Two-roll wire rolling mill

A rolling mill and wire rod technology, applied in metal rolling and other directions, can solve the problems of high energy consumption, difficult threading, easy loss of molds, etc., achieve uniform arrangement, good material density, and reduce useless power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing the specific embodiment of the present invention is described in detail as follows:

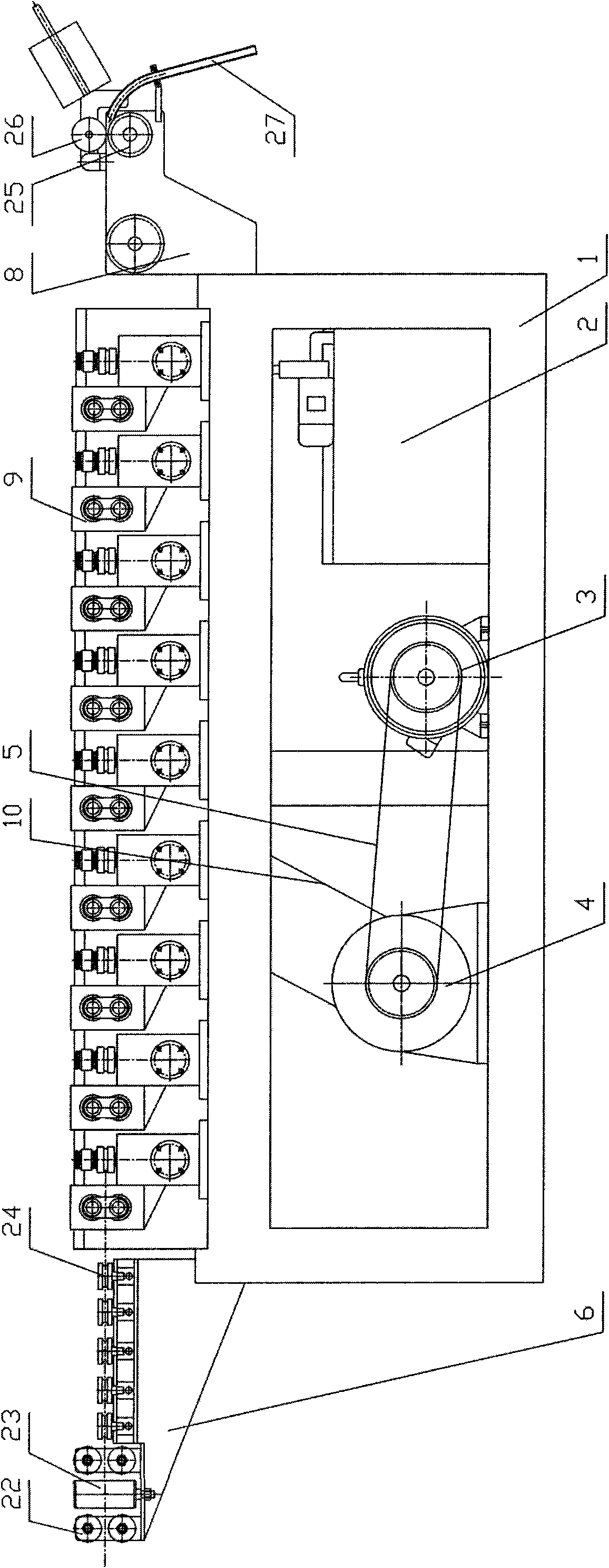

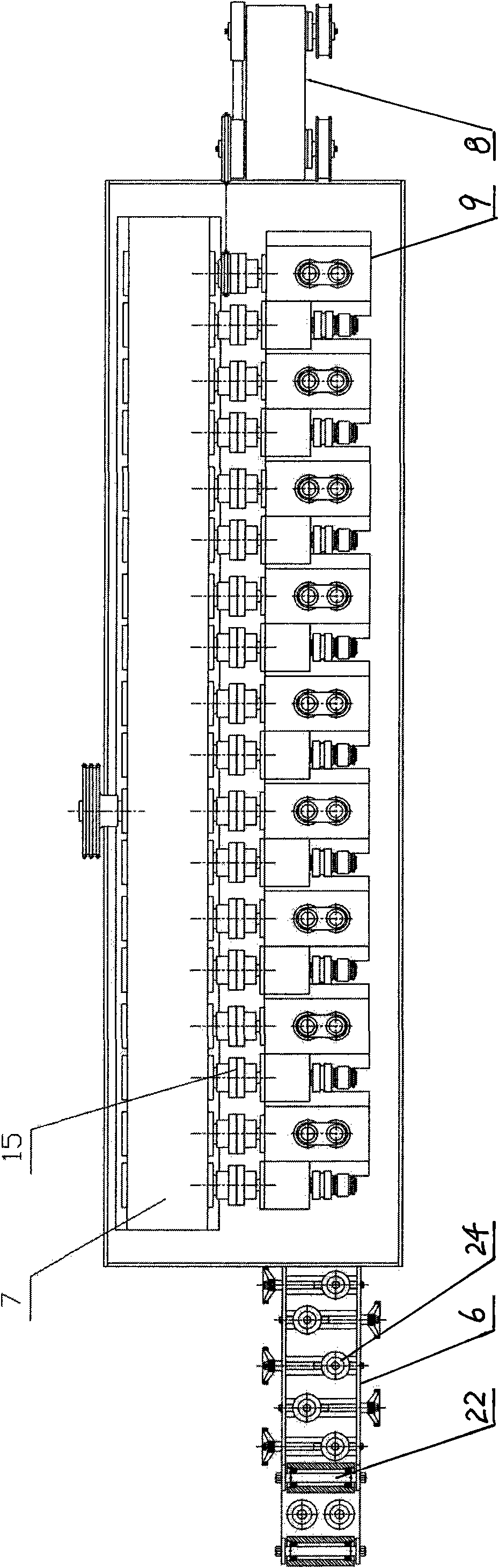

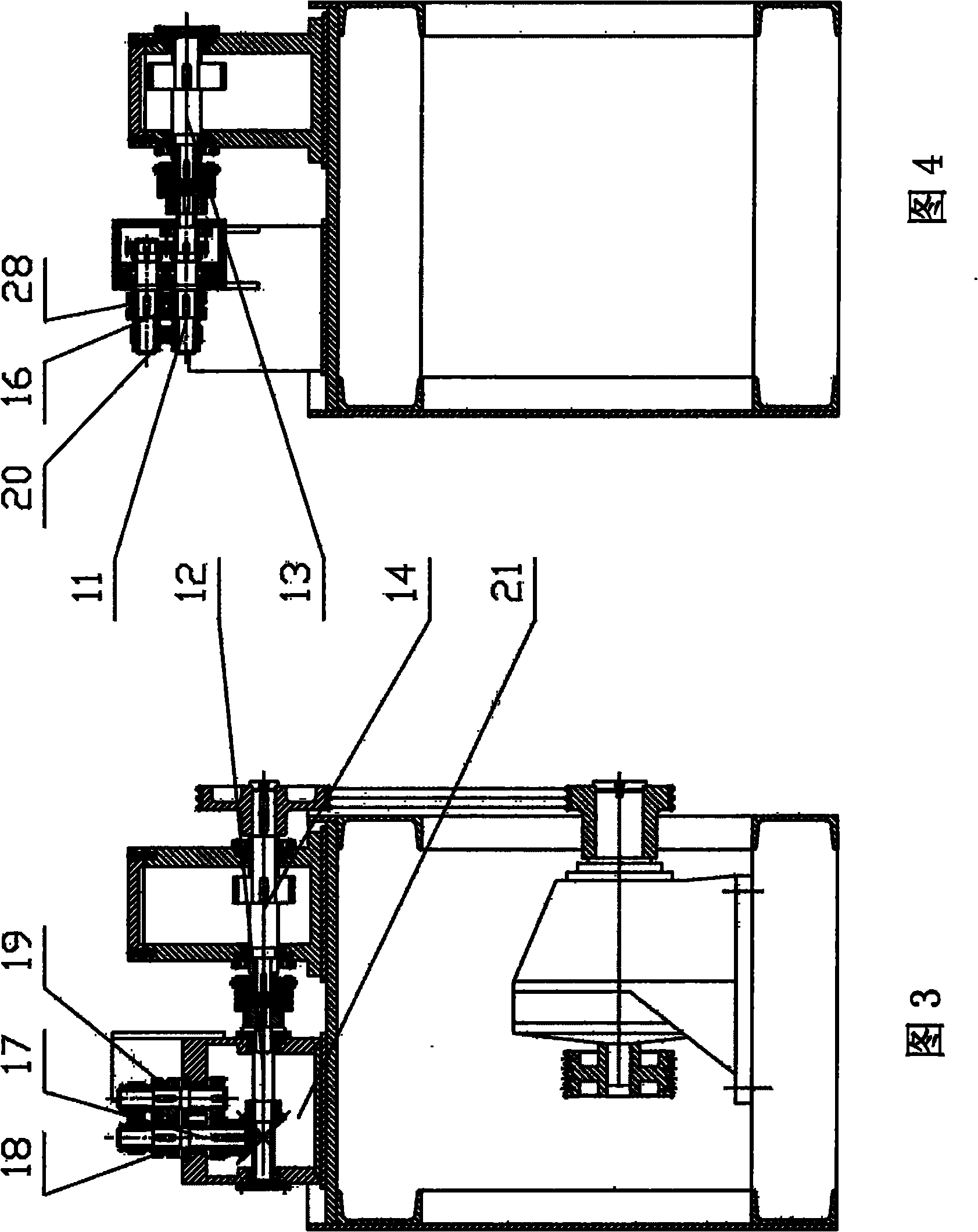

[0032] exist figure 1 , 2 Among them, the two-roller wire rolling mill of the present invention includes a frame 1, a lubrication system 2 and an electric control part, and the lower part of the frame 1 is equipped with a motor 3 and a speed reducer 4, between the output shaft of the motor 3 and the input shaft of the speed reducer 4 Connected with a belt 5, on the frame 1, an incoming line straightening mechanism 6, a main transmission box 7 and an outgoing line drop barrel mechanism 8 are arranged in sequence, and 9 small boxes 9 are installed on one side of the main transmission box 7, each small box The body 9 is equipped with a pair of vertical rolls and a pair of horizontal rolls, the output shaft of the reducer 4 and the input shaft of the main transmission box 7 are connected by a chain 10, and the upper and lower two-layer transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com