High small ultrasonic polishing, collating equipment in use for parts of axes, and processing method

A shaft part and ultrasonic technology, which is applied in the field of high-efficiency ultrasonic finishing equipment and processing, can solve the problems that the effect of improving the surface geometric accuracy of the parts is not obvious, the performance of the product is affected, and the processing accuracy is not very high, and the processing accuracy is improved. The effect of good practicability and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

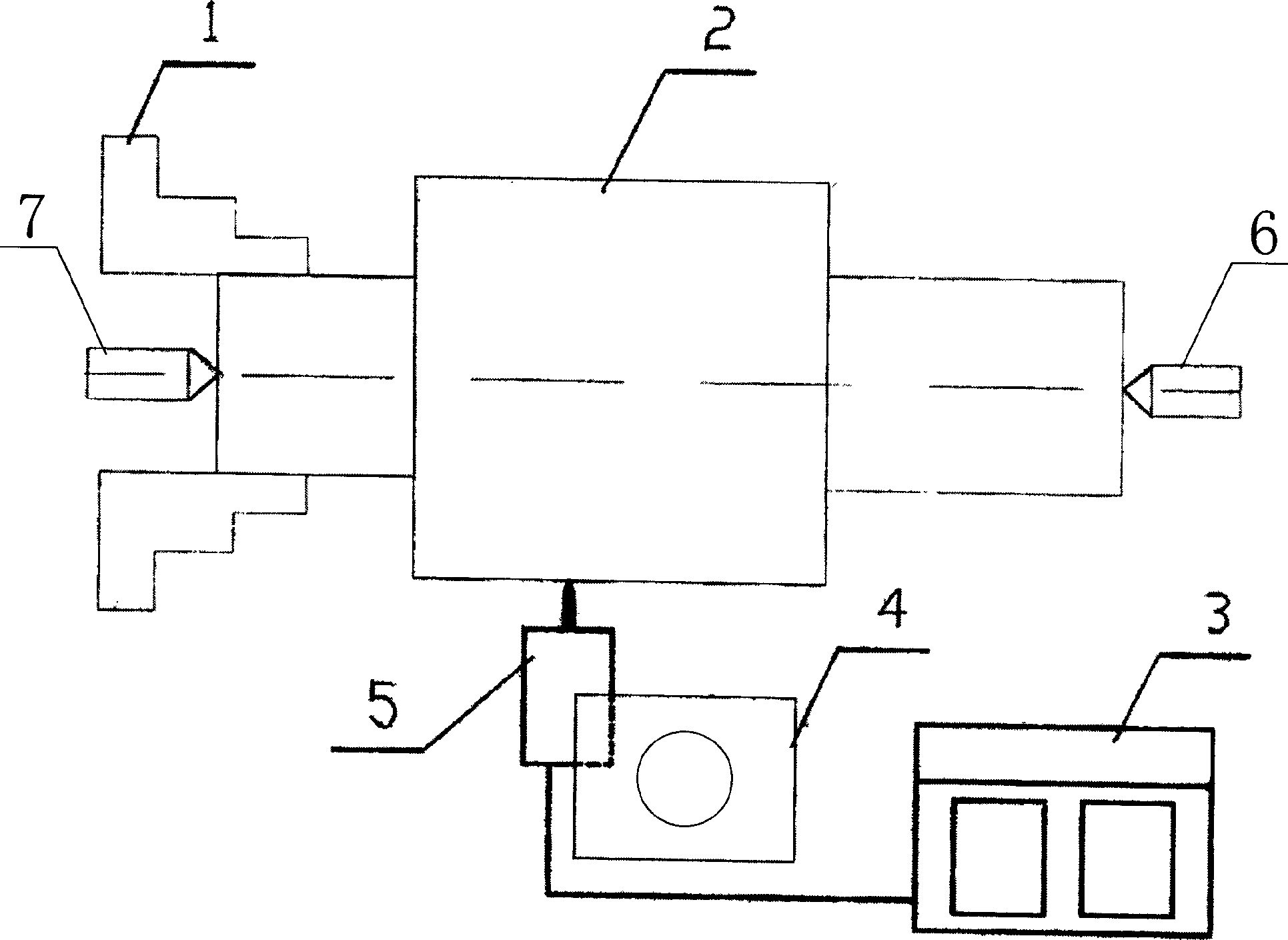

[0027] Such as figure 1 Shown: a high-efficiency ultrasonic surface finishing equipment composed of a high-frequency ultrasonic generator (3) generating 200,000-300,000 Hz per minute and a grinding head (5) connected to it, installed on the common lathe (1) On the turning tool holder (4), and connected with the cooling lubricant, a center hole is made on the two end faces of the workpiece (2) to be processed, and the rear end is tightened by the top (6) of the lathe tailstock, and the front end is installed on the The top (7) in the main shaft of the lathe is pressed tightly, and the workpiece (2) to be processed is fixed and tightened on the chuck jaw of the lathe (1). Using the principle of ultrasonic vibration cold pressing, the grinding head performs high-frequency short bursts on the surface of the workpiece rotating at high speed. The reciprocating vibration movement knocks the surface of the workpiece to be processed with a certain impact force. Its cold pressing proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com