Cutting device for missile stage separation

A cutting device and inter-stage separation technology, applied in the direction of self-propelled bombs, projectiles, offensive equipment, etc., can solve the problems of easy gasification, low melting point, and inability to guarantee the protective cover, etc., and achieve good cutting effect, not easy to gasify, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

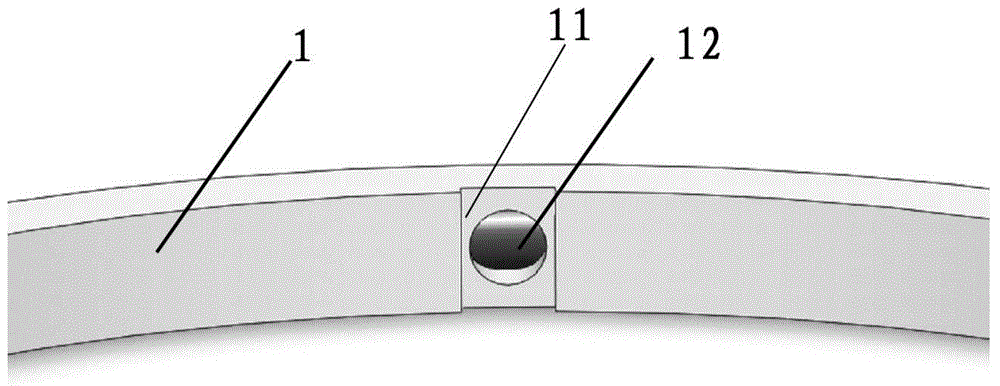

[0057] This embodiment describes the application of a specific product of the present invention in a target missile. The product is composed of protective cover, detonator, cutting cable, rubber protective cover and so on.

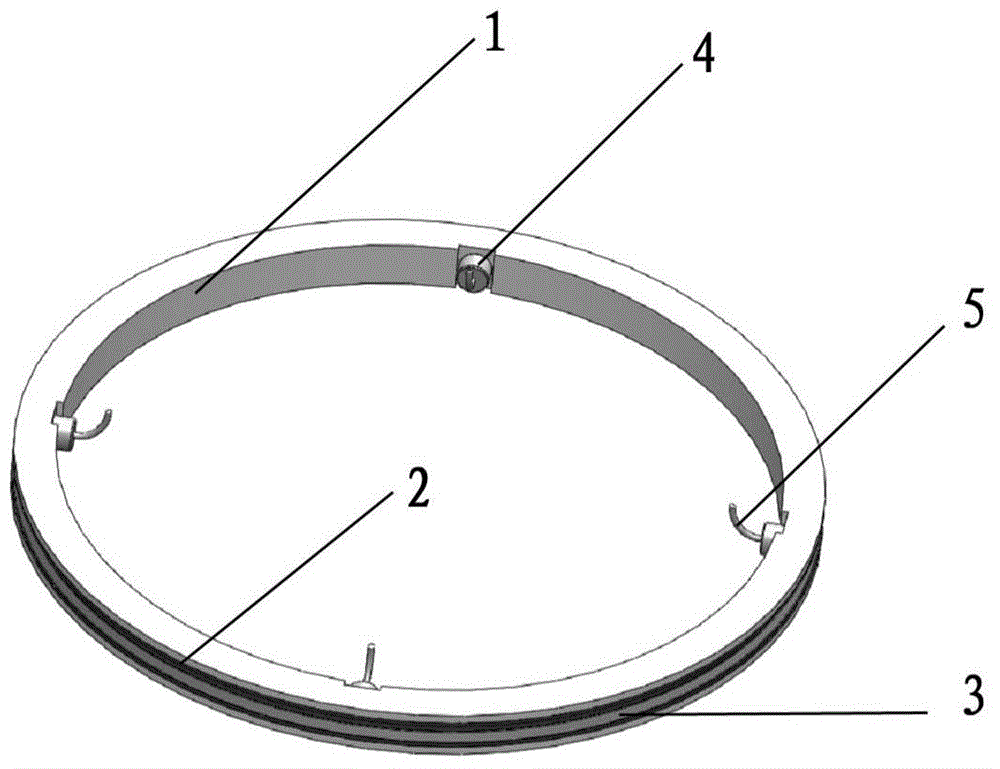

[0058] Such as figure 1 Shown is a perspective view of a specific product of the present invention. The main body of the device is a cutting assembly device adapted to the missile body. The cutting assembly device is a protective cover 1, a rubber protective cover 2, and a cutting cable 3 from outside to inside. Stress grooves are set on the part of the projectile to be cut, and the cutting components are aligned with the stress grooves for installation. 4 detonators 4 that are evenly distributed at 90° intervals along the 360° circle are installed on the protective cover and the rubber protective cover, and the detonators 4 are connected with detonating cables 5 .

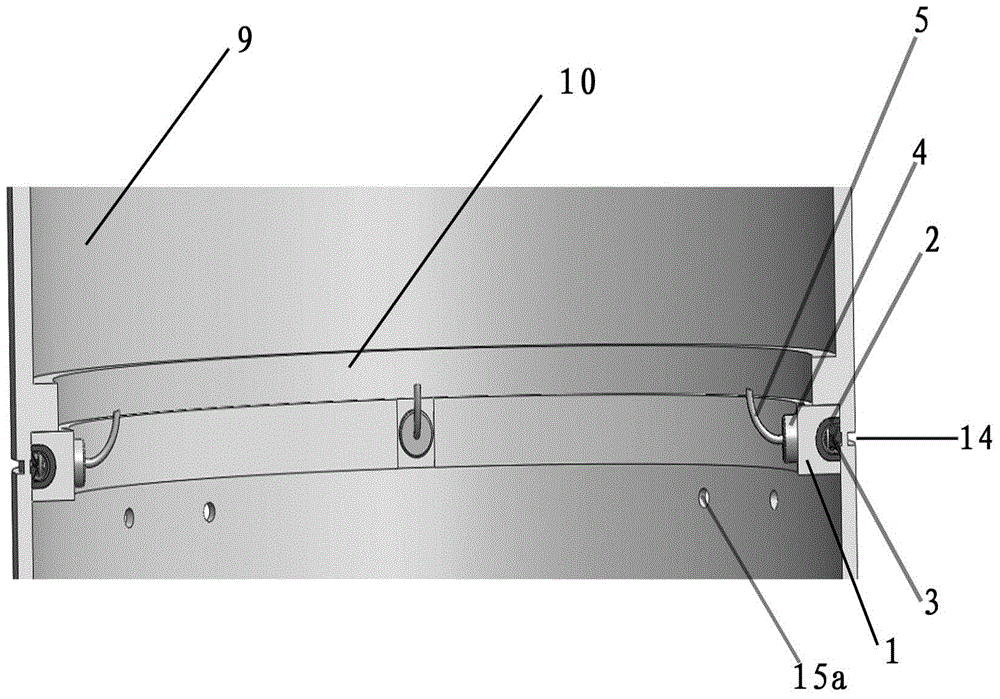

[0059] Such as figure 2 Shown is an inside diagram of a specific product of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com