Method for preparing two-dimensional photonic crystal structure GaN (gallium nitride) based LED (light emitting diode)

A two-dimensional photonic crystal and photonic crystal technology, applied in the field of optoelectronics, can solve problems such as uneven photonic crystal graphics and poor photonic crystal graphics, and achieve the effects of convenient graphics transfer, increased etching selection ratio, and improved light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0050] A method for preparing a GaN-based LED with a two-dimensional photonic crystal structure, comprising the steps of:

[0051] 1. Prepare a hard template containing a two-dimensional photonic crystal pattern, and perform anti-sticking treatment on the hard template. Nanoimprint hard templates can include silicon templates; porous alumina (AAO) templates, and silicon-based porous alumina (AAO) templates.

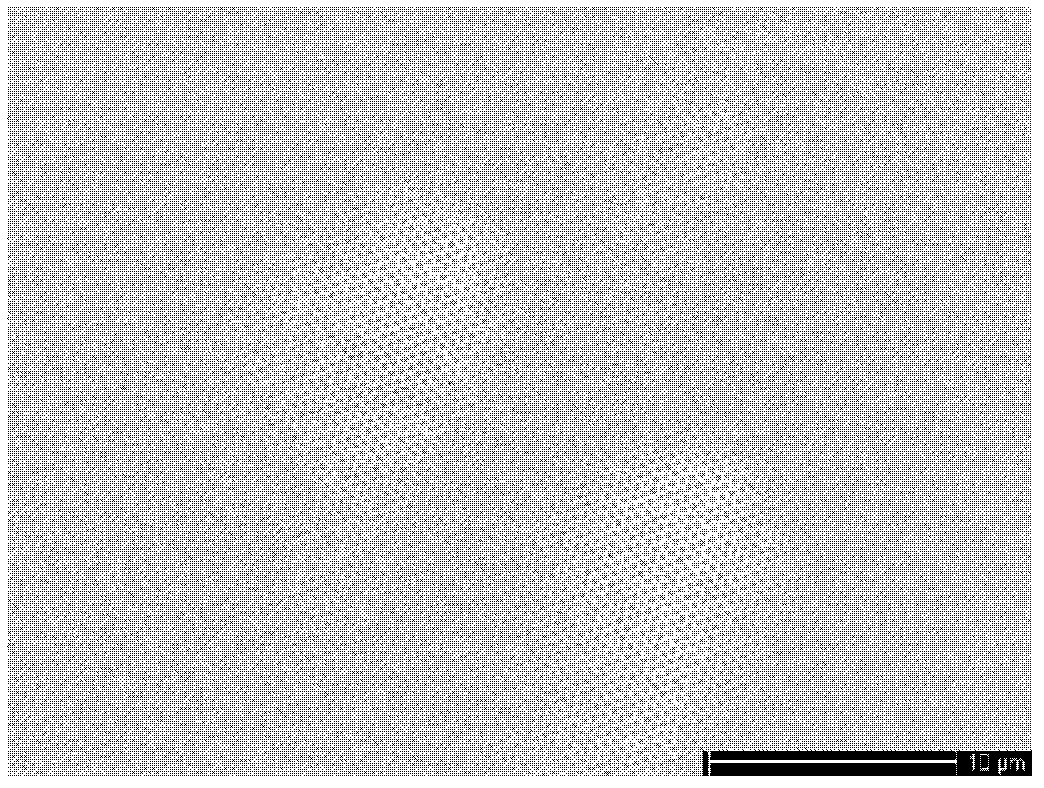

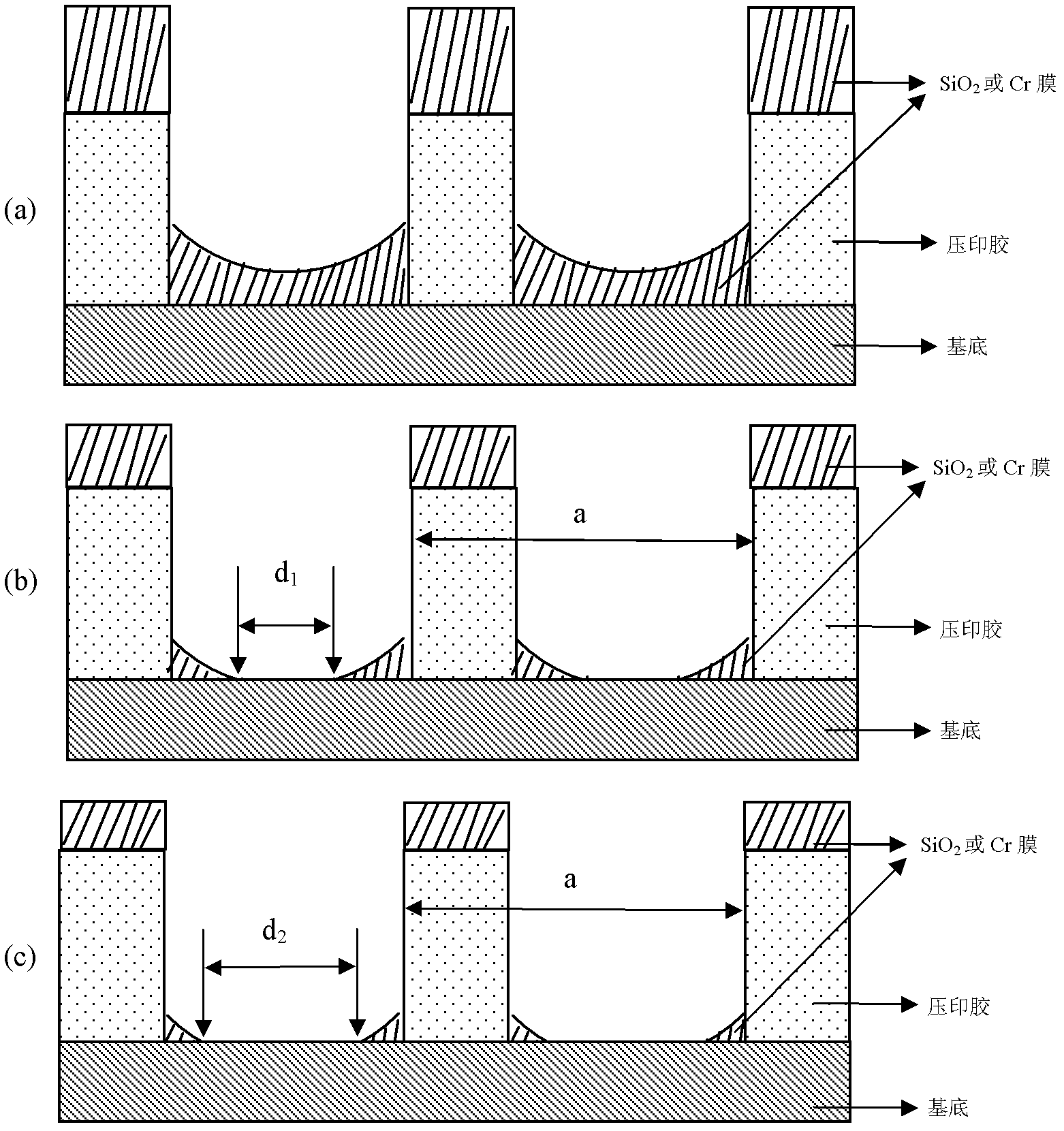

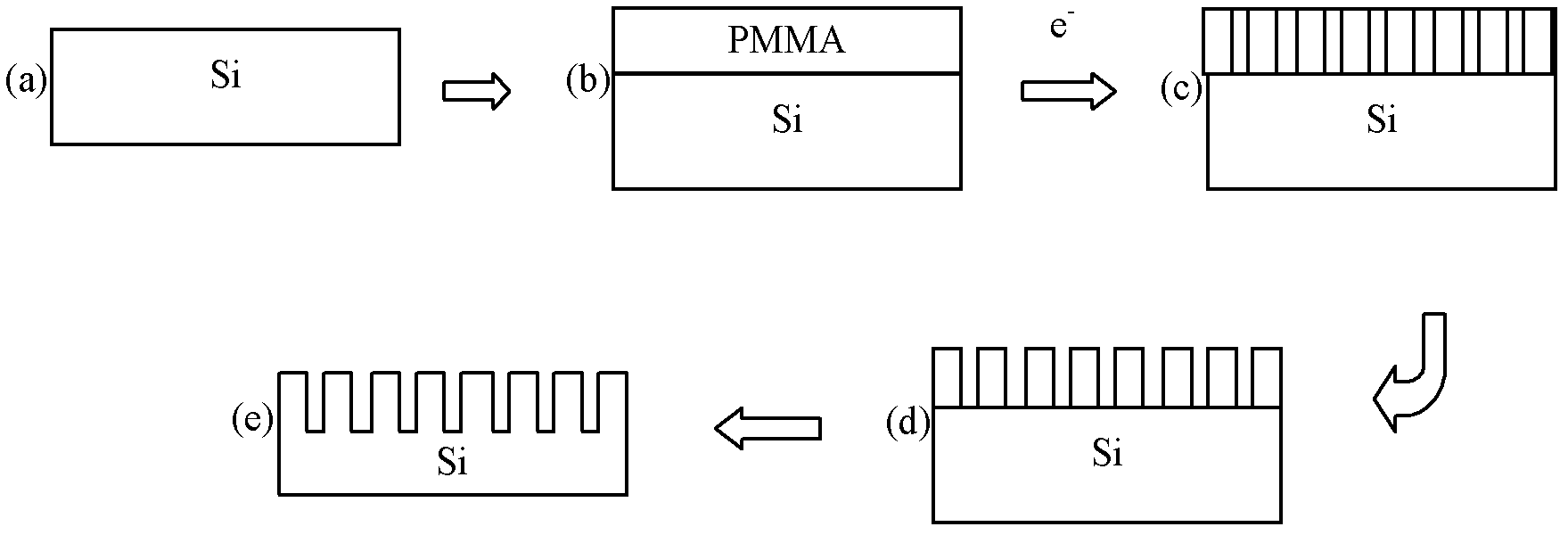

[0052] Among them, the silicon template can be prepared through the following process: clean the silicon wafer and dry it; then apply a layer of PMMA glue; carry out electron beam exposure according to the design pattern; remove the exposed PMMA glue by developing; use PMMA glue as the Mask etching Si to obtain the Si template of the desired pattern, such as image 3 (a)-3(e).

[0053] The AAO template can be prepared by the following process: put pure aluminum (above 99.99%) into a 0.1-0.5mol / L mixed solution of oxalic acid, sulfuric acid or phosphoric acid, and use a ...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that the target wafer is a GaN epitaxial wafer growing an ITO layer, such as Figure 12 shown. Specific steps are as follows:

[0073] 1. The preparation of the nanoimprint hard template is the same as the first step of Example 1.

[0074] 2. The preparation of the soft template for nanoimprinting is the same as the second step of Example 1.

[0075] 3. Preparation of target slices

[0076] Clean the sapphire substrate (1) first, then deposit the buffer layer (2) and the semiconductor epitaxial stack on the substrate (1) by metal organic chemical vapor deposition (MOVCD), molecular beam epitaxy (MBE) and other semiconductor epitaxial growth methods. The layer structure is the target sheet; the semiconductor epitaxial layer at least includes an N-type layer (3), a light-emitting layer (4), a P-type layer (5) and an ITO layer (6) from bottom to top; the light-emitting layer 4 usually has quantum Well structure...

Embodiment 3

[0087] The difference between this embodiment and Embodiment 1 is that the target sheet in this implementation is to adopt a sapphire substrate sheet, such as Figure 13 shown. Specific steps are as follows:

[0088] 1. The preparation of the nanoimprint hard template is the same as the first step of Example 1.

[0089] 2. The preparation of the soft template for nanoimprinting is the same as the second step of Example 1.

[0090] 3. Preparation of target slices

[0091] Prepare the sapphire substrate 1 and clean it.

[0092] 4. Uniform glue: Spin coat a layer of STU UV glue on the target sheet, first rotate at a speed of 500rpm for 5s, so that the hot-pressed glue is evenly spread on the SiO2 surface, and then rotate at a speed of 3000rpm for 45s to shake off the excess Ultraviolet glue will be thinned and homogenized; and then baked on a hot plate at 95°C for 3mins to obtain the target sheet A, such as Figure 8 as shown in (b);

[0093] 5. Embossing: The above soft temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com