Double-wall structured hollow ultrafine polymer fiber and preparation method thereof

A superfine fiber and polymer technology, which is applied in the manufacture of hollow filaments, conjugated synthetic polymer man-made filaments, and fiber processing. The effect of excellent performance, simple equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

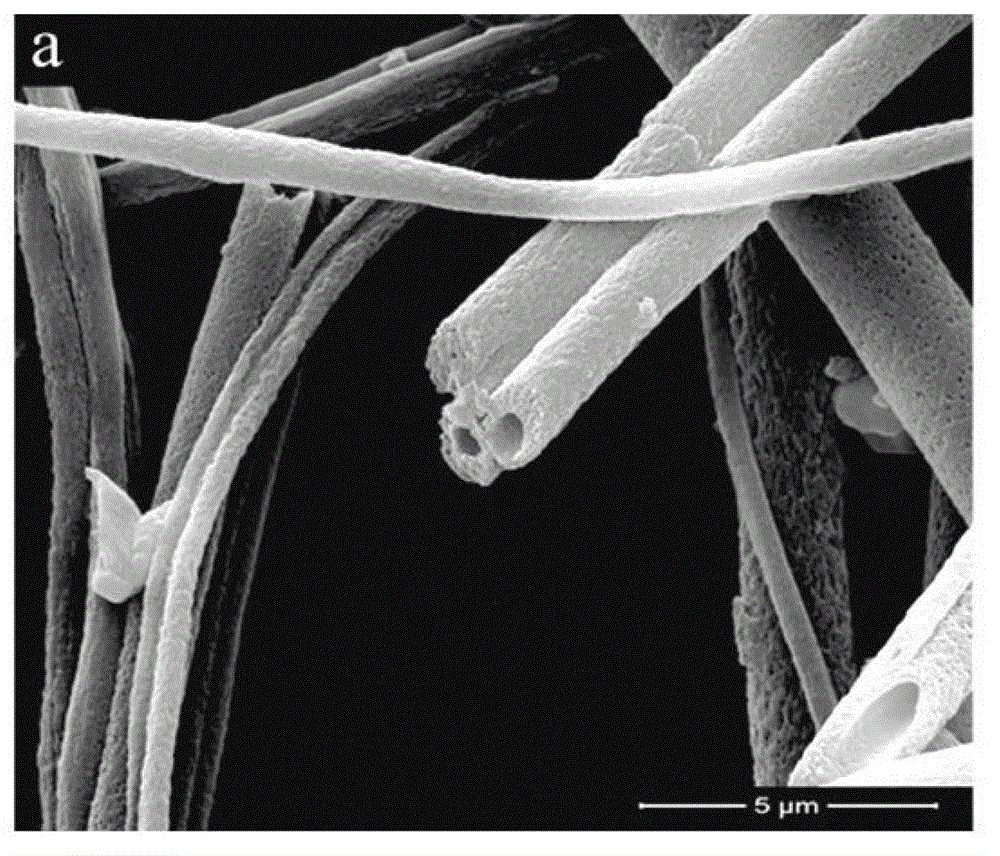

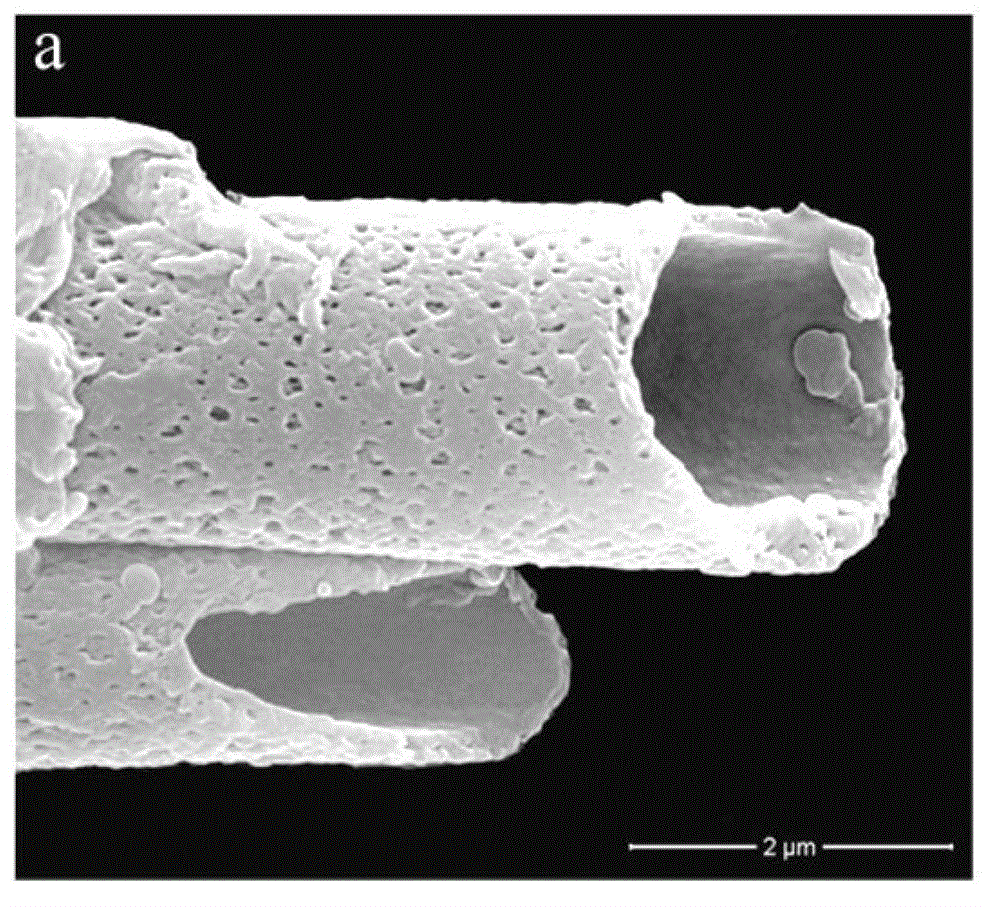

[0038] Example 1: Preparation of polyarylene sulfide sulfone double-wall hollow microfibers:

[0039] Add 100g of polyarylene sulfide sulfone and 300g of N-methylpyrrolidone into a dissolution kettle equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 100°C, defoam and mature for 10h at a vacuum degree of 0.03MPa, and make an electrospinning shell Solution: Add 0.5g of polyvinyl alcohol and 10g of N-methylpyrrolidone into a dissolution kettle with a stirrer and a thermometer, stir and dissolve at a temperature of 100°C, defoam and age at a vacuum of 0.04MPa for 10h, and make an electrospun inner layer solution. The solution is placed on the receiving device by electrospinning, the diameter of the spinneret of the core layer is 0.3mm, the flow rate is 1ml / h; the diameter of the spinneret of the outer liquid is 0.8mm, the flow rate is 5ml / h, and the rapid Volatilized to obtain polyarylene sulfide sulfone double-walled hollow microfibers (where the s...

Embodiment 2

[0040] Example 2: Preparation of polyarylene sulfide sulfone amide double-wall hollow microfibers:

[0041]Add 200g of polyarylene sulfide sulfone amide and 500g of N-methylpyrrolidone into a dissolution kettle equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 30°C, defoam and mature at a vacuum degree of 0.03MPa for 12h, and make an electrospinning shell solution. Add 0.5g of polyethylene glycol and 10g of deionized water into a dissolution kettle equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 40°C, defoam and age at a vacuum of 0.03MPa for 10h, and prepare an electrospinning inner layer solution . The solution is sprayed onto the receiving device by electrospinning, the diameter of the spinneret of the core layer is 0.6mm, and the flow rate is 2ml / h; the diameter of the spinneret of the outer liquid is 1 mm, and the flow rate is 8ml / h, accompanied by the rapid volatilization of the solvent , Obtained polyaryl...

Embodiment 3

[0042] Example 3: Preparation of polyarylene sulfide sulfone amide double-walled hollow microfibers:

[0043] Add 300g of polyarylene sulfide sulfone amide and 1000g of N,N-dimethylacetamide into a dissolution kettle equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 50°C, defoam and mature at a vacuum of 0.05MPa for 11h, Prepare the shell electrospinning solution; add 10g of polylactic acid and 300g of chloroform into a dissolution kettle equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 50°C, defoam and mature at a vacuum degree of 0.03MPa for 10h, and make an electrospinning solution inner layer solution. The solution is sprayed onto the receiving device by electrospinning, the diameter of the spinneret of the core layer is 0.4 mm, and the flow rate is 3ml / h; the diameter of the spinneret of the outer liquid is 0.9 mm, and the flow rate is 8ml / h. , Obtained polyarylene sulfide sulfone double-wall hollow microfibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com