Patents

Literature

156results about How to "Strong solvent resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing thioamide-based chelating nanofiber for adsorbing heavy metal ions

InactiveCN102140705AAchieve enrichmentUniform diameterOther chemical processesFilament/thread formingHeat stabilitySolvent

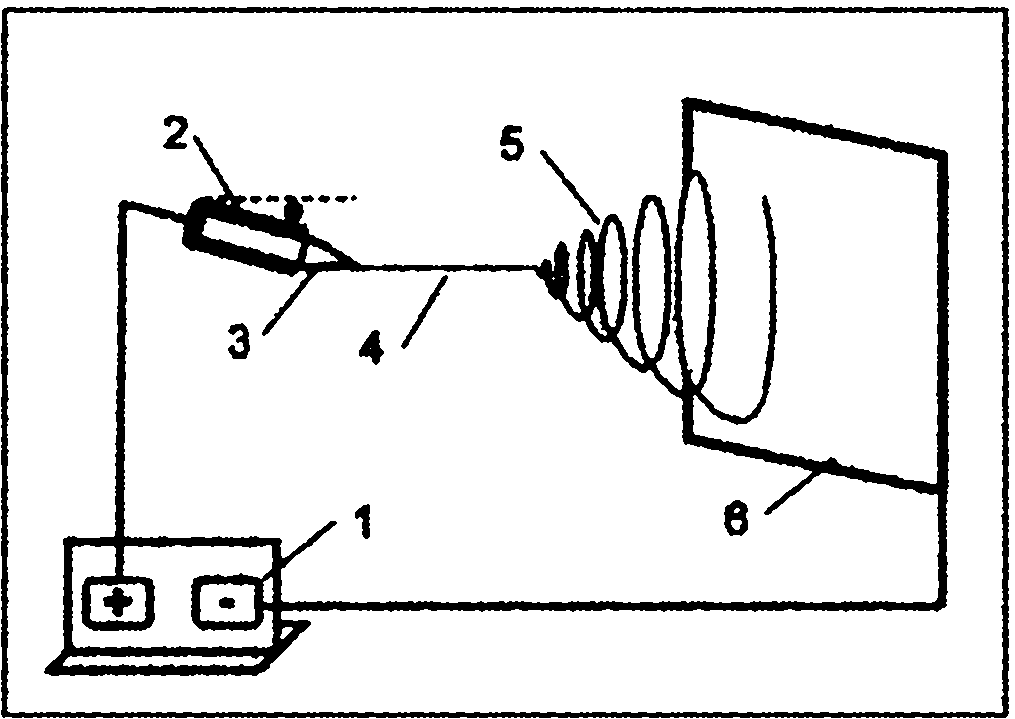

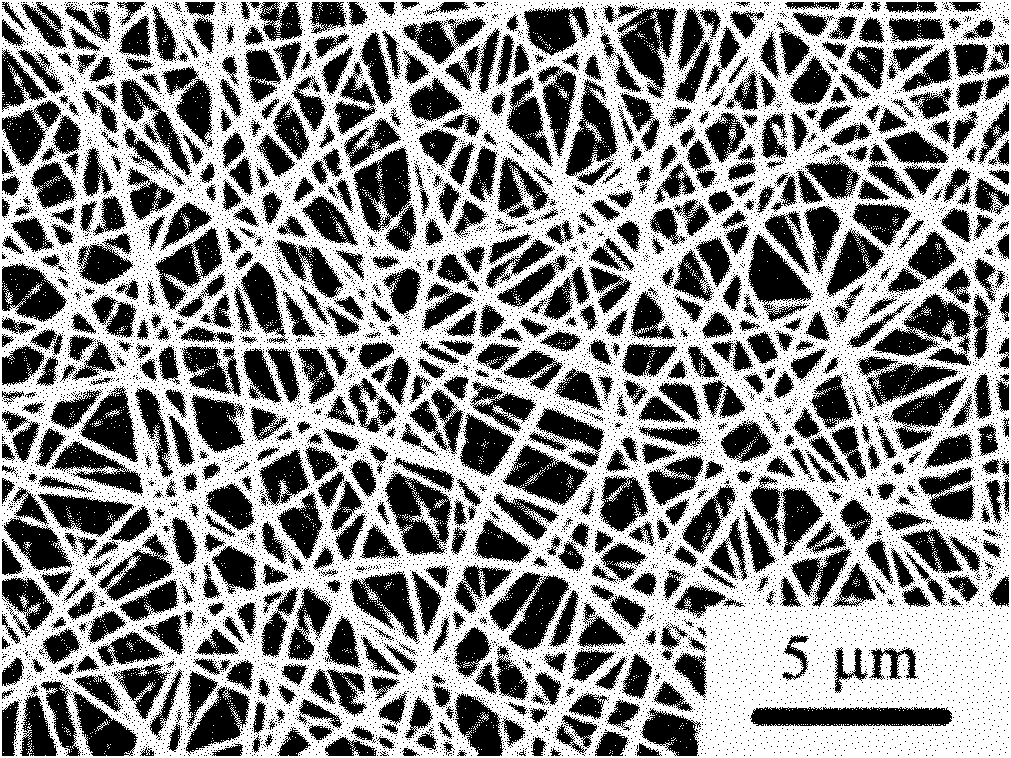

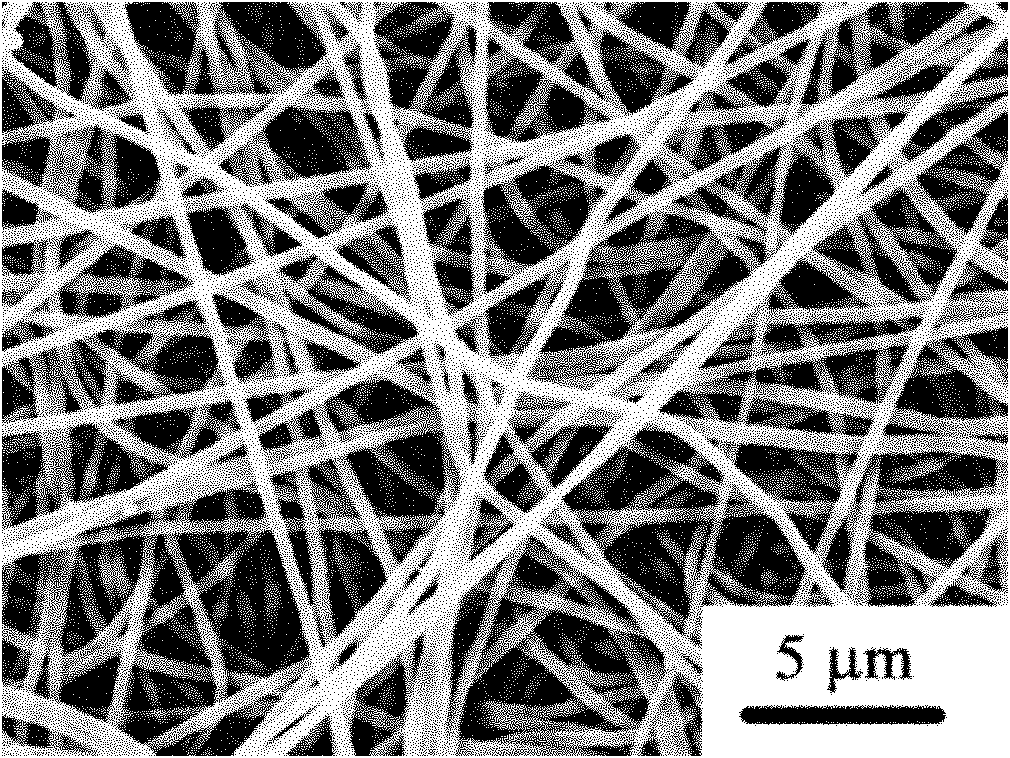

The invention relates to a method for preparing a thioamide-based chelating nanofiber for adsorbing heavy metal ions by combining an electrostatic spinning technology with a chemical grafting technology. The method comprises the following steps of: preparing a nanofiber from polyacrylonitrile which has high chemical stability, is easily subjected to electrospinning and is taken as an initiative raw material of reaction by the electrostatic spinning technology, pre-crosslinking, and performing thioamidation to prepare the chelating nanofiber for adsorbing the heavy metal ions. The fiber membrane of the prepared chelating nanofiber has good appearance, uniform diameter, high mechanical property, heat stability and solvent resistance, and high property of adsorbing the heavy metal ions such as gold, silver, lead, mercury, palladium, cadmium and the like. By the technology, the preparation process is simple, production equipment is low-cost, and the chelating nanofiber has low requirement on production conditions, and high properties, so the chelating nanofiber has high practical value, the content of the heavy metal ions which are produced due to industrial development and harm human health is reduced, and the chelating nanofiber has a wide application prospect for solving the livelihood problem.

Owner:JILIN UNIV

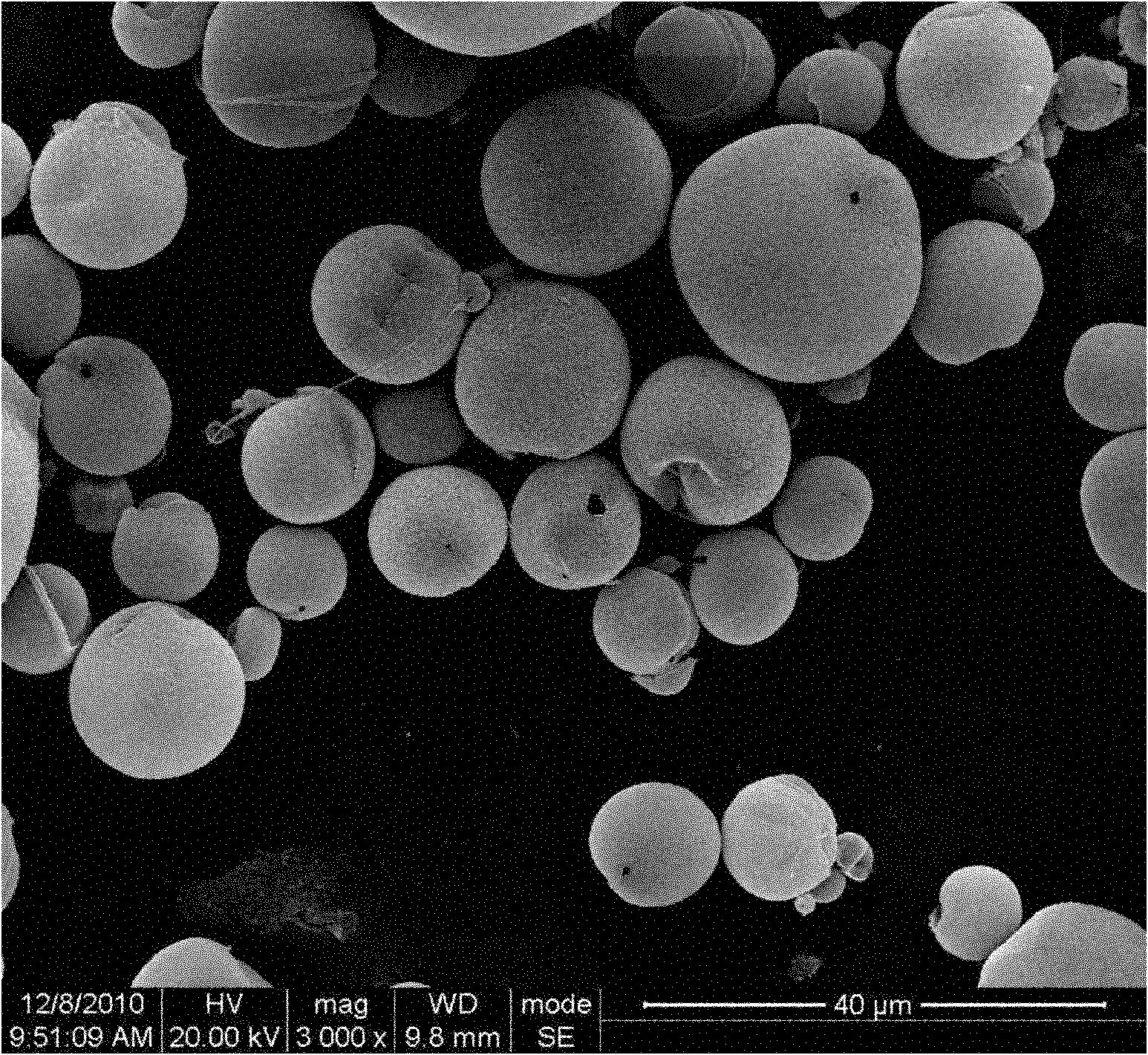

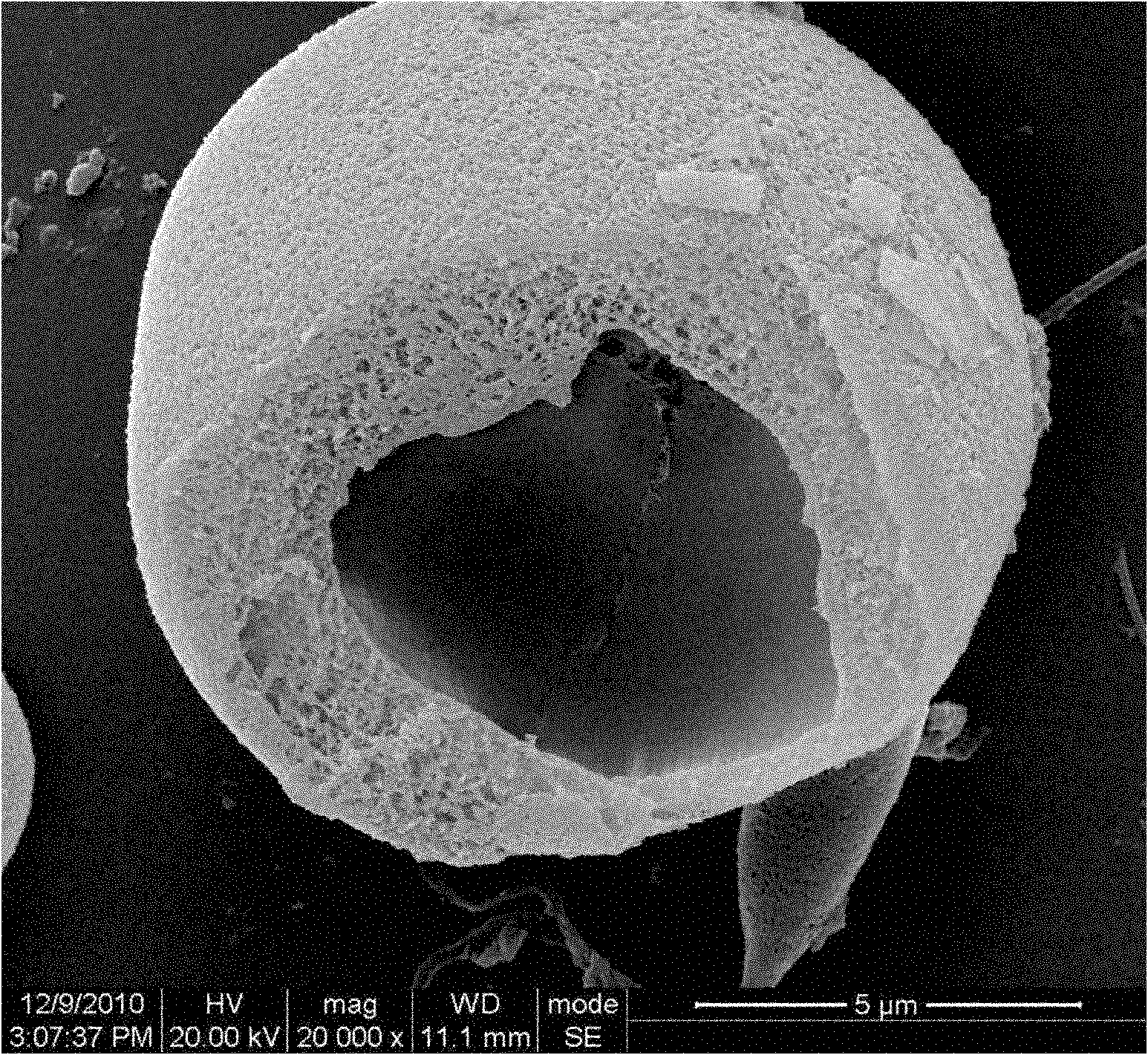

Polymer hollow nano microspheres and preparation method thereof

InactiveCN102127298ASimple equipmentEasy to operateCosmetic preparationsCatalyst carriersSolventThermometer

The invention discloses polymer hollow nano microspheres and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding 10-200 parts by weight of polymer A, 0-200 parts by weight of additive and 100-1000 parts by weight of solvent A into a dissolving kettle provided with a stirrer and a thermometer, dissolving by stirring at 30-100 DEG C, debubbling, and aging to obtain a polymer shell solution; adding 0-400 parts by weight of polymer B and 100-1000 parts by weight of solvent B into a dissolving kettle provided with a stirrer and a thermometer, dissolving by stirring at 30-100 DEG C, debubbling and aging to obtain a core solution; putting the polymer shell solution and the core solution in a high-voltage electrostatic field, and carrying out electrostatic spraying by a coaxial electrostatic sprayer to obtain polymer microspheres, wherein the inner diameter of the needle head of the core is 0.4-0.6mm, the solution flow rate is 1-5ml / h, the inner diameter of the needle head of the shell is 0.9-1.2mm, the solution flow rate is 5-10ml / h, the spraying voltage is adjusted to 5-25kV, the spraying distance is 1-10cm, and the temperature of the receiving bath is 10-50 DEG C; and removing core substances of the microspheres to obtain the polymer hollow nano microspheres.

Owner:SICHUAN UNIV

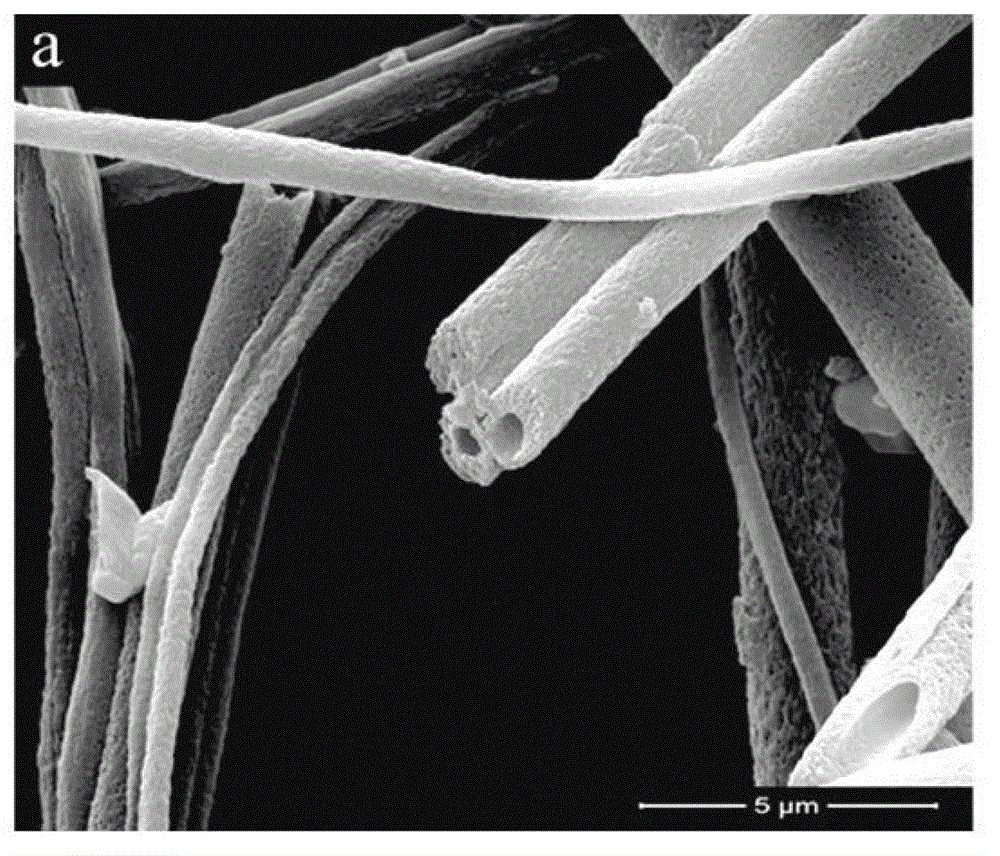

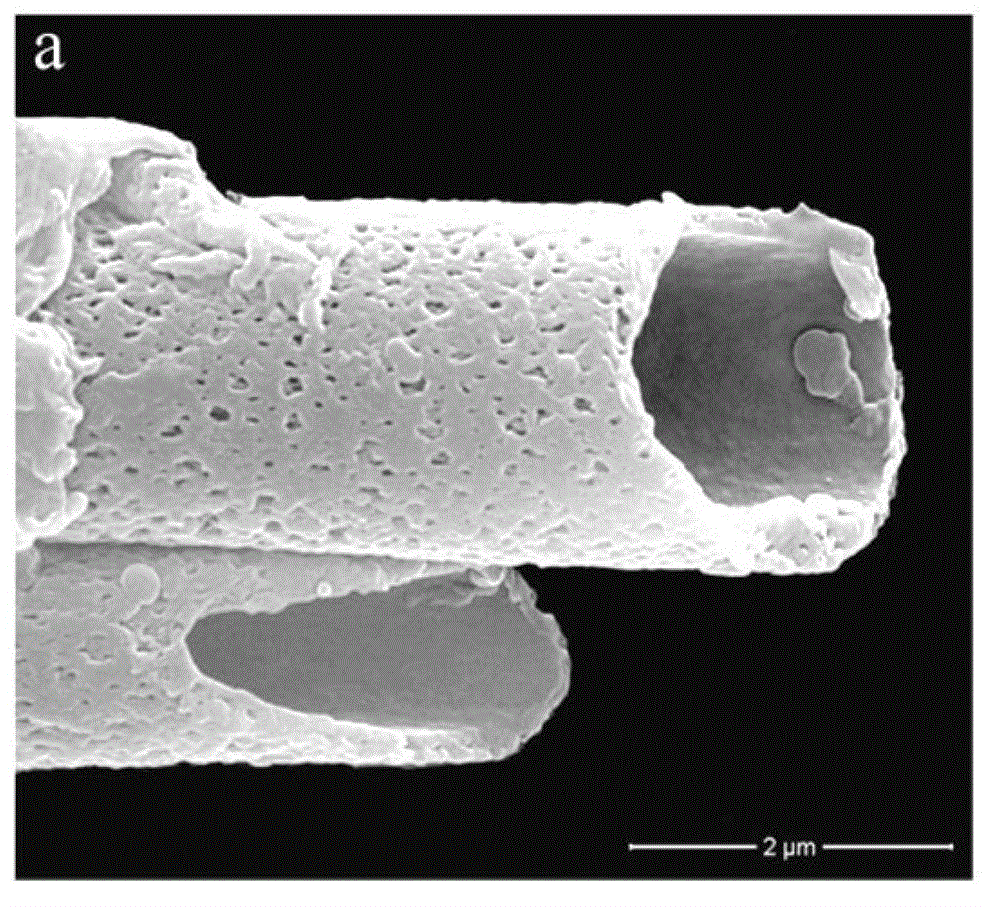

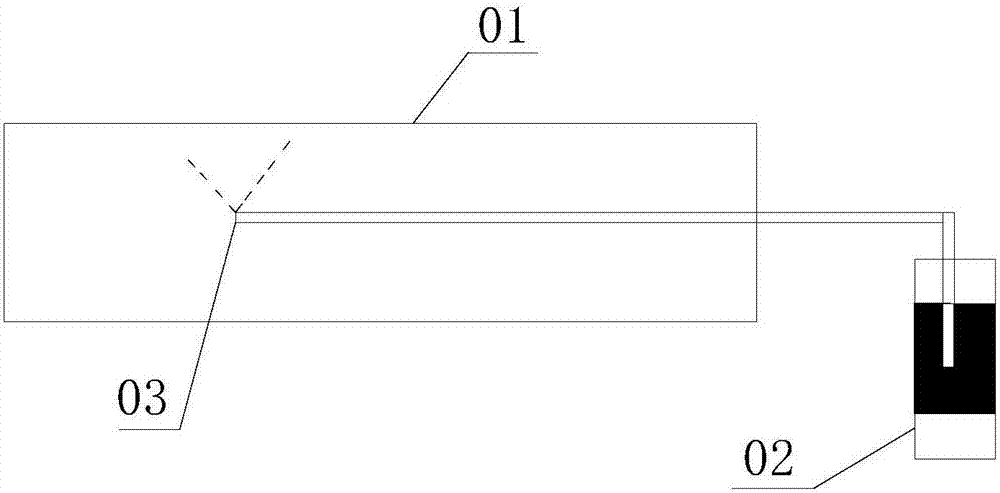

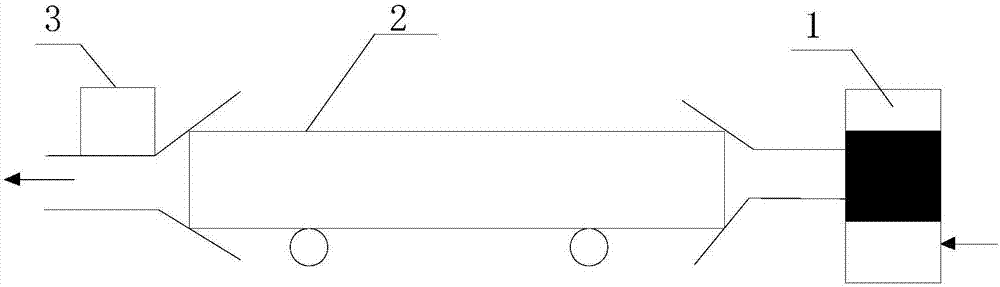

Double-wall structured hollow ultrafine polymer fiber and preparation method thereof

InactiveCN103147165AEasy to operateLow costHollow filament manufactureFilament/thread formingFiberPolymer science

The invention discloses a double-wall structured hollow ultrafine polymer fiber and a preparation method thereof. The preparation method includes a first step of enabling 100-300 parts of polymers A and 300-1000 parts of solvent A to be added in a dissolving kettle provided with a stirrer and a thermometer, stirring and dissolving the polymers A and the solvent A under temperature of 30-100 DEG C, carrying out defoaming and curing for 10-12 hours at vacuum degree of 0.03-0.05 MPa, and obtaining polymer shell layer spinning solution, a second step of enabling 0.5-100 parts of polymers B and 10-1000 parts of solvent B to be added into the dissolving kettle provided with the stirrer and the thermometer, stirring and dissolving the polymers B and the solvent B under temperature of 30-100 DEG C, carrying out defoaming and curing for 10-12 hours at vacuum degree of 0.03-0.05 MPa, and obtaining polymer core layer spinning solution, a third step of enabling the polymer shell layer spinning solution and the polymer core layer spinning solution to pass through a core layer spinning nozzle and a shell layer spinning nozzle, wherein the inner diameter of the core layer spinning nozzle is 0.3-0.6 mm, and flow rate is 1-8 mm / h, the inner diameter of the shell layer spinning nozzle is 0.8-1.2 mm, and the flow rate is 5-10 mm / h, spinning voltage is 15-25 kilovolts, and finally manufacturing the double-wall structured hollow ultrafine polymer fiber through electrostatic spinning. The polymers A can form the outer layer of a hollow polymer fiber wall, and the polymers B can form the inner layer of the hollow polymer fiber wall.

Owner:SICHUAN UNIV

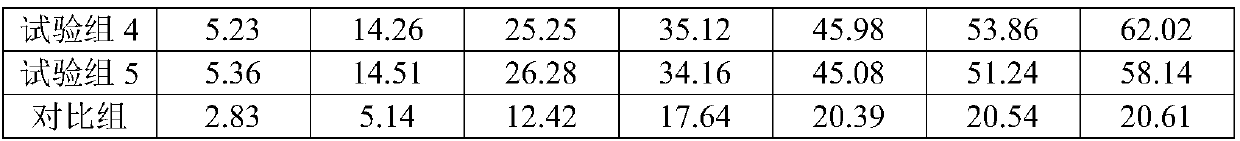

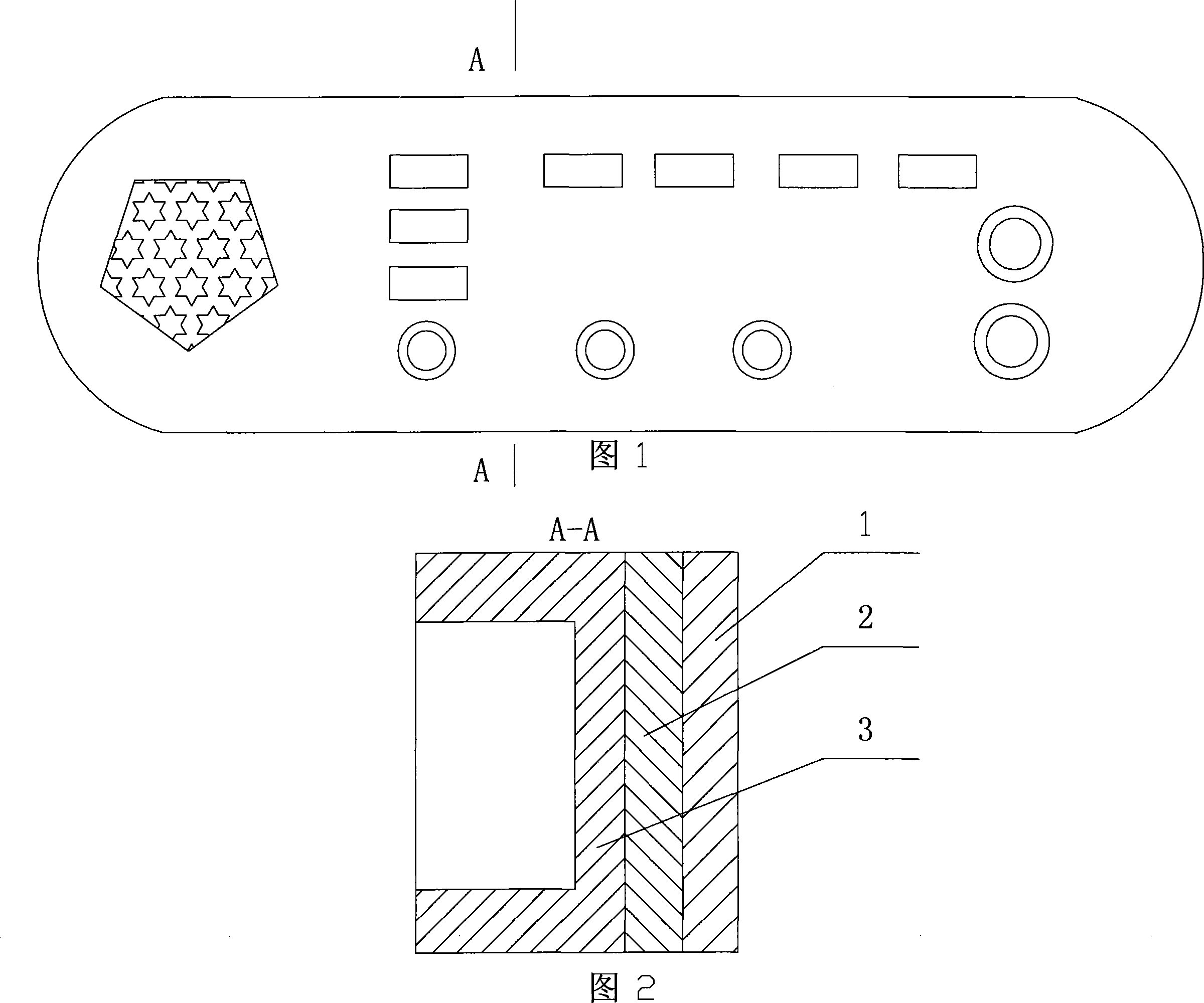

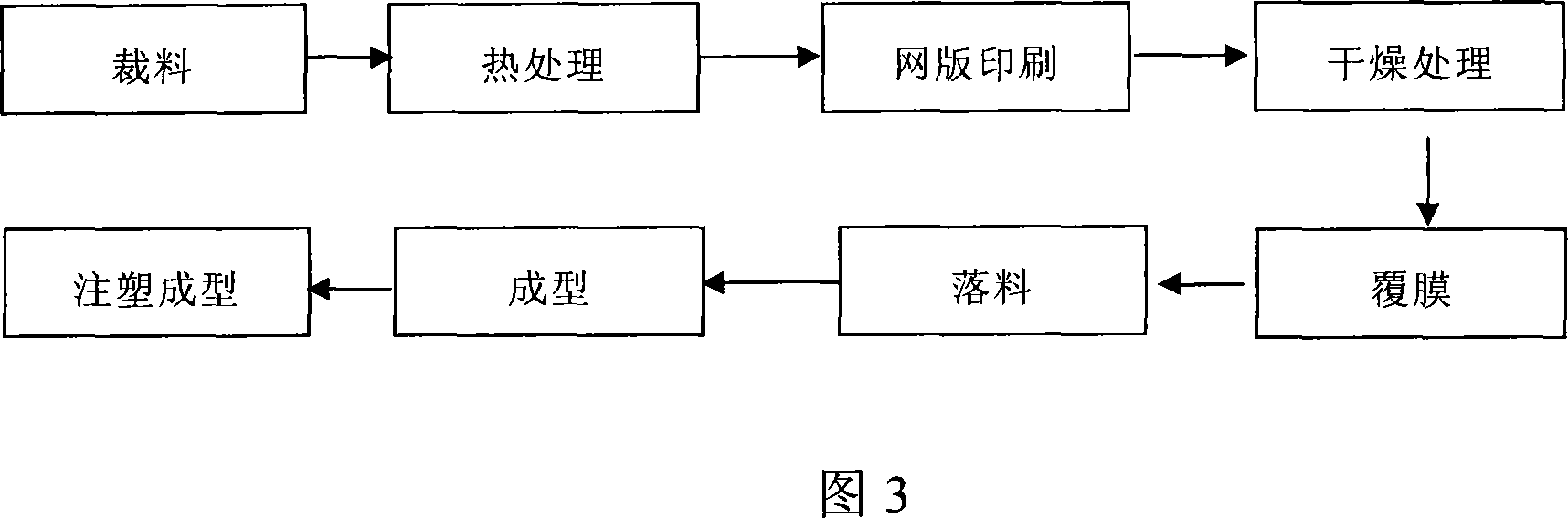

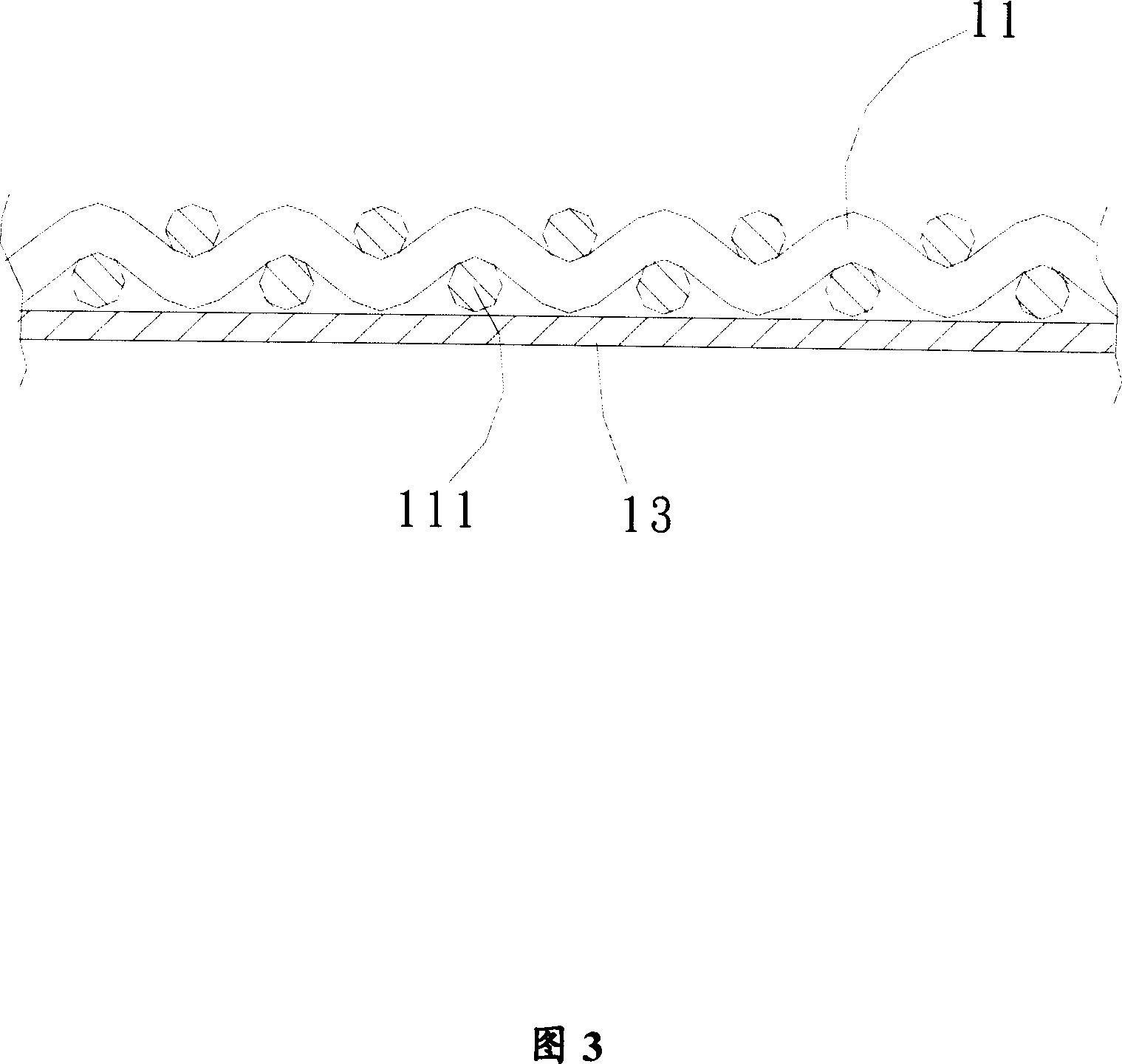

Surface decoration and process for making the same

InactiveCN101200156ABulb uniformAvoid cumbersome stepsSynthetic resin layered productsSpecial ornamental structuresScreen printingGraphics

The invention relates to a surface decoration piece (IMD) and the production process of the surface decoration piece, which is in particular widely used in the information technology products, household appliances, electronic products, personal computers, car accessories and so on and belongs to the technical field of injection molding decoration. The invention is characterized in that the screen-printing of ink patterns is adopted on the reverse side of a transparent sheet. The ink pattern is disposed between the injection molding layer sheet and the formed transparent sheet, which is integrated through the drying, cutting, molding and the injection molding. With the invention, the production time can be shortened and the costs can be reduced with the improvement of product quality and the enhancement of the scratch resistance of the products. With strong solvent resistance, excellent three-dimensional sense, the patterns are clear with excellent anti-light and moisture proof performance. The graphic, logo and color can be changed at any time without the need to replace the die. The convex bubbles of the function keys are uniform with good feel, in which the life expectancy can be up to one million times. The printing precision of the products with three-dimensional shapes is accurate and the error is small.

Owner:无锡市红光标牌有限公司

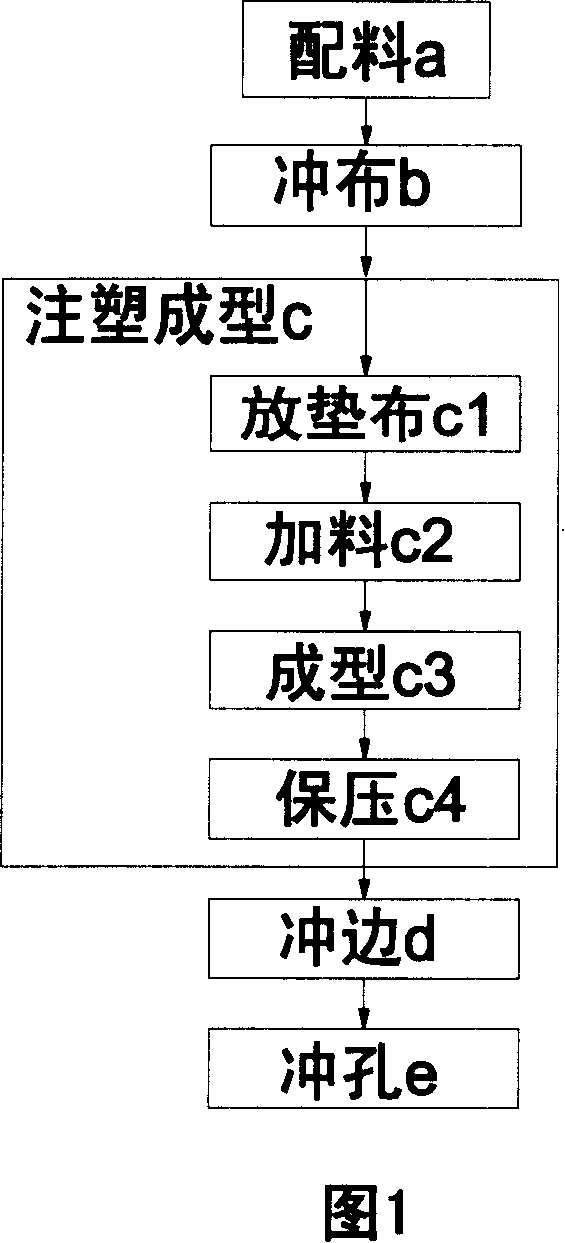

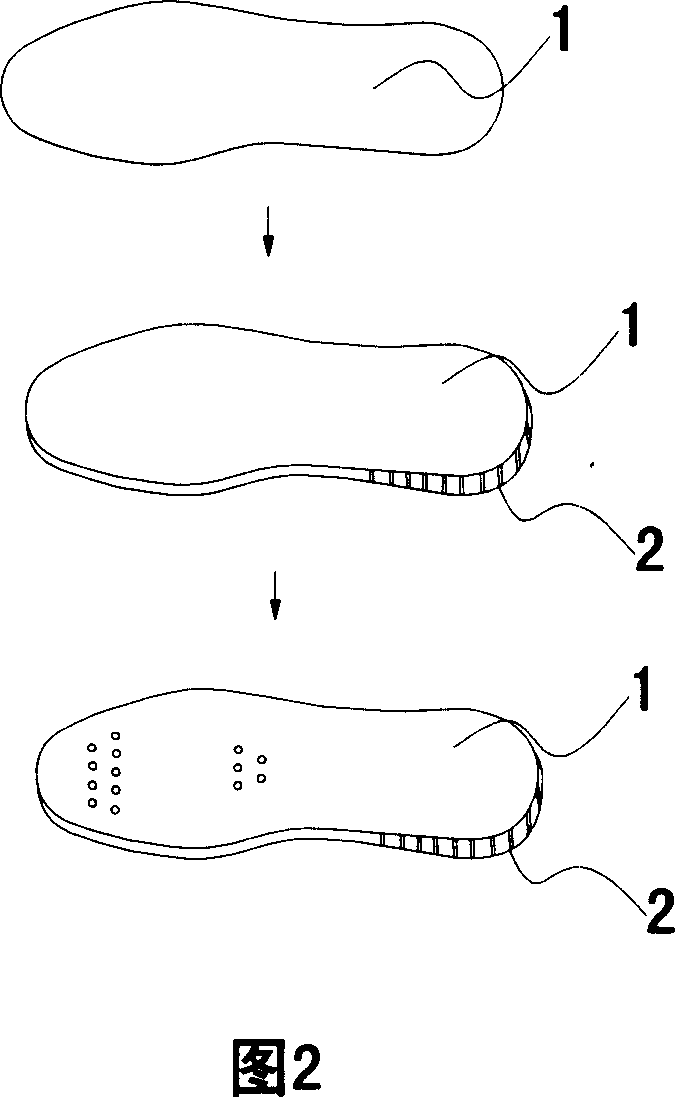

Thermoplasticity elastic sock processing method

InactiveCN101138888AGood flexibilityIncrease elasticityInsolesDomestic footwearInjection pressurePunching

The present invention discloses a processing method of a thermoplastic elastic insole. A TPR thermoplastic elastomer (thermoplastic rubber) as the main raw material, and the following processing steps are adopted, firstly, compounding is that the TPR thermoplastic elastomer and toner are compounded according to the weight ratio of 10000 to 8 till 10000 to 16 and are sent into a kneading machine to be kneaded for 20 to 40 minutes; secondly punching a cloth is that a base material of the cloth is punched and sheared as the shape of a mould of the insole which is needed to for a laying cloth; thirdly injection mold and molding are that at first placing the laying cloth is that the laying cloth is put inside an injection mold and is placed above a lower mold; then feeding is that the well kneaded raw material is put into an injection mold and molding machine, than molding is that the injection mold is sent into the injection mold and molding machine, and the injection mold and molding machine starts to inject towards the injection mold, and the injection temperature is 150 DEG C to 250 DEG C, and injection pressure is 30 bar to 90 bar, and a rotating speed of a screw is 25 to 75 turns per minute, and a backpressure is 3 bar to 4 bar; fourthly punching a margin is that the insole is taken out from the mold, and the redundant marginal material joints are punched down by a punch; fifthly punching is that exhausting pylomes are punched at the insole. The insole produced by the present invention has good breathability, pliability and rebound resilience.

Owner:庄沧涛

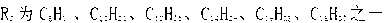

Amphiprotic amphiphilic leather retanning fatting agent and preparation method thereof

ActiveCN103131804APromote absorptionLubricateTanning treatmentLeather impregnationFiberPolymer science

The invention discloses amphiprotic amphiphilic leather retanning fatting agent and a preparation method of the amphiprotic amphiphilic leather retanning fatting agent. The constituent of the amphiprotic amphiphilic leather retanning fatting agent is (methyl) crylic acid-N-alkyl diene propyl amine-diallylamine terpolymer. According to the preparation method of the amphiprotic amphiphilic leather retanning fatting agent, N-alkyl diene propyl amine is firstly prepared, then the N-alkyl diene propyl amine, diallylamine, and (methyl) crylic acid are adopted for a free radical copolymerization reaction under the acidic condition to obtain an aqueous dispersoid containing the (methyl) crylic acid-N-alkyl diene propyl amine-diallylamine terpolymer, the solid content of a product is adjusted to 15-20% with water, and the amphiprotic amphiphilic leather retanning fatting agent is obtained. The molecular structure of the amphiprotic amphiphilic leather retanning fatting agent contains carboxyl of negative ions and tertiary amino of positive ions, and the polymer can display different electrical properties under different conditions of potential of hydrogen (PH), meanwhile the polymer contains alkyl of a long chain, and functions of lubrication fibers can be achieved. The polymer has the function of retanning, fatting and dyeing assistance at the same time, physical and mechanical properties of processed crust leather, such as tensile strength, fullness, softness and elasticity, are all improved, the surface of the processed crust leather is strong in lubrication feel and comfortable in hand feel, and the leather has a good waterproof performance.

Owner:四川德赛尔新材料科技有限公司

Degradation-type composite material and preparation method thereof

The invention provides a degraded composite material and a preparation method thereof, and relates to a degraded composite material. Poly lactic acid in an amount of 10 to 90 parts by weight, butanediol-adipic acid-terephthalic acid in an amount of 10 to 90 parts by weight, glycidyl methacrylate in an amount of 1 to 5 parts by weight, an initiator in an amount of 0.5 to 1 part by weight, and a processing accessory ingredient in an amount of 1 to 3 parts by weight are uniformly mixed in a mixing machine, and are plastified and extruded by a double screw extruder, thus getting the degraded composite material. The method disclosed by the invention is simple. The product can be produced easily with good stability, and has the advantages of excellent mechanical property, mechanical property, excellent degradability and so on. The tenacity and the hand feeling of a film made of the composite material are very excellent, and the composite material can be used as packaging material, environment-friendly material and so on.

Owner:JIANGSU QIONGHUA GRP CO LTD

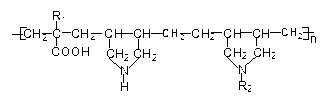

Unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and paint preparation method thereof

ActiveCN105504245AImprove performanceImprove corrosion resistancePolyester coatingsPolyesterShrinkage rate

The invention discloses unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and a paint preparation method thereof. The unsaturated polyester paint is prepared from 90-100 parts of unsaturated polyester gel coat resin, 10-30 parts of activated thinner, 1-5 parts of photoinitiator, 1-3 parts of coinitiator, 0-20 parts of talcum powder, 0-0.5 part of dispersing auxiliary and 0.5-3 parts of other auxiliaries. The weight ratio of photoinitiator to coinitiator is (1-5):(1-3), and unsaturated polyester gel coat resin is a mixture of acrylate-terminated unsaturated polyester and activated thinner. A coating can be prepared from the paint through the UV-LED photocuring technology, deep solidification of a film 200 micrometers thick on a woodware base material can be achieved, and the coating is low in shrinkage rate, good in acid resistance and alkaline resistance, high in luster and good in adhesive force.

Owner:GUANGDONG UNIV OF TECH +1

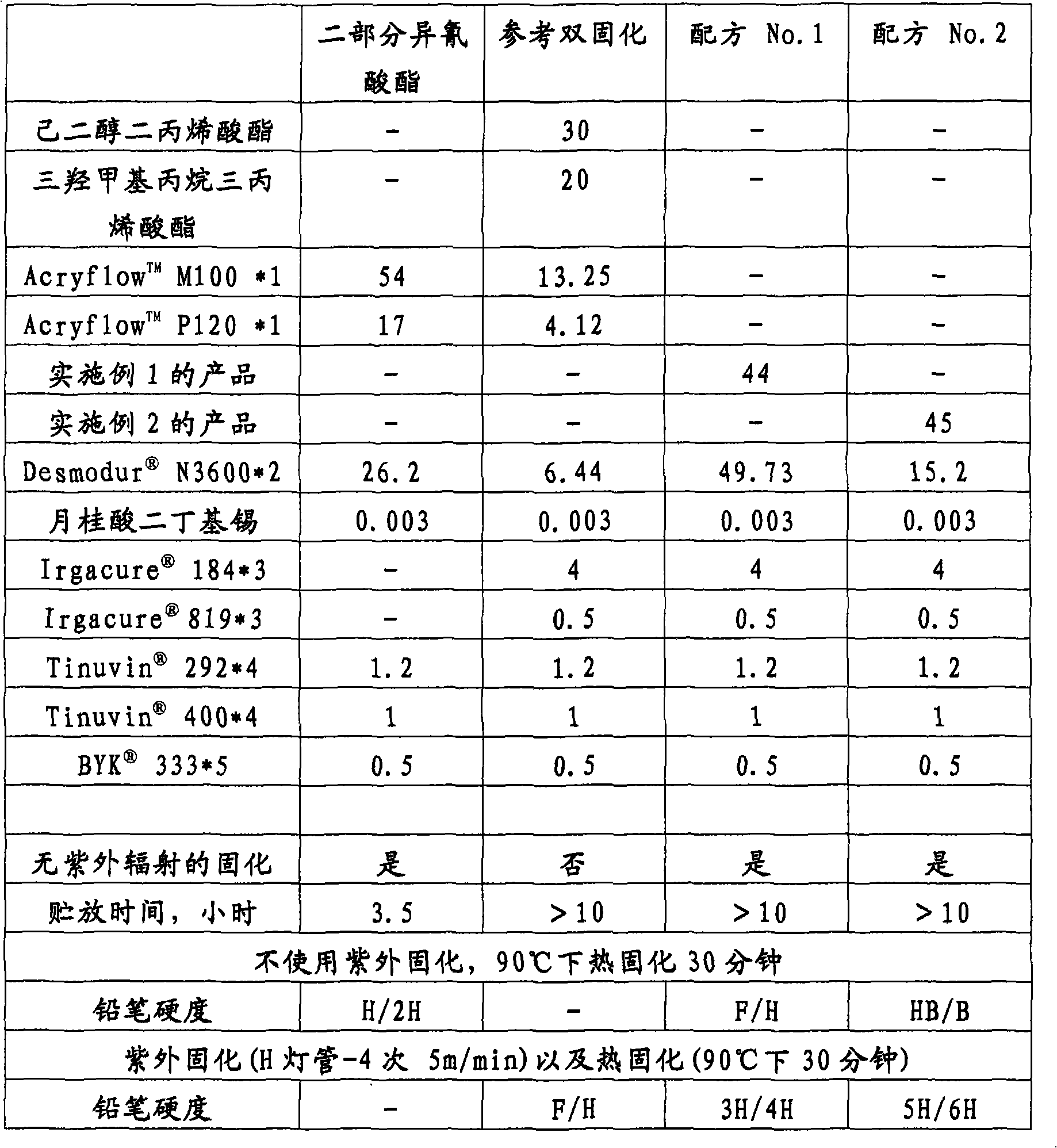

Dual cure composition

ActiveCN101321837AStrong solvent resistanceImprove acid resistancePolyurea/polyurethane coatingsDual curePhotoinitiator

Disclosed is a novel liquid radiation and thermally curing (dual cure) composition comprising (a) at least one partially acrylated tri or polyalcohol and acrylic, having has at least two hydroxyl group's, at least one acrylic or methacrylic double bond, a hydroxyl value of 50-500 mg KOH / g and a double bond concentration of 1-10 mmoles / g, (b) at least one crosslinking agent for hydroxyl functional compounds, which crosslinking agent optionally has at least one olefmic double bond, (c) an additive package comprising at least one photoinitiator, radical scavenger, light stabiliser, wetting agent and / or levelling agent, and optionally (d) at least one monomeric or oligomeric reactive diluent.

Owner:PERSTORP SPECIALTY CHEM AB

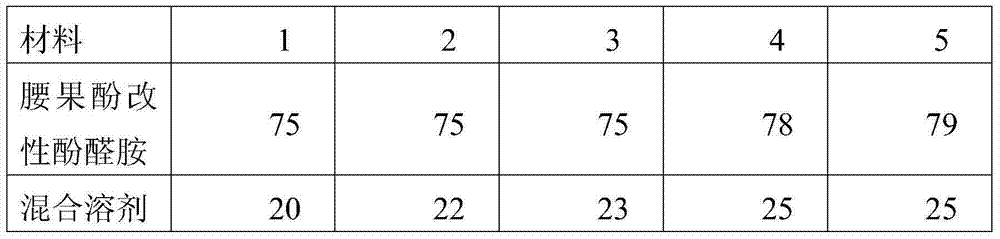

Anticorrosive paint coated under rusted and moist conditions

InactiveCN103756512AImprove protectionIncrease crosslink densityAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention discloses an anticorrosive paint coated under rusted and moist conditions and particularly discloses a bicomponent epoxy anticorrosive paint which can be coated on rusted and moist steel surfaces and can play a protective role. The anticorrosive paint comprises a component A and a component B, wherein the component A is composed of the following components in parts by weight: 25-28 parts of epoxy resin, 33-36 parts of pigment and filler, 3.5-5 parts of rust transforming agent, 30-35 parts of mixed solvent and 0.5-1.5 parts of auxiliaries; and the component B is composed of the following components in parts by weight: 75-80 parts of modified mannich amide hardener and 20-25 parts of mixed solvent. The weight ratio of the component A to the component B is (90-100): (1-1.2), and the component A and the component B are mixed before being used.

Owner:SHANGHAI DATONG TABERNACLE NEW ENERGY SAVING MATERIALS CO LTD

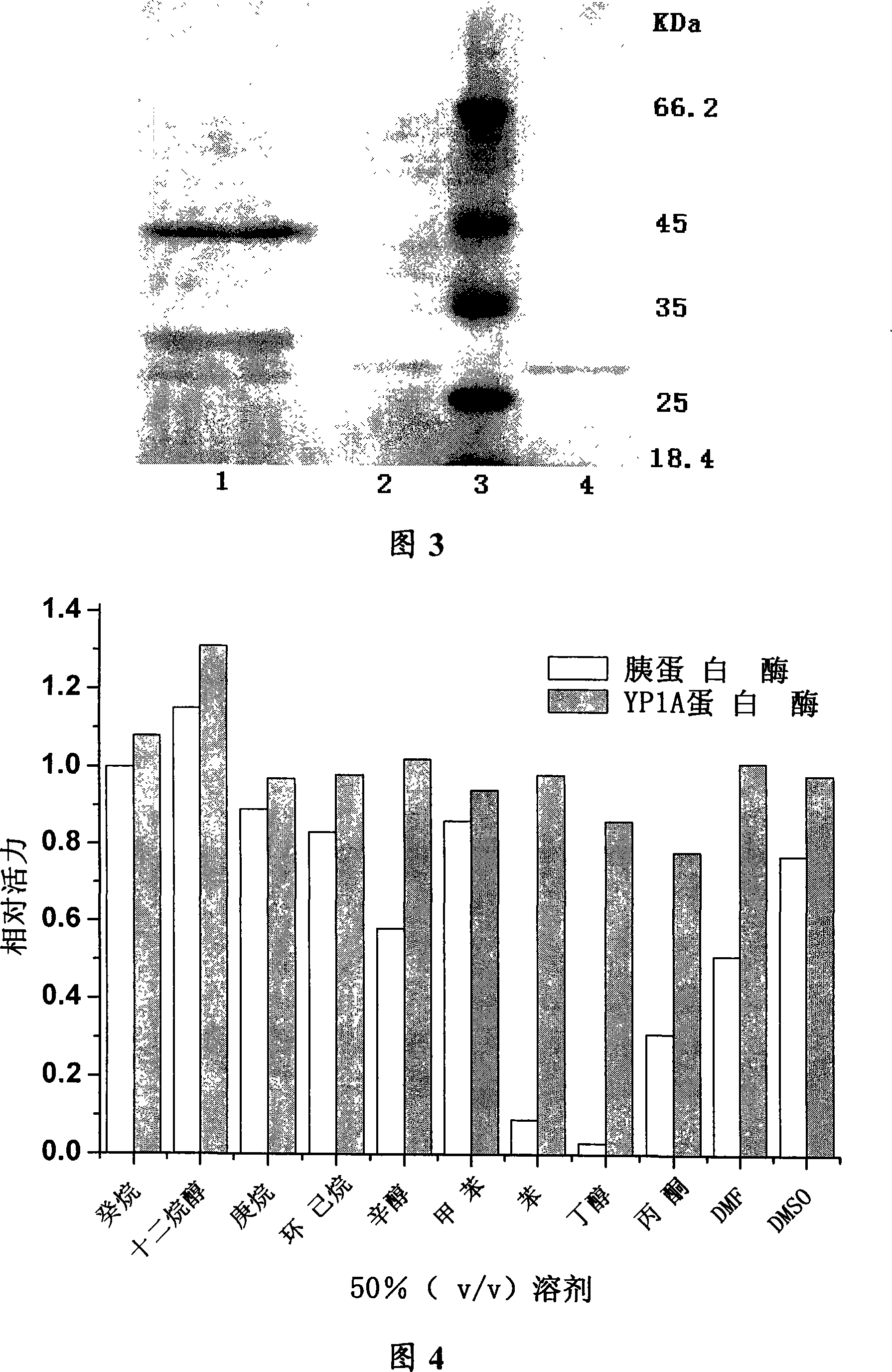

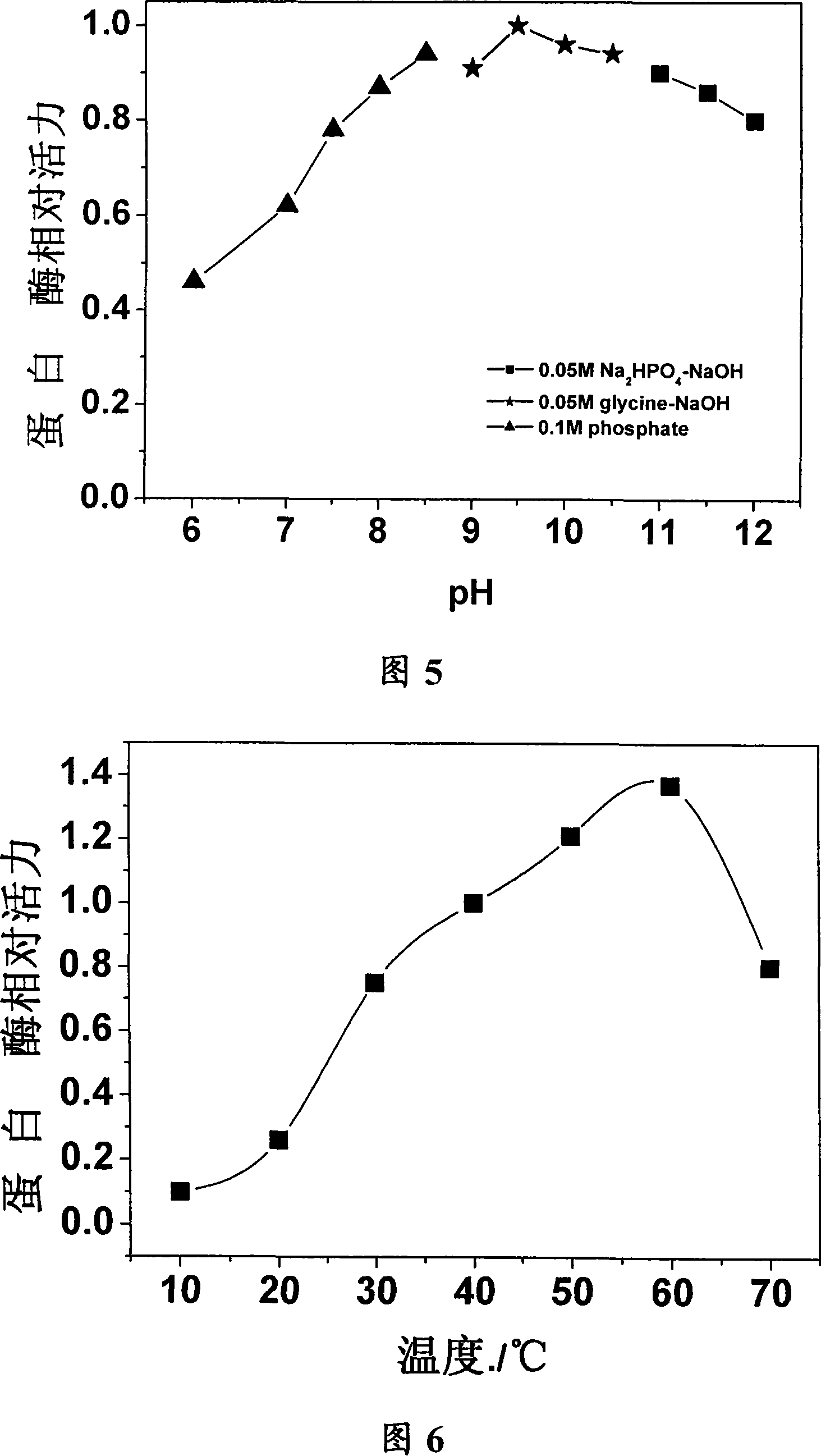

Organic solvent resisting basified protease producing strain, gene and application thereof

InactiveCN101215534AHigh specific activityStrong solvent resistanceBacteriaMicroorganism based processesBacillus licheniformisNucleotide

The invention discloses an organic solvent fastness alkaline proteinase generation strain and the gene and an application for catalyzing peptide to synthesize and resolve racemic amine and amino acid in the organic phase. The bacterial categorization naming is Bacillus licheniformis YP1A whose preservation register number is CCTCC No: M 207021 as Gram-positive bacillus and can tolerate certain density of a plurality of organic solvents. The invention separates and clones to obtain the coding gene of the proteinase generation strain, which is provided with nucleic acid sequence which is represented as SEQ ID NO: 1 and amino acid sequence as SEQ ID NO: 2. The organic solvent fastness alkaline proteinase is high in specific activity, strong in solvent tolerance, wide in action pH scale, strong in thermostable and strong alkalinity tolerance and the like. The proteinase can be applied in the application such as peptide synthesis in the organic phase, racemic amine and amino acid resolution and the like.

Owner:NANJING UNIV OF TECH

A liquid-state protective hands mask and preparation method thereof

ActiveCN1879593AReduce dosageDry fastCosmetic preparationsToilet preparationsOrganic solventAdjuvant

The invention relates to a liquid protection hand film and method for making same, wherein the raw material comprises the following constituents (by weight ratio): film-forming agent 10-15, film-forming adjuvant 8-14, emollient 1-4, auxiliary solvent 1-2, solvent 38-82, and preservative agent 0.01-0.05.

Owner:BEIJING XINLI MACHINERY

UV light-curing coating and its preparation method and its sublimation transfer film-forming technology

InactiveCN102268218AStrong adhesionImprove surface propertiesDuplicating/marking methodsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention provides a UV photocurable coating and its preparation method and the thermal sublimation transfer film forming technology using it. The UV photocurable coating includes components: epoxy acrylic resin, special polyurethane acrylate, fluoride modified hexafunctional group Aliphatic urethane acrylate, polyester acrylate, cellulose acetate, xylene, isopropanol, dipentaerythritol pentaacrylate, silicone leveling agent, fluorine-modified polyacrylate, 1-hydroxy-cyclohexyl-phenylmethanol ketone, 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone, ethyl acetate, butyl acetate and toluene. The UV photocuring paint of the present invention is environmentally friendly and has strong adhesion, and the formed coating film has high strength, high hardness, high wear resistance, high weather resistance and high solvent resistance, and is simple to prepare. Using the thermal sublimation transfer film-forming technology of the UV light-curing coating, the process is simplified, the efficiency is high, and the substrate of the decorative coating is completed. The surface has the high performance brought by the UV light-curing coating, which is more beautiful and decorative. Taller and durable.

Owner:深圳市莱莉雅环保科技有限公司

Positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink

ActiveCN103879169AIncreased sensitivityHigh developing latitudePlate printingFoil printingDouble coatingHeat sensitive

The invention discloses positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink. The positive image thermo-sensitive CTP printing plate material made by high-quality aluminum plate base and double coatings comprises a plate material support body. A resin layer good in solvent resistance and alkaline solubility coats the support body. A positive image thermo-sensitive photosensitive layer coats the resin layer. The main film forming resin also called polymer binder in the resin layer is independently researched and developed by the inventor company, and the photosensitive layer is modified by traditional single-layer thermo-sensitive CTP of the inventor company. The plate material is high in photosensitivity, excellent in screen dot reduction, large in plate making operation tolerance, stable in performance and high in printing adaptability. The plate material can be specially used for UV ink printing and also be used as the long-printing-process plate material of traditional solvent ink printing, and better printing durability is achieved when the plate material is applicable to the mentioned printing after baking.

Owner:LUCKY HUAGUANG GRAPHICS +1

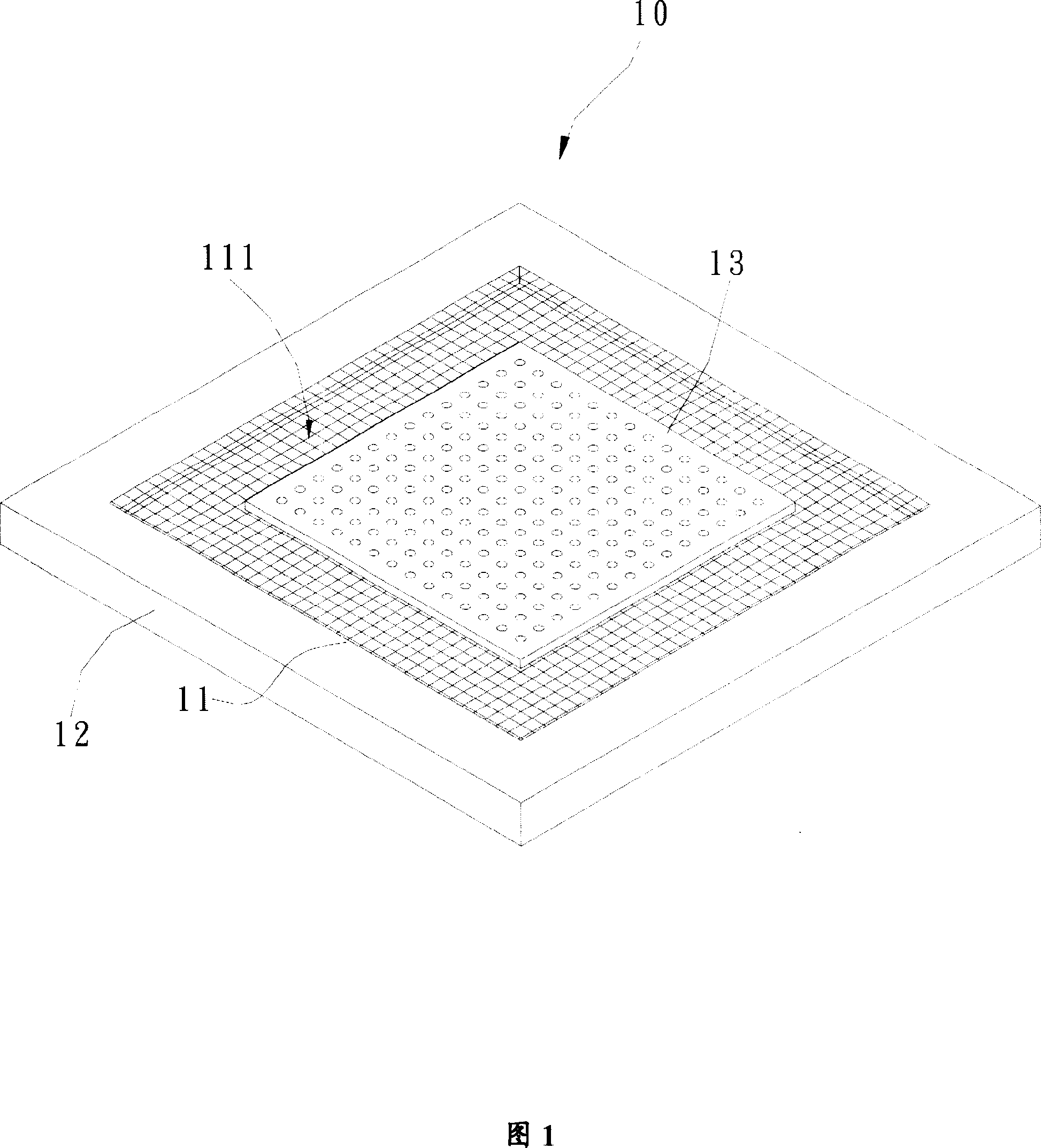

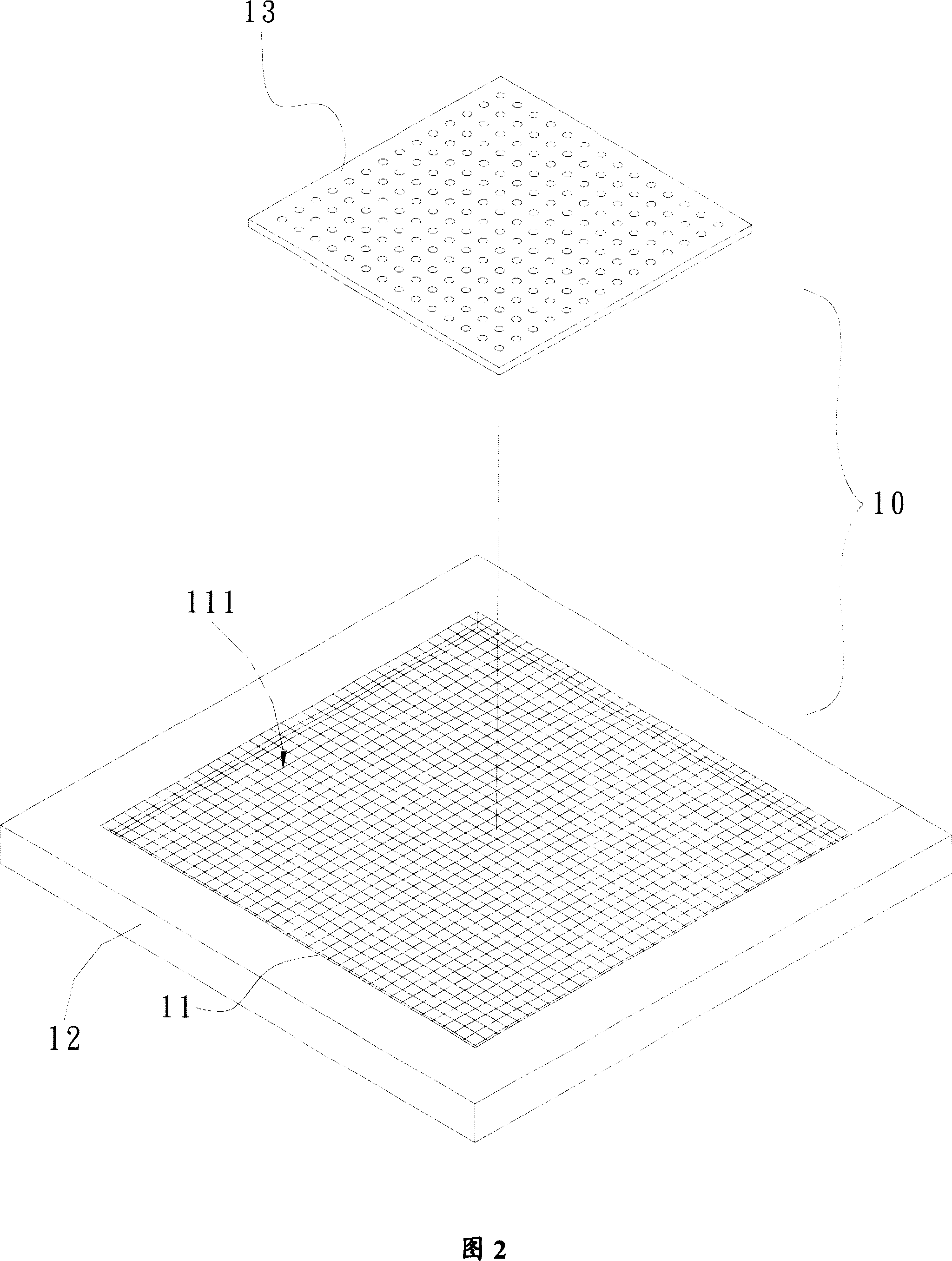

Electroforming foiled film screen-board

InactiveCN101100128AHigh precisionImprove printing qualityScreen printersPrinting pre-treatmentMetal foilMetal

The electroformed foiled screen plate includes one metal screen, one metal foil layer combined to the metal screen and one metal frame, and the metal foil layer is formed onto the metal screen through an electroforming process. The electroformed foiled screen plate has high strength and high printing density and quality.

Owner:FAITHFUL PRINTING EQUIP & SUPPLY

Process for preparing polyacrylonitrile-grafted modified cellulose membrane for gasoline desulfurization

InactiveCN101721924AImprove desulfurization effectPermeate fluxSemi-permeable membranesRefining by dialysisSide chainEvaporation

The invention relates to a process for preparing a polyacrylonitrile-grafted modified cellulose membrane for gasoline desulfurization. The invention adopts the technical scheme that the process comprises the following steps: 1) dissolving a cellulose-polyacrylonitrile grafted copolymer into a certain amount of solvent, continuously stirring the mixture under a sealed condition to obtain even and transparent cellulose-polyacrylonitrile grafted copolymer solution, and then filtering, standing and degassing the membrane preparation solution; and 2) coating the obtained copolymer solution on a glass plate to form a membrane, volatilizing the solvent, drying the membrane, putting the membrane into deionized water to separate the membrane from the glass plate, and drying the membrane for later use. The membrane manufactured by the invention has the characteristic of obvious micro-phase separation structure, wherein the polyacrylonitrile side chain plays a role in supporting the membrane structure and the crosslinked cellulose main chain and inhibiting the swelling of the membrane; and the cellulose chain segment is a main selective permeation material of the membrane, the adjustment to permeability and selectivity depends on the change of contents of different chain segments, and the membrane shows good separation performance and mechanical stability in the permeation-evaporation separation of the gasoline desulfurization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Wooden veneered metal door

InactiveCN101769116AReduce energy consumptionImprove energy consumptionDoor leavesSolid woodSurface layer

The invention discloses a wooden veneered metal composite door and relates to a metal door. A metal plate is used as a base material; a layer of wooden veneer layer is adhered on the surface layer through an adhesive; the outermost layer is a lacquered layer and other protective materials; and a one-component or two-component adhesive is adopted to glue the wooden veneer on the base material of the metal door plate through cold pressing or hot pressing. Therefore, the wooden veneered metal composite door has various unique natural advantages of solid wood materials, has the characteristics of various colors, attractive decorative patterns, comfortable sense of touch, energy conservation and heat insulation, and the like, and has outstanding decorative performance and practicality.

Owner:刘少来

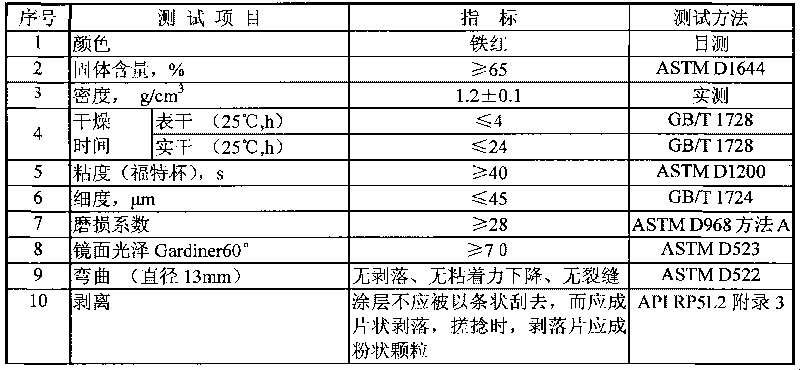

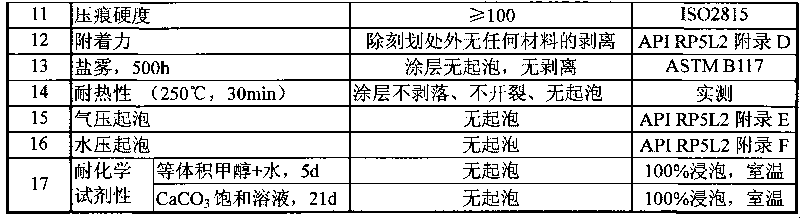

Anti-drag and abrasion-resistant paint for natural gas line

ActiveCN101698773AHigh surface glossPromote wettingEpoxy resin coatingsFerric oxide yellowMicrosphere

The invention discloses an anti-drag and abrasion-resistant paint for a natural gas line. Raw materials of the paint comprise two components A and B, wherein the component A comprises a phenolic aldehyde amine curing agent, a flatting agent, a defoaming agent, a dispersant, a thickening agent, white ceramic powder, red ferric oxide powder, mica ferric oxide, yellow iron oxide powder, light calcium carbonate and an environmentally-friendly mixed solvent; and the component B comprises epoxy resin, the flatting agent and the environmentally-friendly mixed solvent. The anti-drag and abrasion-resistant paint has the following advantages that: 1, compared with the conventional polyamide curing agent, the phenolic aldehyde amine curing agent has the advantages of more convenient construction in winter, better wettability for base materials, high coating crosslinking density, no pinhole and stronger solvent resistance and corrosion resistance; 2, the coating surface of the paint is smooth and specular gloss can reach more than 70 and is improved by15 to 30 percent compared with that of the like products; and 3, the paint is added with an abrasion-resistant filler, such as white ceramic, hollow microsphere and the like, so the abrasion resistance of the coating is greatly improved.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

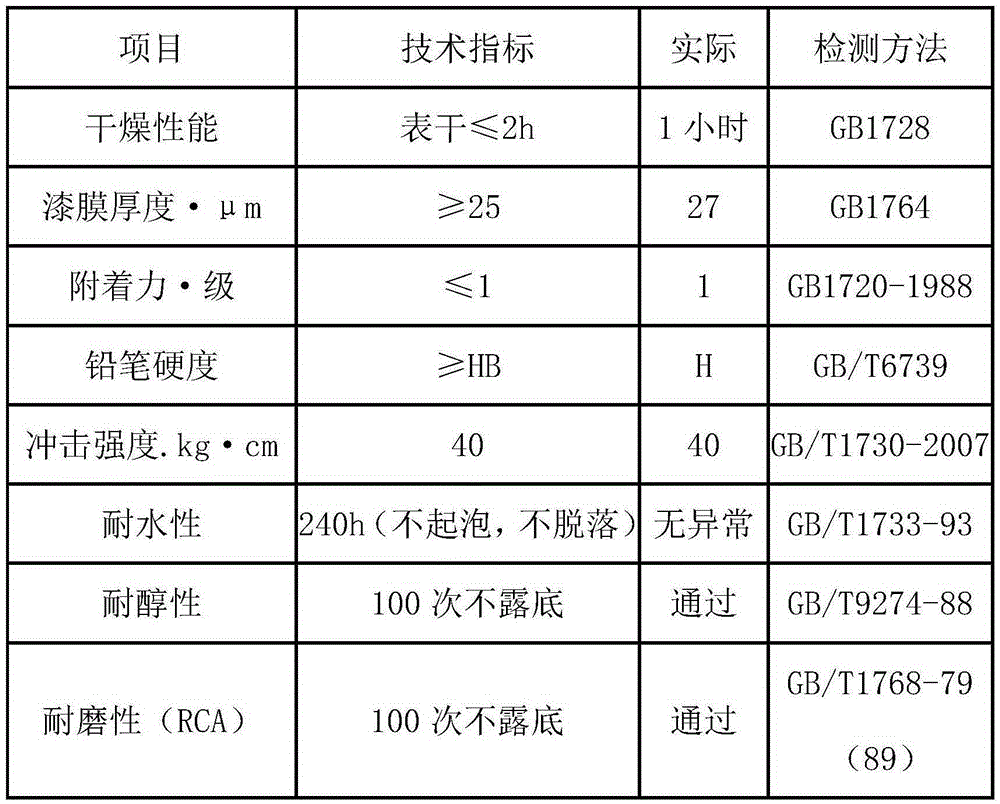

Good wear resistance and alcohol resistance acrylic resin for aqueous plastic cement

The present invention relates to the technical field of resin coatings, and in particular relates to good wear resistance and alcohol resistance acrylic resin for aqueous plastic cement, by reaction of epoxy groups of epoxy organosiloxane and carboxyl groups of an acrylic resin molecular chain, organosiloxane chain segments are introduced into the aqueous acrylic resin system, the organosiloxane chain segments have strong hydrophobicity, wear resistance and solvent resistance, and can wind the acrylic resin main chain to form a film, and a hydrophobic layer is formed between air and the film, acrylic monomers with excellent alcohol resistance and solvent resistance and polyol monomers are copolymerized into the aqueous acrylic resin chain segments for synthesis of the excellent water resistance, stain resistance, weather resistance, smoothness and wear resistance acrylic resin for the aqueous plastic cement.

Owner:王瑞莲

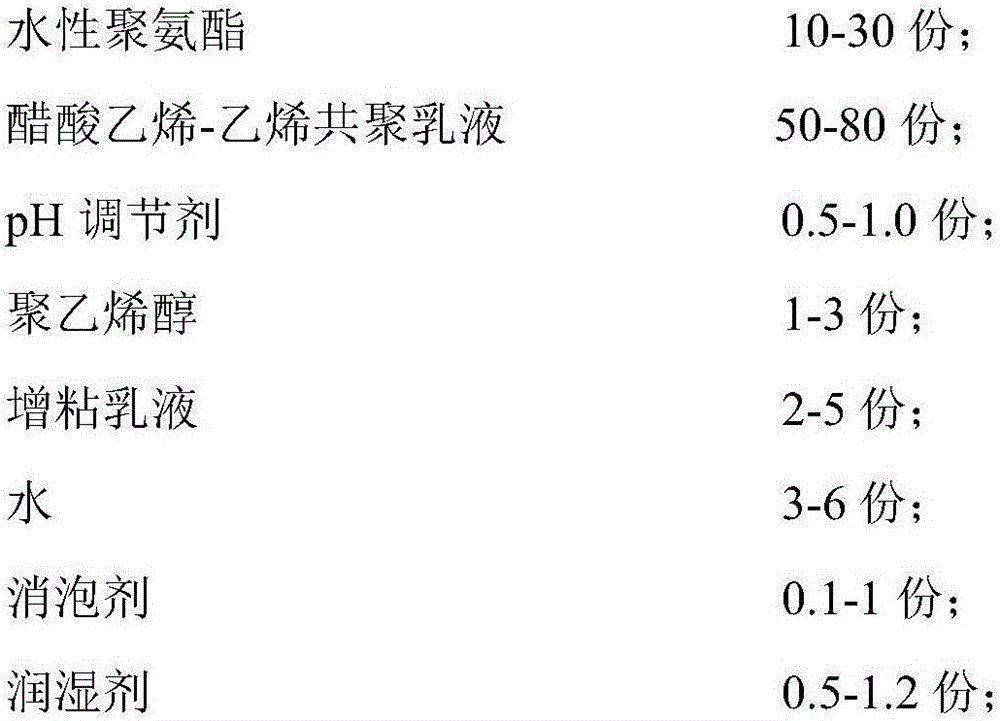

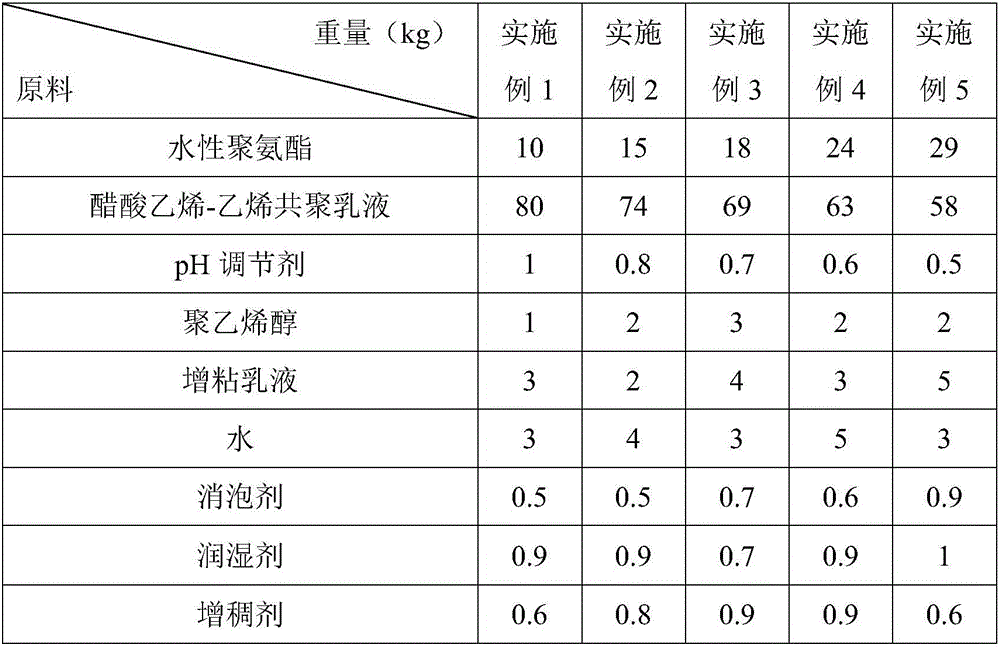

Waterborne half-PU leather bottom material and preparation method thereof

ActiveCN106047224AGood adhesionImprove stabilityMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesEmulsionPolyvinyl alcohol

The invention provides a half-PU leather bottom material and a preparation method thereof. The half-PU leather bottom material comprises the following raw materials in parts by weight: 10-30 parts of waterborne polyurethane, 50-80 parts of vinyl acetate-ethylene copolymer emulsion, 0.5-1.0 part of pH regulator, 1-3 parts of polyvinyl alcohol, 2-5 parts of tackifying emulsion, 3-6 parts of water, 0.1-1 part of antifoaming agent, 0.5-1.2 parts of wetting agent and 0.5-2 parts of thickening agent. In the invention, by compounding the low-modulus anionic waterborne polyurethane and cationic vinyl acetate-ethylene copolymer emulsion, the waterborne half-PU leather bottom material system has perfect stability, adhesive force and water-alkali resistance; and by applying the waterborne half-PU leather bottom material to the bottom layer of half-PU synthetic leather, the peel strength is high and can reach 30N / m or over.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

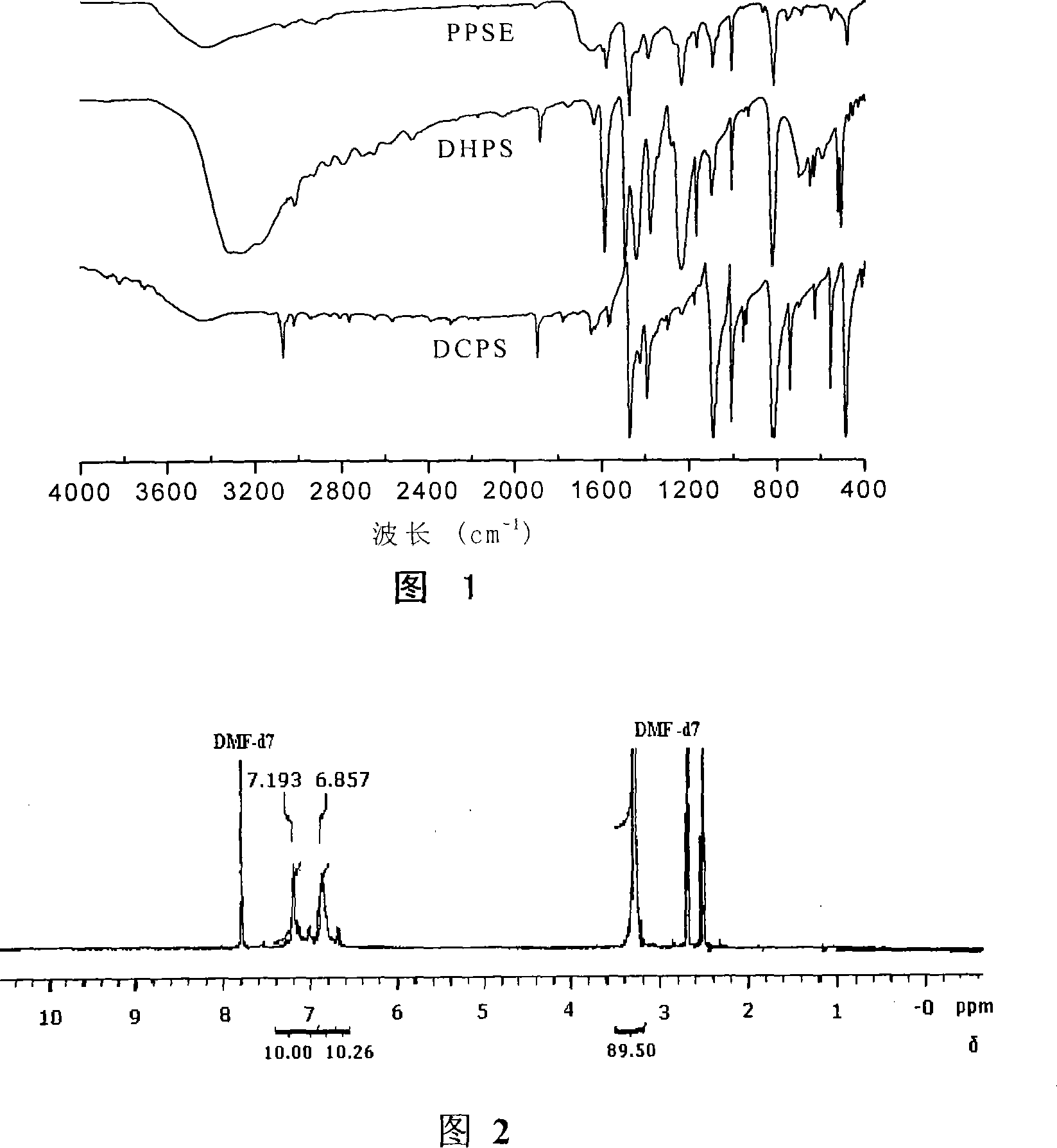

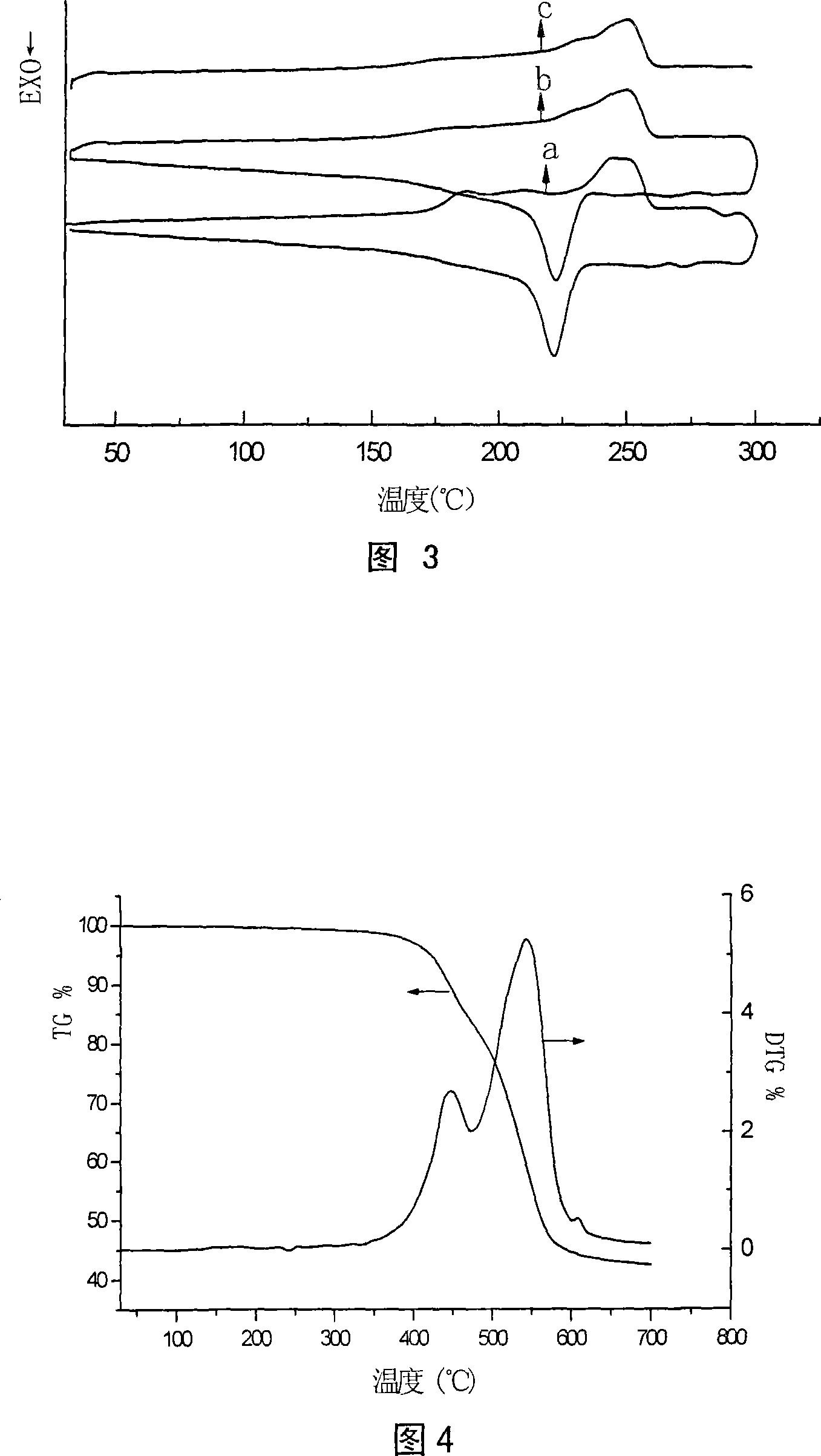

Method for preparing polyphenylene oxide sulfide

This invention discloses a method for preparing poly (phenylene sulfide). The raw materials include: monomers 4, 4'-dihydroxyl diphenyl sulfide (DHPS) and 4, 4'-dihalogen diphenyl sulfide at a mol. ratio of 1:1; additive 1.1-2.6 mol. / mol. DHPS; composite catalyst 0.22-1.08 mol. / mol. DHPS; solvent 400-700 mL / mol. DHPS; azeotropic dehydrating agent 200-400 mL / mol. DHPS. The method comprises: (1) adding the above raw material into a reactor under nitrogen protection, stirring, heating to 140-150 deg.C until azeotropic refluxing, sealing the reactor when water and the azeotropic dehydrating agent are completely distilled out, heating to 180-350 deg.C, and polymerizing for 4-10 h; (2) precipitating the solution, filtering, washing, purifying and vacuum-drying to obtain poly(phenylene sulfide).

Owner:SICHUAN UNIV

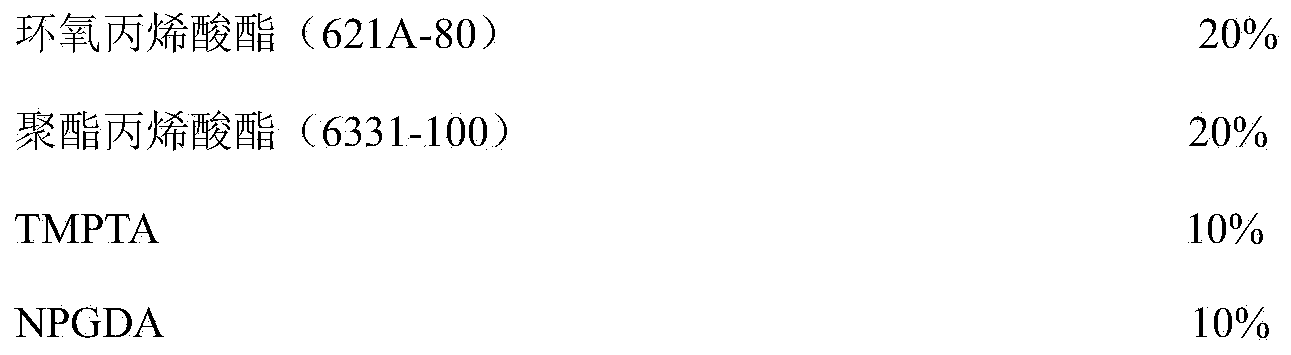

High-adhesion oxidation-resisting UV-curable ink and preparation method thereof

The invention discloses high-adhesion oxidation-resisting UV-curable ink and a preparation method thereof. The UV-curable ink comprises a low polymer, a reactive diluent, a photoinitiator, filler and an additive at a certain weight ratio, wherein the weight ratio of the low polymer to the reactive diluent is 5:3; the photoinitiator is compounded by two kinds of photoinitiators at the weight ratio being 1:1. The invention further discloses a preparation method of the high-adhesion oxidation-resisting UV-curable ink. The preparation method comprises the following steps: at first, weighing all the ingredients in a reactor according to the mass percent, uniformly mixing, placing the mixture into an oven for softening, at last, stirring and dispersing the softened liquid by a high speed disperser, controlling the fineness to 5-20 microns, and canning. The high-adhesion oxidation-resisting UV-curable ink prepared by the preparation method has the advantages that the adhesion force can reach 100%, the curing speed is 8-15 s, the solvent resistance is strong, the deinking phenomenon, caused by that a conventional PE bottle cap is soaked for 4 h in a 1,800 ppm concentrations of peracetic acid solution after being printed with UV-curable ink, and the temperature is controlled to be constant to be 90 DEG C, is overcome, and the sterilization requirements of environmental protection departments are met. The preparation method is simple and feasible, and easy to realize.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

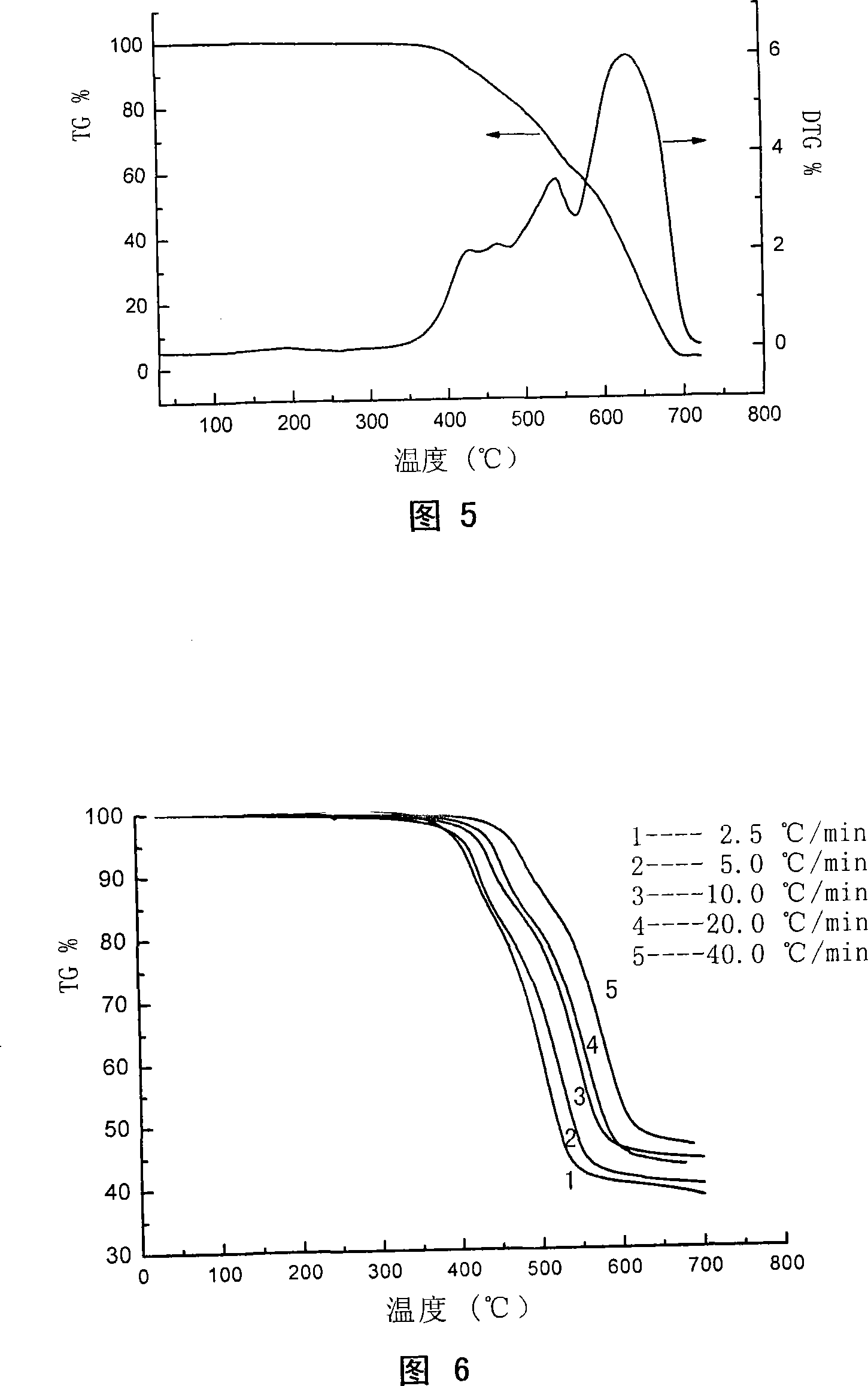

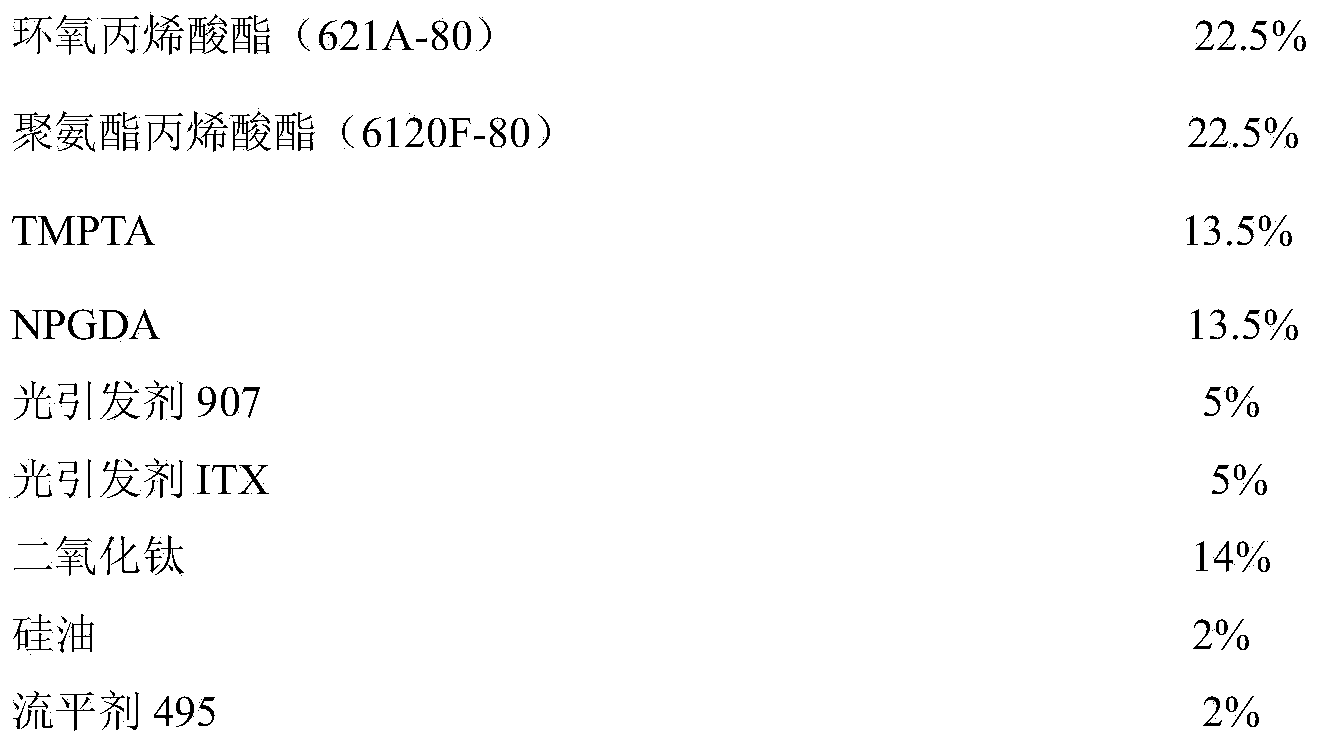

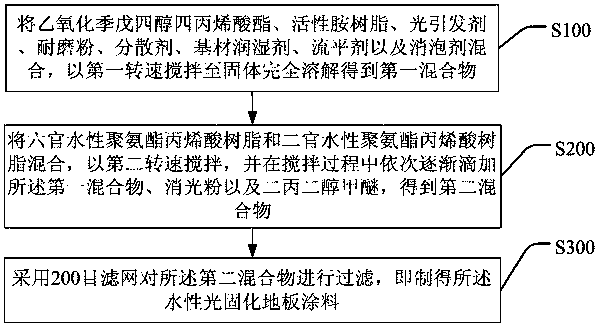

Waterborne photocuring floor coating and preparation method thereof

InactiveCN108977057AOvercoming long curing timeAcceleratePolyurea/polyurethane coatingsSolventPhotoinitiator

The invention discloses waterborne photocuring floor coating and a preparation method thereof. The coating is prepared from, in percentage by weight: 55-65% of hexa-functional group waterborne polyurethane acrylic resin, 5-10% of di-functional group waterborne polyurethane acrylic resin, 5-15% of pentaerythritol tetraacrylate ethyl oxide, 1-5% of active amine resin, 3-12% of a photoinitiator, 2-7%of extinction powder, 1-5% of wearproof powder, 0.2-1% of a dispersing agent, 0.5-2% of a base material wetting agent, 0.1-0.5% of a flatting agent, 0.01-0.1% of a defoaming agent and 5-15% of dipropylene glycol methyl ether. The coating can be rapidly solidified to form a film through ultraviolet irradiation after being subjected to roller coating, the speed is high, the efficiency is high, thecoating has the high performance of coin scratching resistance, solvent resistance, water resistance, iodine resistance and high wear resistance after being the film independently, and the features oflog can be presented.

Owner:广东昊辉新材料有限公司

Coating method for internally coating pipe with clinkering epoxy graphene powder

InactiveCN107377340AGood chemical resistanceStrong solvent resistancePretreated surfacesCoatingsEpoxyImpurity

The invention discloses a coating method for internally coating a pipe with clinkering epoxy graphene powder. The coating method comprises the following specific steps that (1), the steel pipe is preheated, surface impurities are removed, and oxide skin is loosened; (2), an inner sandblasting process is adopted, the steel pipe reaches the metal white, the anchor pattern control depth is controlled to be within the range of 45-95 micrometers, and then surface dust is removed; (3), the steel pipe obtained after surface treatment is completed is uniformly heated with a pollution-free heat source; (4), the epoxy graphene powder is fully fluidized in a fluidization bed firstly; (5), the leveled coating is further gelled and cured; (6), after the overall temperature drops, watering cooling is performed; and (7), when the temperature drops below 150 DEG C, coating film performance detection is performed. According to the coating method for integrally coating the pipe with the clinkering epoxy graphene powder, pipe inner wall coating is more thorough, the anticorrosion coating covering is more uniform, the formed anticorrosion coating can effectively resist the chemical corrosion of organic matter and has the good insulativity, and the anticorrosion time is long.

Owner:武汉中电节能有限公司

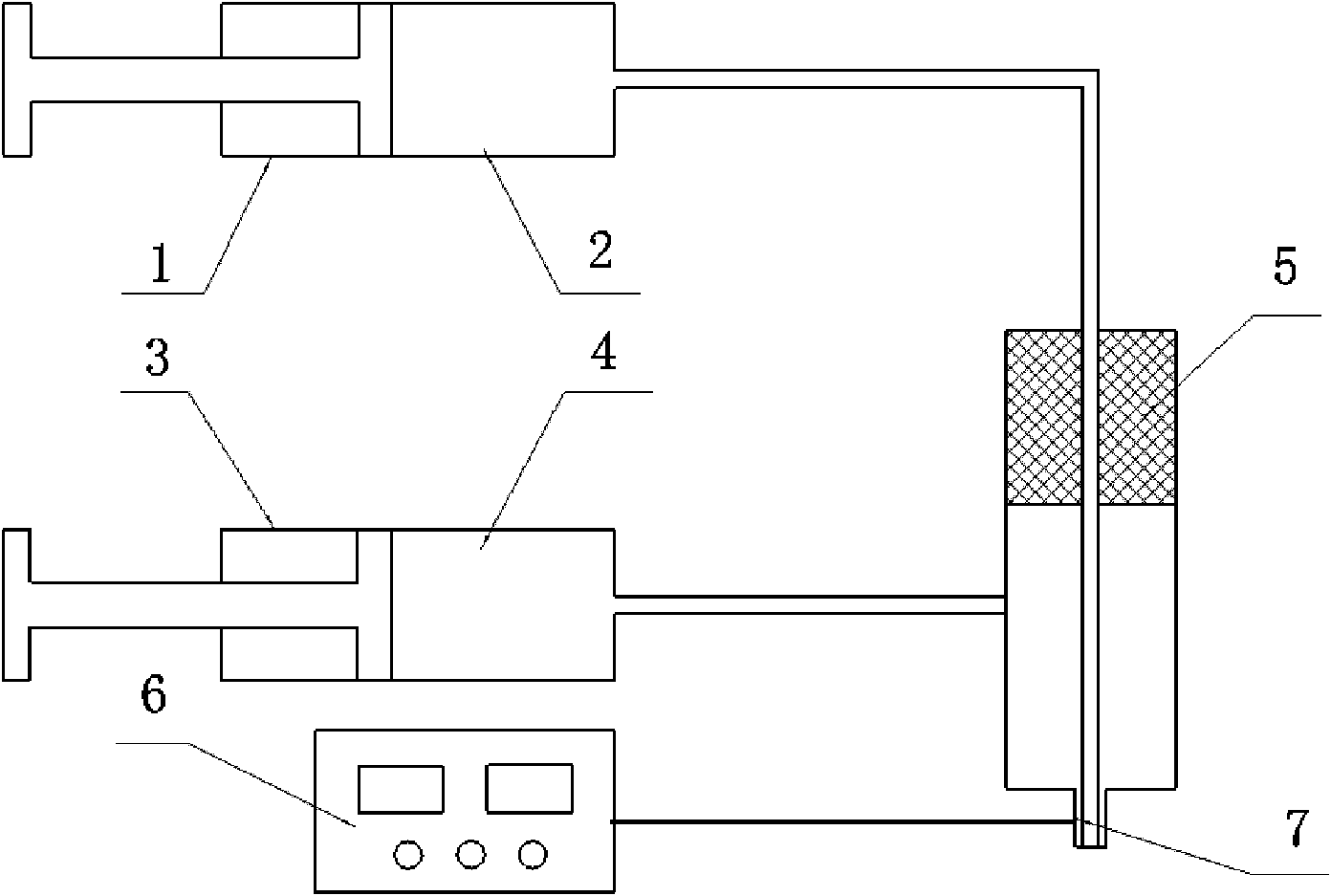

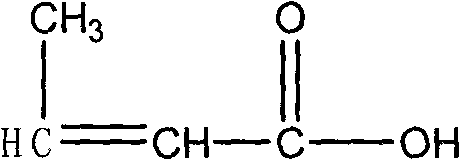

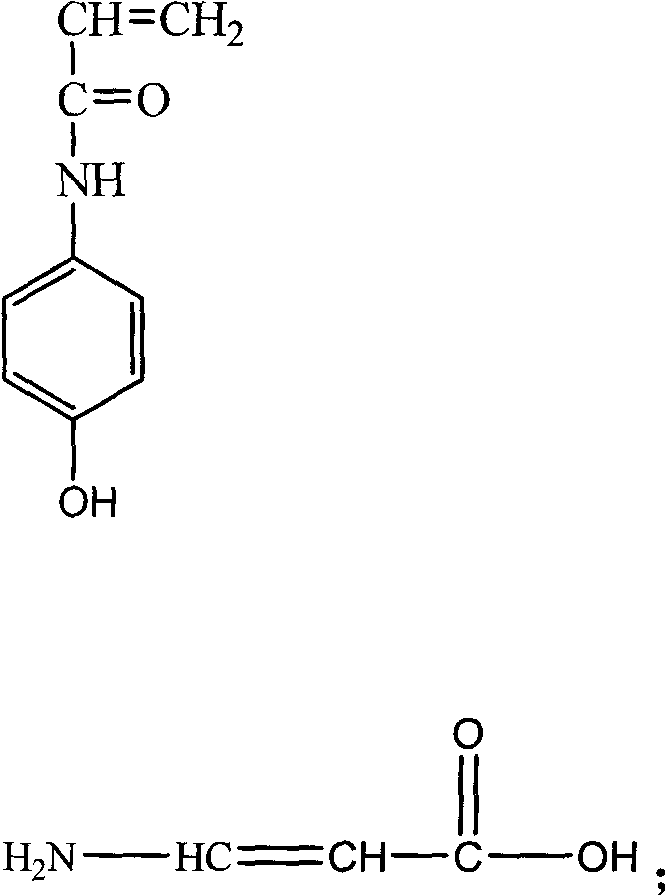

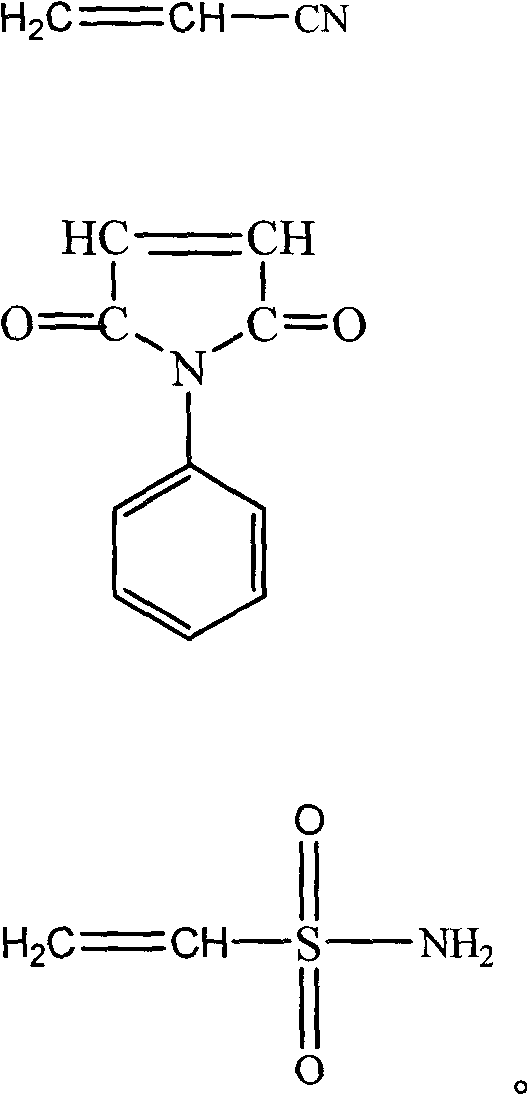

Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof

ActiveCN102532492AGood solvent resistanceImprove thermal stabilityFinal product manufactureSolid-state devicesTerthiophenePolymer science

The invention discloses a crosslinking thiopheno[3,4-b] thiophene conjugated polymer and a preparation method and application thereof. The constitutional formula of the conjugated polymer is as formula I, R1 is a functional group capable of conducting crosslink under the condition that ultraviolet illumination, heating or initiators exist. R2 is a functional group capable of conducting crosslink under the condition that ultraviolet illumination, heating or initiators exist or a substituent group which is different from R1 and is not crosslinked. Arl and Ar2 are units which are identical or different and have conjugated characteristics. X1 and X2 are both selected from the following perssad: H, F, Cl, Br, cyan and ester groups. a / (a+b) is any one of number from 0 to 1, and the a / (a+b) is not zero. n represents repeated number of main polymer chain units, and the value of n is a natural number equal to and larger than 4. The polymer has narrower band gaps, improves anti-solvent performance by crosslinking and has wide application prospect in photoelectric function devices, especially the field of polymer solar batteries.

Owner:INST OF CHEM CHINESE ACAD OF SCI

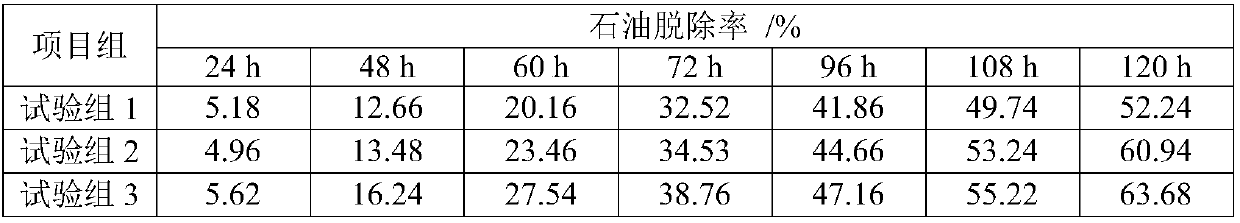

Microorganism loading type resin adsorbent capable of degrading greasy dirt and preparation method of resin adsorbent

The invention relates to the technical field of remediation of oil-overflowing water bodies and particularly relates to a microorganism loading type resin adsorbent capable of degrading greasy dirt and a preparation method of the resin adsorbent. The resin adsorbent is prepared by the steps of dipping a microorganism loading body into an acrylate copolymer emulsion, and drying, wherein the microorganism loading body is prepared by loading a multi-channel carrier particle with petroleum hydrocarbon degrading bacteria, and the carrier particle is a konjac glucomannan aerogel particle. The resinadsorbent is capable of degrading adsorbed petroleum and continuously treating petroleum in water; konjac glucomannan aerogel is loaded with petroleum hydrocarbon degrading bacteria and is embedded into acrylate resin, so that the curing stability of a strain is high; and konjac glucomannan aerogel and acrylate resin are internally provided with rich micro-fine channels, so that the resin adsorbent has huge oil absorption capacity and is high in adsorption velocity.

Owner:ZHEJIANG OCEAN UNIV

High-performance water-based fluorocarbon paint

ActiveCN103788783AImprove adhesionImprove antifouling performanceCoatingsPolymer scienceActive agent

The invention discloses high-performance water-based fluorocarbon paint which comprises the following components in percentage by mass based on 100% in total: 50-80% of water-based fluorocarbon emulsion, 0.1-0.4% of siloxane crosslinking agent, 0.01-0.1% of surfactant, 0.2-0.5% of antifoaming agent, 0.2-0.5% of preservative, 2.0-4.0% of ethylene glycol, 2.0-5.5% of film forming aid, 0.05-0.3% of multifunctional auxiliary, 7.5-30% of titanium dioxide and the balance of water. According to the high-performance water-based fluorocarbon paint disclosed by the invention, through the improvement of the water-based fluorocarbon emulsion and in combination with the siloxane crosslinking agent and other related auxiliaries, the adhesion of the water-based fluorocarbon paint can be effectively improved; the improved fluorocarbon emulsion and the selected fluorine surfactant SURFLONS-386 promote each other; in combination with other related auxiliaries, the antifouling capacity of the water-based fluorocarbon paint can be effectively improved; by adopting the improved fluorocarbon emulsion, siloxane and fluorine surfactant SURFLONS-386 as main functional materials and in combination with the effects of the auxiliaries such as antifoaming agent, a preservative, ethylene glycol, a film forming aid, a multifunctional aid, titanium dioxide, water and the like, the prepared water-based fluorocarbon paint has the advantages of water and alkali resistance, strong solvent resistance, mildew and moisture prevention, high adhesion and good antifouling capacity.

Owner:广东黑马新材料科技有限公司

In-mold decoration (IMD) production technology for switch panel

InactiveCN103117181AStrong (solvent) resistanceVibrant and long-lasting colorElectric switchesEngineeringWear resistance

The invention provides an in-mold decoration (IMD) production technology for a switch panel and relates to the production technology for the switch panel. A traditional production technology is reformed. The IMD technology is applied to production of the switch panel and a socket panel. Various patterns and characters are printed on a sheet, and the sheet coated with a membrane is conveyed to an injection molding main machine hand for in-mold coating and injecting. The patterns on the surface of the switch panel produced by adoption the technology are good in wear resistance, rich and bright in color, and strong in third dimension.

Owner:刘 志勇

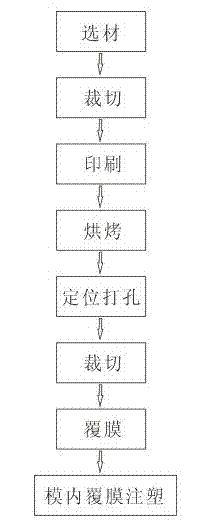

Preparation method of corrosion-resistance and high-electroconductibility composite coating for electrode

ActiveCN109402586AReduce usageEnhance film bindingVacuum evaporation coatingSputtering coatingComposite ceramicAlloy

The invention relates to a preparation method of a corrosion-resistance and high-electroconductibility composite coating for an electrode. The electrode is a Cu alloy electrode, and the composite coating comprises a Ti thin film and a titanium oxide coating thin film which coat the surface of the Cu alloy electrode in sequence. The method comprises the following specific steps that the Cu alloy electrode is taken, deoxidized and subjected to impurity removal; titanium oxide powder and Ti powder are weighed according to the weight ratio of 98:2-99:1, mixed, then put into a sintering furnace andsintered into composite ceramic blocks, and a composite target material is prepared; a magnetron sputtering coating machine is used for making the surface of the Cu alloy electrode coated with the Tithin film, and the thickness of the Ti thin film is 40-100 nm; the magnetron sputtering coating machine is used for making the surface of the Ti thin film coated with the titanium oxide thin film, and the thickness of the titanium oxide thin film is 2-5 microns. According to the preparation method, the surface of the Cu alloy material is coated with the Ti coating and the titanium oxide coating,the service life of the Cu alloy material is prolonged, the material cost is lowered, and accordingly the electrode material has high corrosion resistance and electroconductibility.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Large-membrane thickness PE electrostatic-sprayed paint

InactiveCN104177997ALow resistivityReduce labor intensityPolyester coatingsPolymer scienceElectrostatic coating

The invention discloses large-membrane thickness PE electrostatic-sprayed paint. The large-membrane thickness PE electrostatic-sprayed paint comprises a main agent part A, a cobalt iso-octoate-containing part B and a methylethyl ketone peroxide-containing part C. The main agent part A comprises, by weight, 60-80 parts of unsaturated polyester resin, 0.01-0.03 parts of a polymerization inhibitor, 10-25 parts of an inorganic filling material, 3-5 parts of zinc stearate, 4-8 parts of a solvent, 0.3-0.5 parts of an anti-settling agent, 0.1-0.3 parts of an antifoaming agent, 0.2-0.5 parts of a leveling agent and 0.1-0.5 parts of a conductive agent which is an alkanolamide solution of nonsaturated acidic carboxylate. The alkanolamide solution of nonsaturated acidic carboxylate reduces paint resistance, improves paint conductivity and satisfies electrostatic-coating resistor requirements.

Owner:展辰新材料集团股份有限公司 +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ee3b337a-10f4-4988-b2d9-109f5471fae7/HDA0000126531760000011.png)

![Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ee3b337a-10f4-4988-b2d9-109f5471fae7/HDA0000126531760000012.png)

![Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof Crosslinking thiopheno[3,4-b] thiophene conjugated polymer and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ee3b337a-10f4-4988-b2d9-109f5471fae7/HDA0000126531760000021.png)