Patents

Literature

257results about How to "Not easy to disconnect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

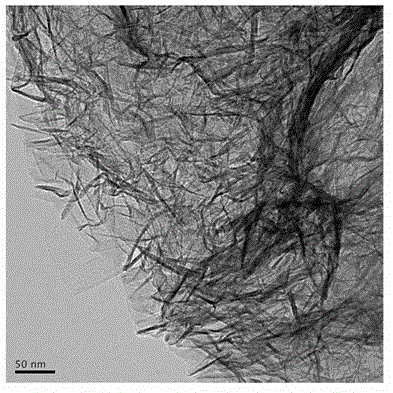

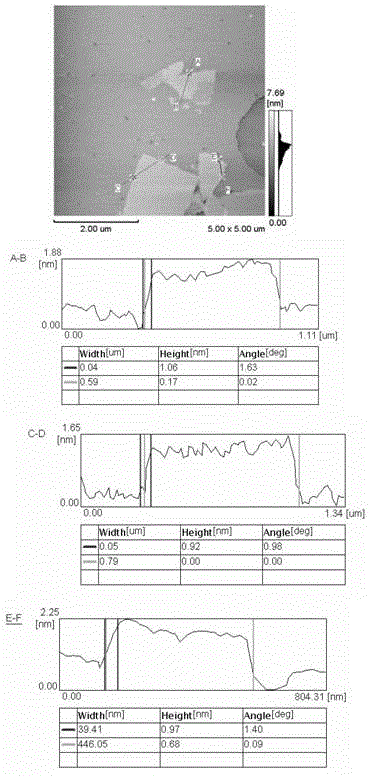

High-thermal conductivity lubricating oil and preparation method thereof

ActiveCN102911762AImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

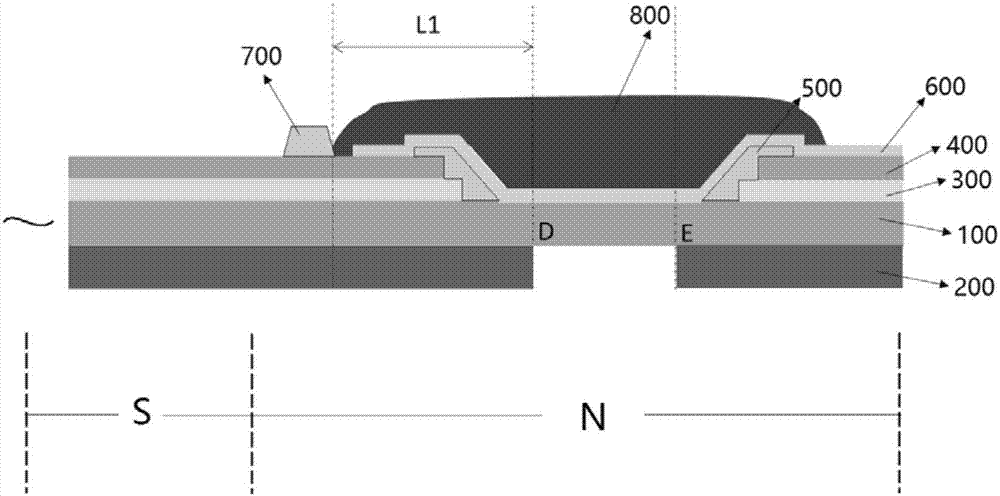

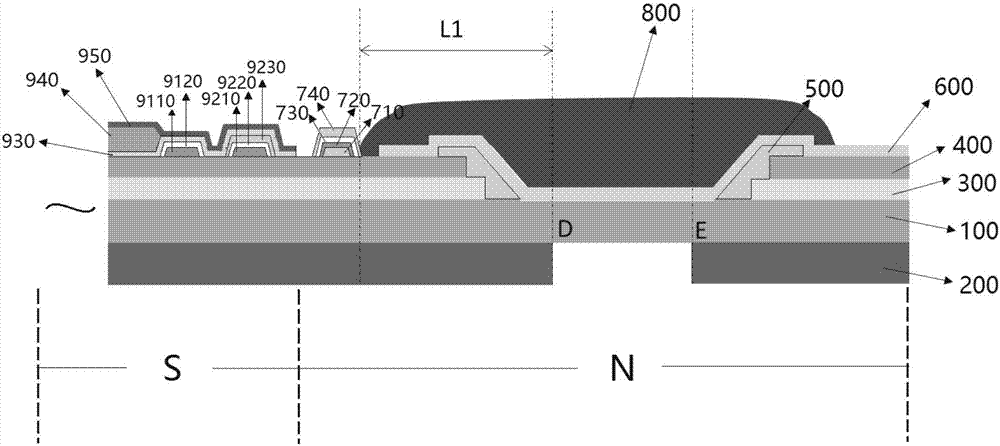

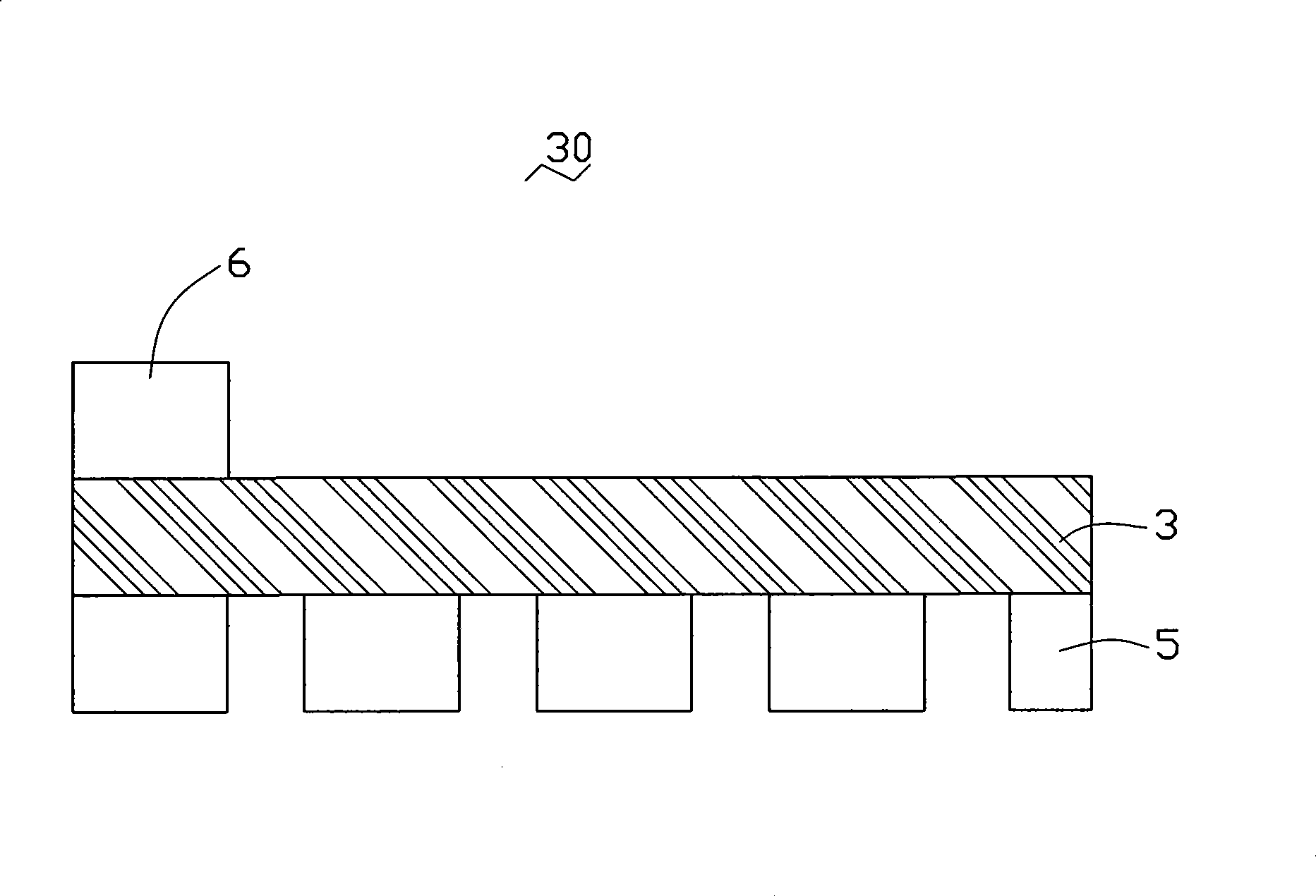

Flexible array substrate as well as manufacturing method and flexible display thereof

ActiveCN107123667ANarrow widthImprove thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a flexible array substrate as well as a manufacturing method and a flexible display thereof. The flexible array substrate comprises a flexible substrate, a display region arranged on one side of the flexible substrate, a non-display region arranged at the periphery of the display region, a protective layer used for covering a source and drain electrode layer of the non-display region and a protective layer block wall arranged on one side, close to the display region, of the non-display region and used for limiting a width of the protective layer. According to the flexible array substrate provided by the invention, the protective layer block wall is arranged on one side, close to the display region, of the non-display region and can limit a glue material from flowing toward a light emitting region when the protective layer of a bending region is manufactured, so that the width of the protective layer can also be limited while the uniformity of the coating thickness of the protective layer is guaranteed, a climbing region can be effectively shortened, and realization of the narrow frame effect is facilitated.

Owner:BOE TECH GRP CO LTD

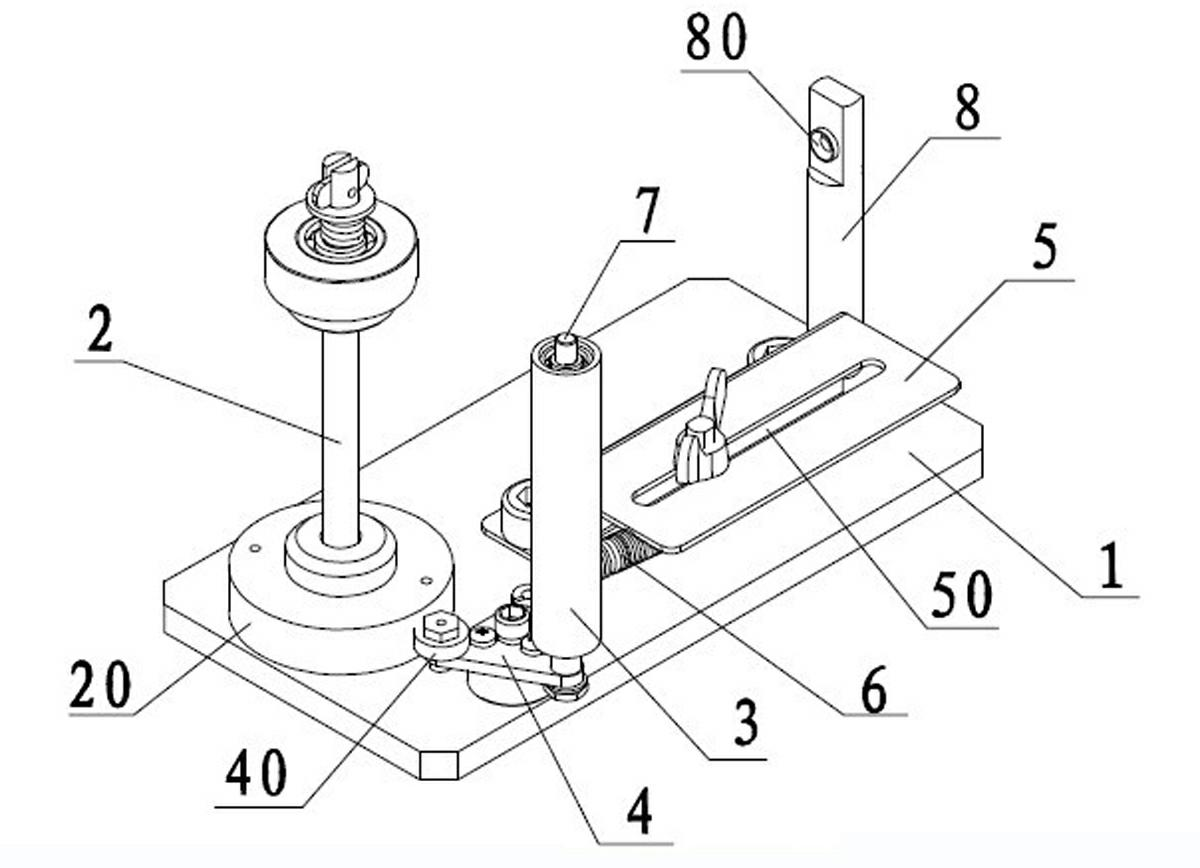

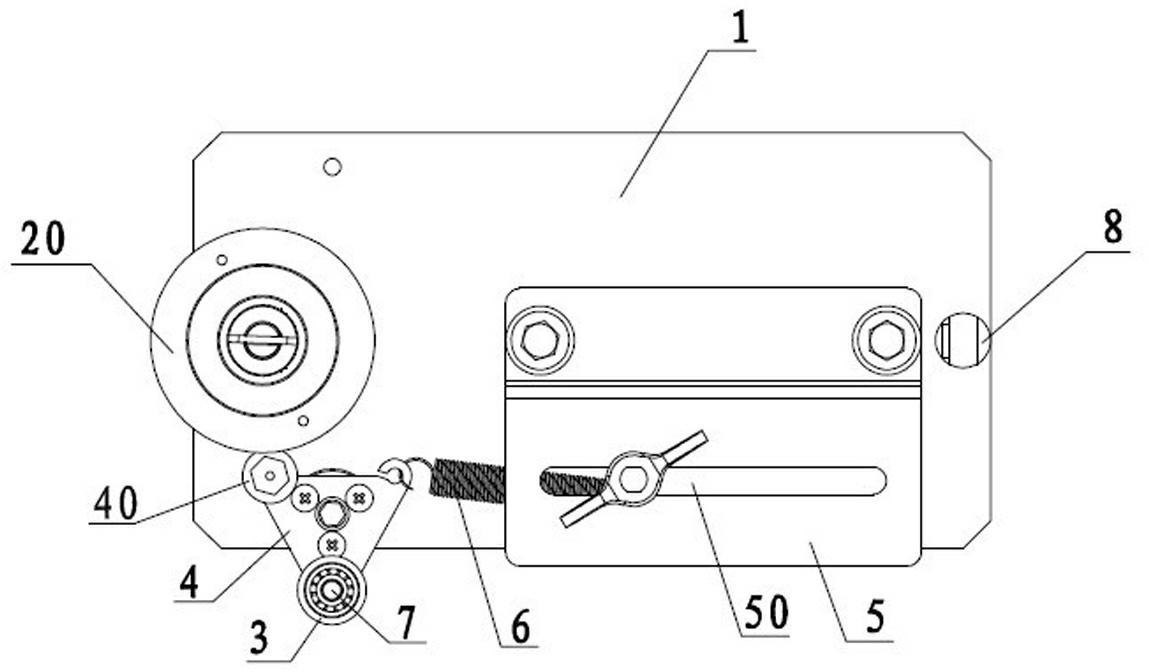

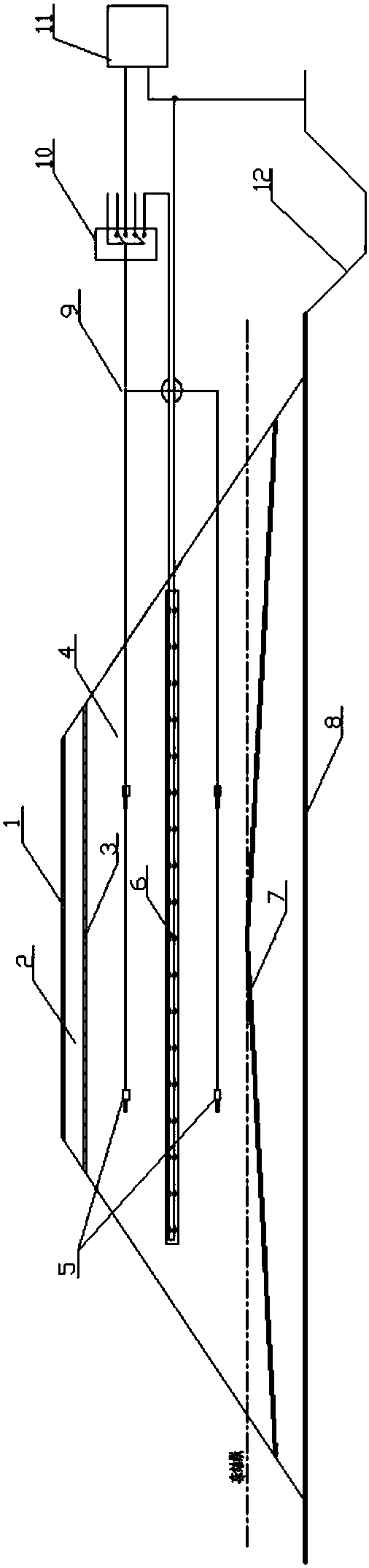

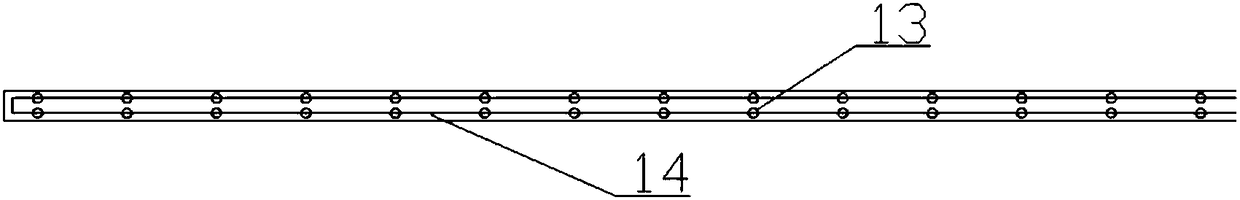

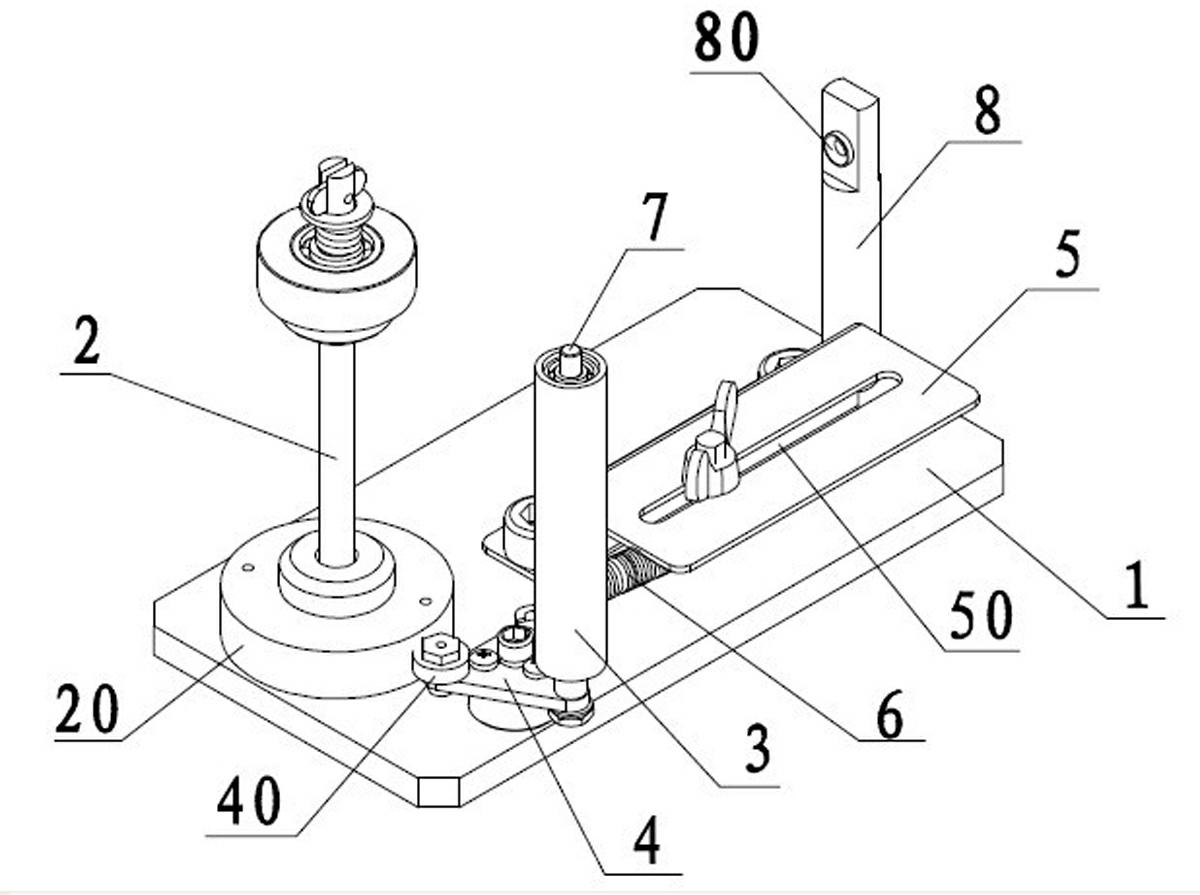

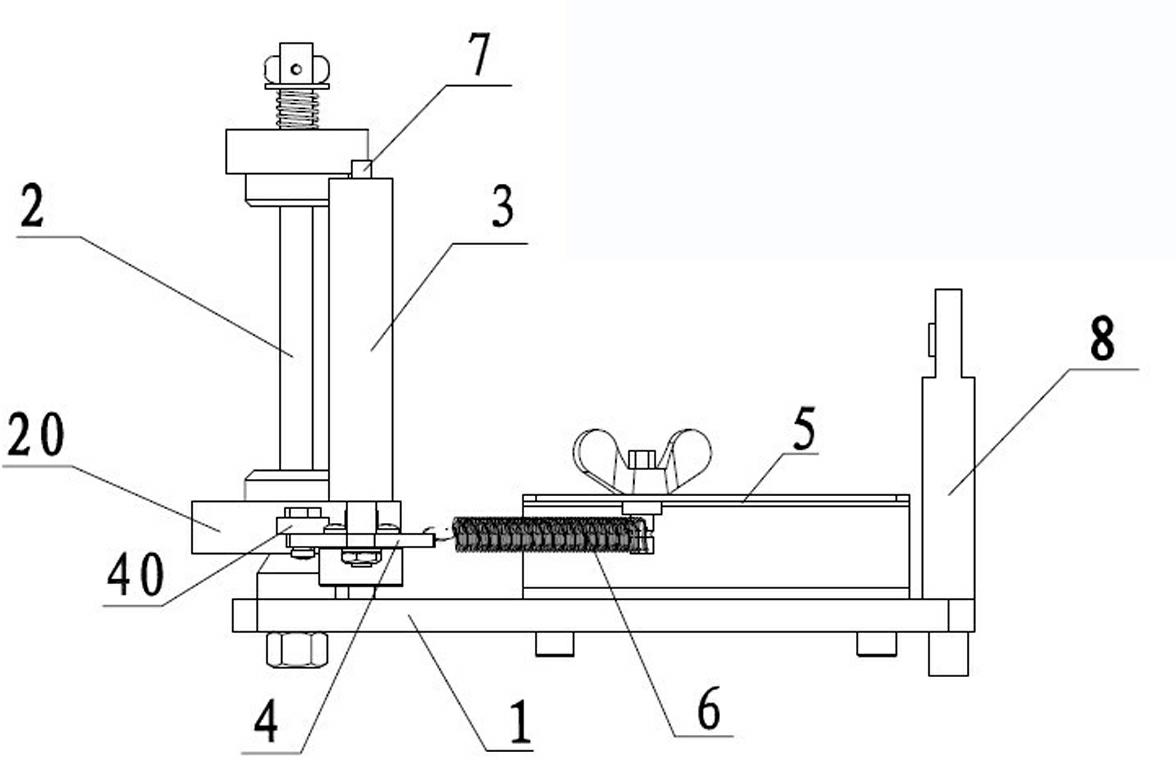

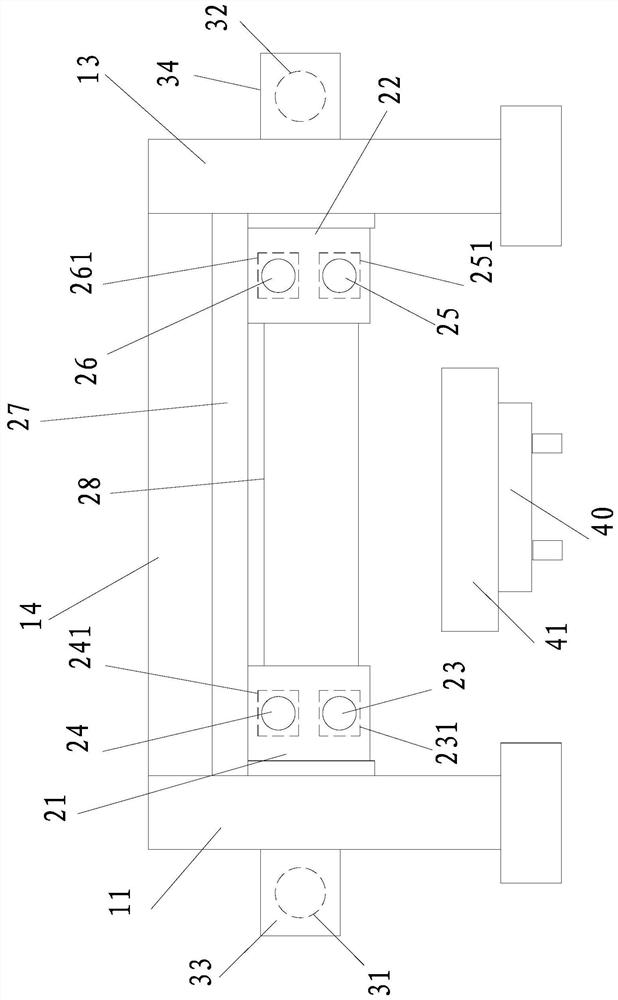

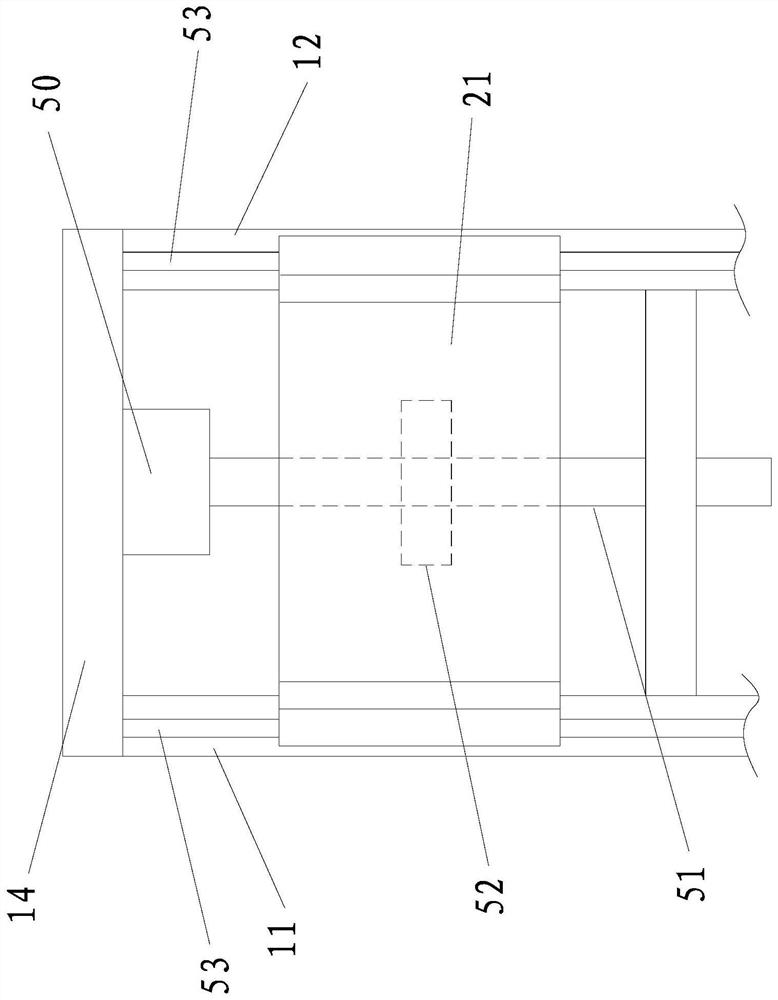

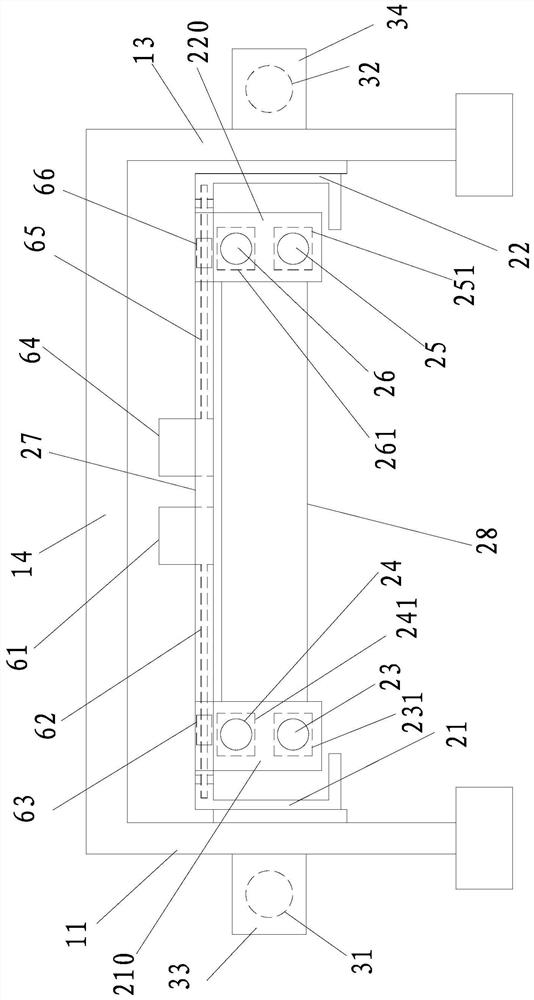

Pay-off frame for ultrathin guide line

ActiveCN102602740AStable pay-off tensionNot easy to disconnectFilament handlingPull forceEngineering

The invention relates to a pay-off frame for an ultrathin guide line. The pay-off frame comprises a base, a main pay-off shaft, a traction guide roller and a tension spring adjusting mechanism, wherein a rotary tray capable of rotating axially by surrounding the main pay-off shaft is arranged at the lower part of the main pay-off shaft; the tension spring adjusting mechanism comprises an adjusting tray, a fixing plate and a tension spring connected between the adjusting tray and the fixing plate; and the adjusting tray is also provided with a friction wheel capable of rubbing and contacting the edge of the rotary tray, and the traction guide roller is arranged on the adjusting tray. When the pay-off speed is normal, the friction wheel props against the edge of the rotary tray so as to provide friction force and pressure to the rotary tray; when the pay-off speed is increased, the tension force of the ultrathin guide line on the traction guide roller is increased, so that the traction guide roller drives the adjusting tray to overcome the tension force of the tension spring, so that the moving tendency of the adjusting tray far away from the rotary tray is increased, the friction force and the pressure of the friction wheel to the rotary tray are reduced, furthermore, the pay-off speed of the ultrathin guide line is increased, the pay-off tension force falls back so as to be kept stable. According to the pay-off frame, the tension force is balanced and the line is not easy to break in the pay-off process.

Owner:苏州久隆新材料科技有限公司

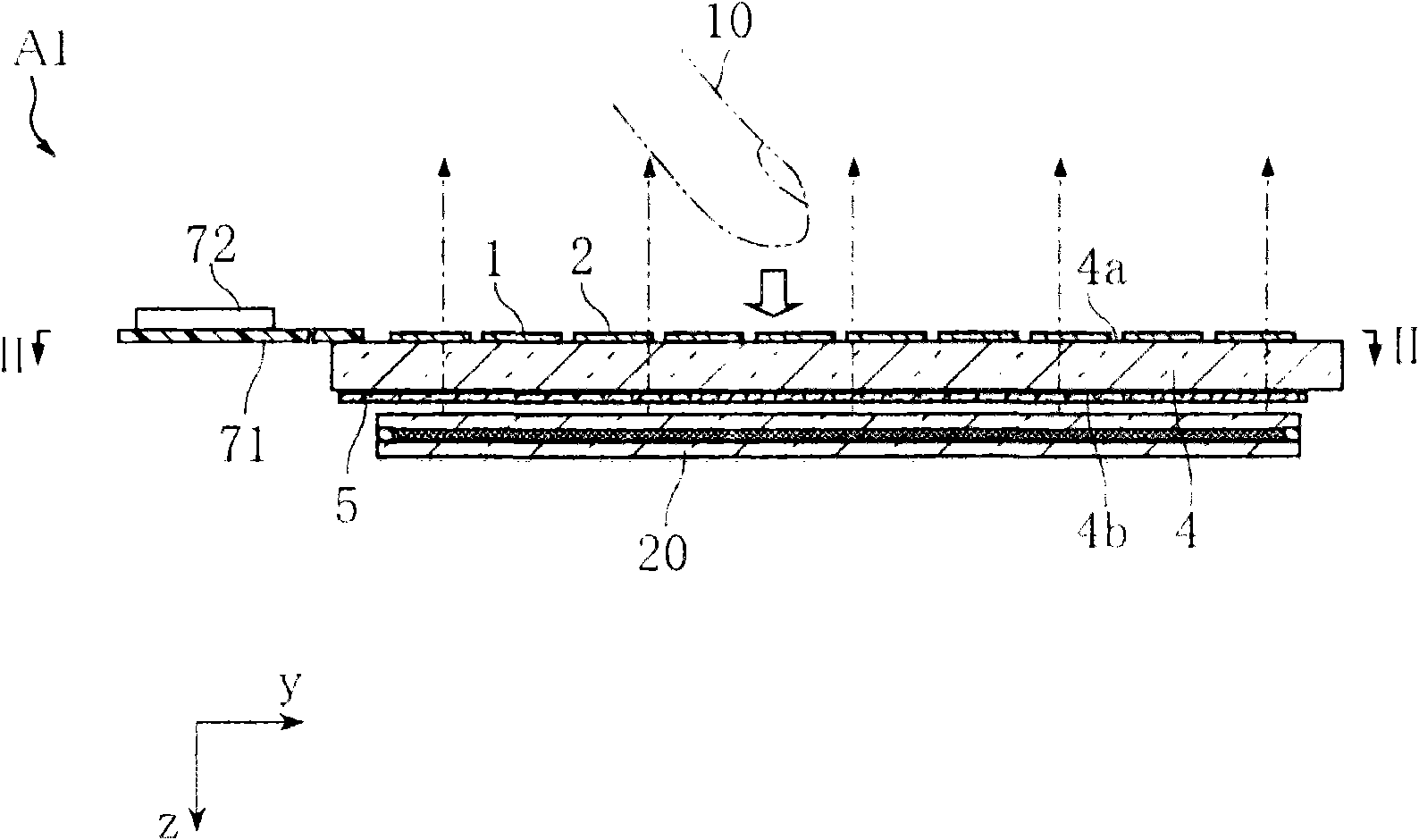

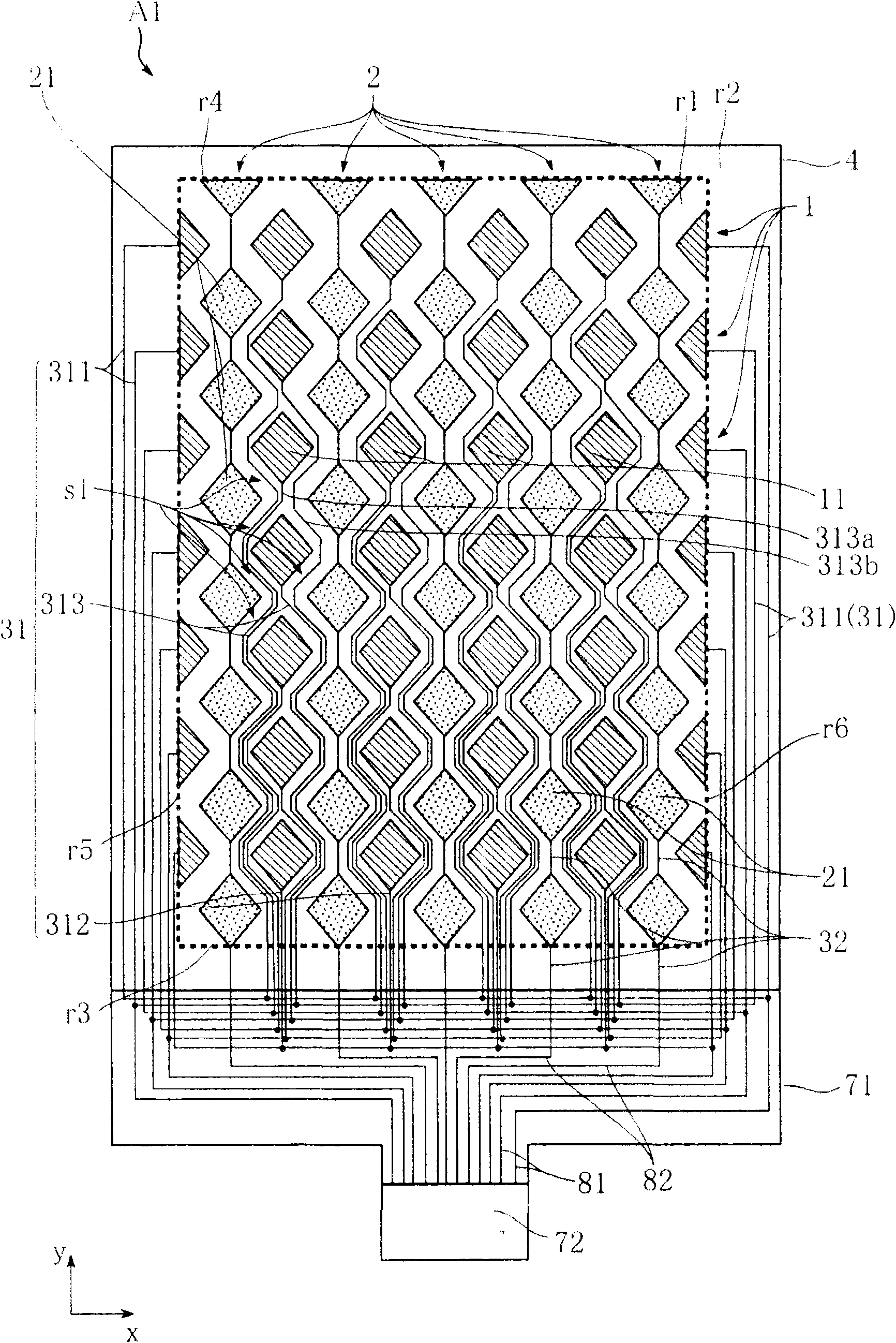

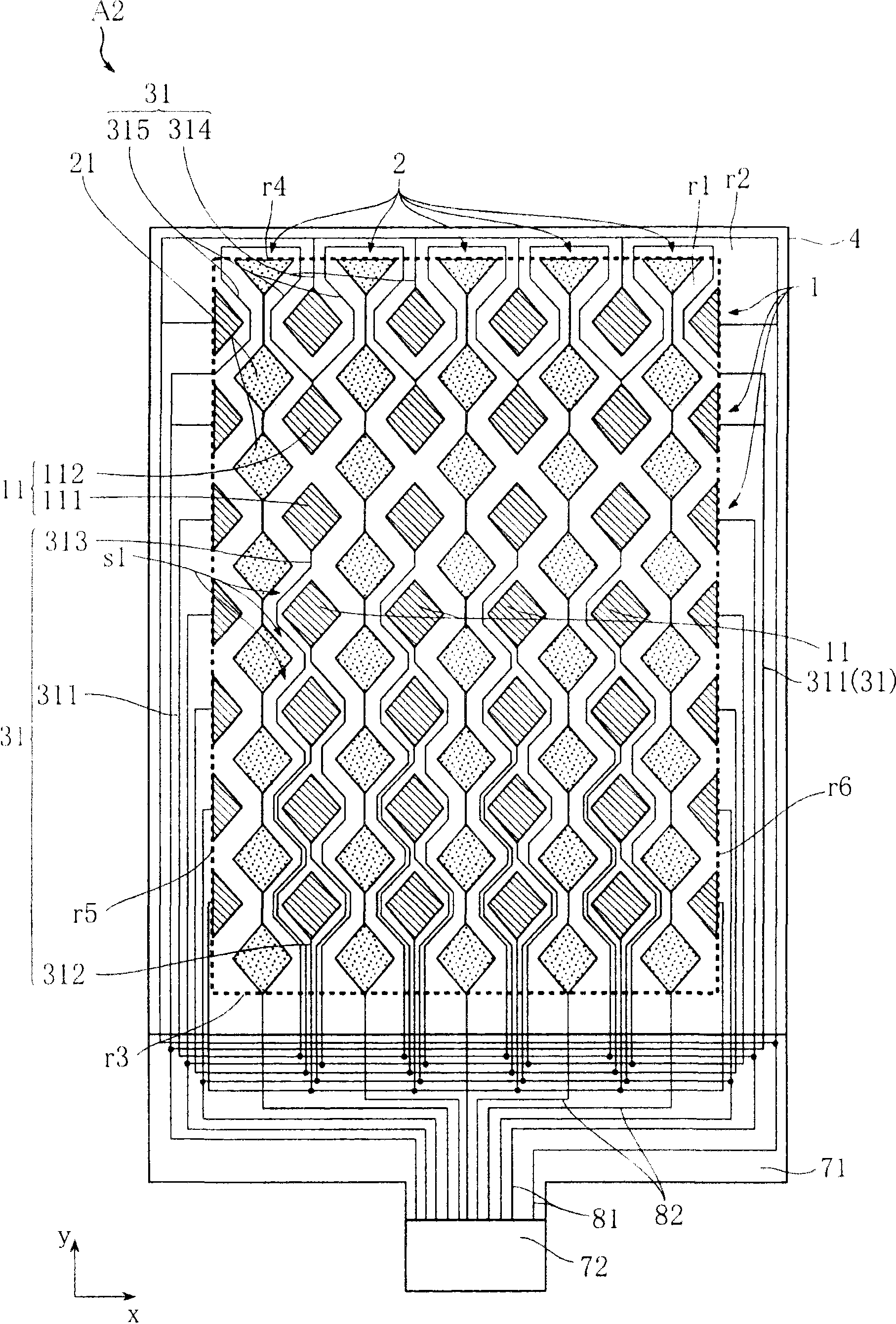

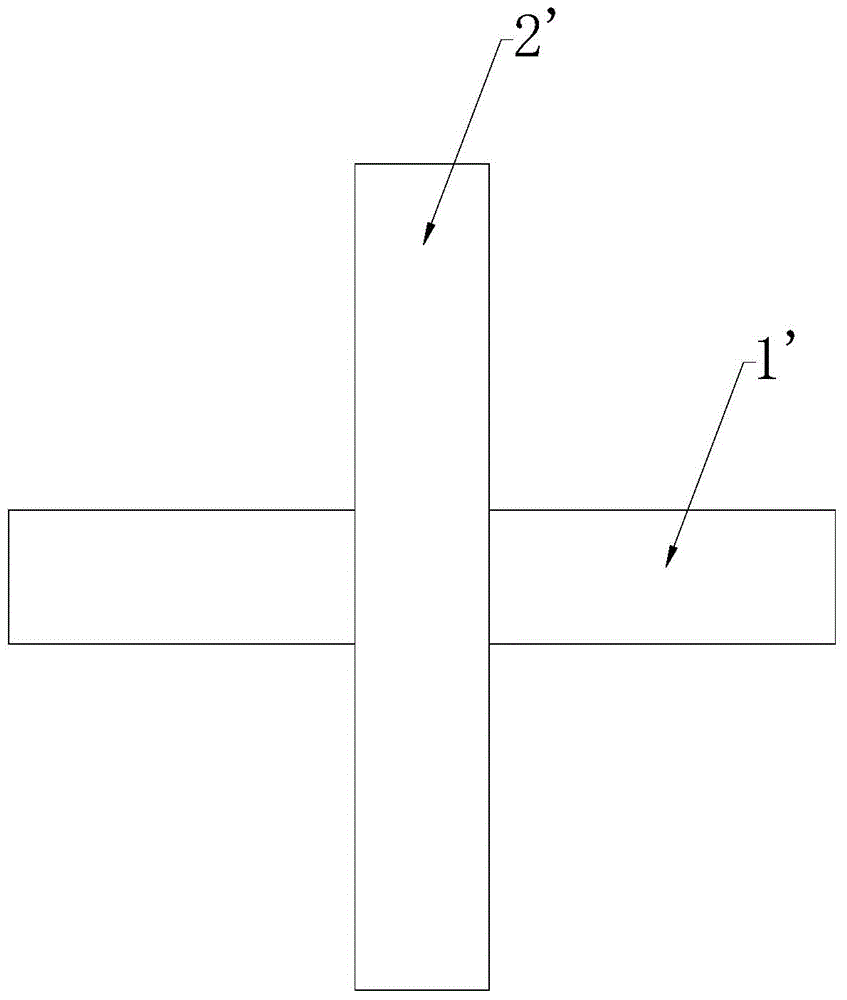

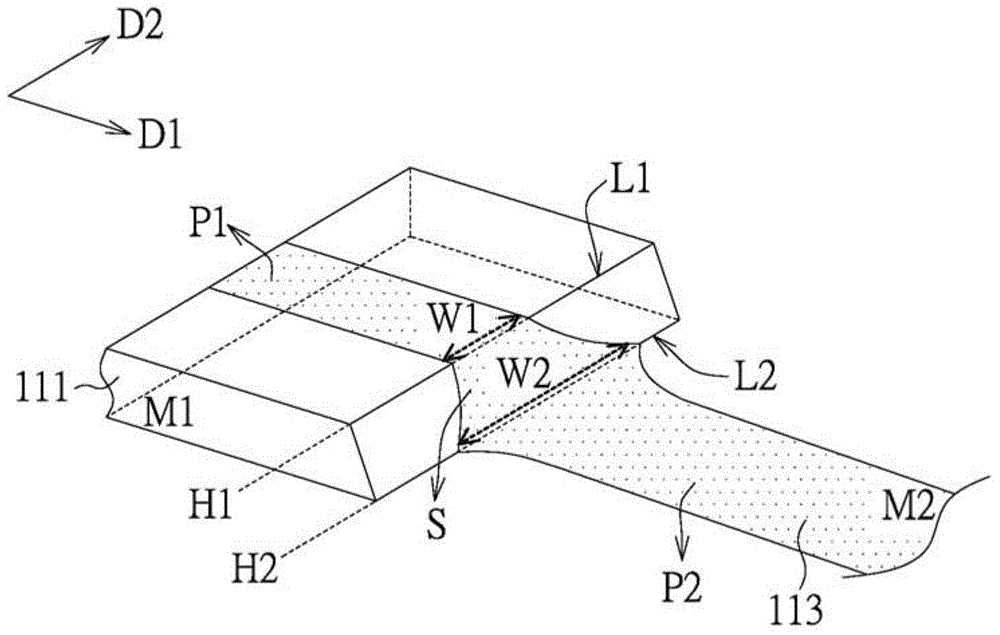

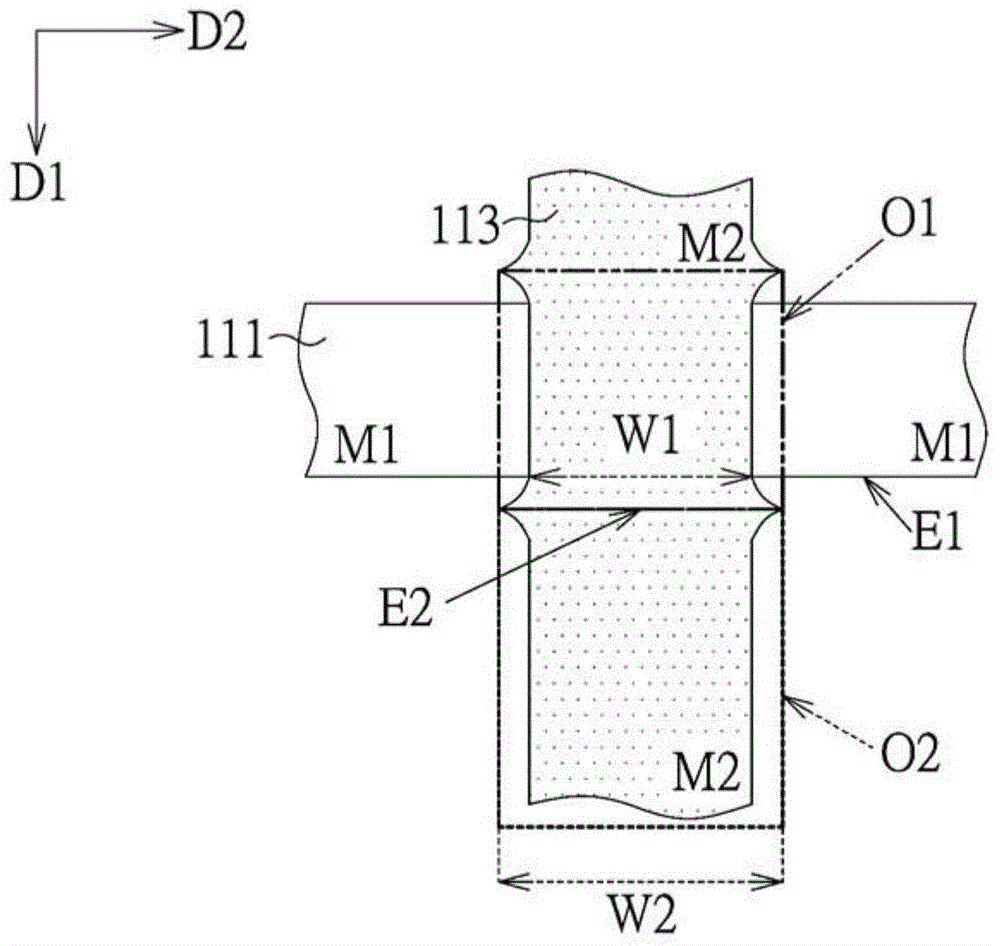

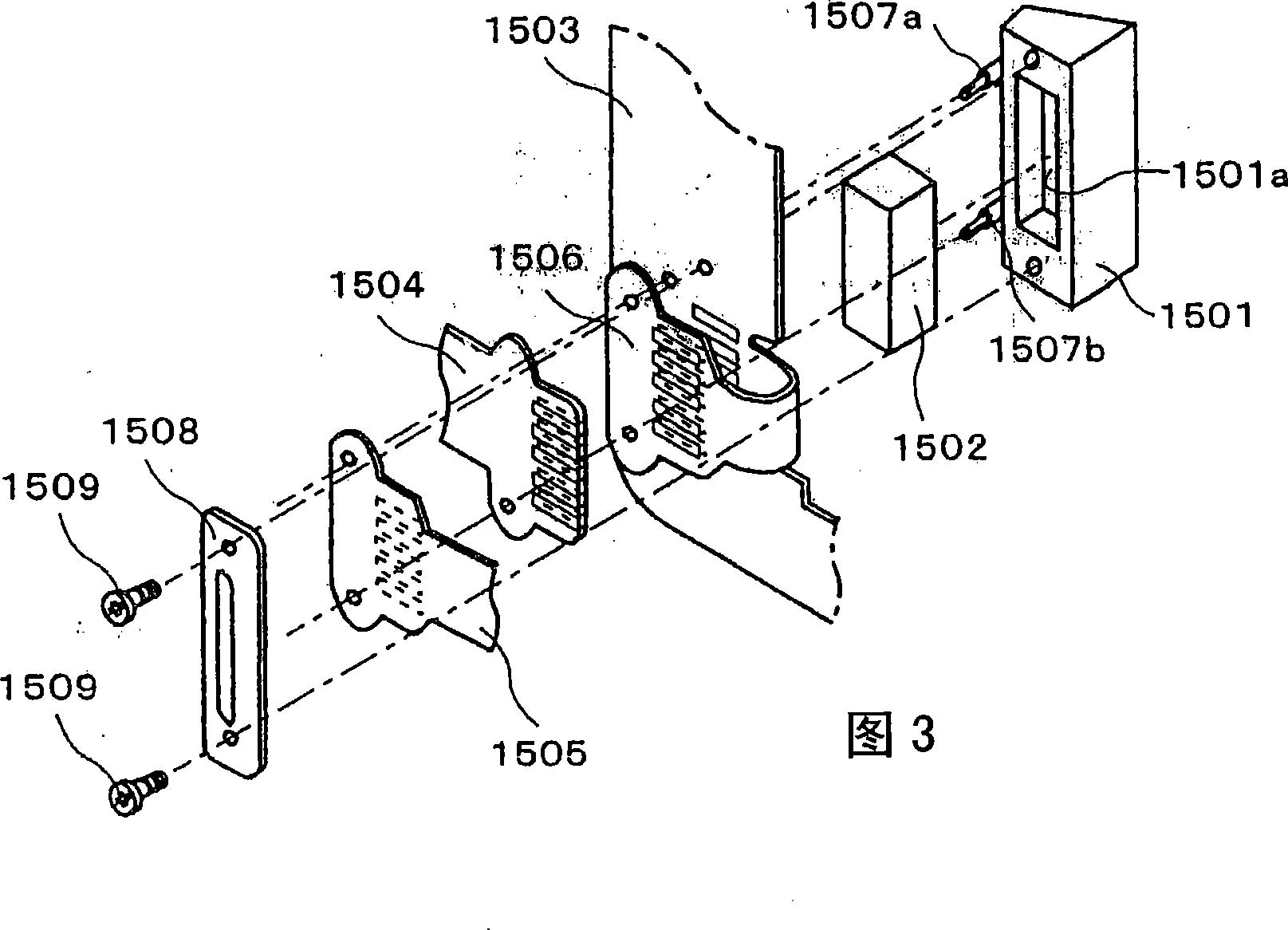

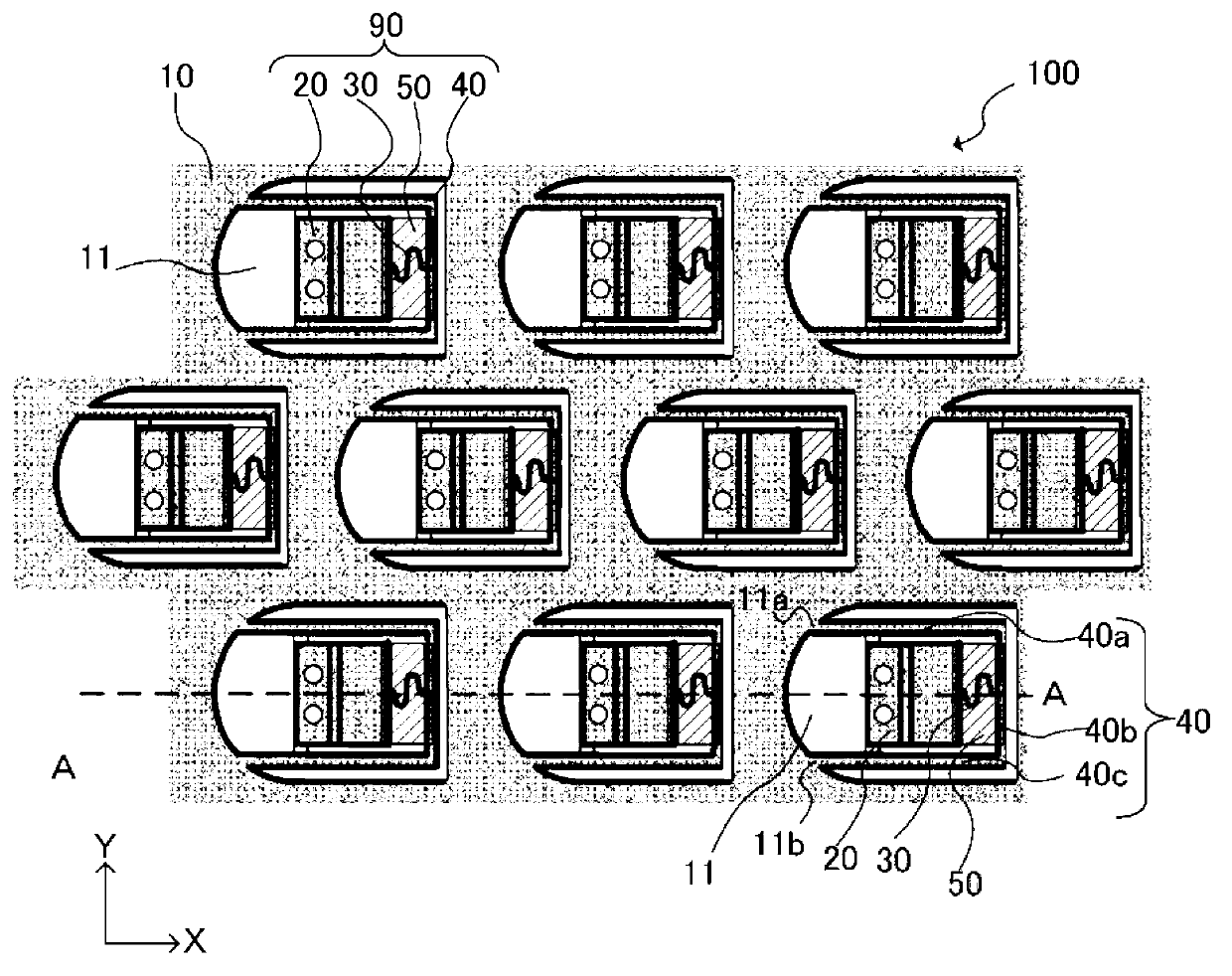

Position input device

InactiveCN101794187ANot easy to disconnectEasy to makeInput/output processes for data processingCapacitanceElectrical conductor

The invention provides a position input device, including: a substrate with a surface and a back; a plurality of first electrodes configured parallel to one another, which include a plurality of first electrode components, formed on the surface of the substrate and configured along the first direction; and a plurality of second electrodes configured parallel to one another, which include a plurality of second electrode components, formed on the surface of the substrate and configured along the second direction different from the first direction. The position input device includes a control unit, when the conductor is adjacent to the first and second electrodes in the thickness direction of the substrate, the approach position of the conductor in the first and second directions is detected based on the variation of the electrostatic capacitance in the first and second electrodes. A plurality of first wirings are formed on the substrate, which makes first electrode components constituting any one of the first electrodes are conducted to each other. Any one of the first wirings is formed in the first gap clipped by the adjacent first and second electrode component.

Owner:ROHM CO LTD

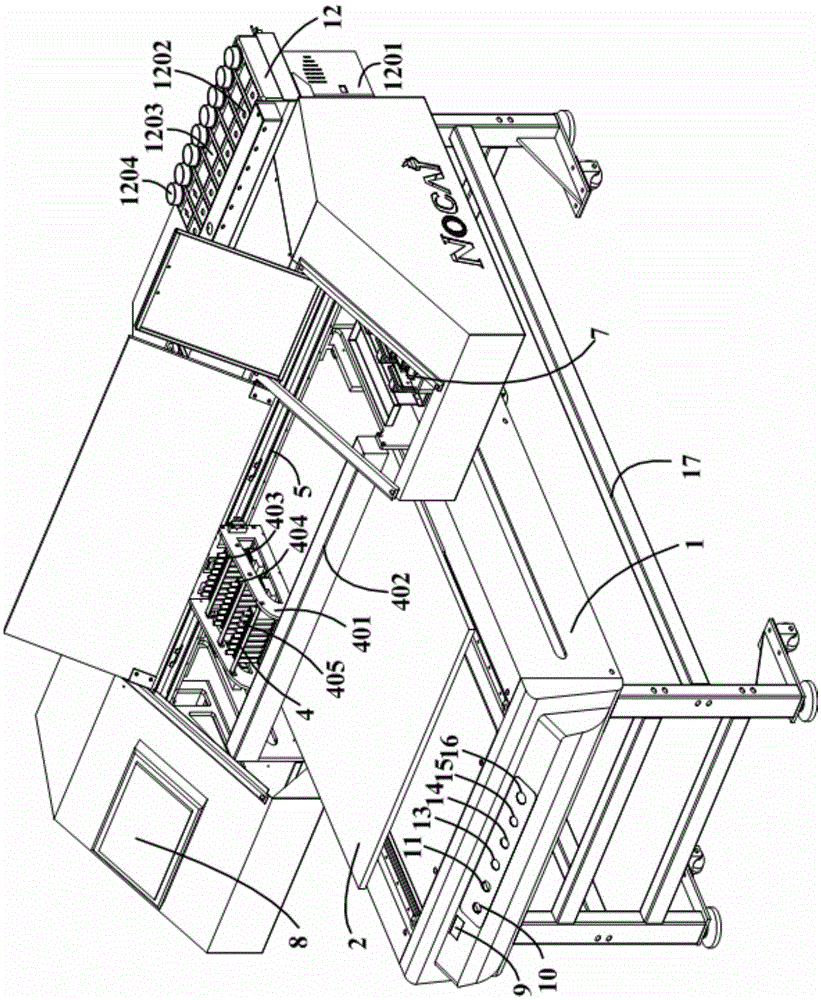

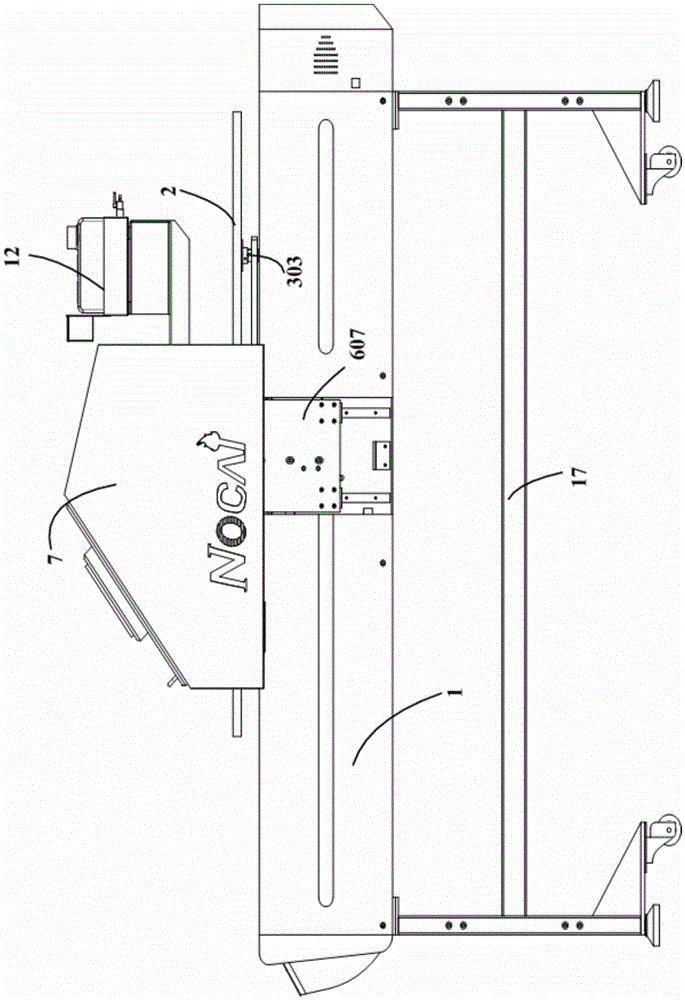

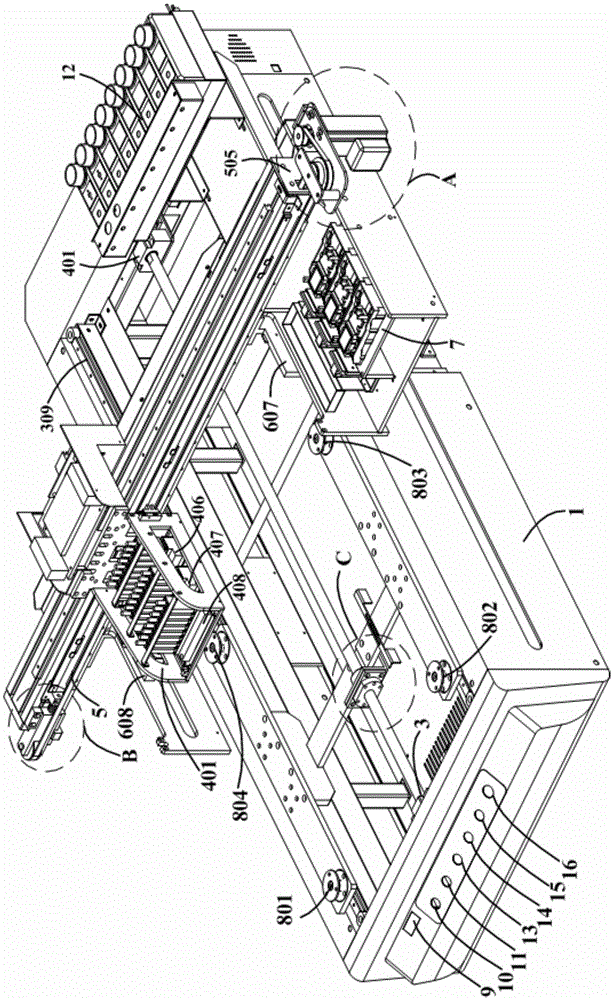

Flat printer

ActiveCN105644155ASimple structureRealize simultaneous printingPower drive mechanismsVarnishFlat panel

The invention discloses a flat printer comprising a printer shell, a working platform, a printer head part, a printer head driving assembly and an ink cartridge, wherein the working platform is arranged on the upper surface of the printer shell; the printer head part is horizontally arranged above the working platform, is parallel to the working platform and comprises a printer body and an ink vehicle located outside the printer body; the printer head driving assembly is located in the printer body and is used for driving the ink vehicle to move relative to the X axis of the printer shell; and the ink cartridge is arranged at one end part of the printer body and is communicated with the ink vehicle comprising a sub ink sac filled with white ink, a sub ink sac filled with colored ink and a sub ink sac filled with a gloss varnish. The flat printer disclosed by the invention is not only simple in structure, but also capable of simultaneously printing the white ink, the colored ink and the gloss varnish; and the front end of the ink vehicle can also be provided with an LED curing lamp capable of curing ink and the gloss varnish and increasing the adhesive forces of the ink and the gloss varnish. In the preferable embodiment, an underframe driving assembly is used for smoothly conveying a printing base material on a bearing platform, and a printer head lifting assembly can also be used for regulating the distance from a spray head to the printing base material according to the thickness of the printing base material, so that the printing effect is greatly improved.

Owner:GUANGZHOU NUOCAI DIGITAL PROD CO LTD

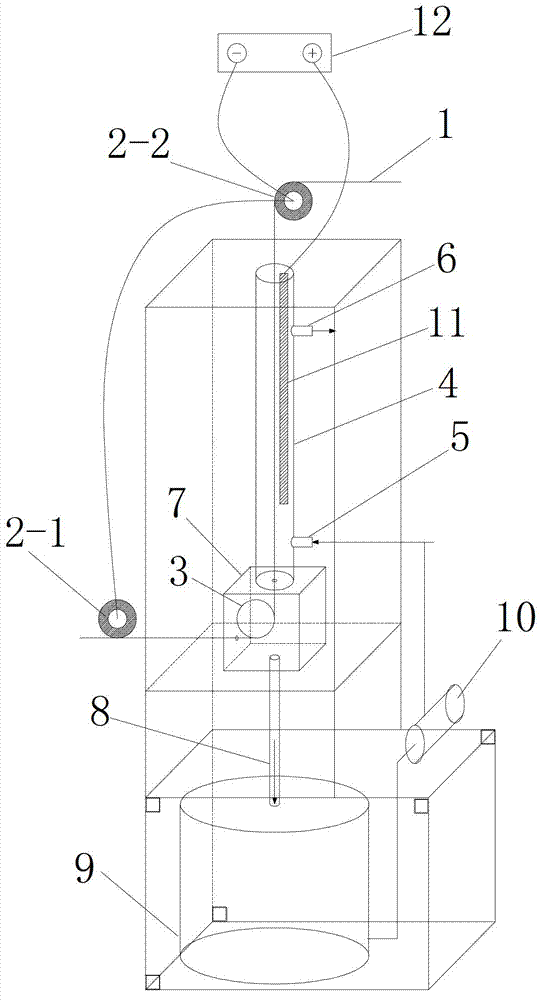

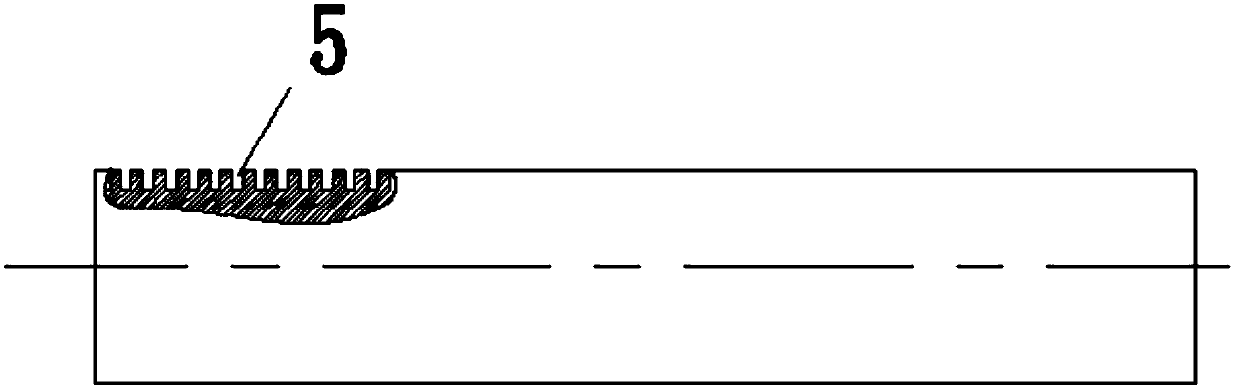

Electroplated diamond wire saw sand-applying device

The invention discloses an electroplated diamond wire saw sand-applying device. The device sequentially comprises the components, from top to bottom: a vertical tubular sand-applying sub tank, a liquid-returning box, and a plating solution master tank. A guide wheel is fixed in the liquid-returning box. A core wire is sequentially wound on a wire-feeding conductive wheel on the bottom of the vertical tubular sand-applying sub tank and the guide wheel. The core wire then penetrates the vertical tubular sand-applying sub tank, and is finally wound on a wire-discharging conductive wheel on the top of the vertical tubular sand-applying sub tank. The wire-feeding conductive wheel and the wire-discharging conductive wheel are connected in parallel, and are then connected to the negative electrode of an electroplating power supply. Metal anodes are arranged around the core wire in the vertical tubular sand-applying sub tank. The metal anodes are connected with positive electrodes of the electroplating power supply. Through a water pump above the plating solution, the plating solution is lifted from the plating solution master tank into the vertical tubular sand-applying sub tank. With the device provided by the invention, sand-application of produced diamond wire is uniform and good. During the production process, current density is high, efficiency is high, internal stresses of the plating and the substrate are small, plating solution application amount is low, and wire breakage probability is low.

Owner:无锡超亚环保设备有限公司

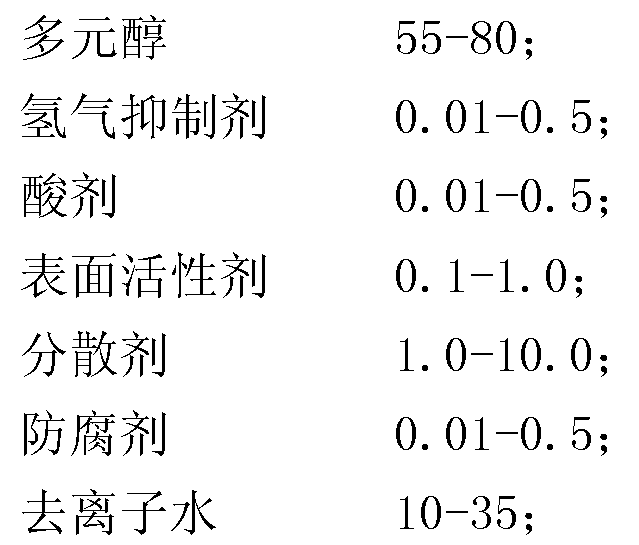

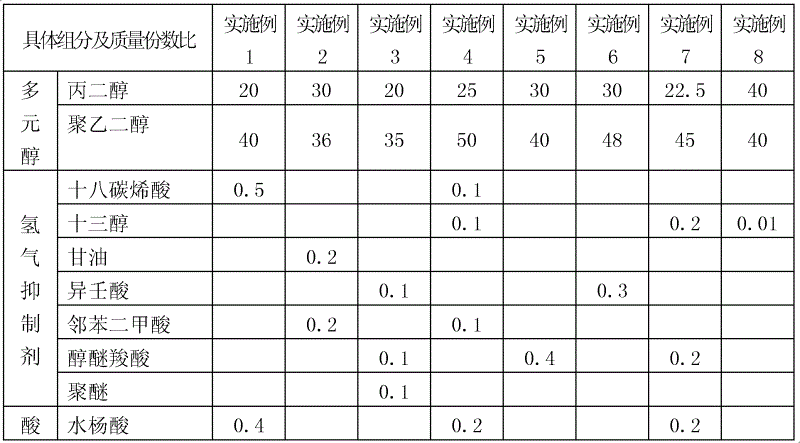

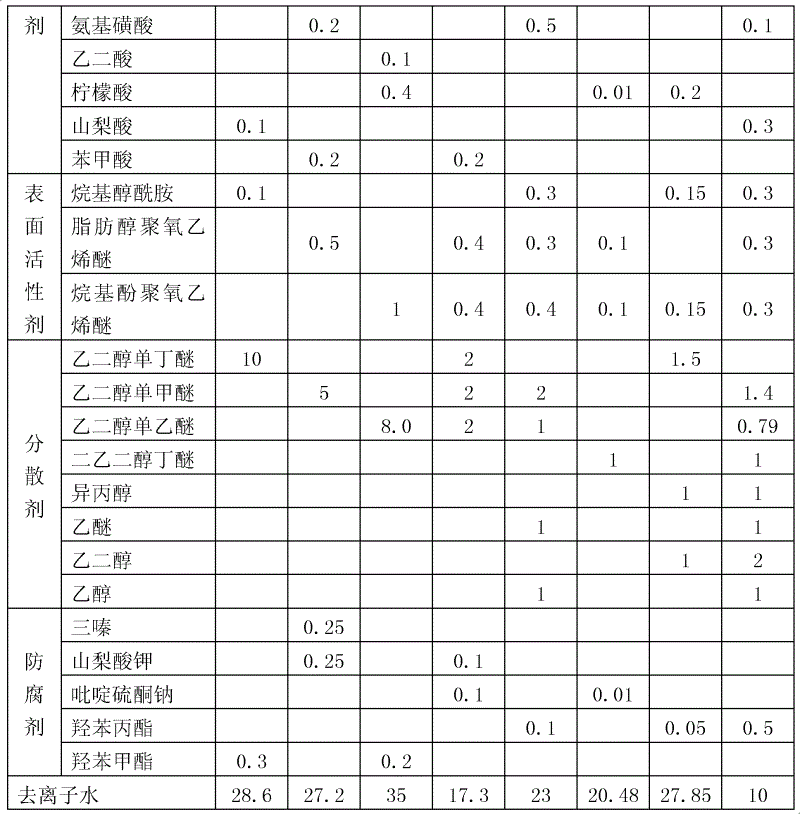

Diamond abrasive wire cutting fluid for semiconductor precision sheet and preparation method of diamond abrasive wire cutting fluid

The invention relates to a diamond abrasive wire cutting fluid for a semiconductor precision sheet. The raw materials of the diamond abrasive wire cutting fluid consist of the following compositions in parts by mass: 30-80 parts of polyalcohol, 0.01-0.5 parts of hydrogen inhibitor, 0.01-0.5 parts of acid, 0.1-1.0 part of surfactant, 1.0-10.0 parts of dispersing agent, 0.01-0.5 parts of preservative and 10-35 parts of deionized water, wherein the polyalcohol is mixture of propylene glycol and polyethylene glycol with ratio being 1 to (1:2) and the molecular weight of the polyethylene glycol is between 100 and 600. The diamond abrasive wire cutting fluid for the semiconductor precision sheet has the characteristics that the hydrogen is effectively inhibited from being generated, the lubricating effect is remarkable, the cleaning is easy to conduct, the cost is low and the performance is stable.

Owner:CHANGZHOU JUNHE TECH

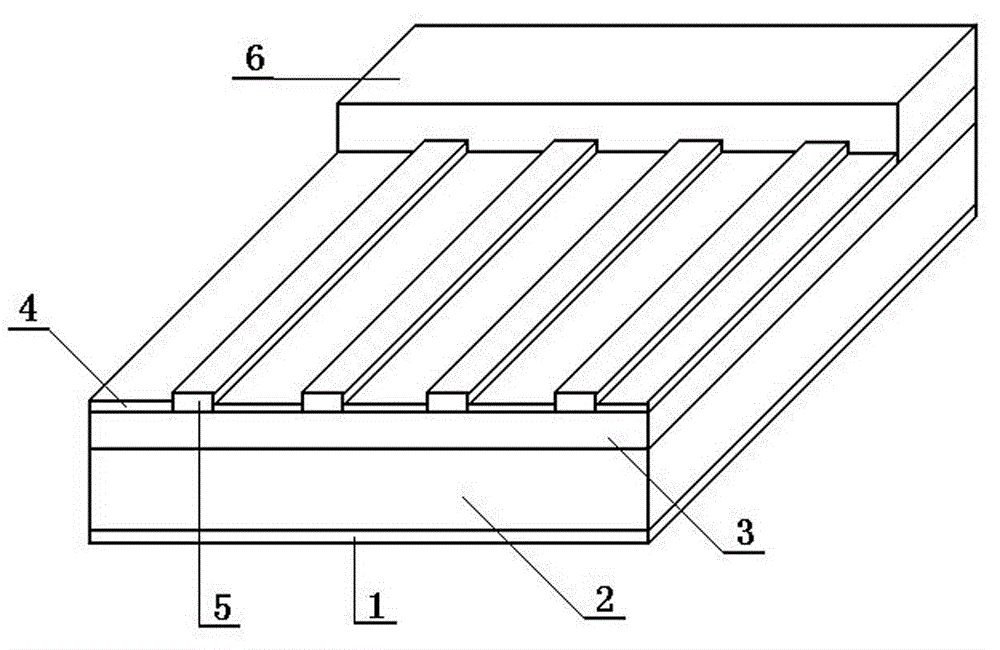

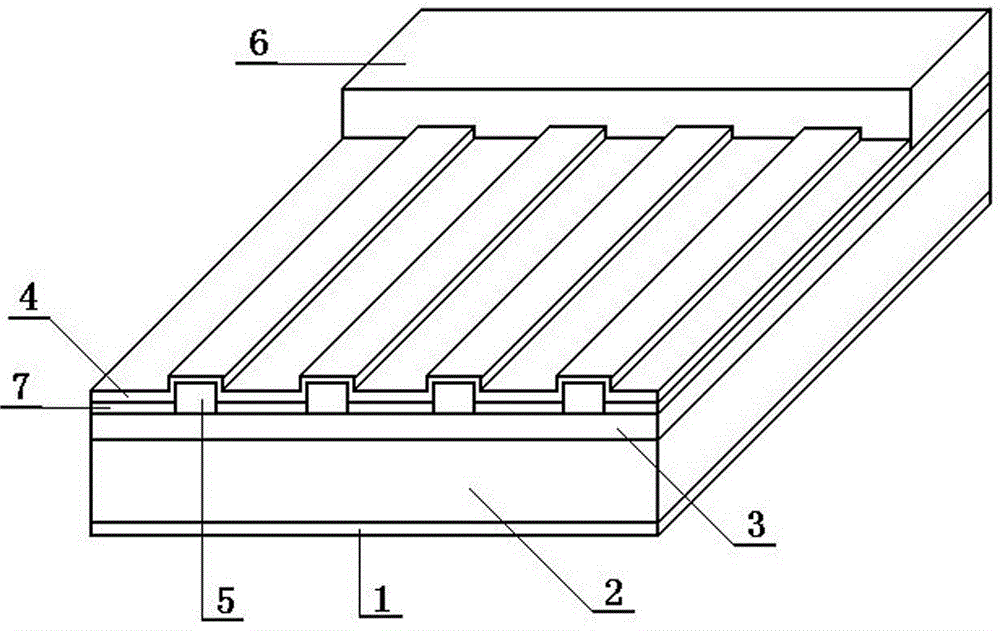

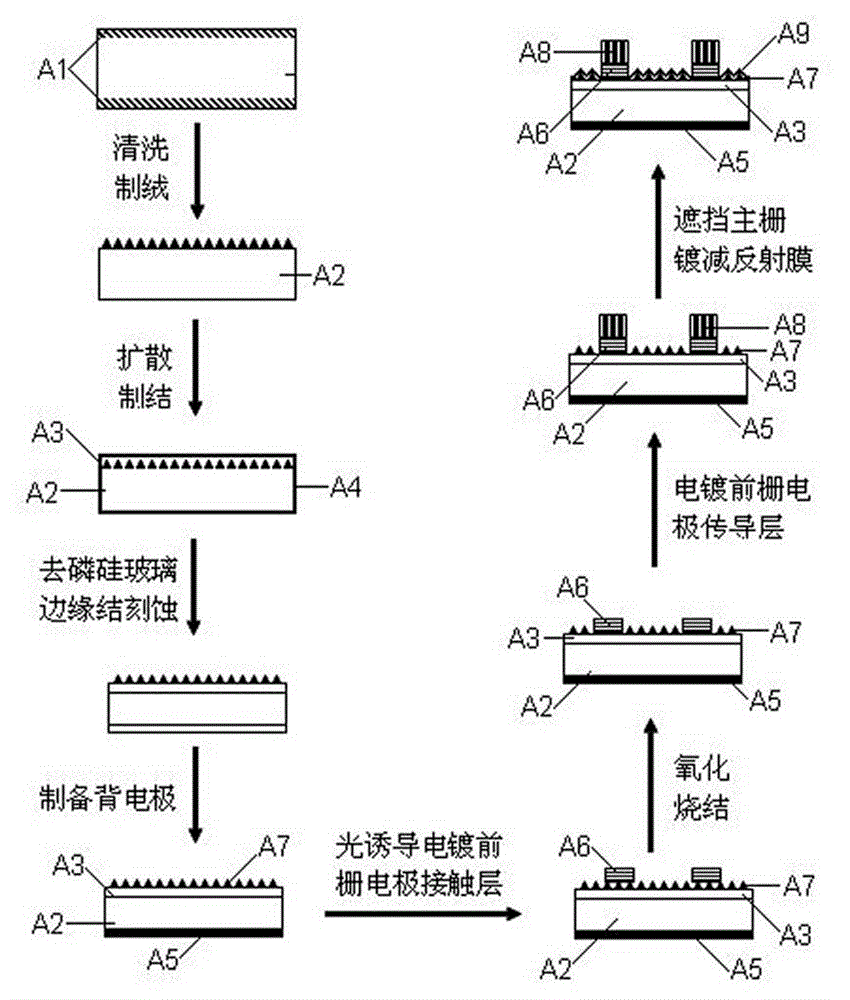

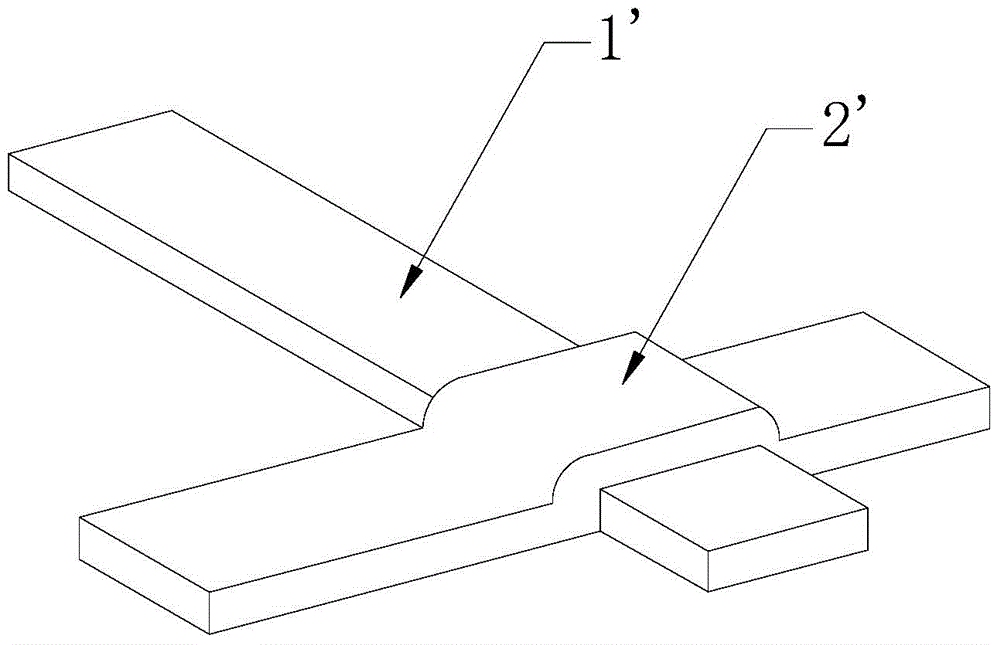

Crystalline silicon solar cell with high-photoelectric conversion efficiency and manufacturing method thereof

InactiveCN102881732AReduce shadow lossTightly boundFinal product manufactureSemiconductor devicesOhmic contactCrystalline silicon

The invention discloses a crystalline silicon solar cell with high-photoelectric conversion efficiency and a manufacturing method thereof. The cell comprises a crystalline silicon P-N node substrate, a back electrode and a front gate electrode, wherein the back electrode is in ohmic contact with the P area of the crystalline silicon P-N node substrate; the front gate electrode is in ohmic contact with the N area of the crystalline silicon P-N node substrate; the front gate electrode is wrapped under the antireflection layer and comprises a SiO2 layer and an antireflection layer; the SiO2 layer is positioned on the surface of the N area of the crystalline silicon P-N node substrate; and the antireflection layer is arranged on the SiO2 layer. The manufacturing method comprises a cleaning and flocking step, a diffusing and knotting step, a phosphorus-washing and etching step, a back electrode-preparing step, a photoinduced front gate electrode electroplating step, an oxidizing and sintering step, a front gate electrode electroplating step and an antireflection layer preparing step. The photoinduced front gate electrode electroplating step and the oxidizing and sintering step are adopted, so that the cell has the characteristics of simple production process, high efficiency, low cost, low front gate electrode shade loss of the solar cell, low contact resistance and body resistance, uneasiness in line breaking of the thin front gate electrode, low cell surface reflectivity and high photoelectric conversion efficiency.

Owner:YUNNAN UNIV

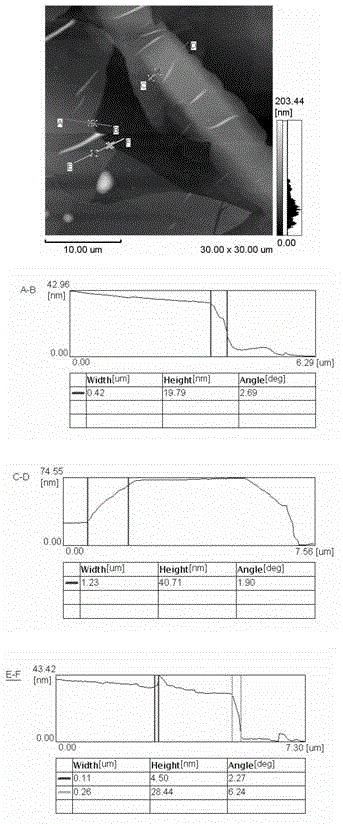

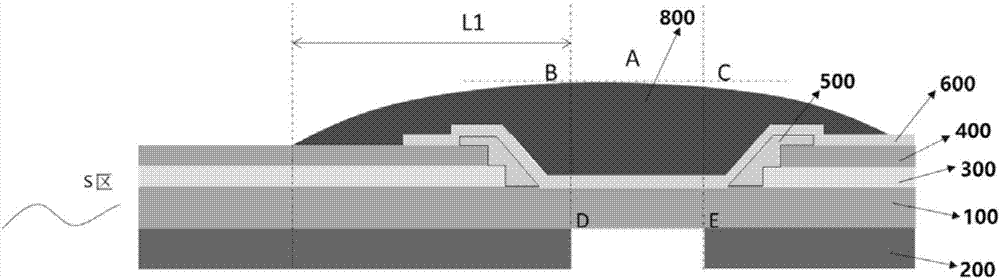

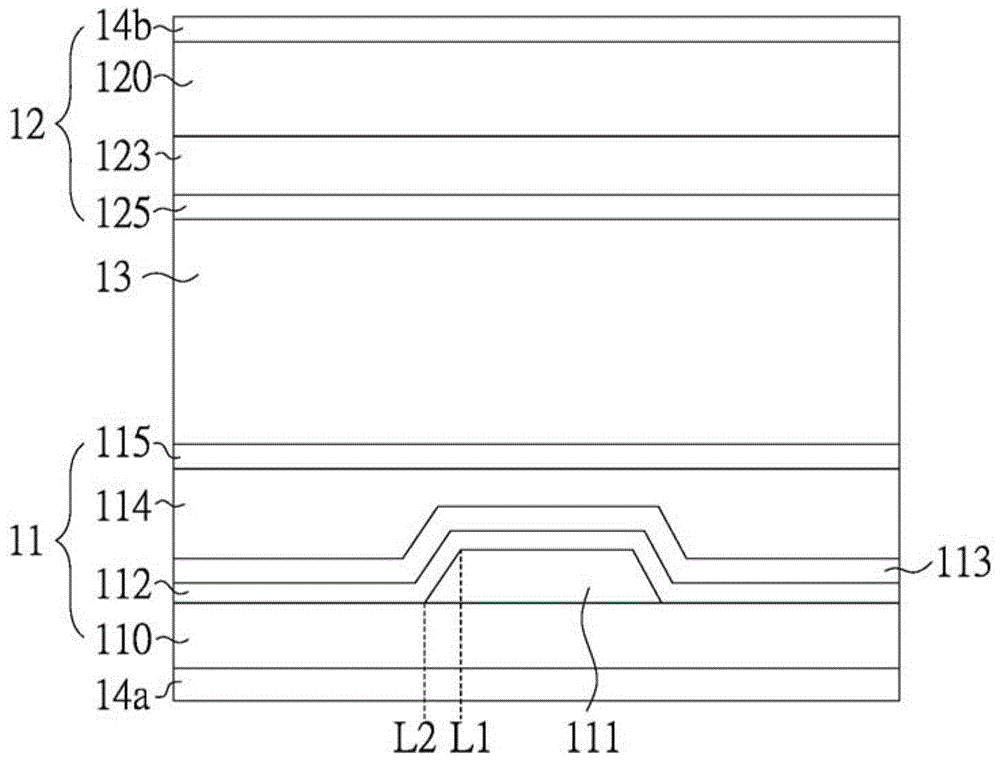

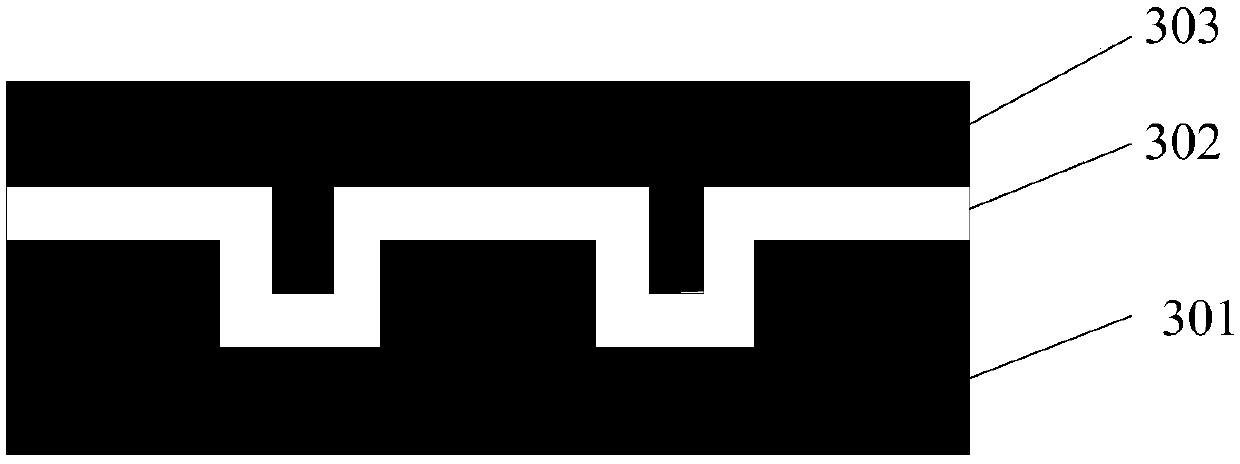

Array substrate, liquid crystal display panel and manufacturing method of array substrate

ActiveCN104460150AHigh strengthNot easy to disconnectSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayUltimate tensile strength

The invention discloses an array substrate, a liquid crystal display panel and a manufacturing method of the array substrate. The array substrate comprises a first metal layer provided with a first metal wire, an insulating layer covering the first metal layer and a second metal layer covering the insulating layer. The second metal layer comprises a second metal wire. The second metal wire overlaps with the first metal wire through the insulating layer to form a grid. The second metal wire is provided with reinforcing parts at four corners of the part overlapping with the first metal wire. The reinforcing parts respectively attach to the lateral sides and the upper surface of the first metal wire through the insulating layer. The array substrate has the advantages that the strength of the climbing parts of the second metal wire is increased by the reinforcing parts, the climbing parts of the second metal wire cannot be easily disconnected, vertical wire disconnection occurrence rate is lowered, and product yield is increased favorably.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

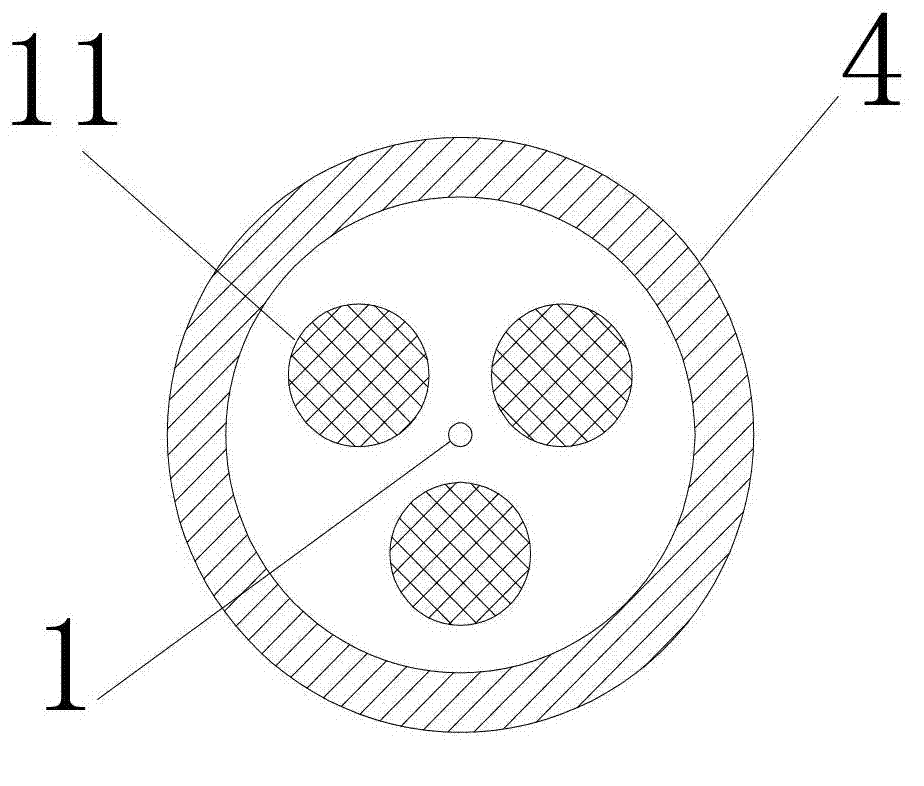

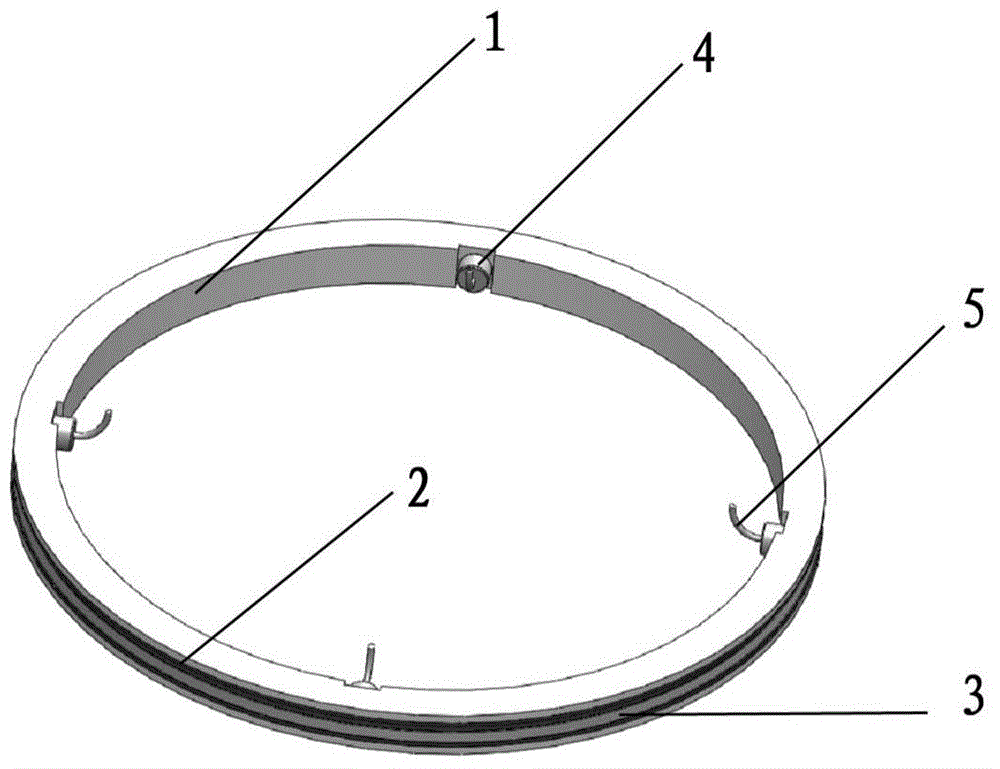

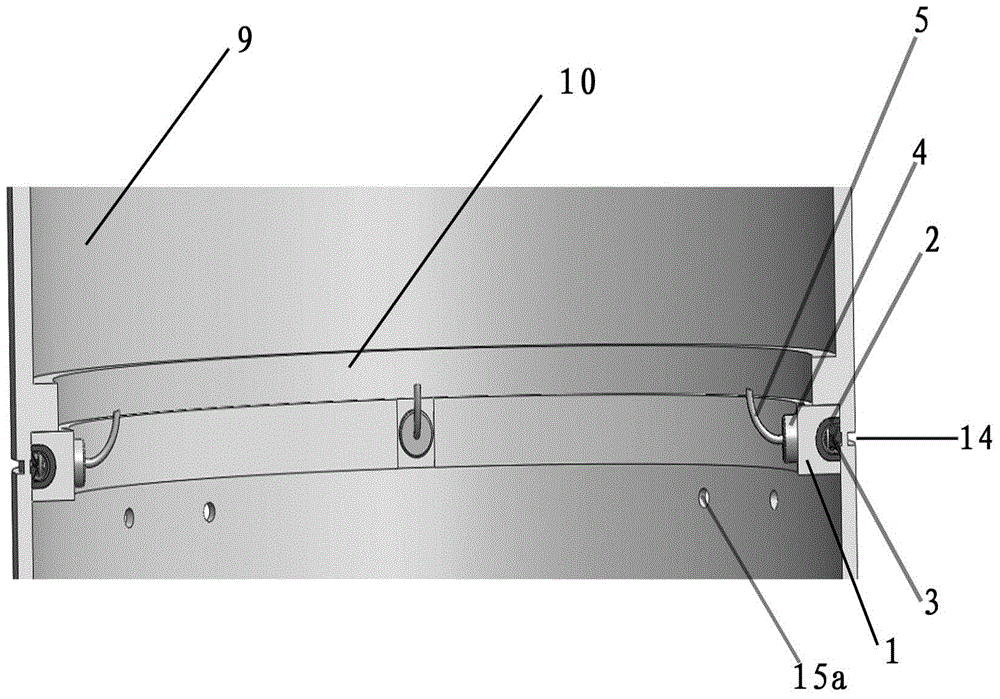

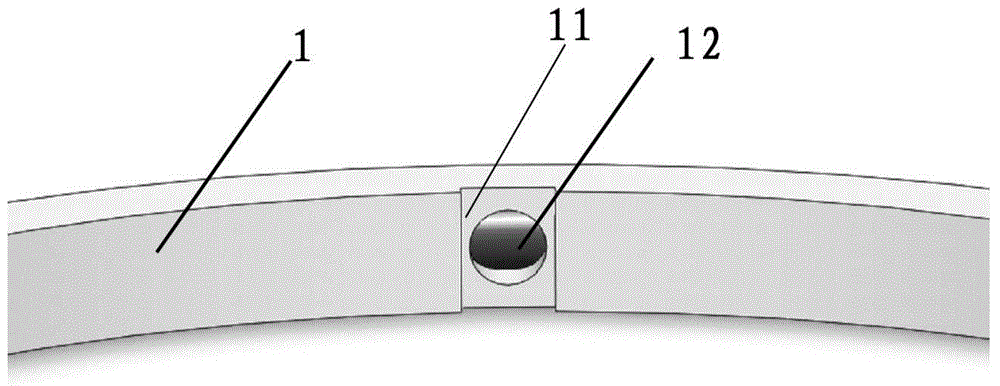

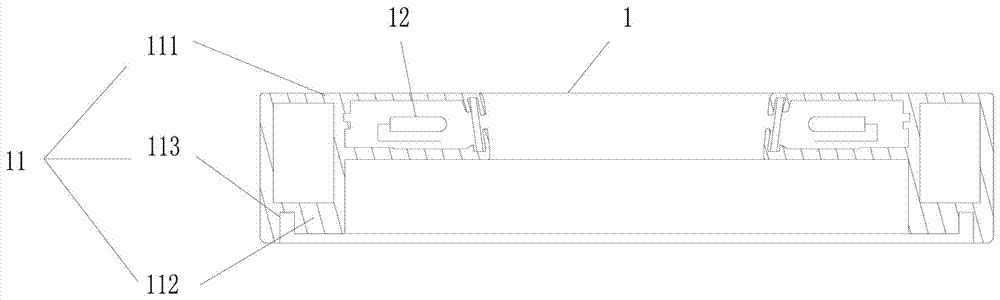

Cutting device for missile stage separation

The invention discloses a cutting device for missile stage separation. The cutting device comprises a shield (1), a rubber shield (2), a cutting rope (3) and exploders (4); the inner edge, which is in contact with the rubber shield (2), of the cutting rope (3) is of a U-shaped structure, the outer edge of the cutting rope (3) is of a V-shaped structure, the opening of which is outward, the two structures are closed to form an annular closed cavity, and explosive is loaded in the cavity; the shield (1) is in contact with the rubber shield (2) to wrap the rubber shield (2) and the cutting rope (3); the inner edge of the shield (1) is provided with four grooves (11), which are evenly distributed at the interval of 90 degrees, and a mounting hole (12) which is connected with the cavity is formed in each groove (11) in order to mount and fix one of the exploders (4); detonating cables (5) are connected with detonation signal cables (8) through steering engine plug connectors, so that a signal can be transmitted to detonate the cables. The cutting device has the advantages of stable connection, high detonation synchronism, low destructiveness and full cutting when being used for missile stage separation.

Owner:北京威标至远科技发展有限公司

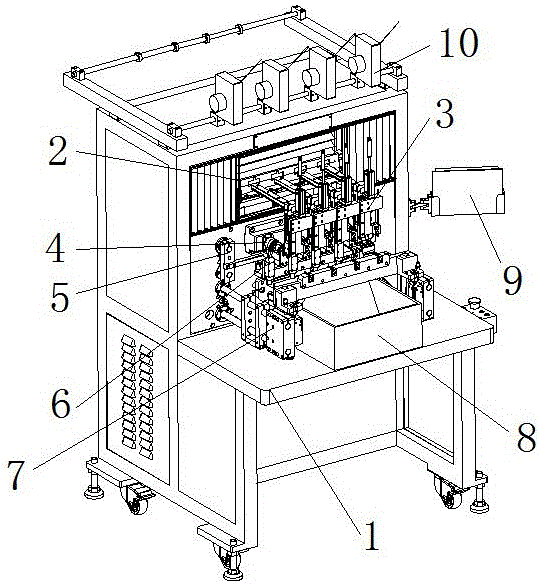

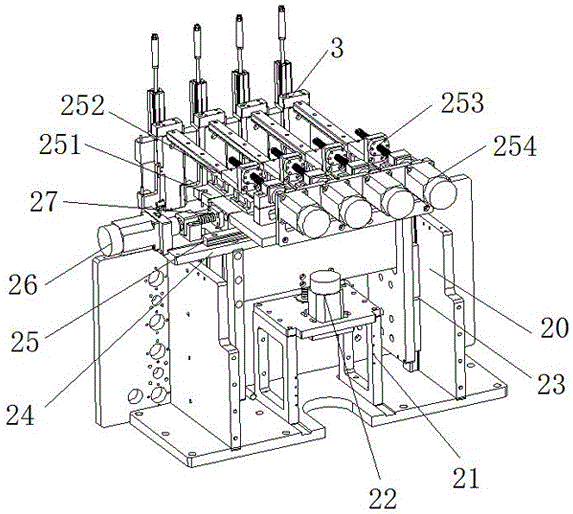

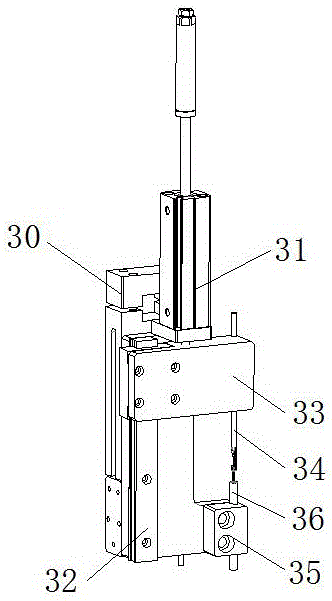

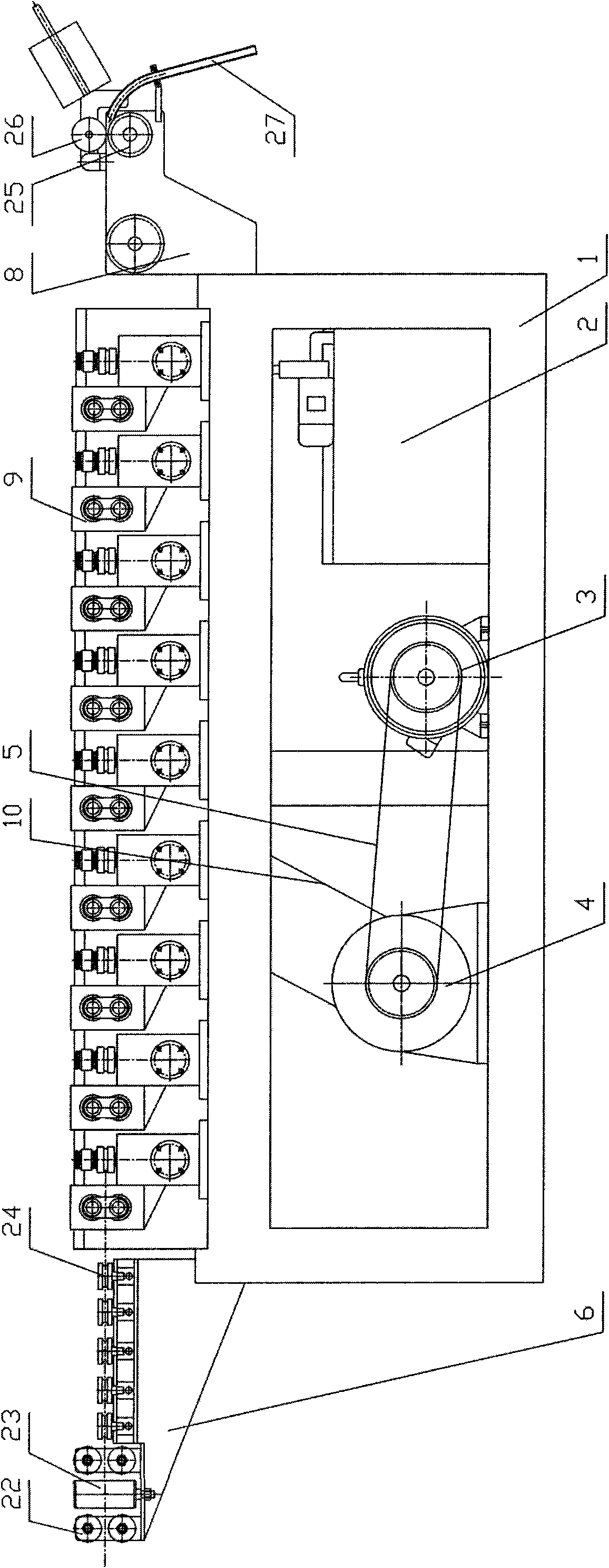

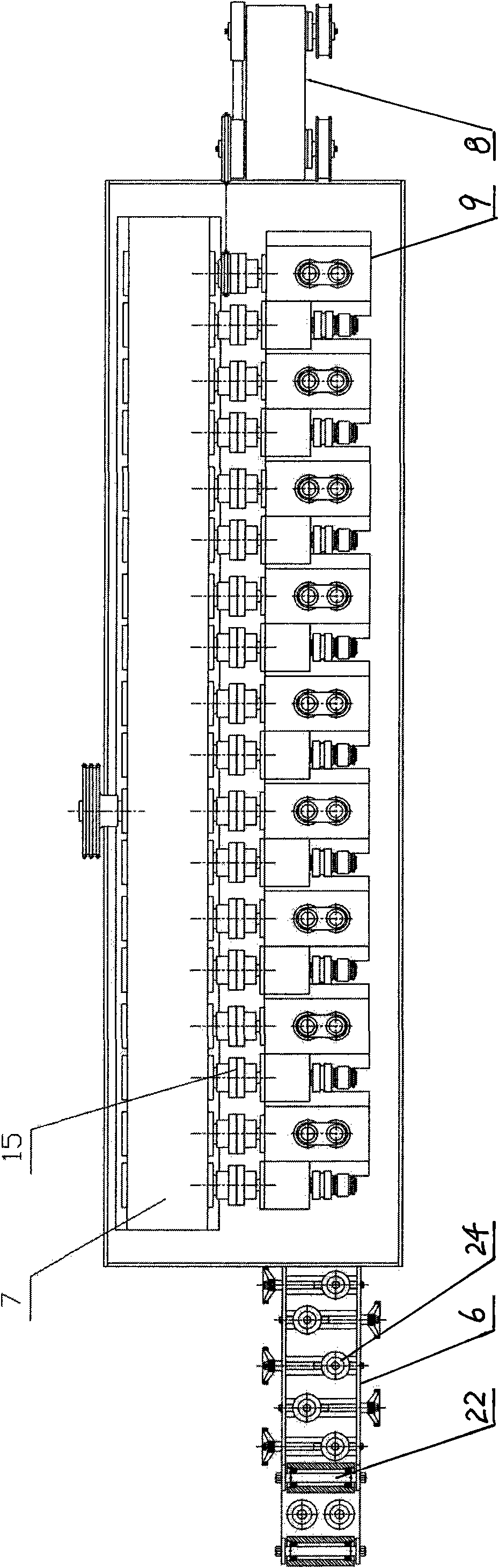

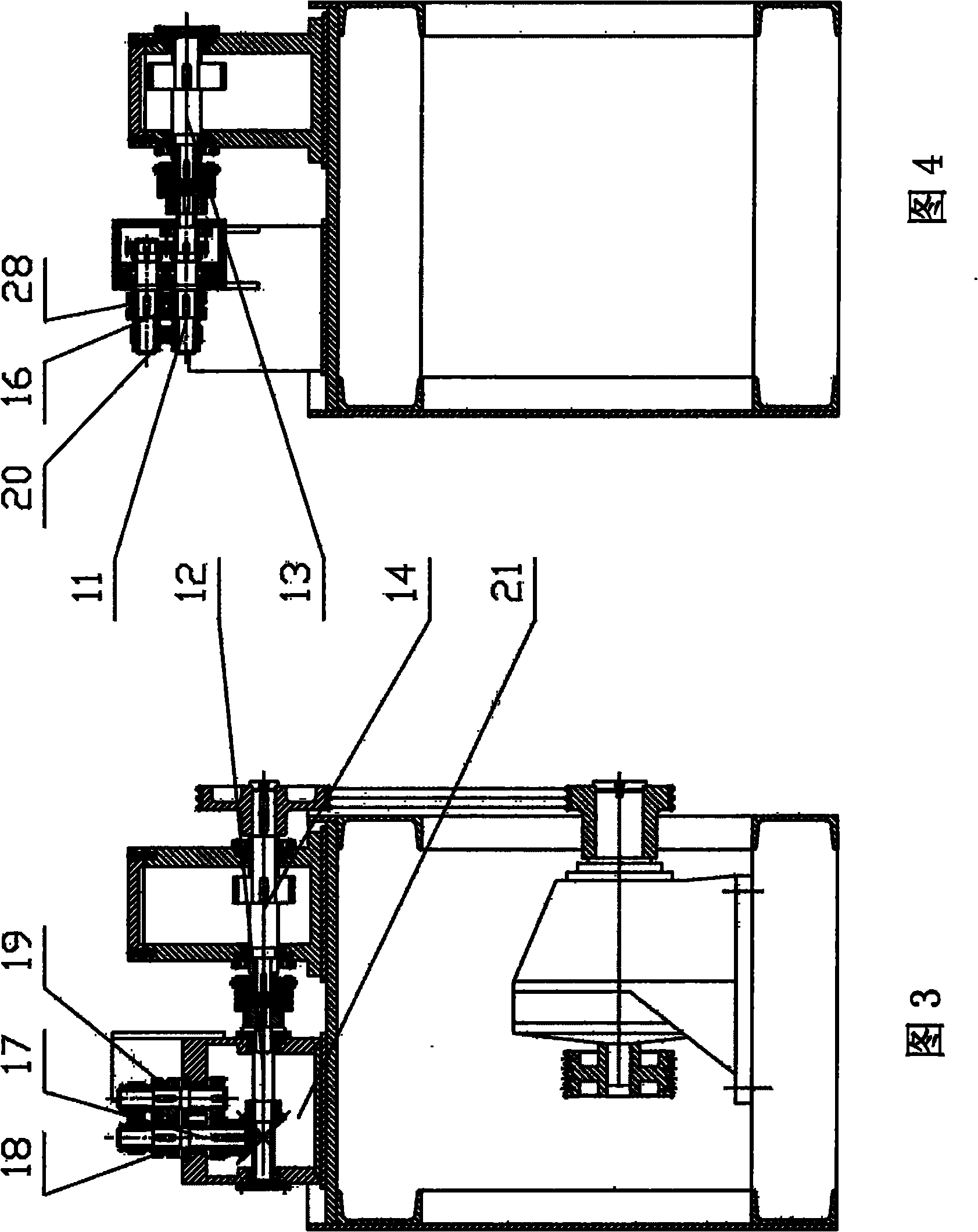

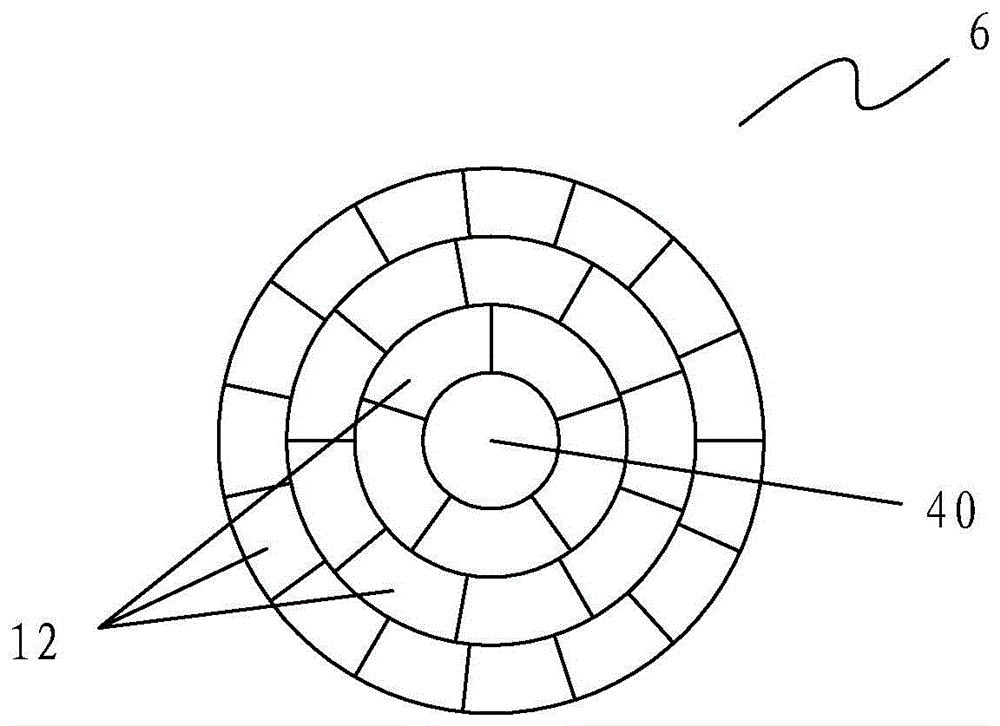

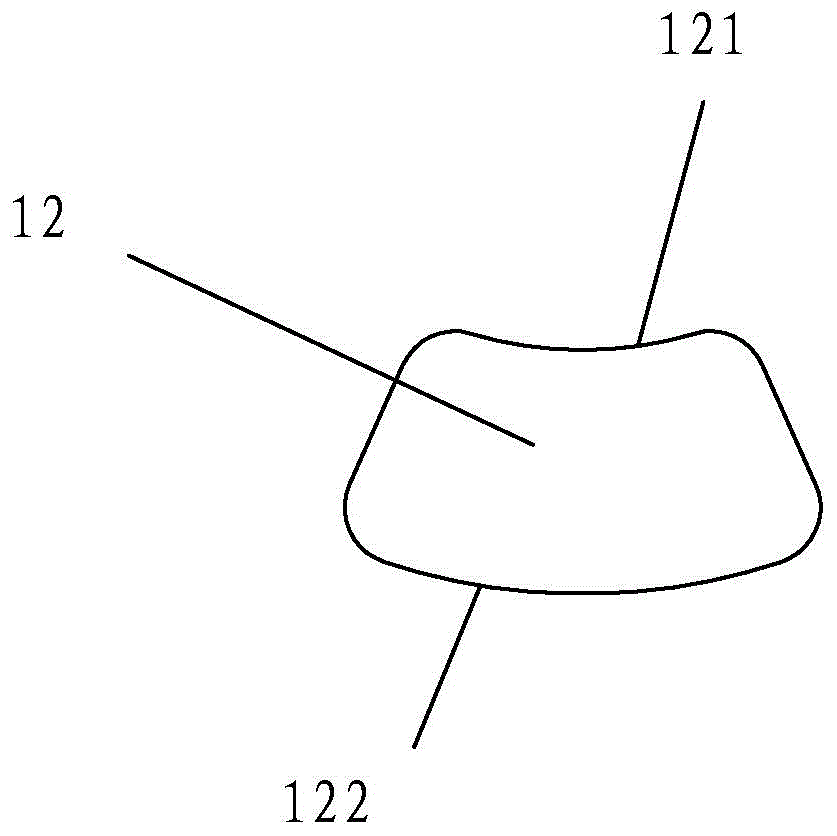

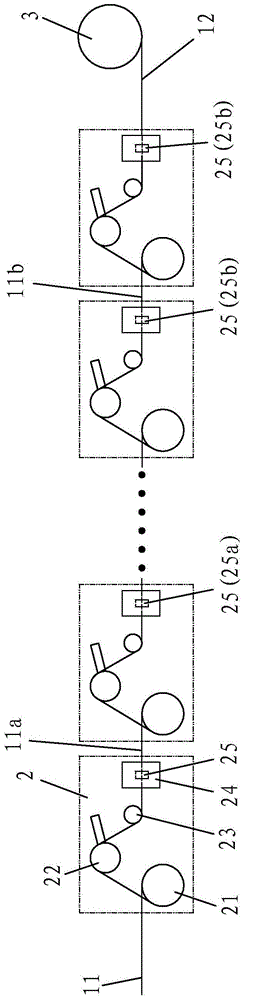

Closed intelligent micro-adjustable entire column full automatic wire winding machine

ActiveCN105810430ANot easy to disconnectPrevent disconnectionCoils manufactureWinding machineEngineering

The invention discloses a closed smart micro-adjustment entire column full automatic wire winding machine. The wire winding machine comprises a machine table, a wire arrangement transmission mechanism, independent wire arrangement mechanisms, a wire winding mechanism, a finished product discharging mechanism, a wire clamping mechanism, a skeleton feeding mechanism, a finished product unloading box, an operation system touch screen and tension mechanisms. According to the wire winding machine, wire skeletons are automatically fed through the skeleton feeding mechanism; wire clamping and wire hooking are carried out by the wire clamping mechanism; full automatic wire winding is realized by matching the wire winding mechanism with the independent wire arrangement mechanisms; the independent wire arrangement mechanisms can arrange the wires independently; the independent wire arrangement mechanisms feed back wire arrangement speeds intelligently through wire arrangement intelligent sensors; the wire arrangement angles of the wire arrangement guide pins are adjusted, thus adapting to the instant wire winding speeds; the independent wire arrangement mechanisms hook the wire from the start ends of the skeletons; breakage conditions in wire hooking and welding processes are avoided; winding without disordered wires is carried on the entire column of the precise coils full automatically; winding, wire hooking and wire arrangement are carried out from the top ends to the bottom ends full automatically when the pin bottoms of start winding ends are winded; the intelligent operation degree is high; and the cost is low.

Owner:苏州创易技研股份有限公司

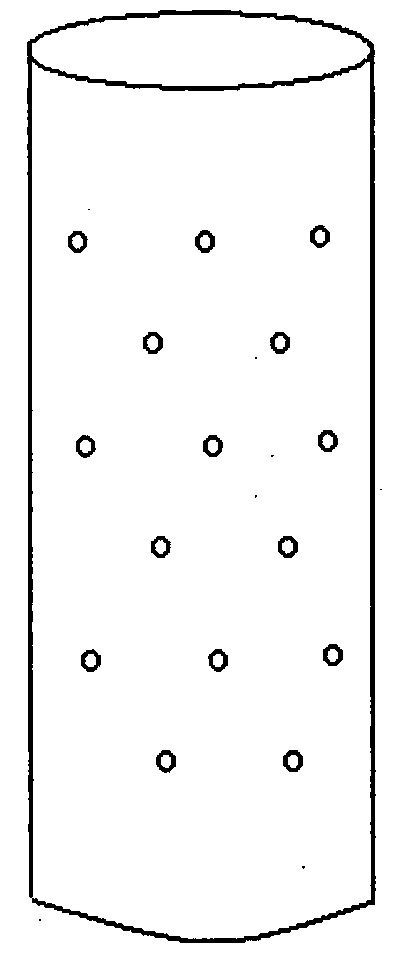

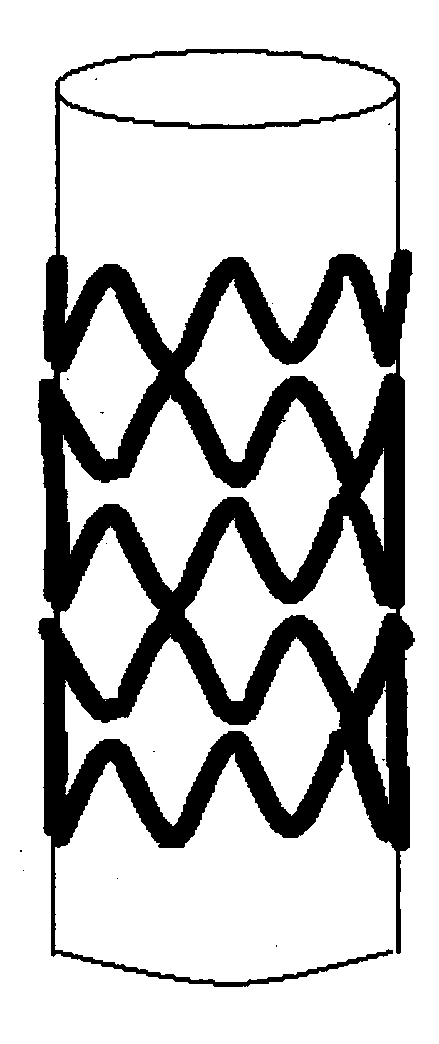

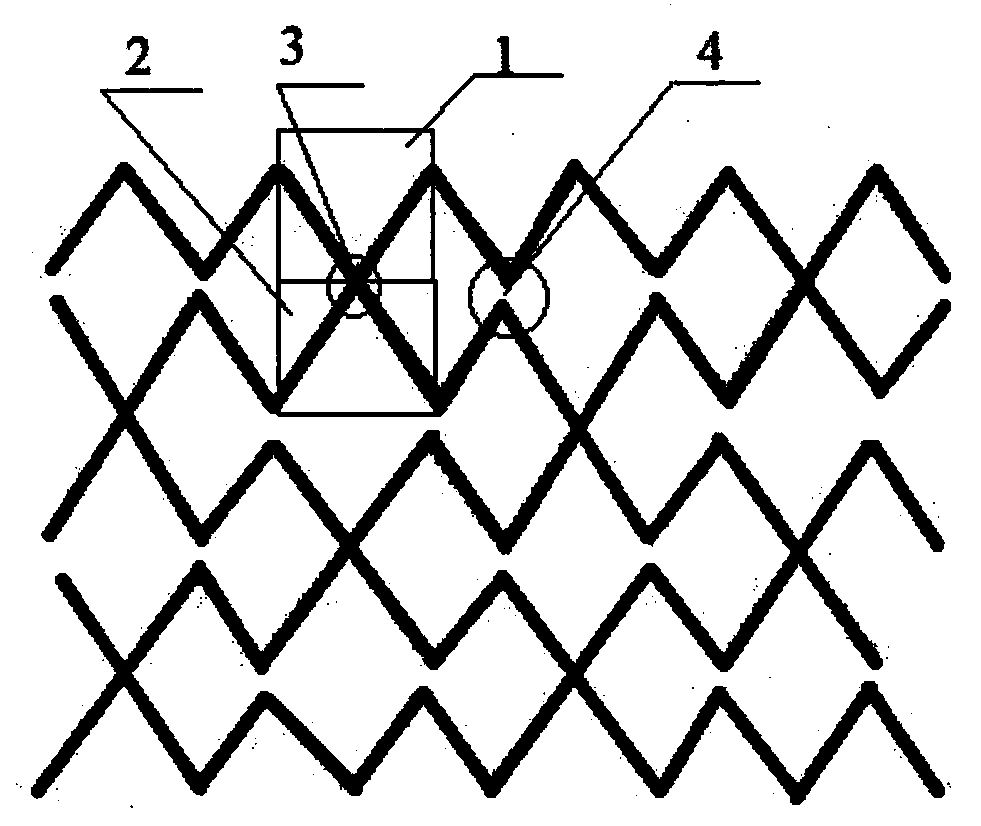

Biodegradable intravascular stent and production method thereof

The invention provides a biodegradable intravascular stent and a production method thereof. The biodegradable intravascular stent is characterized in that the biodegradable intravascular stent comprises an annular net structure made of biodegradable fiber braided threads; the annular net structure is composed of a plurality of rows of wavy structures; each row of wavy structure is composed of a plurality of V-shaped structure units; every two rows of wavy structures are parallel to each other; the endpoint in the middle of each V-shaped structure unit is connected with the endpoint in the middle of the symmetrical V-shaped structure unit in the adjacent row once every other two non-joint points to form a joint point. The biodegradable intravascular stent low in axial shortening rate can radially deform greatly due to the annular net structure, and the V-shaped structure units of two adjacent rows are connected once every other two non-joint points, so that the length of the stent is not changed greatly under the condition of great change of radial diameter of the stent, and the intravascular stent can be implanted conveniently by means of a conveyor.

Owner:DONGHUA UNIV

Display panel of conductive layer with variable line widths

The invention discloses a display panel of a conductive layer with variable line widths. The display panel comprises a first substrate, a second substrate opposite to the first substrate, and a display layer located between the first substrate and the second substrate. The first substrate comprises the conductive layer which is located on the first substrate and extends in the first direction, in the first direction, the conductive layer sequentially comprises a first plane at the first height, a bevel and a second plane at the second height, and the first height is larger than the second height. The first plane of the conductive layer is close to the bevel and has the first line width in the second direction, the bevel of the conductive layer has the second line width in the second direction, the second direction is perpendicular to the first direction, and the first line width is smaller than the second line width.

Owner:INNOLUX CORP

Temperature and humidity control system for subgrade structure of seasonal frozen soil region

PendingCN108316081AAccelerate evaporationAvoid deformationBatteries circuit arrangementsRoadwaysInsulation layerLiquid state

The invention provides a temperature and humidity control system for a subgrade structure of a seasonal frozen soil region. The temperature and humidity control system comprises a drainage preventionsystem arranged at the lower part of a subgrade, a heating device is arranged in the middle of the subgrade and a heat insulation layer arranged at the upper part of the subgrade, wherein the drainageprevention system comprises a substrate composite water drainage plate arranged at the bottom of the subgrade; water drainage side ditches are arranged at two sides of the substrate composite water drainage plate; a herringbone composite water drainage plate is arranged at a frozen line part above the substrate composite water drainage plate. According to the temperature and humidity control system provided by the invention, efficient heating and a heating wire and efficient thermal conductivity of a heating pipe are sufficiently expressed and evaporation of liquid-state water in substrate soil is facilitated; a waterproof and drainage structure and a solar cell for supplying power to the heating device for a long period are combined, so that the subgrade soil keeps a low-moisture-contentstate for a long period, a soil body is prevented from being frozen and the deformation of the subgrade is effectively inhibited.

Owner:SOUTHWEAT UNIV OF SCI & TECH

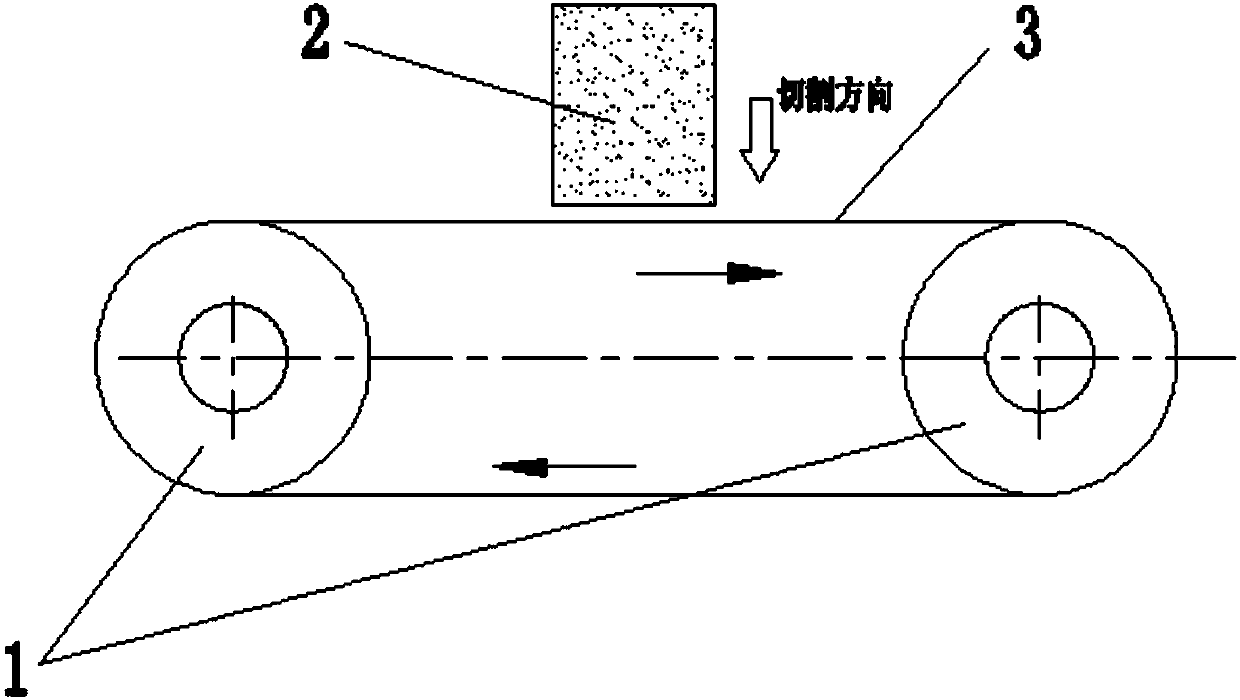

Device for cutting polycrystalline silicon wafer through diamond wires and cutting method

ActiveCN107901256AControl thicknessReduce dosageFine working devicesSpray coolingPolycrystalline silicon

The invention discloses a device for cutting a polycrystalline silicon wafer through diamond wires and a cutting method. The device for cutting the polycrystalline silicon wafer through the diamond wires comprises a cutting machine. The cutting machine comprises two large guide wheels arranged in a spaced manner, the multiple diamond wires arranged between the two large guide wheels in a surrounding manner, and a cooling liquid nozzle for spraying cooling liquid. The device is characterized in that two small guide wheels with the diameter smaller than the diameter of the large guide wheels arearranged at the positions above the two large guide wheels in parallel, the two small guide wheels are located on the inner side between the two large guide wheels, and the upper surfaces of the twosmall guide wheels are flush; a plurality of wire grooves are formed in the surfaces of the small guide wheels at intervals, the diamond wires are wound around the upper surfaces of the two small guide wheels and are located in the wire grooves in the small guide wheels, the part between the two small guide wheels is a cutting area, and the diamond wires can move in both directions. According to the device, wire and net balance is achieved in the cutting process, wire breakage is not likely to happen in the cutting process, and the silicon wafer yield can be increased.

Owner:SHANDONG DAHAI NEW ENERGY DEV

Seedling culture method for promoting rooting during oriental cherry grafting

The invention discloses a seedling culture method for promoting rooting during oriental cherry grafting. Current-year branches of grass cherry (dedicated stock for oriental cherry grafting, suspected to belong to cherry strain) are used as stock, current-year branches of good oriental cherry stock are used as scion, cut-grafting is adopted, cuttage is conducted after grafting, the stock is rooted first after cuttage, and massive secondary rooting is caused at a graft union after transplantation to form oriental cherry variety seedlings with firm interfaces. In mid-to-end of January and early-to-mid of February each year, good stock branches which grow robustly are collected for grafting, then cuttage is conducted directly in a greenhouse or field cutting is conducted directly, stock is transplanted into pots or directly planted in the ground after cutting rooting, and massive rooting and seedling culture of the graft union are induced by means of cultivation techniques. The advantages of the two breeding methods, namely grafting and cuttage, are combined and utilized, universality is high, and the method is suitable for expanding propagation of most oriental cherry varieties and wild oriental cherry germplasm resources; furthermore, massive rooting of a grafting position is achieved, the graft union is not broken easily, and thickness difference of ordinary grafted seedlings is avoided.

Owner:HANGZHOU LANDSCAPING

Two-roll wire rolling mill

The invention discloses a two-roll wire rolling mill which comprises a stand, a lubricating system and an electric control part, wherein a power machine and a reducer are installed at the lower part of the stand, the output shaft of the power machine is connected with the input shaft of the reducer through a transmission device, an inlet wire straightening mechanism, a main transmission box and an outlet wire barrel falling mechanism are sequentially installed at the upper part of the stand, a plurality of small box bodies are installed at one side of the main transmission box, and a pair of vertical rolls and a pair of horizontal rolls are installed on each small box body. Compared with the traditional wire drawing machine, the two-roll wire rolling mill has the advantages of compact structure, smooth transmission, low noise, low energy consumption, high yield, convenient threading operation, difficult wire breakage in the postorder drawing process and the like.

Owner:常德市恒德机械制造有限公司

Method for preparing aluminium alloy trapezoidal conductor

InactiveCN105023651AStable structureImprove bindingCable/conductor manufactureElectrical conductorMaterials science

The invention provides a method for preparing an aluminium alloy trapezoidal conductor, and includes: a drawing step in which a non-sliding wire drawing machine to draw trapezoidal single wires, uses an aluminium alloy rod material as wires to perform paying off, the aluminium alloy rod material passes through each drawing group in sequence and is drawn into trapezoidal single wires, and the trapezoidal single wires are rolled by a wire coil; a stranding step in which a frame type stranding machine is used to strand a trapezoidal conductor, in a stranding process of the frame type stranding machine, a center line of the trapezoidal single wires is guaranteed to be toward a core wire through a directional disc, then the trapezoidal single wires are pre-twisted, a pre-twisting direction is opposite to a rotation direction of the frame type stranding machine, and then each trapezoidal single wire and the core wire converge in the position of a molding device, thereby completing stranding, and forming a stranded conductor. The trapezoidal single wires drawn according to the method have stable structures and smooth and clean surfaces, and wires are not easy to break in a drawing process. The trapezoidal conductor formed by stranding has relatively small torsional stress, and has relatively good surface quality since compacting treatment is not needed, and a filling coefficient can be higher than 0.96.

Owner:福建锦鸿线缆有限公司

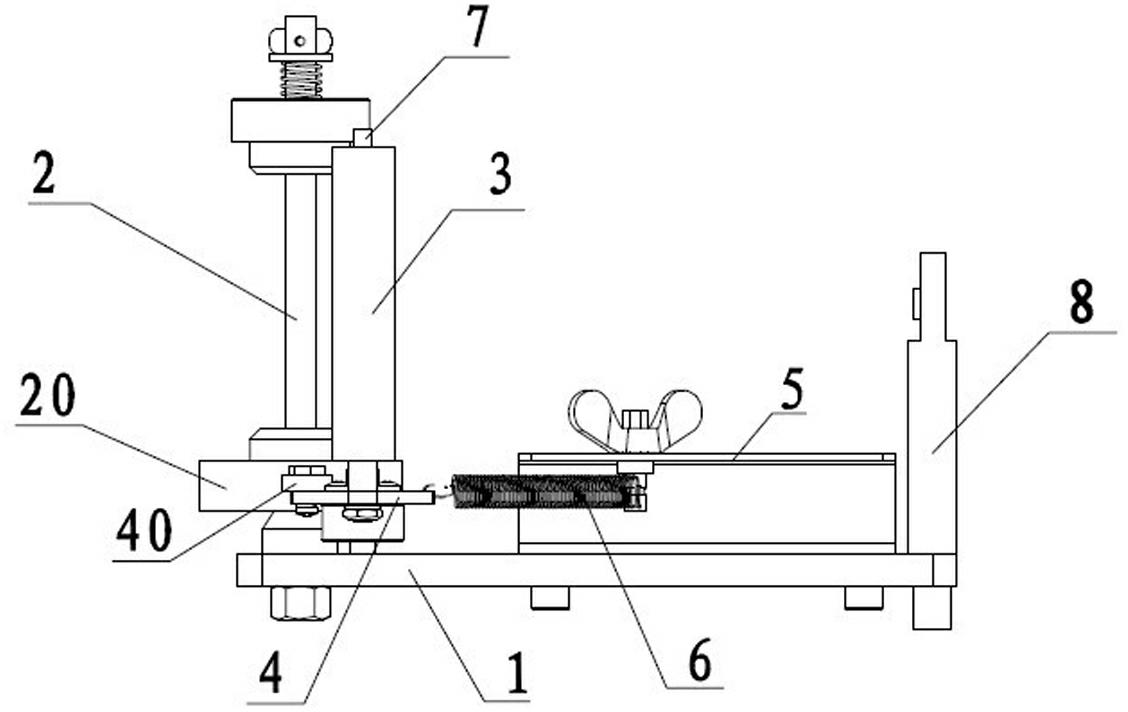

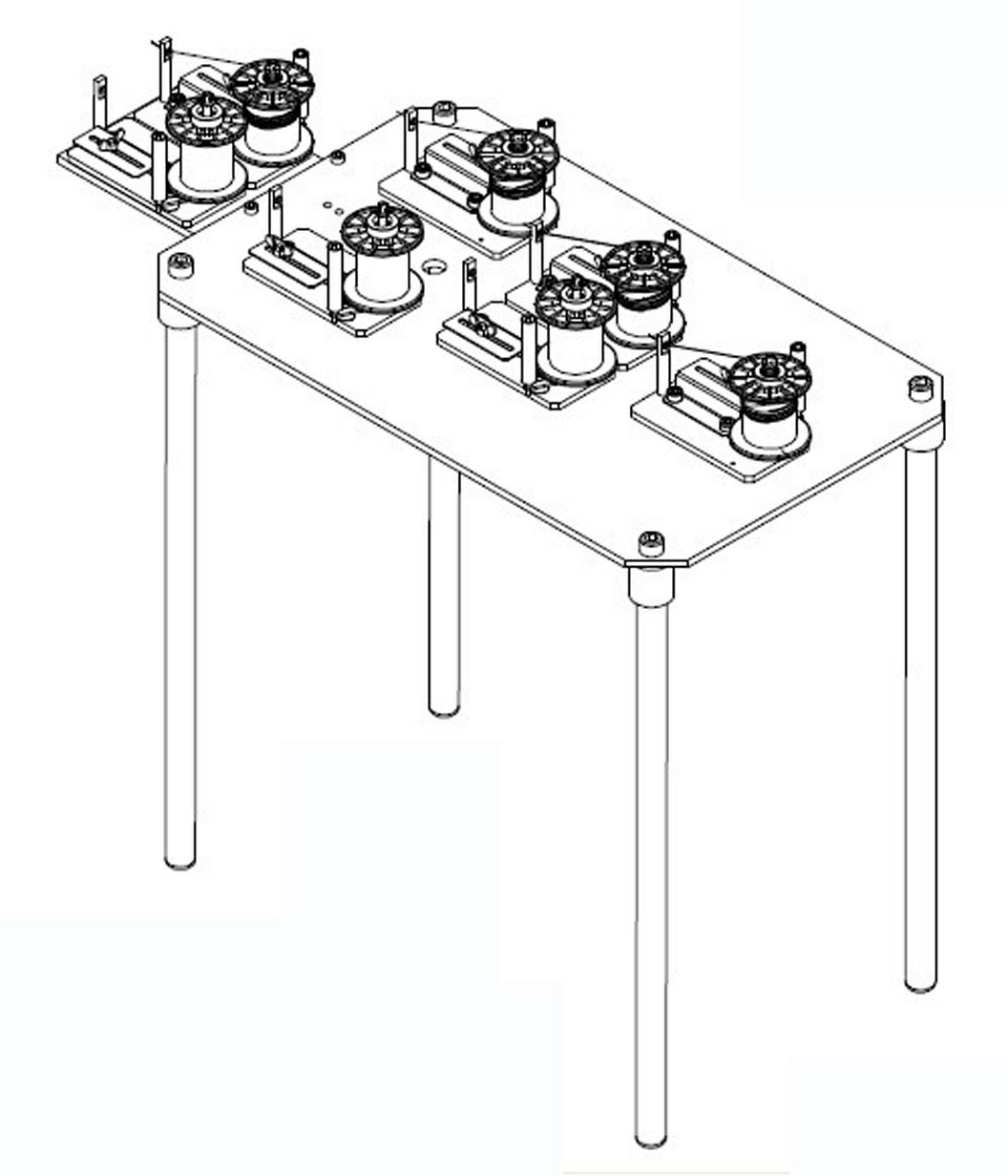

Pay-off apparatus for superfine wires

ActiveCN102610325AStable pay-off tensionNot easy to disconnectCable/conductor manufacturePull forcePhysics

The invention relates to a pay-off apparatus for superfine wires, which comprises a plurality of pay-off stands, wherein each pay-off stand comprises a base, a pay-off spindle, a traction guide roller and a tension spring adjusting mechanism, wherein the lower part of the pay-off spindle is provided with a rotating tray which can rotate around the axial direction of the pay-off spindle; the tension spring adjusting mechanism comprises an adjusting disc, a fixed plate and a tension spring connected between the adjusting disc and the fixed plate; and the adjusting disc is also provided with a friction wheel which is in friction contact with the rotating tray, and the traction guide roller is arranged on the adjusting disc. In general, the rotating tray overcomes the friction force and pressure of the friction wheel and then carries out wire pay-off normally; when the pay-off speed increases, the tensile force of a superfine wire on the traction guide roller increases firstly so as to drive the adjusting disc to have a trend that the tensile force of the tension spring is overcome and the adjusting disc is away from the rotating tray, so that the friction force and pressure between the friction wheel and the rotating tray are reduced, and the pay-off speed of the superfine wire increases; and finally, the pay-off tensile force falls back and keeps stable. By using the pay-off apparatus disclosed by the invention, the tensile force in a pay-off process is balanced, and a situation of wire breakage is not easily caused.

Owner:苏州久隆新材料科技有限公司

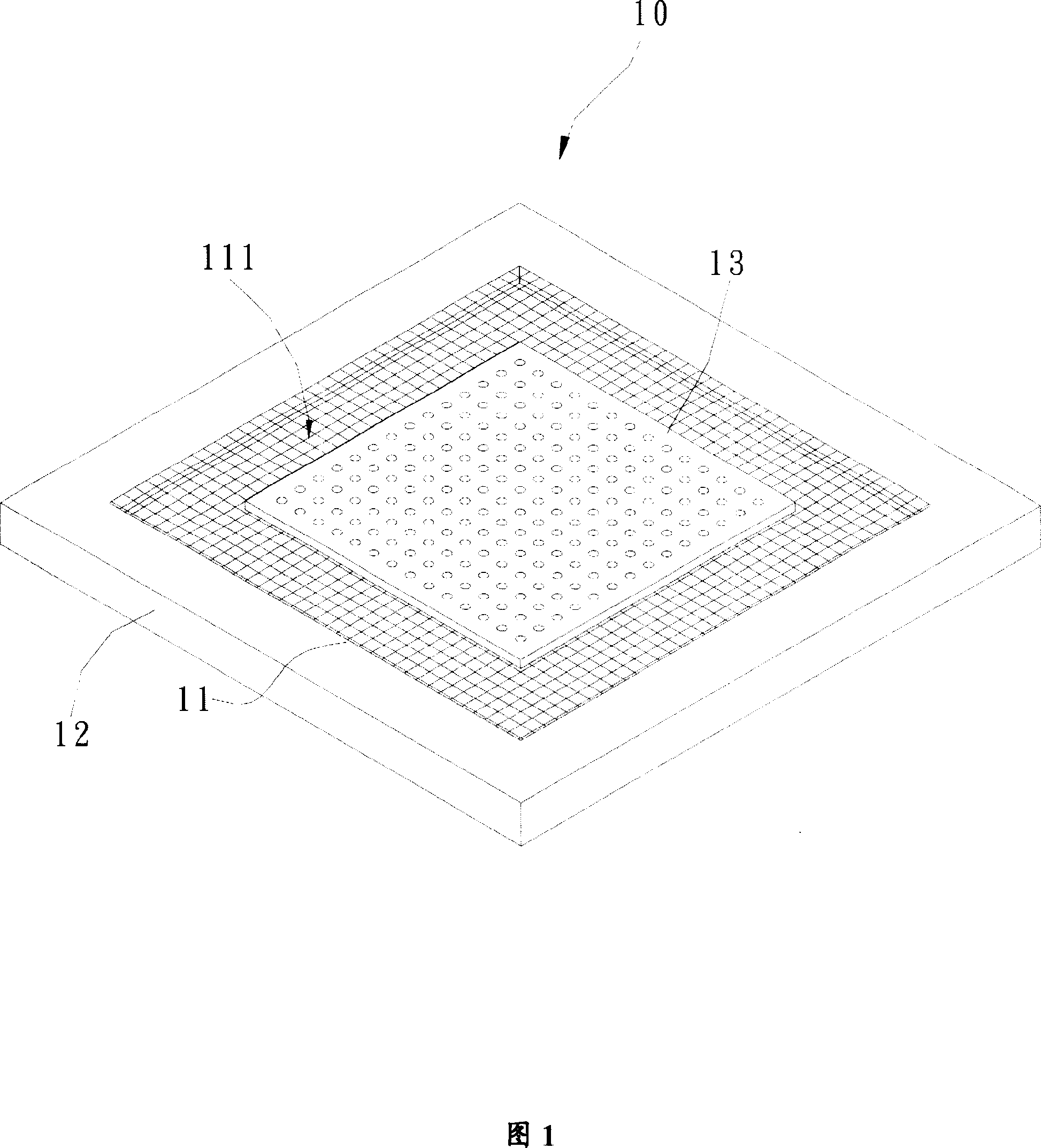

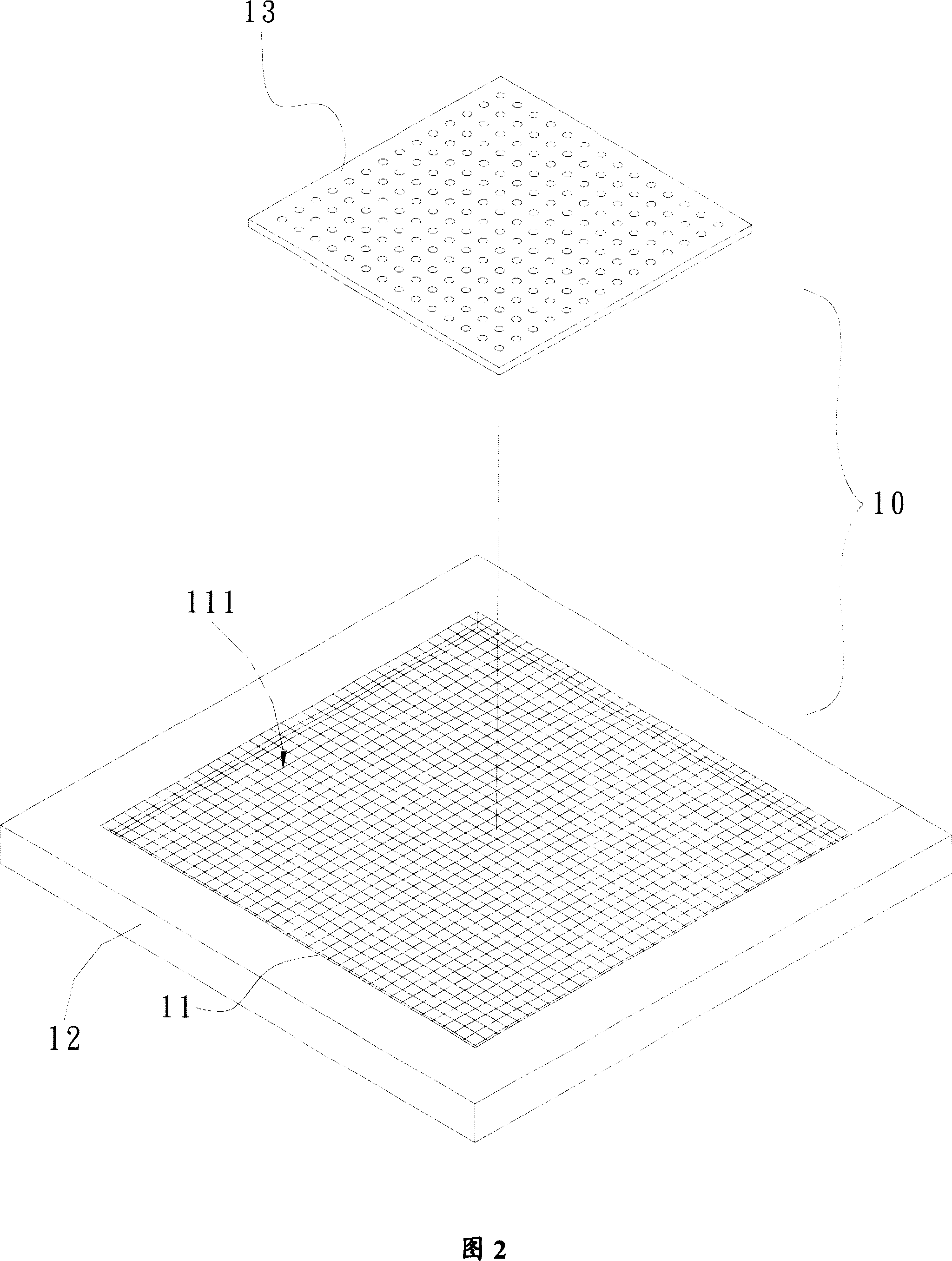

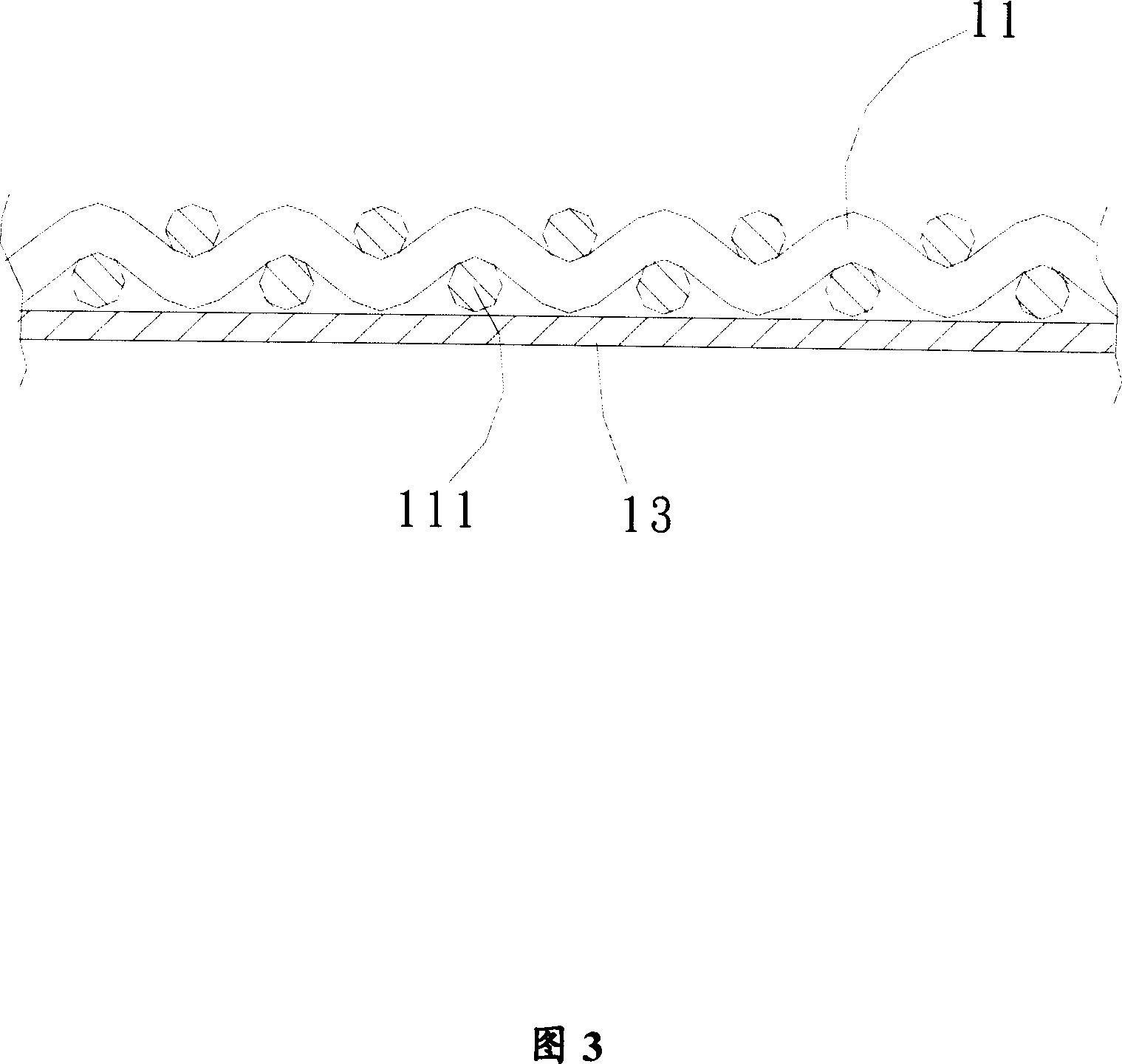

Electroforming foiled film screen-board

InactiveCN101100128AHigh precisionImprove printing qualityScreen printersPrinting pre-treatmentMetal foilMetal

The electroformed foiled screen plate includes one metal screen, one metal foil layer combined to the metal screen and one metal frame, and the metal foil layer is formed onto the metal screen through an electroforming process. The electroformed foiled screen plate has high strength and high printing density and quality.

Owner:FAITHFUL PRINTING EQUIP & SUPPLY

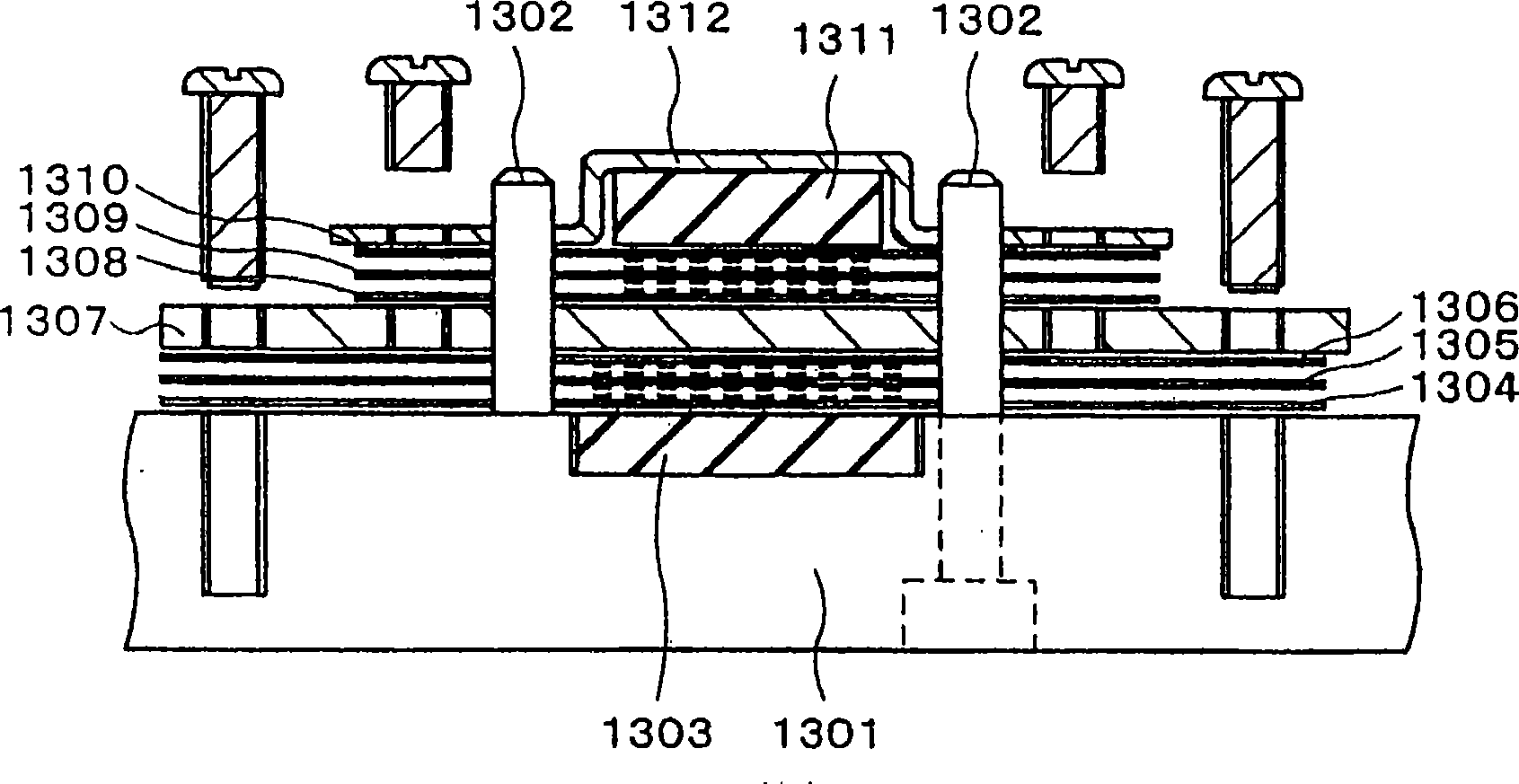

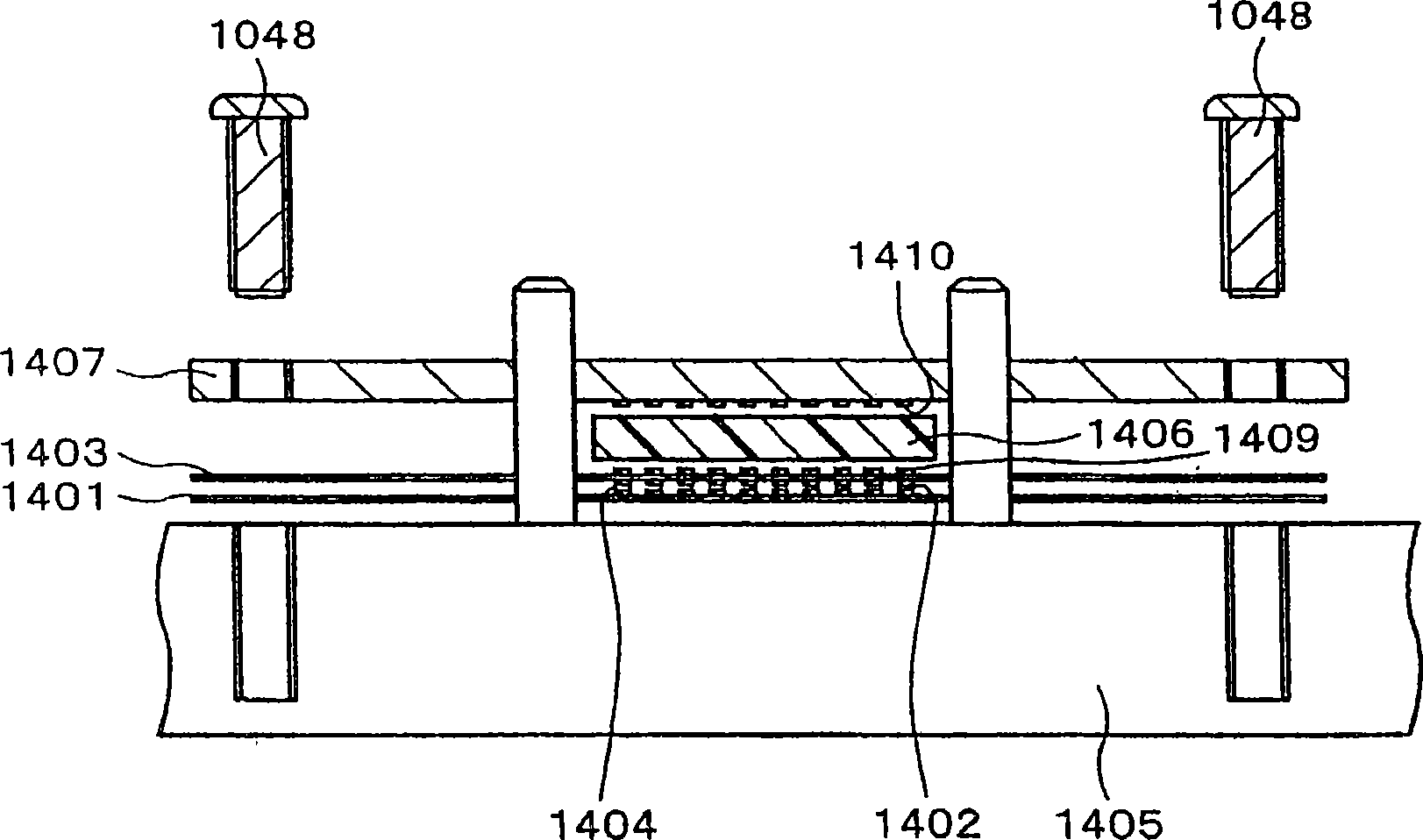

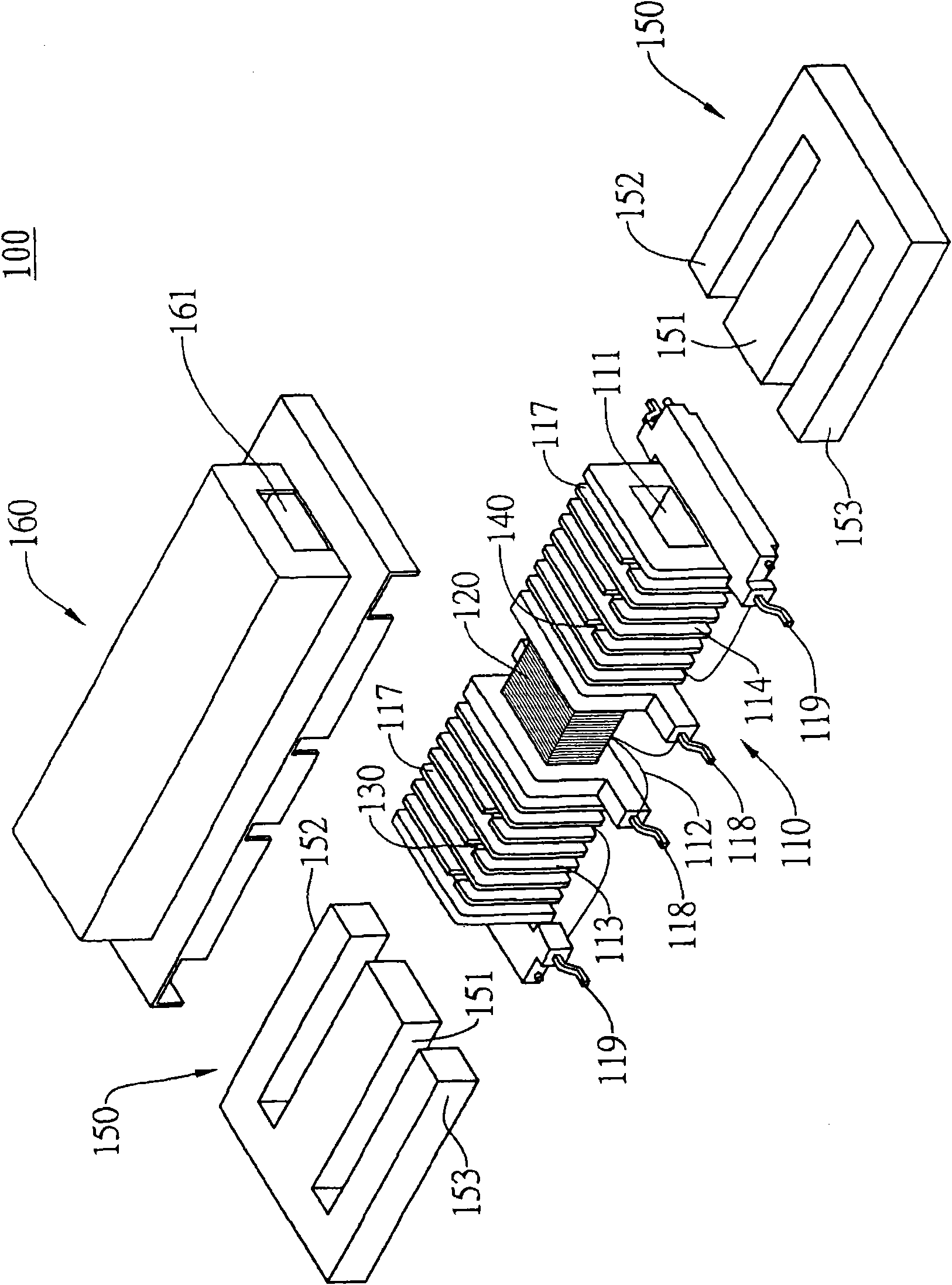

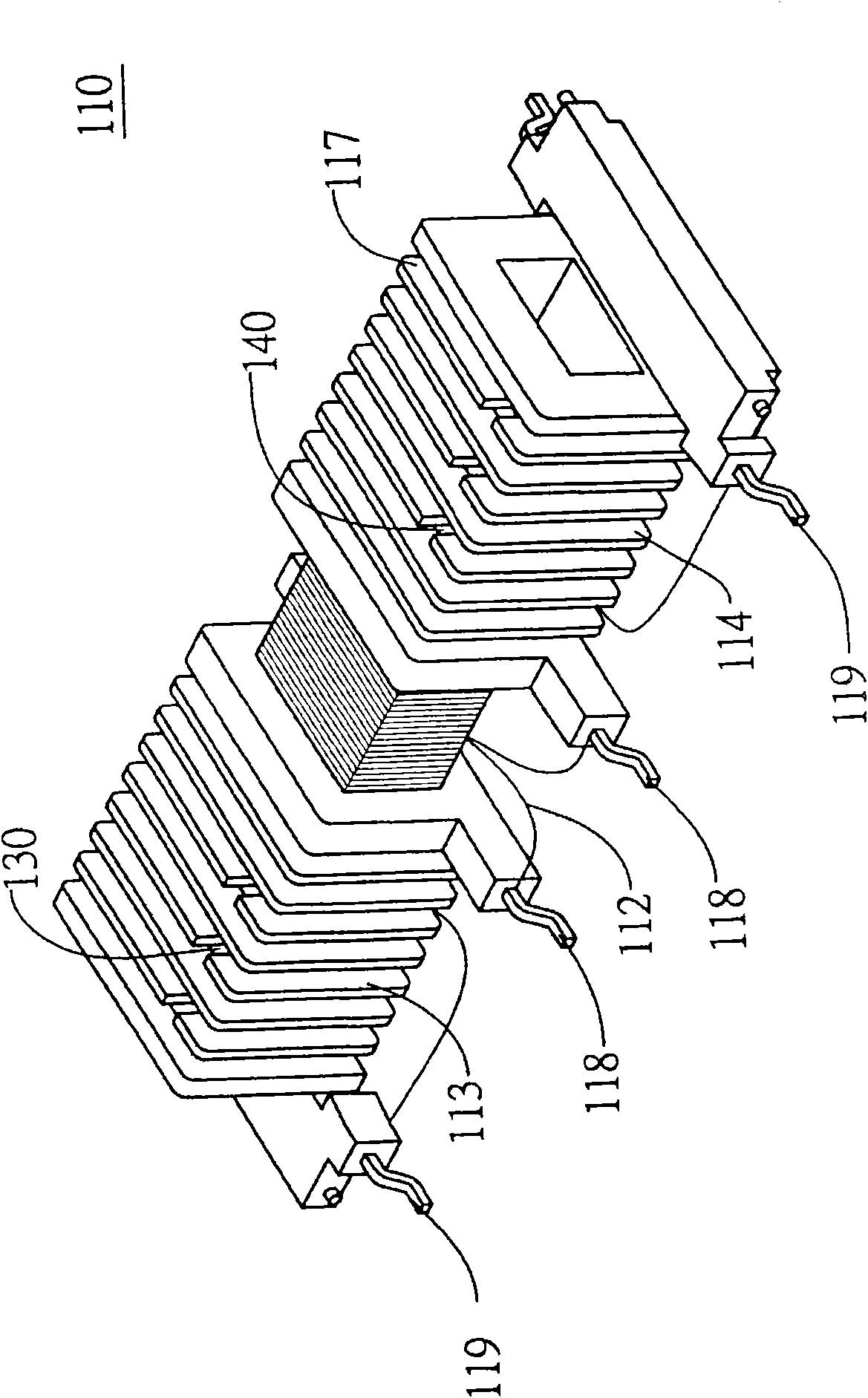

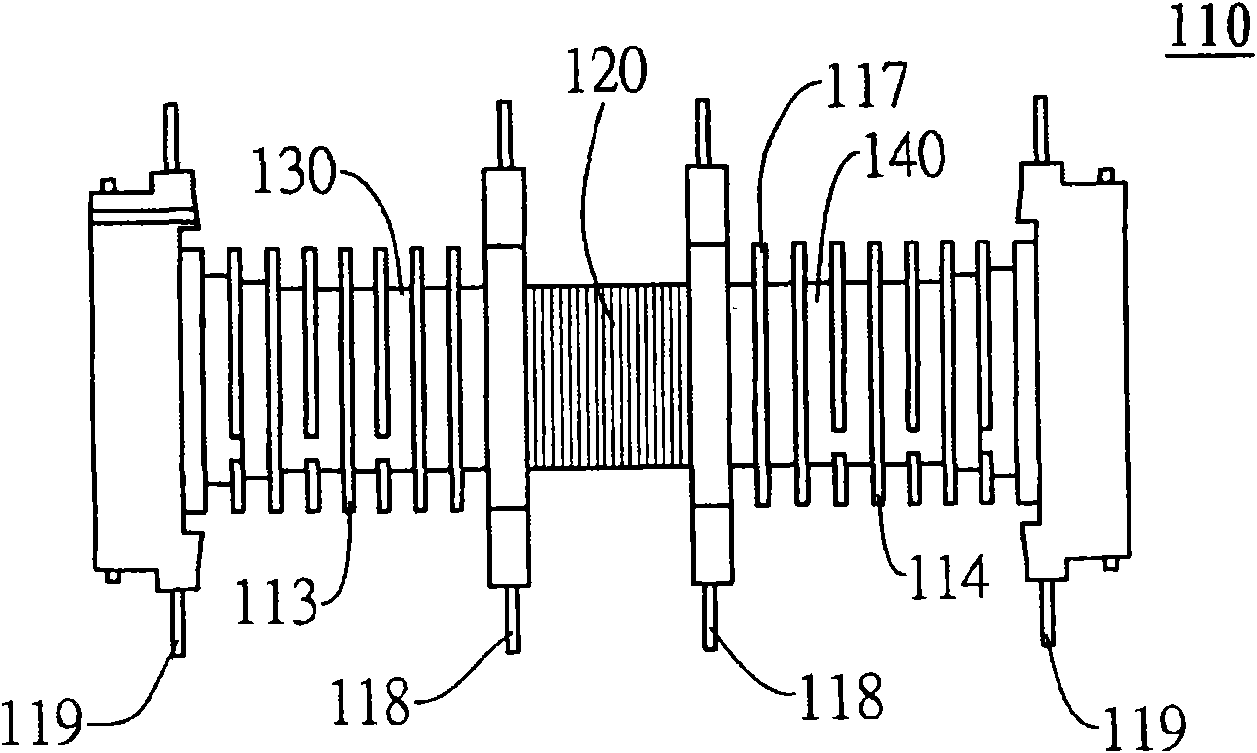

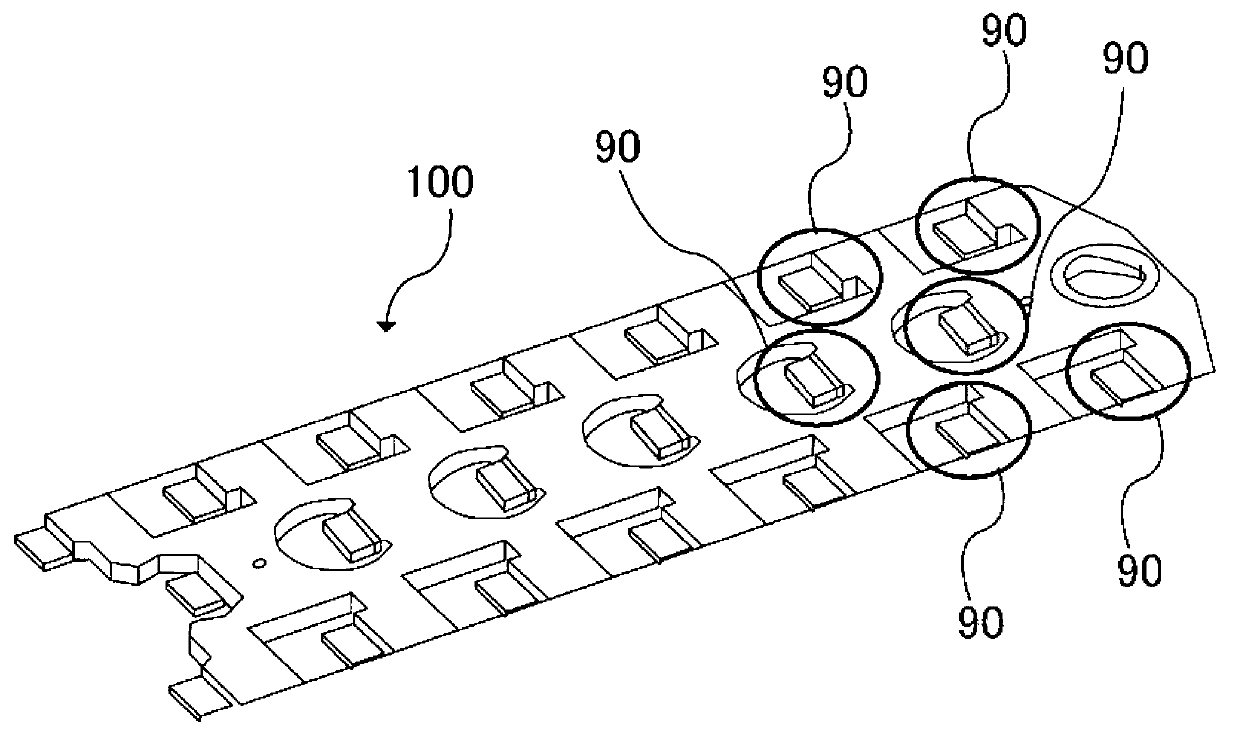

Circuit board device, wiring board connecting method, and circuit board module device

InactiveCN101455131ACollision RestraintAvoid deformationPrinted circuit assemblingSolid-state devicesElectricityAnisotropic conduction

Provided are a circuit board device, a wiring board connecting method and a circuit board module device, which control the compressibility of anisotropically conductive members within the most proper range, which suppress the dispersion of the impact resiliences of the anisotropically conductive members even if a lamination number increases, which can suppress the deformation of the wiring board and the fluctuations of the impact resilience of the anisotropically conductive members even if a static external force or the like is applied, which suppress the linear expansion of the anisotropically conductive members, even if the ambient temperature changes, to raise the stability of electric connections, and which can reduce the impact resilience of the anisotropically conductive members thereby to reduce the thickness. The circuit board device comprises wiring boards (101 - 104), anisotropically conductive members (105) arranged between the individual wiring boards, functional blocks (106) made separate of the anisotropically conductive members (105) and so arranged on the plane common to the anisotropically conductive members (105) as to enclose the anisotropically conductive members (105), and a pair of holding blocks (107, 108) arranged to sandwich the wiring boards (101 - 104). These wiring boards (101 -104) are compressed and held while being clamped between the paired holding blocks (107, 108), so that they are electrically connected with each other by the anisotropically conductive members (105).

Owner:LENOVO INNOVATIONS LTD HONG KONG

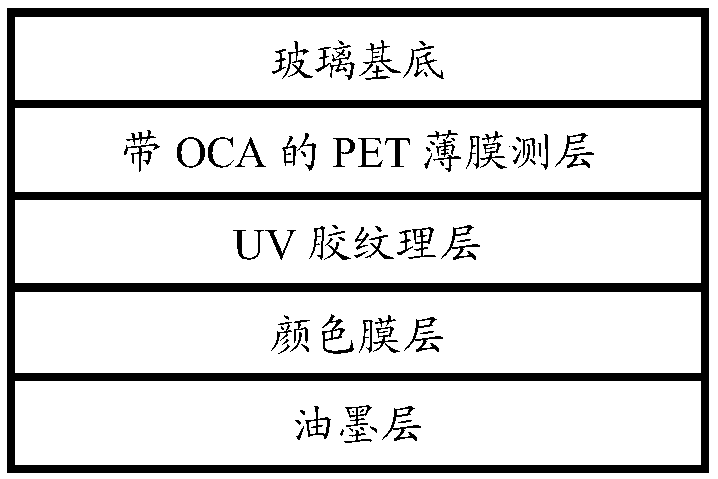

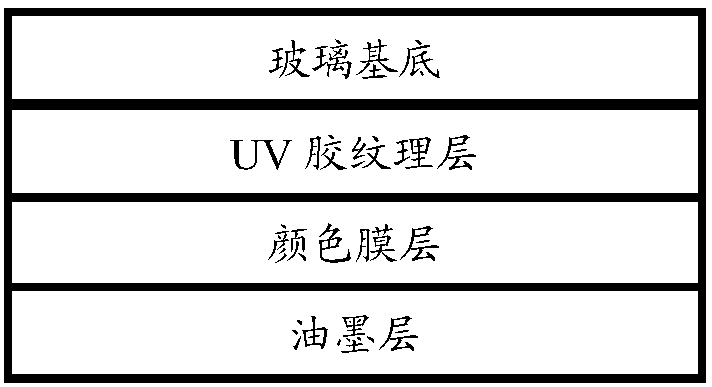

Communication terminal shell and preparation method

The invention discloses a communication terminal shell and a preparation method thereof, which are used for solving the problem that a glass shell in the prior art cannot give consideration to an excellent texture effect and high-yield manufacturing. According to the embodiment of the invention, the texture is directly formed on the surface of the glass substrate, UV glue does not need to be coated on the glass substrate, the manufacturing yield is improved, the texture formed on the surface of the glass substrate is fixed and not easy to deform, and a better texture effect and high-yield manufacturing in the communication terminal shell can be ensured; according to the embodiment of the invention, after the glass substrate is coated with the curing material, the texture is engraved on thecuring material by utilizing the laser, and the laser has higher energy, so that the situations of line breakage and air bubbles are not easy to occur during texture engraving, the yield of texture preparation can be improved, and a better texture effect can be achieved.

Owner:HUAWEI TECH CO LTD

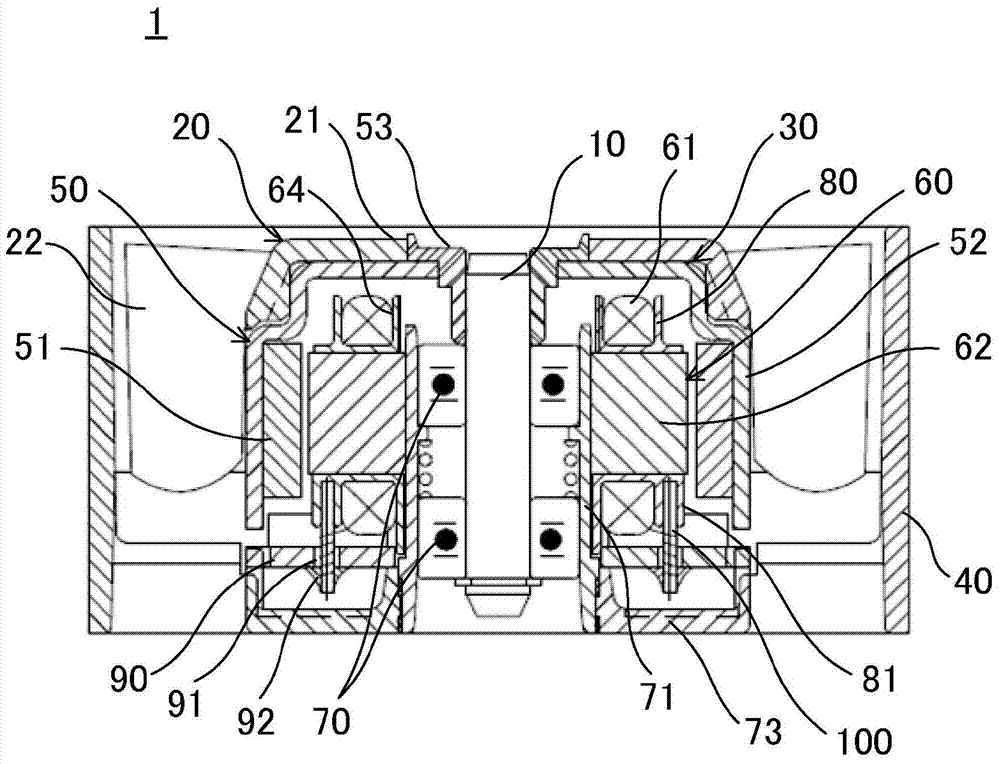

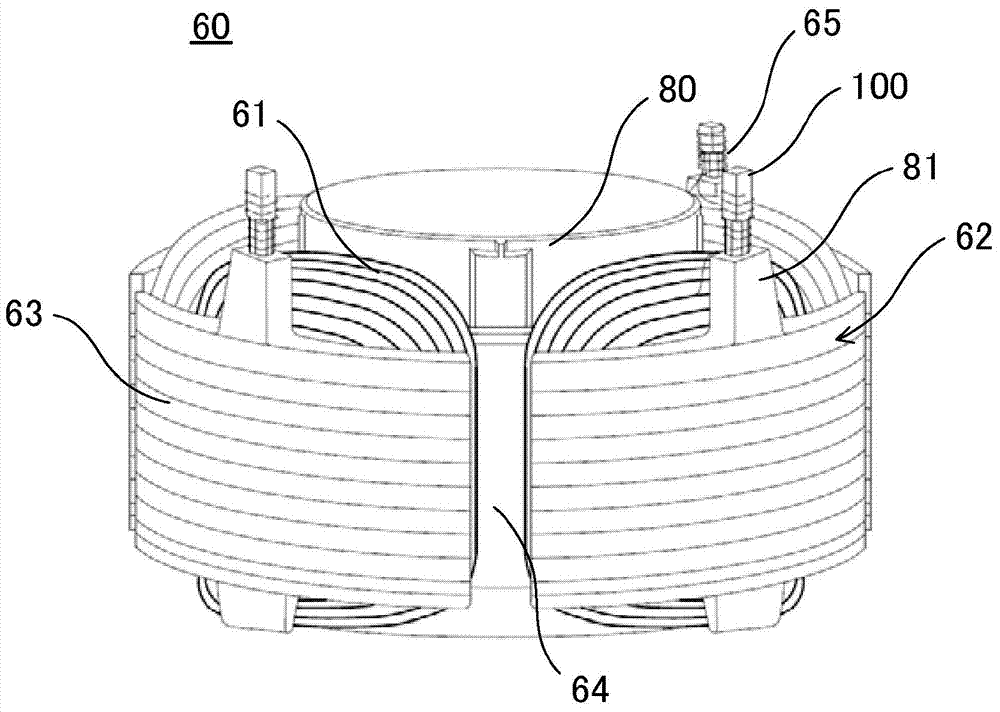

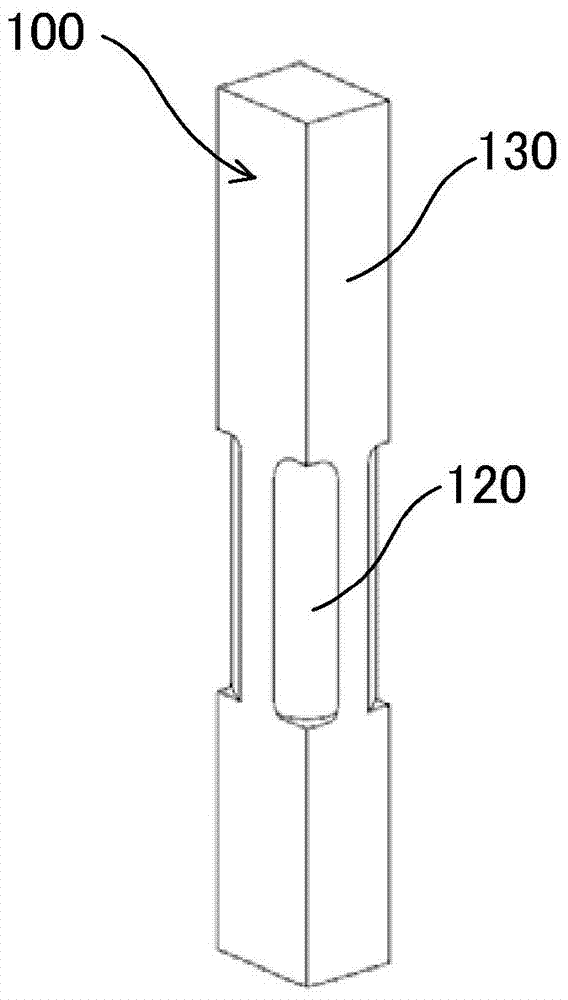

Axial flow fan

The present invention provides an axial flow fan capable of reliably maintaining a film conductive line of the coil. Even when unexpected load is added to the film conductive line, fracture of the line can be prevented. The axial flow fan is provided with conductive pins capable of being automatically cut off corresponding to the film conductive line finishing winding. The conductive pin is configured to electrically connect a coil of a stator and a circuit board, and to hold a film conductive line of the coil. In the conductive pin, one end is fixed to an electrical insulator covering a core stack of the stator, and the other end is electrically connected to the circuit board. The conductive pin is a quadrangular prism pin as a basic configuration and has, in at least a part of a portion exposed from the electrical insulator, a reduced diameter portion having no corners.

Owner:SANYO DENKI CO LTD

Transformer

InactiveCN101593610ANot offlineReduce distanceTransformers/inductances coils/windings/connectionsCoils manufactureElectromagnetic couplingTransformer

The invention provides a transformer with improved structure, which utilizes partition boards which are in unequal interval arrangement to form a plurality of coil chutes, thereby avoiding sparking (flashing) caused by under pressurization. The transformer comprises a coil frame, a primary coil, a secondary coil and an iron core assembly, wherein the coil frame is internally provided with a hollow channel and externally provided with a primary coil region and a secondary coil region; the center of the primary coil region is provided with an annularly wound center partition board; the secondary coil region comprises a plurality of annular heaves and the partition boards which are in unequal interval arrangement to form the plurality of coil chutes; the side of the coil frame is provided with a plurality of first pins and second pins, the first pins are arranged at a place adjacent to the primary coil region, and the second pins are arranged at two opposite sides of the coil frame. The primary coil is wound on the primary coil region of the coil frame, and the joint of the primary coil is connected to the first pins. The secondary coil is wound on the secondary coil region of the coil frame, and the joint of the secondary coil is connected to the second pins. The secondary coil is electromagnetically coupled with the primary coil. The iron core assembly passes through the hollow channel of the coil frame and is jointed to form a loop.

Owner:INNOLUX CORP

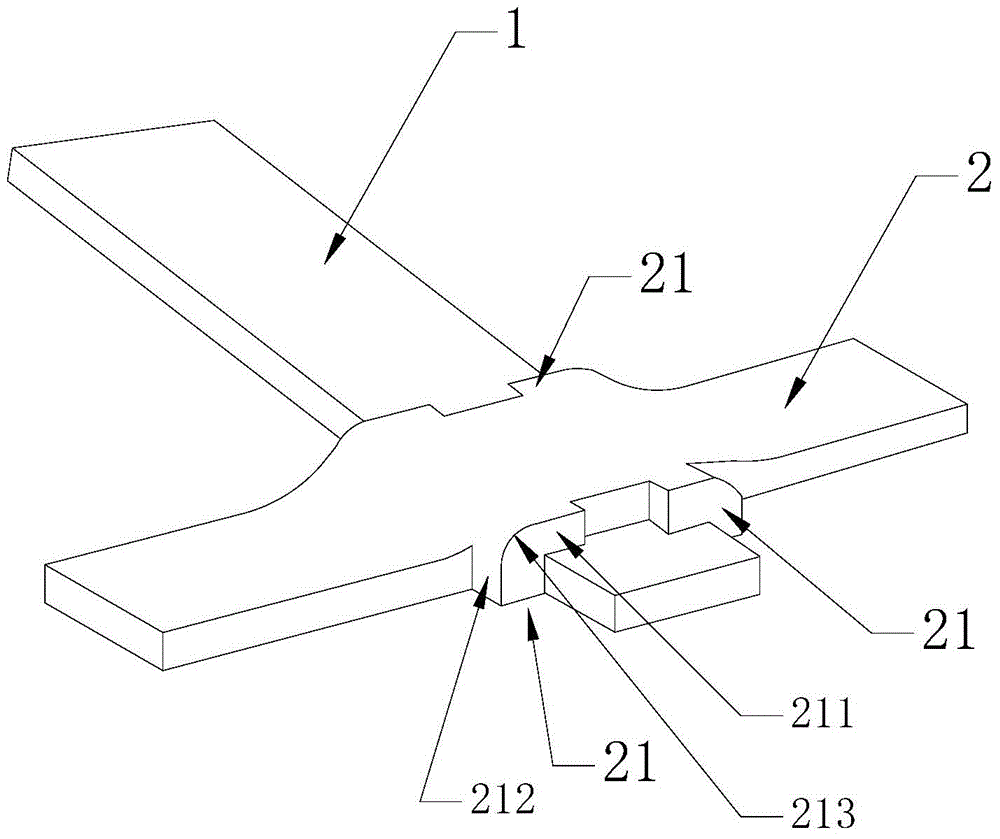

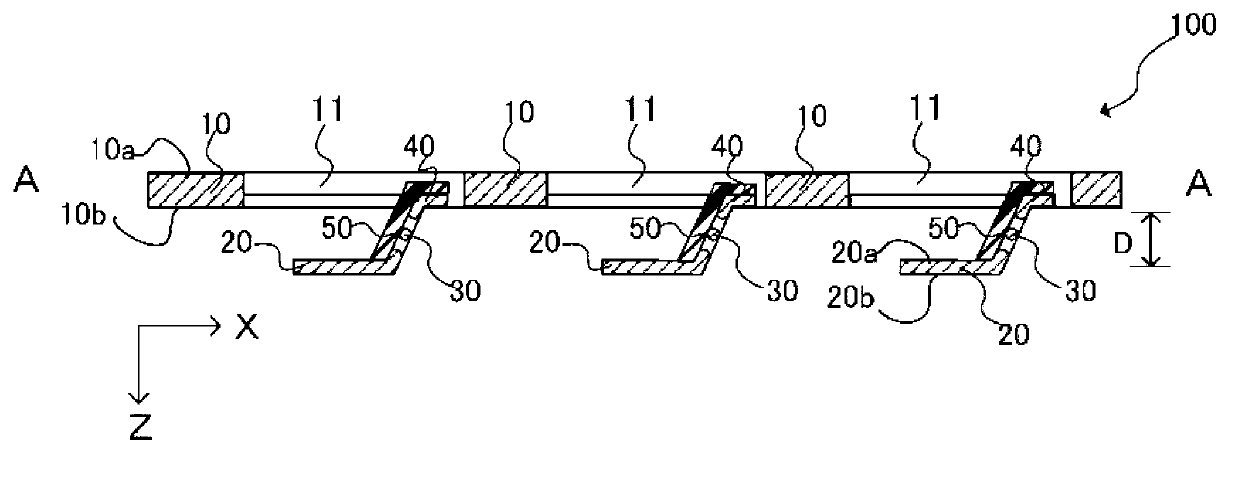

Fuse board and battery block equipped with same

ActiveCN103140912ASimple and easy to manufactureNot easy to disconnectBatteries circuit arrangementsFuse device manufactureEngineeringMetal

Provided is a fuse board having a metal plate, a connector that connects to a battery, a fuse that links the metal plate and the connector part, and an insulating resin film that is adhered to the fuse part. The wiring pattern of the fuse has a curved part, and the insulating resin film is in the form of a rectangular sheet that covers one face of the fuse.

Owner:PANASONIC CORP

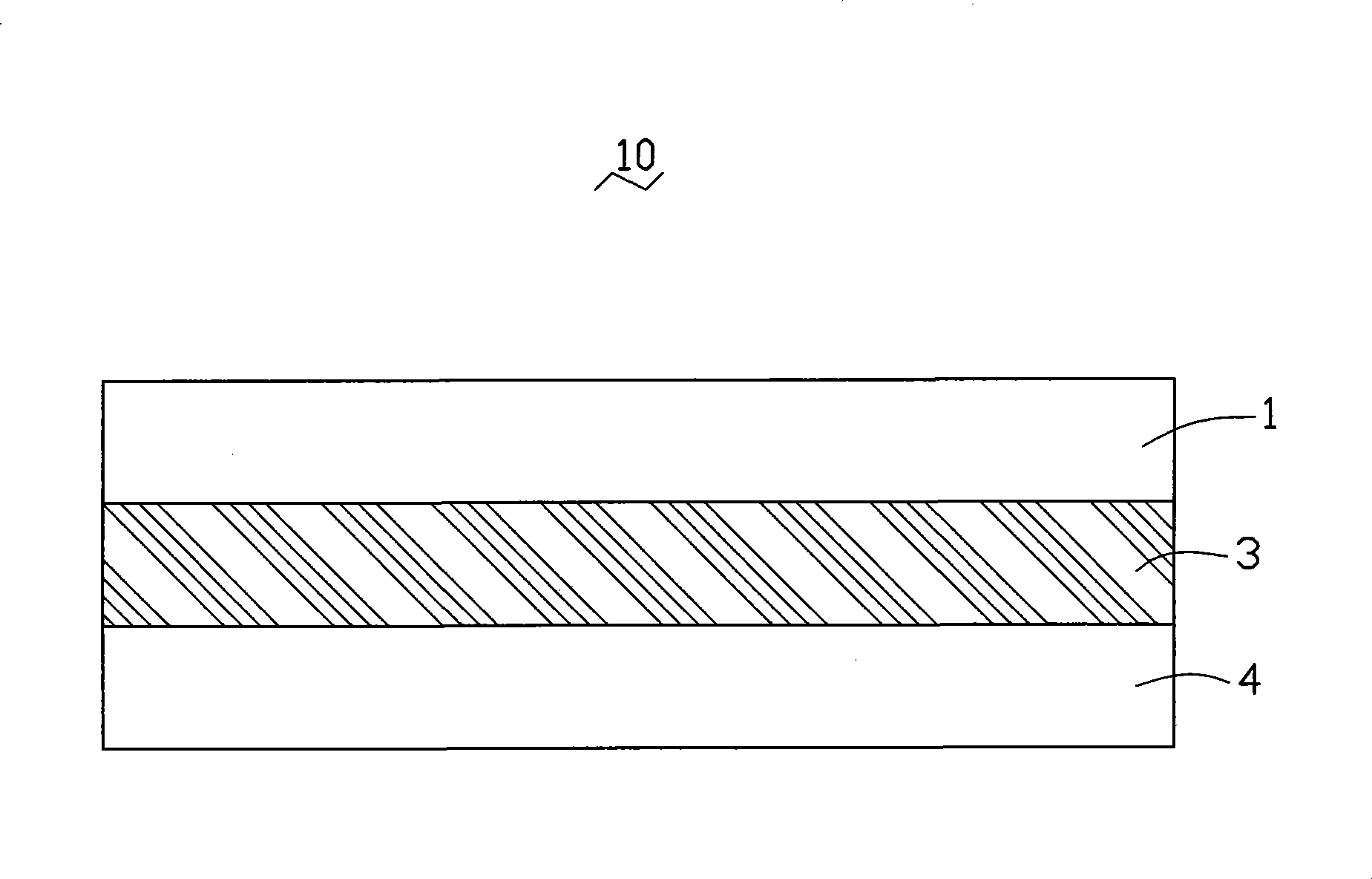

Copper coated substrate material and flexible circuit board having the copper coated substrate material

InactiveCN101365294ANot easy to disconnectLow costPrinted circuit aspectsSynthetic resin layered productsFlexible circuitsCopper foil

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

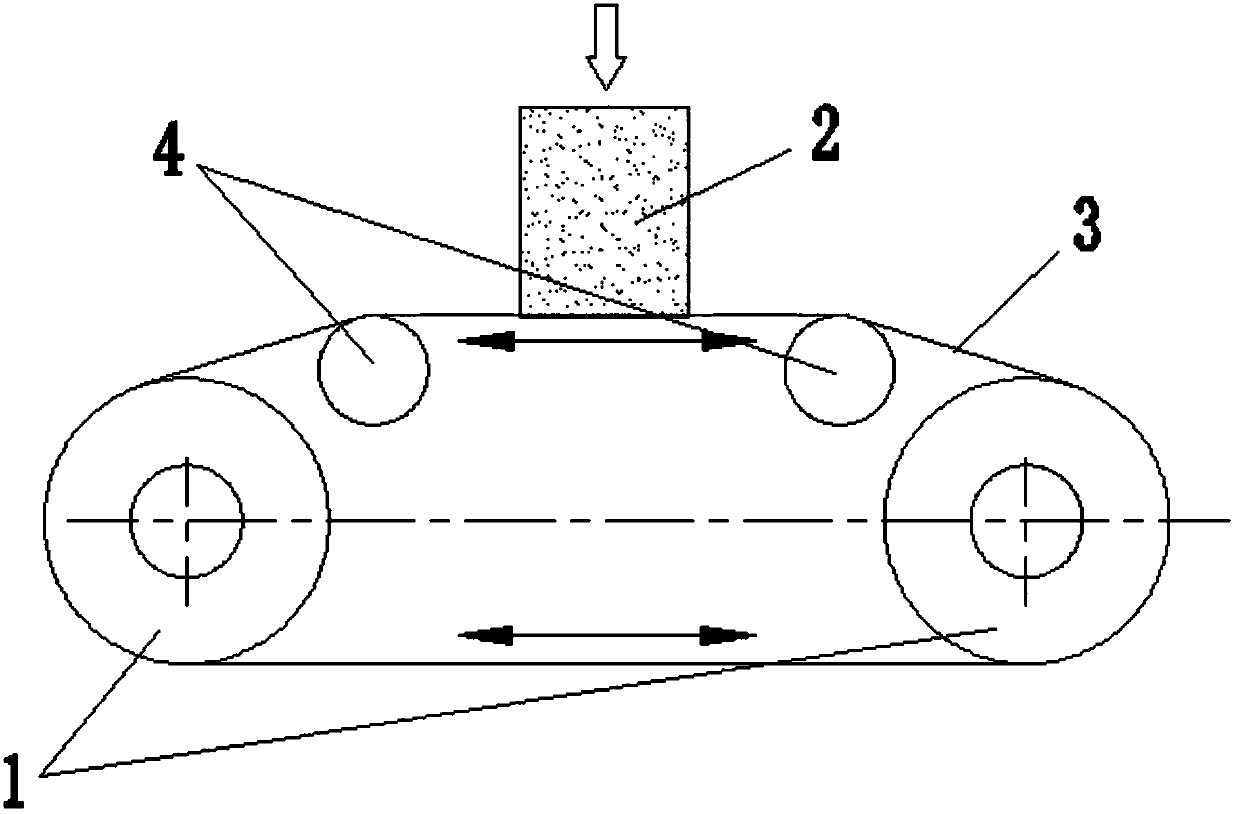

Four-roller downward-pressing-type stone diamond wire cutting machine

PendingCN111745833AEasy to installEasy to debugGrinding carriagesGrinding drivesWire cuttingStructural engineering

The invention relates to a four-roller downward-pressing-type stone diamond wire cutting machine. The four-roller downward-pressing-type stone diamond wire cutting machine comprises a rack, a diamondwire, wire rollers and a take-up and pay-off device; the diamond wire is wound on the wire rollers and connected to the take-up and pay-off device; the wire rollers comprise a first wire roller, a second wire roller, a third wire roller and a fourth wire roller which are all arranged in the horizontal direction; the first wire roller and the second wire roller are rotatably mounted on a mounting frame, and the third wire roller and the fourth wire roller are rotatably mounted on the mounting frame; the mounting frame can be mounted on the rack in an up-down moving mode; and the four-roller downward-pressing-type stone diamond wire cutting machine further comprises a driving mechanism used for driving the mounting frame to move up and down. The mounting frame is driven to move up and down through the driving mechanism, the diamond wire travels in the take-up and pay-off device and moves downwards along with all the wire rollers to form a reciprocating cutting action, stone is cut and does not need to be lifted, energy consumption is reduced, saw cutting is more stable, in addition, all the wire rollers can ascend and descend, and mounting and debugging of the diamond wire are convenient.

Owner:XIAMEN PINHE PRECISION TECH CO LTD

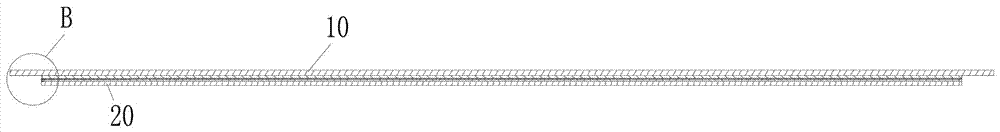

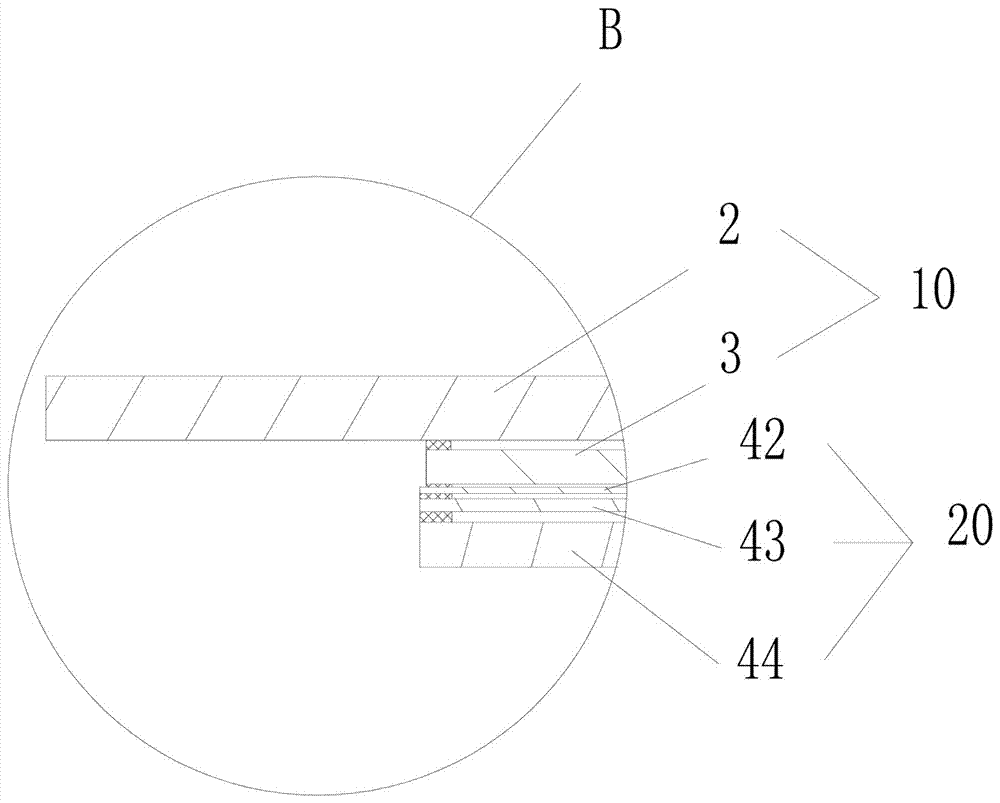

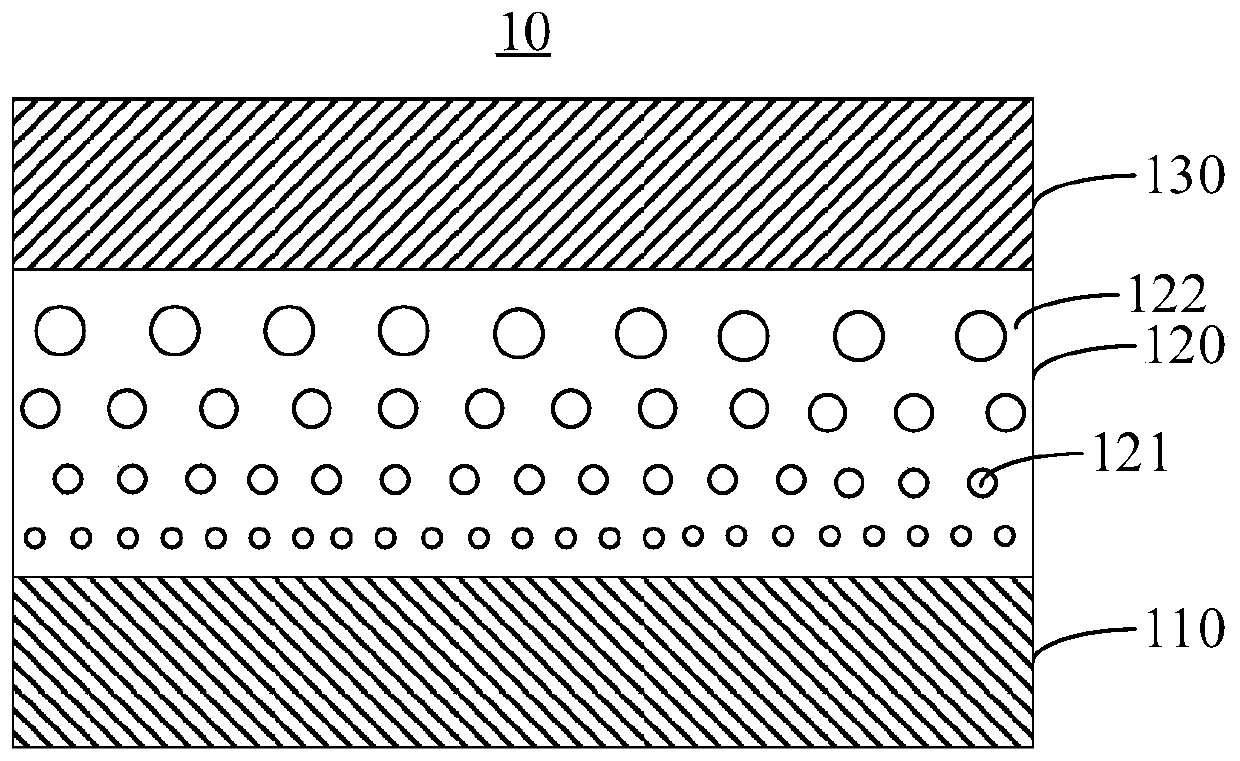

Infrared touch control liquid crystal integrated screen display module

ActiveCN107422518AEasy to disassembleThin and beautiful structureNon-linear opticsInput/output processes for data processingLiquid-crystal displayProtective glasses

The invention discloses an infrared touch control liquid crystal integrated screen display module. An infrared frame of the infrared touch control module comprises a touch control sensing element mounting part and an infrared frame extension part extending downwards along the outer side of the touch control sensing element mounting part; liquid crystal panel protective glass is stuck to the front surface of a liquid crystal panel to form a liquid crystal panel integrated screen; the touch control sensing element mounting part is stuck to the periphery of the front surface of the liquid crystal panel protective glass of the liquid crystal panel integrated screen; the liquid crystal panel of the liquid crystal panel integrated screen is not in contact with the infrared frame of the infrared touch control module; an infrared touch control sensing element is mounted in the touch control sensing element mounting part; a direct type backlight module is located on the back surface of the liquid crystal panel integrated screen; every two adjacent films and every two adjacent plates of the direct type backlight module are stuck to the periphery to form an optical film integrated layer, and the optical film integrated layer is stuck to the edge of an opening part of a back plate; no other supporting part is arranged between the direct type backlight module and the liquid crystal panel; the back plate of the direct type backlight module is buckled with the infrared frame extension part.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

Compact sirospun pure cotton yarn process

InactiveCN109137179AImprove structural strengthNot easy to disconnectYarnVegetal fibresYarnTextile technology

The invention relates to the technical field of cotton thread spinning, in particular to a compact sirospun pure cotton yarn process comprising a blowing-carding process, a combing process, a drawingprocess, a roving process, a spinning process, a winding process, and a packaging process. The spinning process includes: S1, carrying out sirospun processing; S2, carrying out compactness processing;S3, carrying out drawing process; S4, carrying out twisting; S5, carrying out sizing; to be specific, spraying the twisted spun yarn with a sizing agent uniformly by a spraying gun and controlling the temperature to be 100 to 110 DEG C; S6, carrying out winding; and S7, carrying out forming. According to the invention, the sizing agent is added in the spinning procedure; and drying type sizing iscarried out, so that the structural strength of the pure cotton yarn is improved effectively; the yarn is not easy to break; and the industrial development is carried out well.

Owner:YICHENG TIANSHU TEXTILE CO LTD

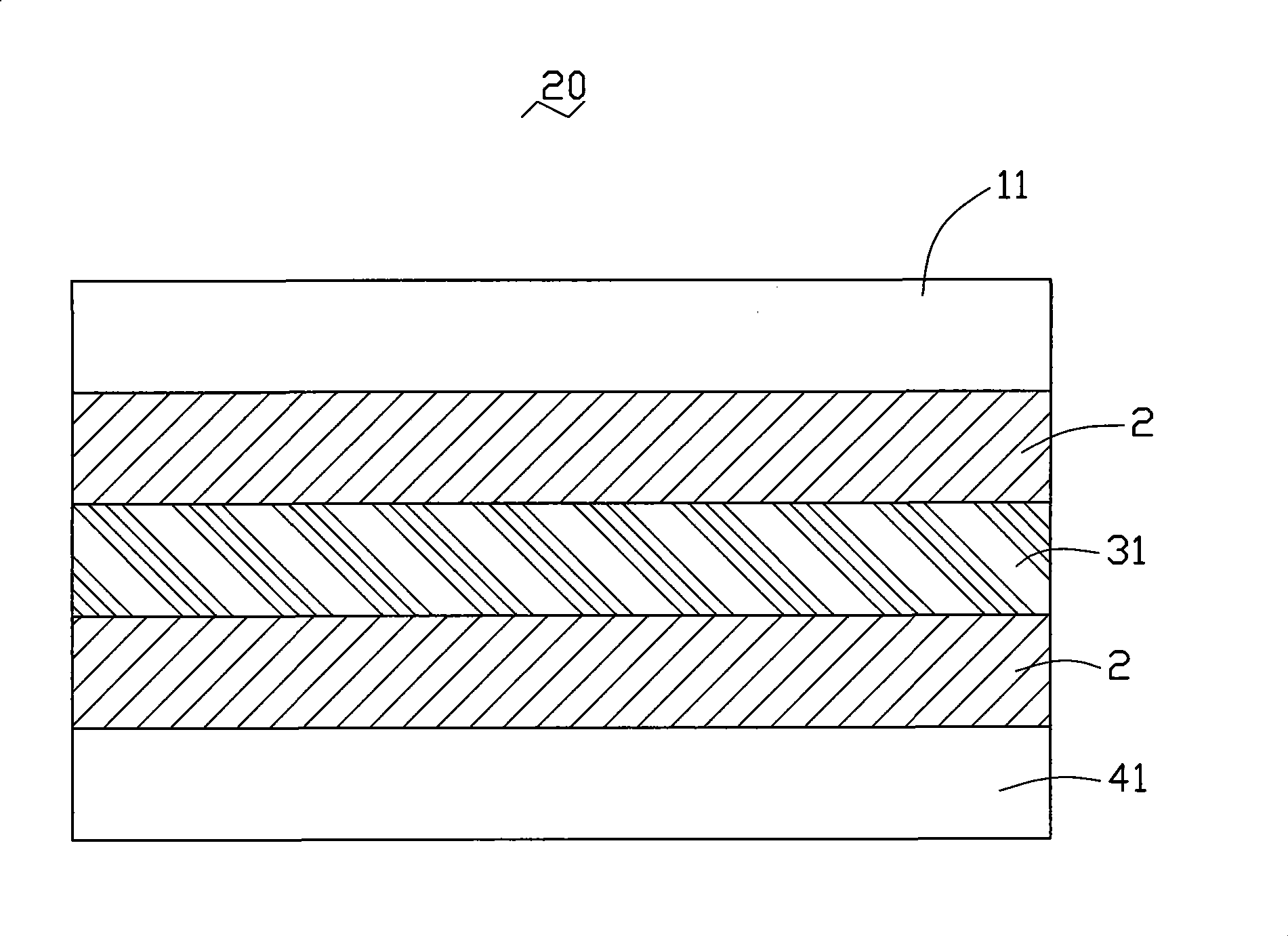

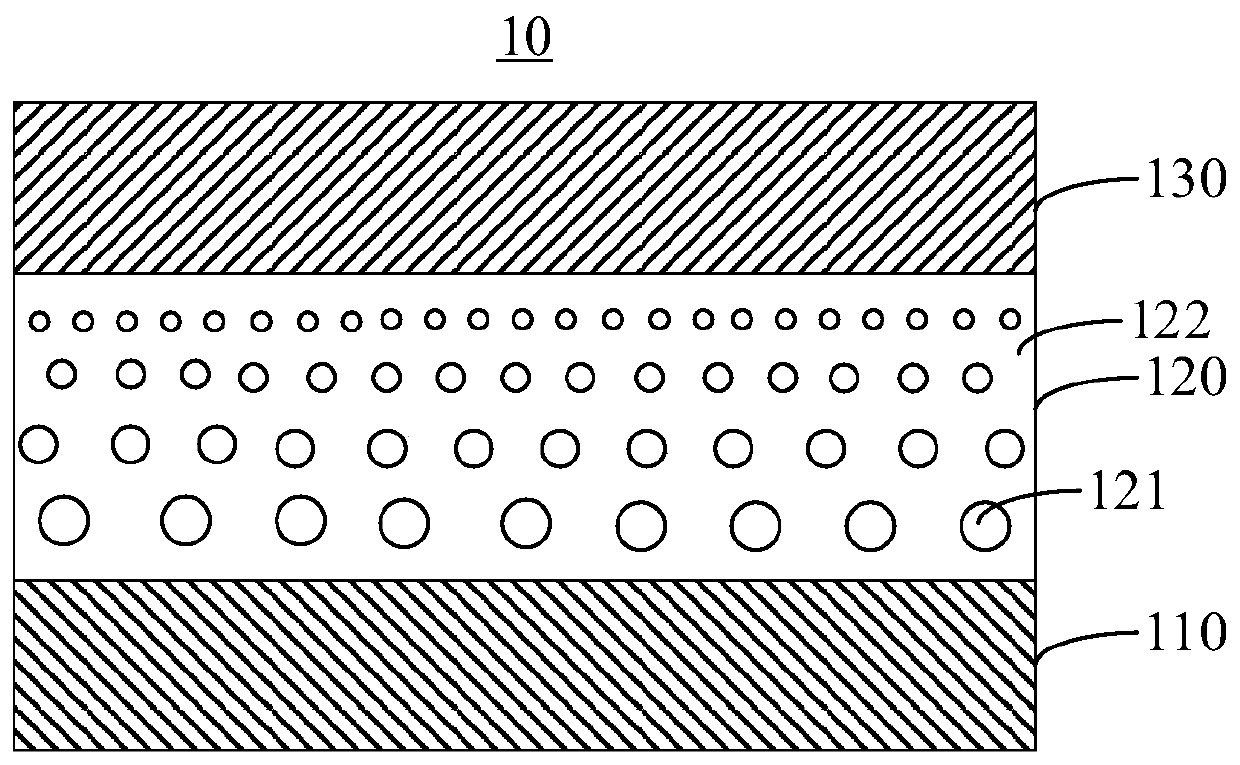

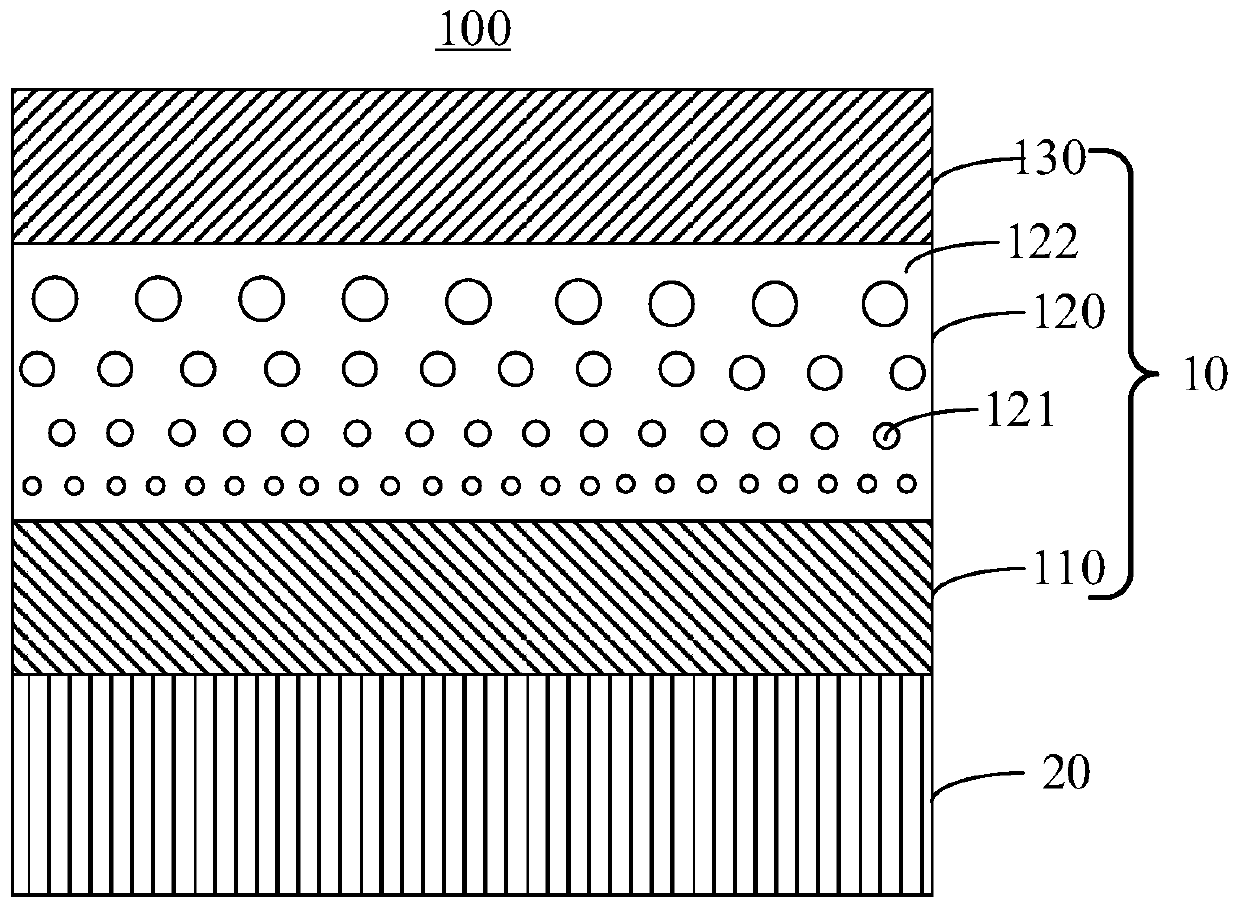

Packaging film, preparation method thereof, display panel and preparation method thereof

ActiveCN109713154AImproves toughness and water-blocking propertiesNot easy to disconnectSolid-state devicesSemiconductor/solid-state device manufacturingChemistryWater block

The invention relates to a packaging film, a preparation method thereof, a display panel and a preparation method thereof. The packaging film includes a first inorganic layer, an organic layer, and asecond inorganic layer which are laminated. The organic layer includes an organic matrix and moisture absorbent particles. The particle sizes of the moisture absorbent particles are in a gradient distribution in a direction toward the second inorganic layer along the first inorganic layer. The organic layer has the moisture absorbent particles are in the gradient distribution in a direction towardthe second inorganic layer along the first inorganic layer, and the toughness and water blocking property of the organic layer can be fully improved. The packaging film provided by the invention canbe applied in a packaging film of a flexible OLED display. The packaging film is not easily broken during a bending process, the erosion of water molecules can be well prevented, and the deteriorationof the performance of the packaging film is avoided.

Owner:YUNGU GUAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com