Blade tip extending structure and method of wind power blade

A wind power blade and blade tip technology, applied in the field of blade tip extension structure, can solve the problems of wasting glass fiber reinforced plastic materials, unable to make full use of blade tip structure design, etc., and achieve the effects of improving reliability, improving reliability and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

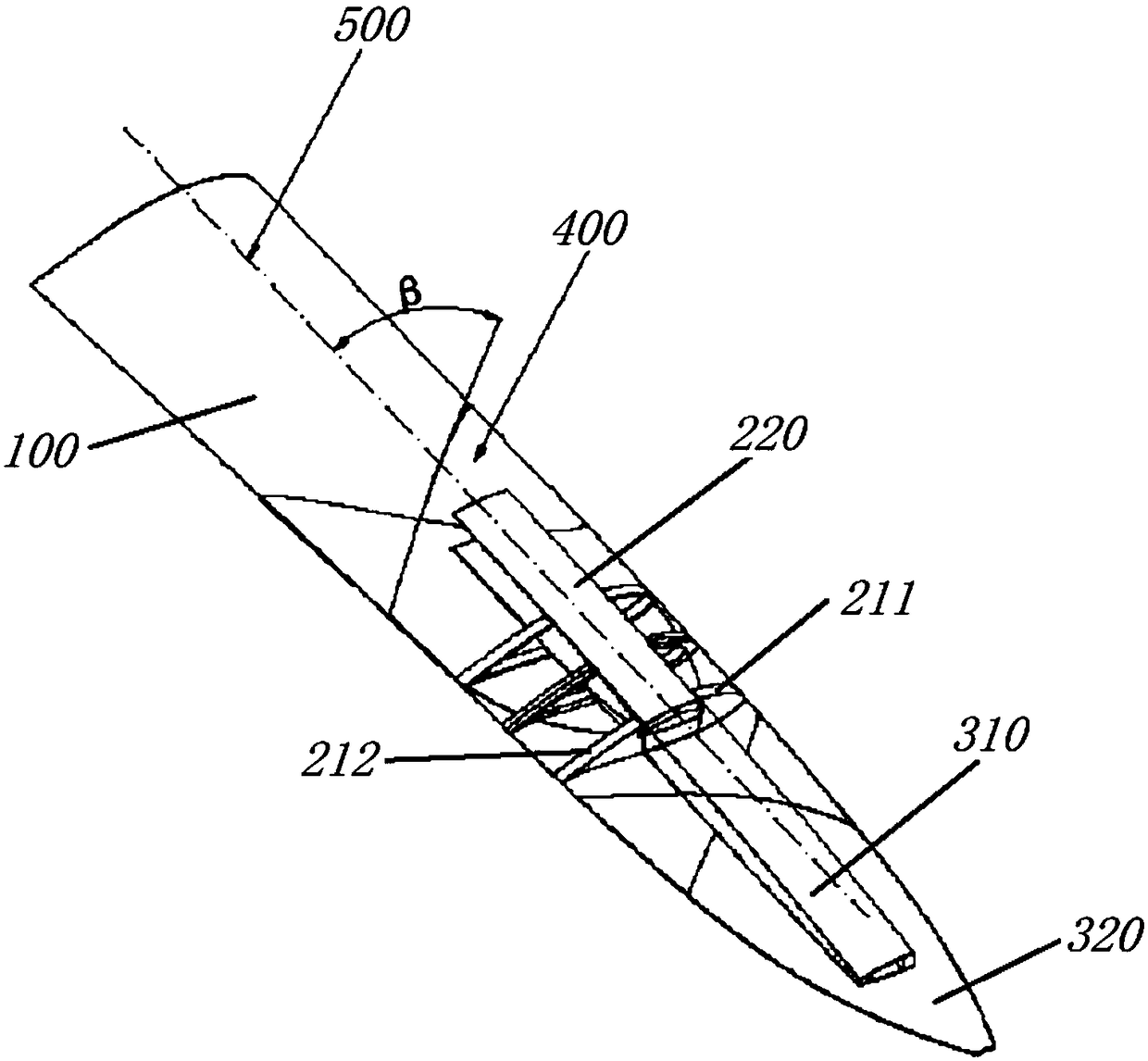

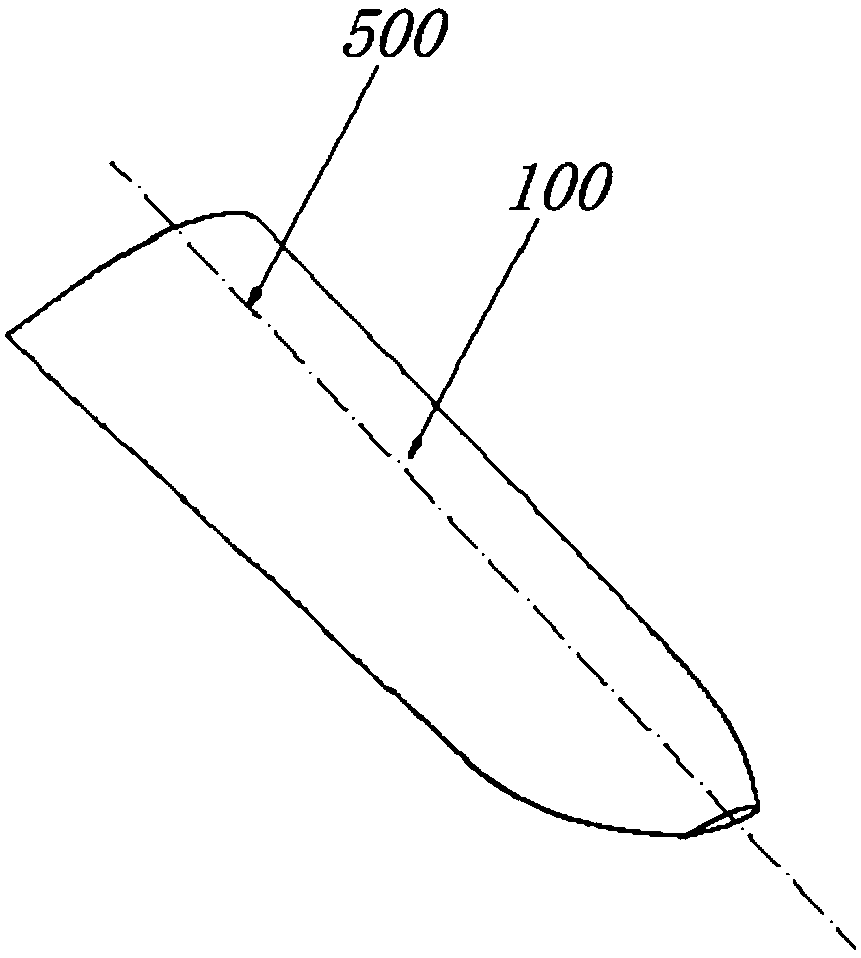

[0053] Such as Figure 1-10 As shown, the blade tip extension structure of the wind power blade of the present invention includes a basic blade tip section 100, a blade tip extension transition assembly 200, a prefabricated blade tip extension section 300 and an extended transition zone skin 400, the basic blade tip section 100, the prefabricated blade tip section The tip extensions 300 are sequentially arranged along the blade pitch axis 500 .

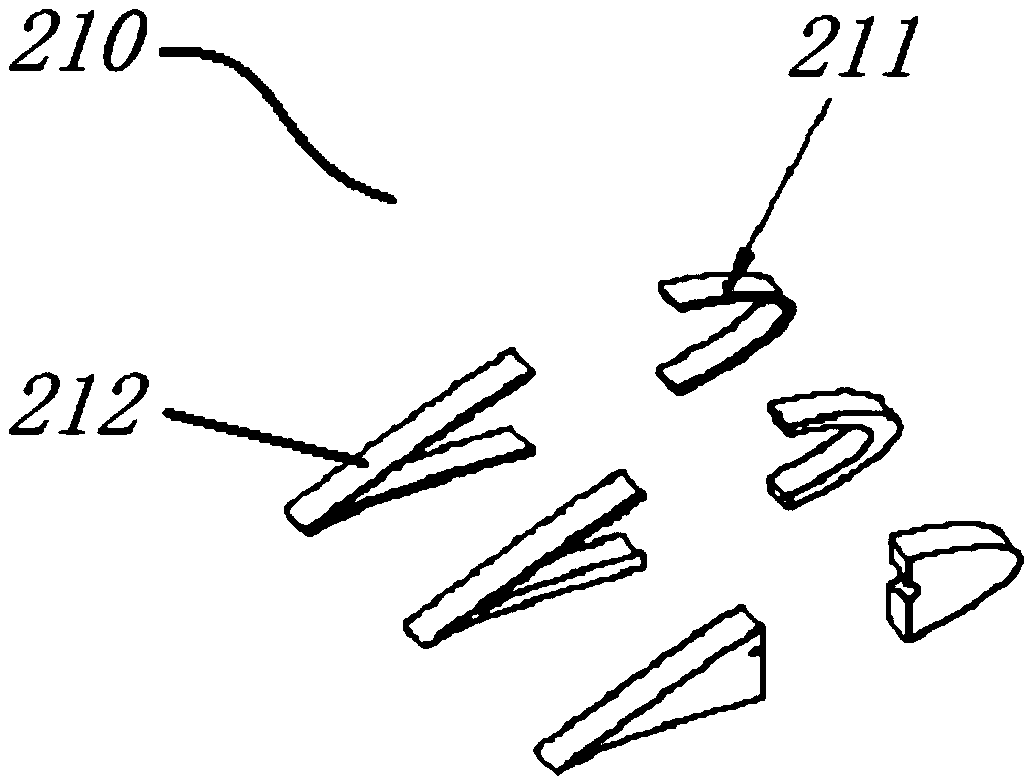

[0054] Such as Figure 2-6 As shown, the blade tip extension transition assembly 200 is arranged in the extension transition area of the base blade tip section 100, and includes several sets of shimmy direction support members 210 and at least one set of flapping direction support members 220, wherein severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com