Manufacturing process of light emitting diode (LED) module group and LED module group

A technology of LED module and manufacturing process, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high production cost and low light output rate, and achieve the effect of high production cost, low cost and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

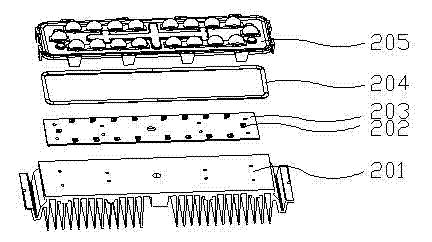

[0046] Such as figure 2 As shown, an LED module includes: a heat sink 201 , a circuit board 202 , an LED device 203 , a sealing silicone 204 , and a lens module 205 .

[0047] The LED device 203 includes an LED chip and a bracket, which are welded on the circuit board 202 . The LED device 203 does not include a light exit lens. The LED device 203 is directly welded on the circuit board 202, and the bottom of the circuit board 202 is in contact with the heat sink 201

[0048] The lens module 205 is covered on the LED device 203 , filled with molding colloid, and forms a sealed structure with the circuit board 202 and the heat sink 201 through the sealing silicone 204 . That is, the space between each pit of the lens module 205 and the LED device 203 is provided with molding colloid that matches the optical refractive index of the lens module 205, the LED device 203 is completely covered by the molding colloid and no air is left between them, and the lens mold A sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com