Fabricated structure system composite floor slab sideband type independent support construction method

A technology of superimposed floor slabs and construction methods, which is applied in the direction of floor slabs, formwork/formwork/work frames, building components, etc., can solve the problems of cumbersome construction, high construction costs, and large consumption of steel pipes, and solve the problems of cumbersome construction, The effect of good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] With regard to the above-mentioned technical solutions, preferred embodiments are given for specific description in combination with figures.

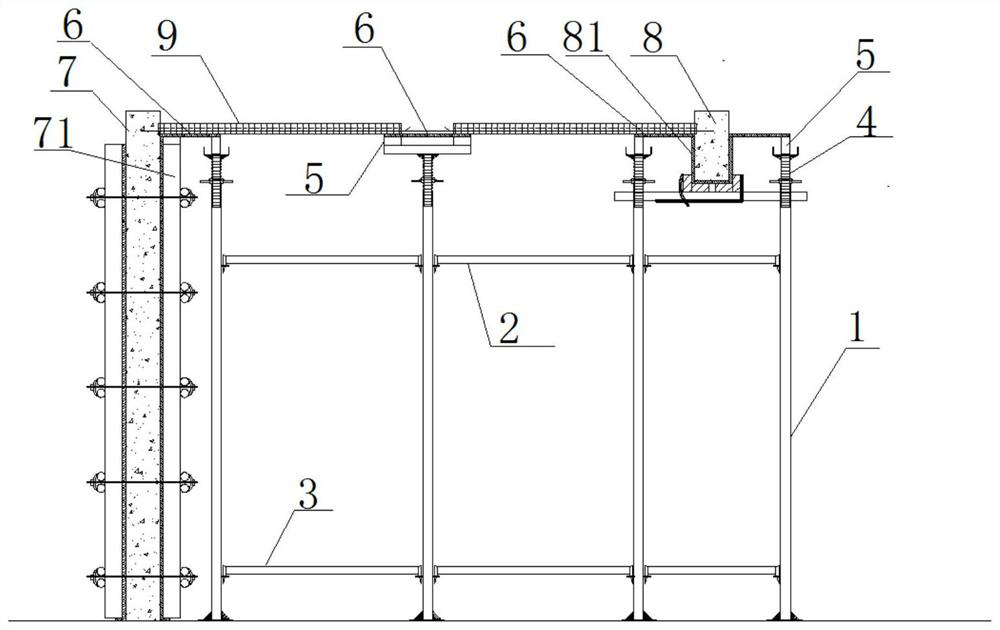

[0014] Such as figure 1 As shown, the prefabricated structure system superimposed floor side belt independent support construction method, the support frame includes a steel pipe vertical pole 1, a horizontal pole 2, a sweeping pole 3, an adjustable bracket 4, wooden squares 5, and a formwork 6. The building includes walls 7 , cast-in-place beams 8 , wall templates 71 , beam templates 81 and laminated panels 9 .

[0015] Step 1), set up the support frame: place the bottom support plate on the ground, and then place it 30cm away from the side of the wall 7 and the cast-in-place beam 8, and below the center of the strip area, along the length direction of the wall, cast-in-place beam, and strip respectively Several steel pipe vertical rods 1 are arranged at intervals, and then each steel pipe vertical rod 1 is connected and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com