Vertical constant force disc spring hanger

A disc spring and hanger technology, which is applied in the field of vertical constant force disc spring hangers, can solve the problems of large volume of constant force spring support hangers, affecting product performance, promotion and application, and difficulty in purchasing and manufacturing, and achieves effective results. Utilize the effect of spring stiffness, improved efficiency, low cost

Inactive Publication Date: 2010-11-10

江苏友恒机械有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the constant-force spring hangers at home and abroad use cylindrical helical compression springs as elastic force-bearing elements, such as: GB10181.LH type, ITT standard 58V type (as shown in Figure 3), and German LESIGAB standard (as shown in Figure 4). Cylindrical helical compression springs with low inherent stiffness and high reactive power are used, and there are problems such as large volume, heavy weight, difficult manufacturing, high energy consumption, inconvenient construction and installation, and partial load of constant force spring hangers to varying degrees; In particular, it is difficult to purchase and manufacture raw materials for large-scale cylindrical coil springs used in large-scale constant force spring hangers, which directly affects product performance and popularization and application.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

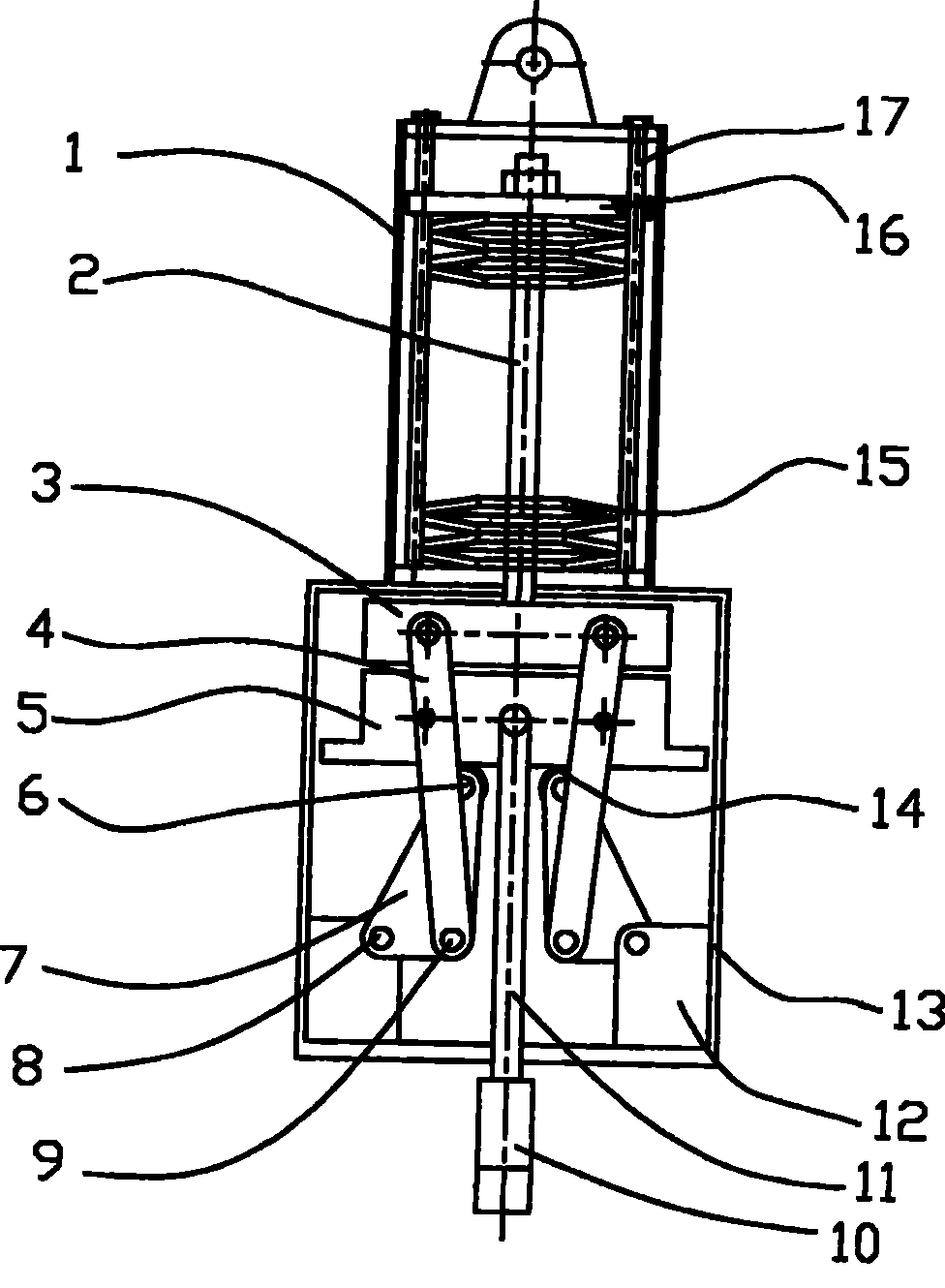

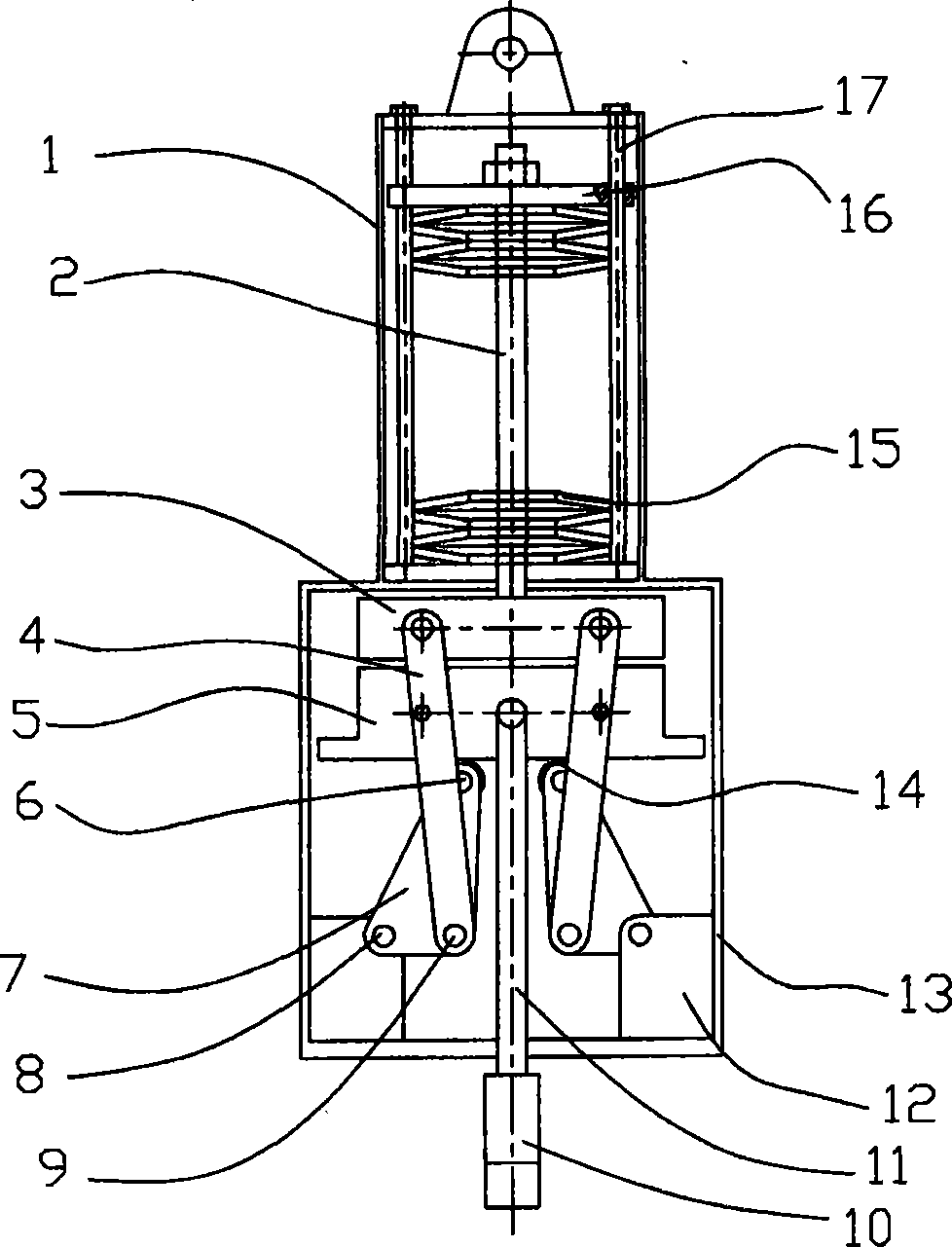

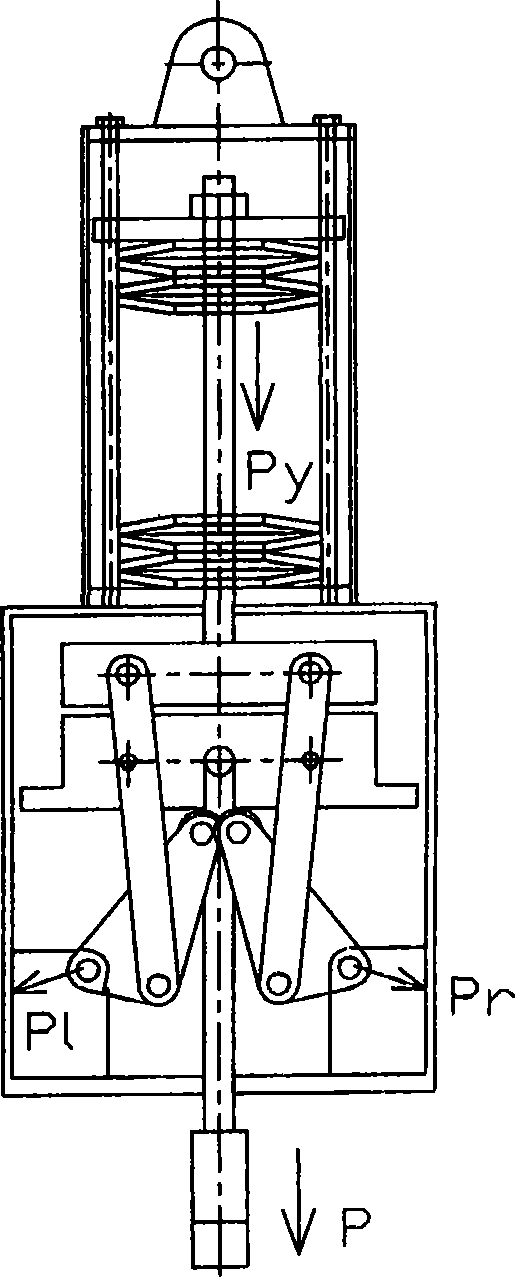

The invention relates to a spring hanger, in particular to a vertical constant force disc spring hanger. The disc spring hanger comprises a cylinder body, a spring arranged in the cylinder body, loading bolts, a gland, a force conversion mechanism arranged on the lower part of the cylinder body, and an elastic nut movably connected with the lower end of the force conversion mechanism; and at least three guide rods which are positioned on the same circumference and are in parallel with the axial line of the cylinder body are arranged on positions close to the cylinder wall in the cylinder body, and the spring is arranged among the guide rods. The vertical constant force disc spring hanger can effectively use the effect of spring rigidity and effectively reduce the useless power of the spring; the wall thickness of the upper part of the cylinder body is thinned so that materials are saved and the reliability is improved; compared with the prior art, the load of the spring is reduced under the condition of bearing the same gravity; and meanwhile, when bearing the same weight, the vertical constant force disc spring hanger has the advantages of smaller volume, lower cost and improved efficiency.

Description

A vertical constant force disc spring hanger technical field The invention relates to a spring hanger, in particular to a vertical constant force disc spring hanger. Background technique At present, most of the constant-force spring hangers at home and abroad use cylindrical helical compression springs as elastic force-bearing elements, such as: GB10181.LH type, ITT standard 58V type (as shown in Figure 3), and German LESIGAB standard (as shown in Figure 4). Cylindrical helical compression springs with low inherent stiffness and high reactive power are used, and there are problems such as large volume, heavy weight, difficult manufacturing, high energy consumption, inconvenient construction and installation, and partial load of constant force spring hangers to varying degrees; In particular, it is very difficult to purchase and manufacture raw materials for the large-scale cylindrical helical springs used in the large-scale constant force spring hangers, which directly aff...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L3/205

Inventor 戴彦青李万勇徐立高

Owner 江苏友恒机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com