Electroforming foiled film screen-board

An electroforming and foil film technology, applied in screen printing machines, rotary printing machines, printing and other directions, can solve the problems of screen printing resistance, lack of precision, poor adhesion of fine patterns, etc., and achieve stable printing quality. , The effect of excellent brush resistance and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

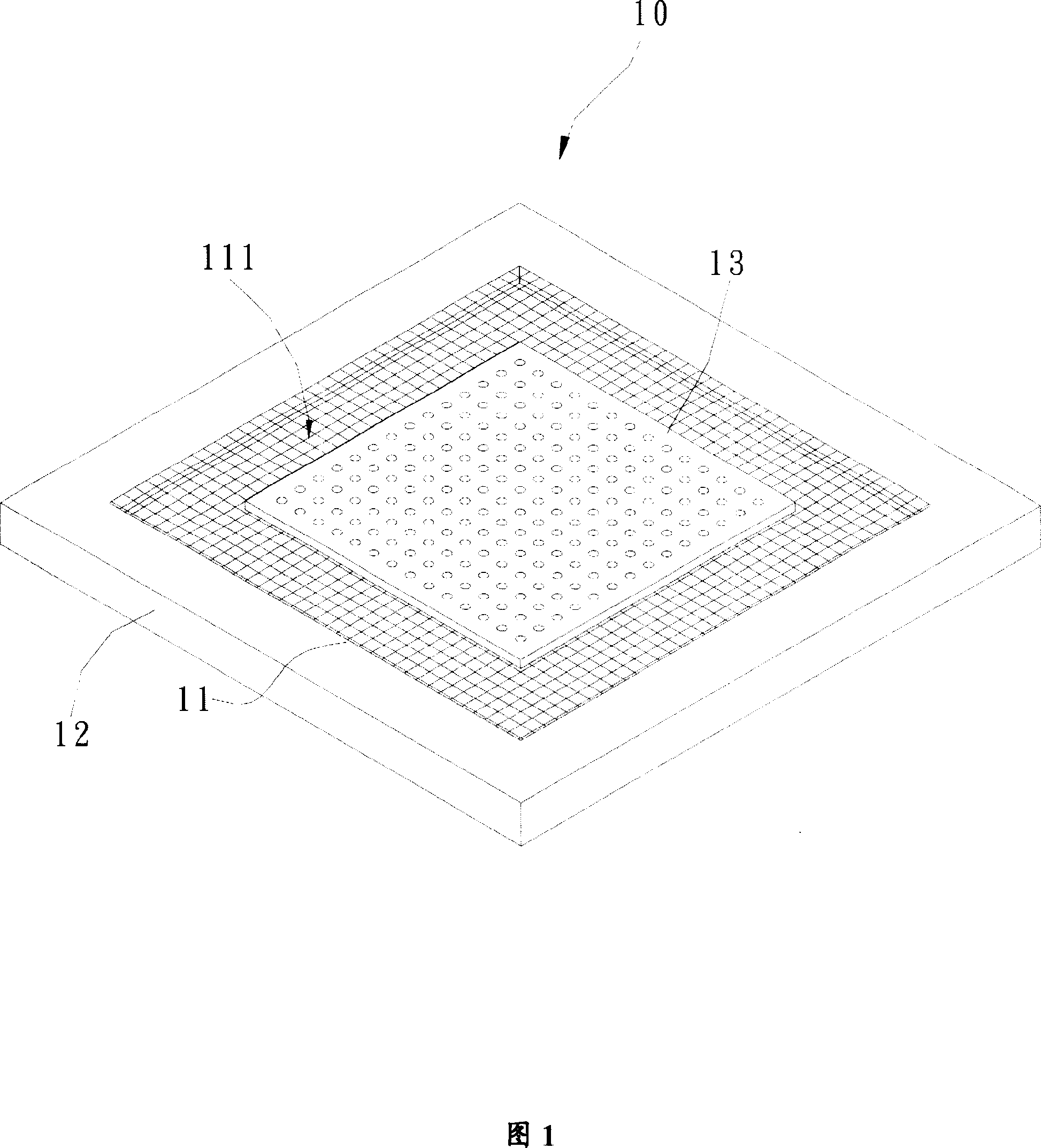

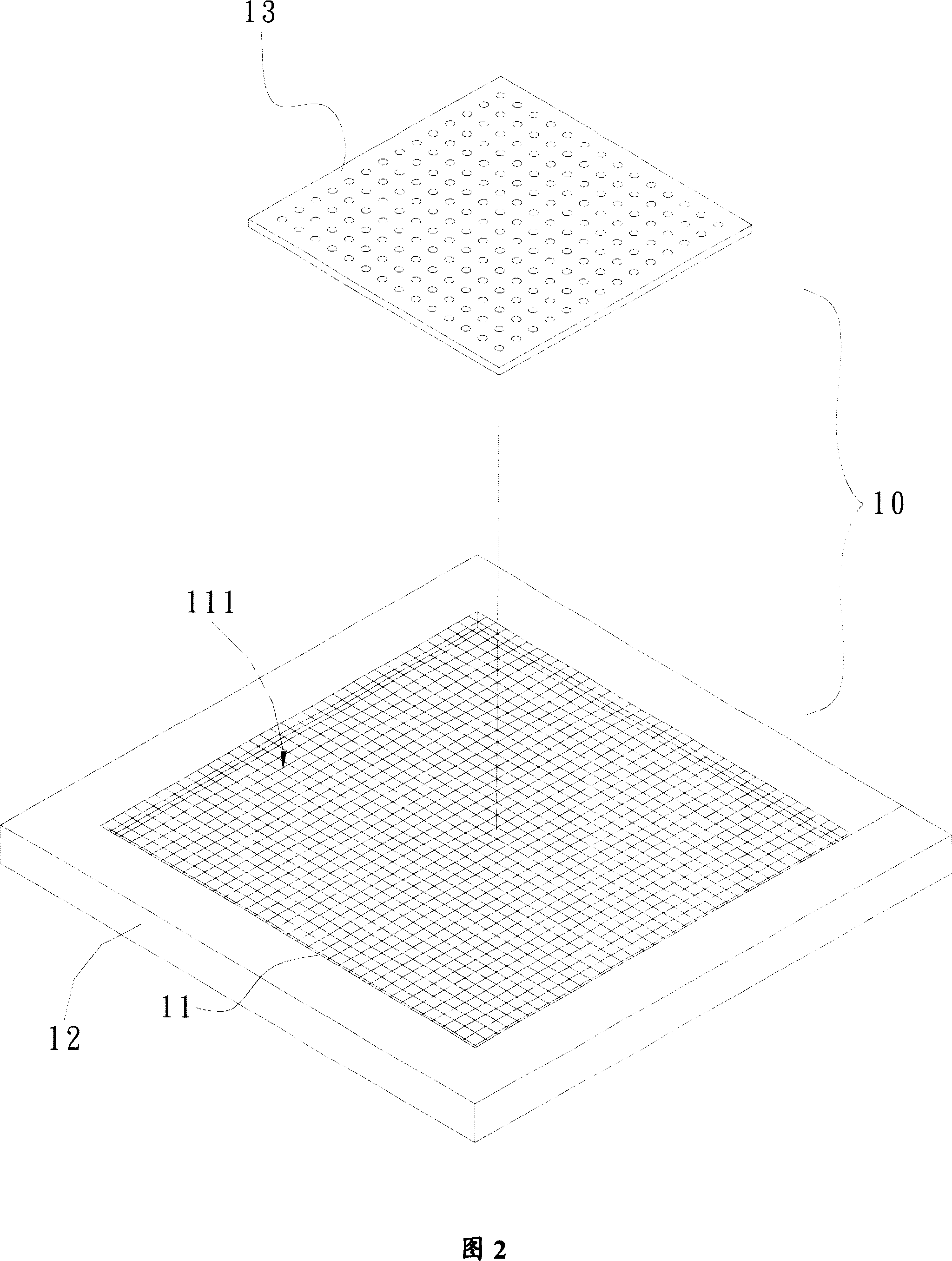

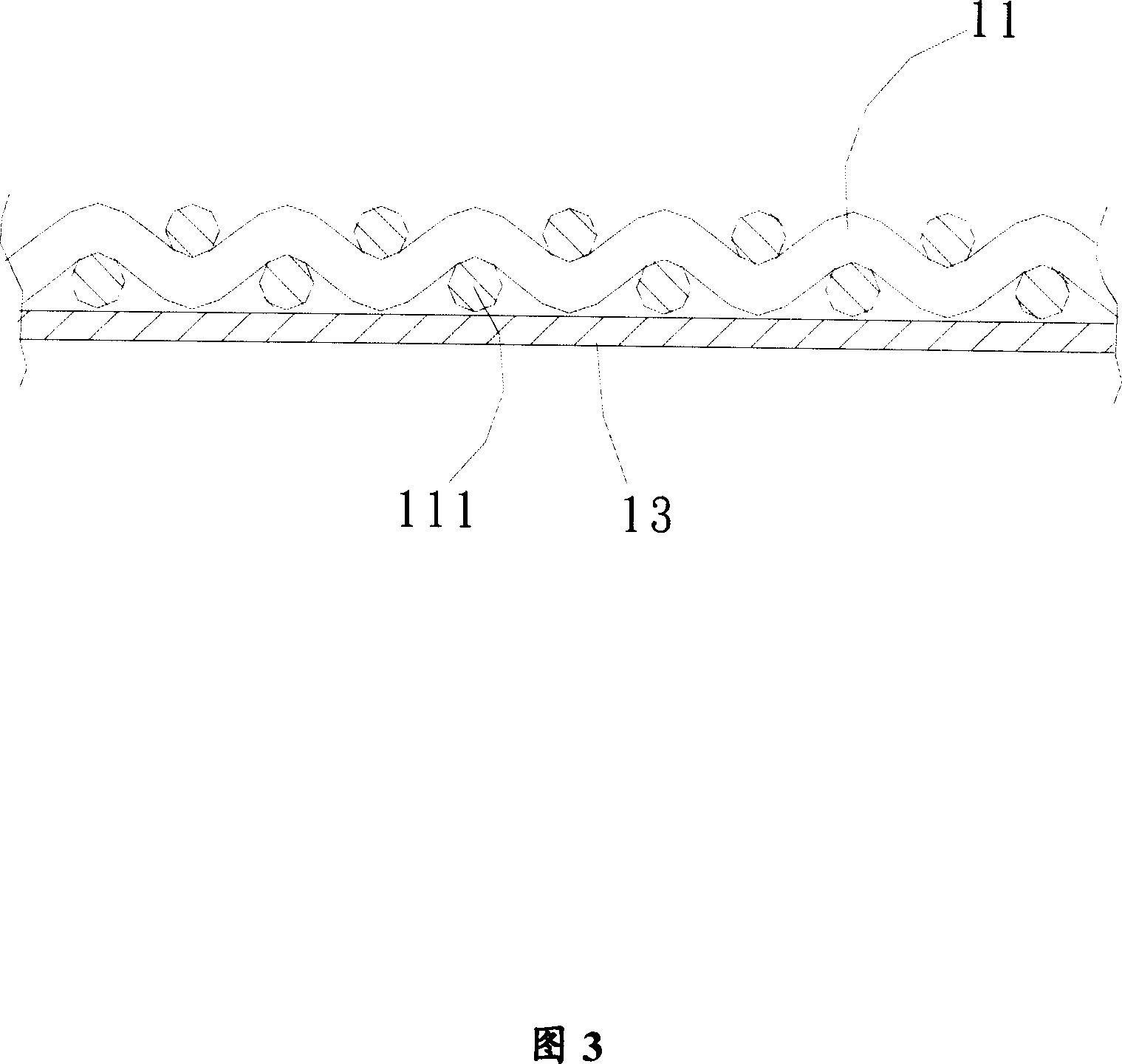

[0017] The preferred embodiment and technical content of the present invention will be described as follows with the accompanying drawings: first, please refer to the electroformed foil film screen 10 of the present invention shown in Figures 1 to 3. In this embodiment, the main It is composed of a metal mesh 11 , a metal frame 12 and a metal foil 13 . Wherein, the metal frame 12 is selected from an iron frame or an aluminum frame, and is used to frame the periphery of the metal mesh 11, and the metal mesh 11 is a steel wire mesh made of stainless steel material, and the metal mesh 11 has an electroformed The surface of an electroforming layer 111 is then formed, and the metal foil 13 is a thin film with an image (not shown) on the surface and cast on the surface of the metal mesh 11 by electroforming technology.

[0018] In more detail, the electroformed foil screen 10 of the present invention is formed by combining the metal mesh 11, the metal frame 12 and the metal foil 13....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com