Scintillation microcrystalline glass embedded with YAG microcrystalline phase and preparation method of scintillation microcrystalline glass

A technology of glass-ceramics and micro-crystals, which is applied in instruments, analytical materials, and material analysis using wave/particle radiation, etc., can solve the problems of difficult preparation, limited application, high price, etc. The effect of increasing crystal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

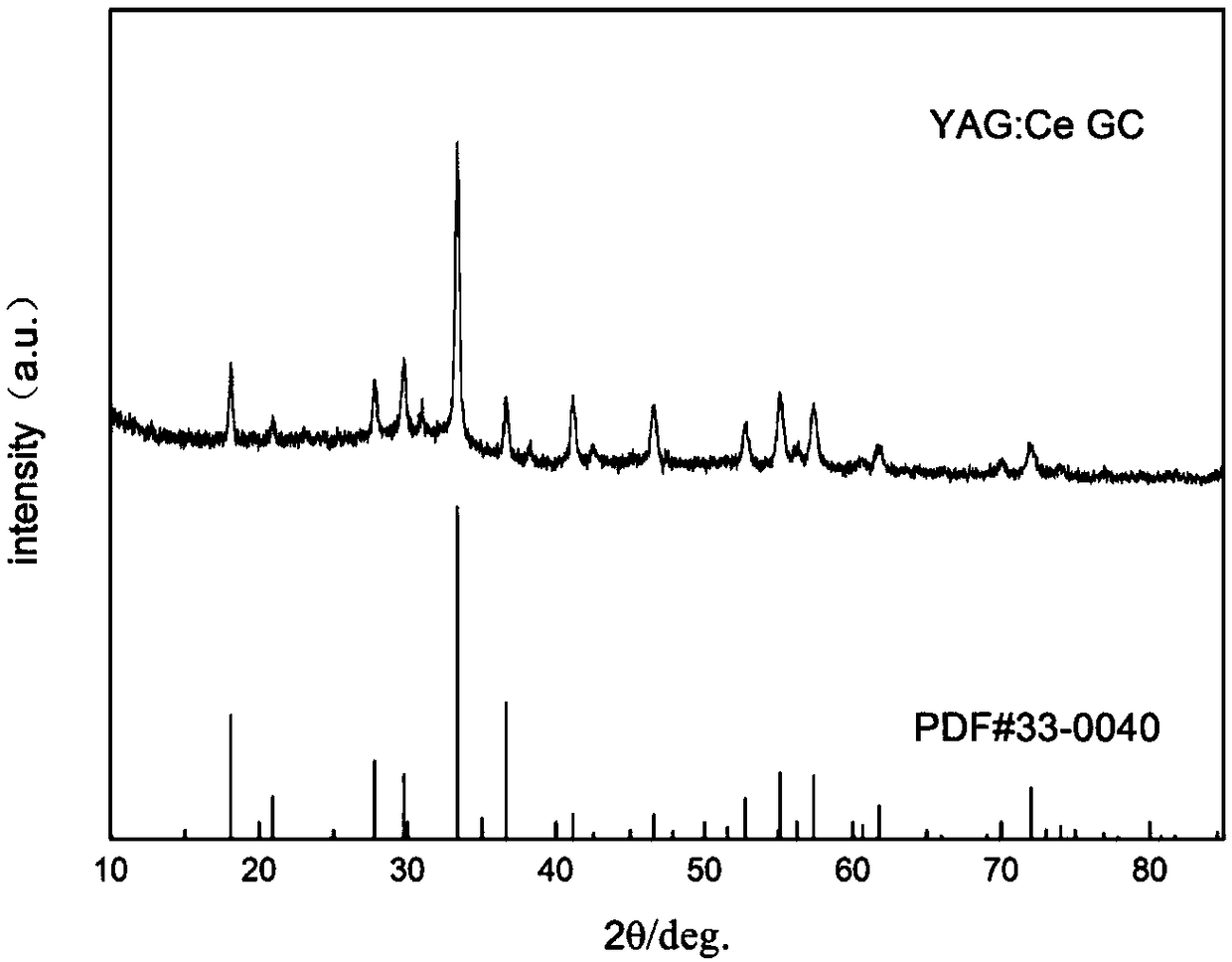

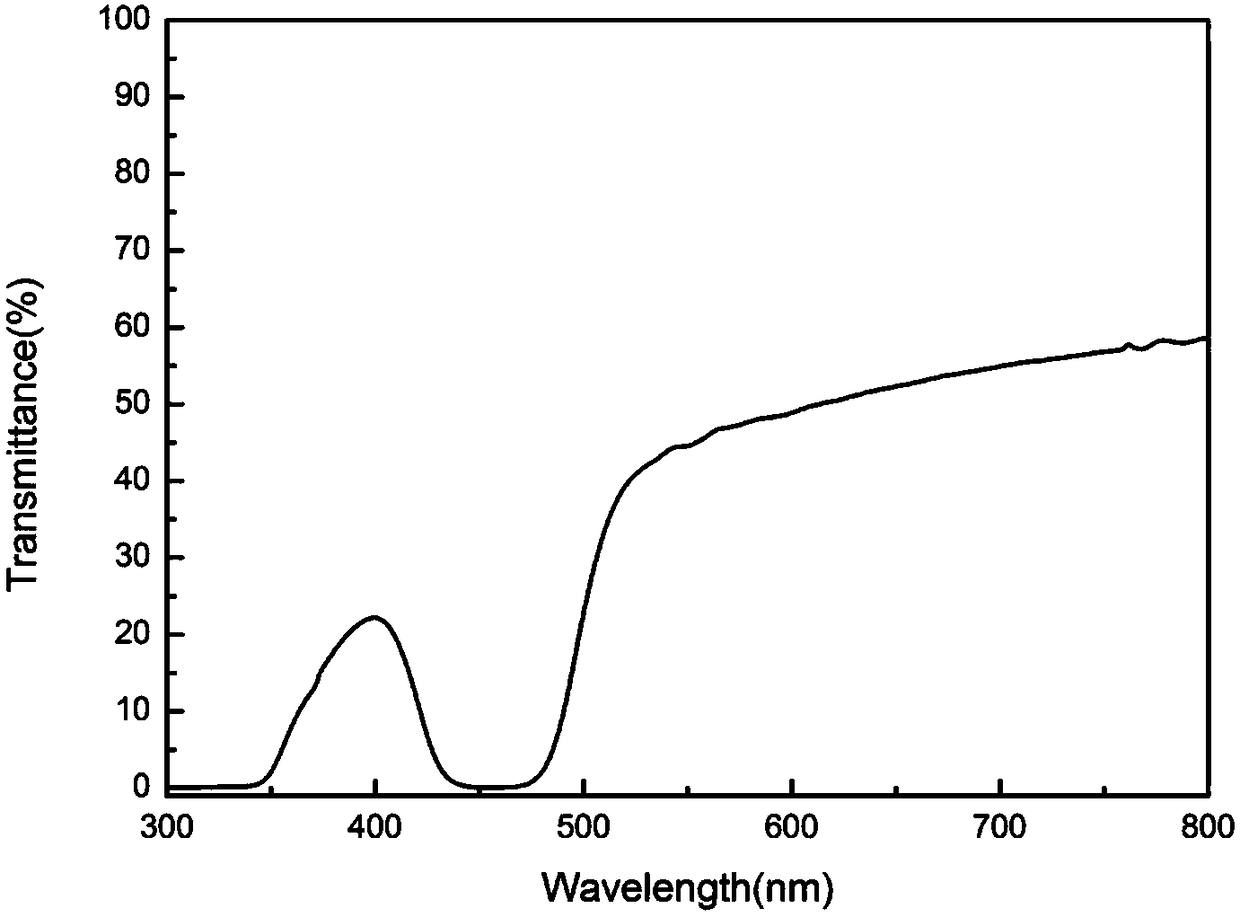

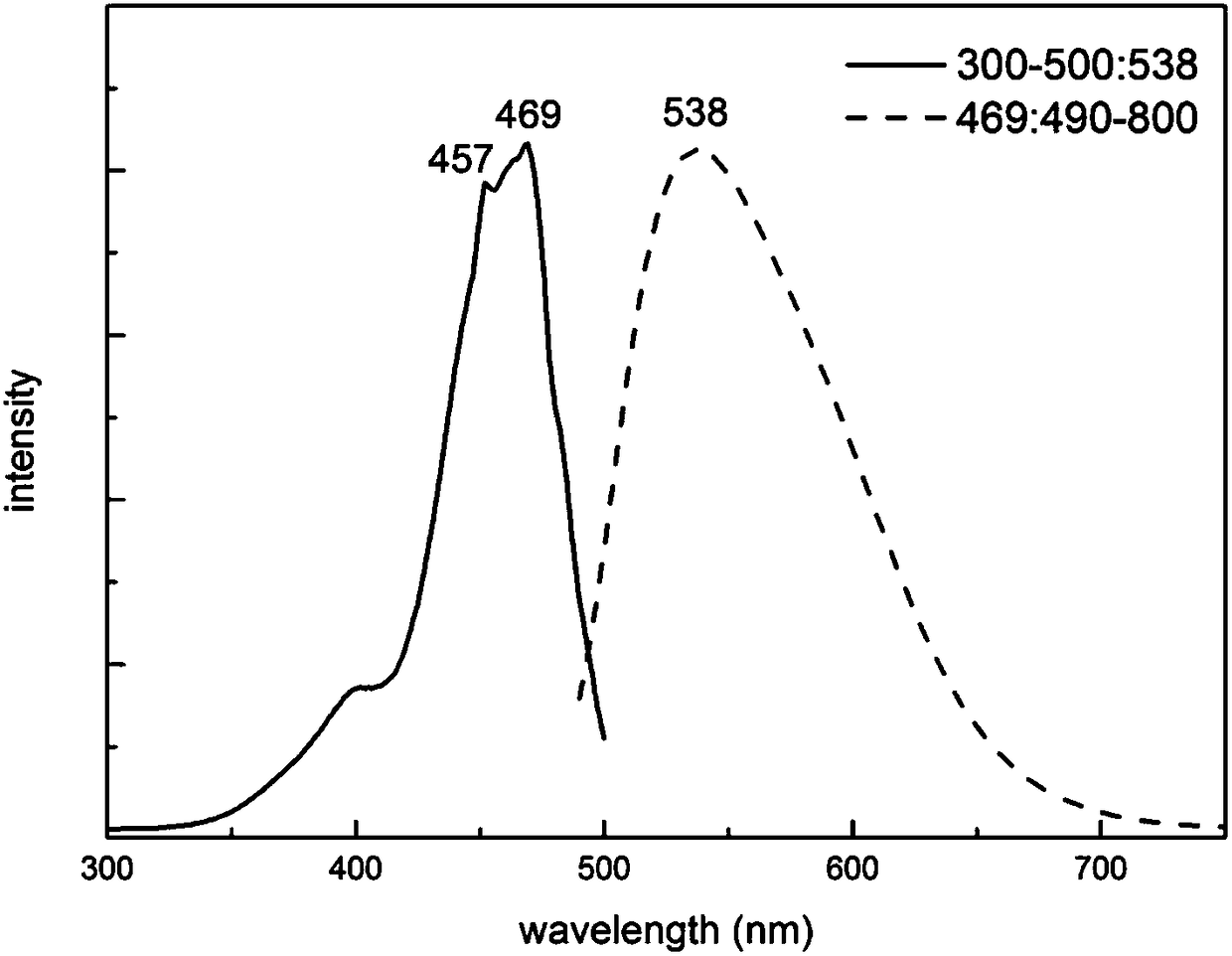

Embodiment 1

[0046] Prepare transparent YAG: Ce glass-ceramics, the specific steps are as follows:

[0047] (1) Glass frit mixing: the analytically pure raw materials are mixed according to 24Y 2 o 3 : 75Al 2 o 3 : 1Ce 2 o 3 The proportioning ratio of (molar ratio) is accurately weighed and placed in a mortar, fully ground and mixed in an agate mortar to obtain a uniform glass mixture;

[0048] (2) Glass frit pressing: the glass mixture is placed in the mould, and a desktop electronic tablet press is used for tableting, and the pressure is set at 10Mpa to obtain a flake glass mixture;

[0049] (3) Glass frit pre-firing: put the flake glass mixture into the crucible, then place the crucible in a muffle furnace and pre-fire it in an air atmosphere, raise the temperature from room temperature to 1600 °C at a rate of 5 °C / min, and keep it warm for 1 hour , and finally cooled to room temperature with the furnace to obtain a bulk glass mixture;

[0050] (4) Preparation of glass by non-con...

Embodiment 2

[0054] Prepare transparent YAG: Ce glass-ceramics, the specific steps are as follows:

[0055] (1) Glass frit mixing: the analytically pure raw materials are mixed according to 49YAlO 3 : 50Al 2 o 3 : 1Ce(NO 3 ) 3 The proportioning ratio of (molar ratio) is accurately weighed and placed in a mortar, fully ground and mixed in an agate mortar to obtain a uniform glass mixture;

[0056] (2) Glass frit pressing: the glass mixture is placed in the mould, and the table-top electronic tablet press is used to press the tablet, and the pressure is set to 30Mpa to obtain the flake glass mixture;

[0057] (3) Preparation of glass by non-container method: place the bulk glass mixture on the nozzle of the pneumatic suspension furnace, and use high-purity O 2 Suspend the sample in the air without contact with any utensils; after the suspension is stable, use CO 2 The laser heats the sample and melts it, and keeps it for 1.5 minutes. After the liquid glass frit is mixed evenly, turn of...

Embodiment 3

[0060] Prepare transparent YAG: Tb glass-ceramics, the specific steps are as follows:

[0061] (1) Glass frit mixing: the analytically pure raw materials are mixed according to 20Y 2 o 3 : 60Al 2 o 3 : 20Tb 2 o 3 The proportioning ratio of (molar ratio) is accurately weighed and placed in a mortar, fully ground and mixed in an agate mortar to obtain a uniform glass mixture;

[0062] (2) Glass frit pressing: the glass mixture is placed in the mould, and the table-top electronic tablet press is used to press the tablet, and the pressure is set to 30Mpa to obtain the flake glass mixture;

[0063] (3) Glass frit pre-firing: Put the flake glass mixture into the crucible, then place the crucible in the muffle furnace for pre-firing, raise the temperature from room temperature to 1200 °C at a rate of 5 °C / min, keep it for 4 hours, and finally heat it up with the furnace. Cool to room temperature to obtain bulk glass mixture;

[0064] (4) Preparation of glass by the flame flota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com