LED module and manufacturing process thereof

A LED module and manufacturing process technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low optical transmittance, low light output efficiency, and low heat dissipation performance, and achieve low cost, good heat dissipation effect, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

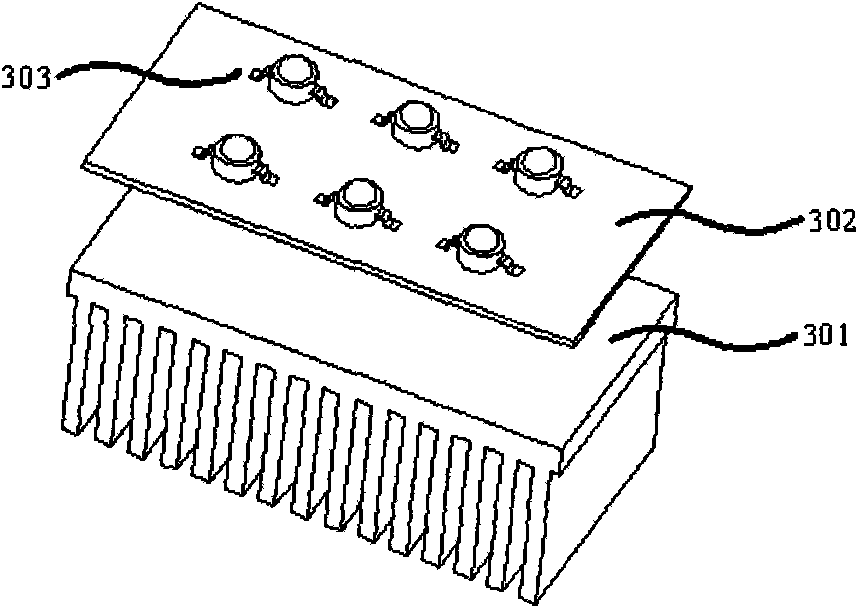

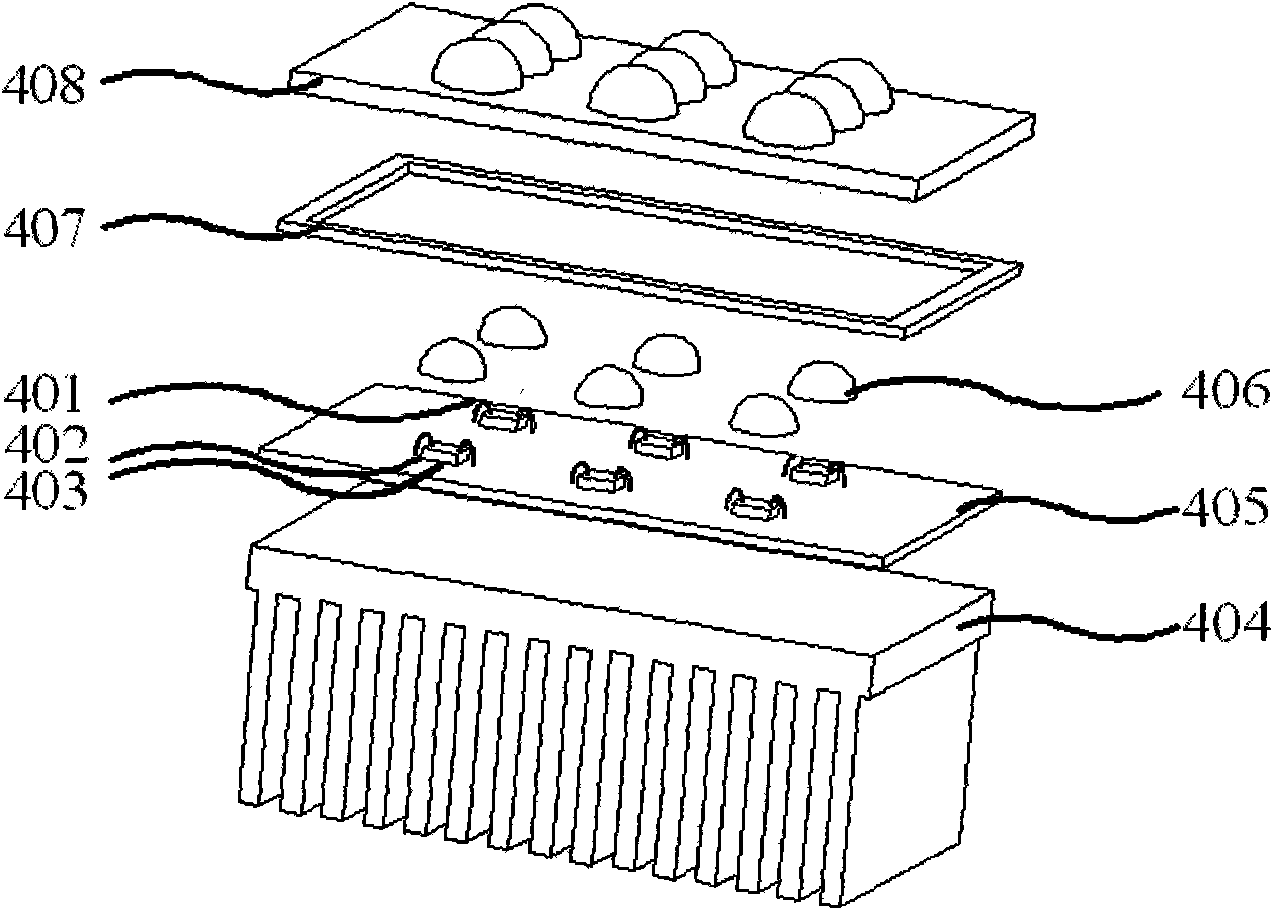

[0041] The core of this application lies in: the existing LED modules usually fix the LED chip on the heat sink of the bracket, package it into LED particles, weld the LED particles on different circuit boards, and then install them on the radiator to form different products , to adapt to more and wider applications, and become a technical bias in the industry, and the structure of this LED module has disadvantages such as poor heat dissipation performance, low optical transmittance, and complicated components. The applicant overcame the existing technical prejudice in the field of LED lighting and its application occasions, and proposed a new LED module structure, in which the LED chip is directly loaded on the circuit board, and the lens module is used for one-time configuration. Light, achieve better heat dissipation effect and higher light extraction efficiency, and solve the packaging problem of LED chips on the circuit board.

[0042] Such as figure 2 As shown, an LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com