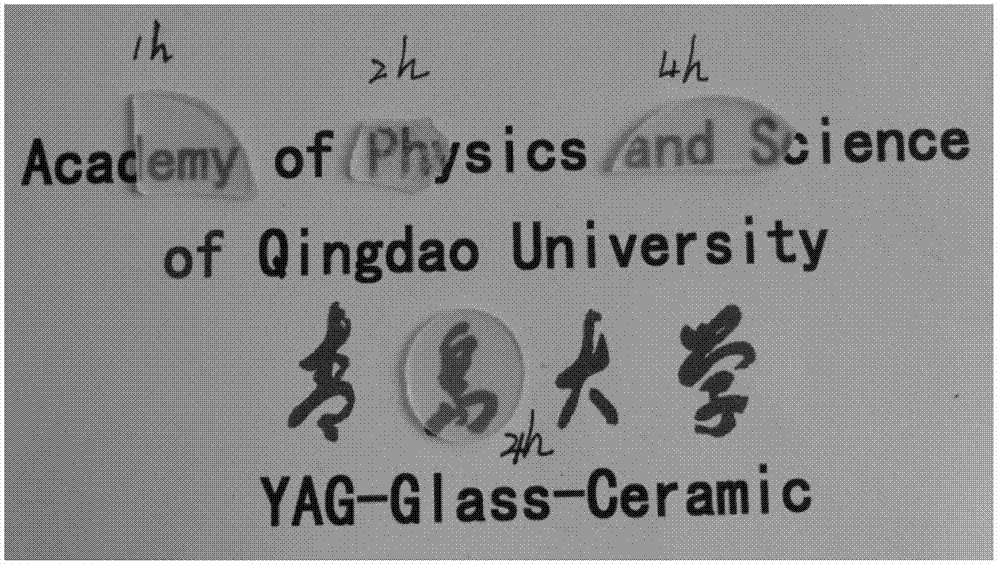

[0017] (3) Heat preservation treatment: drop the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com