Organic light emission diode device and fabrication method thereof

An electroluminescence device and electroluminescence technology, which are applied in the directions of organic semiconductor devices, materials of organic semiconductor devices, and electric solid devices, etc., and can solve the problems of poor light transmittance, poor light transmittance, and inability to emit light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

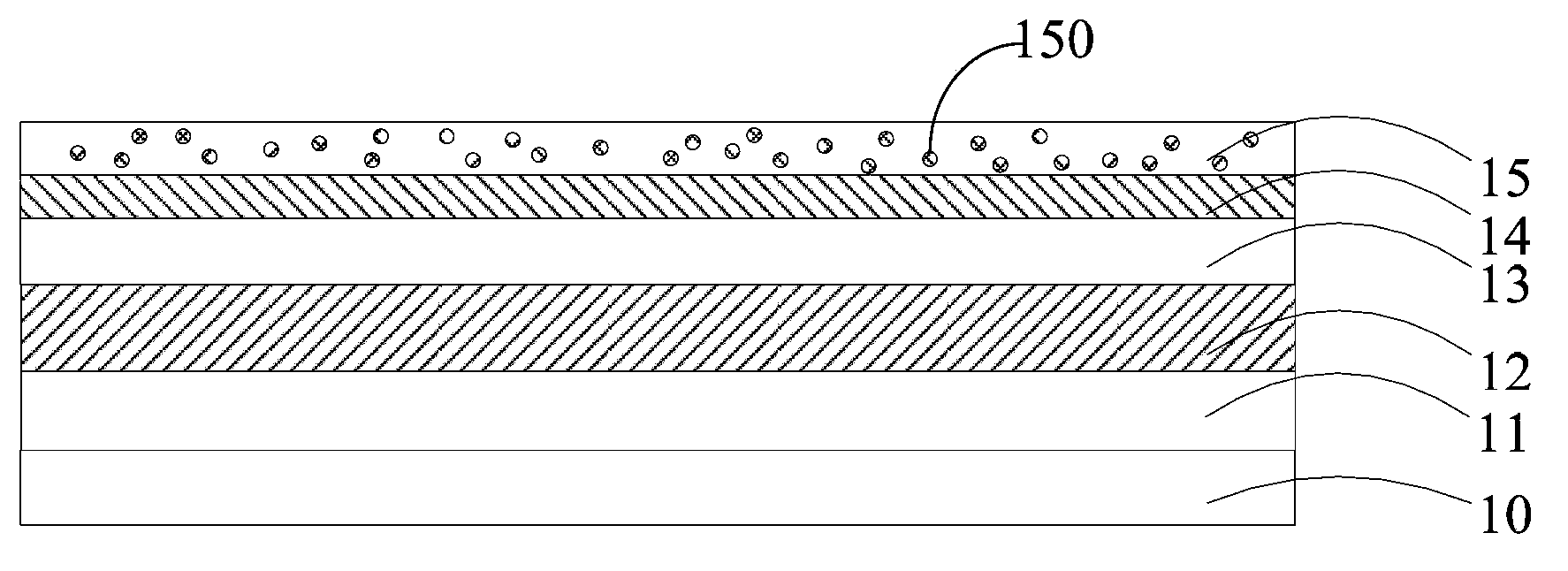

[0052] A method for preparing an organic electroluminescent device, comprising the following steps:

[0053] (1) Place a transparent glass substrate on a 1×10 -4 In the vacuum coating chamber of Pa, a metal Ag film with a thickness of 100nm is prepared on the surface of the substrate by vacuum evaporation as the anode;

[0054] (2) Prepare a light-emitting functional layer on the surface of the anode by vacuum evaporation, including a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, and an electron injection layer in sequence;

[0055] Among them, the hole injection layer is made of CuPc with a thickness of 20nm; the hole transport layer is made of NPB with a thickness of 30nm; the light emitting layer is made of Ir(ppy) 3 Doping mixed materials formed in CBP, where Ir(ppy) 3 The mass ratio to CBP is 10:100, and the thickness is 15nm; the electron transport layer uses TPBi, and the thickness is 30nm; the electron injection la...

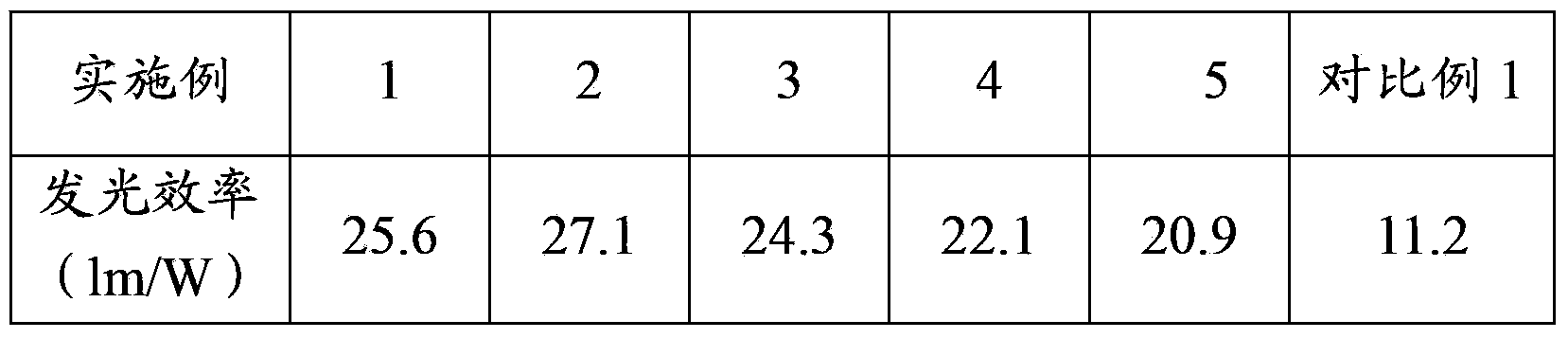

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that the material of the light extraction layer includes titanium dioxide nano-microspheres and photocurable acrylic resin with a mass ratio of 20:100, the particle size of the titanium dioxide nano-microspheres is 100nm, and the screen printing process adopts mesh size A film was formed for 1000-mesh screen printing, and the thickness of the light extraction layer was 80 μm.

Embodiment 3

[0063] The difference between this embodiment and Example 1 is that the material of the light extraction layer includes titanium dioxide nano-microspheres and photocurable acrylic resin with a mass ratio of 20:100, the particle size of the titanium dioxide nano-microspheres is 250nm, and the screen printing process adopts mesh size The film was formed by 800-mesh screen printing, and the thickness of the light extraction layer was 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com