LNOI suspended spot size converter and process implementation method thereof

A mode spot converter and process technology, applied in the field of integrated photonics, can solve the problems of high structural requirements, limited optical mode size amplification capability, unfavorable device packaging application, etc., and achieve the effect of reducing end-face reflection and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

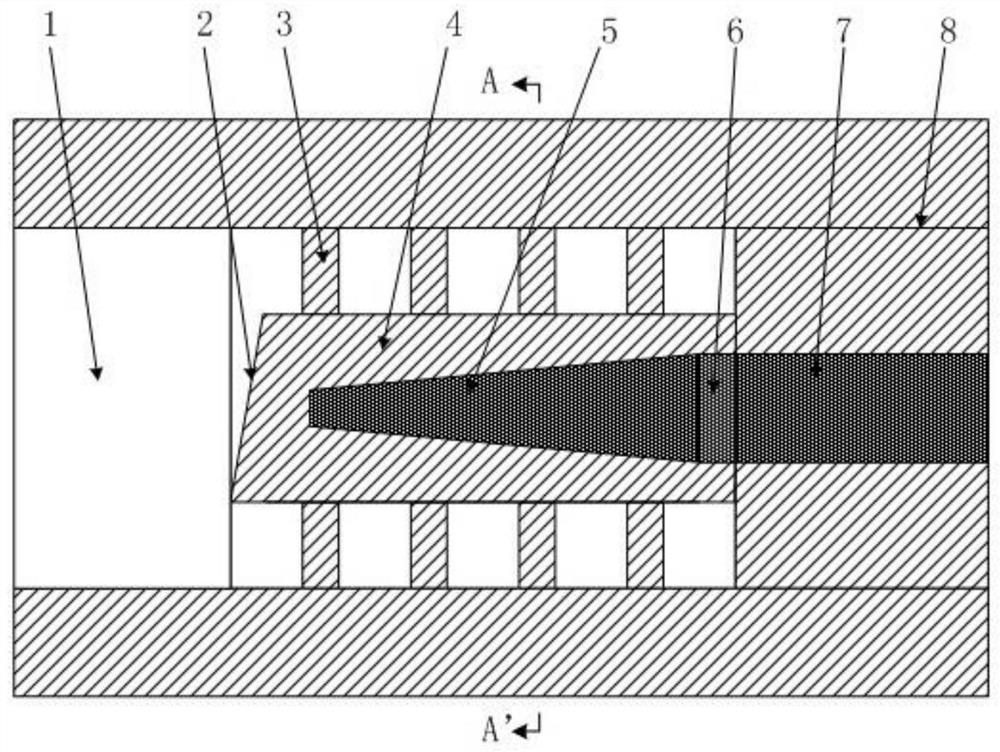

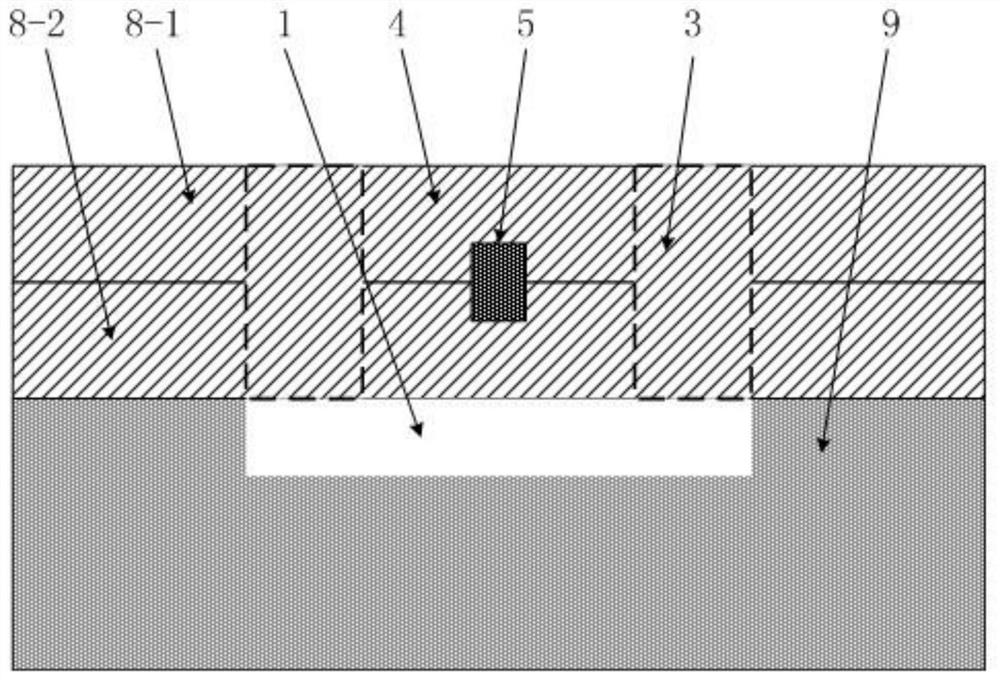

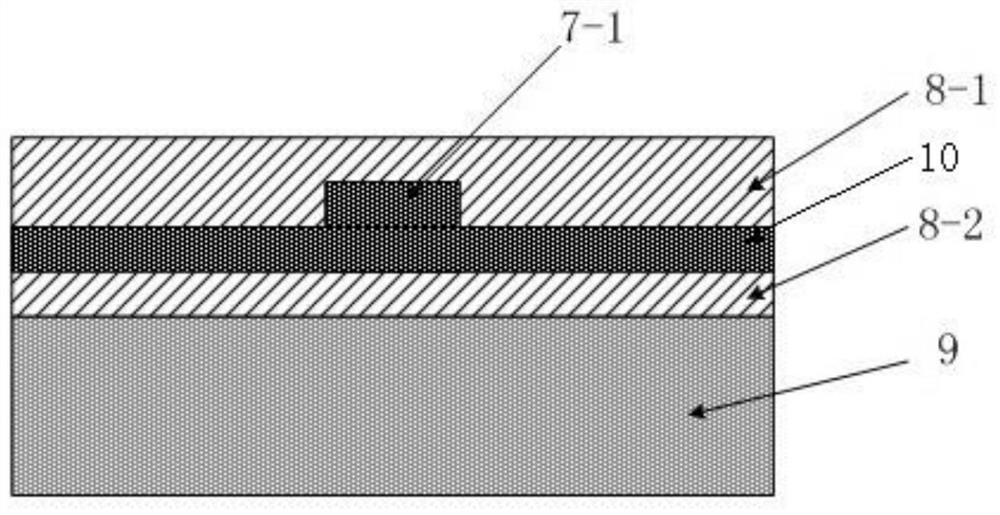

[0049] Such as Figure 4 As shown, the LNOI optical waveguide core layer 7 is a rectangular optical waveguide structure 7-2.

[0050] Such as Figure 5 As shown, a process realization method of LNOI floating mode spot converter includes the following steps:

[0051] Step 1) On the surface layer of the LNOI material, a hard mask is prepared by spin-coating photoresist, exposure, development, metal evaporation, and wet stripping; and under the protection of the hard mask, through a dry etching process, The LNOI optical waveguide core layer 7 is etched;

[0052] Step 2) Etching of LNOI tapered core layer 5 and transition structure 6;

[0053] On the surface layer of the LNOI optical waveguide core layer 7, a hard mask is prepared by spin-coating photoresist, exposure, development, metal evaporation, and wet stripping; and under the protection of the hard mask, through a dry etching process, Etch the LNOI tapered core layer 5 and transition structure 6 to SiO 2 Lower cladding 8-2;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com